Carbon-fiber washing machine for carbon fiber precursor washing

A carbon fiber raw silk, washing machine technology, applied in liquid/gas/vapor fiber/sliver/roving processing, textile material processing, continuous processing of textile materials, etc., can solve the problem of low cleaning efficiency, affecting the mechanical properties of carbon fiber, etc. problem, to achieve the effect of accurate transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

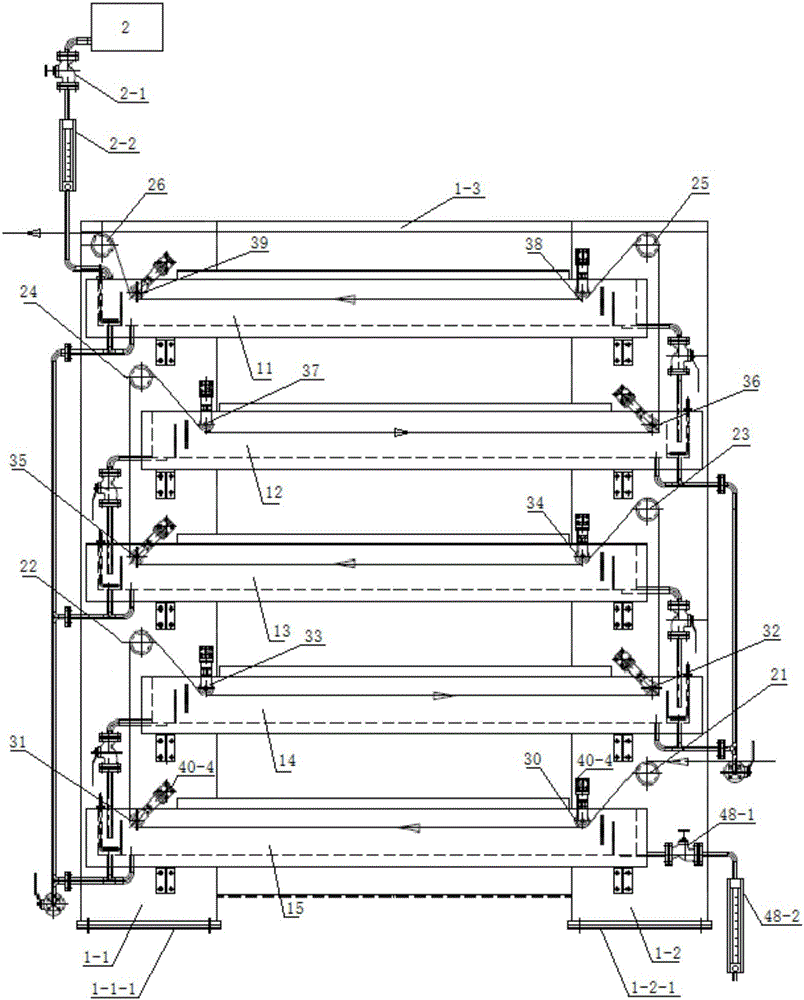

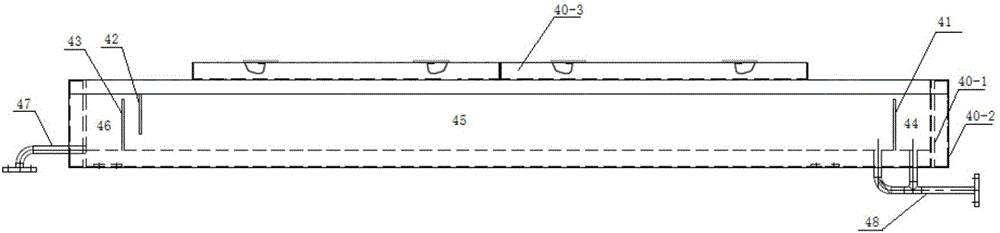

[0070] Embodiment 1: The present invention is used for the carbon fiber washing machine of carbon fiber precursor washing

[0071] The implementation mode of this embodiment is as follows:

[0072] In the carbon fiber water washing machine used for carbon fiber raw silk washing in the present invention, a multi-stage water washing tank is installed on the front of the frame 1, a driving roller and a guide roller are installed on the frame 1, and two sets of transmission systems are installed on the rear of the frame 1; The washing machine is equipped with a multi-stage washing tank at the front of the frame 1, a driving roller and a guide roller on the frame 1, and two sets of transmission systems at the rear of the frame 1;

[0073] The frame 1 is a frame made of angle steel. The frame 1 is provided with a left welding box 1-1 and a right welding box 1-2 on both sides; a left base 1-1 is installed on the lower part of the left welding box 1-1. -1, the right base 1-2-1 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com