Packaging film for two-way stretch polypropylene low temperature self-constriction cigarette and production method thereof

A biaxial stretching and packaging film technology, applied in the field of packaging materials, can solve the problems of obvious wrinkles, scratches on the film surface, damage to the smoothness of the film, etc., and achieve the effect of high shrinkage rate and body-fitting packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

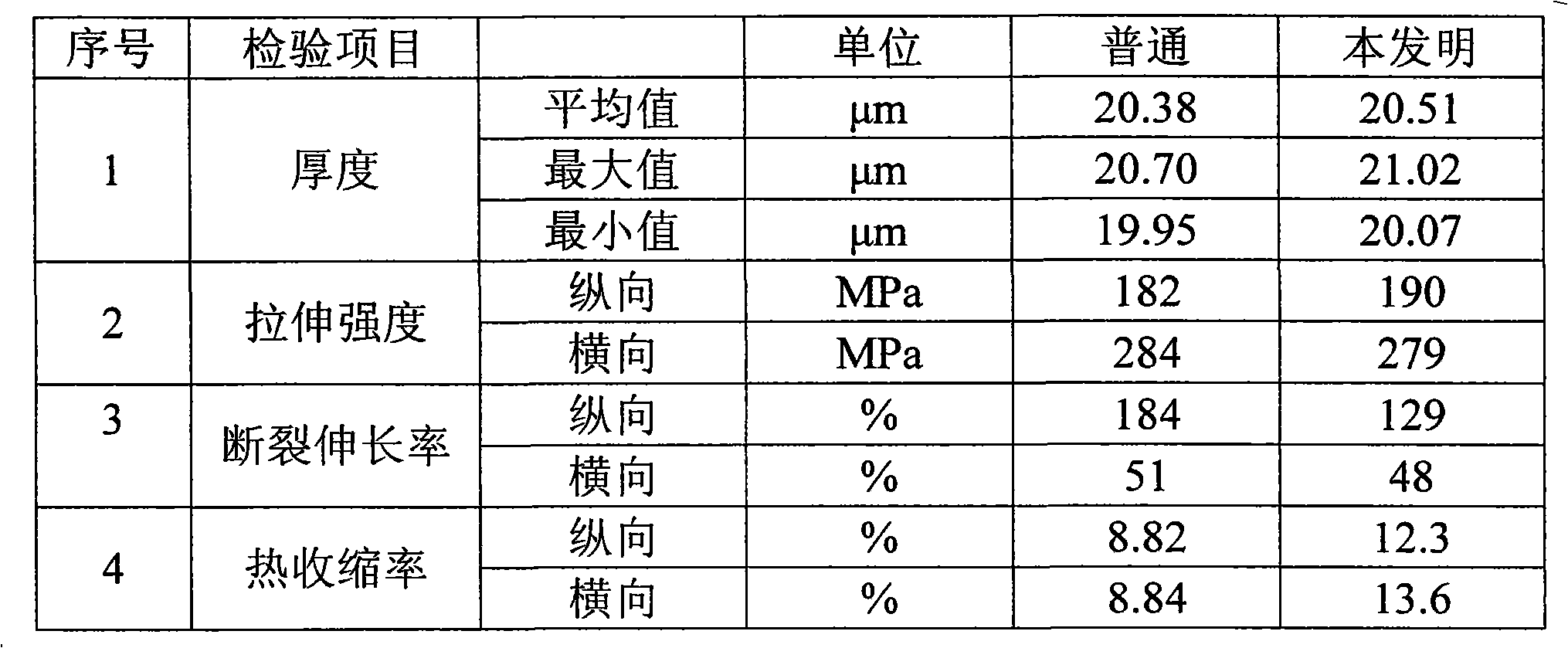

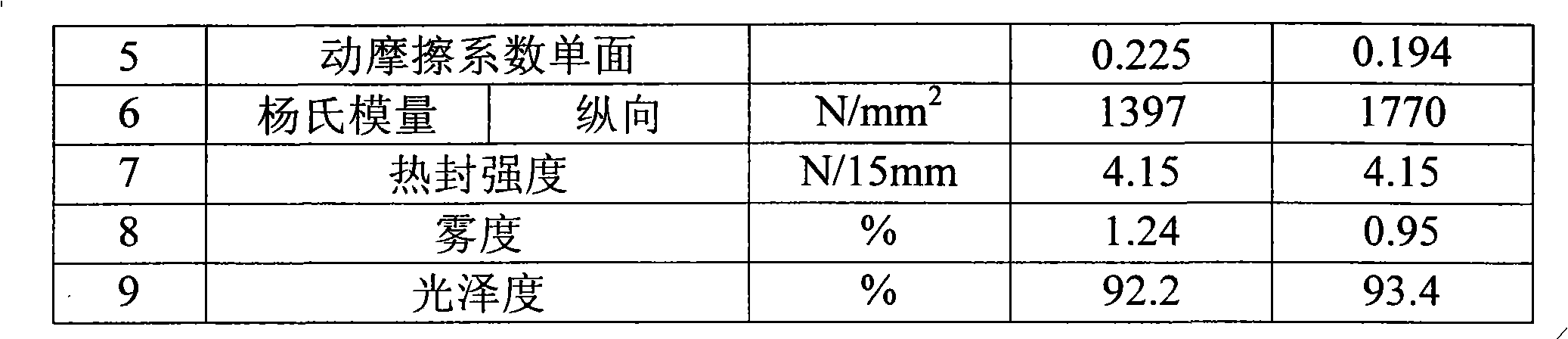

[0027] The raw materials in this example are, the selected raw materials of surface layer A and their weight contents are: 84% of ternary copolymerized polypropylene, 9% of smooth masterbatch, and 7% of anti-blocking masterbatch; the selected raw materials of core layer B and their weight contents It is: 68% homopolypropylene, 28% stiffening masterbatch, 4% antistatic masterbatch; the selected raw materials and their weight content for the surface layer C: 94% ternary copolymerized polypropylene, 3% smooth masterbatch, antistatic Block masterbatch 3%.

[0028] Accurately weigh the polypropylene raw material and masterbatch according to the ratio, put them into the mixer and mix them for 30 minutes, then send them to the feeding bin, and send them to the extruder respectively through the pipeline to pass through the three-layer co-extrusion die head of the extruder to make a thick sheet. The cold roll and cooling water are cooled and sent to the longitudinal stretching machine;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com