Patents

Literature

290results about How to "No decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-bacterial water-based paint and preparation method thereof

InactiveCN102702889AImprove aging resistanceImprove the pulverization performanceBiocideAntifouling/underwater paintsWater basedEscherichia coli

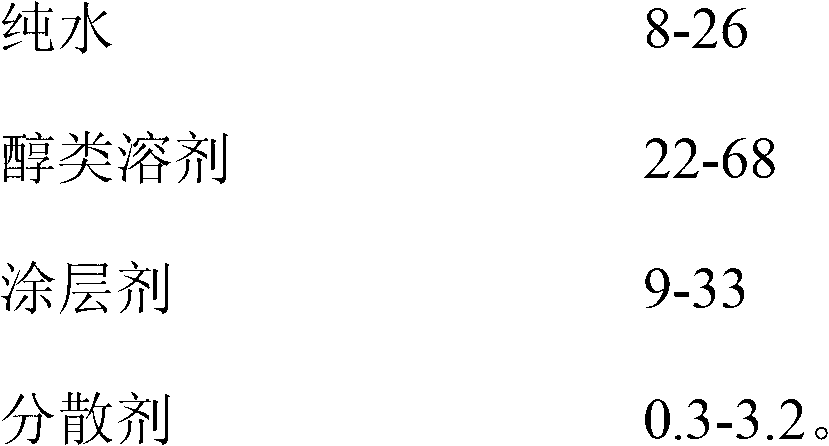

The invention relates to anti-bacterial water-based paint and a preparation method thereof. The paint comprises the following components in parts by weight: 0.2-11 parts of anti-bacterial agent, 8-33 parts of nano material, 23-64 parts of water-based resin dispersoid and 0.75-18 parts of adhesive resin or plasticizer. The preparation method comprises the following steps: firstly preparing a nano silver anti-bacterial agent; mixing deionized water, the anti-bacterial agent, a wetting agent, a dispersing agent and a defoaming agent and uniformly mixing, adding the nano material, uniformly dispersing to obtain the water-based dispersoid; adding the obtained water-based dispersoid to the mixed emulsion or water-based resin dispersoid, then adding the adhesive resin or plasticizer and various conventional assistants, stirring and dispersing evenly; adding pigments or colorant; and supplementing water to obtain the anti-bacterial water-based paint. The long-acting broad-spectrum antibacterial water-based paint has high fungicidal efficiency (more than 99%) on escherichia coli, staphylococcus aureus, black varietas of bacillus subtilis and the like and can reduce the high concentrate of organic matters of formaldehyde to the range of specified concentration index.

Owner:ANHUI JINDUN PAINT

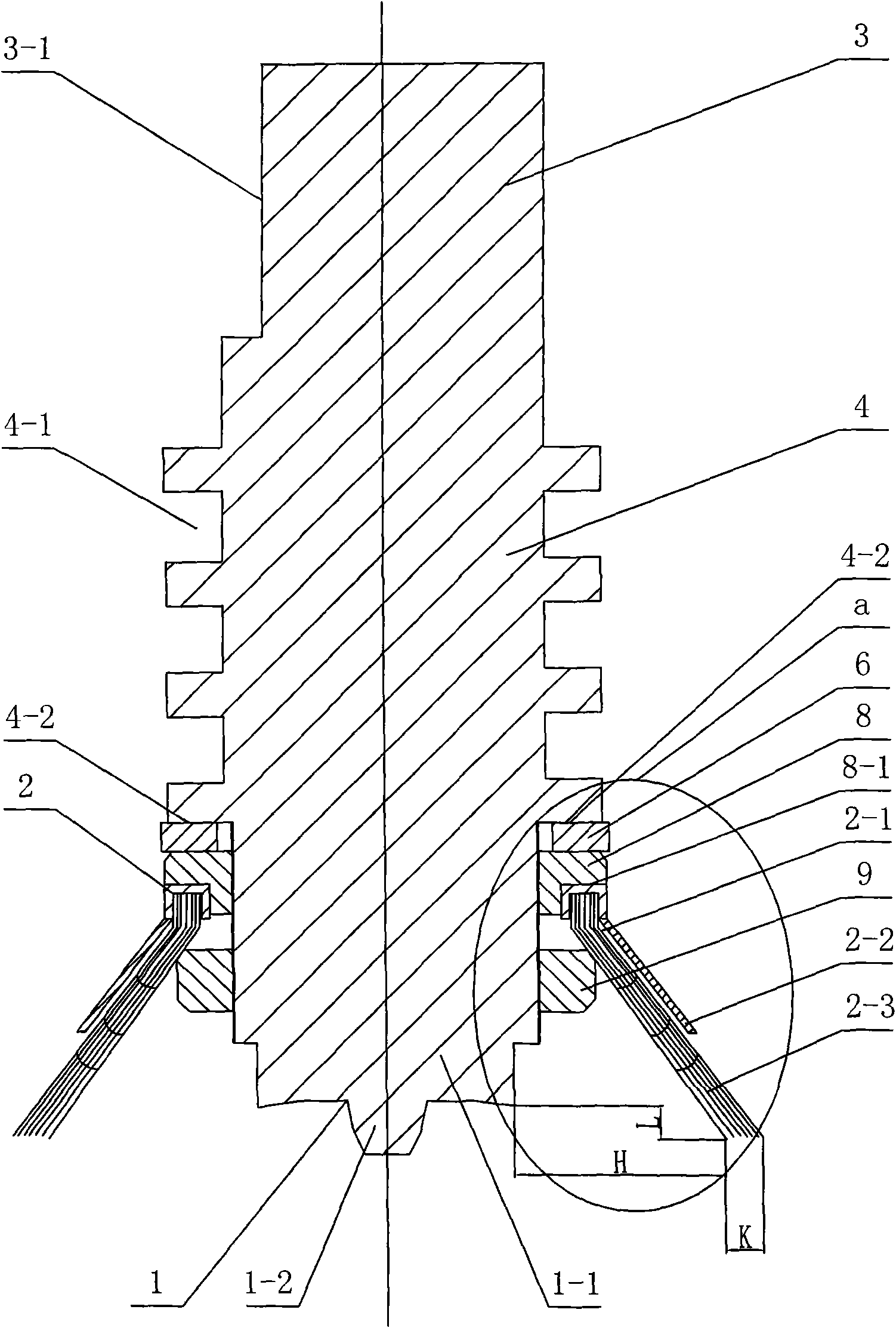

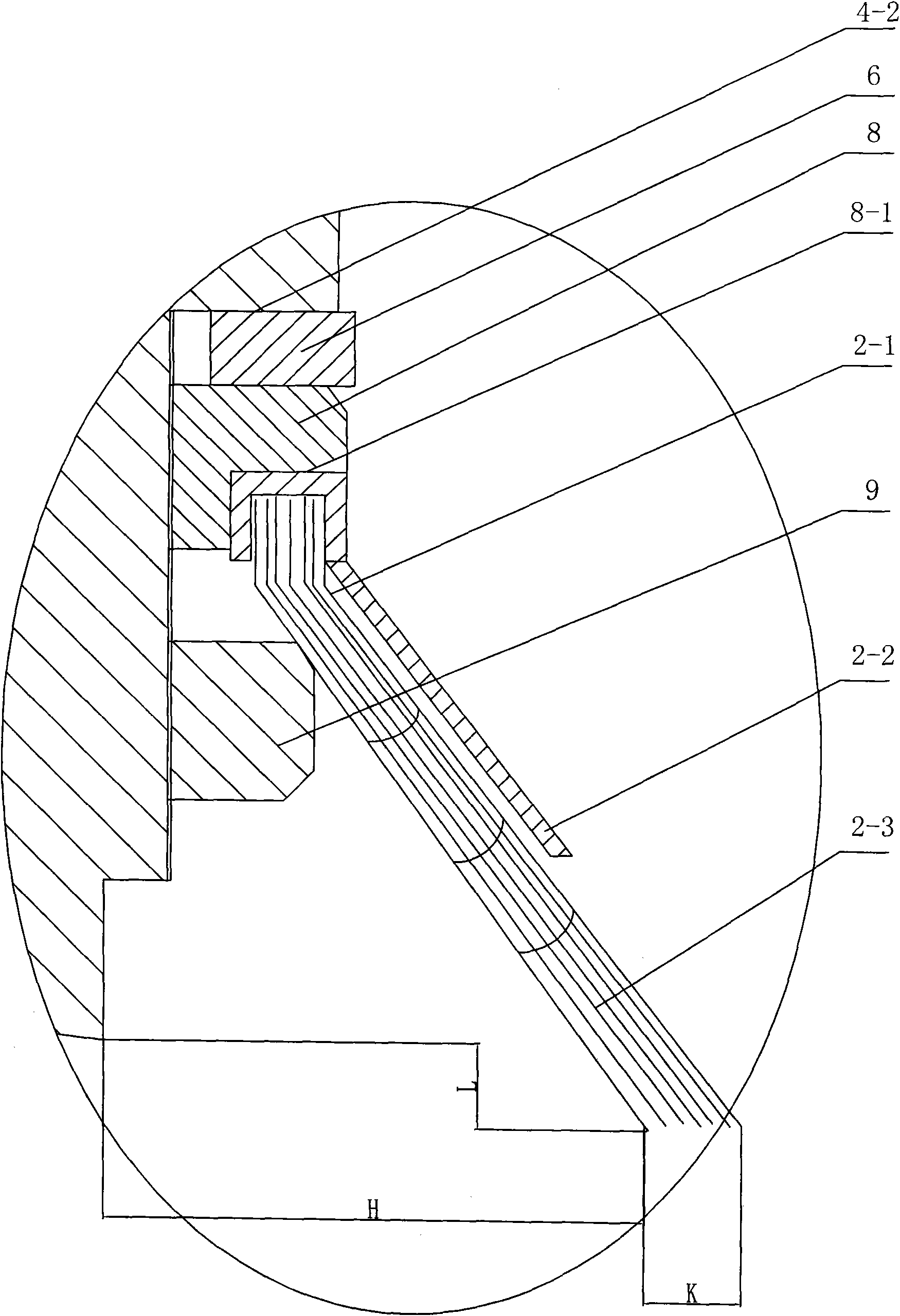

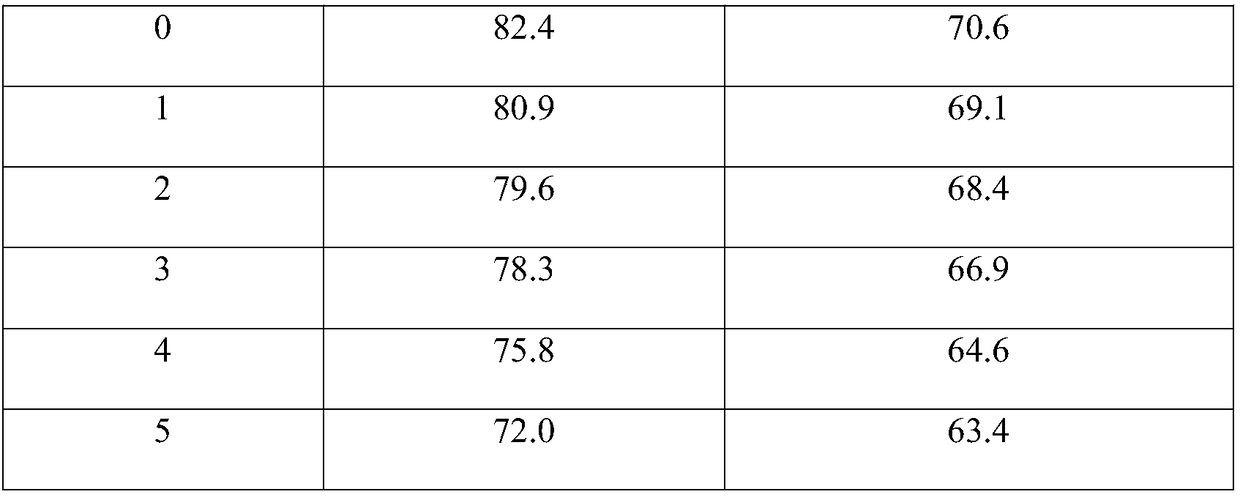

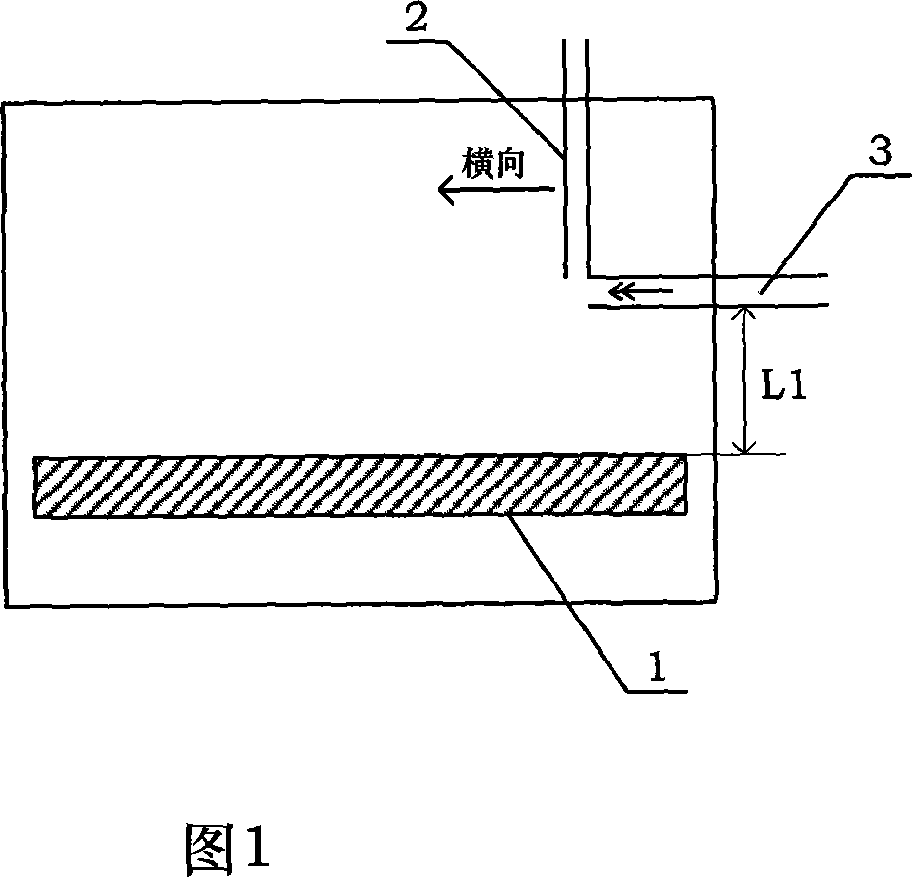

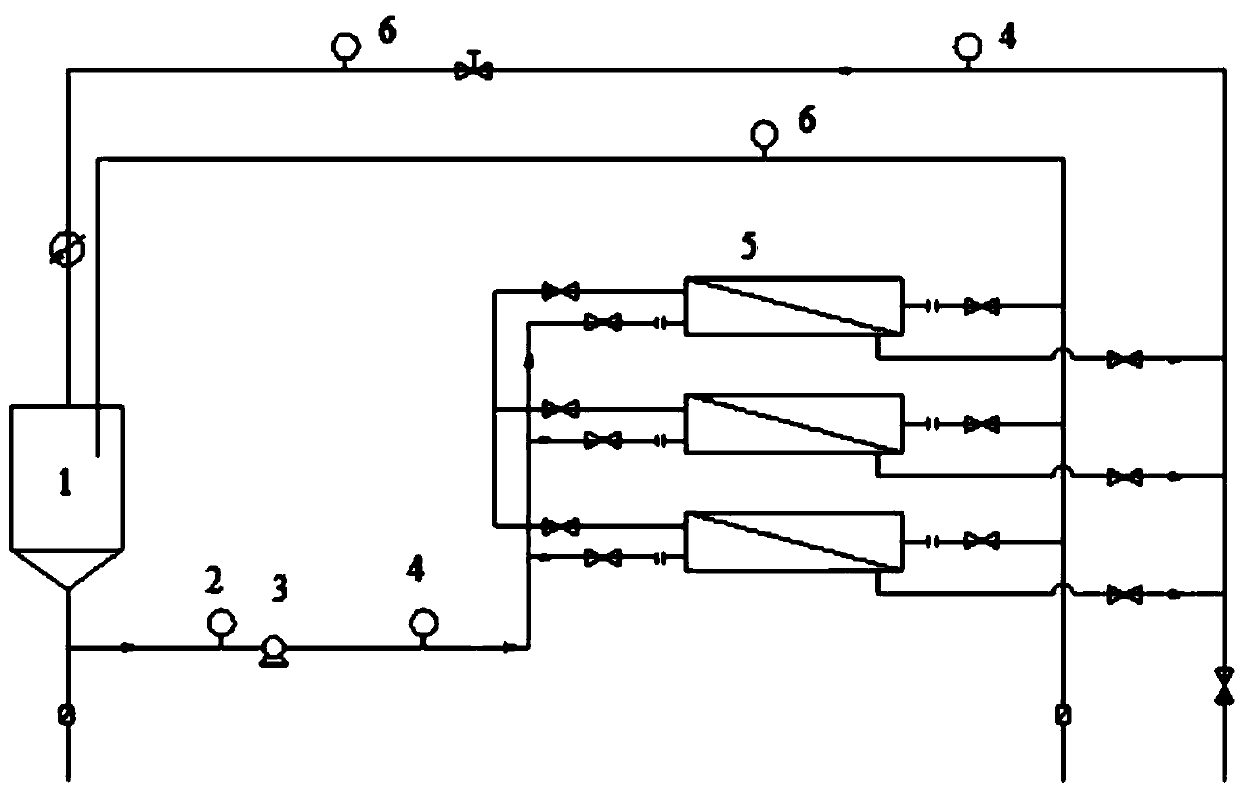

Device for controlling delivery and uniform distribution of reaction gases in MOCVD reaction chamber

ActiveCN101914761AReduce manufacturing costControl consumptionChemical vapor deposition coatingSystem capacityEngineering

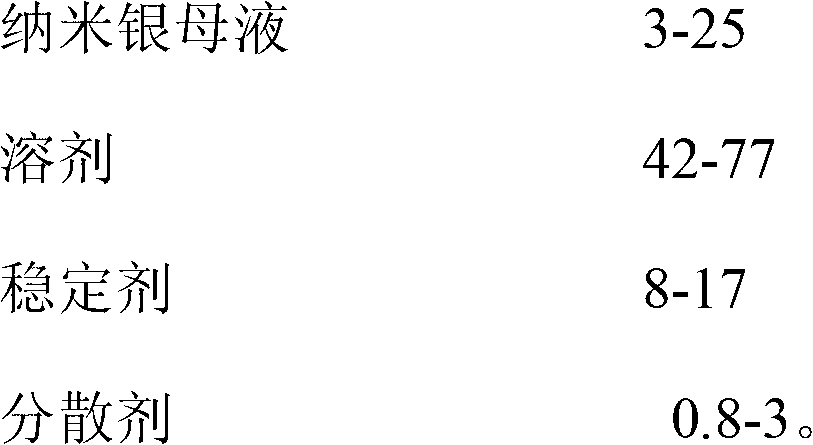

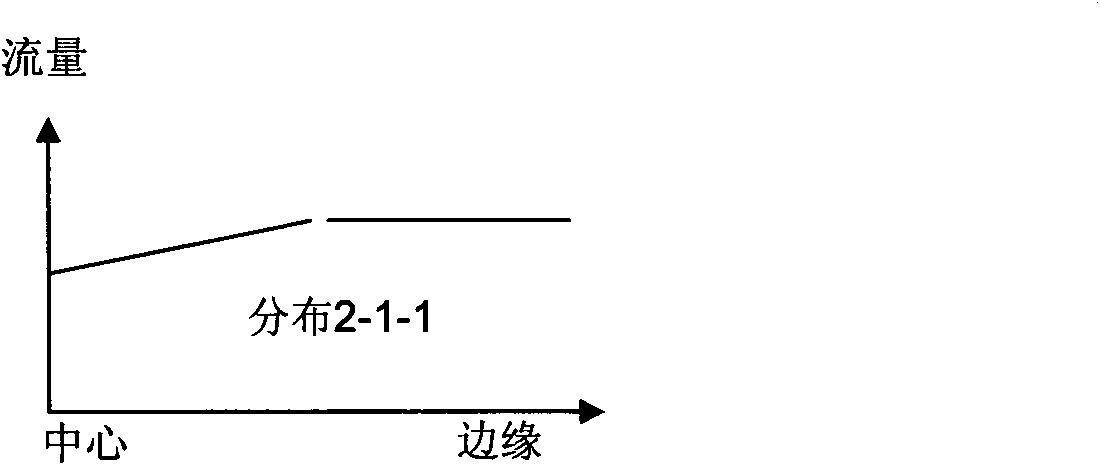

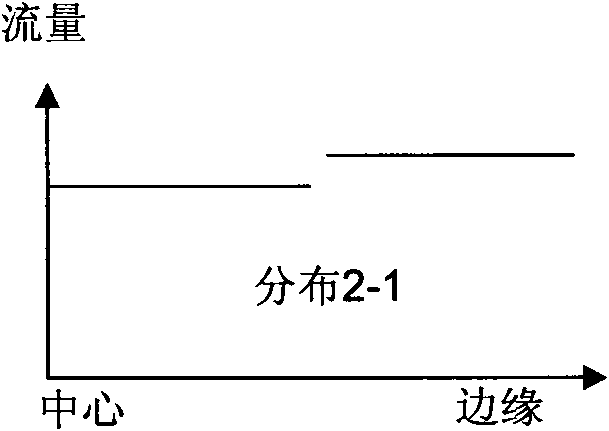

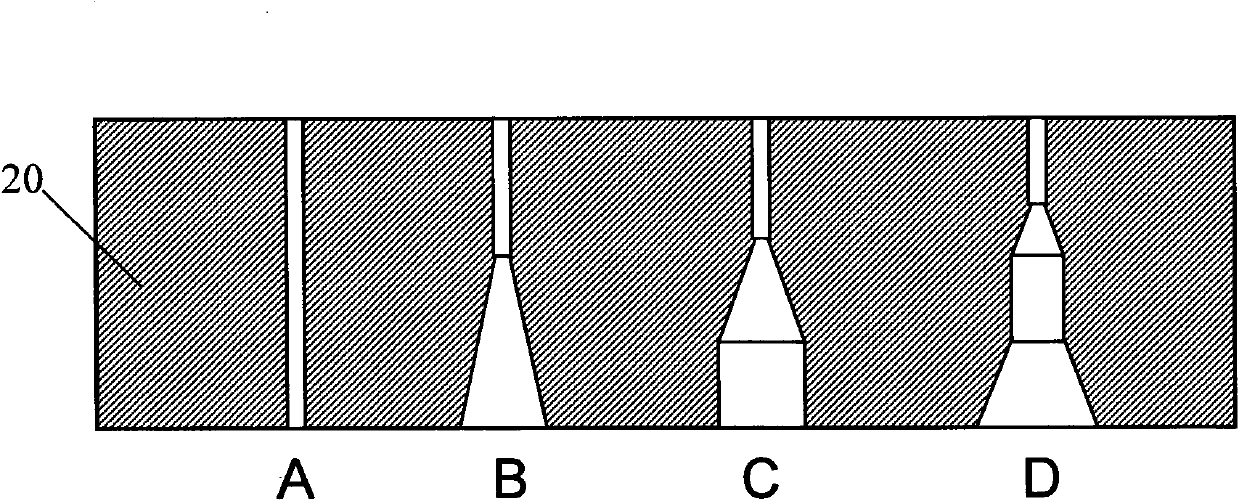

The invention discloses a device for controlling the delivery and the uniform distribution of reaction gas in a MOCVD reaction chamber. By respectively controlling the flow of gas passages non-uniformly distributed radially on a front gas homogenizing plate and input passages at different positions, at least two reaction gases are respectively introduced into two paths which are radially and axially crossed on a spray header, and can be secondarily distributed by nozzles in different shapes, so the uniformly distributed boundary layer concentration, speed and temperature required are achieved on the surface of a rotary epitaxial wafer, the quality of massively produced epitaxial films and the finished product ratio of massively produced epitaxial wafers are improved, the consumption of expensive reaction gases can be effectively controlled and the epitaxial production cost is reduced. By properly increasing the distance between the surface of the spray header and the epitaxial wafer, deposits generated on the surface of the spray header and the nozzles in the epitaxial growth are reduced, the cleaning period is prolonged, and the production efficiency and system capacity are improved. The device also can reduce the processing difficulty and manufacturing cost of the nozzles of the spray header and cooling medium passages.

Owner:JIANGSU ZHONGSHENG SEMICON EQUIP

3D printing composition as well as preparation method and applications thereof

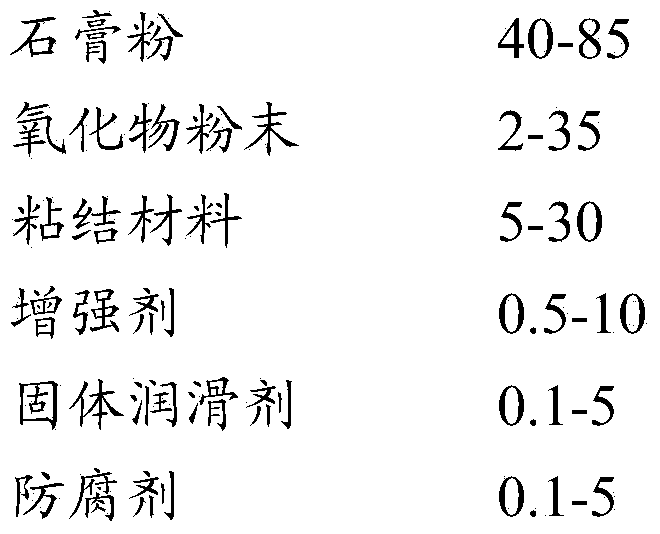

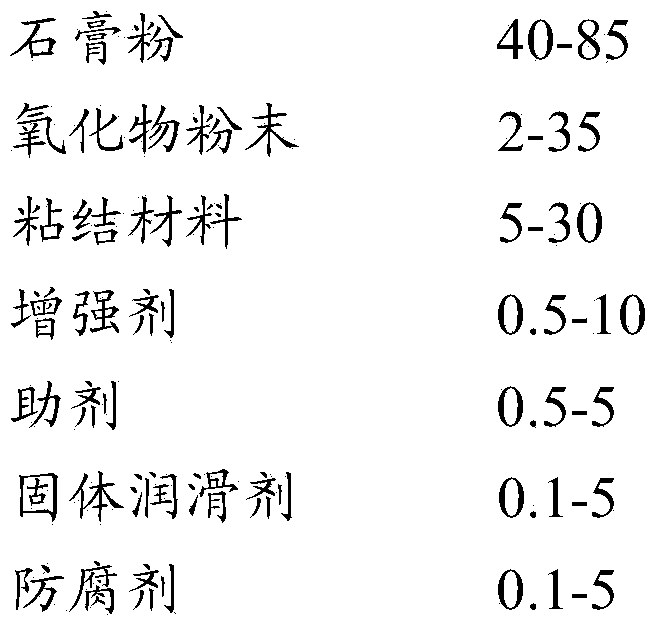

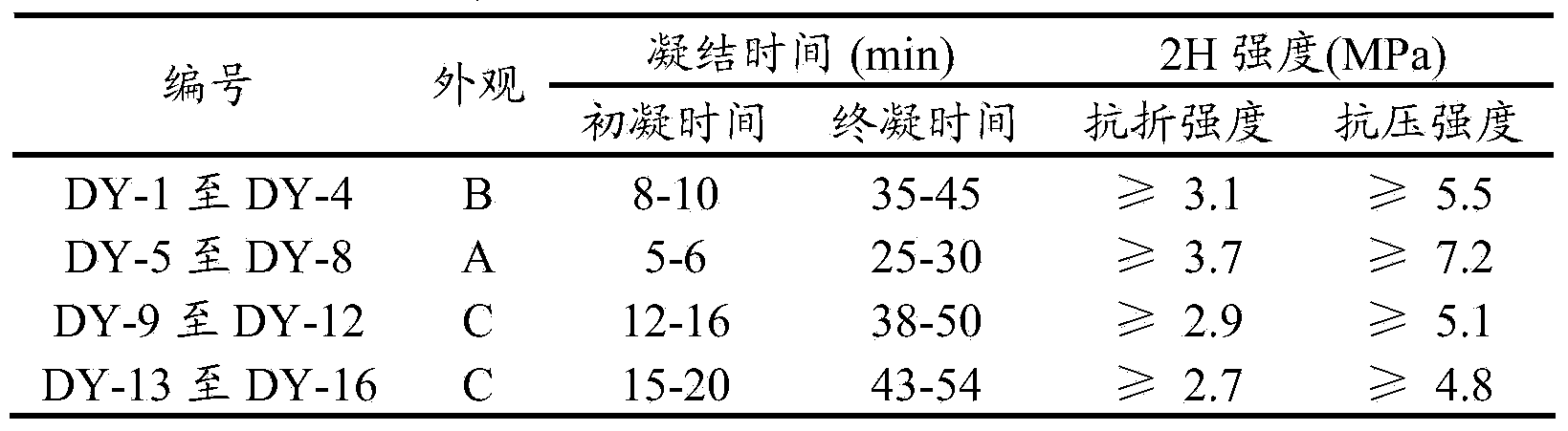

InactiveCN104230289AReduce manufacturing costRaw materials are cheap and easy to getPreservativeUltimate tensile strength

The invention relates to a 3D printing composition as well as a preparation method and applications thereof. The composition comprises gypsum powder, oxide powder, a binding material, a fortifier, a solid lubricant and a preservative, and preferably comprises auxiliaries. The composition is low in cost, good in stability, high in forming strength, good in tenacity, difficult to deform, can be used in the field of 3D printing technology, and the preparation method has the advantages of being pollution-free, green, environment-friendly and the like. Therefore, the 3D printing composition as well as the preparation method and applications thereof have excellent scientific research values and industrial application potential.

Owner:王娟 +1

Method for catalyzing cyclone oxide to synthesizing lactone by using nano magnesium-base catalyst

InactiveCN101186601AHigh catalytic activityHigh selectivityPhysical/chemical process catalystsOrganic chemistryCyclohexanoneCatalytic oxidation

The invention relates to chemical technical field, in particular to a method for using magnesia catalyst to catalyze and oxidize cyclone to synthesize lactone. The invention uses some nanometer sheet magnesia compound as catalyst, uses mixture of cyanobenzene and 1, 4-dioxane at a certain proportion as solvent, at a special reaction temperature, to catalyze and oxidize cyclone to synthesize lactone compound. The invention uses commercial cyclopentanone, cyclohexanone and adamantaneketone as raw materials, at mild condition, to reach the total yield of lactone compound more than 90%. The invention uses hydrogen dioxide water solution as oxidant, to eliminate the environment pollution of traditional oxidation process as peroxyacid, to realize environment-friend catalysis conversion. The invention has low cost, which can be used for industrialized lactone compound production.

Owner:FUDAN UNIV

Preparation process of ethylene propylene diene rubber foaming materials

InactiveCN101824189AUniform Radiation VulcanizationIncreased Radiation Processing EnergyCross-linkVulcanization

The invention discloses a preparation process of ethylene propylene diene rubber foaming materials. A rubber compounding recipe of the invention consists of ingredients of rubber base materials, an anti-aging system, a filling system, a plasticizing agent, a vulcanizing system, a foaming system and a radiation cross linking sensitizing agent. The ethylene propylene diene rubber foaming materials are prepared through vulcanization foaming and demolding after the pretreatment of compounding, sheet cutting and electronic beam radiation pretreatment. The rubber sheets of the invention after radiation pretreatment have a certain pre-cross-linking degree before the heating vulcanization foaming, the fit of the vulcanization speed and the foaming velocity can be realized, the integral performance of products can be improved, the pre-vulcanization time can be shortened, energy sources can be saved, and the production efficiency can be improved.

Owner:BEIJING RADIATION APPL RES CENT

Chemical plating silver copper powder, chemical plating liquid and chemical plating method

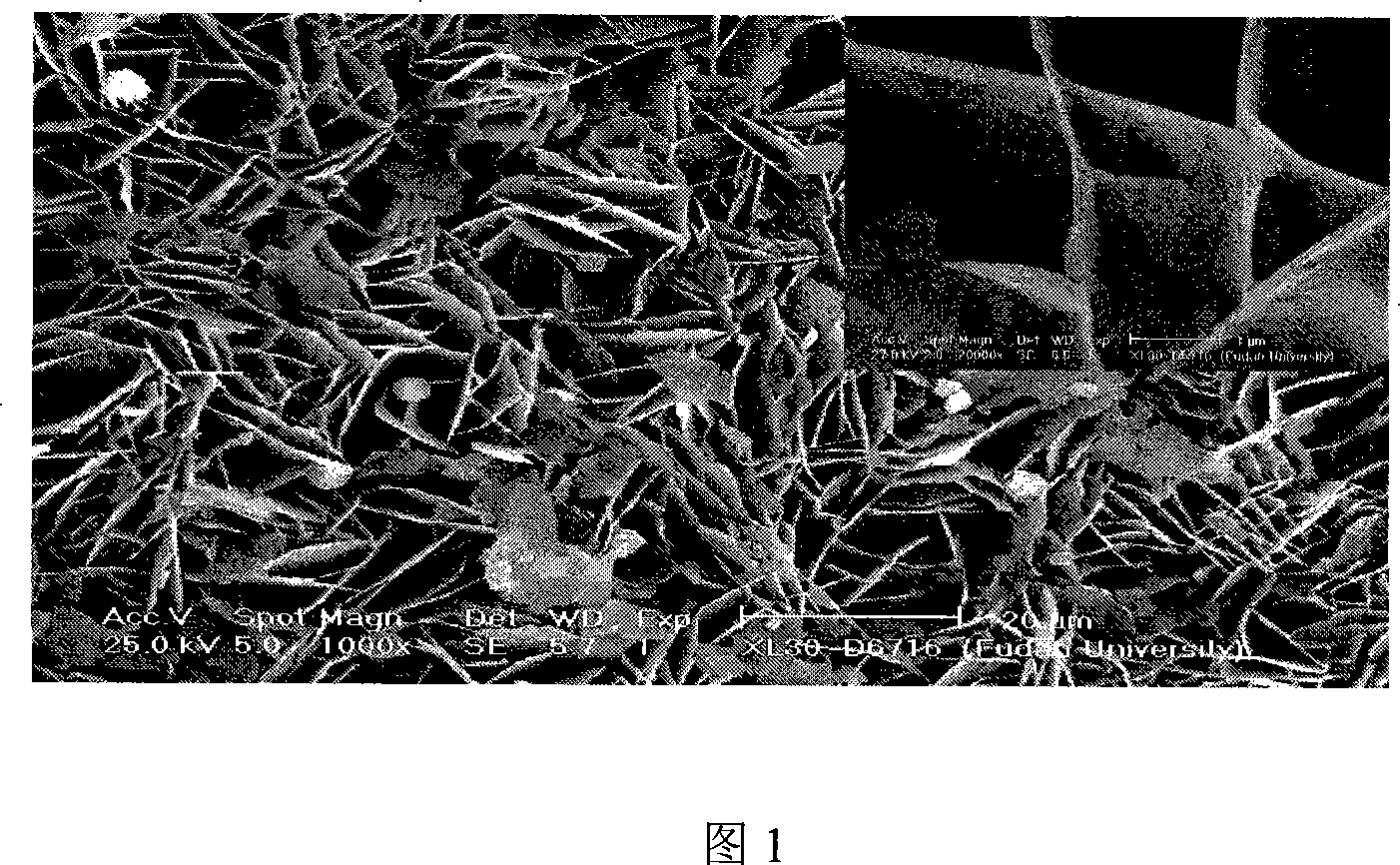

InactiveCN101244459AHigh catalytic activityImprove silver coverageLiquid/solution decomposition chemical coatingYttriumChemical plating

The invention discloses a silver plating copper powder, a chemical plating liquid and a method of chemical plating; wherein, the silver coating ratio of the silver plating copper powder is 10 to 95%; the silver plating layer comprises 0.5 to 1.2wt% rare-earth metal cerium and / or lanthanum and / or yttrium; the chemical plating liquid comprises three independent components of silver nitrate water solution, formaldehyde ethanol solution and rare-earth nitrate water solution. The method of chemical plating is characterized in that (1) the copper powder is washed and is processed by ultrasonic sensitization and ultrasonic activation in sequence, and (2) the three components of the chemical plating liquid are added in sequence and the ultrasonic chemical plating is processed. The method of chemical plating has the advantages of utilizing the modification effect of rare-earth, raising the stability of plating liquid, the catalytic activity of copper powder surface and the reduction activity of silver ion, adjusting the silver coating ratio from 10% to 95% according to different demands, and even distribution, smooth surface and high conductivity and oxidation resistance of silver plating layer.

Owner:HEFEI UNIV OF TECH

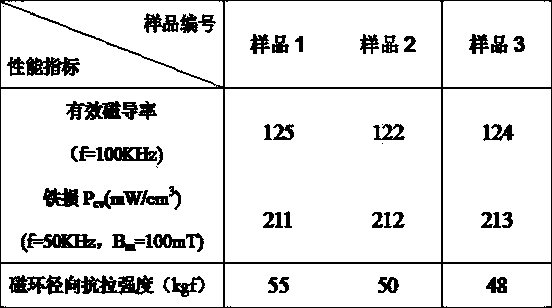

Insulative adhesive for preparing metallic and soft magnetic composite material and using method thereof

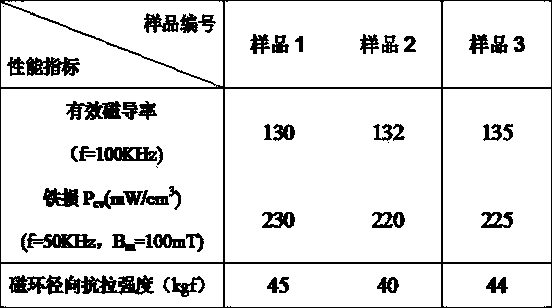

ActiveCN104031601AImprove thermal stabilityImprove insulation performanceNon-macromolecular adhesive additivesInorganic material magnetismAdhesiveOrganosilicon

The invention discloses an insulative adhesive for preparing a metallic and soft magnetic composite material and a using method thereof. The insulative adhesive disclosed by the invention is a nano-modified organic silicon resin insulative adhesive which comprises organic silicon resin and an inorganic nano dispersion liquid. The insulative adhesive greatly improve the heat-resisting temperature of the organic silicon resin and improve the mechanical strength of a magnetic powder core, is reasonable in component selection and good in using effect and has a good insulative adhering effect to Fe-based, nickel-based and metallic soft magnetic powder of other metals. The magnetic powder core prepared by the insulative adhesive prepared by the invention has excellent magnetic performance and mechanical performance.

Owner:ZHEJIANG UNIV

Lithium ion secondary battery using lithium iron phosphate as anode material with overall consideration of high and low temperature performance

InactiveCN101394008AExtended operating temperature rangeWide temperature rangeSecondary cellsPhosphateEthyl butyrate

The invention discloses an aqueous electrolyte solution of a secondary lithium ion battery with ferric phosphate considering as the positive material and with both the high temperature performance and the low temperature performance. The aqueous electrolyte solution comprises LiPF6 lithium salt, an organic solvent and a film-forming additive, and is characterized in that the electrolyte solution further comprises high temperature additive; the organic solvent is composed of one or a plurality of carbonic esters and one or more carboxylic esters with low melting point and high boiling point. The carboxylic esters with low melting point and high boiling point are selected from one or a combination of methyl butyrate, ethyl butyrate, propyl butyrate and butyl acetate. The high temperature additive is 1, 3- propane sultone and 1, 4- butane sultone. The electrolyte solution is used for maintaining both the circulation performance in a high temperature state and the low temperature laying performance of the secondary lithium ion battery with the ferric phosphate lithium as the positive material.

Owner:GUANGZHOU TINCI MATERIALS TECH

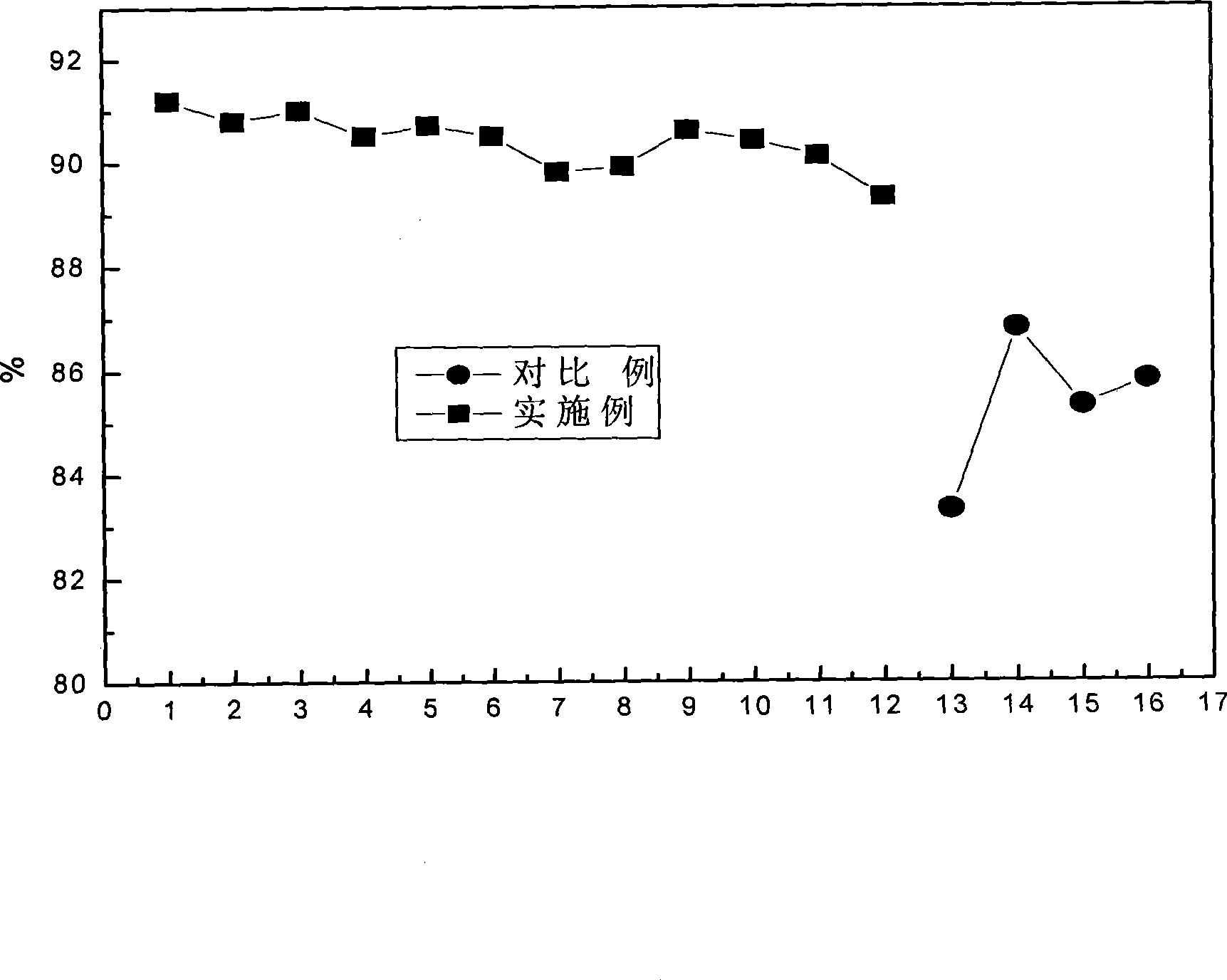

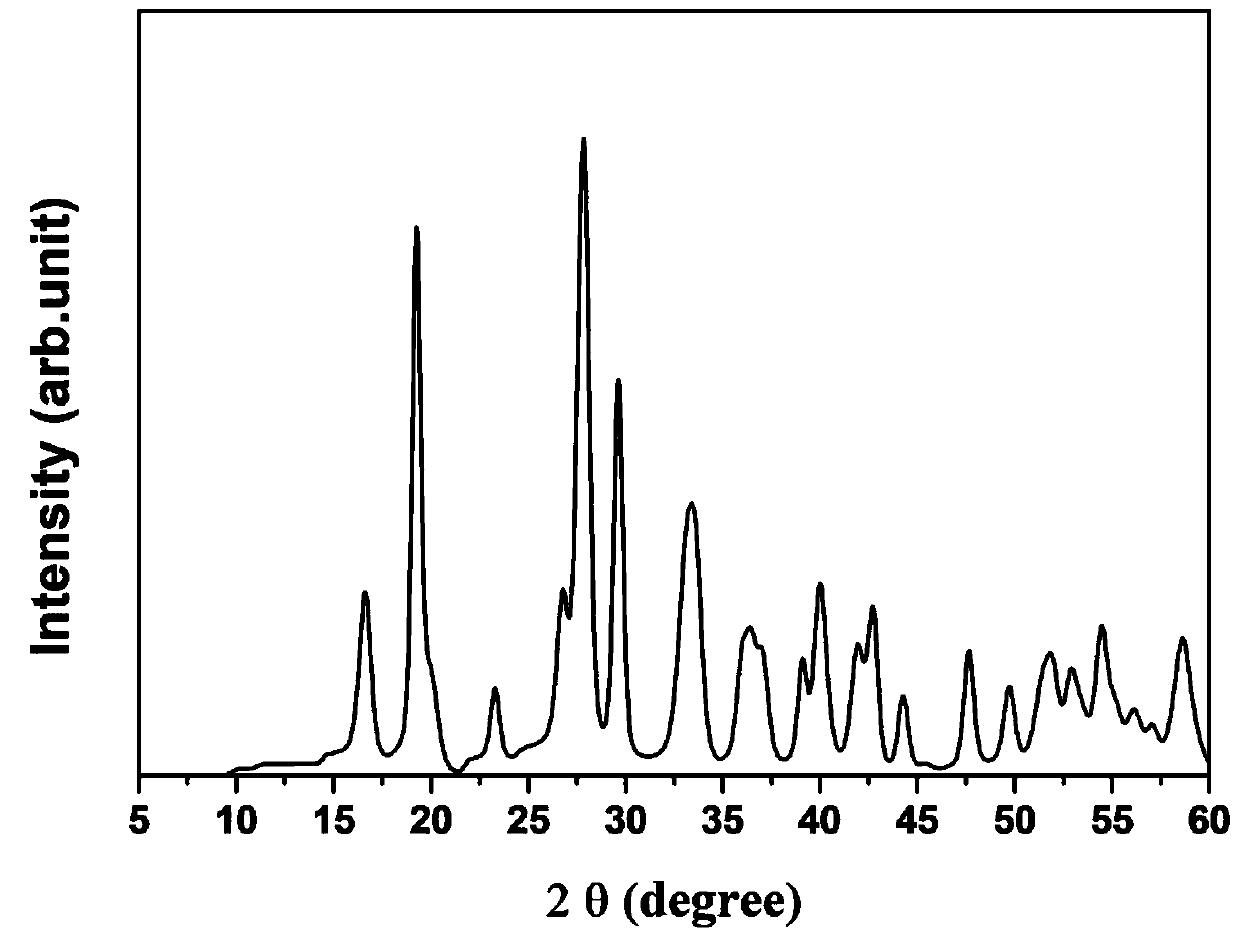

Polybasic solid solution rare earth silicate ceramic powder and preparation method thereof

The invention relates to the technical field of ultrahigh temperature ceramic powder, in particular to polybasic solid solution rare earth silicate ceramic powder and a preparation method thereof. Thechemical formula of the polybasic solid solution rare earth silicate ceramic powder is (Y0.2Yb0.2Re'0.2Re'0.2La0.2)2Si2O7, wherein Re' and Re' are selected from any two of Nd, Ce, Sm, Er and Eu. Thepreparation method comprises the following steps: mixing raw materials by adopting a wet-mixing method, and drying; then placing the mixture in a high-temperature reaction furnace for reacting; performing wet milling and spray drying granulation to obtain the polybasic solid solution rare earth silicate ceramic powder. The polybasic solid solution rare earth silicate ceramic powder has high solidsolubility, excellent high temperature resistance, no decomposition at a high temperature and low thermal conductivity. The preparation method is simple and feasible.

Owner:淄博星澳新材料研究院有限公司

Pin tool suitable for local dry-type friction stir welding in water environment

InactiveCN101554681AAvoid enteringEntry will not happenNon-electric welding apparatusFriction weldingDecomposition

A pin tool suitable for local dry-type friction stir welding in water environment relates to a pin tool of friction stir welding. The invention solves the problems that the existing pin tool of friction stir welding is not applicable to the local dry-type welding in water environment; as underwater welding needs complicated supporting equipment and technical conditions, the difficulty of implementation is comparatively large; and the stability of an electric arc and drop transfer is poor and the decomposition of water at the high temperature of the electric arc can lead to seam hydrogenation so as to cause the deterioration of joint performance. A fitting nut is connected with the upper thread of a shaft shoulder and a positioning backing ring is arranged between the upper end face of the fitting nut and the end face of a shoulder. A U-shaped steel wire brush holder is fixedly installed on the shoulder. The upper ends of a plurality of stainless steel tendons are fixedly installed in the U-shaped steel wire bush holder and an inverted funnel-shaped shade covers the outside of the steel wire brush. The pin tool overcomes the defects of the existing pin tool of friction stir welding in welding under water environment, satisfies the requirements of local dry-type welding under water environment and also boosts the performance of joints.

Owner:HARBIN INST OF TECH

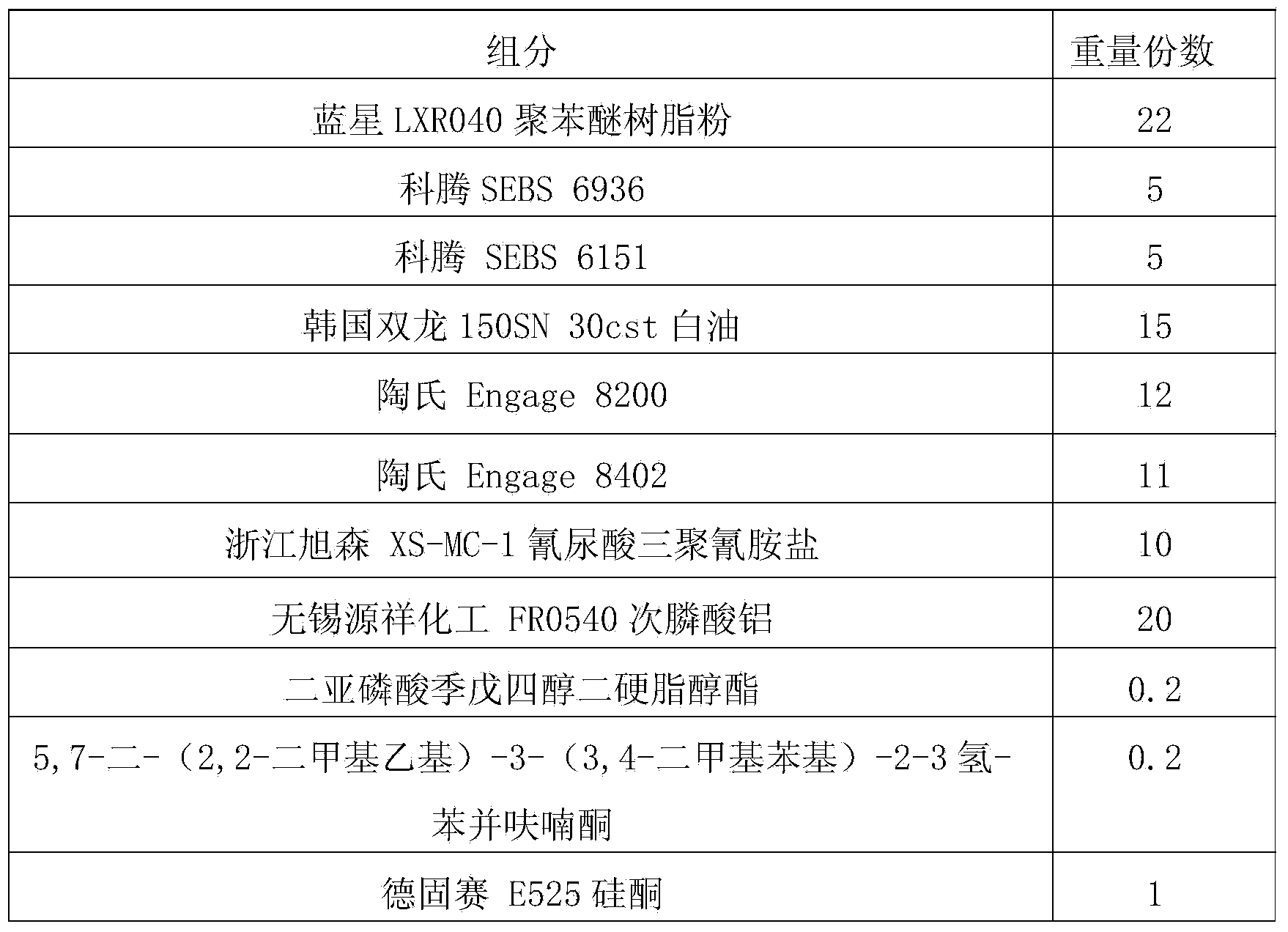

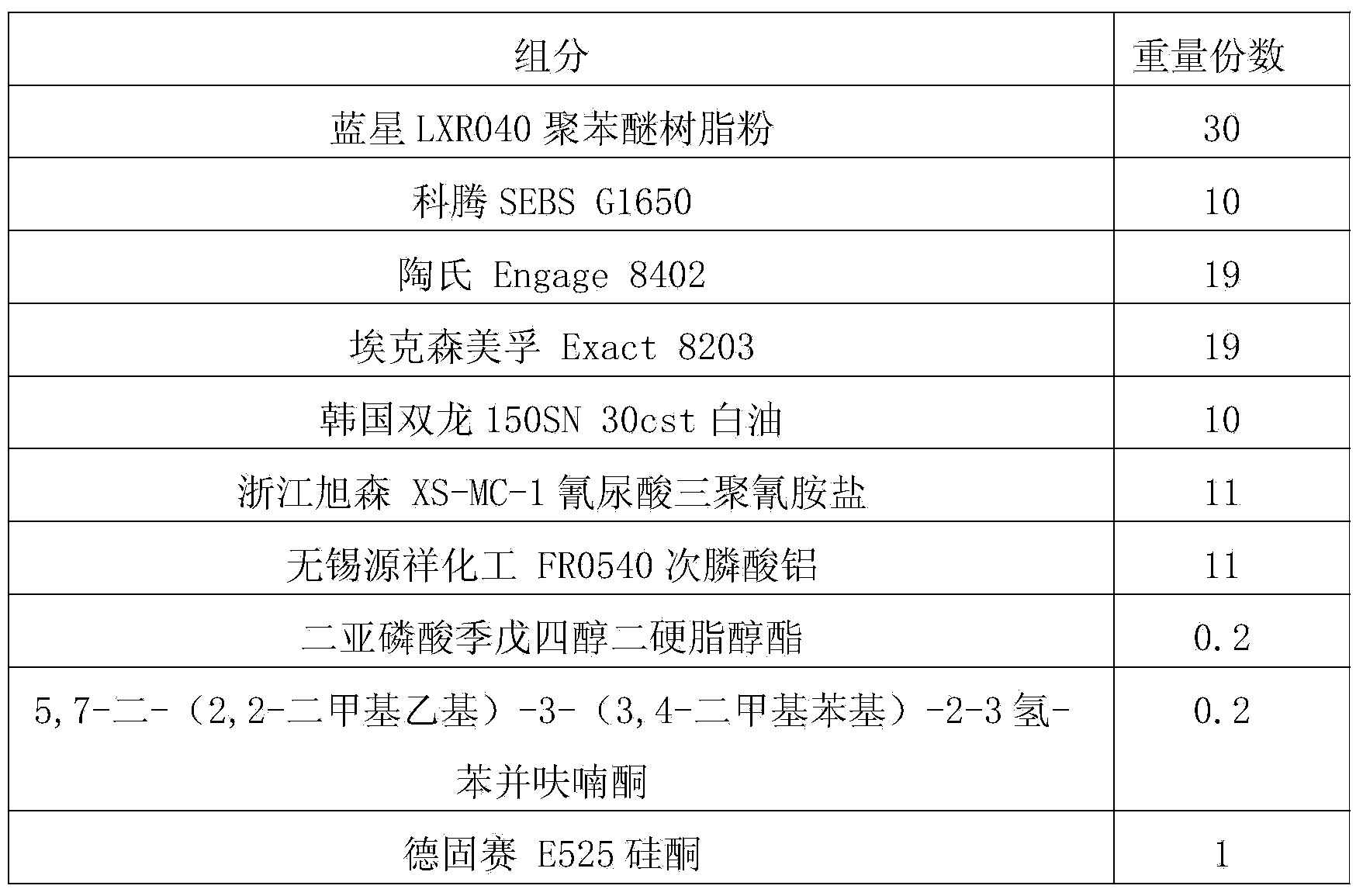

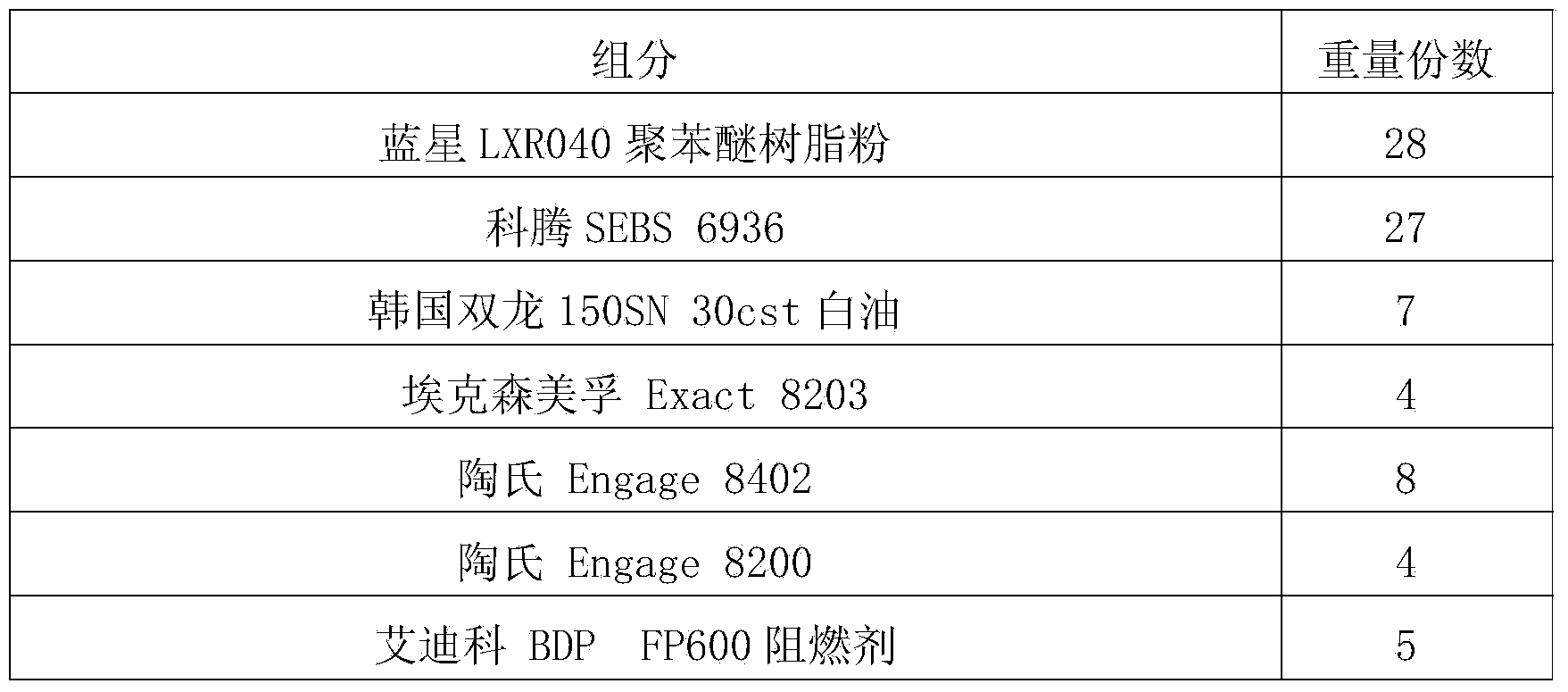

Thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material and preparation method thereof

ActiveCN103910990ASimplify the proportioning processSimplify the manufacturing processThermoplasticElastomer

The invention discloses a thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material and a preparation method thereof. The cable material is used for a soft type electric wire and cable coating, and comprises the following components: polyphenyl ether resin powder, styrene-series elastomers, a plasticizer, a polyolefin elastomer, a compound phosphor-nitrogen flame retardant, an antioxidant and a lubricant. The material components are uniformly stirred in a high-speed mixer, extruded by a twin-screw extruder, pelletized in water, dried and then packaged to obtain a thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material finished product. The thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material designed by the invention has excellent performance such as good processing performance, halogen-free and flame-retardant performance, low density, high tensile strength, good scraping resistance, good softness, good low temperature resistance, capacity of being extruded at a processing temperature of 200 DEG C-280 DEG C and not decomposed, free of cracks on a sample sheet for seven days under a high-temperature high-humidity environment with 98% humidity and a temperature of 85 DEG C, free of precipitates on surface, and the like.

Owner:JIANGSU LINRY NEW MSTAR TECH

Commercial rare earth permanent magnet produced from high-abundance rare earth and preparing method thereof

ActiveCN103794323AImprove remanenceHigh energy productPermanent magnetsInductances/transformers/magnets manufactureElectrode potentialRemanence

The invention discloses a commercial rare earth permanent magnet produced from high-abundance rare earth and a preparing method of the commercial rare earth permanent magnet. The commercial rare earth permanent magnet comprises a main phase and a grain boundary modification phase, wherein the main phase comprises low H (RE100-aMMa)-Fe-B alloy and high H Nd-Fe-B alloy. According to the commercial rare earth permanent magnet, two kinds of main alloy is adopted, the ingredients of the magnet are controlled, a stable 2:14:1 phase is formed by the high-abundance rare earth, and decomposing will not happen in the sintering process; the Cu element high in electrode potential is added into the grain boundary modification phase, the corrosion resistance of the magnet is improved, and meanwhile the microstructure of the magnet can be optimized by the grain boundary modification phase. According to the method, the two main alloy method is combined with the grain boundary modification technology, the advantages of both the two main alloy method and the grain boundary modification technology are achieved simultaneously, the problems that because of addition of the high-abundance rare earth, the corrosion resistance, the residual magnetism and the magnetic energy product of the magnet are reduced are solved, and the prepared rare earth permanent magnet meets the application requirements of commercial magnets.

Owner:ZHEJIANG UNIV +1

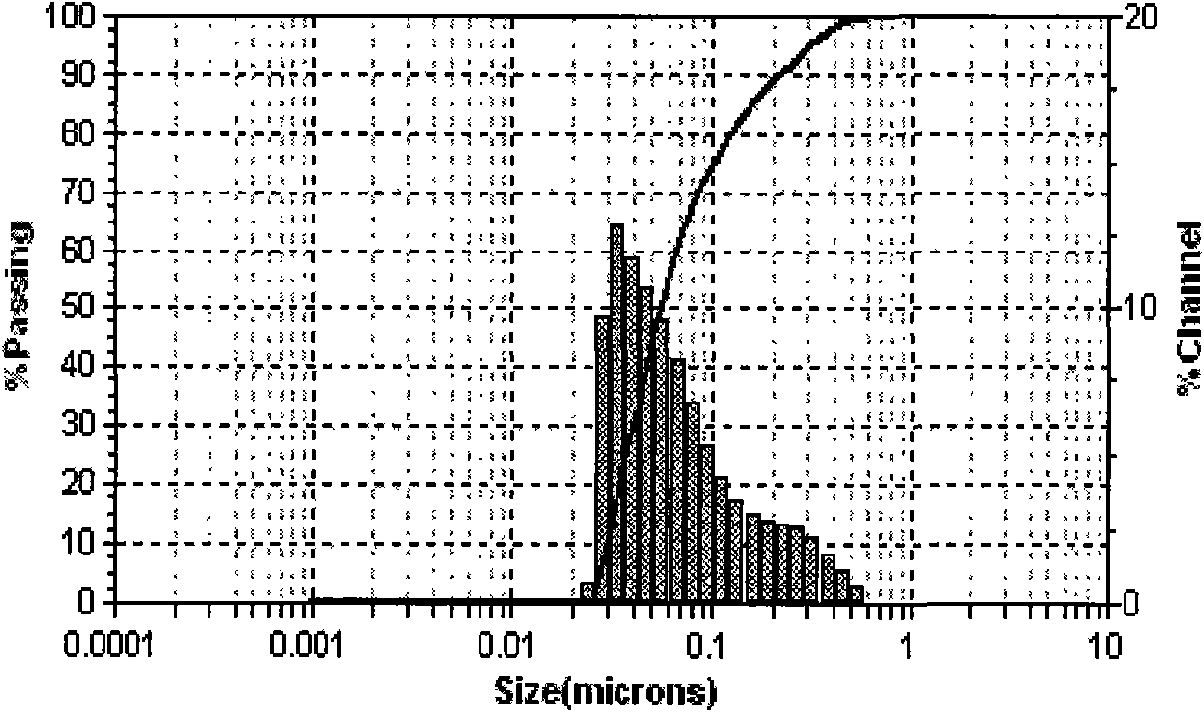

Ivermectin nanoemulsion drug combination and preparation method thereof

ActiveCN101623256AHigh thermodynamic stabilityGood storage stabilityOrganic active ingredientsPharmaceutical non-active ingredientsDistilled waterBioavailability

The invention discloses an ivermectin nanoemulsion drug combination. Oil-in-water type nanoemulsion consisting of ethyl oleate, Tween-80, 1,2- propylene glycol and ivermectin is prepared from being diluted by double distilled water. The ivermectin nanoemulsion drug combination greatly improves the effect of ivermectin in resisting parazoon, enhances the dissolubility, safety and bioavailability and is a high-efficiency antiparasitic nano level medicinal preparation with convenient use and wide ways of administration.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

Condensation polymerization method for preparing hydroxylated acid condensation polymer

The invention provides a condensation polymerization process for preparing hydroxylated acid condensation polymer, characterized in that hydroxylated acid or hydroxylated acid oligomer are subject to molten condensation polymerization reaction or molten / solid phase condensation polymerization reaction at the presence of ionic liquid catalytic action. The obtained hydroxylated acid condensation polymer contains no metallic elements.

Owner:ZHEJIANG UNIV

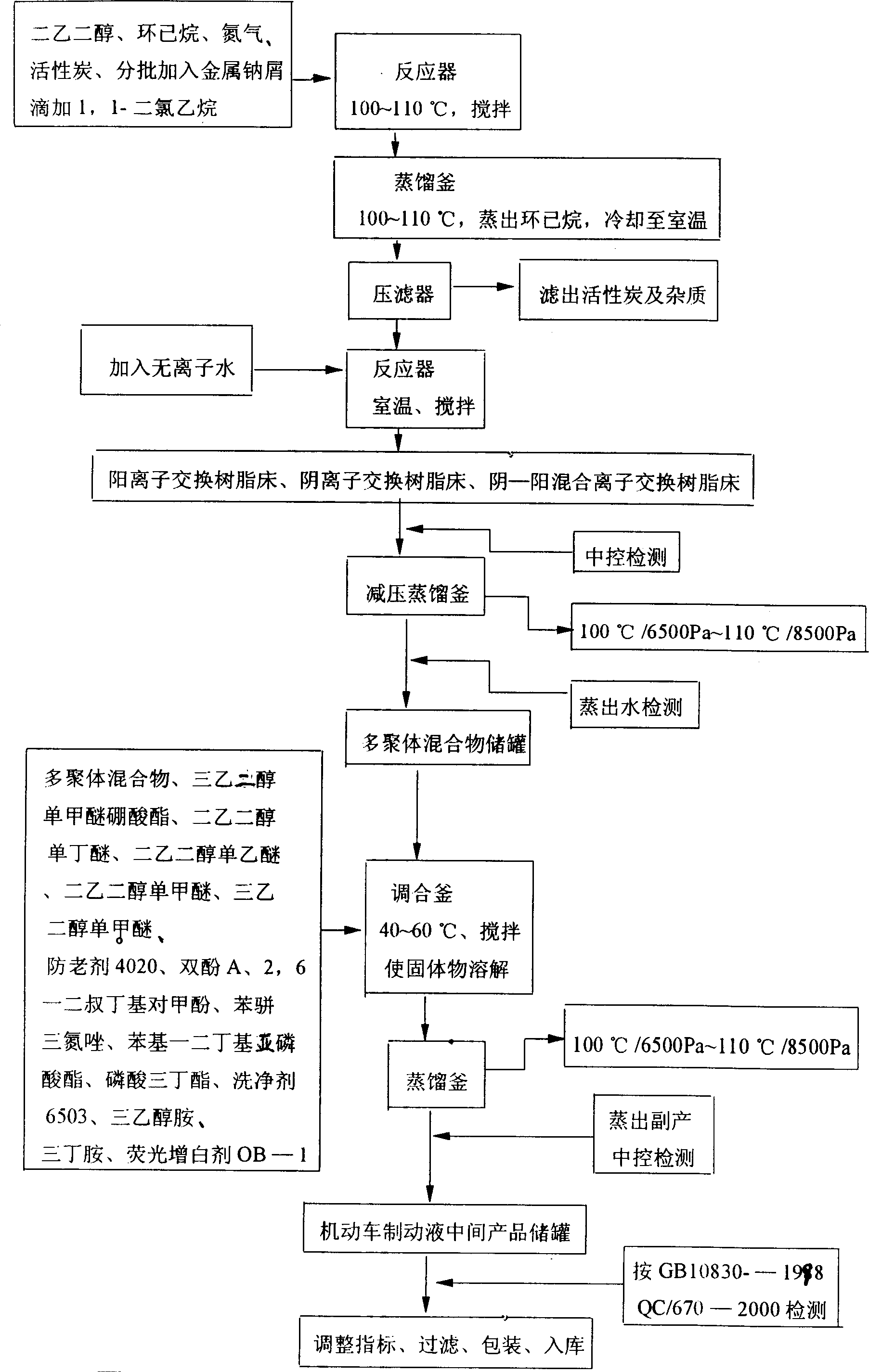

Brake fluid for motor vehicles and its production methods

A brake liquid for the hydraulic brake system of motor-driven vehicle is prepared through preparing polymer mixture by catalytic reaction between biethanediol and 1,1-dichlorethane, adding triethanediol monoethylether borate, triethanediol monomethyl ether, diethanediol monobutylether, diethanediol monoethylether, diethanediol monomethylether and additive, stirring, dissolving, vacuum processing and filtering. It features high properties.

Owner:LIAONING SANTE PETROCHEM

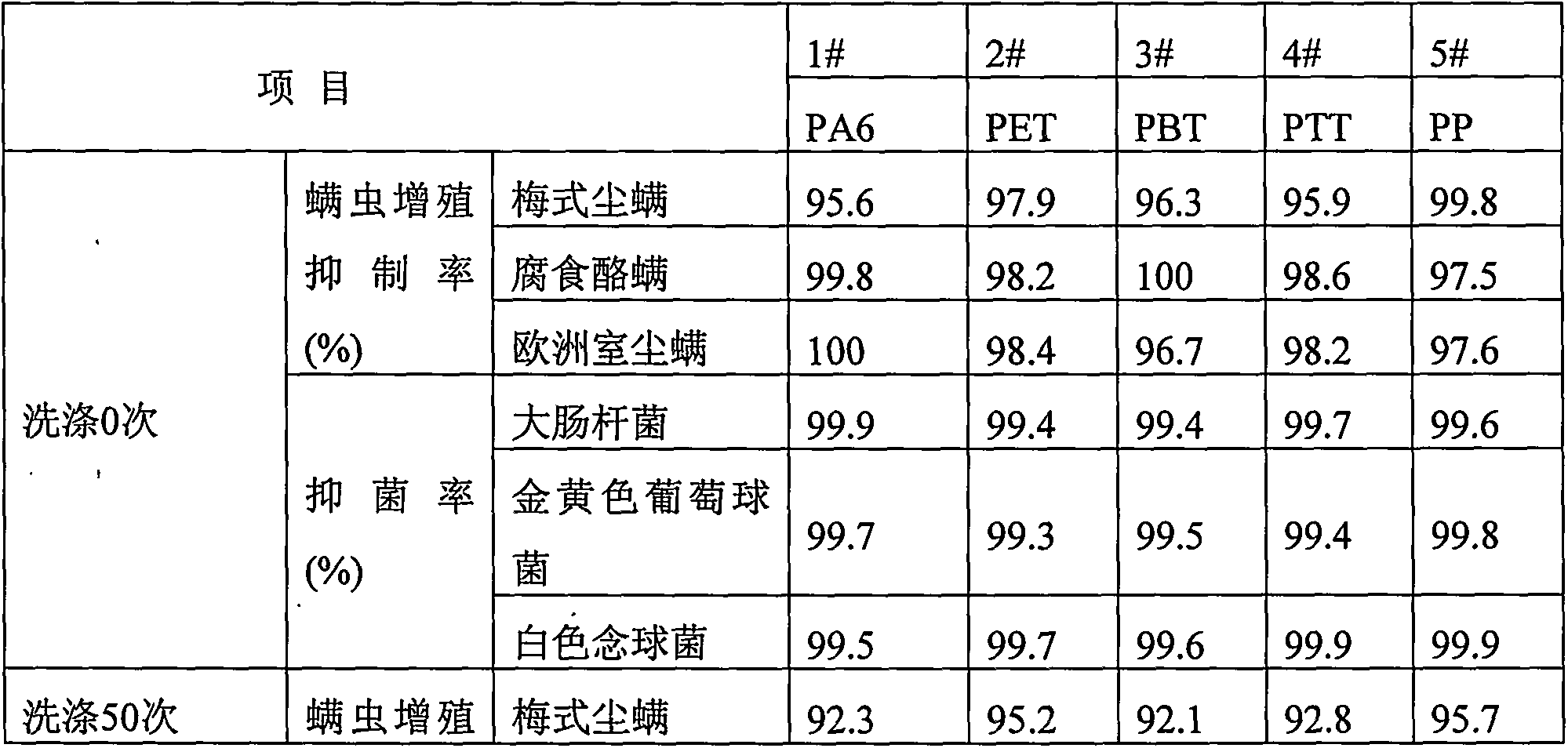

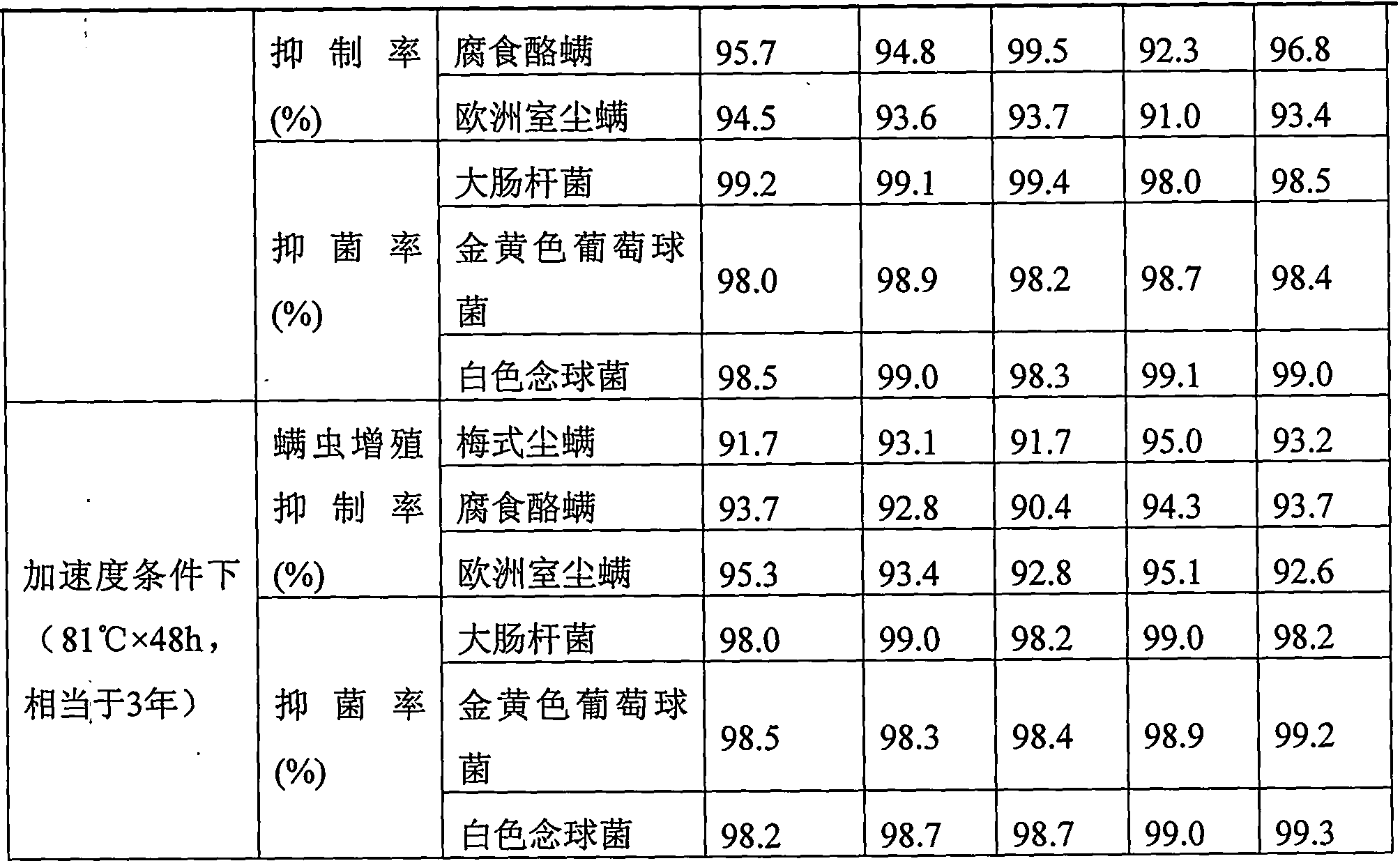

Anti-mite antibacterial thermoplastic polymer melt spun fiber and preparation method thereof

ActiveCN103882543AImprove durabilityAllergy freeSpinning head liquid feederArtificial filament heat treatmentHigh concentrationPolymer science

The invention relates to a thermoplastic polymer melt spun fiber with anti-mite and antibacterial functions and a preparation method thereof. The preparation method comprises the following steps: preparing a silver-loaded soda borosilicate ceramic powder which serves as an anti-mite and antibacterial component through a sol-gel method, performing surface modification on superfine ceramic powder through a coupling agent, granulating to prepare a high-concentration anti-mite and antibacterial master batch which takes a thermoplastic polymer as a matrix in a double-screw extruder, and finally, blending the anti-mite and antibacterial master batch with the thermoplastic polymer according to a certain ratio, and performing melt spinning to obtain the anti-mite and antibacterial fiber. The anti-mite and antibacterial fiber prepared by the method has obvious effects, is high in durability, high in washing resistance and high in safety.

Owner:上海市合成纤维研究所有限公司

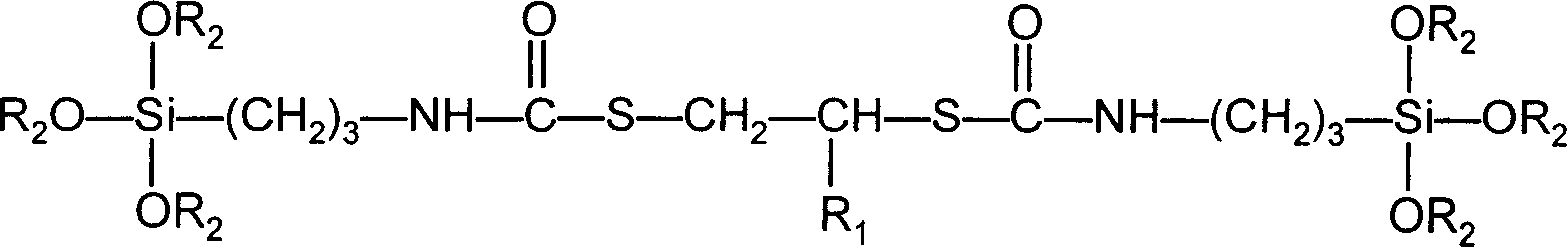

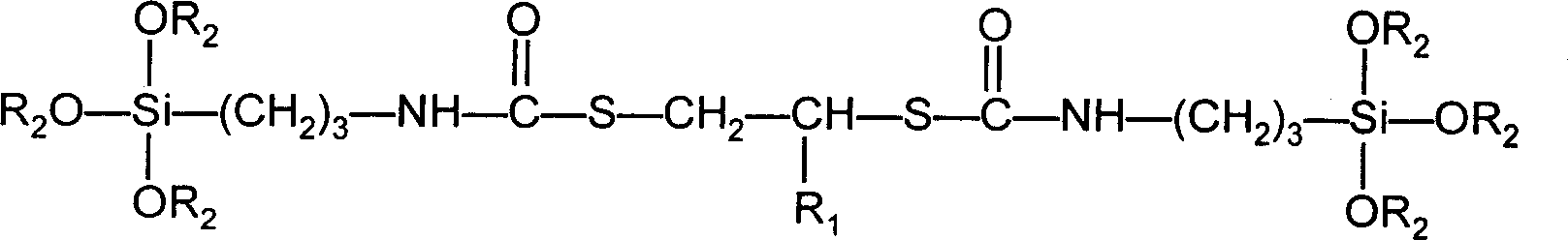

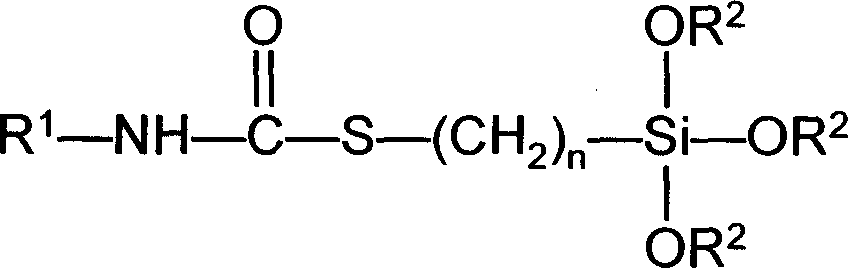

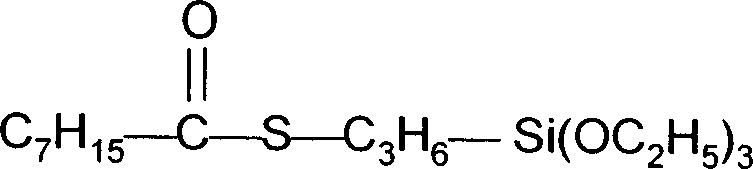

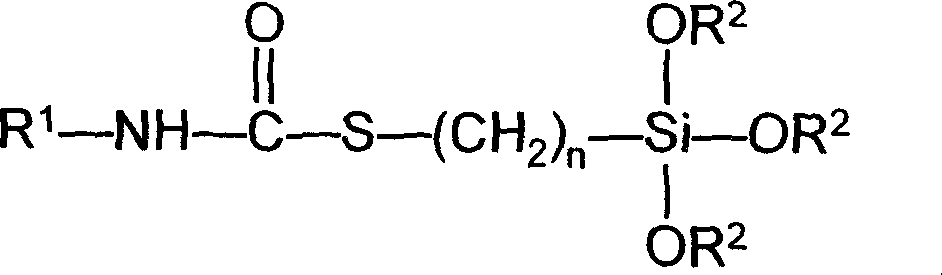

Bisilane coupler contg. sulfur and nitrogen element and prepn. thereof

InactiveCN1834100AEasy to separateSimple production processGroup 4/14 element organic compoundsThiocarbamateOrganocatalysis

This invention discloses a kind of sulphur- and nitrogen-containing silicone coupling reagent and its preparation method, that is, gamma-isocyanate propyl trialkoxyl silicane and dithiol compound react with each other at a mole ratio of 2:1 in organic solvent with the existence of organic catalyst. The mixture is then vacuum distilled to obtain a silicone coupling reagent that has two thiocarbamate units and six alkoxyls. This method has the advantages of simple technique flow, high yield and high practicability. The silicone coupling reagent based on this invention has good thermo stability and considerable coupling effect. It is a good substitution of conventional silicone coupling reagent and can be used in fumed silica-containing rubber so as to promote the comprehensive properties of vulcanized rubber.

Owner:ZHEJIANG UNIV +1

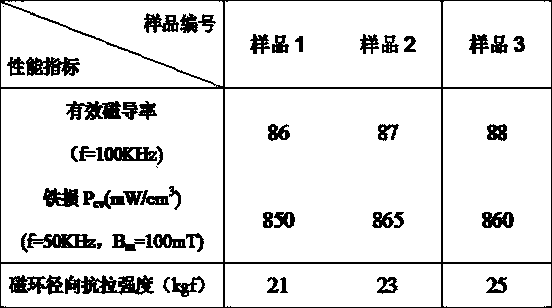

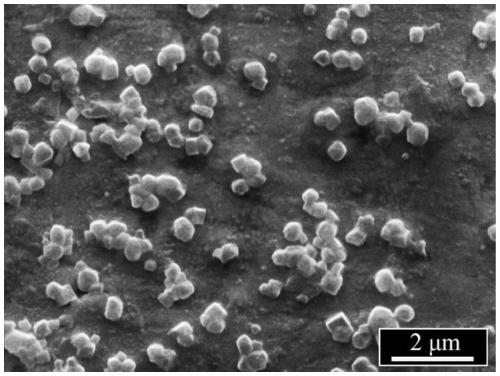

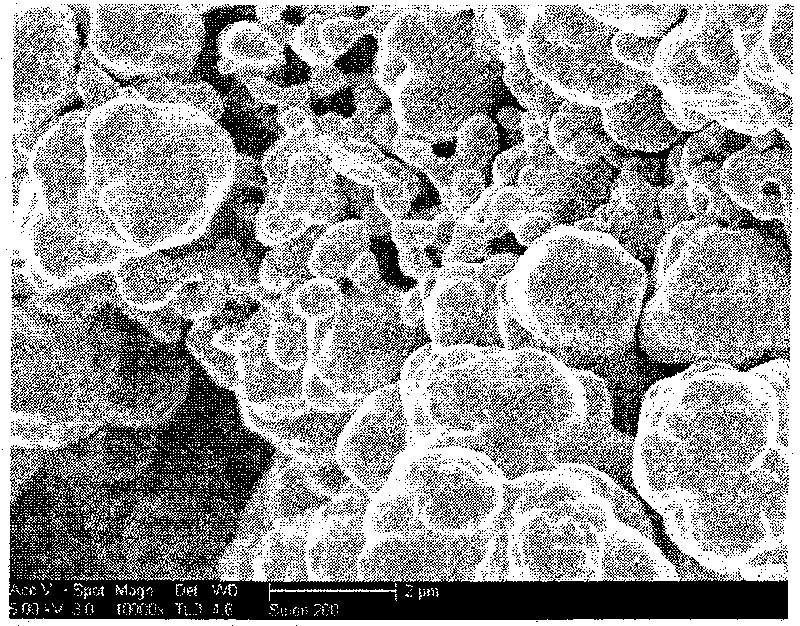

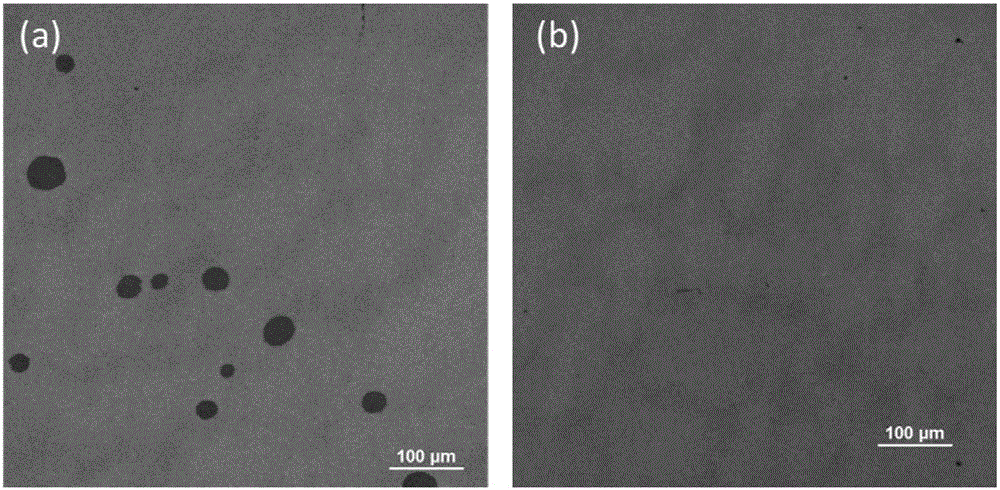

Inhomogeneous nucleation insulation coating processing method of metal soft magnetic composite material

ActiveCN104028747APrecise thickness controlPrecise control of its chemical compositionInorganic material magnetismInsulation layerSpray coating

The invention discloses an inhomogeneous nucleation insulation coating processing method of a metal soft magnetic composite material. The method includes the following steps that (1) particle size distribution is conducted on metal magnetic powder after sieving is conducted; (2) insulation coating is conducted on the distributed metal powder through an inhomogeneous nucleation method, and then the metal powder is dried; (3) the dried magnetic powder and a binding agent are evenly fixed, a release agent is added to conduct dry pressing and forming, and the mixture is pressed to form blank samples; (4) heat preservation is conducted on the blank samples for half an hour to two hours in a protective atmosphere, and air cooling and spray coating are conducted to obtain the target product. The composite powder prepared through the inhomogeneous nucleation method is even and compact in coating and controllable in coating layer thickness, and has high oxidation resistance, high resistivity, high saturation magnetization intensity, the good magnetic property and the good mechanical property; the surface of the metal magnetic powder is evenly coated with an A12O3 insulation layer through the inhomogeneous nucleation method, so that the coating effect is superior to that of an existing method, the operability is high and volume production is facilitated.

Owner:ZHEJIANG UNIV

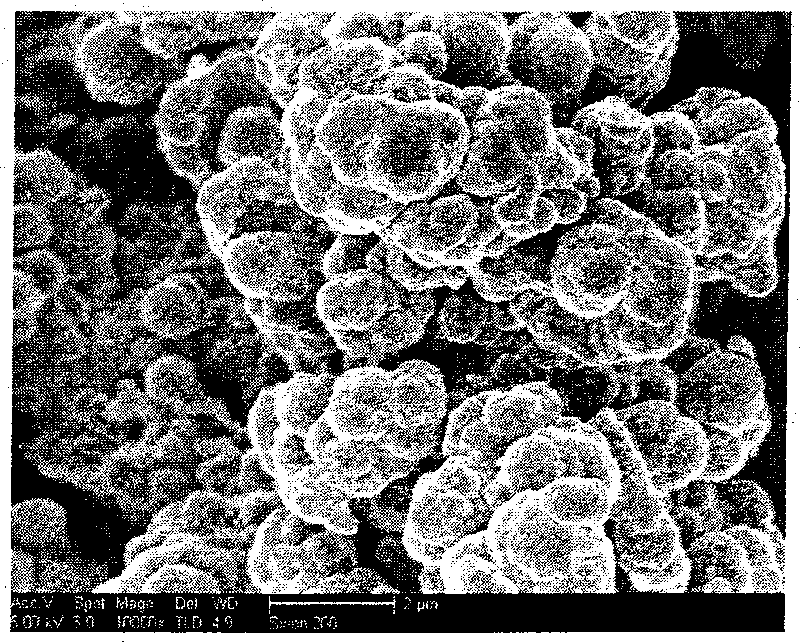

High-bonding-strength insulated coating treatment method of metal soft magnetic composite material

The invention discloses a high-bonding-strength insulated coating treatment method of a metal soft magnetic composite material. The method comprises the following steps: (1) sieving metal magnetic powder, and performing particle size distribution; (2) performing insulated coating on the distributed metal magnetic powder by using a sol-gel method, and then drying the metal magnetic powder; (3) uniformly mixing the dried magnetic powder and an adhesive, adding a release agent, and performing dry pressing to obtain a magnetic ring; (4) performing heat preservation, air cooling and spraying on the magnetic ring in protective atmosphere to obtain a target product. The bonding strength of composite powder prepared by using the sol-gel method and magnetic powder particles is high, the powder is coated uniformly and densely, and a coating layer is controllable in thickness, good, oxidation resistance and high saturation magnetization intensity are achieved, excellent in magnetic property and mechanical property, high in bonding strength, and not prone to disengagement; the coating effect is superior to that of an existing method; the method is high in operability and facilitates batch production; the resistivity of soft magnetic metal particles is effectively improved, and the magnetic core loss of the soft magnetic composite material is greatly reduced.

Owner:ZHEJIANG UNIV

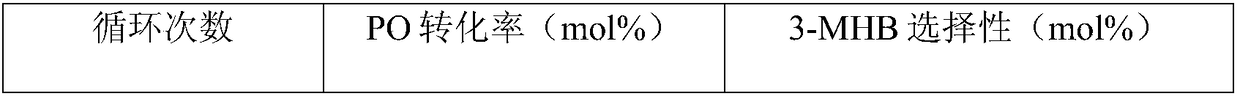

Cobalt-based catalyst as well as preparation method and application thereof to synthesis of 3-hydroxycarboxylate

ActiveCN108380232AStable structureStable in natureCatalyst activation/preparationPreparation by carbon monoxide or formate reactionActive componentSolvent

The invention discloses a cobalt-based catalyst as well as a preparation method and application thereof to synthesis of 3-hydroxycarboxylate. The cobalt-based catalyst comprises: nano metal cobalt which is used as a main active component, a porous material which is used as a composite carrier, and a nitrogen-doped carbon material, wherein the nano metal cobalt is uniformly loaded on the porous material; the surface of the nano metal cobalt is coated with the nitrogen-doped carbon material. The preparation method comprises the following steps: enabling a mixed reaction system containing a cobalt source, a carbon-nitrogen precursor and a solvent to react at 25 to 80 DEG C for 0.5 to 2h, and adding the porous material; then roasting at 550 to 900 DEG C for 2 to 3h in a protective atmosphere to obtain the cobalt-based catalyst. The cobalt-based catalyst provided by the invention has stable structure and properties and high reaction activity and 3-hydroxycarboxylate selectivity; the cobalt-based catalyst has the advantages that the preparation method is simple, the catalyst is easy to separate and recycle after reaction, the catalytic property of the catalyst is not reduced after the catalyst is repeatedly used for a plurality of times and the like, so that the catalyst is more suitable for industrial amplified application.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Multipurpose polyester film and preparation method thereof

The invention relates to a multipurpose polyester film and a preparation method thereof. The preparation method adopts a biaxial orientation technique and comprises the following steps: 1. preparation of functional assistants; 2. precrystallization and drying; 3. melt extrusion: the precrystallized and dried PET (polyethylene terephthalate) slices and the functional assistants are heated and molten by an extruder, and the melt is uniformly delivered to a die head for slab casting under the push of extrusion pressure; 4. slab casting: the uniform and stable melt from the extrusion system runs on rotating quenching rollers through the die head to form an amorphous slab; 5. longitudinal stretching and lateral stretching: the cast slab is subjected to longitudinal stretching after entering a longitudinal stretching machine, and subjected to lateral stretching after entering a lateral stretching machine; and 7. pulling, slicing, corona treatment, rolling and inspection. The method has wide application range, such as environment-friendly films, twist wrap films, high-brightness films, insulation films, capacitive films, car protecting films, bronzing films, aluminizing films and composite packaging films.

Owner:福建百宏高新材料实业有限公司

Drug targeting slow-release carrier material and preparing process thereof

InactiveCN1528461AWide variety of sourcesRich reservesInorganic non-active ingredientsHuman bodyControlled release

The present invention discloses a new type medicine target slowly-releasing carrier material and its preparation process. Said medicine target slowly-releasing carrier material is made up by utilizing attapulgite and Fe3O4. Its principle lies in that it utilizes the large specific surface area and adsorbability of ultrafine high-purity attapulgite and uses it as carrier material of medicine to prolong action time of medicine in interior of human body, raise concentration of local medicine, raise therapeutic effect of medicine and reduce toxic side effect of the medicine, and utilizes magnetization treatment so as to attain the goal of making target administration and controlling release of medicine.

Owner:甘肃省中心实验室

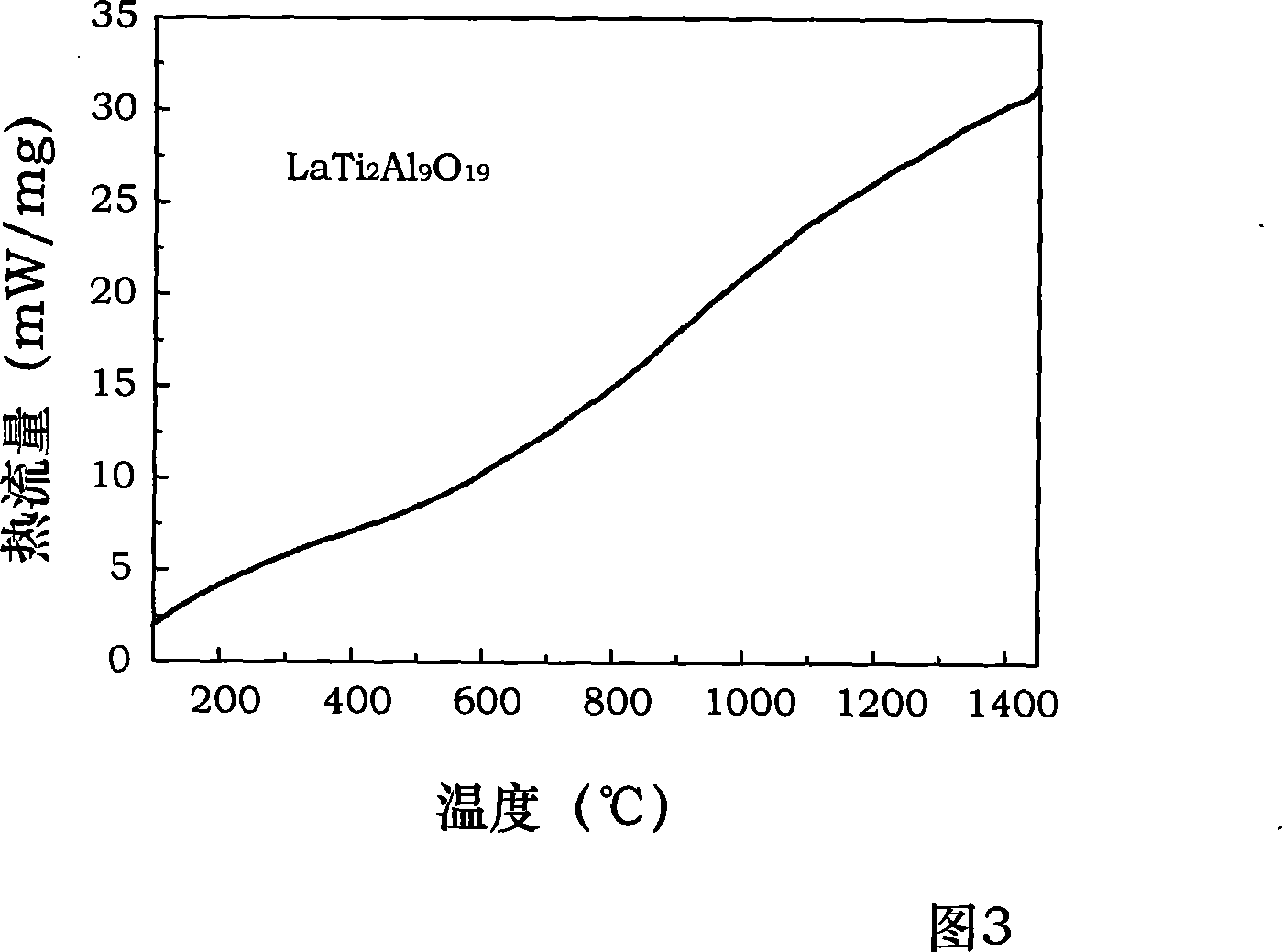

Method for preparing heat barrier coating with column form crystal structure ceramic layer

InactiveCN101078117AAvoid decompositionMaintain high temperature structural stabilityEfficient propulsion technologiesMetallic material coating processesThermal isolationMetallurgy

The invention discloses a thermal barrier coating preparation method with the columnar crystals coating to solve the problem of non-crystal coating and low anti-thermal in normal plasma spraying for the LaTi2Al9O19 ceramic material. It changes the distance and the technique data of the tack coat and ceramic powder channel in the normal plasma spraying process, so the thermal barrier coating of the LaTi2Al9O19 with the stable energetic and the columnar crystal structure. The thermal isolation temperature is 130deg.C-300deg.C and improves the strain limit and anti-thermal character, the hot circle life can reach above 1500 times and improves by 4 times.

Owner:BEIHANG UNIV

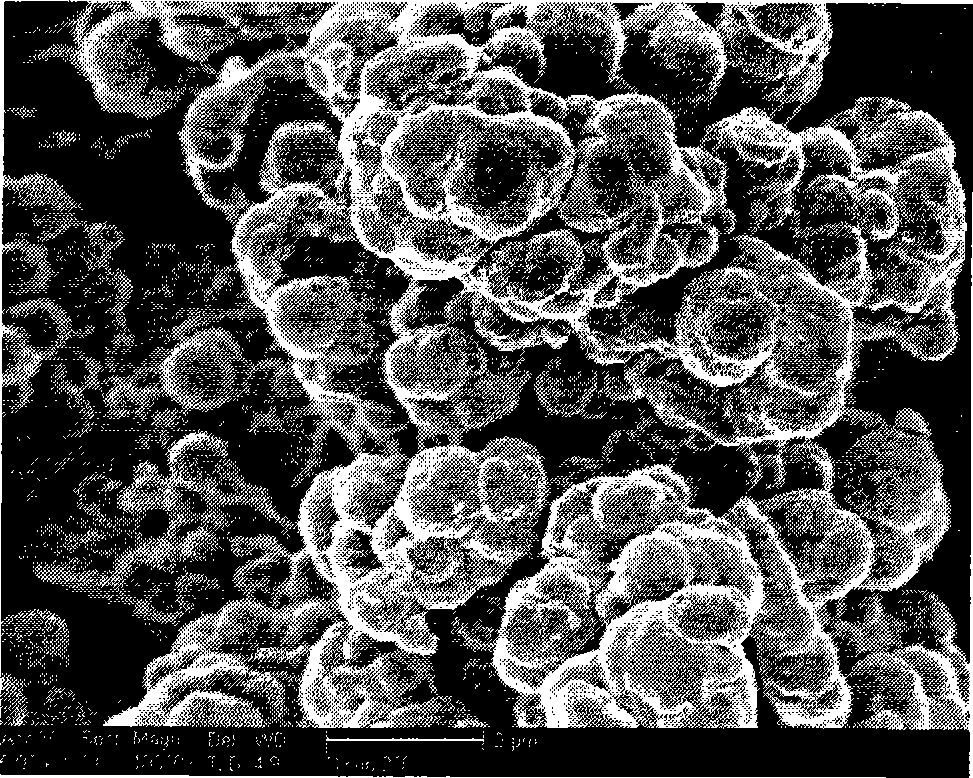

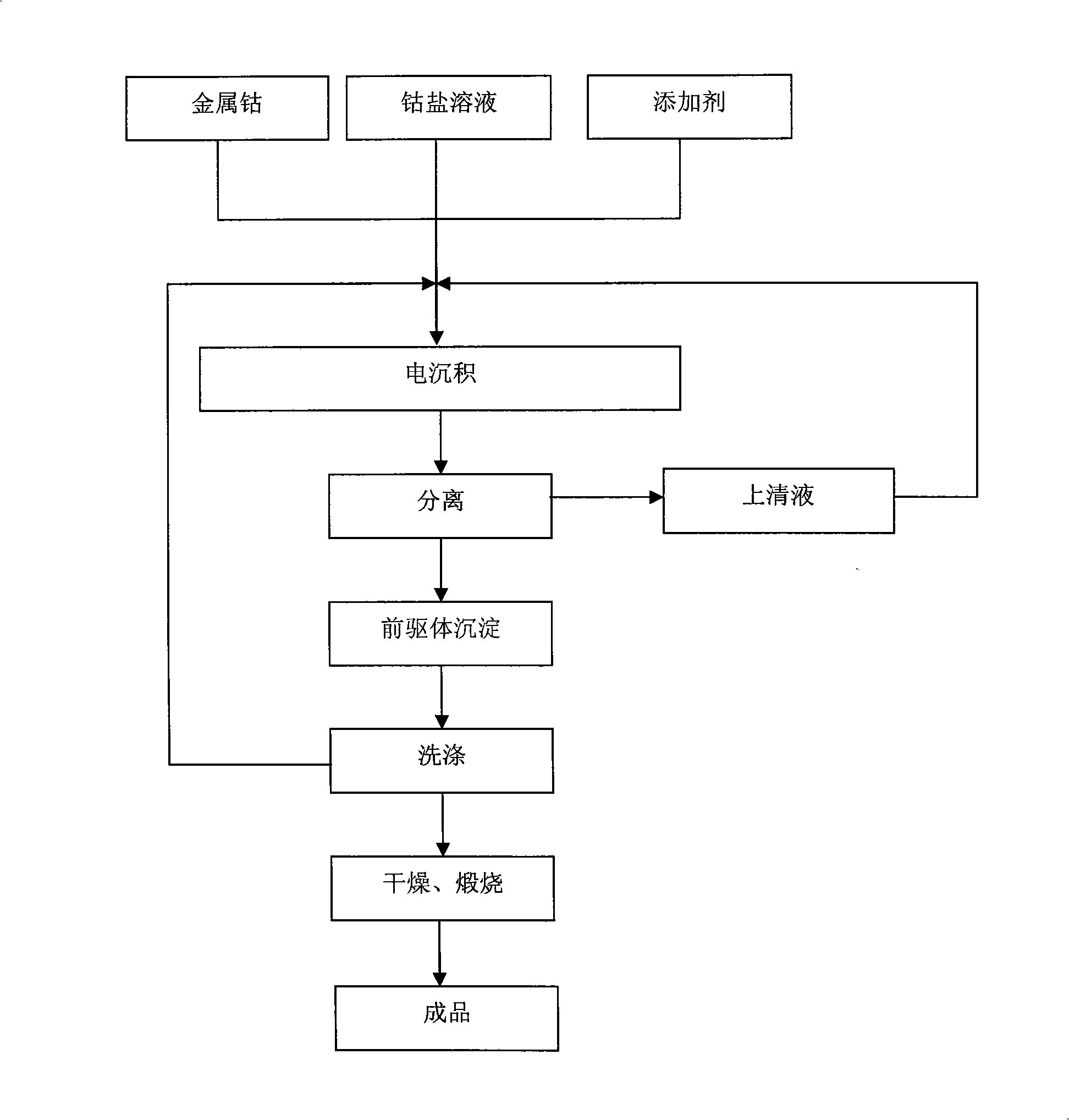

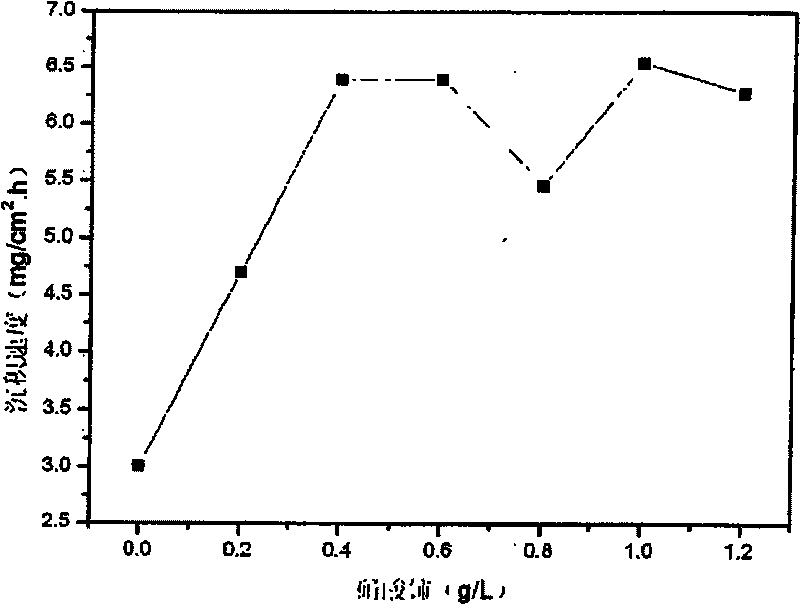

Clean production method for high-purity cobaltosic oxide powder

InactiveCN101525752ASmooth responseNarrow particle size distributionElectrolysis componentsChemistryDecomposition

The invention discloses a clean production method for high-purity cobaltosic oxide powder. The method comprises the following steps: using metal cobalt as an electrolytic anode, using soluble cobalt salt as electrolyte main salt and adding additives; adopting an electrochemical method to prepare a cobaltosic oxide precursor sediment; and then, drying and calcining the precursor sediment to obtain the cobaltosic oxide powder. The cobaltosic oxide powder produced by the method and the process can achieve the purity more than 99.7 percent, no additional precipitator is needed in the whole technological process, the added additives are all easy to wash without decomposition, and electrolyte and washing water can be recycled so as to avoid discharging sewage and generating waste gas. The method can adjust and control the appearance and the grain diameter distribution of the cobaltosic oxide powder by controlling the composition of the electrolyte, the cathode current concentration, the electrodeposition time and the calcining temperature and has the advantages of high product quality, simple production procedures, energy saving, environmental protection, and the like.

Owner:HUNAN UNIV

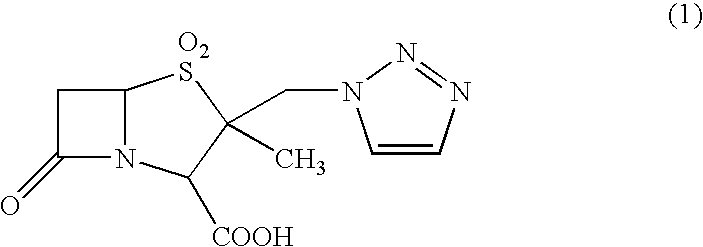

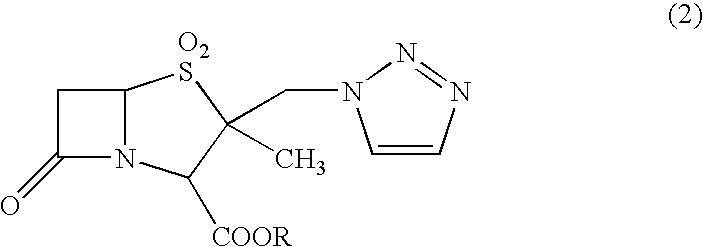

Anhydrous crystal of β-lactam compound and method for preparation thereof

ActiveUS7674898B2Good storage stabilityNo decompositionAntibacterial agentsOrganic chemistryChemical compoundAqueous solution

The present invention provides anhydrous crystals of β-lactam compound represented by the formula:The β-lactam compound of the invention is produced by heating an aqueous solution of a salt of the β-lactam compound and adjusting the pH of the aqueous solution to 3 or lower. The β-lactam compound has excellent storage stability.

Owner:OTSUKA CHEM CO LTD +1

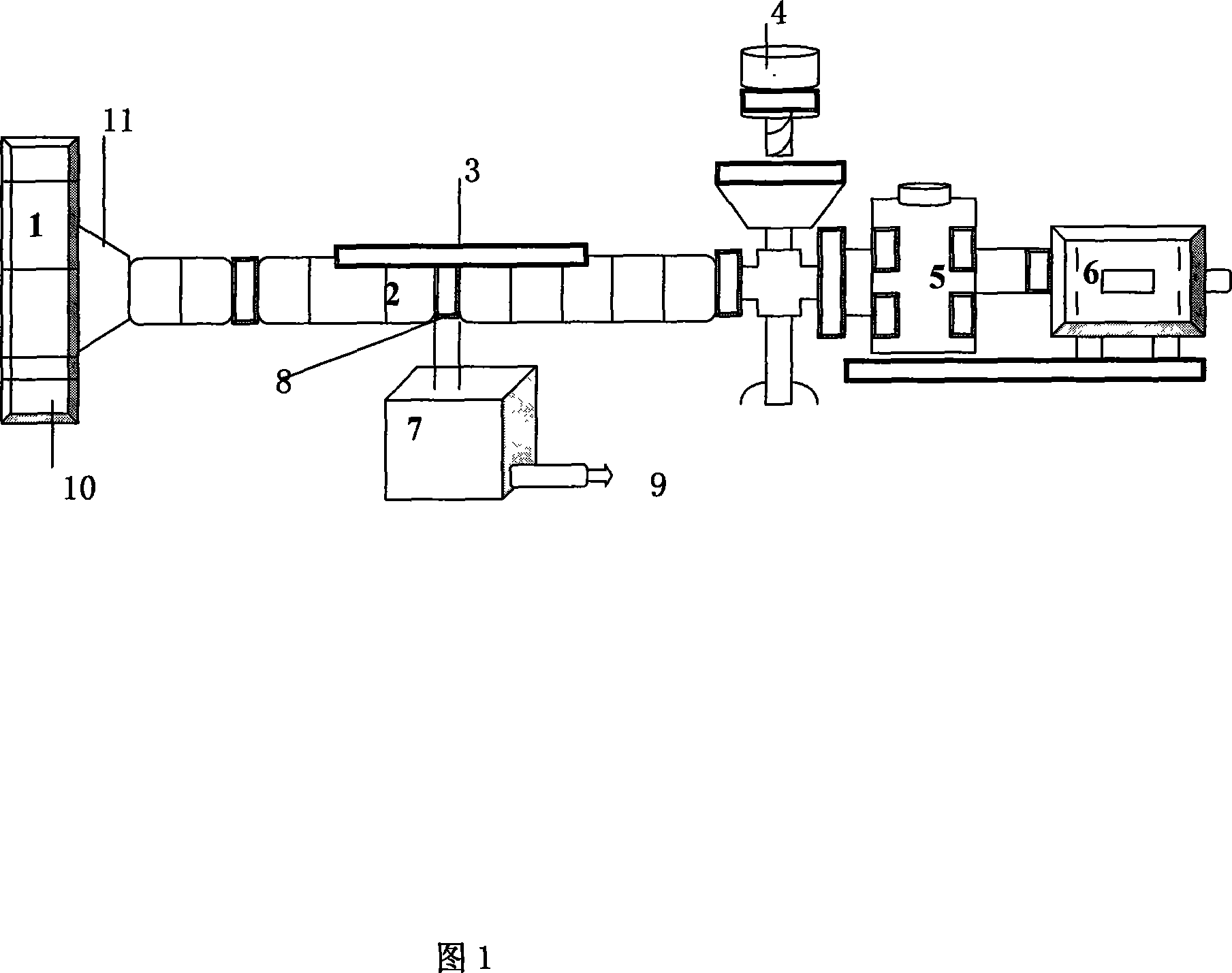

Special type sludge dewatering extrusion granulator

InactiveCN101121107AReduce energy consumptionSave energySludge treatment by de-watering/drying/thickeningGranulation by material expressionWater vaporScrew thread

The present invention provides a novel technical device of sludge dehydration and belongs to the solid waste disposal field. The device is applicable to the dehydration and granulation requirements of sludge with various components. A single screw and reverse screw threads and a peculiar structure arrangement are adopted to make the water of the sludge (a moisture content of which is about 80 percent) is dehydrated as a form of liquid, and make the sludge form a sludge dehydration and granulation process, the moisture content of which is 30 percent to 35 percent. A special sludge dehydration and granulation machine fills a blank that the sludge dehydration has to be dehydrated as the form of water vapor, which greatly reduces the energy cost of the sludge dehydration. With small size, low operation cost, high production efficiency, high mechanization degree and wide scope of application, the present invention is a novel and most energy-saving and cleanly-produced sludge dehydration device.

Owner:朱清海

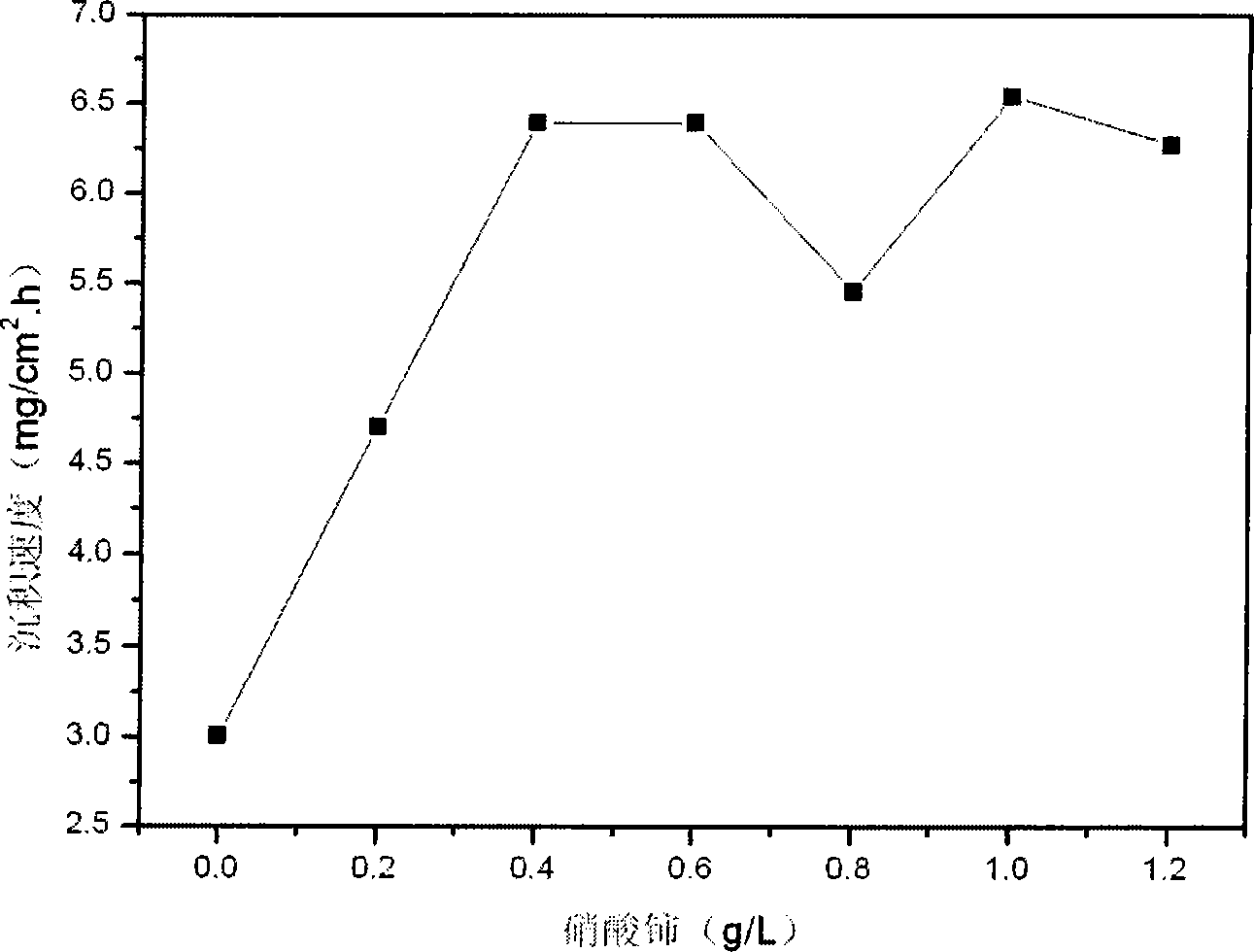

Chemical plating silver copper powder, chemical plating liquid and chemical plating method

InactiveCN101244459BHigh catalytic activityHigh reducing activityLiquid/solution decomposition chemical coatingReduction ActivitySilver plate

The invention discloses a silver plating copper powder, a chemical plating liquid and a method of chemical plating; wherein, the silver coating ratio of the silver plating copper powder is 10 to 95%;the silver plating layer comprises 0.5 to 1.2wt% rare-earth metal cerium and / or lanthanum and / or yttrium; the chemical plating liquid comprises three independent components of silver nitrate water solution, formaldehyde ethanol solution and rare-earth nitrate water solution. The method of chemical plating is characterized in that (1) the copper powder is washed and is processed by ultrasonic sensitization and ultrasonic activation in sequence, and (2) the three components of the chemical plating liquid are added in sequence and the ultrasonic chemical plating is processed. The method of chemical plating has the advantages of utilizing the modification effect of rare-earth, raising the stability of plating liquid, the catalytic activity of copper powder surface and the reduction activity ofsilver ion, adjusting the silver coating ratio from 10% to 95% according to different demands, and even distribution, smooth surface and high conductivity and oxidation resistance of silver plating layer.

Owner:HEFEI UNIV OF TECH

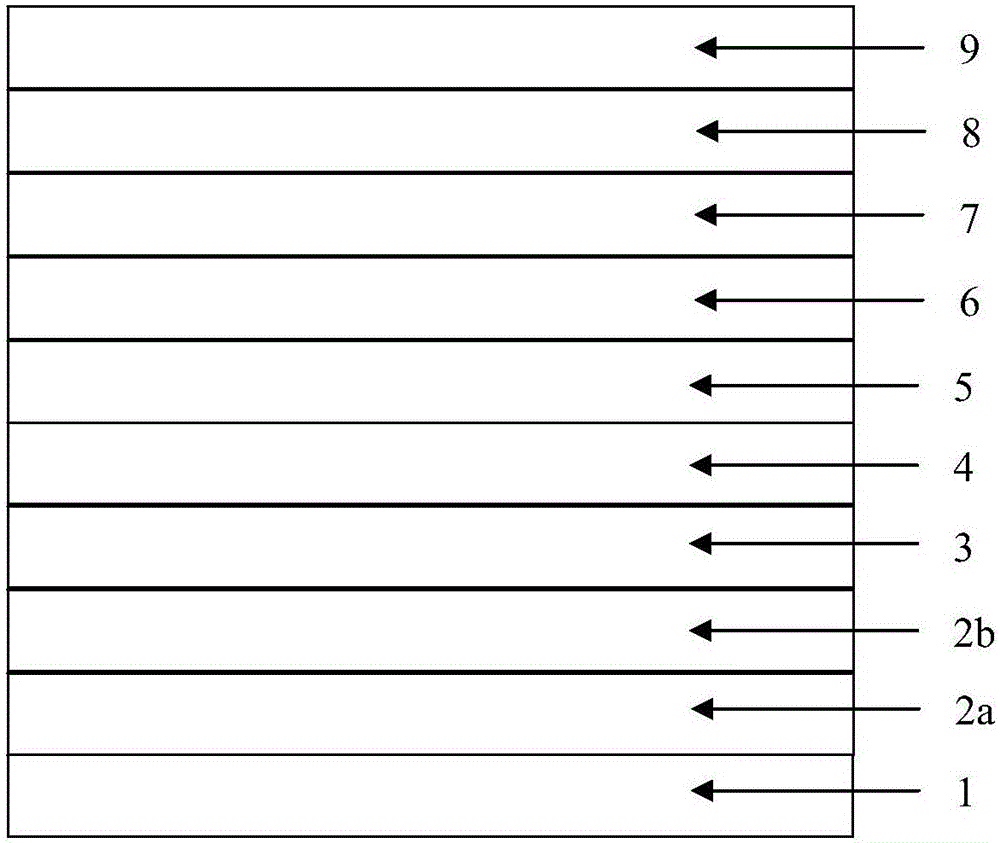

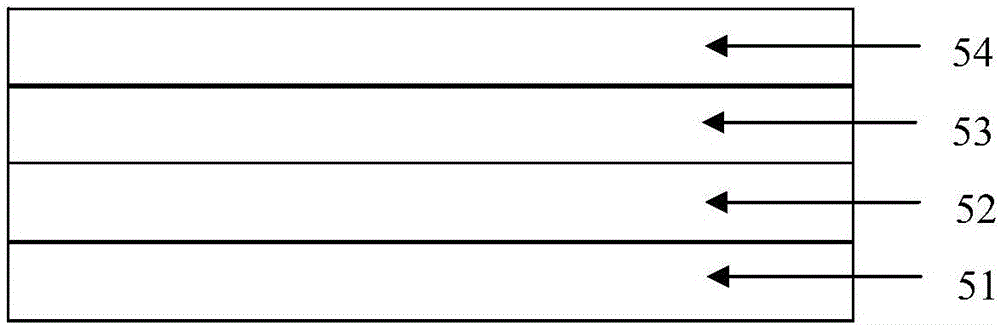

InGaN/GaN quantum well laser and manufacturing method thereof

ActiveCN106785919AEvenly distributedQuality improvementLaser detailsSemiconductor lasersOhmic contactLayer thickness

The invention discloses an InGaN / GaN quantum well laser, comprising a substrate and the following components sequentially arranged on the substrate: a low temperature GaN buffer layer, a high temperature n-type GaN layer and an n-type AlGaN light confinement layer; an n-type InGaN lower waveguide layer on the n-type AlGaN light confinement layer; an InGaN / GaN quantum well active region on the n-type InGaN lower waveguide layer; a u-type InGaN upper waveguide layer on the InGaN / GaN quantum well active region; a p-type AlGaN electron barrier layer on the u-type InGaN upper waveguide layer; a p-type AlGaN / GaN light confinement layer on the p-type AlGaN electron barrier layer; and a p-type GaN ohmic contact layer on the p-type AlGaN / GaN light confinement layer. The invention also discloses a manufacturing method for the InGaN / GaN quantum well laser. The invention adopts the InxGa1-XN of 1 to 2 single-atom layer thickness to be inserted into the cap layer so that the two-dimensional island-like surface of the InGaN quantum well surface becomes smooth, that the distribution of the In group becomes more uniform and that the subsequently formed GaN cap layer has a better quality in which the InGaN quantum well is not decomposed during the temperature rise and does not undergo thermal degradation during the subsequent high temperature growth of the p-type AlGaN / GaN light confinement layer.

Owner:杭州增益光电科技有限公司

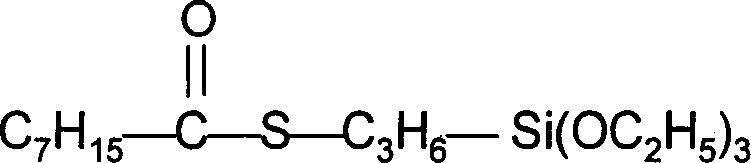

Novel silane coupler containing sulfur and nitrogen element

InactiveCN1970563ASimple production processHigh yieldGroup 4/14 element organic compoundsSilanesStructural unit

The invention discloses a new-typed silane coupling agent with sulphur and nitrogen element and making method, which is characterized by the following: reacting hydrocarbyl silane and alkyl monoisocyanates in the organic solvent with the molar rate at 1: 1 acted by tertiary amine catalyst; decompressing; distilling to make new-typed silane coupling agent with 1 thioamino formic ether structural units and 3 alkoxy groups; possessing higher heat stability and stronger coupling effect than traditional silane coupler; fitting for improving the synthetic property of sulfurized gel in the white carbon black rubber.

Owner:贵州省材料技术创新基地 +1

Method for preparing ageratina adenophora extract by membrane separation

InactiveCN103999882ASimple production processShort processBiocideFruit and vegetables preservationSolventChemistry

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com