Drum washing machine

A drum-type washing machine and washing machine technology, applied to other washing machines, washing machines with containers, washing machine control devices, etc., can solve the problems of easy damage and shrinkage of clothes, and achieve the advantages of prolonging washing time, shortening washing time, and reducing shrinkage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

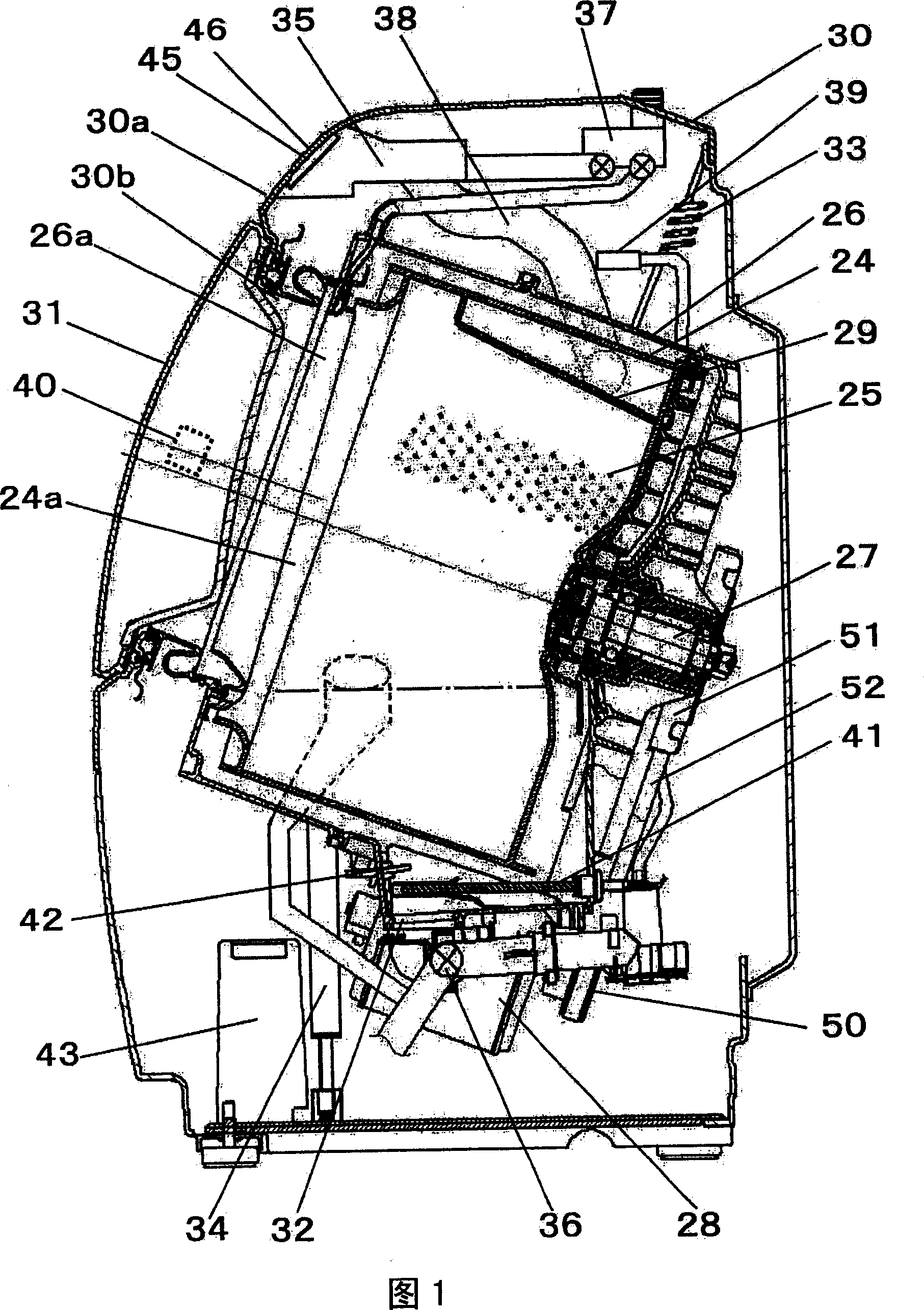

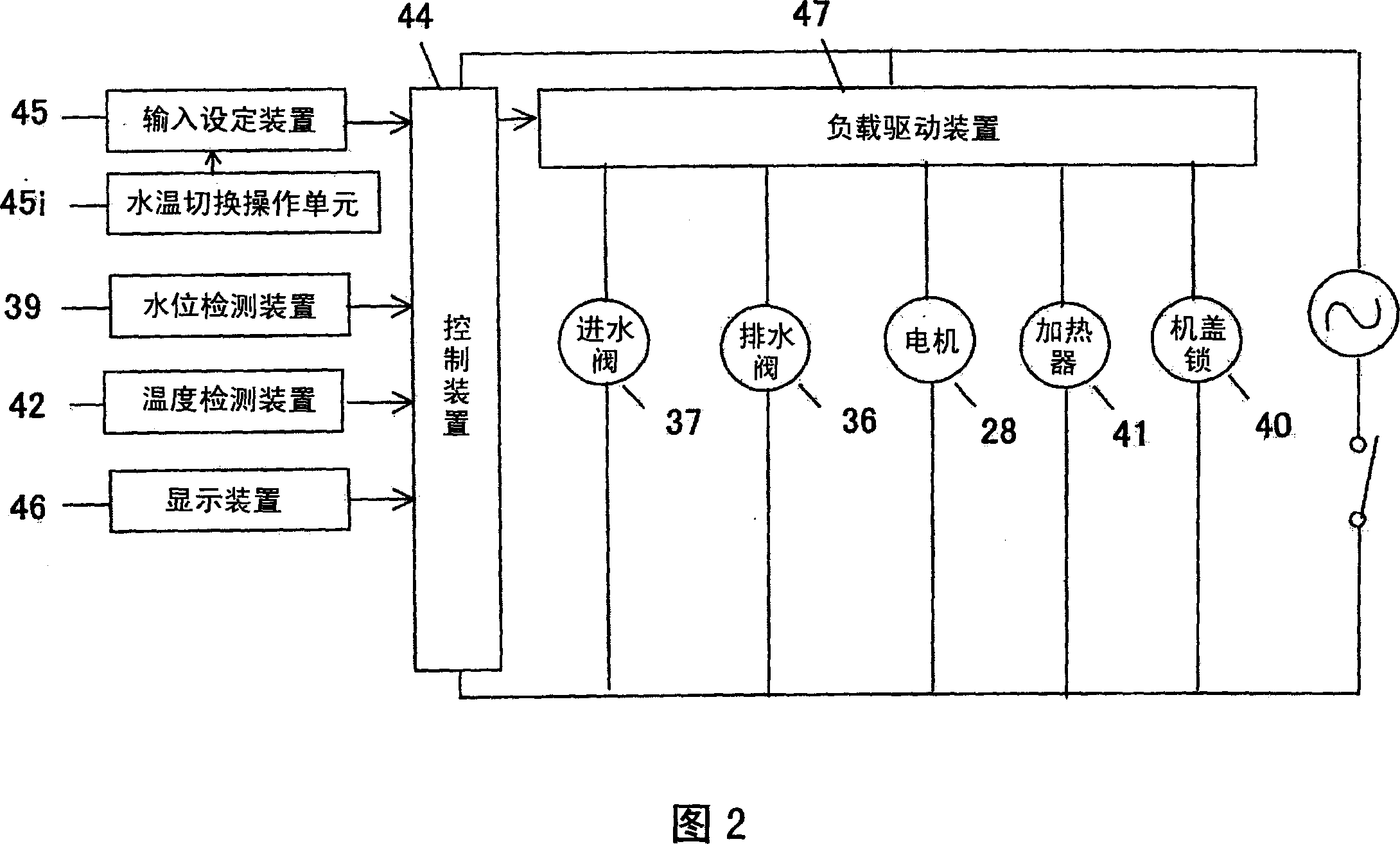

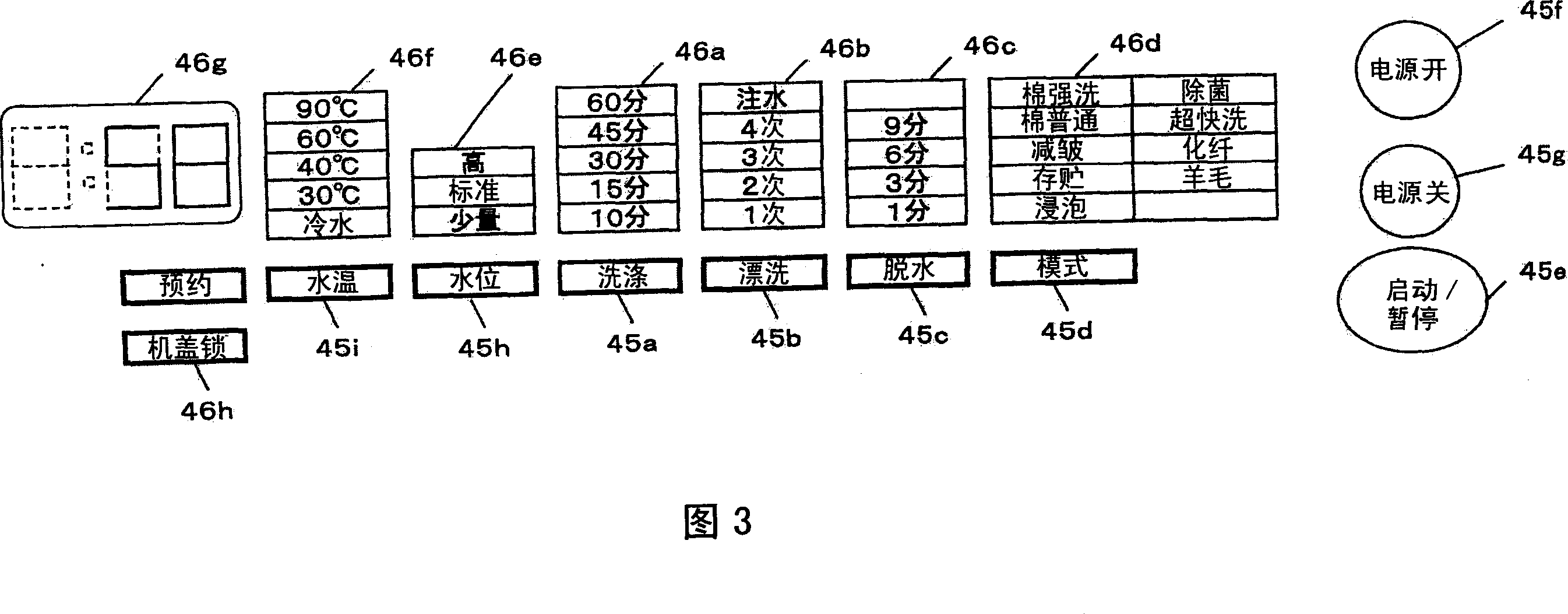

[0041] Fig. 1 is a longitudinal sectional view of a drum-type washing machine in the first embodiment of the present invention, Fig. 2 is a control circuit diagram of the drum-type washing machine (a part of which is drawn as a block diagram), and Fig. 3 is an input setting of the drum-type washing machine The enlarged front view of the device and the display device, Fig. 4 is a schematic operation flowchart of the drum-type washing machine, and Fig. 5 is a high-temperature washing process diagram of the drum-type washing machine.

[0042] As shown in FIG. 1 , the rotary drum 24 is in the shape of a bottomed cylinder with many water holes 25 formed on its entire peripheral wall, and the rotary drum 24 is rotatably installed in a tub 26 . The rotation center of the rotary drum 24 is provided with a substantially oblique rotation shaft (rotation center shaft) 27 , and the axis direction of the rotary drum 24 is inclined downward from the front side to the rear side. Motor 28 is ...

Embodiment approach 2

[0068] Fig. 6 is a schematic operation flowchart of the front-loading washing machine in the second embodiment of the present invention.

[0069] In this embodiment, in the first agitation process when performing the high-temperature washing process, the control device 44 sets a low agitation time with a relatively low agitation time (for example, stirring for 7 seconds and stopping for 23 seconds), and a lower than this low agitation. Stirring and high stirring with a relatively high stirring time (for example, stirring for 20 seconds and stopping for 4 seconds) are combined to form a stirring cycle, and such a cycle is repeated continuously. In this way, the problems of insufficient washing agitation and low water temperature detection accuracy caused by the low actual agitation ratio of the rotating drum in the first half of the first agitation stroke can be solved. Since other configurations are the same as those in Embodiment 1, only the same symbols are assigned here, an...

Embodiment approach 3

[0079] Fig. 7 is a schematic operation flowchart of the front-loading washing machine according to the third embodiment of the present invention.

[0080] In the present embodiment, the control device 44 performs control as follows: when the first predetermined time is detected in the first agitation process of the high-temperature washing process, and when the second predetermined time is detected in the second agitation process Next, control to enter the next stroke. This embodiment relates to control when a certain failure occurs in a heating device or a temperature detection device. Since the other configurations are the same as those in Embodiments 1 and 2, only the same symbols are assigned here, and repeated description thereof will be omitted.

[0081] The operation in the above constitution will be described below. In FIG. 7 , since steps 300 to 308 are the same as steps 100 to 108 in Embodiment 1, descriptions thereof are also omitted here.

[0082] In step 309 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com