Patents

Literature

1150 results about "BoPET" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

BoPET (biaxially-oriented polyethylene terephthalate) is a polyester film made from stretched polyethylene terephthalate (PET) and is used for its high tensile strength, chemical and dimensional stability, transparency, reflectivity, gas and aroma barrier properties, and electrical insulation.

Polypropylene film and capacitor using it as a dielectric

InactiveUS6094337AExcellent in heat resistance and long-term dielectric propertyFixed capacitor dielectricFolded capacitorsPolypropylenePolymer chemistry

PCT No. PCT / JP97 / 02791 Sec. 371 Date Mar. 6, 1998 Sec. 102(e) Date Mar. 6, 1998 PCT Filed Aug. 8, 1997 PCT Pub. No. WO98 / 06776 PCT Pub. Date Feb. 19, 1998Biaxially oriented polypropylene film excellent in heat resistance and long-term dielectric properties at high temperatures, reduced insulation defects, and excellent impregnation of insulating oil into the clearance between film layers and swelling resistance when immersed in the insulating oil; in a capacitor having excellent heat resistance, dielectric properties, corona resistance, long-term thermal durability and electric current resistance, with the polypropylene film serving as dielectric; the film is a biaxially oriented polypropylene film characterized by 98 to 99.5% isotacticity, 99% or more in isotactic pentad fraction, 30 ppm or less in ash content and 0.01 to 0.4 mu m in center line average surface roughnesses on both sides.

Owner:TORAY IND INC

Biaxial tension co-extrusion high-obstruct base material membrane and process for preparing the same

InactiveCN1733397AImprove barrier propertiesImprove qualityTurning toolsHeat deflection temperaturePolyolefin

This invention provides biaxial tension coextrude resistive base material membrane and preparation method. Wherein, the membrane comprises at least a resistive layer that is at least one of PA, PVA, PVDC and MAD6, a splice layer belonged to EAA, EEA, ethylenemethacrylic acid copolymerized resin or polyolefin and neolyn resin that can combine the other tow layers, and a heat-sealing layer that is at least one of the polyolefin resin, EVA and PET; besides, there is nano inorganic material in resistive layer and or heat-sealing layer to improve performance. The product fits to package for all kinds goods.

Owner:朱春蕾 +4

Biaxially stretched multilayer polypropylene film and use thereof

InactiveCN101160209ALow densityLow surface smoothnessSynthetic resin layered productsCoatingsPolymer scienceFilm base

Disclosed is a biaxially stretched multilayer polypropylene film wherein a front layer and back layer composed of a propylene polymer (a1) are respectively arranged on both sides of a biaxially stretched polypropylene film base layer (B) which is composed of a propylene polymer composition (A) obtained by adding an inorganic compound powder (a2) to the propylene polymer (a1). This biaxially stretched multilayer polypropylene film is characterized in that the front and back layers have a surface roughness (three-dimensional center plane average roughness SRa) of less than 0.08 [mu]m and a glossiness (incident angle: 60 degrees) of not less than 114%, and the multilayer polypropylene film has a total light transmittance of not more than 20% and a density of 0.40-0.65 g / cm<3>.

Owner:TOHCELLO CO LTD (JP)

Process for producing olefin polymers, olefin-polymerizing catalyst and polyproylene for biaxially oriented film produced with said catalyst

InactiveUS6337377B1Improve tensile propertiesHigh transparencyOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationXylylenePolymer science

A process for producing an olefin polymer using a catalyst in which (A) is a solid catalyst component which includes magnesium, titanium, halogen and an electron donative compound as essential constituents; (B) is an organoaluminum component; and (C) is at least two electron donative compounds (alpha) and (beta), wherein the pentad stereoregularity of a xylene insoluble fraction of a homopolyproylene is 0<mmrr / mmmm<=0.0068 when electron donative compound (alpha) is used in combination with (A) and (B), and the pentad stereoregularity of a xylene insoluble fraction homoproplyene of a is 0.0068<mmrr / mmmm <=0.0320 when electron donative compound (beta) is used in combination with (A) and (B). A polypropylene produced in the process can be used to obtain a biaxially oriented film. (A) and (B). A polypropylene produced in the process can be used to obtain a biaxially oriented film.

Owner:SUMITOMO CHEM CO LTD

Method for preparing polyvinylidene chloride and acrylic ester copolymerization latex

The invention provides a preparation method of copolymerization latex of polyvinylidene chloride and acrylate, which comprises that reacts raw materials polyvinylidene chloride monomer, second monomer, functional monomer, composite emulsifier, pH adjuster, initiator, seed latex, and water in inertia gas, 0.08-0.12MPa and 50-60DEG C, collects polyvinylidene chloride and acrylate copolymerization latex from reaction product. The inventive PVDC latex is white stably, without changing into yellow after coating, with high stability. The latex can be directly coated on surface of base material as BOPP, BOPET and PVC hard sheet, while the coated or coated and dried film has barrier property, damp proofness, fragrance protectiveness, chemical drug resistance, and fireproof or the like. The film is transparent for long time, without changing into yellow. The inventive product can be used in one-time environment-friend dinnerware and inner layer of paper package, as tobacco, food and drug.

Owner:SHANGHAI CHLOR ALKALI CHEM

Propylene homopolymer having high melt strength and preparation method thereof

The present invention provides a process for preparing high melt strength propylene polymer by direct polymerization, comprising that a propylene polymer with wide molecular weight distribution and containing “very high molecular weight fraction” can be prepared by controlling the species and ratios of the external electron donors in the Ziegler-Natta catalyst system at different reaction stages according to the requirment for different molecular weight fractions in the different propylene polymerization stage of the series operation, and said polymer has excellent mechnical properties, especially with very high melt strength. The present invention also provides a propylene homopolymer with high melt strength, comprising the following features: (1) the MFR is 0.2-10 g / 10 min at 230° C. with a load of 2.16 kg; (2) the molecular weight distribution Mw / Mn is 6-20; (3) the content of the fraction with a molecular weight higher than 5,000,000 is higher than or equal to 0.8 wt %; (4) Mz+1 / Mn is higher than or equal to 70. Said homopolymer can be used in the preparation of foam products, thermoforming products, biaxial stretching films, blown films and blow-molded products.

Owner:CHINA PETROCHEMICAL CORP +1

Method of producing a weld-cut sealing/heat-shrinkable packaging film formed of a polyethylene terephthalate-based block copolymer polyester

A PET-based polyester packaging film capable of weld-cut sealing and heat-shrinkage refers to a film obtained by biaxially orienting a material prepared through block copolymerization of a PET / PETG / polyester elastomer with an epoxy resin and a catalyst. This film eliminates the most serious weak points in physical properties of conventional PET films, and is useful for packaging of books, bottlesets, food containers, etc., for general packaging, packaging of industrial materials, and the like, and is further useful in the field of packing and packaging of daily commodities, civil engineering and construction members, electric and electronic members, and automobile vehicle members, etc. Moreover, this film can be produced through effective use of the huge amount of recycled PET bottles and inexpensive PET for fiber as a prepolymer, and thus is also highly beneficial socially. Still further, even if incinerated after use, this film produces a combustion heat value lower than that of a polyethylene or polypropylene. Thus, this film barely damages incinerators or the like, and emits no toxic gases.

Owner:NAKAMOTO PAKKUSU

Propylene-ethylene random block copolymer and biaxially oriented multi-layer film using the same as a surface layer

ActiveUS20050113517A1High transparencyIncrease flexibilitySynthetic resin layered productsDomestic containersPolymer sciencePolyolefin

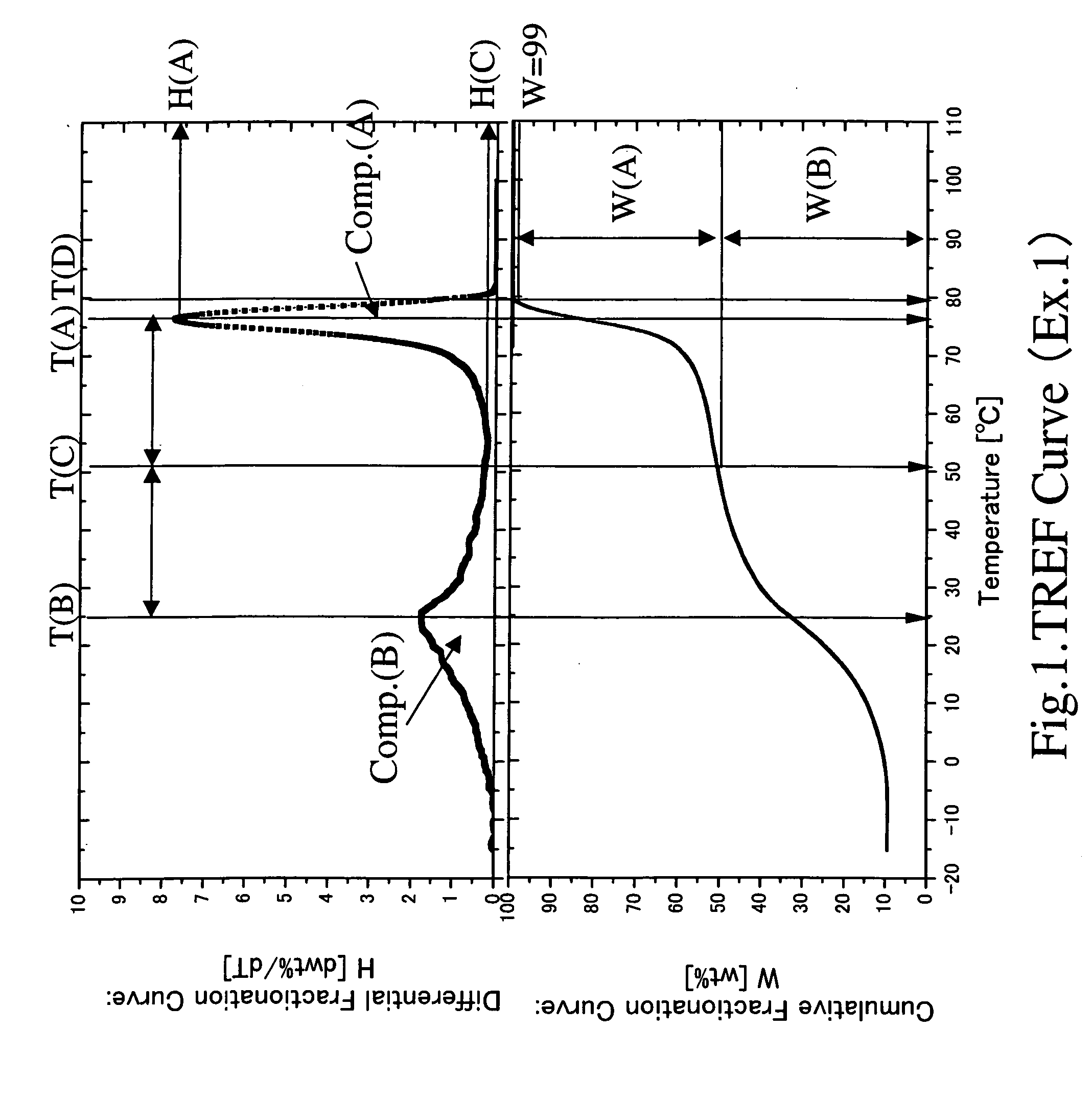

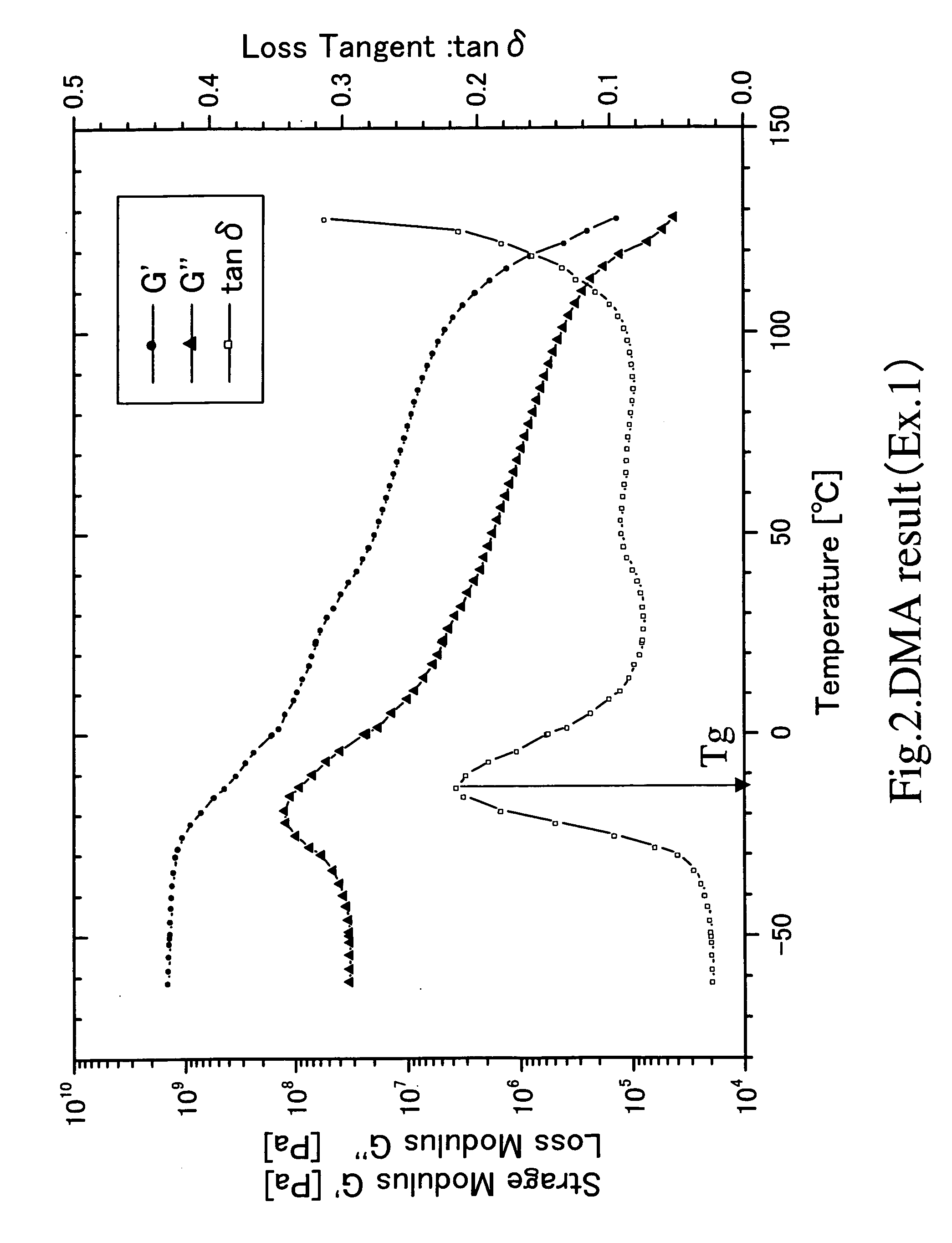

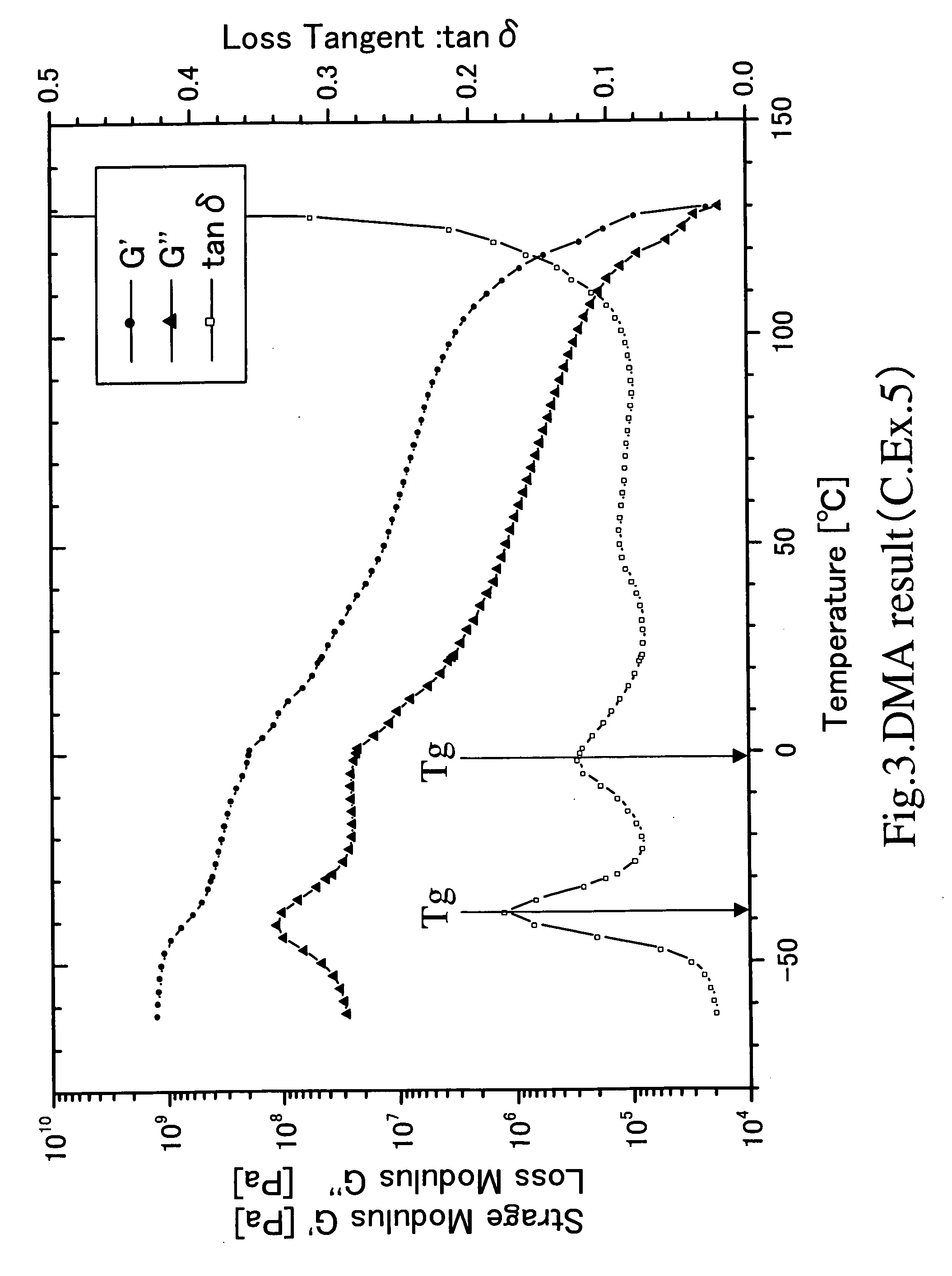

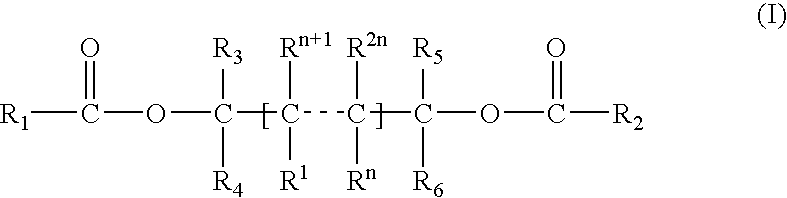

A polyolefin based biaxially oriented multi-layer film having at least one surface layer comprise of the propylene-ethylene random block copolymer; The propylene-ethylene random block copolymer obtained through sequential polymerization catalyzed by a metallocene component which is composed of 30 to 70 wt % of a propylene-ethylene random copolymer component having an ethylene content of 1 to 7 wt % produced in the first step of the polymerization and from 70 to 30 wt % of a low crystallinity or an amorphous propylene-ethylene random copolymer component produced in the second step of the polymerization having an ethylene content of 6 to 15 wt % higher than that of the polymer component obtained in the first step, wherein that shows a single peak at 0° C. or lower in the temperature-loss tangent (tanδ) curve obtained by dynamic mechanical analysis (DMA).

Owner:JAPAN POLYPROPYLENE CORP

Propylene polymer composition and oriented film prepared thereby

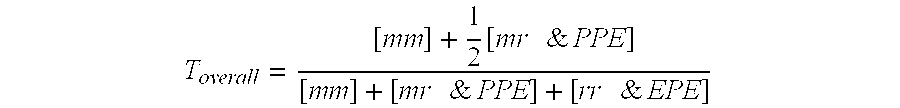

ActiveUS20060182987A1Good physical propertiesHigh modulus and stiffnessSynthetic resin layered productsThin material handlingNMR - Nuclear magnetic resonanceEthylene Homopolymers

The present invention provides a propylene polymer composition for producing a biaxially oriented film, comprising propylene random copolymer and propylene homopolymer; wherein the propylene random copolymer is a copolymer of propylene and ethylene, optionally comprising one or more alpha-olefins of C4-C10; the propylene polymer composition has an overall isotacticity index, as determined by nuclear magnetic resonance method, of greater than or equal to 96.5%, and an ethylene content of greater than 0.3 wt %; and wherein, the melt flow rate of the propylene random copolymer is lower than that of the propylene homopolymer. The biaxially oriented polypropylene film produced by the propylene polymer composition of the present invention exhibits excellent physical properties, and has, in the absence of any stiffening agent, relatively higher modulus and stiffness. Moreover, the process for producing the biaxially oriented polypropylene film is featured with a good film-forming stability and a high film-forming stretching speed.

Owner:CHINA PETROCHEMICAL CORP +1

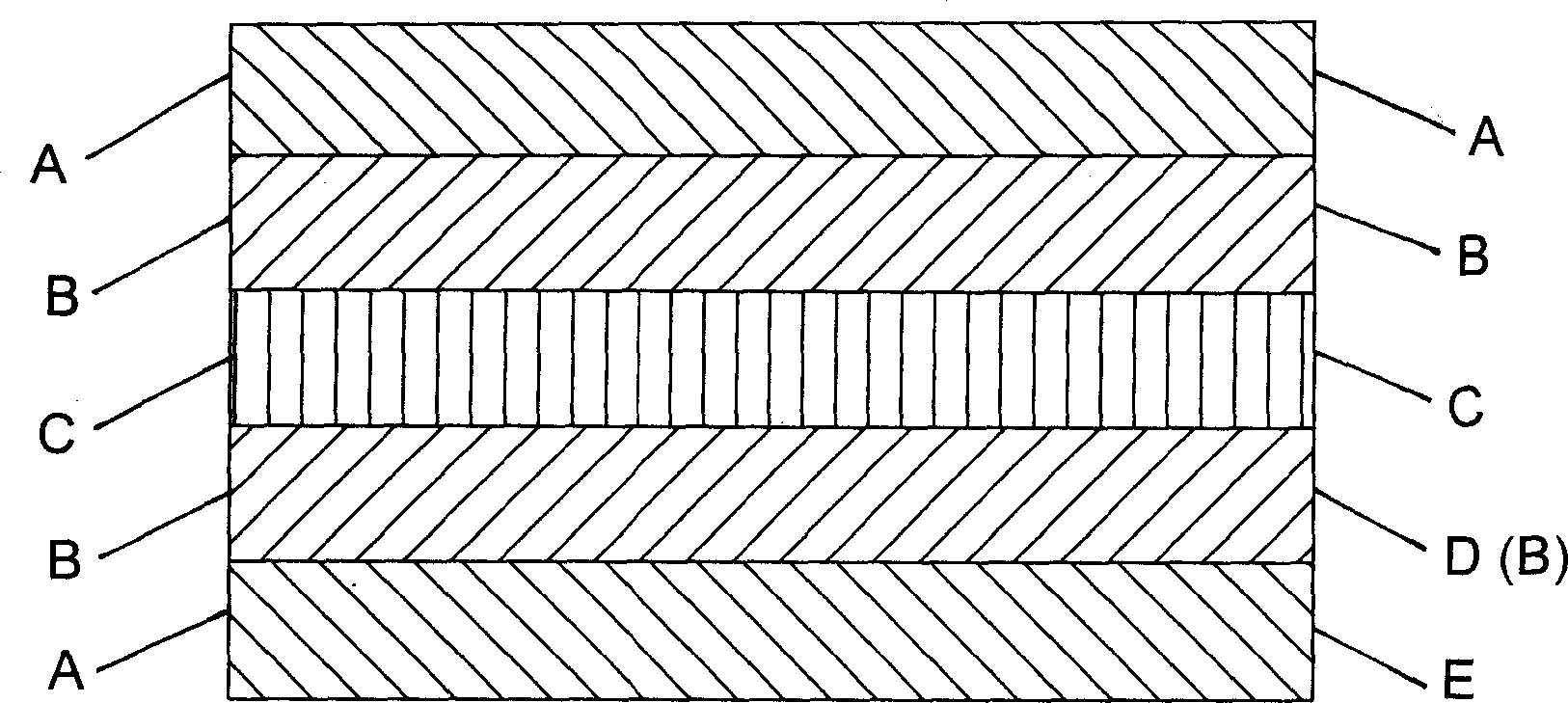

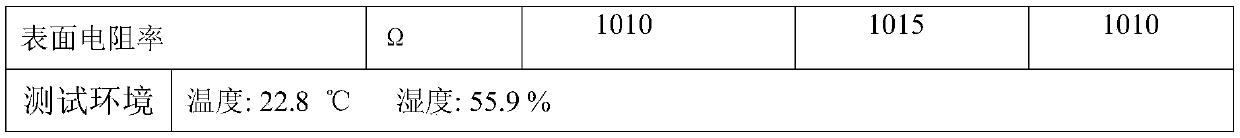

Polyolefin multi-layer porous diaphragm for lithium ion battery and preparation method thereof

InactiveCN102064299AGood heat setting timeLow closed cell temperatureSynthetic resin layered productsCell component detailsPolyolefinBoPET

The invention discloses a diaphragm used for preparing a lithium ion battery. The diaphragm is multilayer material formed by a polyethylene layer and a polypropylene layer which are mutually overlapped, wherein each layer is added with a heat resistant material. The preparation method of the porous diaphragm used for preparing the lithium ion battery comprises the following steps: firstly modifying the surface of a heat resistant inorganic material, uniformly mixing the inorganic material with high boiling point diluent, respectively adding polyethylene and polypropylene as well as the high boiling point diluent mixed with the inorganic material and other auxiliaries into a double screw extruder to be fully plasticized and extruded, preparing a uniform multilayer diaphragm by virtue of a multilayer die head under the control of a metering pump, and carrying out biaxial orientation stretching, washing and extracting, thus the porous diaphragm is obtained. The diaphragm prepared by the invention has higher air permeability and higher anti-puncture strength, more importantly, diaphragm rupturing temperature is higher, obturator temperature is lower, and shrinkage rate is lower, thus the diaphragm prepared by the invention is a novel diaphragm used for the lithium ion battery and has excellent properties.

Owner:FOSHAN JINHUI HIGH TECH OPTOELECTRONICS MATERIAL

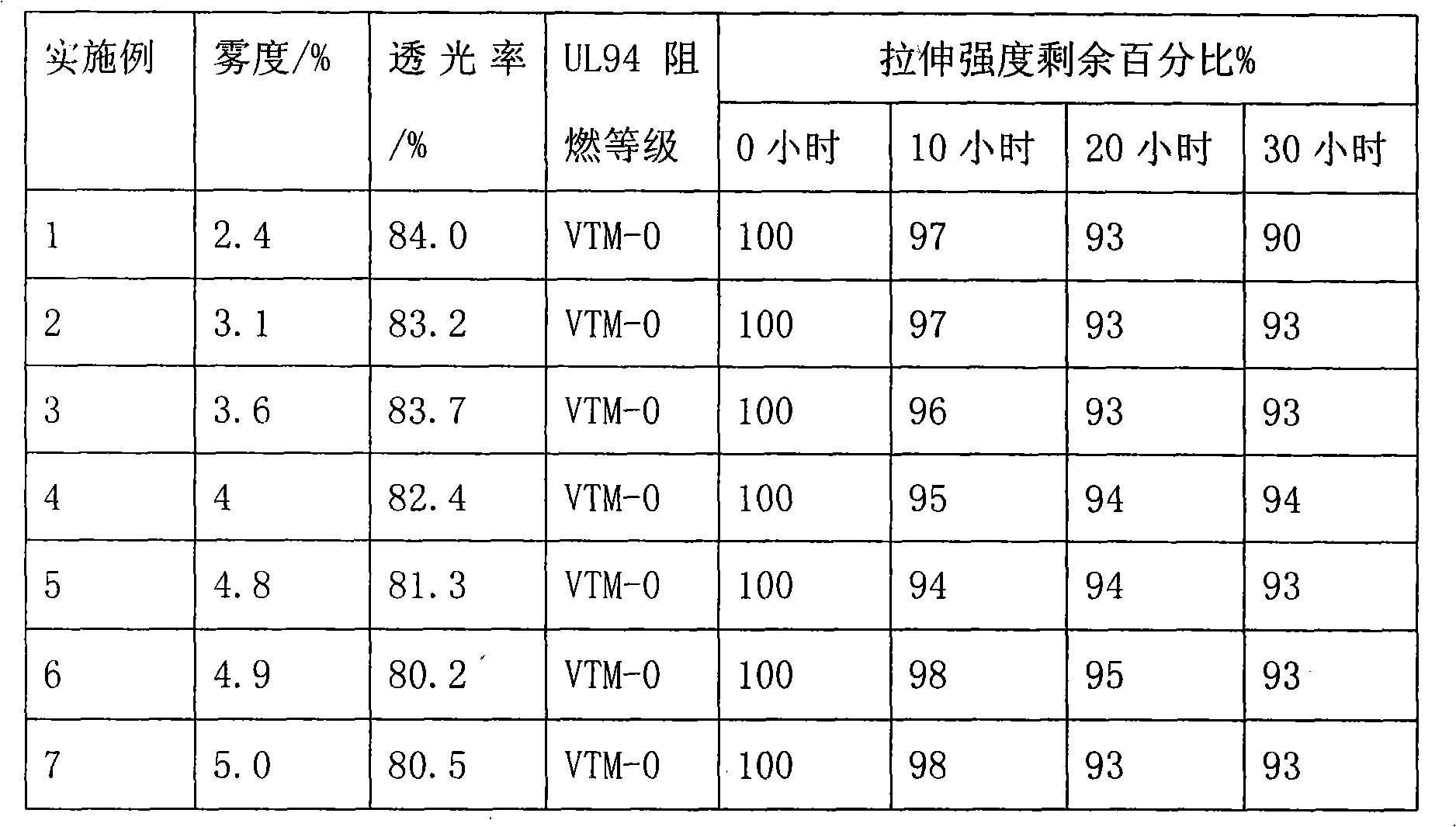

Transparent flame-retarding polyester film and preparation method thereof

ActiveCN101643574AReduce yellowingReduced mechanical propertiesEsterification reactionFire retardant

The invention relates to a preparation method of a transparent flame-retarding polyester film, comprising the following steps: mixing 100 parts of terephthalic acid and 35 parts of glycol; adding mixed liquid of 7.3-11.6 parts of structural phosphorus flame retardant and 30 parts of glycol, 3-4 parts of catalyst and 1.5-3 parts of stabilizing agent; carrying out esterification reaction for 0.5-1hat 100-115 DEG C under 400-600 pa; carrying out condensation polymerization for 2-3h at 260-290 DEG C under 10-70 pa to obtain a copolymerization lame-retarding polyester slice; after 35-50 percent ofcopolymerization lame-retarding polyester slice is crushed, mixing, extruding and granulating the copolymerization lame-retarding polyester slice and 2.6-6.3 parts of addition type flame retardant toprepare a blending lame-retarding polyester slice; after the residual copolymerization lame-retarding polyester slice and the blending lame-retarding polyester slice are crushed, adding 0.04-0.085 part of antiblocking agent, mixing and then transmitting into an extruder in a mixing mode; and preparing a film with a thickness with 50-300 micron by casting pieces, stretching in a bidirectional mode, thermally forming and rolling.

Owner:JIANGSU YUXING FILM TECH

Packaging film for two-way stretch polypropylene low temperature self-constriction cigarette and production method thereof

ActiveCN101537913ABeautify the appearanceAvoid defects caused by heatingFlexible coversWrappersThick plateSurface layer

The invention relates to a packaging film for two-way stretch polypropylene low temperature self-constriction cigarette and a production method thereof. The film comprises a surface layer A, a core layer B and a surface layer C; the surface layer A includes the raw materials according to the following weight percent: 80-90 of propylene copolymer, 5-10 of lubricate master batches and 5-10 of antiblocking master batches; the core layer B includes the raw materials according to the following weight percent: 62-77 of propylene homopolymer, 20-35 of hardness increase master batches and 3-5 of antistatic master batches; and surface layer C includes the raw materials according to the following weight percent: 80-94 of propylene copolymer, 3-10 of lubricate master batches and 3-10 of antiblocking master batches. The production method includes the following steps: (1) mixedly preparing; (2) making thick plates; (3) performing three-point stretching to the thick plates by three groups of stretching rollers to finally realize 6-8 multiples of longitudinal stretching after the thick plates enter into a longitudinal stretching machine; (4) transversely stretching; (5) towing and rolling up; and (6) dividing and cutting. The invention enables a cigarette factory to cancel a burning device and realizes the self-constriction in use of the cigarette film, thereby improving the packaging quality and beautifying the appearance of cigarette packs.

Owner:JIANGYIN ZHONGDA FLEXIBLE PLASTIC NEW MATERIALS CO LTD

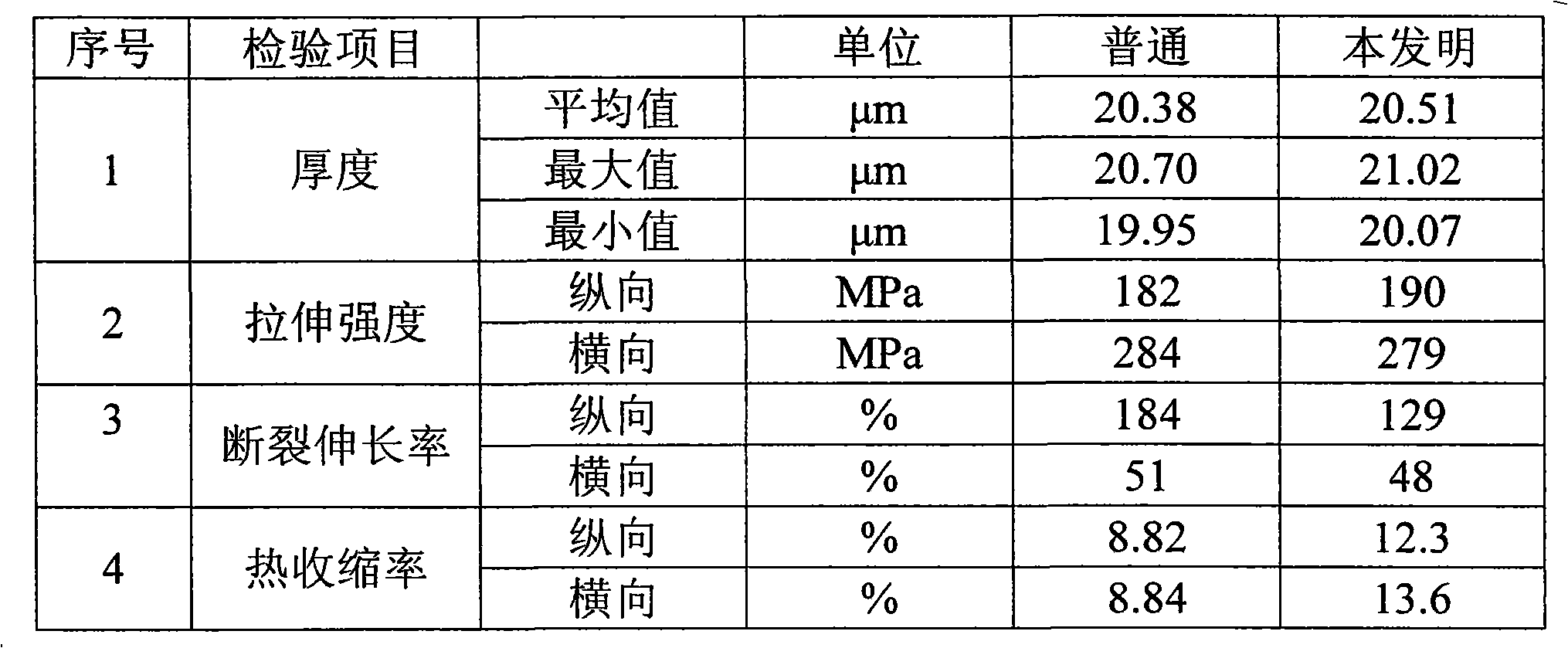

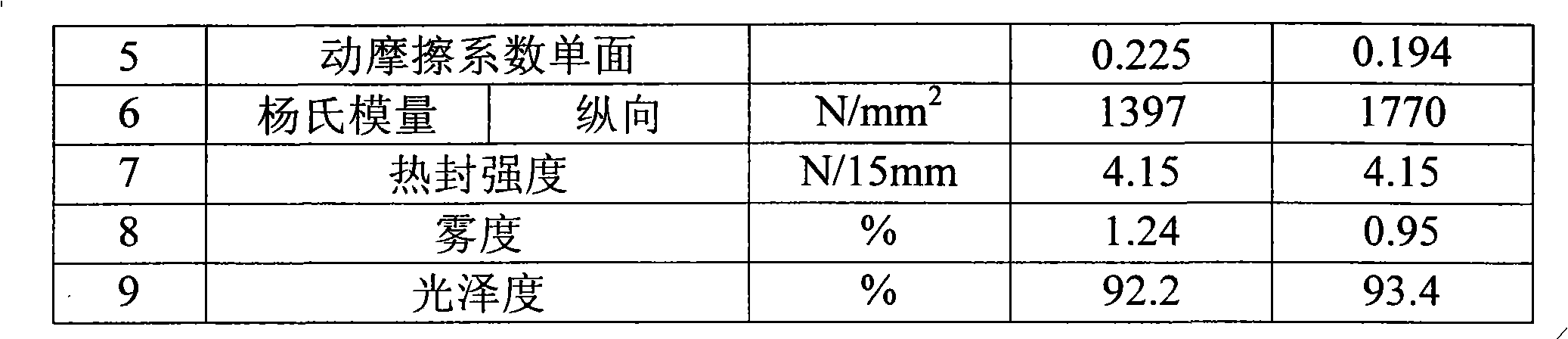

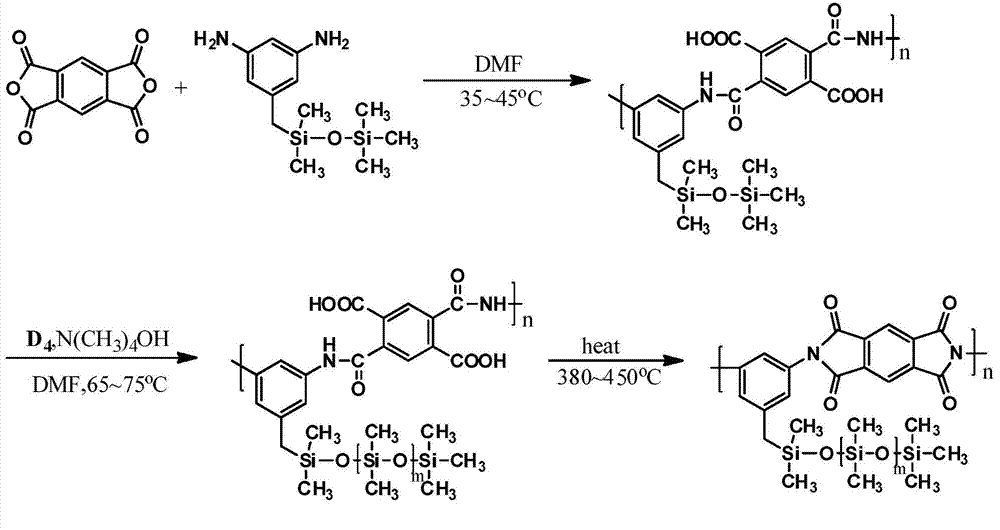

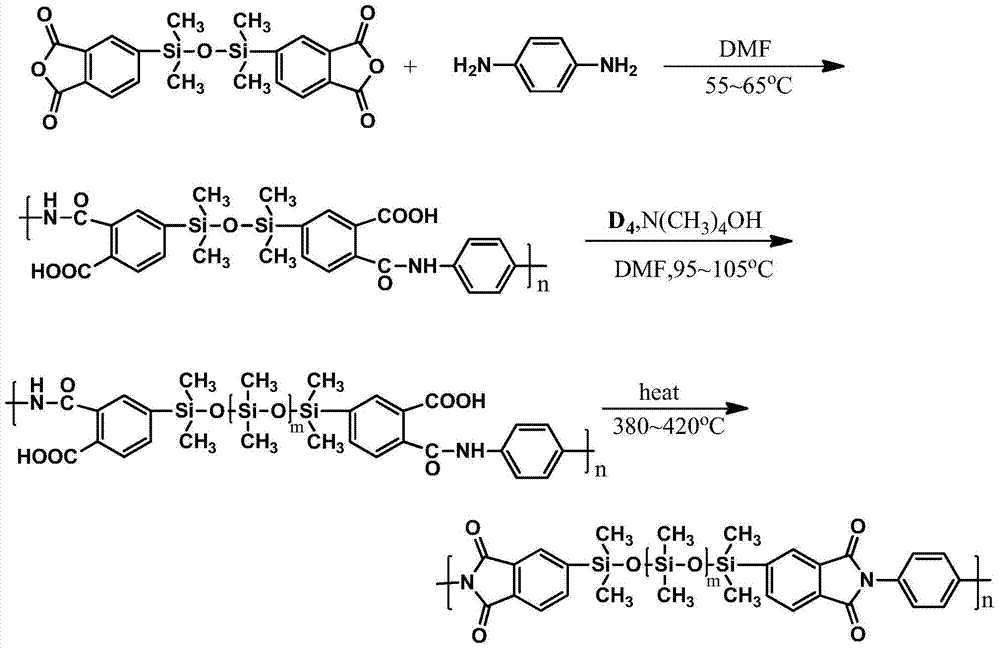

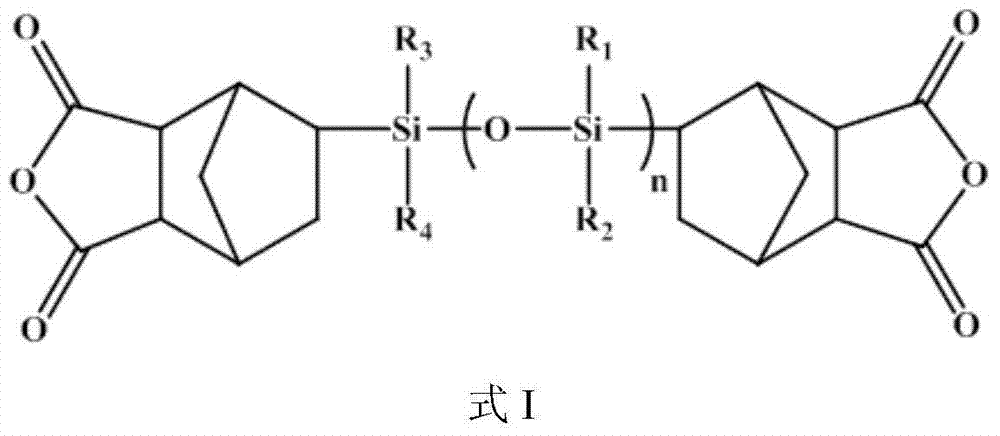

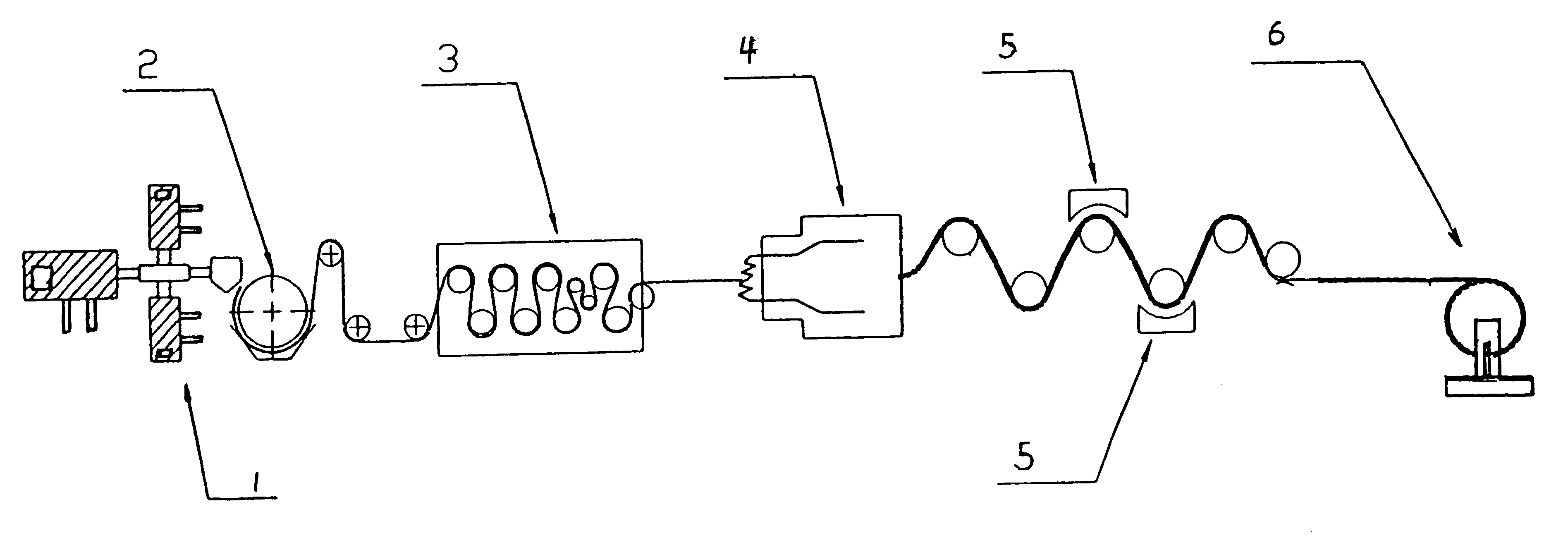

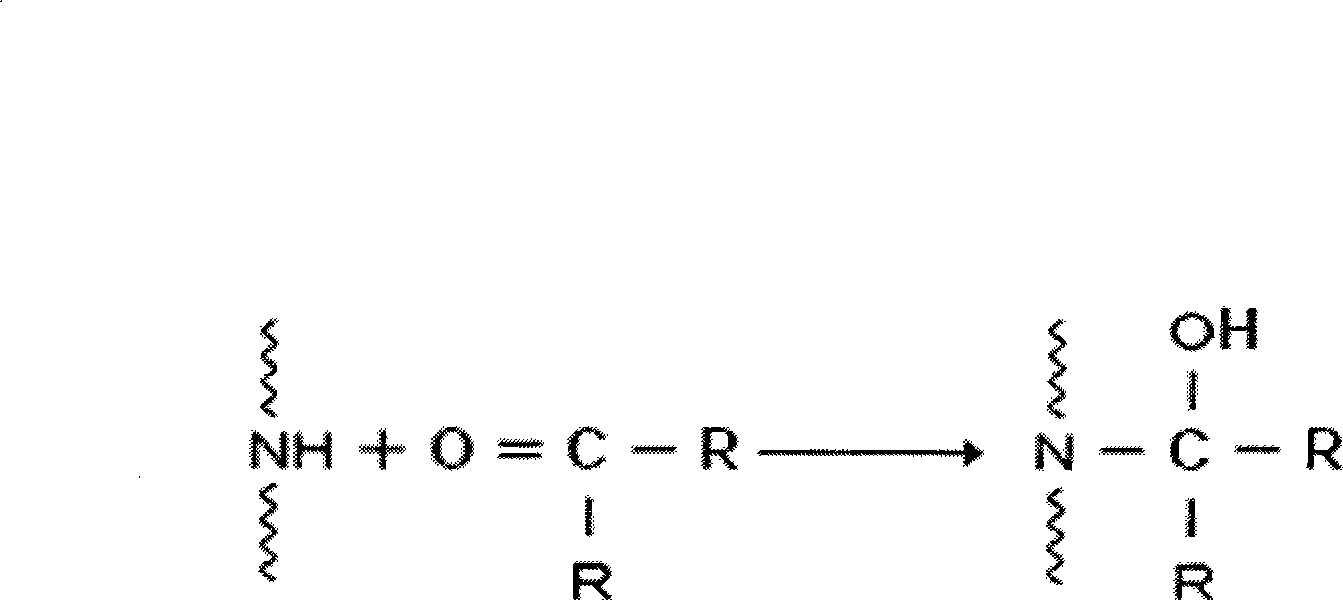

Novel electronic-grade polyimide film with low linear expansion coefficient and production method thereof

The invention relates to a preparation method of an electronic-grade polyimide film with low linear expansion coefficient. The method comprises the following steps that (1) the step-by-step condensation polymerization technology is used for obtaining polybasic block copolymerization polyamide acid glue solutions comprising one or more bar-shaped rigid chain sections containing para-benzene or biphenyl and one or more soft chain sections containing ether bonds or silicon-oxygen bonds and the like; (2) polyamide acid comprising one or more bar-shaped rigid chain structures containing para-benzene or biphenyl and polyamide acid comprising one or more soft chain structures containing ether bonds or silicon-oxygen bonds are independently compounded, and the two or more polyamide acid glue solutions different in rigidity and softness are mixed and compounded; (3) the compounded glue solutions are subjected to filtration, vacuum defoamation, casting filming, bidirectional stretching, chemical amidization or thermal amidization, infrared complete amidization, high-temperature thermal forming processing, corona processing and a reeling process, and therefore the electronic-grade polyimide film with the thickness being 7.5-125 micrometers, the linear expansion coefficient being 5-18ppm / DEG C, and good physical mechanical performance is obtained.

Owner:宏威高新材料有限公司 +1

Preparation method and product of polytetrafluoroethylene (PTFE) film

ActiveCN101920559AReduce the temperatureReduce processing costsFlat articlesTetrafluoroethylenePolymer science

The invention discloses a preparation method and a product of a polytetrafluoroethylene (PTFE) film. The preparation method comprises the steps of: mixing PTFE resin powder with a liquid lubricant, extruding, calendering, longitudinally stretching, laterally stretching and heat setting, and rapidly spraying cooling water under certain pressure to obtain a bidirectional stretched PTFE microporous film with the micropore aperture of 0.2-10, the lateral shrinkage of smaller than 3%, and the longitudinal shrinkage of smaller than 5%. The PTFE film has stable lateral and longitudinal dimension, great improvement of film usability, simple process and low cost.

Owner:ZHEJIANG KERTICE HI TECH FLUOR MATERIAL

Bi-axially stretched breathable film, process for making the same and use thereof

The invention relates to A bi-axially stretched breathable film comprising a polymeric mixture, said polymeric mixture comprising based on the total weight of the polymeric mixture / —at least 50% of at least one polyether block copolymer; and—from 0.5 to less than 50% of at least one polyester. The invention also relates to a method to manufacture said film, and uses of said film. The invention also relates to a method for producing a bi-axially stretched breathable film comprising at least one polyether block copolymer.

Owner:DUPONT TEIJIN FILMS U S LLP

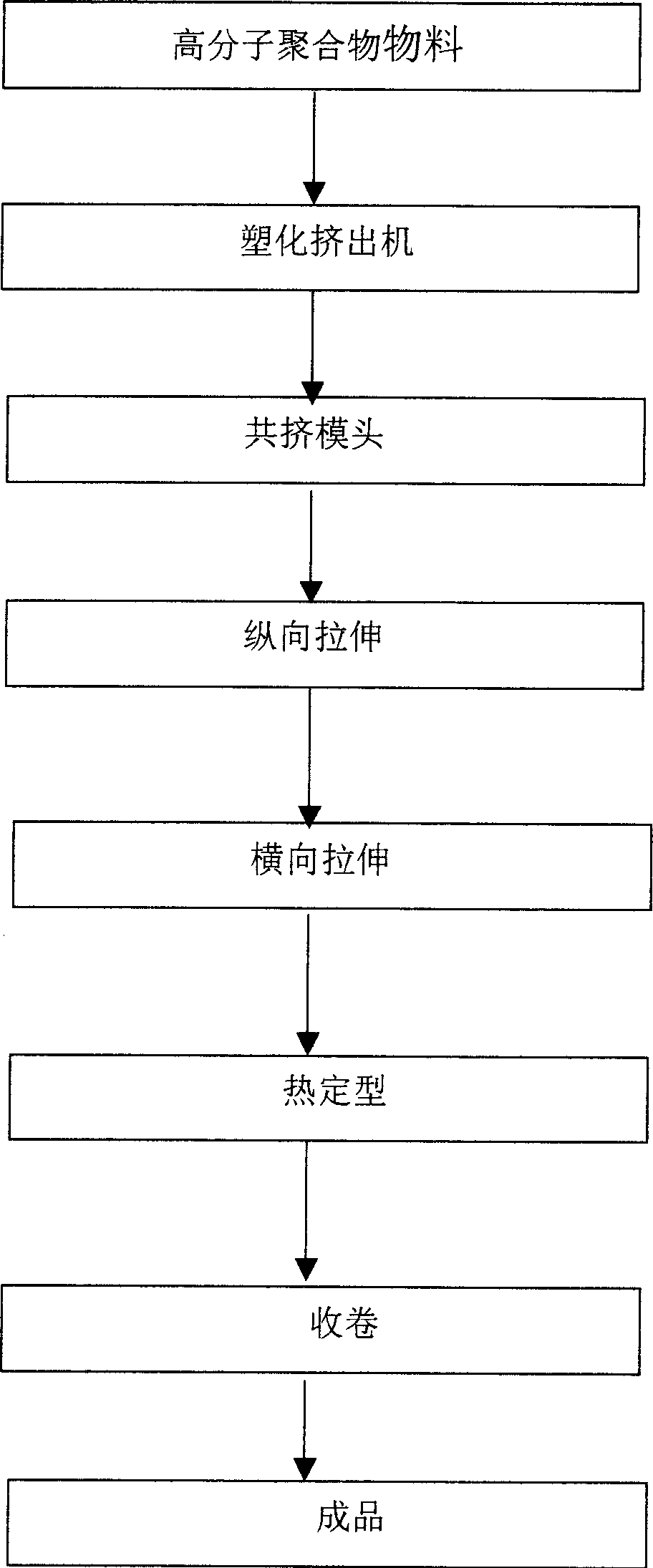

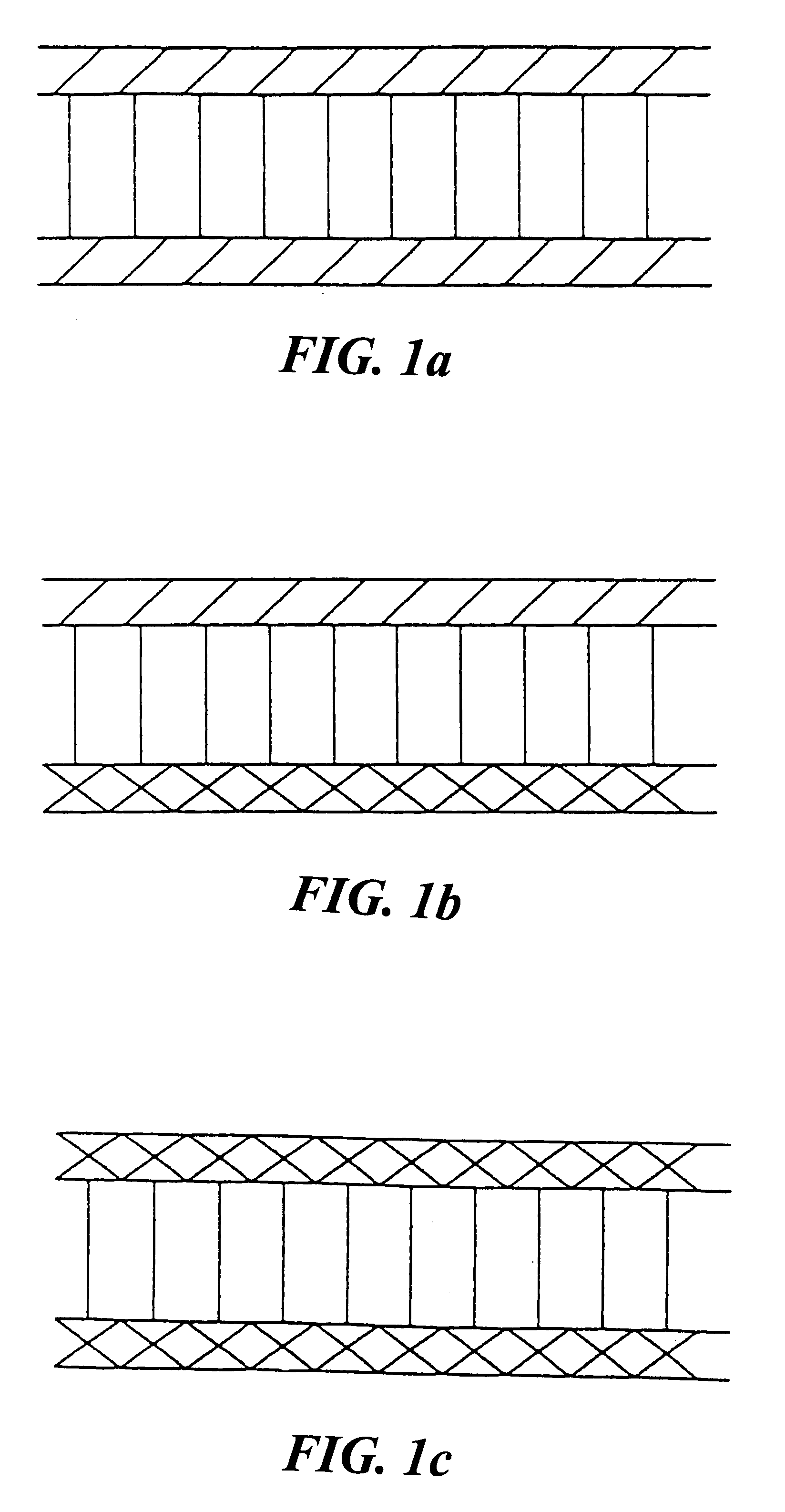

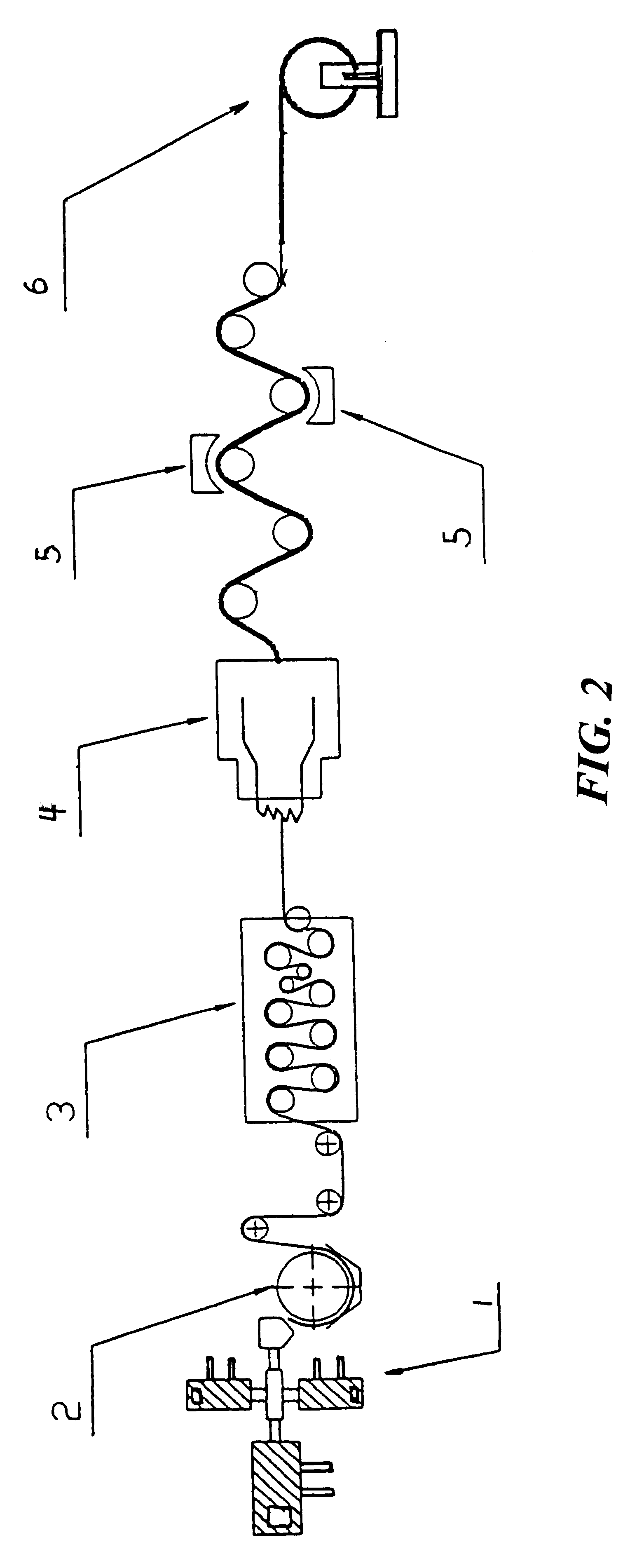

Process for producing a 3-layer co-extruded biaxially oriented polypropylene synthetic paper of thickness 25-250 mum

InactiveUS6364988B1High glossGood printabilityLamination ancillary operationsLayered product treatmentPolymer scienceBoPET

Disclosed is a process for producing a 3-layer co-extruded biaxially polypropylene (hereinafter as BOPP) synthetic paper of thickness 25-250 mum. More particularly, the invention relates to a process for producing a 3-layer biaxially-oriented PP synthetic paper by means of 3-layer co-extrusion wherein two different PP resin compositions are separately extruded by one primary and two secondary extruders first, and then are co-flowed by a same T-die to form a three layers coating sheet, and through cooling, biaxial orientation, corona treatment and winding to form a 3-layer co-extrusion synthetic paper of thickness 25-250 mum. The 3-layer structure of said 3-layer co-extrusion synthetic paper of thickness 25-250 mum can be made into three kinds, such as: paper sheet layer / foamed intermediate layer / paper sheet layer with double side paper sheet layer, paper sheet layer / foamed intermediate layer / resin layer with single side paper sheet layer and resin layer / foamed intermediate layer / resin layerwith double side high gloss resin layer.

Owner:NANYA PLASTICS CORP

Biaxially oriented matte BOPA (Biaxially oriented polyamide film) thin film and preparation method thereof

ActiveCN102924905AOvercome stabilityOvercome yieldSynthetic resin layered productsBoPETThin membrane

The invention discloses a biaxially oriented matte BOPA (Biaxially oriented polyamide film) thin film which is formed by a single frosted surface layer, or is formed by laminating the frosted surface layer and a smooth surface layer, or is formed by sequentially laminating the frosted surface layer, a middle layer and the frosted surface layer or is formed by sequentially laminating the frosted surface layer, the middle layer and the smooth surface layer. A method for preparing the biaxially oriented matte BOPA thin film comprises the following steps of: 1, placing the raw materials on each layer into a corresponding extruder to carry out melting and carrying out coextrusion by a die head to form a layer structure; 2, cooling and forming to obtain a crude product nylon thin film; and 3, carrying out biaxial stretching, heat setting, corona treatment and winding on the crude product nylon thin film to obtain the matte BOPA thin film product. The invention can overcome the defects of unstable quality of a conventional process, low yield, fussy process and high cost of the product; and the produced biaxially oriented matte BOPA thin film has a high quality.

Owner:FSPG HI TECH

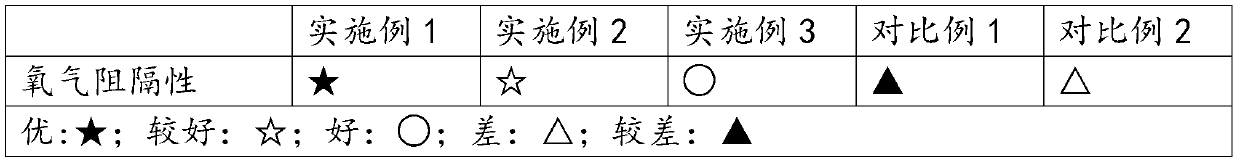

Coated high-barrier biaxially stretched polylactic acid film and preparation method thereof

ActiveCN110774713ASimple processImprove performanceSynthetic resin layered productsPolyurea/polyurethane coatingsPolymer scienceBoPET

The invention relates to a coated high-barrier biaxially stretched polylactic acid film and a preparation method thereof. The coated high-barrier biaxial tensile polylactic acid film structurally comprises a high-barrier coating, a bottom coating and a substrate layer from inside to outside in sequence, wherein the substrate layer is composed of three layers of a co-extruded biaxially stretched PLA (polylactic acid) film, namely a layer A, a layer B and a layer C; the layer A and the layer C comprise the following components in parts by mass: 68-93.2 parts of PLA, 5-20 parts of a toughening agent, 1-3 parts of a compatibilizer, 0.2-1 part of a chain extender, 0.2-1 part of an antioxidant, 0.5-3 parts of an antistatic agent, 0-1 part of an open agent and 0-1 part of a smoothening agent; thelayer B comprises the following components in parts by mass: 76-93.8 parts of PLA, 5-20 parts of a toughened resin, 1-3 parts of a compatibilizer and 0.2-1 part of a chain extender; and the high barrier coating is a water-resistant modified PVA coating. Production procedures are simple, green and environmental protection materials are used, and the film is excellent in performance, and still hasa good barrier effect in case of a very thin high-barrier coating.

Owner:中仑新材料股份有限公司 +1

Capacitor film with biaxially oriented polypropylene as base body and preparation method thereof

InactiveCN103102588AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethyleneEpoxy

The invention discloses a capacitor film with biaxially oriented polypropylene as a base body and a preparation method thereof. The capacitor film comprises the raw materials in parts by weight: 68-72 parts of biaxially oriented polypropylene, 23-28 parts of LDPE (low-density polyethylene), 10-15 parts of homo-polypropylene, 3-5 parts of epoxy linseed oil, 2-3 parts of polyving akohol, 1-2 parts of aluminium hydroxide, 1-2 parts of polyisobutene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 0.7-0.9 part of poly-4-methyl-1-amylene, 10-12 parts of K-feldspar powder, 1-3 parts of nanosilicon dioxide, 0.9-1.1 parts of 2,6-di tert butyl phenol-alpha-dimethylamino phenol, 1-3 parts of calcium stearate, 1.4-1.6 parts of phenyltriethoxysilane, and 1.7-2.3 parts of modified tree ash. The biaxially oriented polypropylene serving as a primary material, low-density polyethylene serving as an auxiliary material and a plurality of auxiliary materials are mixed, extruded and subjected to film blowing, shaping and cutting to prepare the capacitor film. The capacitor film is simple in preparation method; and the diatomite, the K-feldspar powder, the nanosilicon dioxide and the modified tree ash are added to the materials at the same time. Therefore, the barrier property and the gas tightness of the film are increased; and the capacitor film has good resistance to pressure and shock resistance, and has the characteristics of high heat sealing strength and good heat sealing property at the same time.

Owner:TONGLING YIHENGDA ELECTRONICS

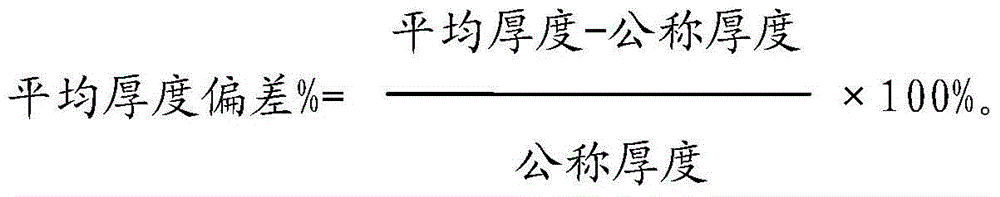

Two-way stretch polylactic acid film capable of being directly thermally sealed and preparation method of two-way stretch polylactic acid film

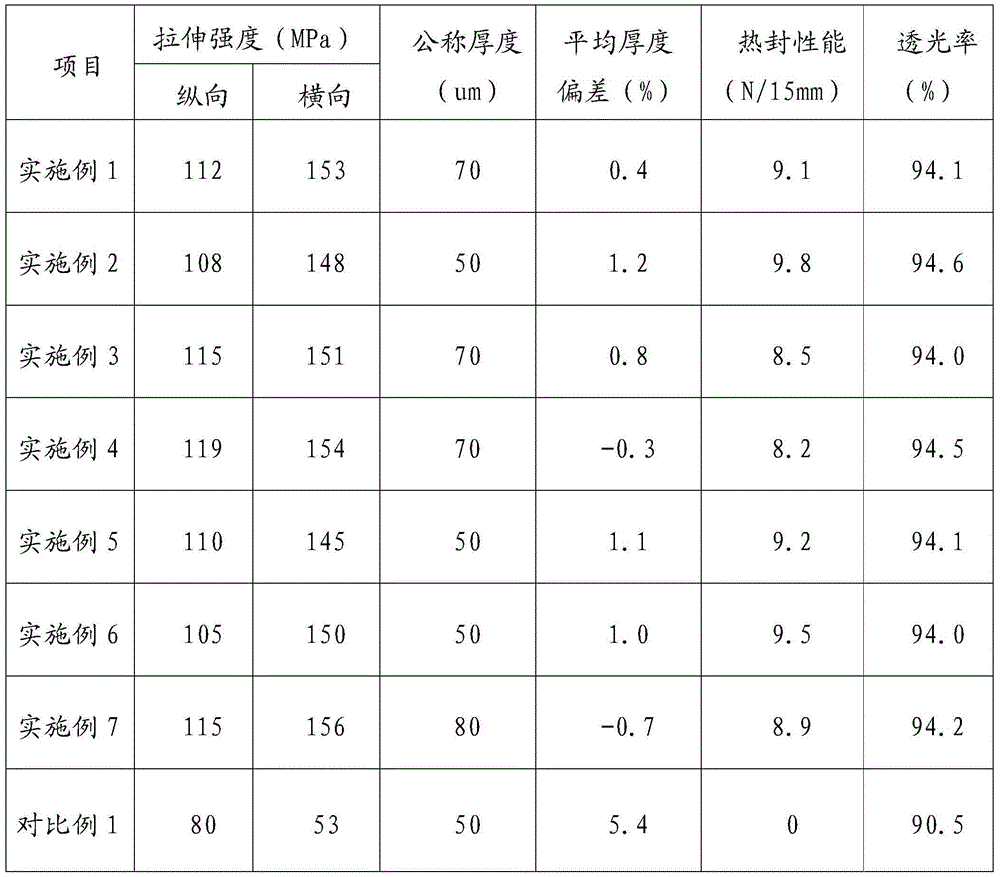

ActiveCN104608448AUniform thicknessHigh tensile strengthLamination ancillary operationsSynthetic resin layered productsBoPETPolylactic acid

The invention discloses a two-way stretch polylactic acid film capable of being directly thermally sealed and a preparation method of the two-way stretch polylactic acid film. The two-way stretch polylactic acid film comprises an A layer, a B layer and a C layer, which are sequentially arranged, wherein the A layer is a surface layer heat-seal layer, the B layer is a middle core layer, the C layer is an anti-adhesion layer. The preparation method comprises the steps of melting and extruding raw material sections of the layer A, the layer B and the layer C respectively at the temperature of 180 to 220 DEG C by virtue of a double-screw extruder, placing fused mass in a three-layer co-extrusion die head, casting the fused mass to form PLA sheets, preheating the PLA sheets, carrying out longitudinal stretch and cooling stereotyping on the PLA sheets, re-preheating the PLA sheets after the longitudinal stretch and cooling stereotyping, then transversely stretching the PLA sheets, carrying out stereotyping crystallization and cooling stereotyping on the PLA sheets, carrying out the pulling sectioning and corona treatment on the PLA sheets, and carrying out the coiling to prepare the two-way stretch polylactic acid film capable of being directly thermally sealed with thickness of 20 to 100 micrometers. The two-way stretch polylactic acid film capable of being directly thermally sealed can be directly produced on a BOPET production line, the prepared film can be directly thermally sealed, and the application range of the polylactic acid film can be enlarged.

Owner:SHANDONG SHENGHE PLASTIC DEV

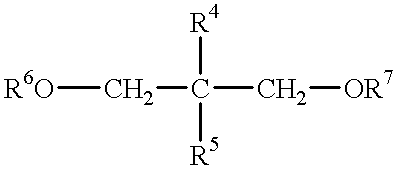

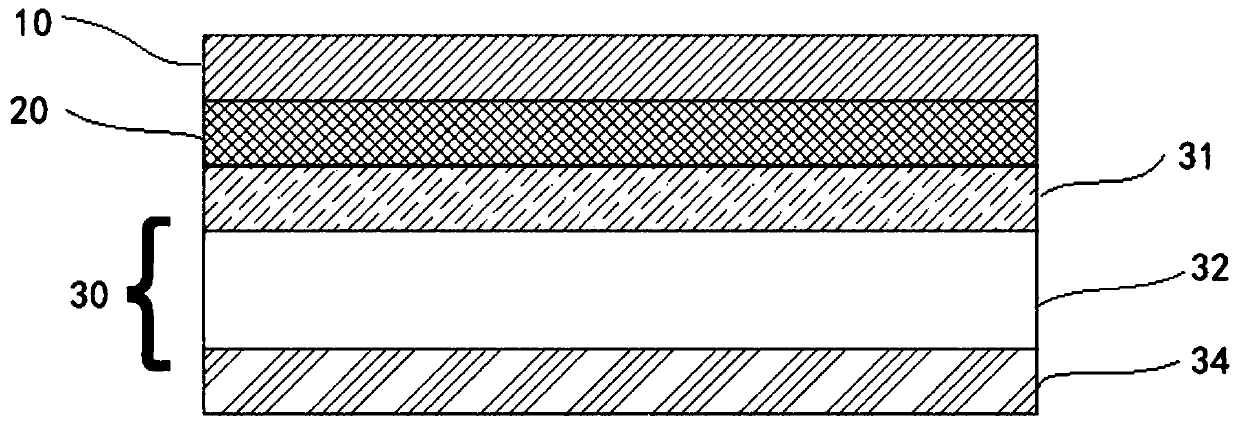

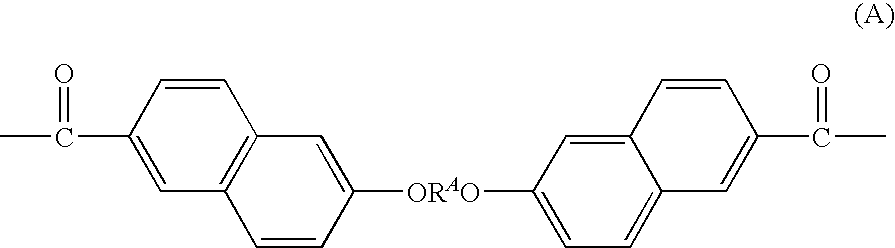

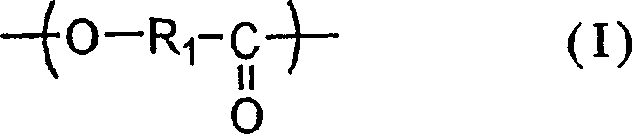

Biaxially oriented laminated film

ActiveUS20100190037A1Good dimensional stabilityFew voidMagnetic materials for record carriersBase layers for recording layersBoPETSurface roughness

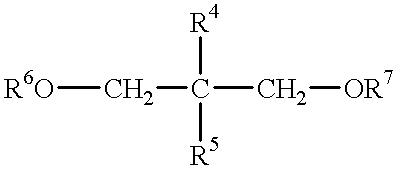

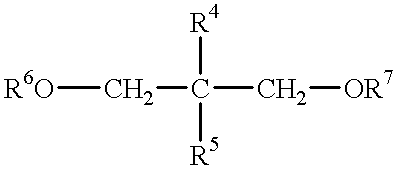

It is an object of the present invention to provide a biaxially oriented laminated polyester film which has excellent dimensional stability to environmental changes such as temperature and humidity variations and excellent flatness and windability.The present invention is a biaxially oriented laminated polyester film comprising a film layer B on one side of a film layer A and having a surface roughness (RaB) on the film layer B side which is 1.0 nm or more larger than the surface roughness (RaA) on the film layer A side, whereinat least one of the film layers comprises an aromatic polyester (I) composed of a glycol component and a dicarboxylic acid component containing 5 mol % or more and less than 80 mol % of a recurring unit represented by the following formula (A):wherein RA is an alkylene group having 1 to 10 carbon atoms.

Owner:TEIJIN LTD

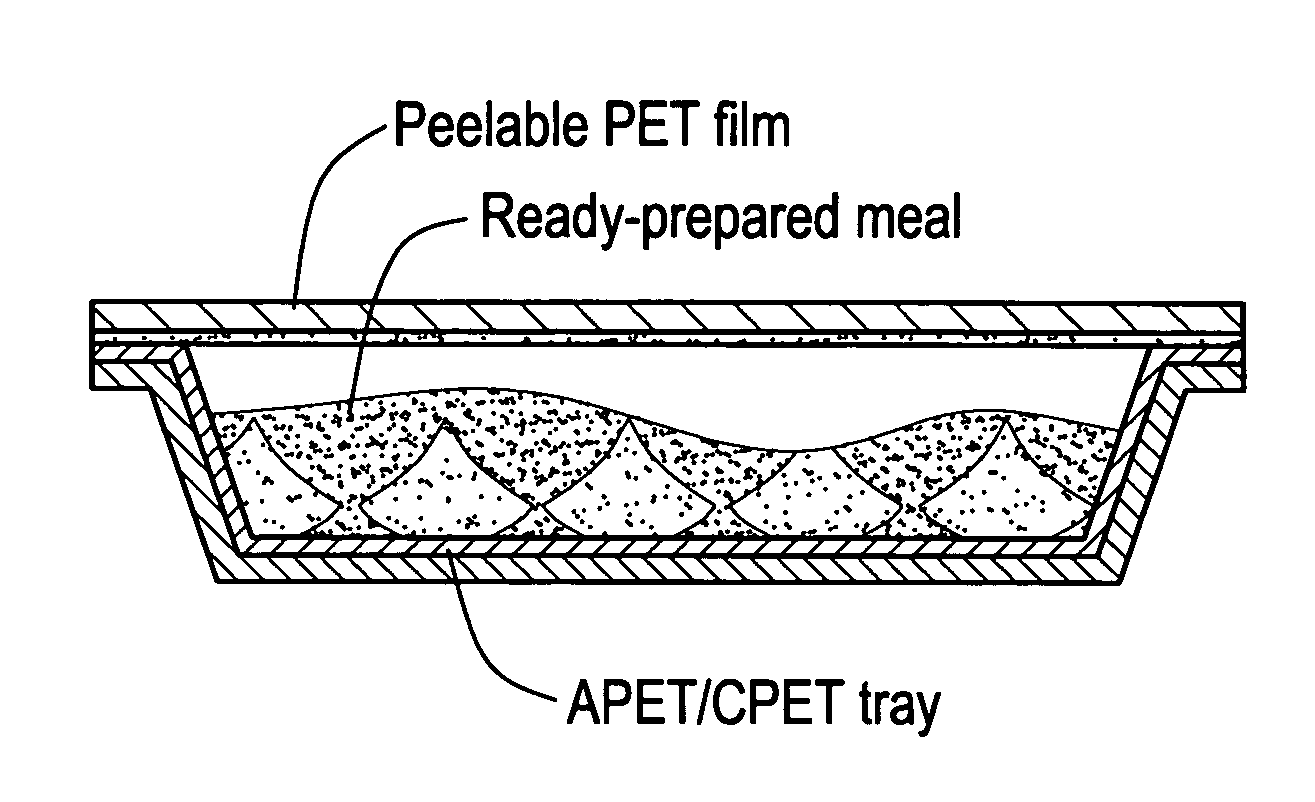

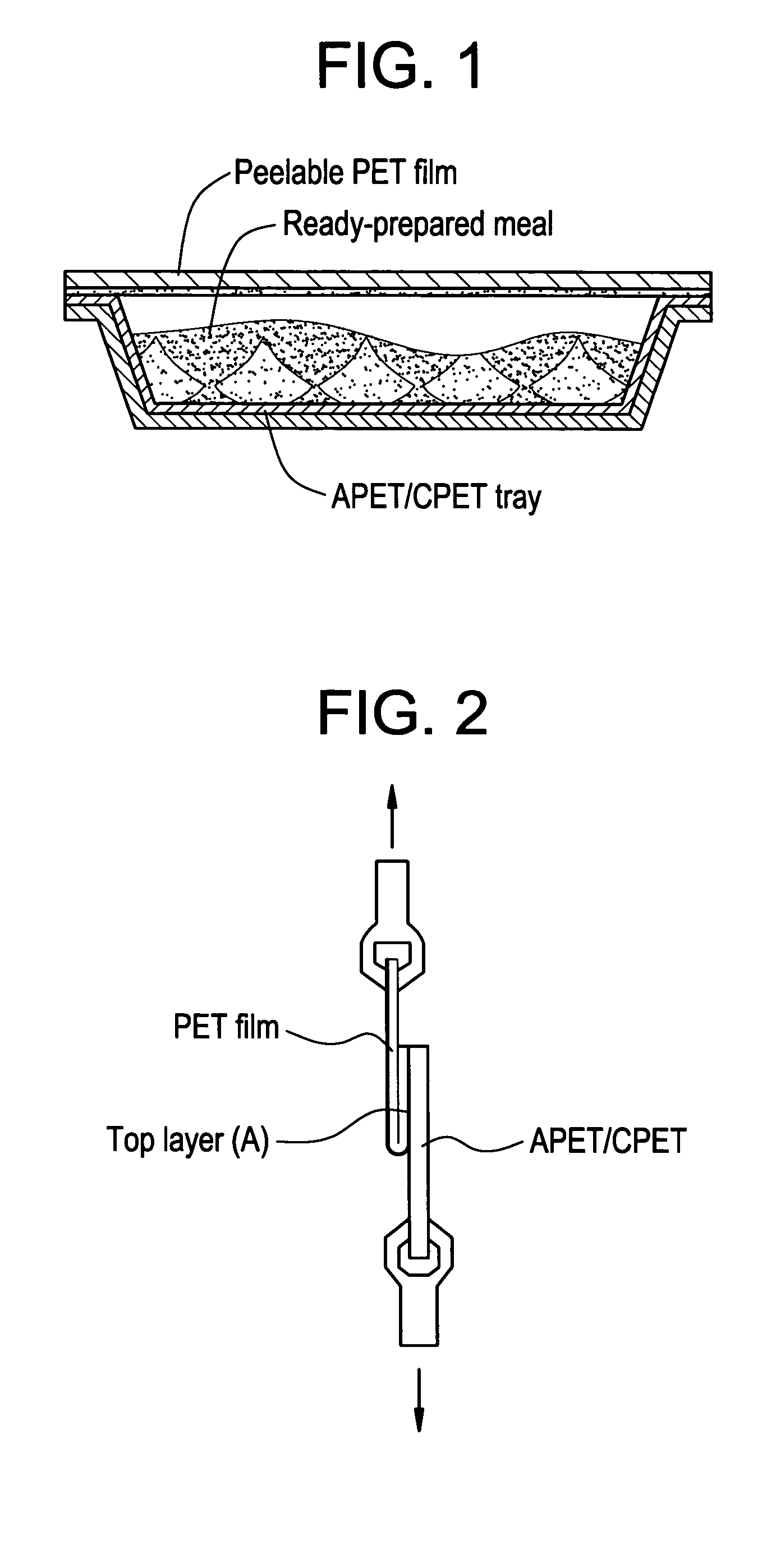

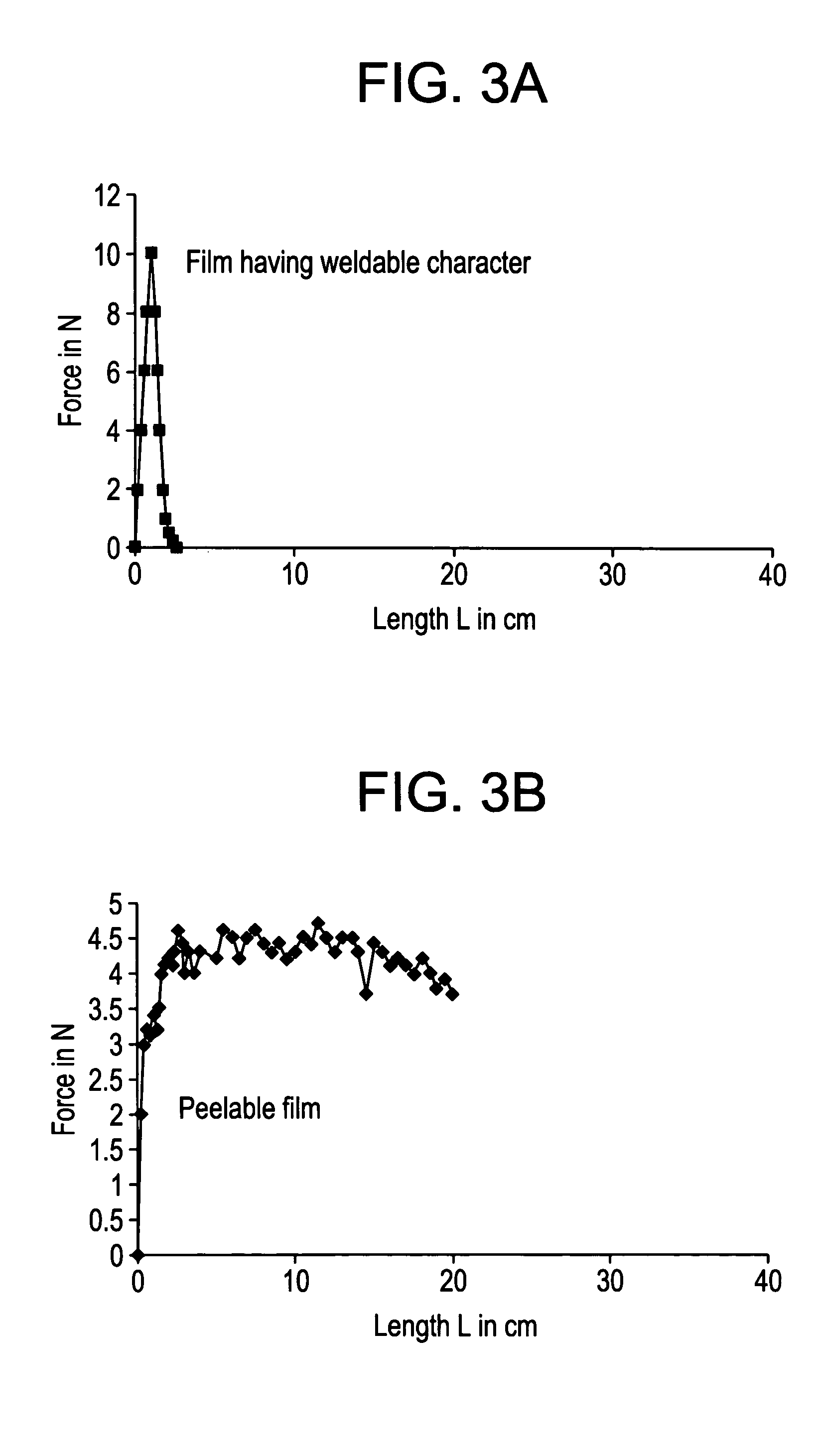

Coextruded, hot-sealable and peelable polyester film having high peeling resistance, process for its production and its use

This invention relates to a coextruded, transparent, biaxially oriented polyester film comprising a base layer (B) and a heatsealable top layer (A) which is peelable from at least the APET side of an APET / CPET tray, the heatsealable and peelable top layer (A) consisting ofa) 50–95% by weight of polyester andb) 5–40% by weight of a polyester-incompatible polymer (=anti-PET polymer)based on the mass of the top layer (A), whereinc) the polyester is composed of 20–95 mol % of units derived from at least one aromatic dicarboxylic acid and 5–80 mol % of units derived from at least one aliphatic dicarboxylic acid, andd) the layer thickness dA is from 1.3 to 3.0 μm.The invention further relates to a process for producing the film and to its use.

Owner:MITSUBISHI POLYESTER FILM

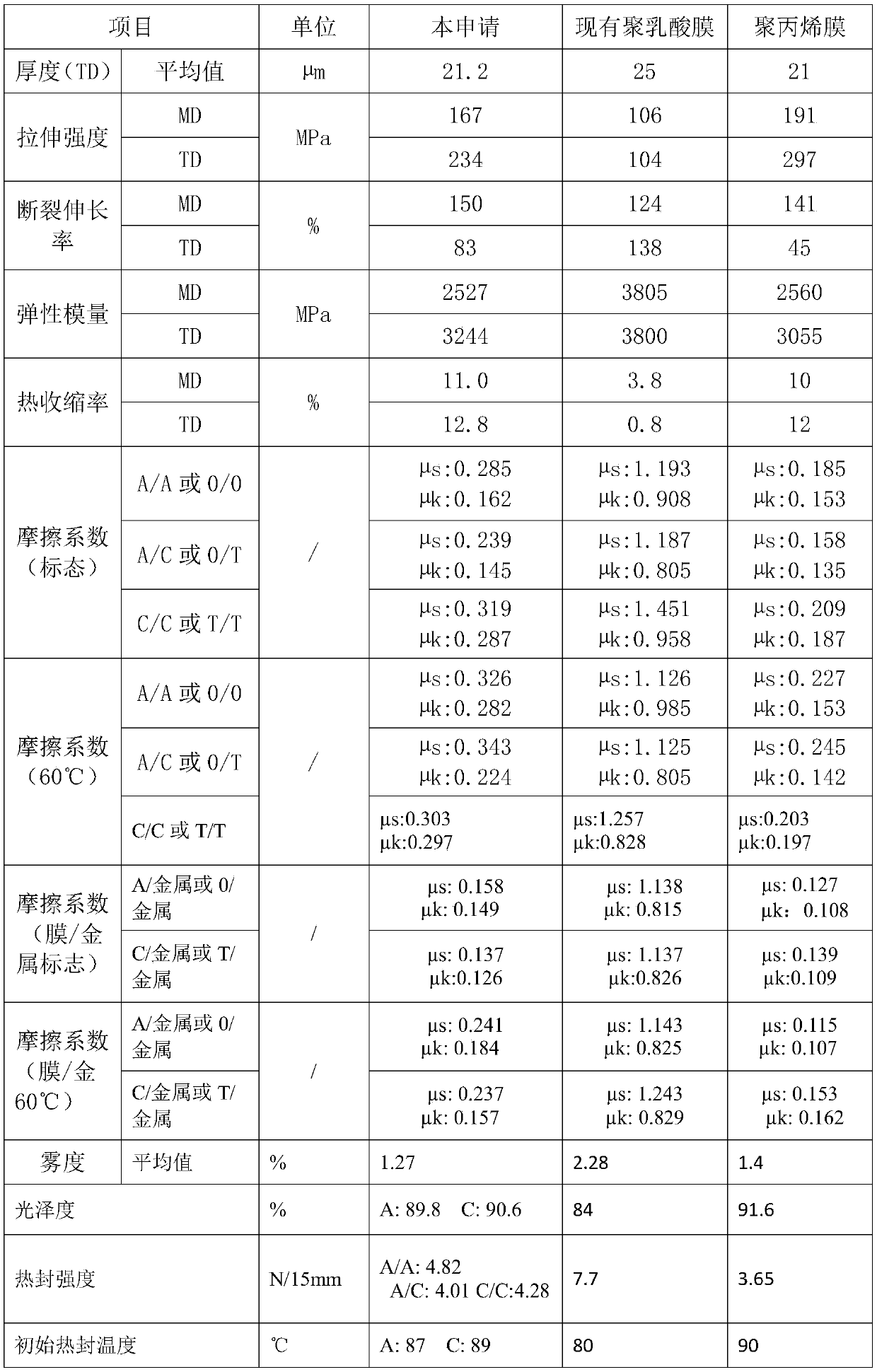

Degradable biaxially-oriented polylactic acid cigarette film and preparation method thereof

ActiveCN110774714AReduce coefficient of frictionReduce the possibility of static electricityFlexible coversWrappersPolymer scienceBoPET

The invention relates to the technical field of polylactic acid films, especially to a degradable biaxially-oriented polylactic acid cigarette film and a preparation method thereof. The invention overcomes the problems that an existing polypropylene cigarette film is non-degradable and an existing degradable polylactic acid film is difficult to be applied to cigarette films. According to a technical scheme, the degradable biaxially-oriented polylactic acid cigarette film is composed of a layer A, a layer B and a layer C which are co-extruded and stretched. The layer A comprises, by mass, 80%-90% of heat-seal I-type PLA, 8%-15% of a slipping agent and 2%-5% of an anti-blocking agent, wherein the heat-seal I-type PLA is composed of 70%-80% of crystalline PLA and 20%-30% of non-crystalline PLA. The layer B comprises 90-95% of crystalline PLA, 1-5% of an antistatic agent, 1-2% of a stiffening agent and 1-5% of a toughening agent. The layer C comprises 94-97% of heat-seal II-type PLA, 2-3%of a slipping agent and 1-3% of an anti-blocking agent, wherein the heat-seal II-type PLA is composed of 75-85% of crystalline PLA and 15-25% of non-crystalline PLA. The preparation method comprises the following steps: drying the above components according to the use amounts, carrying out melt extrusion, performing biaxially stretching, carrying out corona treatment, and then successively conducting rolling, aging, and slitting.

Owner:JIANGYIN ZHONGDA FLEXIBLE PLASTIC NEW MATERIALS CO LTD

White, sealable, flame-retardant, biaxially oriented polyester film, its use and process for its production

The invention relates to a white, sealable, flame-retardant coextruded, biaxially oriented polyester film composed of at least one base layer B and of outer layers A and B applied to the two sides of this base layer. The film also comprises at least one flame retardant and one white pigment. The invention also includes the use of the film and a process for its production.

Owner:MITSUBISHI POLYESTER FILM

Method for manufacturing porous multilayer composite diaphragm for lithium battery and diaphragm

The invention discloses a method for manufacturing a porous multilayer composite diaphragm for a lithium battery and a diaphragm manufactured by the same. In the method, polyethylene mixed with solvent and heat-resistant resin mixed with the solvent are extruded by using a multilayer die head of a double-screw extruder, and the extruded products are subjected to chill casting, two-way stretch, washing, drying and heat setting to manufacture the porous multilayer composite diaphragm. An integral structure of the manufactured diaphragm comprises a polyethylene layer and a heat-resistant resin layer, has low closed-cell temperature given by the polyethylene and high diaphragm breaking temperature given by the heat-resistant resin layer simultaneously. Simultaneously, the addition of the heat-resistant resin layer reduces the heat contractibility of the multilayer diaphragm and improves the puncture strength of the multilayer diaphragm, so the multilayer diaphragm has more excellent performance.

Owner:FOSHAN JINHUI HIGH TECH OPTOELECTRONICS MATERIAL

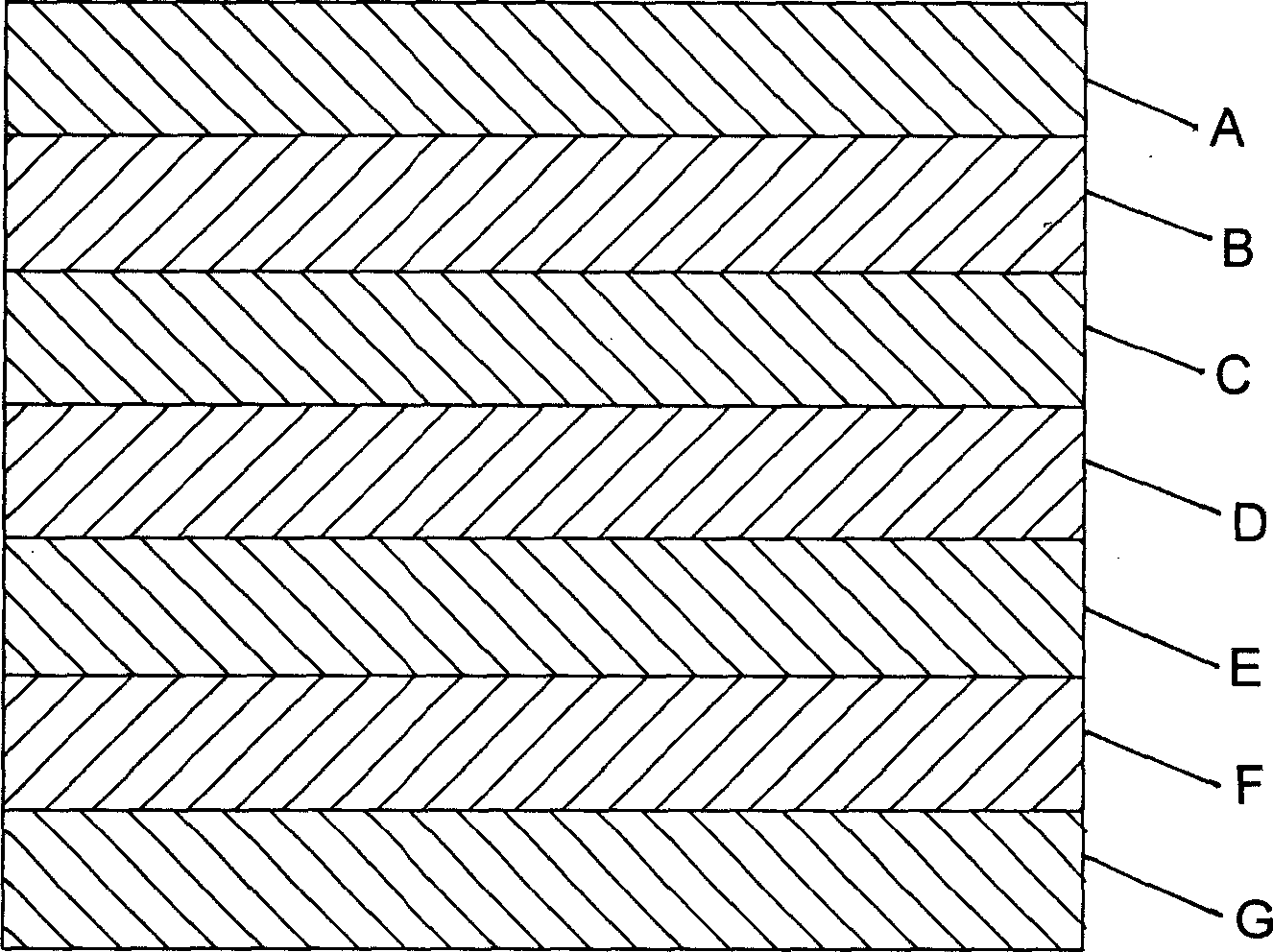

Five layer co-extruding biaxial stretched synthetic PP paper and its prepn process

InactiveCN1846984ALow densityImprove stiffnessSynthetic resin layered productsHigh stiffnessComposite film

The present invention relates to five layer co-extruded biaxial stretched synthetic PP paper and features the five layer co-extruded superposed composite film structure comprising the first or upper layer of high bright resin or white extinction material, the second layer of organic foamed material, the third layer of inorganic foamed material, the fourth layer of organic foamed material and the fifth layer of high bright resin. The preparation process includes separately extruding the fiver layers of material, and superposing with the same mold head to form the five layer composite film structure. The five layer co-extruded biaxial stretched synthetic PP paper features low density, high stiffness, fine and smooth surface, high whiteness, high surface tension maintenance, etc.

Owner:申达集团有限公司 +1

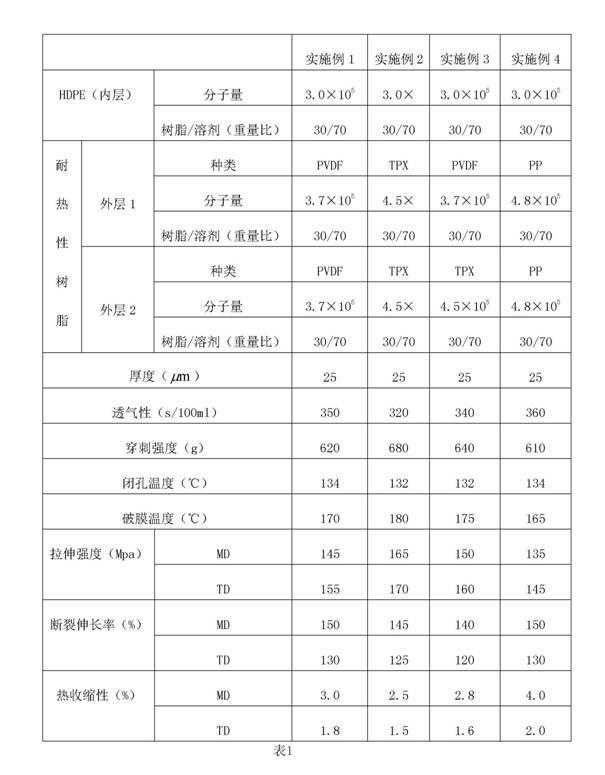

Laminated film and method for producing same

InactiveCN1735508AExcellent dielectric propertiesSynthetic resin layered productsNetwork structureComposite material

A laminated film which is excellent in thermal dimensional stability, cushion properties and low dielectric characteristics is disclosed. The laminated film comprises at least two layers among which at least one layer is a biaxially oriented film composed of a thermoplastic resin composition and at least one other layer is a film having a network structure.

Owner:TORAY IND INC

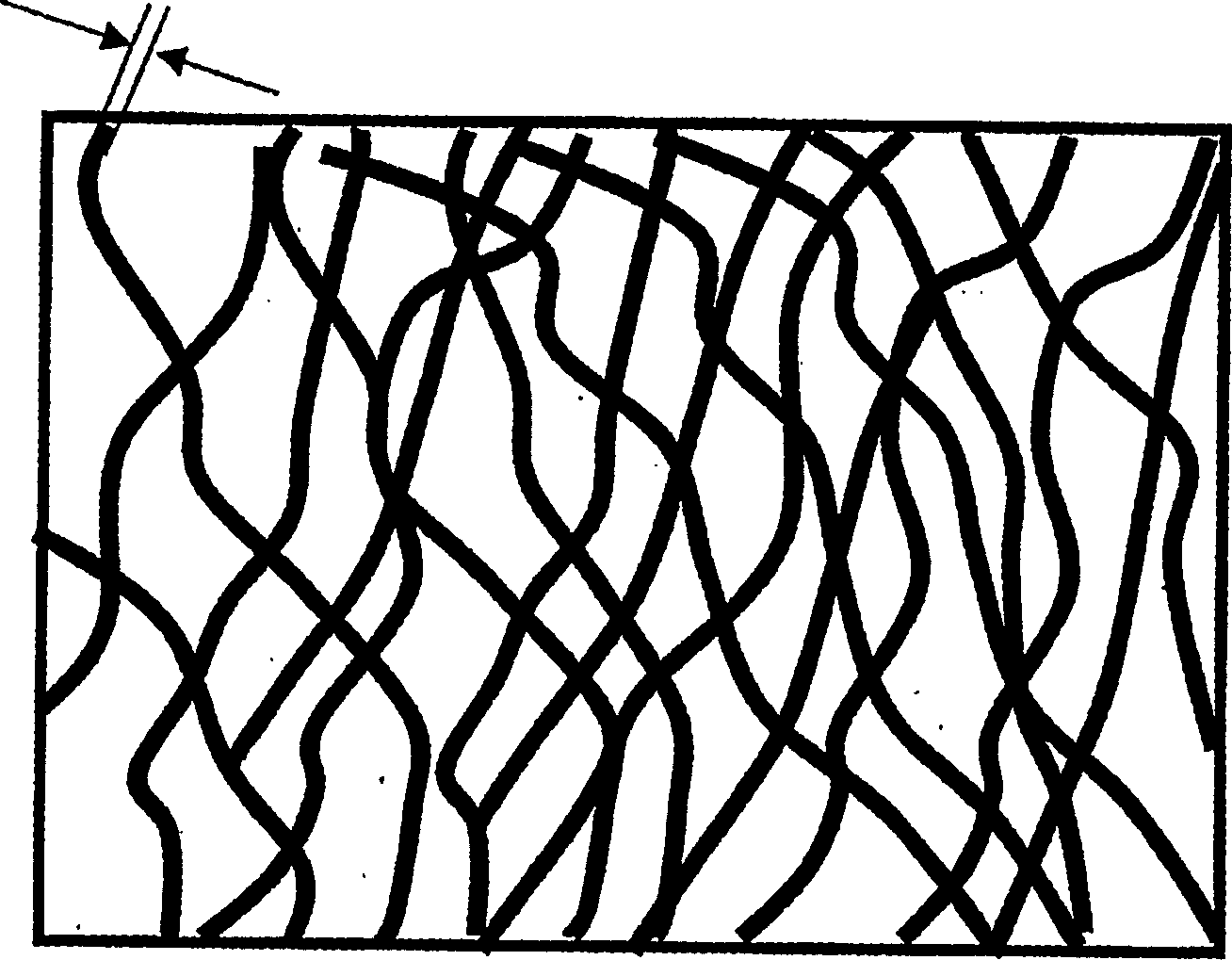

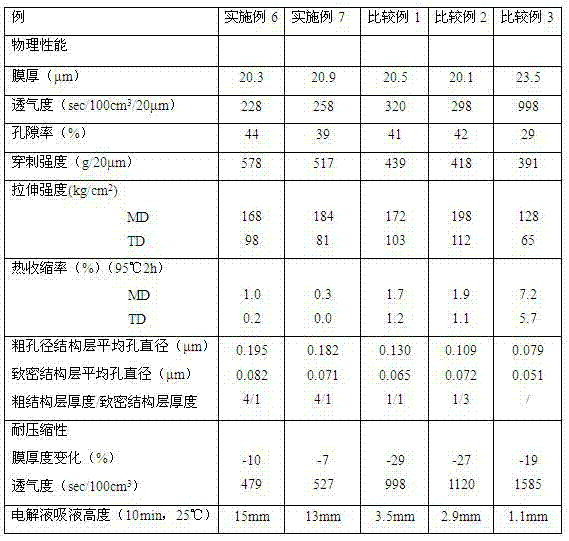

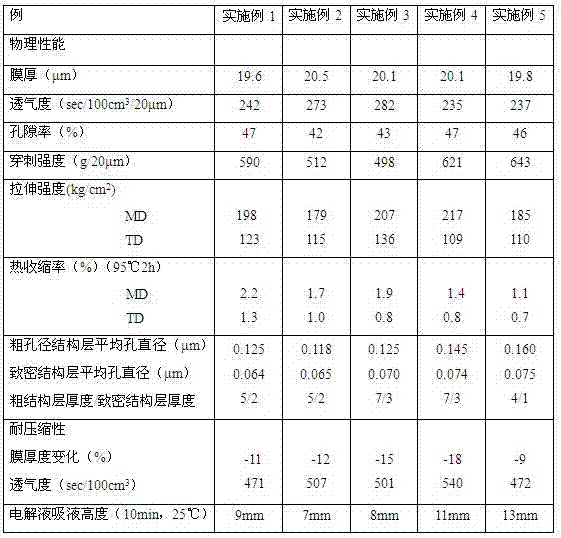

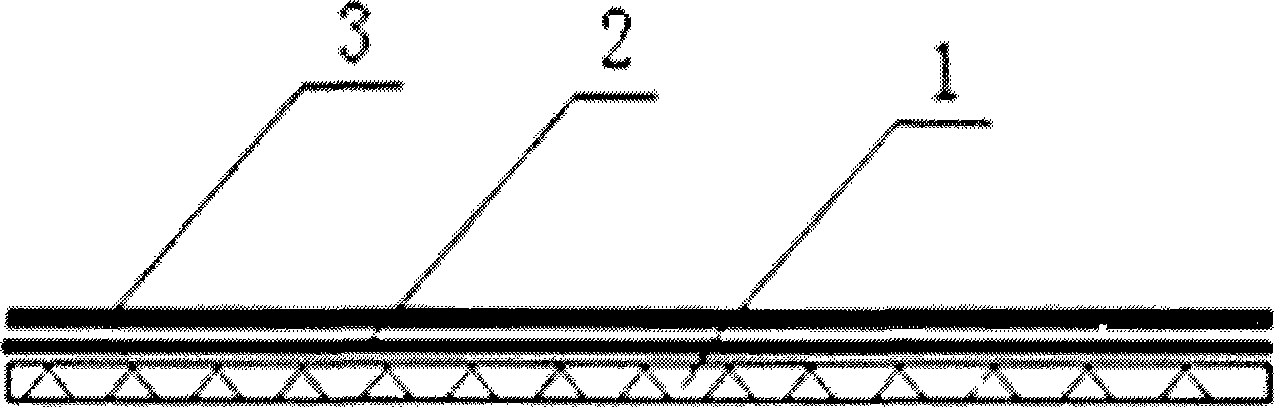

Method for preparing polyolefin micro-porous film

InactiveCN102774009ALarge apertureImprove puncture strengthFlat articlesElectrolytic agentPolymer science

The invention discloses a method for preparing polyolefin micro-porous film. The method includes fusing and mixing a polyolefin resin and a film forming solvent in an extruder to prepare a polyolefin homogeneous melt; extruding the polyolefin homogeneous melt from a flat film die to form a molded melt, imposing various temperature fields on the surface of the molded melt for cooling, and imposing a shear force in the thickness direction during the cooling to form sheets; preheating the sheets, and performing longitudinal or bidirectional drawing on the sheets to form micro fibrillated film; extracting the film forming solvent in the micro fibrillated film with an extraction solvent, and drying the film forming solvent to form micro-porous film; preheating the micro-porous film, and subjecting the micro-porous film to secondary drawing and heat shaping. According to the method for preparing polyolefin micro-porous film, the pore diameter of the micro-porous film changes in the film thickness direction, and a compact structure layer and a coarse pore diameter structure layer are provided. The micro-porous film has the advantages of being rapid in electrolyte absorption, high in puncture strength, small in air permeability change and the like, and can meet the use requirements of lithium ion battery diaphragms.

Owner:CHONGQING YUNTIANHUA NEWMI-TECH CO LTD

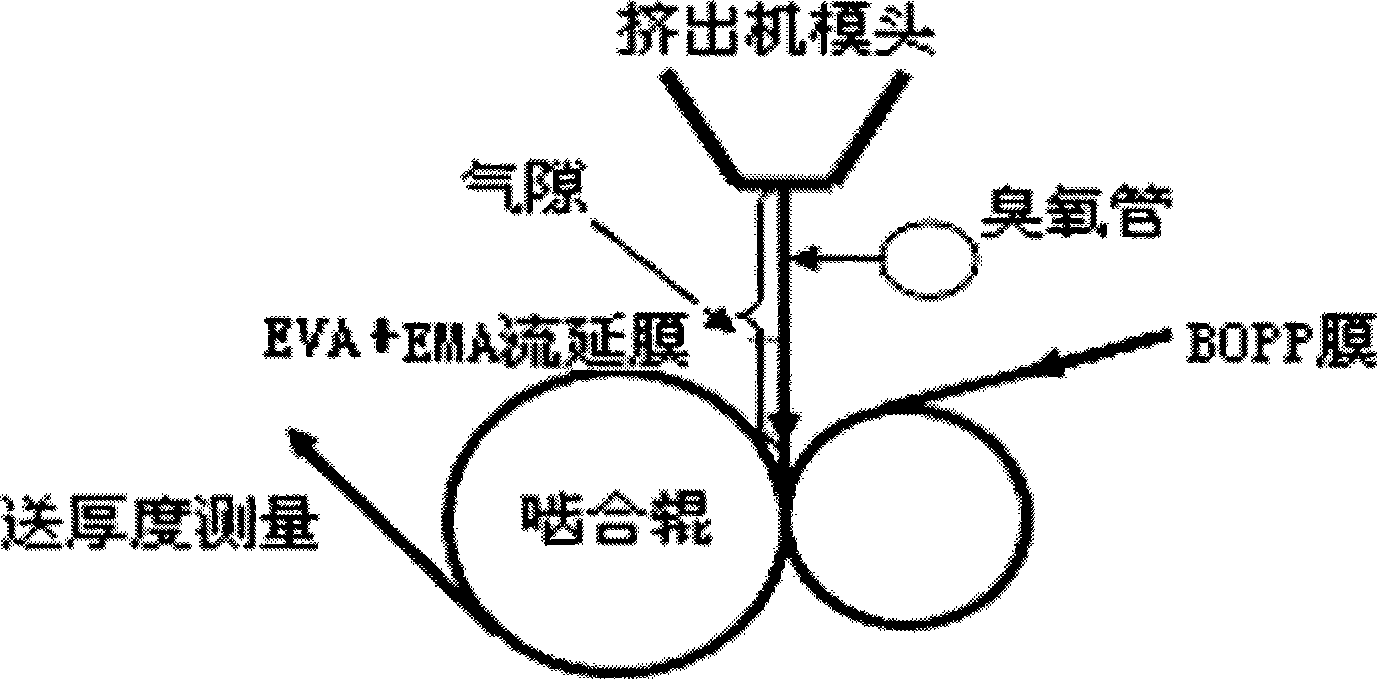

Metallization biaxial stretching polyester (BOPET) pre-coating film using chemical treatment

ActiveCN101396892AImprove barrier propertiesIncrease brightnessLamination ancillary operationsSynthetic resin layered productsChemical treatmentCompound (substance)

The invention relates to a chemical treated metalizing BOPET precoating film and a processing technique. The precoating film comprises a substrate, an intermediate layer and a hot cement layer, and is characterized in that the substrate is a chemical treated metalizing BOPET, the intermediate layer is PEI and the hot cement layer is EVA. The intermediate layer and the hot cement layer are coated and compounded on one surface of the substrate, thus obtaining the chemical treated metalizing BOPET precoating film. As the substrate layer of the precoating film adopts the chemical treated metalizing BOPET, after the presswork is laminated during the application process of the metalizing BOPET, various printings can be carried out on the chemical layer of the surface of the substrate, and otherprecoating films can not be applied in the way like the metalizing BOPET; in addition, being metalized, the substrate has good blocking performance and lightproof; meanwhile, the precoating film alsohas the advantages of high brightness and high tensile strength that the common BOPET precoating film can not compare with.

Owner:KANGDE XIN COMPOSITE MATERIAL CO LTD

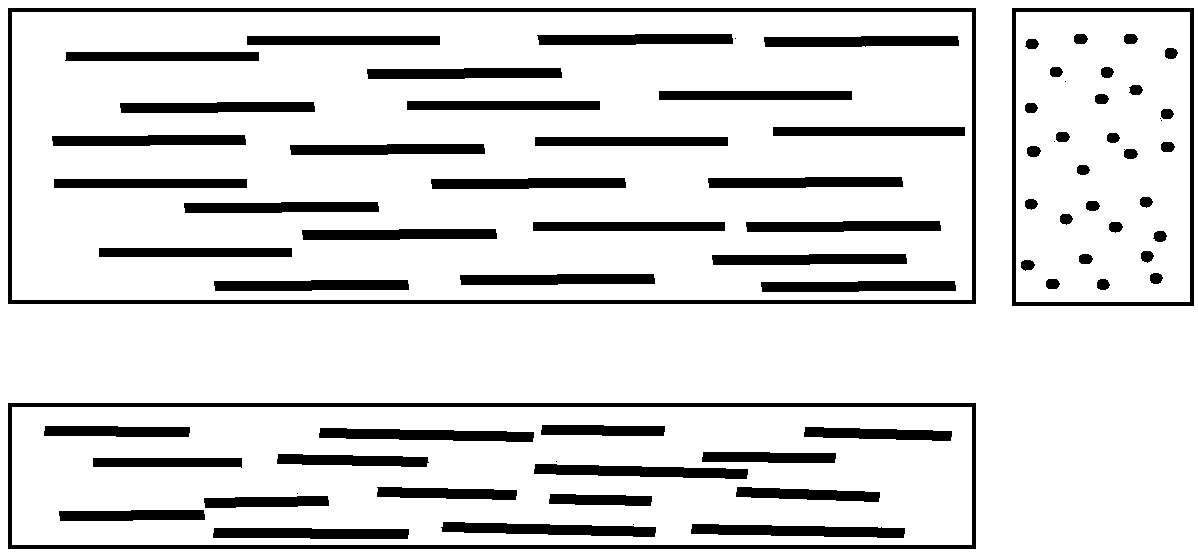

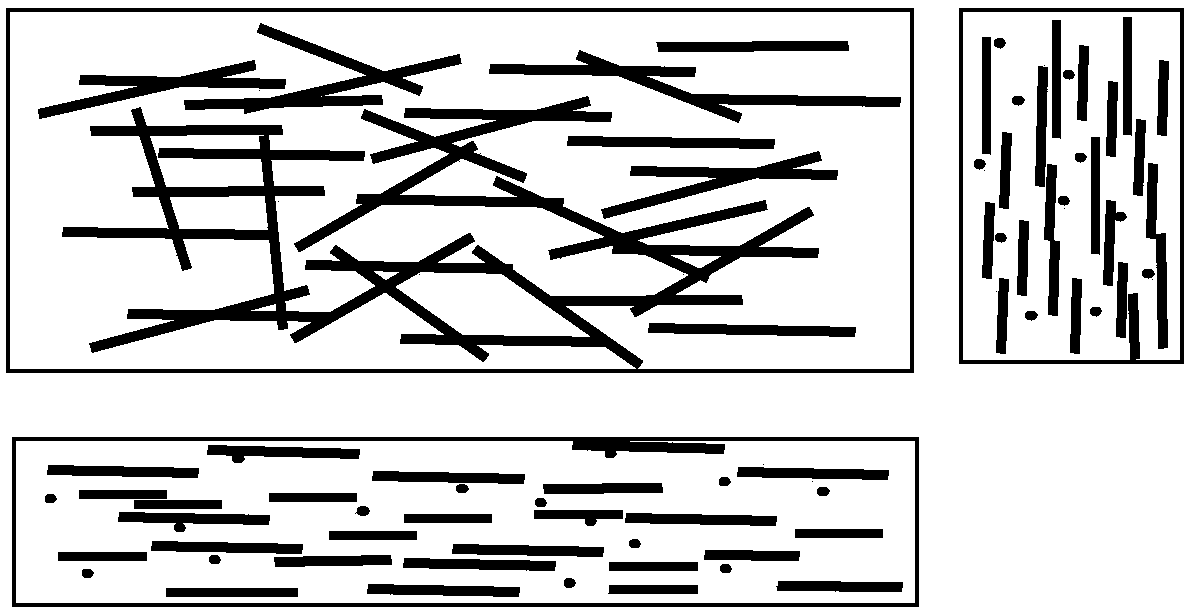

Multifunctional composite material and preparation method thereof

The invention discloses a multifunctional composite material and a preparation method thereof. The composite material is prepared from the following components: 30 to 70 mass parts of thermoplastic resin, 30 to 70 mass parts of heat-conducting or / and electricity-conducting filler, 0 to 20 mass parts of a processing auxiliary agent; the multifunctional composite material is prepared by preparing aparison through an extruding casting or solution casting method, and then performing unidirectional drawing or bidirectional drawing; the multifunctional composite material is characterized in that the filler with an asymmetrical structure forms an orientation structure in a resin matrix, so that different heat conductivity or / and electricity conductivity in different directions of the composite material are ensured. The heat-conducting or / and electricity-conducting functional composite material disclosed by the invention has high heat conductivity or / and electricity conductivity, and can be used in other application fields of electronic and electric products, heat management and the like with a directional requirement on the heat conductivity or / and the electricity conductivity.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com