Preparation method of microcrystalline pollucite

A cesium garnet and microcrystalline technology, applied in the directions of aluminum silicate and silicate, can solve the problems of difficult capture and collection of Cs airborne substances, high temperature volatilization of Cs, and high synthesis temperature, which is beneficial to environmental protection and avoids high temperature. The effect of volatilization and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

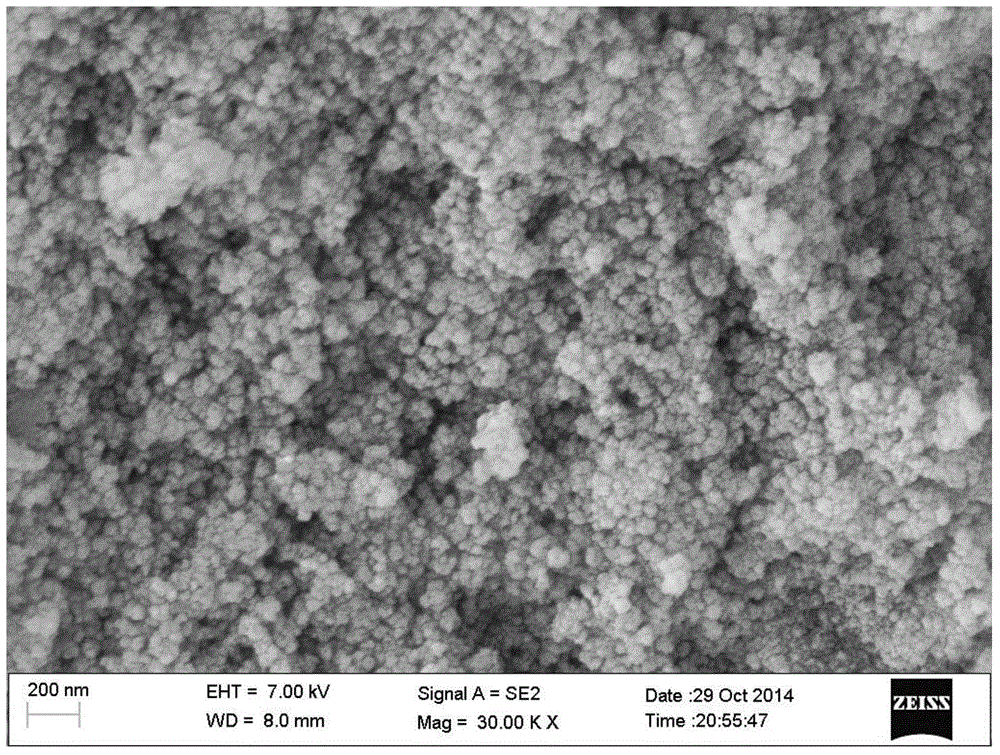

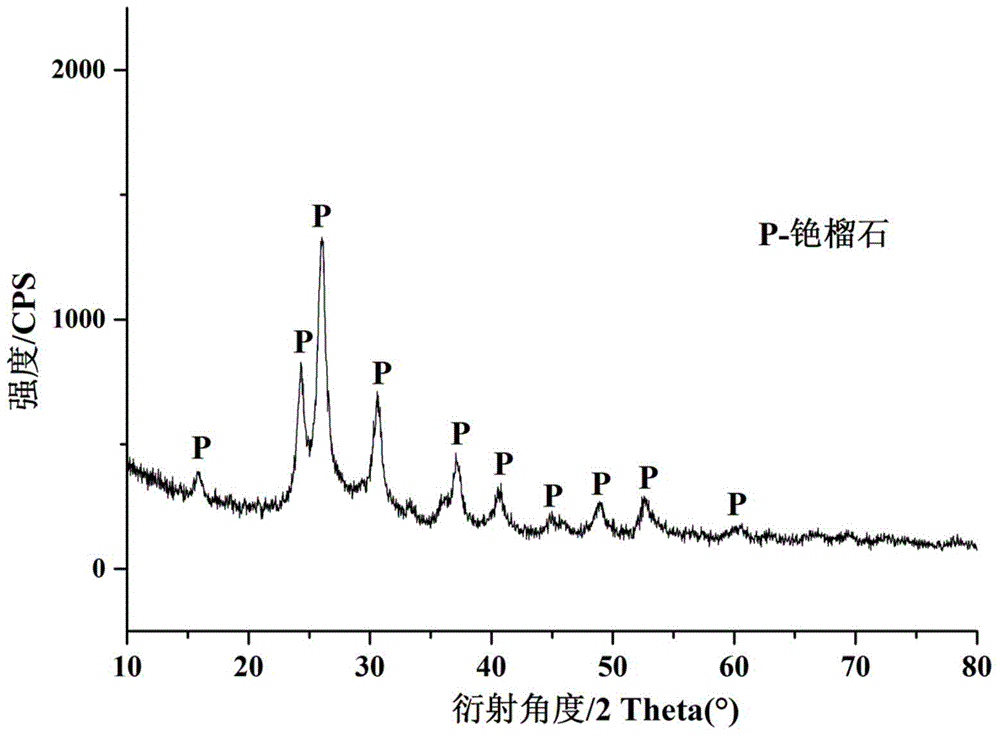

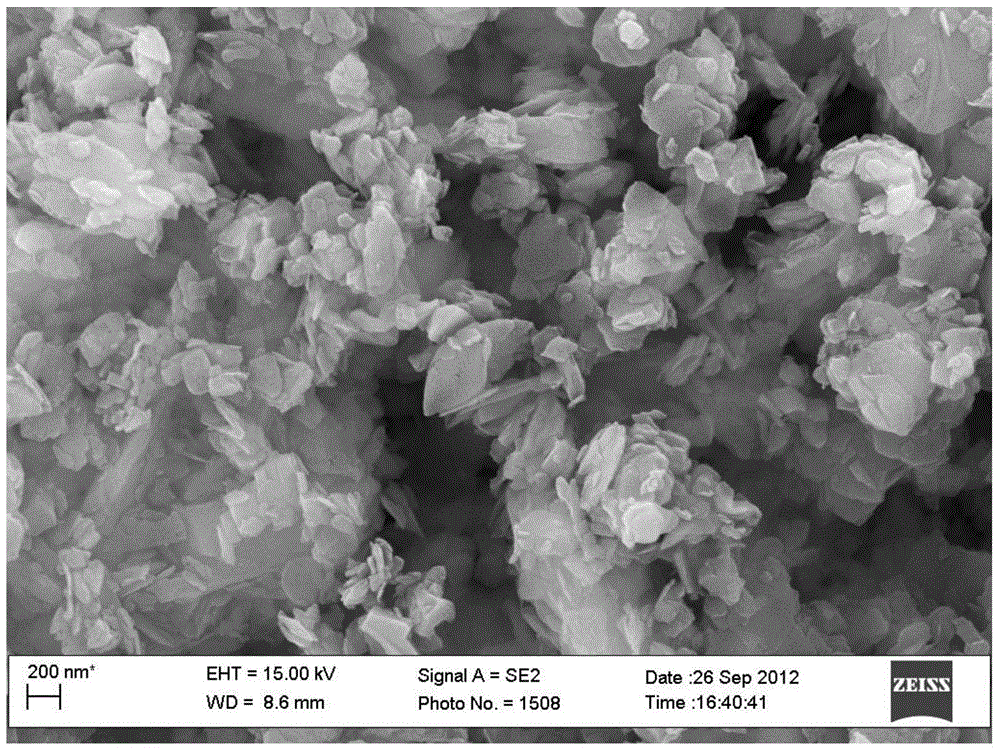

[0024] According to the mass ratio of cesium hydroxide and potassium silicate solution is 0.3:1 weighing ratio, cesium hydroxide is dissolved in potassium silicate solution, stirred and dissolved, cooled to room temperature to form potassium cesium silicate solution; potassium cesium silicate After the solution is cooled, metakaolin is added according to the mass ratio of potassium cesium silicate solution to metakaolin at 1.2:1, and stirred evenly to form a slurry; the slurry is poured into a steel mold, sealed at room temperature for 3 to 5 hours, and then demoulded. Blocky solid; blocky solid is placed in an autoclaved reactor, crystallized in a steam environment of 180°C and 0.8MPa for 4 to 8 hours, and then cooled to obtain a blocky solid of microcrystalline cesium garnet.

Embodiment 2

[0026] According to the mass ratio of cesium hydroxide and potassium silicate solution is 0.47:1 weighing ratio, cesium hydroxide is dissolved in potassium silicate solution, stirred and dissolved, cooled to room temperature to form potassium cesium silicate solution; potassium cesium silicate After the solution is cooled, metakaolin is added according to the mass ratio of potassium cesium silicate solution to metakaolin at 1.27:1, stirred evenly to form a slurry; the slurry is poured into a steel mold, sealed at room temperature for 3 to 5 hours, and then demolded into a Blocky solid; blocky solid is placed in an autoclaved reactor, crystallized in a steam environment of 180°C and 0.8MPa for 4 to 8 hours, and then cooled to obtain a blocky solid of microcrystalline cesium garnet.

Embodiment 3

[0028] According to the mass ratio of cesium hydroxide and potassium silicate solution is 0.67:1 weighing ratio, cesium hydroxide is dissolved in potassium silicate solution, stirred and dissolved, cooled to room temperature to form potassium cesium silicate solution; potassium cesium silicate After the solution is cooled, metakaolin is added according to the mass ratio of potassium cesium silicate solution to metakaolin is 1.44:1, stirred evenly to form a slurry; the slurry is poured into a steel mold, sealed at room temperature for 3 to 5 hours, and then demolded into a Blocky solid; blocky solid is placed in an autoclaved reactor, crystallized in a steam environment of 180°C and 0.8MPa for 4 to 8 hours, and then cooled to obtain a blocky solid of microcrystalline cesium garnet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com