Anti-bacterial water-based paint and preparation method thereof

A water-based paint and coating technology, which is applied to the preparation of antibacterial water-based paints and the field of antibacterial water-based paints, can solve the problems of restricting the promotion and use of inorganic antibacterial agents, the problem of antibacterial stability, and the reduction of antibacterial properties, and achieve long-term antibacterial effect. , the effect of stabilizing chemical properties and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] An antibacterial water-based paint is made of 0.2 parts by weight of nanometer silver antibacterial agent; 8 parts by weight of nanometer zinc oxide; 26 parts by weight of acrylic resin dispersion; and 18 parts by weight of adhesive resin or plasticizer. The specific preparation method is as follows: mix and stir deionized water, antibacterial agent, wetting agent, dispersant, and defoamer evenly, add nanomaterials, and disperse evenly to obtain an aqueous dispersion; add the obtained aqueous dispersion to the stirred emulsion or aqueous In the resin dispersion, add adhesion resin or plasticizer, wetting agent, leveling agent, thickener, anti-sedimentation agent, pH regulator and stir to disperse evenly; add pigment or colorant; replenish water to make antibacterial water-based coating.

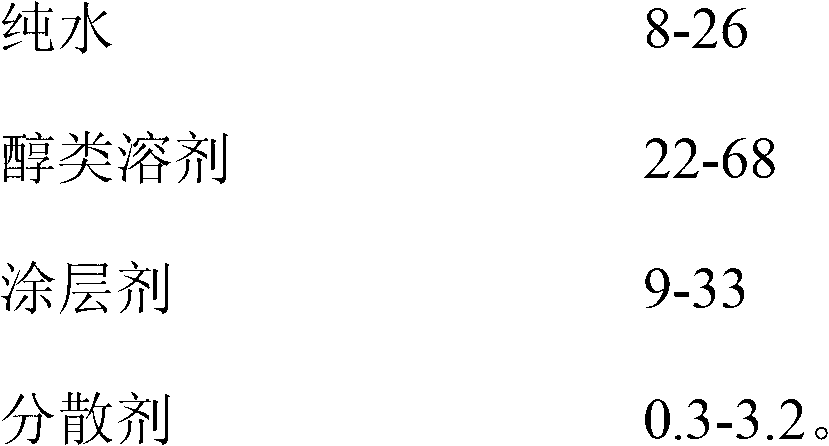

[0047] Wherein the preparation method of the nano-silver antibacterial agent is as follows: first configure the nano-silver mother liquor, and its ratio by weight is: nano-silver collo...

Embodiment 2

[0051] An antibacterial water-based paint is made of 11 parts by weight of nano silver antibacterial agent; 22 parts by weight of nano titanium dioxide; 23 parts by weight of polyester resin dispersion; 10 parts by weight of adhesion resin or plasticizer. Its preparation method is with embodiment 1.

[0052] Wherein the preparation method of the nano-silver antibacterial agent is as follows: first configure the nano-silver mother liquor, and its ratio by weight is: nano-silver colloid 42; pure water 26; alcohol solvent 22; coating agent 9; dispersant 0.3.

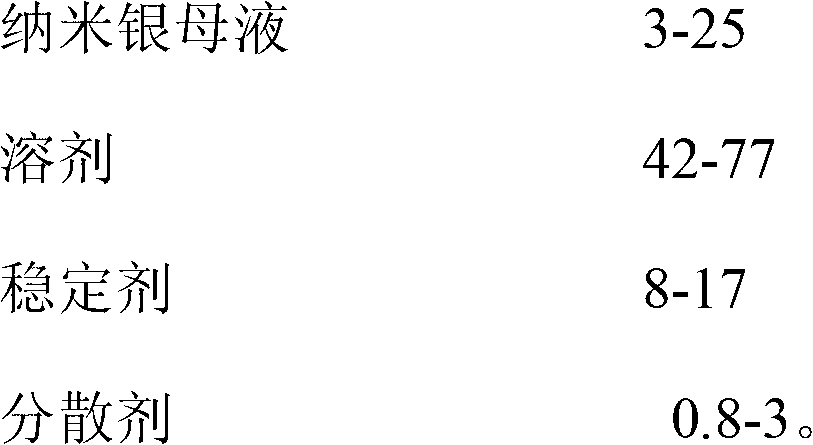

[0053] Then use the above-mentioned nano-silver mother liquor to configure the nano-silver antibacterial agent, and the ratio according to parts by weight is: nano-silver mother liquor 25; solvent 77; stabilizer 8; dispersant 1.4.

[0054] The concrete preparation method of nano-silver antibacterial agent is with embodiment 1.

Embodiment 3

[0056] A kind of antibacterial water-based paint, by the nano-silver antibacterial agent of 7 weight parts; The nano-scale silver powder / nanometer titanium dioxide of 33 weight parts; The polyester resin dispersion of 64 weight parts; become. Its preparation method is with embodiment 1.

[0057] Wherein the preparation method of the nano-silver antibacterial agent is as follows: first configure the nano-silver mother liquor, and its ratio by weight is: nano-silver colloid 27; pure water 21; alcohol solvent 45; coating agent 33; dispersant 3.2.

[0058] Then, the nano-silver mother liquor is used to configure the nano-silver antibacterial agent, and the ratio according to parts by weight is: nano-silver mother liquor 17; solvent 60; stabilizer 17; dispersant 0.8.

[0059] The concrete preparation method of nano-silver antibacterial agent is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com