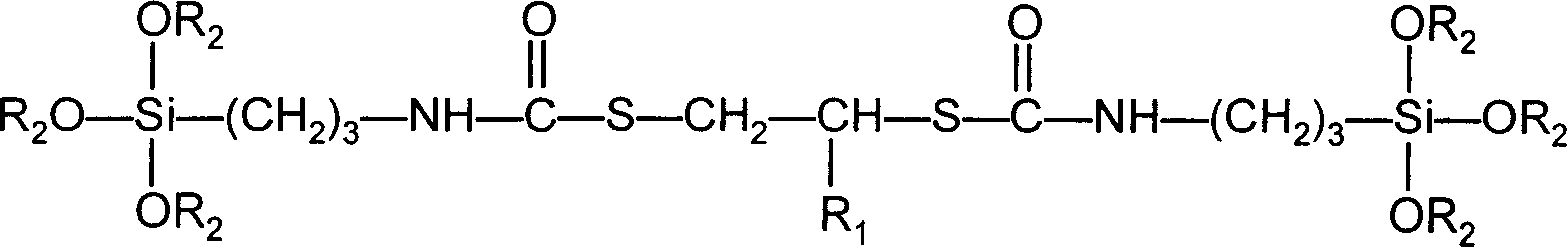

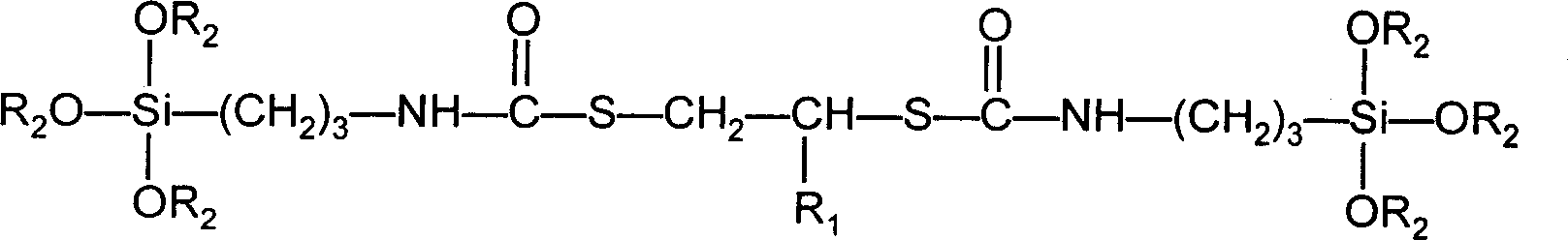

Bisilane coupler contg. sulfur and nitrogen element and prepn. thereof

A technology of double silane coupling agent and nitrogen element, which is applied in the field of double silane coupling agent containing sulfur and nitrogen elements and its preparation, can solve the problem of rubber scorch, increased Mooney viscosity, and unfavorable white carbon black particles. Dispersion, rubber porosity and other problems, to achieve the effect of not easy to scorching rubber, obvious coupling effect, and conducive to dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using γ-isocyanatopropyltrimethoxysilane and 1,2-propanedithiol as raw materials to prepare a sulfur- and nitrogen-containing disilane coupling agent:

[0026] Add 7.80L of benzene into a reaction vessel equipped with a reflux condenser, a stirrer and a thermometer, add 2mol (410g) of γ-isocyanatopropyltrimethoxysilane to make a solution with a mass concentration of 5%, add 1mol (100g) 1,2-Propanedithiol, 380mg triethylamine, controlled temperature at 40°C, reacted under mechanical stirring and reflux conditions for 24h, and distilled the filtrate under reduced pressure to remove low-boiling fractions to obtain a light yellow liquid product with a yield of 75.6 %.

Embodiment 2

[0028] Using γ-isocyanatopropyltriethoxysilane and 1,2-butanedithiol as raw materials to prepare a sulfur- and nitrogen-containing disilane coupling agent:

[0029] Add 99ml of toluene into a round-bottomed three-necked flask equipped with a reflux condenser, a stirrer and a thermometer, add 0.1mol (24.7g) of γ-isocyanatopropyltriethoxysilane to make a solution with a mass concentration of 20%, add 0.05mol (5.7g) 1,2-butanedithiol, 280mg tri-n-propylamine, controlled temperature at 100°C, reacted for 5h under mechanical stirring and reflux conditions, and distilled the filtrate under reduced pressure to remove low-boiling fractions to obtain light yellow Liquid product, yield 92.3%.

Embodiment 3

[0031] Using γ-isocyanatopropyltrimethoxysilane and 1,2-pentanedithiol as raw materials to prepare a sulfur- and nitrogen-containing disilane coupling agent:

[0032] Add 370ml of ethylbenzene into a three-necked round-bottomed flask equipped with a reflux condenser, a stirrer and a thermometer, add 0.2mol (41g) of γ-isocyanatopropyltrimethoxysilane to form a solution with a mass concentration of 10%, and add 0.1mol (12.8g) of 1,4-butanedithiol, 130mg of tributyltin hydroxide, controlled temperature at 80°C, reacted under mechanical stirring and reflux conditions for 15h, distilled the filtrate under reduced pressure to remove low-boiling fractions, and obtained Yellow liquid product, yield 84.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com