Metal-imitated color plate membrane with three-dimensional effect, and preparation method of metal-imitated color plate membrane

A three-dimensional effect, imitation metal technology, applied in the field of imitation metal color plate film and its preparation, can solve the problem of rising market share, and achieve the effect of improving product grade, enriching product variety, and excellent adhesion fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

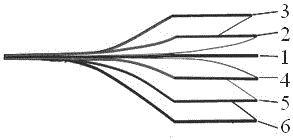

[0029] like figure 1 As shown, the present invention includes that the BOPET film and the metal aluminum foil provided with the three-dimensional pattern are bonded together through a colored composite adhesive layer. The surface of the BOPET film is provided with a three-dimensional pattern layer formed by UV radiation curing using precision micro-replication engraving technology; the surface of the metal aluminum foil layer is provided with a hot-melt adhesive composite resin layer to improve bonding strength. Its preparation method comprises the following steps:

[0030] (1) Select the base film: select a bending-resistant and impact-resistant BOPET film.

[0031] (2) Coating primer layer: apply a primer with excellent adhesion fastness and no sticking back on the surface of the BOPET film.

[0032] (3) Preparation of three-dimensional effect pattern layer: the three-dimensional pattern layer is formed on the surface of the BOPET film by UV radiation curing using precisio...

Embodiment 2

[0039] The BOPET film of this embodiment is resistant to 180 º Bending life 1.5×10 4 Times, impact strength 90kj / m, tear strength 57 N / mm, tensile strength 108MPa, elongation at break 24%. The primer is selected from a yellowing-resistant polyurethane resin with excellent adhesion fastness and no stickiness. A three-dimensional pattern layer formed by UV radiation curing using precision micro-replication marking technology. The three-dimensional pattern is a flashing pattern imitating a golden monkey, with a thickness of 5±0.3μm. The colored composite adhesive layer is a high-temperature cooking-resistant solvent-based polyurethane composite adhesive with high bonding strength to BOPET film and metal aluminum foil. The composite strength is 180º, the peel strength is 35±2MPa, the boiling temperature is 101°C, and the boiling time is 85min. . The colored pigment in the colored composite adhesive is composed of black pigment and white pigment according to the mass ratio of 20...

Embodiment 3

[0042] The BOPET film of this embodiment is resistant to 180 º Bending life 2.0×10 4 Times, impact strength 100kj / m, tear strength 52 N / mm, tensile strength 120MPa, elongation at break 30%. The primer is selected from the anti-yellowing polyurethane resin with excellent adhesion fastness and no sticking back and the dual-cure system polyacrylate resin is mixed according to the mass ratio of 75:25wt%. A three-dimensional pattern layer formed by UV radiation curing using precision micro-replication marking technology. The three-dimensional pattern is a flash pattern imitating a combination of ribs and stainless steel rings, with a thickness of 4.5±0.3μm. The colored composite adhesive layer is a high-temperature cooking-resistant solvent-based polyurethane composite adhesive with high bonding strength to BOPET film and metal aluminum foil. The time is 75 minutes. The colored pigment in the colored composite adhesive is made of black pigment and white pigment according to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com