Patents

Literature

37results about How to "Control the rate of diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid fracturing process of oil gas well mining temperature control various mucic acid

ActiveCN101353958AReduce fluid lossEasy to form non-uniform etchingFluid removalDrilling compositionAcid etchingMucic acid

The invention relates to an acid fracturing method of a temperature-control and variable-viscosity acid in the exploitation of an oil-gas well, which comprises the steps that: a common chlorohydric acid pickling process is firstly used for removing the pollution of an embrasure; then, the temperature-control and variable-viscosity acid fracturing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing process, or a temperature-control and variable-viscosity acid fracturing enclosed acidizing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing enclosed acidizing process is adopted; the weight ratio of the components of the temperature-control and variable-viscosity acid are as follows: 100 portions of basic acid solution, 0.5 portion to 1.5 portions of the main agent of the temperature-control and variable-viscosity acid, 1 portion to 3 portions of a corrosion inhibitor of the temperature-control and variable-viscosity acid, 0.5 portion to 1 portion of an emulsion breaker, 0.5 portion to 1 portion of a ferric ion stabilizer and 0.5 portion to 1 portion of a high efficient discharge aiding agent; 2-percent KCL clear water is used for displacing the temperature-control and variable-viscosity acid into the stratum. The temperature-control and variable-viscosity acid is easily prepared on site, with low friction drag and strong pumpability, thereby being capable of being applied to high-discharge construction; under the high temperature condition of a storing layer, both the fresh acid and the residue acid have high viscosity, thus increasing the length of acid-etching cracks. After the construction is finished, the viscosity of the residue acid is reduced, which is beneficial to the back discharge of the residue acid.

Owner:PETROCHINA CO LTD

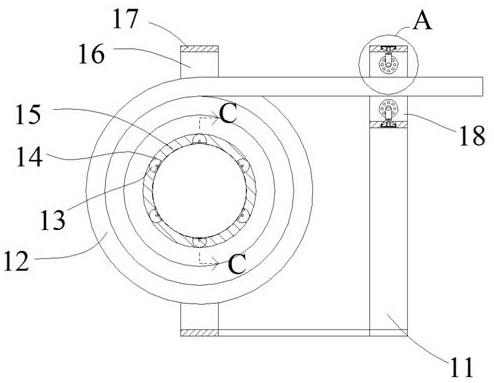

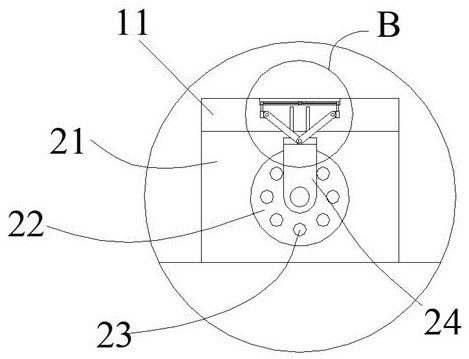

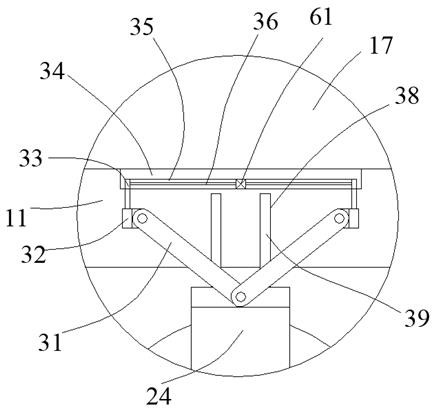

Device for controlling delivery and uniform distribution of reaction gases in MOCVD reaction chamber

ActiveCN101914761AReduce manufacturing costControl consumptionChemical vapor deposition coatingSystem capacityEngineering

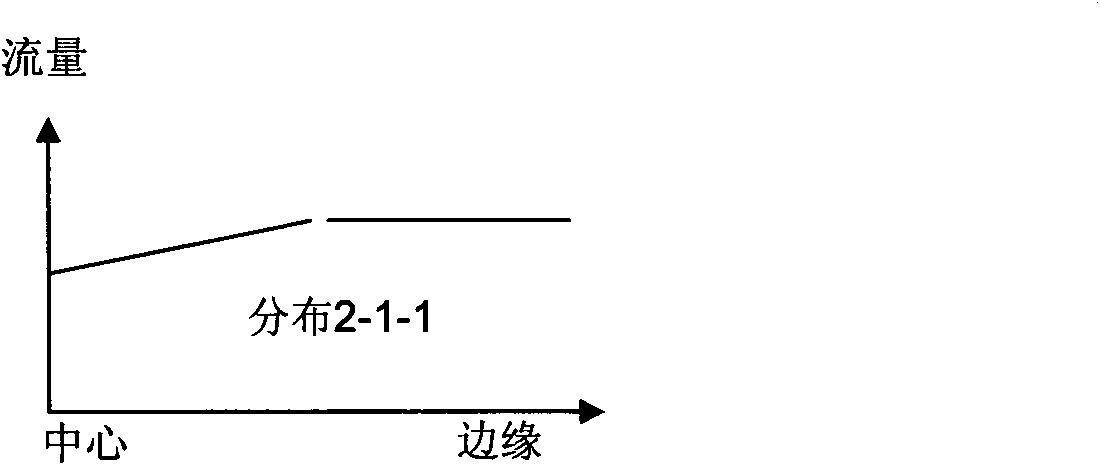

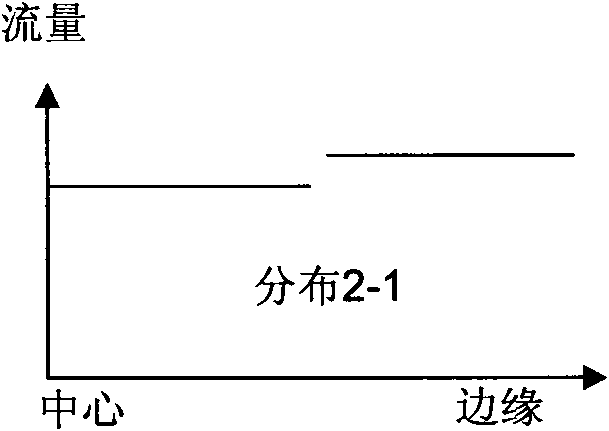

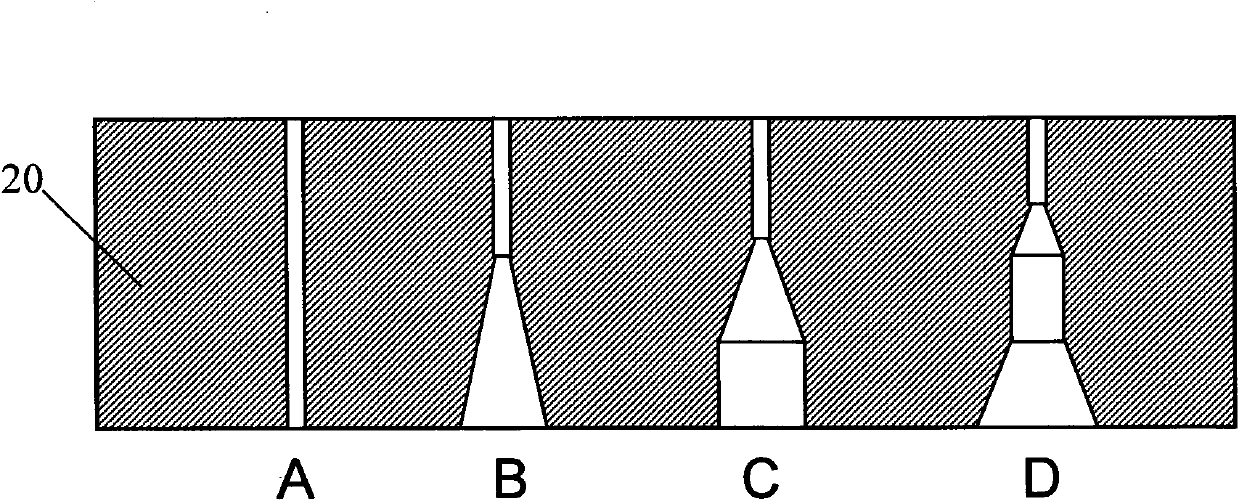

The invention discloses a device for controlling the delivery and the uniform distribution of reaction gas in a MOCVD reaction chamber. By respectively controlling the flow of gas passages non-uniformly distributed radially on a front gas homogenizing plate and input passages at different positions, at least two reaction gases are respectively introduced into two paths which are radially and axially crossed on a spray header, and can be secondarily distributed by nozzles in different shapes, so the uniformly distributed boundary layer concentration, speed and temperature required are achieved on the surface of a rotary epitaxial wafer, the quality of massively produced epitaxial films and the finished product ratio of massively produced epitaxial wafers are improved, the consumption of expensive reaction gases can be effectively controlled and the epitaxial production cost is reduced. By properly increasing the distance between the surface of the spray header and the epitaxial wafer, deposits generated on the surface of the spray header and the nozzles in the epitaxial growth are reduced, the cleaning period is prolonged, and the production efficiency and system capacity are improved. The device also can reduce the processing difficulty and manufacturing cost of the nozzles of the spray header and cooling medium passages.

Owner:JIANGSU ZHONGSHENG SEMICON EQUIP

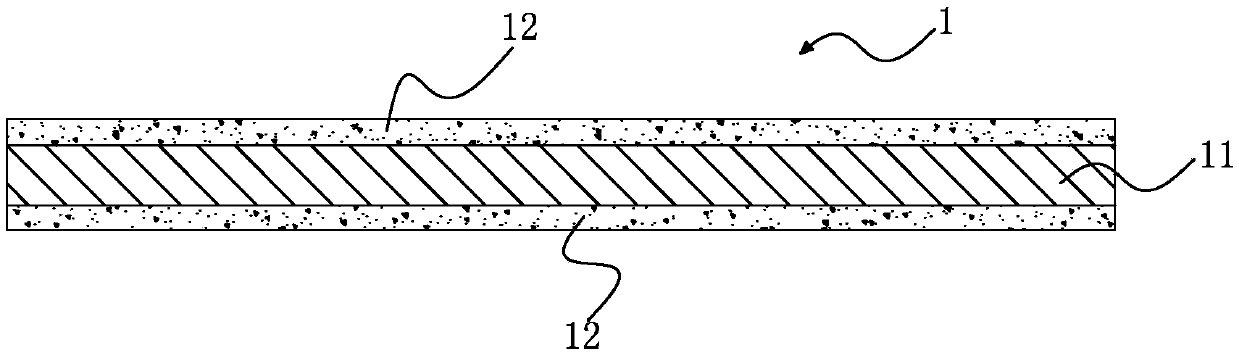

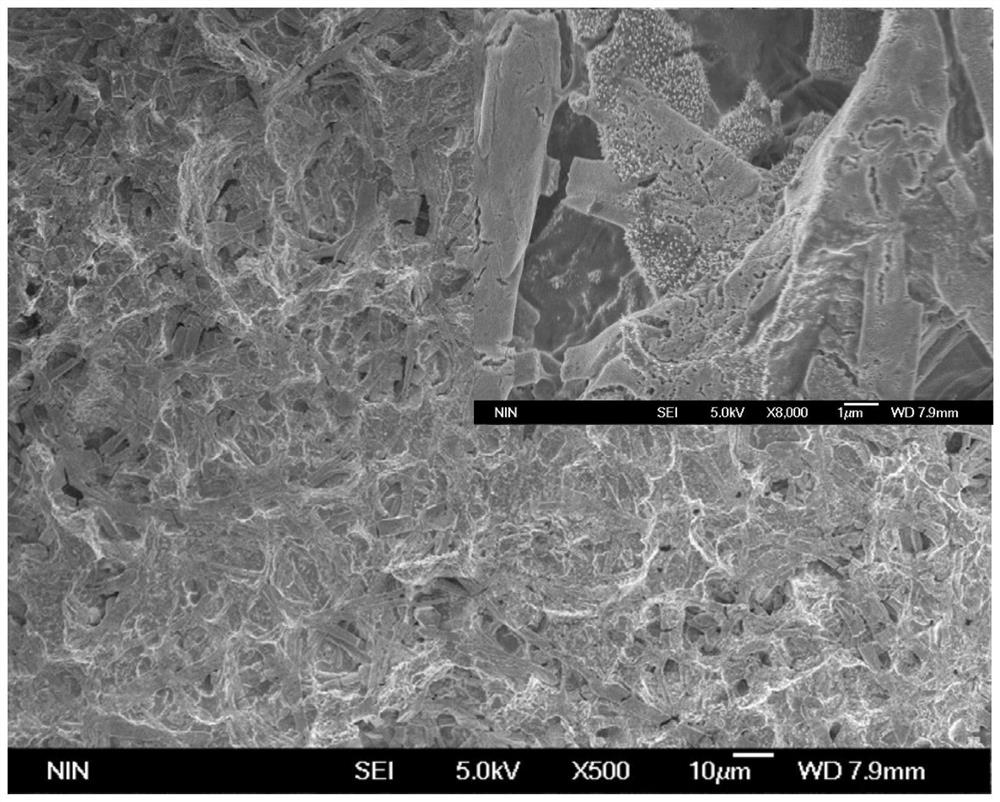

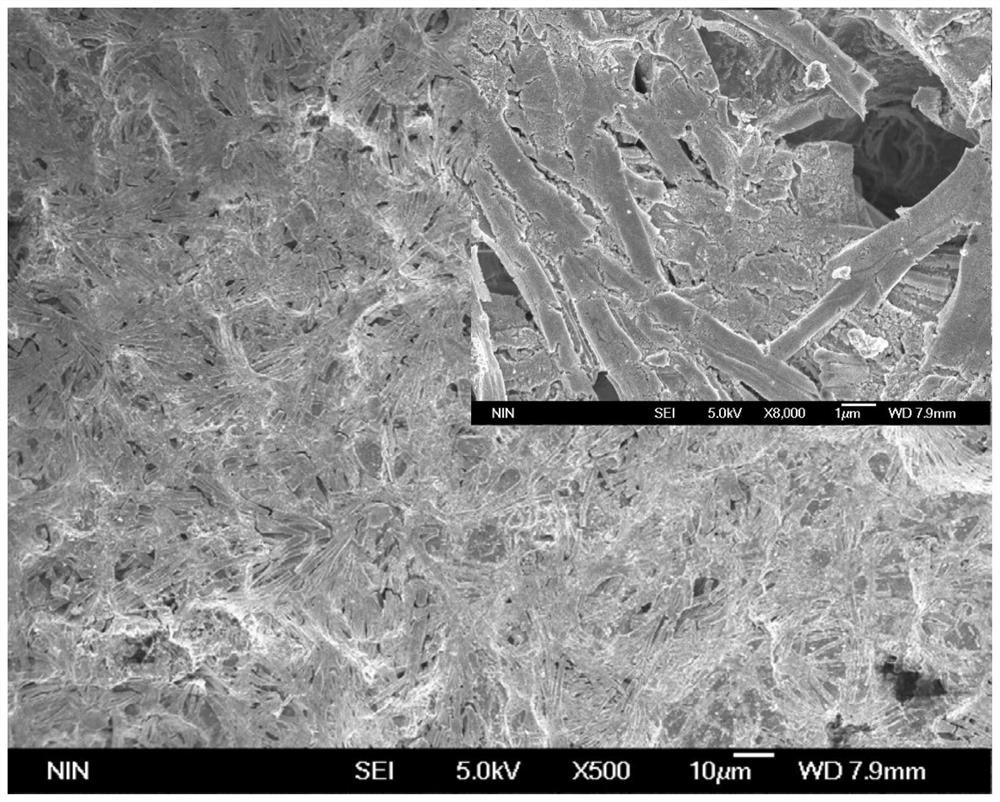

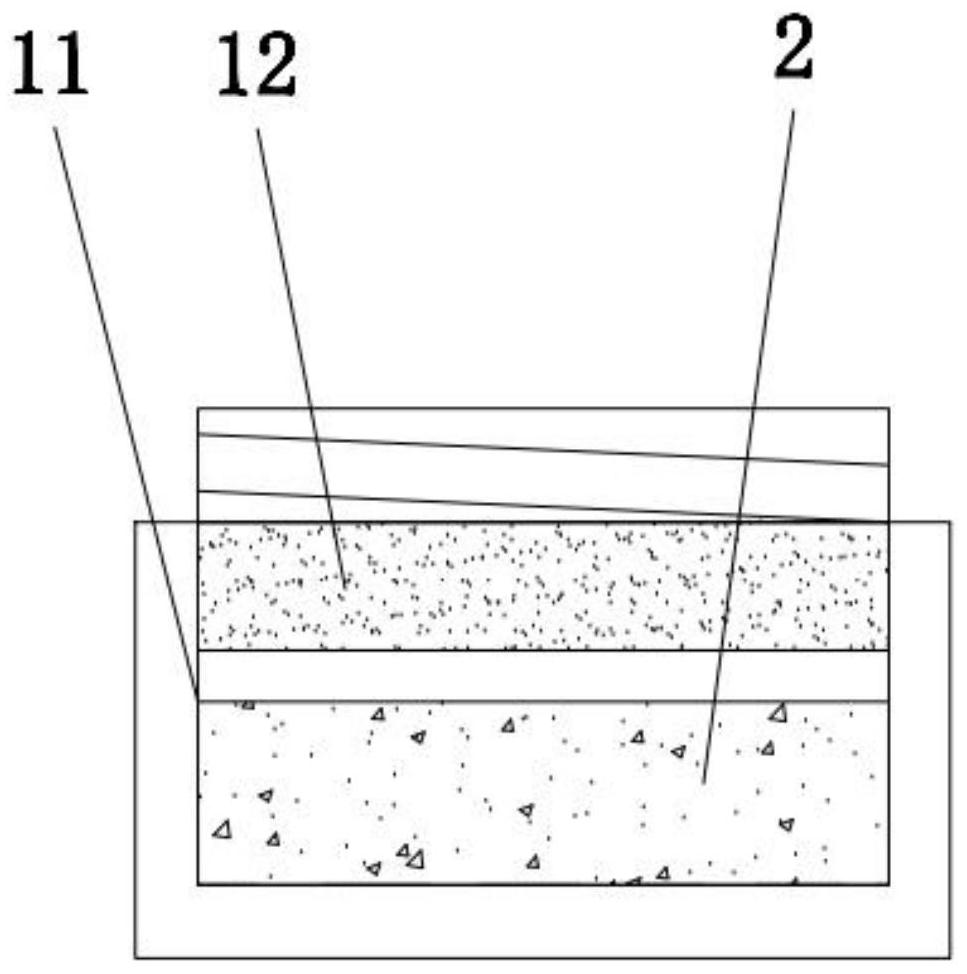

Impact-resistant and corrosion-proof cement-based composite material and preparation method thereof

The invention relates to an impact-resistant and corrosion-proof cement-based composite material and a preparation method thereof. The impact-resistant and corrosion-proof cement-based composite material comprises a cementing material, aggregate, steel fibers, polypropylene fibers, carbon nanotubes, polyvinyl alcohol, a water reducing agent and water. The mass ratio of the cementing material: the aggregate: the water is 1: 0.8-1: 0.26-0.32. With the weight of the cementing material counted as 100 parts, the composite material comprises 0.6-1.0 part of steel fibers, 0.5-0.8 part of polypropylene fibers, 1-1.5 parts of carbon nanotubes, 0.5-1 part of water reducing agent and 0.18-0.32 part of polyvinyl alcohol. According to the technical scheme of the preparation method, firstly, polypropylene fibers, carbon nanotubes, the water reducing agent and the polyvinyl alcohol are added into water and then obtained materials are stirred. Secondly, the cementing material and the aggregate are added and then obtained materials are stirred. Thirdly, the steel fibers are added and then obtained materials are stirred. Finally, obtained materials are subjected to casting, vibrating and molding to obtain the impact-resistant and corrosion-proof cement-based composite material.

Owner:WUHAN UNIV OF TECH

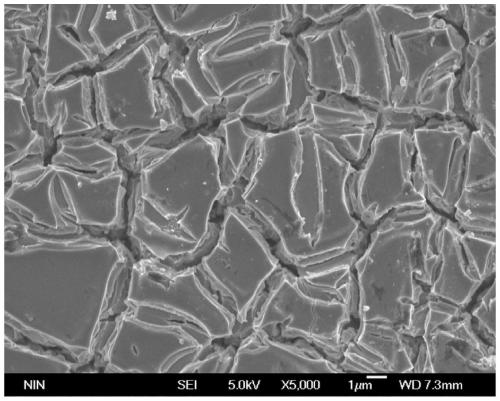

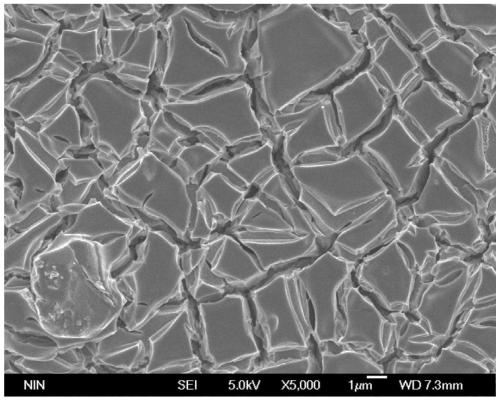

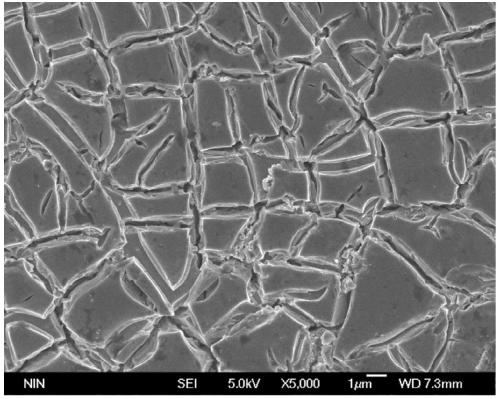

Grain boundary diffusion method of R-Fe-B rare-earth sintered magnet, HRE diffusion source and fabrication method thereof

InactiveCN107871602ASmall surface areaAdjustment methodInductances/transformers/magnets manufactureMagnetic materialsDiffusion methodsRare-earth element

The invention discloses a grain boundary diffusion method of an R-Fe-B rare-earth sintered magnet, an HRE diffusion source and a fabrication method thereof. The grain boundary diffusion method comprises the following steps of forming film engineering A on a high-temperature resistant carrier, wherein HRE compound powder is attached onto the film, and the HRE is selected from at least one of Dy, Tb, Gd and Ho; and placing the R-Fe-B rare-earth sintered magnet and the high-temperature resistant carrier processed by the engineering A in a processing room, performing thermal treatment on the R-Fe-B rare-earth sintered magnet and the high-temperature resistant carrier in vacuum or inert atmosphere, and supplying HRE engineering B to a surface of the R-Fe-B rare-earth sintered magnet from the high-temperature resistant carrier. By the method, consumption of a heavy rare-earth element can be reduced, and the loss of residual magnetism Br of the magnet is controlled as well as the coercivity is improved.

Owner:XIAMEN TUNGSTEN

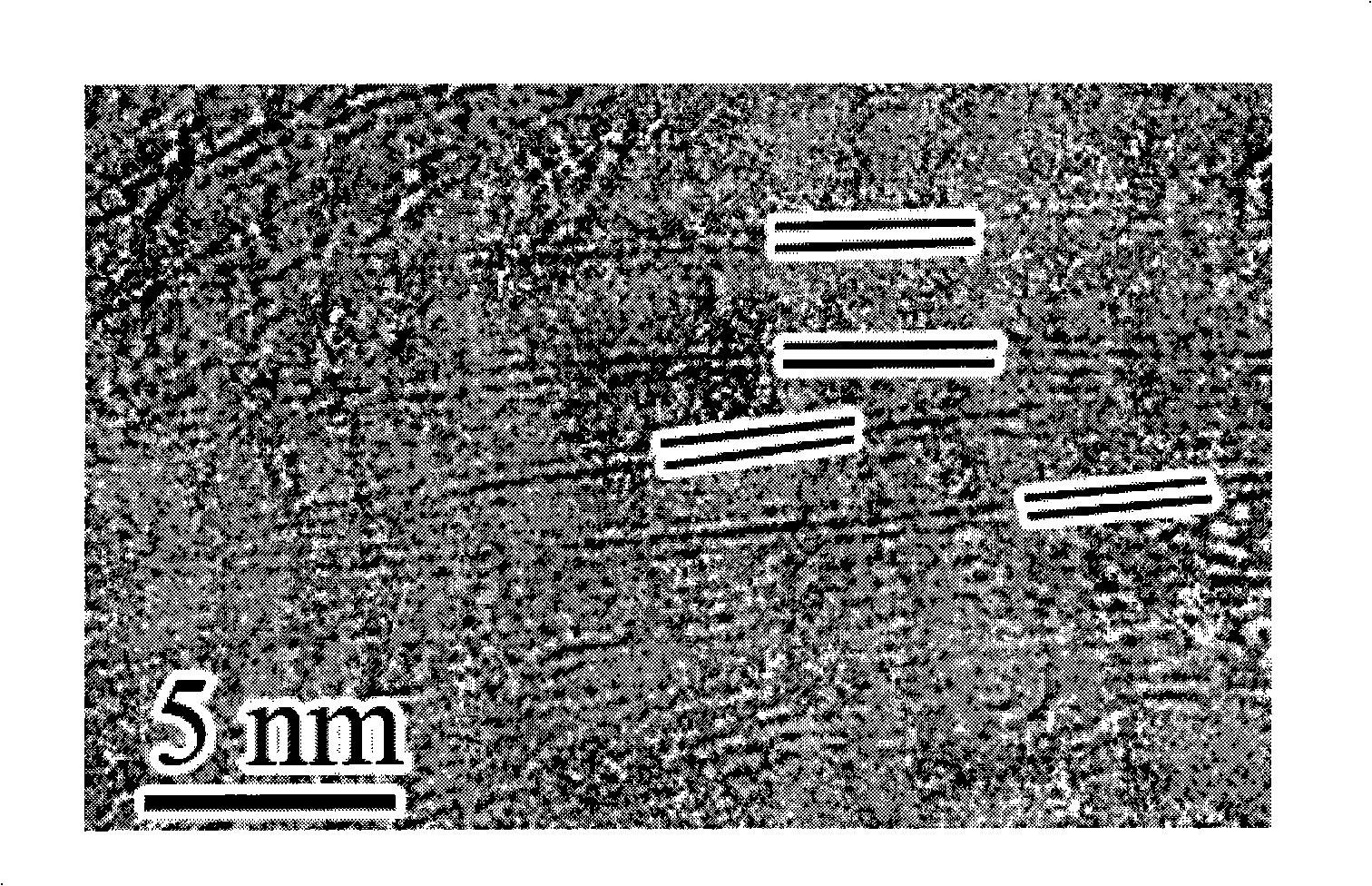

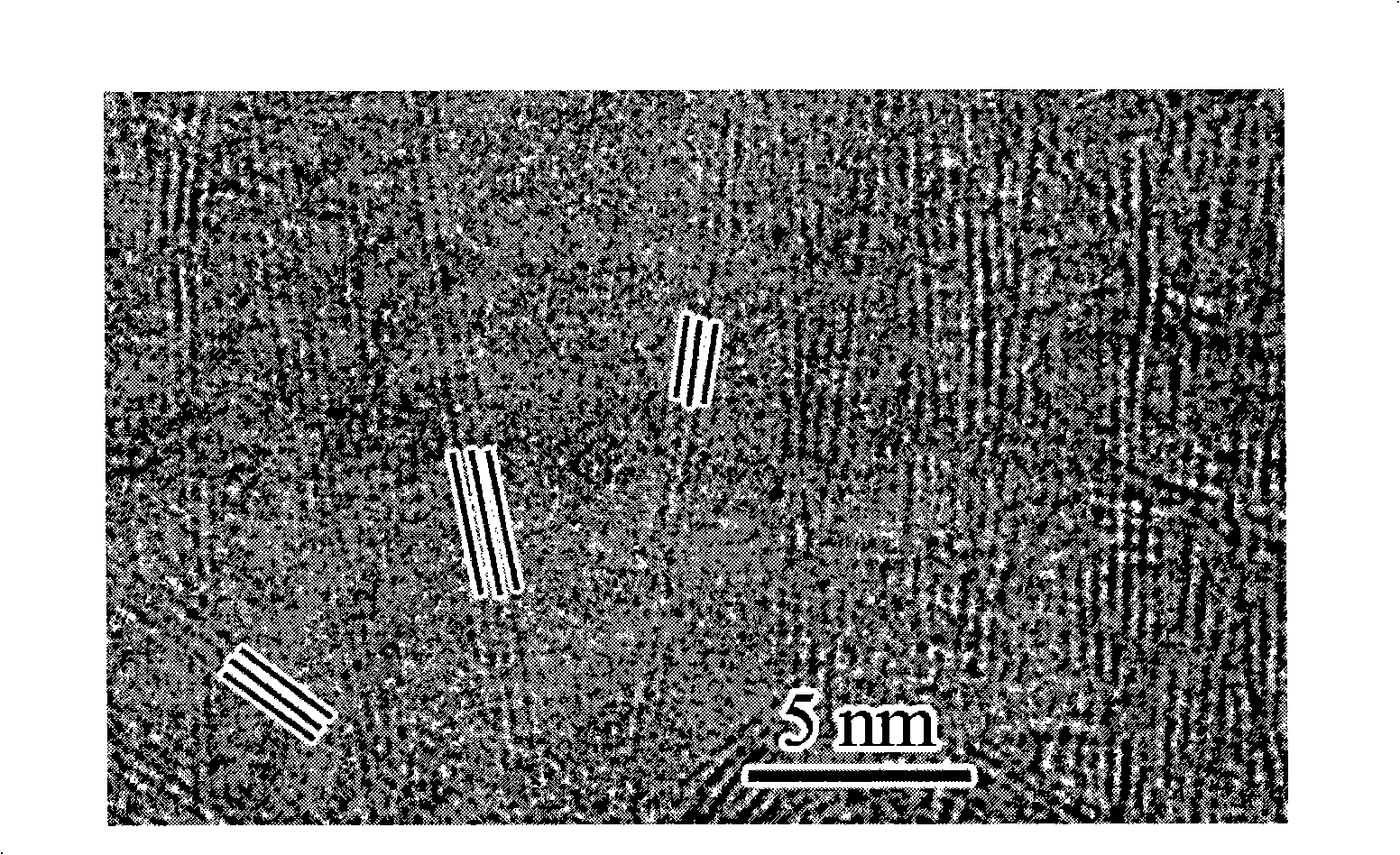

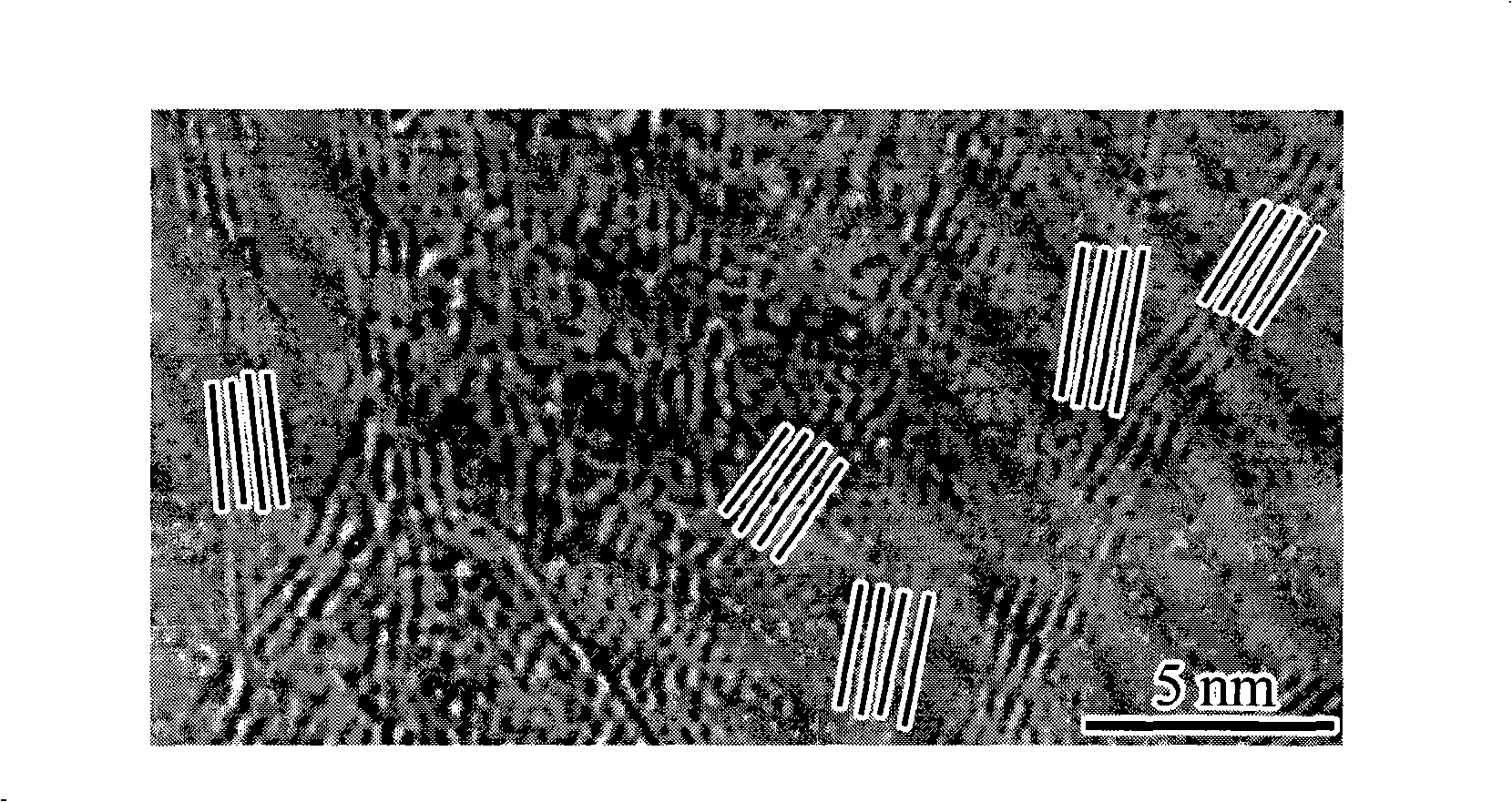

Preparation of tube wall layer number-controllable nano-carbon tube

InactiveCN101302006AControl the rate of diffusionControl the number of pipe wall layersPolycrystalline material growthFrom chemically reactive gasesCarbon nanotubeNano carbon

The invention discloses a method for preparing a carbon nano-tube with controllable number of tube wall layers. The method comprises the following steps of: preparing transition metal salt, support salt and dispersant into sol or solution with de-ionized water after the transition metal salt, the support salt and the dispersant are mixed, and drying the sol or the solution with a sol-gel method or a freeze-drying method, thereby acquiring catalyst; putting the catalyst into a catalyst chamber which is sent into a thermostatic reactor of a CVD device and feeding carbon source gas in the protecting atmosphere to grow the carbon nano-tube. The method can control the diffusion velocity of carbon atoms in metallic nano-particles through changing the flow rate of the carbon source gas and the mol ratio of the transition metal salt to the support salt to the dispersant, thereby controlling the number of the tube wall layers of the carbon nano-tube. The method has a simple process, and prepares the carbon nano-tube with controllable number of the tube wall layers with high purity, thereby overcoming the defects that the prior prepared multi-wall carbon nano-tube is actually a carbon nano-tube mixture with uncertain number of tube wall layers, and providing a foundation for scientific research on various carbon nano-tubes with different numbers of the tube wall layers.

Owner:ZHEJIANG UNIV

Preparation method of titanium anode for water treatment

PendingCN111099702AExtended service lifeReduce manufacturing costWater/sewage treatmentLiquid/solution decomposition chemical coatingPhysical chemistryTitanium

The invention relates to a preparation method of a titanium anode for water treatment. The preparation method specifically comprises the following steps: carrying out pretreatment on a titanium substrate; preparing an active coating solution; and performing sintering. WO3 which is good in chemical stability, has catalytic activity and is low in cost is introduced into a traditional ruthenium-titanium active component, the service life of the anode is effectively prolonged, and the manufacturing cost of the anode is reduced.

Owner:XIAN TAIJIN INDAL ELECTROCHEM TECH

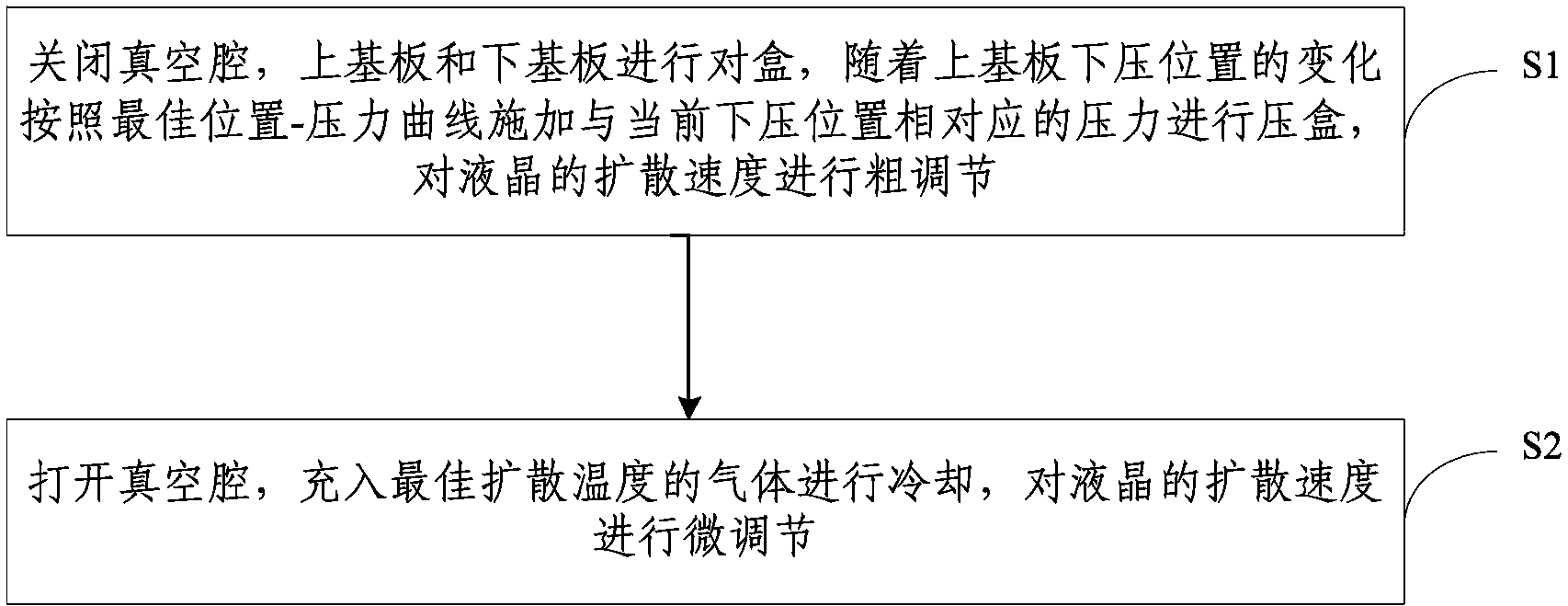

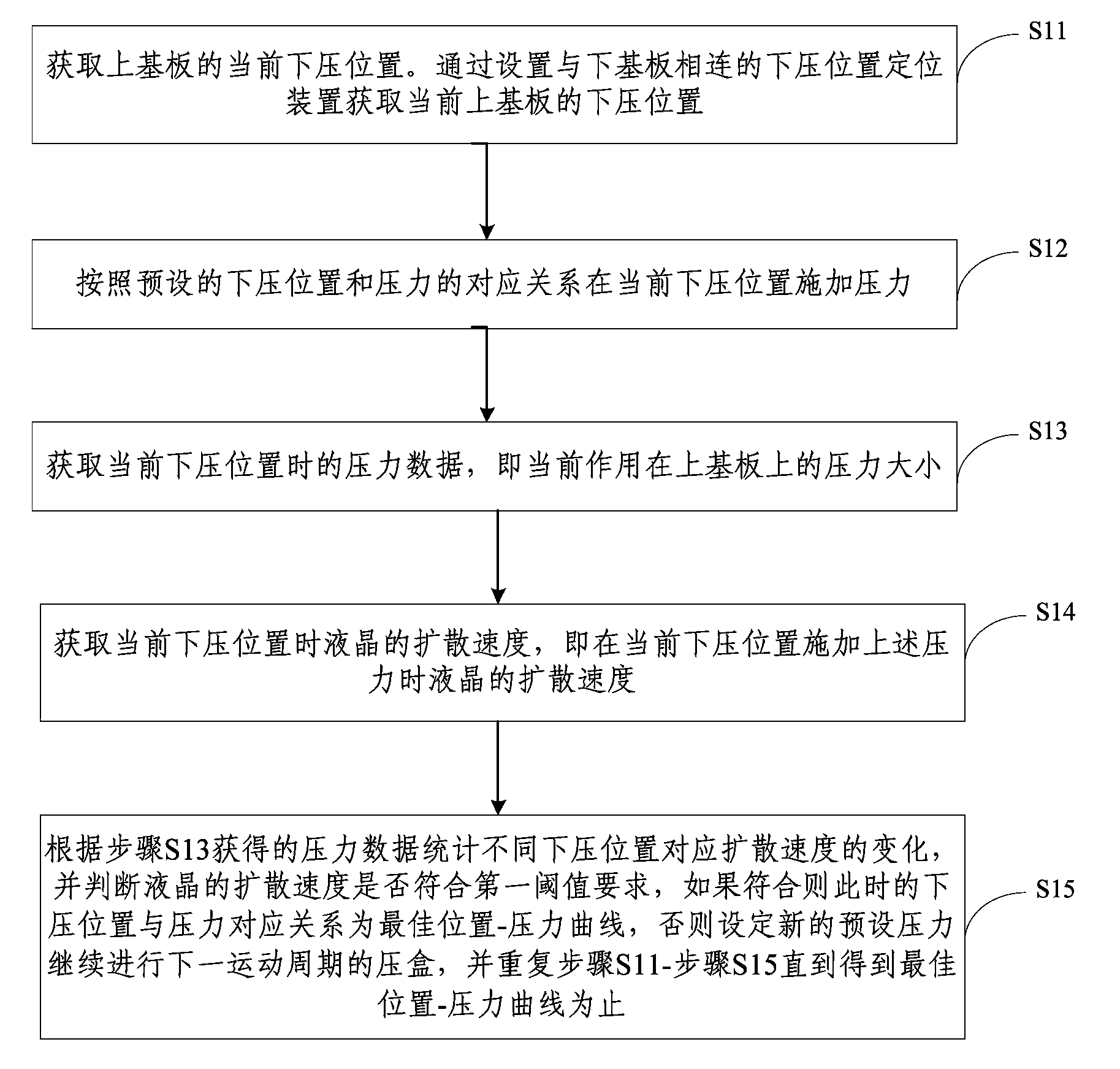

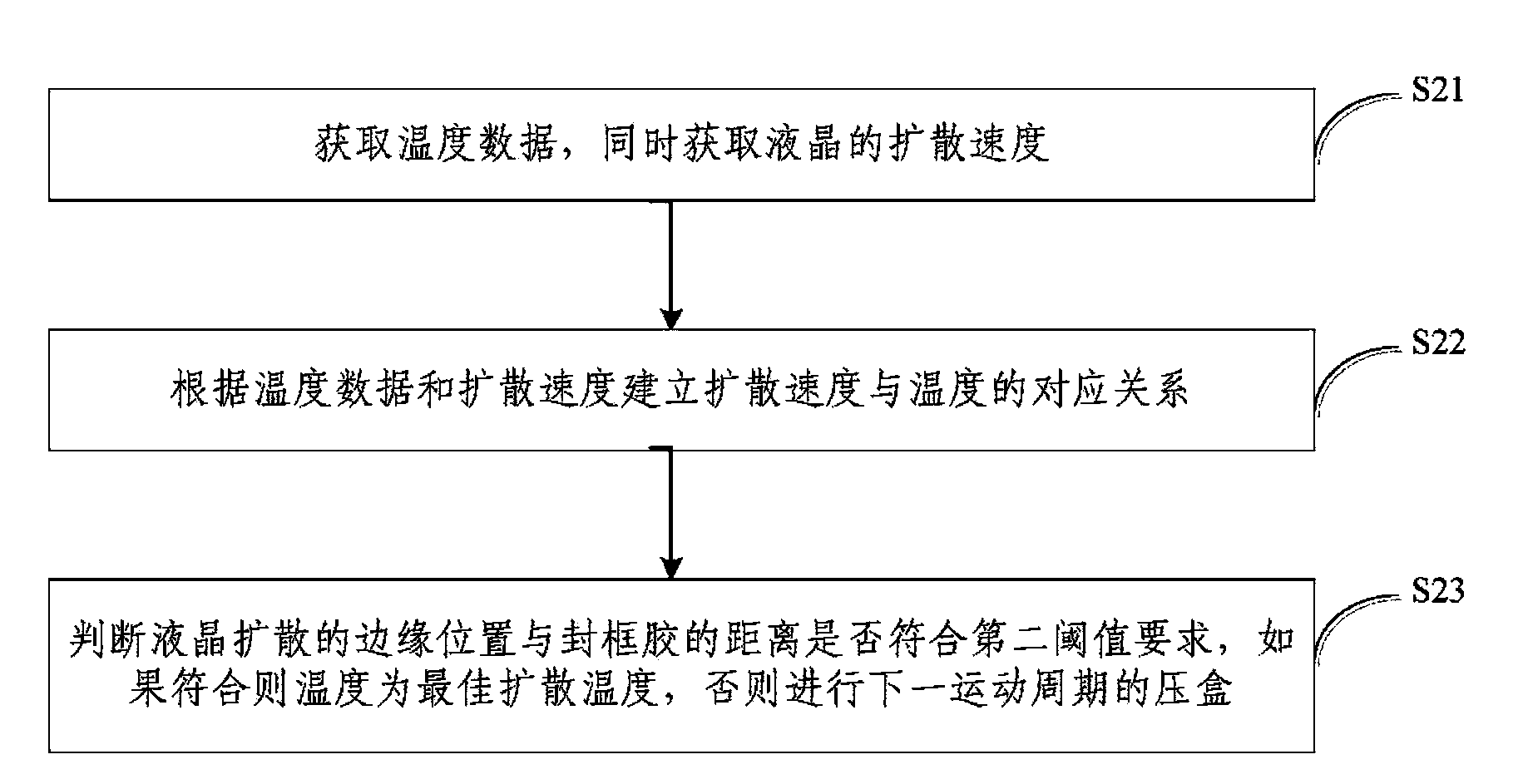

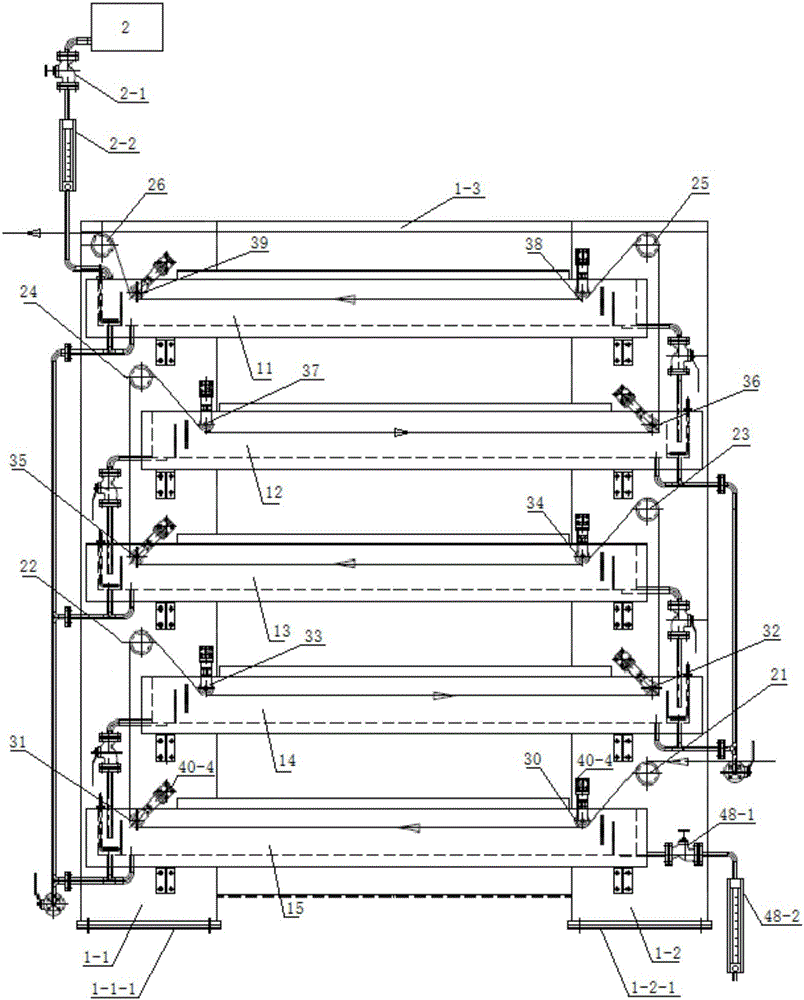

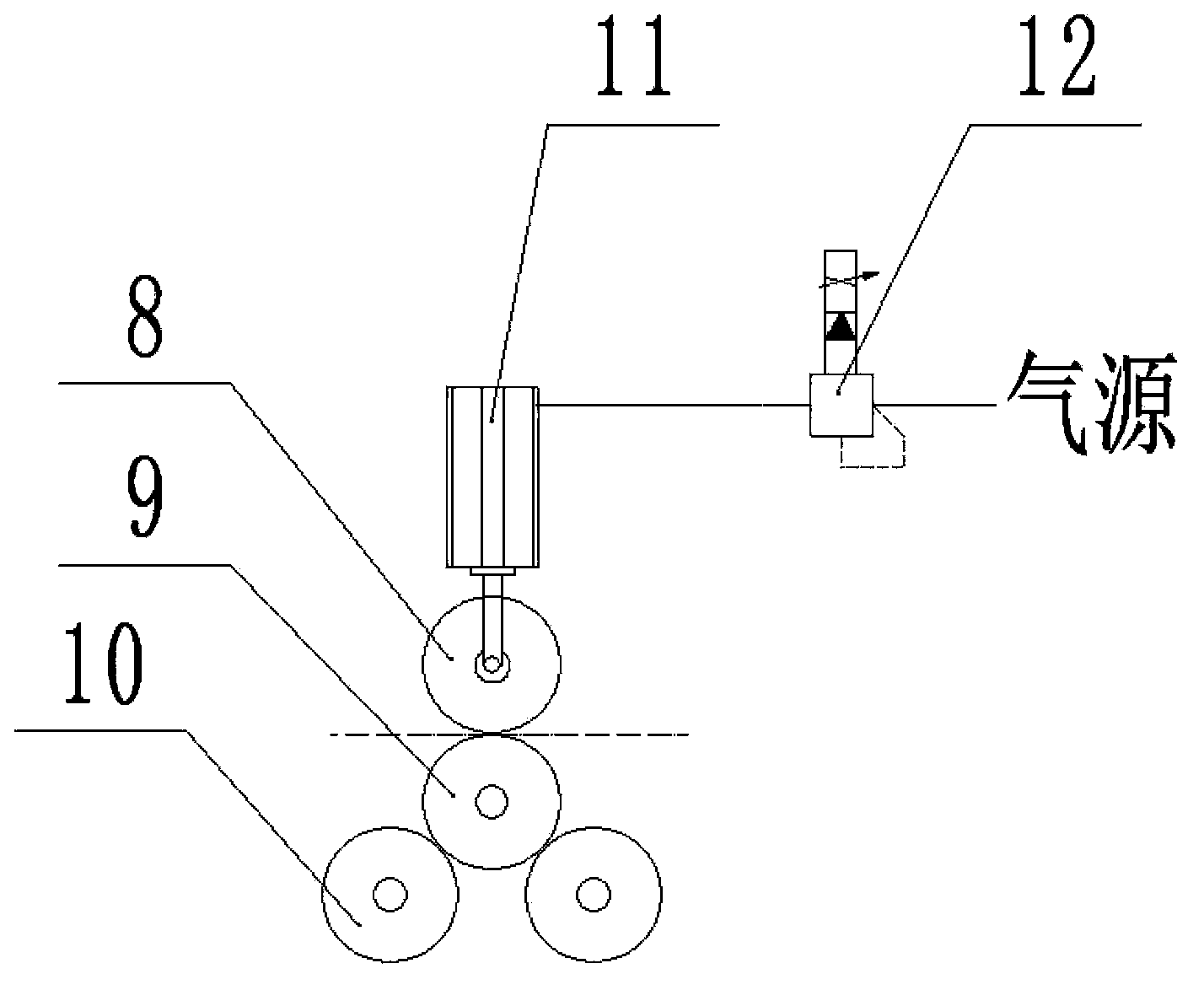

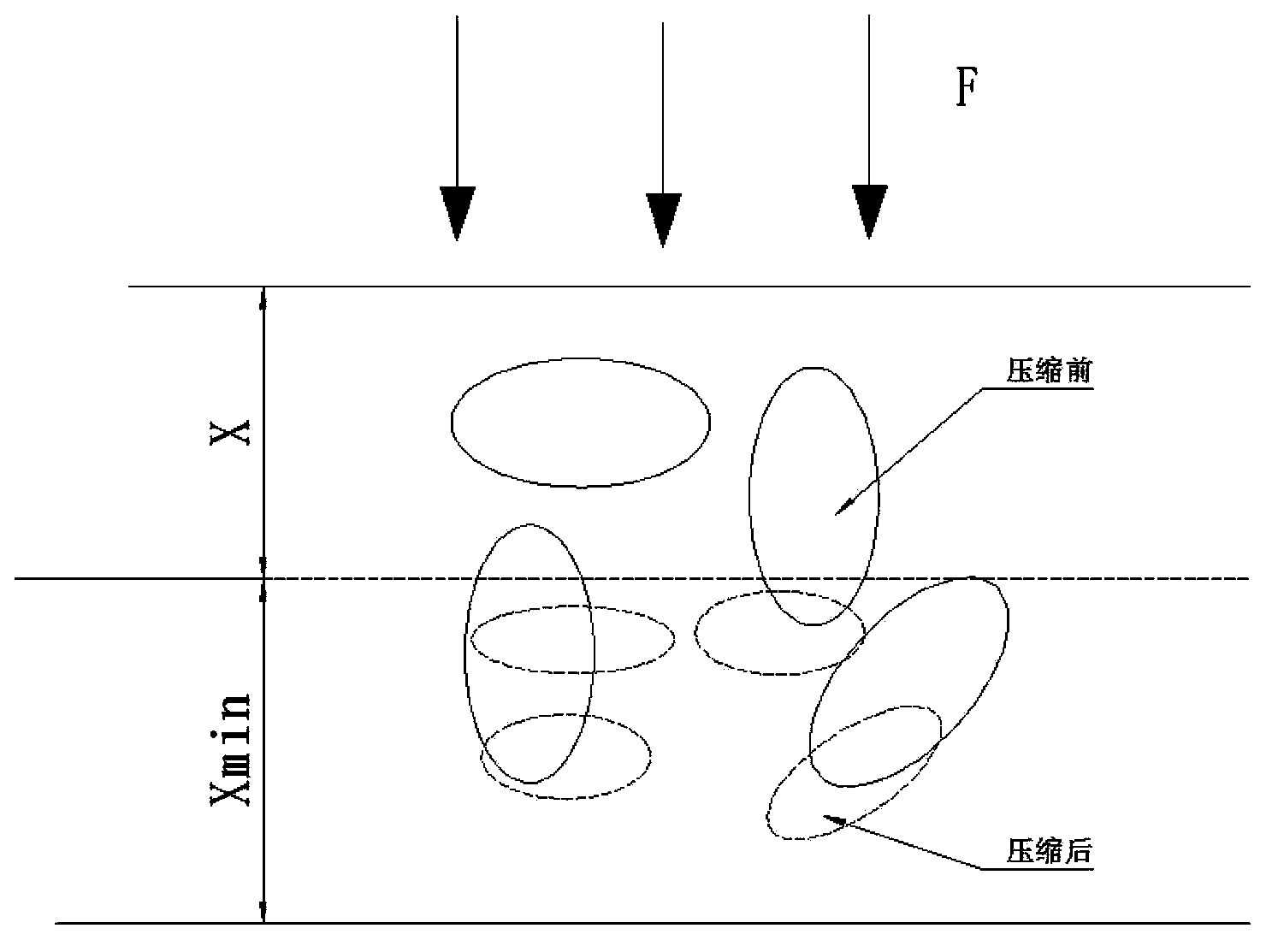

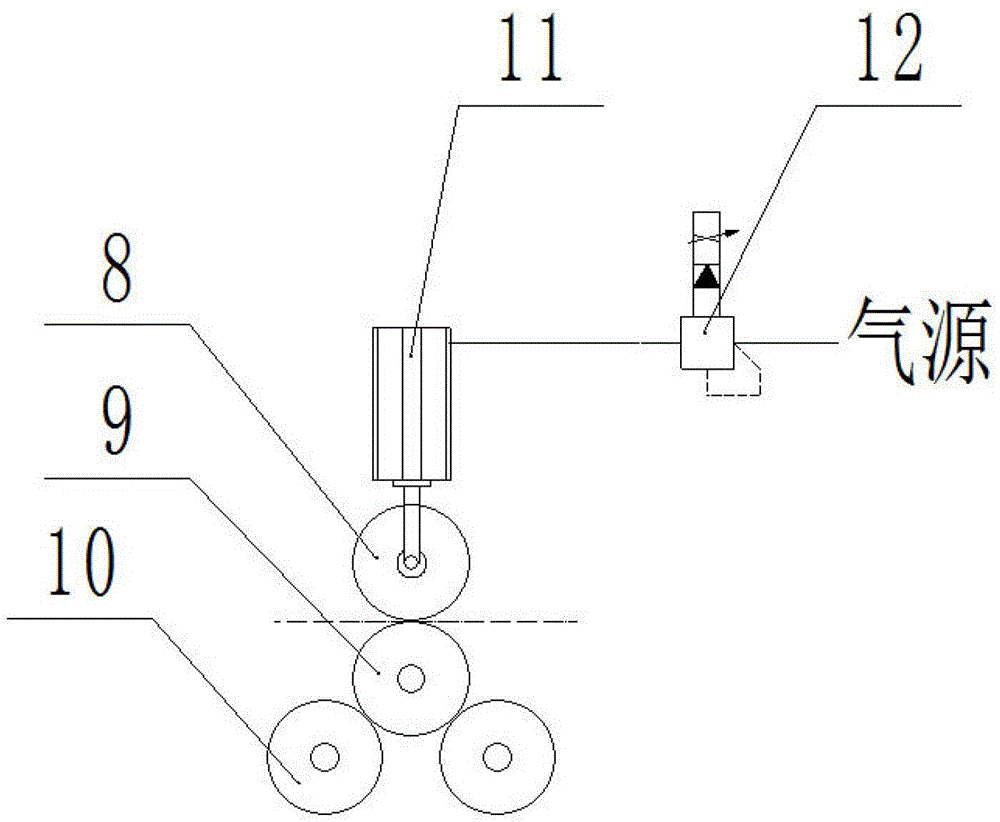

Method and system for controlling liquid crystal diffusion velocity and cell pressing device

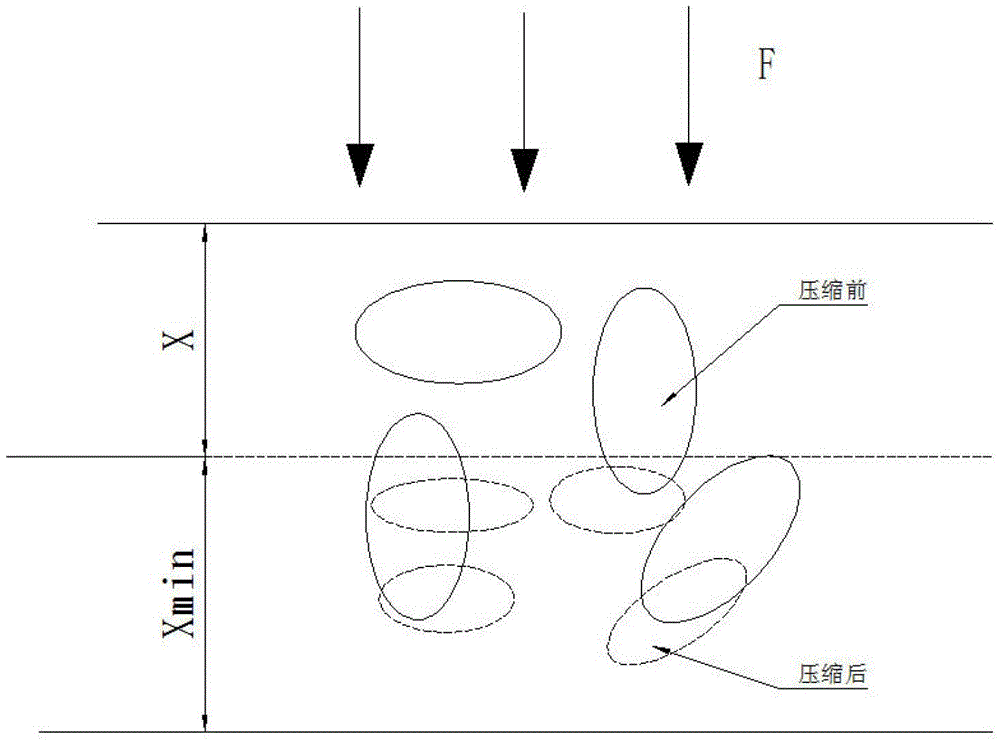

InactiveCN103529582AControl the rate of diffusionDiffusion speed fine-tuningNon-linear opticsLiquid crystallineVacuum chamber

The invention discloses a method for controlling the liquid crystal diffusion velocity. According to the method, a vacuum chamber is closed, an upper substrate and a lower substrate are aligned, pressure corresponding to the current pressing position is applied according to an optimal position-pressure curve along with the change of the pressing position of the upper substrate to achieve cell pressing, and then coarse adjustment is carried out on the liquid crystal diffusion velocity; air with the optimal diffusion temperature is added into the vacuum chamber to achieve cooling, and then fine adjustment is carried out on the liquid crystal diffusion velocity. In a cell pressing process, pressure is adjusted according to the pressing position of the upper substrate, the liquid crystal diffusion velocity is then controlled, and liquid crystal is diffused fast under the action of the pressure; the vacuum chamber needs to be opened when the liquid crystal is diffused to a position close to frame sealing glue, the diffusion velocity is reduced by adding the air with the optimal diffusion temperature to achieve cooling, then fine adjustment is carried out on the liquid crystal diffusion velocity, the liquid crystal is prevented from being diffused to the position of the frame sealing glue to react with the frame sealing glue to cause glue breaking, and then liquid crystal leakage is avoided.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

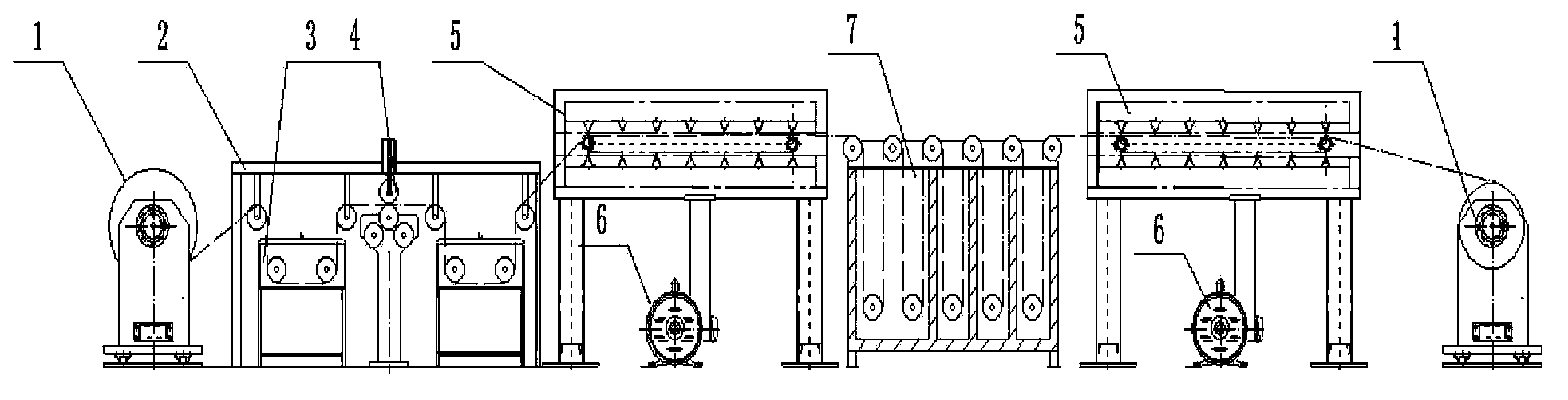

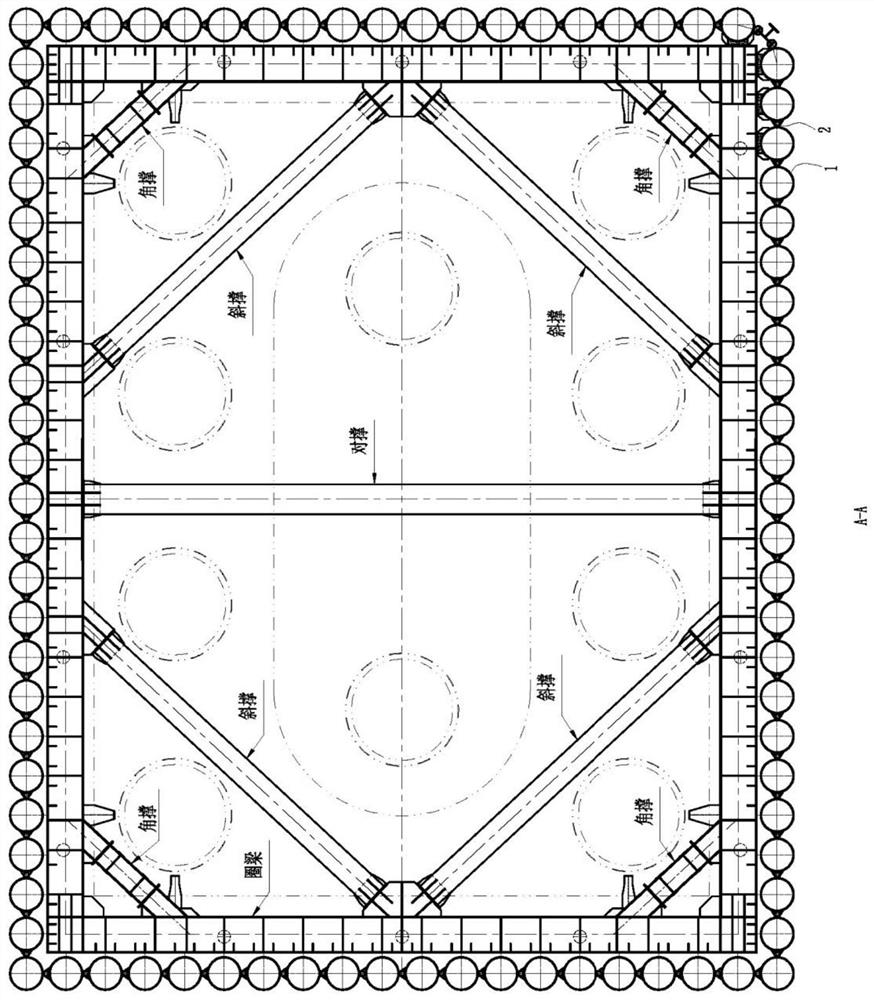

Carbon-fiber washing machine for carbon fiber precursor washing

ActiveCN106521848AAccurate transmissionSmooth transmissionSucessive textile treatmentsTextile treatment containersWater useFiber

The invention relates to a carbon-fiber washing machine for carbon fiber precursor washing. A multilevel washing trough is installed at the front portion of a machine frame 1, a driving roller and a guiding roller are installed on the machine frame 1, and two transmission systems are installed at the back portion of the machine frame 1. The carbon-fiber washing machine is superposed by five-level water troughs in a dislocation mode, the washing time is prolonged, and the occupied area of the device is saved to a maximum degree. As liquid level plates, flow stopping plates and overflowing plates are designed in the washing troughs, the washing process is intensified; as the two ends of the washing troughs are distributed in a dislocation mode, the number of driving roller is reduced, the contact area of fibers and rollers is reduced, and the broken filament generating probability caused by friction is reduced; deionized water used by the carbon-fiber washing machine flows to the next washing trough from the last washing trough and is recycled, and the cost is reduced while the washing effect is improved. The carbon-fiber washing machine has the advantages of being simple in structure and convenient to daily maintain and operate.

Owner:THE NORTHWEST RES INST OF CHEM IND

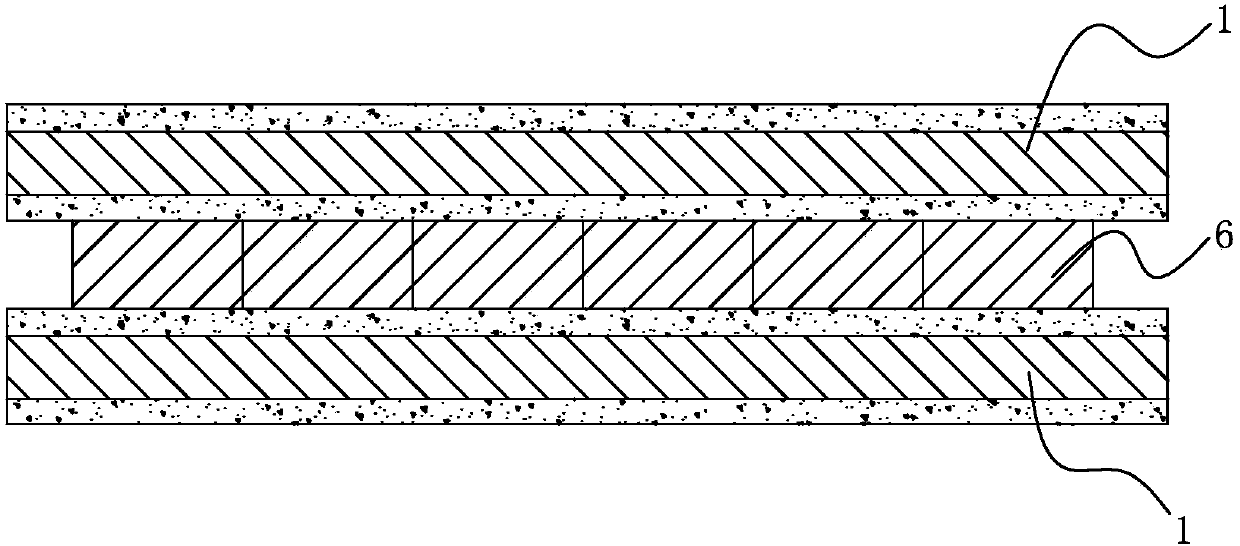

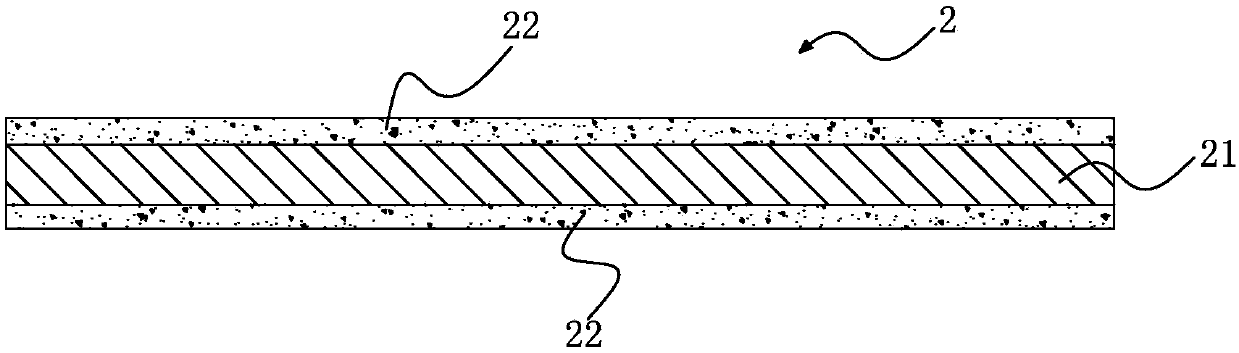

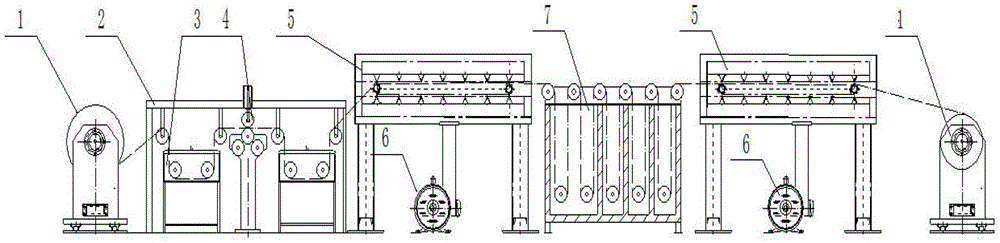

Preparation device of composite separation membrane

ActiveCN103566775AThickness is easy to controlImprove performanceSemi-permeable membranesAgricultural engineeringConductor Coil

The invention relates to a preparation device of a composite separation membrane. The preparation device comprises two material winding and unwinding frames, a reaction frame, two solution tanks, a liquid level control roller group, two thin film drying boxes and a post-treatment water tank, wherein the two winding and unwinding frames are respectively arranged at the front end and the back end of the device, the solution tanks and the liquid level control roller group are mounted in the reaction frame, the two solution tanks are respectively arranged on the two sides of the liquid level control roller group, and the two thin film drying boxes are respectively arranged on the two sides of the post-treatment water tank; and the composite separation membrane sequentially connects the first material winding and unwinding frame, the reaction frame, the first solution tank, the liquid level control roller group, the second solution tank, the first thin film drying box, the post-treatment water tank, the second thin film drying box and the second material winding and unwinding frame through a transition guide roller. The device provided by the invention has the characteristics of compact structure, capability of precisely controlling the content of a solution adsorbed in a support body and relatively high drying efficiency, and the obtained composite separation membrane has good physical properties.

Owner:BEIJING JIUZHANG ENVIRONMENTAL ENG CO LTD

Core-shell lightweight aggregate and preparation method thereof

ActiveCN109796275AImprove the utilization rate of solid waste resourcesImportant economyCultivating equipmentsSoilless cultivationHydroponicsInorganic salts

The invention provides core-shell lightweight aggregate and a preparation method thereof. The core-shell lightweight aggregate comprises a core and a shell according to a mass ratio of 1:1-2:1, the core comprises, by weight, 65-85% of sludge, 6-12% of calcium superphosphate, 5-10% of potassium sulfate, 3-8% of manganese nitrate, 5-11% of ammonium phosphate and 4-10% of sodium chloride, and the shell comprises, by mass, 75-85% of polluted soil, 10-15% of sludge and 5-10% of glass powder. The preparation method includes: adopting the sludge as a main raw material, and adding inorganic salt and phytonutrient containing nitrogen and phosphorus to prepare the core; adopting the polluted soil as a main raw material, and adding the glass powder which is a sintering aid to prepare the shell; coating the shell onto the core by means of high-temperature sintering. Recycling rate of solid waste like the sludge and the polluted soil is increased, the lightweight aggregate suitable for plant hydroponics is developed, and the lightweight aggregate is of quite important economic, environment-protection and scientific-research significance.

Owner:WUHAN UNIV OF TECH

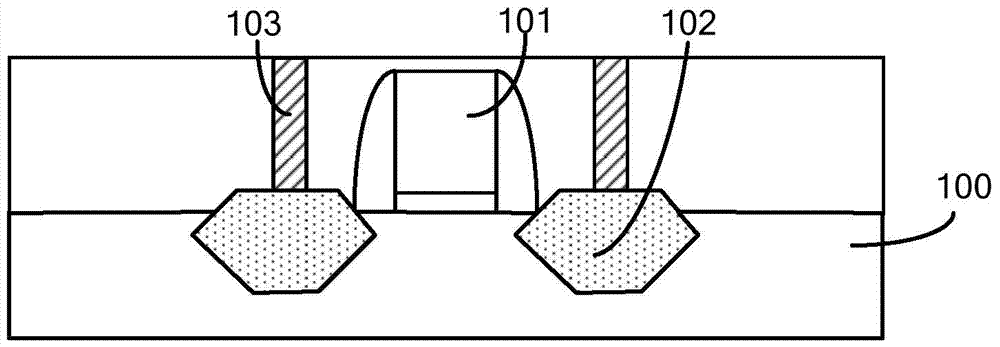

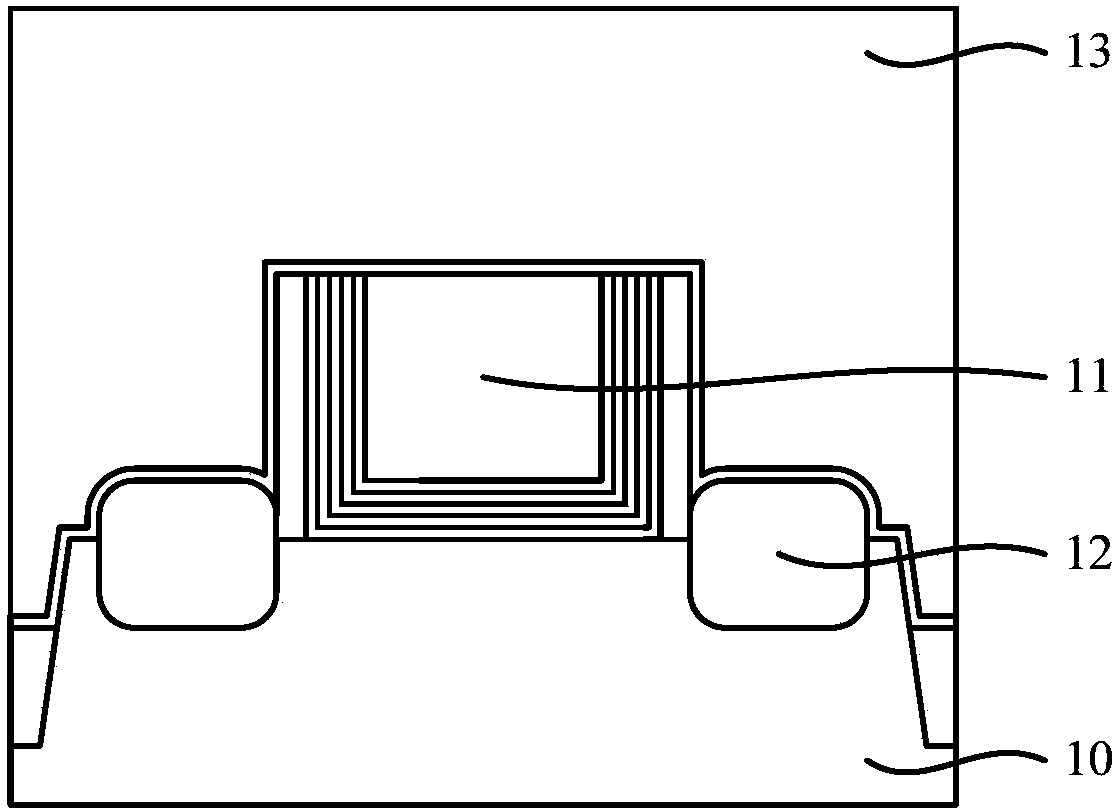

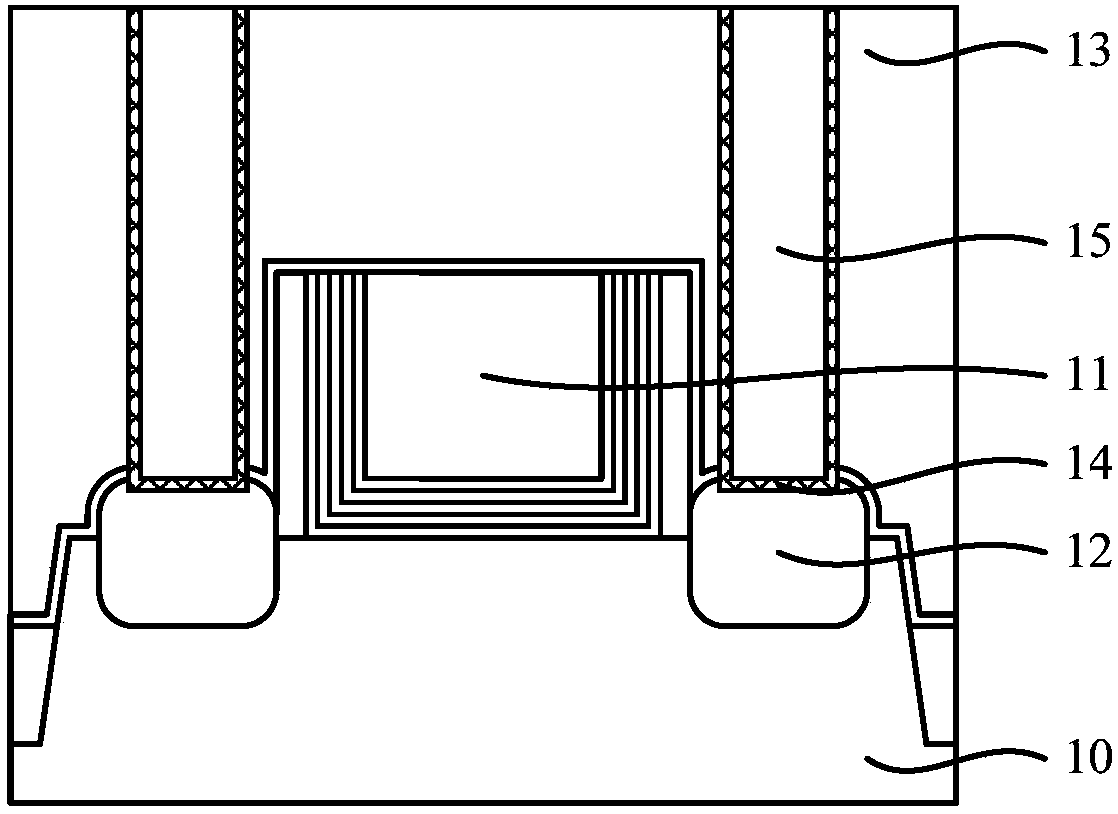

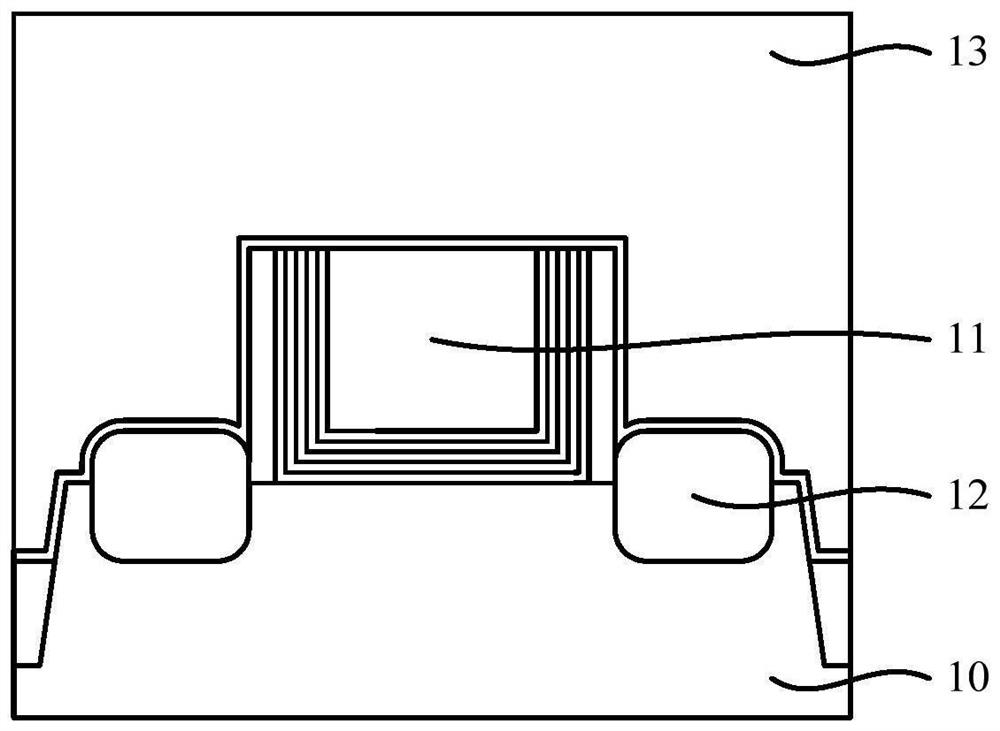

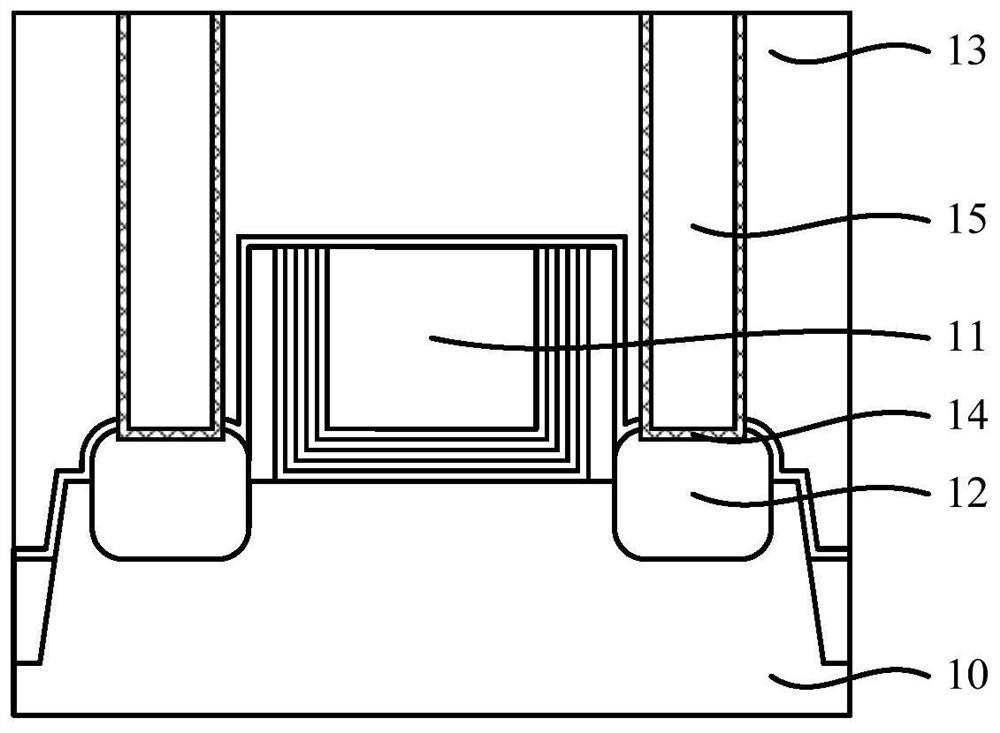

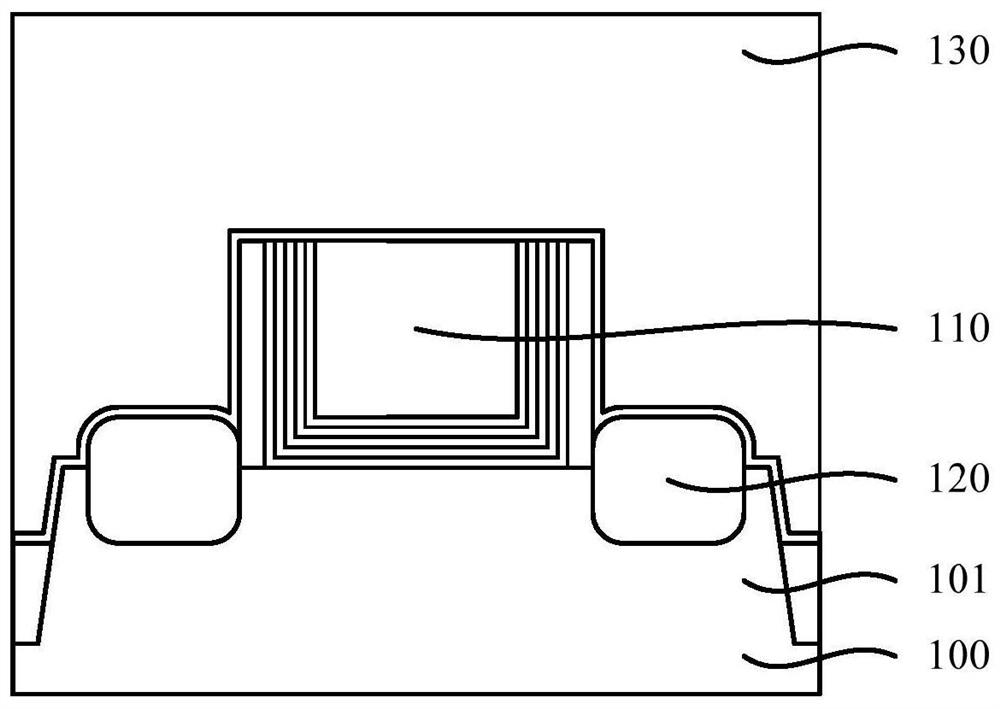

Transistor forming method

ActiveCN104752212AImprove performanceUniform thicknessSolid-state devicesSemiconductor/solid-state device manufacturingSalicideCharge carrier mobility

Various embodiments provide transistors and methods for forming the same. In an exemplary method, a substrate can be provided. A gate structure can be formed on the substrate. A stress layer can be formed in the substrate on both sides of the gate structure. Barrier ions can be doped in the stress layer to form a barrier layer in the stress layer. The barrier layer can have a preset distance from a surface of the stress layer. An electrical contact layer can be formed using a portion of the stress layer on the barrier layer by a salicide process. The electrical contact layer can contain a first metal element. The first metal element can have a resistivity lower than a resistivity of a silicidation metal. The barrier layer can prevent atoms of the first metal element from diffusing to a bottom of the stress layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

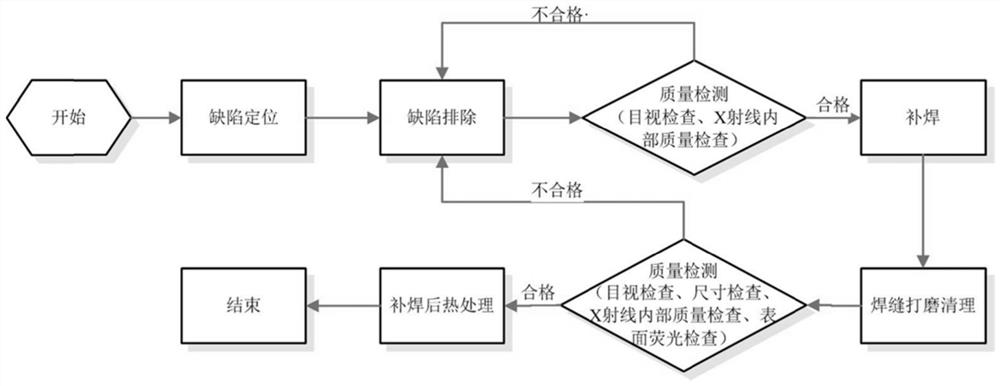

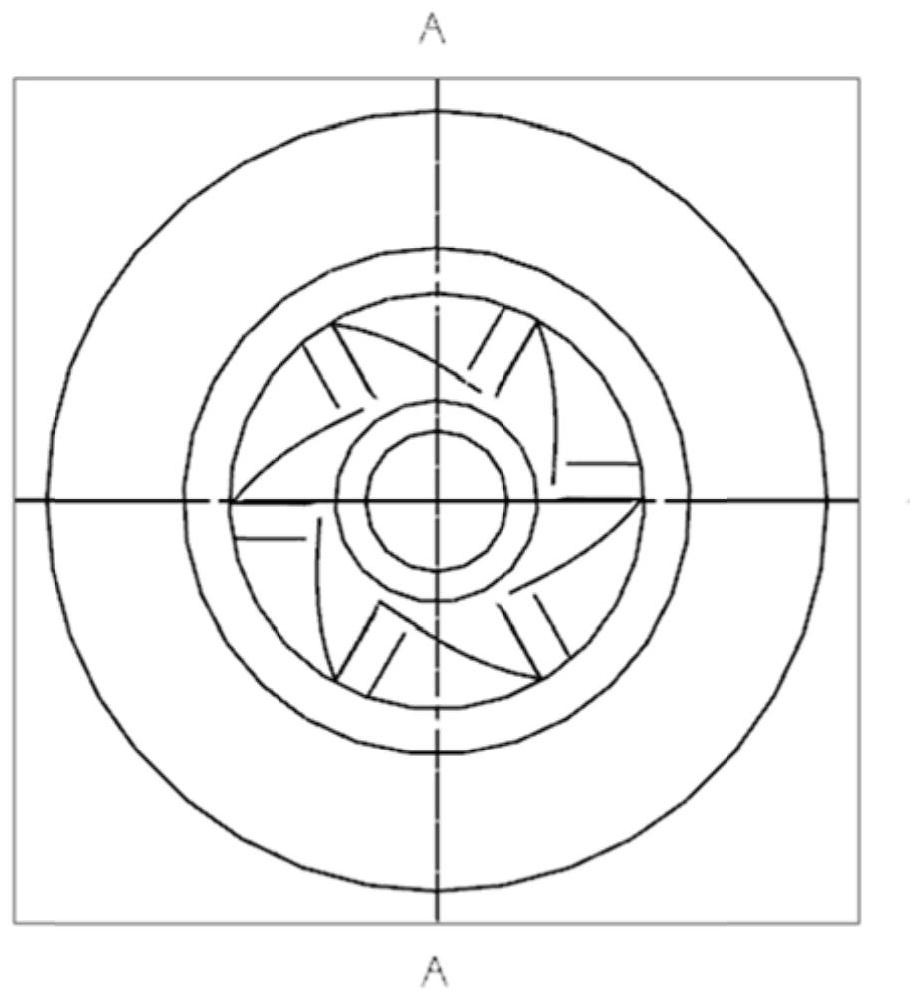

Defect repairing method of investment precision casting for liquid rocket engine

ActiveCN112059531AEliminate unevennessControl the rate of diffusionArc welding apparatusWelding/cutting media/materialsDefect repairEngineering

The invention provides a defect repairing method of an investment precision casting for a liquid rocket engine. The defect repairing method comprises the following steps of: positioning defects; removing the defects; machining a groove; treating a repair welding part; performing welding; and performing postweld treatment. According to the defect repairing method, welding wires for ZG03Cr13Ni5Co9Mo5 and ZG06Cr14Ni7Mo castings are defined, and a welding process database based on the initial thickness of repair welding parts of the castings and a postweld heat treatment system are established; acorresponding repair process is adopted; the tensile strength of an obtained ZG03Cr13Ni5Co9Mo5 weld joint at a room temperature is greater than 1070 MPa (the matrix strength is not lower than 1180 Mpa), the rate of elongation is not lower than 15%, and the low-temperature impact toughness at the temperature of minus 196 DEG C is not lower than 39 J; the tensile strength of a ZG06Cr14Ni7Mo weld joint at a room temperature is greater than 900 MPa (the matrix strength is not lower than 980 Mpa), the rate of elongation is not lower than 12%, and the low-temperature impact toughness at the temperature of minus196 DEG C is not lower than 31 J; the internal quality and the surface quality of the weld joints are qualified; and the weld joints meet the I-grade weld joint standard of QJ1842-95 structural steel and stainless steel fusion welding technical conditions and the use requirements of spaceflight products.

Owner:XIAN SPACE ENGINE CO LTD

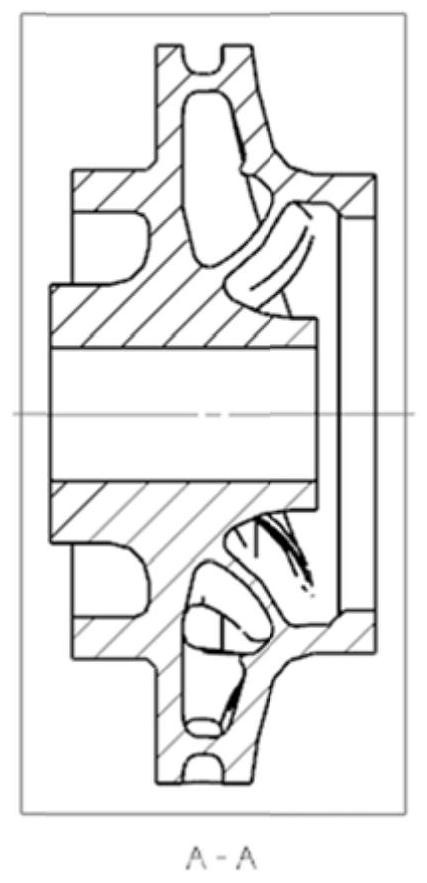

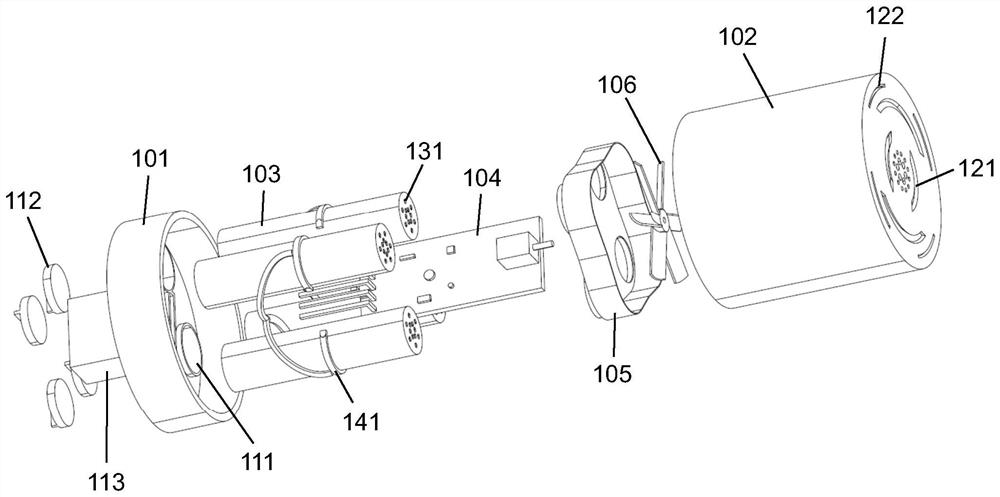

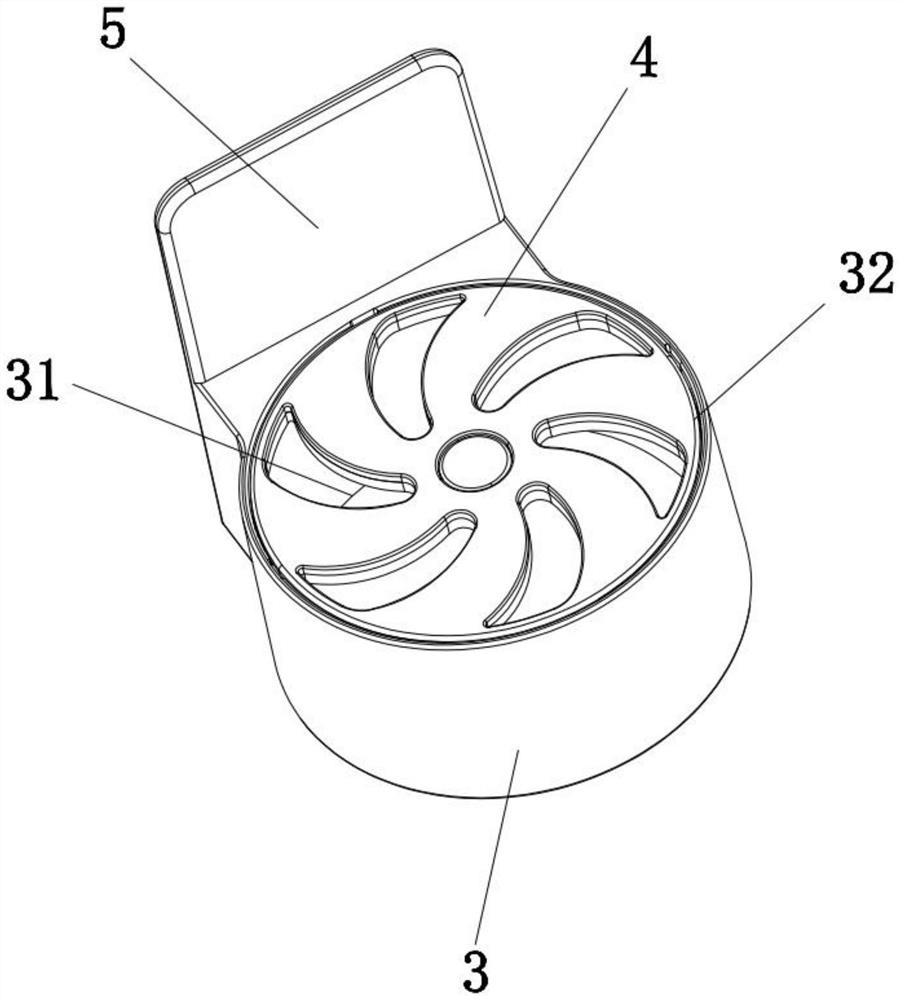

Vehicle-mounted fragrance system and control method thereof

ActiveCN113119696AControl the rate of diffusionMonitor usageAir-treating devicesIn vehicleControl engineering

The invention discloses a vehicle-mounted fragrance system. The vehicle-mounted fragrance system comprises fragrance equipment, a controller and interaction equipment, the fragrance equipment comprises a plurality of fragrance bodies with different fragrance smells and characteristic parameters, and the fragrance device obtains the characteristic parameters of the fragrance bodies, controls opening or closing of the fragrance bodies, detects correction parameters in the cabin and adjusts the diffusion speed of fragrance. The controller recognizes the fragrance body according to the characteristic parameters and knows the state of the fragrance body, adjusting parameters are calculated according to the correction parameters, and the fragrance equipment adjusts the diffusion speed of fragrance according to the adjusting parameters. The interaction device displays the recognized fragrance body and the state of the fragrance body and receives a user instruction, and the controller controls the fragrance device to operate the fragrance body according to the user instruction. The invention further discloses a control method of the vehicle-mounted fragrance system. The system has the self-learning and self-adapting functions, and the rotating speed of the fan can be adjusted according to the actual situation in the cabin so as to control the diffusion rate of fragrance.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

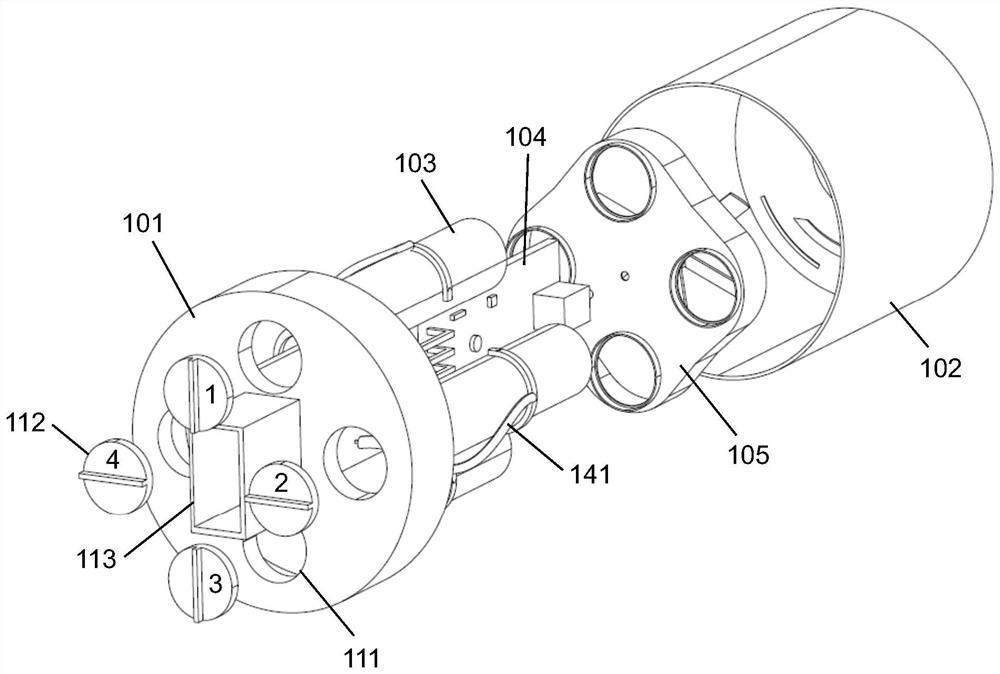

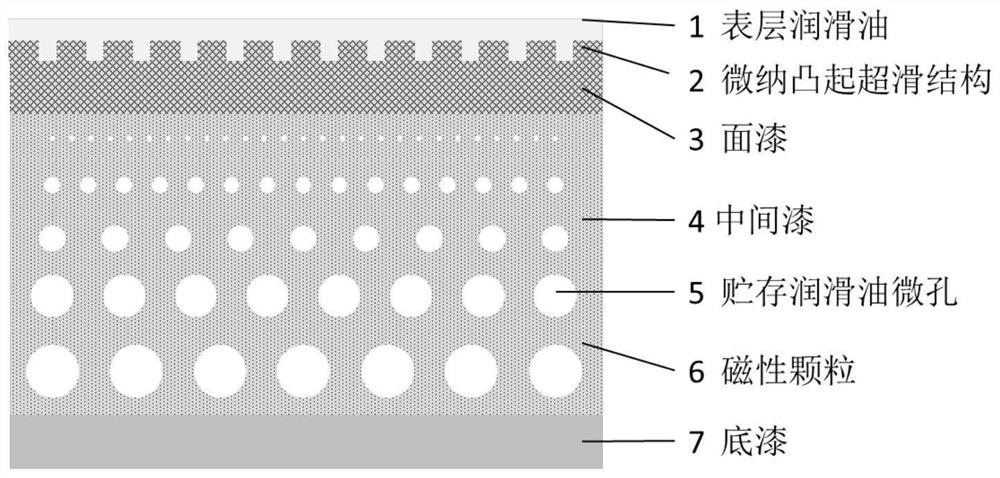

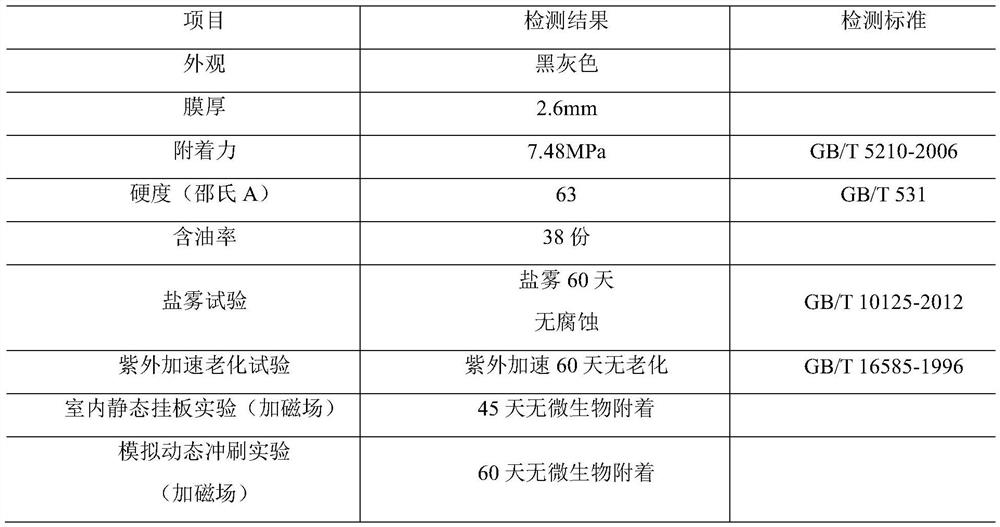

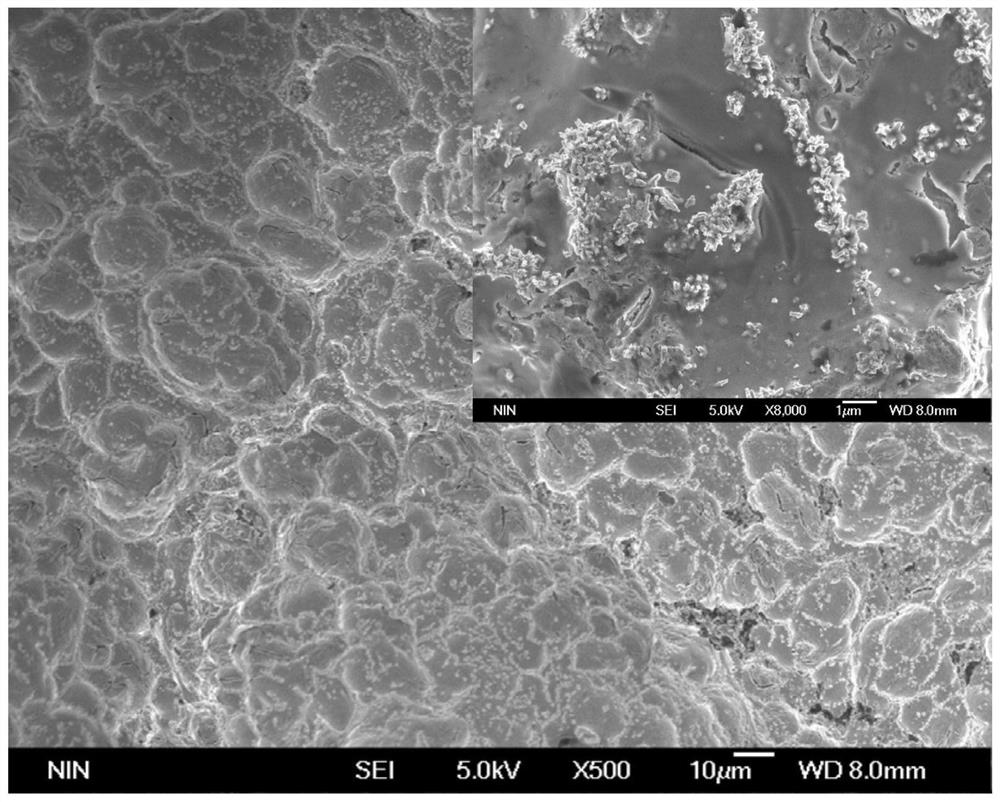

Magnetic response dynamic autocrine coating as well as preparation method and use method thereof

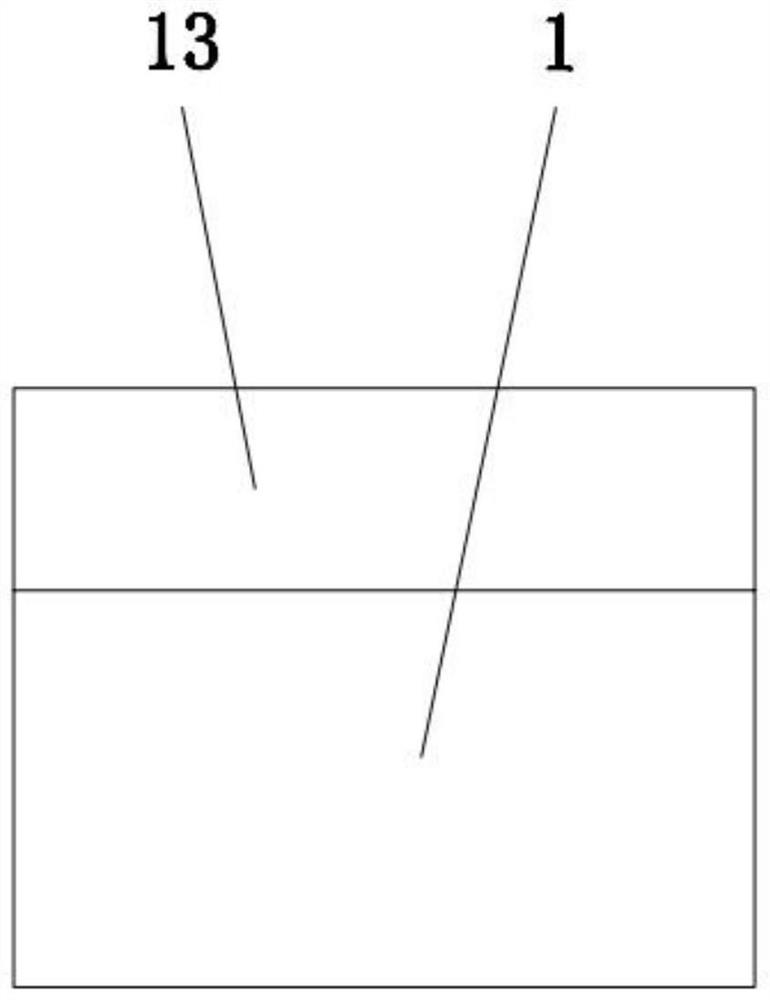

ActiveCN112409918AWith dynamic response functionExtended super-slip protection functionAnti-corrosive paintsPolyether coatingsMagnetic responseCoating

The invention discloses a magnetic response dynamic autocrine coating as well as a preparation method and a use method thereof, and belongs to the field of surface protection. The coating comprises three film layers including priming paint, intermediate paint and finish paint. The priming paint is used for enhancing the adhesive force between the coating and a substrate, and the intermediate paintis doped with magnetic filler, contains lubricating oil and can deform and vibrate under the condition of an alternating magnetic field. A pore-forming agent is added into the intermediate paint filmlayer, and bottom micropores are large in size while upper micropores are small in size, so that a large amount of lubricating oil can be stored in the micropores and diffused to the surface; The exterior of the finish paint is of a micro-nano rough structure, and when lubricating oil permeates into the surface layer, a super-smooth surface is formed. The coating can quickly respond to a magneticfield to form a micro-vibration surface to extrude internal oil bags to deform to secrete lubricating oil. Due to the synergistic effect of the super-smooth surface and the dynamic surface, the anti-corrosion, anti-fouling and protection functions are greatly enhanced, and the service life of the super-smooth surface is greatly prolonged. The coating has important enlightenment significance for the development of an anti-fouling technology.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of dispersing dye microcapsule

InactiveCN1216949CControl the rate of diffusionGood sustained release effectOrganic dyesMicroballoon preparationDisperse dyeAdjuvant

The present invention provides a method for preparing disperse dye microcapsule by utilizing melamine resin performed polymer and ethylene monomer as monomer for forming microcapsule well material and adopting in-situ polymerization. The wall material has good slowly-releasing property, centralized grain size distribution (generally, the grain size is 2-14 micrometer), small dose of adjuvant. It can control release of dye, can be used for dyeing and multiple transfer printing of polyester fabrics, and can raise utilization rate of dye and reduce pollution.

Owner:SHANGHAI WOODGE TEXTILE TECH

Preparation method of precious metal anode for PCB horizontal electroplating

ActiveCN112663124AImprove conversion efficiencyControl the rate of diffusionLiquid/solution decomposition chemical coatingProcess efficiency improvementIridiumOrganic solvent

The invention belongs to the technical field of PCB horizontal electroplating, and relates to a preparation method of a precious metal anode for PCB horizontal electroplating. The method comprises the following steps that 1), the surface of a titanium substrate is pretreated; 2), an active solution is prepared, specifically, an iridium source, a tantalum source and a cobalt source are dissolved in an organic solvent to form a solution A, a solution B and a solution C, the solution A, the solution B and the solution C are uniformly mixed according to a molar ratio of Ir:Ta:Co of 7:3:(1.5-6) to form an active solution D; and 3), sintering is conducted. According to the preparation method, Co3O4 with good stability is introduced into a traditional iridium-tantalum system coating, good catalytic activity is achieved, the Fe2+ conversion efficiency is improved, and the anode cost is reduced; and besides, an n-butyl alcohol solvent with high viscosity is adopted as the preparation solvent of the active solution, so that the diffusion rate of the solution is well controlled, and noble metal active components are more uniformly dispersed on the surface of the titanium substrate.

Owner:XIAN TAIJIN NEW ENERGY & MATERIALS SCI TECH CO LTD

Acid fracturing process of oil gas well mining temperature control various mucic acid

ActiveCN101353958BReduce fluid lossEasy to form non-uniform etchingFluid removalDrilling compositionAcid fracturingDemulsifier

The invention relates to an acid fracturing method of a temperature-control and variable-viscosity acid in the exploitation of an oil-gas well, which comprises the steps that: a common chlorohydric acid pickling process is firstly used for removing the pollution of an embrasure; then, the temperature-control and variable-viscosity acid fracturing process, or an ahead-fluid temperature-control andvariable-viscosity acid fracturing process, or a temperature-control and variable-viscosity acid fracturing enclosed acidizing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing enclosed acidizing process is adopted; the weight ratio of the components of the temperature-control and variable-viscosity acid are as follows: 100 portions of basic acid solution, 0.5 portion to 1.5 portions of the main agent of the temperature-control and variable-viscosity acid, 1 portion to 3 portions of a corrosion inhibitor of the temperature-control and variable-viscosity acid, 0.5 portion to 1 portion of an emulsion breaker, 0.5 portion to 1 portion of a ferric ion stabilizer and 0.5 portion to 1 portion of a high efficient discharge aiding agent; 2-percent KCL clear water is used for displacing the temperature-control and variable-viscosity acid into the stratum. The temperature-control and variable-viscosity acid is easily prepared on site, with low friction drag and strong pumpability, thereby being capable of being applied to high-discharge construction; under the high temperature condition of a storing layer, both the fresh acid and the residue acid have high viscosity, thus increasing the length of acid-etching cracks. After the construction is finished, the viscosity of the residue acid is reduced, which is beneficial to the back discharge of the residue acid.

Owner:PETROCHINA CO LTD

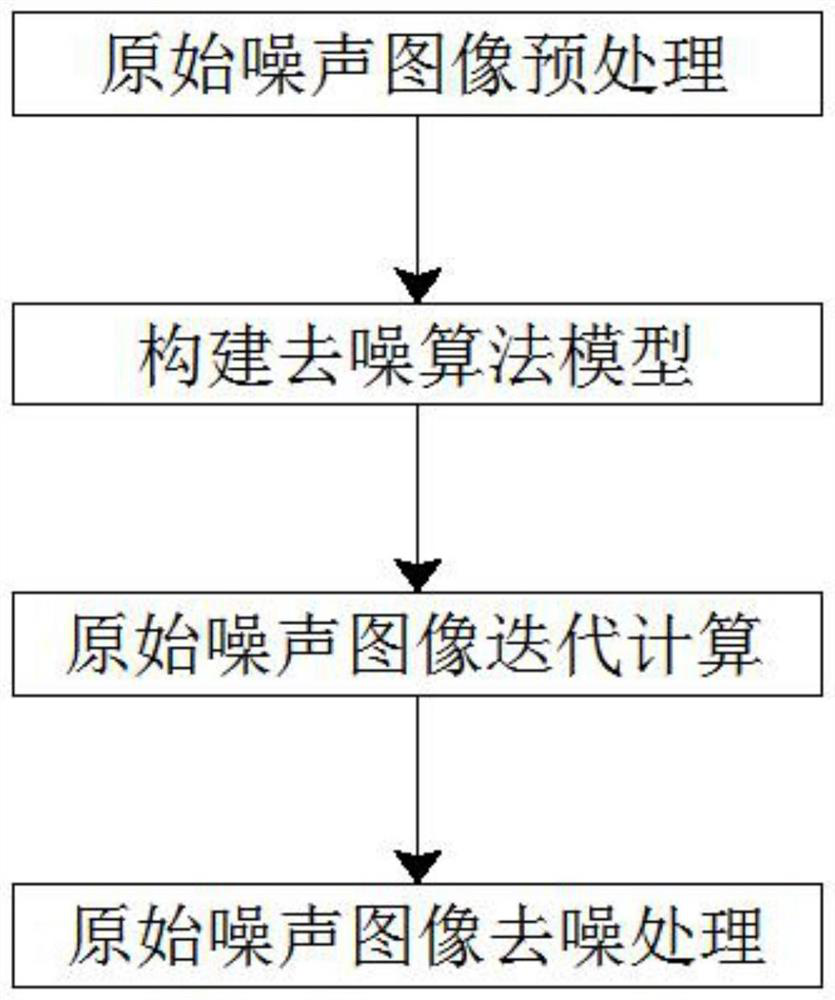

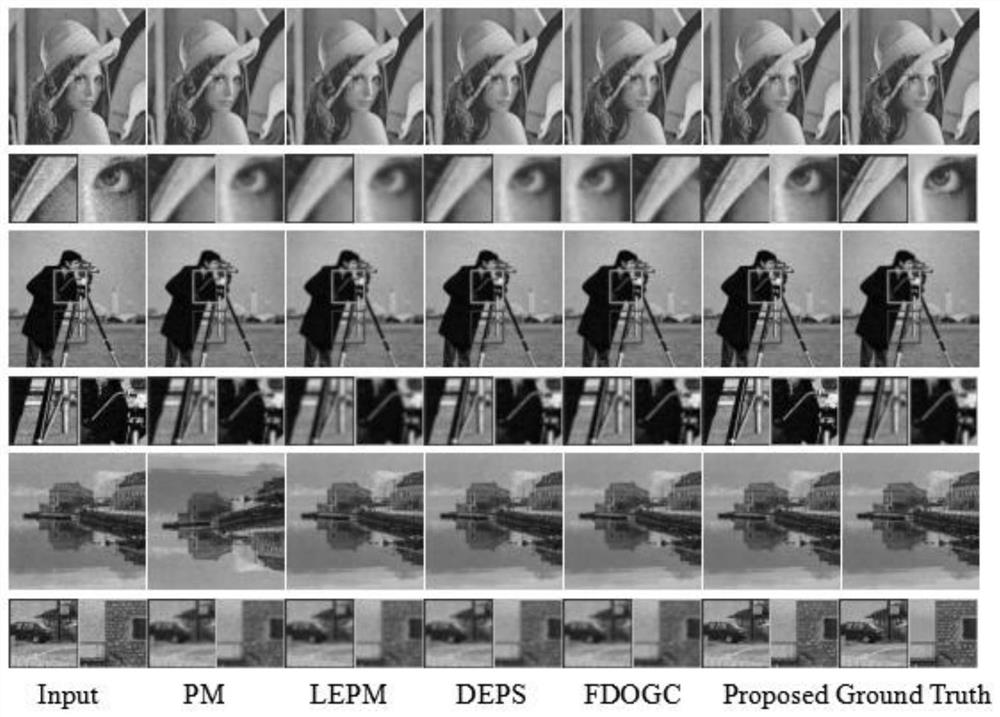

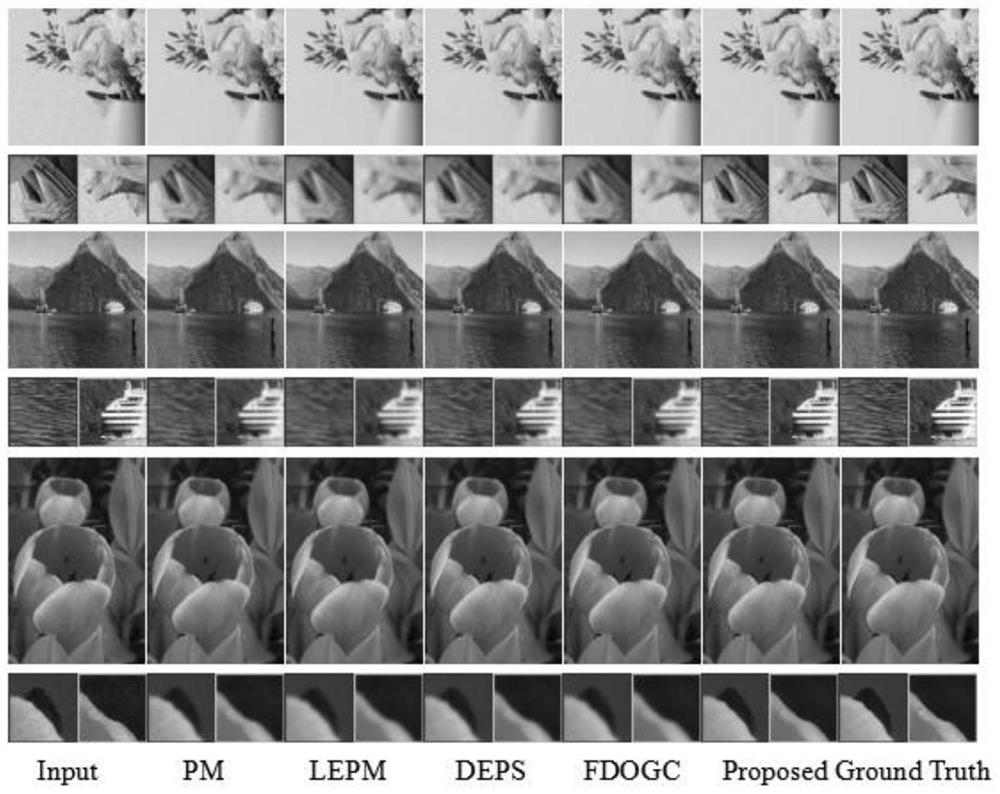

Adaptive edge preserving denoising method based on anisotropic diffusion model

PendingCN114022384AImprove visual effectsImprove fidelityImage enhancementImage analysisImaging processingDenoising algorithm

The invention discloses a self-adaptive edge preserving denoising method based on an anisotropic diffusion model. The method comprises the following steps of preprocessing an original noise image, constructing a denoising algorithm model, performing iterative calculation on the original noise image and performing denoising processing on the original noise image. According to the method, the diffusion coefficient of the adaptive image denoising algorithm based on the combination of the fractional order differential operator and the Gaussian curvature is improved, bilateral filtering and local variance are added, the regularization item is introduced into the diffusion model, the image edge preserving effect is improved, the diffusion coefficient of the adaptive image denoising algorithm model is corrected, the denoising and edge maintaining effects are better, and the visual effect of the image is improved; the diffusion coefficient is adjusted by using the local variance so as to better control the diffusion speed; the image fidelity is improved by adding a regularization item, and an adaptive threshold is used, so that the medical image processing method is superior to a traditional image processing method in the aspect of processing a medical image besides a natural image.

Owner:ANHUI UNIVERSITY

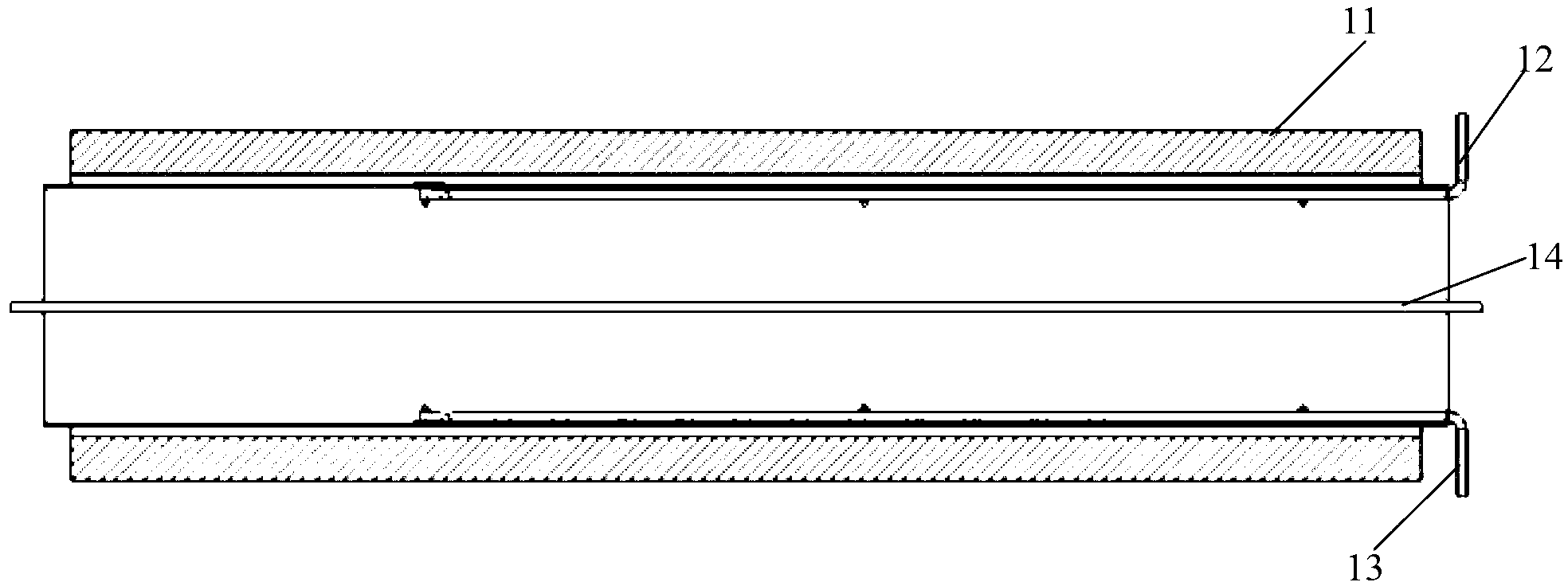

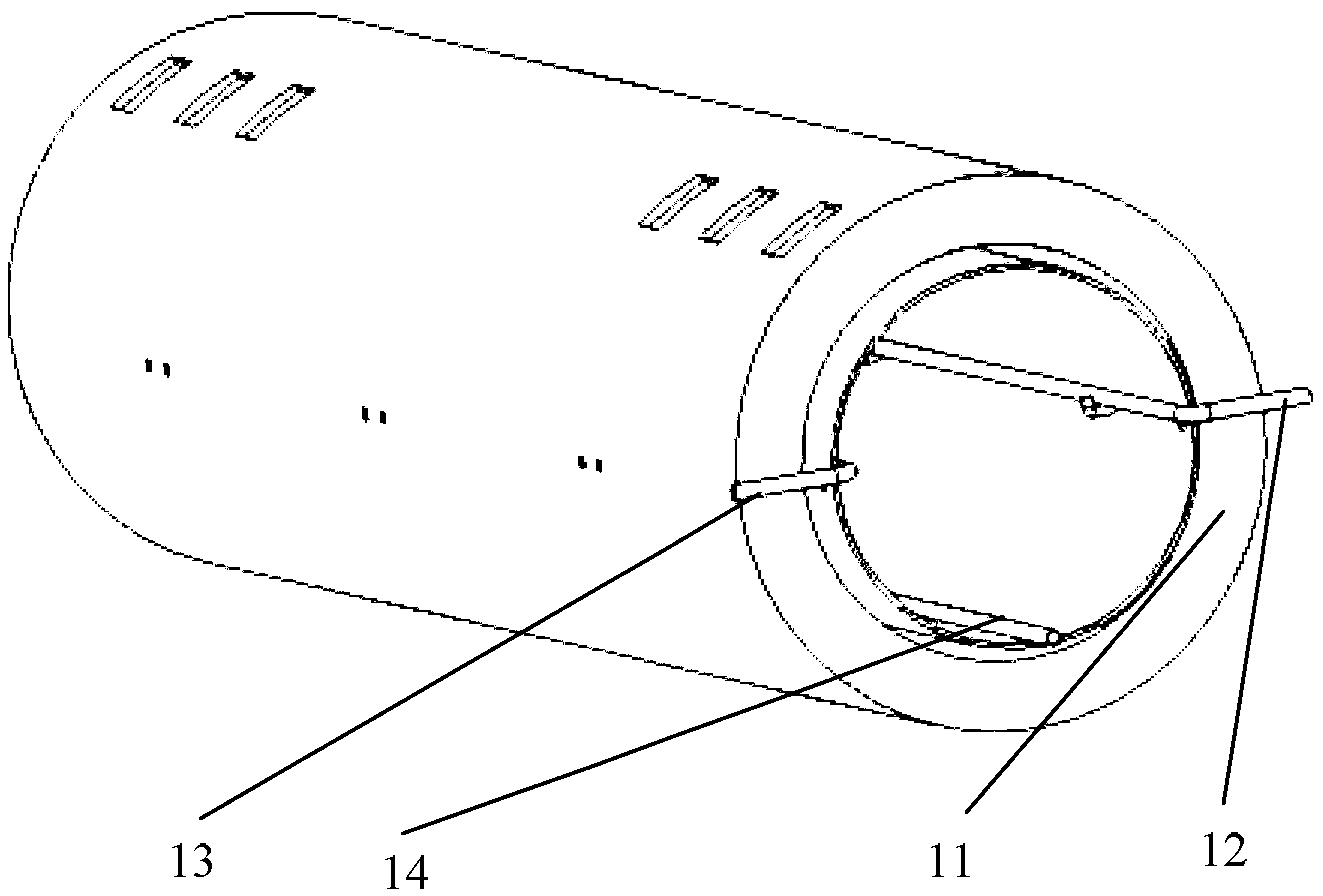

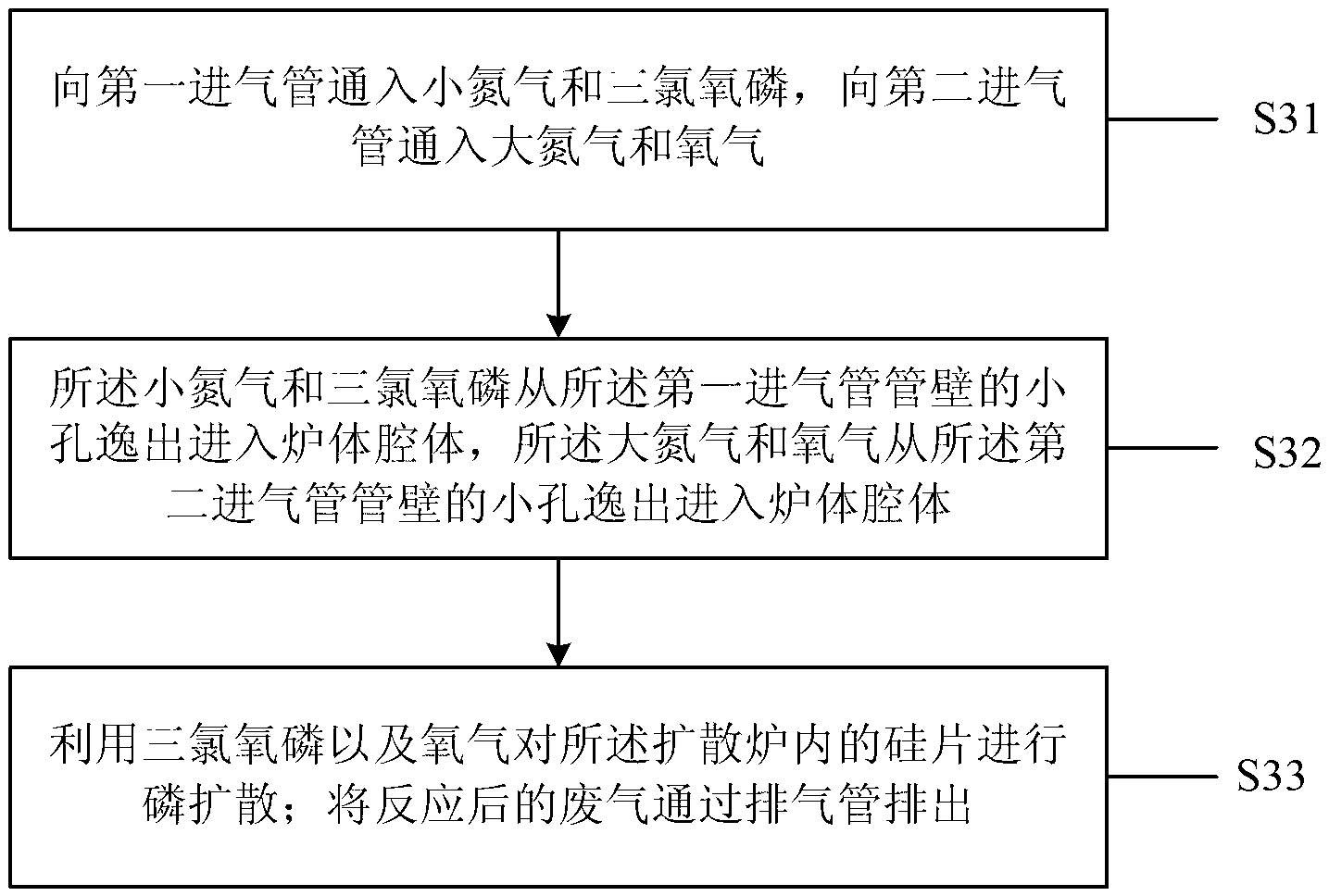

Continuous diffusion furnace and its ventilation method

The invention provides a continuous diffusion furnace which comprises a furnace body with two open ends, a first air inlet pipe with an open end and an enclosed end, a second air inlet pipe with an open end and an enclosed end, and an exhaust pipe which is fixedly arranged on the inner wall of the furnace body chamber, wherein the first air inlet pipe is fixedly arranged on the inner wall of the furnace body chamber; the wall of the first air inlet pipe is uniformly provided with several small holes which are far from the inner wall of the furnace body chamber; the second air inlet pipe is fixedly arranged on the inner wall of the furnace body chamber; the wall of the second air inlet pipe is uniformly provided with several small holes which are far from the inner wall of the furnace body chamber; two ends of the exhaust pipe are both opened; negative pressure is applied on the two ends of the exhaust pipe; and the wall of the exhaust pipe is provided with several small holes which are far from the inner wall of the furnace body chamber. By the adoption of the ventilation method of the continuous diffusion furnace, consistent density of reactant gases around silicon chips in the same batch is realized. PN junctions of the silicon chips are uniform. And two breather pipes are simultaneously used for ventilation, so as to avoid obstruction of breather pipe holes.

Owner:SHANGHAI XUKANG ELECTRONICS TECH

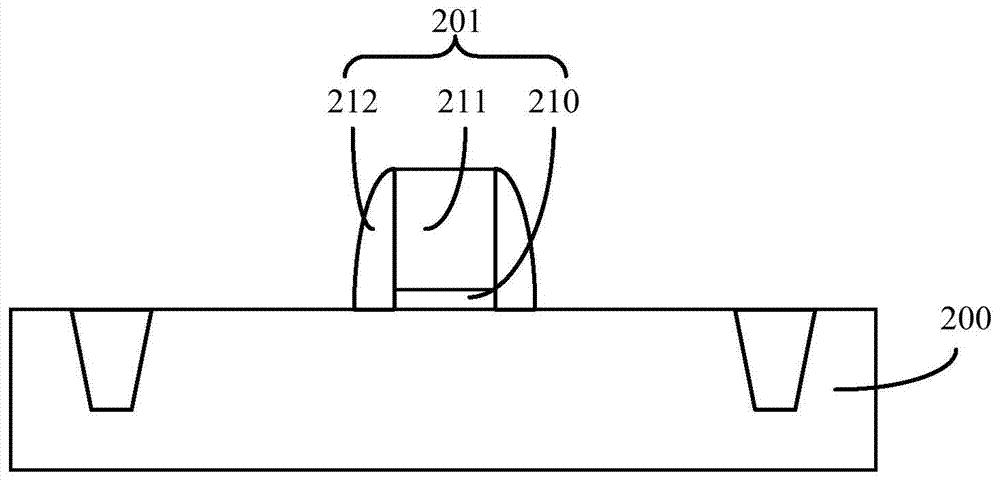

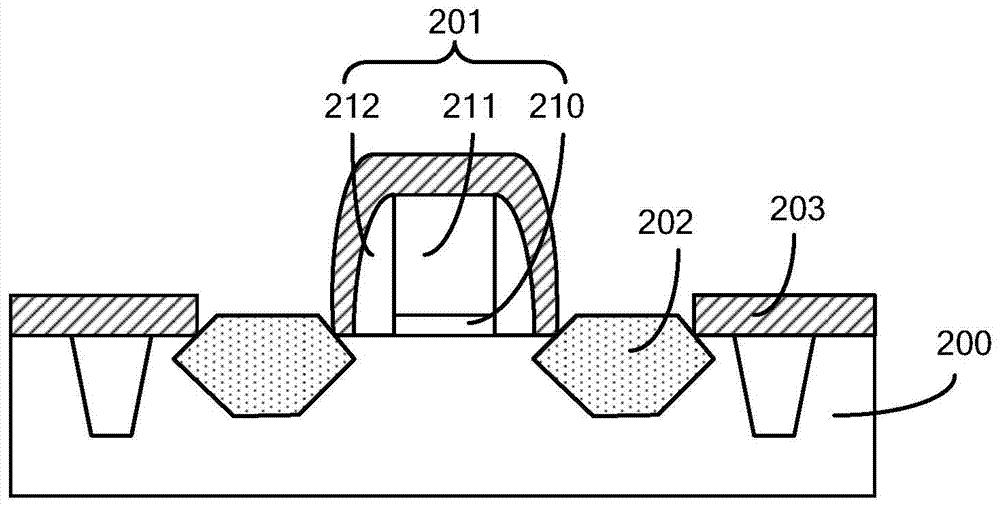

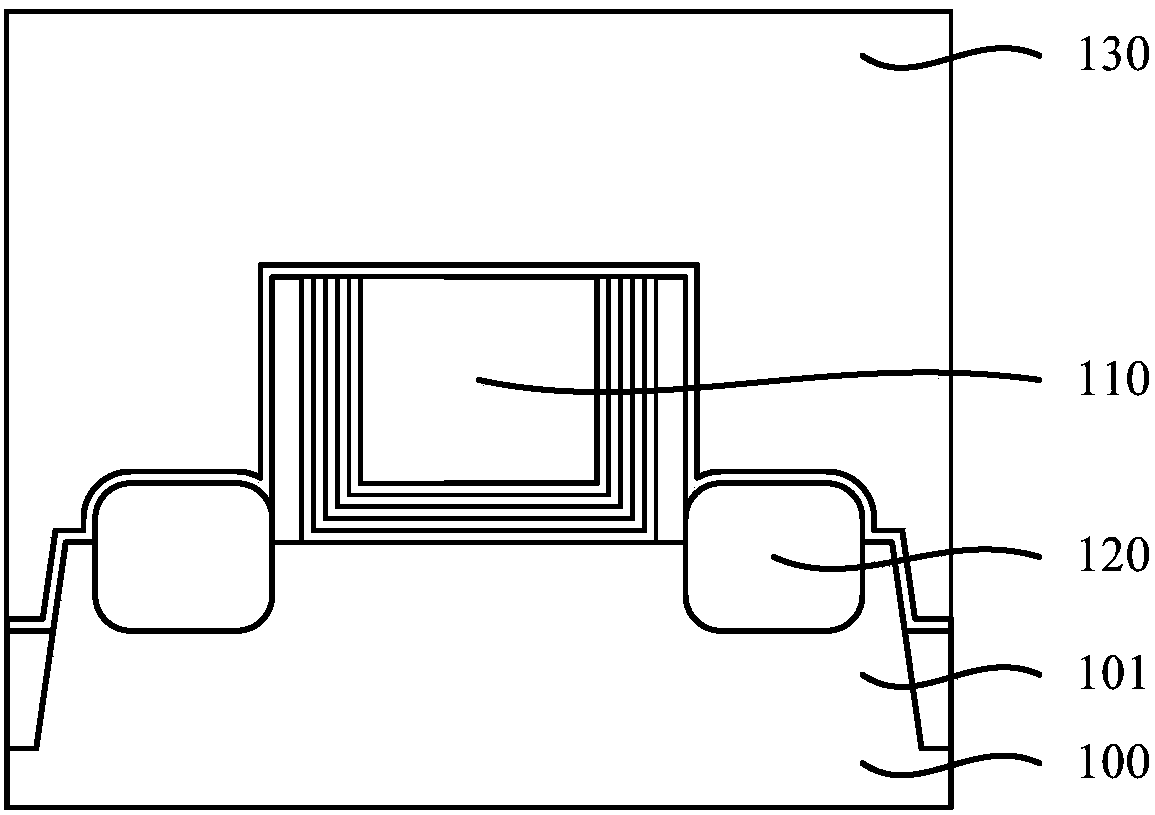

Semiconductor structure and forming method thereof

ActiveCN108573910AReduce contact resistanceReduced induced gap state phenomenonSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureOptoelectronics

Disclosed are a semiconductor structure and a forming method thereof. The forming method includes the following steps: forming a substrate; forming a gate structure on the substrate; forming source-drain doping regions located in the substrate on two sides of the gate structure; forming a dielectric layer on the substrate exposing from the gate structure, wherein the dielectric layer covers the source-drain doping regions; forming contacting holes passing through the dielectric layer, wherein the bottoms of the contacting holes expose the source-drain doping regions; forming an oxide metal layer on the source-drain doping regions exposing from the contacting holes; and forming plugs in the contacting holes in which the oxide metal layer is formed. The technical scheme of the invention caneffectively inhibit the phenomenon of Fermi level pinning at the interface of the plugs and the source-drain doping regions, thereby benefiting the reduction of the contact resistance between the plugs and the source-drain doping regions, and benefiting the improvement of the performance of the formed semiconductor structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

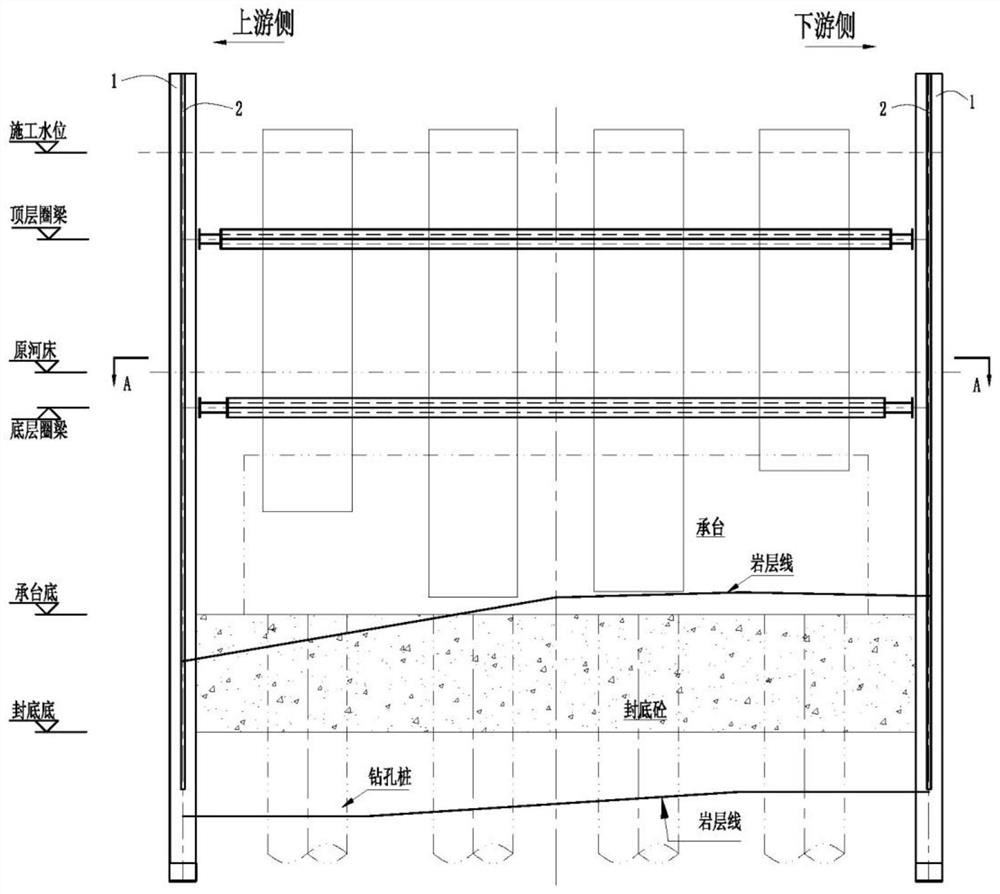

Water stopping method for steel pipe pile fore shaft

InactiveCN112211209AThe setting time can be adjustedControl the rate of diffusionBulkheads/pilesO-Phosphoric AcidWater flow

The invention discloses a water stopping method for a steel pipe pile fore shaft. The water stopping method comprises the following steps that a phosphoric acid solution and a water glass solution areinjected into the bottom of the fore shaft at the same time through a drill rod, and a grout stopping layer is formed; and cement paste and the water glass solution are injected into the area above the grout stopping layer of the fore shaft through the drill rod at the same time for plugging. According to the water stopping method for the steel pipe pile fore shaft, the diffusion speed and distance of grout in water can be effectively controlled, it is guaranteed that a water flowing channel is rapidly blocked under the condition that water flows, and therefore the water stopping effect is good, grouting can go deep into the bottom of the fore shaft through the drill rod, saturated grouting is conducted from bottom to top, and water stop effect is better.

Owner:1ST ENG OF CHINA ZHONGTIE MAJORBRIDGE GROUP

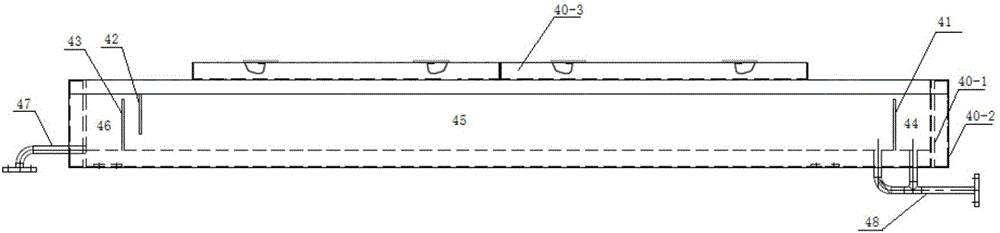

Composite separation membrane preparation equipment

ActiveCN103566775BThickness is easy to controlImprove performanceSemi-permeable membranesAgricultural engineeringConductor Coil

The invention relates to a preparation device of a composite separation membrane. The preparation device comprises two material winding and unwinding frames, a reaction frame, two solution tanks, a liquid level control roller group, two thin film drying boxes and a post-treatment water tank, wherein the two winding and unwinding frames are respectively arranged at the front end and the back end of the device, the solution tanks and the liquid level control roller group are mounted in the reaction frame, the two solution tanks are respectively arranged on the two sides of the liquid level control roller group, and the two thin film drying boxes are respectively arranged on the two sides of the post-treatment water tank; and the composite separation membrane sequentially connects the first material winding and unwinding frame, the reaction frame, the first solution tank, the liquid level control roller group, the second solution tank, the first thin film drying box, the post-treatment water tank, the second thin film drying box and the second material winding and unwinding frame through a transition guide roller. The device provided by the invention has the characteristics of compact structure, capability of precisely controlling the content of a solution adsorbed in a support body and relatively high drying efficiency, and the obtained composite separation membrane has good physical properties.

Owner:BEIJING JIUZHANG ENVIRONMENTAL ENG CO LTD

Deodorization and bacteriostasis composition, deodorant container and adjustable deodorant container

PendingCN114053467AGood odor eliminationInhibits the growth of E. coli and Staphylococcus aureusBiocideFungicidesChemistryEnterobacter

The invention provides a deodorization and bacteriostasis composition, a deodorant container and an adjustable deodorant container, and relates to the field of deodorization of public toilets. The invention aims to solve the problem that odor remains in public toilets and cannot be removed in the prior art. The invention firstly provides the deodorization and bacteriostasis composition. The deodorization and bacteriostasis composition is prepared from the following substances: cineole, camphene, phellandrene, terpilenol, geraniol acetate, isovaleraldehyde, citronellal, piperonone and d-limonene. According to the deodorization and bacteriostasis composition, various plant extracts are adopted for formula synthesis, plant single ions can be automatically emitted when the deodorization and bacteriostasis composition is placed in a natural environment, and when the single ions meet odor molecules, the single ions and the odor molecules can be rapidly subjected to gas capacity reaction to form odorless salt molecules and water molecules; and the deodorization and bacteriostasis composition disclosed by the invention has a good effect of eliminating peculiar smell, also has an effect of inhibiting growth of escherichia coli and staphylococcus aureus, and further has an effect of effectively repelling mosquitoes.

Owner:黄印章

Non-woven fabric sterilization equipment

The invention discloses non-woven fabric sterilization equipment, which comprises a box body, a penetrating inner cavity is formed in the box body; a side inner cavity located in the box body is formed in one side of the penetrating inner cavity, the penetrating inner cavity and the side inner cavity are arranged in a penetrating mode, the penetrating inner cavity located in the box body is formedin the upper side of the side inner cavity, a middle cylinder is rotationally arranged in the end wall of the penetrating inner cavity, a non-woven fabric is wound on the outer surface of the middlecylinder body; the non-woven fabric penetrates through the penetrating inner cavity; according to the equipment, the non-woven fabric is continuously dragged by equipment in an external space; the non-woven fabric is continuously moved, the coiled non-woven fabric is fully disinfected in an alcohol dipping mode when the non-woven fabric is wound, and alcohol in the non-woven fabric is volatilizedand further disinfected in a heating roller extrusion mode when the non-woven fabric is pulled out of the equipment.

Owner:余颖

A kind of core-shell light aggregate and its preparation method

ActiveCN109796275BImprove the utilization rate of solid waste resourcesReduce adverse effectsCultivating equipmentsCeramic materials productionSludgeEnvironmental chemistry

The invention provides a core-shell light aggregate and a preparation method thereof. The core-shell light aggregate includes an inner core and an outer shell; the mass ratio of the inner core and the outer shell is 1:1 to 2:1; and in terms of mass percentage, the inner core includes the following components : Sludge: 65% to 85%, superphosphate: 6% to 12%, potassium sulfate: 5% to 10%, manganese nitrate: 3% to 8%, ammonium phosphate: 5% to 11%, sodium chloride : 4% to 10%; by mass percentage, the shell includes the following components: polluted soil: 75% to 85%, sludge: 10% to 15%, glass powder: 5% to 10%. The core-shell light aggregate of the present invention uses sludge as the main raw material and adds inorganic salts and plant nutrients containing nitrogen and phosphorus to prepare the core, and then uses polluted soil as the main raw material and adds sintering aid glass powder to prepare the shell. The sintering method wraps the outer shell on the inner core. On the one hand, it improves the utilization rate of solid waste such as sludge and polluted soil. On the other hand, it develops a light aggregate suitable for plant hydroponics, which is very Important economic, environmental protection and scientific research significance.

Owner:WUHAN UNIV OF TECH

Semiconductor structures and methods of forming them

ActiveCN108573910BReduce contact resistanceReduced induced gap state phenomenonSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structurePhysical chemistry

Disclosed are a semiconductor structure and a forming method thereof. The forming method includes the following steps: forming a substrate; forming a gate structure on the substrate; forming source-drain doping regions located in the substrate on two sides of the gate structure; forming a dielectric layer on the substrate exposing from the gate structure, wherein the dielectric layer covers the source-drain doping regions; forming contacting holes passing through the dielectric layer, wherein the bottoms of the contacting holes expose the source-drain doping regions; forming an oxide metal layer on the source-drain doping regions exposing from the contacting holes; and forming plugs in the contacting holes in which the oxide metal layer is formed. The technical scheme of the invention caneffectively inhibit the phenomenon of Fermi level pinning at the interface of the plugs and the source-drain doping regions, thereby benefiting the reduction of the contact resistance between the plugs and the source-drain doping regions, and benefiting the improvement of the performance of the formed semiconductor structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

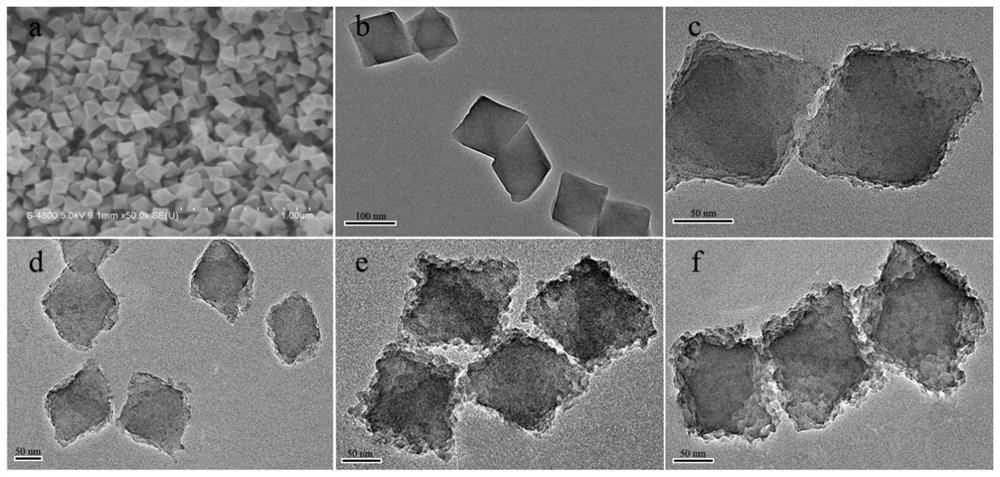

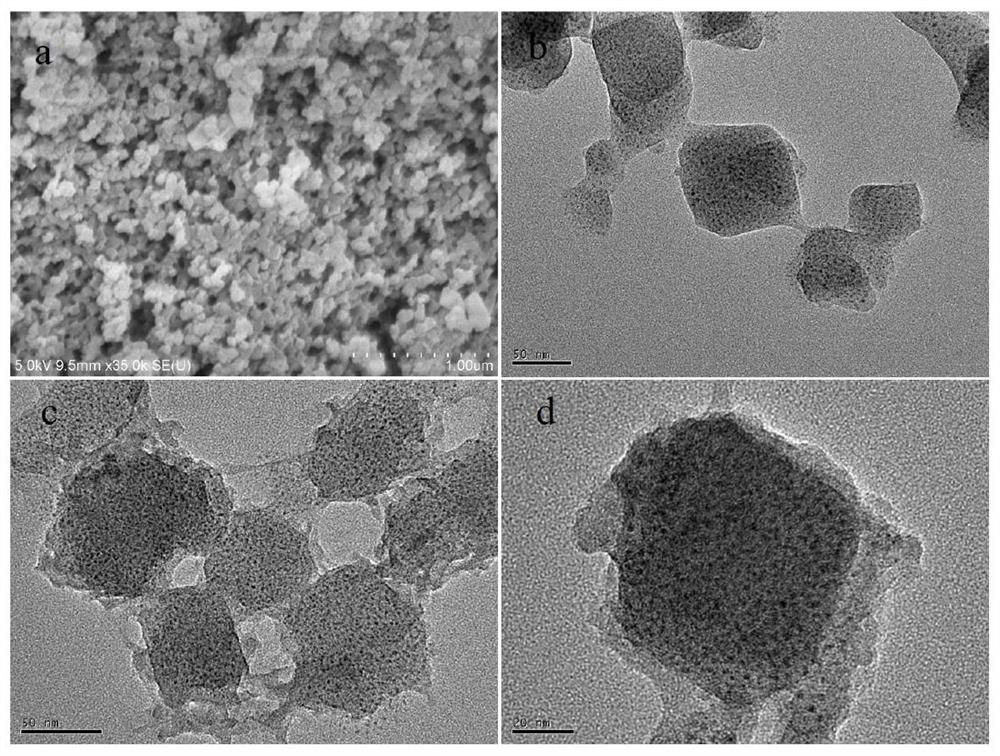

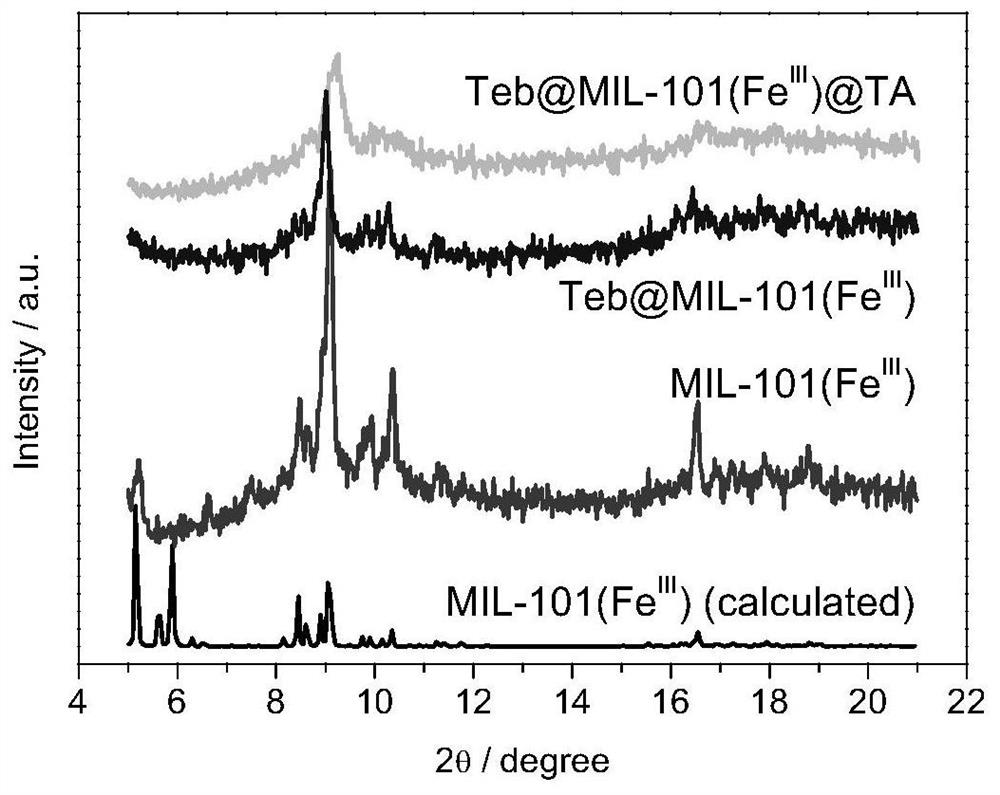

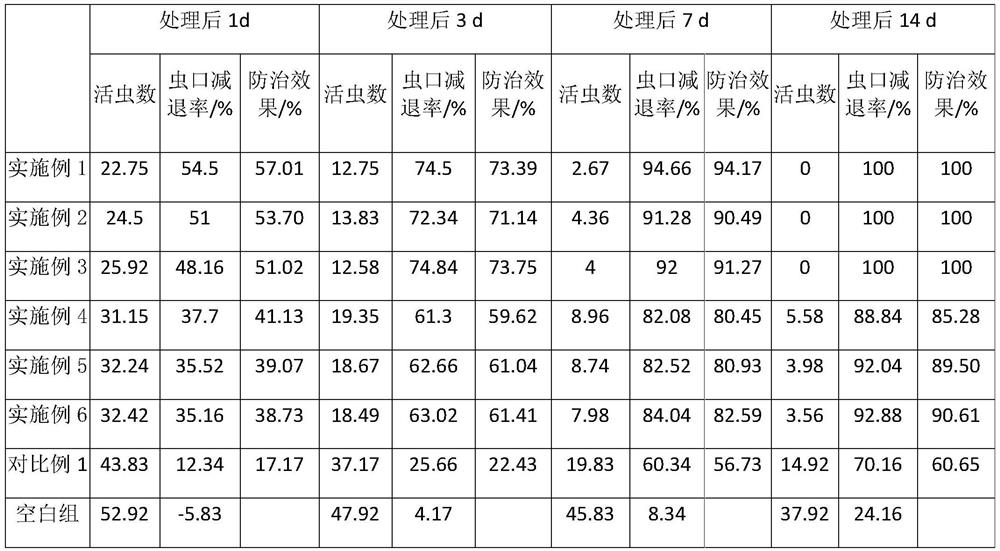

Preparation and application of metal-organic framework nano-pesticides encapsulated by coordination polymers

ActiveCN111011371BNot easy to gatherLarge specific surface areaBiocideAnimal repellantsNanoparticleInsect pest

The invention discloses a preparation method of a metal organic framework nano-pesticide encapsulated by a coordination polymer, using MOF(Fe III ) or MOF (Cu II ) as a pesticide carrier, load pesticide molecules in the solution, and then use tannic acid (tannic acid, TA) or tannic acid-Fe in aqueous solution III (TA‑Fe III ) or tannic acid-Cu II (TA‑Cu II ) Coordination polymers encapsulate pesticide-loaded metal-organic framework nanoparticles. The nanopesticide controlled-release preparation described in the present invention prevents the early release of pesticide molecules in a solvent, increases the lasting efficacy of the pesticide, is environmentally friendly, and achieves the purposes of preventing and controlling pests and increasing agricultural production and quality. The nano-pesticide controlled-release preparation provided by the present invention has a high drug loading rate and good biocompatibility, and the materials used are environmentally friendly, cheap in cost, and simple in the preparation process, and can realize the controlled release performance of pesticides with multiple biological interfaces and environmental responses. Easy to degrade and not easy to accumulate in plants.

Owner:NANJING UNIV

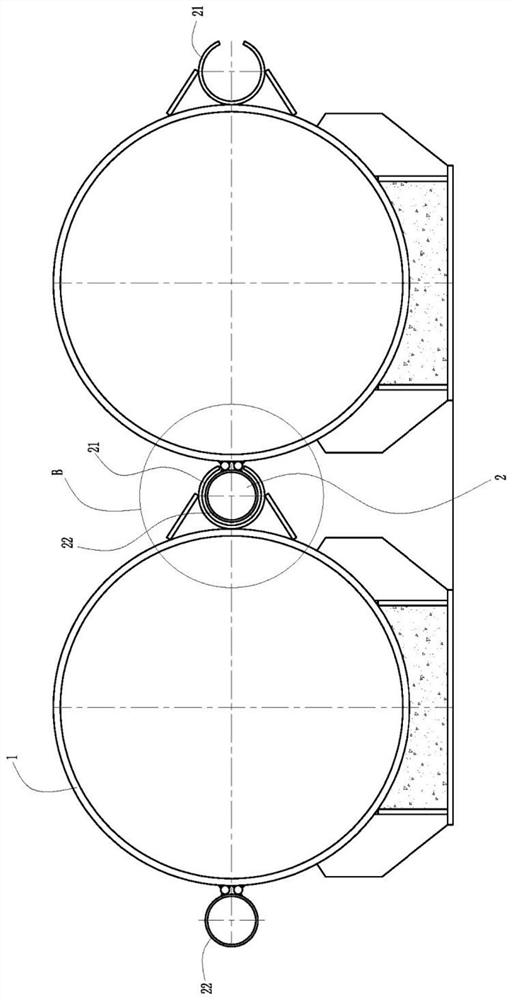

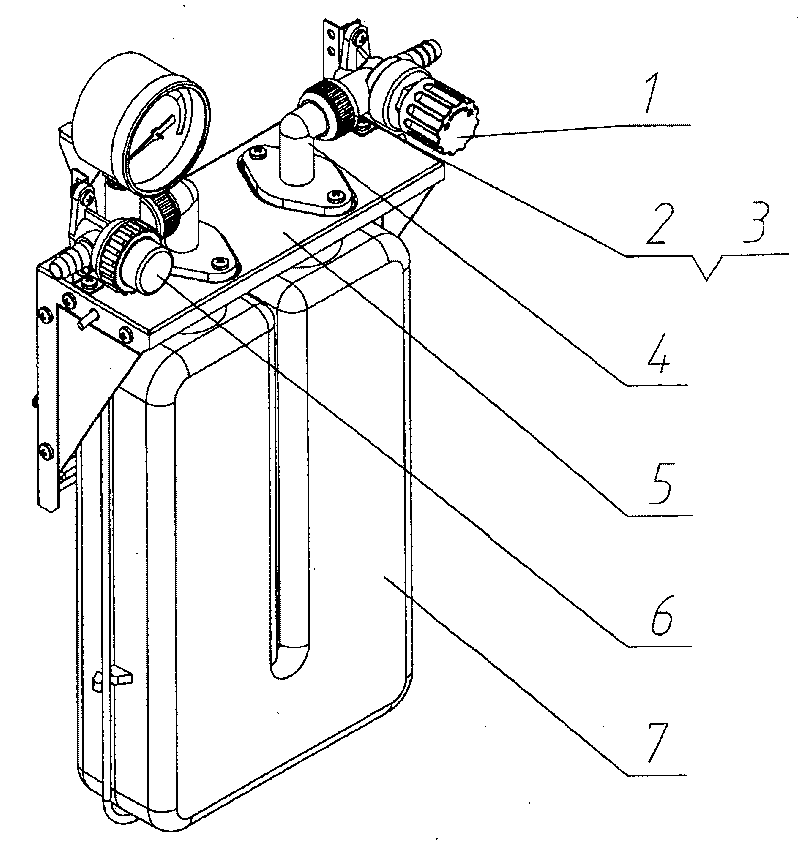

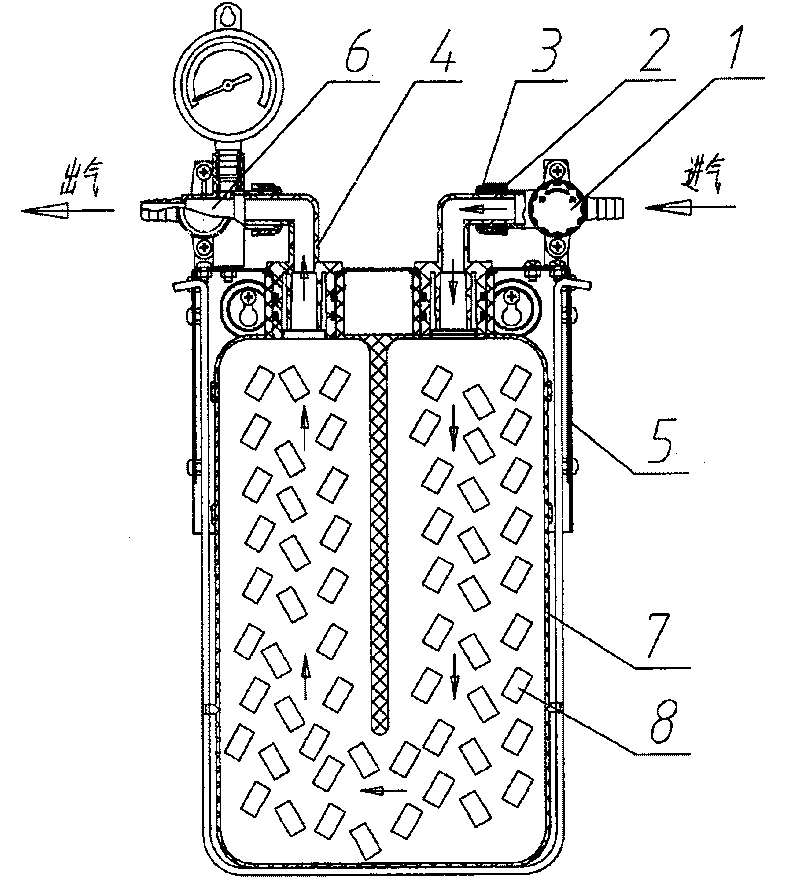

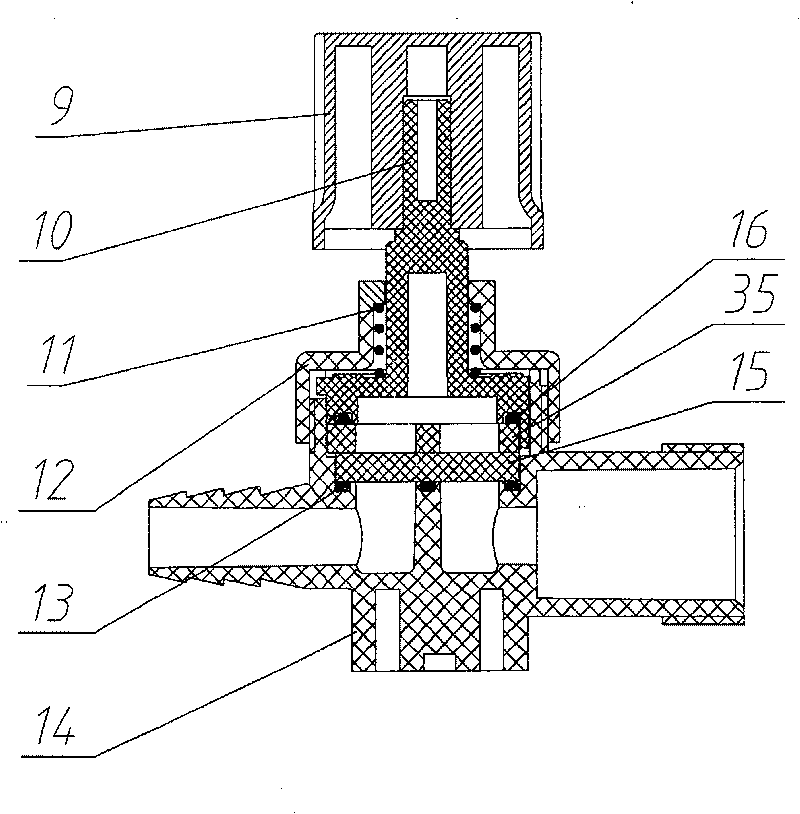

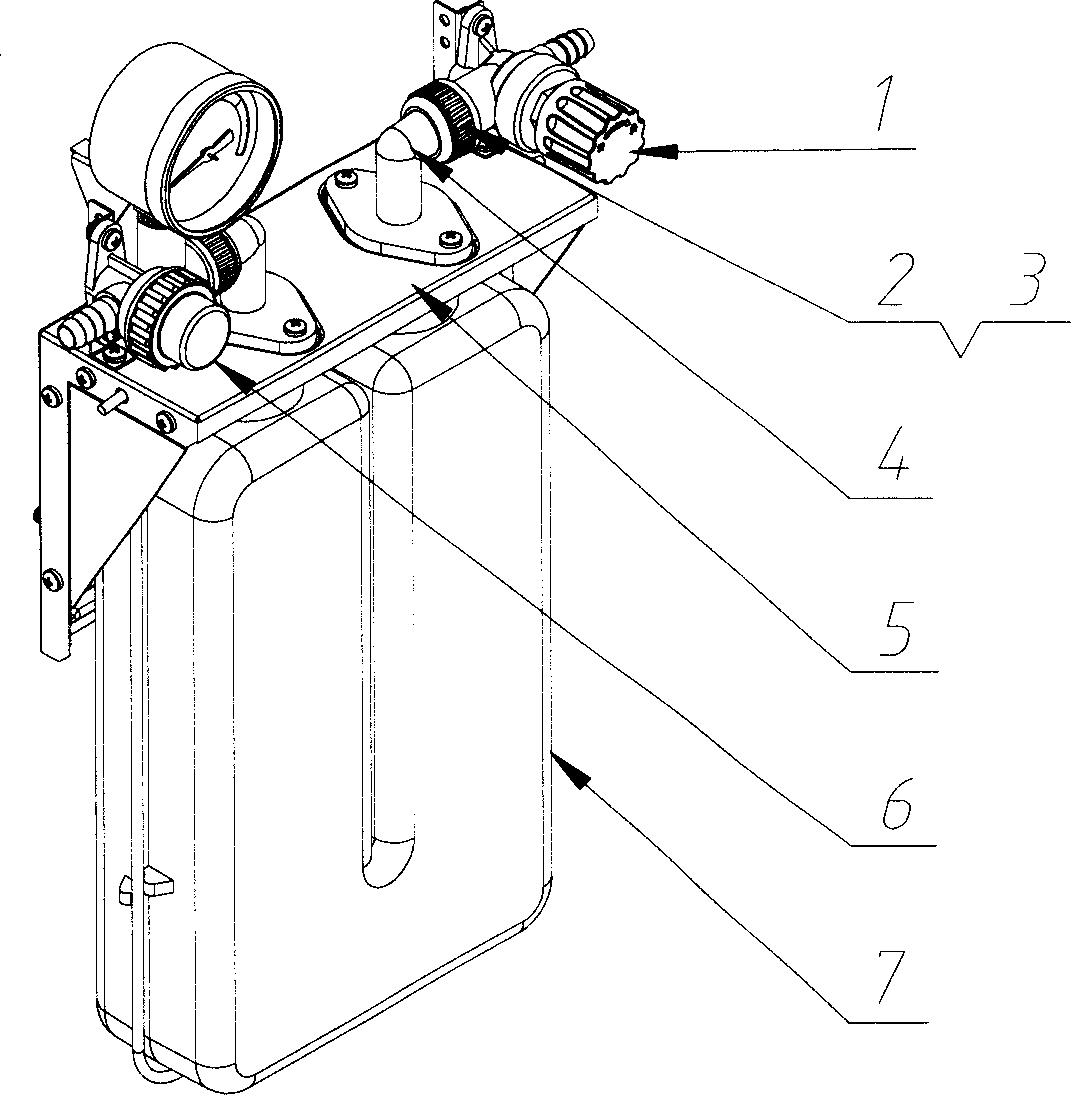

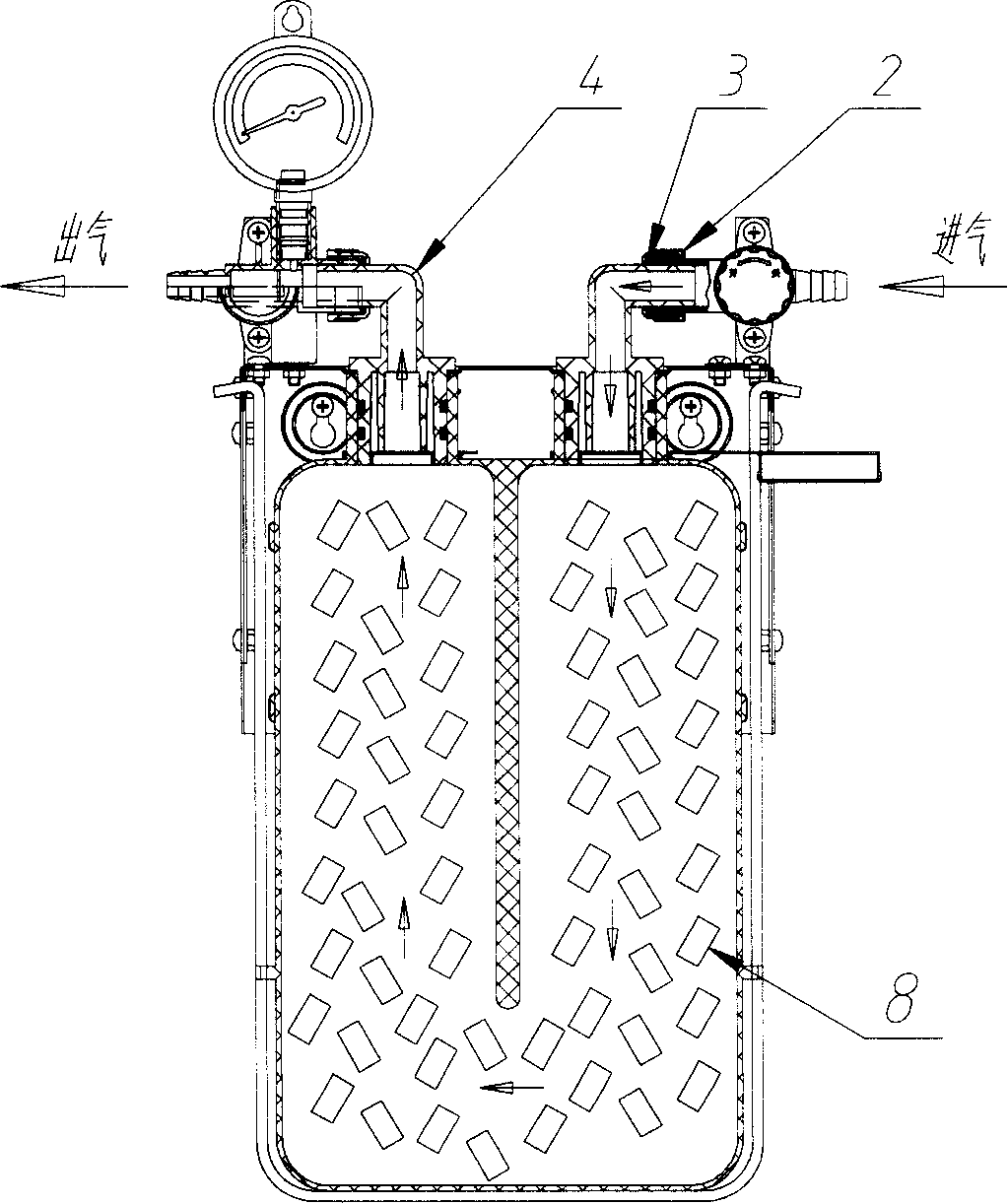

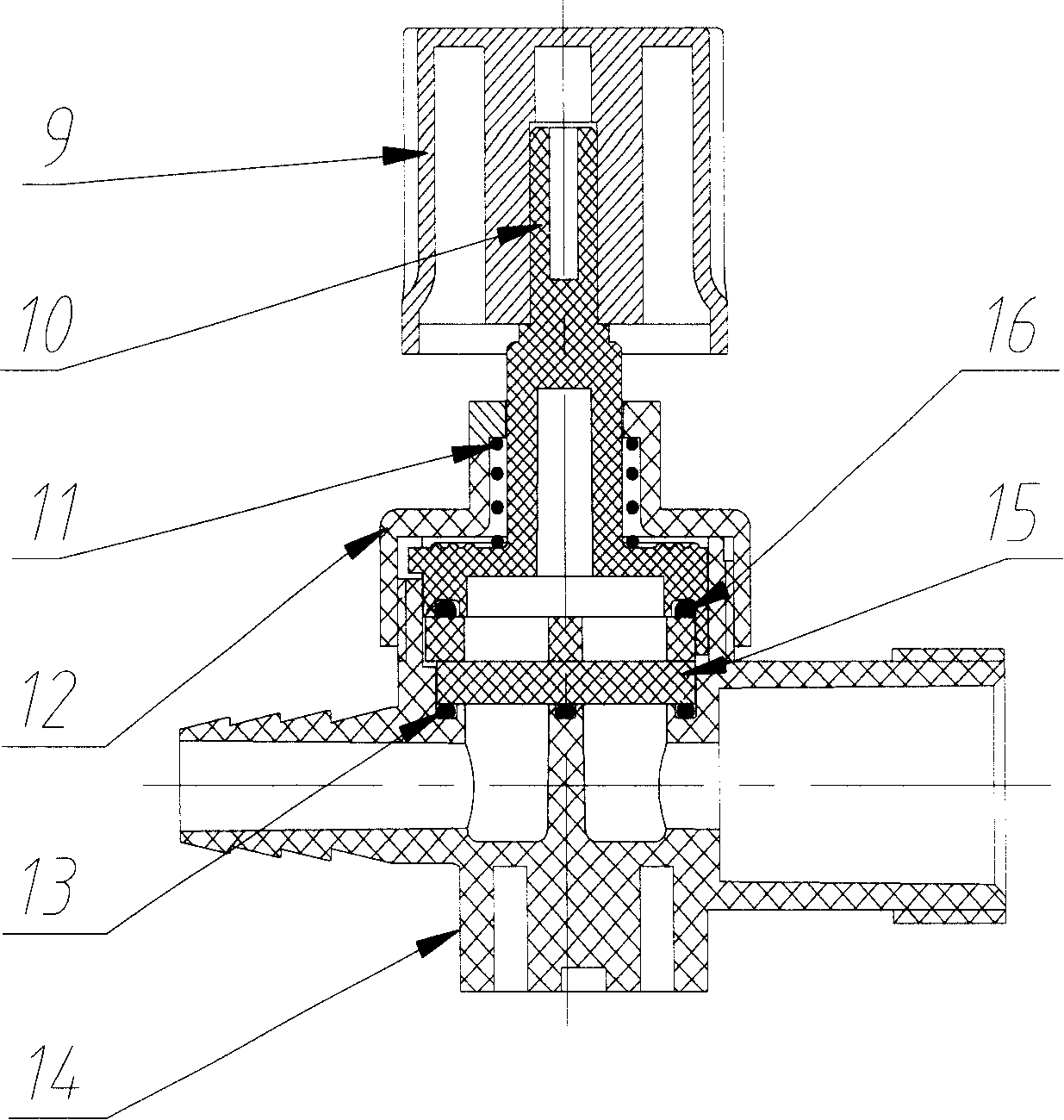

Methane purifier with quickly mutually-changing desulfurized bottle

InactiveCN101169254BQuick changeAvoid spillingDomestic stoves or rangesLighting and heating apparatusDisplay deviceEngineering

The invention provides a biogas purifier and a pressure gauge device being capable of quickly exchanging the desulfurizing bottle, which mainly solves the technical problems of the prior biogas purifier as unreasonable structure, inconvenient operation and frequent corrosion to the equipment. The invention has the points of the technical proposal that two bottle stoppers are symmetrically arrangedon the main body of a devulcanizer support component by using a bolt; the thread interface of the valve body of an adjusting control component and the short tube of the bottle stopper of a bottle stopper at one side are communicated by a plastic nut and a sealing sleeve, and are fixed on a small support at one side of the devulcanizer support component by a bolt; the thread interface of the display body of a display component and the short tube of the bottle stopper of a bottle stopper at the other side are communicated by a plastic nut and a sealing sleeve, and are fixed on a small support at the other side of the devulcanizer support component by a bolt; and then the pressure gauge is fixed on the profile of a small support at the side by a bolt.With simple and reliable structure and convenient disassembly and assembly, the invention, as the adjusting component adopts the ceramic valve core, is light and wearable; moreover, adopting the display with the desulfurizer state, the invention can timely indicate the user to reproduce or change the desulfurizer.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI

Methane purifier with quickly mutually-changing desulfurized bottle and pressure meter device

InactiveCN101169254AQuick changeAvoid spillingDomestic stoves or rangesLighting and heating apparatusLight touchDisplay device

A biogas purifier and pressure gauge device for quickly interchangeable desulfurization bottles. It mainly solves technical problems such as unreasonable structure, inconvenient operation, easy waste of resources and easy corrosion of equipment in the existing biogas purifier. The key points of the technical scheme are: the two bottle stopper parts are symmetrically installed on the main body of the desulfurizer support part with screws, the wire interface of the valve body of the regulating valve part is connected with the short pipe of the bottle stopper of one side of the bottle stopper part with a plastic nut and a sealing sleeve and fixed on the small bracket on one side of the desulfurizer bracket part with screws; the wire interface of the display body of the display part is connected with the short tube of the bottle stopper of the bottle stopper part on the other side with plastic nuts and sealing sleeves, and fixed with screws On the small bracket on the other side of the desulfurizer bracket part; then use screws to fix the pressure gauge fixing card on the side of the small bracket on this side. Its structure is simple and reliable, easy to disassemble and install. The control valve part adopts ceramic valve core, which is light in hand and durable. It adopts a display with desulfurizer status, which can prompt the user to regenerate or replace the desulfurizer in time.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI

A kind of self-flow drying agent and its preparation method and application

ActiveCN110402951BPrecise prevention and controlEnhance the ability of targeted drug deliveryBiocidePlant growth regulatorsDesiccantActive agent

The invention relates to the technical field of pest control, and specifically discloses a self-flowing drying agent and its preparation method and application. The self-flowing dry injection agent includes the following components by weight percentage: thickener: 0.3%-18%, synergist: 1%-5%, fertilizer: 0.1%-8%, solvent: 3.7% ~19%, surfactant: 0.3%~38%, insecticide: 2%~6%, antifreeze: 0.2%~3%, and the balance is water; the synergist is sodium nitrophenolate. The self-flowing desiccant prepared by the invention is stable and effective, and can be popularized and applied in a large area.

Owner:HEBEI ACAD OF FORESTRY SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com