Polybasic solid solution rare earth silicate ceramic powder and preparation method thereof

A rare-earth silicate and ceramic powder technology, which is applied in the field of multi-component solid-solution rare-earth silicate ceramic powder and its preparation, can solve the problems of limited application fields, difficult and harsh preparation processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

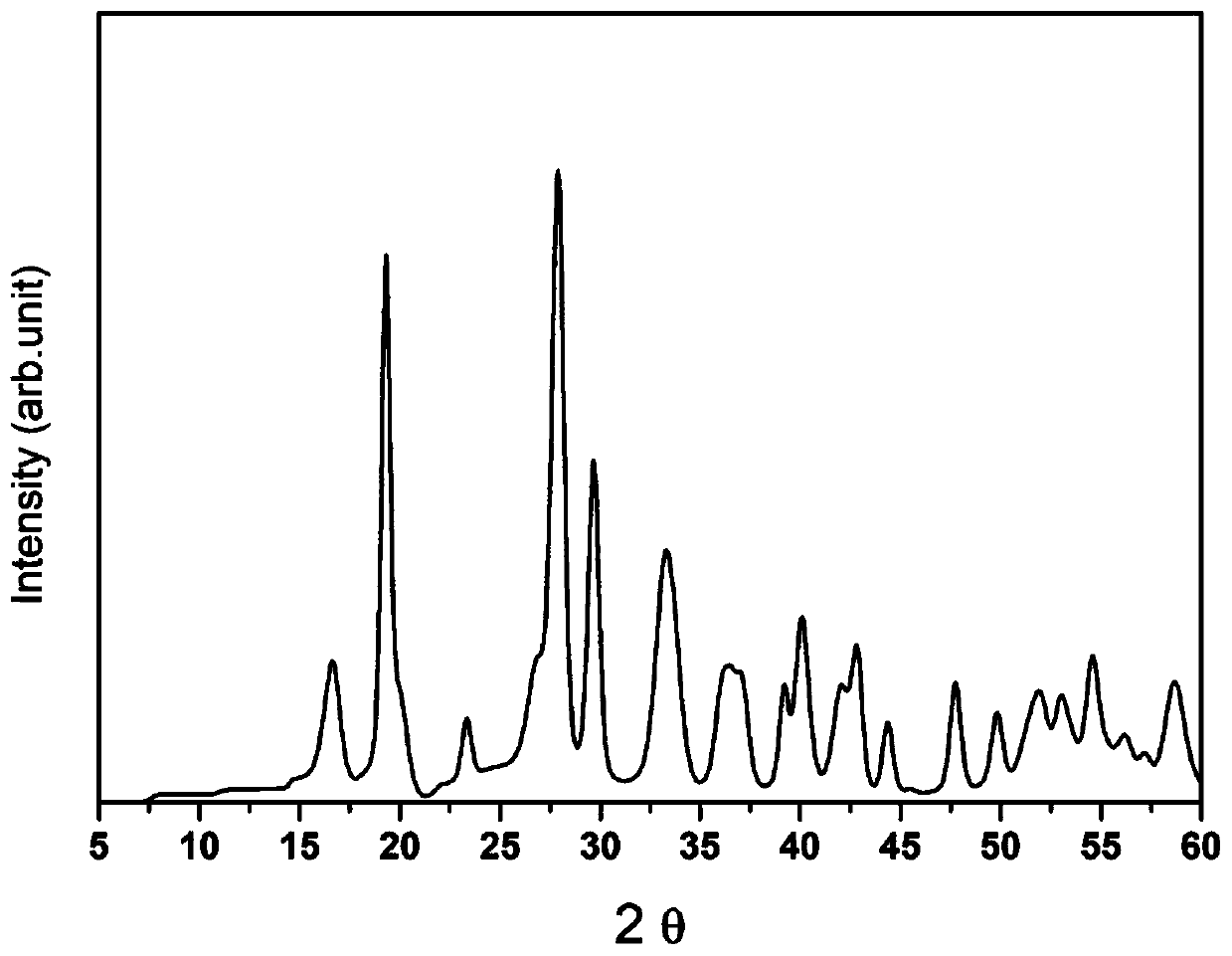

[0045] Preparation of multi-element solid solution rare earth silicate ceramic powder (Y 0.2 Yb 0.2 Nd 0.2 SM 0.2 La 0.2 ) 2 Si 2 o 7 :

[0046] (1) According to the molar ratio of Y:Yb:Nd:Sm:La:Si=0.2:0.2:0.2:0.2:0.2:1.0, Y 2 o 3 , Yb 2 o 3 、Nd 2 o 3 、Sm 2 o 3 , La 2 o 3 and SiO 2 The raw material powder is weighed, mixed in a deionized water medium for 30 hours, the rotating speed of the ball mill is 150 r / min, and the uniformly mixed raw material is vacuum-dried at a temperature of 25 ° C for 48 hours to obtain a mixed raw material;

[0047] (2) Put the mixed raw materials in a high-temperature reaction furnace, and in a flowing air atmosphere, heat-preserve and react at a temperature of 1500° C. for 10 hours to obtain multi-component solid-solution rare earth silicate ceramic particles;

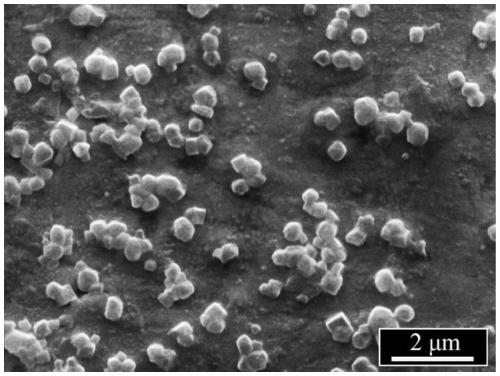

[0048] (3) Mill the multi-component solid-solution rare earth silicate ceramic particles in the water medium for 24 hours with an alumina ball, and the speed of the ball...

Embodiment 2

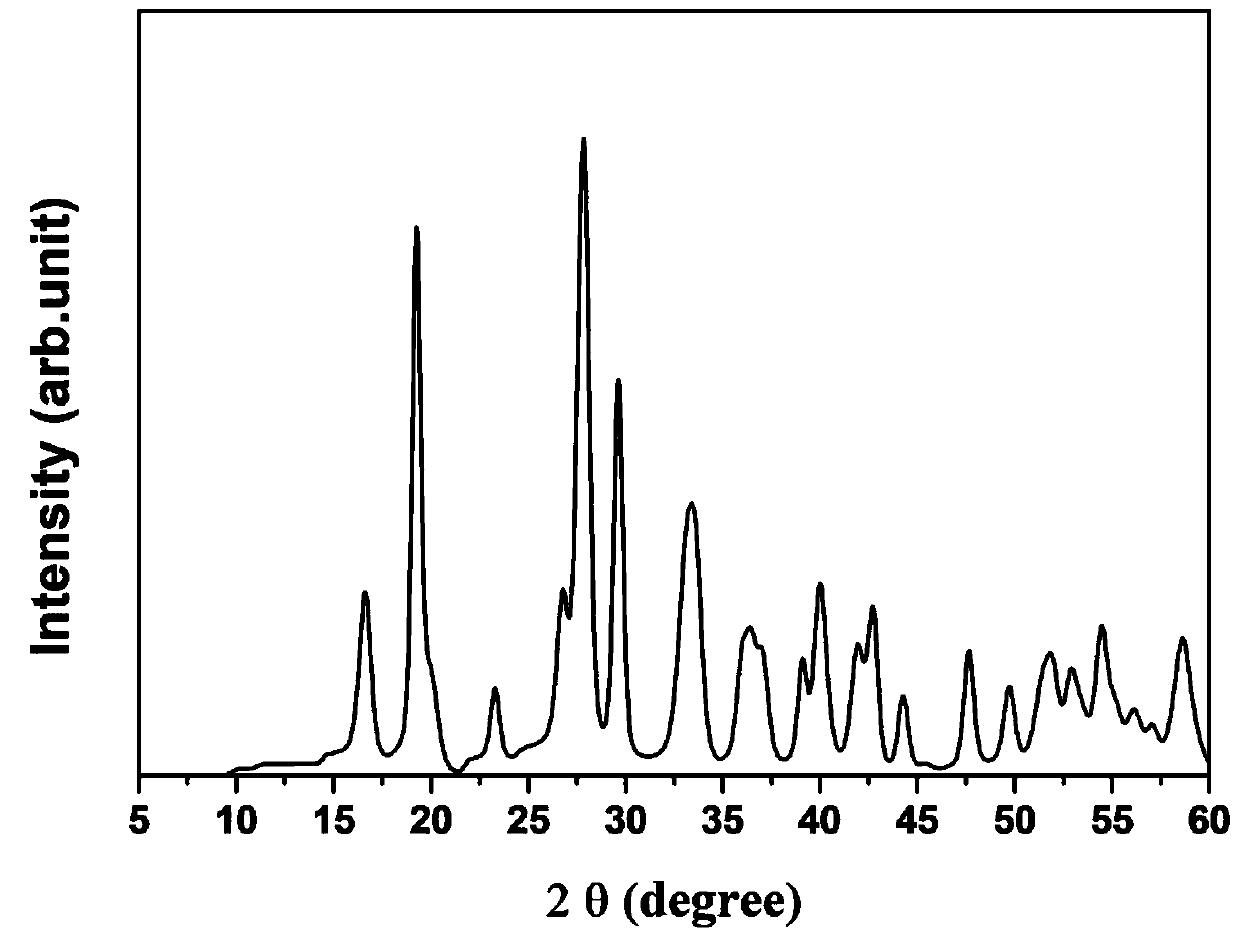

[0055] Preparation of multi-element solid solution rare earth silicate ceramic powder (Y 0.2 Yb 0.2 Ce 0.2 SM 0.2 La 0.2 ) 2 Si 2 o 7 :

[0056] (1) According to the molar ratio of Y:Yb:Ce:Sm:La:Si=0.2:0.2:0.2:0.2:0.2:1.5, Y 2 o 3 , Yb 2 o 3 , CeO 2 、Sm 2 o 3 , La 2 o 3 and SiO 2 The raw material powder is weighed, mixed in a deionized water medium for 24 hours, the speed of the ball mill is 300r / min, and the uniformly mixed raw material is dried at a temperature of 55°C in flowing air for 48 hours to obtain a mixed raw material;

[0057] (2) Put the mixed raw materials in a high-temperature reaction furnace, and in a flowing air atmosphere, heat-preserve and react at 1700° C. for 2 hours to obtain multi-component solid-solution rare earth silicate ceramic particles;

[0058] (3) Mill the multi-component solid-solution rare earth silicate ceramic particles in the water medium for 20 hours with zirconia balls, and the speed of the ball mill is 320r / min; Drying...

Embodiment 3

[0061] Preparation of multi-element solid solution rare earth silicate ceramic powder (Y 0.2 Yb 0.2 Er 0.2 Eu 0.2 La 0.2 ) 2 Si 2 o 7 :

[0062] (1) According to the molar ratio of Y:Yb:Er:Eu:La:Si=0.2:0.2:0.2:0.2:0:1.5, Y 2 o 3 , Yb 2 o 3 、Er 2 o 3 、Eu 2 o 3 , La 2 o 3 and SiO 2 The raw material powder is weighed, mixed in a deionized water medium for 36 hours, the speed of the ball mill is 100r / min, and the uniformly mixed raw material is dried at a temperature of 45°C in flowing air for 36 hours to obtain a mixed raw material;

[0063] (2) Put the mixed raw materials in a high-temperature reaction furnace, and in a flowing air atmosphere, heat-retain and react at 1650° C. for 5 hours to obtain multi-component solid-solution rare earth silicate ceramic particles;

[0064] (3) Mill the multi-component solid-solution rare earth silicate ceramic particles in water medium for 2 hours with zirconia balls, and the ball mill speed is 400r / min; Drying and granulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com