Patents

Literature

36results about How to "Glossy and elegant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for fabricating soft knitting face fabric from cotton

InactiveCN101003936ADimensionally stableDoes not reduce strengthFabric breaking/softeningBiochemical fibre treatmentAgricultural engineeringSizing

The present invention discloses a processing method of flexible cotton knitted face fabric. Said processing method includes the following several steps: weaving, enzymatic washing, kiering and bleaching, dyeing, oversoftening, dewatering, opening, drying, sizing and pre-shrinking.

Owner:浙江盛泰服装集团股份有限公司

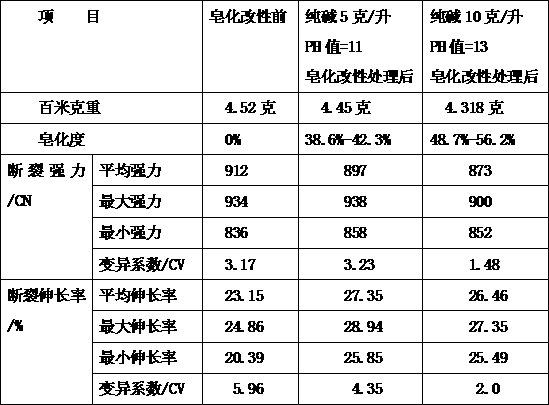

High-elastic warming gigging knitted fabric and manufacturing method thereof

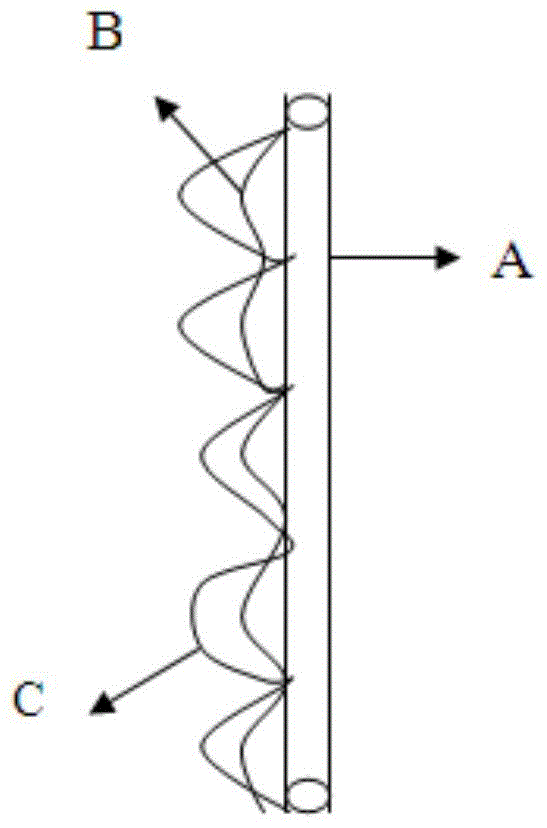

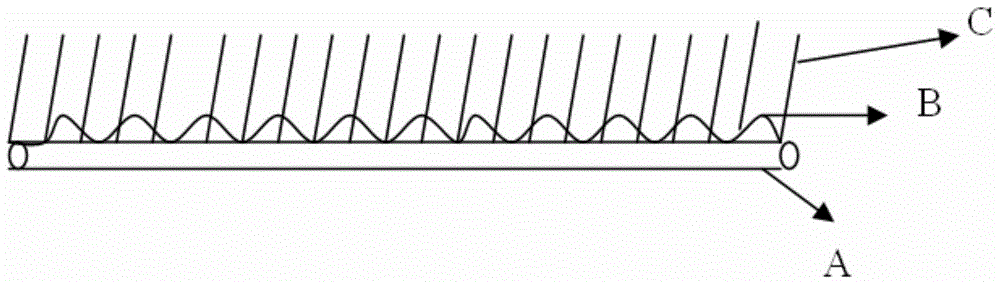

The invention provides high-elastic warming gigging knitted fabric and a manufacturing method thereof. The high-elastic warming gigging knitted fabric comprises three layers, the first layer is a flat weft plain stitch layer, the intermediate reinforcing layer is wavy, and the gigging layer is shaped in fluffy polar fleece. The fabric is knitted by chinlon filaments, naked spandex filaments and polyester filaments. Elasticity of the fabric is improved and production cost is reduced by an independent naked spandex filament feeding method. Loops of a gigging surface of the fabric are lengthened, the fabric has excellent extensibility and fluffy sense of the fabric is improved. The chinlon filaments are used for the surface layer of the fabric, and pilling resistance is better. Furthermore, a weft-knitting loop knitting machine is adopted in the manufacturing method, gram weight of the fabric can be controlled better, and the manufactured fabric is more uniform.

Owner:NINGBO DAQIAN TEXTILE

Environmental protection lining tenel cloth production process

InactiveCN101182664AGood drapabilityColor depthTextile treatment machine partsFibre cleaning/openingYarnCarding

The invention discloses a production method of the environment-protecting fabric tencel cloth. The tencel cloth is made in the way that the tencel fiber is spun to get the yarns and the yarns are then woven to produce the tencel cloth. The production method comprises the working procedures of the raw material damping in a grading chamber, cotching, carding, drawing, roving, spinning, winding, scudding, sizing, reeding, weaving, perching, packing, warehousing, and so on. The environment-protecting fabric tencel cloth produced with the invention is provided with the top-grade quality, the soft and smooth texture, the distinctive cloth surface lines, and the wool-imitating feeling, and is completely suitable for the subsequent processing of top-grade products.

Owner:丁宏利

Water-based environment-friendly colorful texture coating and preparation method thereof

ActiveCN104109443AEnvironmentally friendlyHydrophobicMulticolor effect coatingsWater basedSoftened water

The invention discloses a water-based environment-friendly colorful texture coating and a preparation method thereof to solve the problems that a product is poisonous and inflammable and pollutes the environment as the existing colorful coating contains organic solvent. The water-based environment-friendly colorful texture coating comprises the following components in parts by mass: 30-50 parts of emulsion, 20-40 parts of color particles, 0.5-1.5 parts of thickener, 0.4-0.8 part of dispersant, 0.2-0.4 part of wetting agent, 0.5-2 parts of propylene glycol, 0.2-0.5 part of defoaming agent, 1-3 parts of titanium dioxide, 3-5 parts of talcum powder, 1-5 parts of calcium carbonate, 0.1-0.3 part of neutralizer and 10-40 parts of softened water. Modified starch and pigment are used as raw materials to prepare color particles, the color particles and composite starch emulsion are used as raw materials to prepare the environment-friendly colorful particle coating, and the water-based environment-friendly colorful texture coating is environment-friendly, free of color bleeding, good in compatibility, good in repeatability and the like.

Owner:GANSU GLDARK NEW MATERIAL

Silk cotton knitted fabric and production method thereof

ActiveCN102127863AHigh glossGlossy and elegantShrinkingBiochemical fibre treatmentCotton effectLiquid state

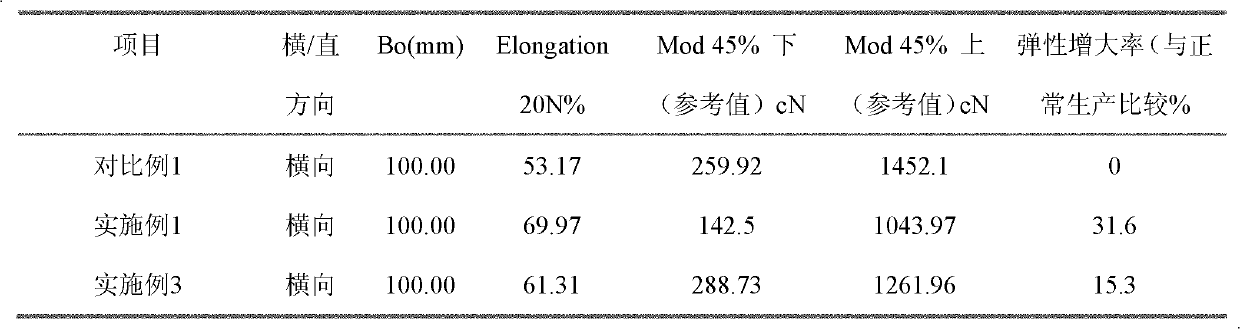

The invention discloses a silk cotton knitted fabric and a production method thereof. The silk cotton knitted fabric is formed by performing special bright treatment and a soft finish process on cotton and elastic cotton knitted fabrics and allowing the fabrics to pass through a squeezing machine (a cloth face is flatly pressed to improve mirror reflection so as to improve glossiness), so that the silk cotton knitted fabric obtained by treatment of the process is silkily soft and smooth, does not have hair on the cloth face and has elegant glossiness and a liquid-state cotton effect with excellent drape; the resilience of cloth is greatly enhanced; and the content of formaldehyde in the cloth is less than 20mu g / g JISL (04), and the color fastness reaches American association of textile chemists and colorists (AATCC) level-4 numerical value. Compared with the conventional mode, the production method has the advantages of short flow, no need of special production equipment and low cost and is easy and convenient to operate.

Owner:PACIFIC (PANYU) TEXTILES LTD

Method for producing copper ammonia and PHBV blended fabric

The invention discloses a method for producing copper ammonia and PHBV blended fabric, and relates to a method for producing textile fabric. The method includes the following steps: (1) selecting blended filaments with different PHBV proportions and copper ammonia yarns, (2) carrying out warping processing on the blended filaments and the copper ammonia yarns, (3) carrying out sizing processing on the blended filaments and the copper ammonia yarns, (4) carrying out warp re-beaming processing on the blended filaments and the copper ammonia yarns, and (5) carrying out silk drawing and reed inserting processing on the blended filaments and the copper ammonia yarns, and carrying out spinning to obtain the fabric. Compared with the prior art, the fabric produced with the method is low in cost and high in degradable degree, and can be generally and completely degraded within five years to ten years after being abandoned; meanwhile, the fabric is flexible in touch and elegant in gloss, the quality of the fabric is similar to that of real silk, the strength and the size stability of the fabric are much better than the strength and the size stability of the real silk, and the fabric is a woven product quite suitable for the fast fashion concept.

Owner:NINGBO XINDACHANG WEAVING

Processing method for wool knitted fabric

InactiveCN104762819ACompact structureStrong bodyDyeing processLiquid/gas/vapor textile treatmentEngineeringSizing

The invention discloses a processing method for wool knitted fabric. The processing method for the wool knitted fabric comprises the steps of knitting weaving; water washing; dyeing; mellowing treating; dewatering, scotching and drying; sizing; calendaring; preshrinking. The processing method for the wool knitted fabric overcomes the defect that the wool knitted fabric produced by traditional processing technology is loose and untight in organization structure, the processed wool knitted fabric is stiff and smooth in body, tight in structure, high in resilience, smooth in cloth cover, simple and elegant in gloss and smooth and full in hand feeling.

Owner:NANTONG BIMAN HOME TEXTILE

Silk blended fabric

The invention discloses a silk blended fabric. The fabric is prepared by blending the raw materials including mulberry silk, polyester fibers and polyvinyl alcohol fibers to prepare warps and wefts and then interweaving the warps and the wefts, wherein the warps are prepared by blending the mulberry silk and the polyester fibers; the wefts are prepared by bending the mulberry silk and the polyvinyl alcohol fibers; the diameters of the warps are 25 microns; the diameters of the wefts are 20 microns; the density of the warps is 50 / cm; and the density of the wefts is 62.5 / cm. The silk blended fabric not only maintains the luster, handfeel and air permeability of the mulberry silk, but also adds the characteristics of stiffness, smoothness, wrinkle resistance and machine washability, imitates all-silk fabrics and has high appearance cost performance.

Owner:太仓市珠江线带厂

Method for preparation of colorful rotor-spinning viscose stocking yarns

InactiveCN104695077AEvenlyFeel lubricatedContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The invention relates to the technical field of yarn preparation, in particular to a method for preparation of colorful rotor-spinning viscose stocking yarns. The method includes the steps: 1) selection and matching of raw materials; 2) pretreatment of dyed viscose fibers; 3) bale arrangement; 4) blowing and carding; 5) drawing; 6) rotor spinning; 7) final inspection and baling. Due to adoption of the technical scheme, the prepared colorful rotor-spinning viscose stocking yarns are novel yarns made by blending of various colorful viscose fibers, and later-stage spinnability of the dyed fibers is greatly improved due to oil feeding treatment of the dyed fibers in preparation. Fabrics made of the yarns integrate advantages of all of the raw materials and are skin friendly, soft, elegant and glossy, the yarns made by an international most advanced rotor spinning machine have the advantages of uniformity in unevenness, flawlessness, knot avoidance, smoothness in handfeel, high abrasion resistance and the like and are most ideal raw materials for high-grade knitted underwear, and successful development of the colorful rotor-spinning viscose stocking yarns opens a new field of rotor-spinning yarns.

Owner:ZHEJIANG HUZHOU WEIDA TEXTILE GRP

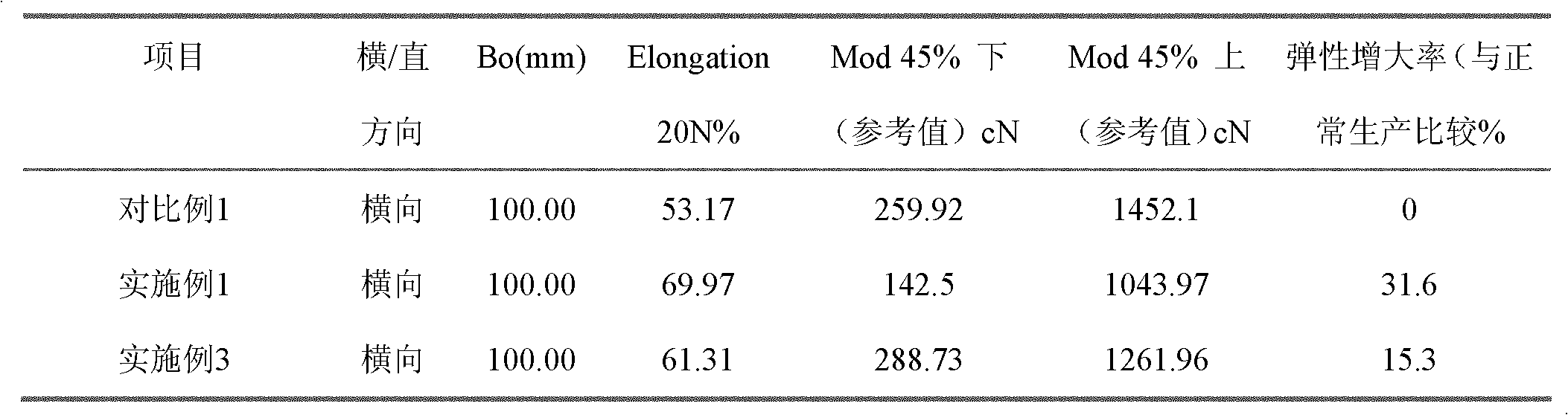

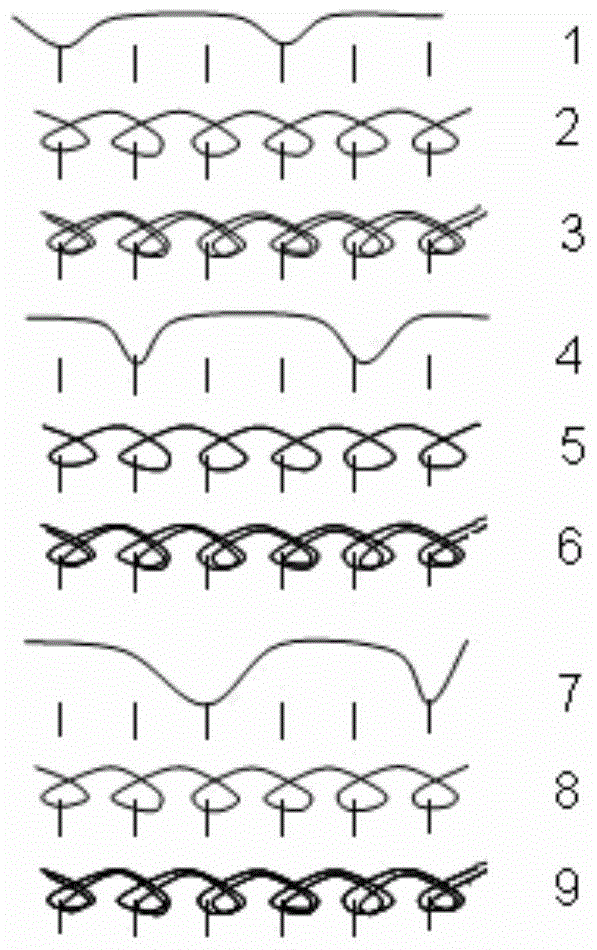

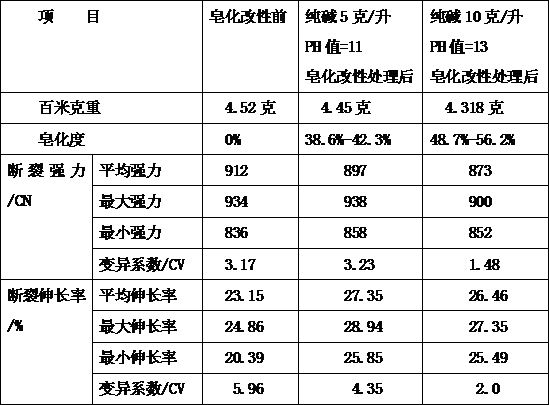

Saponification dyeing method of polyamide acetate fiber composite yarns

The invention provides a saponification dyeing method of polyamide acetate fiber composite yarns. The method includes the steps: (1) carrying out saponification modification treatment of the polyamideacetate fiber composite yarns which needs dyeing; (2) dyeing the polyamide acetate fiber composite yarns after saponification modification treatment with a reactive dye; (3) dyeing with a dispersed acidic dye; and (4) washing with water after dyeing. Firstly, an acetic acid fiber component contained in the polyamide acetate fiber filament composite yarns is subjected to partial saponification modification, after the modification of the acetic acid fiber, the reactive dye is adopted, dyeing is performed by a dispersed and acidic dye two-bath dyeing process, and the polyamide acetate fiber filament composite yarns are dyed by the creative dyeing method and have the advantages of bright color and luster, elegant luster, bright dyeing, strong dyeing fastness, and soft and smooth hand feeling.The soaping fastness of a dark color system can reach 4 level or more.

Owner:恒天宝丽丝生物基纤维股份有限公司

Acrylon-real silk interwoven jacquard fabric for undervest production

The invention discloses an acrylon-real silk interwoven jacquard fabric for undervest production. The grey cloth of the jacquard fabric is formed in a way that real silk yarns, as warp yarns, spun by real silk filaments and acrylon blend yarns, as weft yarns, formed by blending acrylon fibers and wool are interweaved according to the jacquard structure. Therefore, the jacquard fabric provided by the application adopts the warp-wise real silks and weft-wise acrylon blend yarns, and makes full of the advantages of the two fiber materials. Moreover, the jacquard fabric avoids the defects that a full-real silk fabric is poor in wrinkle resistance, easy to loop, difficult to trim and bad in acrylon fiber activating feeling, embodies the advantages of flexible hand feeling, soft and graceful luster, and easiness in trimming; meanwhile, the rebound resilience of the product is good and therefore the fabric is suitable for undervest production.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

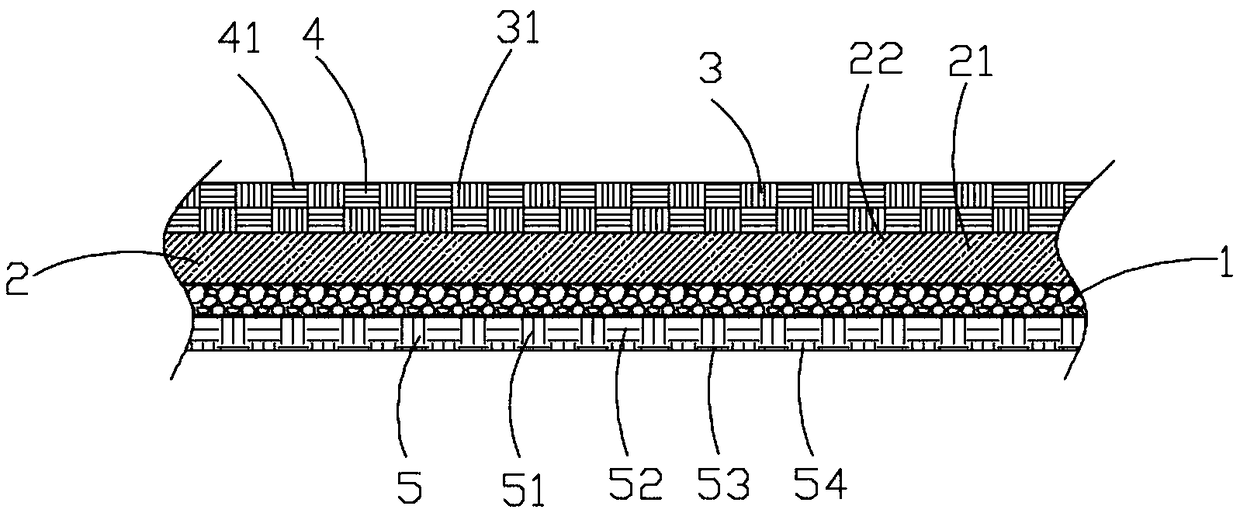

Double-side compound texture fabric

The invention discloses double-side compound texture fabric. The double-side compound texture fabric comprises a middle fabric layer and is characterized in that an antibacterial fabric layer is arranged on one side of the middle fabric layer, a fabric outer layer is arranged on one side of the antibacterial fabric layer, the fabric outer layer is knitted by first fabric slivers and second fabricsilvers, a fabric lining layer is arranged on one side of the antibacterial fabric layer, the fabric lining layer is knitted by first silk slivers and second silk slivers, a third silk sliver penetrates each horizontal second silk sliver, and the part between every two adjacent third silk slivers is connected with the first silk slivers and the second silk slivers through knitting threads. A production method of the antibacterial fabric layer includes the steps of S1, knitting a plurality of Tencel fiber yarn on a weft knitting machine, and four kinds of yarn are fed in each yarn path. The fabric is soft and stiff, and the wrinkle resistance of flax is well improved.

Owner:深圳市影儿服饰有限公司

Weft knitting shapewear fabric

The invention discloses a weft knitting shapewear fabric. The weft knitting shapewear fabric comprises wefts and warps, wherein the wefts are spandex yarn, and the warps are nylon yarn. The surface of the weft knitting shapewear fabric has gloss and looks elegant, and the weft knitting shapewear fabric is soft and fine in hand feel, free of turned edges and high in elasticity, and is a good choice of shapewear fabric.

Owner:常熟市华尔达制衣有限公司

Method for preparing all-cotton high-count strong twisted knitted double-faced fabrics

InactiveCN109487472AFeel plumpGlossy and elegantSucessive textile treatmentsMercerising of indefinite length fabricsYarnPolymer science

The invention relates to a method for preparing all-cotton high-count strong twisted knitted double-faced fabrics. 100 s / 2 strong twisted knitting yarns are used as raw materials for the all-cotton high-count strong twisted knitted double-faced fabrics, and double-faced large circular knitting machines are used as weaving machines. The method includes weaving cloth and then boiling off and bleaching the cloth; then mercerizing, dyeing and setting the cloth to obtain the all-cotton high-count strong twisted knitted double-faced fabrics. The method has the advantages that the luster and dimensional stability of textile fabrics can be improved by the aid of mercerization technologies, the cloth is dyed by high-fastness reactive dye, accordingly, high-class knitted fabrics with elegant appearance and the good dimensional stability can be produced by the aid of the method, and the method can be widely applied to knitted fashionable garments.

Owner:NINGBO BETTER TEXTILE&GARMENTS

High-grade silk comfortable blended fiber

The invention discloses a high-grade silk comfortable blended fiber. The fiber is formed by weaving a first fiber body and a second fiber body which are mutually blended and woven, wherein the first fiber body is formed by blending and weaving copper ammonia fibers, mulberry silk fibers, chitin fibers and milk protein fibers, and the second fiber body is formed by blending and weaving tussah silk fibers and seashell silk fibers. The blended fiber has the advantages of being soft and smooth in texture, elegant, glossy, high in strength, good in heat retention property, good in moisture absorption and air permeability and comfortable to wear.

Owner:TAICANG HONGYING PRINTING

Soft fabric

InactiveCN106666891AFeel smoothElegant lusterProtective garmentSpecial outerwear garmentsYarnEngineering

The invention provides soft fabric comprising following components: cotton yarn, dimity, wool yarn, polyacrylonitrile fiber, nylon yarn, soybean fiber, sea-island fiber, flannel, real silk and silk. The fabric has soft and smooth hand feeling and elegant gloss, excellent rebound resilience and dimension stability, and good appearance after washing; the processed fabric has the super-soft feature of liquid state cotton. The raw material of the fabric is simple and easy to obtain; the operation process is simple and convenient; the cost is low the fabric has certain market development prospect.

Owner:RUGAO XIAYUAN SCI & TECH ESTABLISH A BUSINESS SERVICES CO LTD

High-end stiff and smooth fabric

The invention relates to high-end stiff and smooth fabric. The high-end stiff and smooth fabric is characterized in that warps are mixed by 20-30% of all-cotton filaments and 70-80% of polyester fibers, and the diameter of the warps is 50-90 micrometers; wefts are mixed by 30-40% of polyamide fibers and 60-70% of wool, and the diameter of the wefts is 80-120 micrometers; during spinning, warp density is 10-25 / cm, and weft density is 10-20 / cm. The high-end stiff and smooth fabric has the advantage that cheap artificial fibers are mixed with expensive natural fibers to obtain the high-end fabric which is stiff and smooth, stylish, good in drapability, soft and smooth in touch and less prone to wrinkling.

Owner:WUXI BENNIU BIOTECH CO LTD

Water-based environmental protection colorful texture paint and preparation method thereof

Owner:GANSU GLDARK NEW MATERIAL

Metal-imitated color plate membrane with three-dimensional effect, and preparation method of metal-imitated color plate membrane

InactiveCN106696393ANot brokenNo crackSpecial ornamental structuresCoatingsBoPETResin-Based Composite

The invention relates to a metal-imitated color plate membrane with a three-dimensional effect, and a preparation method of the metal-imitated color plate membrane. The metal-imitated color plate membrane comprises a biax orientation polyester (BOPET) film layer and a metal aluminum foil layer, wherein a primer coating layer is arranged on the upper surface of the BOPET film layer, and a three-dimensional pattern layer is arranged on the upper surface of the primer coating layer; the lower surface of the BOPET film layer is stuck with the metal aluminum foil layer by a colored composite adhesive layer; the lower surface of the metal aluminum foil layer is provided with a hot melt adhesive composite resin layer used for improving bonding strength. The preparation method comprises the processing steps of selecting a base membrane, coating the primer coating layer, preparing the three-dimensional pattern layer, coating the composite adhesive layer, compounding metal aluminum foil, and coating the hot melt adhesive composite resin layer. The metal-imitated color plate membrane has decorative patterns with the three-dimensional effect, is high in metal texture and soft in luster, and has novel and unique appearance, so that the product grade is improved, and the product categories are enriched.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

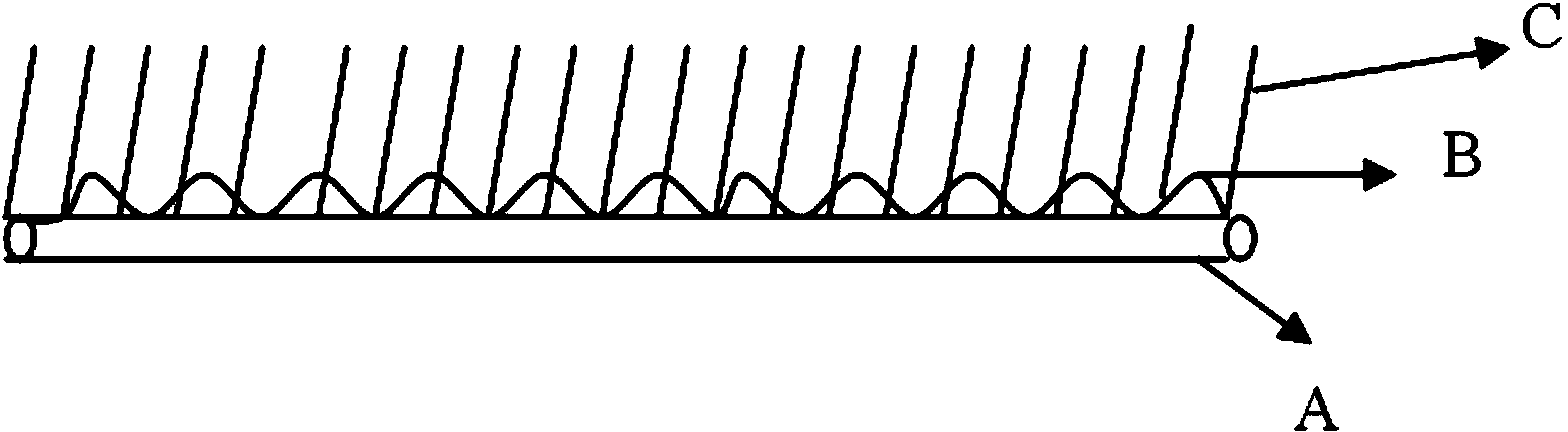

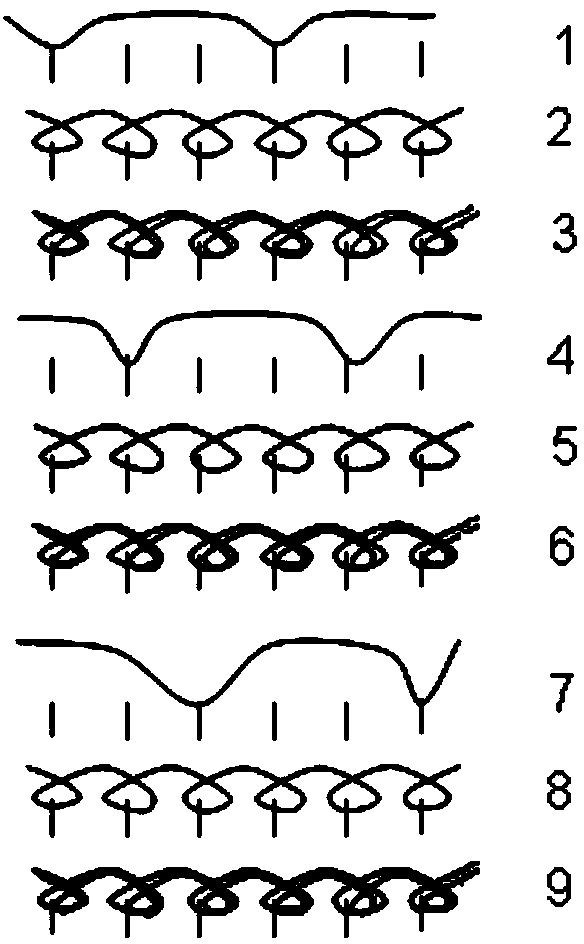

A kind of knitted fabric with smooth color change and preparation method thereof

ActiveCN104018286BPattern transition is smoothFeel comfortableWeft knittingBiochemical fibre treatmentYarnDark ground

The invention relates to a knitted fabric with smooth design and color change and a preparation method thereof, comprising a veil on the surface layer, a ground yarn on the middle layer and a lining yarn on the inner layer, the fabric is a plaited cushion structure; the veil and the The ground yarn is made of dark color A, light color B and A / B mixed color yarn, and the lining yarn is made of any color C yarn, and the fabric with smooth color changes is formed through color gradient weaving. The fabric designed by the three-layer weave and color matching of the present invention has the characteristics of smooth pattern transition, comfortable hand feeling, warmth retention, fineness, plumpness, gorgeous appearance, and elegant luster; it solves the problem that conventional yarn-dyed knitted fabrics are difficult to process and smooth color changes Industry problems, its preparation process is simple, the cost is low, and it has a good application prospect.

Owner:NINGBO DAQIAN TEXTILE

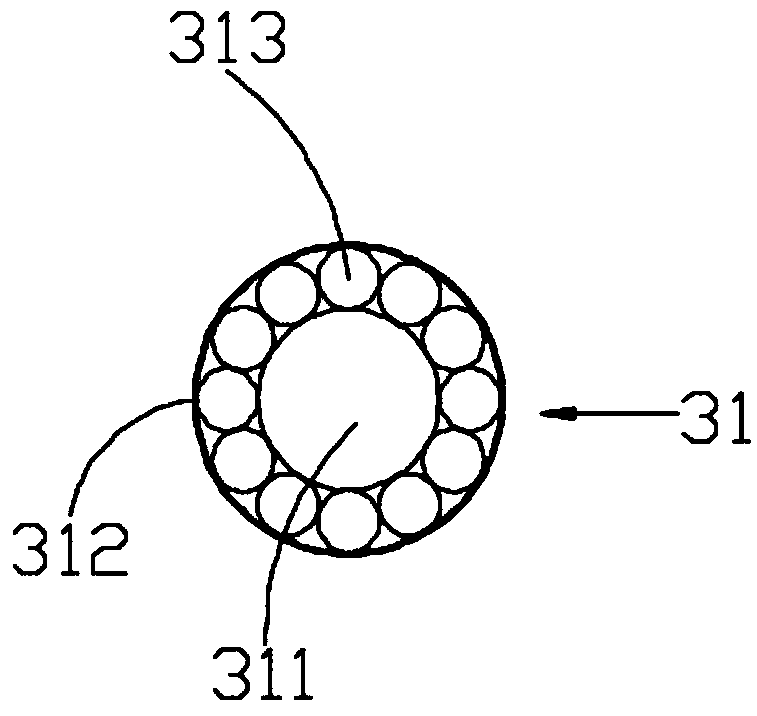

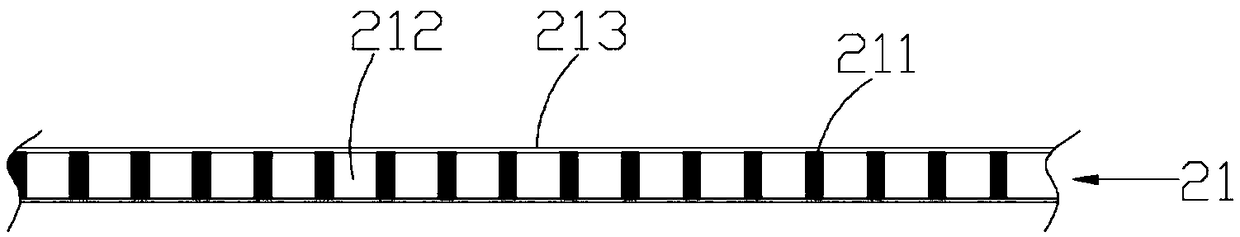

Chemical fiber filament

InactiveCN109898203AImprove rigidityImprove lodging resistanceFilament/thread formingYarnMoisture permeabilityEngineering

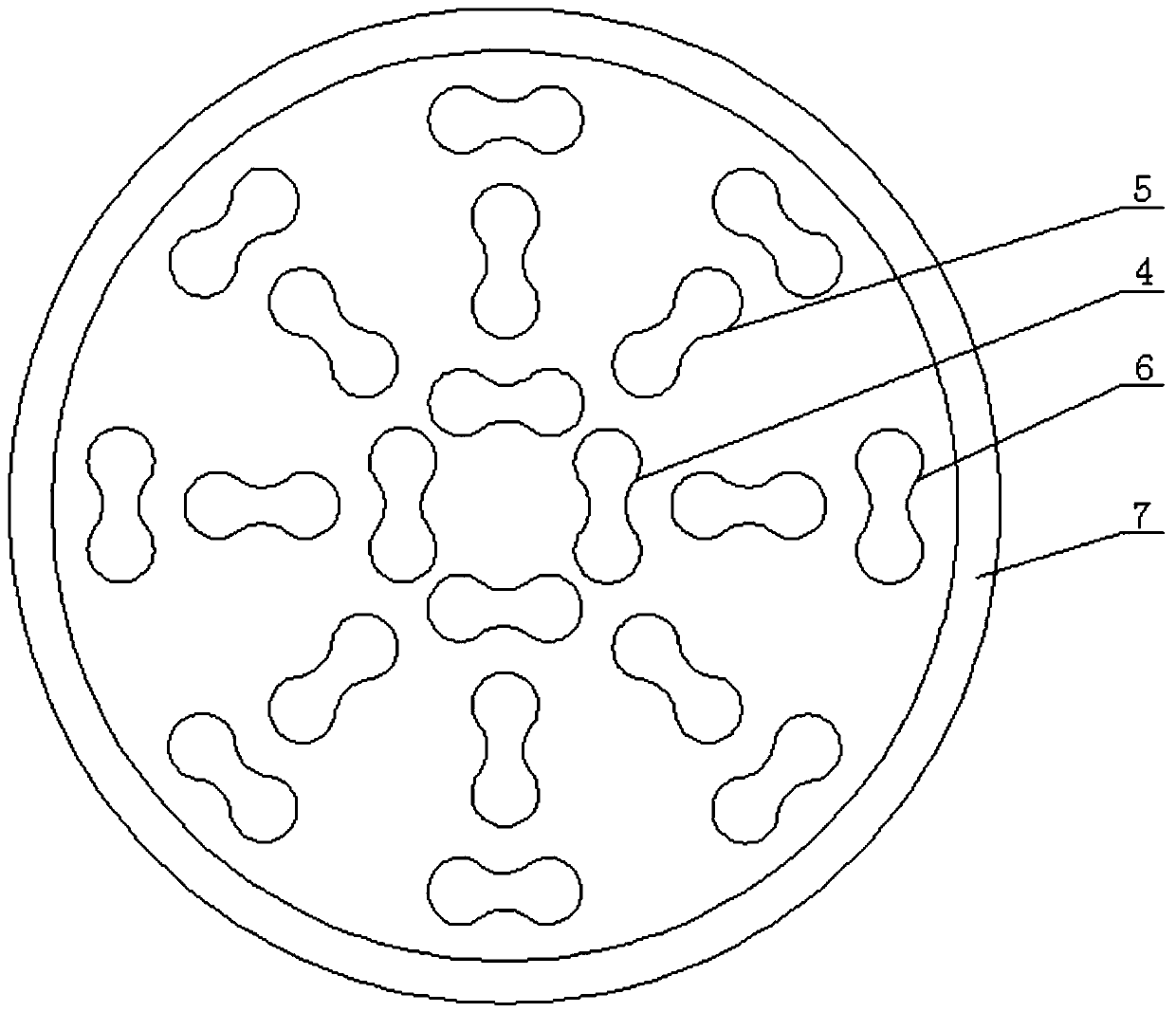

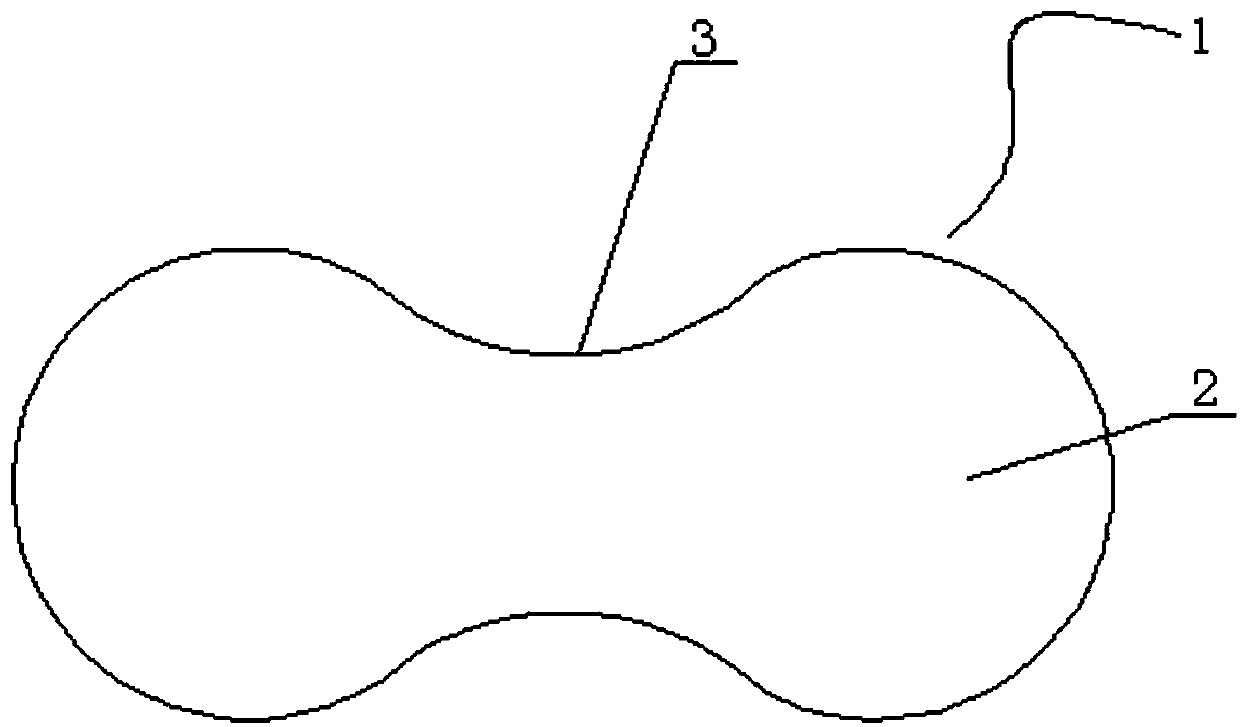

The invention discloses a chemical fiber filament. The chemical fiber filament comprises a plurality of monofilaments and an annular natural fiber layer. Each monofilament has a splayed cross section,and two symmetrical circular protrusion heads are formed at both ends of each monofilament; two symmetrical arc-shaped grooves are formed in the middles of the two sides of each monofilament; the every two protrusion heads are in transition connection through the corresponding groove; a first monofilament layer, a second monofilament layer and a third monofilament are sequentially arranged in thenatural fiber layer from inside to outside; the first monofilament layer comprises four horizontal monofilaments which are distributed in a square manner and do not intersect with one another; the second monofilament layer comprises eight longitudinal monofilaments, and the four spaced monofilaments in the second monofilament layer are perpendicular to the four monofilaments of the first monofilament layer respectively; the third monofilament layer comprises eight horizontal monofilaments, and the eight monofilaments of the third monofilament layer are perpendicular to the corresponding eightmonofilaments of the second monofilament layer respectively; the natural fiber layer is a silk layer. The chemical fiber filament has high lodging resistance, elasticity and moisture permeability.

Owner:SHAOXING JINCHEN BIOLOGICAL TECH CO LTD

Processing method of copper ammonia filament yarn-dyed high-grade fabric

ActiveCN113737357AEnsure level dyeingHigh strengthHeating/cooling textile fabricsDyeing processPolymer sciencePolymer chemistry

The invention discloses a processing method of a copper ammonia filament yarn-dyed high-grade fabric. The method comprises the following technological processes of copper ammonia filament twisting, bobbin polyester thread coating, yarn loosening, yarn dyeing, weaving and gray fabric after-treatment. The yarn dyeing comprises a sodium carbonate pretreatment procedure and a dyeing procedure. A formula of a pretreatment agent adopted in the sodium carbonate pretreatment procedure comprises 2-4 g / L of a pretreatment refining agent, 2-4 g / L of sodium carbonate and 1-5 g / L of hydrogen peroxide with the mass concentration of 27.5%; the heat preservation temperature in the sodium carbonate pretreatment procedure is 80-110 DEG C, the heat preservation time is 30-60 minutes, and a bidirectional circulation mode is adopted for water flow. A reactive dye is adopted in the dyeing procedure, and a sodium carbonate solution with the concentration of 5-10 g / L is adopted as a color fixing agent for color fixation after dyeing. The processing method is high in yield, and the processed fabric is high in strength and physical test index, good in color uniformity, small in fiber damage, high in utilization rate, soft and smooth in hand feeling and elegant in gloss and is the first-choice fabric for high-grade clothes.

Owner:NINGBO YOUNGOR YINGCHENG UNIFORM +1

Wool-like fiber and production method thereof

The invention discloses a wool-like fiber. Different varieties of fibers are utilized for intermingled production on a draw machine, and the self-crimping effect of one variety of fiber is better than that of the other varieties; the fineness of the wool-like fiber is 130D-240D, the number of the fibers is 60-144 pieces, and the number of nets is 80-90 pieces / m. The invention further designs a production method of the wool-like fiber. The production method comprises the step that the draw machine is adopted for production, and is characterized in that different varieties of fibers are utilized for intermingled production on the draw machine, and the self-crimping effect of one variety of fiber is better than that of the other varieties. According to the wool-like fiber and the production method thereof, difference crimping effects can be generated by different varieties in the production process, the total wool-like effect is good, the process is simple, the cost is low, the wool-like fiber has comfortable elasticity and elegant gloss and is suitable for twisting for use, and cloth prepared from the fiber has senses of cotton and wool as well as soft and dry hand feeling and has a good market prospect.

Owner:NANTONG YONGSHENG FIBER NEW MATERIAL

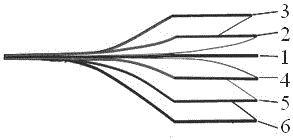

Method for making acrylic fibre by fine denier dry method and spinning nozzle

InactiveCN100392162CImprove spinnabilityMeet needsSpinnerette packsMonocomponent synthetic polymer artificial filamentHigh densityTemperature difference

The present invention optimizes and properly regulates the technological conditions of original Dupont dry spinning of acrylic fibre, such as properly raising temperature difference of internal and external side temperatures of mass, reasonably controlling nitrogen gas temperature and flow rate, water-washing temperature and draft multiple and speed and using cotton type oil agent to oil, etc. and reasonably designs the spinneret with high-density nozzle hole, its hole number is 3600-4400, its aperture is 0.09-0.13 mm, and the holes are arranged and distributed on 15-21 concentric circles, so that it can implement industrial production of fine-denier dry acrylic fibre.

Owner:浙江金甬腈纶有限公司

Method for fabricating soft knitting face fabric from cotton

InactiveCN100497789CDimensionally stableDoes not reduce strengthFabric breaking/softeningBiochemical fibre treatmentAgricultural engineeringSizing

The present invention discloses a processing method of flexible cotton knitted face fabric. Said processing method includes the following several steps: weaving, enzymatic washing, kiering and bleaching, dyeing, oversoftening, dewatering, opening, drying, sizing and pre-shrinking.

Owner:浙江盛泰服装集团股份有限公司

A kind of high elastic warm fleece knitted fabric and preparation method thereof

Owner:NINGBO DAQIAN TEXTILE

Method for processing soft twist yarn knitted fabric

InactiveCN102071523BGlossy and elegantGood dimensional stabilityWeft knittingFibre treatmentEngineeringDehydration

The invention discloses a method for processing a soft twist yarn knitted fabric. The method is characterized in that: the whole process sequentially comprises the following specific steps of: yarn dyeing, doubling and twisting, weaving, fabric water-washing, softening finishing, dehydration, scutching and drying, calendering and shaping. The method has the advantages that: two single yarns are doubled to form a soft twist yarn so as to overcome the shortcomings of weak strength, weaving difficulties, severe cloth cover skewing and the like of the conventional single soft twist yarn; the method is simple in process; the knitted fabric processed by the method has the effects of elegant gloss, high size stability, fluffy and soft handfeel and the like; in addition, if two single yarns with different colors and an identical yarn count are doubled and twisted, the processed knitted fabric has a unique heather effect.

Owner:浙江盛泰服装集团股份有限公司

Method for processing woolen knitted fabric

ActiveCN102191682BStrong bodyCompact structureDry-cleaning apparatus for textilesAnimal fibresMachining processComputer science

The invention discloses a method for processing woolen knitted fabric. The method is characterized by adding the procedures of fulling, drying, calendaring and preshrinking into an after-finishing procedure of the traditional processing technology of the woolen knitted fabric. The whole processing flow sequentially comprises the specific technical steps of knotting fabric, washing, softening, dehydrating and scutching, drying, fulling, drying, sizing, calendaring, preshrinking and checking a finished product. The invention has the advantages that because the four procedures of fulling, drying, calendaring and preshrinking are added into the after-finishing procedure, the processed woolen knitted fabric has the characteristics of stiff and smooth body, compact structure, elasticity, smooth surface, quietly elegant luster and slip and full hand feel, is beneficial to overcoming of the defects of loose organizational structure and defective tightness of the woolen knitted fabric produced with the traditional processing technology and is very suitable for making coats of high-grade leisure suits or jackets, and the like.

Owner:SHENGZHOU SHENGTAI KNITTING

Saponification Dyeing Method of Nylon Acetate Fiber Composite Yarn

The invention provides a saponification dyeing method of polyamide acetate fiber composite yarns. The method includes the steps: (1) carrying out saponification modification treatment of the polyamideacetate fiber composite yarns which needs dyeing; (2) dyeing the polyamide acetate fiber composite yarns after saponification modification treatment with a reactive dye; (3) dyeing with a dispersed acidic dye; and (4) washing with water after dyeing. Firstly, an acetic acid fiber component contained in the polyamide acetate fiber filament composite yarns is subjected to partial saponification modification, after the modification of the acetic acid fiber, the reactive dye is adopted, dyeing is performed by a dispersed and acidic dye two-bath dyeing process, and the polyamide acetate fiber filament composite yarns are dyed by the creative dyeing method and have the advantages of bright color and luster, elegant luster, bright dyeing, strong dyeing fastness, and soft and smooth hand feeling.The soaping fastness of a dark color system can reach 4 level or more.

Owner:恒天宝丽丝生物基纤维股份有限公司

Silk cotton knitted fabric and production method thereof

ActiveCN102127863BHigh glossGlossy and elegantShrinkingBiochemical fibre treatmentCotton effectMirror reflection

The invention discloses a silk cotton knitted fabric and a production method thereof. The silk cotton knitted fabric is formed by performing special bright treatment and a soft finish process on cotton and elastic cotton knitted fabrics and allowing the fabrics to pass through a squeezing machine (a cloth face is flatly pressed to improve mirror reflection so as to improve glossiness), so that the silk cotton knitted fabric obtained by treatment of the process is silkily soft and smooth, does not have hair on the cloth face and has elegant glossiness and a liquid-state cotton effect with excellent drape; the resilience of cloth is greatly enhanced; and the content of formaldehyde in the cloth is less than 20mu g / g JISL (04), and the color fastness reaches American association of textile chemists and colorists (AATCC) level-4 numerical value. Compared with the conventional mode, the production method has the advantages of short flow, no need of special production equipment and low cost and is easy and convenient to operate.

Owner:PACIFIC (PANYU) TEXTILES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com