Patents

Literature

177results about How to "Fill the void" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Artificial Flagstone For Providing A Surface With A Natural Random Look

InactiveUS20070217865A1Natural lookEnd result is extremely stableCovering/liningsNatural patternsMechanical engineeringIrregular shape

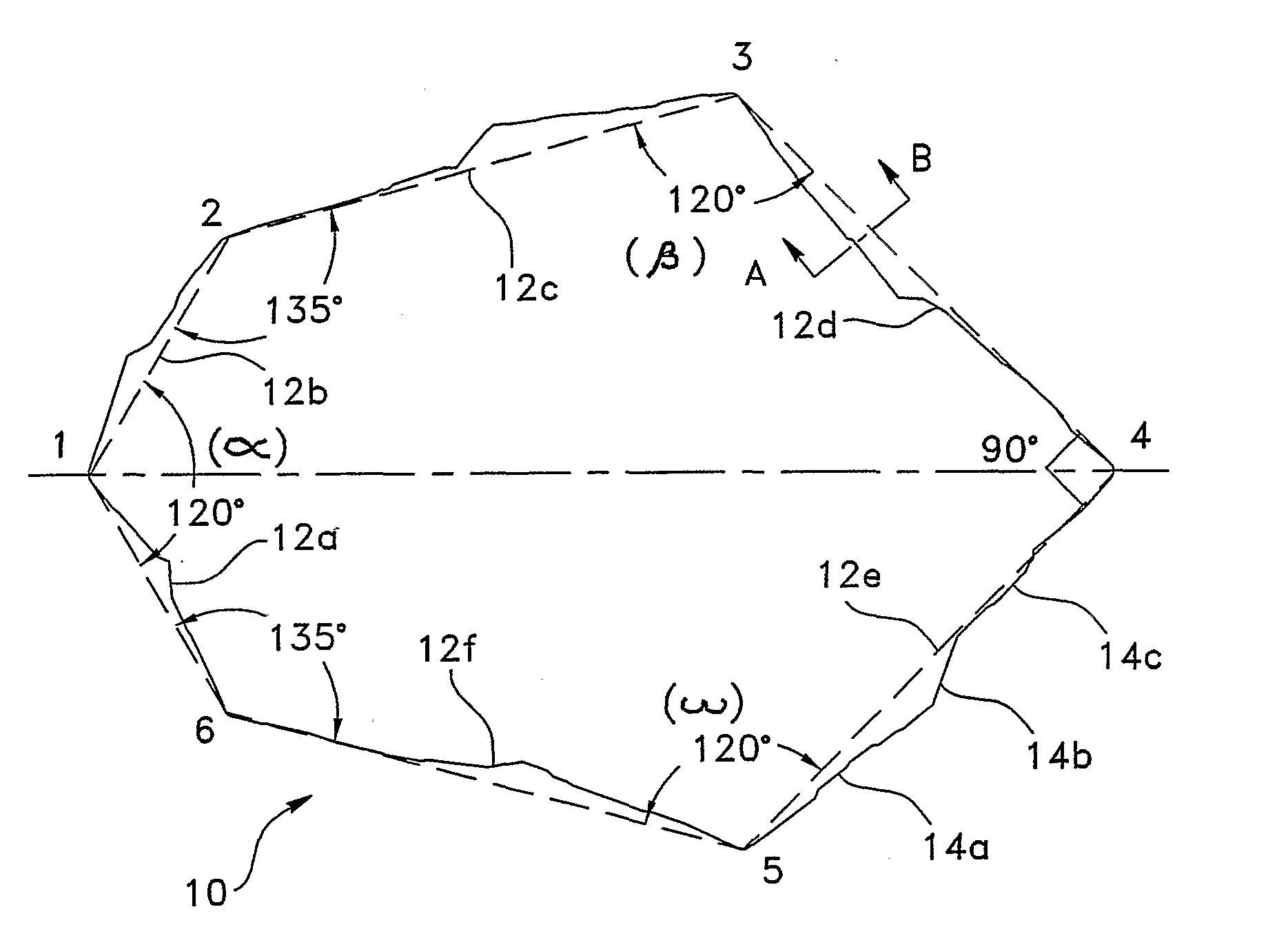

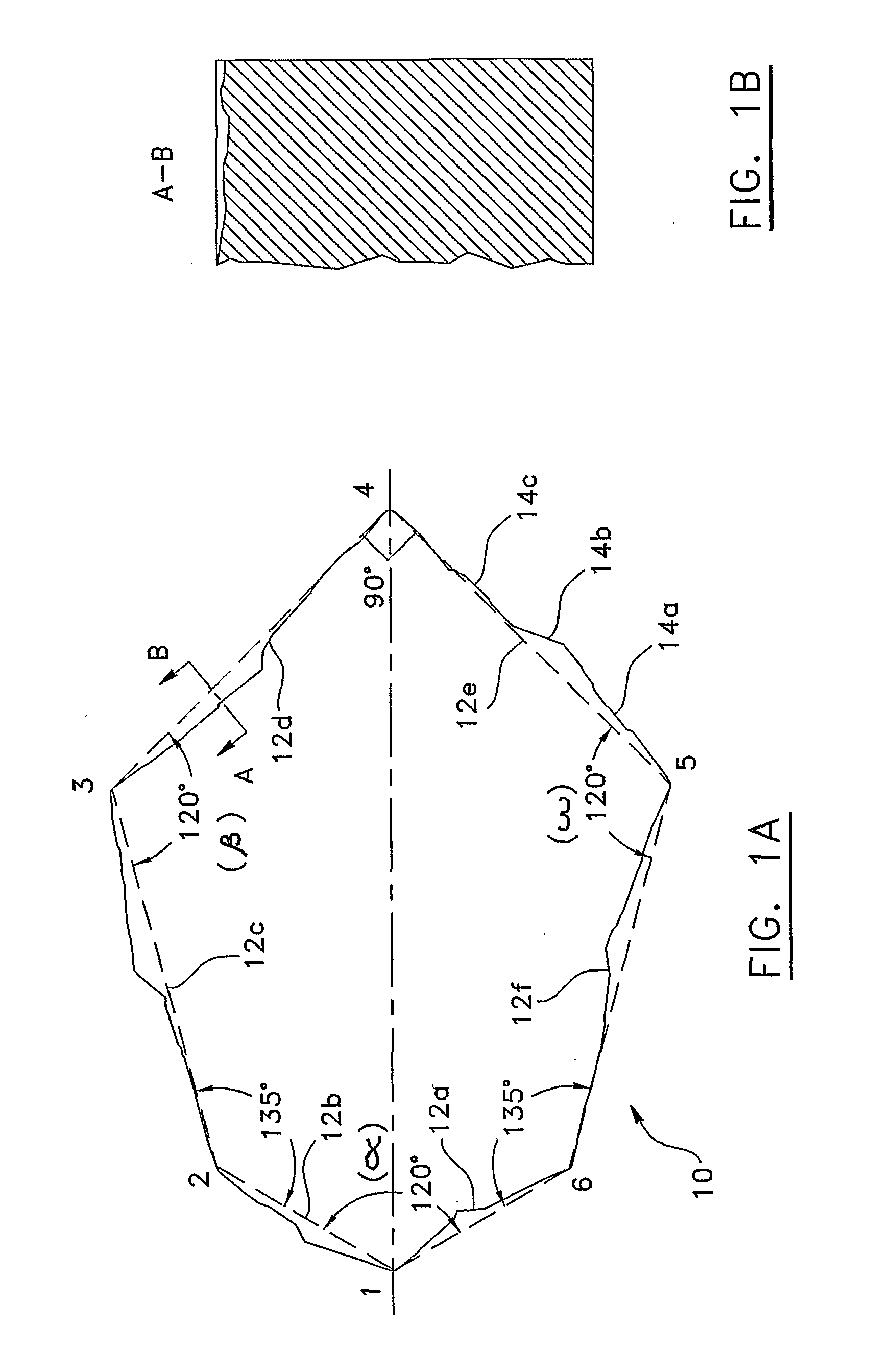

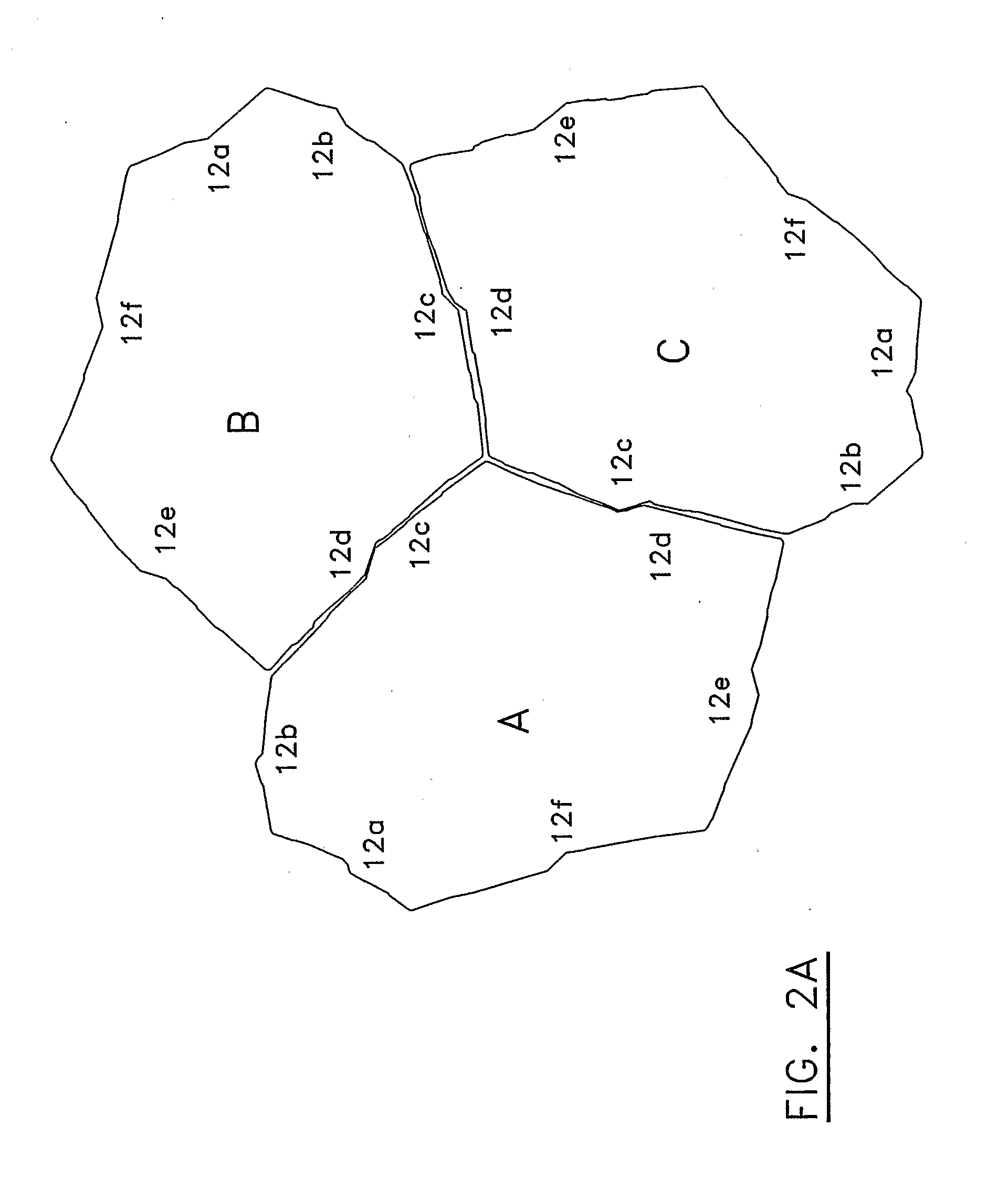

An artificial flagstone for use in combination with other similar flagstones for covering a surface with a natural random look, the flagstone having a generally hexagonal body comprising a first, second, third, fourth, fifth and sixth consecutive vertices; a first pair of generally congruent irregularly-shaped first and second sides extending radially from the first vertex and being rotationally spaced from each other by an angle α of approximately 120°; a second pair of generally congruent irregularly shaped third and fourth sides extending radially from the third vertex and being rotationally spaced from each other by an angle β of approximately 120°; a third pair of generally congruent irregularly shaped fifth and sixth sides extending radially from the fifth vertex and being rotationally spaced from each other by an angle ω of approximately 120°; wherein the sides of each of the first, second and third pair of sides have at least one split deviation along their length and are respectively rotational images of each other, whereby in use in combination with other flagstones, each one of the sides is matingly engageable with the sides of an equivalent pair of sides of a neighbouring flagstone.

Owner:OLDCASTLE BUILDING PROD CANADA INC

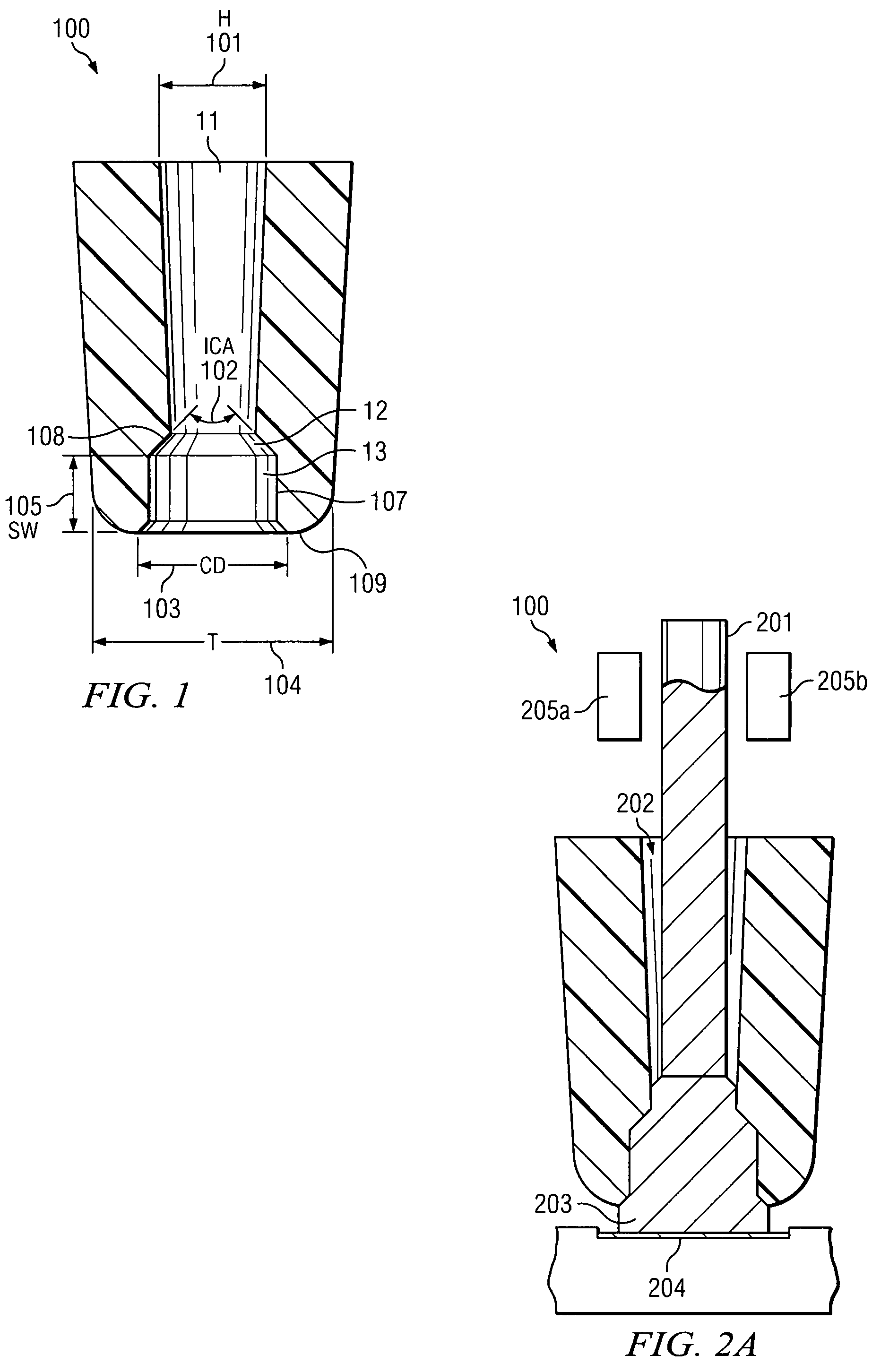

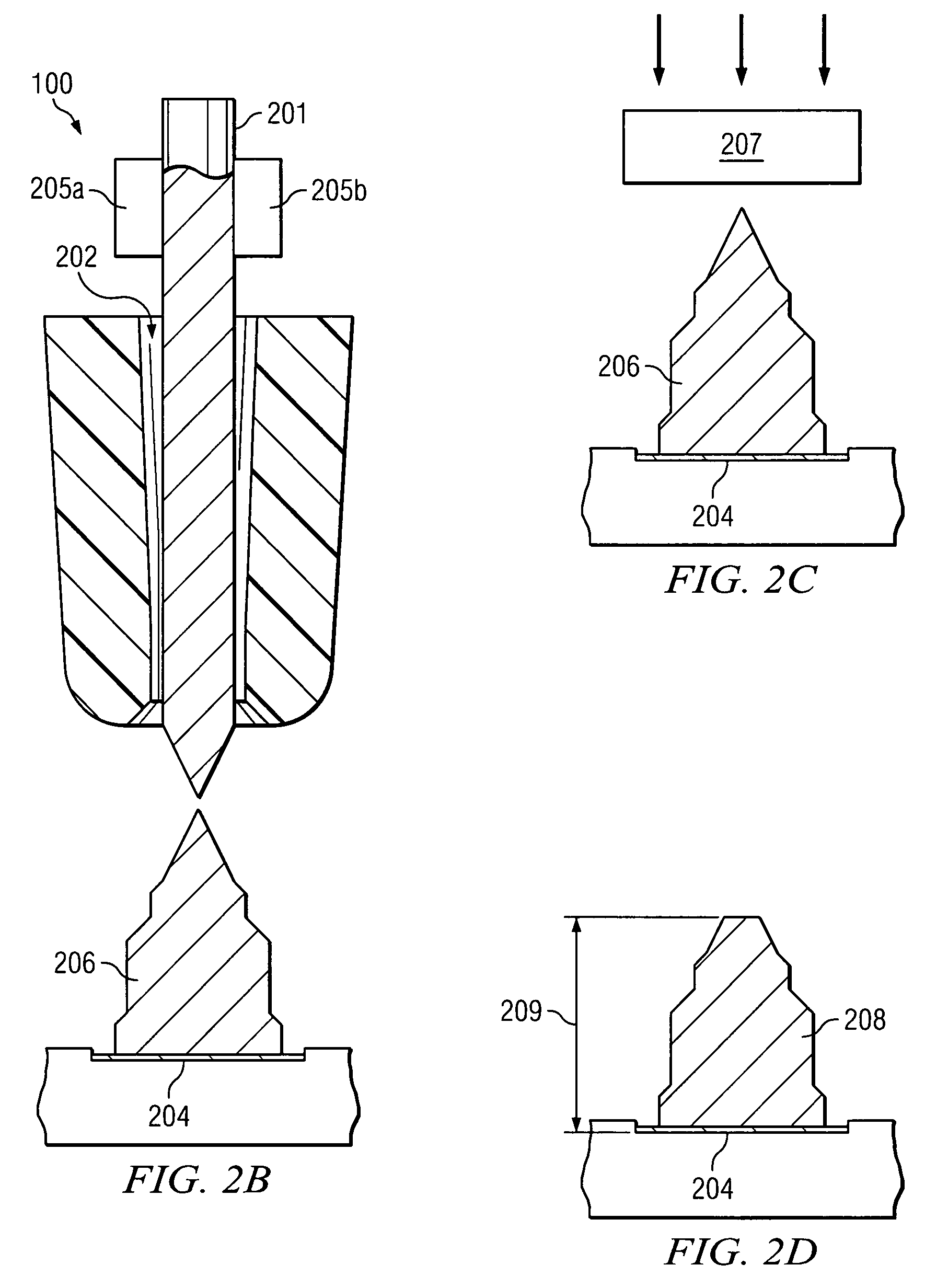

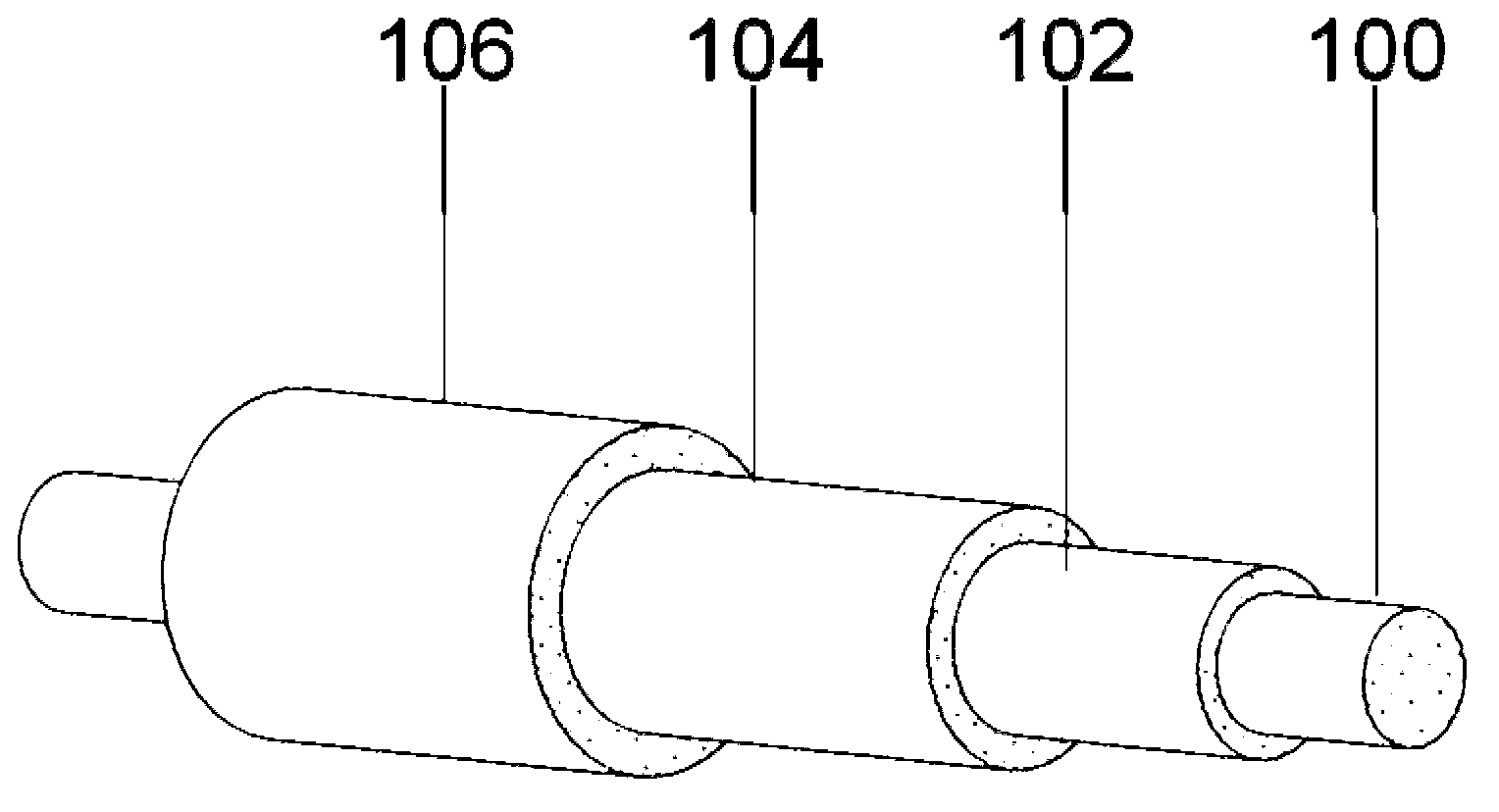

System and method for increased stand-off height in stud bumping process

ActiveUS7521284B2Increase ground clearanceIncrease spacingSemiconductor/solid-state device detailsWelding/cutting auxillary devicesProcess systemsEngineering

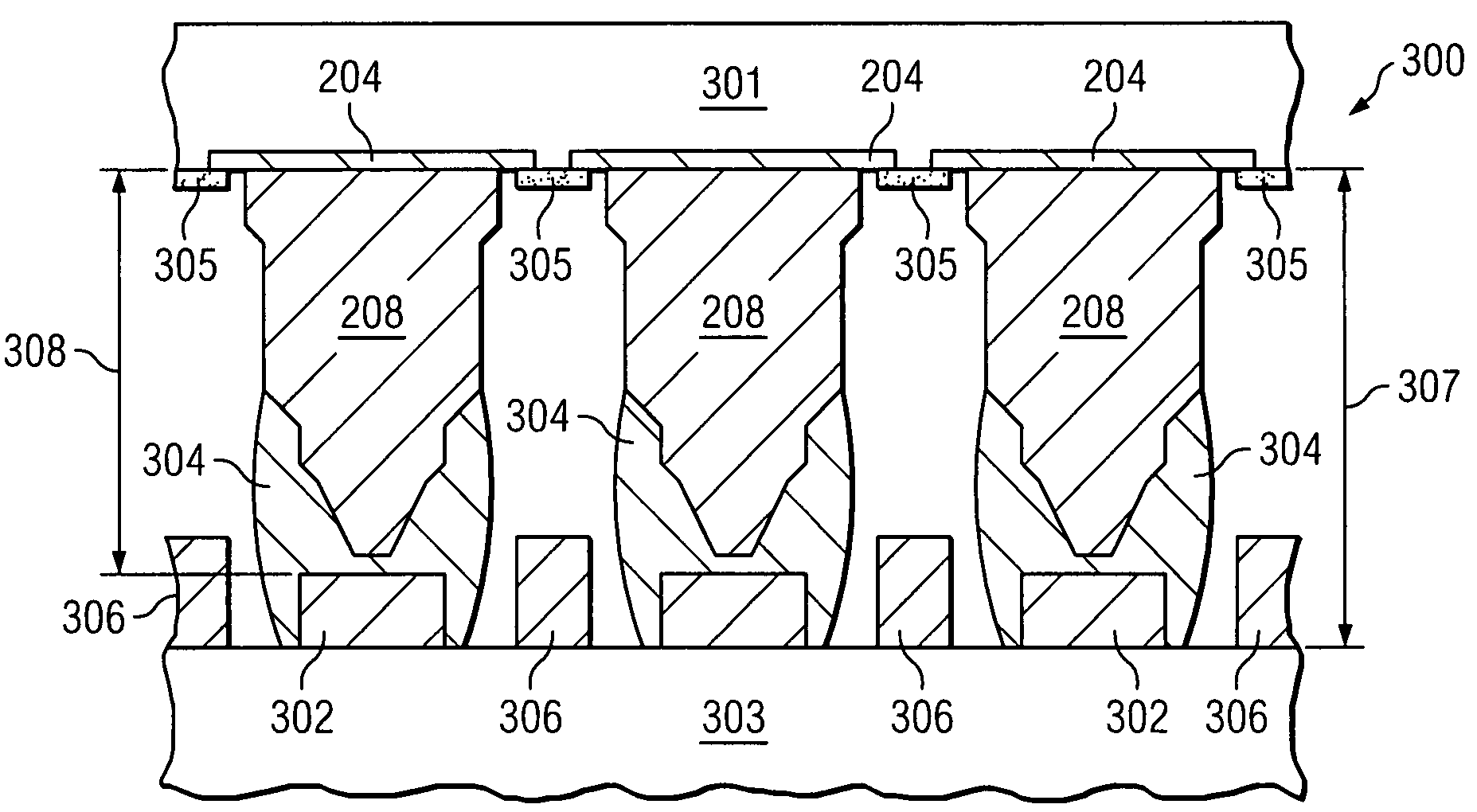

System and method for creating single stud bumps having an increased stand-off height. A preferred embodiment includes a method of using a capillary for creating stud bumps in a flip chip assembly, the capillary includes a hole section adapted to pass a wire, a chamfer section providing a transition from the hole section to a stud bump section, and a sidewall within the stud bump section, the sidewall having a sidewall height, wherein the side wall height is equal to, or greater than, the a diameter of the stud bump section.

Owner:TEXAS INSTR INC

Method of manufacturing composite board

InactiveUS20060145384A1Improve flow characteristicsIncreased flexural modulusMouldsFrozen sweetsFiberThermoplastic

A composite board is made from waste medium density fiber (MDF) board or waste particle board that includes solid urea formaldehyde. The waste board is chopped and milled into particles having a size between 20 mesh and 150 mesh, creating a waste flour. After removing moisture from the waste flour, the dried waste flour is mixed with a thermoplastic to bind and encapsulate the waste flour. Internal lubricants are added to improve the flow characteristics of the blended material, and external lubricants are added to present sticking of the mixture to an extruder or mold. Mineral fillers are added to improve the flexural modules of the composite board, and a plasticizer can be added to improve the physical properties or mechanical characteristics of the mixture. An ultraviolet absorber, a biocide, and a pigment can also be added. The blended material is extruded or molded into a desired shape. When cooled, the thermoplastic hardens to form a solid composite board.

Owner:MASCO CABINETRY

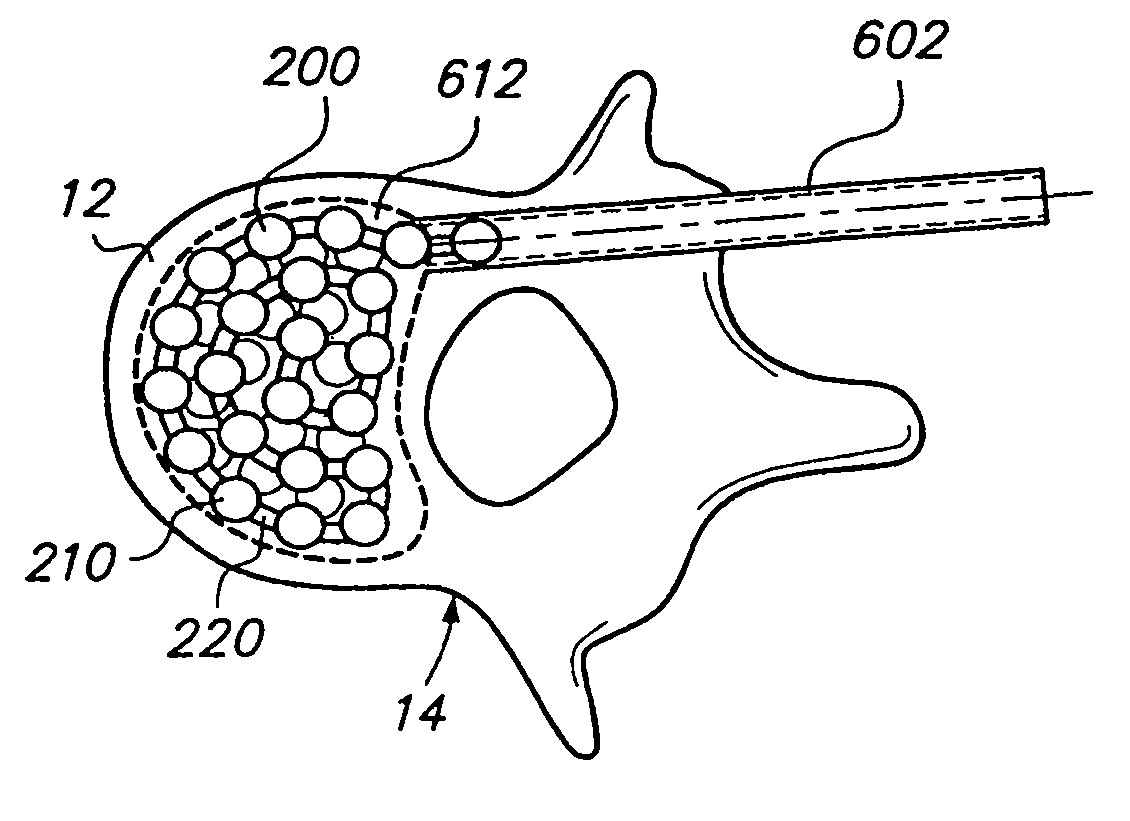

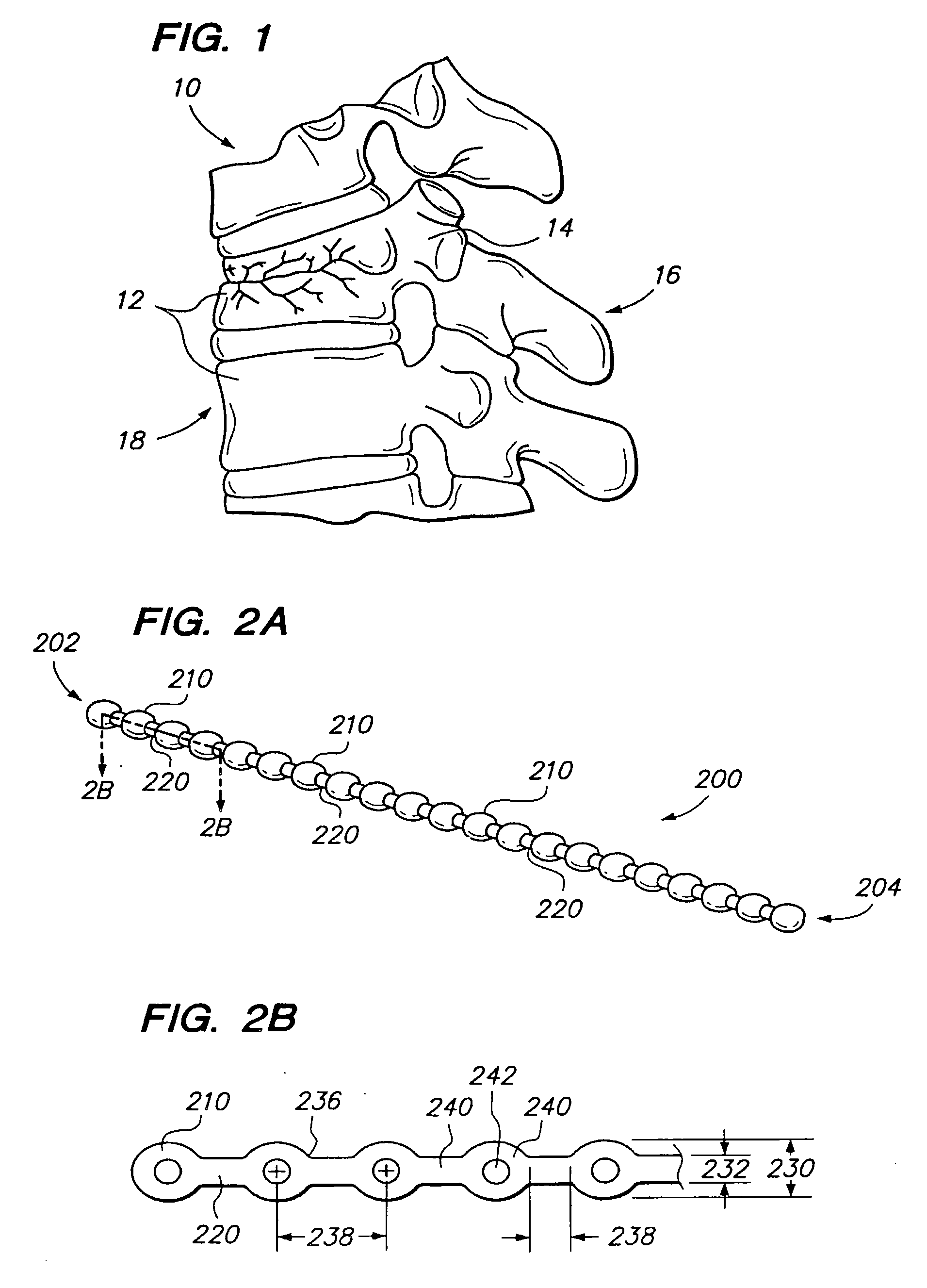

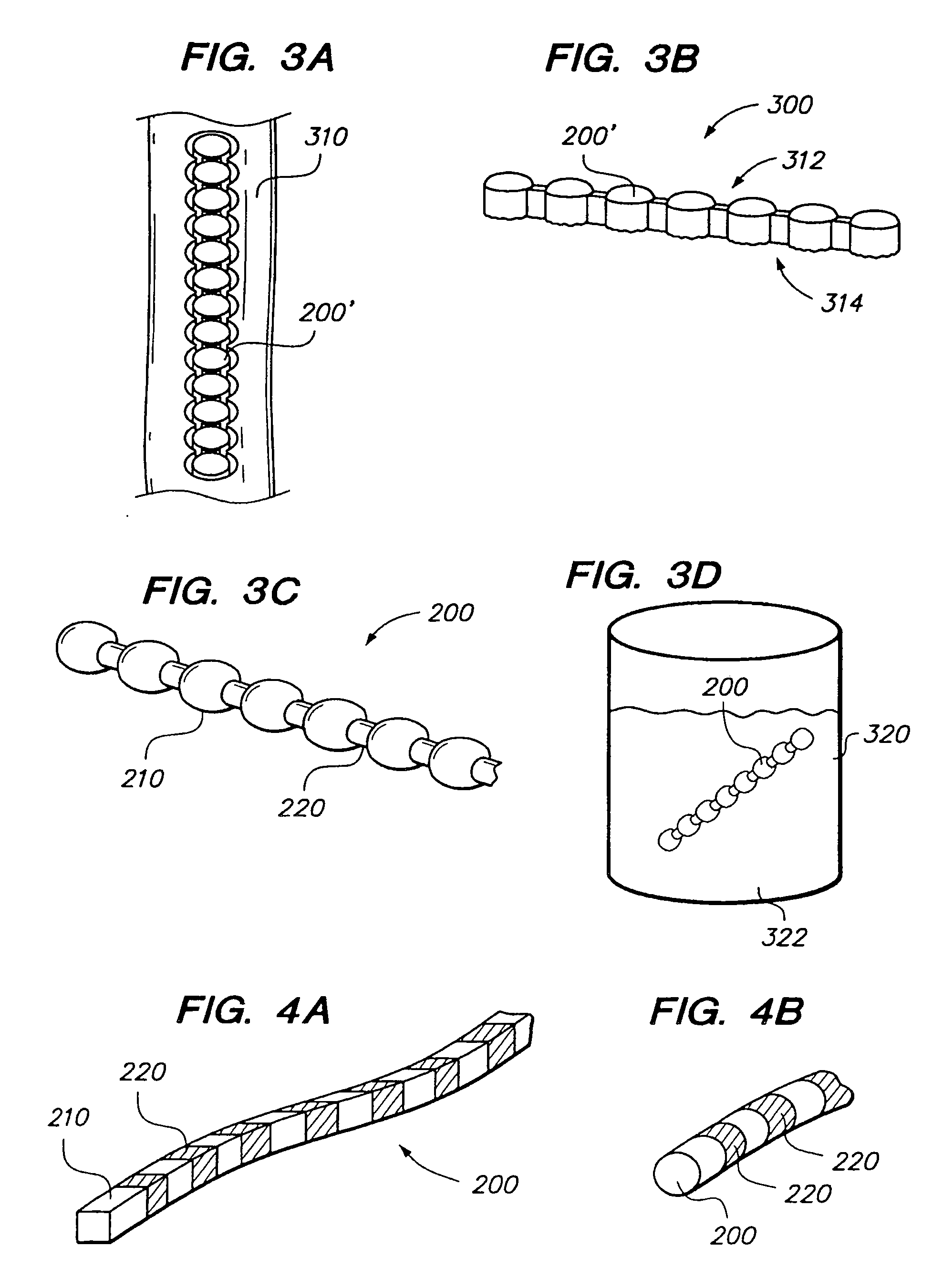

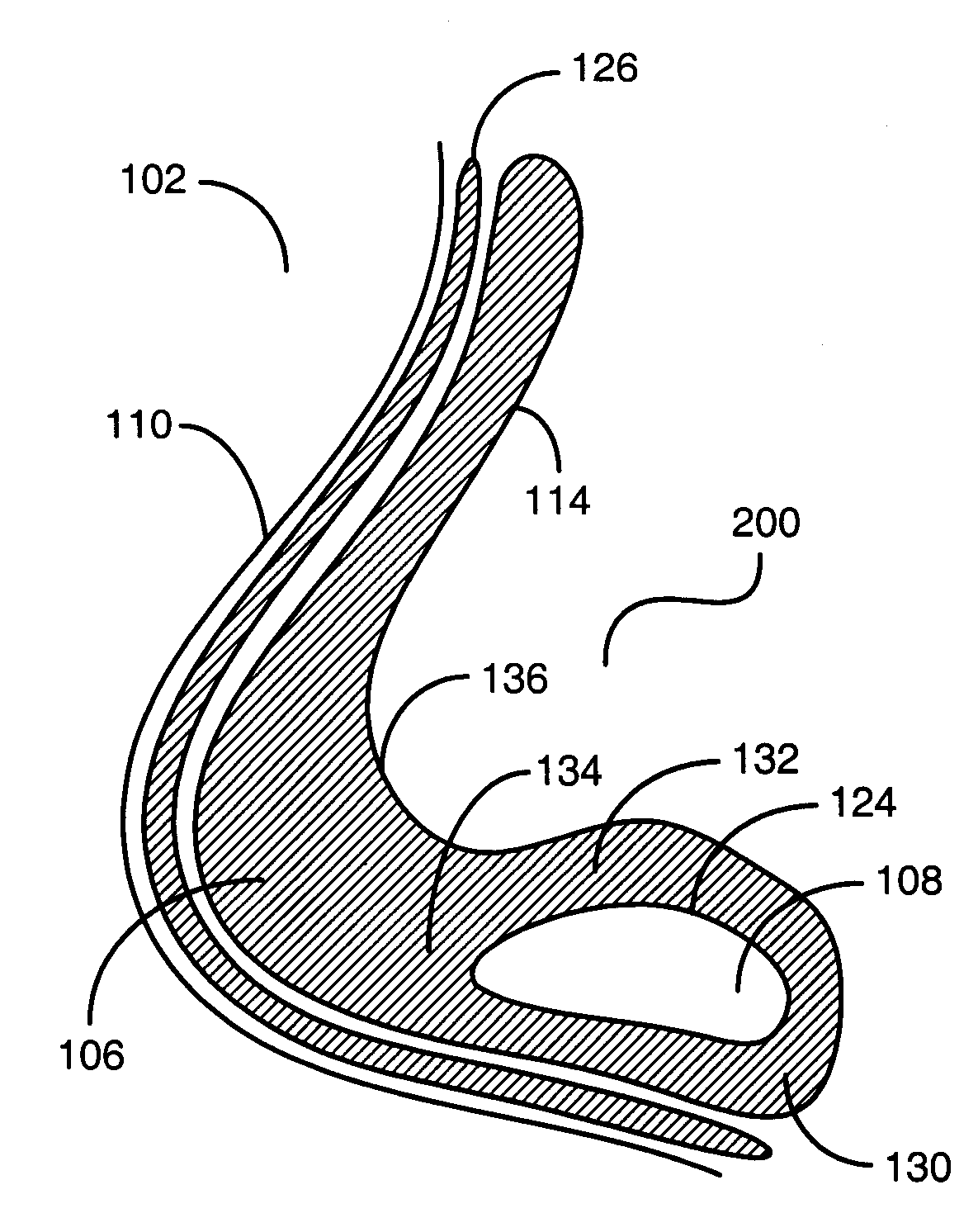

Flexible elongated chain implant and method of supporting body tissue with same

Implants and methods for augmentation of the disc space between two vertebral bodies to treat disease or abnormal pathology conditions in spinal applications. The implant includes a chain of biocompatible material suitable for insertion into a disc space between two adjacent vertebral bodies in a patient's spinal column, wherein the spinal disc space has a transverse plane. The chain comprises a plurality of adjacent bodies having a height configured to reside within the disc space between two adjacent vertebral bodies and a length configured to reside in the disc space between two adjacent vertebral bodies when the chain is curved in an orientation substantially along the transverse plane of the spinal disc space.

Owner:DEPUY SYNTHES PROD INC

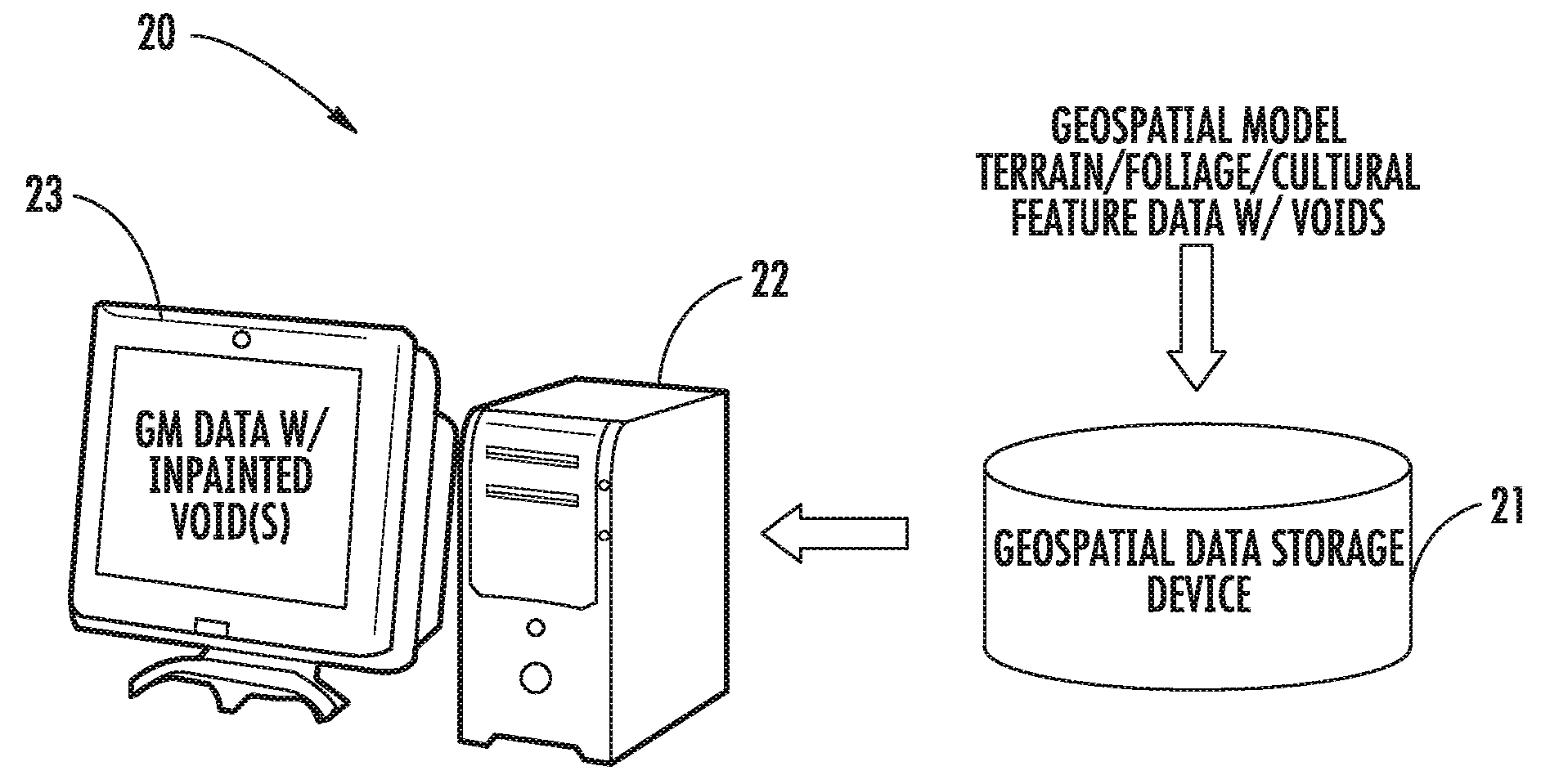

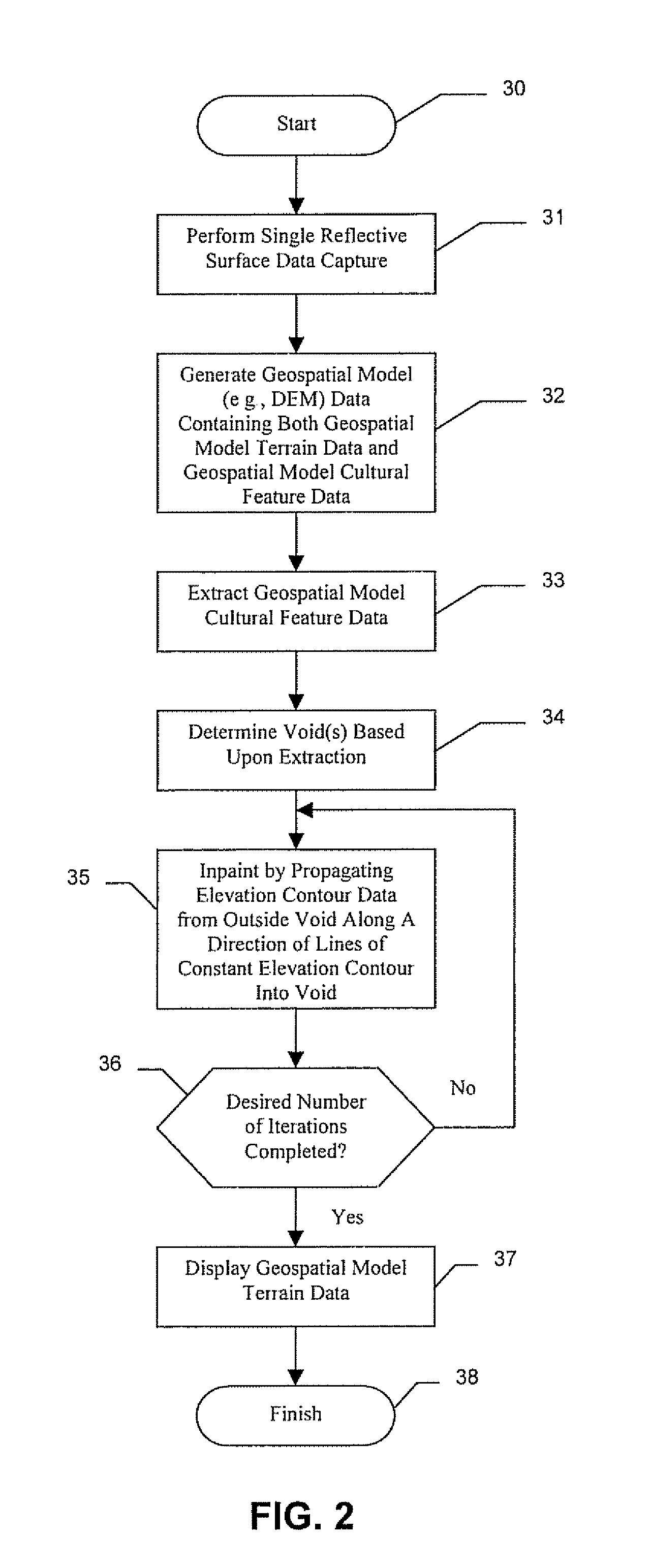

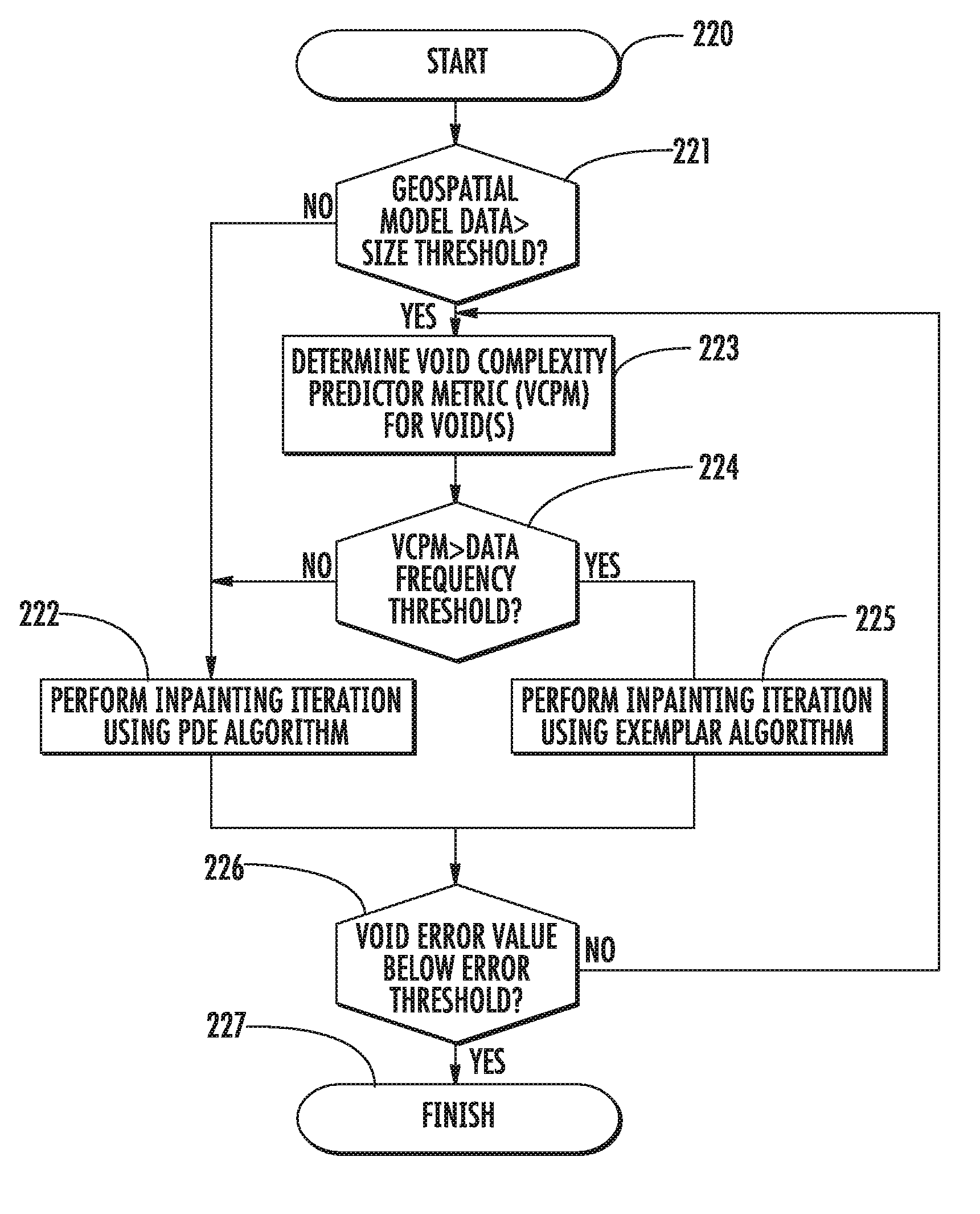

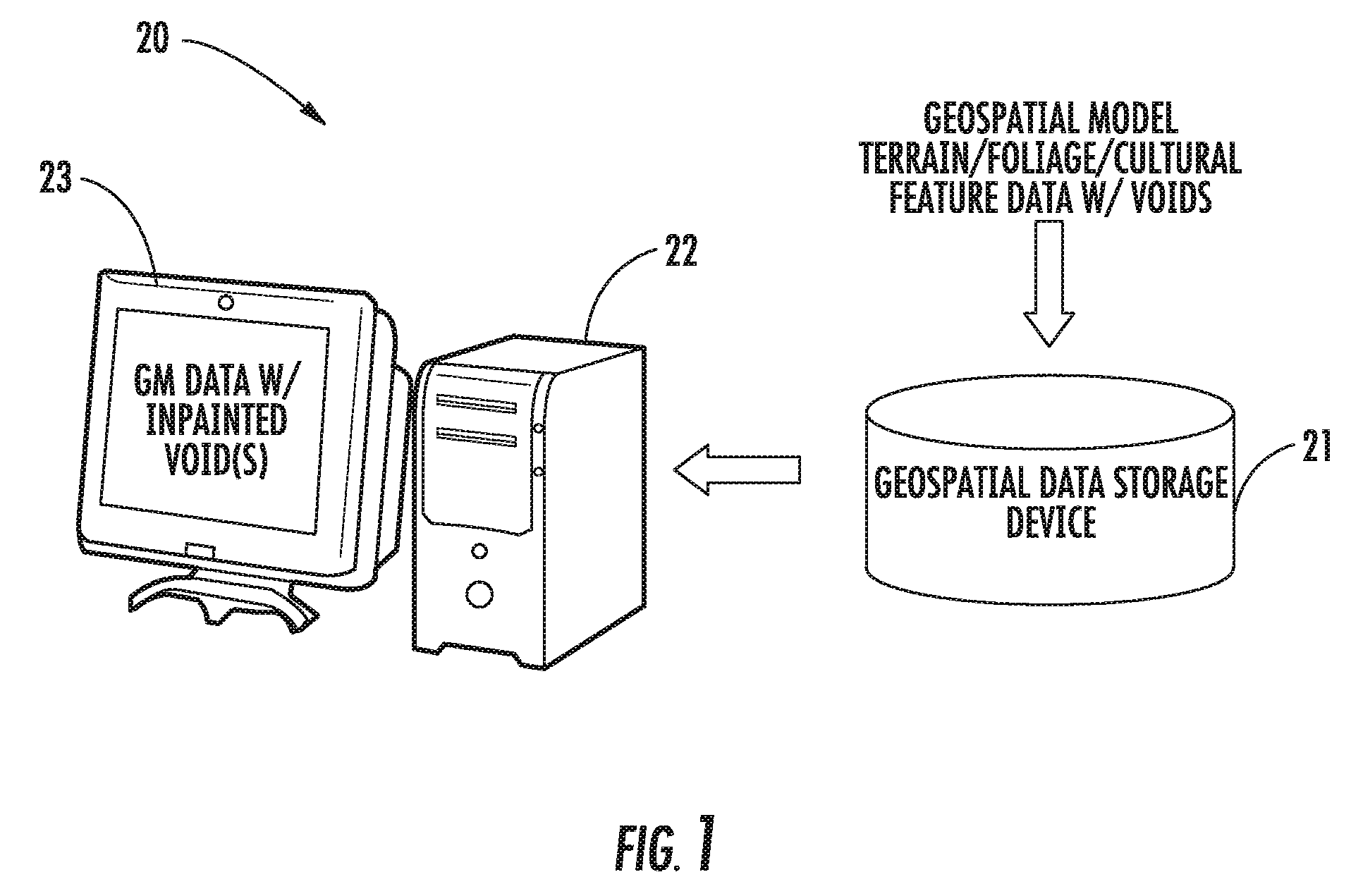

Exemplar/pde-based technique to fill null regions and corresponding accuracy assessment

InactiveUS20080319723A1Fill the voidDigital data processing detailsCharacter and pattern recognitionPartial differential equationAlgorithm Selection

A geospatial modeling system may include a geospatial data storage device, and a processor cooperating with the geospatial data storage device for selectively inpainting data into at least one void in geospatial model data using a partial differential equation (PDE) algorithm and an exemplar algorithm.

Owner:HARRIS CORP

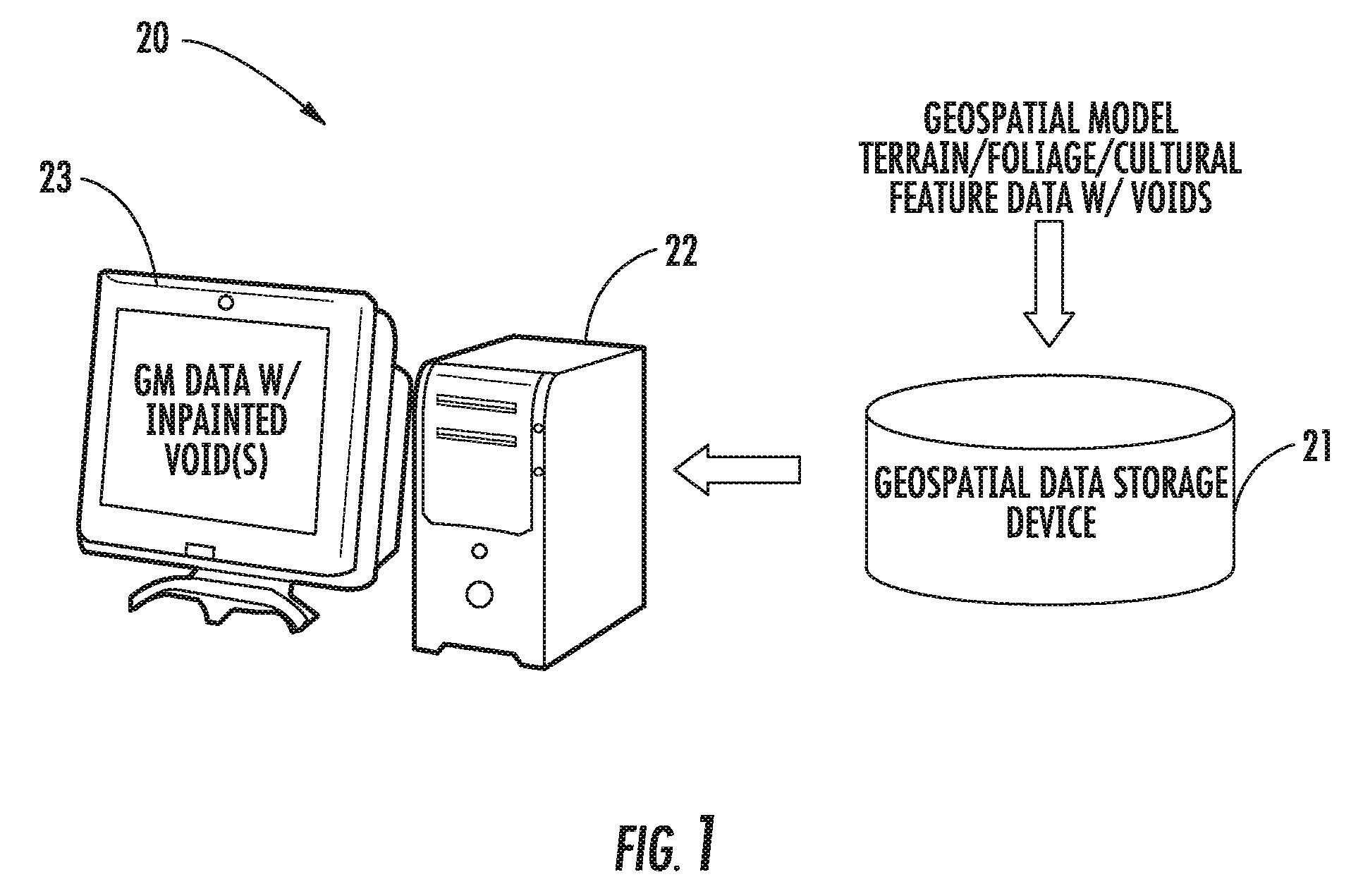

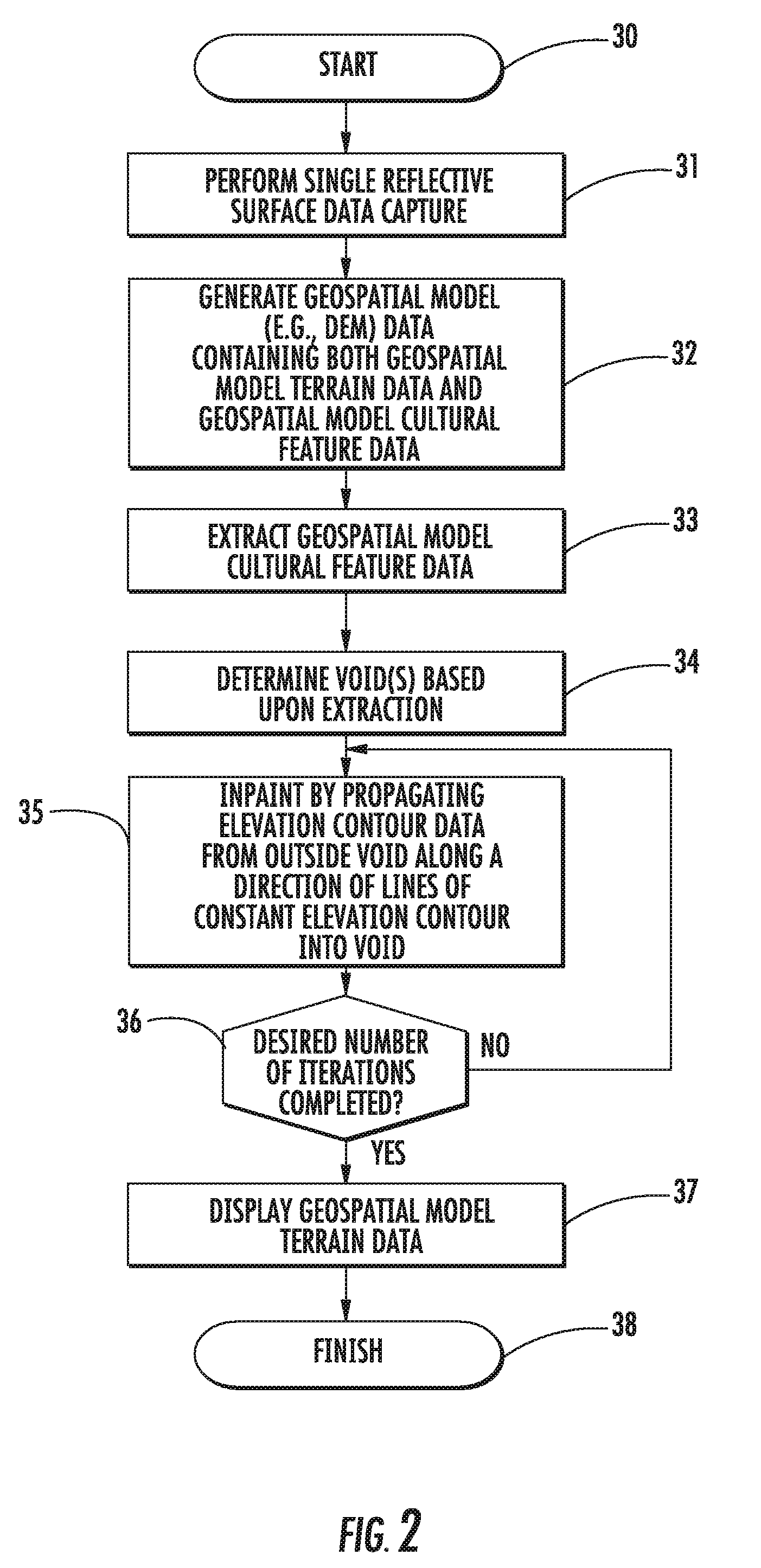

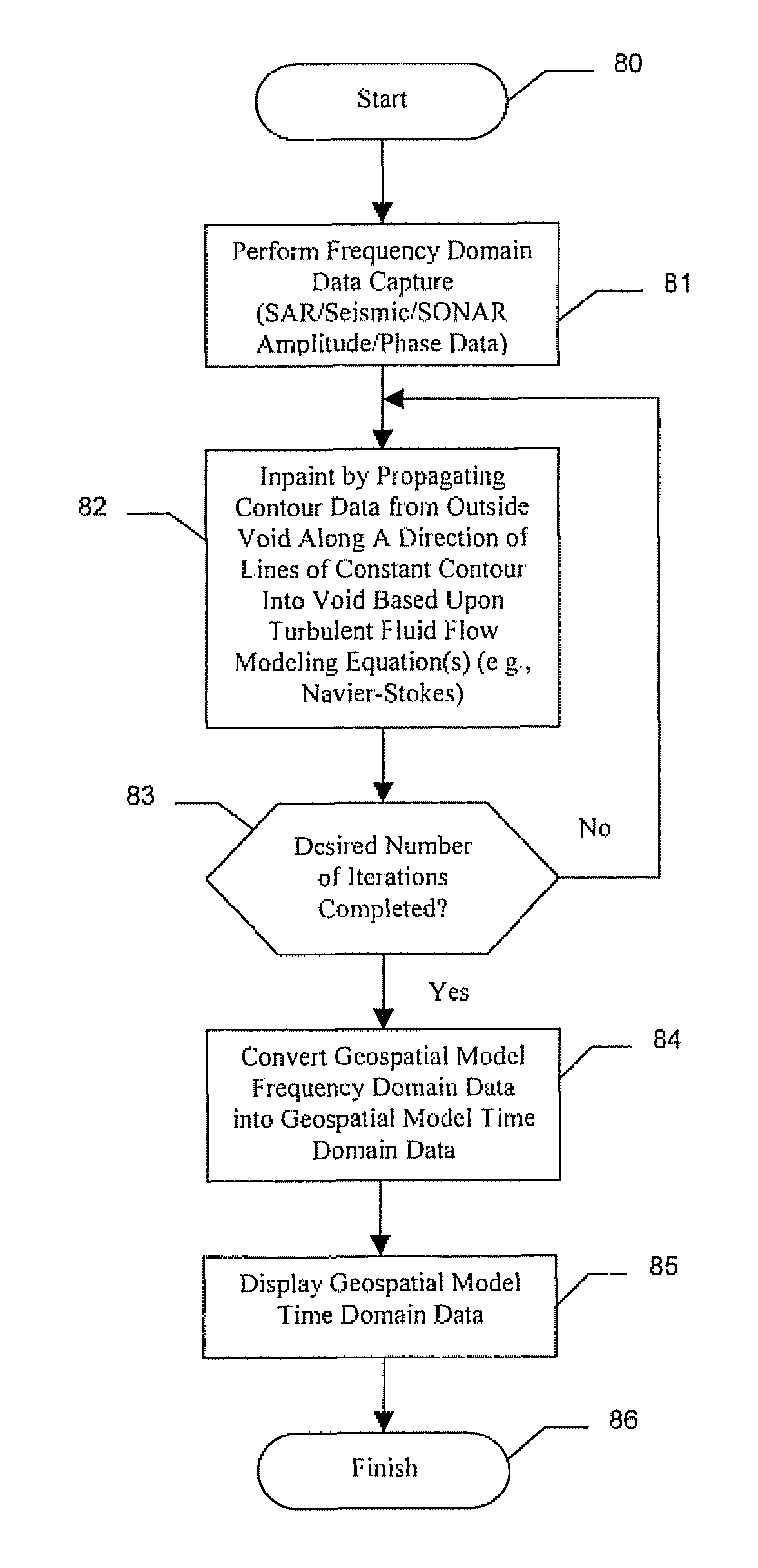

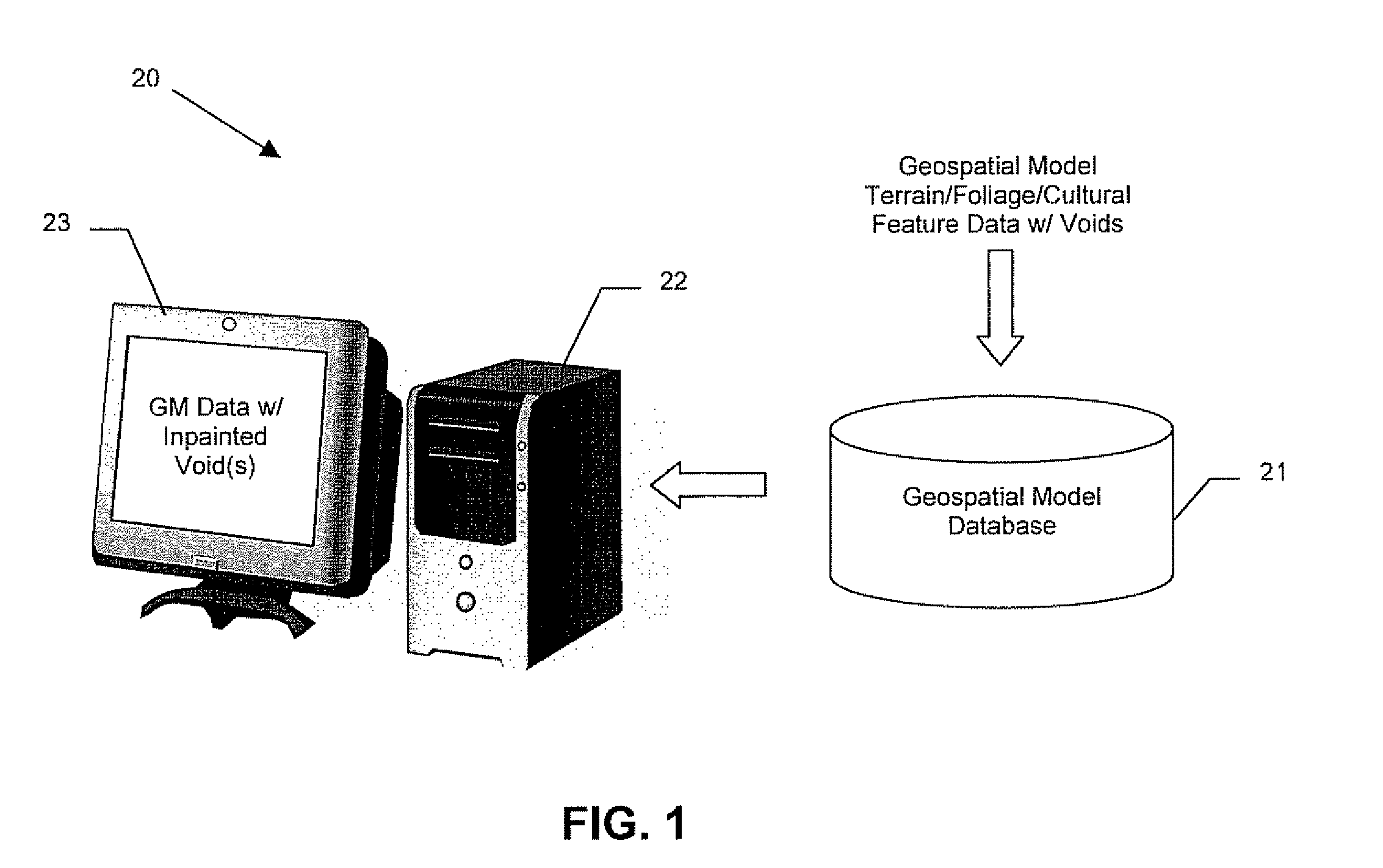

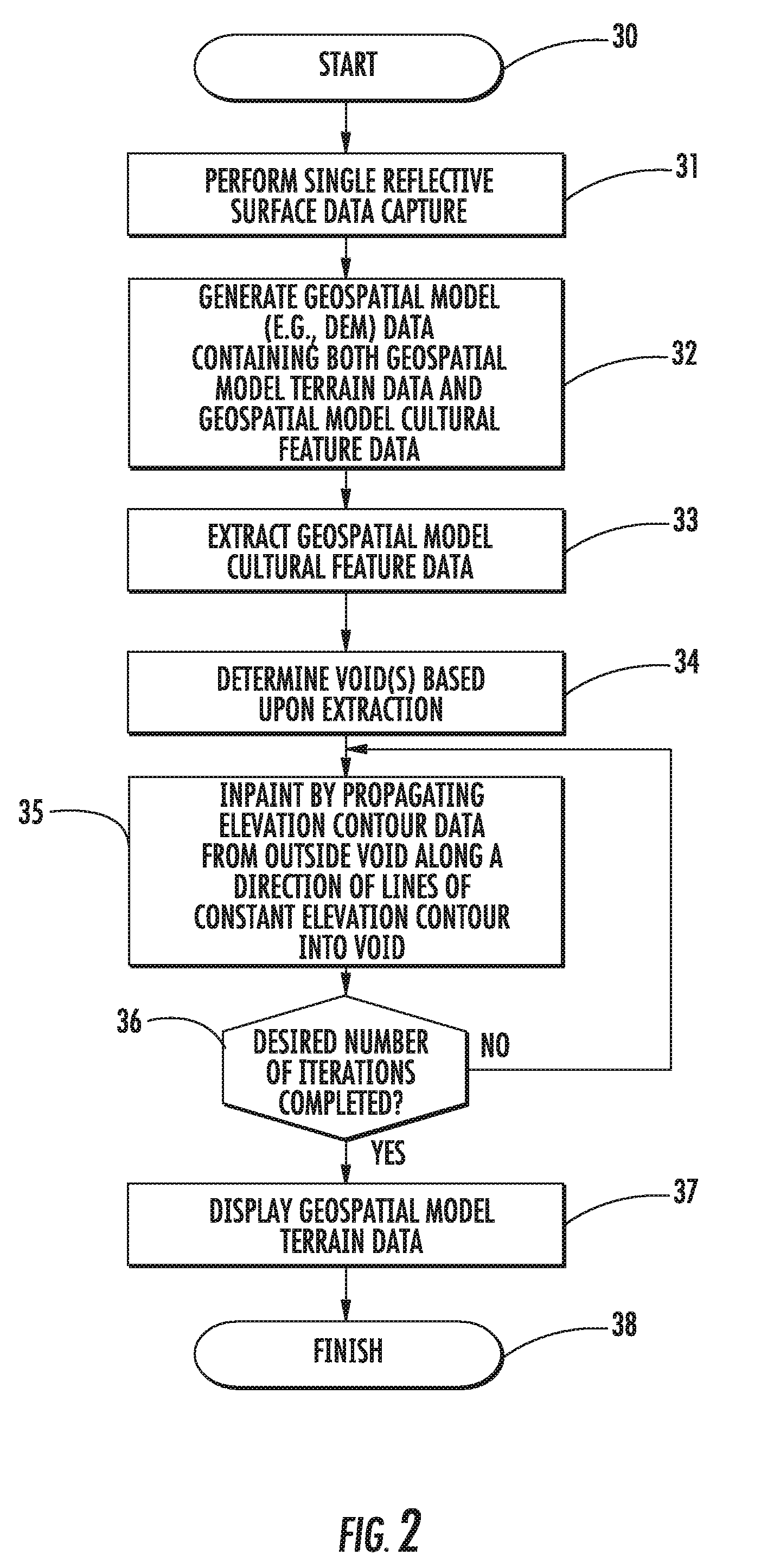

Geospatial modeling system providing non-linear in painting for voids in geospatial model frequency domain data and related methods

InactiveUS7760913B2Fill the voidImage enhancementCharacter and pattern recognitionSpatial simulationSpatial model

A geospatial modeling system may include a geospatial model database and a processor. More particularly, the processor may cooperate with the geospatial model database for inpainting data into at least one void in geospatial model frequency domain data based upon propagating contour data from outside the at least one void into the at least one void, and for converting the geospatial model frequency domain data after inpainting into geospatial model spatial domain data.

Owner:HARRIS CORP

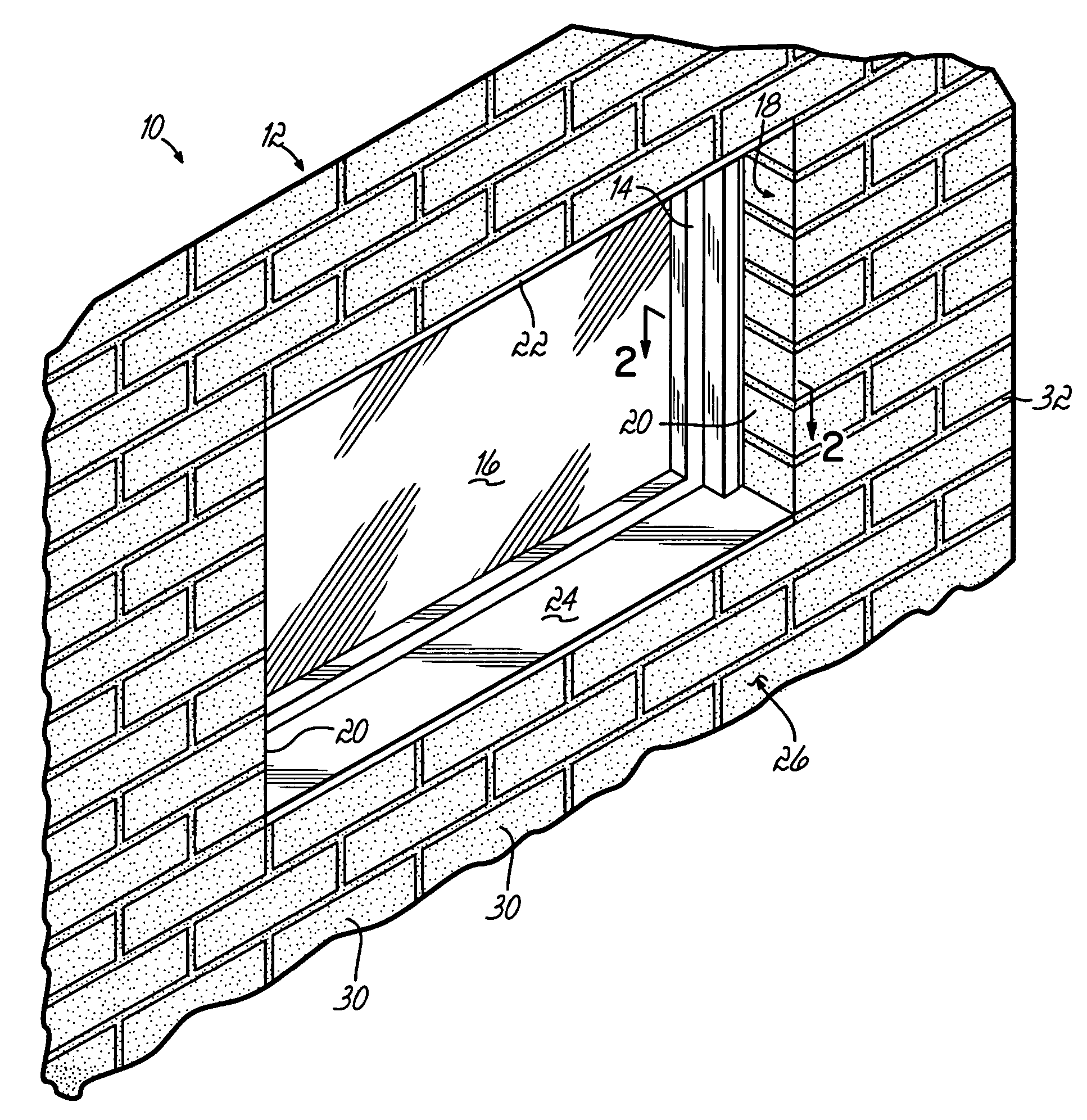

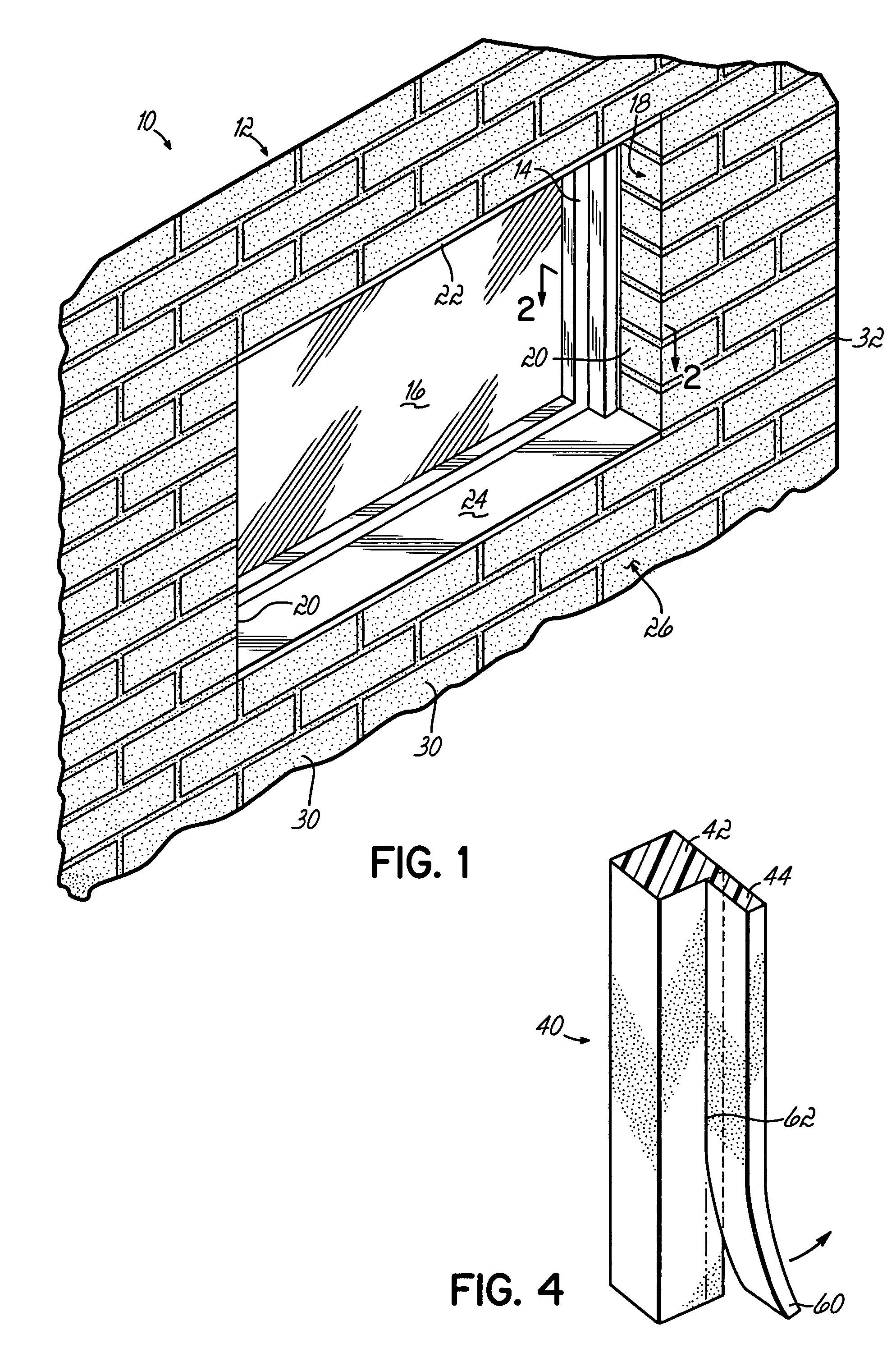

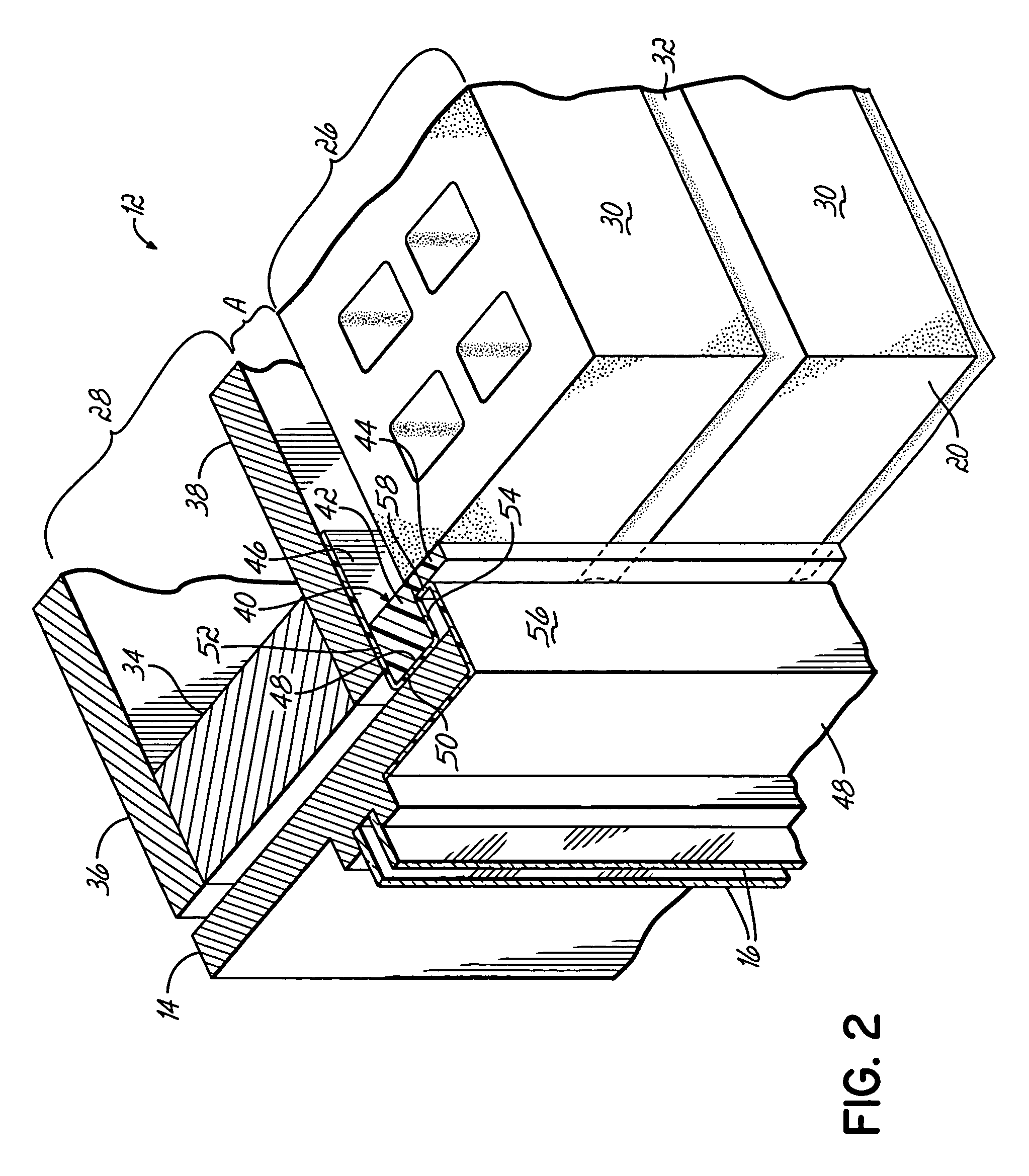

J-channel backer material

ActiveUS7526897B2Efficient and reliableAccurately transitionBuilding roofsCovering/liningsHighly skilledCavity wall

A finishing member for masonry walls allows for simple installation and accurate placement of caulking around windows and doors in cavity wall construction. This invention accommodates a wide variety of window or door frame profiles, particularly those having an outwardly directed channel such as so called J-channel frames, for the detailing and finishing work required for proper installation of a window or door into a masonry veneer or cavity wall construction without requiring a highly skilled and labor intensive installation.

Owner:TY DAS BUILDING PROD LLC

Exemplar/PDE-based technique to fill null regions and corresponding accuracy assessment

InactiveUS7881913B2Fill the voidDigital data processing detailsCharacter and pattern recognitionPartial differential equationData science

A geospatial modeling system may include a geospatial data storage device, and a processor cooperating with the geospatial data storage device for selectively inpainting data into at least one void in geospatial model data using a partial differential equation (PDE) algorithm and an exemplar algorithm.

Owner:HARRIS CORP

Graphene composite copper thick film conductive slurry and preparation method thereof

InactiveCN104021842AImprove conductivityGraphene with excellent conductivity improvesNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesion forceConductive polymer

The invention discloses graphene composite copper thick film conductive slurry. The graphene composite copper thick film conductive slurry comprises the following components in percentage by mass: 60%-80% of conductive phase, 0.5%-5% of glass phase, 15%-39.5% of organic carrier, totaling 100%. The preparation method comprises the steps of mixing the components, heating to 35-40 DEG C, and uniformly stirring. According to the graphene composite copper thick film conductive slurry disclosed by the invention, by adding graphene with an excellent conductive property, the conductive property of the slurry is improved; by bismuth oxide low-melting glass, the conductive thick film slurry has excellent electrical properties and adhesion force even when being sintered at a low temperature. The slurry has the advantages of good conductivity and small printing thickness, can be effectively applied to production of a conductive material for various products, has the advantages of simple preparation process, convenience in operation, good conductivity, uniform distribution of particle sizes and easiness in coating, and is suitable for mass production of enterprises.

Owner:XI'AN POLYTECHNIC UNIVERSITY

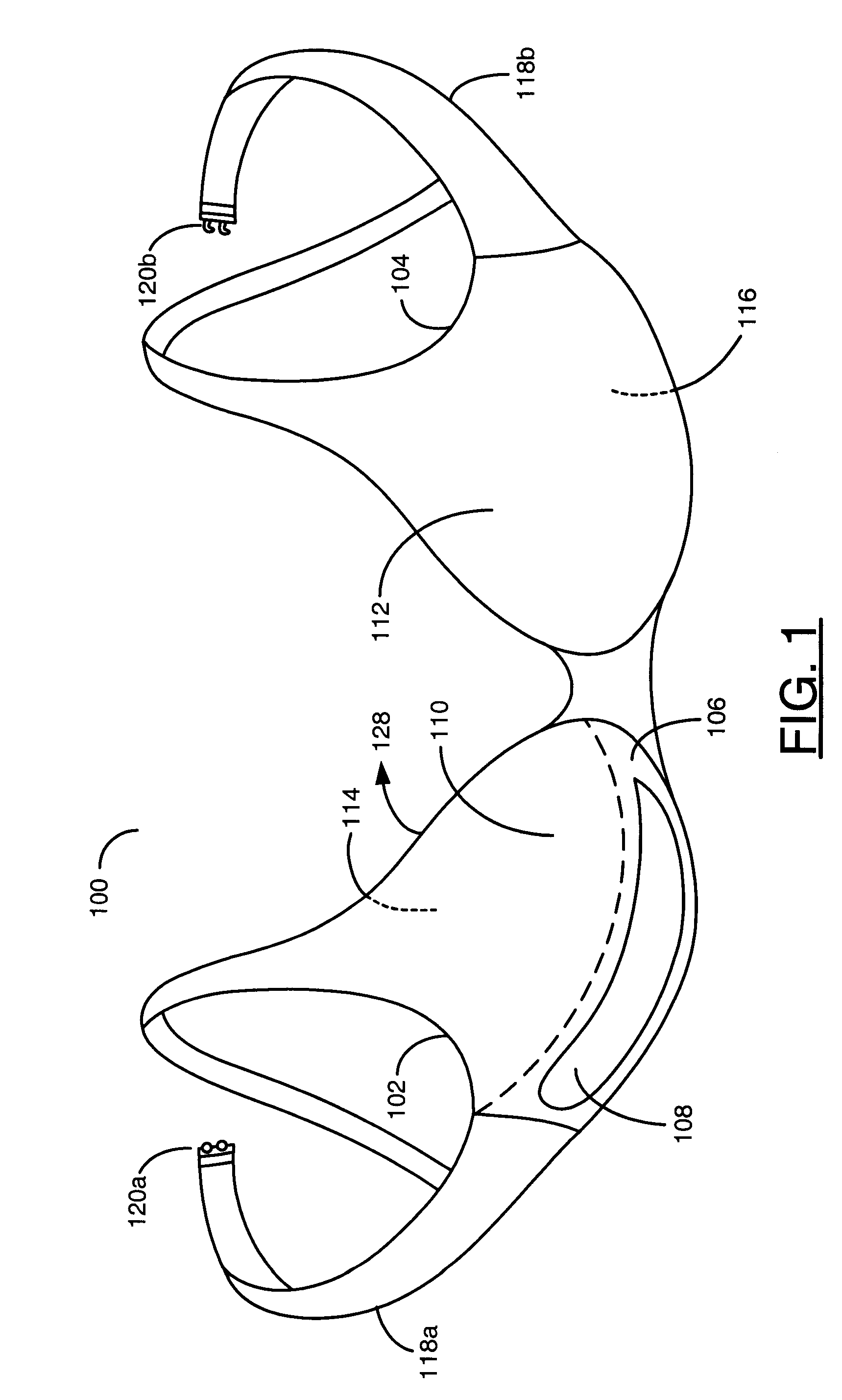

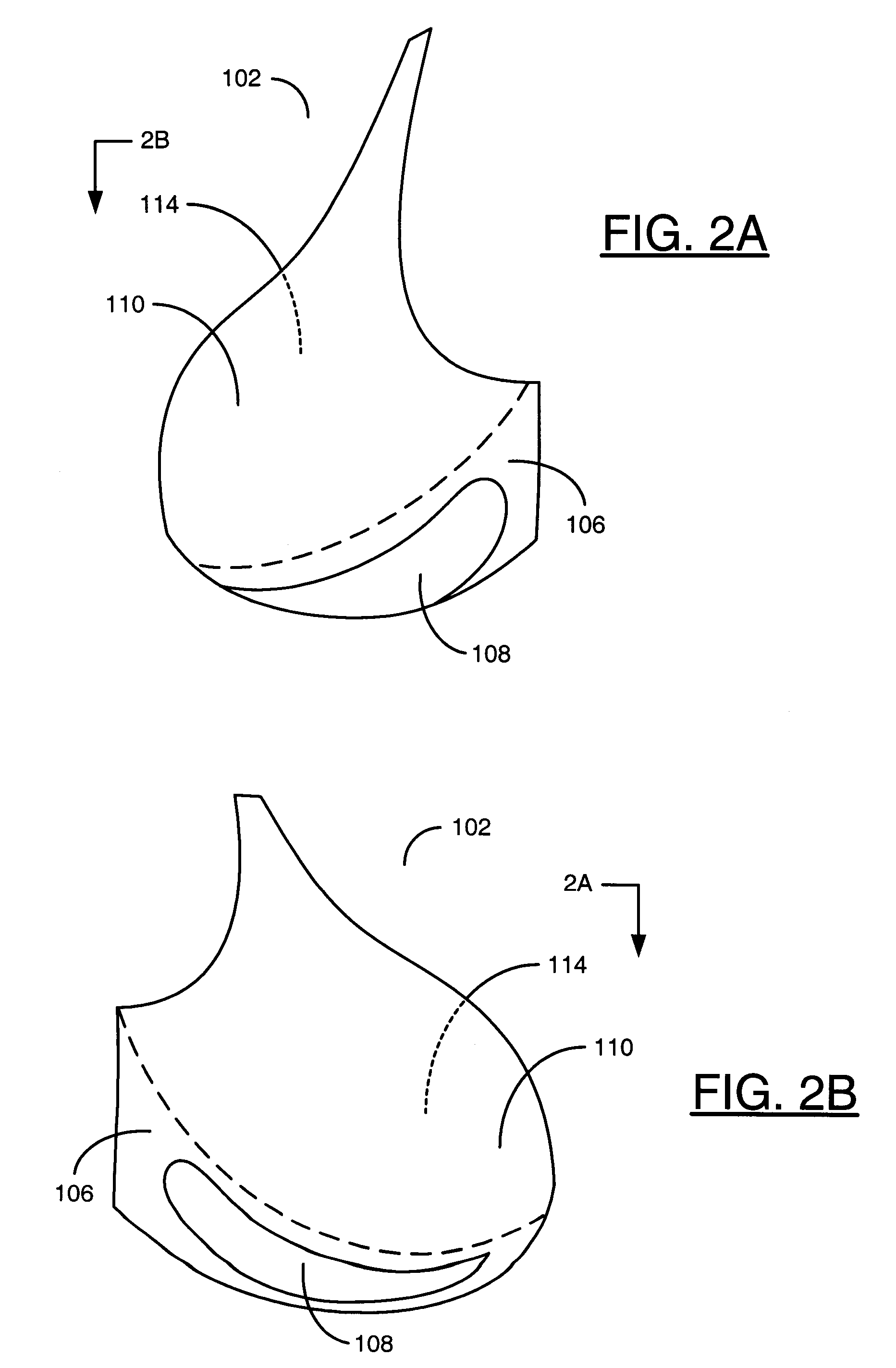

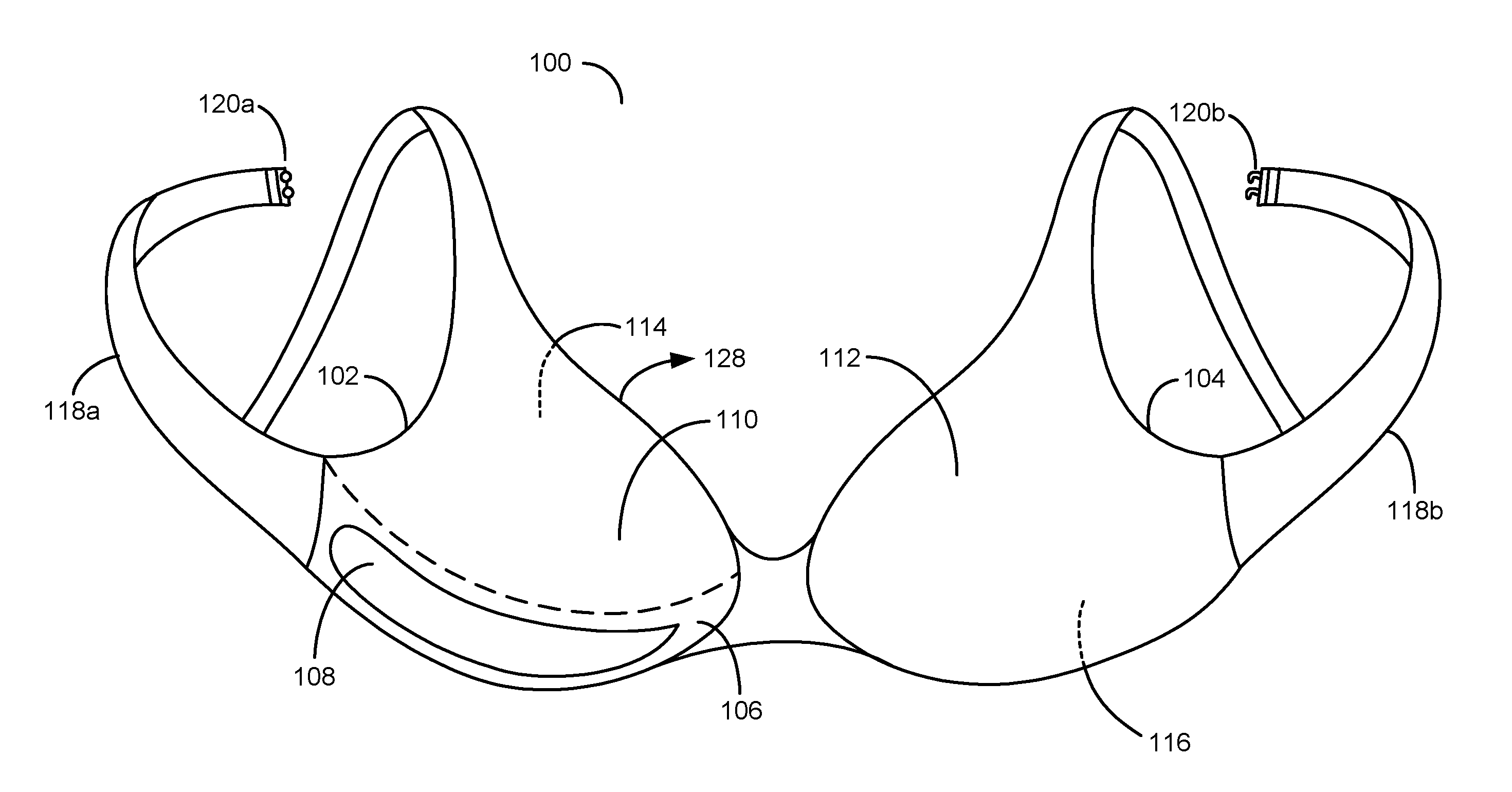

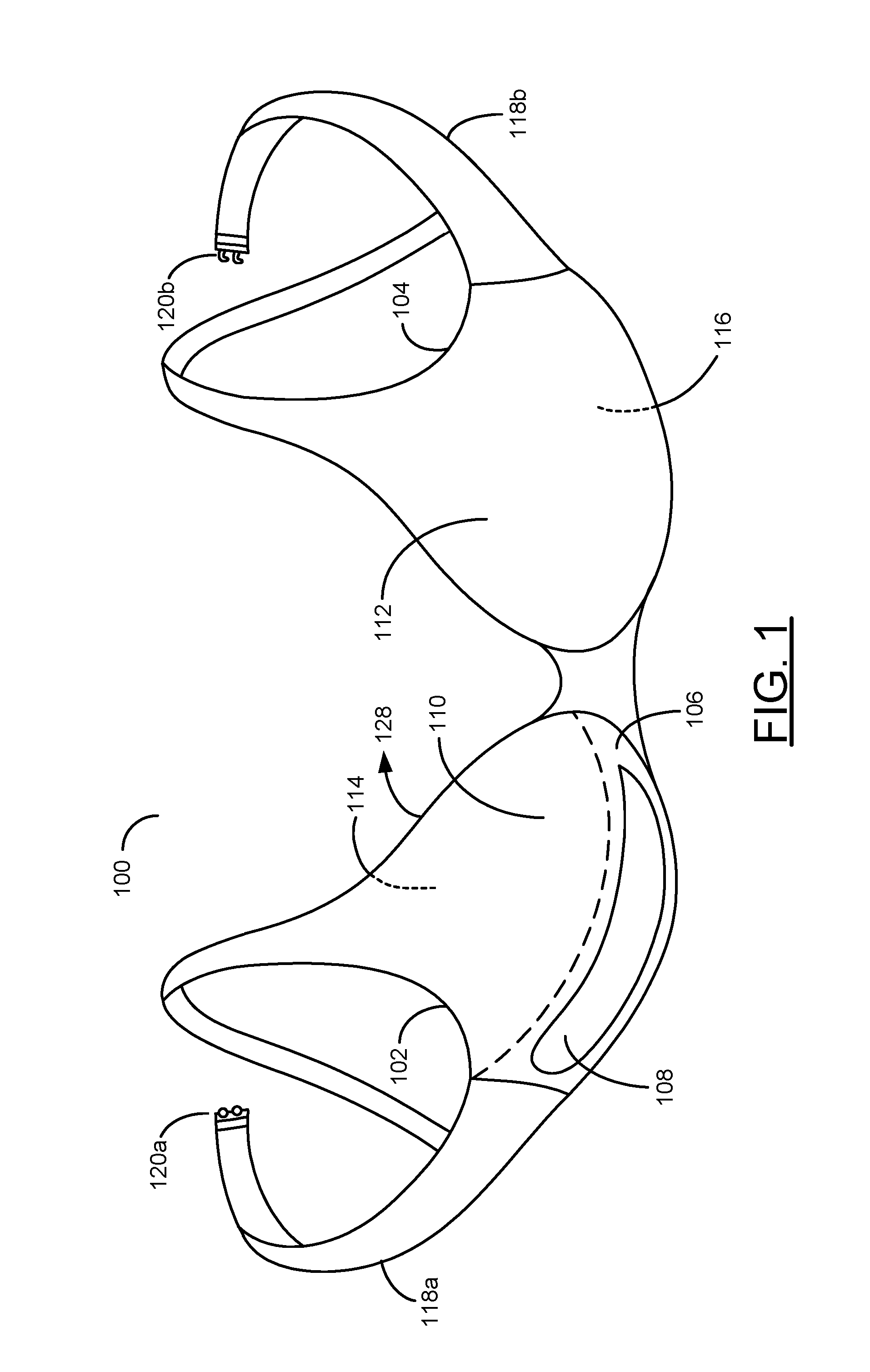

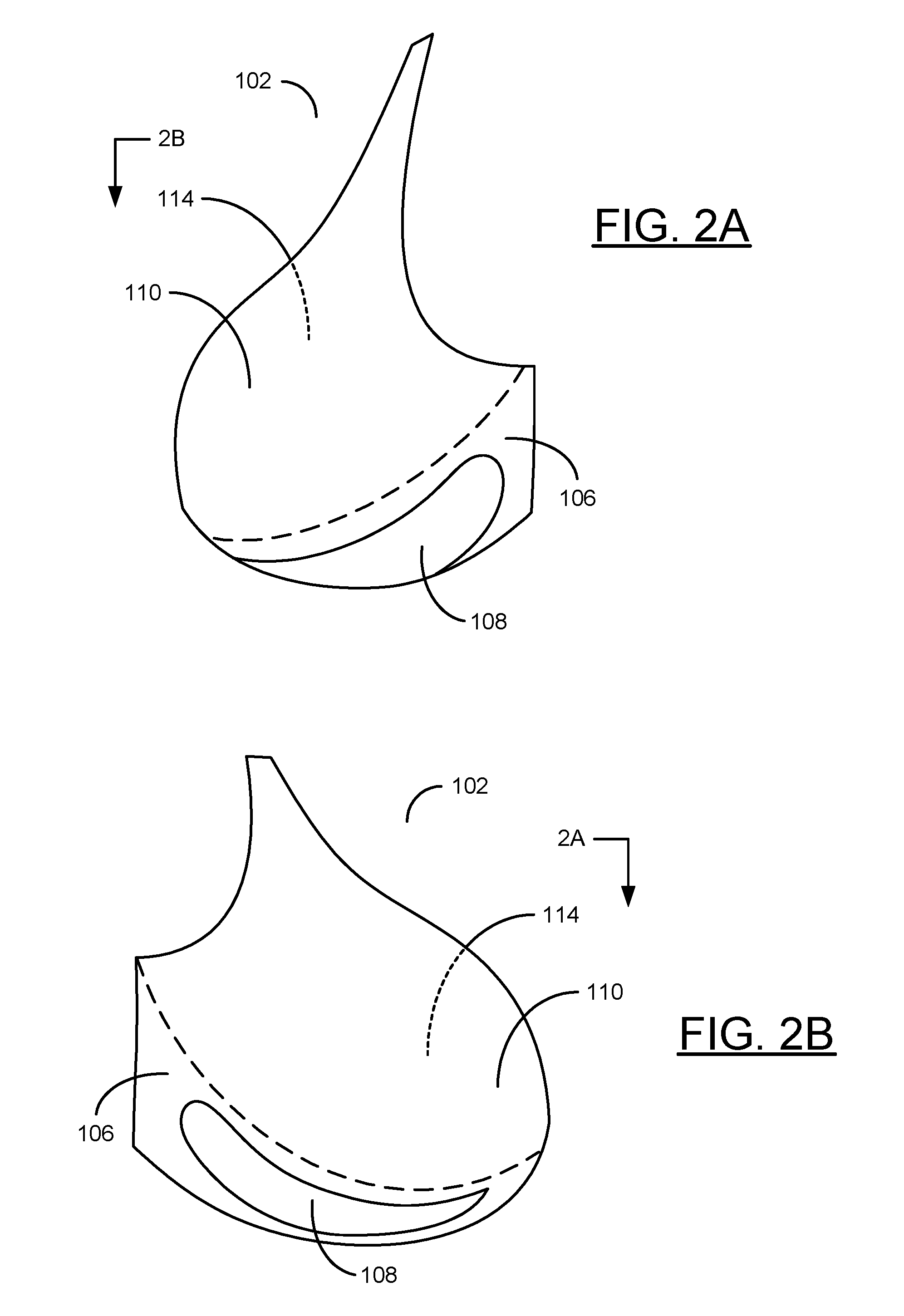

Bra and/or bra pad for providing the appearance of symmetry to asymmetrical breasts

InactiveUS7413495B1Size be equalFill the voidShoulder strapBrassieresBiomedical engineeringAsymmetrical breasts

Owner:SOBAH WILHELM MARY C

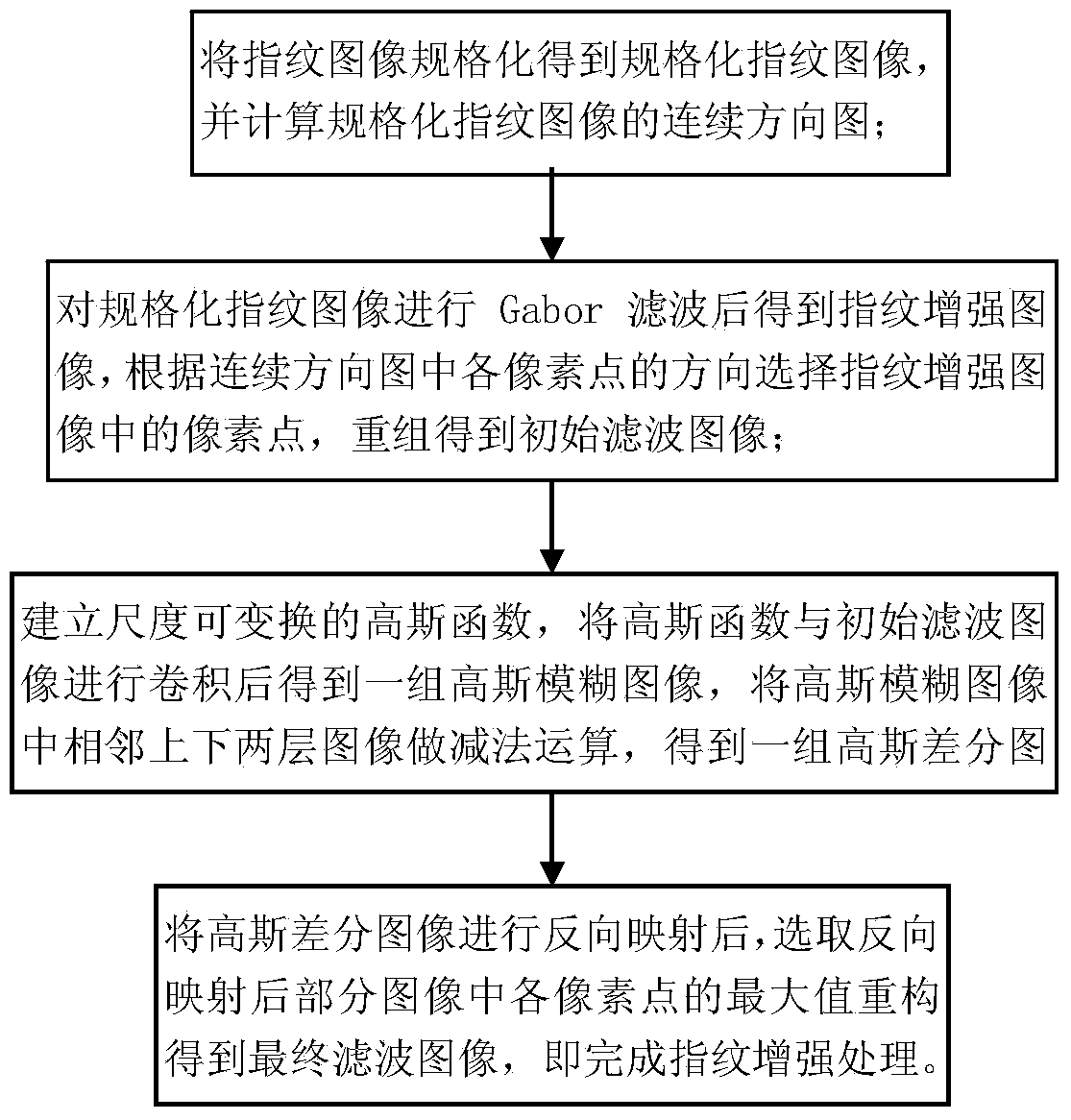

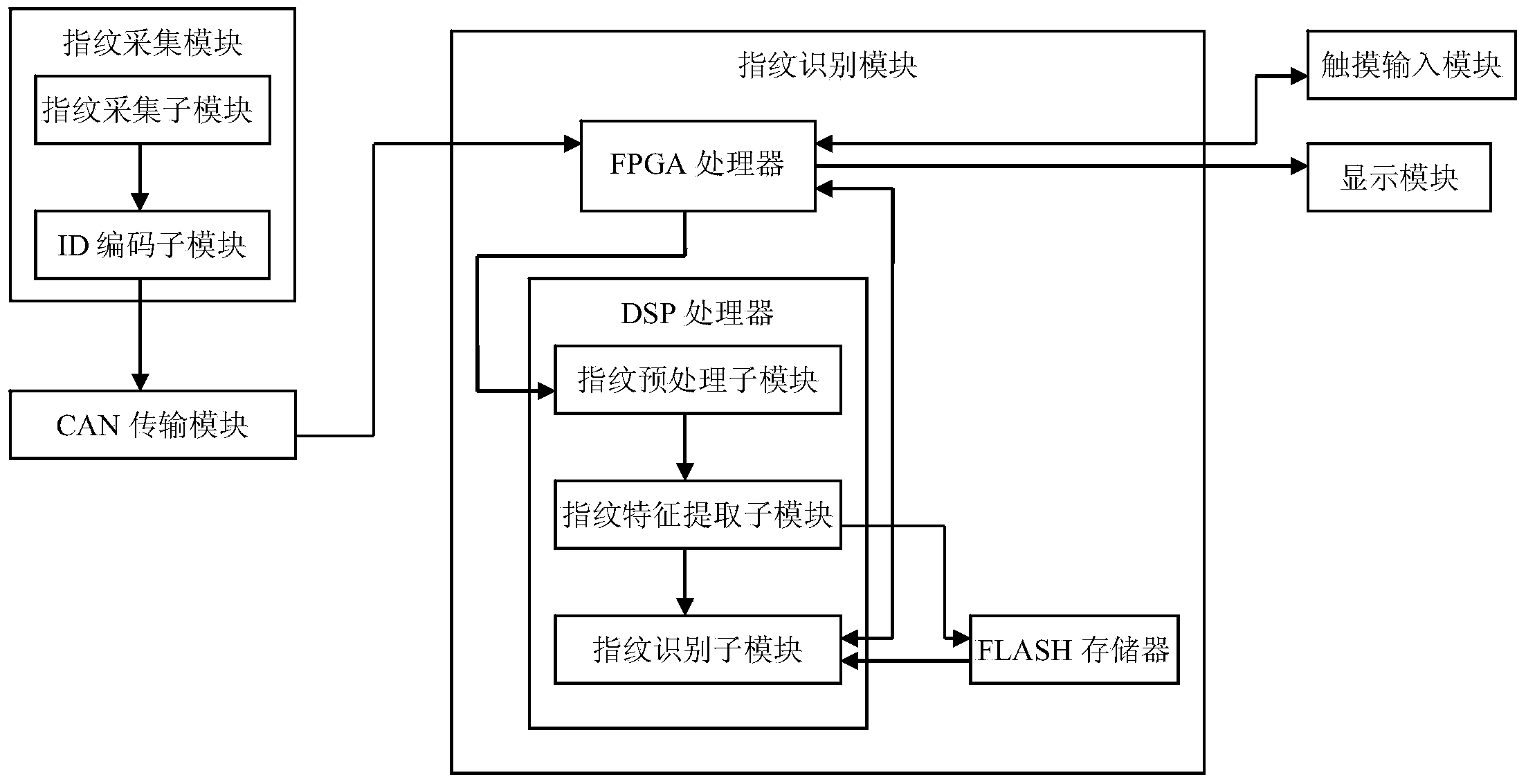

Fingerprint enhancement method and fingerprint recognition device

ActiveCN103714323AEnhanced Edge ResponseImprove acceleration performanceCharacter and pattern recognitionDifference of GaussiansFiltration

The invention aims to provide a fingerprint enhancement method. The fingerprint enhancement method includes the following steps that A, a fingerprint image is normalized to obtain a normalized fingerprint image, and the continuous directional diagram of the fingerprint image is calculated; B, a fingerprint enhancement image is obtained after the normalized fingerprint image is subjected to Gabor filtration, and an initial filtering image is obtained by recombining a continuous directional diagram; C, Gaussian blur is performed on the initial filtering image to obtain a Gaussian blur image, and Gaussian difference is performed on the Gaussian blur image to obtain a Gaussian difference image; D, after being mapped in the opposite direction, the Gaussian difference image is reconstructed to obtain a final filtering image. The invention further provides a fingerprint recognition device. According to the fingerprint enhancement algorithm, the Gabor filtering and the Gaussian difference are combined, and thus the denoising capacity is enhanced, and the defects that an existing fingerprint enhancement algorithm is large in calculation amount and poor in enhancement effect are overcome. Through the fingerprint enhancement method, the fingerprint recognition device is combined with the processing structure of a DSP and the processing structure of an FPGA, and thus the fingerprint recognition efficiency and the fingerprint storage efficiency are improved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

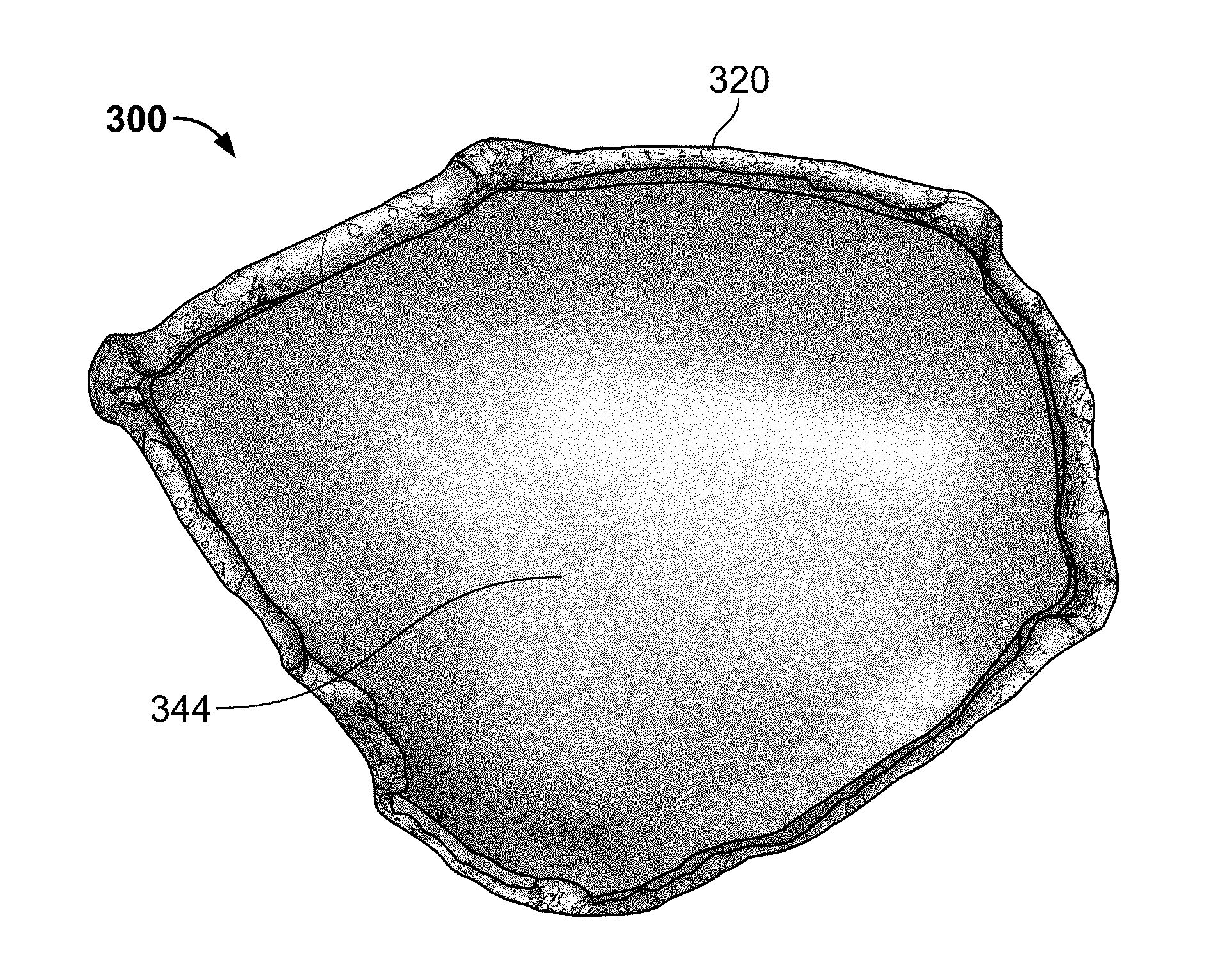

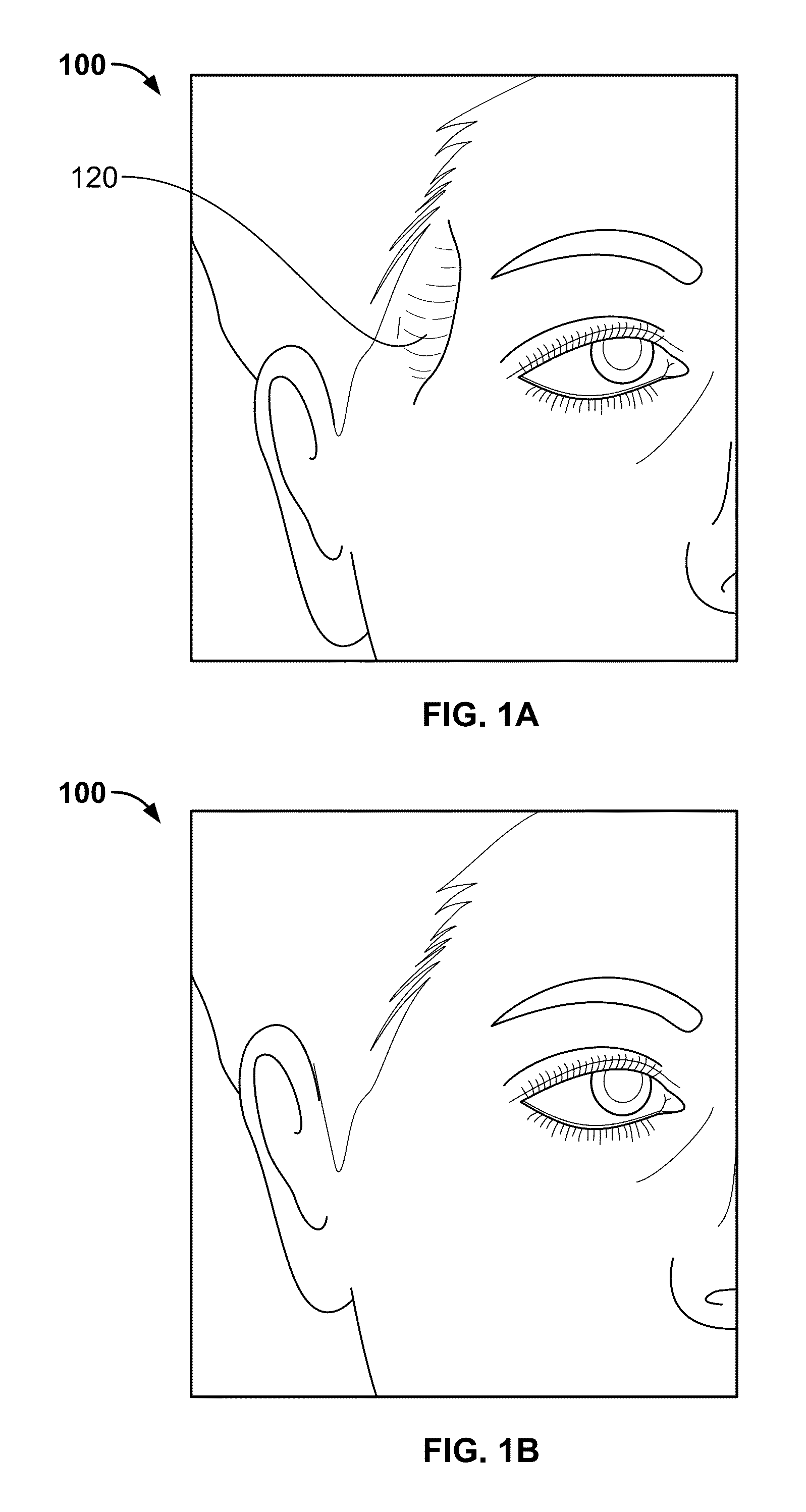

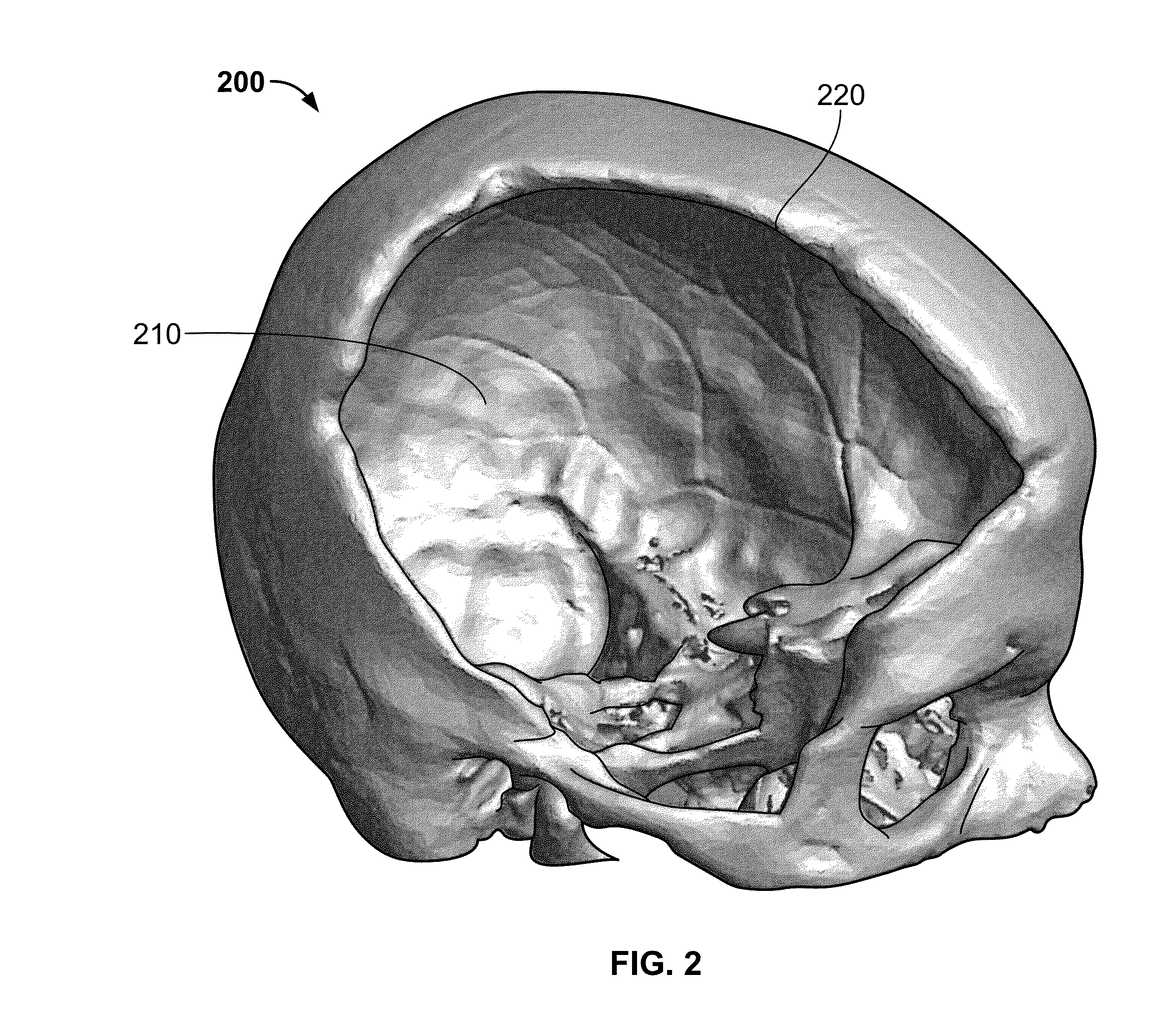

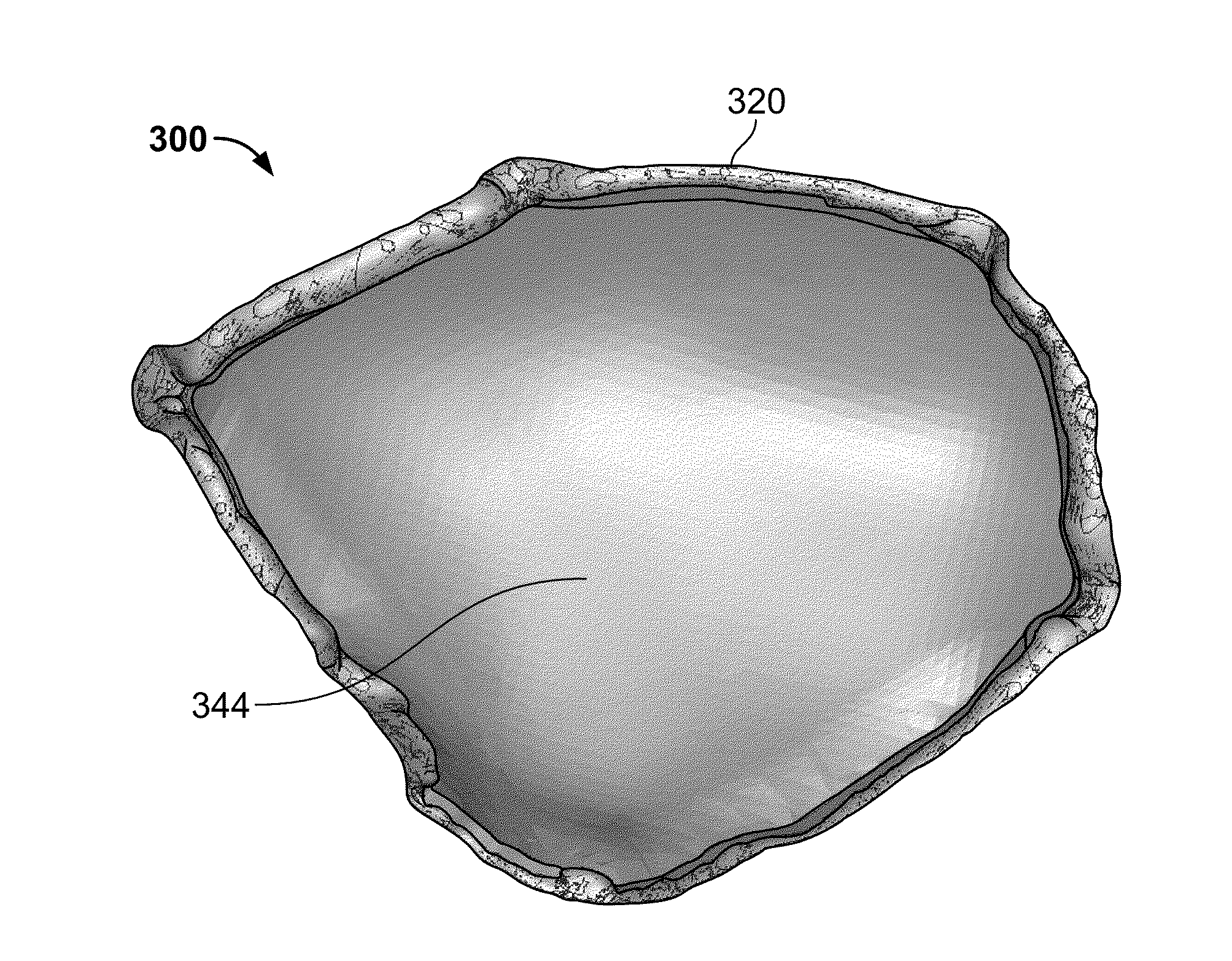

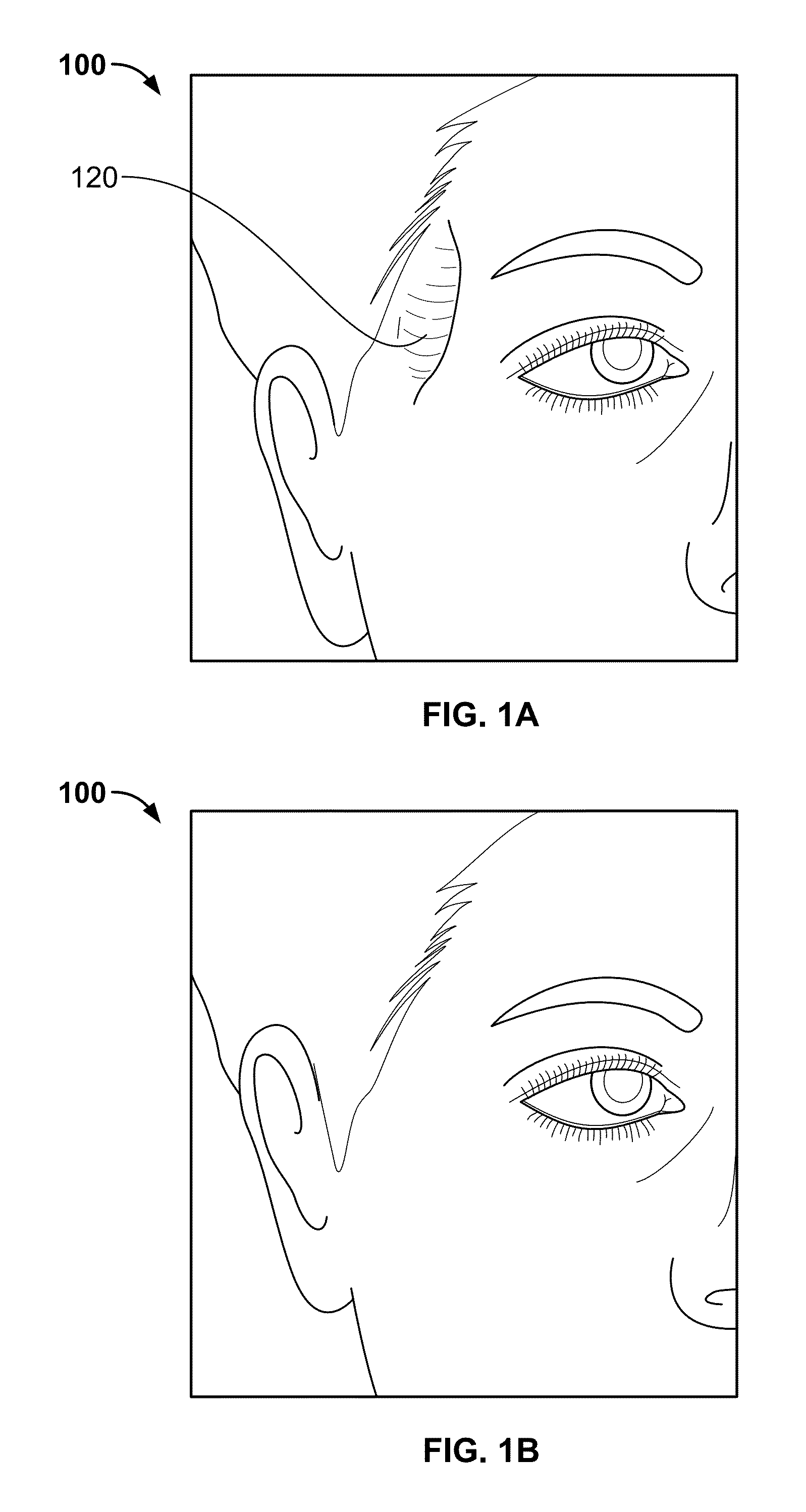

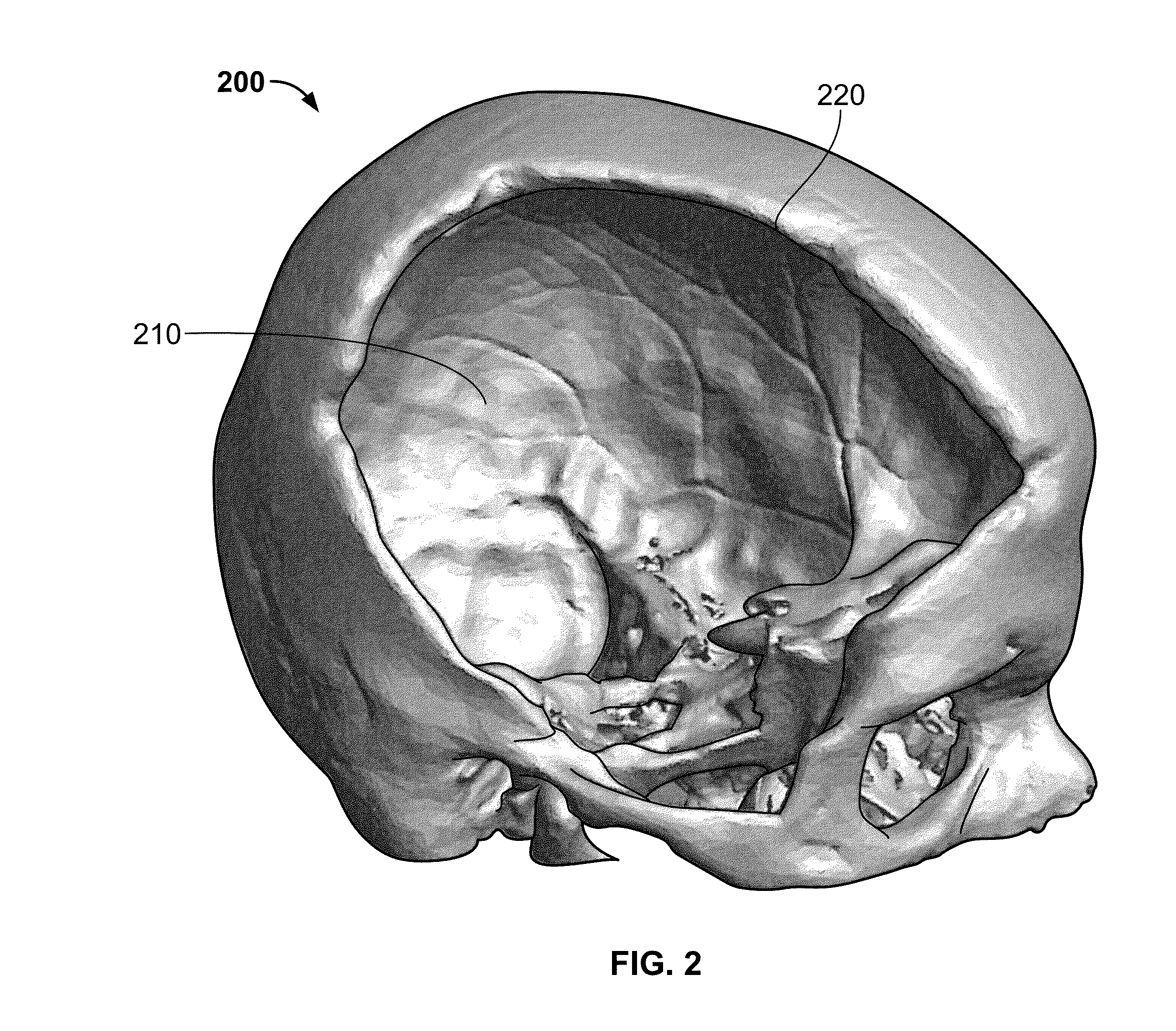

Patient-specific craniofacial implants

ActiveUS20150045897A1Restore appearanceAugmenting temporal areaCosmetic implantsTomographyTemporal resolutionSoft tissue deformation

Disclosed herein are patient-specific craniofacial implants structured for filling bone voids in the cranium as well as for simultaneously providing soft tissue reconstruction and / or augmentation for improved aesthetic symmetry and appearance. Pterional voids or defects generally result from a chromic skull deformity along with a compromised temporalis muscle or soft tissue distortion from previous surgery. When muscle atrophy occurs in the pterion, temporal hollowing generally results where there would be soft tissue but for the atrophy. The patient-specific temporal implants herein are configured to have an augmented region adjacent the temporal region of the cranium in order to account for and correct any such temporal hollowing.

Owner:HOWMEDICA OSTEONICS CORP

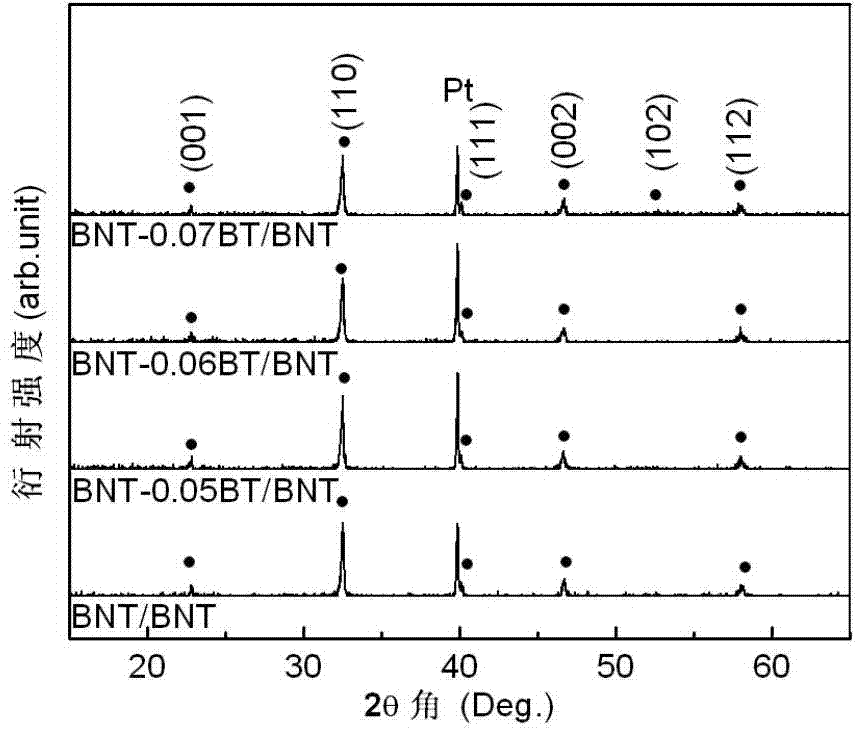

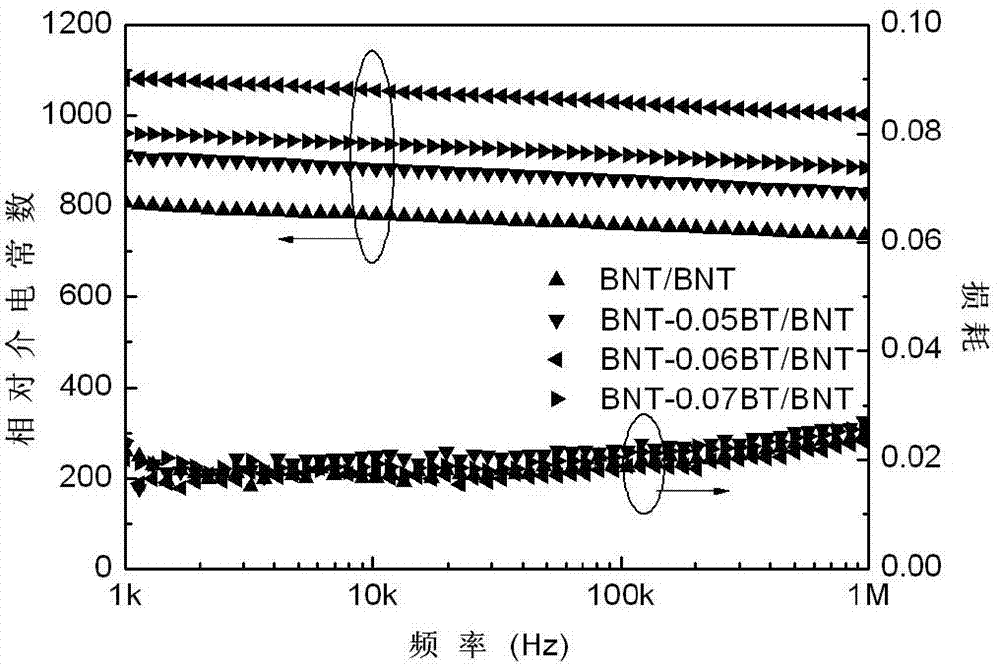

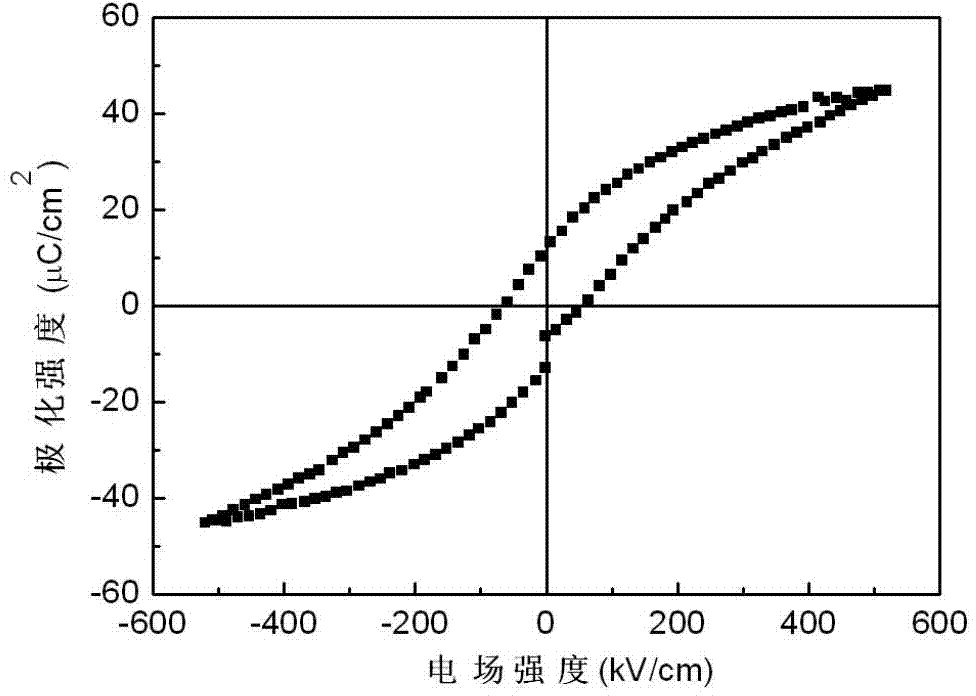

Preparation method of bismuth sodium titanate-barium titanate lead-free composite piezoelectric thick film

InactiveCN103708828AHigh viscosityIncreasing the thicknessPiezoelectric/electrostrictive device manufacture/assemblyMicro nanoComposite film

The invention discloses a preparation method of a bismuth sodium titanate-barium titanate lead-free composite piezoelectric thick film and belongs to the technical field of the preparation of piezoelectric materials. The preparation method includes the following steps: 1) preparing a micro-nano bismuth sodium titanate-barium titanate powder according to a stoichiometric ratio of (1-x) Bi0.5Na0.5TiO3-xBaTiO3; 2) preparing a sodium bismuth titanate precursor sol according to a stoichiometric ratio of Bi0.5Na0.5TiO3; 3) dispersing the bismuth sodium titanate-barium titanate powder in the sodium bismuth titanate precursor sol to prepare a mixed slurry; 4) conducting spin coating deposition of the bismuth sodium titanate precursor sol, heat treatment, spin coating deposition of the mixed slurry and heat treatment, so as to prepare a single-layer composite film; and 5) repeating the step 4) to prepare the sodium bismuth titanate-barium titanate lead-free composite piezoelectric thick film with thickness of 1-20 mum. The invention makes improvement to the existing sol gel technology, has the advanategs of low process cost, flexible film thickness and good repeatability, and breaks the critical thickness restriction of the ordinary sol-gel technology.

Owner:XI AN JIAOTONG UNIV

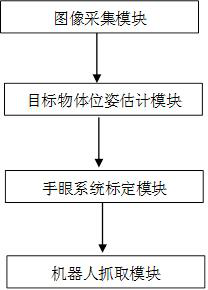

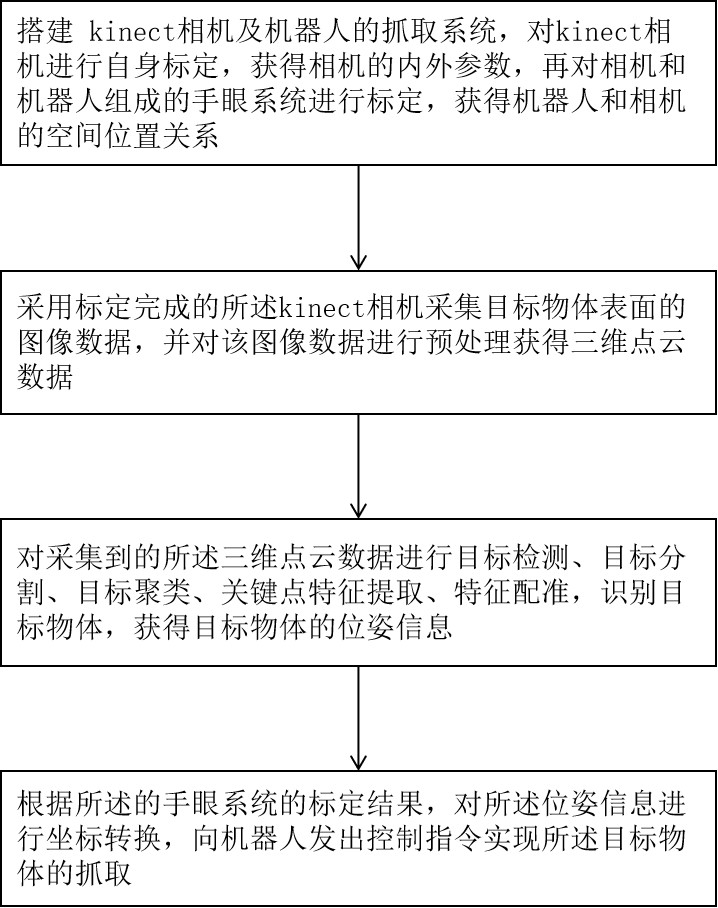

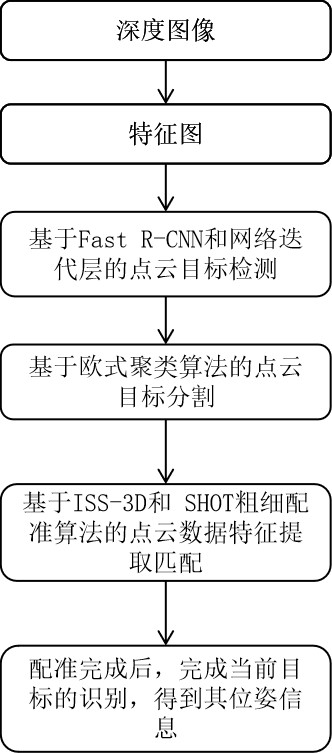

Robot disordered grabbing method and system based on machine vision and storage medium

ActiveCN112070818AHigh precisionImprove integrityImage enhancementImage analysisFeature extractionMachine vision

The invention discloses a robot disordered grabbing method and system based on machine vision. The method comprises the steps that a kinect camera and a grabbing system of a robot are built, the kinect camera is used for collecting image data of the surface of a target object, and the image data are preprocessed to obtain three-dimensional point cloud data; target detection, target segmentation, target clustering, key point feature extraction, feature registration and target object recognition are performed on the acquired three-dimensional point cloud data to obtain pose information of the target object; and according to the calibration result of the hand-eye system, coordinate conversion is carried out on the pose information, and a control instruction is sent to a robot to grab the target object. By analyzing the defects of the algorithm in the disordered grabbing process of the robot and improving the existing algorithm, the complex environment where the robot is located is adapted, and therefore the disordered grabbing accuracy of the robot and the flexibility of the robot are improved.

Owner:纳博特南京科技有限公司

Bra and/or bra pad for providing the appearance of symmetry to asymmetrical breasts

Owner:SOBAH MARY C

Patient-specific craniofacial implants

ActiveUS9216084B2Augmenting temporal areaIncrease the areaCosmetic implantsJoint implantsCranium boneSoft tissue deformation

Owner:HOWMEDICA OSTEONICS CORP

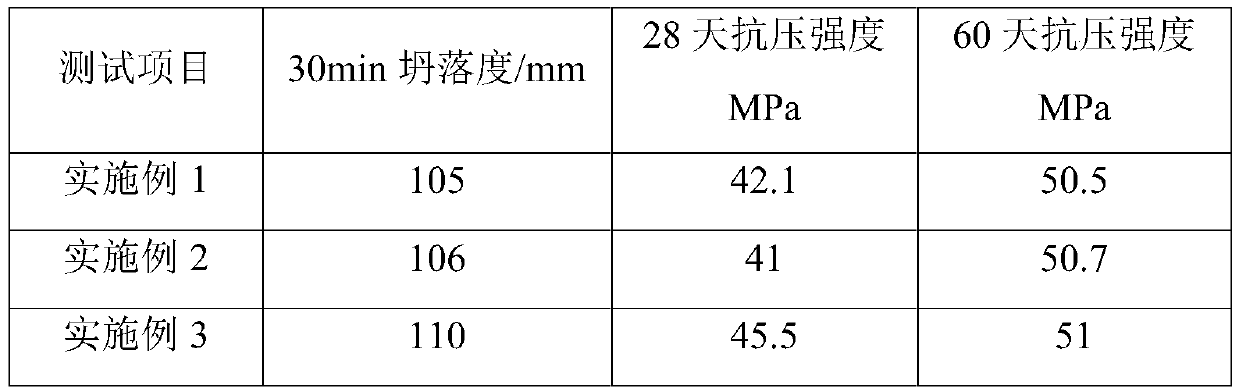

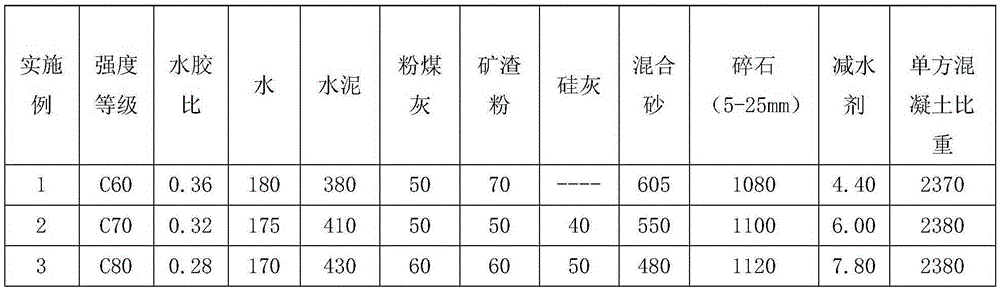

High-compressive-strength recycled concrete and preparation process thereof

The invention discloses high-compressive-strength recycled concrete and a preparation process thereof. The high-compressive-strength recycled concrete comprises the following components in parts by weight: 300-420 parts of reinforced recycled aggregate, 25-35 parts of recycled micro powder, 100-200 parts of natural coarse aggregate, 120-200 parts of natural fine sand, 120-170 parts of cement, 50-130 parts of fly ash, 50-120 parts of mineral powder, 6-12 parts of a waterproof agent, 0.8-2.2 parts of an air entraining agent, 120-160 parts of water and 20-35 parts of polypropylene mixed filler. The preparation process comprises the following steps: S1, weighing corresponding amounts of cement and natural fine sand, putting the cement and the natural fine sand into a stirrer, and stirring for40-60 seconds; S2, weighing the regenerated micro-powder, the fly ash, the mineral powder and the polypropylene mixed filler according to corresponding proportions, adding the weighed materials into the stirrer in the step S1, continuing to stir and mix for 30-40 seconds, adding half of the water according to the proportion, continuing to stir for 30-40 seconds, and mixing to obtain mortar with uniform color; and S3, adding the rest half of the water, the reinforced recycled aggregate, the natural coarse aggregate, the air entraining agent and the waterproof agent according to the proportion in the step S2, and continuously stirring for 60-80 seconds until the mixture is uniform.

Owner:西安百固源混凝土有限公司

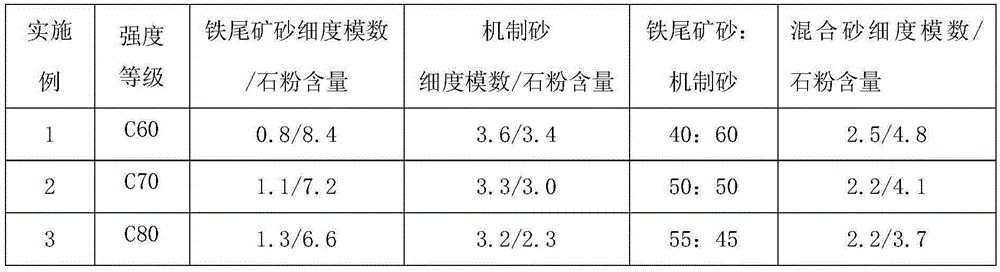

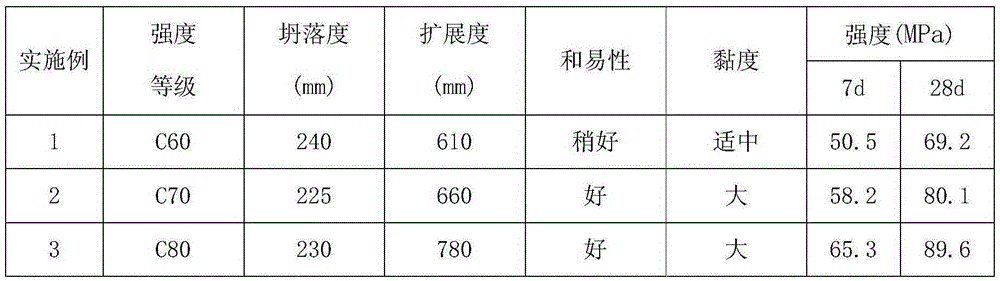

Iron tailings mixing sand concrete

InactiveCN105236860AFill the voidImprove distributionSolid waste managementCrushed stoneWater reducer

The present invention discloses an iron tailings mixing sand concrete, which comprises, by mass, 16-20% of 52.5-grade cement, 22-27% of iron tailings mixing sand, 45-48% of crushed stone, 5.5-6.5% of an admixture, 7.3-8.1% of water, and 0.2-0.3% of a polycarboxylic acid efficient water reducer. The iron tailings mixing sand concrete of the present invention has characteristics of good water retention property, easy vibration molding, and good workability.

Owner:CHINA MCC17 GRP

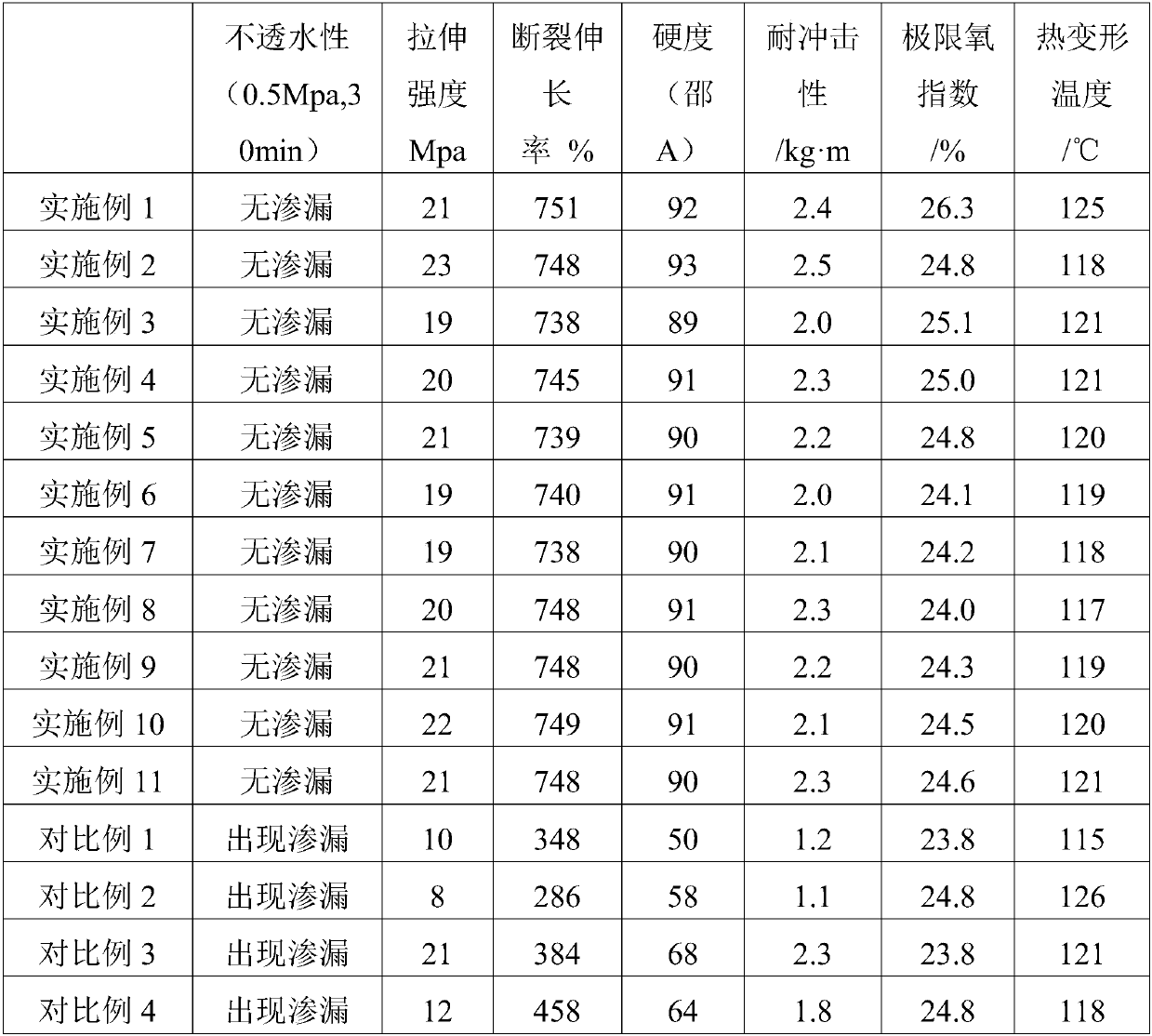

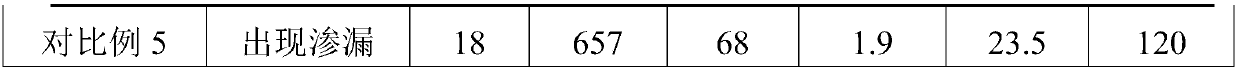

Thermal-insulating flame-retardant waterproof coating

The invention relates to the technical field of coatings and in particular to a thermal-insulating flame-retardant waterproof coating which comprises the following substances in parts by weight: 100 parts of an epoxy resin, 10-25 parts of amino modified quartz powder, 20-42 parts of sepiolite, 5-10 parts of a flame retardant, 80-150 parts of reinforcing fibers, 0.5-3 parts of a surfactant and 100-150 parts of a solvent, wherein the reinforcing fibers comprise a reinforcing fiber A and a reinforcing fiber B; the diameter of the reinforcing fiber A is 10-50nm; the length of the reinforcing fiberA is 0.5-2mu m; the diameter of the reinforcing fiber B is 100-300nm; the length of the reinforcing fiber B is 3-5mu m. As an epoxy substrate is doped with reinforcing fibers which are different in diameter and length, a meshed structure is formed, and the coating is excellent in thermal insulation effect; meanwhile the amino modified quartz powder can be matched with the reinforcing fibers to form a reinforced framework, the overall toughness and the strength of the coating are improved.

Owner:汪涛

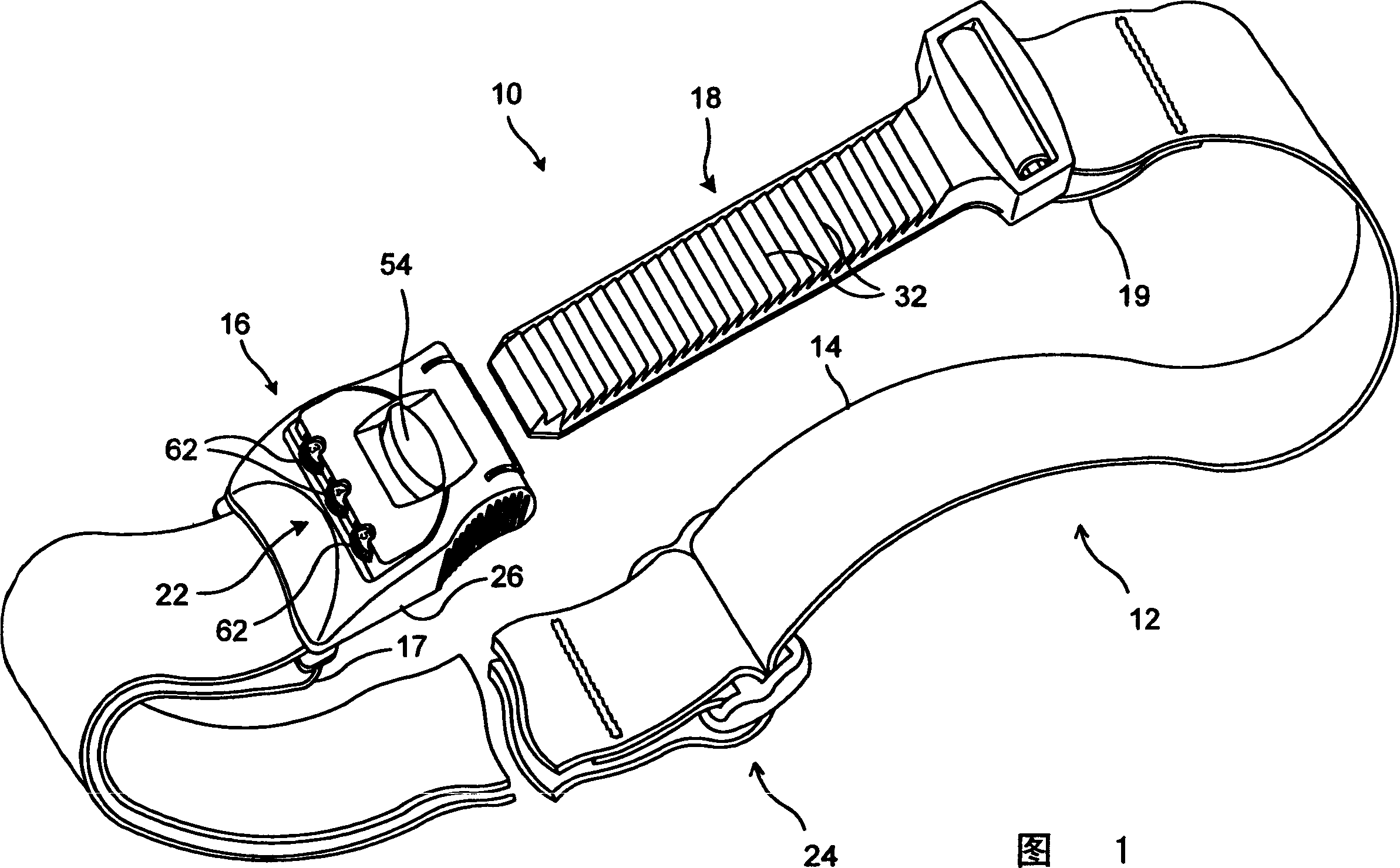

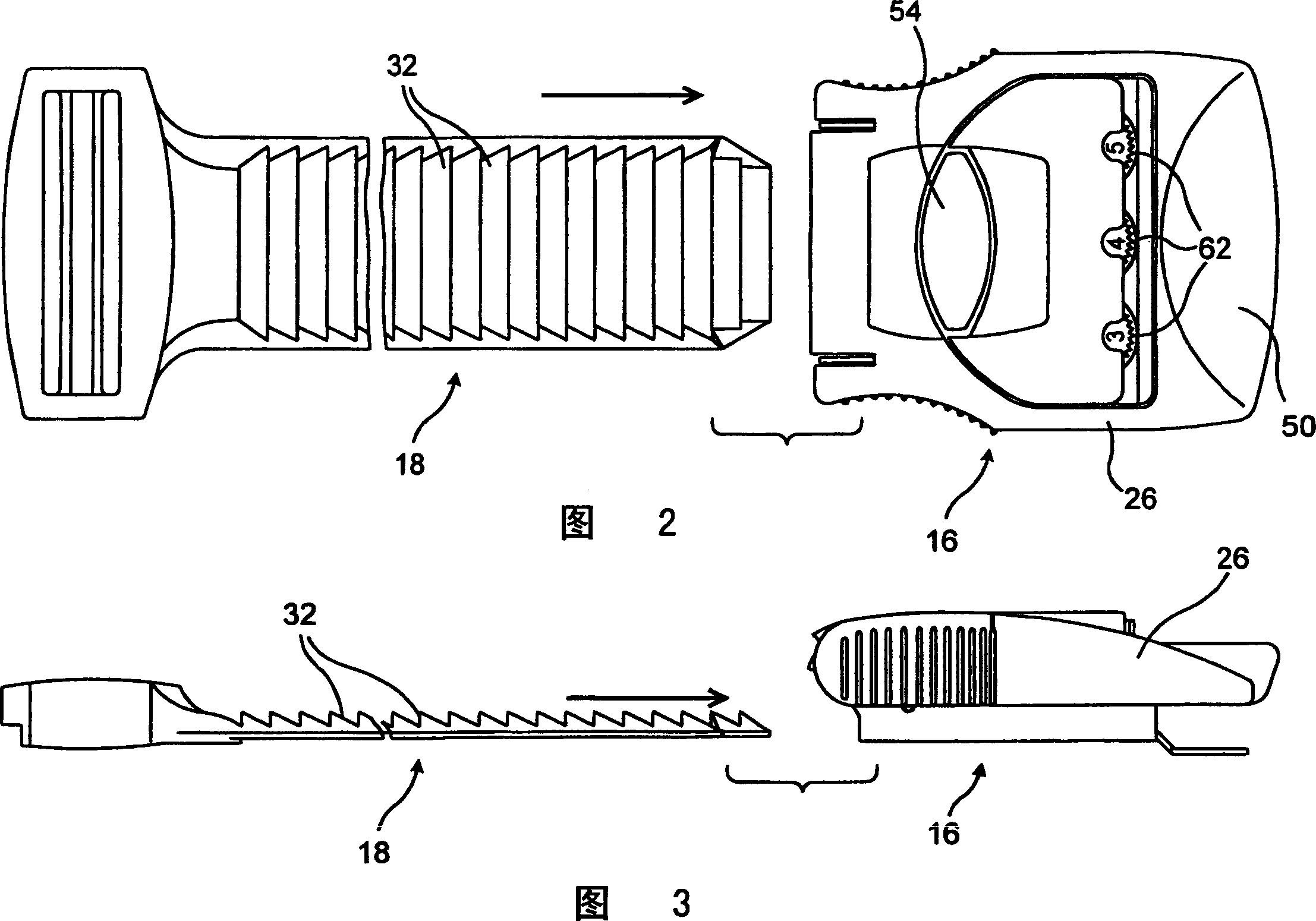

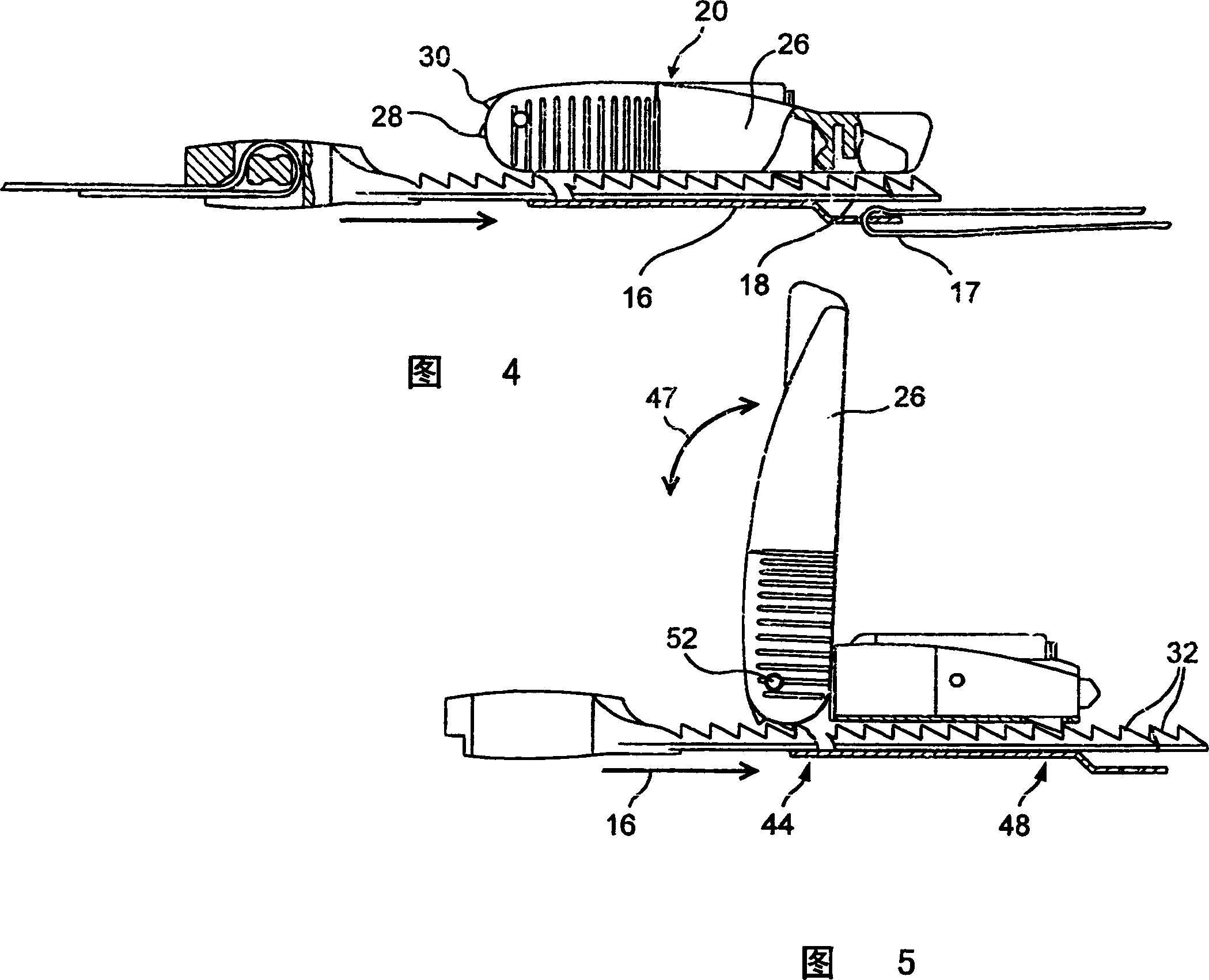

Luggage belt with lock and ratchet mechanism

InactiveCN1406832AIncrease overlapFill the voidFlexible elementsPadlocksEngineeringMechanical advantage

Owner:ZELCO INDS

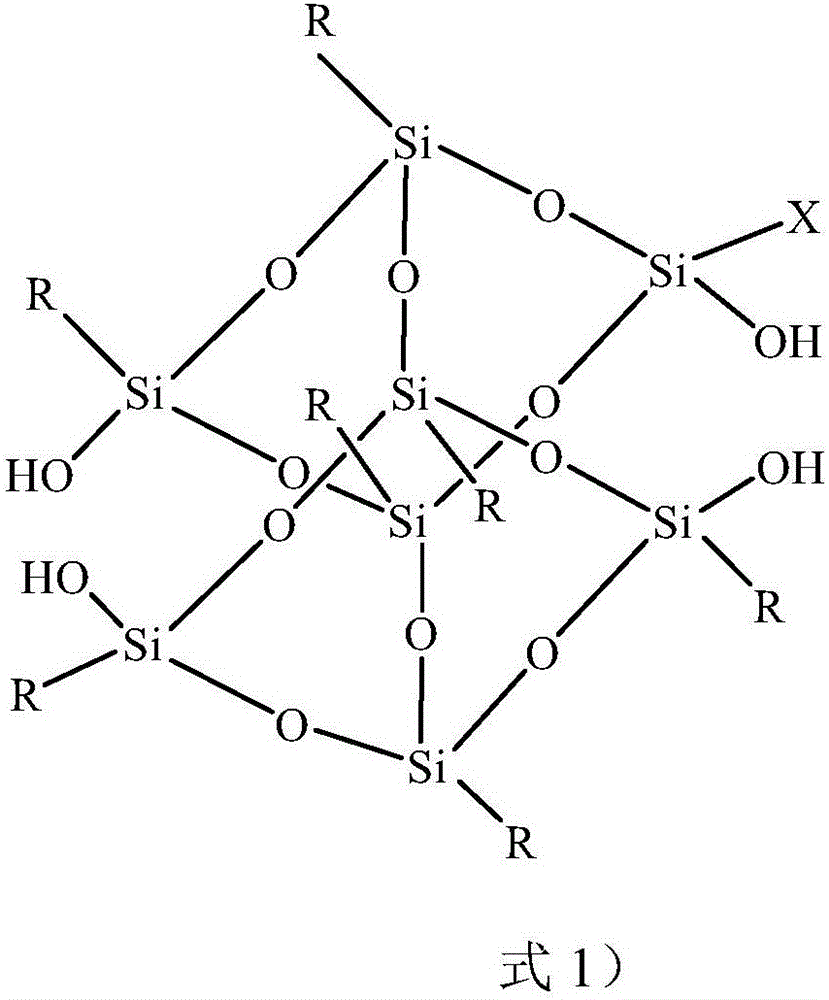

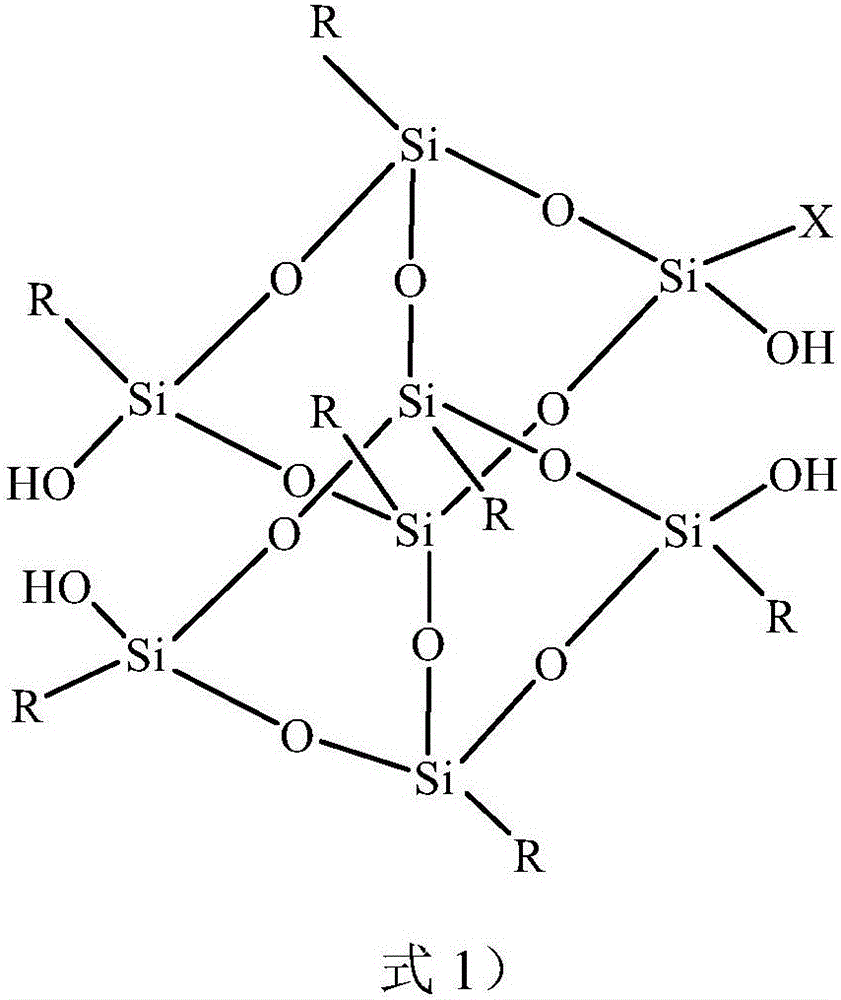

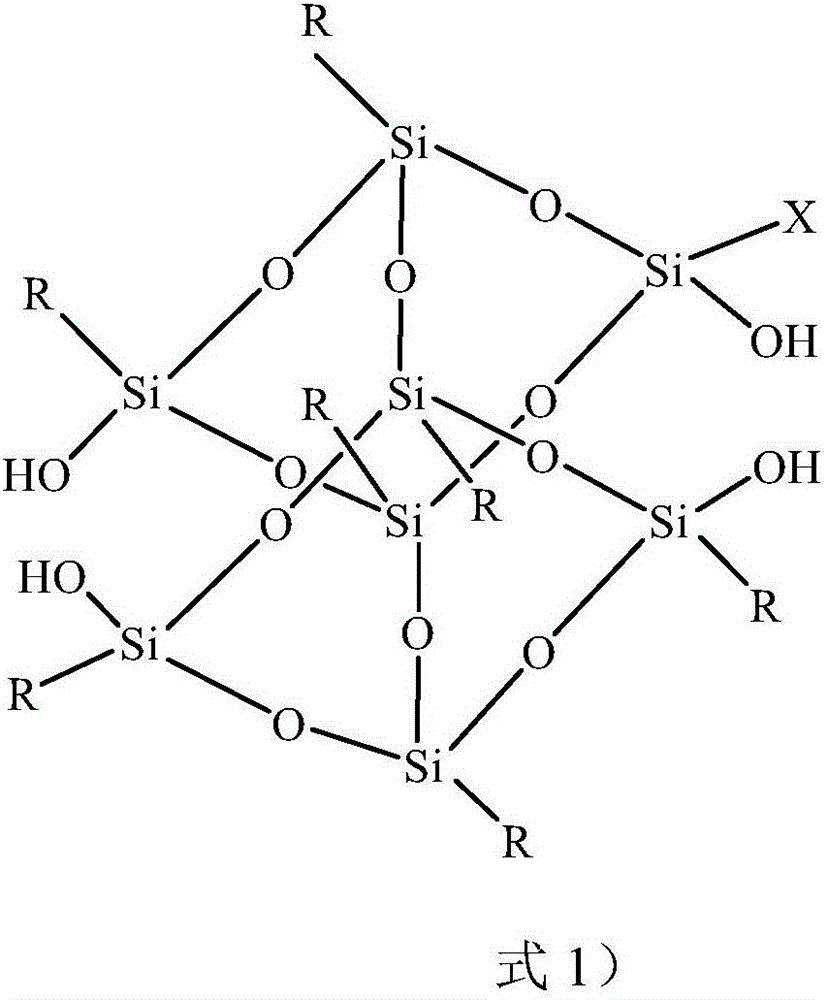

Modified light-cured resin composition and preparation method thereof

The invention discloses a modified light-cured resin and a preparation method thereof. The modified light-cured resin composition is prepared from acrylic resin, epoxy resin, reactive diluent, radical initiator, kation initiator, polyhydric alcohols, flatting agent, flatting agent, wetting dispersant, half-cage type POSS, nanosilicon dioxide, and pigment. Compared with the prior art, the invention applies the half-cage type POSS to modify the light-cured resin; the POSS resin has excellent temperature resistance, and is able to effectively improve the vitrification transformation temperature of the resin system, and the aging resistance is good; moreover, the POSS can effectively fill gaps in the polymer, and reduce the contraction of the polymer. Meanwhile, the half-cage type POSS is in good compatibility with resin, and can completely dissolve in the epoxy resin, thus the dispersing problem during the resin preparation process is reduced. Therefore, the modified light-cured resin prepared by the invention is featured by high temperature resistance, high strength, aging resistance, and stable dimension.

Owner:HANGZHOU LEYI NEW MATERIAL TECH CO LTD

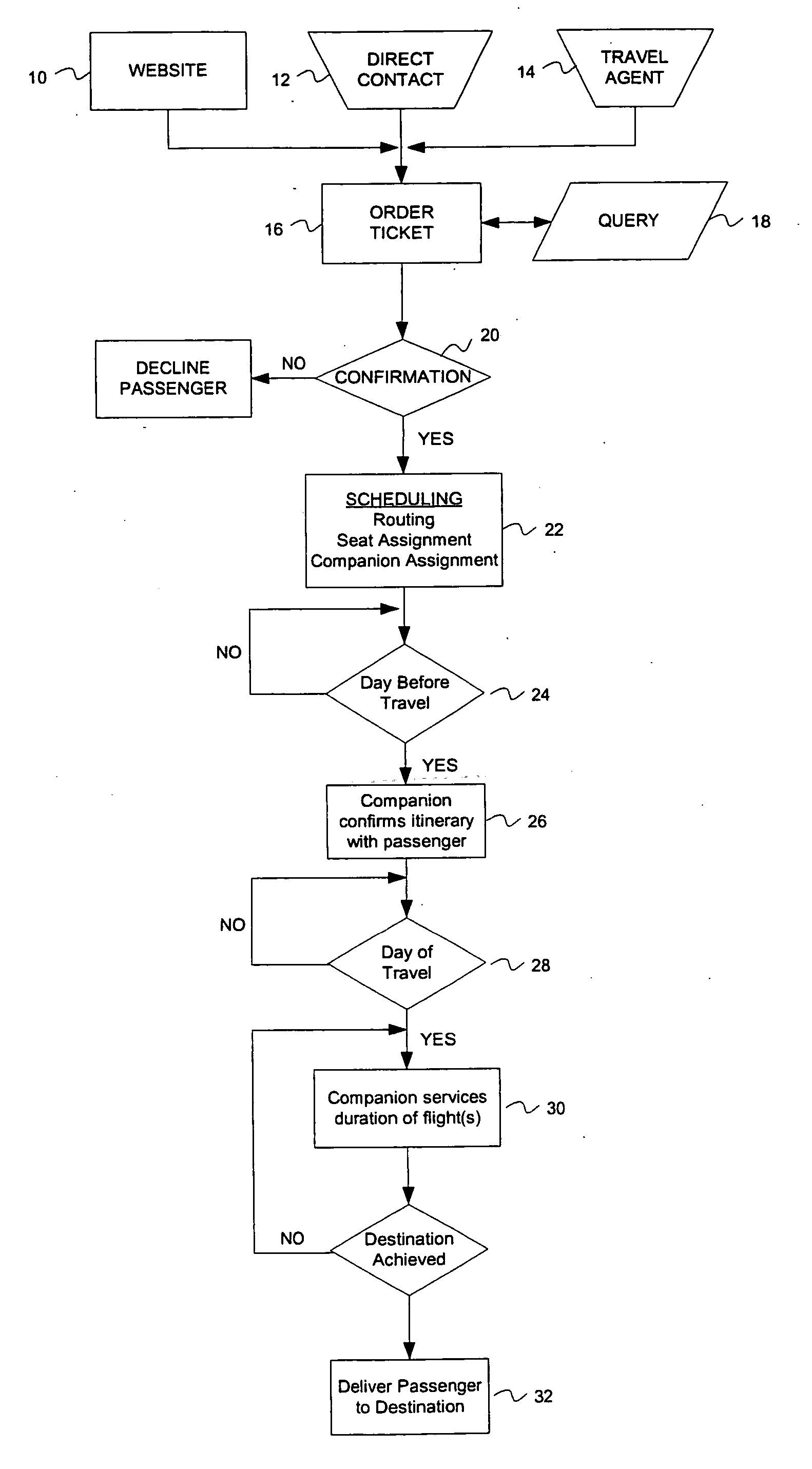

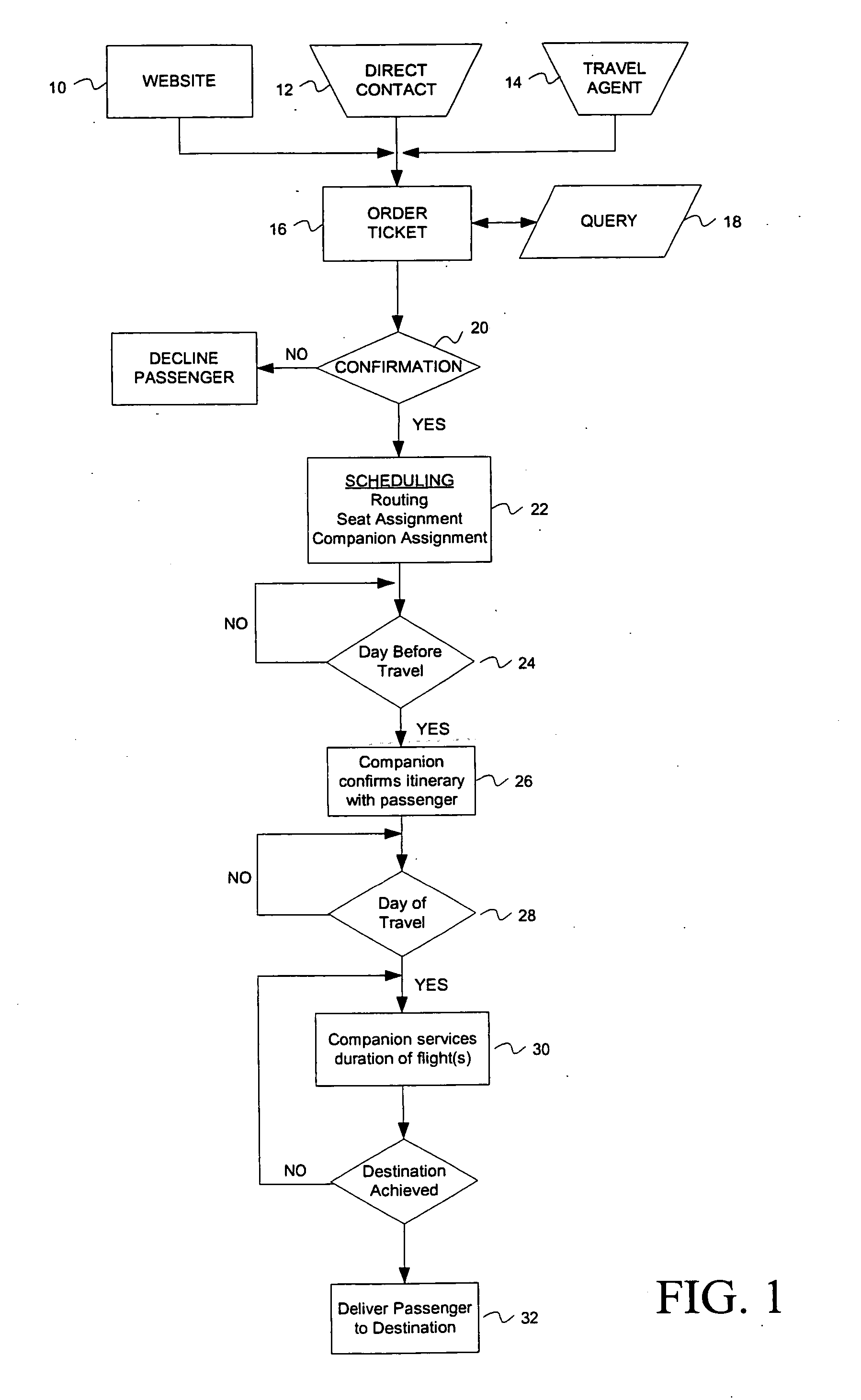

Travel assistance program

InactiveUS20050267786A1Fill the voidImprove securityReservationsOffice automationService provisionProgram planning

The subject invention provides a unique and advantageous system for providing travel companion services, thereby effectively filling customer service need for travelers. In another aspect the subject invention provides an effective business model that is beneficial to travelers, travel companion providers, and the travel industry.

Owner:LANG MARY PATRICIA

Method for improving antioxidation performance of graphite electrode with surface modification

InactiveCN102497689AImprove the bonding strength of the interfaceIncreasing the thicknessMolten spray coatingElectric discharge heatingSteelmakingElectric arc furnace

The invention discloses a method for improving an antioxidation performance of a graphite electrode with surface modification. The method comprises: a graphite electrode is embedded in Si powder to carry out high-temperature reaction, so that a SiC surface protective layer is obtained; and a vacuum plasma spraying technology is applied to spray a fusing SiC coating on the surface of the obtained SiC protective layer, so that a surface defect of the SiC protective layer obtained by the embedding method is filled up and modified and thus the quality of the surface protective layer is improved. According to the method provided in the invention, surface modification processing is carried out on the graphite electrode, so that the high-temperature antioxidation performance of the graphite electrode can be substantially improved. Moreover, the method can be widely applied to the manufacturing industry of graphite electrodes used for steelmaking of an arc furnace and external refinement.

Owner:NANJING UNIV OF SCI & TECH +1

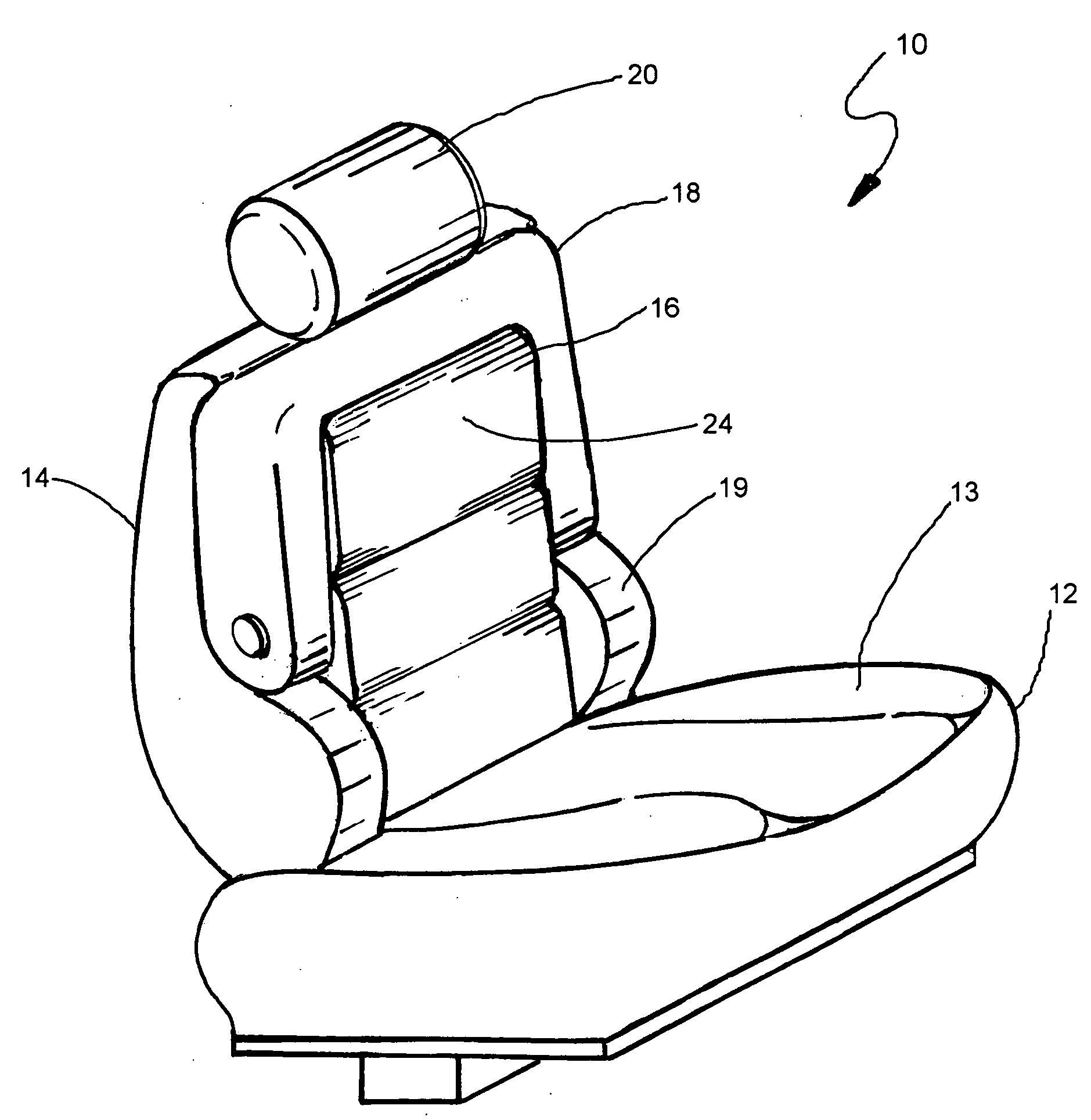

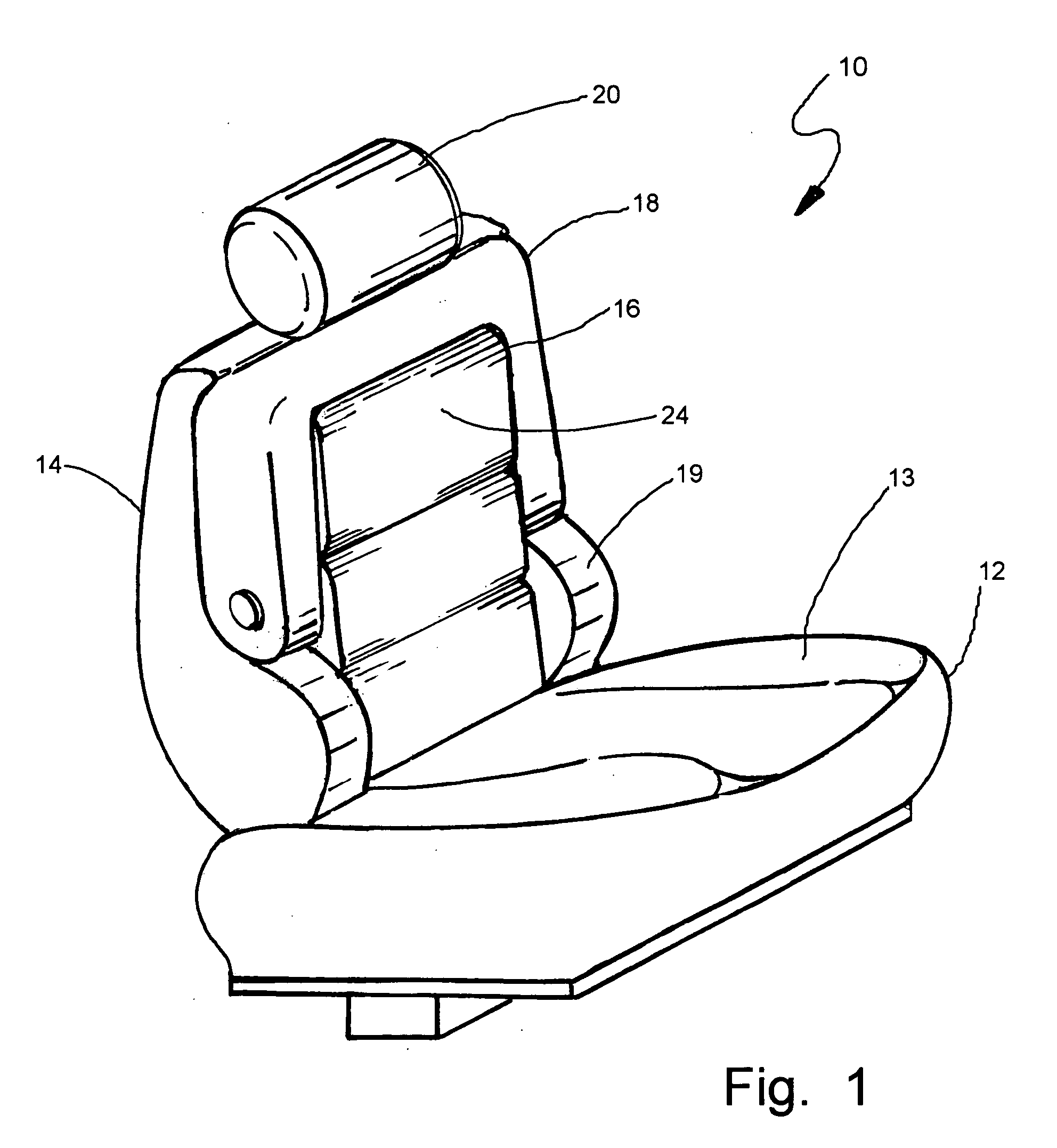

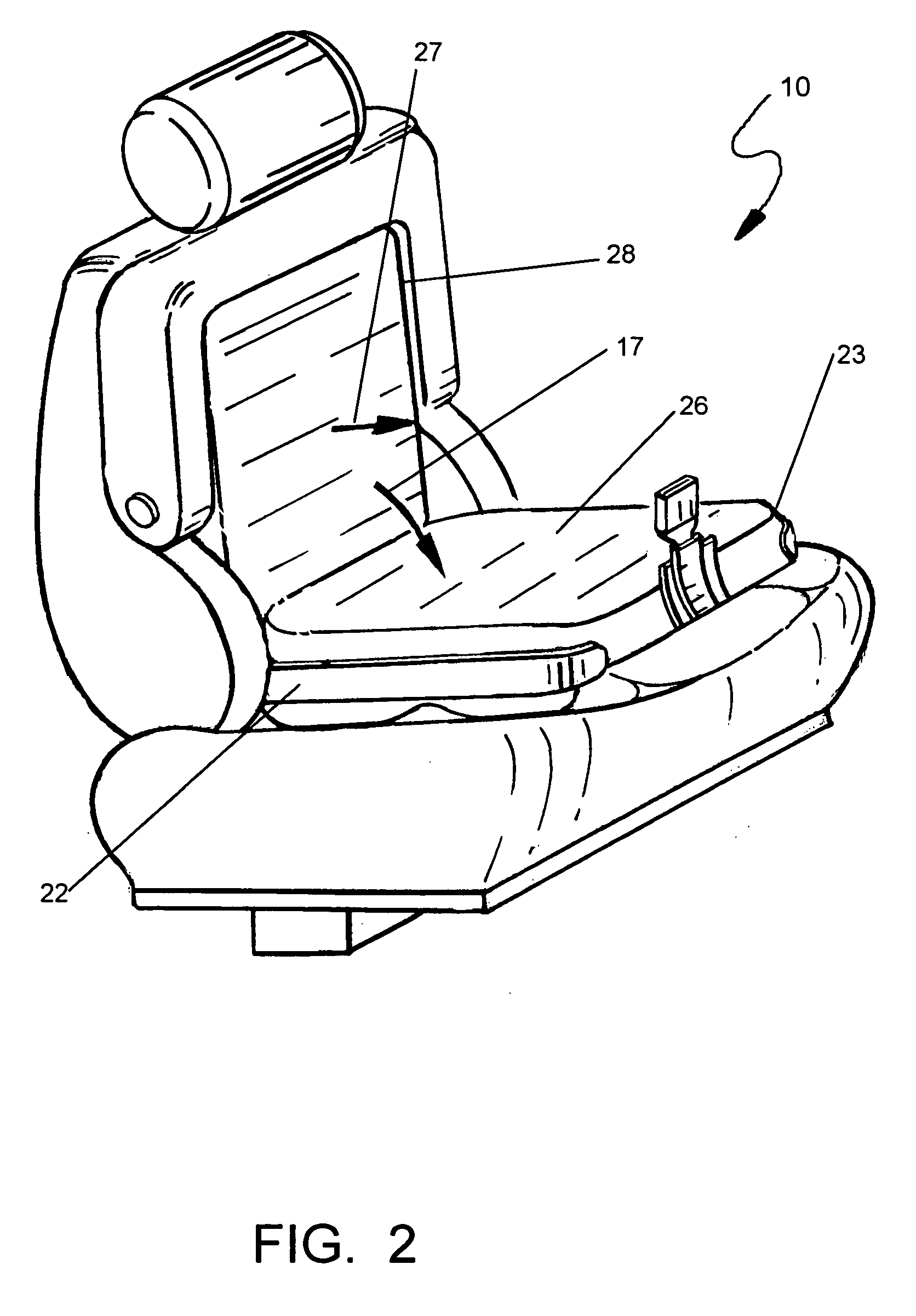

Vehicular seat assembly

The present invention relates to a vehicular seat assembly that may be configured in four different arrangements to accommodate an adult in its first position, a youth in its second position, a toddler in its third position, and infant in its fourth position. When configured to seat an infant, the infant is retrained using a restraint system that is integral to the seat assembly, and when configured to seat a toddler, the toddler is restrained by a separate and distinct restraint system that is also integral to the seat assembly.

Owner:THOMAS RODNEY EDWARD

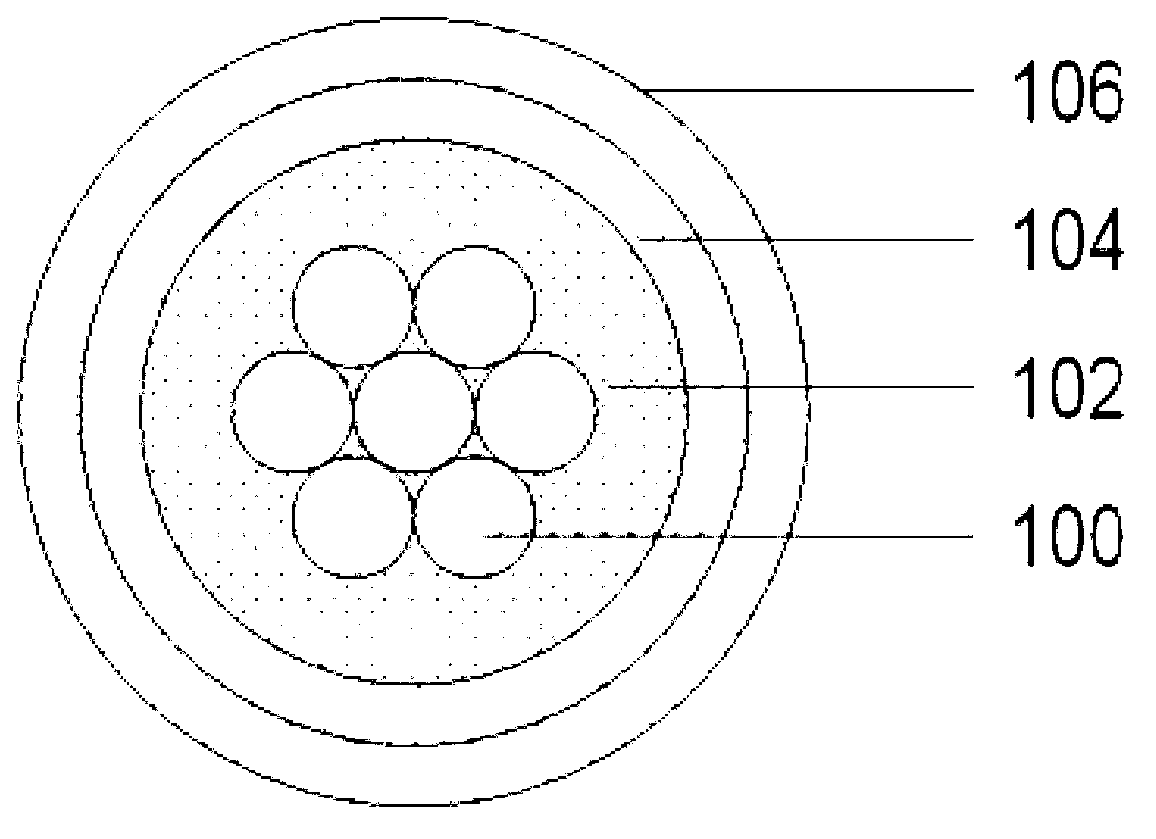

Method for forming insulating layer on overhead power transmission line

ActiveCN103310915APromote formationImprove insulation performancePolyurea/polyurethane coatingsEpoxy resin coatingsElectrical tapePower transmission

The invention provides a method for forming an insulating layer on an overhead power transmission line. The method includes painting solventless coatings on the power transmission line to form a first coating, winding an electric insulating rubber tape on the first coating to form a rubber tape layer after the first coating is half-dry or dry, and painting the solventless coatings on the rubber tape layer to form a second coating. Gaps among guide lines of the overhead power transmission line are filled, and the rubber tape and the coatings are provided to form the insulating layer, so that good insulating and waterproof effects are realized.

Owner:3M CHINA

Seepage-proofing aerated concrete building block and preparation method thereof

A seepage-proofing aerated concrete building block and a preparation method thereof are disclosed. The building block is composed of following raw materials in parts by weight: 20 to 25 parts of cement, 15 to 20 parts of quicklime, 10 to 15 parts of gypsum, 40 to 45 parts of fly ash, 0.1 to 0.2 part of aluminum powder, 1 to 2 parts of sulfonated lignin, 20 to 25 parts of slag, 10 to 15 parts of cotton straw powder, 10 to 15 parts of grapevine powder, 2 to 3 parts of waste engine oil, 1 to 2 parts of sodium persulfate, 2 to 3 parts of sweet rice flour, and a right amount of water. The aerated concrete building block adopts oil foot and waster engine oil components, which have been modified by initiator, to increase water-resistance ability of the building block, and the seepage-proofing ability of the building block is also largely improved. The seepage-proofing aerated concrete building block has been used in an outer wall body of a community for more than 3 years, and no seepage phenomenon has been found. But adopting conventional aerated concrete building blocks, every spring resident houses have seepage phenomenon. Sweet rice flour is used to prepare pulp, which can fill the cracks in the building block to reduce the possibility of seepage.

Owner:TONGLING FENGZE BUILDING MATERIALS TECH

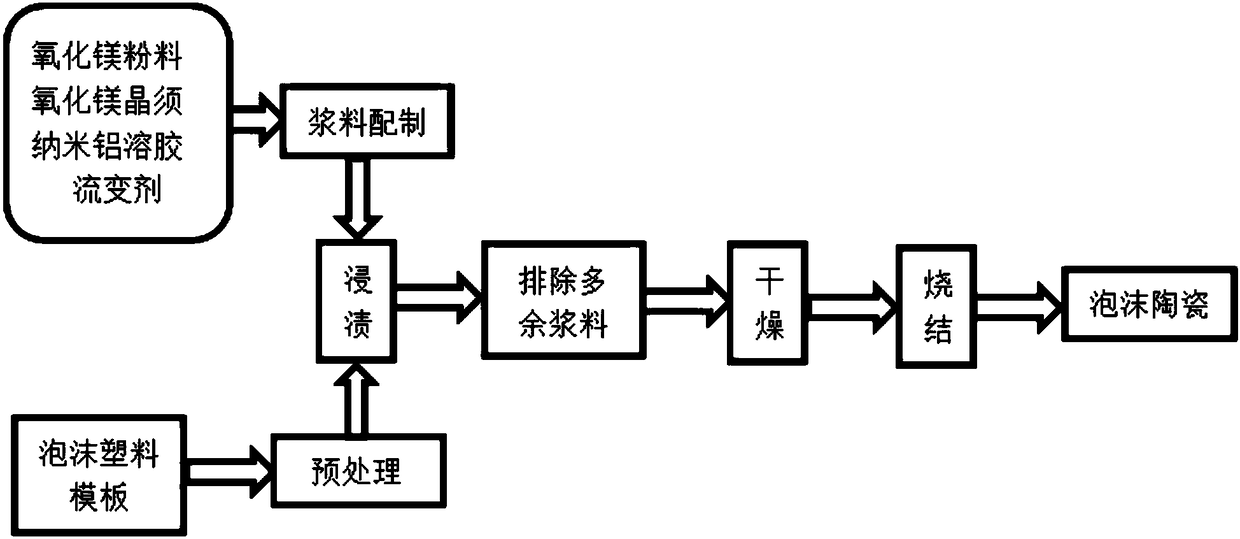

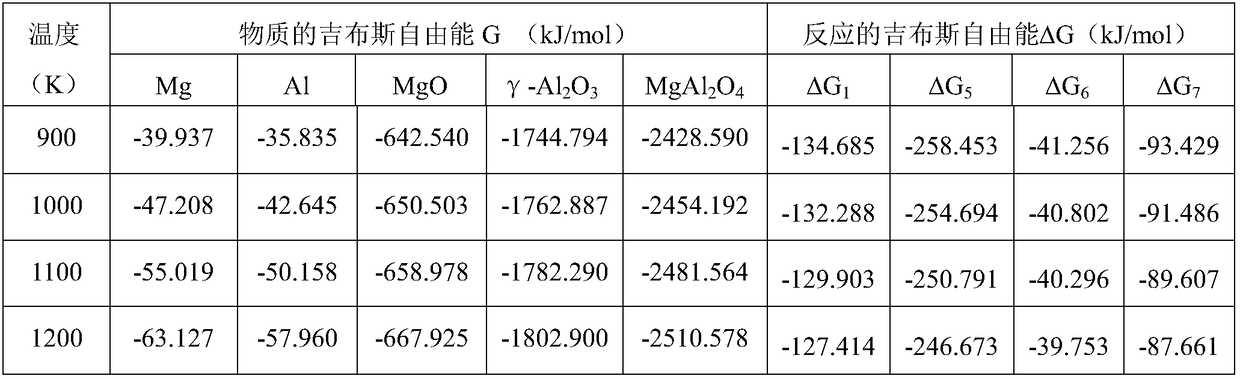

Magnesium oxide whisker in-situ synthesis magnesium aluminate spinel enhanced magnesium-oxide-based foam ceramic filter and preparation method thereof

ActiveCN108484182AAvoid obstructionAct as a binderFiltration separationCeramicwareRoom temperatureSlurry

The invention discloses a magnesium oxide whisker in-situ synthesis magnesium aluminate spinel enhanced magnesium-oxide-based foam ceramic filter with chemical stability and excellent thermal shock resistance capable of sintering in a low temperature and a preparation method thereof. The preparation method comprises the following steps: (1) according to a mass percent, compounding by 15%-25% of nano-aluminum sol, 0.8%-1.5% of rheological agent, and the balance of magnesia ceramics powder containing magnesium oxide whisker, adding deionized water, ball-milling, uniformly mixing, and preparing ceramic slurry of which the solid content is 60%-70% through vacuum exhaust; (2) immerging a polyurethane foamed plastic template in the ceramic slurry, extruding the polyurethane foamed plastic template through a roller press so as to remove redundant immerging slurry, preparing a biscuit, heating the biscuit to 80-120 DEG C, and drying; and (3) placing the dried biscuit in a sintering furnace, warming to 1400-1600 DEG C, and sintering in a high temperature, cooling to room temperature along with the furnace, to obtain the magnesium-oxide-based foam ceramic filter.

Owner:JIANGSU FAVOUR AUTOMOTIVE NEW STUFF SCI TECH +1

Formed part preparation method based on reduced graphene oxide and copper composite material

InactiveCN110819842AGood formabilityEasy dischargeTransportation and packagingMetal-working apparatusHydrogen atmosphereHigh conductivity

The invention relates to a formed part preparation method based on a reduced graphene oxide and copper composite material. According to the method, graphene oxide / copper mixed powder is prepared through wet ball milling; then, the mixed powder is reduced under hydrogen atmosphere; and finally, the reduced graphene oxide and copper composite material is obtained through a repressing and resinteringpowder metallurgy method. By means of the method, reduced graphene oxide is well and evenly scattered in a copper matrix, the prepared reduced graphene oxide / copper composite material has the advantages of being high in strength, high in plasticity and high in conductivity, the repressing and resintering sintering forming method is simple and controllable in process, low in production cost and high in production efficiency, and large-scale industrialized production is easy to achieve. Formed pieces prepared through the formed part preparation method are little in oxide, less in pore and highin compactness and has excellent comprehensive performance such as high strength, high conductivity and high plasticity.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

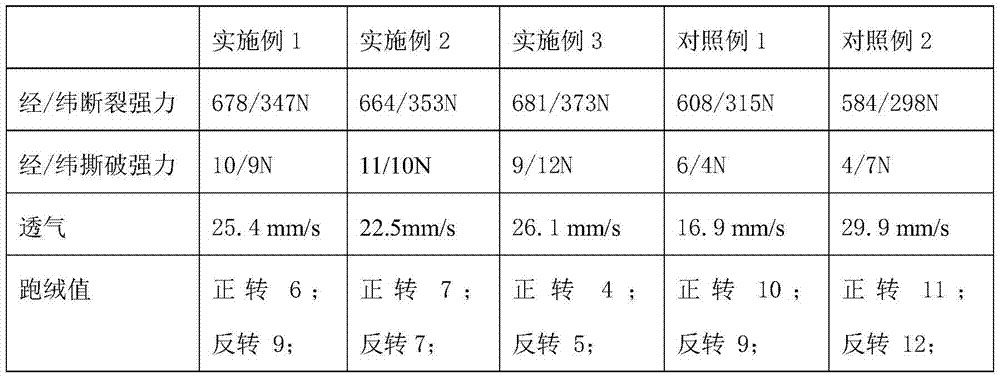

Dyeing and finishing method for soft and breathable down-proof fabric

The invention provides a dyeing and finishing method for a soft and breathable down-proof fabric. The fabric is obtained by interweaving warp and weft, wherein both the warp and the weft are cross-blended yarn of staple cotton and tencel G100. The dyeing and finishing method comprises the steps of conducting refining on gray fabric, and carrying out stentering and whitening, softening and shaping, and pre-shrinking sequentially. The down-proof fabric processed according to the dyeing and finishing method touches soft and exquisite, is excellent in down-proof performance, safe and environmentally friendly.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

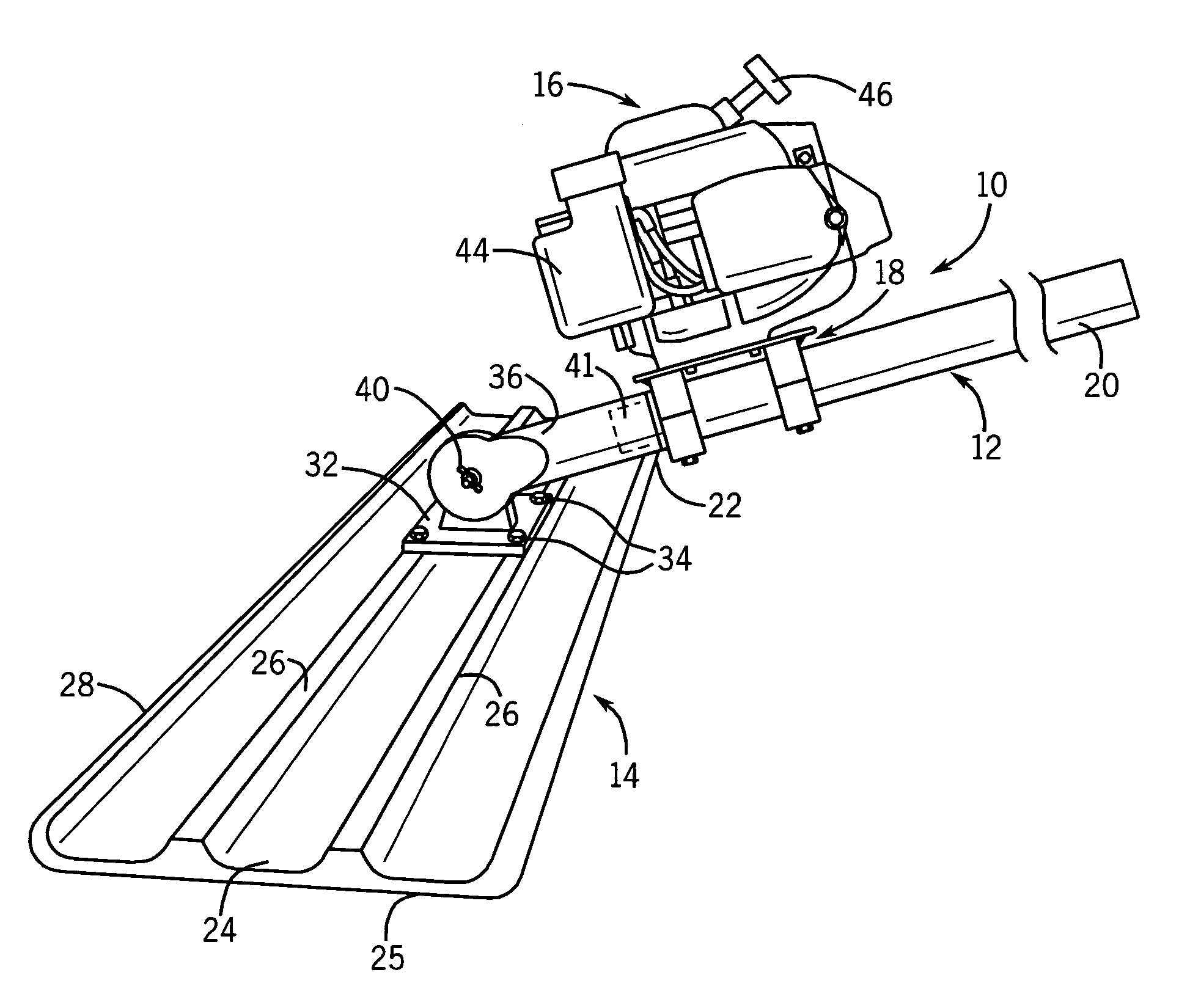

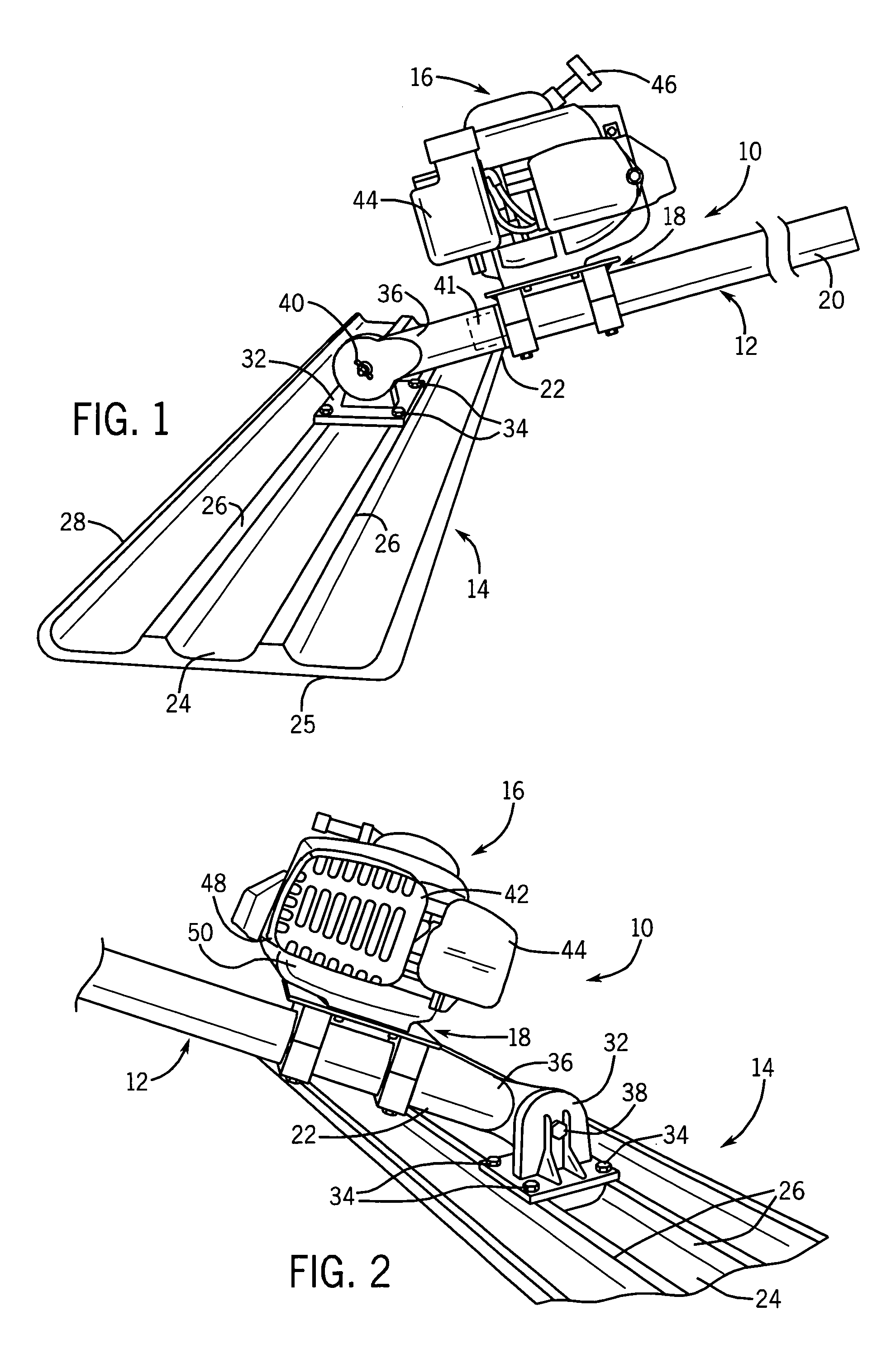

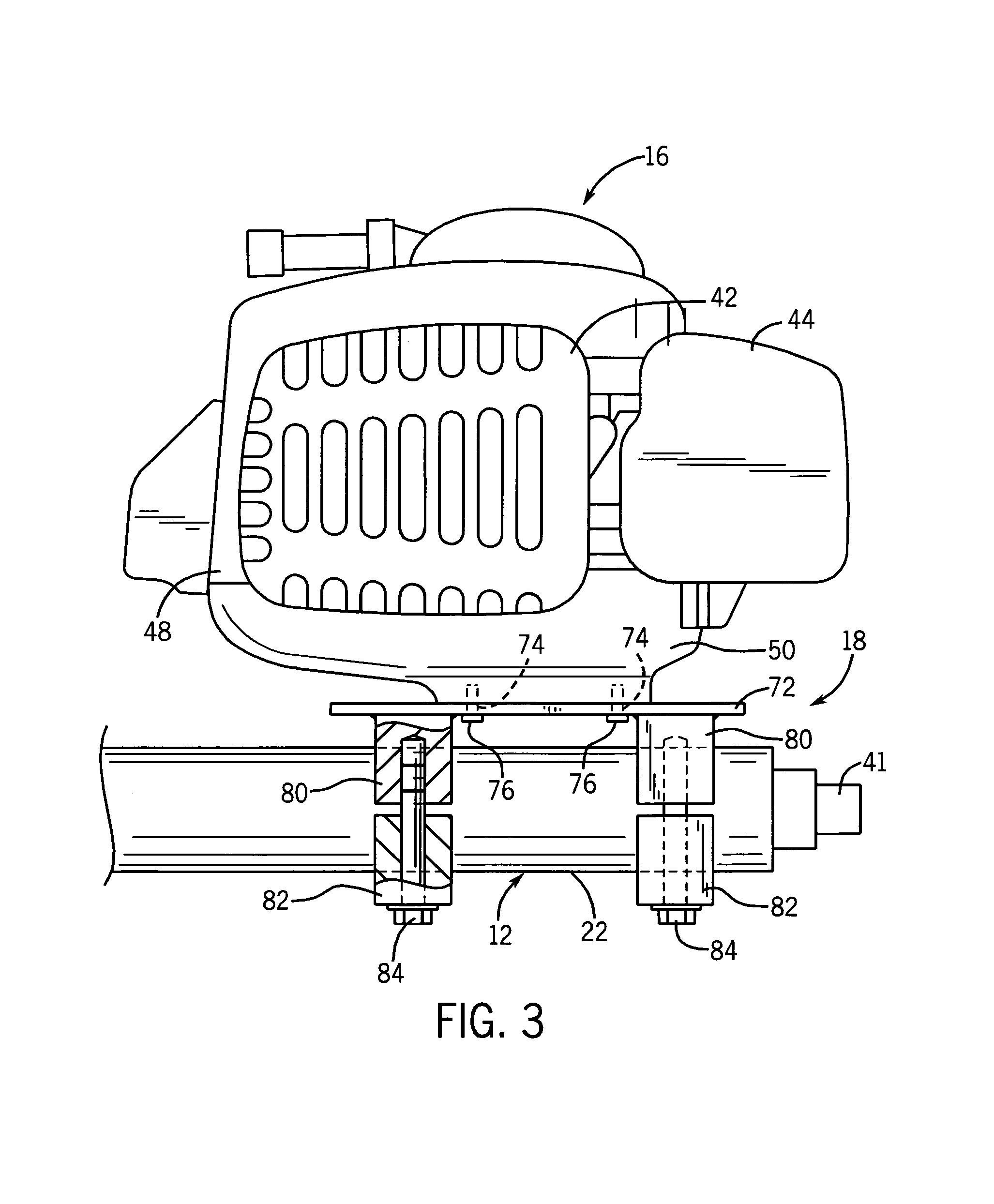

Concrete finishing tool with handle-mounted vibrating arrangement

InactiveUS7156577B1Additional toolFill in the gapsBuilding constructionsRoads maintainenceExternal connectionCrankshaft

A vibratory concrete finishing tool includes an elongated handle formed with a cylindrical configuration having an uppermost end and a lowermost end. A concrete working device has a planar bottom surface adapted to engage a wet concrete surface, and a receiver for removably receiving the lowermost end of the handle. A clamping and vibration transmitting arrangement is coupled externally to the lowermost end of the handle. An engine-driven vibratory mechanism is fixed to the clamping and vibration transmitting arrangement so that the vibratory mechanism is held in spaced relationship with the handle. The vibratory mechanism has a spinning crankshaft assembly with an eccentric weight mounted thereon.

Owner:ROZINSKI RICHARD M

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com