Metallization biaxial stretching polyester (BOPET) pre-coating film using chemical treatment

A biaxially oriented polyester, chemical treatment technology, applied in metal layered products, chemical instruments and methods, coatings, etc., can solve fire hazards, reduce lamination yield, affect print finish, clarity and color Brightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: Taking a chemically treated metallized biaxially oriented polyester (BOPET) precoat film with a width of 1425 mm as an example, it will be described in detail.

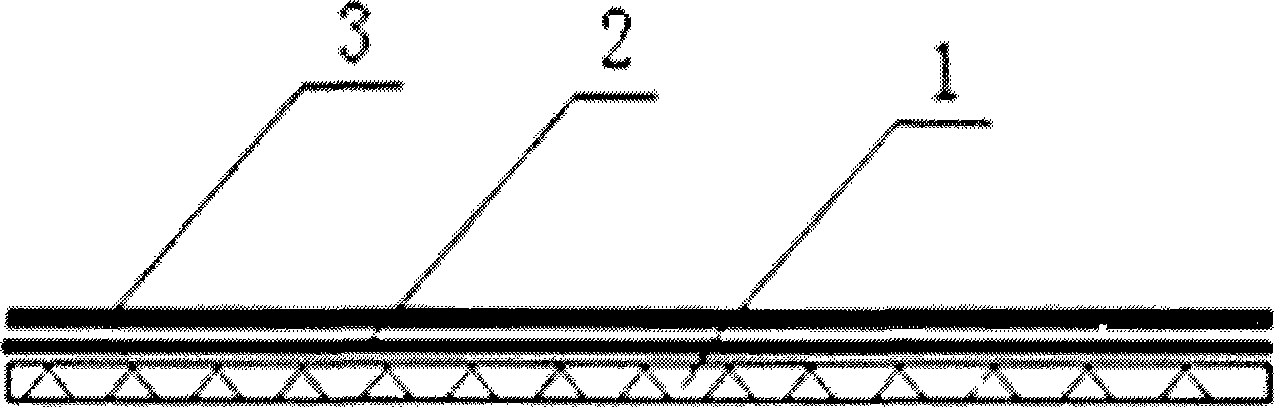

[0049] see first figure 1 . Chemically treated metallized biaxially oriented polyester (BOPET) pre-coated film, consisting of a base material 1, an intermediate layer 2 and a hot melt adhesive layer 3. The substrate 1, the middle layer 2 and the hot melt adhesive layer 3 have the same width.

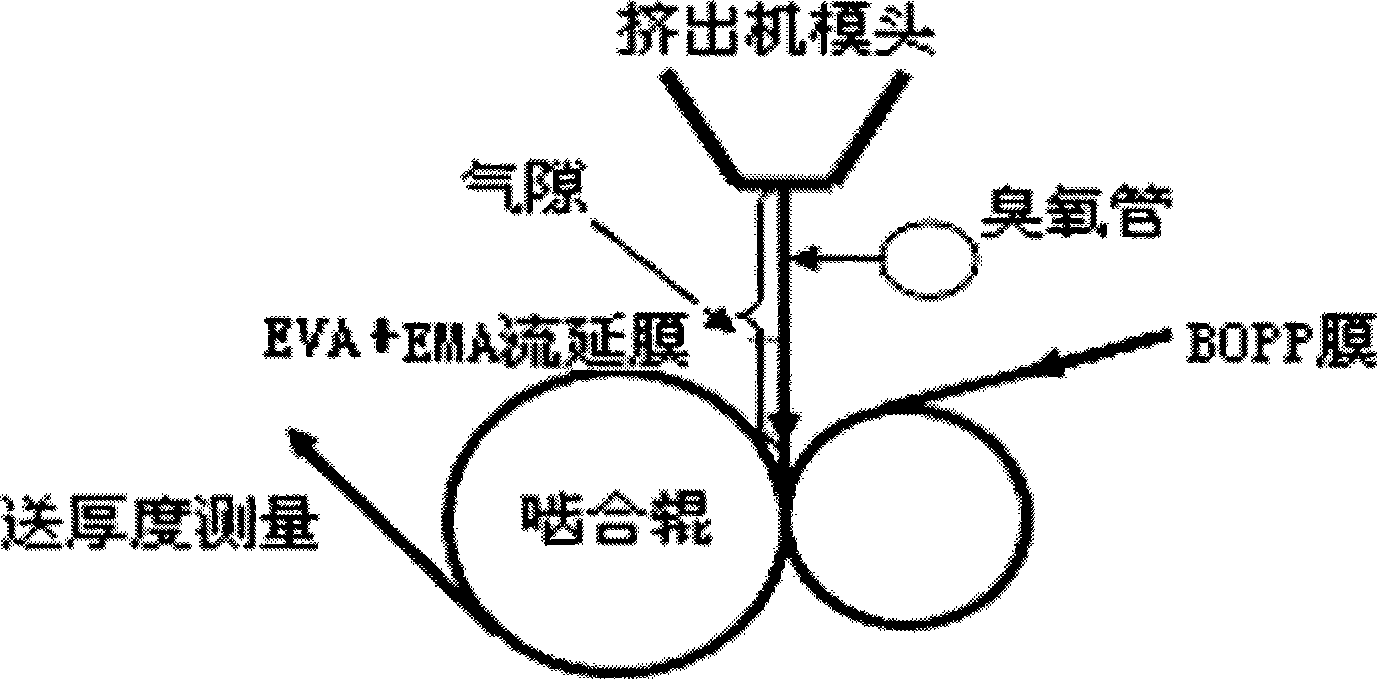

[0050] Chemical treatment metallized biaxially oriented polyester (BOPET) pre-coating film processing method:

[0051] 1. Preparation of materials for middle layer 2 and hot melt adhesive layer 3

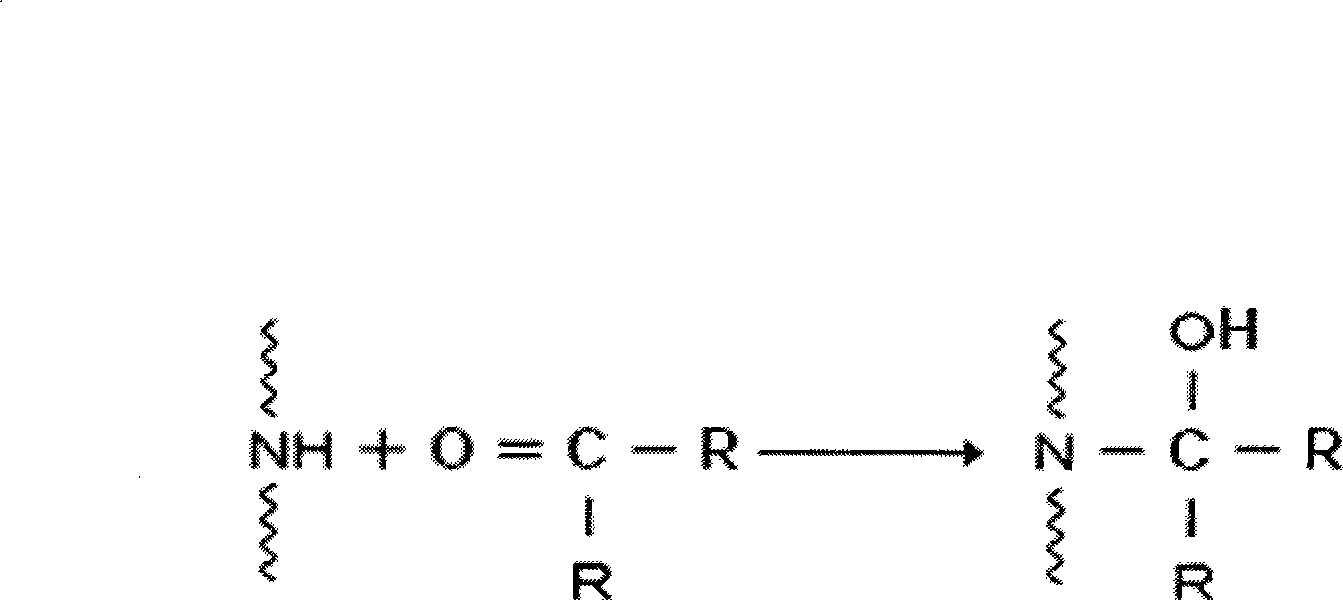

[0052] Preparation of materials for the middle layer 2: Prepare a polyethyleneimine (PEI) aqueous solution with a solid content of 5% in a container to form a polyethyleneimine (PEI) aqueous solution with a solid content of 0.95%, and then add alcohol (analytical pure) , The weight ratio of 0.95% polyethylenei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com