Method for cladding and molding mobile internet device antenna by employing out-mold decoration

A technology of mobile Internet and high-voltage transfer printing, which is applied to the antenna support/installation device, the structural form of the radiating unit, the structural form of the radiating element, etc., and can solve problems such as warping and uneven joints, insufficient bonding force, and holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

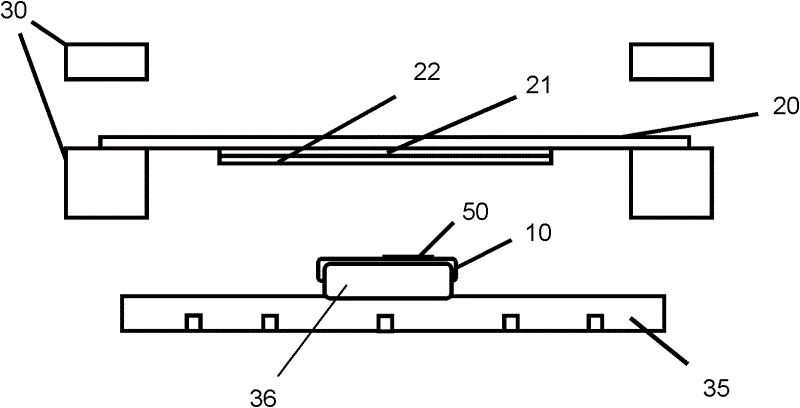

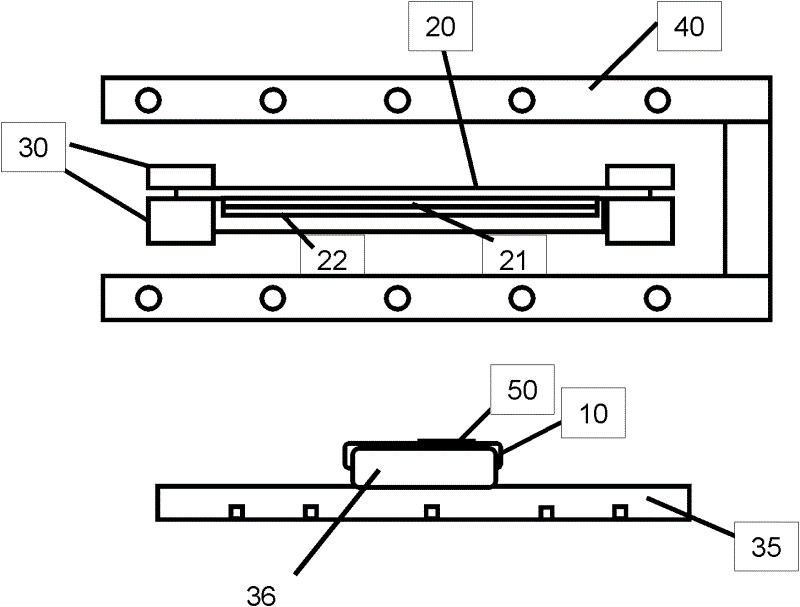

[0033] Take a MID substrate 10 and a film 20 (preferably a plastic film); wherein the MID substrate 10 is generally a plastic injection part, and a metal layer 50 has been formed thereon, and the metal layer 50 is an antenna circuit; The film 20 can be plain, or printed with a pattern 21 and coated with an adhesive material 22 . The film 20 is clamped on a holder 30, and the MID substrate 10 is placed on a positioning support jig 36, and the positioning support jig 36 is installed on a base 35 ( figure 1 );

[0034] Then heat and soften the film 20 with the heater 40 ( figure 2 ).

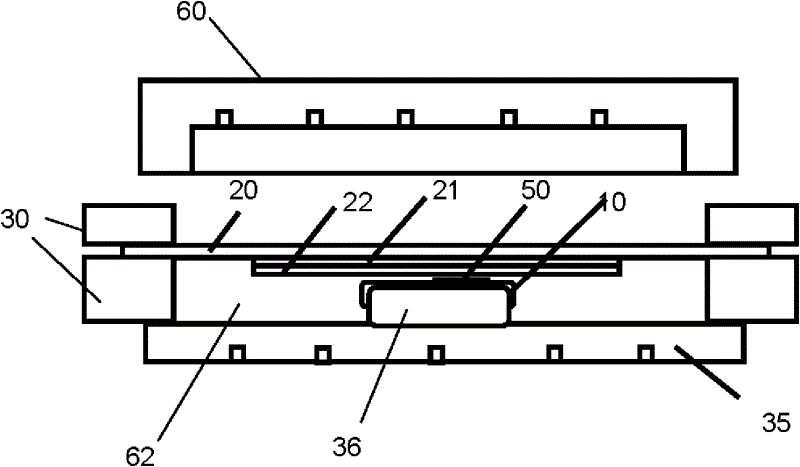

[0035] Then remove the heater 40, cover the holder 30 together with the film 20 on the top of the MID substrate 10, and after the holder 30 and the base 35 are closed, form a lower cavity 62 below the film 20 ( image 3 ).

[0036] First, the lower cavity 62 is evacuated, then an isolation cavity 60 and the holder 30 are closed, and an upper cavity 61 is formed above the film 20, and then high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com