Anti-mite antibacterial thermoplastic polymer melt spun fiber and preparation method thereof

A polymer and thermoplastic technology, applied in melt spinning, stretch spinning, fiber treatment, etc., can solve the problems of easy elution and loss, human irritation, uneven dispersion, etc., and achieve long-lasting weather resistance and sun resistance , no shedding and loss, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

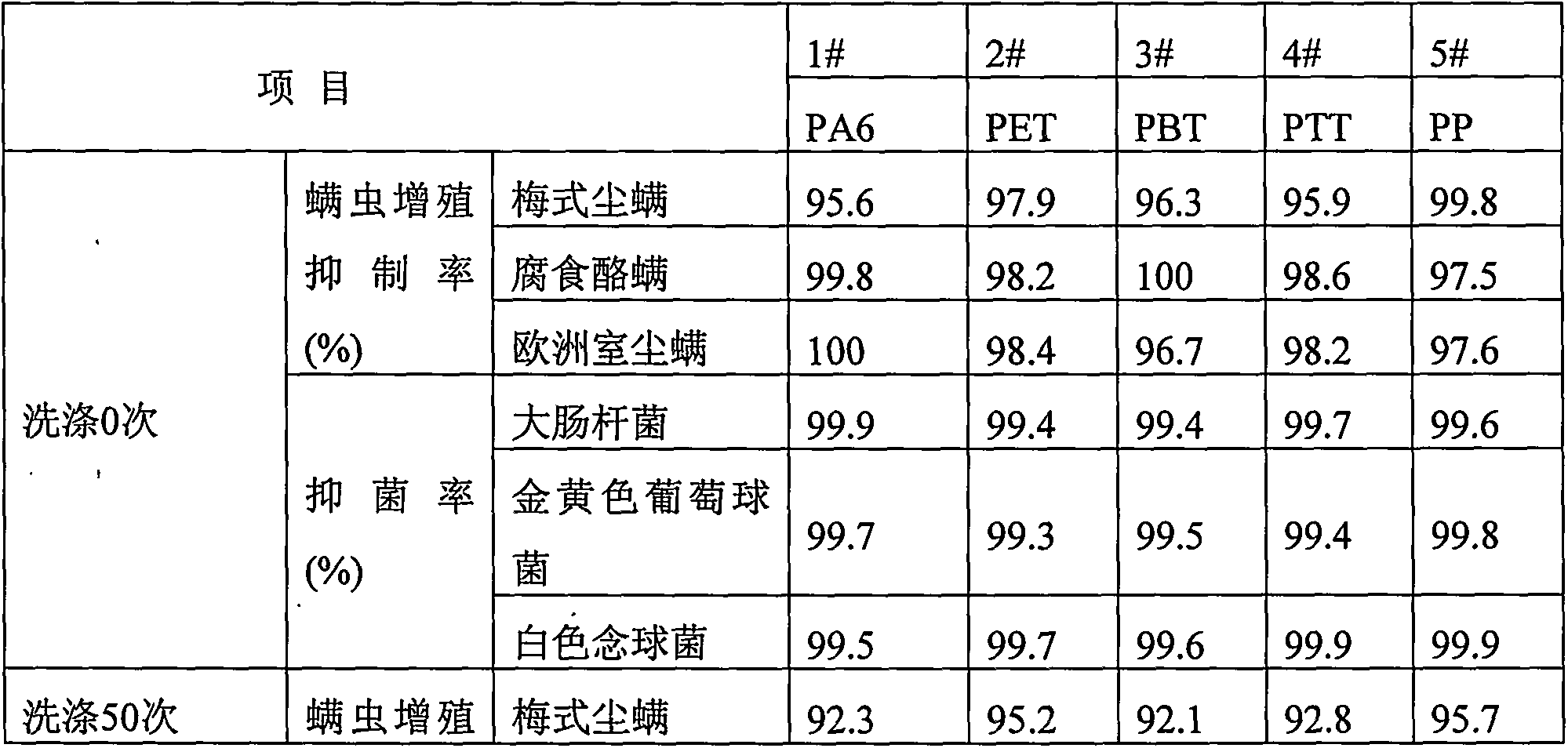

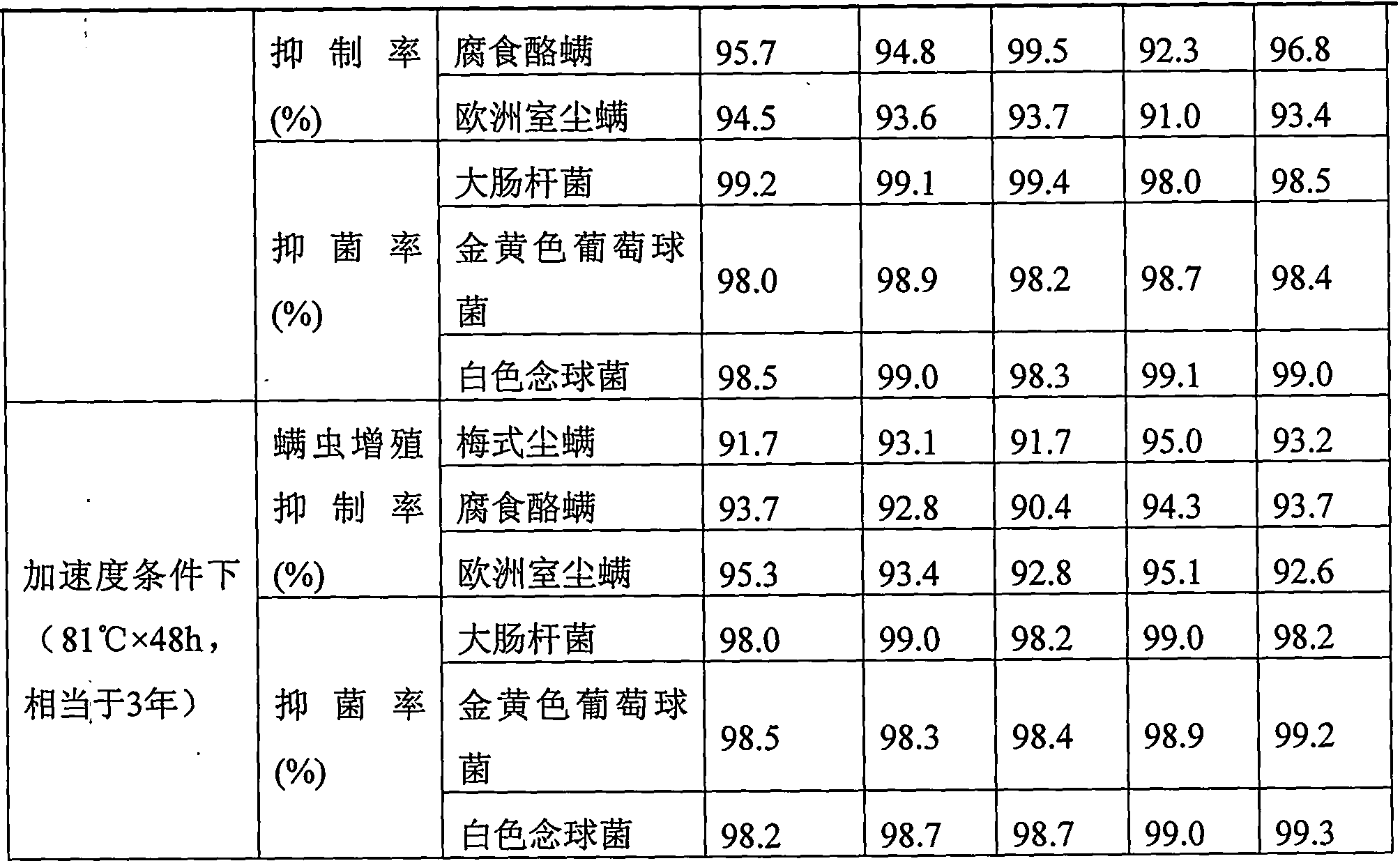

Examples

Embodiment 1

[0028] The anti-mite principle of the present invention is different from that of general organic anti-mite agents or repellants that use neurotoxins to kill mites or volatilize organic components that are annoying to mites. The main component of the anti-mite is silver-loaded sodium borosilicate ceramic powder boric acid and its sodium salt. The anti-mite principle of the present invention is to allow mites to contact with silver-loaded sodium borosilicate ultrafine ceramic powder and ingest them orally. The boron trioxide, boric acid and sodium salt contained in the ultrafine powder will be Causes the mites to be dehydrated, the back and abdomen of the mites will be sunken, relatively fragile, and unable to reproduce. On the other hand, it will reduce the concentration of the allergen of the mites, so while reducing the number of mites, it also reduces the allergies caused to the human body harm. The antibacterial principle of the present invention is based on the combinati...

Embodiment 2

[0035] Step 1: By weight, 2.5 parts of sodium acetate and 6.5 parts of boric acid are added successively to 67 parts of ethanol and water mixed solvent, wherein the weight ratio of ethanol to water is 6:4, slowly add 30 parts of boric acid under stirring Ethyl orthosilicate, add 0.01mol / L nitric acid solution dropwise to adjust the pH value to 5~6, heat and stir in a water bath at 50°C for 3 hours, add 12 parts of 0.1mol / L silver nitrate solution, and keep the constant temperature at 50°C Stir the reaction for 3 hours in the dark to obtain a uniform and transparent sol, keep the obtained sol in the dark and keep it at a constant temperature until a gel is formed, then dry the gel at a constant temperature of 110°C to 120°C for 12 hours, grind it and place it in a muffle furnace Heating at a heating rate of 10°C / min to 500°C for 3 hours to prepare silver-loaded sodium borosilicate ultrafine ceramic powder.

[0036] Step 2: By weight, put 20 parts of ceramic powder in a mixed so...

Embodiment 3

[0040] Step 1: By weight, 2 parts of sodium acetate and 6 parts of boric acid are successively added to 67 parts of ethanol and water mixed solvent, the weight ratio of ethanol to water is 6:4, and 28 parts of boric acid are slowly added under stirring Ethyl orthosilicate, add 0.01mol / L nitric acid solution dropwise to adjust the pH value to 5~6, heat and stir in a water bath at 50°C for 3 hours, add 14 parts of 0.1mol / L silver nitrate solution, and keep the constant temperature at 50°C Stir the reaction for 3 hours in the dark to obtain a uniform and transparent sol, keep the obtained sol in the dark and keep it at a constant temperature until a gel is formed, then dry the gel at a constant temperature of 110°C to 120°C for 12 hours, grind it and place it in a muffle furnace Heating at a heating rate of 10°C / min to 500°C for 3 hours to prepare silver-loaded sodium borosilicate ceramic powder.

[0041] Step 2: Put 20 parts of ceramic powder in a mixed solvent of 80 parts of et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com