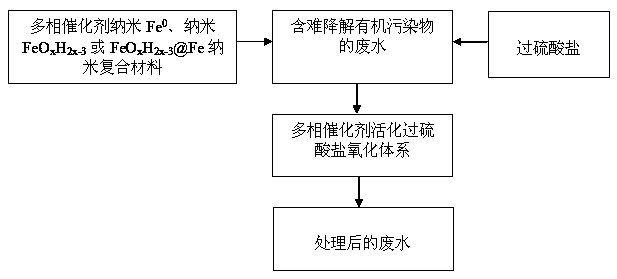

Method for utilizing heterogeneous catalyst to efficiently activate persulfate so as to treat organic wastewater

A technology for activating persulfate and heterogeneous catalysts, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of a large amount of iron sludge and low effective utilization rate of persulfate, and achieve high utilization rate, easy recovery and reuse, no The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

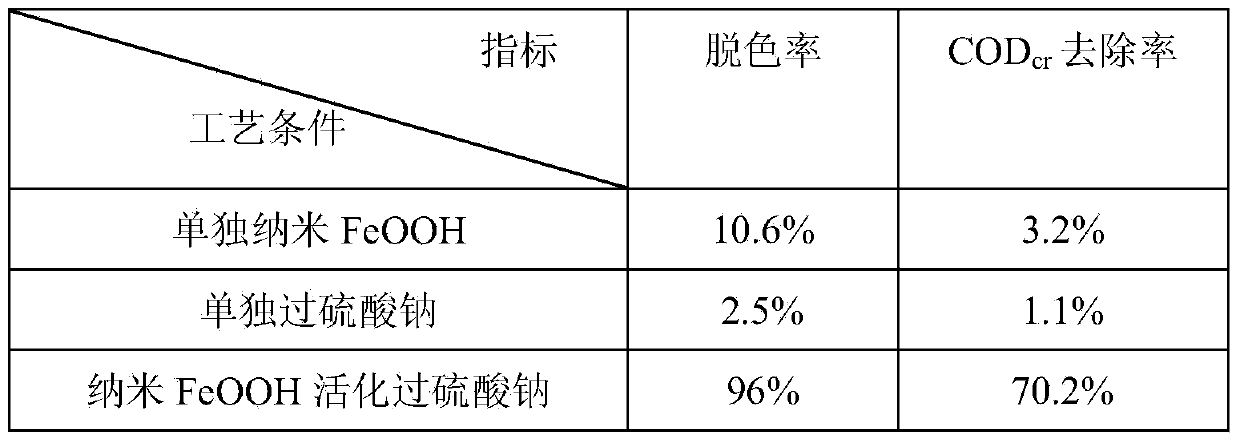

[0038] Embodiment 1: The experiment has compared the decolorization rate and COD of AO7 by using nano-FeOOH to activate sodium persulfate, adding nano-FeOOH and adding sodium persulfate separately cr removal rate.

[0039] Nano-Fe 0 In the heterogeneous reaction of activated sodium sulfate, the Erlenmeyer flask is used as the reactor, the reaction volume of the wastewater is 250mL, and the treatment conditions are that the initial concentration of the wastewater containing AO7 is 70mg / L, COD cr It is 133mg / L, and pH is 7.0, adds nanometer FeOOH and sodium persulfate to make its concentration be respectively 0.5g / L and 476mg / L in reaction bottle simultaneously, and reaction bottle is placed in shaking bed, and rotating speed is 150rpm, temperature is 25°C.

[0040] In the experiment of adding nano-FeOOH alone, there is no need to add sodium persulfate, and other conditions are the same as above.

[0041] In the experiment of adding sodium persulfate alone, there is no need t...

Embodiment 2

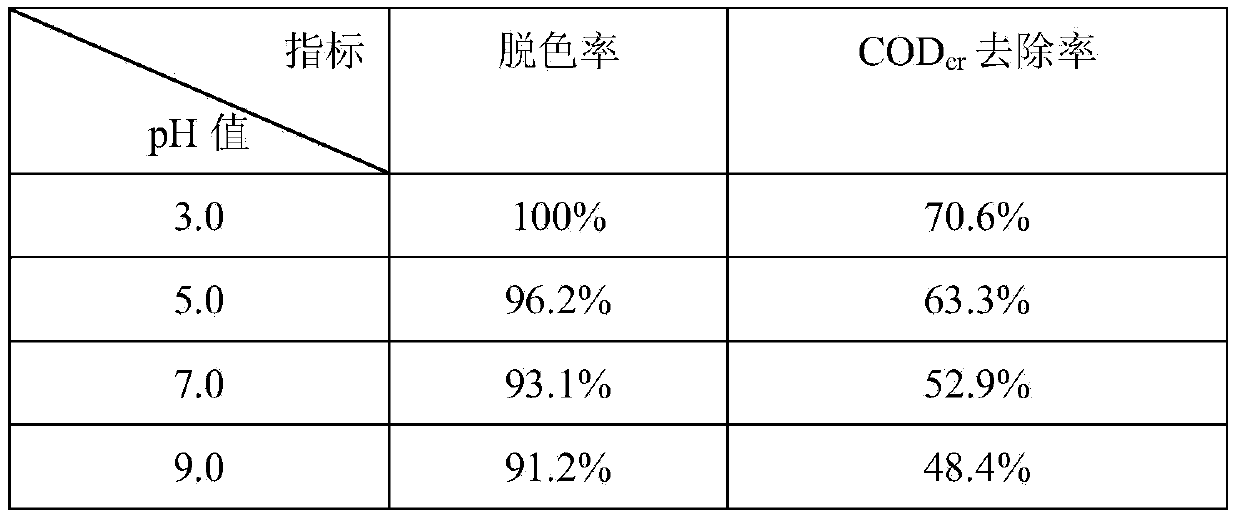

[0047] Embodiment 2: Experiment has compared utilizing nanometer Fe 0 AO7 decolorization rate and COD of activated sodium persulfate under acidic, neutral and alkaline conditions cr removal rate.

[0048] Nano-Fe 0 In the heterogeneous reaction of activated sodium sulfate, the Erlenmeyer flask is used as the reactor, the reaction volume of the wastewater is 250mL, the treatment conditions are that the initial concentration of the wastewater containing AO7 is 70mg / L, and the COD cr to 133mg / L, adjust the pH of the wastewater to four different pH environments of 3.0, 5.0, 7.0, and 9.0, and add nano-Fe to the reaction bottle at the same time 0 and sodium persulfate so that the concentrations were 0.3g / L and 476mg / L respectively, and the reaction bottle was placed in a vibrating bed with a rotating speed of 150rpm and a temperature of 25°C.

[0049] Nano Fe 0 Its shape is regular spherical particles with a particle size of about 50nm.

[0050] The wastewater treatment time is...

Embodiment 3

[0054] Embodiment 3: in this embodiment contrasted different initial concentration AO Waste water solution is in nanometer Fe 2 o 3 Fe 0 Decolorization Efficiency and COD in Activated Sodium Persulfate System cr The effect of removal rate.

[0055] Nano-Fe 2 o 3 Fe 0 In the heterogeneous reaction of activated sodium persulfate, the Erlenmeyer flask is used as the reactor, the reaction volume of the wastewater is 250mL, the initial concentration of the wastewater containing AO7 is changed, the pH of the wastewater is not adjusted (pH is 3.8), and nano Fe 2 o 3 Fe 0 Make the concentration 0.5g / L and sodium persulfate, the ratio of the concentration of sodium sulfate added (mg / L) to CODcr (mg / L) is 5:1.

[0056] Finally, the reaction bottle was placed in a vibrating bed with a rotation speed of 150 rpm and a temperature of 25°C.

[0057] Nano Fe 2 o 3 Fe 0 Its form is regular spherical particles with a particle size of 80-100nm.

[0058] The wastewater treatment tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com