Patents

Literature

104results about How to "Simple configuration process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-bacterial water-based paint and preparation method thereof

InactiveCN102702889AImprove aging resistanceImprove the pulverization performanceBiocideAntifouling/underwater paintsWater basedEscherichia coli

The invention relates to anti-bacterial water-based paint and a preparation method thereof. The paint comprises the following components in parts by weight: 0.2-11 parts of anti-bacterial agent, 8-33 parts of nano material, 23-64 parts of water-based resin dispersoid and 0.75-18 parts of adhesive resin or plasticizer. The preparation method comprises the following steps: firstly preparing a nano silver anti-bacterial agent; mixing deionized water, the anti-bacterial agent, a wetting agent, a dispersing agent and a defoaming agent and uniformly mixing, adding the nano material, uniformly dispersing to obtain the water-based dispersoid; adding the obtained water-based dispersoid to the mixed emulsion or water-based resin dispersoid, then adding the adhesive resin or plasticizer and various conventional assistants, stirring and dispersing evenly; adding pigments or colorant; and supplementing water to obtain the anti-bacterial water-based paint. The long-acting broad-spectrum antibacterial water-based paint has high fungicidal efficiency (more than 99%) on escherichia coli, staphylococcus aureus, black varietas of bacillus subtilis and the like and can reduce the high concentrate of organic matters of formaldehyde to the range of specified concentration index.

Owner:ANHUI JINDUN PAINT

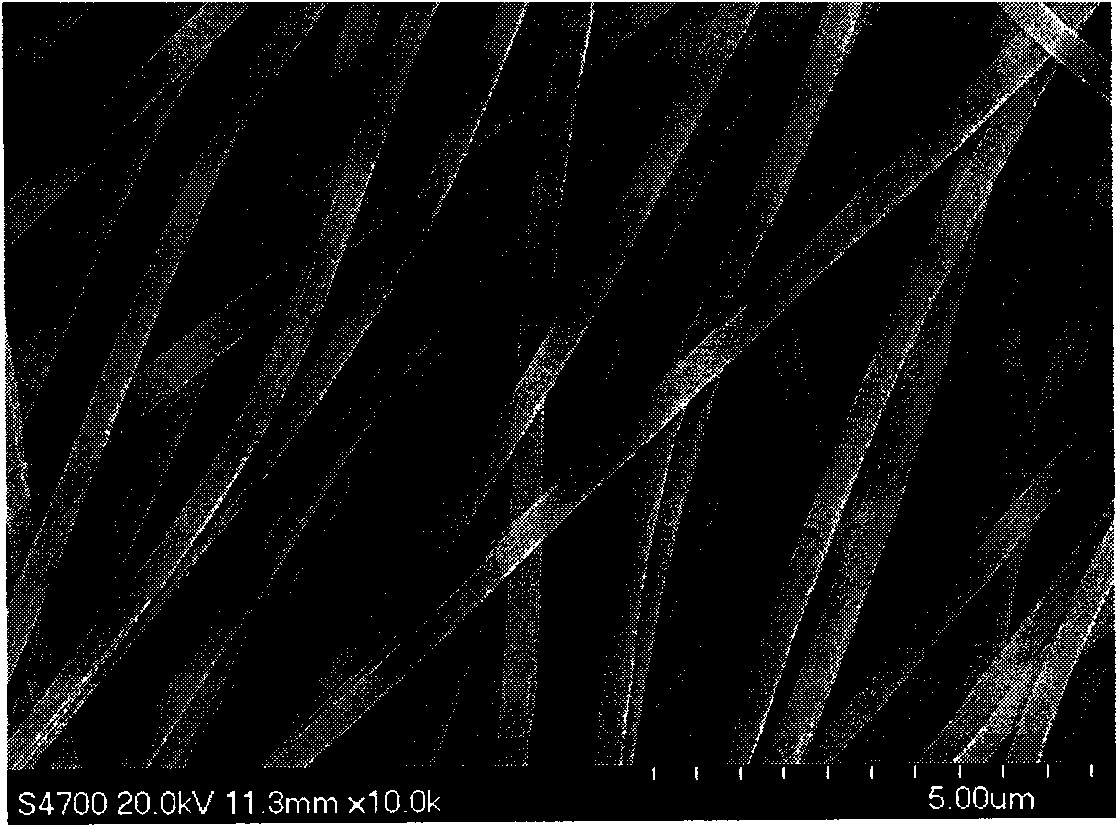

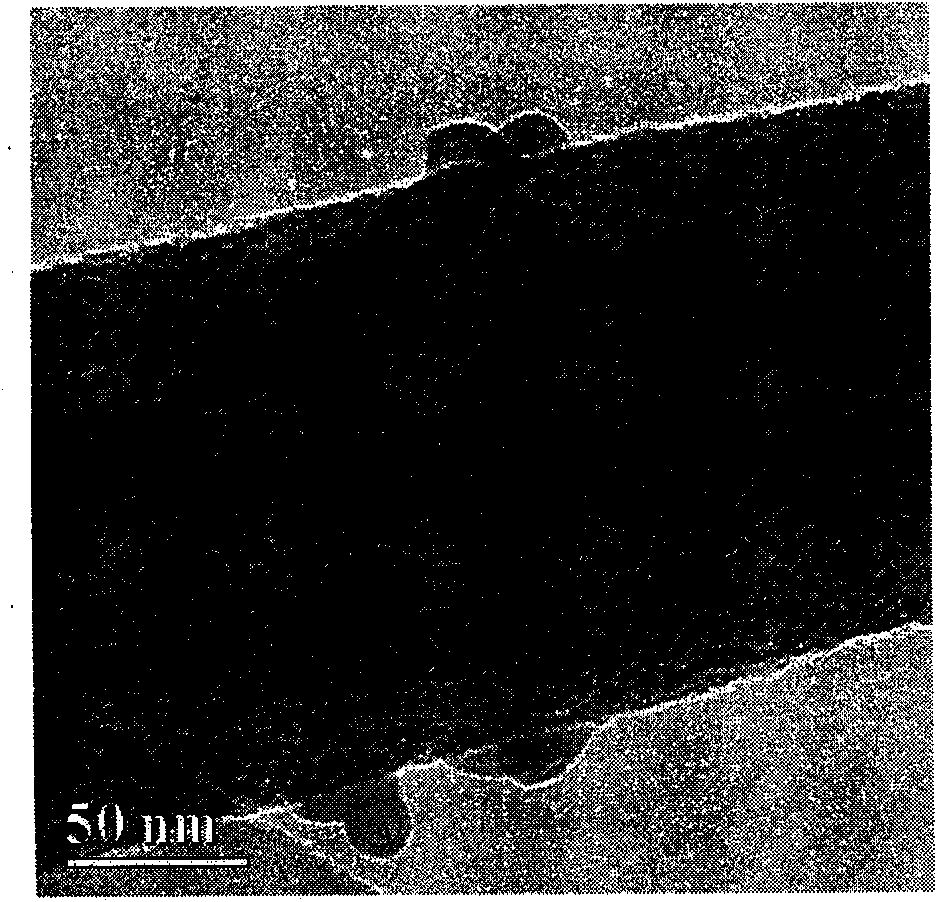

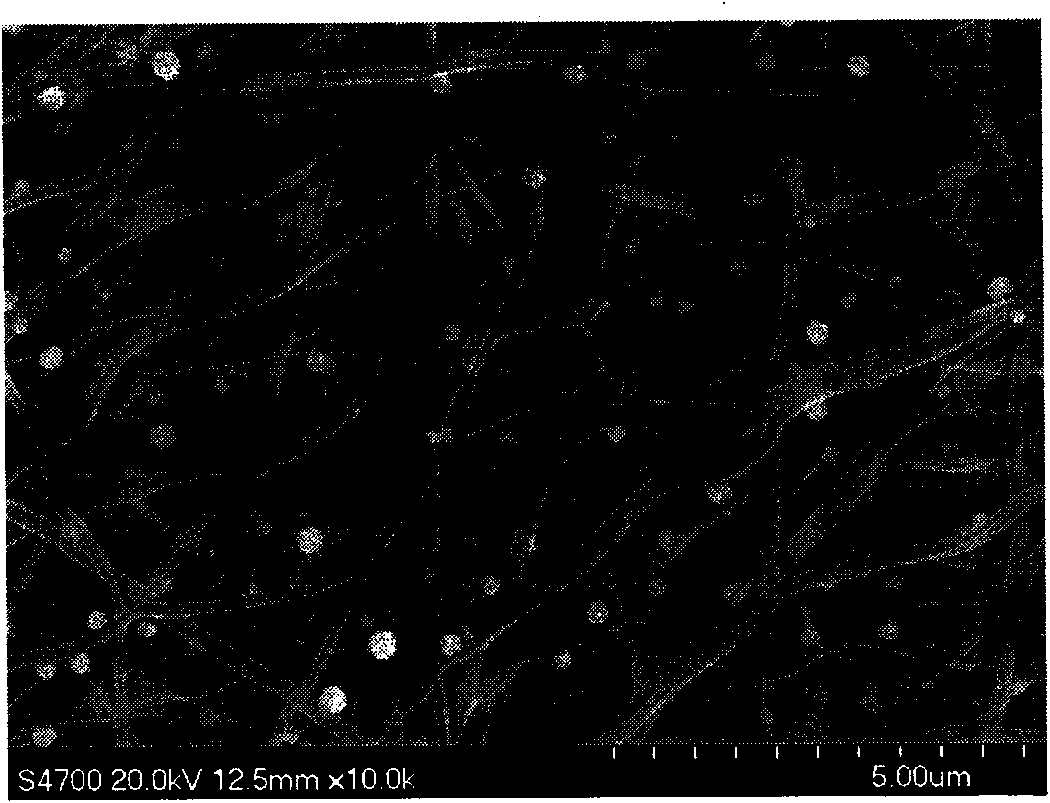

Stannum and carbon composite nano-fiber film negative-electrode material and preparation method thereof

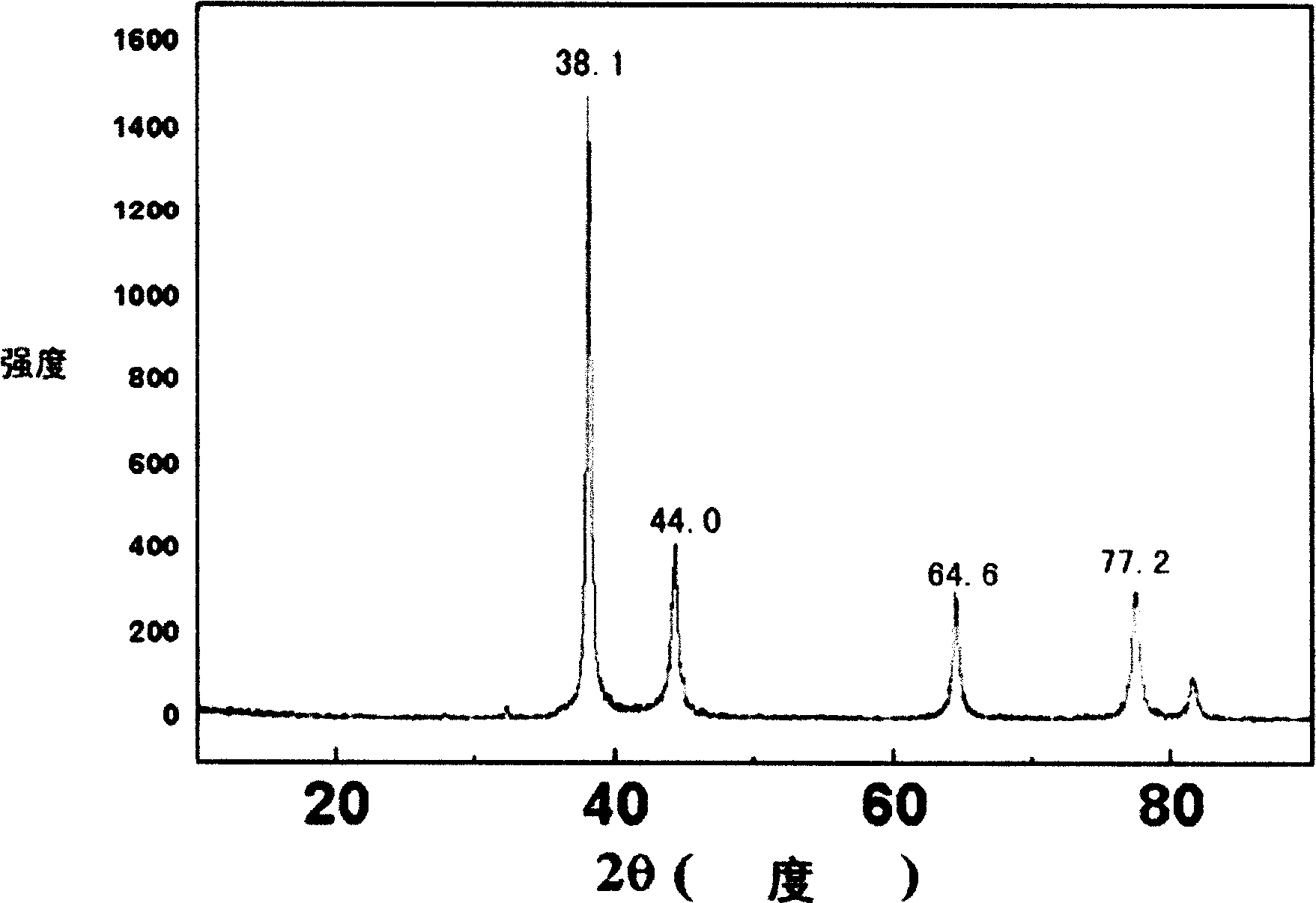

ActiveCN101626075AExcellent discharge performance and charge-discharge cycle stabilitySimple configuration processElectrode manufacturing processesSolventCarbon composites

The invention relates to stannum / carbon nano-fiber composite film material used in the negative electrode of a lithium ion battery and a preparation method thereof and also provides an assembly method of the stannum / carbon nano-fiber composite film material generated according to the preparation method and used as the electrode of the lithium ion battery. The preparation method comprises the following steps: preparing an uniform spinning solution by mixing a stannum precursor compound, a solvent, a precursor polymer of carbon nano-fibers and an organic solvent together; obtaining a polymer nano-fiber film by electro spinning according to a suitable electrostatic spinning technology; and obtaining a stannum / carbon nano-fiber composite film used in the negative electrode of the lithium ion battery through final treatment technologies, such as preoxidation, carbonization, and the like, thereby effectively collaborating the electrochemical performance of stannum / carbon nano-fibers and improving the specific capacity, the first charge-discharge efficiency and the cycle performance of the lithium ion battery.

Owner:BEIJING UNIV OF CHEM TECH

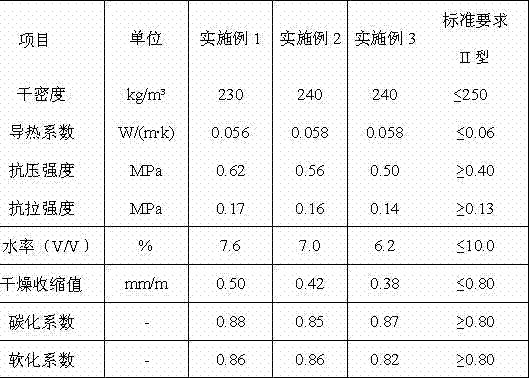

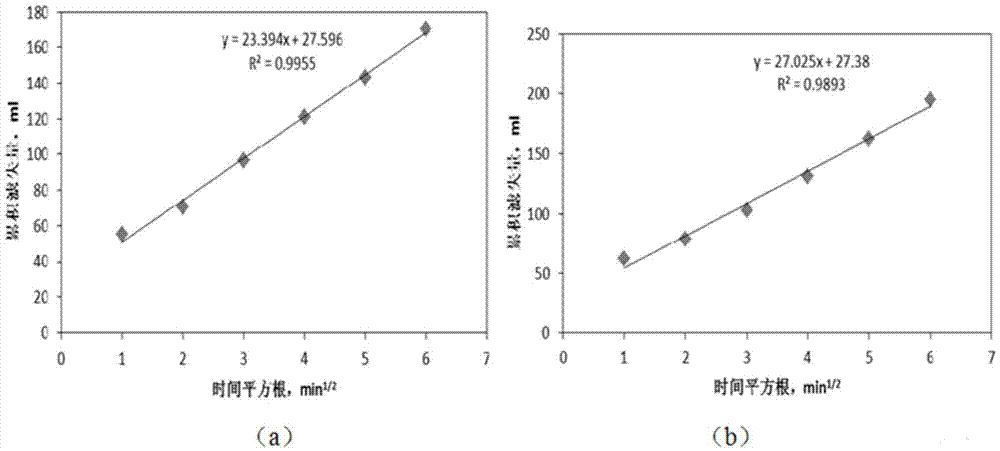

Composite foamed cement heat retaining panel using high-volume fly ash and preparation method thereof

The invention discloses a composite foamed cement heat retaining panel using high-volume fly ash and a preparation method thereof; the composite foamed cement heat retaining panel is prepared by 60-80 parts of cement, 20-40 parts of fly ash, 0.6-3.0 parts of moisture repellent, 0.12-0.30 part of a water reducing agent, 0.8-3.0 parts of an exciting agent, 0.3-0.50 part of anti-crack fiber, 30-60 parts of water and 4-8 parts of a foaming agent (by weight); the preparation method comprises the following steps: weighing each raw material; adding the water, the anti-crack fiber, the moisture repellent, the cement, the fly ash, the water reducing agent; stirring a mixture; adding the exciting agent; stirring the mixture; adding the foaming agent; stirring the mixture so as to prepare mixed slurry; then, injecting the mixed slurry into a mould; putting the mould statically for 4-5 hours; removing the mould; after 24 hours, cutting and packaging a product; and maintaining the product until age is 28 days. According to the invention, a part of the cement is substituted by fly ash; cost is low; environment pollution is reduced; and social efficiency and economic benefit are obvious.

Owner:JIANGSU NIGAO SCI & TECH +1

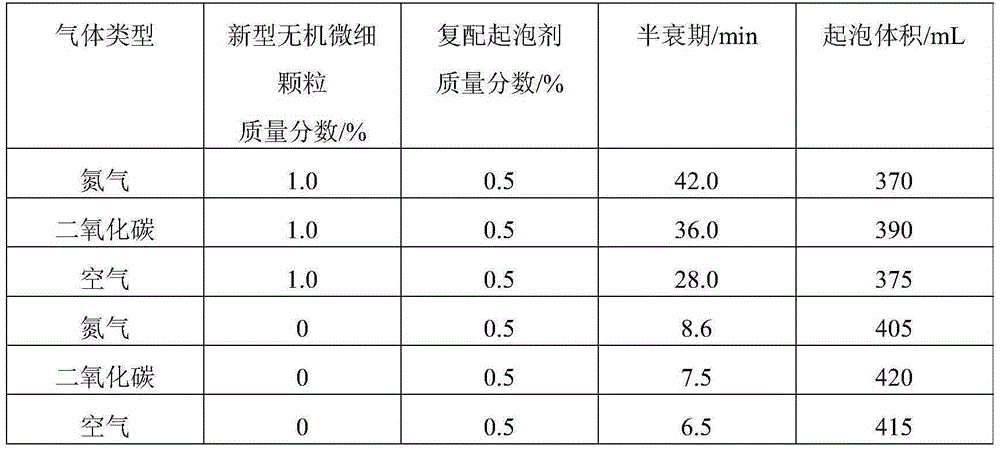

Novel inorganic fine particle enhanced foam system for oil and gas fields, and preparation method thereof

ActiveCN105238380AFormation damage is smallImprove performanceDrilling compositionFoaming agentGas phase

The invention relates to a novel inorganic fine particle enhanced foam system for oil and gas fields, and a preparation method thereof. The enhanced foam system comprises a gas phase and a liquid phase; the gas phase is nitrogen, carbon dioxide or air; the liquid phase comprises 0.2-0.8wt% of a foaming agent, 0.5-2.0wt% of novel inorganic fine particles, and the balance of water; and the novel inorganic fine particles are fine particles with the particle size being not greater than 2.5[mu]m, trapped and screened from air. The invention also provides the preparation method of the foam system. The enhanced foam system can be used to benefit efficient exploitation of oil and gas resources, can change the novel inorganic fine particles into valuables, reduces pollution of the novel inorganic fine particles to air environment, and has the advantages of low cost of the raw materials, simple preparation process, low operation cost, good oil and gas yield increasing effect, and high economic benefit.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Graphene composite copper thick film conductive slurry and preparation method thereof

InactiveCN104021842AImprove conductivityGraphene with excellent conductivity improvesNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesion forceConductive polymer

The invention discloses graphene composite copper thick film conductive slurry. The graphene composite copper thick film conductive slurry comprises the following components in percentage by mass: 60%-80% of conductive phase, 0.5%-5% of glass phase, 15%-39.5% of organic carrier, totaling 100%. The preparation method comprises the steps of mixing the components, heating to 35-40 DEG C, and uniformly stirring. According to the graphene composite copper thick film conductive slurry disclosed by the invention, by adding graphene with an excellent conductive property, the conductive property of the slurry is improved; by bismuth oxide low-melting glass, the conductive thick film slurry has excellent electrical properties and adhesion force even when being sintered at a low temperature. The slurry has the advantages of good conductivity and small printing thickness, can be effectively applied to production of a conductive material for various products, has the advantages of simple preparation process, convenience in operation, good conductivity, uniform distribution of particle sizes and easiness in coating, and is suitable for mass production of enterprises.

Owner:XI'AN POLYTECHNIC UNIVERSITY

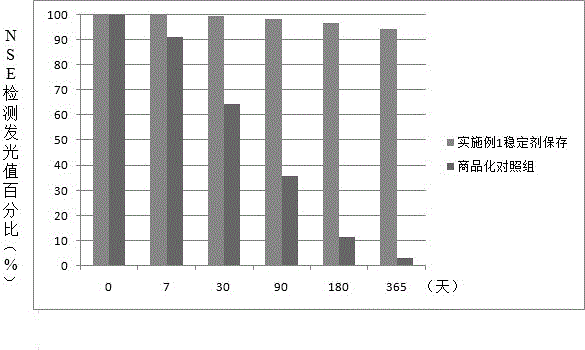

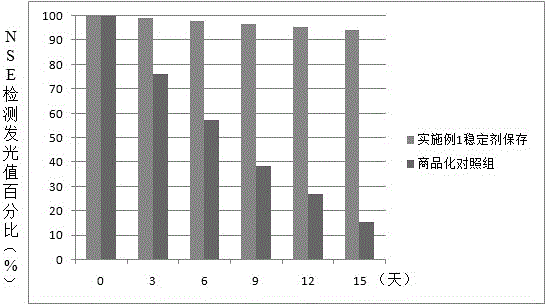

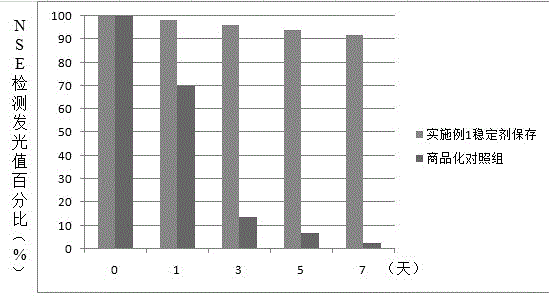

Neuron-specific enolase stabilizer and preparation method thereof

InactiveCN106568976AImprove overall lifespanReduce manufacturing costBiological testingFreeze-dryingBovine serum albumin

The invention relates to a neuron-specific enolase stabilizer. The stabilizer is prepared from a Tris.HCl buffer solution, NaCl, sucrose, trehalose, casein, bovine serum albumin, PEG6000, lysine, disodium ethylene diamine tetraacetate, dithiothreitol, glycerin, Tween-20, Triton X-100, aprotinin with the final concentration of 100-300 KIU / mL, and Proclin 300, and above substances are uniformly mixed in Millipore ultrapure water used as a solvent, is filtered by a 0.22 [mu]m filter membrane, and finally is preserved at 0-10 DEG C. The stabilizer greatly improves the preservation stability of neuron-specific enolase, prolongs the shelf life of a kit, simplification of the production technology and the doctor's detection operation process of a neuron-specific enolase detection kit, improvement of the metamorphism resistance in the preparation, transportation and storage process of the neuron-specific enolase, and reduction of inter-assay variation caused by a freeze-drying technology.

Owner:JIANGSU FLON BIOTECH

Carbon nano tube composite copper thick membrane electroconduction slurry and preparation method thereof

InactiveCN104021841AImprove conductivitySmall printing thicknessNon-conductive material with dispersed conductive materialCable/conductor manufactureCarbon nanotubeSlurry

The invention discloses carbon nano tube composite copper thick membrane electroconduction slurry. The carbon nano tube composite copper thick membrane electroconduction slurry comprises the following components in percentage by mass: 60%-80% of electroconduction phase, 4%-10% of a glass phase and 15%-30% of an organic carrier. The preparation method comprises the following steps: mixing all the components, heating to 35-40 DEG C, and stirring uniformly, thereby obtaining the carbon nano tube composite copper thick membrane electroconduction slurry. According to the carbon nano tube composite copper thick membrane electroconduction slurry, a carbon nano tube is added in the electroconduction phase in copper slurry; the electroconduction performance of the electroconduction slurry is improved, and the printing thickness is low; lead-free environmental-friendly low-fusing-point glass of a CaO-ZnO-B2O3 system is adopted so as to form electroconduction slurry which is sintered at low temperature and also shows excellent electric performance and adhesive powder; the electroconduction slurry can be effectively applied to electronic devices; the slurry preparation technology is simple, is convenient to operate, is good in electroconduction property, is easy to coat, and is suitable for scale production of enterprises.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Ultrahigh-characteristic-value three-phase flue gas foam for oil-gas field and preparation method thereof

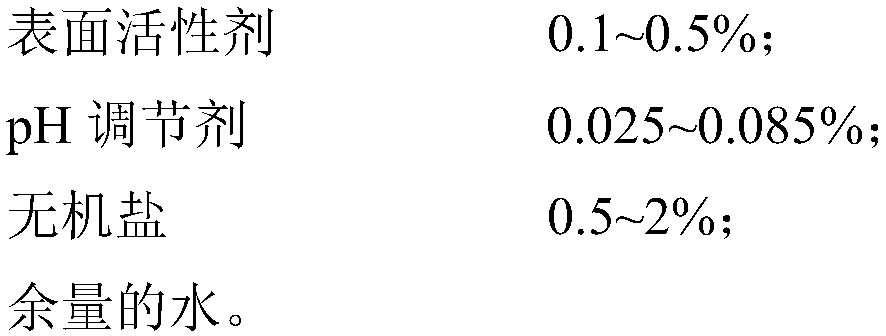

ActiveCN109517592AReduce moisture contentReduce water consumptionDrilling compositionGas phaseHigh pressure

The invention discloses ultrahigh-characteristic-value three-phase flue gas foam for an oil-gas field and a preparation method thereof. The three-phase flue gas foam is composed of a gas phase, a liquid phase and a solid phase, wherein the gas phase is flue gas produced by a coal-fired power plant; the liquid phase is a water solution of a surfactant, a pH (Potential of Hydrogen) value regulator and inorganic salt; the solid phase is a compound of fly ash and nano silicon dioxide; and the characteristic value of the foam is 90 to 99 percent. According to the ultrahigh-characteristic-value three-phase flue gas foam disclosed by the invention, a used solid-phase foam stabilizer is a compound system of fly ash particles and nano silicon dioxide particles; the cost is relatively low and a stable solid-phase particle adsorption layer can be formed on a foam liquid membrane; and unstable characteristics including liquid membrane cracking of the foam, gas dispersion, foam coalescence and thelike are greatly weakened and the stability of the foam is effectively improved. The ultrahigh-characteristic-value three-phase flue gas foam system disclosed by the invention can be adaptive to hightemperature of 230 DEG C and the stability is enhanced along the rising of pressure; and the ultrahigh-characteristic-value three-phase flue gas foam has good temperature resistance and pressure resistance and can be applicable to development operation of high-temperature and high-pressure oil and gas reservoirs.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

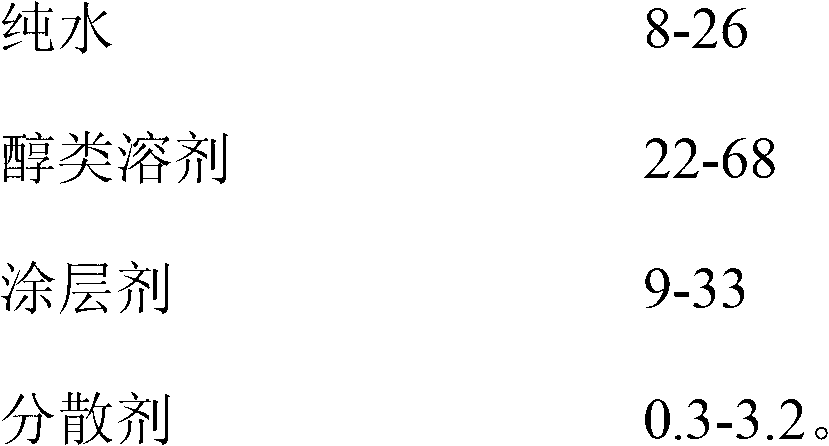

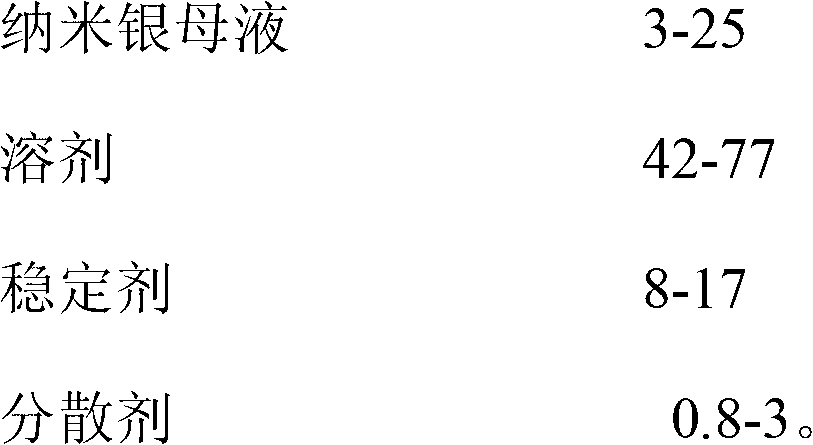

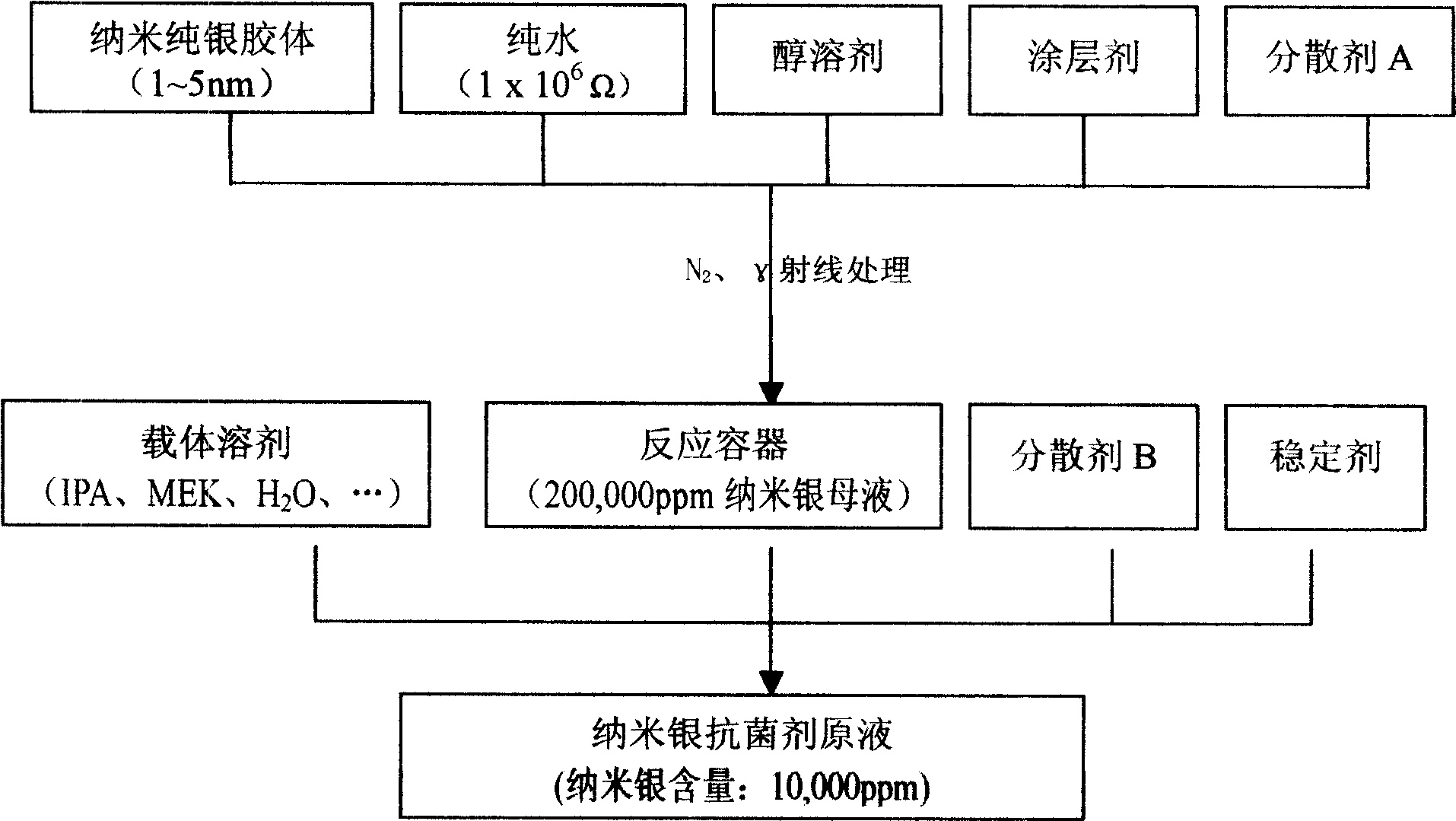

Antimicrobial stock solution for nano-silver antibacterial paint, preparation method and application thereof

InactiveCN101543226ALong-term sterilization effectImprove sterilization effectBiocideAntifouling/underwater paintsMicro nanoSingle substance

The invention belongs to the field of nanotechnology application, and in particular relates to an antimicrobial stock solution prepared from micro nano particles consisting of nano silver single substance and added in an antibacterial paint, a preparation method thereof and application thereof in the paint. The preparation method comprises that: firstly, nano pure silver colloid, pure water, alcohol solvent, an coating agent, a dispersant and the like are prepared into nano silver mother solution; then, the nano silver mother solution is mixed with solvent, a stabilizing agent and the dispersant to prepare the antimicrobial stock solution for the nano-silver antibacterial paint; and finally, the antimicrobial stock solution for the nano-silver antibacterial paint is added into a water paint or an oil paint required to be used. The invention can provide the antimicrobial stock solution prepared from nano silver single substance; the antimicrobial stock solution uses liquid nano silver stock solution to replace the common powder antimicrobial, solves the problems of small dosage, difficult dissolution and dispersion and easy glomeration, is applied to the paint and can be widely applied to various oil and non-oil (namely solvent and non solvent) paints.

Owner:SHENZHEN YITONGLANGBO TECH

Composite powder fire extinguishing agent and preparation method thereof

InactiveCN102319498AGood anti-reburning performanceImprove flow propertiesFire extinguisherFire hazardBromine

The invention discloses a composite powder base fire extinguishing agent and a preparation method thereof, which are characterized in that the vacuum pumping is carried out on 85 to 95 percent of layer double hydroxide with the grain diameter lower than 10mum according to the mass percent of the system to a value lower than 0.01 MPa in a pressure-resistant container, 2-bromine-3, 3, 3-trifluoropropene liquid is filled for soaking the powder, and the materials are stirred for more than 12 hours at a speed of 300 to 600r / min at -5 to 10 DEG C; then, the powder is separated through extraction filtering and is placed for 6 to 10 hours at room temperature, then, 0.8 to 2.2 percent of magnesium stearate with the grain diameter lower than 10mum according to the mass percent of the system is added and is uniformly mixed; the obtained composite powder fire extinguishing agent simultaneously has hydrophobicity and lipophobicity, the moisture-proof performance and the anti-reignition performance are good, the fire extinguishing efficiency is high, the composite powder fire extinguishing agent can be used as the fire extinguishing agent and can also be used as additives of powder extinguishing agents, raw materials have low price and can be easily obtained, the preparation process is simple, and the composite powder fire extinguishing agent is suitable for being used for various fire extinguishers to extinguish various kinds of fire hazards.

Owner:UNIV OF SCI & TECH OF CHINA

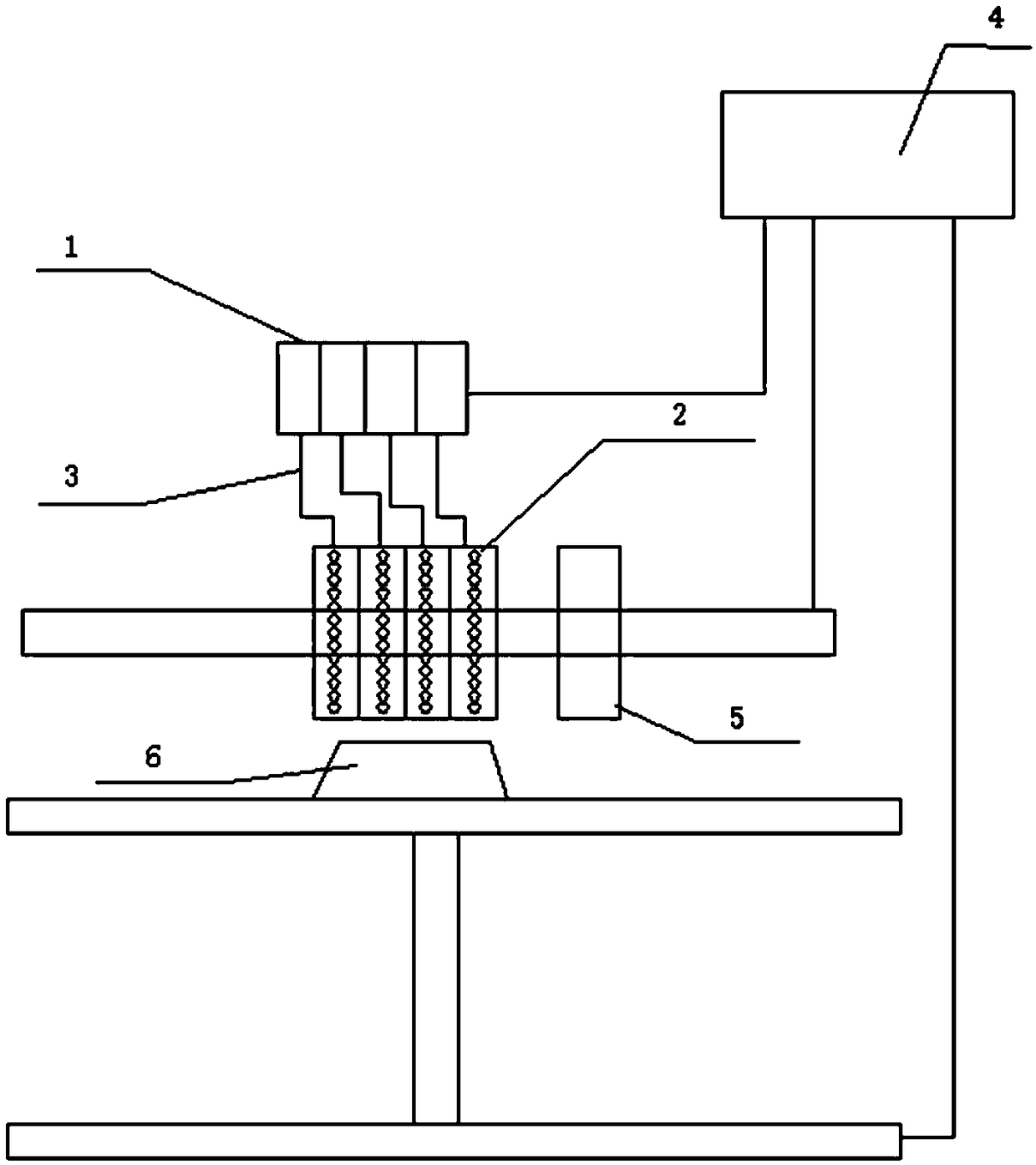

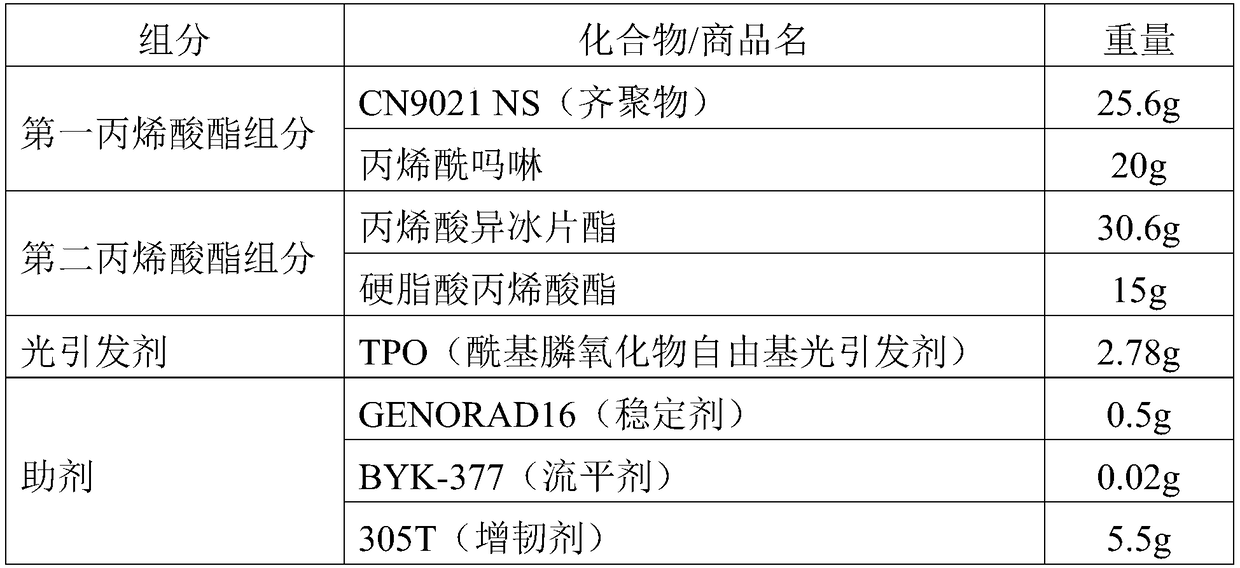

Photocurable non-transparent material for 3D printing, preparation method thereof, 3D printing product and 3D printer

ActiveCN109232791AImprove qualityAvoid easy cloggingManufacturing irradiation arrangements3D object support structuresDiacrylate esterEngineering

The invention provides a photocurable non-transparent material for 3D printing, a preparation method thereof, a 3D printing product and a 3D printer. The photocurable non-transparent material for 3D printing comprises the following components in parts by weight: 30-70 parts of a first acrylate component, 20-60 parts of a second acrylate component, 0.5-5 parts of a photoinitiator, 0.5-8 parts of anauxiliary agent and 0-4 parts of a colorant, wherein the first acrylate component is a polar acrylate component; and the second acrylate component is selected from at least one of weakly polar and non-polar acrylate components. According to the photocurable non-transparent material for 3D printing provided by the invention, a 3D printing product can be made non-transparent without adding white pigments such as titanium dioxide, so that the photocurable non-transparent material for 3D printing has the characteristics of high stability, the smoothness in a 3D printing process is ensured, the 3Dprinting product has good quality, and the 3D printer containing the photocurable non-transparent material for 3D printing has good performance.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

Powdered putty for exterior wall, prepared from ultrafine steel slag micropowder

The invention relates to powdered putty for an exterior wall prepared from ultrafine steel slag micropowder, belonging to the technical field of solid waste comprehensive utilization and chemical building materials. Ultrafine steel slag micropowder is used as a main raw material, and a certain amount of cement, desulphurization gypsum, talc powder, emulsion powder and water-retaining agent are added to prepare the powdered putty for the exterior wall after sufficiently and uniformly mixing. The powdered putty for the exterior wall takes industrial solid waste as the raw material, the production cost of the putty for the exterior wall is greatly reduced; the putty is in a powdered state, so that the putty is convenient to transport; the powdered putty for the exterior wall has a simple production process and is convenient to construct; and the powdered putty for the exterior wall has the characteristics of strong bonding force, no cracking, water resistance, alkali resistance and the like.

Owner:SHANGHAI UNIV +2

Ecological shell powder coating substrate

The invention relates to an ecological shell powder coating substrate, and belongs to the technical field of building materials. The ecological shell powder coating substrate is prepared from the following raw materials in parts by weight: 40-50 parts of shell powder, 20-28 parts of talcum powder, 3.2-5.5 parts of sodium bentonite, 8.5-9.8 parts of a pure acrylic emulsion, 0.2-0.4 part of an antifoaming agent, 0.5-0.6 part of a dispersing agent, 0.26-0.4 part of HPMC (hydroxypropyl methyl cellulose), 0.2-0.35 part of a bactericide, 20-35 parts of water and 0.25-0.45 part of a mildew preventive; a preparation method comprises the following steps: step 1, preparing the shell powder; step 2, preparing the ecological shell powder coating substrate. According to the ecological shell powder coating substrate, provided by the invention, the production cost is extremely low, the cost of the ecological coating is greatly reduced, and a greater price advantage and quality guarantee are achieved; besides, the prepared exterior wall coating has the characteristics of ultraviolet radiation protection, air purification, corrosion resistance, scratch resistance, temperature regulation and control, good stain resistance and the like, and the preparation method is simple in preparation processes, environment-friendly and low-carbon.

Owner:周春莲

Waterborne resin antifogging coating special for films and antifogging film

ActiveCN108084853AHigh light transmittanceLow costOther chemical processesPolyester coatingsPolyester resinWear resistance

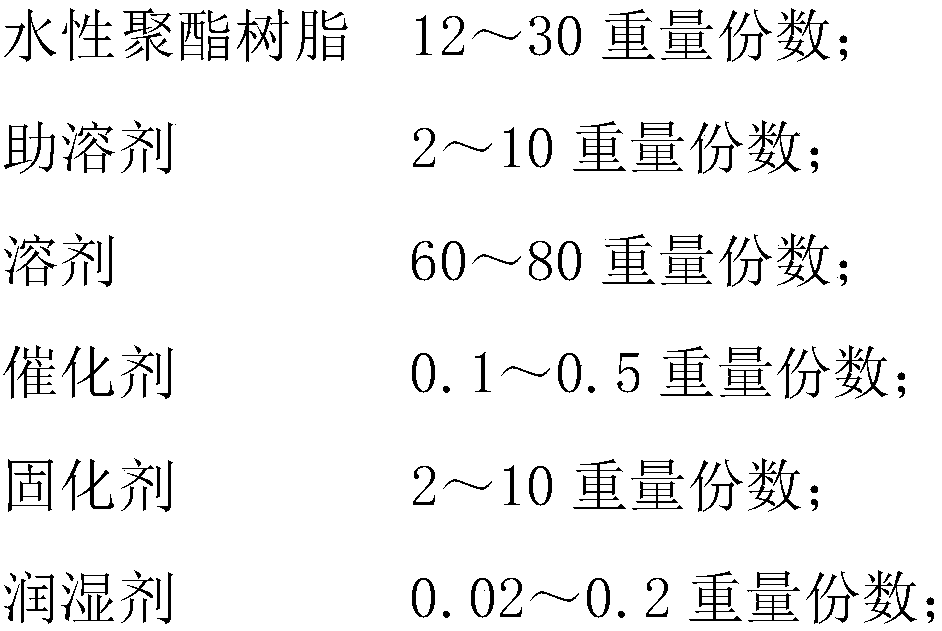

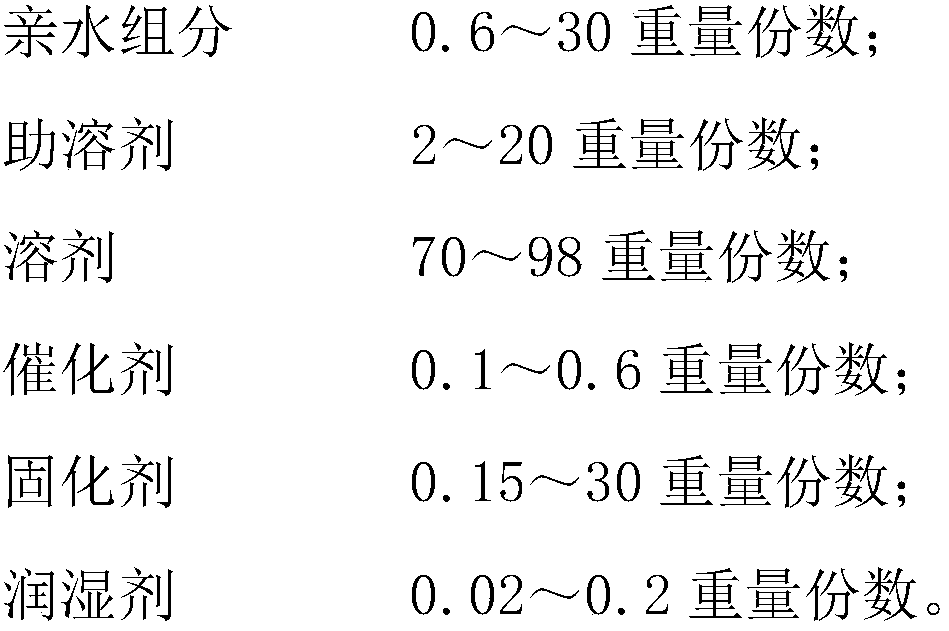

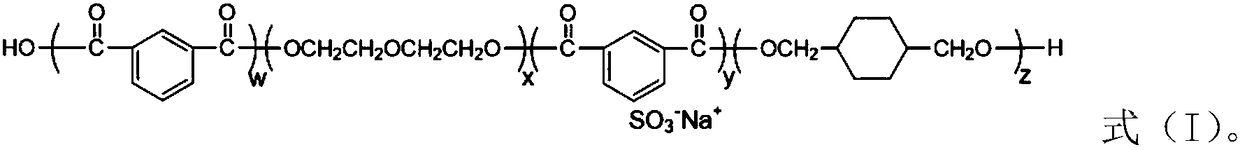

The invention discloses waterborne resin antifogging coating special for films and an antifogging film. The waterborne resin antifogging coating comprises a first composition and a second composition,wherein the first composition comprises waterborne polyester resin, a cosolvent, a solvent, a catalyst, a curing agent and a wetting agent; the second composition comprises a hydrophilic component cosolvent, a solvent, a catalyst, a curing agent and a wetting agent. The antifogging film is coated with the coating above. The waterborne resin antifogging coating has the advantages that the antifogging coating is colorless and transparent and has extremely high light transmittance; the waterborne polyester resin and the hydrophilic component in the antifogging coating are chemically crosslinkedvia the curing agents, so that the coating layer formed by the antifogging coating and a film base material have lasting antifogging performance, water resistance and wear resistance.

Owner:HUBEI UNIV

Method for preparing aromatic polyamide fiber paper base material by electrospinning technology

InactiveCN103046427AReduce weightImprove mechanical propertiesSynthetic cellulose/non-cellulose material pulp/paperWater bathsElectrospinning

The invention discloses a method for preparing an aromatic polyamide fiber paper base material by an electrospinning technology and belongs to the preparing field of aramid fiber papers. The method for preparing the aromatic polyamide fiber paper comprises the steps that (1), an aromatic polyamide fiber spinning solution is prepared; (2), the aromatic polyamide fiber spinning solution is sprayed under high-pressure spinning to form an aromatic polyamide fiber film; and (3), the aromatic polyamide fiber film is subjected to water bath, drying, then high temperature press polish treatment and hot press molding, so that the aromatic polyamide fiber paper base material is formed. Aromatic polyamide fiber paper base materials prepared by traditional paper making methods have the problems that the fiber dispersing performance is poor, the forming strength is low, the paper uniformity is bad, the hot press performance can not be guaranteed, the requirement for papermaking performance is strict, so that the large-scale development of the aromatic polyamide fiber paper base materials is restricted. However, according to the aromatic polyamide fiber paper base material prepared by the method of spinning the aromatic polyamide fiber spinning solution by high-pressure multiple nozzles, the operation is simple and easy to implement, and the prepared aromatic polyamide fiber paper base material has excellent performance and more stable nature.

Owner:SOUTH CHINA UNIV OF TECH

Agent used for preventing and treating powdery mildew of impatiens balsamina L

InactiveCN104146000ASimple configuration processEasy to useBiocideFungicidesQuisqualis indicaToxicology

The invention discloses an agent used for preventing and treating powdery mildew of impatiens balsamina L. The agent comprises the following components in parts by weight: 16-26 parts of dimethirimol, 20-24 parts of 60% chlorothalonil, 5-9 parts of sulfate, 3-8 parts of polyoxyethylene alkyl ether, 4-6 parts of casein, 3-7 parts of diethylaminoethyl hexanoate, 10-14 parts of ethanol, 2-3 parts of astragalus polysaccharide, 4-8 parts of tripterygium wilfordii powder, 4-7 parts of citric acid, 4-8 parts of fructus quisqualis powder and 40-50 parts of water. An application method of the agent is characterized by comprising the steps of preparing the components in proportion, mixing the components and stirring the components uniformly, thus obtaining the agent for prevention and treatment; and then spraying the agent for prevention and treatment around affected plants after diluting the agent for prevention and treatment. The agent has good prevention effects, is convenient to use and is beneficial to reduction of the dosages of pesticides, reduction of environmental pollution and ecological balance.

Owner:JIANGSU DAHEZHUANGYUAN AGRI SCI & TECH

Medicament for controlling anthracnose of michelia figo (lour.) spreng and application method thereof

InactiveCN104041528AHarm reductionImprove survival rateBiocideFungicidesCentella asiatica extractAstragalus polysaccharide

The invention discloses a medicament for controlling anthracnose of michelia figo (lour.) spreng and an application method thereof. The medicament comprises the following components in parts by weight: 13-15 parts of 40% imazalil emulsion in water, 10-14 parts of 25% Tanteling powder, 14-16 parts of herba centellae extract, 2-4 parts of astragalus polysaccharides, 2-4 parts of cinnamyl aldehyde, 3-8 parts of diethyl aminoethyl hexanoate, 10-14 parts of wintergreen barberry root extract, 10-14 parts of isopropyl alcohol, 6-8 parts of kudzuvine root extract and 50-60 parts of water. Meanwhile, the application method of the medicament is simple and convenient. The medicament has good control effects, is simple in preparation process and convenient to use, reduces the pesticide dosage and environmental pollution, and is beneficial to ecological balance.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

Preparation for improving photosynthetic efficiency and resistance of green house cultured crop

The invention relates to a composite agent for improving the photosynthetic efficiency and reverse resistance of greenhouse plant. Wherein, it comprises that triacontanol at 1 deal, fruitone 1 deal, mycose at 1000 parts, while it also can contain monobasic potassium phosphate at 1000 parts, aquacare at 1000 parts, addex-magnesium at 800 parts, copperas at 100 parts, manganese chloride at 100 parts, and borax at 100 parts. Its processing agent can be mixed powder or liquid agent. The invention has simple process, simple formula, low cost and non side effect. When using, said liquid agent via sprayer can be sprayed on the surface of plant, to improve the chlorophyll content and photosynthetic efficiency, to improve the healthy white root number and yield.

Owner:GUANGXI UNIV

High-performance pumpable concrete for well drilling wall and preparation method thereof

InactiveCN104446261AReduce frictionSatisfy mobilitySolid waste managementContinuous/uninterruptedSlag

The invention discloses high-performance pumpable concrete for a well drilling wall and a preparation method thereof. The high-performance pumpable concrete comprises the following components in parts by weight: 400-450 parts of cement, 0-30 parts of silicon powder, 40-100 parts of coal ash, 0-100 parts of slag, 460-600 parts of a bonding material, 620-730 parts of sand, 1060-1110 parts of stone, 160-170 parts of water and a water reducer and a pumping agent which accounts for 1-3% of the total weight of the components. The concrete disclosed by the invention can satisfy the mobility of pumping request and the slump of the concrete is over 160mm; the concrete is good in homogeneity and the high-performance concrete prepared is not layered or separated and does not bleed under a great slump, so that the pump concrete discharged is in a continuous and uninterrupted turbulent condition; the frictional resistance of the concrete with a pipe wall is small and the preparation process is simple; the concrete is low in heat of hydration, high in durability and ant-crack and anti-permeability performances.

Owner:安徽恒源煤电股份有限公司

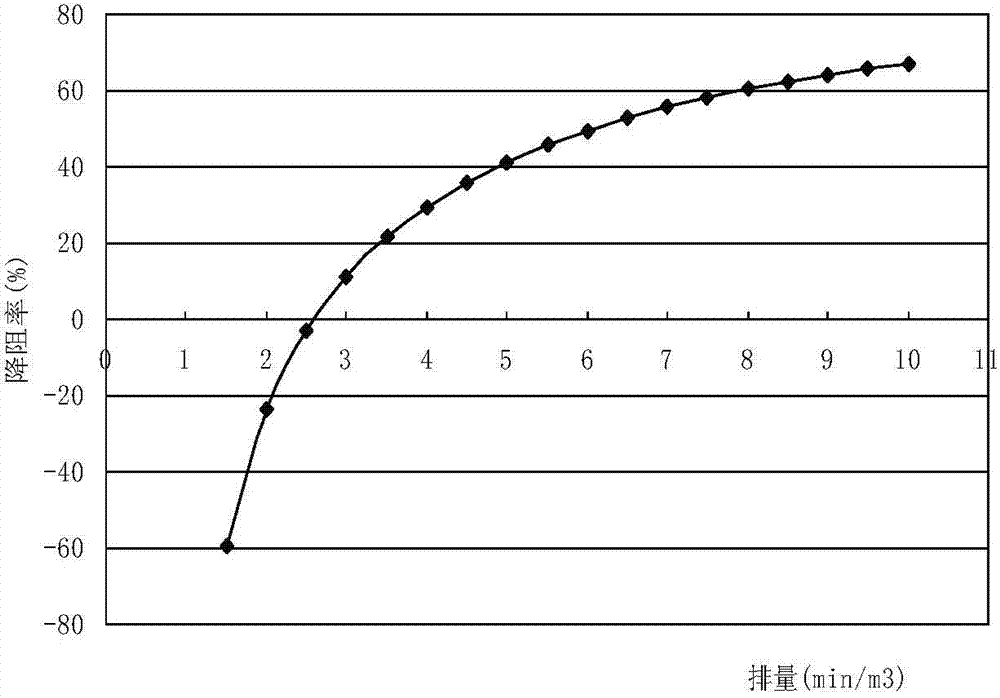

Nano coating fiber active fracturing fluid

InactiveCN104498019AWith anti-expansion effectHas the effect of reducing resistanceDrilling compositionFiberCarrying capacity

The invention belongs to the technical field of shale gas well fracturing increase production, and particularly relates to a nano coating fiber active fracturing fluid. The invention aims at providing a fracturing fluid system having an integrated function of swelling prevention, resistance reduction and high sand carrying capacity, which is favorable for the fracturing modification construction of shale gas reservoir. According to the technical scheme, the nano coating fiber active water fracturing fluid is formed by compounding an antiswelling agent, a resistance reducing agent, nano coating fibers and water. The invention also provides a compounding method of the nano coating fiber active water fracturing fluid. The fracturing fluid has an antiswelling and resistance reduction effect, the sand carrying performance of the fracturing fluid is improved, the deposition way is changed, and the deposition rate of a supporting agent is reduced; and the filter loss is effectively reduced, and the damage rate for the shale reservoir is low. The compounding process is simple and easy, the damage for the shale reservoir is small, and the nano coating fiber active fracturing fluid is easy to flow back.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

Preparation for preventing and controlling Magnolia figo leaf blight and use method of preparation

The invention discloses a preparation for preventing and controlling Magnolia figo leaf blight and a use method of the preparation. The preparation comprises the following components in parts by weight: 31-40 parts of Bismerthiazol, 15-20 parts of Bordeaux mixture, 10-15 parts of wintergreen barberry root extract, 8-14 parts of red-knees herb extract, 10-40 parts of rhizoma acori graminei extract, 5-8 parts of alkyl naphthalene sulfonate, 5-10 parts of polyvinyl alcohol, 5-10 parts of zingerone, 10-15 parts of magnesium sulfate, 4-7 parts of citric acid and 70-80 parts of water. The use method of the preparation is simple and convenient. The preparation has the beneficial effects that the prevention effect is good, a preparation process is simple, the use is convenient, the use amount of a pesticide is reduced, the environmental pollution is alleviated, and the ecological balance is benefited.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

Coal combustion supporting energy-saving additive

InactiveCN104974813AImprove combustion efficiencySignificant coal saving effectSolid fuelsPotassium manganateComponents of crude oil

The invention discloses a coal combustion supporting energy-saving additive, which mainly comprises the following components in percentage by weight: 5-15% of nitrified rare earth, 5-20% of sodium chloride, 10-20% of magnesium nitrate, 5-10% of potassium permanganate, 5-10% of ammonium nitrate and the balance of water. The additive is obtained by proportioning according to the weight of the materials, dissolving while stirring and mixing uniformly. The additive is sprayed onto coal in a ratio of 1:3000-1:5000, and the additive and the coal are mixed uniformly. By adopting the nitrified rare earth and potassium permanganate as catalytic combustion supporting active ingredients of the catalytic combustion supporting and smoke eliminating additive, the coal combustion efficiency is high, the coal saving effect is obvious, and 5-20% of coal can be saved; by adopting a metal compound of rare earth, magnesium, sodium, potassium, manganese and the like as a sulfur fixing agent, the sulfur fixing and emission reducing efficiency is high, and the sulfur dioxide emission of a coal-fired boiler can be reduced by more than or equal to 30%; the adopted active ingredients are good in chemical stability and are easily dissolved into an aqueous solution; after the additive is mixed with corresponding coal uniformly, the additive can be kept stable for a long term; and the additive is relatively simple in preparation and good in popularization and application.

Owner:HARBIN YONGHENGXIN TECH DEV

Gas-solid composite powder base fire-extinguishing agent and preparation method thereof

InactiveCN101417166BImprove fire extinguishing efficiencyImprove liquidityFire extinguisherGas solidVacuum pumping

Owner:UNIV OF SCI & TECH OF CHINA

Detecting liquid for identifying irridiation treatment of rice grain and using method

Present invention discloses a detection liquid for detecting irradiation of rice and grain foodstuff and use method. Detecting liquid is composed of following weight percentage compositions with pH value 2-5, acetic acid 4-6 per cent, propionic acid 5-15 per cent, oxalic acid 7-12 per cent, the others being distilled water. Detection method as follows: taking two equiponderant rice and grain powder respectively loading in two tanks, wherein adding detecting liquid in one tank adding distilled water in another tank, after uniformly stirring to proceed cooking-steaming viscosity spectra comparison, if the viscosity spectra curve of rice and grain added with detecting liquid being higher than that of distilled water, then judging it being processed by irradiation, otherwise judging being not processed by irradiation. Said invented detecting has low cost, simple configuring technology, can fast identify any kind of not gelatinized starch foodstuff whether being processed by irradiation with simple, fast and high accuracy.

Owner:浙江省技术物理应用研究所 +1

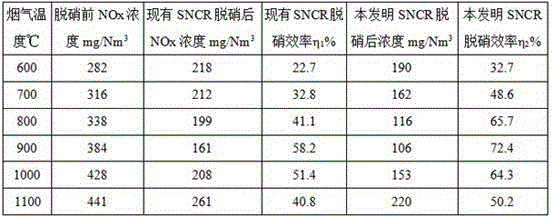

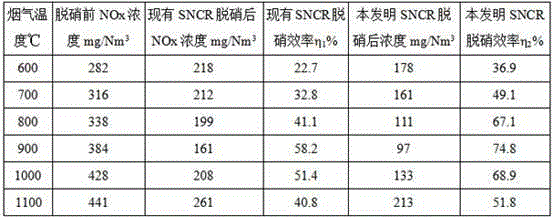

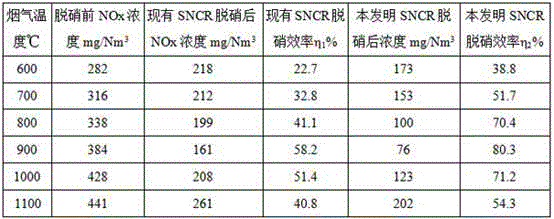

Method for optimizing SNCR (selective non-catalytic reduction) denitrification system of garbage incinerator by adding anionic surfactant

InactiveCN104645794AImprove efficiencyOvercome the disadvantages of complex and expensive configurationDispersed particle separationActive agentAqueous droplet

The invention discloses a method for optimizing a SNCR (selective non-catalytic reduction) denitrification system of a garbage incinerator by adding an anionic surfactant. The method comprises the step of adding a certain amount of anionic surfactant in an ammonium water diluting process based on the existing SNCR denitrification method. After the anionic surfactant and an ammonium water solution are mixed and sprayed to a hearth, the mixture is decomposed at high temperatures to generate active free radicals such as -OH, so that the reaction efficiency and time of atomized ammonium water drops and NOx in smoke are effectively ensured, the integral denitrification efficiency of the SNCR system is improved, the optimum reaction temperature region is expanded, and moreover, no adverse influence is brought to stable combustion of the incinerator. Compared with the existing SKCR denitrification compound additives, the method disclosed by the invention is simple in process, single in additive and low in cost, and thus is a method which can effectively improve the SNCR denitrification efficiency of the garbage incinerator and has a relatively broad application prospect.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Method for preparing cactus pear scar-removal composition

InactiveCN107320417APrevent drynessSolve the slackOrganic active ingredientsCosmetic preparationsPEARLAMINARIA ANGUSTATA

The invention belongs to the technical field of preparation of skin-care products and relates to a method for preparing a cactus pear scar-removal composition used for removing and healing scars. The cactus pear scar-removal composition comprises the following raw materials: cactus pear, centella asiatica, kelp, fresh ginger and vitamin E. The preparation method comprises the following steps: taking acquired fresh cactus pear to prepare a cactus pear extract liquid; then grinding centella asiatica and kelp into a centella asiatica serous fluid and a kelp serous fluid; grinding fresh ginger into fresh ginger juice; proportionally mixing the raw materials; adding vitamin E; and performing uniform stirring to obtain the cactus pear scar-removal composition. The prepared cactus pear scar-removal composition does not contain additives, is good in absorption effect and is suitable for removing and healing scars, the selected raw materials are good in natural feature, the formula is scientific and reasonable, the configuration process is simple, and the application environment is friendly.

Owner:QINGDAO UNIV

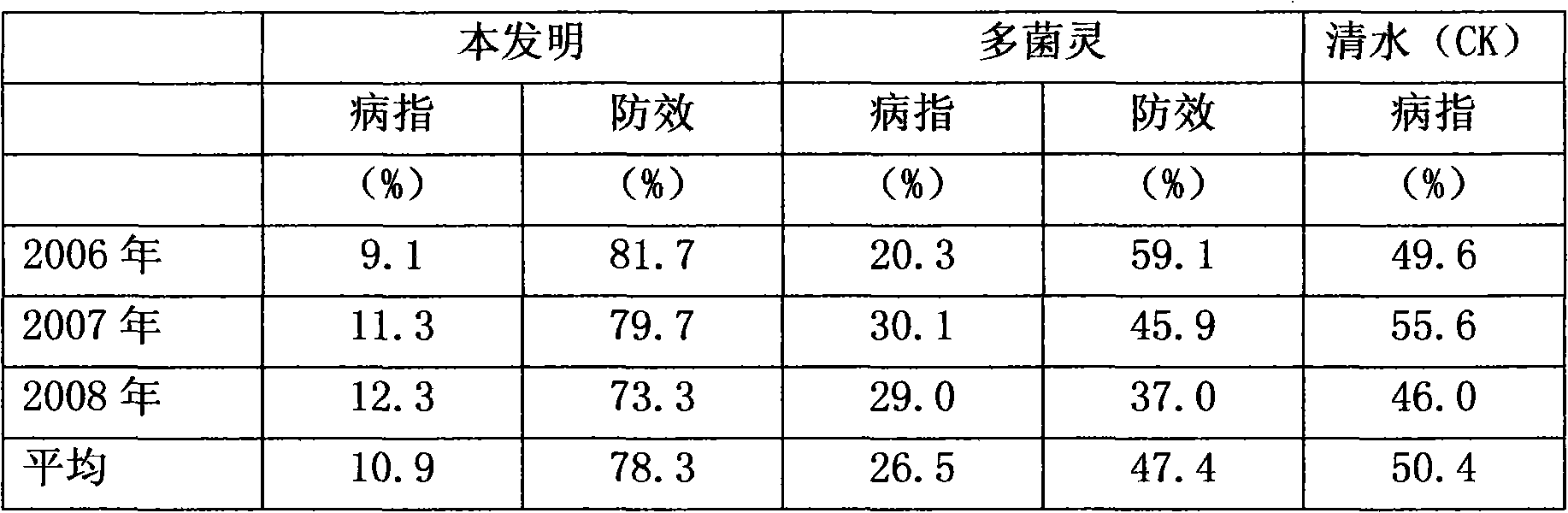

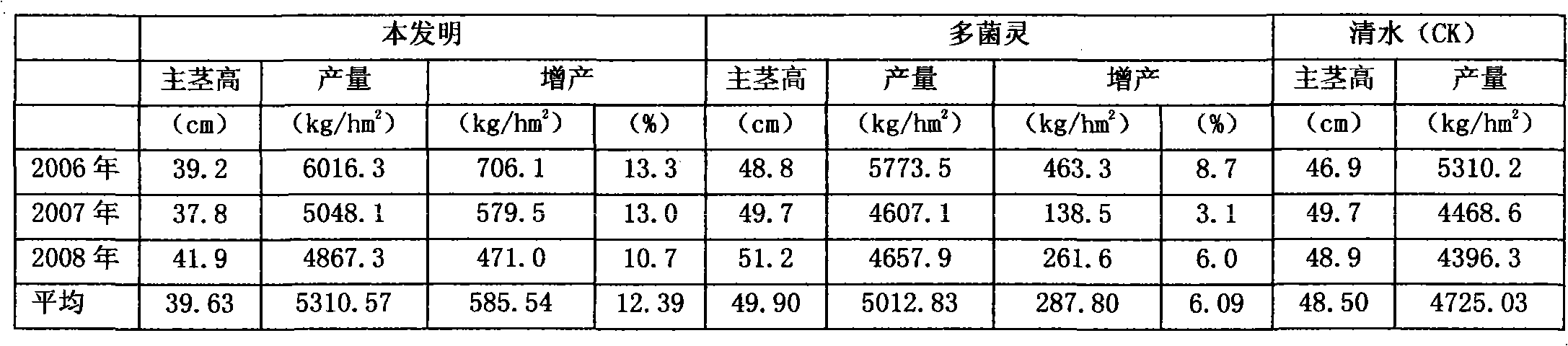

Blending medicament preventing and curing cercospora brown spot of peanut and using method thereof

InactiveCN101803607AControl leggyIncrease productionBiocideDead plant preservationDiseaseExcessive growth

The invention discloses a blending medicament preventing and curing cercospora brown spot of peanut, comprising the following materials in parts by weight: 1-10 parts of diniconazole, 1-10 parts of carbendazim, 1-20 parts of GZM and 1500-24000 parts of water. The preparation ratio of diniconazole to carbendazim to GZM is 1:1:1-2, and the mass fraction ratio of mixture to water is 1:500-600. In the invasion initial stage of brown blotch, blending medicament is sprayed twice at the medicament spraying interval of 10-14 days. The invention can effectively prevent and cure cercospora brown spot of peanut, can obviously control peanut excessive growth, improve bean yield, perform the dual action of obviously preventing disease and inhibiting growth, and perform the function of one medicine with multiple purposes. In addition, pesticide dosage is reduced to lighten environment pollution and bring benefits for ecological balance. Physical protective agent GZM is added to perform certain physical protection action on peanut plants, prolongs pesticide effect time and reduces application times.

Owner:SHANDONG PEANUT RES INST

Special prevention and cure agentia for southern blight of money trees and use method thereof

InactiveCN103960317AHarm reductionImprove survival rateBiocideFungicidesAgricultural pesticidesNitrobenzene

The invention discloses a special prevention and cure agentia for the southern blight of money trees and a use method thereof. The agentia comprises the following components in parts by weight: 10-15 parts of 1% copper sulfate liquid, 10-15 parts of 40% pentachloronitrobenzene, 10-14 parts of 25% hectogram missible oil, 3-7 parts of fresh ginger, 2-6 parts of radix aconiti agrestis, 2-4 parts of baicalein, 2-4 parts of astragalus polysaccharides, 5-10 parts of allium cepa infusion, 2-4 parts of cinnamaldehyde, 5-9 parts of areca, 2-7 parts of Chinese goldthread, 5-8 parts of edible salt and 90-110 parts of water. All the components are prepared and mixed according to a proportion, and then are uniformly agitated so as to obtain the prevention and cure agentia a 800-1,000 times diluent liquid of the prevention and cure agentia is sprayed to the surrounding of damaged plants for 2-4 times, and the time interval of each time of agentia application is 5-8 days. The special prevention and cure agentia has good prevention and cure effects, is simple in preparation process and convenient to use, reduces the use amount of agricultural pesticide, relieves pollution to the environment, and facilitates the ecological equilibrium.

Owner:泗阳县农业科学研究所

Medicament for controlling scale insects on michelia figo (lour.) spreng and application method thereof

The invention discloses a medicament for controlling scale insects on michelia figo (lour.) spreng and an application method thereof. The medicament comprises the following components in parts by weight: 10-14 parts of 10% cypermethrin emulsifiable concentrate, 15-18 parts of sucrose fatty ester, 10-14 parts of orange peel extract, 8-14 parts of lightyellow sophora root extract, 12-15 parts of pepper extract, 13-16 parts of geraniol, 6-12 parts of citric acid, 11-15 parts of salt and 80-95 parts of water. Meanwhile, the application method of the medicament is simple and convenient. The medicament has good control effects, is simple in preparation process and convenient to use, reduces the pesticide dosage and environmental pollution, and is beneficial to ecological balance.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

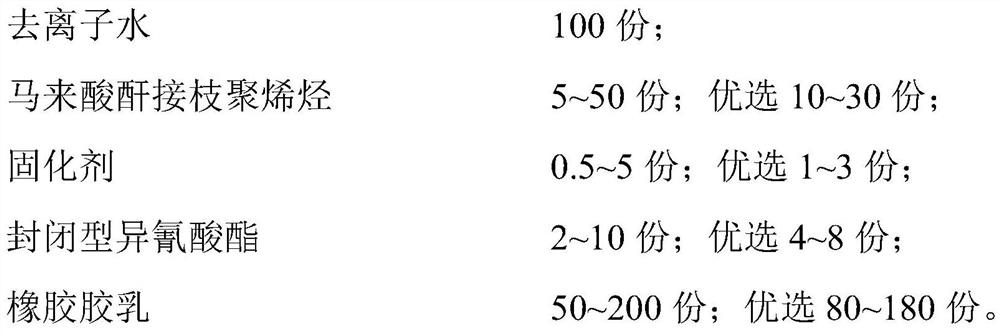

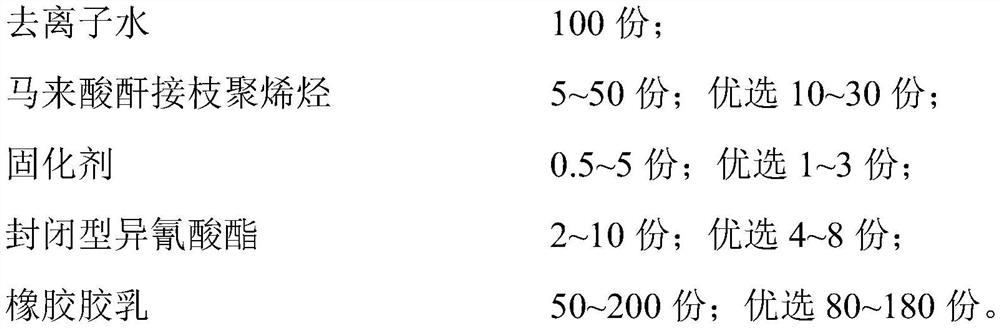

Environment-friendly impregnation system for fiber surface treatment, preparation method and impregnation method

InactiveCN112064358AImprove surface reactivityIncrease the degree of cross-linkingFibre typesAdhesive processes with surface pretreatmentPolymer sciencePolyolefin

The invention discloses an environment-friendly impregnation system for fiber surface treatment, a preparation method and an impregnation method. The impregnation system comprises 100 parts of deionized water, 5-50 parts of maleic anhydride grafted polyolefin, 0.5-5 parts of a curing agent, 2-10 parts of blocked isocyanate and 50-200 parts of rubber latex. The raw materials adopted by the impregnation system are green and environment-friendly, and are industrial products, the preparation of an impregnation liquid and the fiber impregnation process are simple, and the process is short; and theisocyanate can enhance the activity of the fiber surface, and meanwhile, the maleic anhydride grafted polyolefin can be effectively co-vulcanized with the rubber latex, so that the formula system cangreatly improve the bonding effect between the fiber and the rubber, and can effectively replace an RFL impregnation system.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com