Patents

Literature

50results about How to "Increase washing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

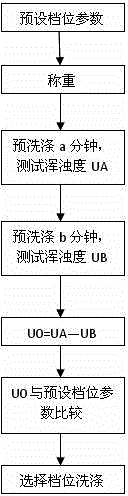

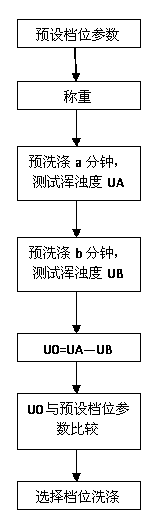

Method for distinguishing smudgy degree of clothes

ActiveCN102720033AShorten washing timeIncrease washing timeOther washing machinesControl devices for washing apparatusMachine controlStart time

The invention relates to a washing machine control method, which is particularly characterized in that the corresponding clothes washing control method is selected after the smudgy degree of clothes is judged. According to the method, firstly, the turbidity degree of water in the starting time period of the clothes washing is compared, the smudgy degree of clothes to be washed is distinguished, and then, the washing time, the washing intensity, the detergent addition quantity, the rinsing time and the like are regulated according to the smudgy degree of the clothes. The corresponding clothes washing procedure is selected according to the smudgy degree of the clothes, the clothes washing time of cleaner clothes can be reduced, the washing time of dirtier clothes is increased, and the clothes washing efficiency is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

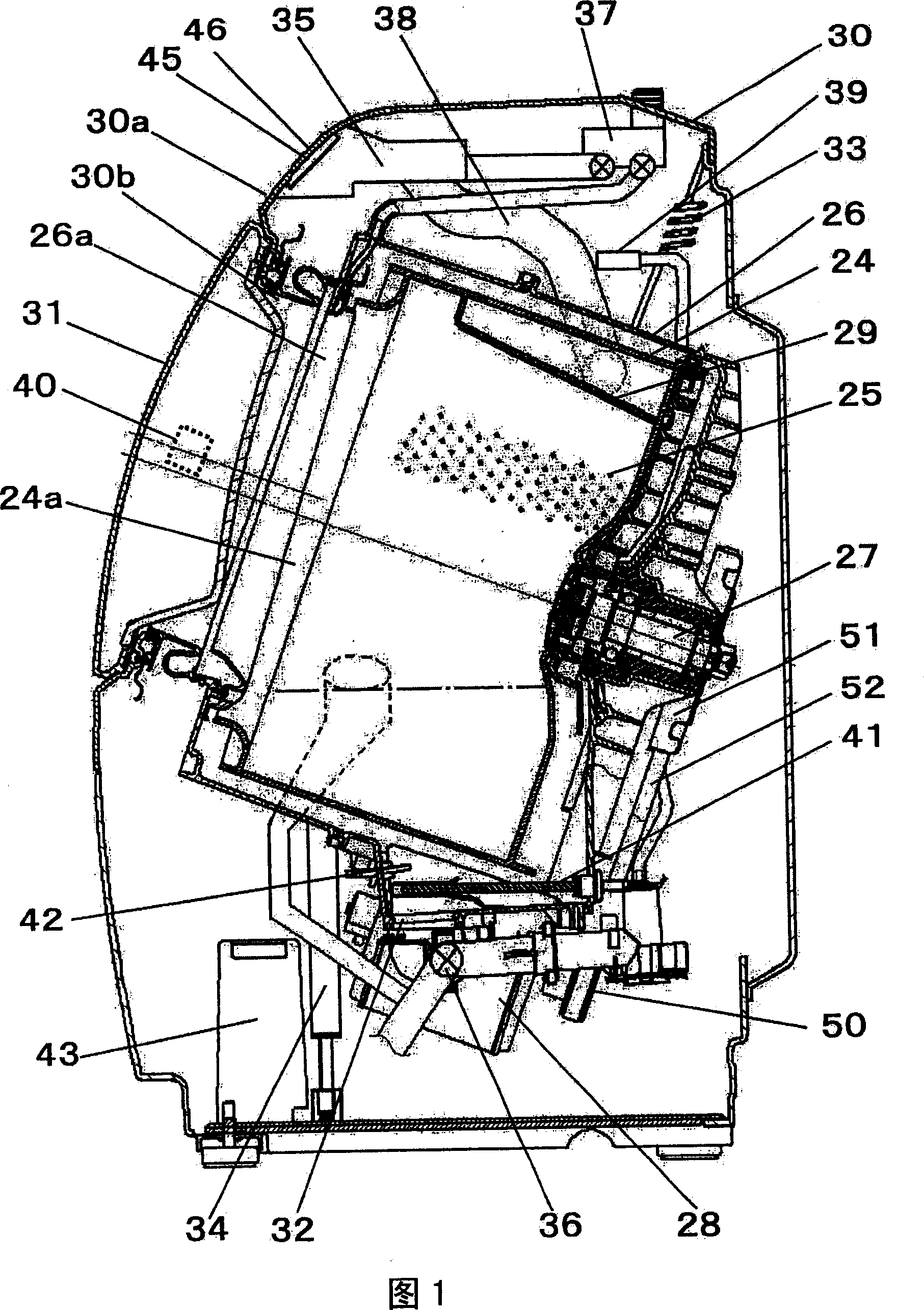

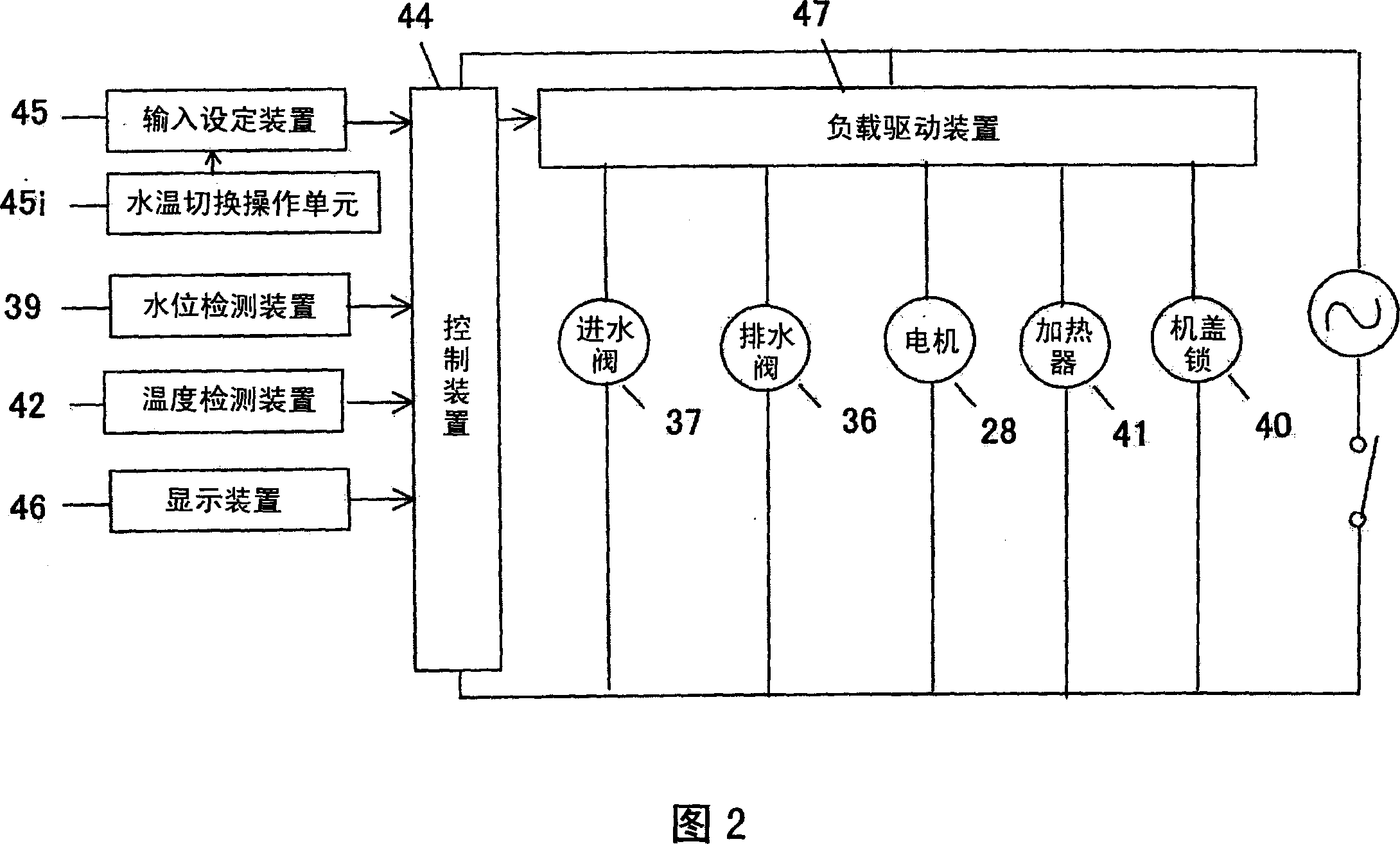

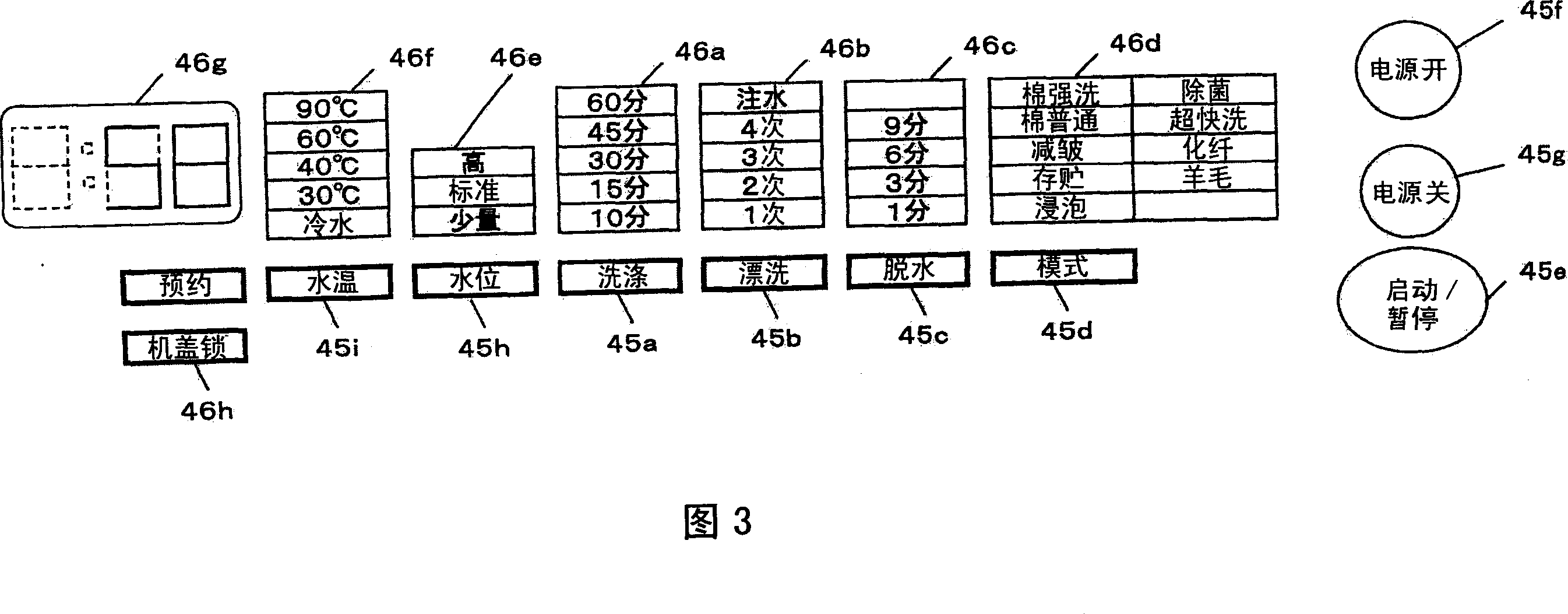

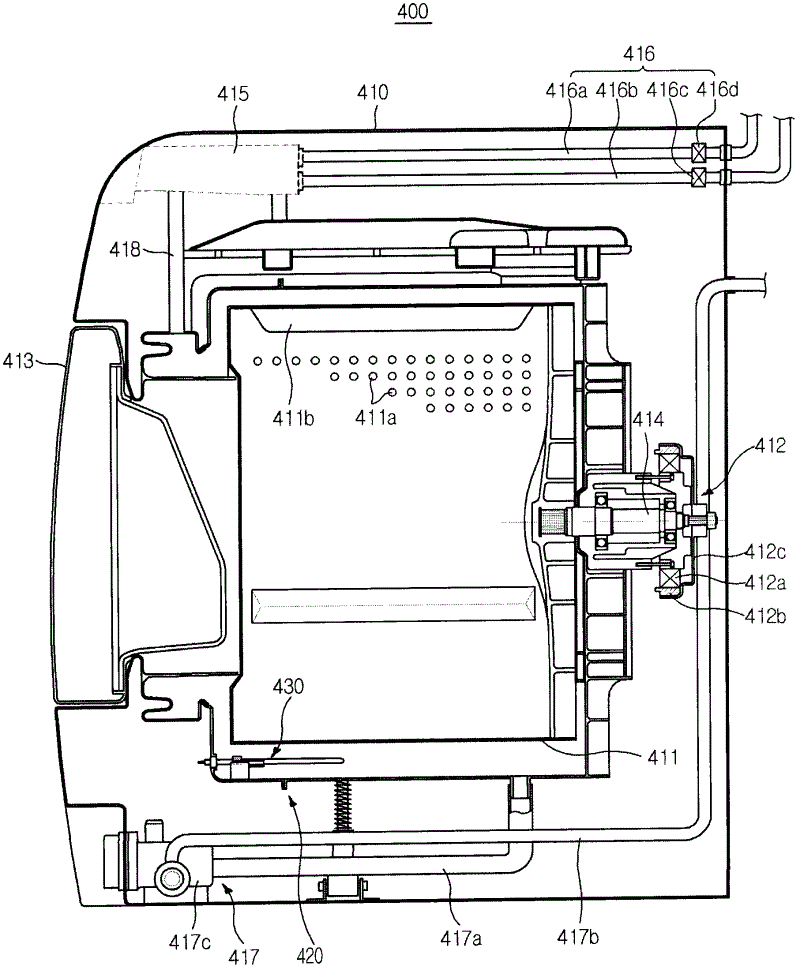

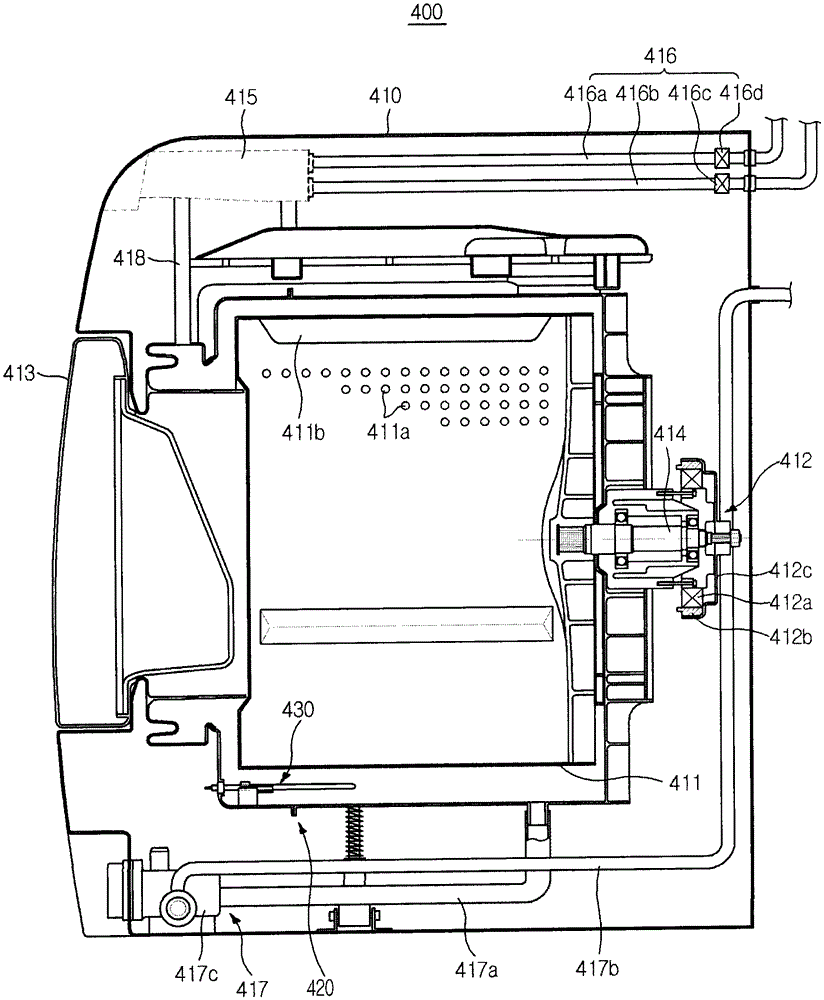

Drum washing machine

ActiveCN1928198AReduce poor driveIncrease washing timeOther washing machinesControl devices for washing apparatusElectric machineryProcess engineering

The invention provides a drum type washing machine capable of reducing the defective driving caused by the rise of the temperature of a motor in a high-temperature washing process, improving and adjusting the washing performance and disinfectant performance according to the quantity of the laundry and temperature of fed water, and reducing the damage and shrinkage of fabrics. The washing machine has the high-temperature washing process for heating washing water at least at a first prescribed temperature T1 by controlling a heater (41) for washing. The high-temperature washing process is divided into a first agitation process in the first half and a second agitation process in the latter half. The first agitation process is a process to be continued till the fed washing water is heated to a second prescribed temperature T2 set lower than the first prescribed temperature T1, and the second agitation process is a process to be continued till the washing water is heated from the second prescribed temperature T2 to the higher first prescribed temperature T1. The ratio of period of time for driving a motor (28) in the first agitation process is set lower than the ratio in the second agitation process.

Owner:PANASONIC CORP

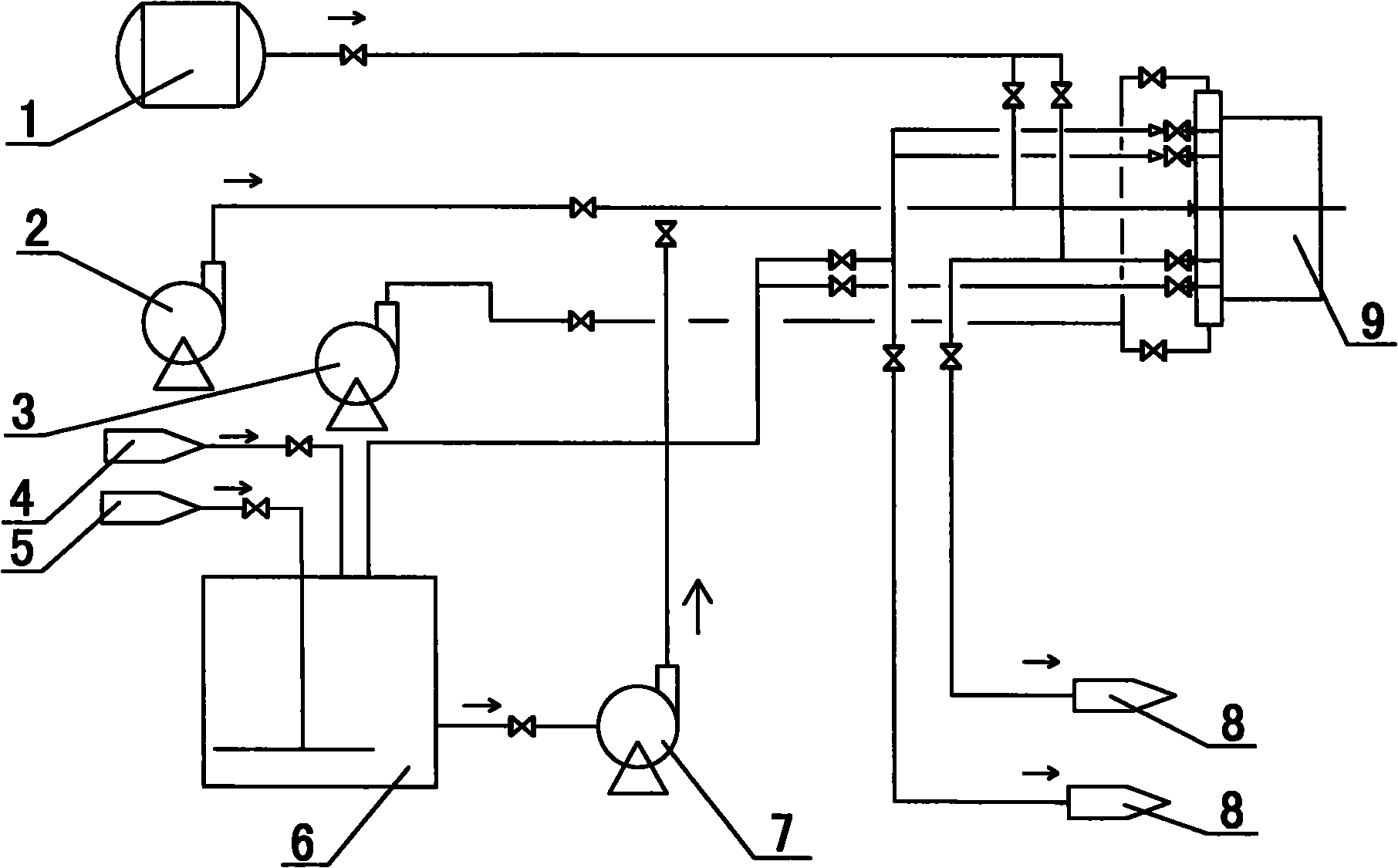

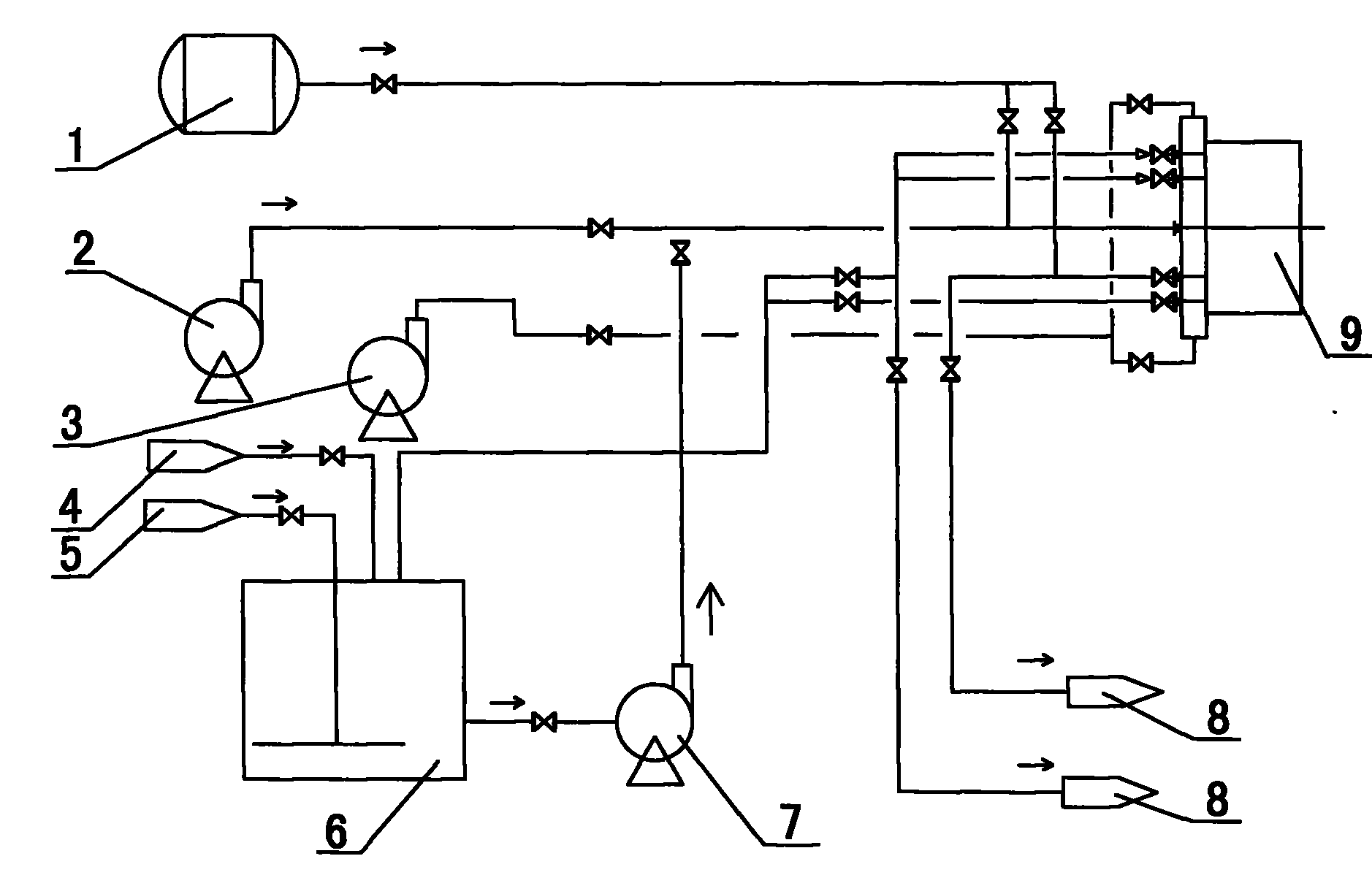

Alkali cleaning system for filter cloth of press filter and cleaning method thereof

The invention relates to an alkali cleaning system for filter cloth of a press filter and a cleaning method thereof. The alkali cleaning system for the filter cloth of the press filter comprises a compressed air storage tank, a filter cake washing pump, a process water pump, a steam pump, an alkali tank, an alkali cleaning pump, sewage treatment ponds, the press filter and pipelines, wherein the whole system is connected through the pipelines, and is provided with corresponding valves; the alkali tank is externally connected with the steam pump and the process water pump; an alkali liquor runback pipeline is connected to the press filter; another pipeline is connected to the alkali cleaning pump; the output pipeline of the alkali cleaning pump and the output pipeline of the compressed air storage tank are converged with the feeding pipeline of the press filter, and then connected to the press filter together; another pipeline of the compressed air storage tank is connected with sewage recycling pipelines; and the output pipeline of the filter cake washing pump is connected to the press filter. In the invention, on the basis of the original press filtering system, the alkali cleaning system is added, so that the alkali cleaning system for the filter cloth of the press filter and the cleaning method thereof are convenient to carry out and have high cleaning efficiency and an good cleaning effect, in addition, the cleaning operations are simplified, the cost is saved, and the production efficiency is ensured.

Owner:WUXI HENGCHENG SILICON IND CO LTD

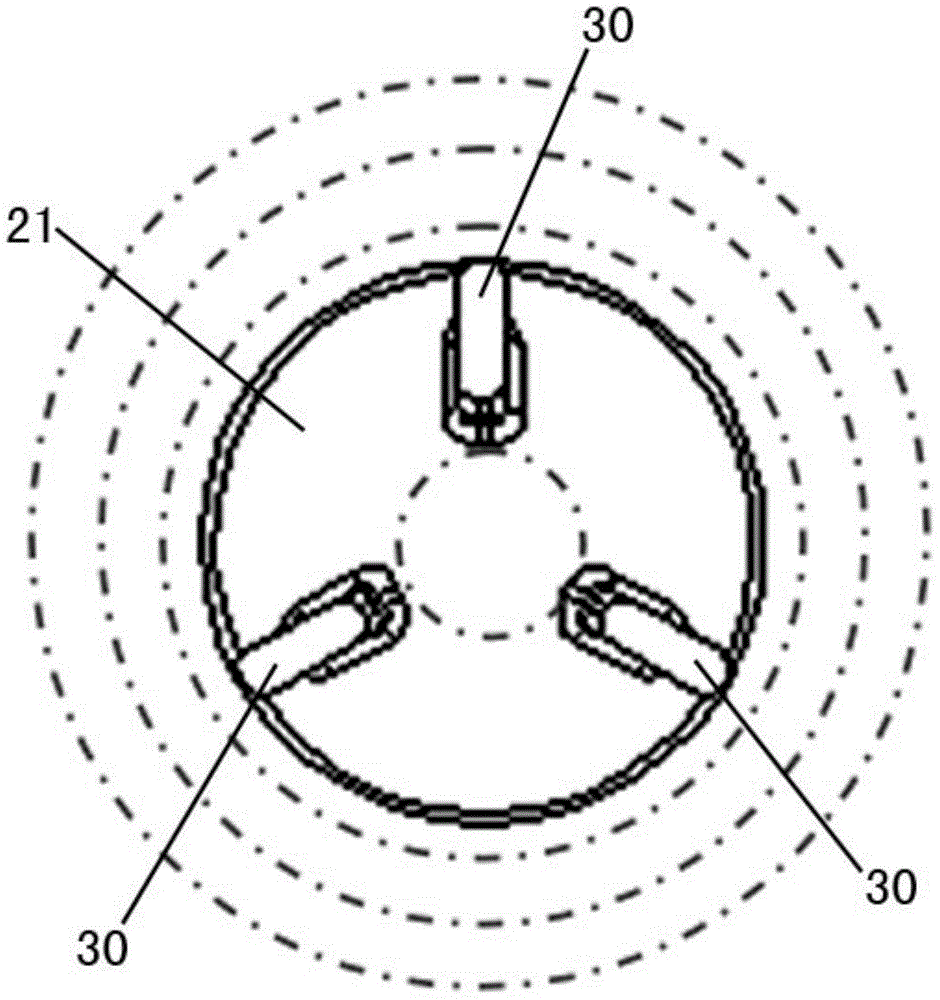

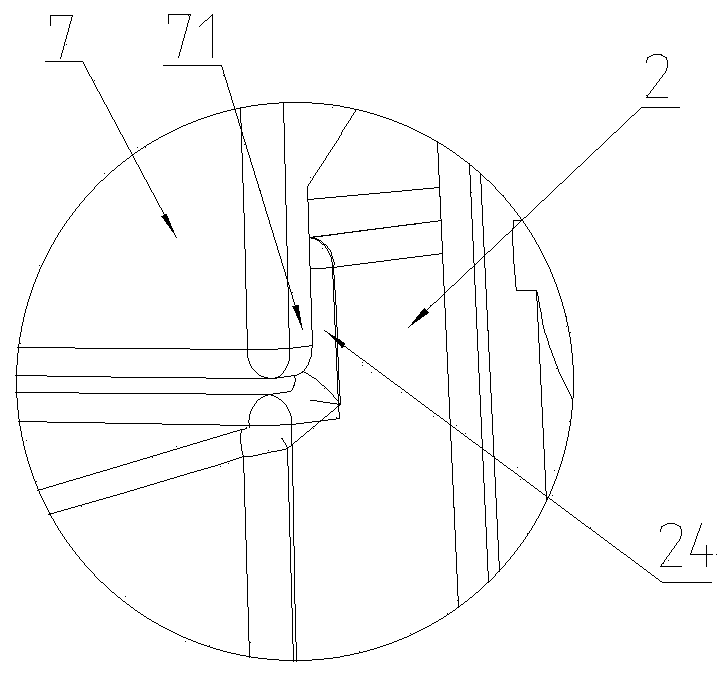

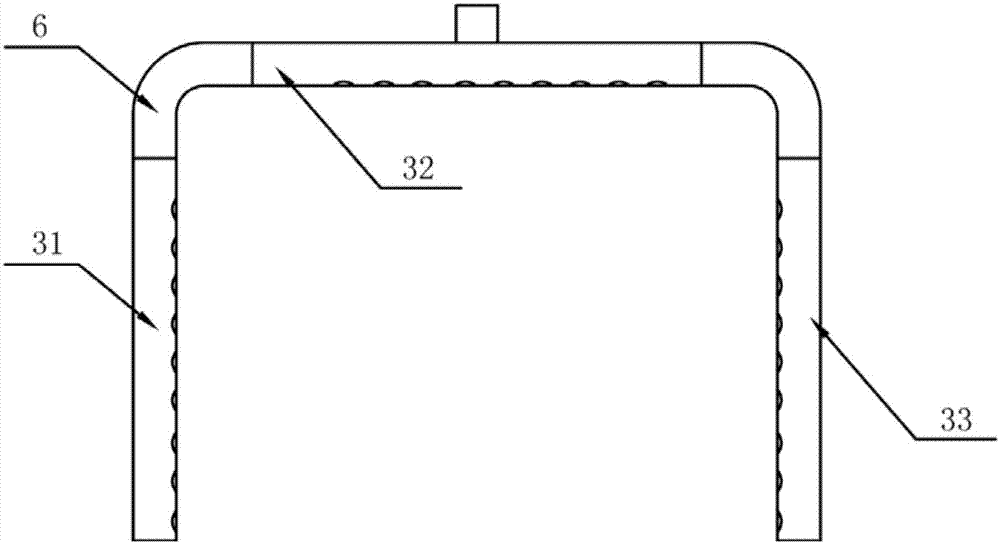

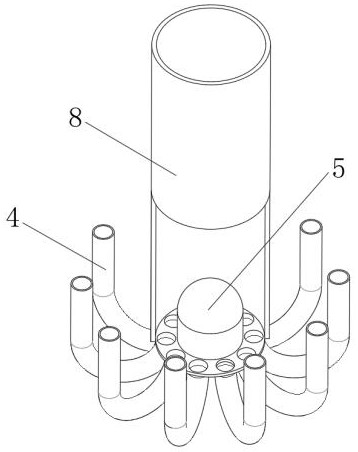

Spraying device of washing machine, and roller washing machine with same

ActiveCN105369566AImprove spraying effectShorten washing timeOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention discloses a spraying device of a washing machine, and a roller washing machine with the same. The spraying device of a washing machine comprises a water filled element, a water guide element, and a plurality of diversion elements. The water filled element is internally provided with a water filled channel. The upper end face of the water filled element is provided with a water inlet communicated with the water filled channel, and the lower end face is provided with a water outlet communicated with the water filled channel. The water guide element is arranged under the water filled element. The water guide element is provided with a conical water guide surface opposite to the water outlet. The lower ends of the plurality of diversion elements are connected with the conical water guide surface at equal interval along the circumferential direction of the conical water guide surface, and are between the top point and the peripheral edge of the conical water guide surface. The upper ends of the plurality of diversion elements are respectively connected with the water filled element. The spraying device of a washing machine is advantaged by improving utilization rate of a detergent, and improving washing time and washing effect.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

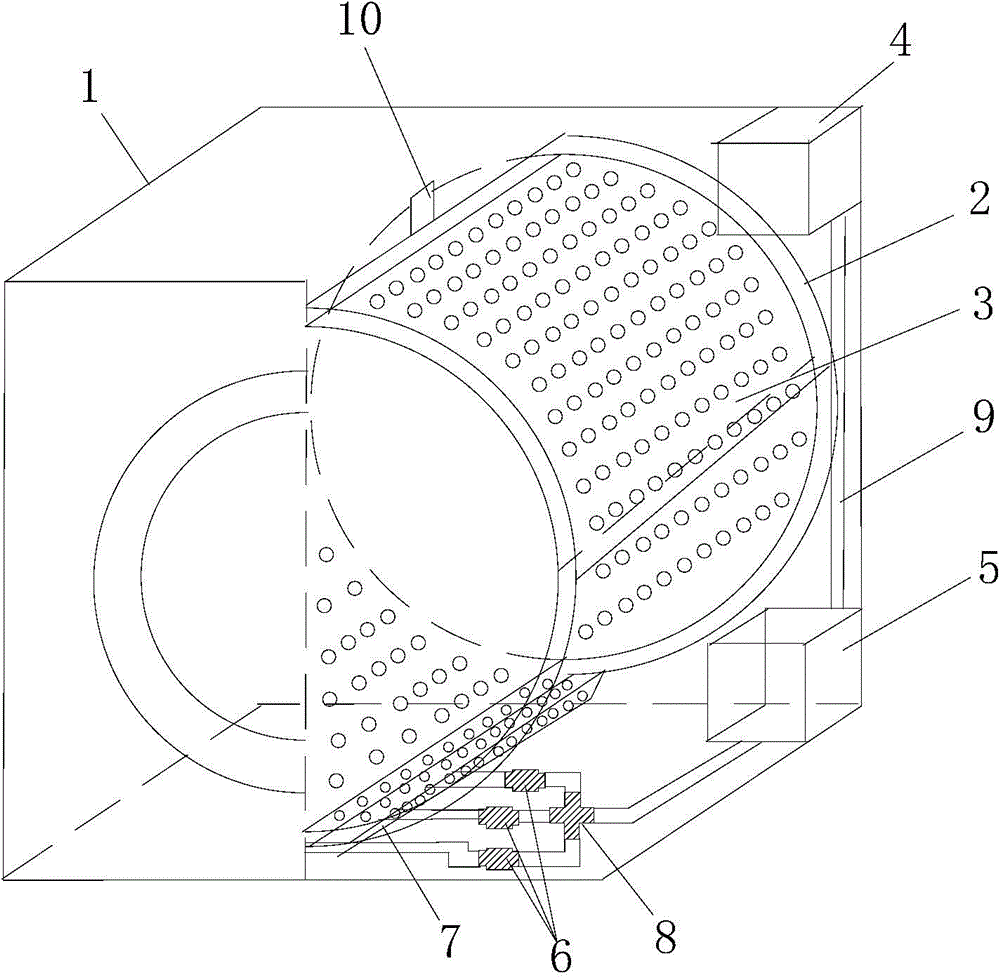

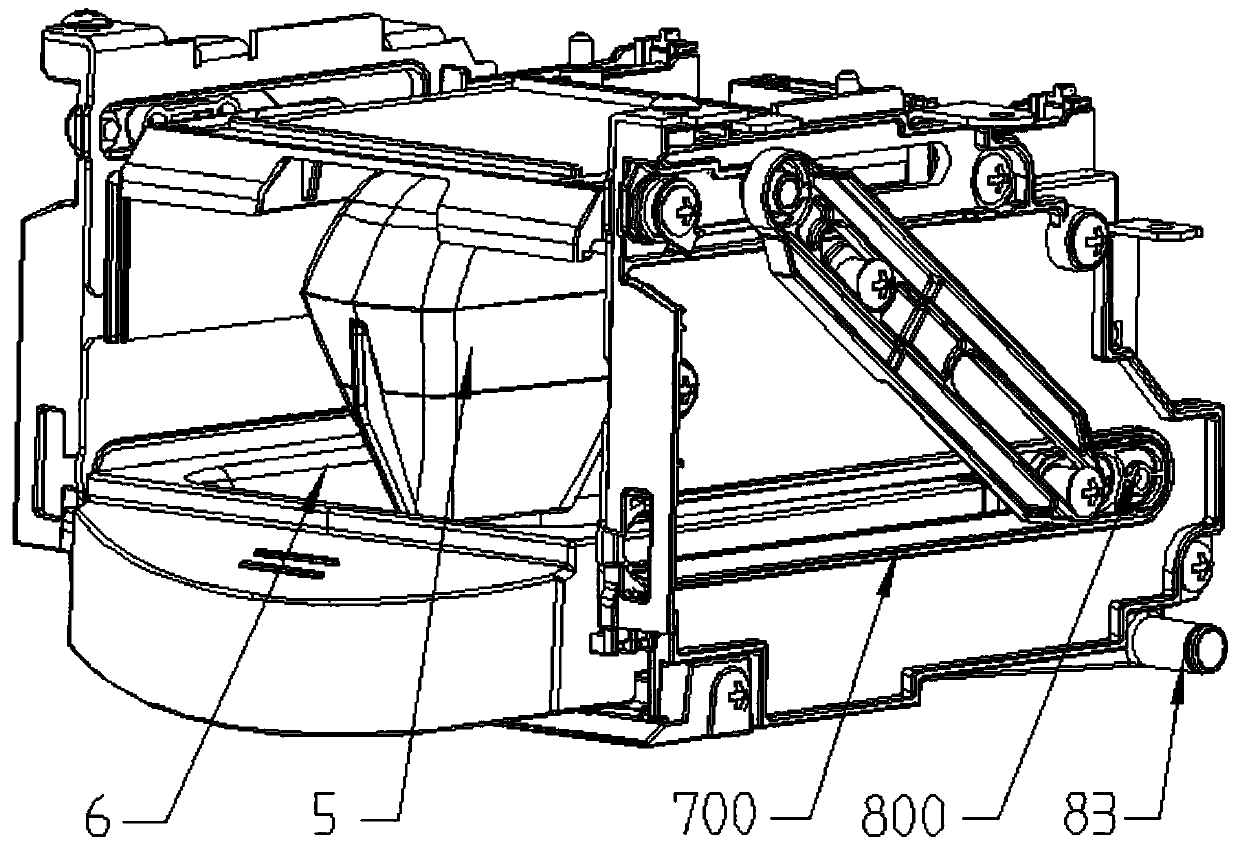

Blowing type roller washing machine and clothes-washing method thereof

ActiveCN105316909ADissolve fastEasy to dissolveOther washing machinesTextiles and paperStopped workEngineering

The invention discloses a blowing type roller washing machine and a clothes-washing method thereof. The washing machine comprises an inner barrel, an outer barrel, air chambers blowing air into the outer barrel to generate bubbles and an air pump. A gas heating device is arranged on an access for conveying air to the air chambers, and during washing, the air chambers are controlled to blow hot air into the outer barrel to act on water to generate hot bubbles. The number of the air chambers is at least two, the air chambers comprise a first air chamber and a second air chamber, and the blowing direction of the first air chamber and the blowing direction of the second air chamber are correspondingly consistent with the forward rotation direction and the reverse rotation direction of the inner barrel respectively. The air chambers further comprises a third air chamber, the third air chamber is arranged at the bottommost end of the outer barrel to be axially distributed, the blowing direction is upwards, and the first air chamber and the second air chamber are located on the two sides of the third air chamber respectively. When the washing machine is used for washing, the air pump and the gas heating device work, the air chambers blow the hot bubbles into the outer barrel; during the rinsing, the gas heating device stops working, the air pump works, and natural wind is formed in air chambers. According to the blowing type roller washing machine, the clothes washing ratio is improved, electric energy consumption is reduced, and the clothes-washing time is saved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

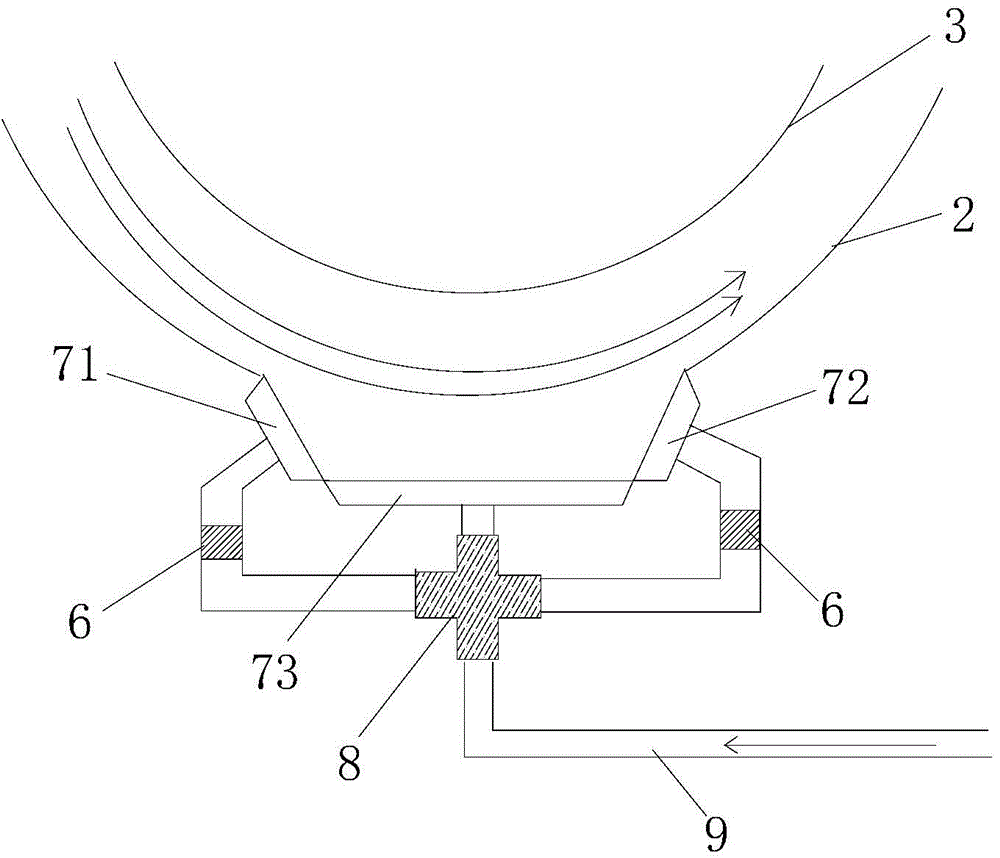

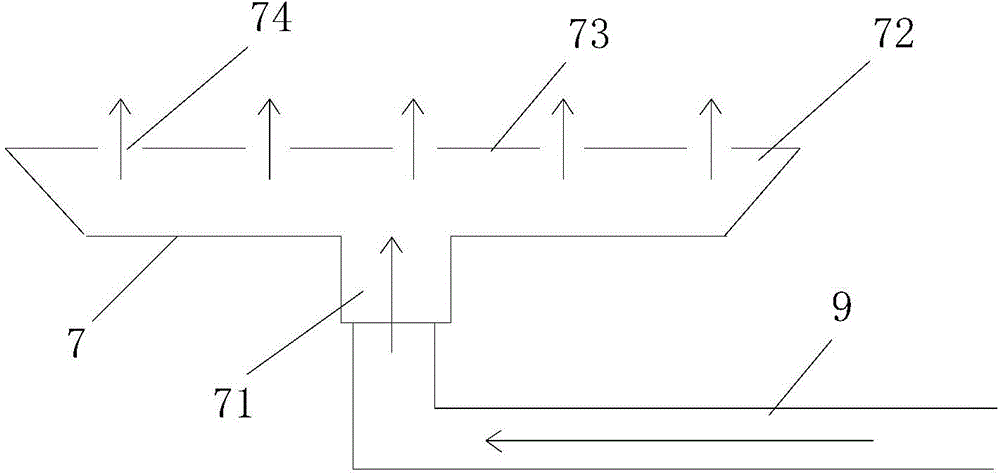

Air-blowing-type roller washing machine and clothes-washing method thereof

ActiveCN105220399AExtension of timeShorten washing timeOther washing machinesControl devices for washing apparatusCheck valveEngineering

The invention discloses an air-blowing-type roller washing machine and a clothes-washing method thereof. The washing machine comprises an internal cylinder, an external cylinder, at least two air chambers used for externally blowing air and an air pump. All the air chambers are independent. The air-blowing direction of at least one air-blowing chamber is the same as the forward-rotating direction of the internal cylinder. The air-blowing direction of at least another air-blowing chamber is the same as the backward-rotating direction of the internal cylinder. During washing, an air chamber in the air-outlet direction same as the rotation direction of the internal cylinder is controlled to blow air into the external cylinder in order to generate bubbles. All the air chambers are communicated with the same air pump by means of an air-flow distributor. Check valves are arranged among the air-flow distributor and all the air chambers. An air-heating device is arranged between the air-flow distributor and the air pump. During washing / rinsing operation of the washing machine, the internal cylinder rotates forward and an air chamber in the air-blowing direction same as the forward-rotating direction of the internal cylinder is controlled to blow air. The internal cylinder rotates backward and an air chamber in the air-blowing direction same as the backward-rotating direction of the internal cylinder is controlled to blow air. During washing, hot air is blown by air chambers and natural air is blown by air chambers. The air-blowing-type roller washing machine has a simple structure and helps to save clothes-washing time and increase clothes-washing efficiency.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

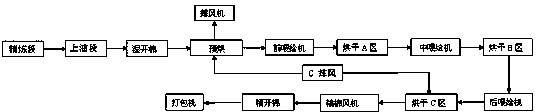

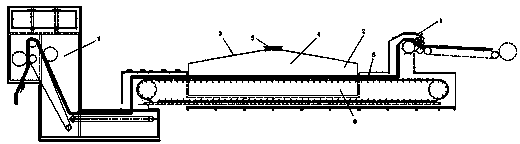

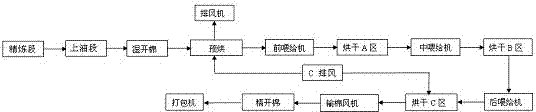

High-capacity viscose staple fiber post-treatment production line

InactiveCN103422290AIncrease washing timeWash Time GuaranteeSucessive textile treatmentsLiquid/gas/vapor removalProduction lineSingle process

The invention aims at providing a high-capacity viscose staple fiber post-treatment production line in order to reach the annual yield of 100 thousand tons. The production line comprises a refining system and a drying system. A refiner in the refining system comprises a refining section and an oiling section. The high-capacity viscose staple fiber post-treatment production line is characterized in that the breadth of the refiner of the refining system is 4000mm, the refining section is divided into 13-18 process areas, the oiling section is divided into 2 process areas and the length of a single process area is 2500mm. The viscose staple fiber post-treatment production line comprises the refining system and the drying system, and has the advantages that the production capacity is strong, the operation stability is high, the automation level is high and the product quality is guaranteed.

Owner:YIBIN GRACE +2

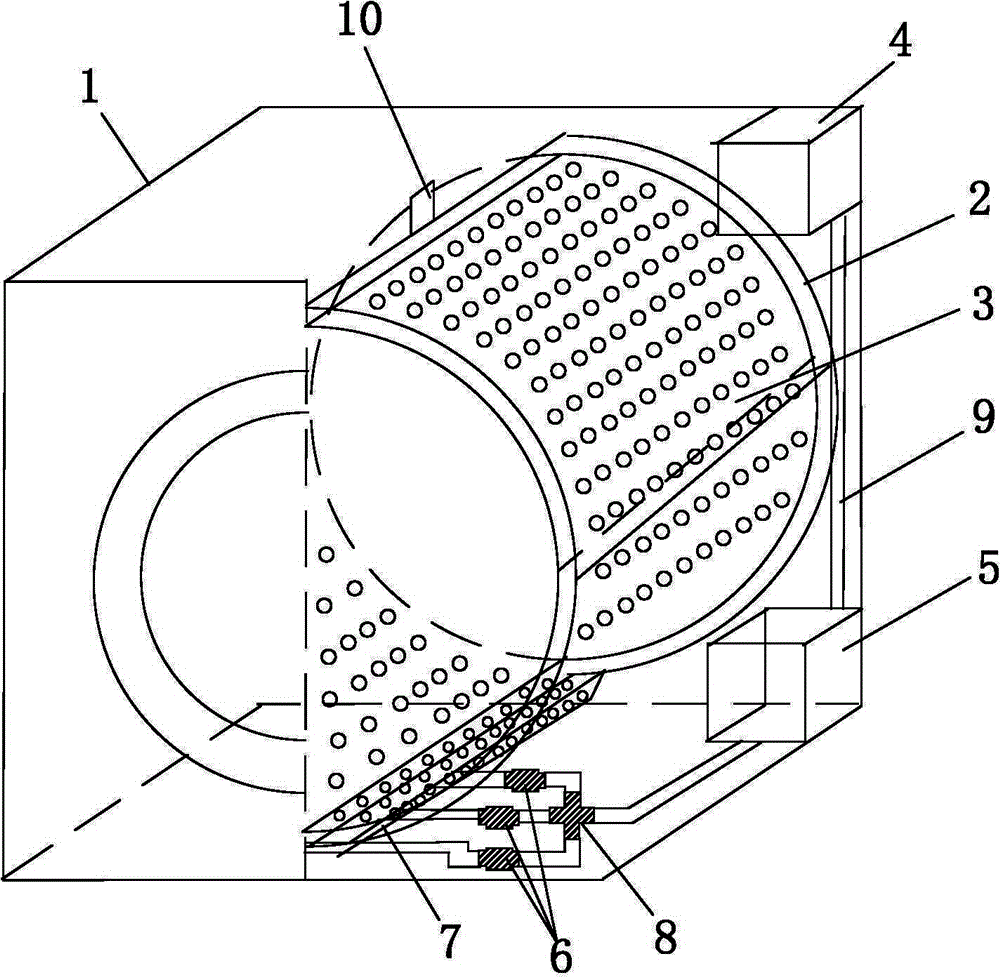

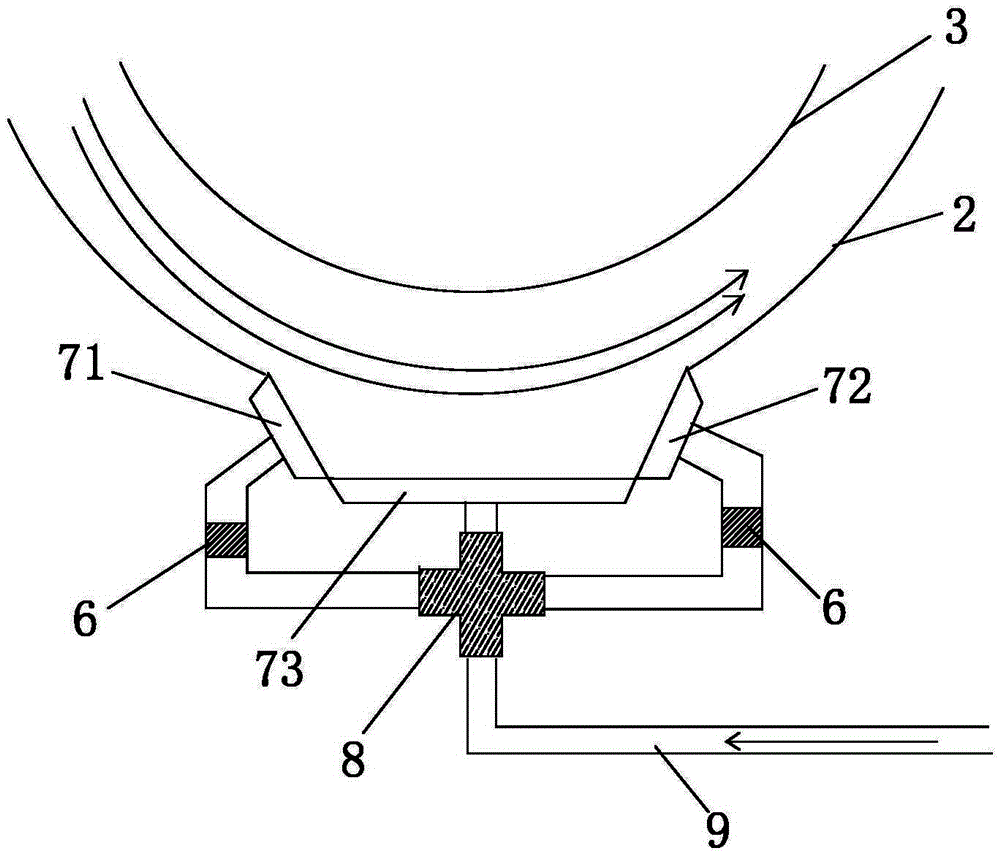

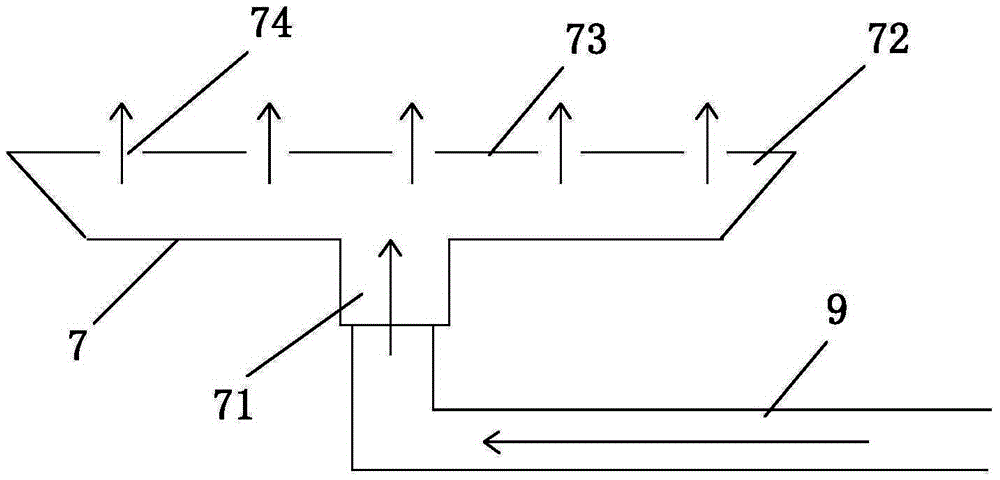

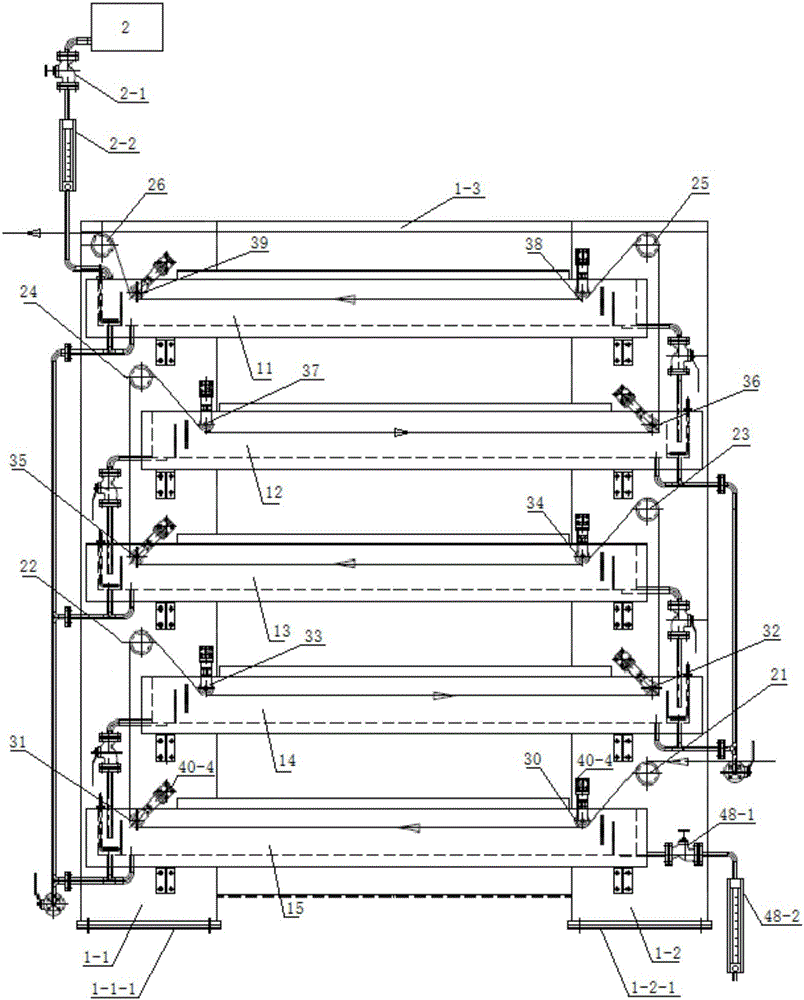

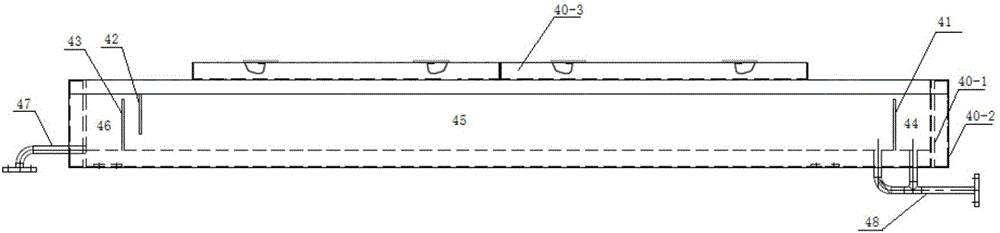

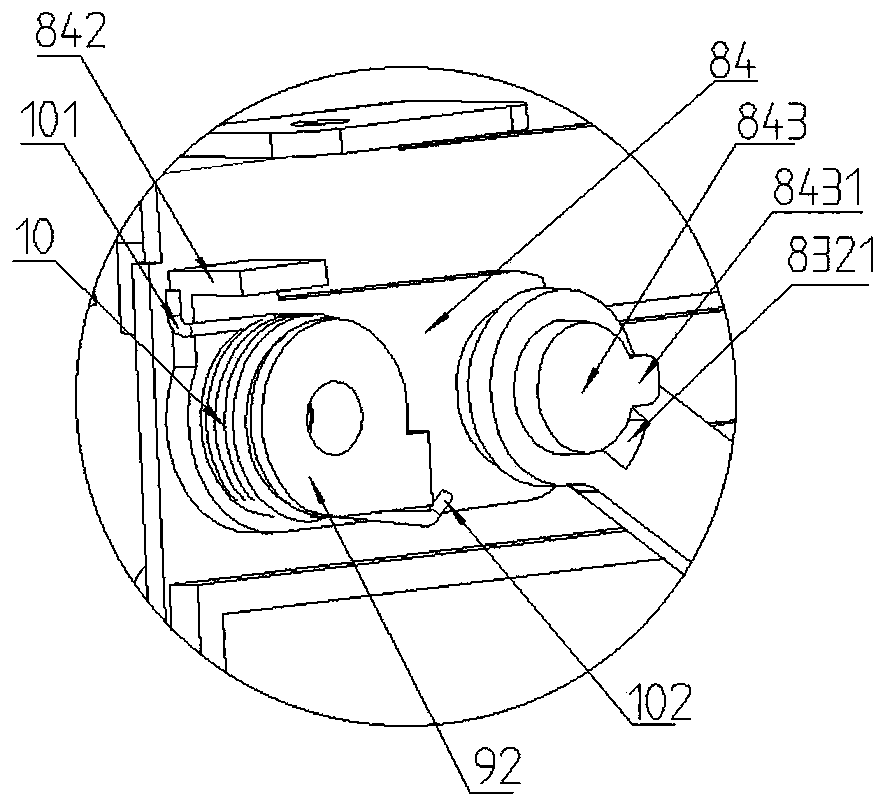

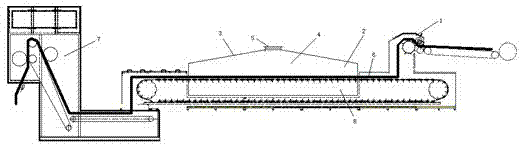

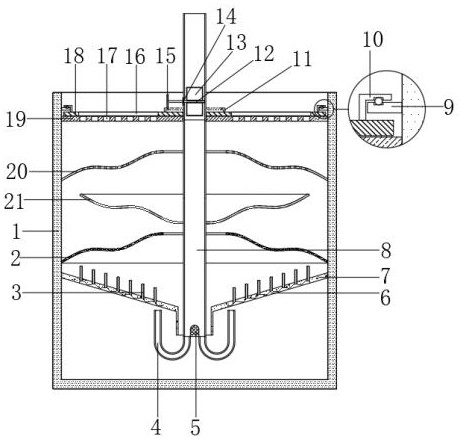

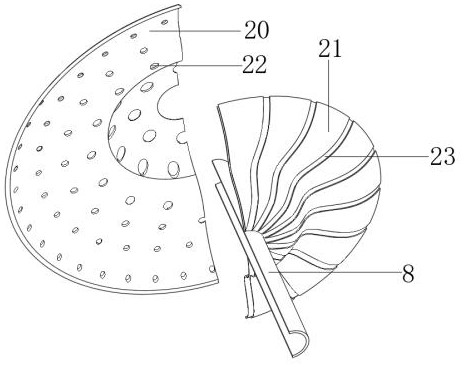

Carbon-fiber washing machine for carbon fiber precursor washing

ActiveCN106521848AAccurate transmissionSmooth transmissionSucessive textile treatmentsTextile treatment containersWater useFiber

The invention relates to a carbon-fiber washing machine for carbon fiber precursor washing. A multilevel washing trough is installed at the front portion of a machine frame 1, a driving roller and a guiding roller are installed on the machine frame 1, and two transmission systems are installed at the back portion of the machine frame 1. The carbon-fiber washing machine is superposed by five-level water troughs in a dislocation mode, the washing time is prolonged, and the occupied area of the device is saved to a maximum degree. As liquid level plates, flow stopping plates and overflowing plates are designed in the washing troughs, the washing process is intensified; as the two ends of the washing troughs are distributed in a dislocation mode, the number of driving roller is reduced, the contact area of fibers and rollers is reduced, and the broken filament generating probability caused by friction is reduced; deionized water used by the carbon-fiber washing machine flows to the next washing trough from the last washing trough and is recycled, and the cost is reduced while the washing effect is improved. The carbon-fiber washing machine has the advantages of being simple in structure and convenient to daily maintain and operate.

Owner:THE NORTHWEST RES INST OF CHEM IND

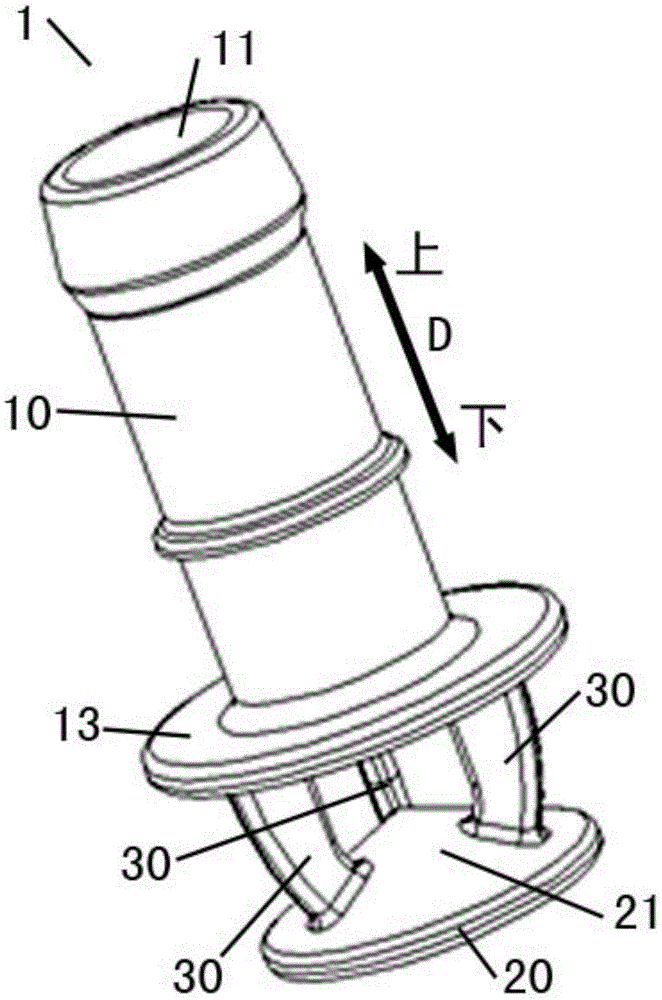

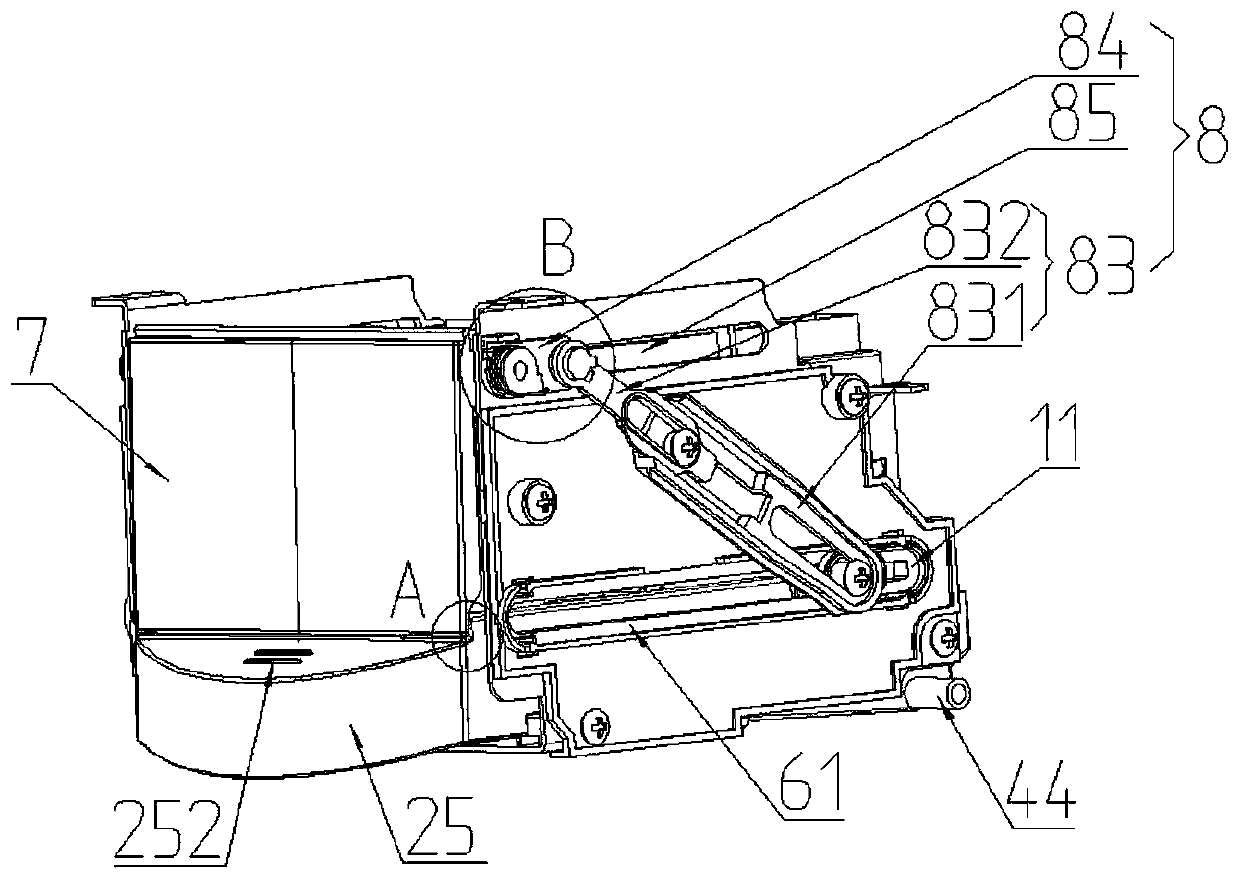

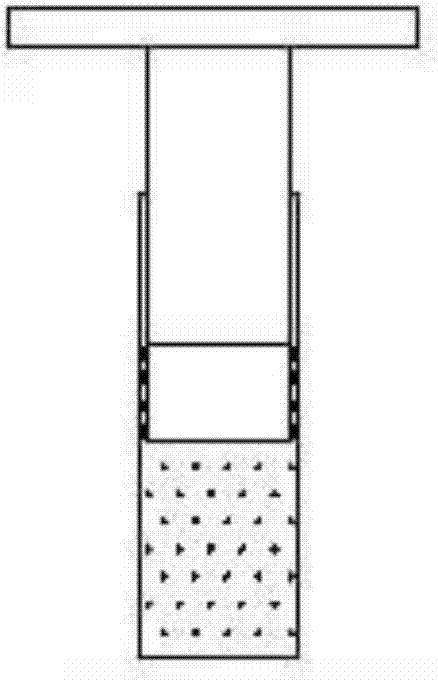

Ultrasonic device and clothes treating apparatus

PendingCN110685107AEasy to operateImprove experienceTextiles and paperVibration washing machinesWater flowAcoustics

The invention belongs to the technical field of ultrasonic waves, and aims to solve the problem that an existing ultrasonic device without a proper liquid drainage mode cannot timely drain liquid in awater containing component when a user does not use the existing ultrasonic device. The ultrasonic device comprises a shell, a water containing component and an opening-closing assembly, the opening-closing assembly is closed when the water containing component is pulled out of the shell to stop water in the water containing component from flowing out, and the opening-closing assembly is opened when the water containing component is pushed into the shell to allow the water in the water containing component to flow out. When the user does not use the ultrasonic device, the liquid in the watercontaining component can be timely drained, so that bacteria breeding caused by liquid accumulation in the water containing component is avoided.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

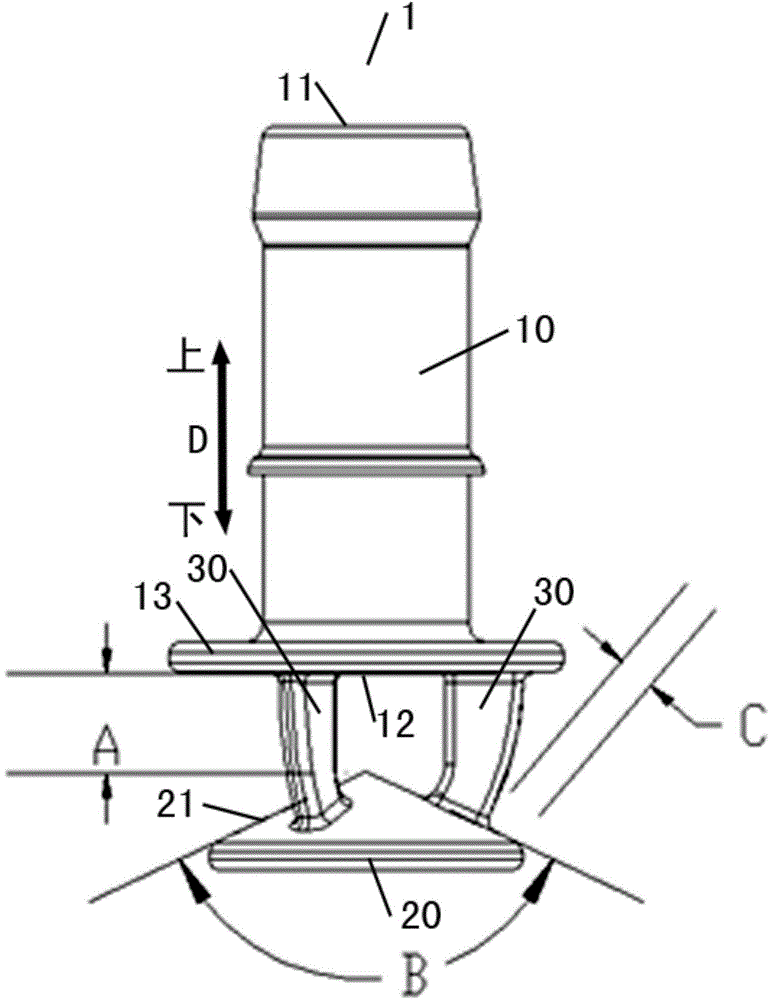

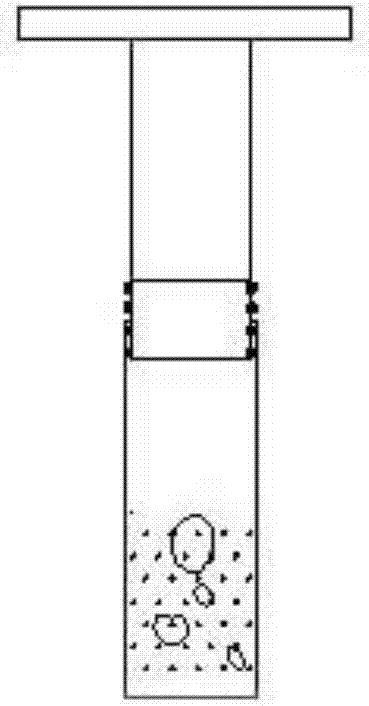

Ultrasonic device and clothes treating apparatus

PendingCN110699904AEasy to useImprove experienceOther washing machinesTextiles and paperAcousticsUltrasonic technology

The invention belongs to the technical field of ultrasonic wave and aims to solve the problem that the existing ultrasonic device is inconvenient for a user to use. To this end, the invention providesan ultrasonic device, comprising a housing and an ultrasonic mechanism; the housing is provided with a first sliding portion, and the ultrasonic mechanism is provided with a second sliding portion insliding fit with the first sliding portion so that the ultrasonic mechanism can be pulled out of the housing and pushed into the housing. The first sliding portion and / or the second sliding portion is provided with an anti-separation component capable of preventing the first sliding portion from being separated from the second sliding portion. According to the invention, the ultrasonic device isconvenient for a user to use, and particularly, is convenient for the user to separately clean local parts of clothes or small articles.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

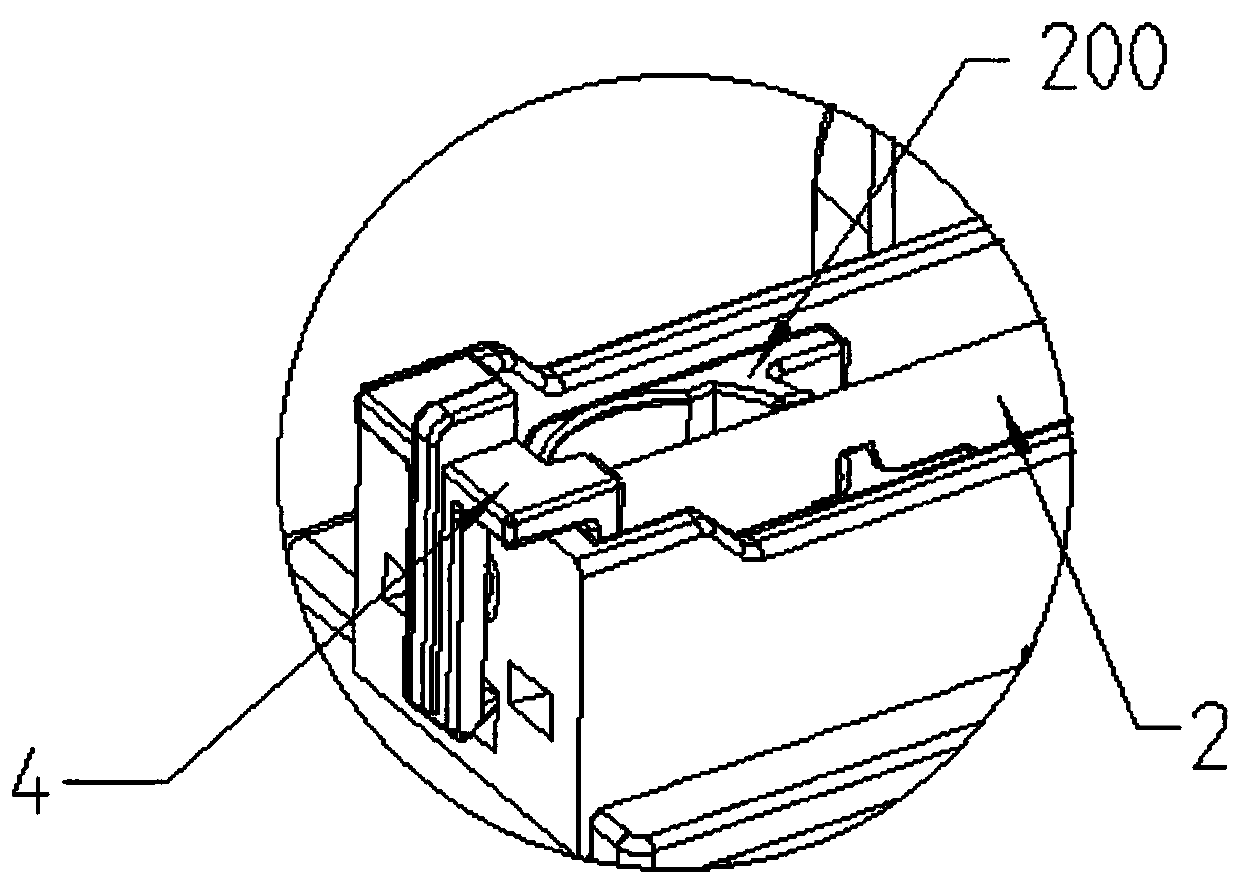

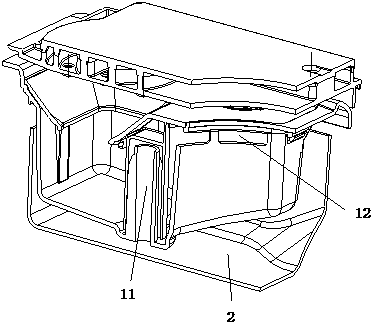

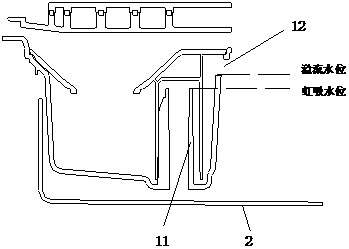

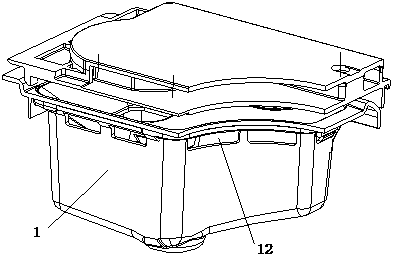

Water inlet method of washing machine

ActiveCN107841849AIncrease the speed of water intakeIncrease washing timeOther washing machinesControl devices for washing apparatusEngineeringInlet valve

The invention provides a water inlet method of a washing machine. A detergent box, a water inlet pipe and a water inlet valve are arranged in the washing machine, and the water inlet pipe is used forsupplying water into the detergent box. A siphon and an overfall gap are arranged in the detergent box. The method includes the steps of A, mixed water inlet; B, siphon water inlet; C, executing the step A and the step B multiple times. By arranging the siphon water inlet step, a detergent in the detergent box is sufficiently dissolved, and the detergent at the bottom of a cavity can be easily discharged through siphon; the detergent is prevented from being left in the detergent box, and the utilization rate of the detergent and the rinsing clean ratio are increased; by arranging the mixed water inlet step before the siphon water inlet step, on one hand, the water inlet speed of the washing machine can be increased, for instance, the water inlet speed is too slow when only the siphon waterinlet step is adopted, and the water inlet time is too long; on the other hand, the detergent high in concentration is prevented from being directly sprinkled on clothes in a washing tub, and the uniformity of the concentration of the detergent in the washing tub is facilitated.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

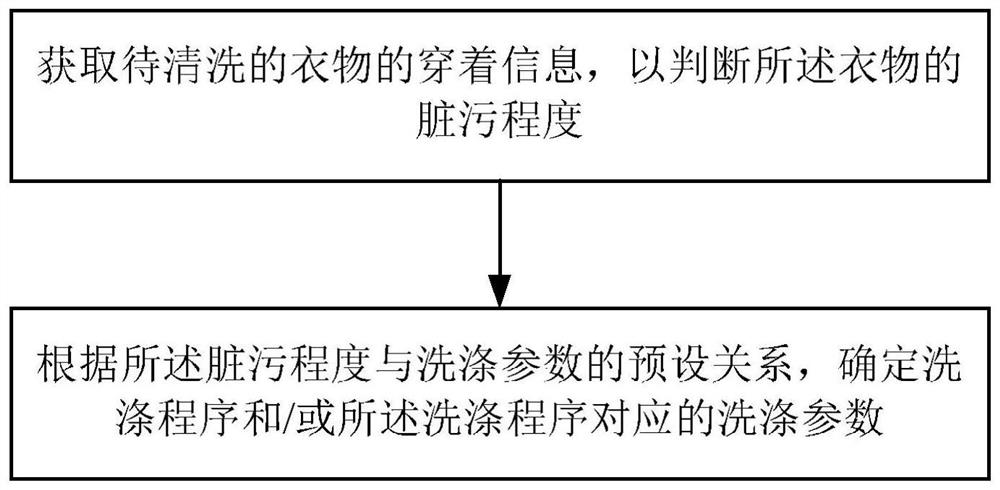

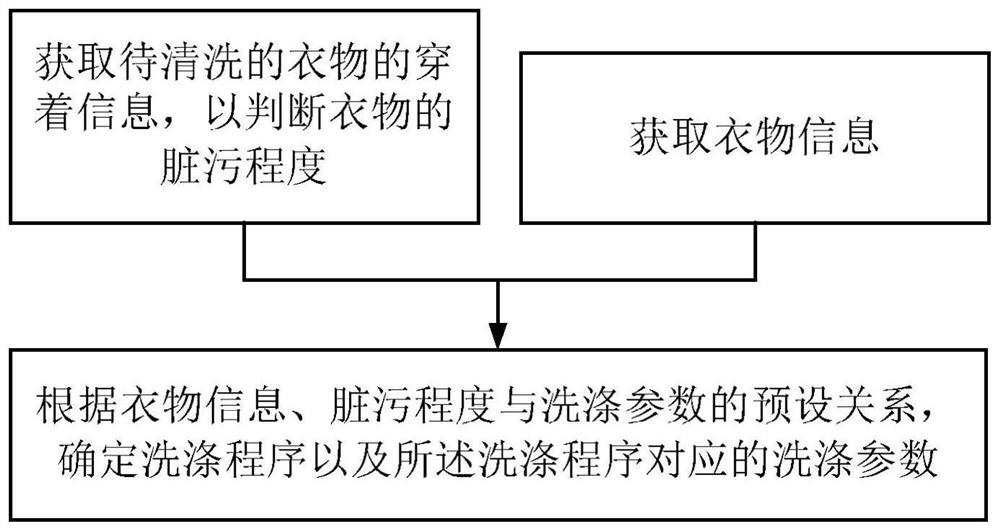

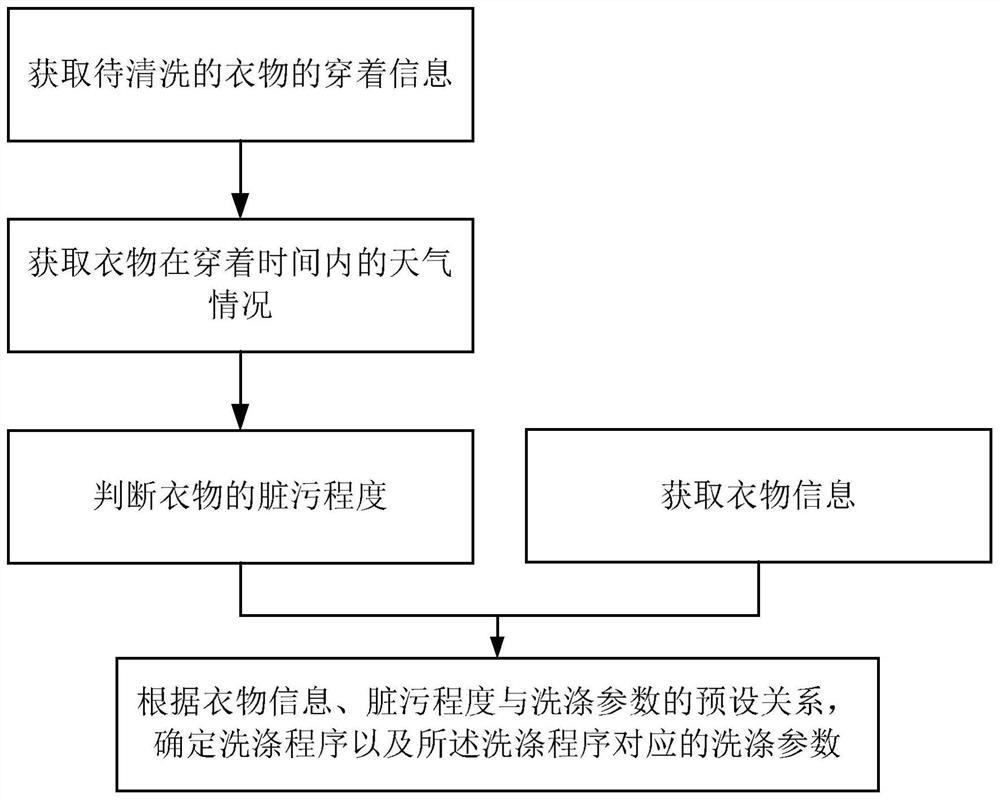

Washing machine control method and washing machine

PendingCN112941804AIncrease washing timeImprove user experienceControl devices for washing apparatusTextiles and paperLaundry washing machineProcess engineering

The invention relates to the technical field of household appliances, in particular to a washing machine control method and a washing machine. The washing machine control method includes the following steps: obtaining wearing information of clothes to be washed to judge the degree of fouling of the clothes; and determining a washing program and / or washing parameters corresponding to the washing program according to a preset relationship between the degree of fouling and the washing parameters. According to the washing machine control method, the degree of fouling of the clothes can be judged according to the wearing information of the clothes to be washed, so that the degree of fouling of the clothes can be obtained without pre-washing, the washing program and the washing parameters more suitable for the clothes can be selected on the basis of avoiding increasing washing time of the clothes, and therefore, the user experience is improved.

Owner:HEFEI HAIER WASHING MACHINE +1

Dish-washing machine

InactiveCN107960971AImprove cleanlinessReduce energy consumptionTableware washing/rinsing machine detailsCleaning equipmentEngineeringDistributor

The invention relates to the technical field of household appliances, and in particular to a dish-washing machine. The dish-washing machine comprises a liner and a water collecting groove which is arranged in the bottom of the liner, wherein a water inlet spraying mechanism is arranged on at least one sidewall of the liner; and the water inlet spraying mechanism is connected to a water inlet pipeby virtue of a water inlet electromagnetic valve. According to the dish-washing machine provided by the invention, by arranging the water inlet spraying mechanism on the at least one sidewall of the liner, water can enter the liner of the dish-washing machine from external side by virtue of the water inlet spraying mechanism which is arranged on the sidewall of the liner; and meanwhile, bowls anddishes in the liner can be also sprayed and flushed, so that washing of the dish-washing machine in a water feeding process is achieved. Since the washing of the dish-washing machine is achieved in the water feeding process and the water inlet spraying mechanism is arranged on the sidewall of the liner, washing time is prolonged in the water feeding process, and subsequently, a cleaning effect ofwashing the bowls and dishes is guaranteed. Meanwhile, in the water feeding process, the operation of spraying and washing is free from the use of a washing pump and a water distributor, so that energy consumption, which is required when the washing pump and the water distributor work, is further reduced.

Owner:QINGDAO HAIER DISHWASHER

Method for distinguishing smudgy degree of clothes

ActiveCN102720033BShorten washing timeIncrease washing timeOther washing machinesControl devices for washing apparatusMachine controlStart time

The invention relates to a washing machine control method, which is particularly characterized in that the corresponding clothes washing control method is selected after the smudgy degree of clothes is judged. According to the method, firstly, the turbidity degree of water in the starting time period of the clothes washing is compared, the smudgy degree of clothes to be washed is distinguished, and then, the washing time, the washing intensity, the detergent addition quantity, the rinsing time and the like are regulated according to the smudgy degree of the clothes. The corresponding clothes washing procedure is selected according to the smudgy degree of the clothes, the clothes washing time of cleaner clothes can be reduced, the washing time of dirtier clothes is increased, and the clothes washing efficiency is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

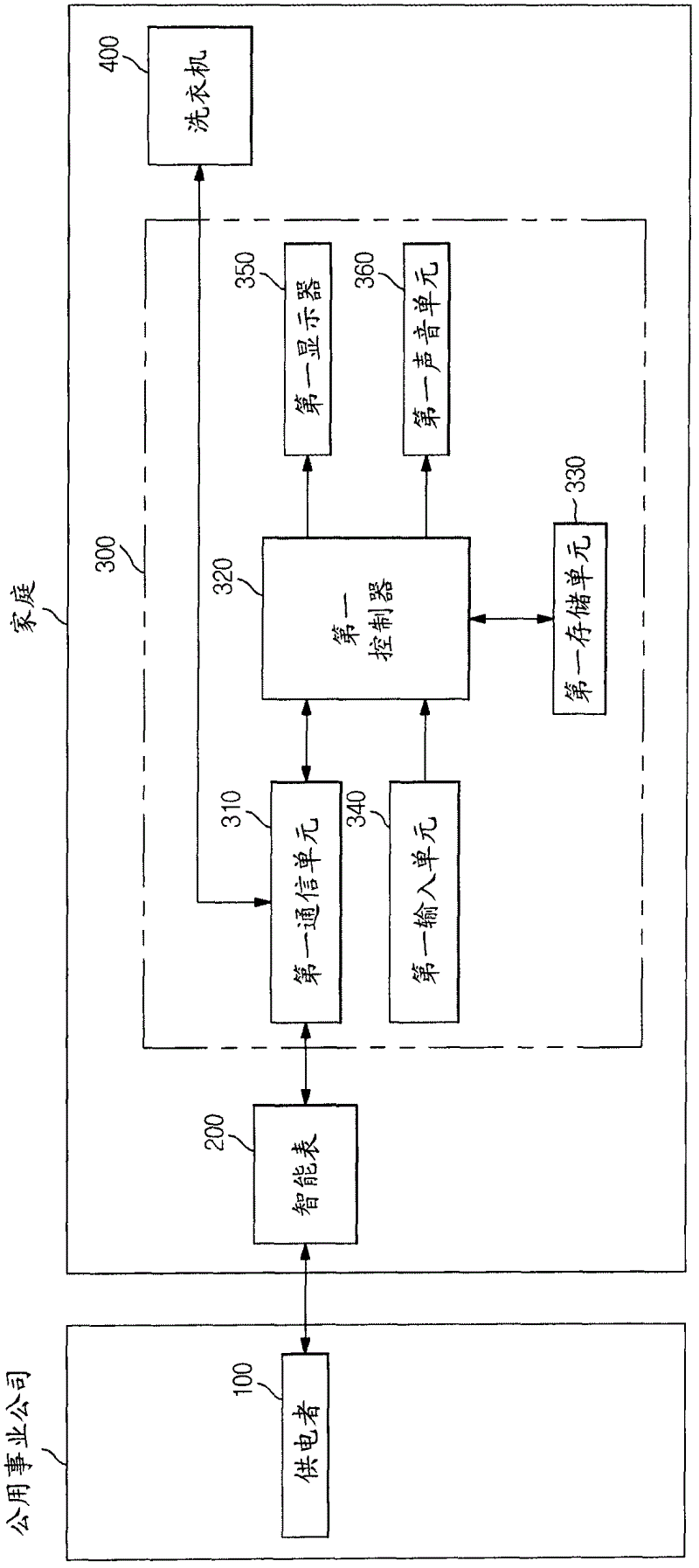

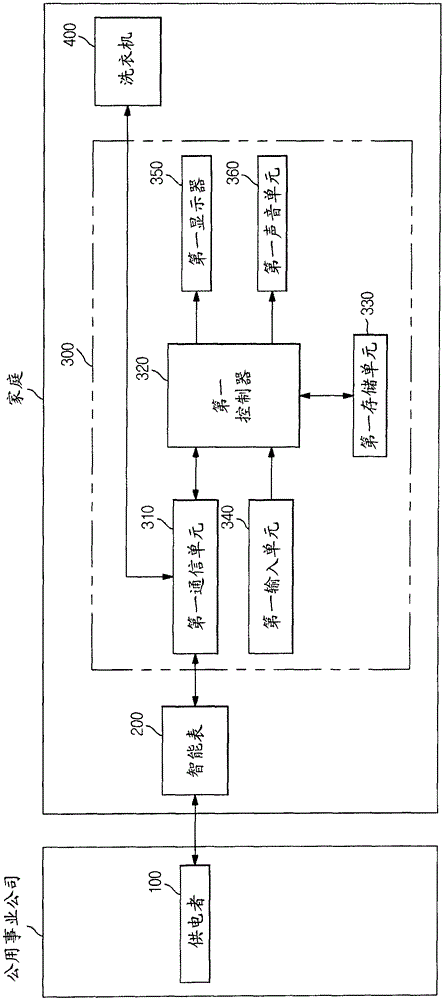

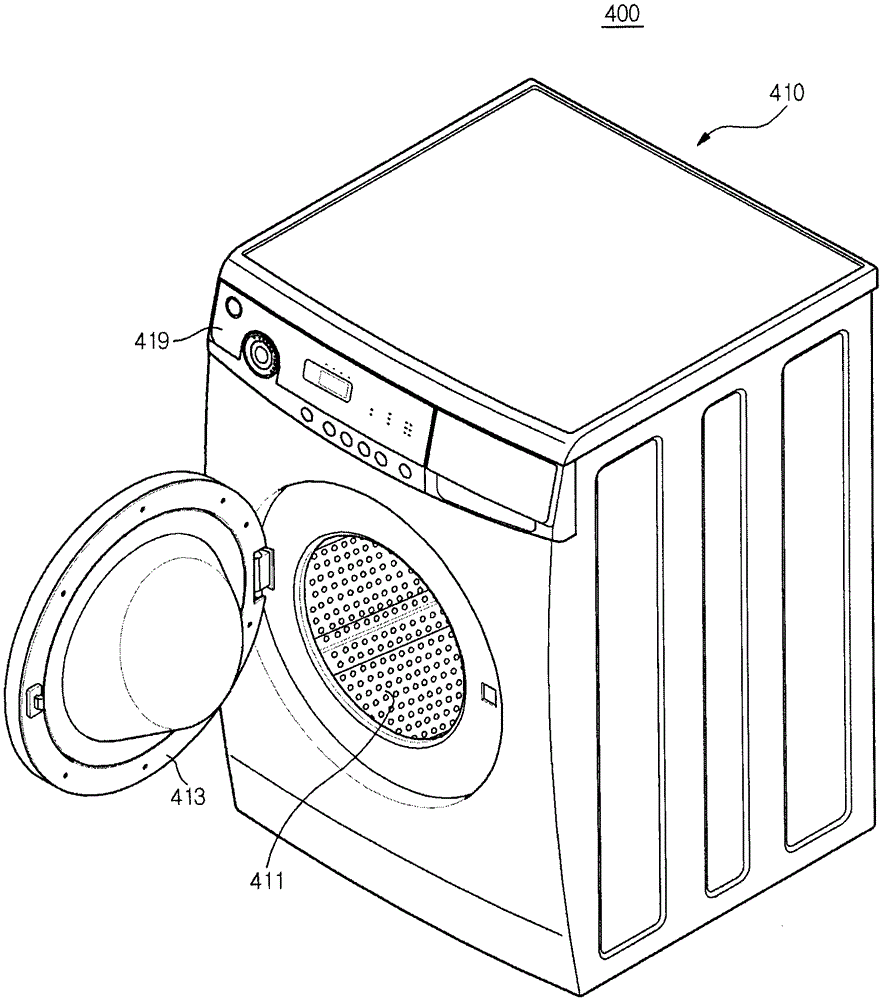

Washing machine and method of controlling the same

ActiveCN102619071AImprove operating rateIncrease washing timeOther washing machinesControl devices for washing apparatusCommunication unitStart time

Owner:SAMSUNG ELECTRONICS CO LTD

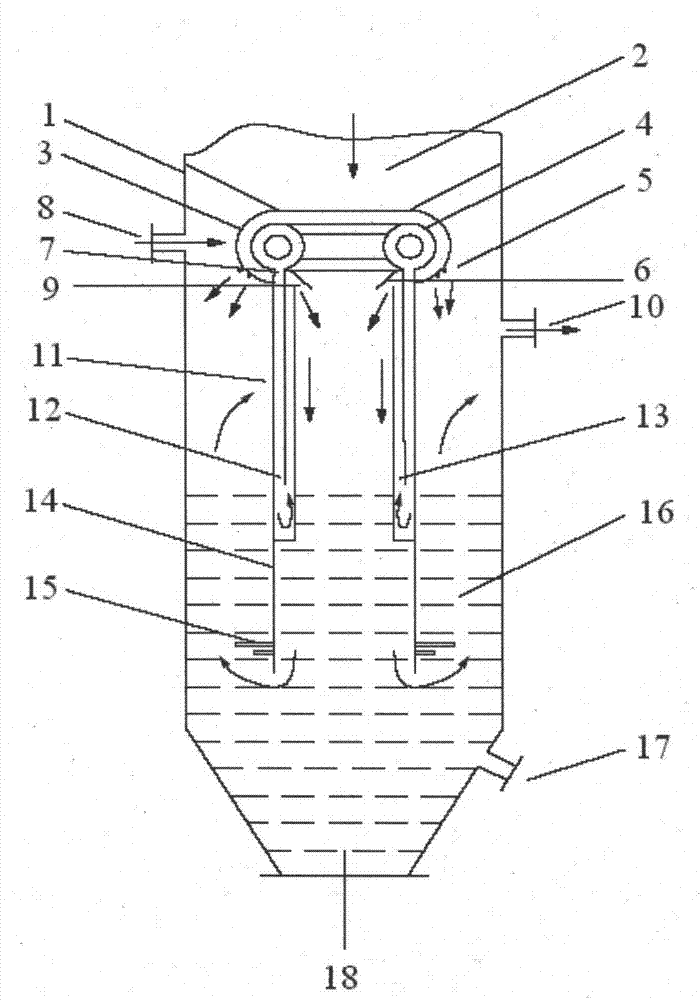

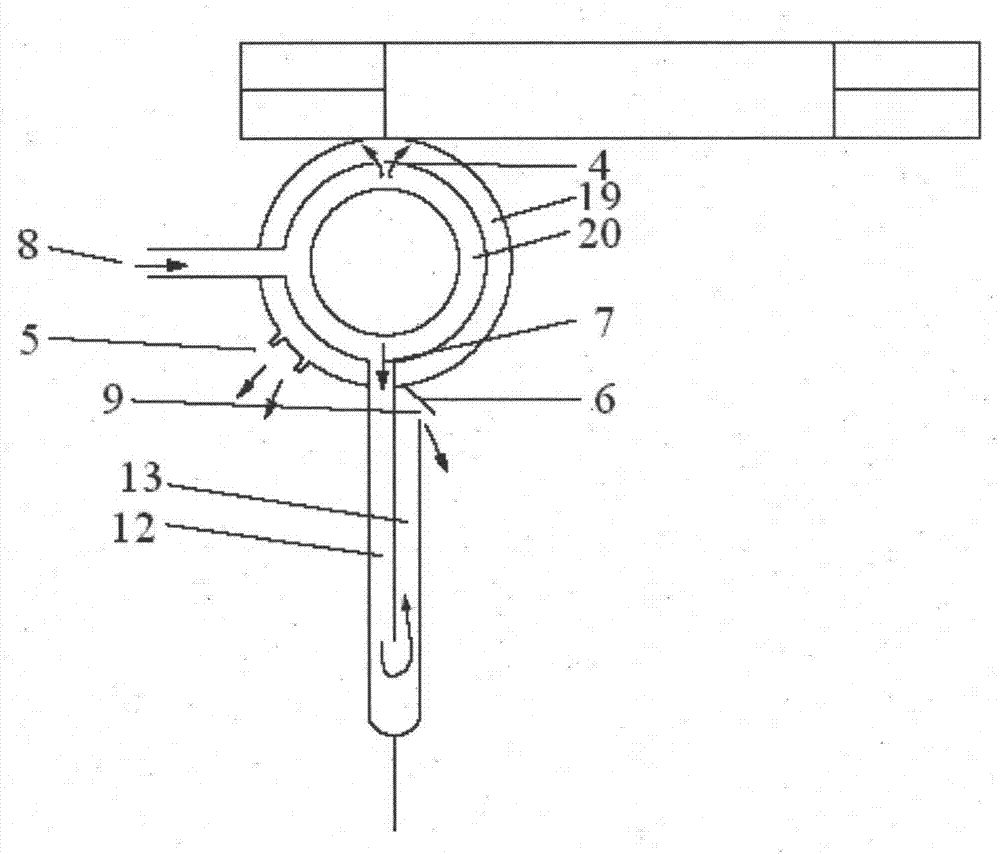

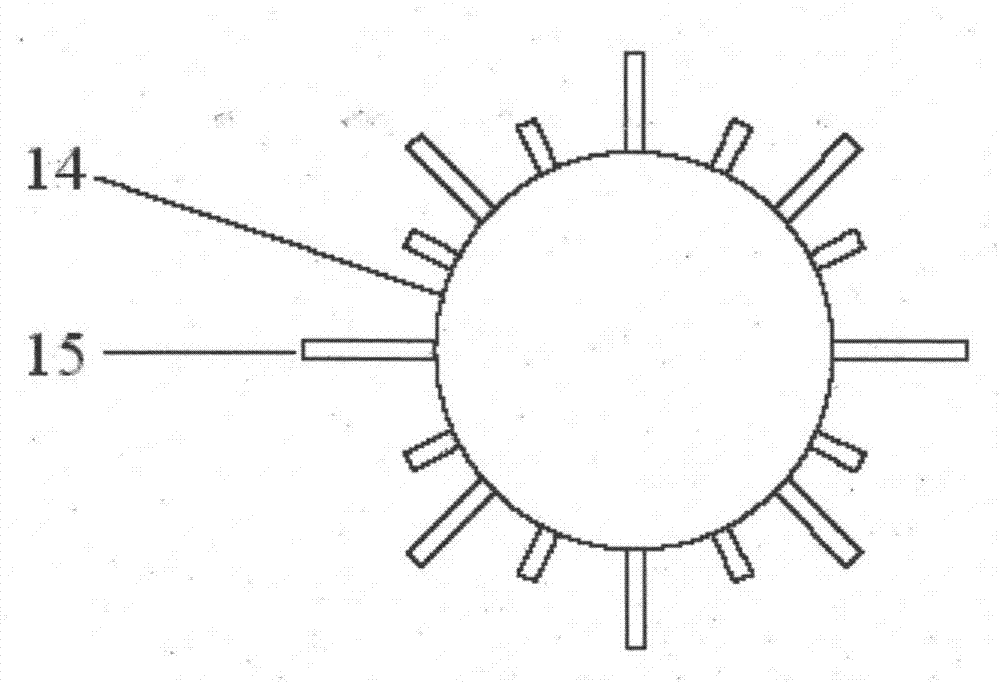

Cooling and washing equipment for high-temperature coal gas

ActiveCN103484167AProtection from burnsAvoid uneven distributionGas purification by non-gaseous materials condensationCombustible gas productionEngineeringSlug

The invention discloses cooling and washing equipment for high-temperature coal gas. The cooling and washing equipment is characterized by comprising a pressure bearing casing, wherein a washing water inlet and a synthesis gas outlet are formed in two sides of the pressure bearing casing respectively; a liquid discharge opening and a slug discharge opening are formed in the bottom; the upper part of the pressure bearing casing is a gasification chamber, and the bottom of the pressure bearing casing is a dreg pool; the lower side of the gasification chamber is connected with a water ejecting ring; the water ejecting ring comprises an outer water ejecting ring and an inner water ejecting ring; the washing water inlet is communicated with the inner water ejecting ring; an opening is formed in the upper side of the inner water ejecting ring; the inner water ejecting ring is communicated with the outer water ejecting ring through the opening; the lower side of the water ejecting ring is connected with a downcomer; at least one atomization nozzle is arranged on the outer side of the outer water ejecting ring at the position outside the downcomer. According to the invention, double-layer structure water ejecting rings which are communicated in the inner part are adopted, the requirement that the cooling water enters the downcomer from the inner layer is met, and the requirement of water supply for the atomization nozzle on the outer layer is met; the downcomer with the double ring wall structure can effectively overcome uneven distribution of the water film, and can effectively protect the downcomer from burning damage.

Owner:SHANGHAI BOILER WORKS

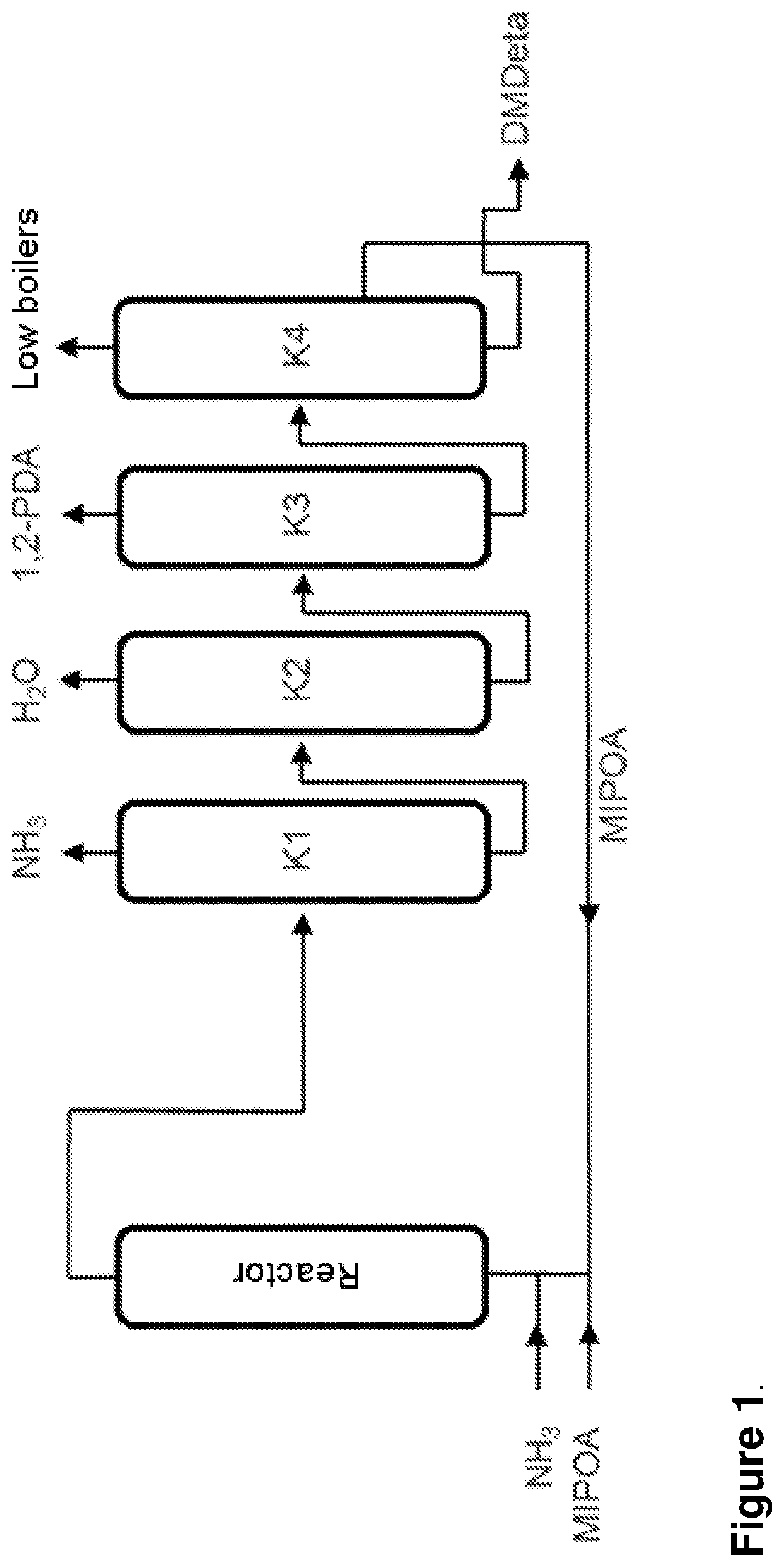

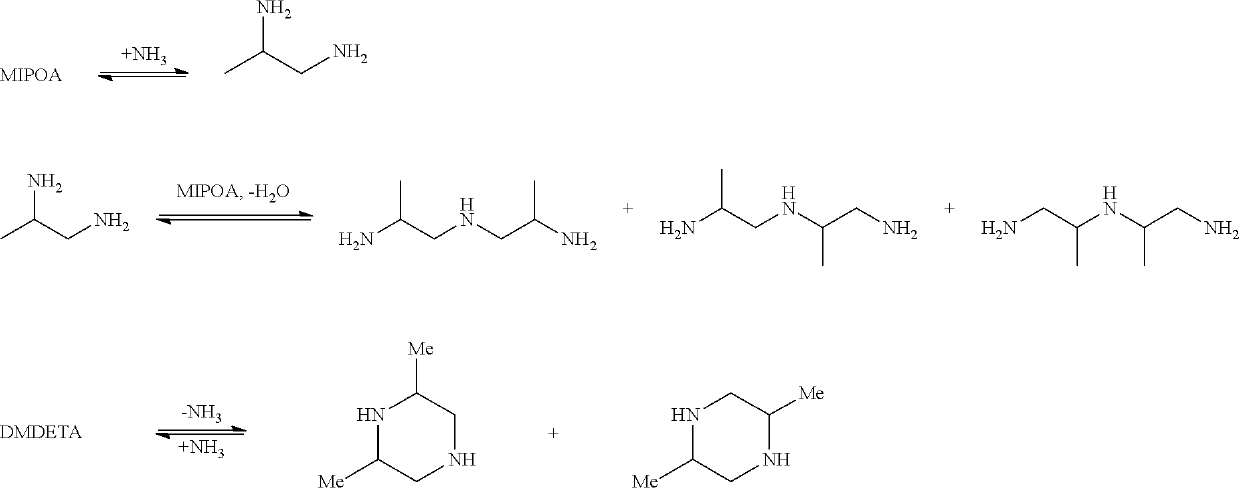

Process for the continuous preparation of 1,2-propylene diamine (1,2-pda) and dimethyldiethylene triamine (dmdeta)

ActiveUS20200385332A1Reduce contentIncrease washing timeAmino compound purification/separationOrganic compound preparationPtru catalystFluid phase

A process for the continuous preparation of 1,2-propylenediamine (1,2-PDA) and dimethyldiethylenetriamine (DMDETA) via reaction of monoisopropanolamine (MIPOA) with ammonia in the presence of hydrogen and a supported heterogeneous hydrogenation catalyst (catalyst), wherein the reaction is effected in the liquid phase at an absolute pressure in the range from 60 to 170 bar.

Owner:BASF AG

Washing machine and method for controlling same

ActiveCN102619071BImprove operating rateIncrease washing timeOther washing machinesControl devices for washing apparatusElectricity priceCommunication unit

The invention provides a washing machine and a method for controlling the washing machine. The washing machine includes: a motor for rotating a rotary tub containing laundry; a heater for heating water accommodated in the rotary tub; a communication unit for receiving from an energy management system (EMS) An energy-saving signal of information; the controller, upon receiving the energy-saving signal, determines a load with the largest power consumption among the motor and the heater in the process to be executed at the energy-saving start time, and reduces the operating rate of the determined load. The operating rate of the load of the washing machine is changed before the current electricity price exceeds the reference electricity price, thereby significantly reducing power consumption.

Owner:SAMSUNG ELECTRONICS CO LTD

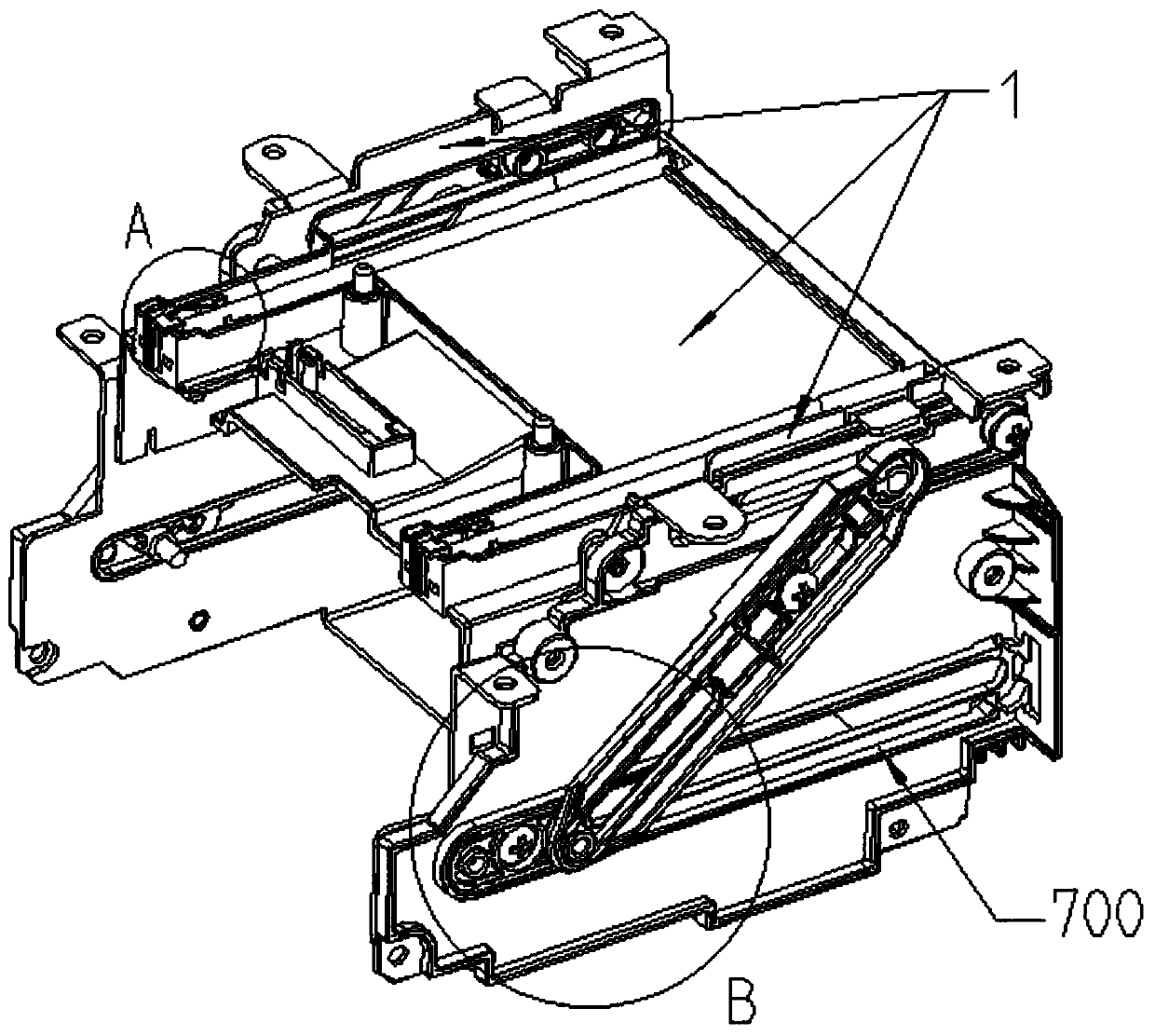

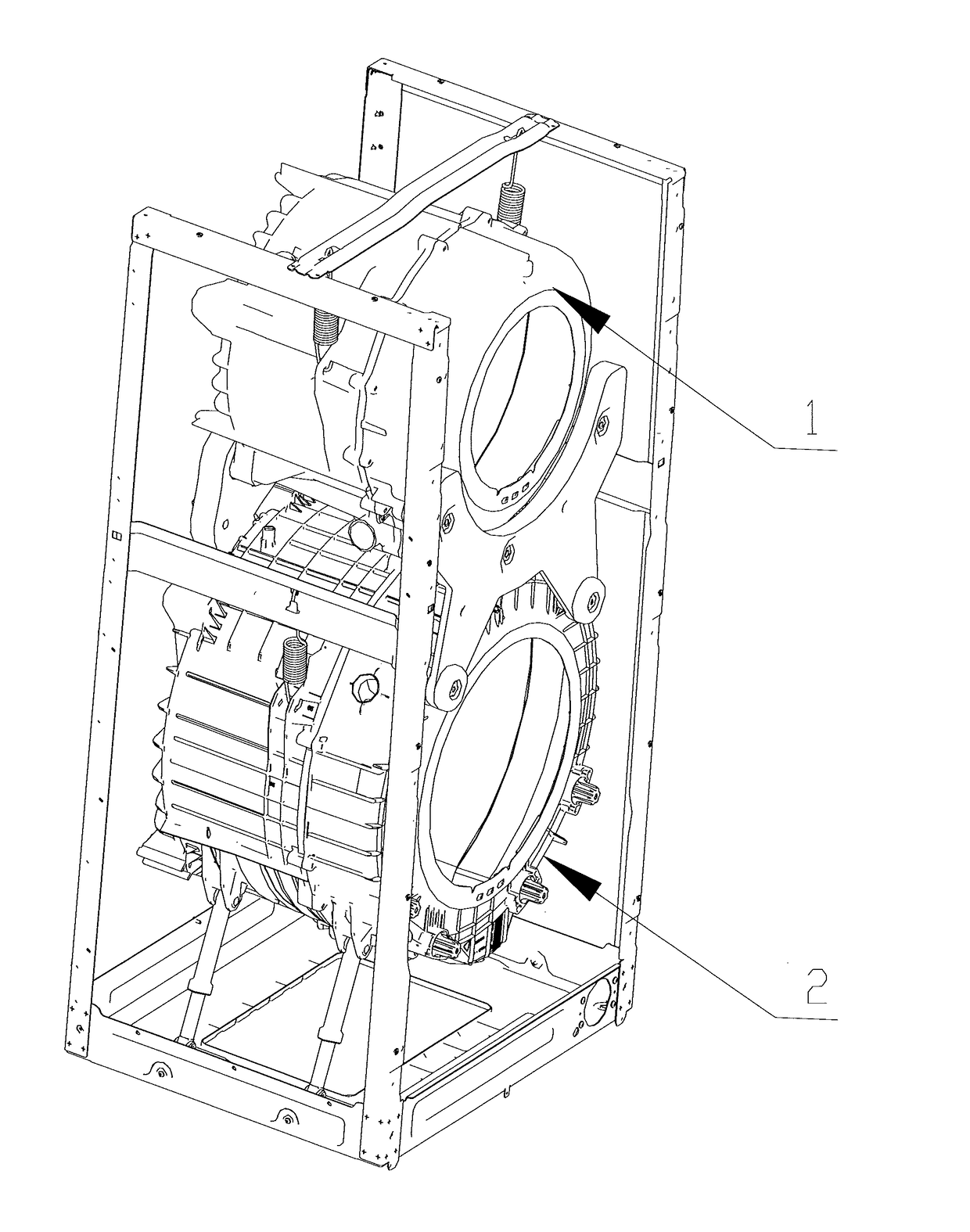

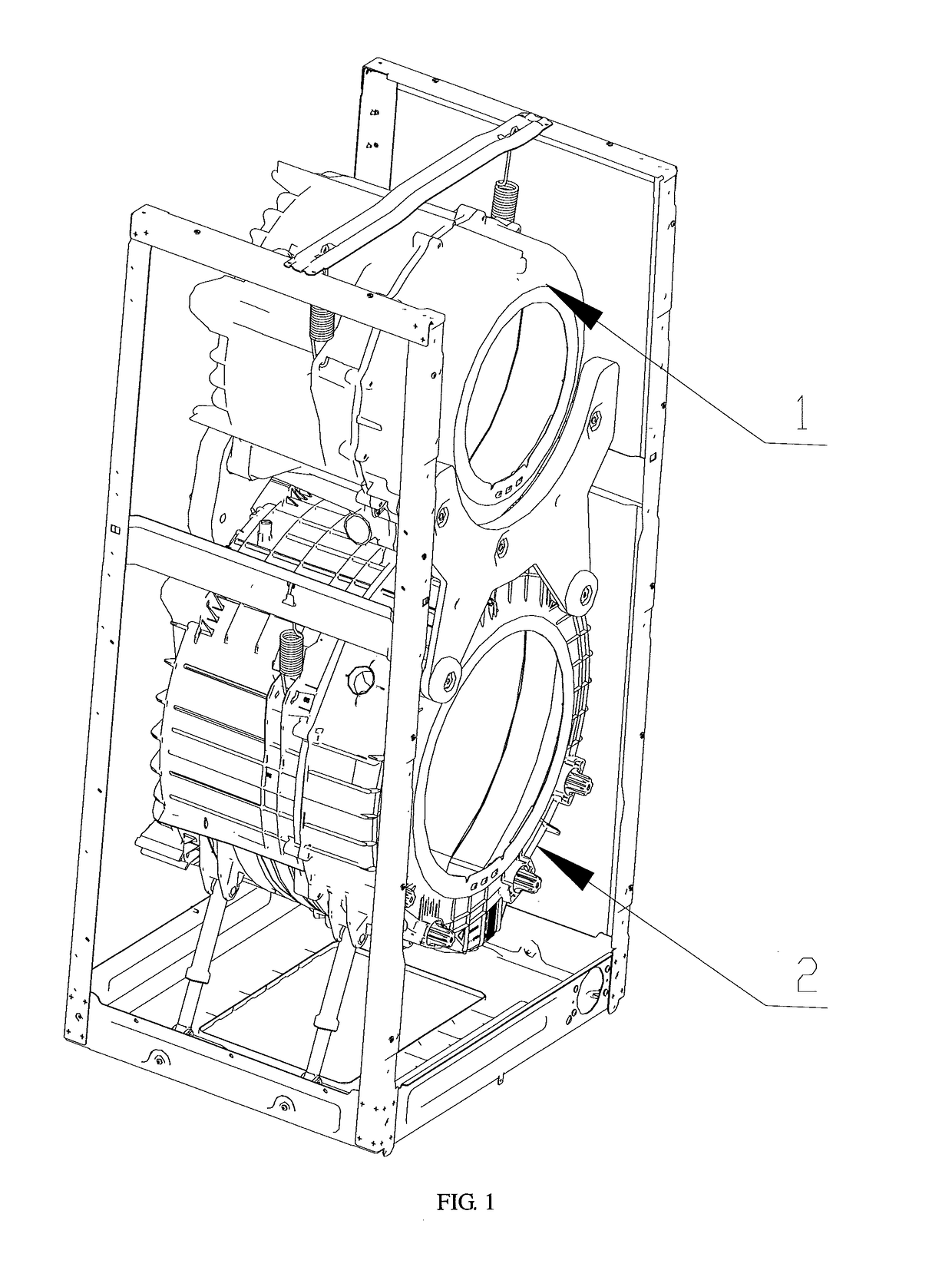

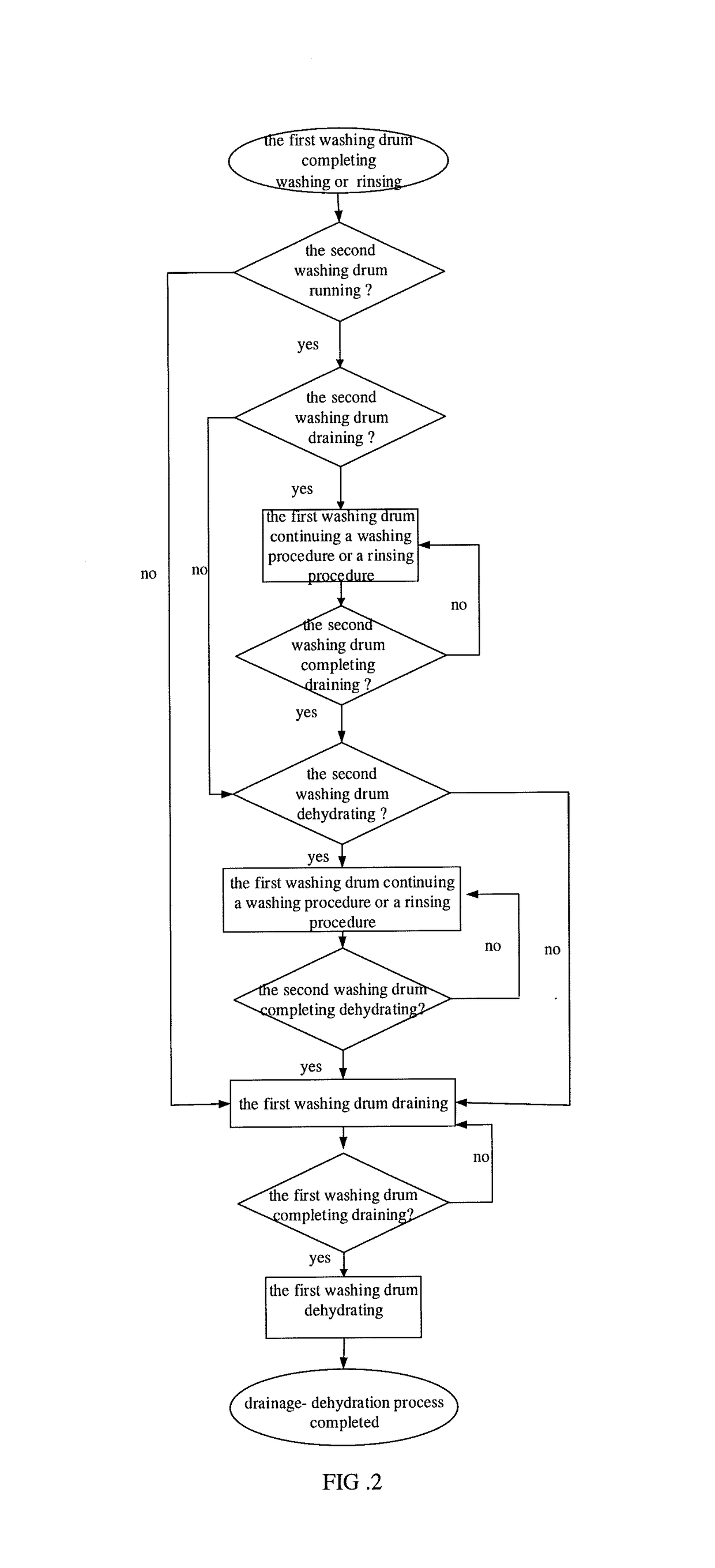

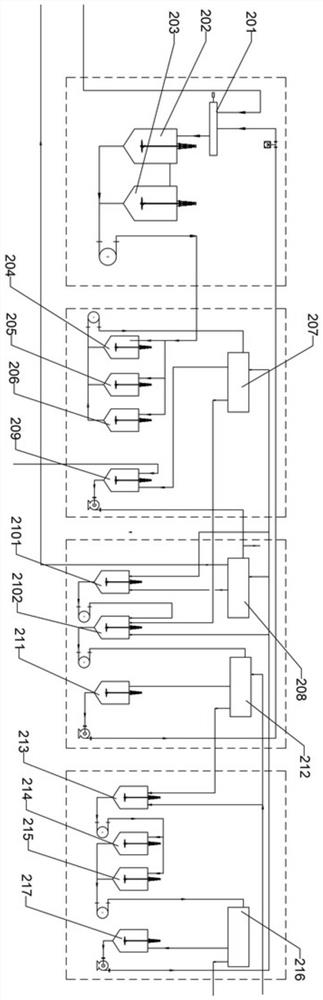

A drainage-dehydration control method of a multi-drum washing machine

InactiveUS20170350055A1Wash time be increaseAffect wash cleanlinessOther washing machinesControl devices for washing apparatusProcess engineeringDehydration Procedure

A drainage-dehydration control method of a multi-drum washing machine, the washing machine at least comprising a first washing drum and a second washing drum; the method comprising: before the first washing drum executing drainage or dehydration procedure, judging whether the second washing drum is draining or dehydrating. If yes, the first washing drum continuing executing a washing procedure or a rinse procedure, or suspending executing the drainage or dehydration procedure until the second washing drum finishes dehydration; if no, the first washing drum starting drainage and dehydration. By the above method, the first washing drum and the second washing drum cannot execute the drainage-dehydration procedure at the same time; and during the waiting process of one washing drum, another washing drum continues a washing procedure or a rinse procedure, so as to make the rational use of waiting time and improve the efficiency of washing clothing.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

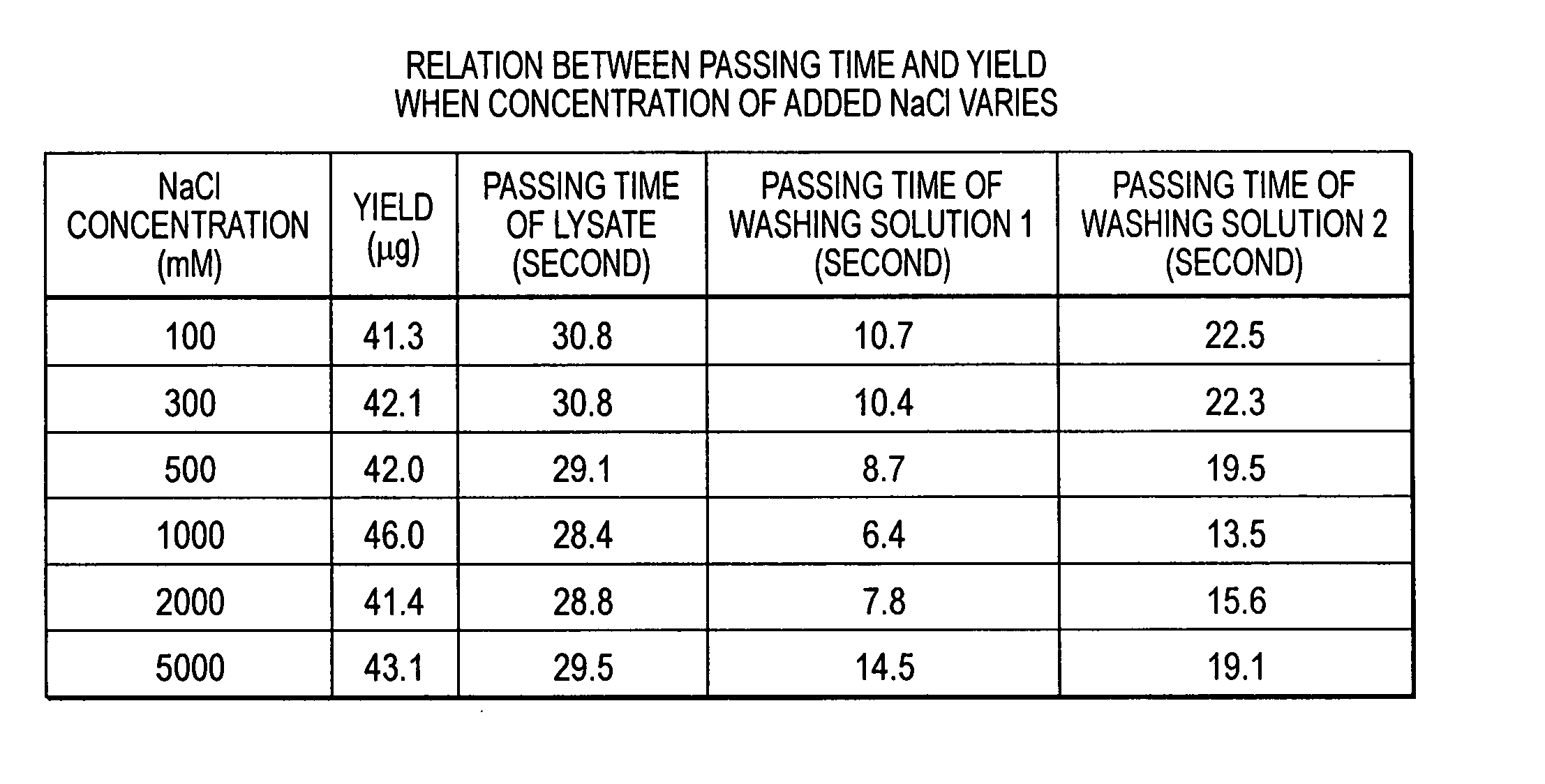

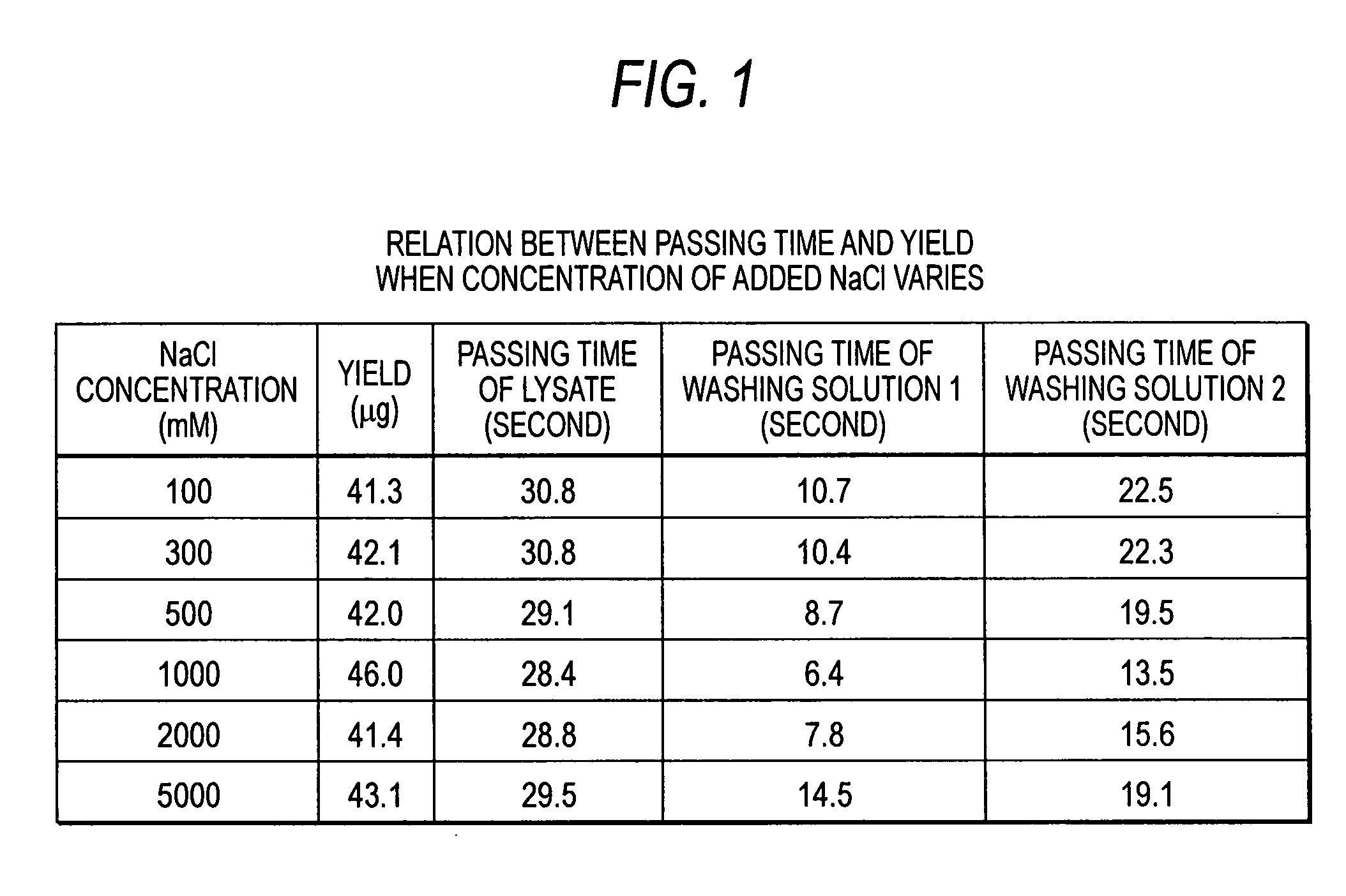

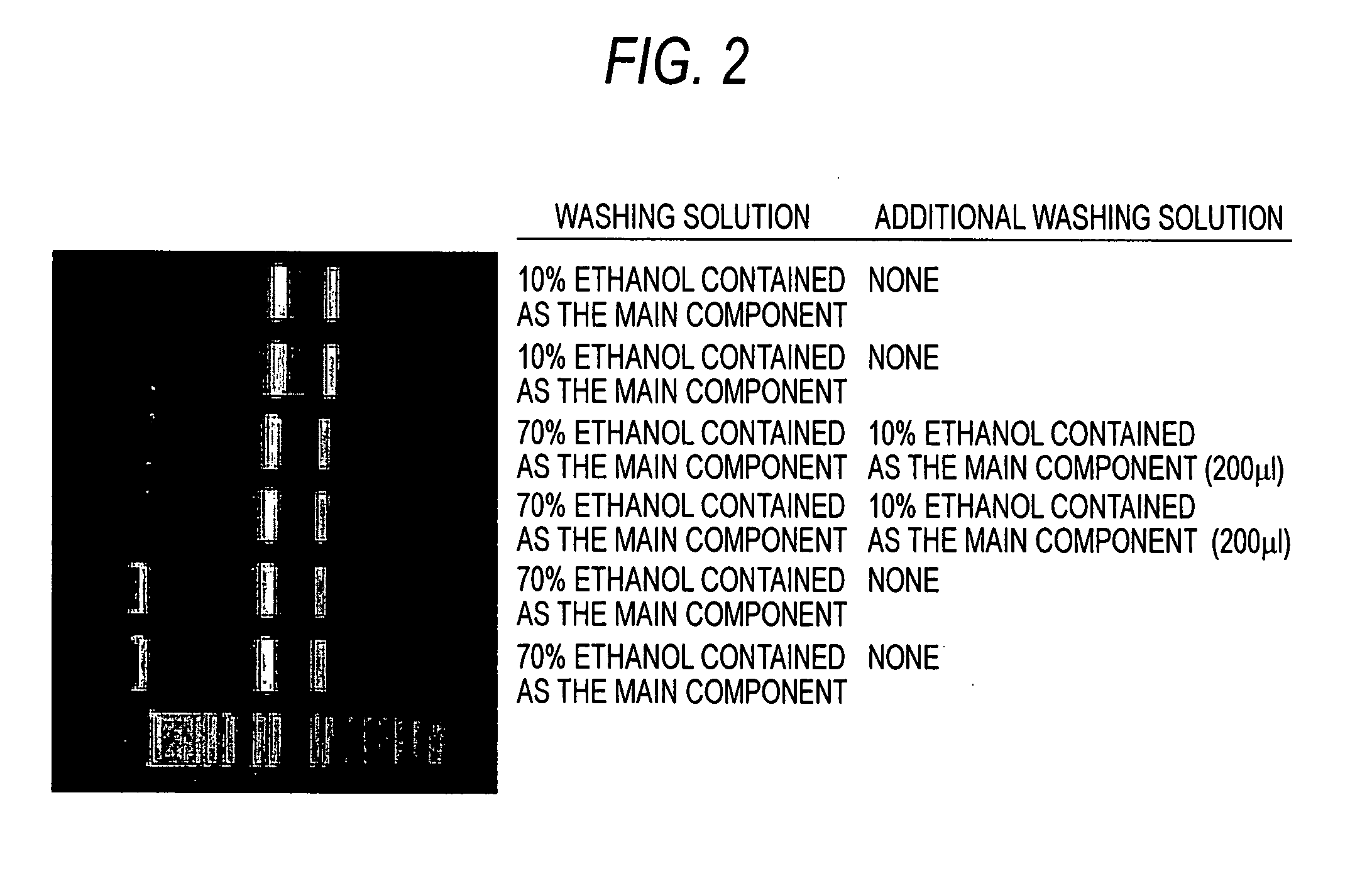

Method for extracting nucleic acid

InactiveUS20080033161A1High purityReduce the presence of impuritiesSugar derivativesDNA preparationOrganic solventWater soluble

A method for extracting nucleic acid comprises: (a) putting a biological material in contact with a lysing solution to dissolve out nucleic acid; (b) adding a water-soluble organic solvent to an obtained solution of the dissolved nucleic acid, to prepare a lysate solution; (c) putting the lysate solution in contact with a solid material, to allow the nucleic acid to be adsorbed onto the solid material; (d) washing off impurities on the solid material, using a washing solution, wherein twice or more washing procedures are conducted, and a liquid face formed with a washing solution applied in at least one washing procedure other than the first washing procedure among the twice or more washing procedures is higher than a liquid face formed with a washing solution applied in the first washing procedure; and (e) desorbing the nucleic acid adsorbed onto the solid material, using a recovering solution.

Owner:FUJIFILM CORP

Fly ash washing desalination system

PendingCN114850196AIncrease washing timeFully washedGeneral water supply conservationSolid waste disposalProcess engineeringDesalination

The invention discloses a fly ash washing desalination system which is provided with a mixer and a premixing tank, first tank washing; a first solid-liquid separation device A; a first solid-liquid separation device B; according to the first filter tank, the second dissolving tank, the second washing tank, the second solid-liquid separation device, the second filter tank, the third washing buffer tank, the third washing tank, the third solid-liquid separation device and the third filter tank, the fly ash washing time is prolonged, it is ensured that the fly ash is fully washed, and dissolving out of chloride ions in the fly ash is facilitated.

Owner:安徽海螺环保集团有限公司

High-capacity viscose staple fiber post-treatment production line

InactiveCN103422290BWash fineFine desulfurizationSucessive textile treatmentsLiquid/gas/vapor removalProduction lineSingle process

The invention aims at providing a high-capacity viscose staple fiber post-treatment production line in order to reach the annual yield of 100 thousand tons. The production line comprises a refining system and a drying system. A refiner in the refining system comprises a refining section and an oiling section. The high-capacity viscose staple fiber post-treatment production line is characterized in that the breadth of the refiner of the refining system is 4000mm, the refining section is divided into 13-18 process areas, the oiling section is divided into 2 process areas and the length of a single process area is 2500mm. The viscose staple fiber post-treatment production line comprises the refining system and the drying system, and has the advantages that the production capacity is strong, the operation stability is high, the automation level is high and the product quality is guaranteed.

Owner:YIBIN GRACE +2

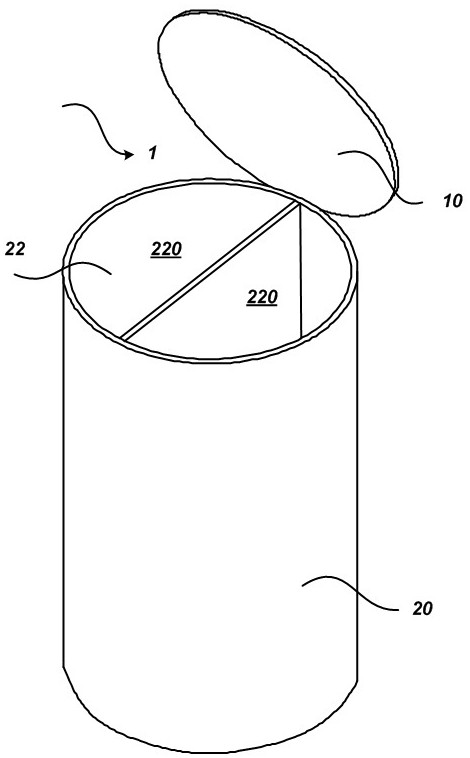

Static clothes washing method and washing machine

InactiveCN107268235AUnlimited types of washingNo wearOther washing machinesTextiles and paperMechanical engineeringPiston

The invention discloses a static clothes washing method. The static clothes washing method includes the steps; a step 1), putting clothes into a container; a step 2), pouring water to the container; a step 3), sealing the container; and a step 4), circularly adjusting the pressure of the container till dirt is removed from the clothes. The invention also discloses a static washing machine. The static washing machine includes a cover assembly and a barrel assembly. The cover assembly includes an upper rack; a barrel cover is arranged in the upper rack; a piston transmission system is arranged on the top of the barrel cover; and a lifting transmission structure for controlling the cover assembly to lift is arranged on an edge of the barrel cover. The barrel assembly includes a lower rack; a washing barrel is arranged in the lower rack; and when the washing barrel and the barrel cover are closed, the washing barrel and the barrel cover are in seal connected to form the container. The static clothes washing method and the washing machine overturn the conventional washing modes, and initiate a brand new washing idea.

Owner:陈武

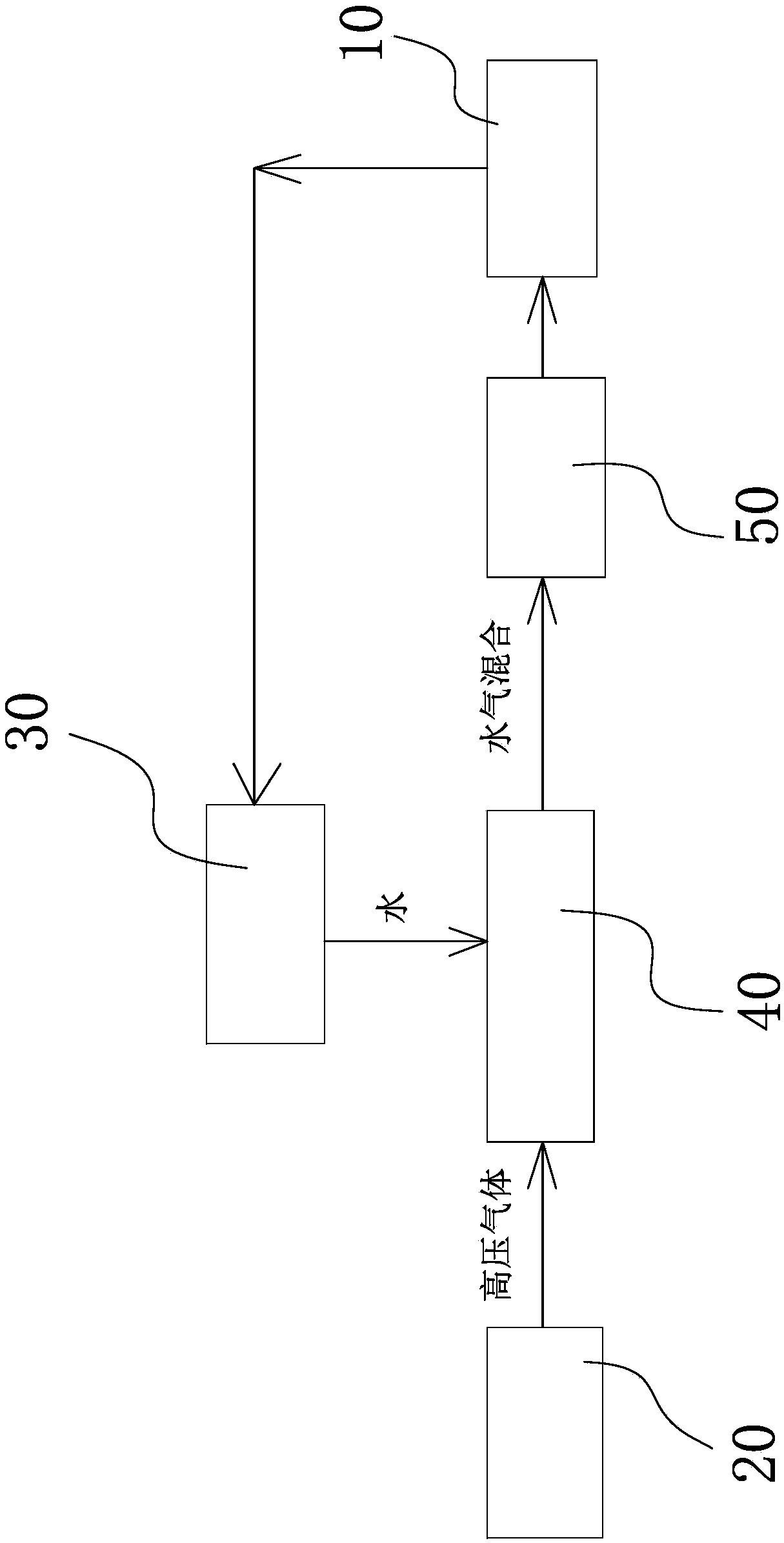

Cleaning device and cleaning method thereof

PendingCN108272416ACompact structureImprove washing effectTableware washing/rinsing machine detailsCleaning equipmentCleaning methodsEddy current

The invention provides a cleaning device. The cleaning device comprises a cleaning carrier, a spraying structure arranged in the cleaning carrier, a power source used for conveying high-pressure gas,a water supply structure used for conveying water, and a mixing structure connected with the power source, the water supply structure and the spraying structure separately. After the power source conveys the high-pressure gas into the mixing structure, the high-pressure gas and water are mixed to form a water-gas mixed medium, and water-gas eddy current and air micro-bubbles are formed; the water-gas mixed medium is conveyed into the cleaning carrier through the spraying structure. The cleaning device has the advantages of being better in cleaning effect, higher in efficiency and free of pollution.

Owner:NINGBO OULIN IND CO LTD

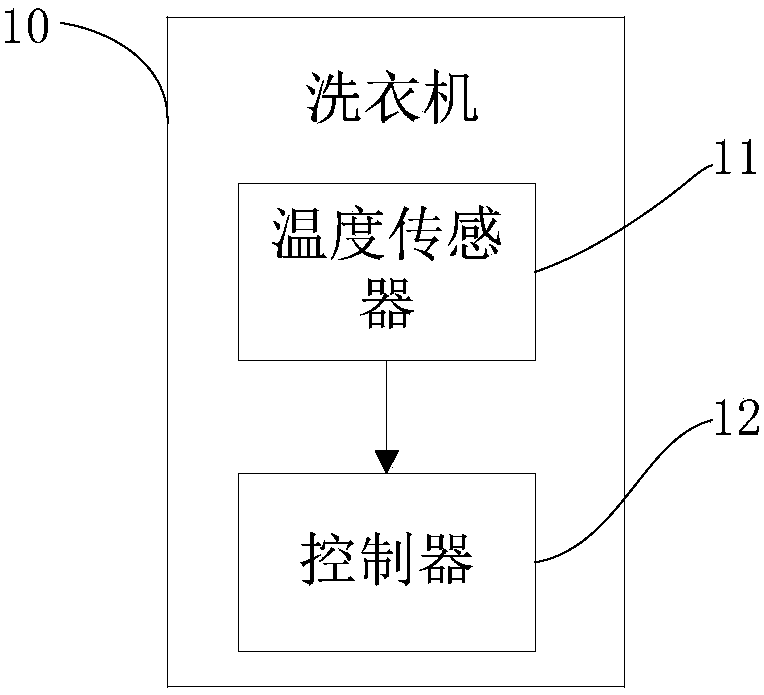

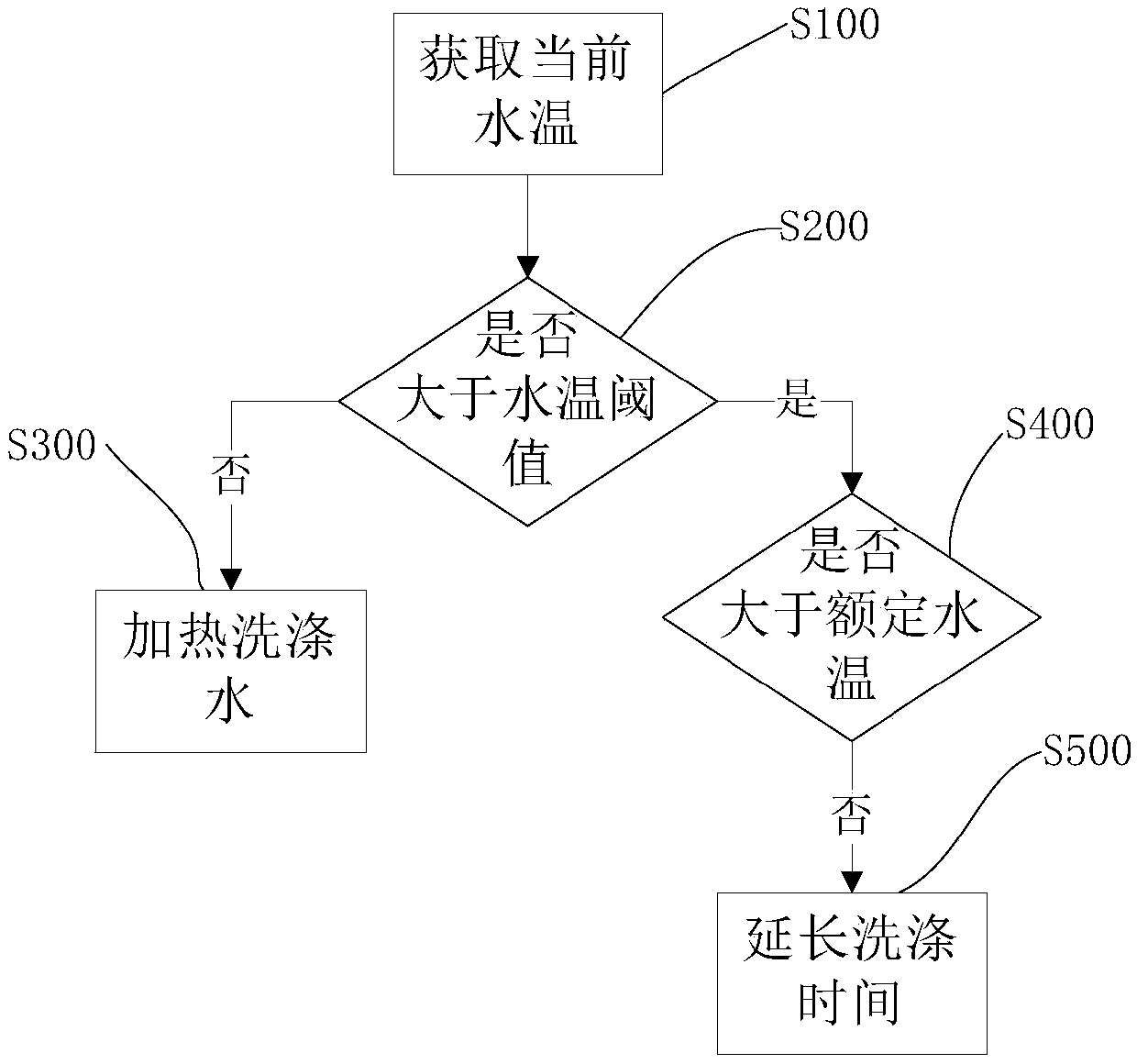

Method for adjusting washing programs based on water temperature and washing machine

PendingCN110318209AGuaranteed washing effectReduce energy consumptionOther washing machinesControl devices for washing apparatusProcess engineeringWater temperature

The invention belongs to the technical field of clothes processing, and particularly provides a method for adjusting washing programs based on the water temperature and a washing machine. The problemthat an existing washing machine with the heating function wastes electric energy is solved. The method comprises the following steps of obtaining the current water temperature of the washing machine;when the current water temperature is lower than a water temperature threshold value, heating the washing water to the rated water temperature; when the current water temperature is higher than the water temperature threshold value and not lower than the rated water temperature, appropriately prolonging the washing time of the washing machine, wherein the water temperature threshold value is smaller than the rated water temperature. The washing machine adopting the method can lower energy dissipation while the washing effect can be ensured, and electric energy is saved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

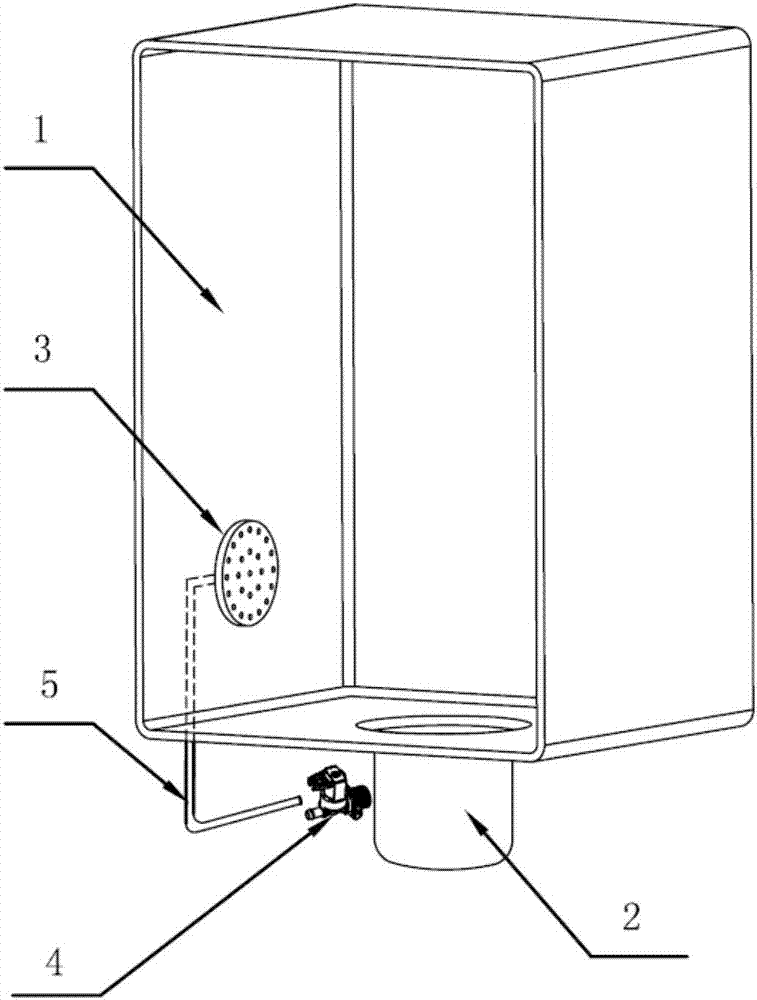

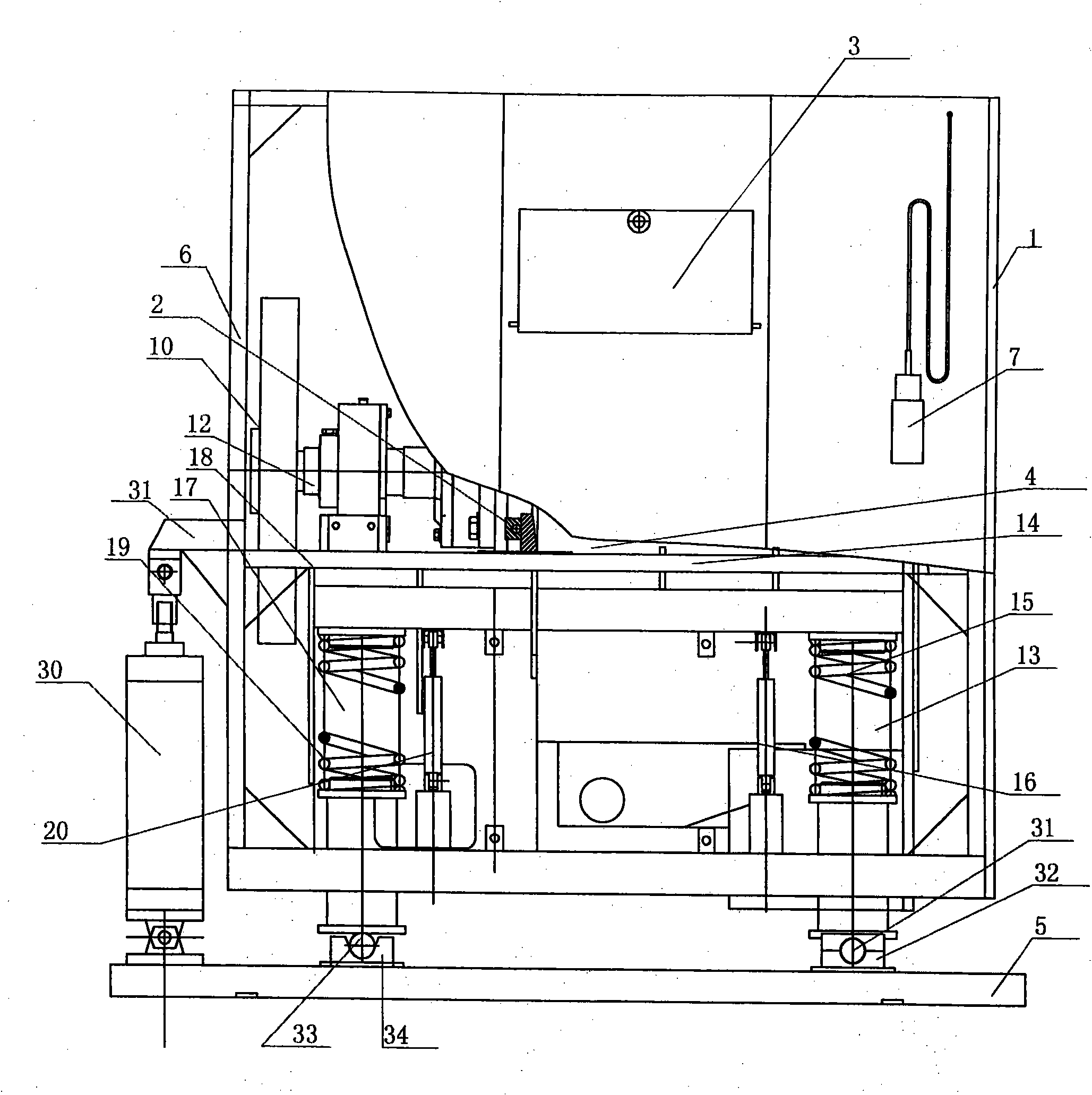

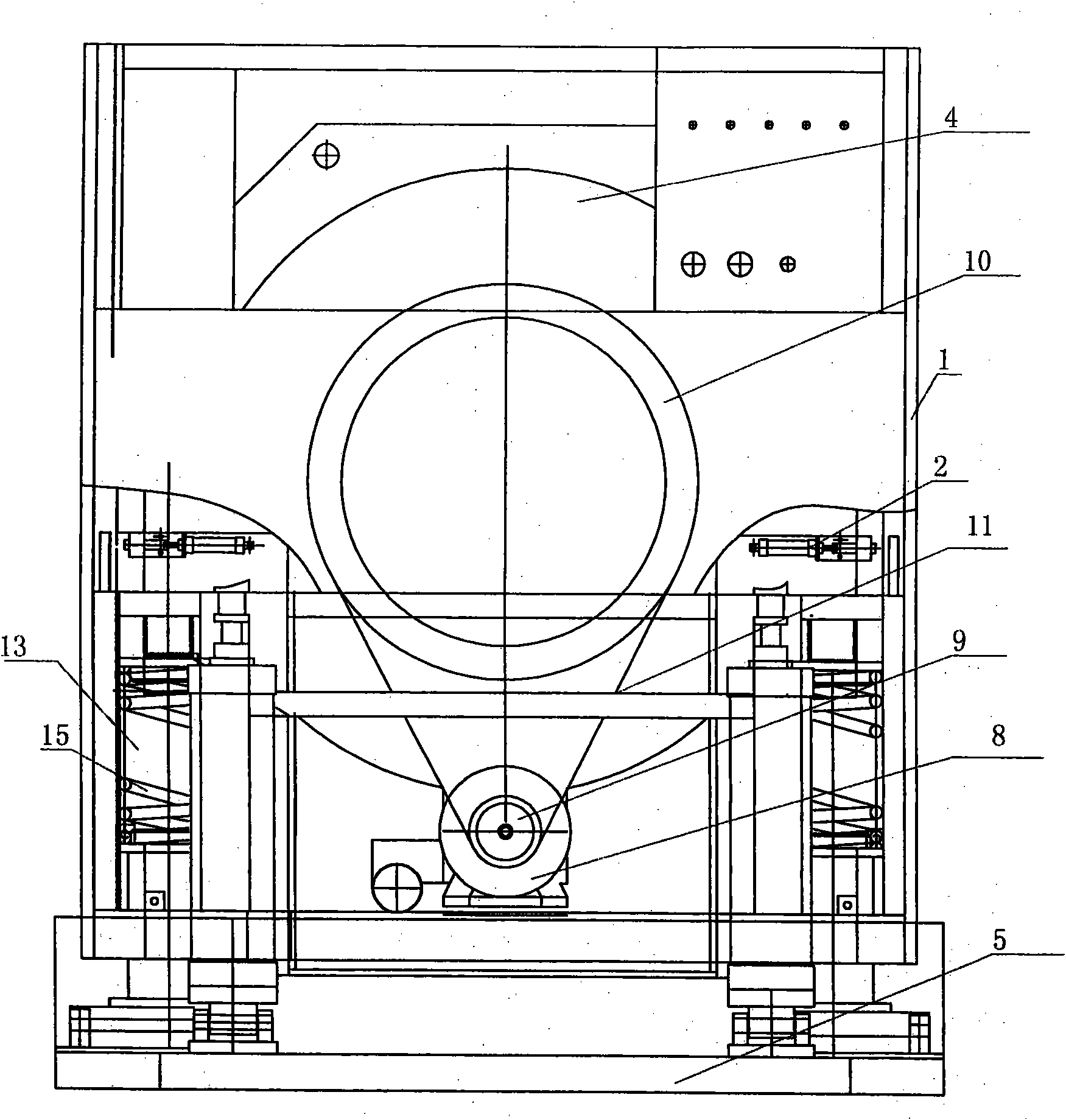

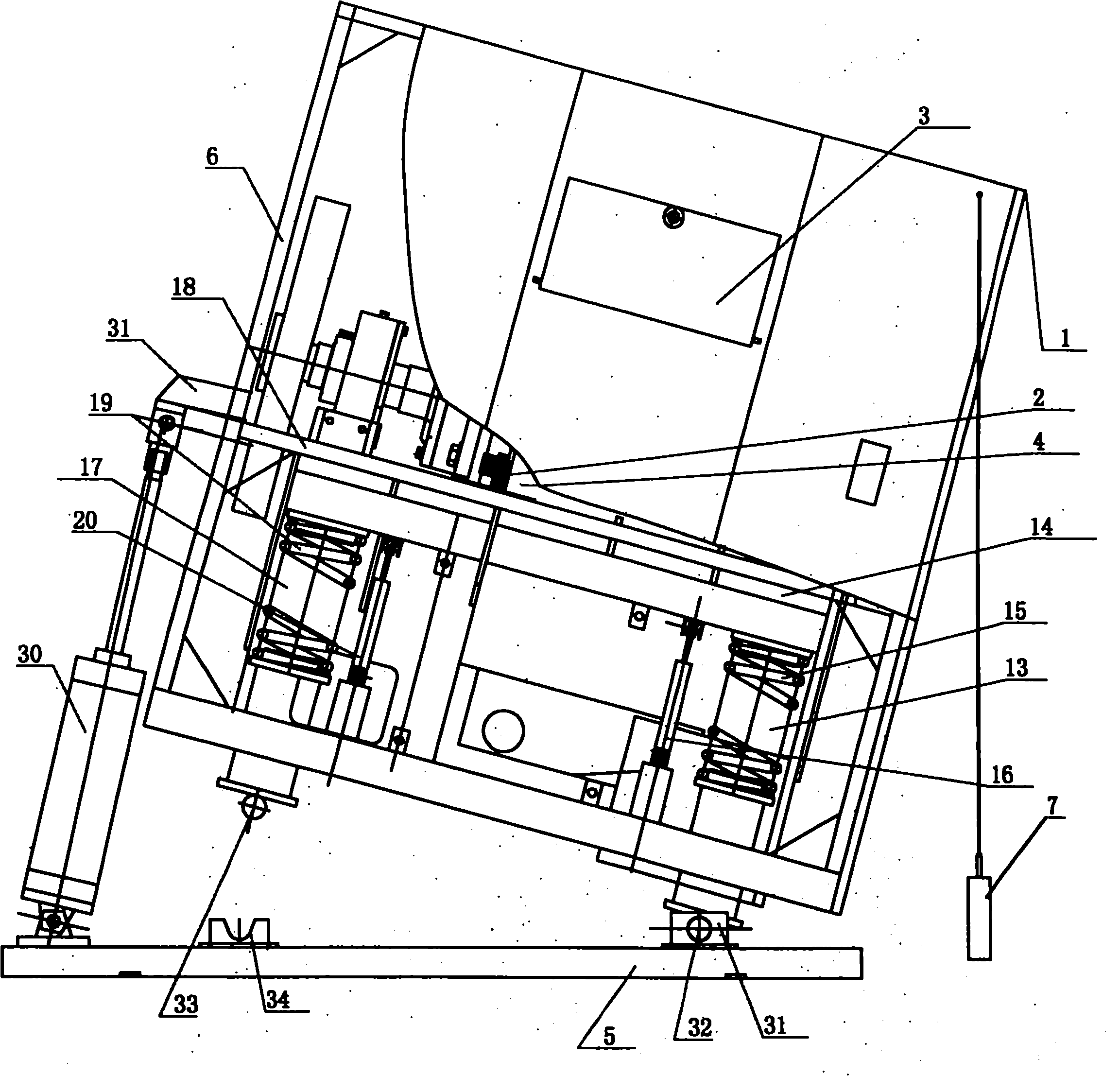

Washing and dehydrating machine capable of automatically unloading

InactiveCN102041652AAvoid bending deformationAvoid automatic unloading problemsOther washing machinesWashing machine with receptaclesRemote controlSelf locking

The invention discloses a washing and dehydrating machine capable of automatically unloading, which is provided with a shell (1) of which the side is provided with an agent feeding box (3). A washing device is arranged in the shell (1) and comprises a washing cage (4) and an actuating device, wherein the actuating device is positioned on the rear part of the washing cage (4); the bottom of the washing device is provided with a front damping suspended support device and a rear damping suspended support device, and the washing device is supported by the front damping suspended support device and the rear damping suspended support device; the bottom of the shell (1) is provided with a lifting base (5); the bottom of the front damping suspended support device passes through the shell (1) to be rotatably connected with the lifting base (5); the rear damping suspended support device passes through the shell (1) to be detachably connected with the lifting base (5); and a self-locking lifting mechanism is arranged between a support frame (6) on the rear part of the shell (1) and the lifting base (5) and is connected with a remote control box (7).

Owner:袁廷荣

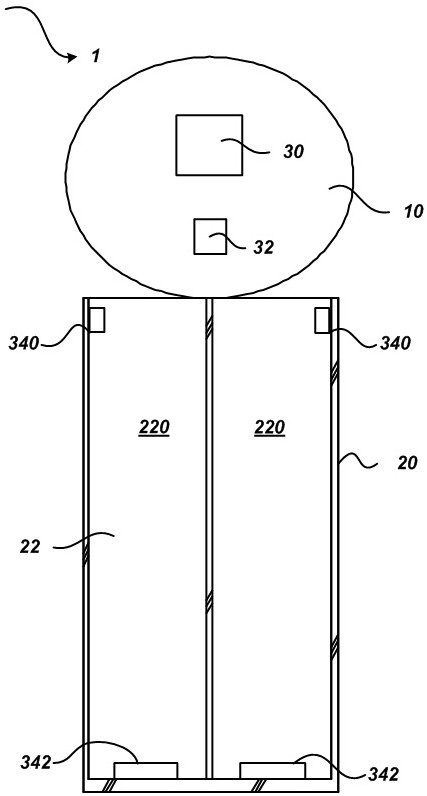

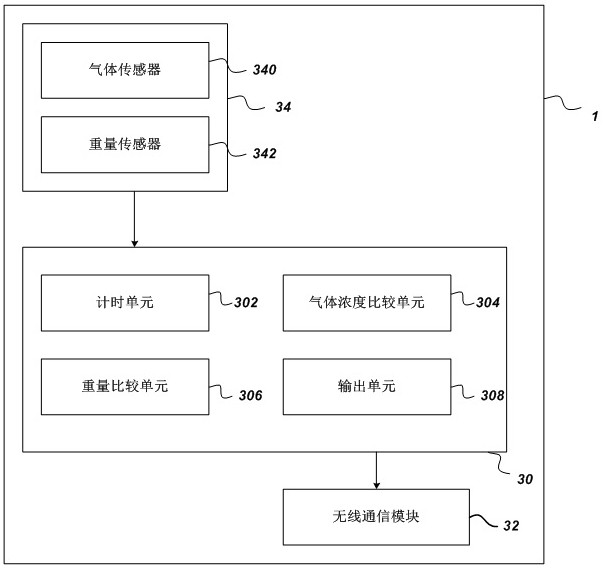

Clothes storage device and control method of clothes storage device

ActiveCN111826888AIncrease washing timeAffect processing powerOther washing machinesTextiles and paperControl engineeringProcess engineering

The invention discloses a clothes storage device. A cavity is formed inside the clothes storage device. The clothes storage device comprises a sensing module and a control module. The sensing module is used for detecting the environmental conditions in the cavity and / or the characteristics of clothes in the cavity, and the control module is used for automatically generating a washing scheme of theclothes in the cavity on the basis of data information generated by the sensing module. The invention further discloses a control method of the clothes storage device. According to the clothes storage device and the control method of the clothes storage device, the control module effectively converts the immediate state in the cavity into the washing scheme and reminds a user on the basis of a detection result of the sensing module, and the phenomenon that the handling capacity of clothes handling equipment is affected due to the fact that the clothes are excessive is avoided. Meanwhile, theenvironmental conditions in storage units and the characteristics of the clothes in the storage units are detected, and therefore the clothes storage device effectively reduces the damage and the pollution caused by long-time accumulation of the dirty clothes, the user is scientifically guided to use the clothes handling equipment, and the remote monitoring is achieved through the interconnectionand the intercommunication among a wireless communication module, the clothes handling equipment and a mobile terminal.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

A waste gas washing device

ActiveCN111389136BReduce bubble sizeIncrease contact rateGas treatmentUsing liquid separation agentEnvironmental engineeringMechanical engineering

The invention belongs to the technical field of waste gas treatment, especially a water washing device for waste gas. In view of the fact that the traditional water washing device is relatively simple and the ventilation is fast, the bubble volume of the gas in the water is relatively large, and the contact rate with water is low, resulting in For the general problem of water washing effect, the following scheme is now proposed, including a water washing box and an air washing pipe. An air distribution mechanism is installed on the end of the air washing pipe close to the water washing box, and a fixed frequency sealing mechanism is installed on the top of the water washing box. A conical chassis is welded on the peripheral outer wall of one end close to the port of the gas washing pipe, and a first curved cover plate is welded on the circumferential inner wall of the water washing tank close to the conical chassis. The invention can lead the gas evenly to the equidistant wave-shaped air guide grooves under the action of the auxiliary bump and the air distribution pipe, and effectively reduce the size of the gas bubbles in the water under the further subdivision of the air outlet pipe , increase the contact rate of gas and water, and improve the washing effect.

Owner:山东中科博联智能环保装备有限公司

High-capacity viscose staple fiber refining production line

Owner:YIBIN GRACE +2

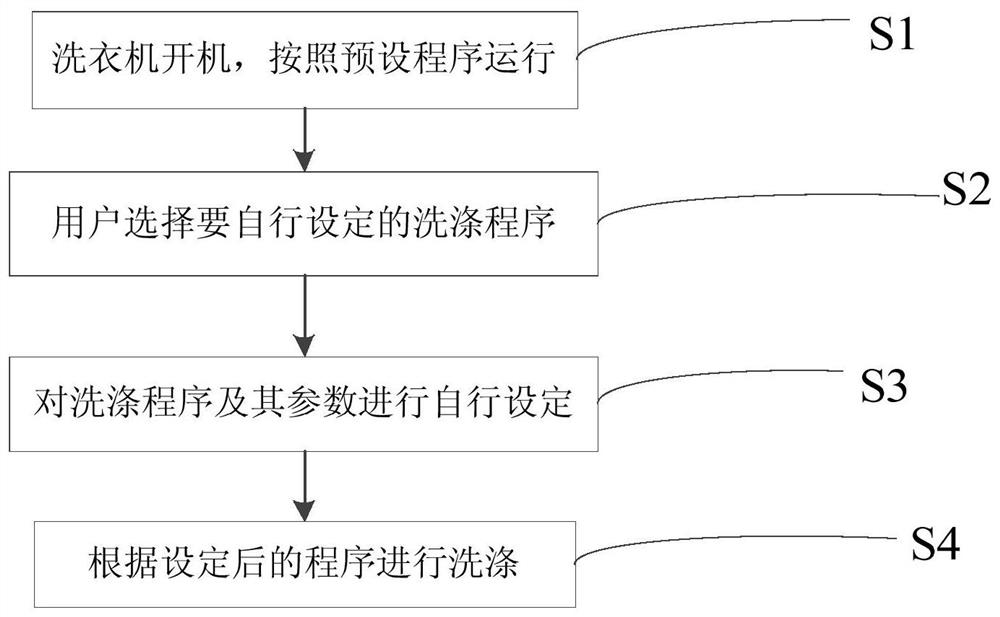

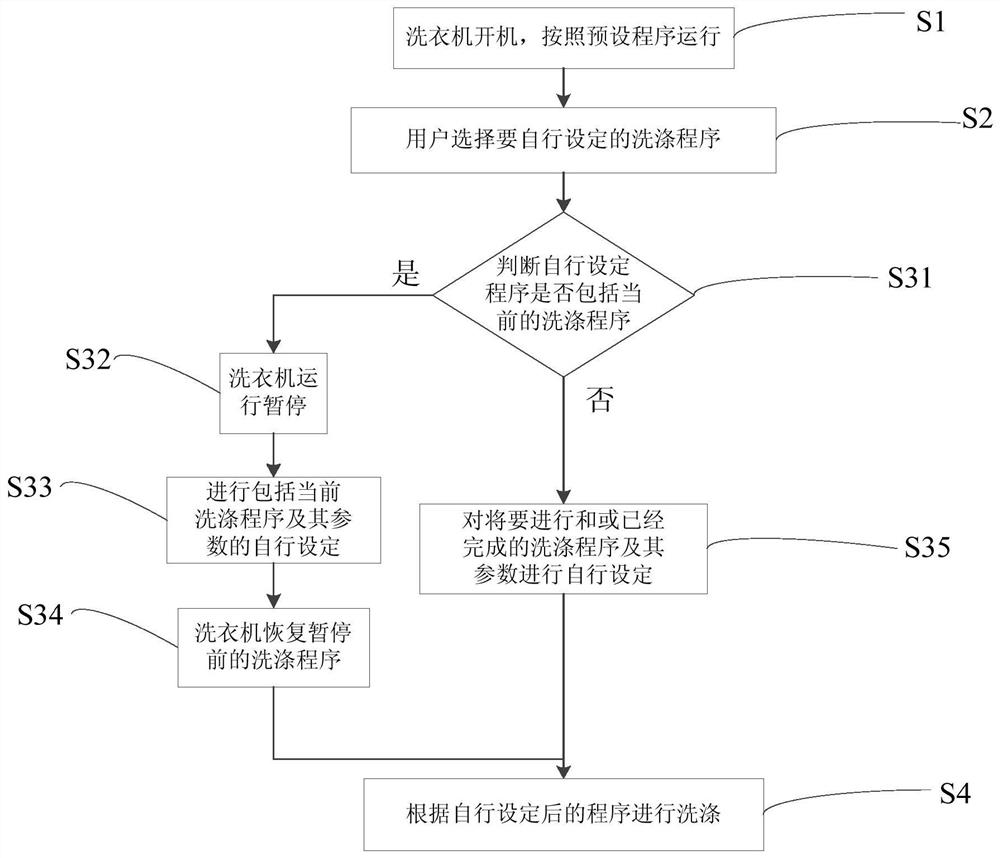

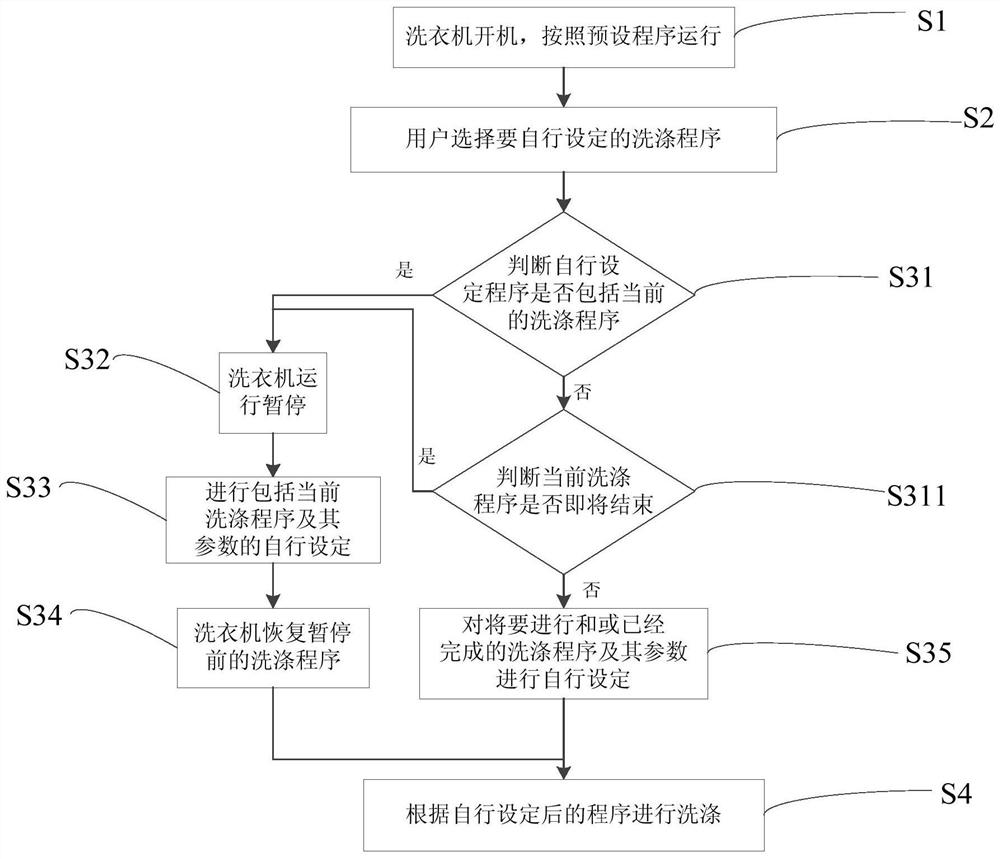

A washing machine control method and washing machine

ActiveCN107435206BIncrease washing timeExtended soaking timeControl devices for washing apparatusTextiles and paperLaundry washing machineProcess engineering

The present invention relates to the technical field of washing machines, in particular to a washing machine control method and the washing machine. The control method includes self-setting of washing procedures and parameters thereof which are being performed and / or will be performed and / or have been completed by the washing machine, Let the washing machine wash according to the set program. The present invention also provides a washing machine using the control method, which can set the washing and / or drying program of the washing machine, and freely change the parameters of the programs such as soaking, washing, rinsing, dehydration and drying to achieve full washing It greatly improves the user experience and is suitable for promotional use.

Owner:上海海尔洗涤电器有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com