Fire-proof magnesium composite board

A composite board and magnesium technology, which is used in building components, ceramic molding machines, thermal insulation and other directions, can solve the problems of potential safety hazards, unreachable fireproof composite boards, poor strength, etc., and achieve good promotion prospects and application value. Flammable, high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0013] The high-strength magnesia calcium silicate cementitious material is used as material A, and the core layer of calcium silicate is used as material B. Material A is prepared from the following components: magnesium sulfate 20%, calcium silicate 15%, silica fume fiber 3 %, magnesium oxide 30%, plant fiber 3%, aluminum sulfate fiber 3%, modifier 3%, bentonite 3%, foaming agent 3%, phosphoric acid 1%, and the rest is water. Wherein the modifying agent is formulated from the following components: 35% citric acid, 35% tartaric acid, 10% methyl cellulose, 11% sodium methylene bis-naphthalene sulfonate (NNO diffusing agent), 9% alum; foaming The agent is prepared from the following components: bone glue 5%, sodium hydroxide 40%, soda ash 9%, rosin 30%, and the rest is water. The material of the core layer B is prepared from the following components: 80% of calcium silicate, 10% of polystyrene particles, 1% of acrylic acid, and the rest is water; the above components are all pe...

example 2

[0016] Same as Example 1, the difference is that the high-strength magnesia calcium silicate cementitious material (A material) is formulated by the following components: magnesium sulfate 25%, calcium silicate 20%, silica fume fiber 5%, magnesium oxide 40%, plant fiber 5%, aluminum sulfate fiber 5%, modifier 5%, bentonite 5%, foaming agent 5%, phosphoric acid 3%, and the rest is water. The core layer (material B) is prepared from the following components: 80% magnesia calcium silicate, 10% polystyrene particles, 2% acrylic acid, and the rest is water; the above components are all percentages by weight.

example 3

[0018] Same as Example 1, the difference is that the high-strength magnesia calcium silicate cementitious material (material A) is formulated from the following components: magnesium sulfate 23%, calcium silicate 18%, silica fume fiber 4%, magnesium oxide 35%, plant fiber 4%, aluminum sulfate fiber 4%, modifier 4%, bentonite 4%, foaming agent 4%, phosphoric acid 2%, and the rest is water. The core layer (material B) is prepared from the following components: 80% magnesium calcium silicate, 10% polyphenylene particles, 0.5% acrylic acid, and the rest is water; the above components are in weight percentage.

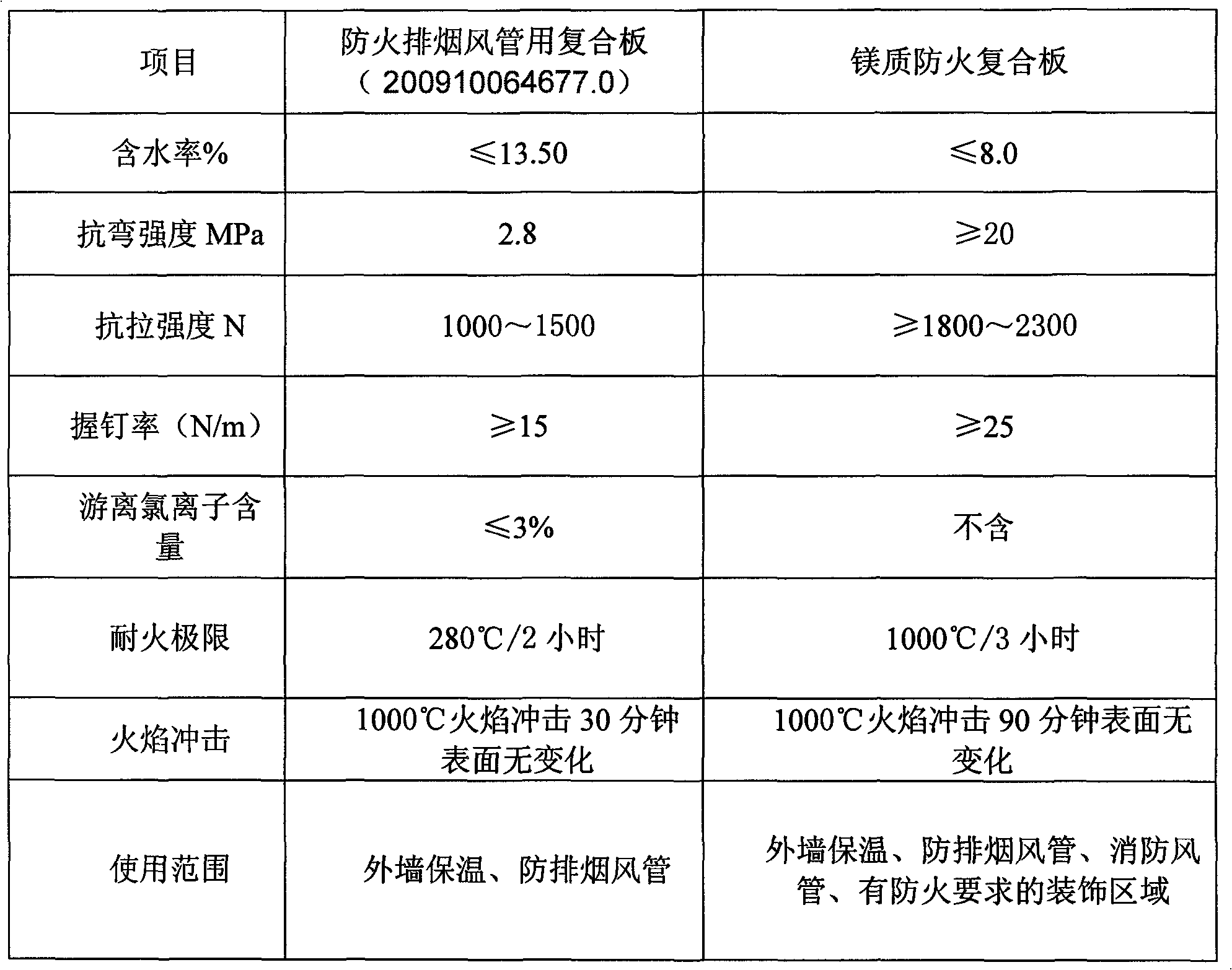

[0019] The performance index of the composite fireproof board prepared in the embodiment of the present invention is as follows, and the performance comparison has been carried out with the composite board (200910064677.0) for fireproof and smoke exhaust air duct:

[0020]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com