Brake fluid for motor vehicles and its production methods

A production method and brake fluid technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of frequent brake system temperature rise, etc., and achieve the effects of low cost, high economic benefit, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

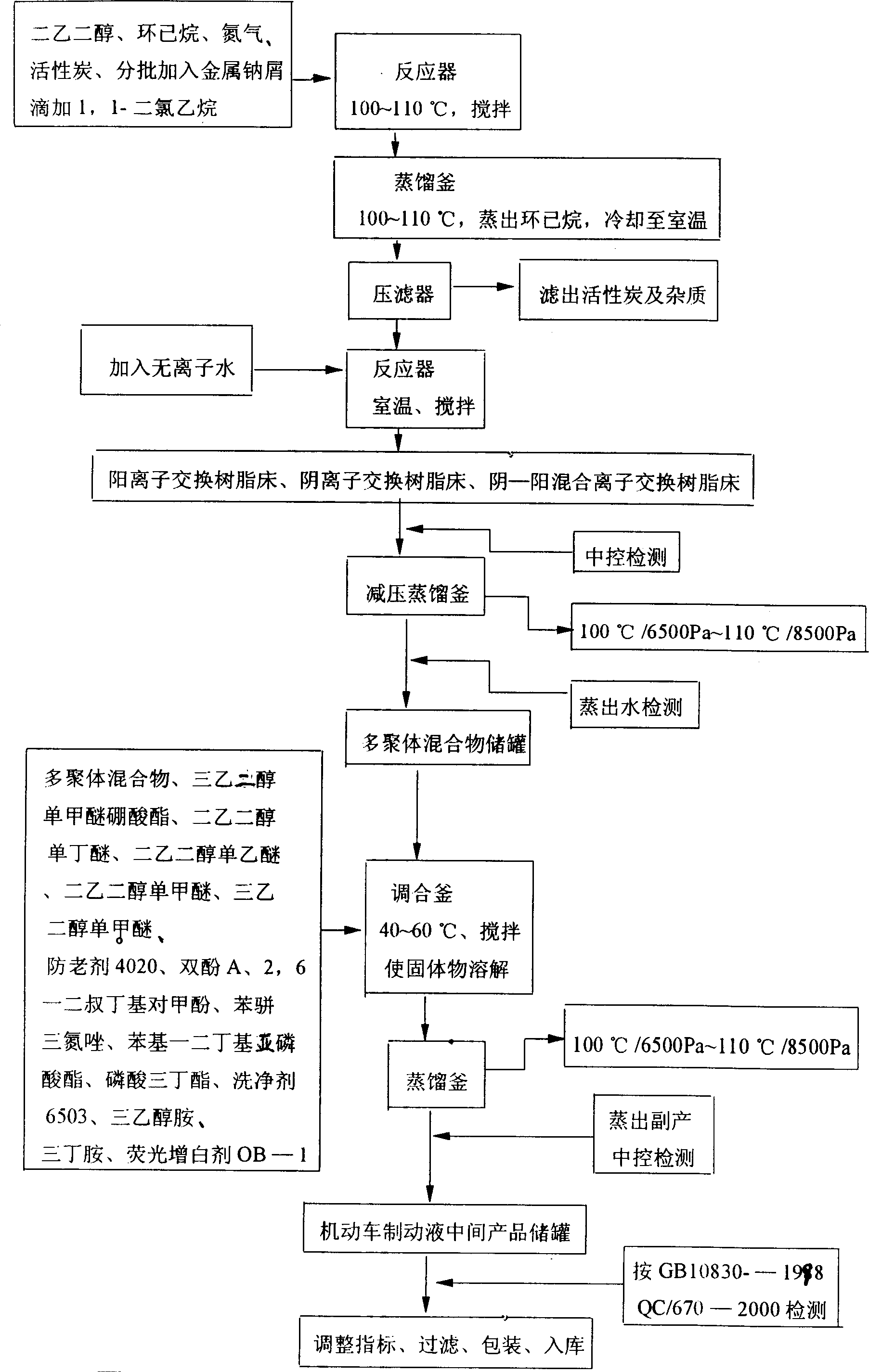

Method used

Image

Examples

Embodiment 1

[0060] Preparation of polymer mixture

[0061] Take 430kg of diethylene glycol, 100Kg of cyclohexane, and 10kg of activated carbon into the reactor, add nitrogen gas, raise the temperature to 100°C, stir, add 46kg of metal sodium scraps in batches, and add 198kg of 1,1-dichloroethane, 2 After hours of dripping, keep at 100°C for 2 hours, distill off cyclohexane, cool to room temperature, press filter, add 100kg of non-ionized water to the filtrate, stir for 20 minutes at room temperature to obtain material A, and pass material A through 732 cation exchange resin bed, 717 in turn Anion exchange resin bed and anion-cation mixed ion exchange resin bed, wherein the mass ratio of anion exchange resin 717 and cation exchange resin 732 in the anion-cation mixed ion exchange resin bed is 1:1. Material B is obtained from the outflow of material liquid, and the conductivity of material B is 2.1μScm. -1 , Chloride ion <1.2ppm. Add material B into a vacuum distillation kettle and distill off ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com