Coated high-barrier biaxially stretched polylactic acid film and preparation method thereof

A biaxially stretched, high-barrier technology, applied in chemical instruments and methods, coatings, flat products, etc., can solve the problems of pinhole defects on the film surface, decrease in film softness, and affect film barrier properties, etc., and achieve simple process , Water resistance improvement, the effect of improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

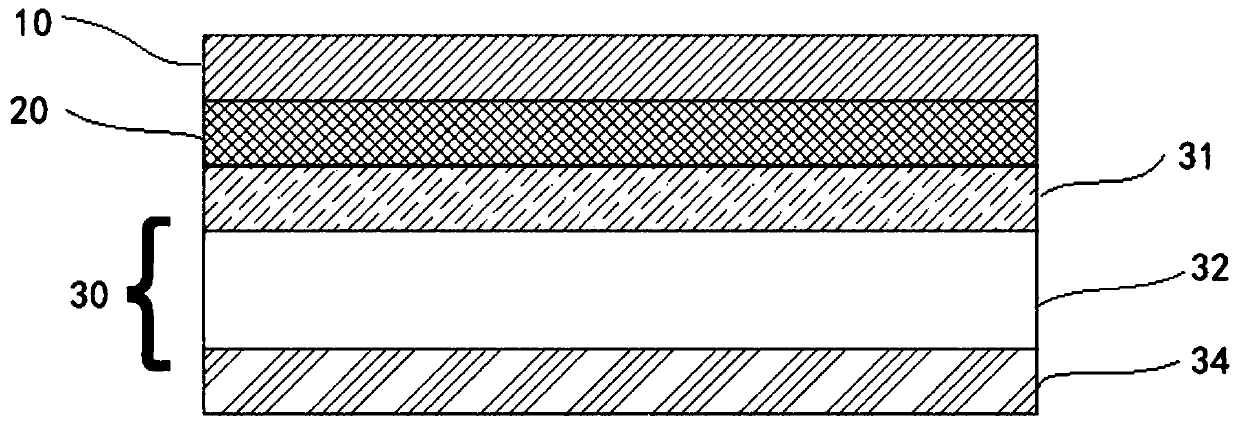

[0048] A coating-type high-barrier biaxially oriented polylactic acid film preparation method, the total film thickness is 19 μm; the film thickness of the high-barrier coating is 2 μm, the film thickness of the primer layer is 2 μm, the film thickness of A layer is 3 μm, the film thickness of B layer is 9 μm, and the film thickness of C layer The film thickness is 3 μm.

[0049] Its preparation steps are as follows:

[0050] Step a, preparing the substrate layer:

[0051] Step a1, blending PLA, toughening agent, compatibilizer, chain extender, antioxidant, antistatic agent, antiblocking agent, smooth agent in proportion, melt blending, extruding through twin-screw extruder, Granulating, drying the masterbatch obtained, for subsequent use;

[0052] Step a2, blending PLA, toughening resin, compatibilizer, and chain extender in proportion, melt blending, extruding, and granulating through a twin-screw extruder, and drying the obtained masterbatch for subsequent use;

[0053] St...

Embodiment 2

[0066] A coating-type high-barrier biaxially oriented polylactic acid film preparation method, with a total film thickness of 18 μm; a high-barrier coating film thickness of 1.5 μm, an undercoat film thickness of 1.5 μm, a layer A film thickness of 3 μm, and a B layer film thickness of 9 μm. The film thickness of layer C is 3 μm.

[0067] Its preparation steps are identical with embodiment 1.

[0068] In step a1, the material ratio is: 85 parts of PLA, 10 parts of toughening agent, 2 parts of compatibilizer, 1 part of chain extender, 0.5 part of antioxidant, 0.5 part of antistatic agent, 0.5 part of anti-blocking agent, 0.5 part of cooling agent lubricant;

[0069] In step a2, the material ratio is: 87 parts of PLA, 10 parts of toughening resin, 2 parts of compatibilizer, and 1 part of chain extender;

[0070] In step b, the mass ratio of PVA: acrylic emulsion: polyurethane emulsion is 5:4:1; the content of layered silicate is 0.1%-1%; the neutralization degree of NaOH is 10...

Embodiment 3

[0073] A coating-type high-barrier biaxially stretched polylactic acid film preparation method, with a total film thickness of 17 μm; a high-barrier coating film thickness of 1 μm, an undercoat film thickness of 1 μm, a layer A film thickness of 3 μm, a B layer film thickness of 9 μm, and a C layer The film thickness is 3 μm.

[0074] Its preparation steps are identical with embodiment 1.

[0075] In step a1, the material ratio is: 74 parts of PLA, 20 parts of toughening agent, 3 parts of compatibilizer, 1 part of chain extender, 0.5 part of antioxidant, 0.5 part of antistatic agent, 0.5 part of anti-blocking agent, 0.5 part of cooling agent lubricant;

[0076] In step a2, the material ratio is: 76 parts of PLA, 20 parts of toughening resin, 3 parts of compatibilizer, and 1 part of chain extender;

[0077] In step b, the mass ratio of PVA: acrylic emulsion: polyurethane emulsion is 5:4:1; the content of layered silicate is 0.1%-1%; the neutralization degree of NaOH is 10mol%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com