Chemical plating silver copper powder, chemical plating liquid and chemical plating method

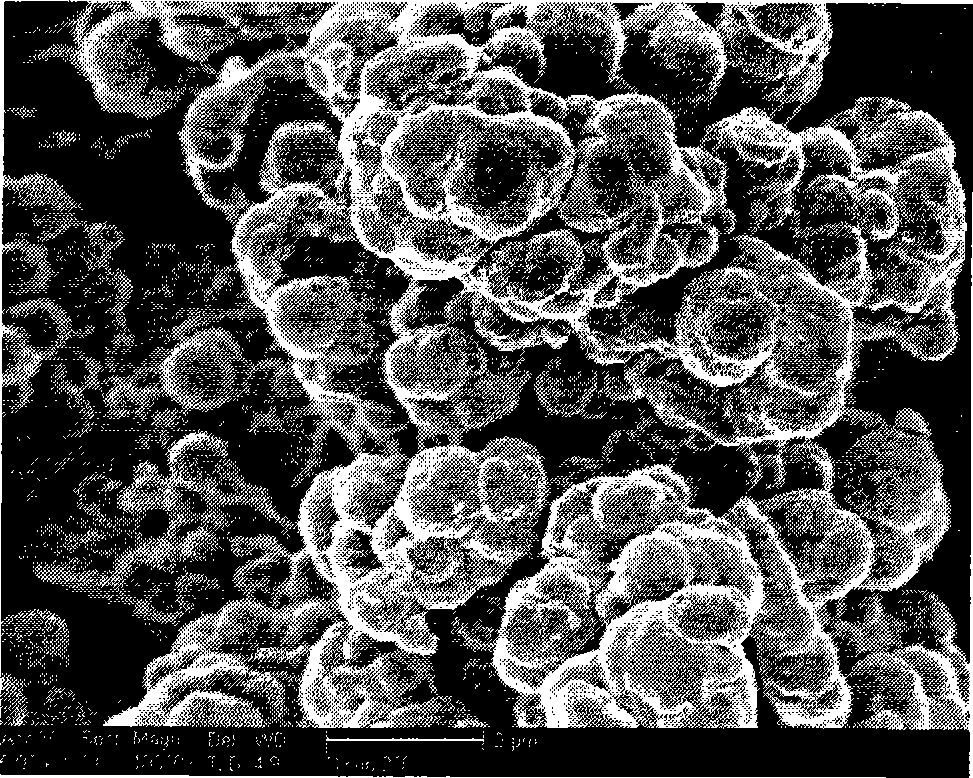

A technology of chemical silver plating and chemical plating solution, which is applied in the direction of liquid chemical plating, coating, metal material coating process, etc., can solve the problem of poor stability of plating solution, affecting the oxidation resistance, conductivity, and Repeated silver plating and other problems to achieve the effect of improving the silver coating rate, high bonding force, and uniform distribution of the silver layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

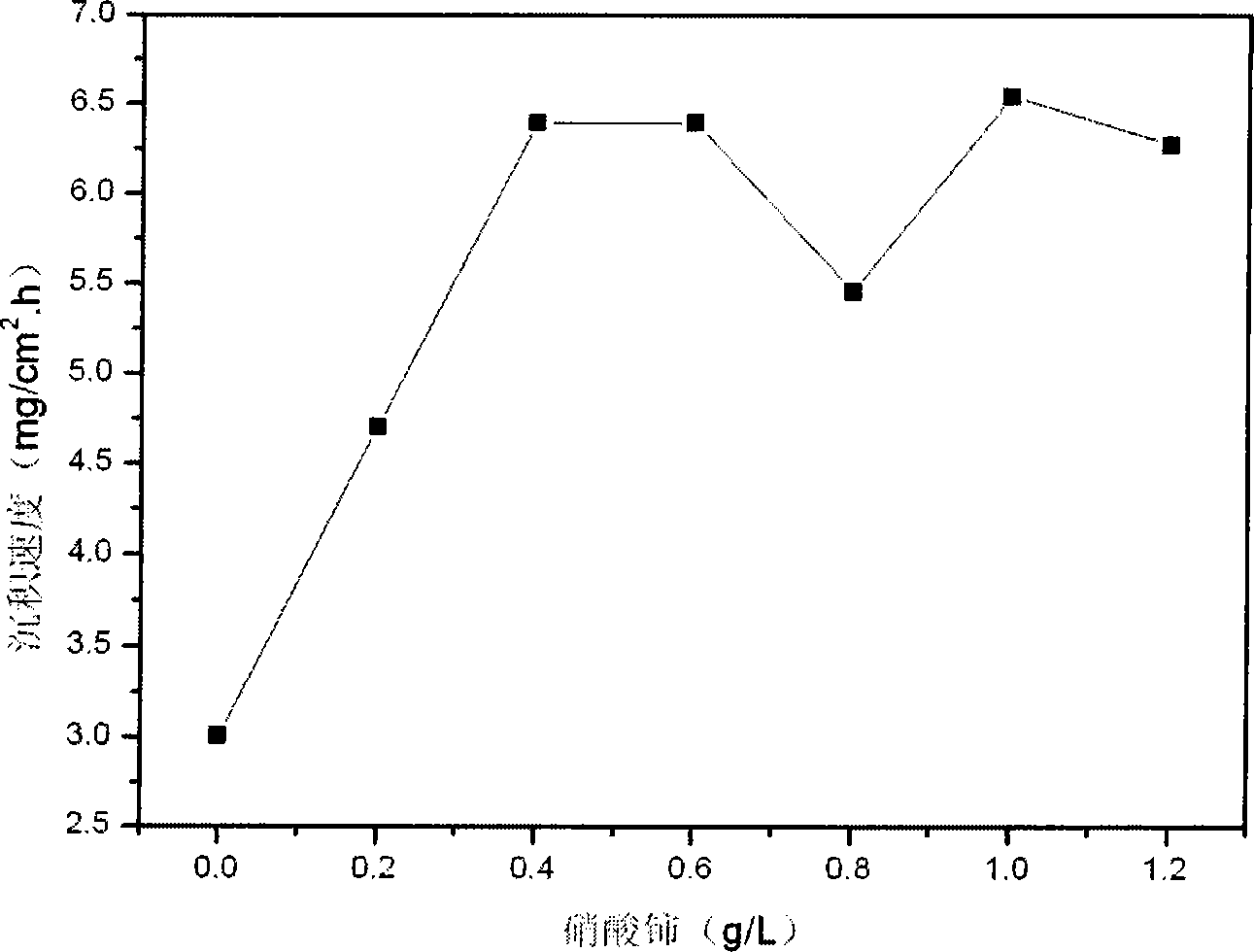

Embodiment 1

[0026] Example 1: Put 15g of copper powder into a glass container, add a certain amount of absolute ethanol, and stir for 1 hour with a temperature-controlled magnetic stirrer. Wash the copper powder with distilled water for 2 times, then wash the copper powder with 3% dilute HCl, and then wash the copper powder with distilled water for 3 times. Copper powder is put into the sensitization solution (stannous chloride 10g / L; Hydrochloric acid 30g / L; Distilled water surplus) container that places ultrasonic generator to carry out sensitization treatment, ultrasonic frequency is 40kHz, ultrasonic power is 110W, temperature The temperature is 20°C, the sensitization time is 5min, and the copper powder is washed twice with distilled water. Copper powder is put into the activation solution (palladium chloride 0.5g / L; Hydrochloric acid 25g / L; Distilled water surplus) container that places ultrasonic generator and carry out activation treatment, ultrasonic frequency is 40kHz, ultrasoni...

Embodiment 2

[0027] Example 2: Put 15g of copper powder into a glass container, add a certain amount of absolute ethanol, and stir for 1 hour with a temperature-controlled magnetic stirrer. Wash the copper powder with distilled water for 2 times, then wash the copper powder with 3% dilute HCl, and then wash the copper powder with distilled water for 3 times. Copper powder is put into the sensitization solution (stannous chloride 12g / L; Hydrochloric acid 30g / L; Distilled water surplus) container that places ultrasonic generator to carry out sensitization treatment, ultrasonic frequency is 40kHz, ultrasonic power is 110W, temperature The temperature is 20°C, the sensitization time is 5min, and the copper powder is washed twice with distilled water. Copper powder is put into the activation solution (palladium chloride 0.5g / L; Hydrochloric acid 25g / L; Distilled water surplus) container that places ultrasonic generator and carry out activation treatment, ultrasonic frequency is 40kHz, ultrasoni...

Embodiment 3

[0028]Example 3: Put 30 g of copper powder into a glass container, add a certain amount of absolute ethanol, and stir with a temperature-controlled magnetic stirrer for 1 hour. Wash the copper powder with distilled water for 2 times, then wash the copper powder with 3% dilute HCl, and then wash the copper powder with distilled water for 3 times. Copper powder is put into the sensitization solution (stannous chloride 15g / L; Hydrochloric acid 40g / L; Distilled water surplus) container that places ultrasonic generator and carry out sensitization treatment, ultrasonic frequency is 40kHz, ultrasonic power is 110W, temperature The temperature is 20°C, the sensitization time is 5min, and the copper powder is washed twice with distilled water. Copper powder is put into the activation solution (palladium chloride 0.8g / L; Hydrochloric acid 30g / L; Distilled water surplus) container that places ultrasonic generator and carry out activation treatment, ultrasonic frequency is 40kHz, ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com