Device for controlling delivery and uniform distribution of reaction gases in MOCVD reaction chamber

A technology of uniform distribution of reactive gas, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of high manufacturing cost and high welding processing requirements, and achieve the effect of reducing production cost and controlling consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

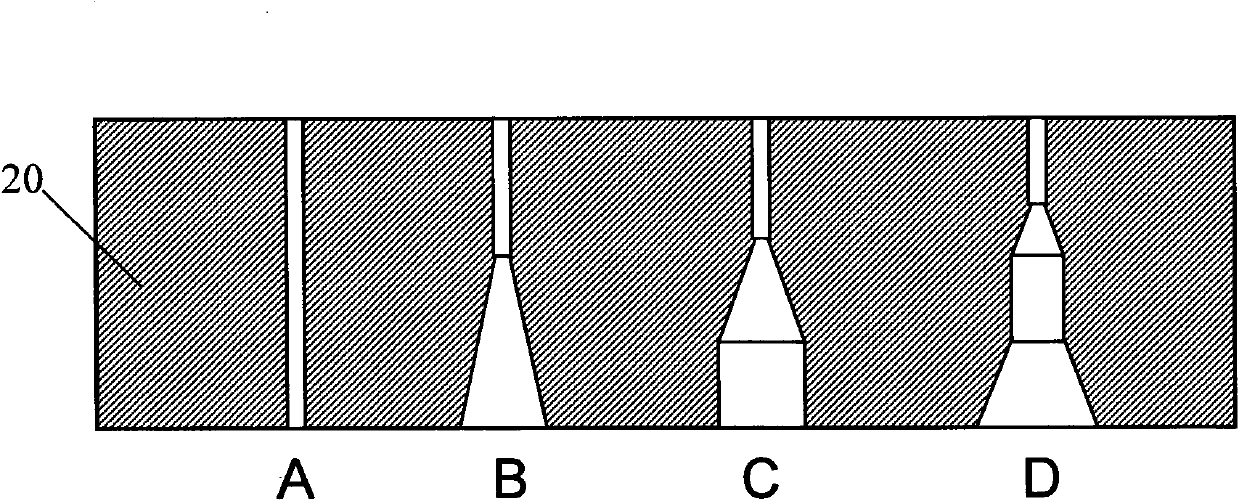

[0056] The specific implementation of the present invention will be described below by taking the introduction and control of the uniform distribution of two reactive gases as an example with reference to the accompanying drawings. Wherein, the flow direction of the first reaction gas is indicated by solid arrows, the flow direction of the second reaction gas is indicated by dovetail arrows; the dotted arrows are used to indicate the direction of heat transfer.

[0057] Such as Figure 4 As shown, the device used in the present invention for controlling the delivery and uniform distribution of reaction gases in the MOCVD reaction chamber is connected to the reaction chamber cover 51 at the top of the reaction chamber 50, and the bottom surface is parallel to the surface of several epitaxial wafers 531 placed on the tray 53 . The MOCVD reaction chamber also includes a heater 54 arranged under the tray 53 and an exhaust port 55 arranged at the bottom of the MOCVD reaction chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com