Self-compacting concrete prepared from iron ore tailings, and preparation method thereof

A technology for self-compacting concrete and iron ore tailings, which is applied in the field of building materials, can solve the problems of difficulty in complete compaction, narrow cross-section, and dense reinforcement of structures, so as to reduce the cost of concrete, reduce environmental damage, and reduce the ecological environment. the effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1—4

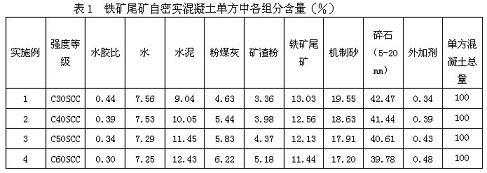

[0032] Table 1 lists the content of each component in the iron ore tailings self-compacting concrete of the present invention.

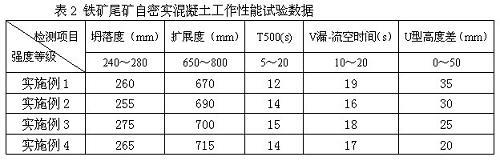

[0033] Table 2 lists the working performance test data of iron ore tailings self-compacting concrete of the present invention.

[0034] Table 3 lists the test data of the compressive strength of the iron ore tailings self-compacting concrete of the present invention.

[0035]

[0036]

[0037]

[0038] The basic performance tests of self-compacting concrete are carried out according to the above mix proportions, including long-term durability tests such as anti-rapid carbonation performance, chloride ion permeability coefficient, Coulomb electricity test, rapid freeze-thaw performance, dry shrinkage deformation performance, etc., and all performance indicators can fully meet the requirements of concrete Basic technical requirements for long-term durability.

[0039] Table 4 lists the content of each component in the self-compacting concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com