Patents

Literature

46results about How to "Shrunk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for fabricating soft knitting face fabric from cotton

InactiveCN101003936ADimensionally stableDoes not reduce strengthFabric breaking/softeningBiochemical fibre treatmentAgricultural engineeringSizing

The present invention discloses a processing method of flexible cotton knitted face fabric. Said processing method includes the following several steps: weaving, enzymatic washing, kiering and bleaching, dyeing, oversoftening, dewatering, opening, drying, sizing and pre-shrinking.

Owner:浙江盛泰服装集团股份有限公司

Processing method for low-elastic non-ironing knitted face fabric

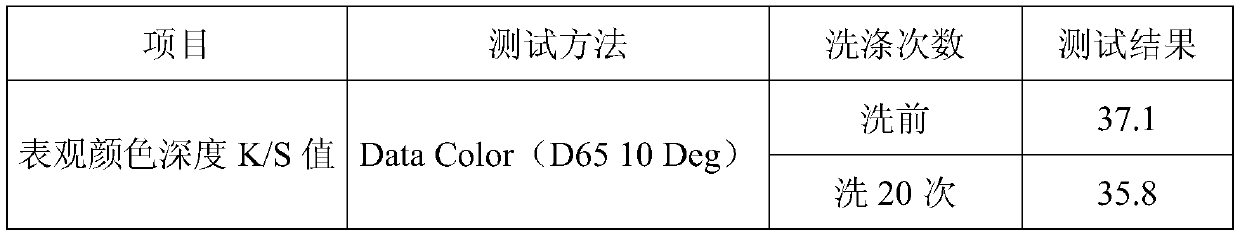

InactiveCN101200852AShrunkGood color retentionWeft knittingBiochemical fibre treatmentAmmoniaComputer science

The present invention discloses a processing method of a low-elasticity, wrinkle-free knitted fabric, which includes steps: greige cloth weaving, boiling and bleaching, bio-enzyme washing, dyeing, softening, dehydration, scutching, drying, shaping and preshrinking. The present invention is characterized in that the processing steps of pre-relaxation and ammonia mercerization are added before boiling and bleaching, so that the whole processing steps are changed as greige cloth weaving, pre-relaxation, ammonia mercerization, boiling and bleaching, bio-enzyme washing, dyeing, softening, dehydration, scutching, drying, shaping and preshrinking; the pre-relaxation processing is to add refining agent of 0.5 to 1.5g / L, the processing temperature is between 90 and 130 DEG C, and the processing period is twenty to sixty minutes; in the step of ammonia mercerization, the pre-relaxed fabric receives the processing of ammonia mercerization in an ammonia mercerizing machine at the speed of 15 to 50m / min. The present invention ensures that the cotton and the blended elastic knitted fabric can have soft, smooth handfeel and high washing resistance and shape-keeping property.

Owner:浙江盛泰服装集团股份有限公司

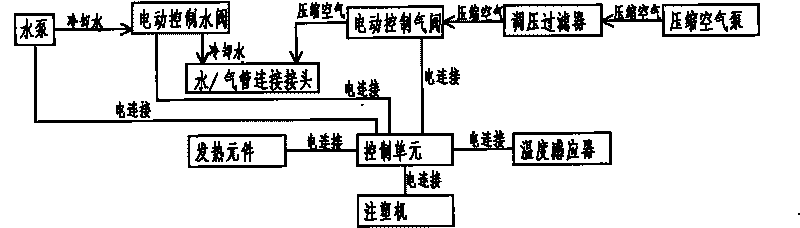

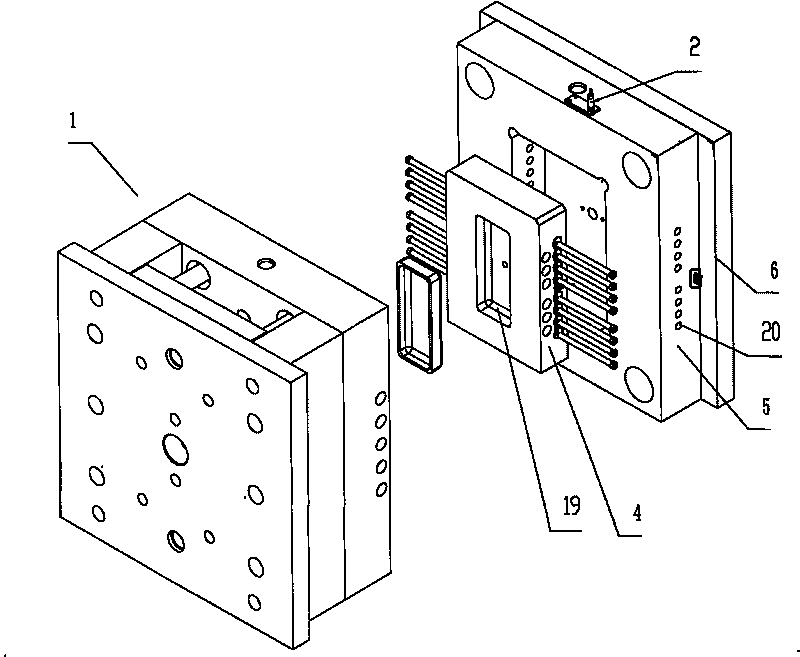

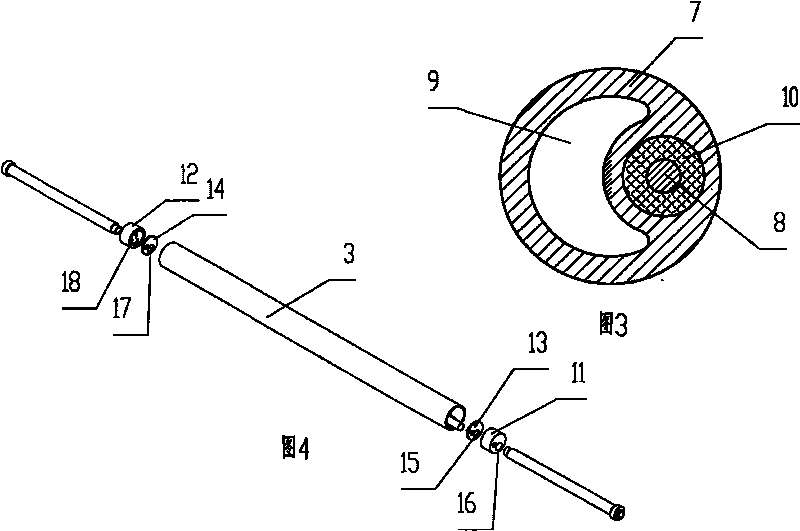

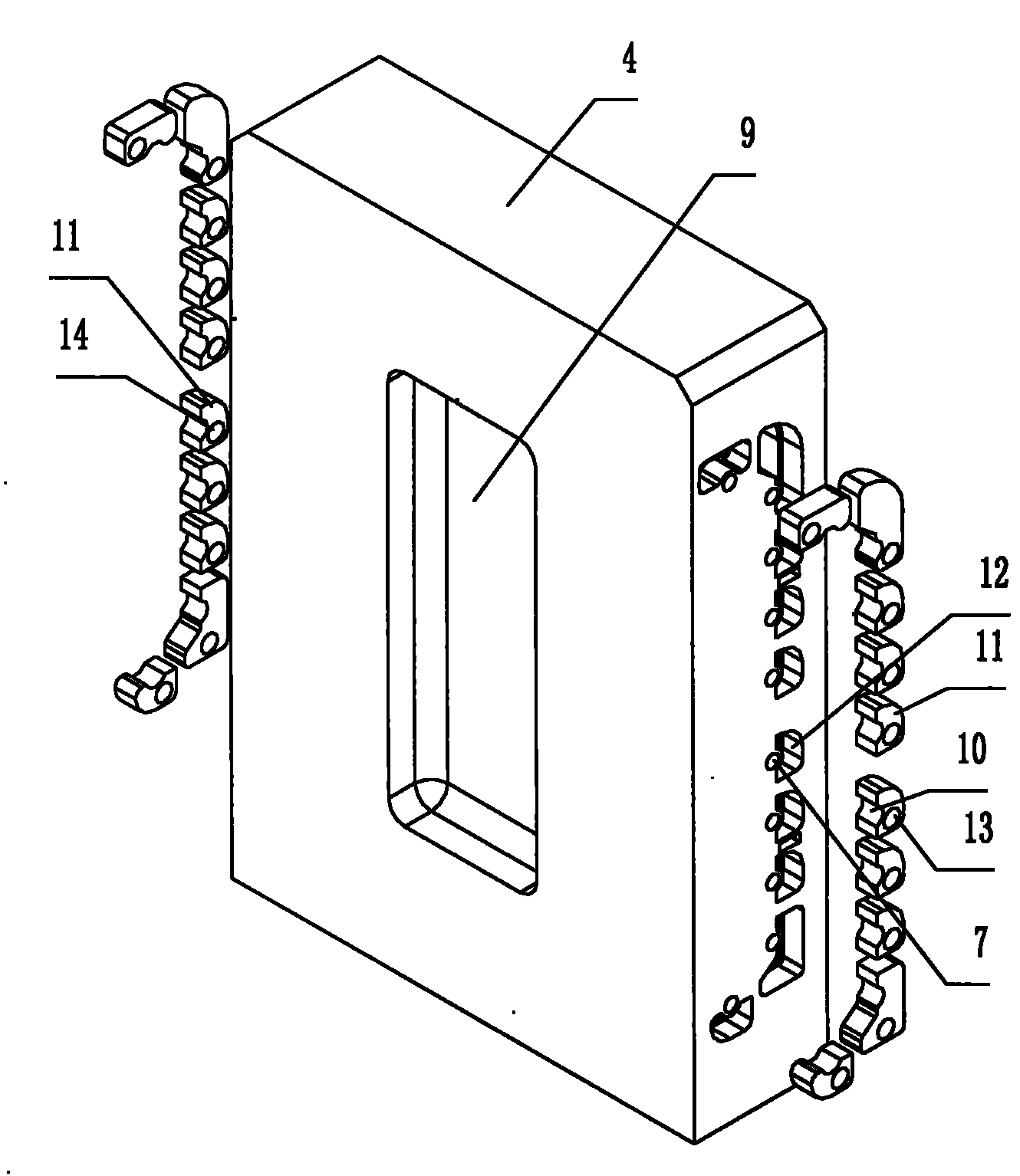

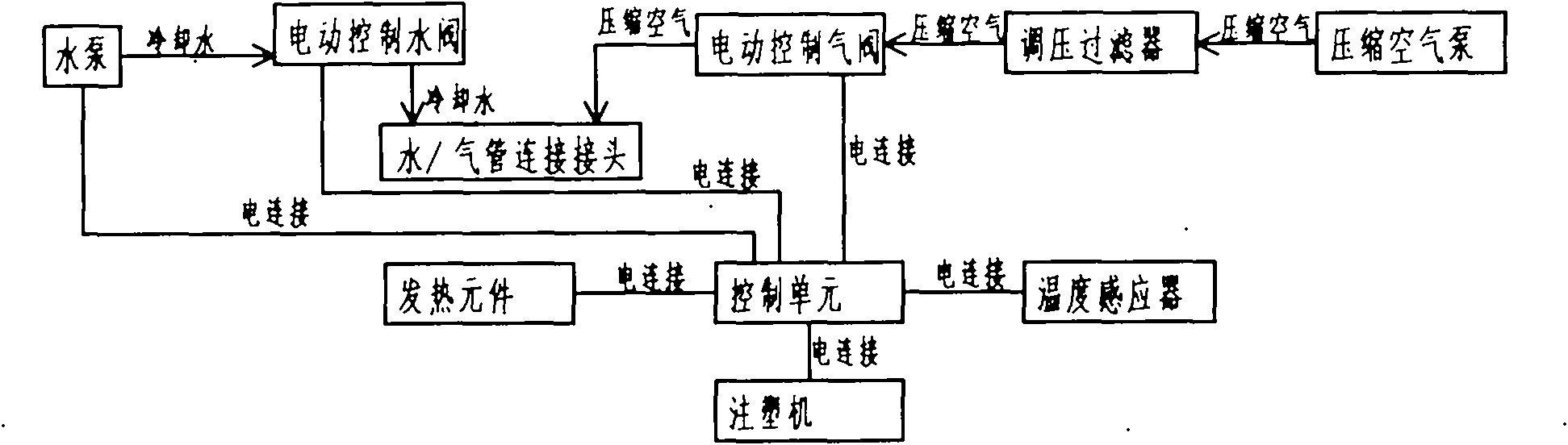

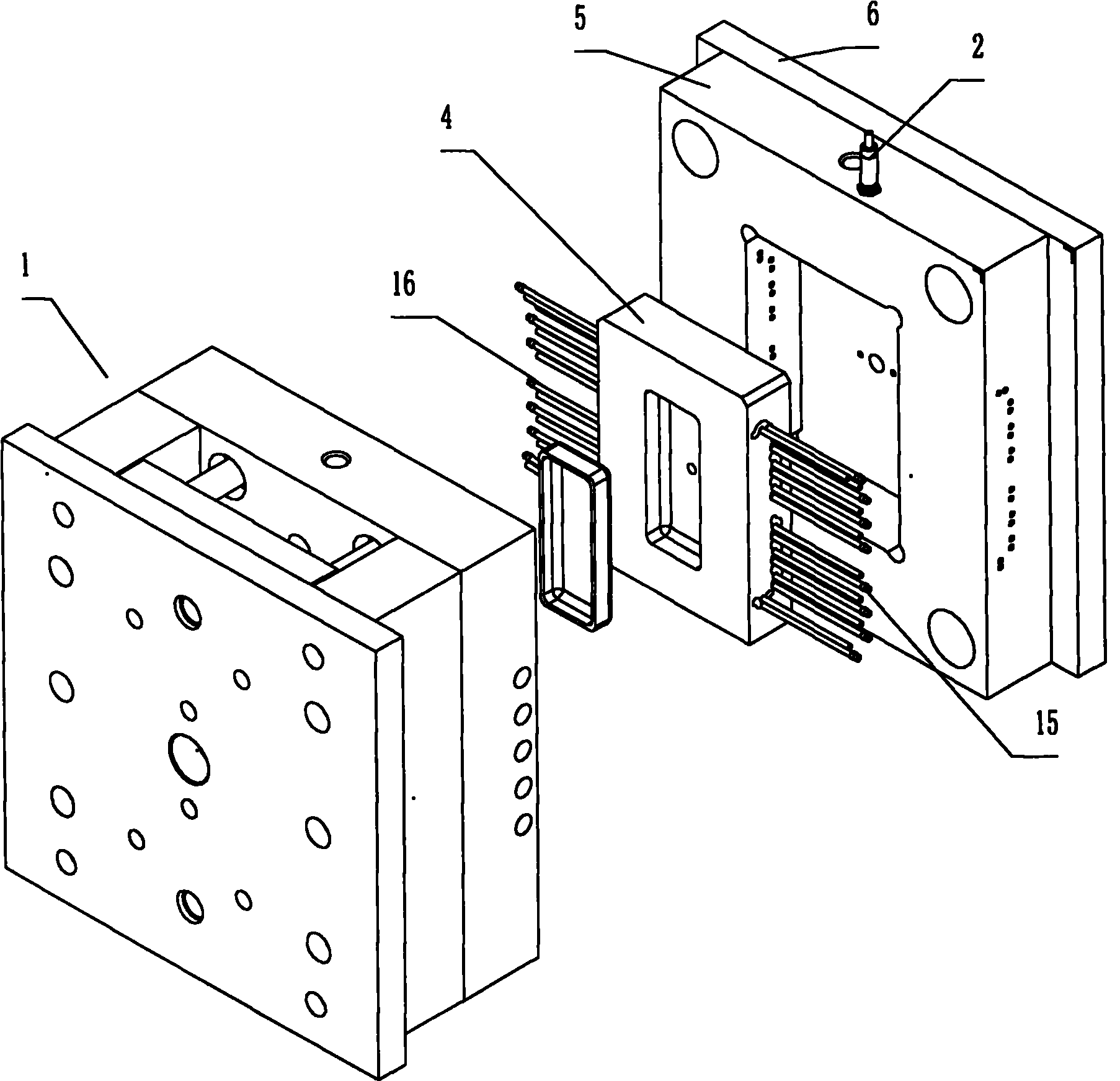

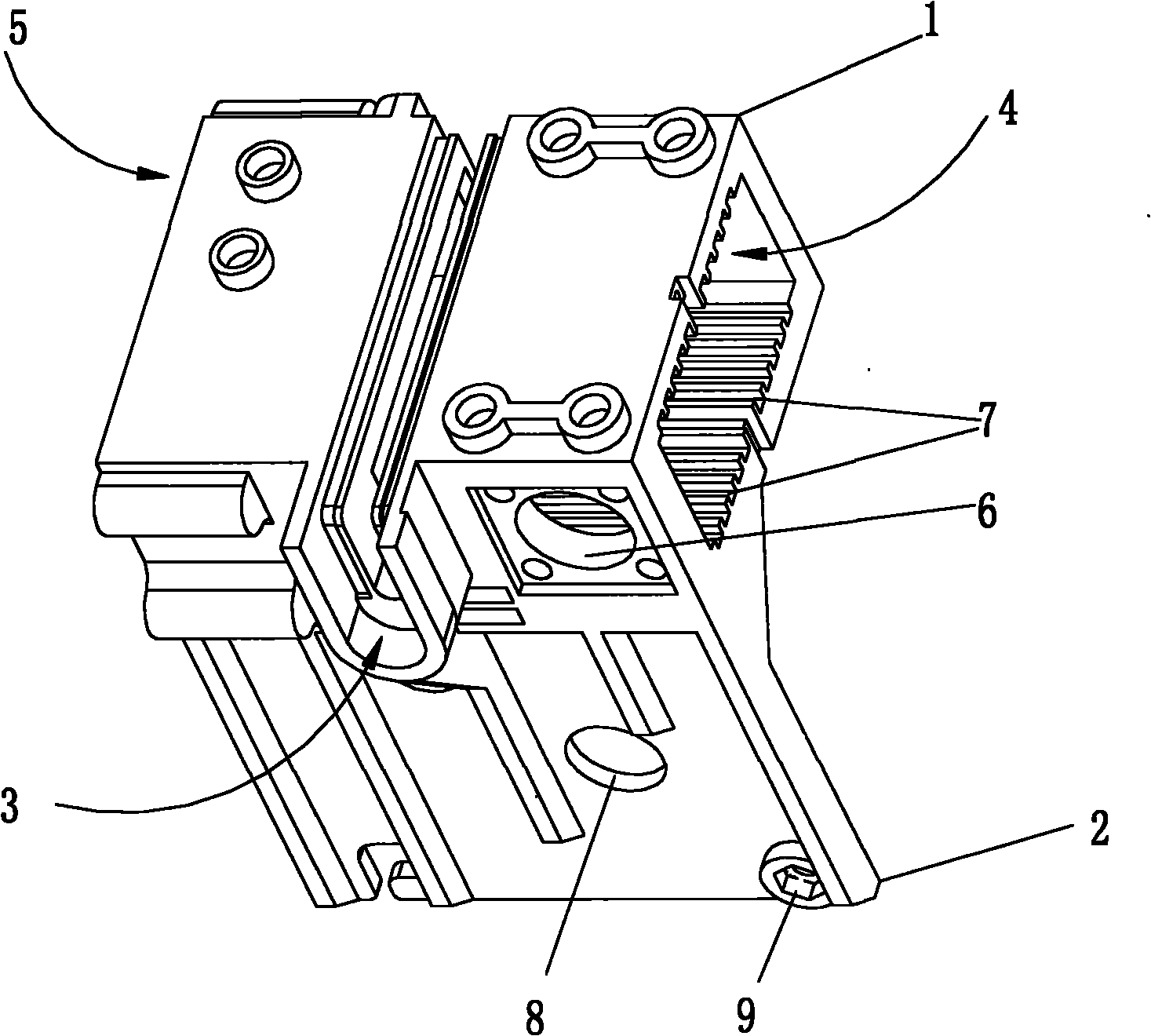

Mold heating and cooling rod and mold capable of realizing rapid cooling and rapid heating

The invention relates to a mold heating and cooling rod which comprises a heating and cooling rod body and a heating element, a cooling thermal insulation hole for introducing a cooling medium when a mold needs to be cooled and discharging the cooling medium when the mold needs to be heated and a heating element accommodating hole are arranged in the heating and cooling rod body along the axial direction, and the heating element is mounted in the heating element accommodating hole; the mold capable of realizing rapid cooling and rapid heating comprises a mold core and the heating and cooling rod, and the heating and cooling rod is in contact with the mold core; and one side of the heating and cooling rod which is provided with the heating element is near to a molding surface of the mold core. The advantages are that, as the molding surface can be rapidly and evenly heated and cooled and rapidly heated to the temperature which is near to or equal to that of melting materials, a molded product has the advantages of good quality, difficult production of weld marks, flow marks, surface bubbles and the like, even color and luster, even density of the product, small shrinkage and ability of reducing the injection pressure and the product deformation caused by residual stress after consolidating and molding the molten materials.

Owner:杨东佐

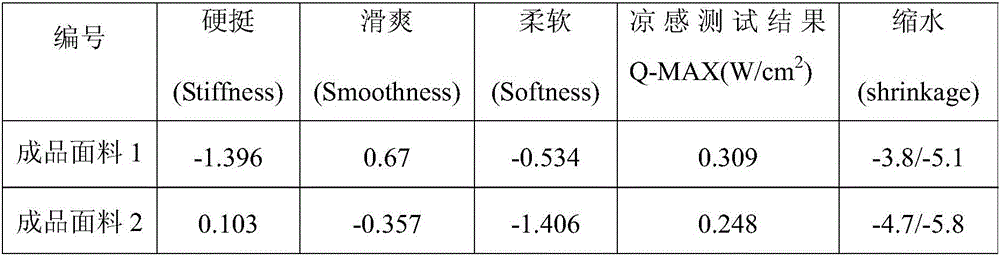

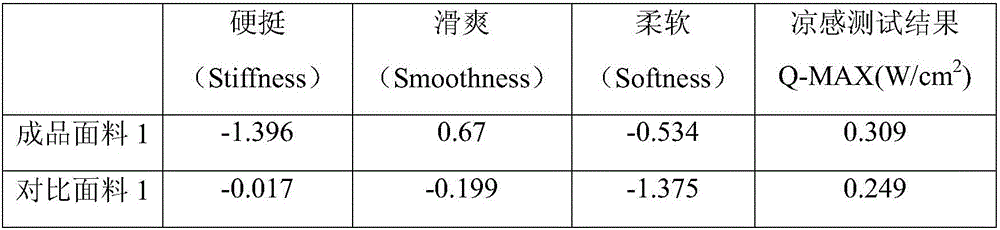

Knitted fabric containing cotton and having silky luster, handfeel and cool feeling and manufacturing method thereof

ActiveCN105734963ACompact structureNo blemishes on the clothWeft knittingBiochemical treatment with enzymes/microorganismsWoolDyeing

The invention provides knitted fabric containing cotton and having silky luster, handfeel and cool feeling and a manufacturing method thereof.The method includes the following steps that yarn is woven into gray fabric with a circular knitting machine, wherein the needle number of the circular knitting machine is 18-40, the yarn count is 20-80 S / 1, length 50 C of the yarn is 90-200 mm, and the gram weight of the gray fabric is 60-240 g / m<2>.The tissue structure of the gray fabric includes tabby, half cardigan, knitted cotton, rib, looped pile and ball wool or jacquard weave; open width alkali mercerizing, boiling-off, enzyme washing, dyeing, drying, soft stabilized finishing and preshrinking are conducted to finally obtain the knitted fabric containing cotton and having silky luster, handfeel and cool feeling.The knitted fabric containing cotton and having silky luster, handfeel and cool feeling has the advantages of being smooth, stiff, good in drapability, resistant to crease and small in shrinking amount and integrates smoothness, stiffness and crease resistance.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Production process for cotton-linen knitted belt

InactiveCN107385877ASoft touchEasy to processShrinkingMercerising of indefinite length fabricsConvex structureMoisture permeability

The invention relates to a production process for a cotton-linen knitted belt. According to the invention, multiple steps of the production process for the cotton-linen knitted belt are improved from multiple aspects, so the produced cotton-linen knitted belt is ensured to be good in elasticity and wear resistance, stable in dimension, small in washing shrinkage, straight, not prone to creasing, easy to wash and fast to dry under dry and wet conditions; the linen component of the knitted belt is capable of preventing ultraviolet rays and suppressing and resisting bacteria; the production process for the cotton-linen knitted belt overcomes the inherent disadvantage of stiff and itchy handle feel of natural fibrilia fabrics; and the prepared cotton-linen knitted belt has a special concave-convex structure, excellent low irritability, moisture permeability and crease resistance, and good indexes like moisture absorption performance and permeability, is knitted by fully natural fiber, is a low-carbon environment-friendly belt, and accords with the current fashionable trend of international textiles and garments.

Owner:HUZHOU UNIFULL LABEL FABRIC CO LTD

Mould capable of realizing rapid heat cycle

The invention discloses a mould capable of realizing a rapid heat cycle, which comprises a mould core provided with a moulding surface and heating rods with set number. Heating rod accommodating holes are formed at positions close to the moulding surface in the mould core and accommodate the heating rods; cooling insulation holes corresponding to the heating rods are formed at positions close to the heating rods in the mould core provided with the moulding surface, and are positioned on one side of the heating rods far from the moulding surface; the overall outline of the cross section of each cooling insulation hole is a closed curve; and one or more cooling insulation holes enclose corresponding heating rods in three directions. The mould has the advantages that: the moulding surface can be rapidly and uniformly heated and cooled, and can be rapidly heated to the temperature approaching to or equal to the temperature of a fused material, so the moulded products have good quality, weld marks, flow marks, surface bubbles and the like are not generated easily, the products have uniform luster and density and low shrinkage, and injection pressure and product deformation caused by residual stress after the fused material is solidified and moulded are reduced.

Owner:杨东佐

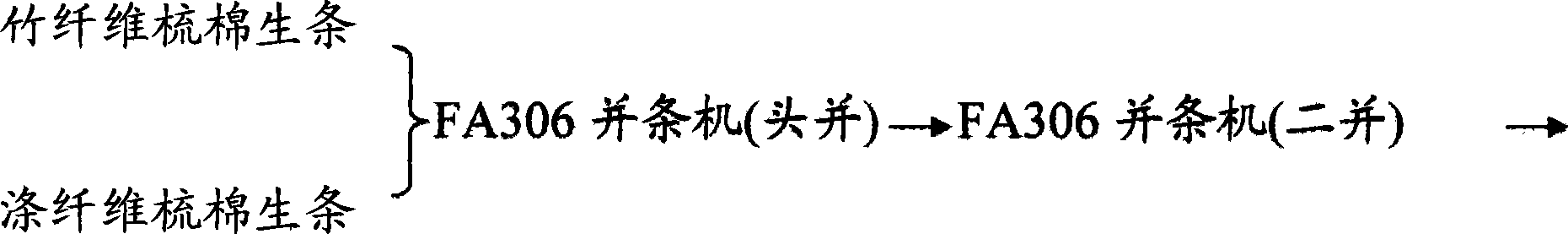

Bamboo / polyester blended fabric and production process thereof

The invention discloses a bamboo / Terylene mixed fabric and a production process thereof. The weight proportion of bamboo fiber to Terylene fiber is 60-80 to 40-20, and mixing and twisting coefficient is between 350 and 375. Mixed fabric technological conditions are strictly controlled to improve spinnability. According to the production process; after mixing, the strength of the fabric can increase by 10 to 20 percent; and according to technological design, gram weight knitted fabric is mastered (shrinkage mass is about between 5 and 8 percent), wherein ball bursting strength NGB / 8878-2001 reaches 325, and the dyed luster of the mixed fabric keeps original style of bamboo fiber fabric, and the strength of the mixed fabric is superior to that of other varieties.

Owner:FUJIAN HONGYUAN GROUP CO LTD

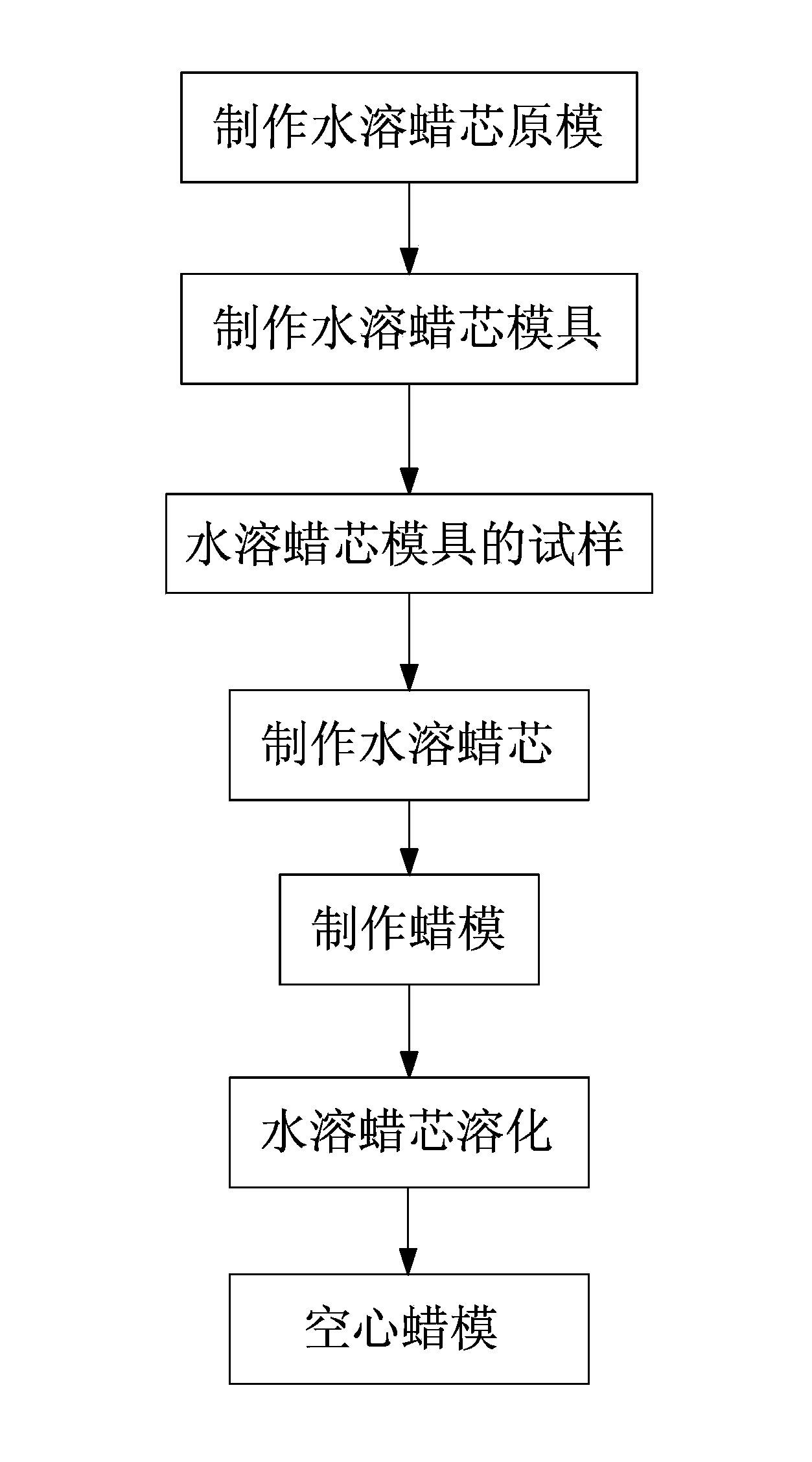

Method for preparing hollow wax mold by utilization of water-soluble wax

The invention discloses a method for preparing a hollow wax mold by utilization of water-soluble wax, and relates to the technical field of dewaxing casting. The method comprises the following steps: first, a water-soluble wax core original mold is prepared; second, a water-soluble wax core mold is prepared; third, sample testing of the water-soluble wax core mold is carried out; fourth, a water-soluble wax core is prepared; fifth, a wax mold is prepared; sixth, melting of the water-soluble wax core is carried out, and therefore a hollow wax mold is obtained. The beneficial effects of the method are that, the method solves the technical problem that all-around hollowing cannot be achieved when a special-shaped hollow workpiece is prepared in the traditional wax casting technology; all-around hollowing is achieved by utilization of water soluble wax, workpiece weight is lowered, the wall thickness of the prepared hollow wax mold is uniform, and the yield is raised.

Owner:SHENZHEN JINBAOYING CULTURE

Processing method for chemical-preventing fabric

ActiveCN104963188AImprove permeabilityImprove breathabilityShrinkingLiquid/gas/vapor removalCooking & bakingYarn

The invention discloses a processing method for chemical-preventing fabric, and belongs to the technical field of textile industry. The method is carried out on the basis of gray fabric woven from pure cotton yarns or polyester cotton yarns, and comprises the processes of blank inspection, seam overturning, singeing, cold batching, short steaming, washing and dyeing. The method is characterized by also comprising the steps of A, open-width washing, B, chemical-preventing arrangement, C, preshrinking treatment, and D, baking. The chemical-preventing fabric processed by the method has a function of preventing sulfuric acid, hydrochloric acid, nitric acid and caustic soda, has a good function of preventing chemical solvents such as o-xylene, methyl alcohol and acetone, and meets an EN14325 chemical-preventing standard.

Owner:HEBEI NINGFANG GRP

Woolen sweater

InactiveCN101871151AReduce tensionHigh tensile strengthWeft knittingWarp knittingWear resistanceLow shrinkage

The invention discloses a woolen sweater, which is formed by knitting 30 to 50 weight percent of wool, 5 to 15 weight percent of cashmere, 10 to 30 weight percent of nylon, and 20 to 40 weight percent of artificial cotton. The woolen sweater has the advantages of low shrinkage, difficult pilling, static resistance, wear resistance, difficult deformation, low cost and the like.

Owner:太仓市隆丝达针织时装有限责任公司

Soft shell fabric

The invention discloses soft shell fabric, which is applied to manufacturing various clothes. The shell fabric is composed of three layers of materials, respectively a knitted shell fabric layer, a silk shell fabric layer and a cambric shell fabric layer. The knitted shell fabric layer is at the innermost side and formed by weaving cotton and sesame in a mixed manner. The silk shell fabric layer is in the middle layer and made of a real silk material. The cambric shell fabric layer is at the outermost side and used for improving the aesthetic extent of the whole shell fabric. By means of the way, the size stability and the recovery property on fabric are greatly improved; therefore, the cotton knitted shell fabric is burnished, soft, smooth in hand fell, low in shrink, flat in cloth cover, resistant in washing, durable and free from deformation; furthermore, the shell fabric also has good appearance after being washed; and the processed shell fabric has the characteristics of ultra-soft liquid cotton.

Owner:CHANGSHU HENGQIN GARMENT

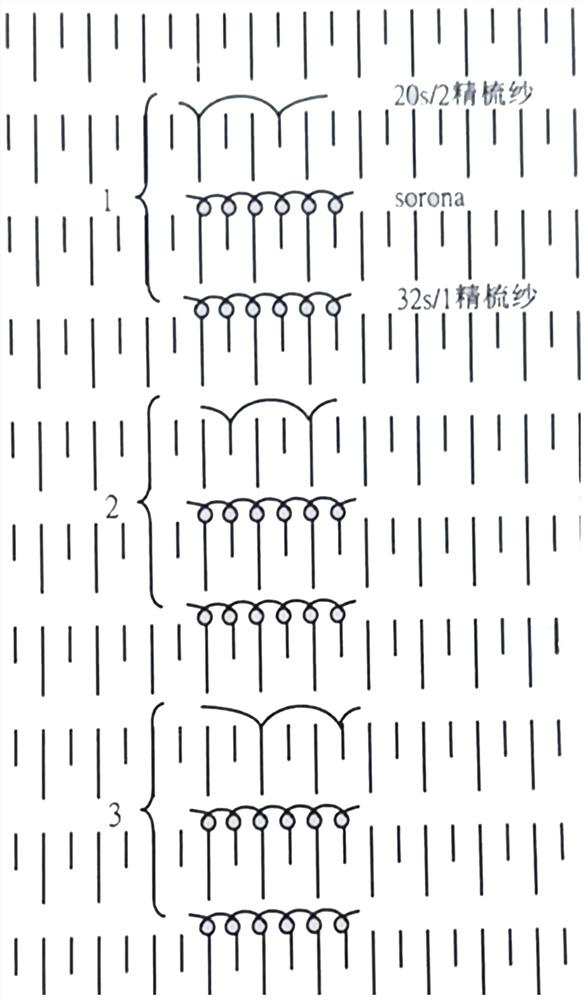

Textile fabric setting process

The invention discloses a textile fabric setting process. The setting process comprises the following steps of S1, weaving; S2, blank fixing; S3, front surface singeing; S4, boiling off; S5, fluff etching; S6, dyeing; S7, scouring and etching; S8, cloth drying; S9, bottom surface fluff sucking; and S10, finished product setting. In order to overcome the defects in the prior art, the invention provides the textile fabric setting process which is simple and capable of effectively reducing fluffing or linting on the surface of a SORONA textile fabric, effectively improving the anti-wrinkle performance and the tensile resilience and reducing the shrinkage of the fabric.

Owner:渡帮针织科技(中山)贸易有限公司

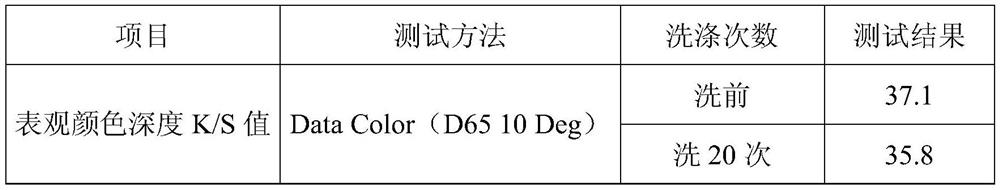

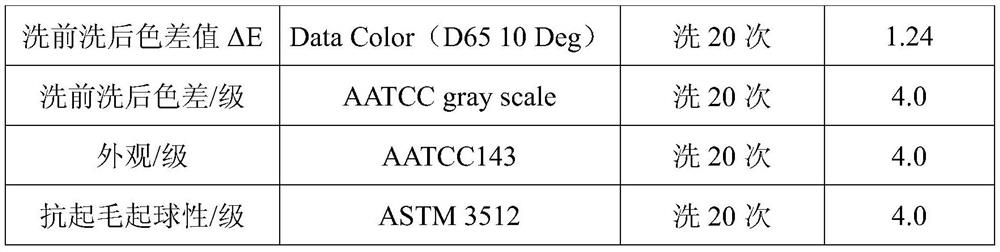

Dark non-ironing washable pure cotton knitted fabric and preparation method and application thereof

ActiveCN110029501AIncrease the ammonia removal timeIncrease Ⅲ contentSucessive textile treatmentsLiquid/gas/vapor removalYarnChemistry

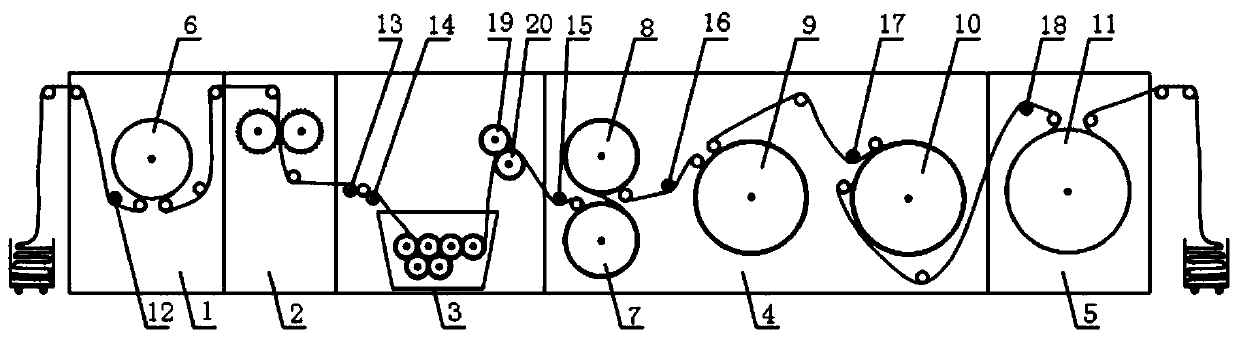

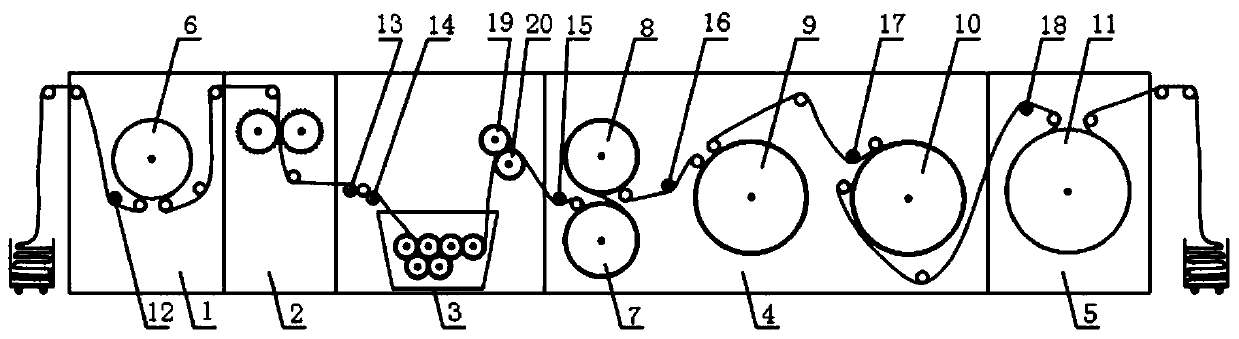

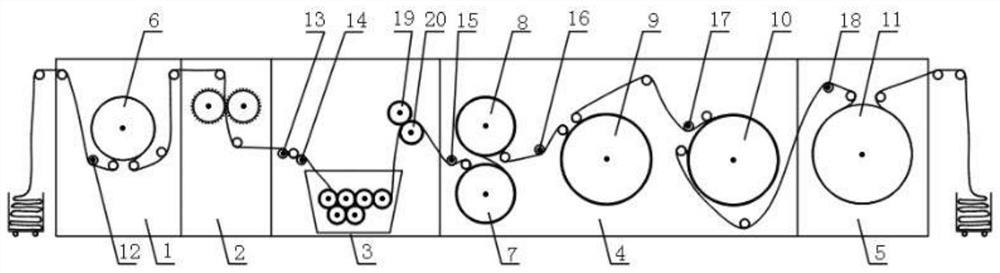

The invention provides a dark non-ironing washable pure cotton knitted fabric and a preparation method and application thereof. The preparation method includes the steps that yarn is subjected to greycloth knitting, scouring, enzyme washing, dyeing, liquid ammonia finishing and resin shaping in sequence to obtain the knitted fabric; during liquid ammonia finishing, a knitted fabric body obtainedafter dyeing, scutching and drying passes through a drying unit, a brushing unit, an ammonia leaching unit, a drying-cylinder ammonia removal unit and a steaming unit in sequence and then is cropped;during liquid ammonia finishing, according to a fabric passing path, the knitted fabric body passes through a fabric guide roller to enter the drying unit and then passes through an edge flattening roller and a fabric guide roller to enter a woolen blanket cylinder body of a drying cylinder of the drying unit; after getting out of the woolen blanket cylinder body, the knitted fabric body passes through a fabric guide roller to enter the brushing unit, passes through an edge flattening roller and a fabric guide roller to enter a liquid ammonia leaching tank of the ammonia leaching unit to passthrough a fabric guide roller and then passes through a first padder roller and a second padder roller; the knitted fabric body enters a plurality of drying cylinders continuously arranged inside thedrying-cylinder ammonia removal unit through the corresponding edge flattening rollers and fabric guide rollers, and then after the knitted fabric body enters a woolen blanket cylinder of a steaming box of the steaming unit through edge flattening rollers and fabric guide rollers, cropping is conducted.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Production method of weft-knitted double knitted polar fleece

InactiveCN110565246AIncrease elasticityLight in massWeft knittingHeating/cooling textile fabricsRoll formingEngineering

The invention discloses a production method of weft-knitted double knitted polar fleece, and relates to a fabric production method. The problem that double napping is poor in effect is solved. The production method of the weft-knitted double knitted polar fleece comprises the following specific steps of S1 gray fabric preparation, S2 dyeing process implementation, S3 finishing for shaping and S4 cutting and packaging for roll forming. The production method of the weft-knitted double knitted polar fleece adopts traditional common raw materials, in combination with a double-sided mini-jacquard weaving technology, and under the assistance of a conventional dyeing and finishing process, a knitted fabric with one side being cotton and the polar fleece side being terylene is produced, and the knitted fabric has the prominent advantages of being fluffy and soft in cloth body, good in elasticity, light in weight, thick in hand feeling, high in skin-friendly feeling, good in heat retention property, good in structural stability, small in shrinkage and the like, can be widely used for bottoming underwear or T-shirts, small casual coats with hoods, baby shoes and the like of spring, autumn and winter clothing, and has broad market application prospects.

Owner:FOSHAN HENGTE TEXTILE CO LTD

Method for preparing bamboo-fiber summer sleeping mat

The invention discloses a method for preparing a bamboo-fiber summer sleeping mat. The method comprises the following steps of weaving, singeing, cold-heap enzyme desizing, high-temperature washing, alkali heap, high-temperature washing, pre-shaping, printing, steaming, washing, soft and non-iron shaping finishing, calendering, pre-shrinking and acquisition of a finished product. The shrinkage ofthe bamboo-fiber summer sleeping mat produced by means of the preparation method is reduced, the deformation generated when the fabric is washed in the later period is small, and the situation cannotoccur that the summer sleeping mat shrinks and is not matched with a bed; the fuzzing and pilling performance is good, the level is high, the wool length of the surface of the product is uniform, andthe visual and tactile comfort degree is increased; after washing, the hand-feel touch change of the mat is soft, and the skin demand is better met.

Owner:NANJING MENGQIRUI DIGITAL WEAVING CO LTD

Top-grade shirt fabric formed by interweaving long stapled cotton and mulberry silk

ActiveCN104082888AConvenient careOvercome the shortcomings of poor washing and easy shrinkageSucessive textile treatmentsBiochemical fibre treatmentBreaking strengthYarn

The invention discloses a top-grade shirt fabric formed by interweaving long stapled cotton and mulberry silk. The top-grade shirt fabric is formed by blending 42-65wt% of Egyptian long stapled cotton and 35-58wt% of the mulberry silk, the Egyptian long stapled cotton is warp, the mulberry silk is weft, the density of the warp is 80-120 pieces per centimeter, the density of the weft is 58-65 pieces per centimeter, and the specification of yarn made of the long stapled cotton is 180 N / 3. The top-grade shirt fabric has the advantages that the Egyptian long stapled cotton is added to the mulberry silk, characteristics of cotton are integrated with real silk, the smooth and skin-care characteristics of a common real silk fabric are achieved, real silk raw materials are saved, and accordingly production cost is reduced, and the product can be popular with more consumers; meanwhile, due to the adoption of cotton yarn, the fabric is easy to clean, the defects that the real silk is not suitable for being washed in water and is prone to wrinkling are overcome, water shrinkage is reduced, and elastic resilience, wear resistance, breaking strength and moisture absorption are improved; when the fabric is worn next to the skin, and the fabric does good to the human body, enables the skin to be smooth and has good moisture absorption performance and breathability.

Owner:苏州新超针纺织有限公司

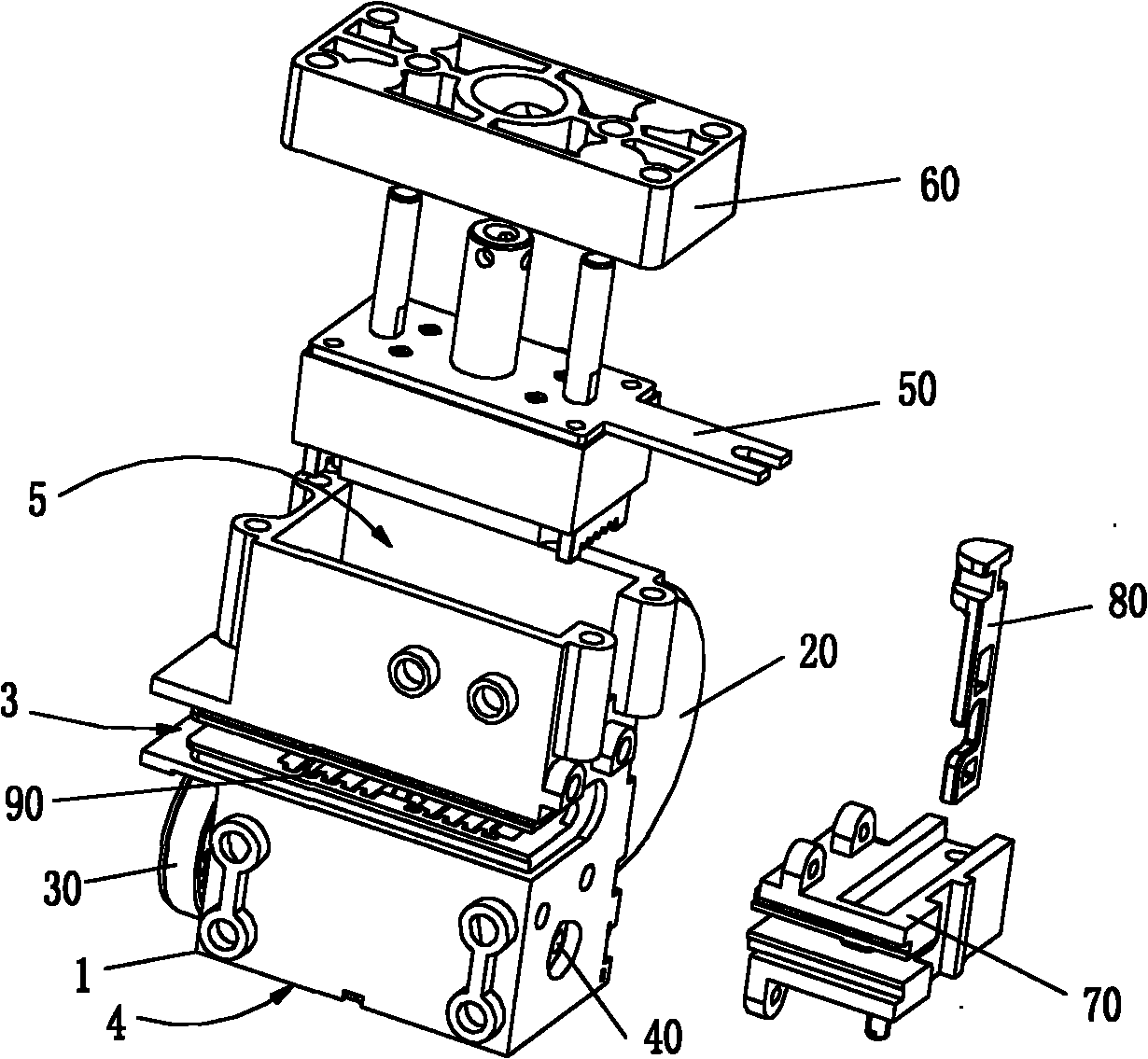

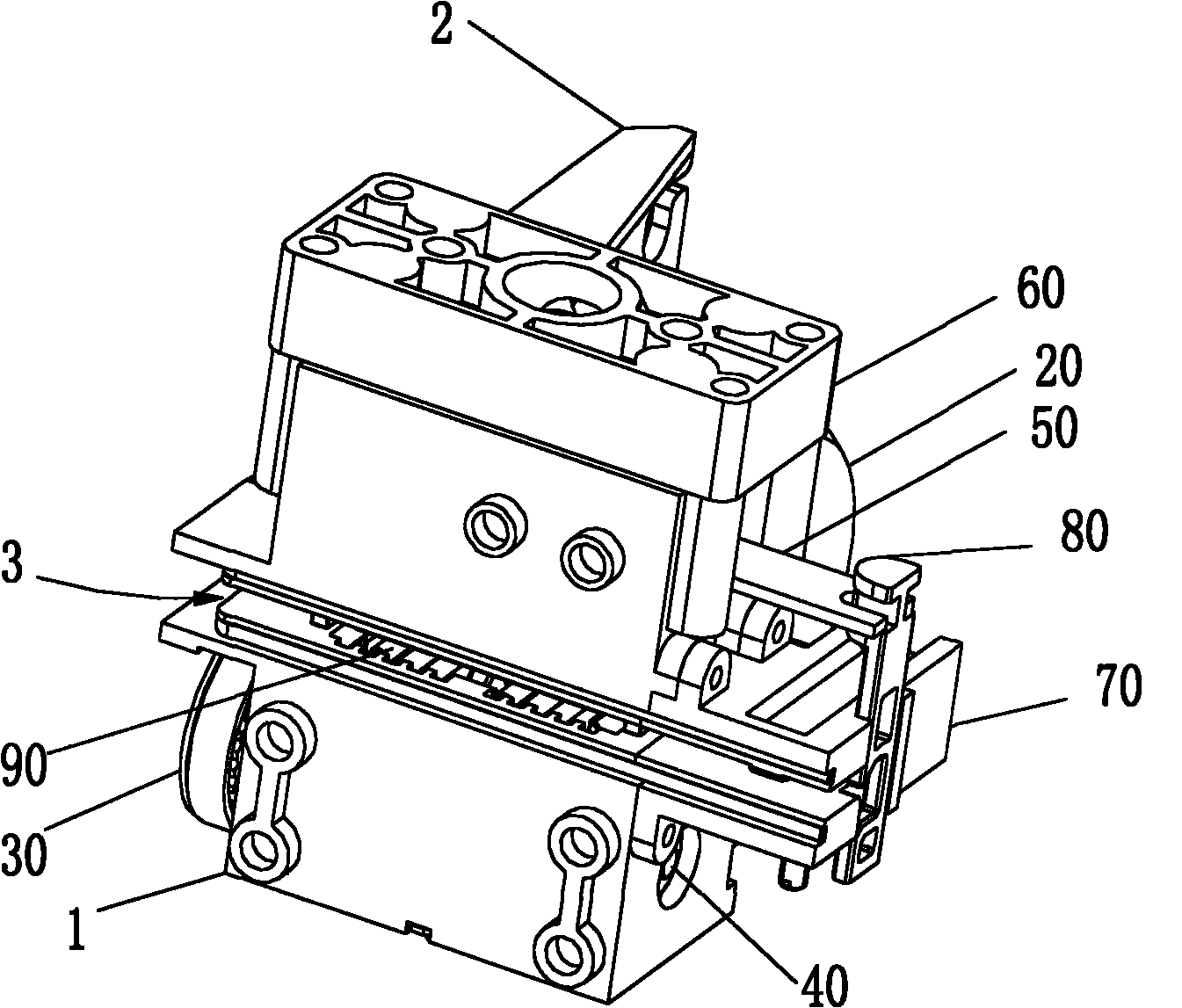

Infusion pump and pump body bracket thereof

ActiveCN101810896AReduce assemblyImprove alignment accuracyPressure infusionFailure ratePeristaltic pump

The invention discloses an infusion pump and a pump body bracket thereof. The infusion pump comprises the pump body bracket, and a motor and a peristaltic pump which are arranged on the pump body bracket, wherein the pump body bracket has an integral structure and comprises a motor mounting part, a peristaltic pump mounting part, and an infusion tube mounting groove through which an infusion tubepasses through; the peristaltic pump mounting part comprises a pump body mounting chamber and a pressure plate mounting chamber; the infusion tube mounting groove is positioned between the pump body mounting chamber and the pressure plate mounting chamber; and the pump body bracket adopts a synthetic plastic, consisting of PPE, PS and 30 percent of GF, as a base material, and is formed by an injection molding process. The pump body bracket of the infusion pump has the integral structure and is molded integrally by adopting a plastic to improve the alignment precision of each pump body component arranged on the pump body bracket and reduce the working failure rate of the infusion pump; besides, the plastic material has the characteristics of self-lubrication, rub resistance, small deformation and stable size, so the failure rate of the infusion pump is reduced, and the service life of the infusion pump is prolonged.

Owner:SHENZHEN MINDRAY SCIENTIFIC CO LTD

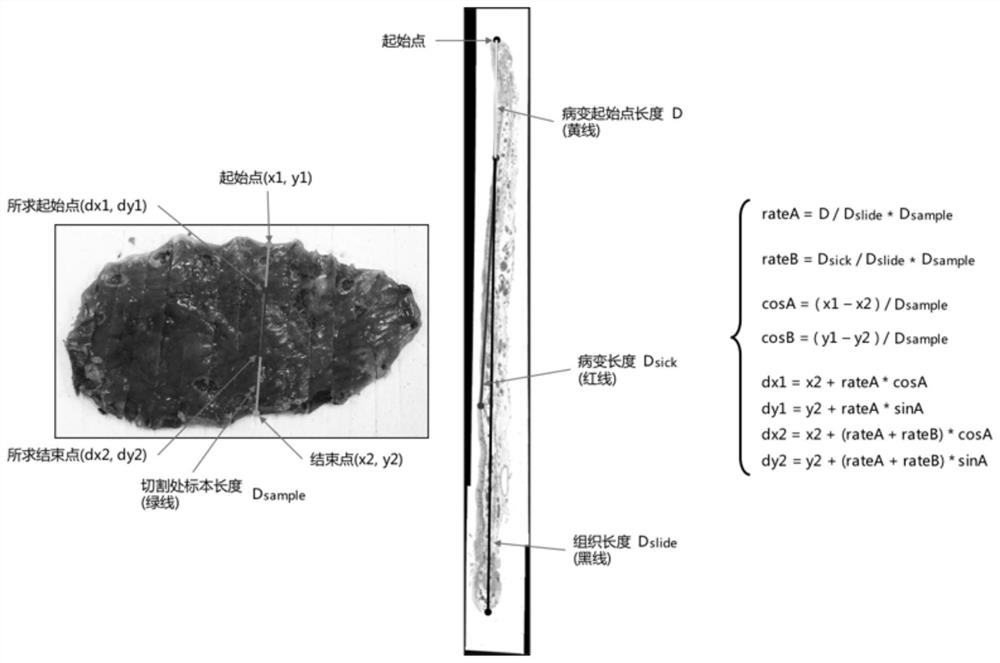

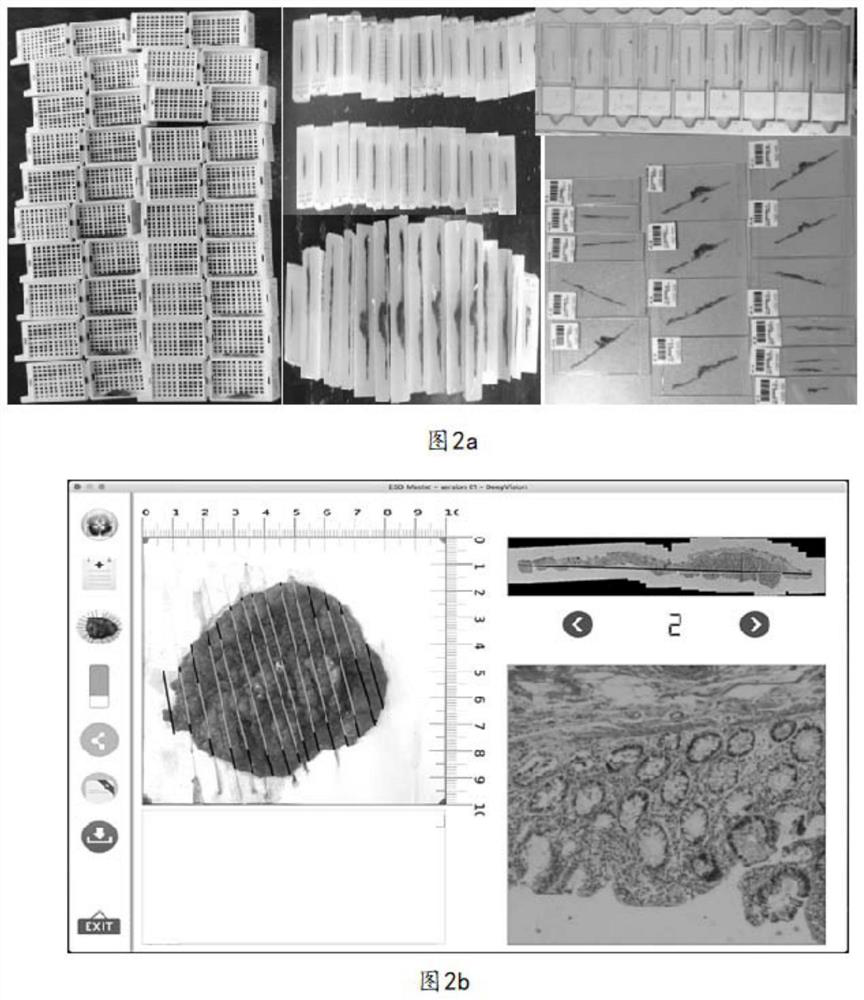

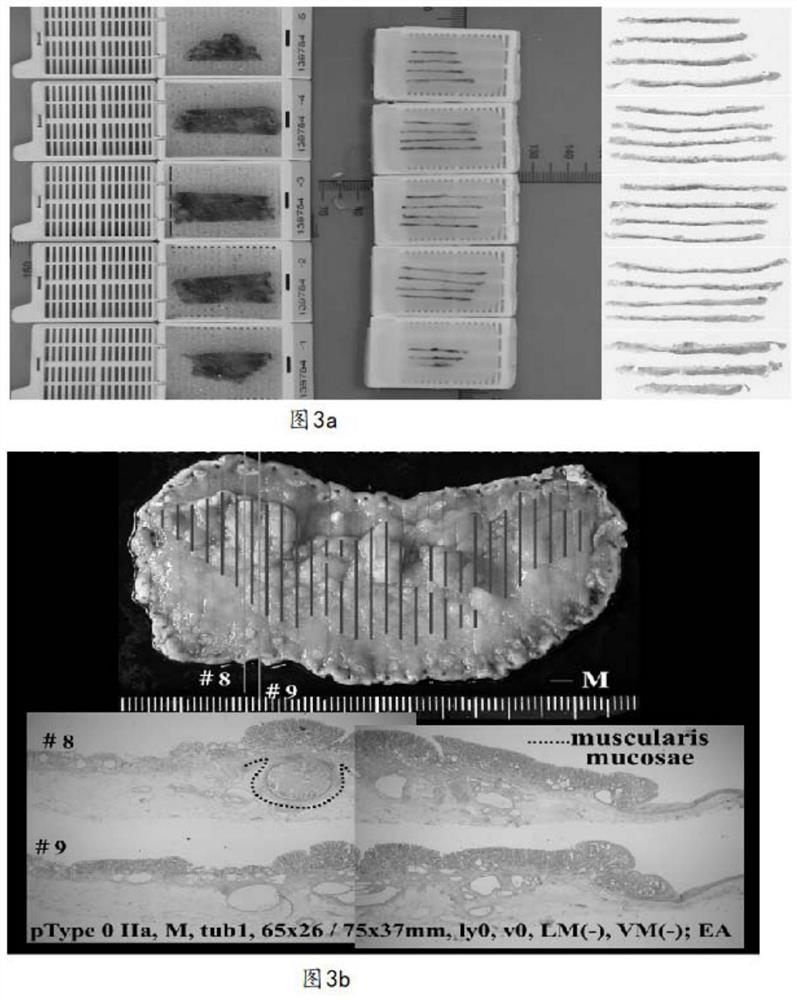

Application of pathological specimen manufactured by dehydration set in digital evaluation system

PendingCN111795879AImprove the level of diagnosis and treatmentReduce workloadPreparing sample for investigationMaterial analysis by optical meansTissue shrinkageTissue Embedding

The invention discloses application of a pathological specimen manufactured by a dehydration set in a digital evaluation system, belongs to the field of computer-assisted medical treatment, and can solve the problem that a traditional slicing technology cannot be used for digital evaluation of tumor diagnosis and treatment. A tissue slice is manufactured by utilizing the dehydration set and an optimized dehydration process, the specimen is good in flexibility, tissue embedding is facilitated, and the tissue slice is particularly suitable for thin, long and thin strip tissues with the length of3 cm or above and large tissues with the length of 5 cm or above; the tissue shrinkage rate is low, cell-level point-to-point measurement under a computer is facilitated, and the true appearance of an original specimen is restored; hundreds of slices can be continuously sliced in three-dimensional reconstruction, wax blocks do not need to be repeatedly frozen, and the real face of the specimen can be accurately restored. The pathological specimen can be widely applied to postoperative pathological evaluation of tumor specimens of single-incision tumor specimens, all organ tumors, omentum tissues with lymph nodes on the periphery and associated organ tissues.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV +1

Soft shell fabric

InactiveCN104856323AGood dimensional stabilityResponsiveLayered productsProtective garmentYarnAgricultural engineering

The invention relates to soft shell fabric. The soft shell fabric is characterized in that the soft shell fabric is composed of three layers of materials of a knitted fabric layer, a silk fabric layer and a flax yarn fabric layer. The knitted fabric layer is located on the innermost and is formed by weaving cotton and hemp in a mixed mode, the silk fabric layer is located in the middle and made of silk, and the flax yarn fabric layer is located on the outermost. According to the soft shell fabric, the size stability and the resilience of the fabric are improved greatly, cotton weft knitted fabric has smooth and soft hand heading, is small in shrinkage, smooth in cloth cover, washable, durable and free of deformation, the fabric has good appearance after washing, and the processed fabric has the characteristics of super-soft liquid cotton.

Owner:JIANGYIN SHANGFENG TEXTILE

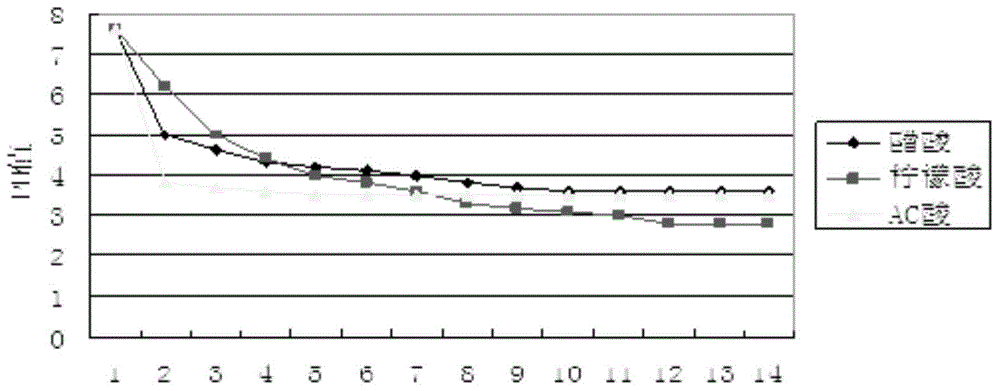

Shrinkproof treatment process for wool tops

InactiveCN104233824AEnvironmentally friendly ingredientsEfficient removalBiochemical fibre treatmentAnimal fibresDecompositionAdditive ingredient

The invention discloses a shrinkproof treatment process for wool tops. The shrinkproof treatment process comprises the following steps: producing an acid aqueous solution, wherein the acid aqueous solution is formed by mixing ammonium persulfate and pure water; soaking the wool tops which are made of wool into the acid aqueous solution, swelling scales on the surface of the wool tops, taking out the wool tops after 15 minutes, and swaying and flushing the wool tops in flowing clean water; producing a decomposition solution, wherein the decomposition solution is formed by mixing papain and pure water; soaking the washed wool tops in the decomposition solution so as to decompose the scales on the surface of the wool tops, and taking out the wool tops after one hour; adequately washing the wool tops after the surface decomposition, and drying the wool tops for later use. Through the way, the shrinkproof treatment process for the wool tops has a simple treatment process, the solution ingredients are environmentally friendly, the cost is low, the chaff scales on the surface of the wool can be effectively eliminated, and the shrinkage of a fabric made by the wool can be reduced.

Owner:JIANGSU JIANLU WOOLEN

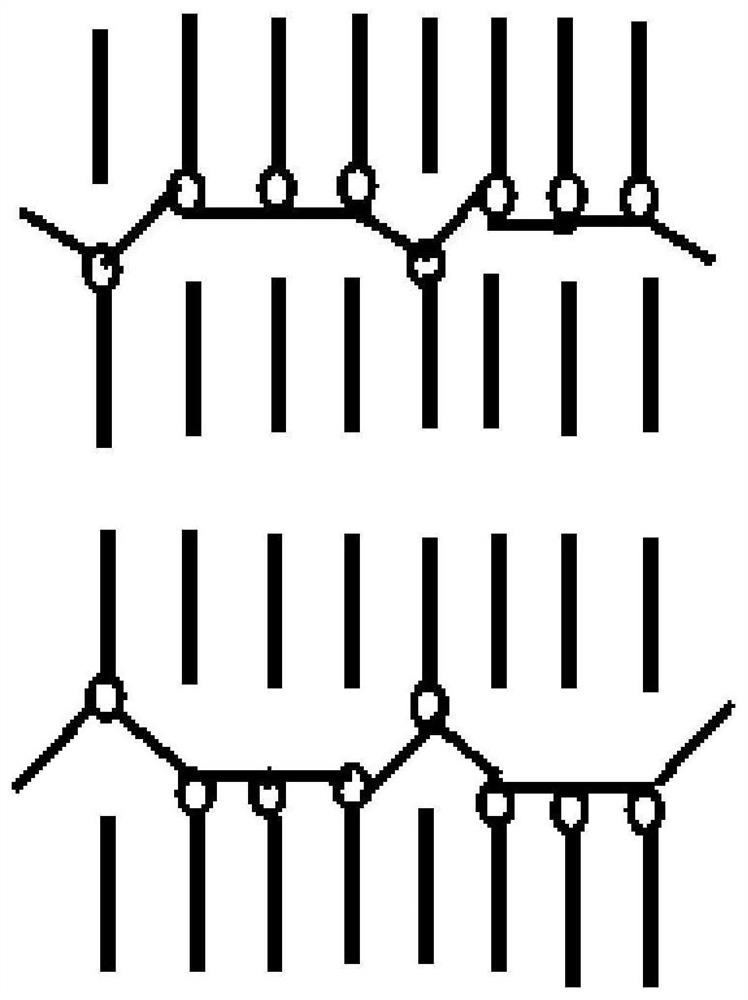

Three-core stretch yarn, preparation method of stretch yarn and high-elasticity and low-shrinkage stretch yarn fabric

The invention discloses three-core stretch yarn. The three-core stretch yarn comprises a yarn core and an external wrapping layer; the yarn core is wrapped by the external wrapping layer in a spiral mode; the yarn core is composed of polyurethane stretch yarn and polyester stretch yarn which are twisted; the polyurethane stretch yarn and the polyester stretch yarn are combined together under the respective draw ratios; the draw ratio of the polyurethane stretch yarn is at least two times that of the polyester stretch yarn, so that the extensibility of the polyurethane stretch yarn is limited by the polyester stretch yarn when the stretch yarn is in a tensioned state; the external wrapping layer is natural chopped fibers; and the external wrapping layer surrounds and obviously covers the whole length of the yarn core when the stretch yarn is in the tensioned state and a relaxed state. The elastic resilience can be improved, and the elasticity losing phenomenon due to water washing is reduced.

Owner:FOSHAN NANHAI DEYAO TEXTILE IND CO LTD

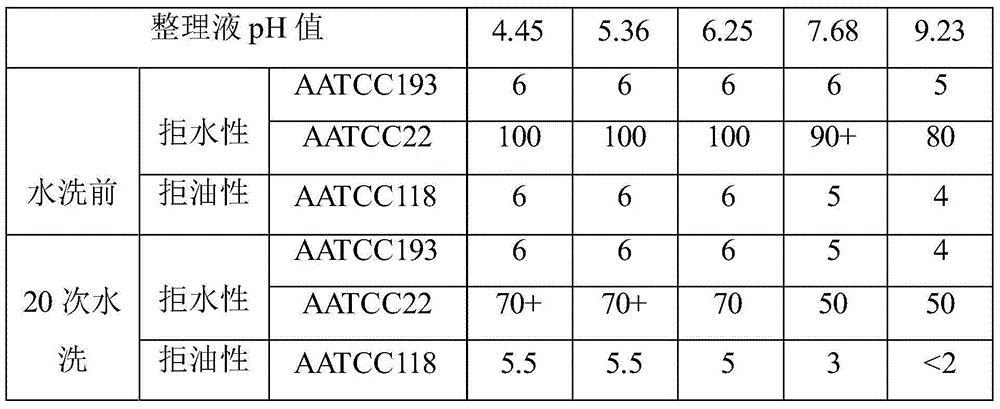

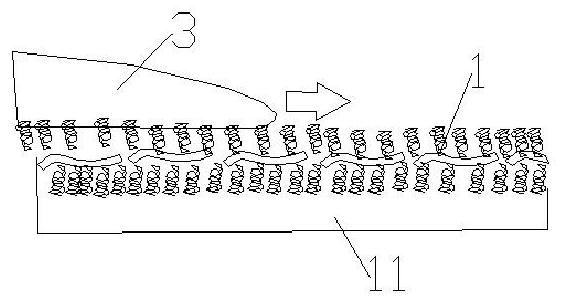

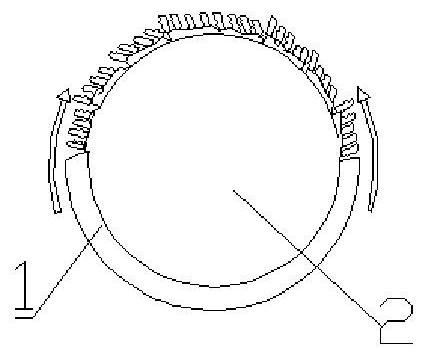

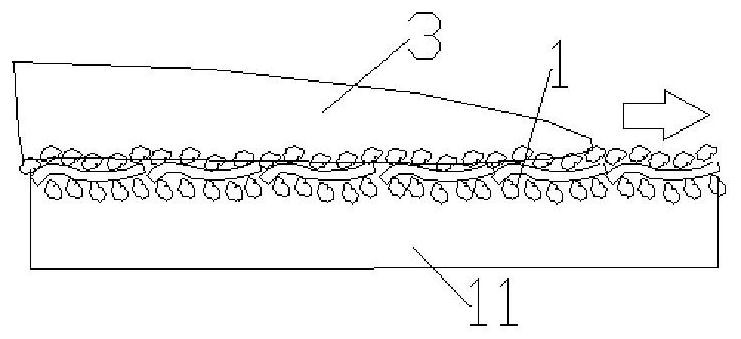

Processing method of cotton knitted fabric with bionic function and post-finishing device for processing

PendingCN112111886ASimplify processing stepsPracticalLiquid/gas/vapor treatment machines driving mechanismsGrip property fibresYarnProcess engineering

The invention discloses a processing method of a cotton knitted fabric with a bionic function. The processing method comprises the following steps of: 1) scouring and bleaching: scouring and bleachinga cotton yarn fabric in airflow dyeing equipment; 2) dyeing; 3) mercerizing, washing and drying; 4) preparing a finishing liquid, and combining the finishing liquid with the cotton yarn fabric treated in the step 3) to obtain a semi-finished product of the cotton knitted fabric with the bionic function, wherein the combination of the finishing liquid and the cotton yarn fabric treated in the step3) comprises the steps that uniform permeation of the fluid and the cotton yarn fabric is realized in a process of padding in the finishing liquid and stacking, and preliminary cross-linking of a temperature control adjuvant Adaptive AC-06 and the cotton yarn fabric is realized in a calendering process, and cross-linking of the adjuvant and the cotton yarn fabric is realized in a shaping process;and 5) pre-shrinking. The invention further discloses a post-finishing device for processing. The fabric has a dynamic intelligent temperature control effect, the fabric can be uniformly padded withthe finishing liquid in the cold-batching pretreatment process, the stacking process is completed under the dynamic condition, and consistent finishing effect is ensured.

Owner:BIEM L FDLKK GARMENT CO LTD

Preparation process of vertical polypropylene infusion bag capable of avoiding shrinkage and cracking

PendingCN112592532AFusion smoothlyHigh strengthPharmaceutical containersMedical packagingPolypropyleneInfusion solution

The invention relates to the technical field of medical supplies, and discloses a preparation process of a vertical polypropylene infusion bag capable of avoiding shrinkage and cracking, which comprises the following preparation steps of: (1) preparing a polypropylene raw material; (2) preparing a bag blank; and (3) preparing an infusion bag. According to the preparation process of the vertical polypropylene infusion bag capable of avoiding injection molding shrinkage and cracking, infusion bag preparation raw materials are compounded and prepared again, long carbon fibers and alkali-free glass fibers are added, the raw materials are fused more smoothly through a compatilizer and a coupling agent, the overall strength of the raw materials is enhanced, the toughness is improved, the shrinkage probability is reduced, the error-tolerant rate is high, and the yield is increased; and the raw materials are heated to 180-220 DEG C in an injection molding machine, so that the raw materials aremelted, moisture in the raw materials is evaporated, it is guaranteed that the raw materials cannot be uneven in thickness during forming in the mold through repeated short-time pressure maintaining,it is guaranteed that the raw materials cannot crack due to sudden temperature change by checking the temperature of the mold, and the rejection rate is reduced.

Owner:ANHUI DOUBLE CRANE PHARMA

Preparation method of anti-wrinkle glossy cotton and linen fabric

InactiveCN113337933AHigh glossImprove silky feelingBiochemical fibre treatmentWoven fabricsPolymer sciencePlant Gums

The prepared fabric is made of natural fibers, is nontoxic and harmless to the human body and has certain benefits to the skin. Milk protein fibers are added and blended with cotton and linen fibers, so that the softness and the skin-friendly performance of the fabric are improved, and the glossiness and the silky feeling of the fabric are improved. The fibers are modified, so that the fabric made of the modified fibers is smooth and not prone to wrinkling; and negative ion powder is added, so that the fabric has the sterilization and health care effects. Doubling threads are soaked in a solution containing a fixing agent, so that the doubling threads are not prone to wrinkling and shrinking; and the fixing agent adopts propolis, gum, glycerin and the like as adhesive substances and is harmless to the human body. The fabric made of the cotton and linen fibers is prone to wool sticking, and the milk fibers are poor in heat resistance and acid and alkali resistance; in order to prevent pilling of the fabric, a protective layer coats the fabric to protect the fabric; and insect wax in a protective agent serves as a coating film, and vegetable gum forms the protective layer, so that the fabric is comfortable, skin-friendly and free of itching feeling.

Owner:美雅(龙南)服饰有限公司

Soft type waterproof fabric

The invention relates to soft type waterproof fabric. The soft type waterproof fabric is characterized by being composed of three layers of materials, namely, a knitted fabric layer, a silk fabric layer and a hair cord fabric layer, the knitted fabric layer is located in the innermost side and formed by mixing and knitting cotton and hemp, the silk fabric layer is located in the middle layer and made of real silk materials, and the hair cord fabric layer is located on the outermost side. By means of the soft type waterproof fabric, the size stability and reversibility of fabric are greatly improved, the cotton knitted fabric has the smooth, soft and slippery hand feeling, is small in shrinkage, flat in cloth cover, washable, durable in use and not prone to deformation and has the excellent after-washing appearance; the machined fabric has the ultra-soft characteristic of liquid cotton.

Owner:JIANGYIN YUEDA DYEING & PRINTING

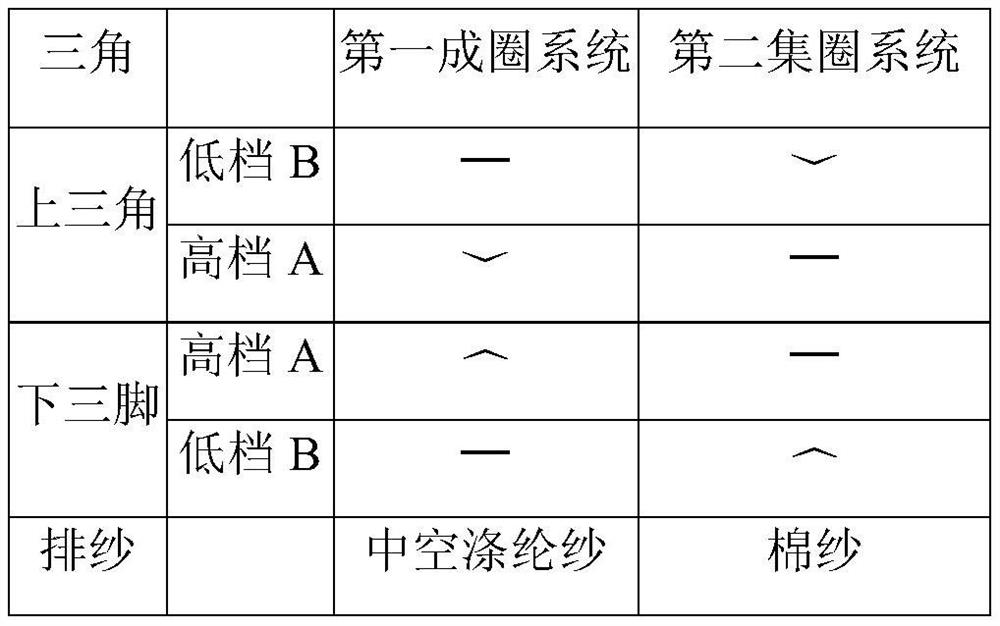

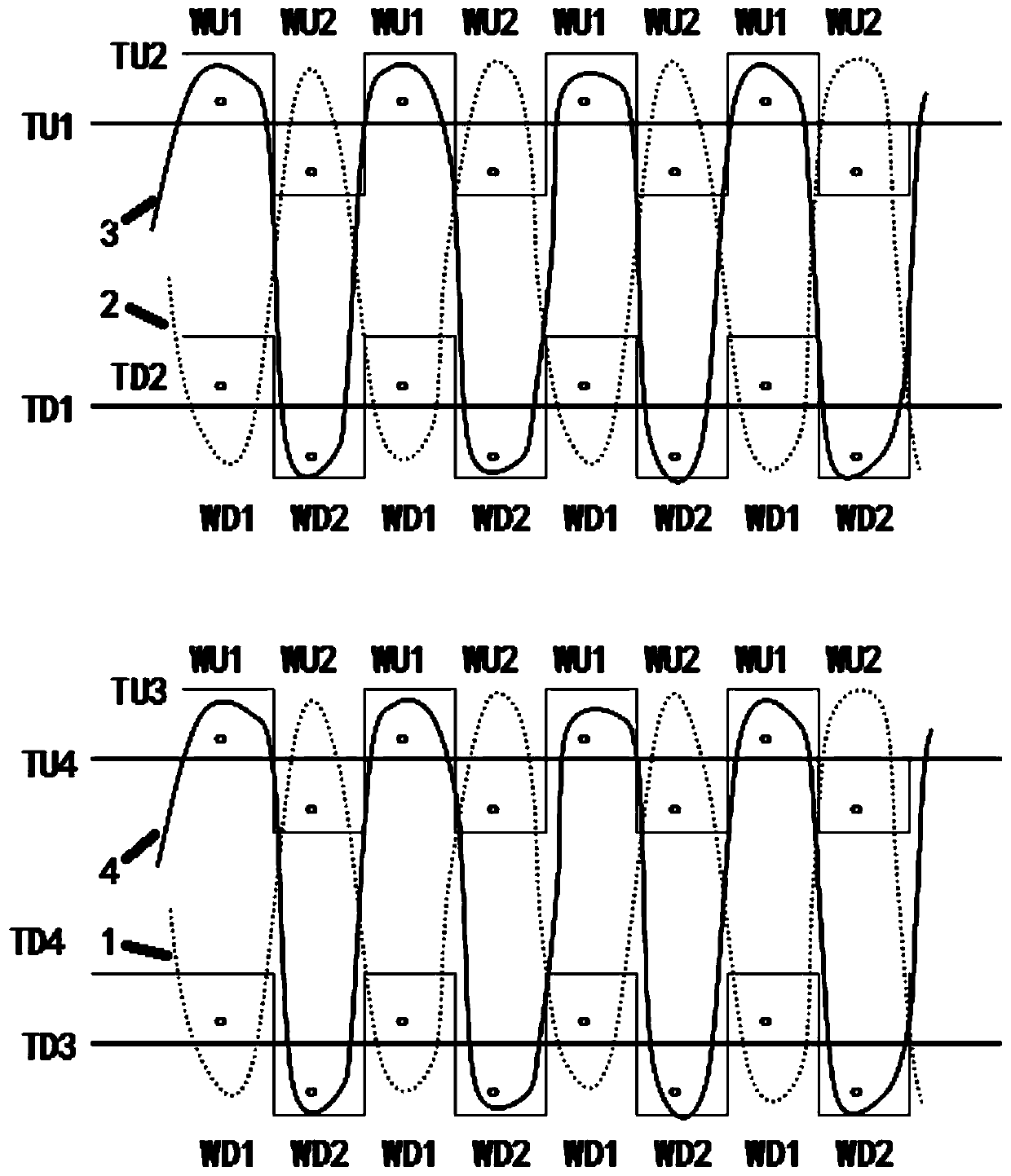

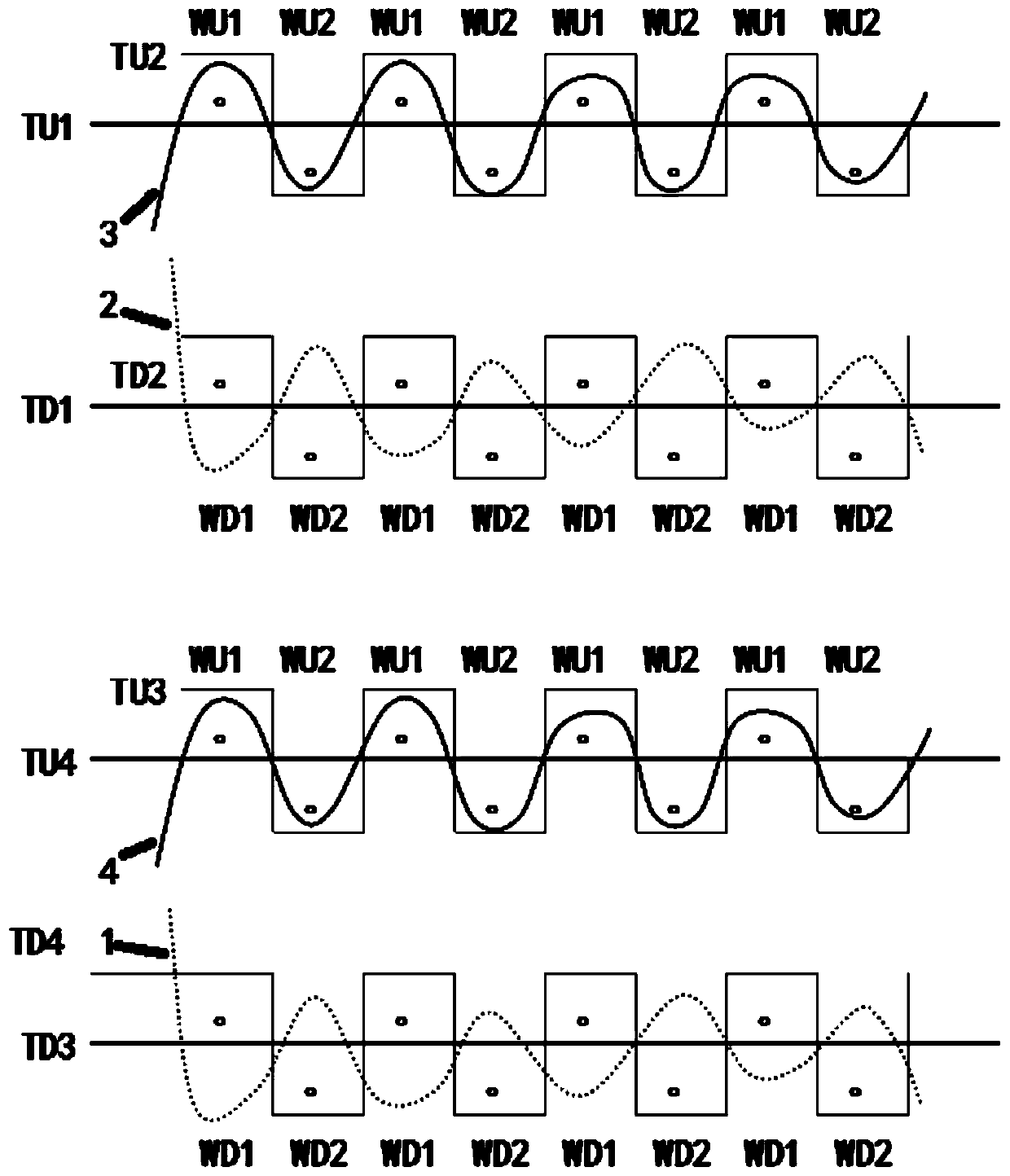

Hollow three-dimensional warm-keeping fabric and preparation method thereof

The invention relates to the technical field of knitted fabrics, in particular to a hollow three-dimensional warm-keeping fabric and a preparation method thereof. According to the preparation method, cotton yarns and hollow polyester yarns are selected as yarn raw materials, a unique weaving structure design is combined to weave a double-faced cloth fabric, the fabric is prepared through a dyeing and finishing process and after-finishing processing, and the fabric has good fluffy stereoscopic impression, soft hand feeling and a heat preservation effect. Wherein the wettability and hygroscopicity of the fabric are improved through a combined process of oil removal, high-temperature scouring and bleaching, dyeing processing and softening processing, so that the fabric is soft, comfortable, breathable and warm; a non-ironing resin treatment process is adopted in the after-finishing and shaping process, so that the size stability of the fabric can be greatly improved, the shrinkage of the fabric is reduced, and the quality of the fabric is improved. Meanwhile, the preparation method is easy to implement industrially, low in cost and high in production efficiency, and the prepared fabric is high in quality and stable in quality.

Owner:DONGGUAN TEXWINCA HLDG

Pure-cotton jacquard woven home textile fabric woven based on double-rapier cut-pile loom and preparation method thereof

ActiveCN109706590AStrong three-dimensional senseSoft lusterSucessive textile treatmentsPile-fabric loomsComfort levelsWeft yarn

The invention provides a pure-cotton jacquard woven home textile fabric woven based on a double-rapier cut-pile loom and a preparation method thereof. According to the pure-cotton jacquard woven hometextile fabric, pure-cotton yarns are taken as the raw material, a piece of upper layer base cloth is composed of upper layer warps and upper layer wefts, a piece of lower layer base cloth is composedof lower layer warps and lower layer wefts, the upper layer base cloth and the lower layer base cloth are connected and woven by pile warps, piles of a double-layer textile are cut at the cutter point portion of the loom to form a pure-cotton home textile blank fabric with upper and lower layers with equal pile height. According to the method, on the same base cloth, floral patterns are formed bythe combination of a piling area and a non-piling area through a specific manner, the fabric has an extremely high sense of three dimension and flexible glossiness, yarns are fine when the fabric iswoven, the needle and thread density is high, the fabric is not deformed when used, the comfort level is high, the fabric is solid and durable, and the fabric is suitable for being used as a sofa fabric.

Owner:沂水恒泰纺园有限公司

Production process of sea island cotton plain weave fabric

ActiveCN113699639AImprove gloss durabilityImprove stabilitySingeingHeating/cooling textile fabricsPulp and paper industryIndustrial engineering

The invention discloses a production process of a sea island cotton plain fabric. The production process comprises the following steps: S1, weaving; S2, greige fabric setting ; S3, singeing; S4, boiling off; S5, hair burning; S6, dyeing; S7, cleaning; S8, cloth drying; S9, finished product shaping; and S10, preshrinking. Through proper process steps and process conditions, the glossiness durability of the fabric is effectively improved, the stability of the fabric is effectively improved, shrinkage is reduced, and the brethability of the fabric is effectively improved.

Owner:渡帮针织科技(中山)贸易有限公司

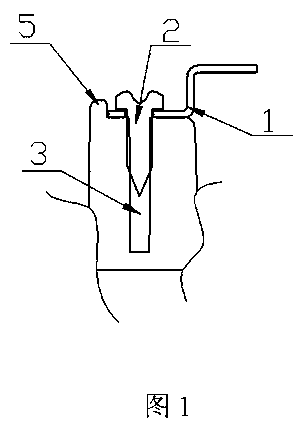

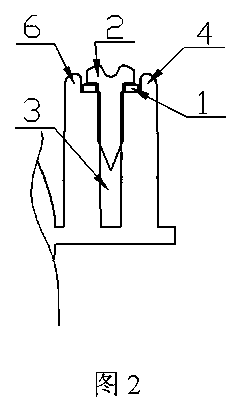

Lamp body mounting pillar structure

InactiveCN103363473AIncrease core pullingGuaranteed wall thicknessGas-tight/water-tight arrangementsRoad vehiclesEngineering

The invention discloses a lamp body mounting pillar structure, comprising a tapping screw (1), a sealing cushion (2), a lamp body (3), a shrink resistant decoration ring and a mounting pillar (4), wherein the shrink resistant decoration ring consists of a slider loose core (5) and a decoration frame (6); the center of the mounting pillar (6) is solid and is arranged in the lamp body (3) through the tapping screw (1) and the sealing cushion (2); and the lamp body (3) and the decoration frame (6) are connected through the mounting pillar (4). The lamp body mounting pillar structure is characterized in that an overflow bag capable of preventing fracture is arranged on the lamp body (3); the weld marks of the lamp body are collected to the edge; and the mounting pillar is prevented from be broken. The shrink resistant decoration ring is locked with the lamp body through the tapping screw, and the sealing cushion takes the sealing and water-proof effects.

Owner:王建国

A kind of dark non-ironing and washable pure cotton knitted fabric and its production method and application

ActiveCN110029501BImprove washabilityGood non-ironing effectSucessive textile treatmentsLiquid/gas/vapor removalYarnPolymer science

The invention provides a dark color non-ironing and washable pure cotton knitted fabric and its production method and application. The method comprises making the yarn successively undergo weaving, scouring, enzyme washing, dyeing, liquid ammonia finishing, and resin setting to obtain knitted fabrics. Fabrics; liquid ammonia finishing is to make knitted fabrics dyed and dried in open width sequentially through the drying unit, brushing unit, ammonia soaking unit, drying cylinder ammonia removal unit, and steaming unit, and then drop the cloth; the liquid ammonia finishing process wears The cloth route is that the knitted fabric enters the cloth drying unit through the cloth guide roller, and then passes through the edge roller, and the cloth guide roller enters the felt cylinder of the drying cylinder of the cloth drying unit; after exiting the cylinder, it enters the brush unit through the cloth guide roller; The rollers and cloth guide rollers enter the cloth guide rollers of the liquid ammonia dipping tank of the ammonia soaking unit, and then pass through the first padding roller and the second padding roller; the knitted fabric enters the drying cylinder sequentially through the corresponding edge rollers and cloth guide rollers In several drying cylinders set continuously in the ammonia removal unit; the knitted fabric enters the blanket cylinder of the steam box of the steaming unit through the edge roller and cloth guide roller, and then falls off.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com