Patents

Literature

268results about How to "High barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for graphene oxide with high barrier property and polymer nanocomposite film

The invention provides a preparation method for graphene oxide with high barrier property and a polymer nanocomposite film. The preparation method comprises the following steps: graphene oxide is added in solvent for stirring to obtain a colloidal suspension of graphene oxide during the ultrasonic processing at the temperature of 20 to 45 DEG C; a polymer is added in the colloidal suspension of graphene oxide for stirring during the ultrasonic processing at the temperature of 20 to 120 DEG C, until the polymer is completely dissolved to obtain a solution of graphene oxide / polymer; and after air bubbles in the solution of graphene oxide / polymer are removed, the graphene oxide / polymer nanocomposite film is obtained by a casting method or blow molding method. The carbon dioxide transmission coefficient of the prepared nanocomposite film containing graphene oxide is reduced by more than 150 times, and the prepared nanocomposite film containing graphene oxide can be used for packaging food and drugs with higher requirements of barrier property.

Owner:XIAN UNIV OF TECH

Preparation method of edible film with antibacterial and antioxidant functions

InactiveCN103159970AHas antibacterial propertiesAntioxidantFlexible coversWrappersAntioxidantGlycerol

The invention relates to a preparation method of an edible film with antibacterial and antioxidant functions, and belongs to the technical field of edible packaging materials. The preparation method disclosed by the invention comprises the following steps: 1) dissolving and gelatinizing corn starch; 2) dissolving gelatin; 3) dissolving chitosan; 4) adding glycerin and plant essential oil or essential oil components; 5) mixing, homogenizing and refining; 6) degassing; 7) tape-casting; and 8) drying and stripping the film. The preparation method disclosed by the invention has the beneficial effects that the chitosan, the corn starch and the gelatin are taken as base materials of the edible film, the sources of the raw materials are wide, the cost is low, and the prepared edible film has the advantages of strong mechanical properties, high barrier performance and great transparency. Oregano oil, carvacrol and cinnamaldehyde are taken as an antibacterial agent and an antioxidant so as to be added into the edible film, the processing process is simple and easy to operate, the cost is low, the edible film is non-toxic and safe to eat, and the prepared edible film has great antibacterial and antioxidant properties.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

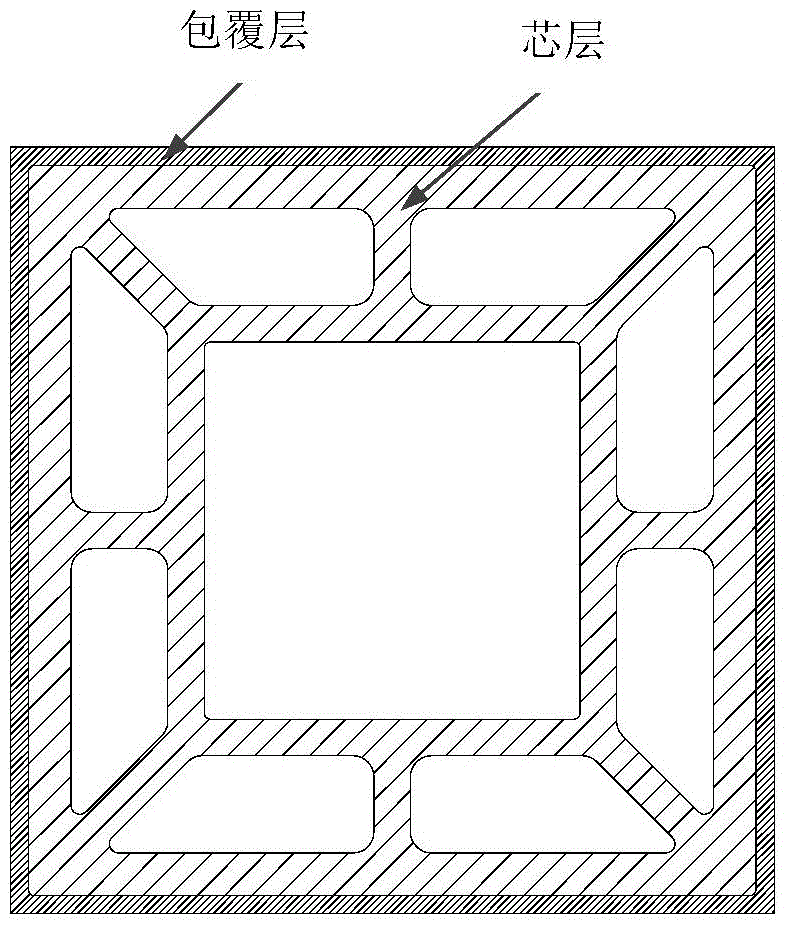

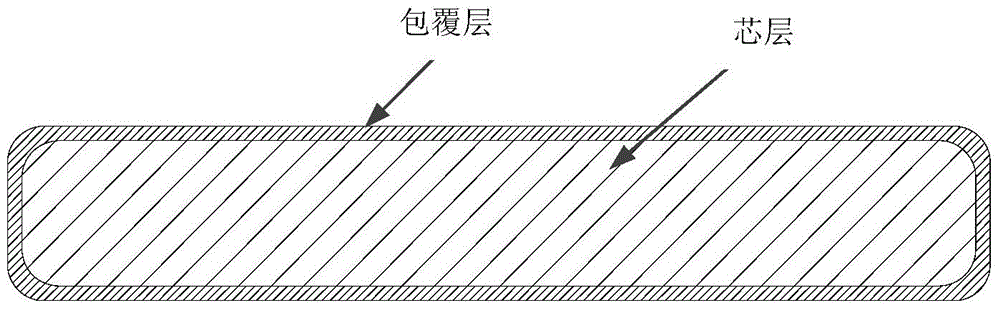

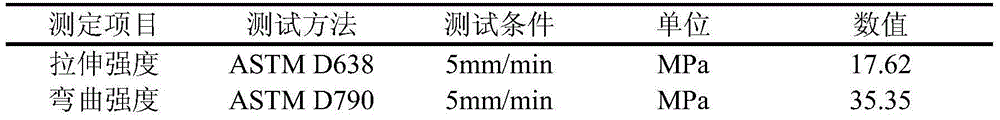

High strength wood-plastic coated coextruded composite material and preparation method thereof

InactiveCN105644074APlay the role of "filling"Improve mechanical propertiesSynthetic resin layered productsLaminationFiberDiameter ratio

The invention provides a high strength wood-plastic coated coextruded composite material. The material is composed of a core layer and a coating layer. The coating layer coats the surface of the core layer through a co-extrusion technology, biomass powder in the core layer is improved to a biomass fiber material, because of a large length-diameter ratio, the biomass fiber material not only plays a "filling" role in a wood-plastic composite material, but also plays a "reinforcing" role, greatly improves the mechanical properties of the composite material, especially improves the impact resistance, creep resistance and other properties, thereby broadening the application scope of the wood-plastic composite material. In addition, the coating layer involved in the invention preferably contains ethylene-methyl acrylate copolymer resin, ethylene-vinyl alcohol copolymer resin and high strength fiber, thus being conducive to further enhancing the mechanical properties of the composite material and the binding force with the core layer.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

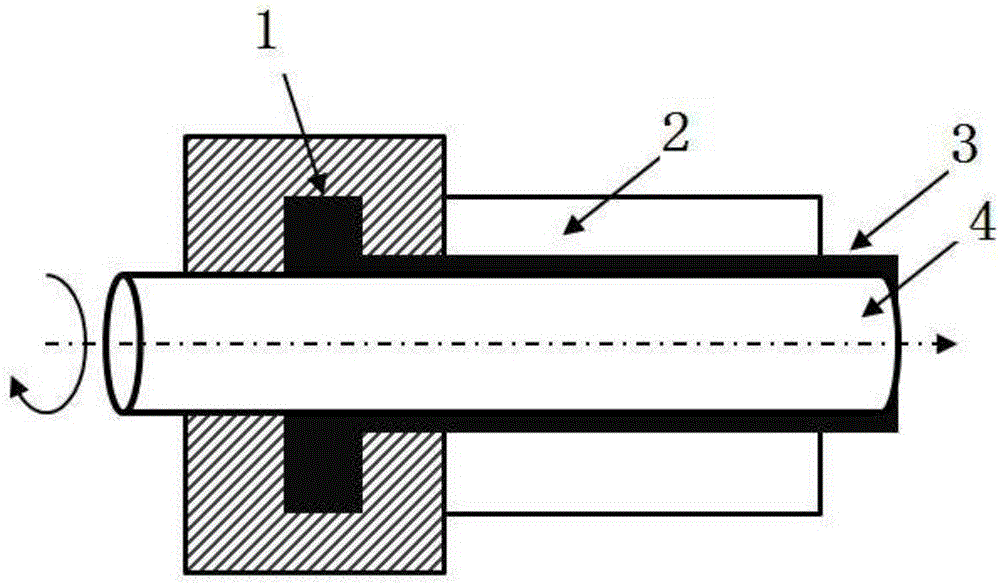

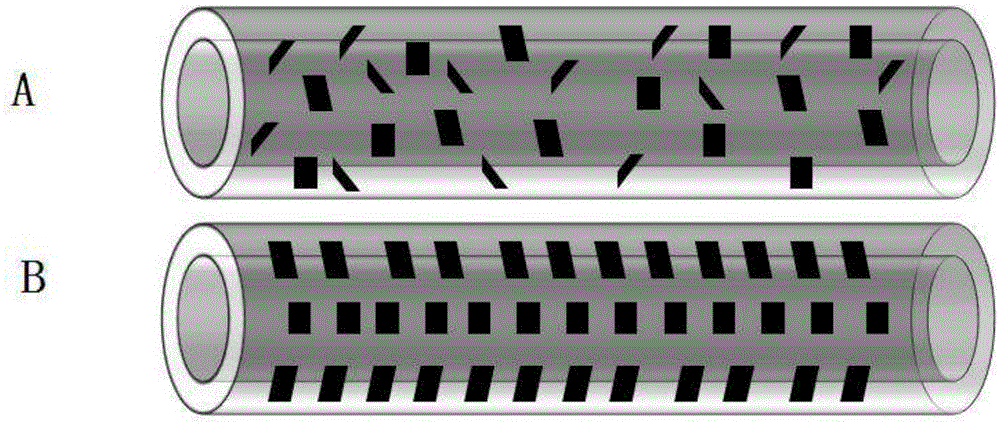

High-oxygen barrier property high-strength polyolefin heat conduction pipe and preparation method thereof

The invention provides a high-oxygen barrier property high-strength polyolefin heat conduction pipe and a preparation method thereof. The high-oxygen resistance high-strength polyolefin heat conduction pipe comprises, by weight, 100 parts of polyolefin resin, 0.1-5 parts of graphene slice layers, 0.1-15 parts of a compatilizer and 0.01-0.2 parts of an anti-oxidant. The graphene slice layers are uniformly distributed in the polyolefin resin in a ring way around a pipe central axis as a center. Through use of the graphene slice layers and a rotary core rod mouth mold, a polyolefin crystallization degree is high, a lot of oriented crystals are formed and pipe mechanical properties, heat conduction and heatproof performances are obviously improved. The graphene slice layers are uniformly distributed in the pipe in a ring way so that graphene slice layer obstruction performances are greatly improved and thus the good oxygen barrier property is kept under the condition of a very small amount of an anti-oxidant.

Owner:TIANJIN KINGFA NEW MATERIAL

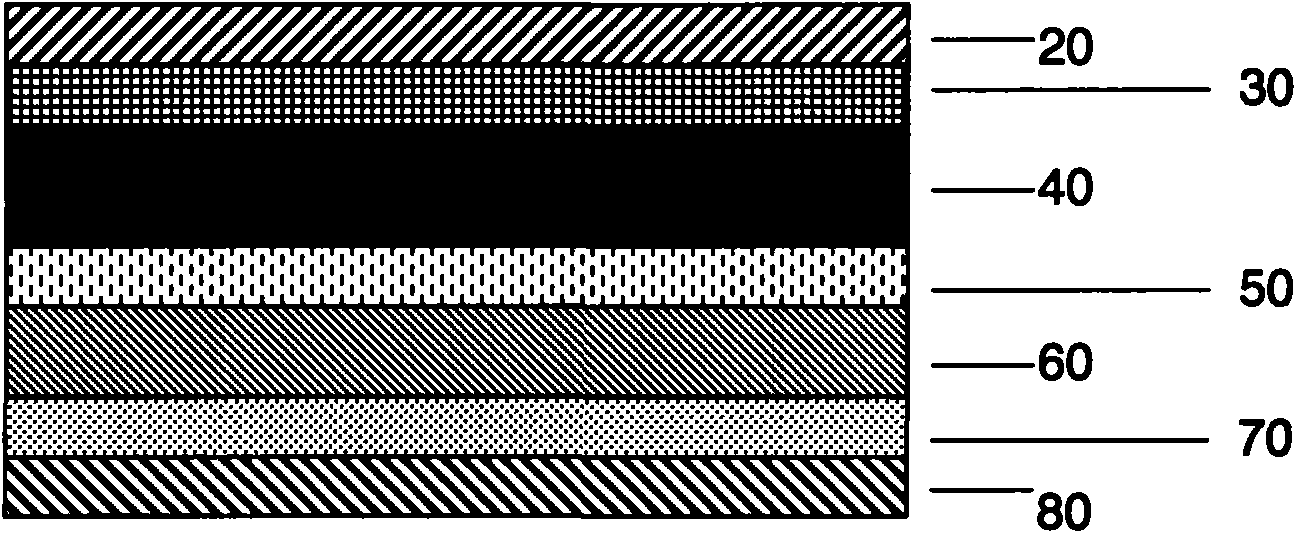

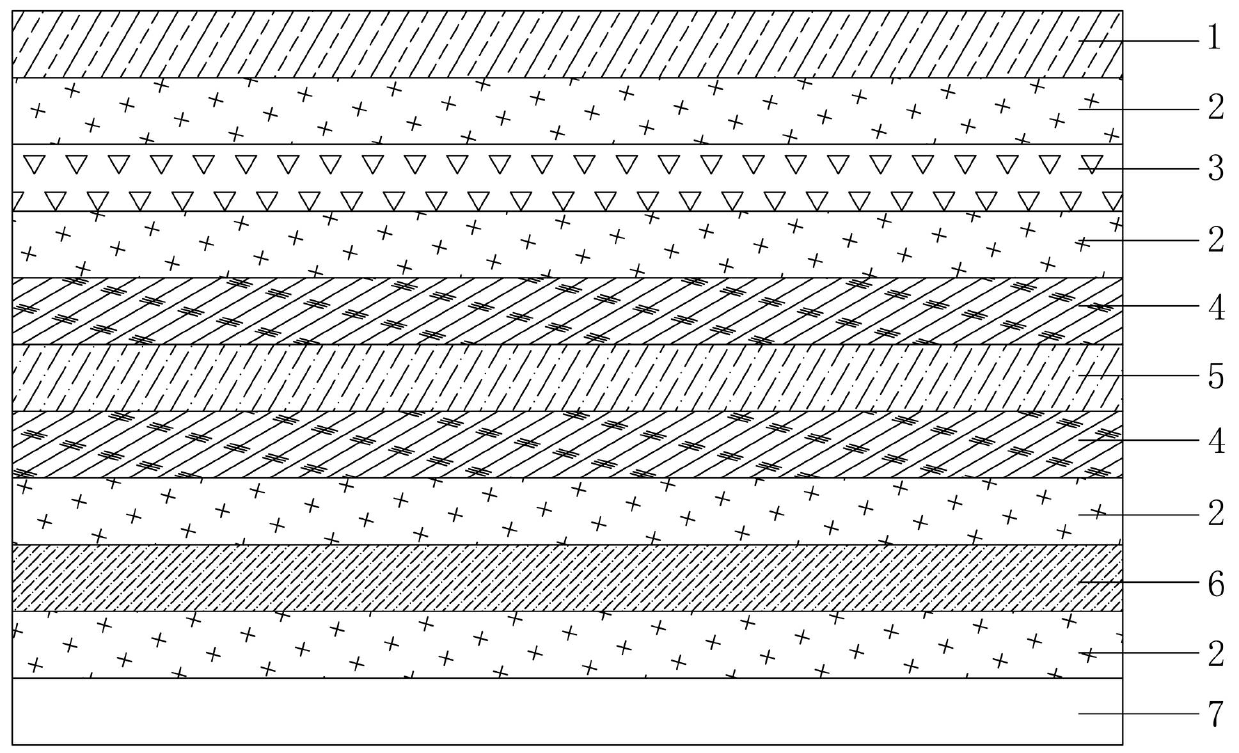

Isolation laminated packaging material

ActiveCN101875420AThe number of layers increasesLayer thickness reductionFlexible coversWrappersInter layerIsolation layer

The invention discloses an isolation laminated packaging material, which comprises a base material layer component, a compound isolation layer component, an outer layer component or an inner layer component or an middle layer component, and a bonding layer component, wherein the base material layer component conducts a supporting function and at least contains a paper or polymer base layer; the compound isolation layer component is laminated on the inner side of the base material layer component, the compound isolation layer component at least comprises a repetitive unit prepared by layer-redoubling and co-extrusion which are realized by repeated cutting, re-lamination and convergence and a compound isolation layer at least containing two individual layers, at least one of the compound layers only contains two polymer components, and at least one component contains at least one isolation polymer; and the bonding layer component is used for bonding the component layers and all layers in the components. In the invention, the structure, performance and price of the packaging material are selected and designed by the selection of the component and the selection and design of the structure of each component, particularly the layer-redoubled co-extruded compound layer component. Compared with other conventional aluminum foil-free laminated packaging material, the isolation laminated packaging material has obvious advantages.

Owner:厦门天策材料科技有限公司

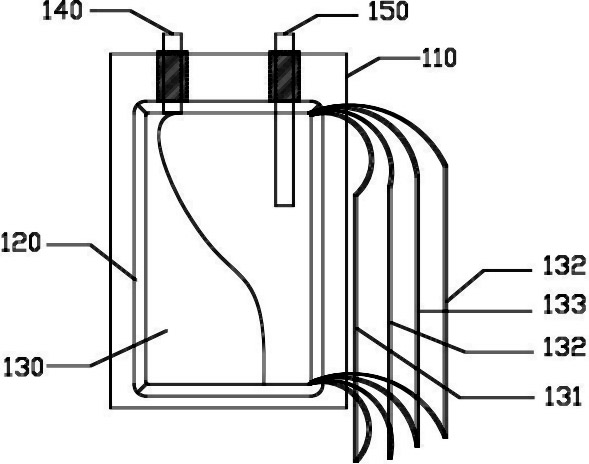

Anti-corrosion, anti-puncture and anti-short circuit melting through aluminum-plastic packaging film for lithium battery and manufacture method thereof

ActiveCN102602081AExcellent electrolyte resistanceAvoid corrosionLamination ancillary operationsLaminationPlastic packagingElectrical battery

The invention discloses an anti-corrosion, anti-puncture and anti-short circuit melting through aluminum-plastic packaging film for lithium battery and a manufacture method thereof. The aluminum-plastic packaging film has a layer structure, comprises at least seven layers which are respectively to be a protecting layer A, an adhesive layer, a coating material layer, an aluminum foil layer, another coating material layer, another coating material layer and a heat-seal layer, and further comprises a protecting layer B arranged on the protecting layer A by the adhesive layer and / or a protecting layer C arranged between the coating material layer and the adhesive layer at the lower surface of the aluminum foil layer through another adhesive layer. According to the invention, the corrosion of electrolyte can be effectively stopped, the anti-puncture intensity, the tensile strength and the wear-resistant property of the aluminum-plastic film can be improved, the yield and the reliability of the battery can be improved, the heat-seal short circuit caused by the improper operation or the abnormal temperature of a machine during heat sealing can be completely avoided, and the service life of the battery can be greatly prolonged, so that the invention is high in reliability.

Owner:东莞市金恒晟新材料科技有限公司

Laminated material without metal foil for blocking package

The invention discloses a laminated material without metal foil for a blocking package. The material at least comprises a substrate layer assembly and a composite blocking layer assembly, wherein the substrate layer assembly and the composite blocking layer assembly are laminated together; the substrate layer assembly has the effect of supporting; and the composite blocking layer assembly comprises at least one composite blocking layer which is prepared through a partition-laminated confluence layer multiplication and coextrusion method and comprises a plurality of repeated units. The material is characterized in that each repeated unit at least comprises three polymer constitutes, and each polymer constitute can form an individual layer or more than one individual layer; and only one of the polymer constitutes is a blocking polymer constitute which can block gas.

Owner:厦门天策材料科技有限公司

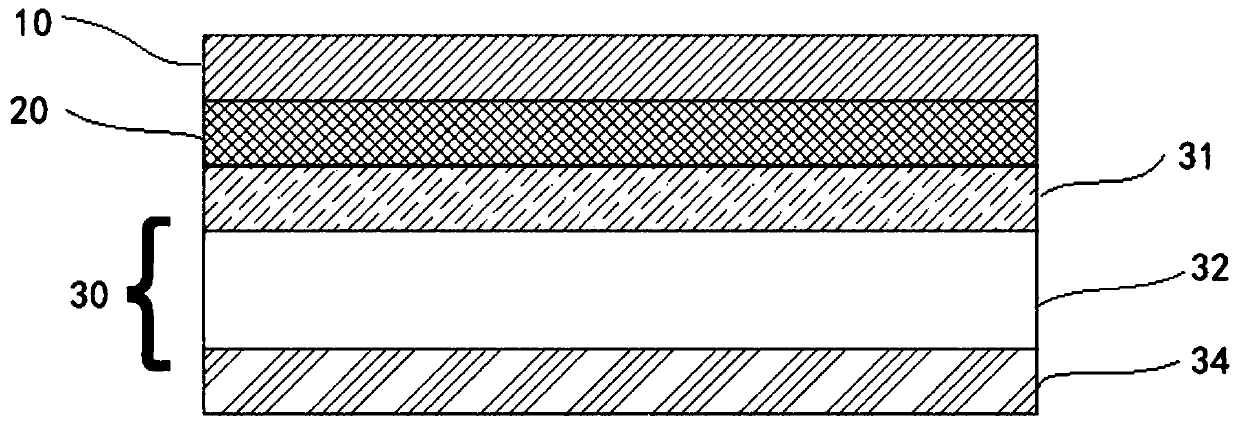

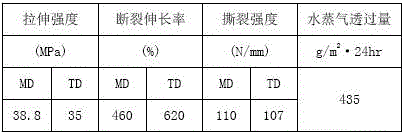

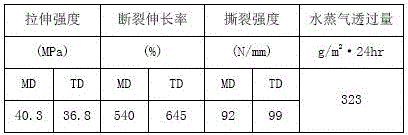

Coated high-barrier biaxially stretched polylactic acid film and preparation method thereof

ActiveCN110774713ASimple processImprove performanceSynthetic resin layered productsPolyurea/polyurethane coatingsPolymer scienceBoPET

The invention relates to a coated high-barrier biaxially stretched polylactic acid film and a preparation method thereof. The coated high-barrier biaxial tensile polylactic acid film structurally comprises a high-barrier coating, a bottom coating and a substrate layer from inside to outside in sequence, wherein the substrate layer is composed of three layers of a co-extruded biaxially stretched PLA (polylactic acid) film, namely a layer A, a layer B and a layer C; the layer A and the layer C comprise the following components in parts by mass: 68-93.2 parts of PLA, 5-20 parts of a toughening agent, 1-3 parts of a compatibilizer, 0.2-1 part of a chain extender, 0.2-1 part of an antioxidant, 0.5-3 parts of an antistatic agent, 0-1 part of an open agent and 0-1 part of a smoothening agent; thelayer B comprises the following components in parts by mass: 76-93.8 parts of PLA, 5-20 parts of a toughened resin, 1-3 parts of a compatibilizer and 0.2-1 part of a chain extender; and the high barrier coating is a water-resistant modified PVA coating. Production procedures are simple, green and environmental protection materials are used, and the film is excellent in performance, and still hasa good barrier effect in case of a very thin high-barrier coating.

Owner:中仑新材料股份有限公司 +1

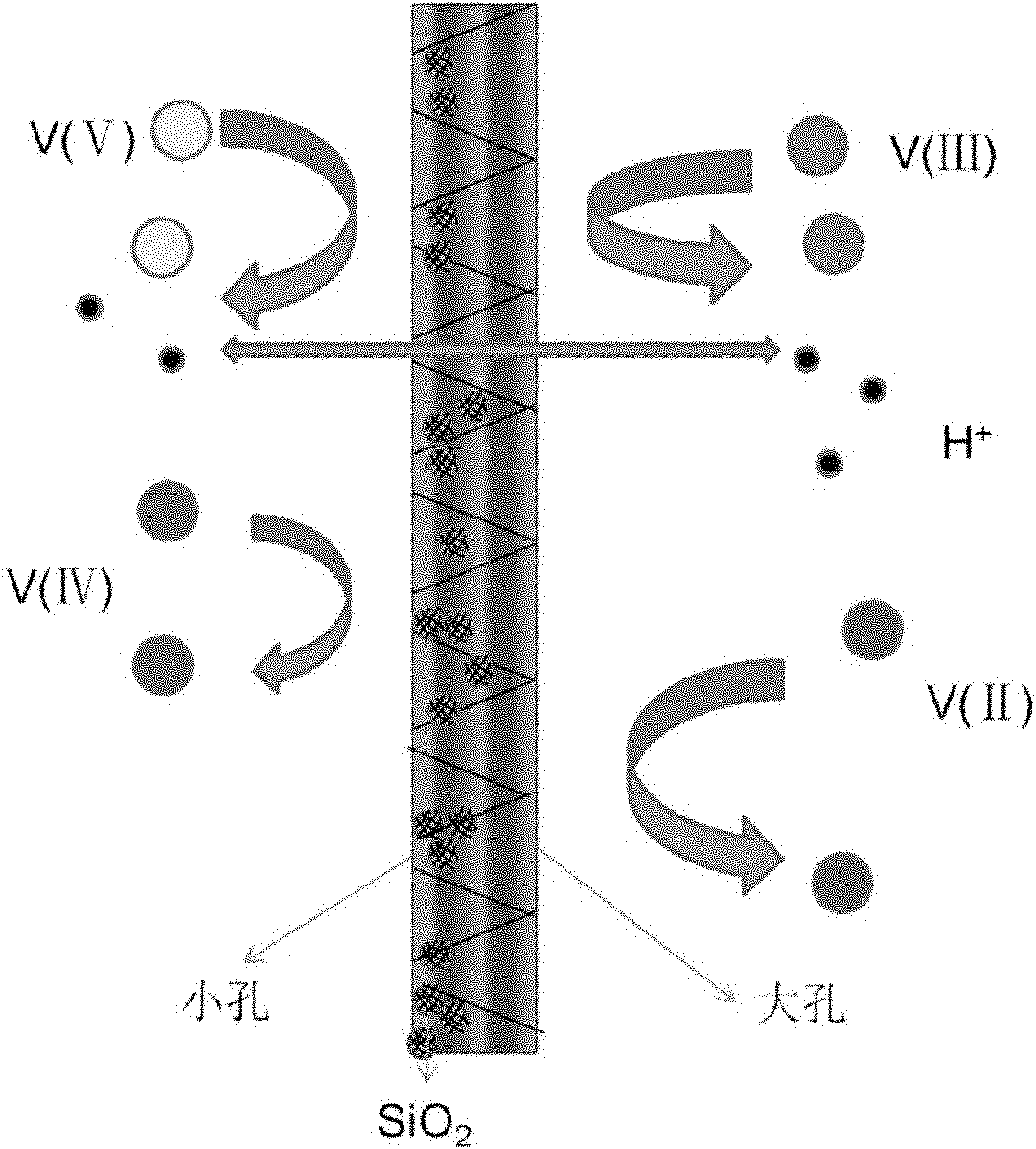

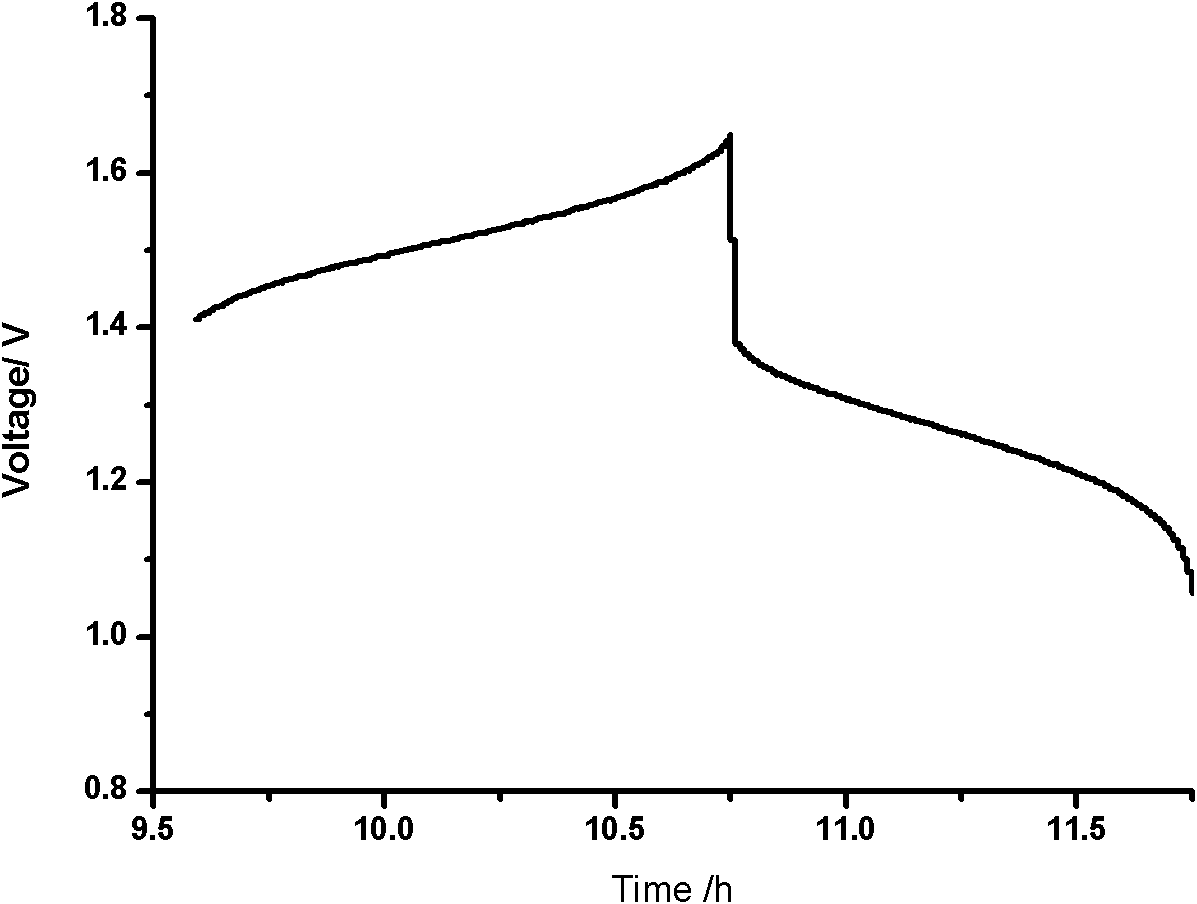

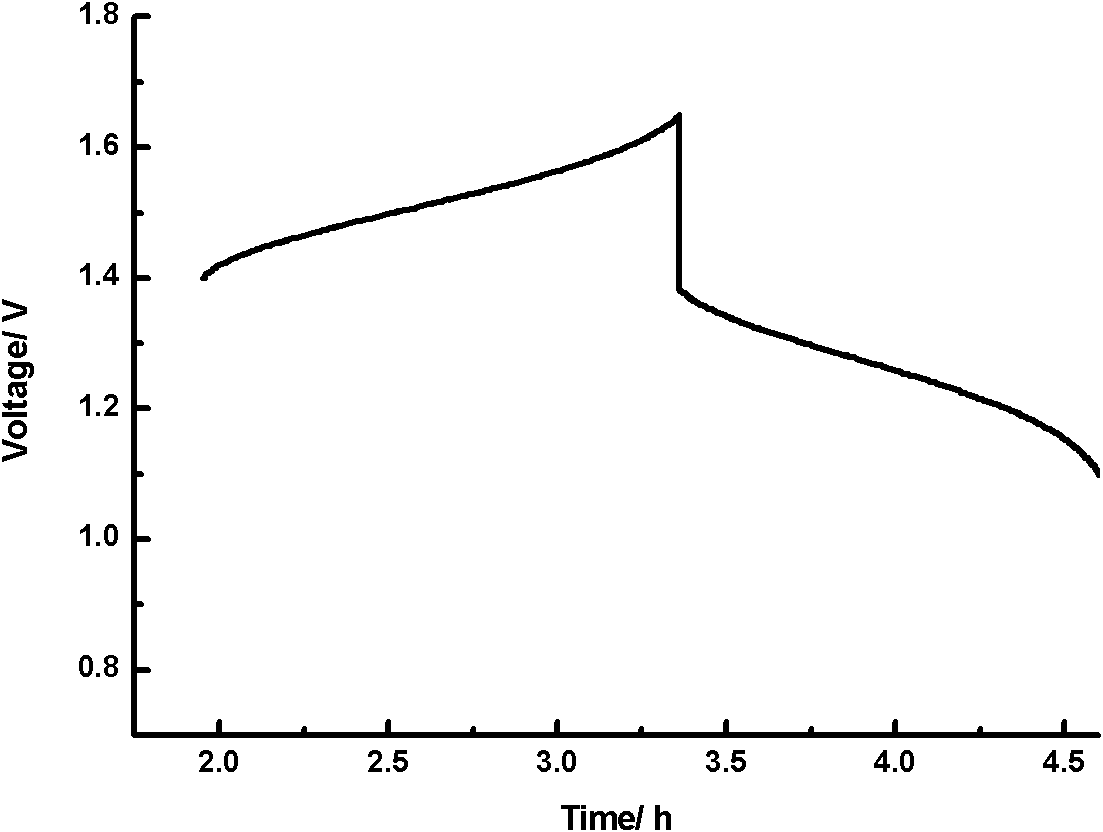

Inorganic matter-filled poriferous composite membrane for liquid flow energy-storage cell and use thereof

ActiveCN102569839ASelection throughEasy to prepareFinal product manufactureCell component detailsIon exchangeSilicon oxide

The invention discloses an inorganic matter-filled poriferous composite membrane for a liquid flow energy-storage cell and a use thereof. The inorganic matter-filled poriferous composite membrane for a liquid flow energy-storage cell is characterized in that one or more of organic polymer resins and sulfonated organic polymer resins are prepared into a poriferous diaphragm as a matrix; inorganic matter particles are filled into apertures of the matrix so that the inorganic matter-filled poriferous composite membrane is obtained; and the inorganic matter particles are prepared from one or more of silicon oxide, zirconia, titanium oxide, lead oxide, tungsten oxide and zirconium phosphate. The inorganic matter-filled poriferous composite membrane can be prepared by simple processes, has controllable apertures, is suitable for large-scale production, has high ion selectivity, hydrophily and ion conductivity, can realize ion transport without introduction of any ion exchange groups, and broadens a selection scope of liquid flow energy-storage cell membrane materials.

Owner:DALIAN RONGKE POWER

High-barrier full-biodegrade mulching film and preparation method thereof

The invention relates to the technical field of biodegrade mulching films, in particular to a high-barrier full-biodegrade mulching film and a preparation method thereof. The mulching film is prepared from, by weight, 15-40 parts of PPC, 25-65 parts of PBAT, 10-47 parts of PHBH, 3-10 parts of plasticizer, 3-8 parts of inorganic filler, 0.2-1 part of crosslinking agent, 0.1-1.2 parts of light stabilizer, 0.1-1.2 parts of antioxidant, 0.3-2 parts of lubricant and 0.015-0.08 part of coupling agent, wherein the coupling agent is 0.5-1% of the inorganic filler in weight. The preparation method comprises the steps of filler surface treatment, material drying, mixing, melt extruding for granulation and blow inflation for molding. The PHBH, the PPC and the PBAT in the mulching film are compounded and blended, the components complement each other's advantages, the barrier property is good, the mechanical mechanics performance, use effect and heat preservation and moisturizing properties can meet the requirements of general mulching films, the high-barrier full-biodegrade mulching film can be decomposed completely within 1 year and is simple in preparation process.

Owner:SHENZHEN HONGCAI NEW MATERIAL TECH

Subnanometer enhanced and toughened transparent master batch and preparation method thereof

The invention discloses a subnanometer enhanced and toughened transparent master batch and a preparation method thereof. The subnanometer enhanced and toughened transparent master batch comprises the following components in percentage by weight: 70-85 percent of subnanometer powder, 1-5 percent of dispersing agent, 0.3-1 percent of lubricating agent, 1-3 percent of coupling agent, 0.3-0.5 percent of thermal stabilizing agent, 0.1-0.5 percent of antioxidant and 10-25 percent of carrier resin. The preparation method comprises the following steps of: putting the subnanometer powder into a high speed mixer, selecting a high gear for stirring and heating, adding the coupling agent and treating for three minutes, then adding other raw materials, discharging and cooling after the raw materials are evenly stirred and mixed by the high speed mixer, then crushing, and extruding and pelleting through an extruding and pelleting device. The invention solves the problem that the mechanical performance of a plastic film is reduced after the common master batch is used in the prior art, in particular the problem that the light transmittance and the transparency are reduced; the mechanical performance of a film product is improved at the same time of reducing the cost; meanwhile, the invention achieves the purposes of enhancing and toughening and can be used in the fields of foods and medicines.

Owner:宁波益可达新材料有限公司

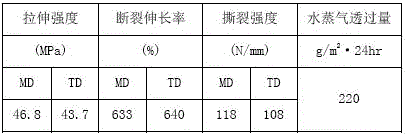

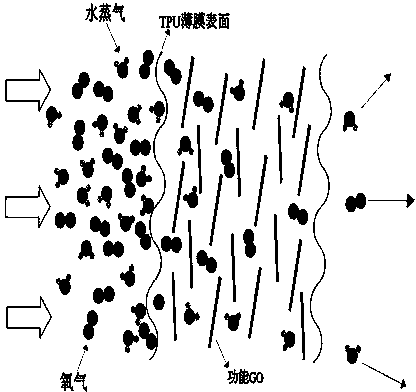

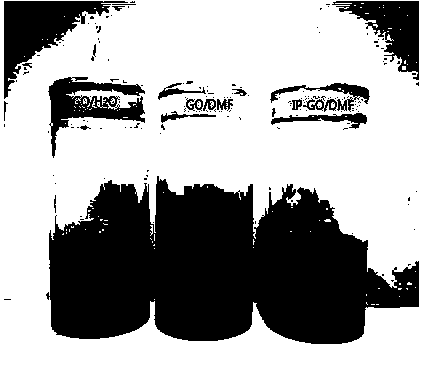

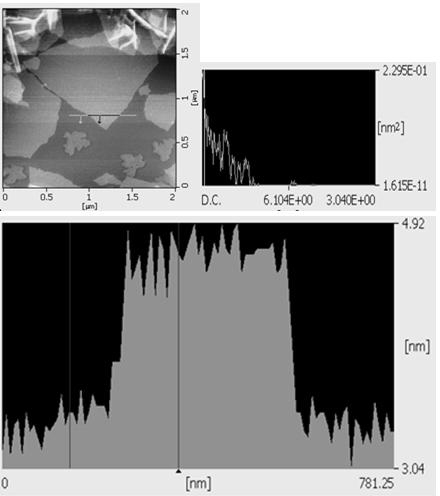

Blocking thermoplastic polyurethane (TPU)/functional graphite oxide composite film and preparation method thereof

The invention discloses a blocking thermoplastic polyurethane (TPU) / functional graphite oxide composite film and a preparation method thereof. The method comprises the following steps: firstly, preparing graphene oxide by adopting an improved hummers method, and then carrying out organic modification on the graphite oxide by using different fluorine ketone diisocyanate to obtain functional graphite oxide; finally, compositely building a film on a film coating machine by using the functional graphite oxide and TPU. By adopting the composite material film prepared by the method disclosed by the invention, the functional graphite oxide can be evenly dispersed into a TPU substrate as a good impermeable material, so that the composite film has good ability of blocking small molecule materials such as vapor, oxygen and the like, the barrier property is greatly enhanced, the mechanical property is also definitely improved, the film is good in transparency, and he blocking TPU / functional graphite oxide composite film can be widely applied to the fields such as food packaging and drug packaging encapsulation materials and the like. The blocking TPU / functional graphite oxide composite film is scientific and reasonable in preparation method, simple in process, and strong in maneuverability, and industrial production can be carried out on a large scale.

Owner:福建宸琦新材料科技有限公司

Preparation method of hemicellulose based edible film

The invention discloses a preparation method of a hemicellulose based edible film. The method includes taking hemicellulose or modified hemicellulose as a base material, adding additives such as an antibacterial agent, a plasticizer and a separator into hydrolysate of the base material, dissolving, mixing evenly, homogenizing, degassing, preparing a film, drying finally, and preparing the edible food packaging film with a certain intensity and water-solubility. The preparation method is simple, easy to industrialize, good in film formation and high in intensity; and the formed film has good separating performance and water resistance, and can satisfy packaging requirements of bread, cakes, fruit and other food.

Owner:KUNMING UNIV OF SCI & TECH

Water-insoluble modified polyvinyl alcohol coating liquor and its preparation process

The invention discloses an insoluble modified polyvinyl alcohol coating liquid and preparing method and film through the coating liquid, which comprises the following parts: polyvinyl alcohol, modifier, inorganics, crosslinking agent, catalyst and water. The coating liquid improves levelling, adhering and even property greatly, which increases obstruct property for kinds of gas.

Owner:刘建林

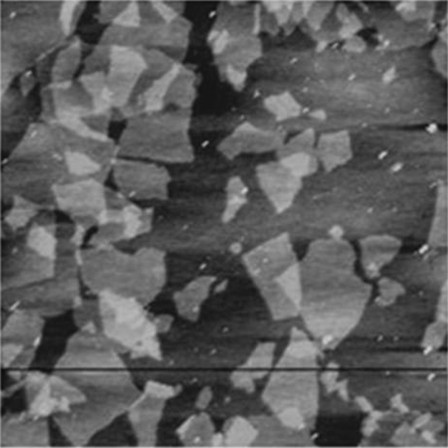

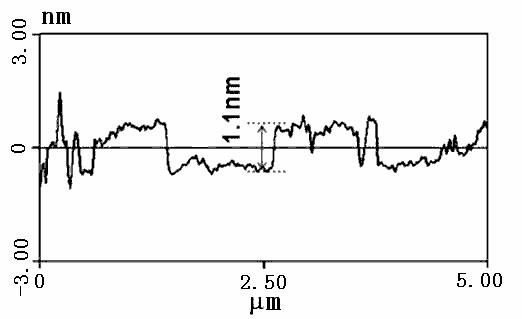

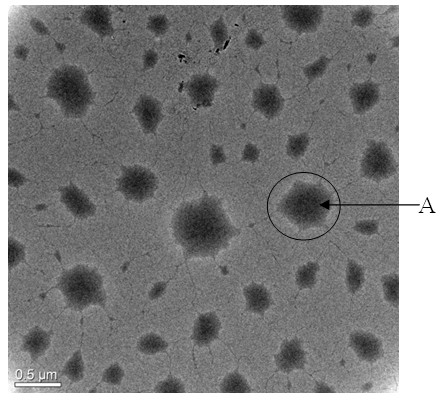

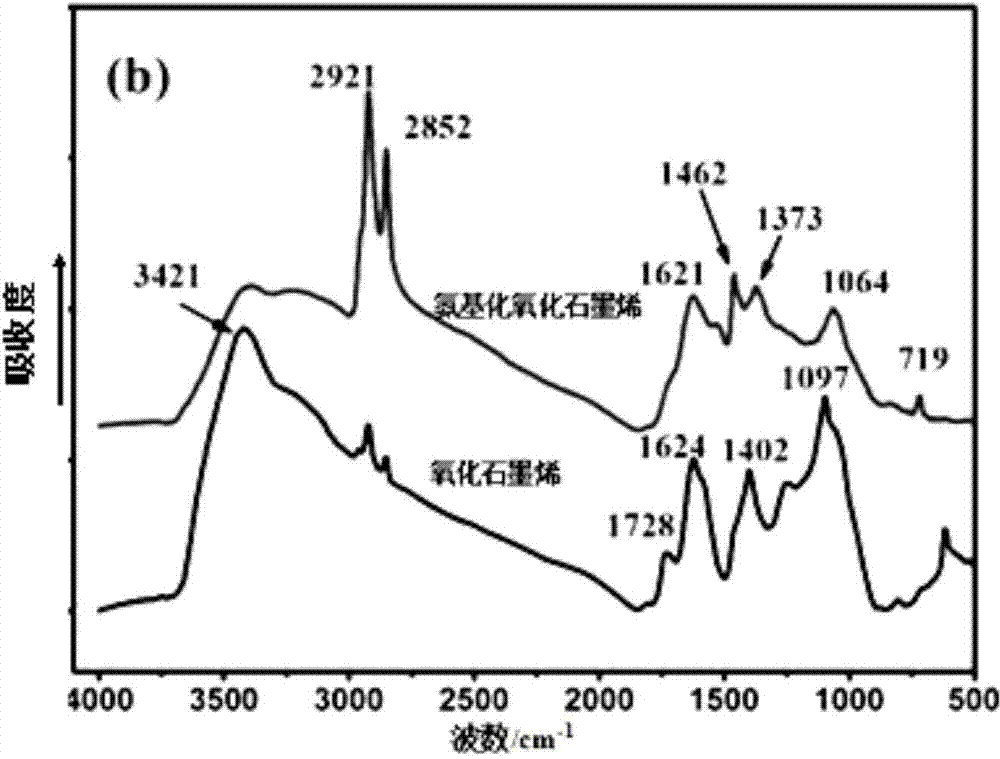

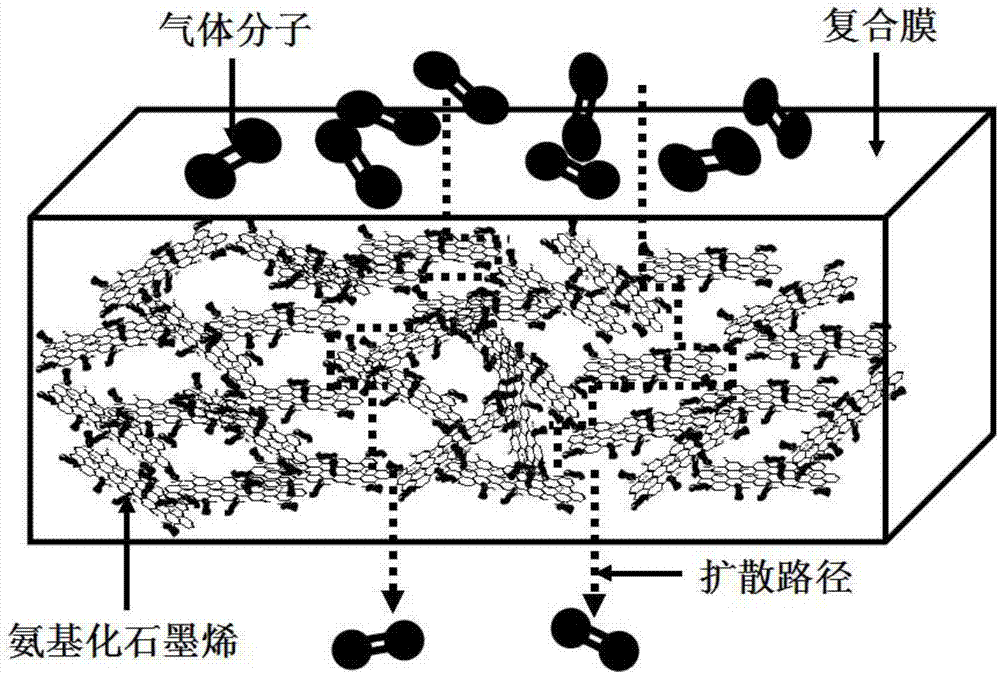

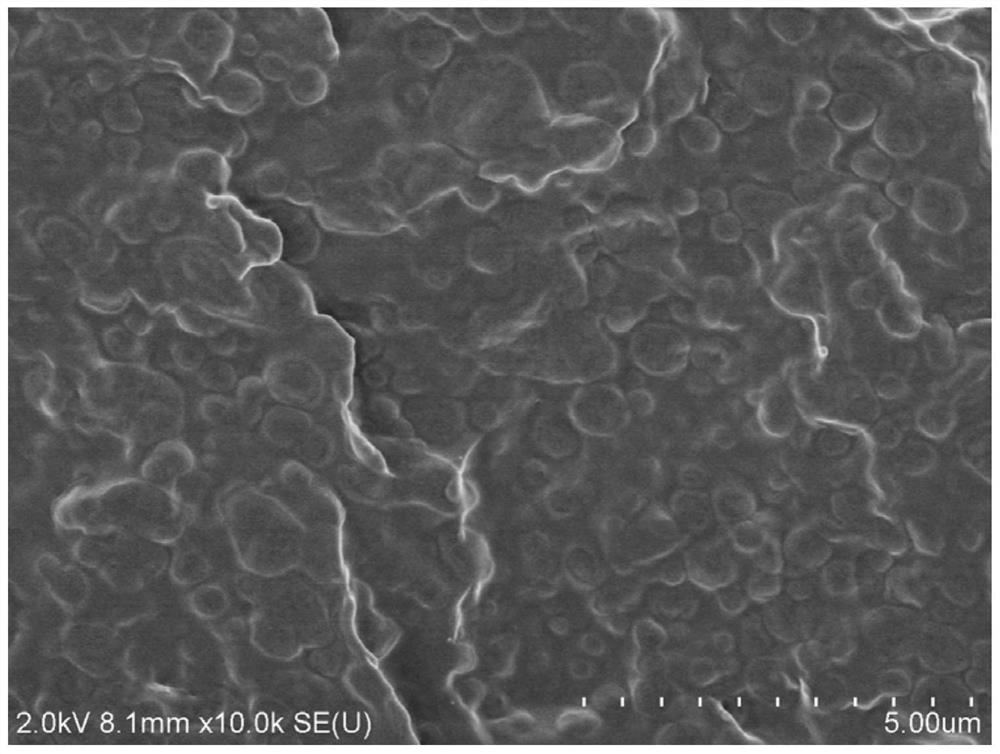

Aminated graphene oxide/high-density polyethylane nano composite membrane and preparation method thereof

ActiveCN104497385AImprove interface compatibilityHigh barrierGraphiteHigh-density polyethyleneGraphite oxide

The invention discloses an aminated graphene oxide / high-density polyethylane nano composite membrane and a preparation method thereof, which belong to the technical field of high-molecular composite material. A technical scheme is characterized in that graphene oxide and lauryl amine are reacted to prepare the aminated graphene oxide, the aminated graphene oxide and high density polyethylane powder are fully mixed in xylene to prepare a fluid suspension, pumping filtration under vacuum and drying processes are carried out on the fluid suspension, melting hot-pressing treatment is carried out, so that the aminated graphene oxide / high-density polyethylane nano composite membrane is prepared. According to the invention, technology is simple, cost is low, a polymer is not required for being dissolved, and interface compatibility of between the nano composite membrane and a polar polymer / a non-polar polymer can be effectively increased. Simultaneously, a shell-core isolation structure which is characterized in that the aminated graphene oxide is taken as a shell and high density polyethylane is taken as a core can be formed through high-temperature hot pressing, gas permeable area can be greatly reduced, gas diffusion path can be obviously complicated, and the gas barrier property of the material can be obviously increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Antibiotic composite plastic packing film

InactiveCN101092196AImprove barrier propertiesHigh mechanical strengthFlexible coversWrappersPlastic packagingHeat resistance

The invention provides an antibacterial composite plastic packing membrane and the making process thereof. And it comprises heat sealing layer, middle layer, and outer layer, where the composition of the heat sealing layer contains: LLDPE 5-40 parts, LDPE 10-35parts, MPE 15-35parts, and antibacterial agent 0.5-5 parts,the composition of the middle layer contains MPE 3-5parts, LDPE 15-25parts, LLDPE 55-70parts, antibacterial agent 0.2-3parts,the composition of the outer layer contains MPE 3-13parts, LDPE 15-35parts and LLDPE 45-65parts. And it carefully chooses antibacterial agent which has high-efficiency broad-spectrum property, is safe and nontoxic to human body, and has good heat resistance and succeeds in combining the antibacterial agent with PE membrane which has common physical and mechanical properties and makes the antibacterial agent uniformly distributed on the surface of the PE membrane, thus improving antibacterial function of the membrane and the surface polarity and hydrophily of the membrane, so as to make the membrane have good antistatic property.

Owner:哈尔滨上洋包装制品有限公司

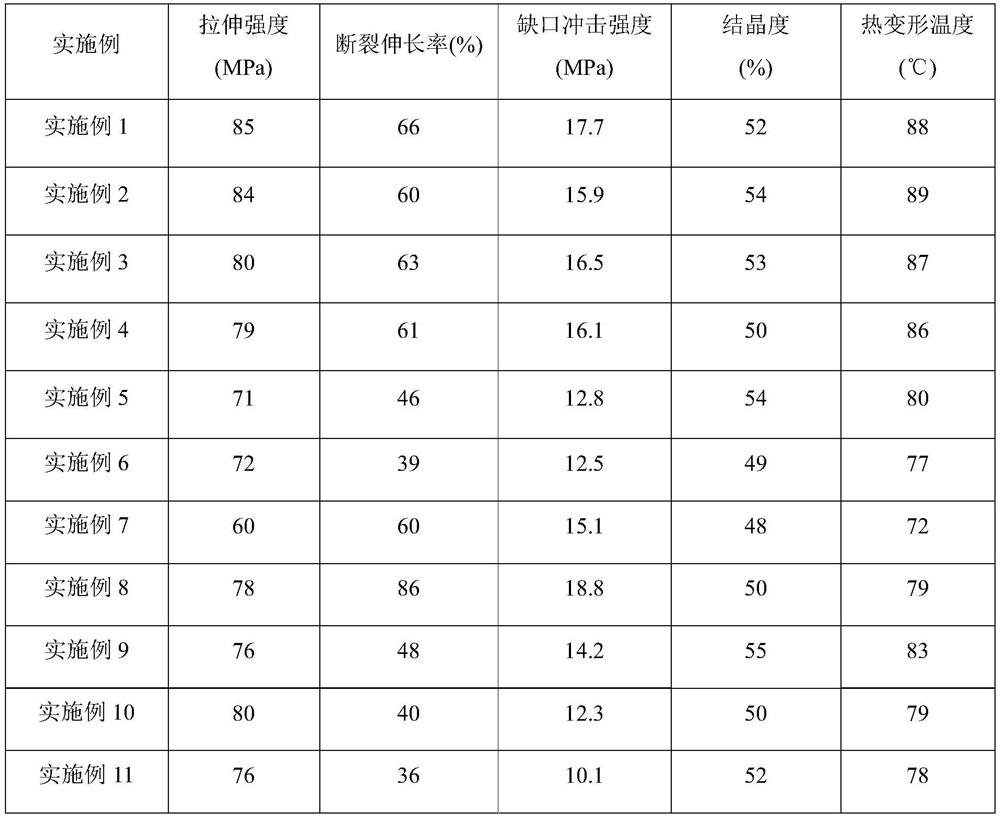

High-performance polyglycolic acid-based composite material and preparation method thereof

InactiveCN113088055AImprove interface interaction forceImprove heat resistancePolyesterPolymer science

The invention discloses a high-performance polyglycolic acid-based composite material and a preparation method thereof, and belongs to the technical field of polymer processing. A compatilizer is added, so that the interfacial interaction force between a polyglycolic acid matrix and degradable polyester B is remarkably improved, and the toughening effect of the degradable polyester B is further remarkably improved in cooperation with a specific blending process; in addition, an added functional filler is subjected to an in-situ reaction with a polyglycolic acid matrix, so that dispersion is promoted, a crystallization effect is favorably provided, and the heat resistance of the composite material is better improved. The polyglycolic acid composite material disclosed by the invention is high in material toughness, strength and heat resistance, and can be applied to the field of equipment manufacturing and packaging of high-performance degradable materials.

Owner:JIANGNAN UNIV

Flame retardant polypropylene material

InactiveCN102040775ALow shrinkageImprove toughnessCell component detailsHeat resistanceFire retardant

The invention discloses a flame retardant polypropylene material, relating to the technical field of high molecule plastics. The flame retardant polypropylene material comprises the following compositions in percentage by weight: 25-50 percent of high fluidity homo polypropylene, 25-50 percent of high fluidity propylene copolymer, 10-33 percent of flame retardant, 5-30 percent of inorganic strengthening agent, 1-10 percent of barrier additive, 0.1-3 percent of heat resistance strengthening agent, 0.1-4 percent of antioxygen and nucleating agent, 0.1-3 percent of compound pigment and 1-5 percent of internal and external lubricant. The flame retardant polypropylene material reaches V0 grade flame retardation property without lowering the mechanical performance of the material and has good heat resistance and good anti-seep performance.

Owner:LUOYANG CITY HEZHIYANG MACROMOLECULE MATERIAL

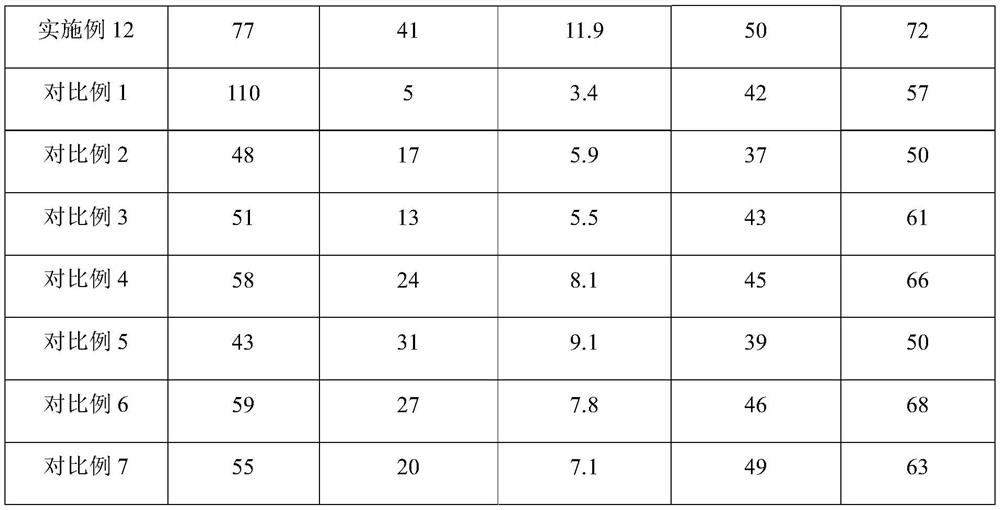

Flexible package film for external resistance layer of polymer lithium ion battery

InactiveCN102386355AHigh bonding strengthHigh adhesive strength, high initial tackCell component detailsPolyethylene terephthalate glycolLithium electrode

The invention provides a flexible package film for the external resistance layer of a polymer lithium ion battery, aiming to provide a flexible package film for an external resistance layer. The flexible package film can be bonded and compatible with a metal aluminum foil, cannot be cracked when an outer membrane and an adhesive molecular chain plastically flow and extend in the scour depth process, and has high shock-resistant, peel-strength-resistant and externally environmental-infiltration-resistant performances and good extensibility. The flexible package film for the external resistance layer comprises at least one layer of heat resistant resin film, and is characterized in that the heat resistant resin film is one of polyethylene terephthalate (PET), nylon (BOPA) and polyethylene naphthalate (PEN), wherein PEN / PET copolyester film contains SiO2 particles the mass fraction of which is from 0.1% to 0.4% and can be synthesized into an intermediate 2,6-naphthalic acid gylcol ester (BHEN) by an ester exchange reaction between naphthalene dicaboxylate (NDC) and ethylene glycol (EG), and the BHEN contents are 8% (molar fraction); and a two-component polyurethane resin adhesive is coated on the inner side of the heat resistant resin film.

Owner:刘继福

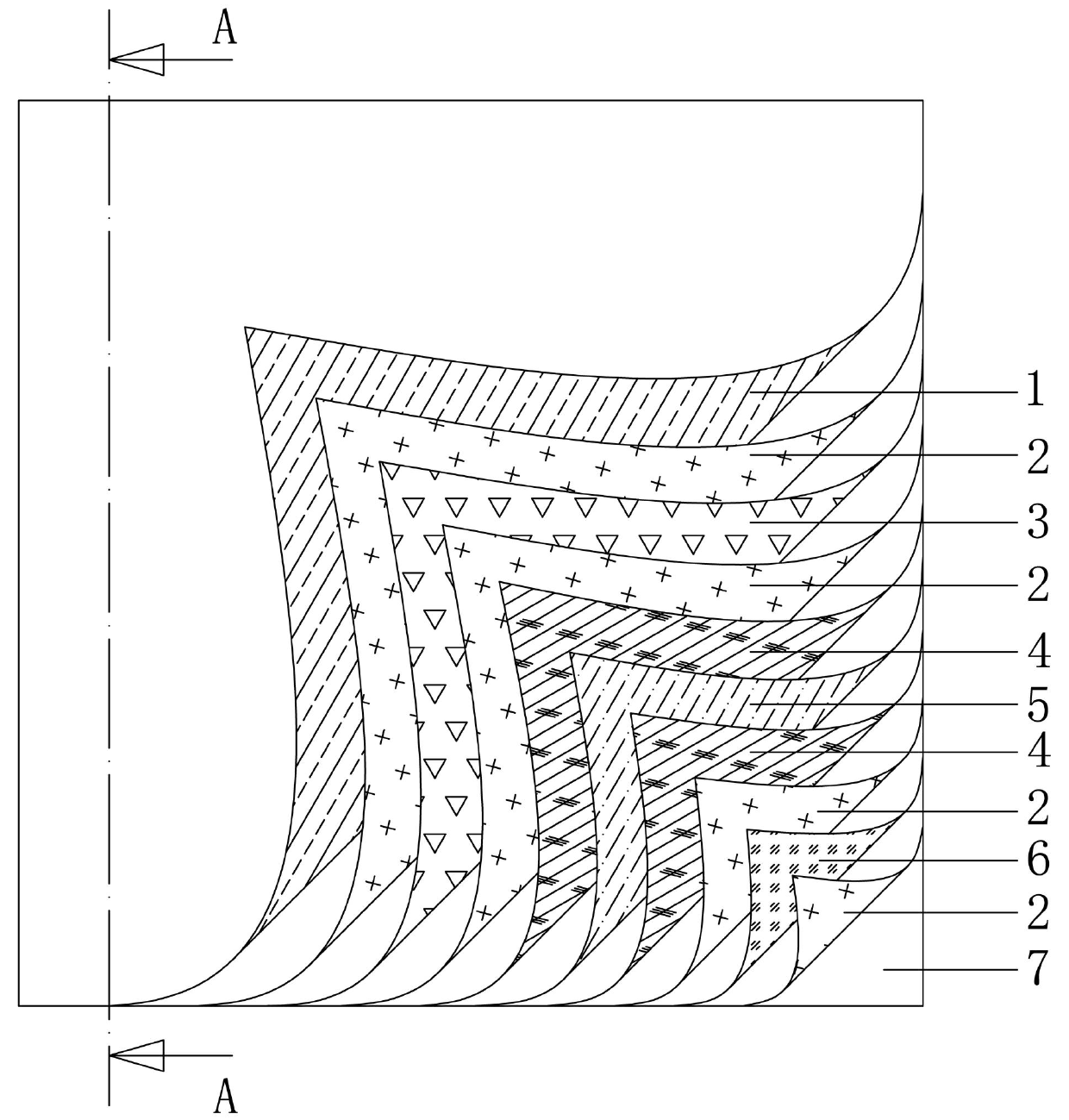

Fuel tank made from Nano composite material of nylon / clay, and preparation method

InactiveCN1796456AGood mechanical propertiesThe mechanical properties will not affectUnderstructuresFuel tanksNylon materialIn situ polymerization

This invention discloses a process for preparing a nylon / clay nanocomposite fuel tank. In the process, in situ polymerization is employed for the insertion into the interlayers of the nanocomposite so that clay can be dispersed to the degree of nanoscale in the nylon matrix, which results in a very large interfacial area. The ideal adhesion between the dispersed inorganic phase and the polymer matrix can eliminate the problem of thermal expansion coefficient mismatch between the inorganic phase and the polymer matrix, and sufficiently exploit the intrinsic good mechanical properties and heat durability of the inorganic phase. The composite fuel tank prepared by this invention exhibits improved heat-resisting property while has little influence on the mechanical properties of the matrix material.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

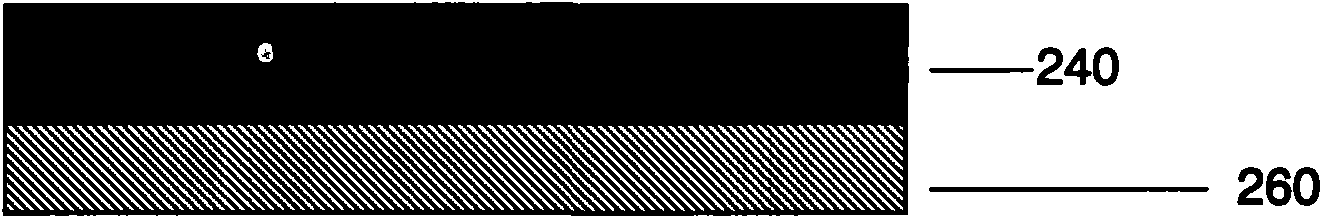

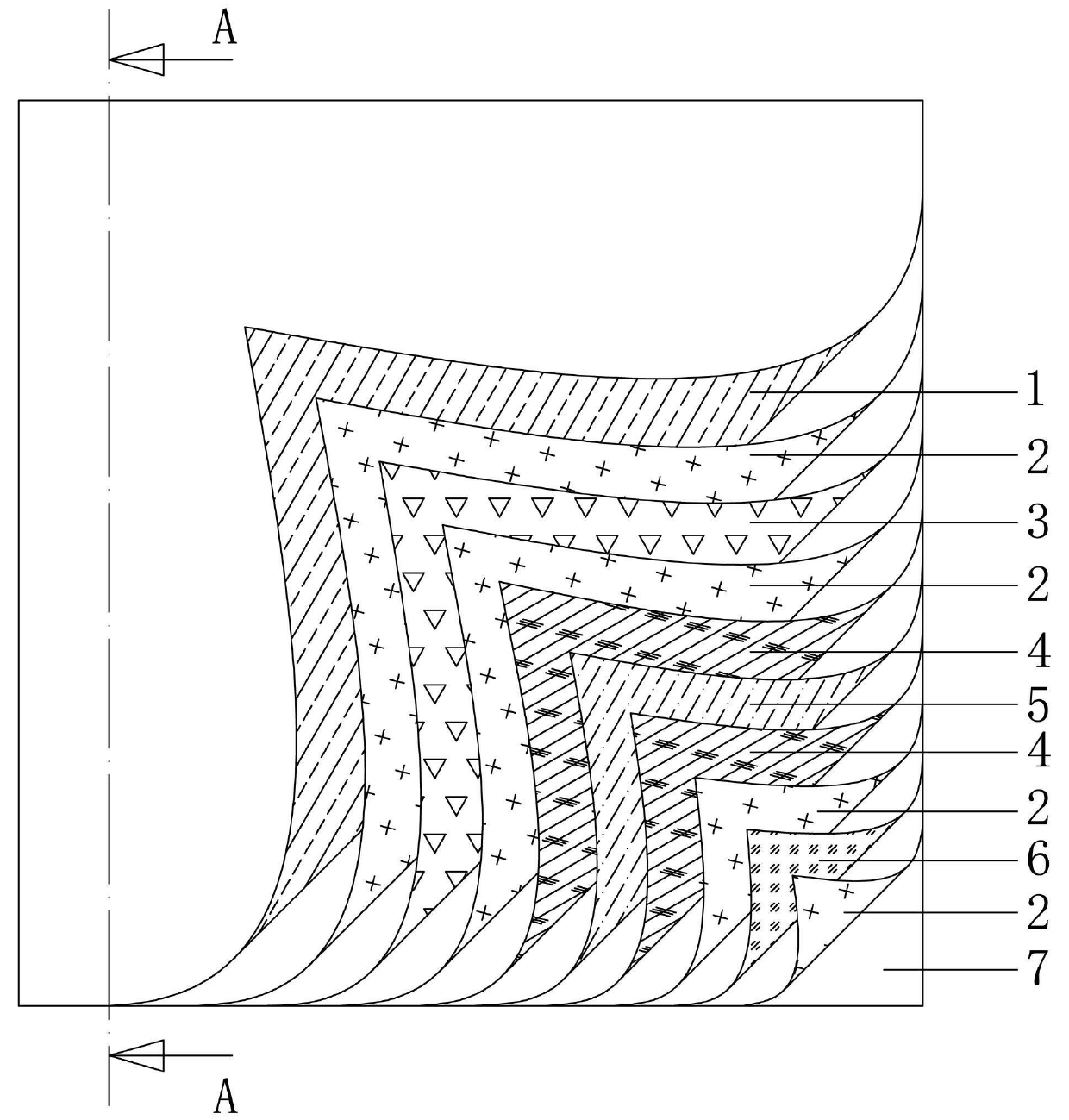

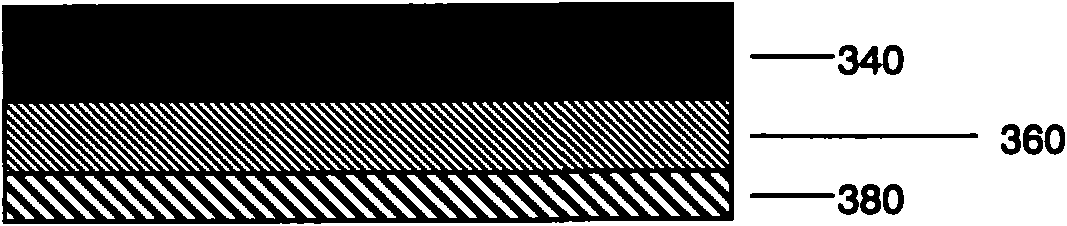

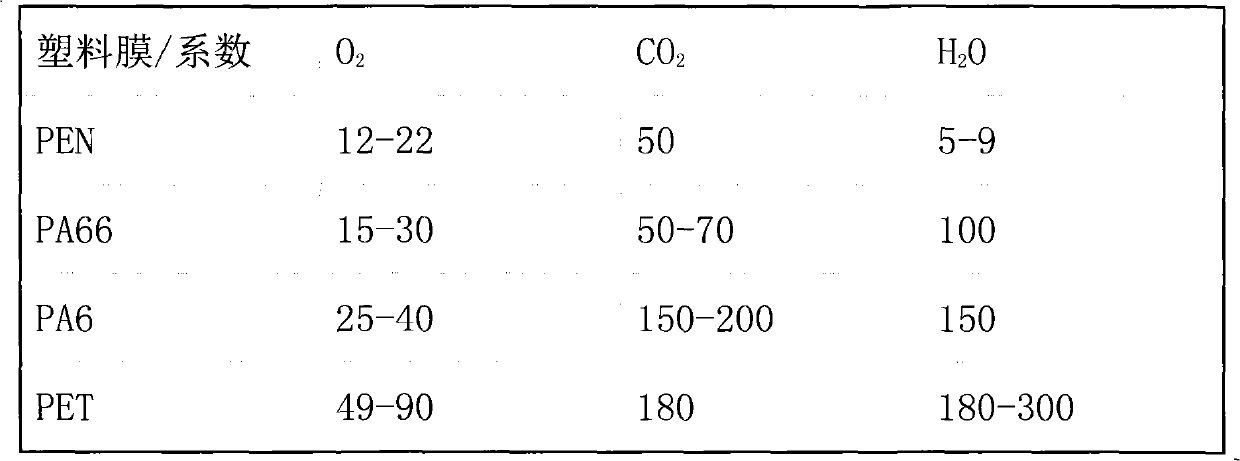

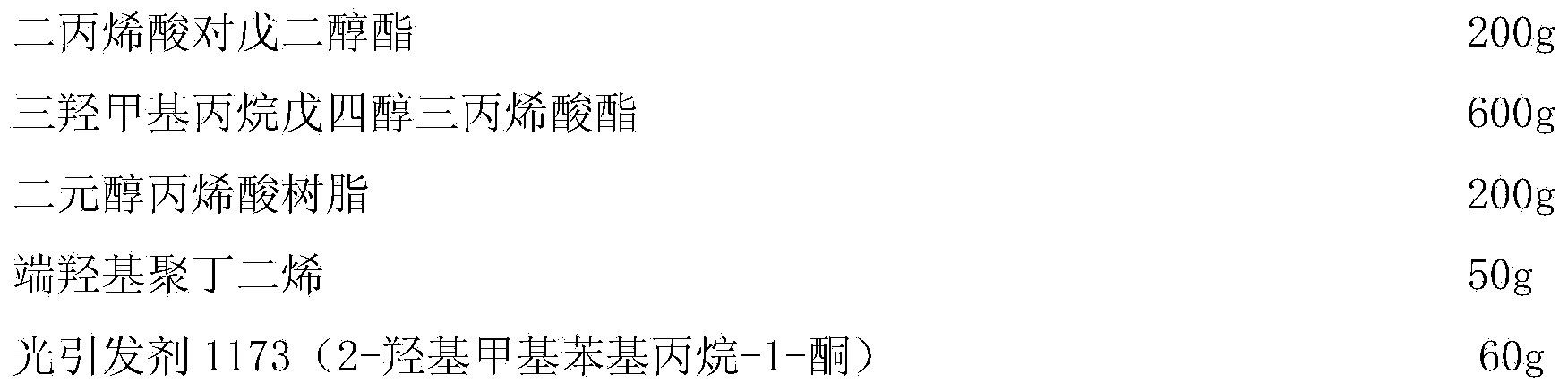

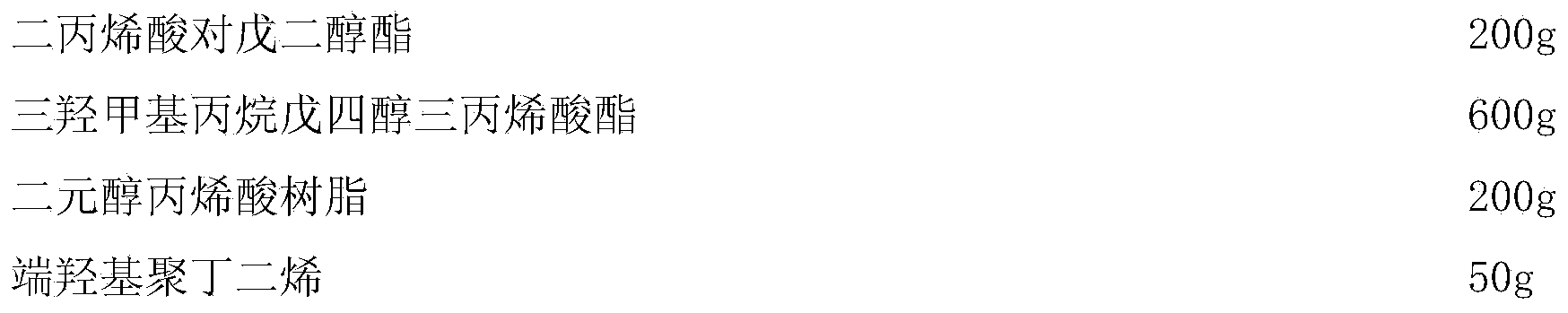

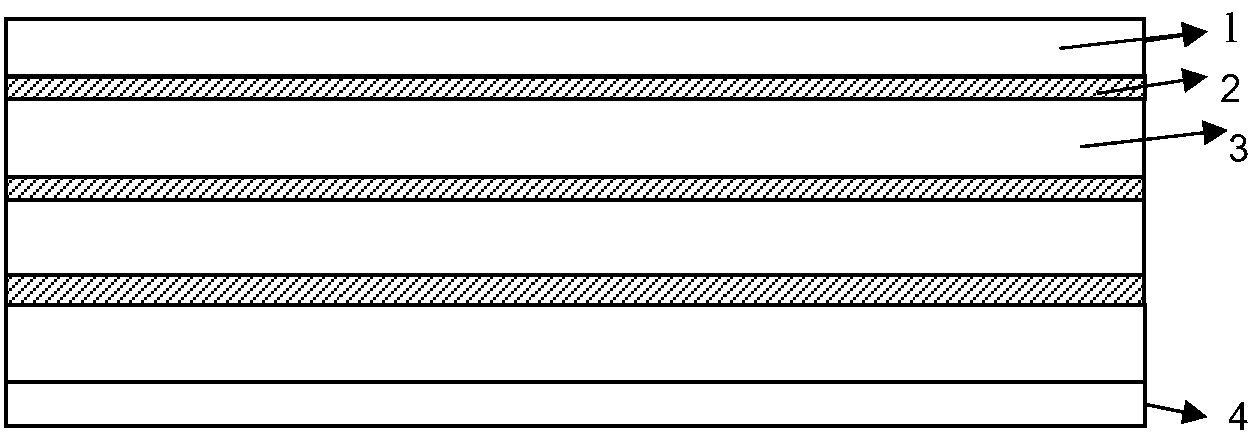

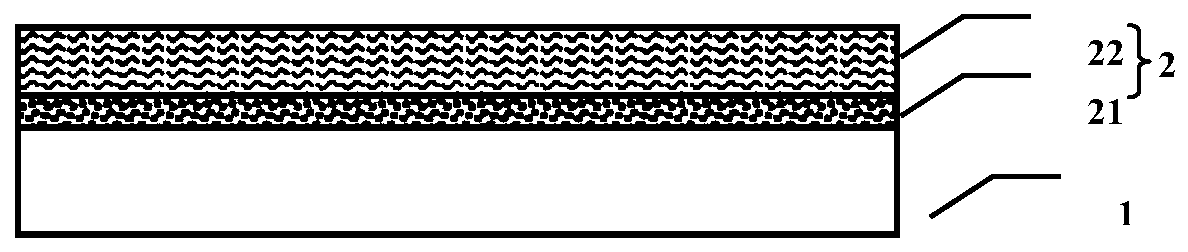

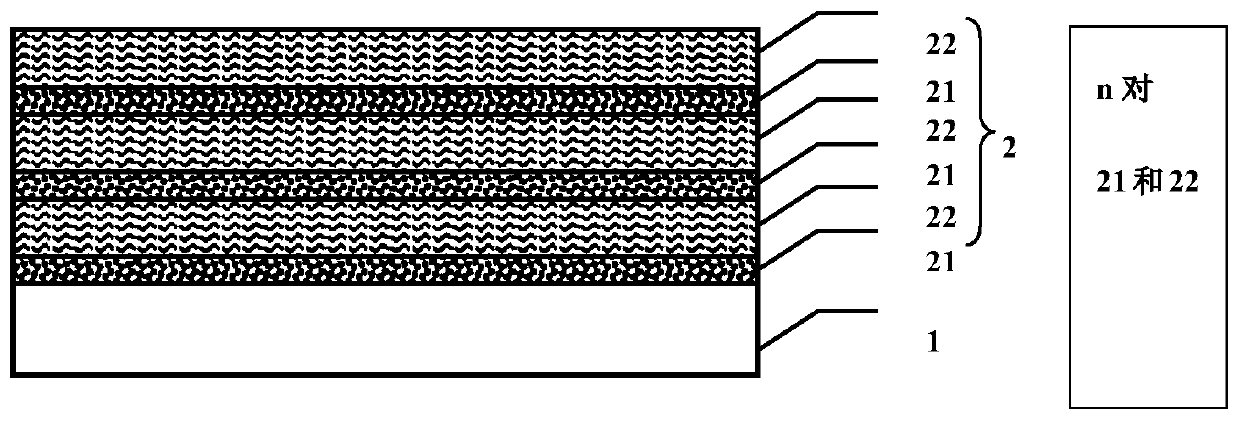

Blocking thin film used for encapsulation of flexible electronic product and preparation method for blocking thin film

ActiveCN104385731AImprove bending resistanceReduce surface roughnessSynthetic resin layered productsVacuum evaporation coatingOrganic solar cellElectrical battery

The invention provides a blocking thin film used for encapsulation of a flexible electronic product and a preparation method for the blocking thin film. The blocking thin film comprises a basis material layer and a blocking composite layer formed on at least one surface of the basis material layer; the blocking composite layer comprises at least a first inorganic cladding, a flexible organic coating and a second inorganic cladding in sequence in the direction far away from the basis material layer; the flexible organic coating is formed through solidification of organic composition comprising acrylate compound, and hydroxy and aminocontianed oligomer; the thickness of the flexible organic coating is controlled within 200-2000 nanometers; the material of the first inorganic cladding and the second inorganic cladding is formed by oxide, nitride or carbonide of silicon, aluminum, magnesium, zinc, tin, nickel and titanium; the thickness of the first inorganic cladding and the second inorganic cladding is controlled within 5-600 nanometers respectively. The blocking thin film has not only favorable blocking effect, but also excellent bending resisting property, and can be used as a gas blocking element for various flexible electronic products of flexible display element, flexible organic solar battery, flexible organic electroluminescence element, and the like.

Owner:FSPG HI TECH

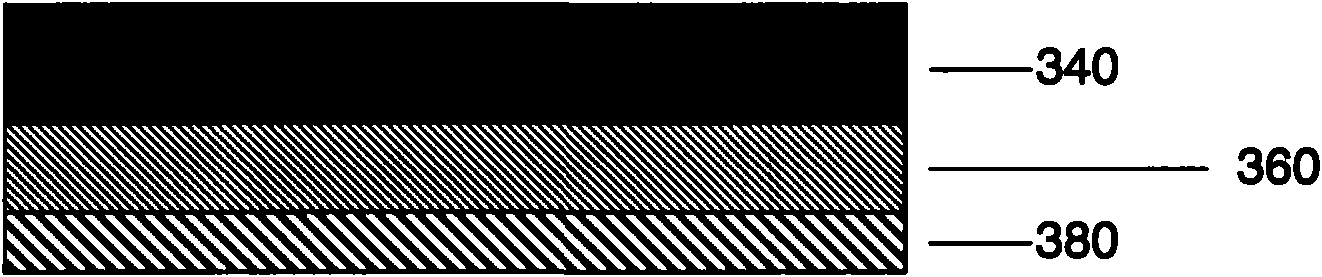

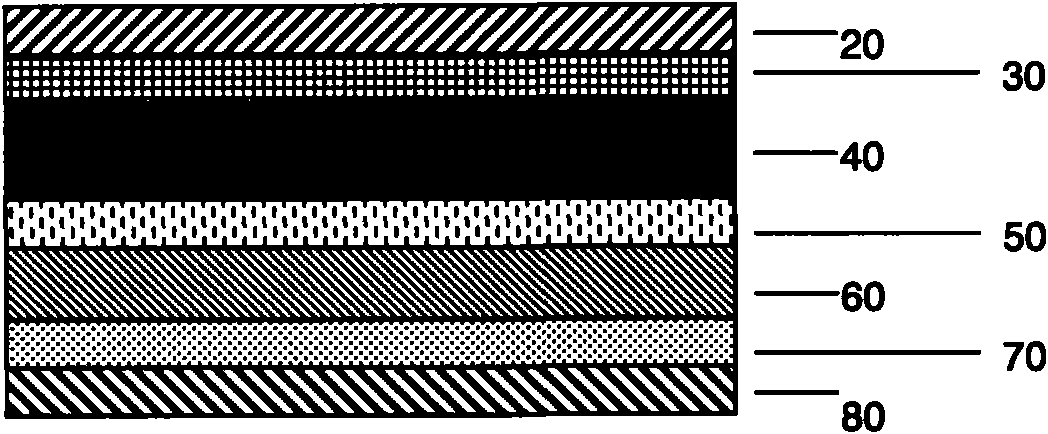

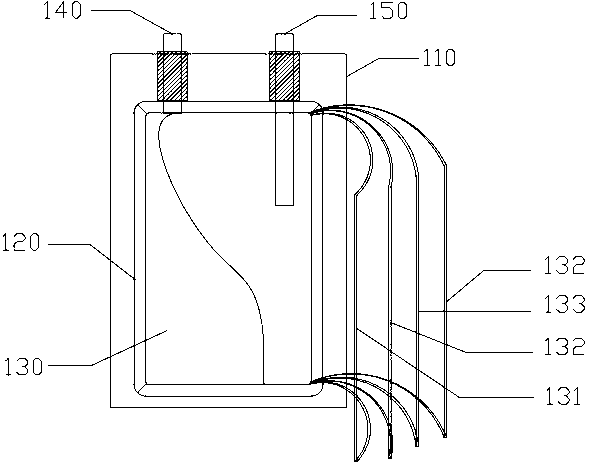

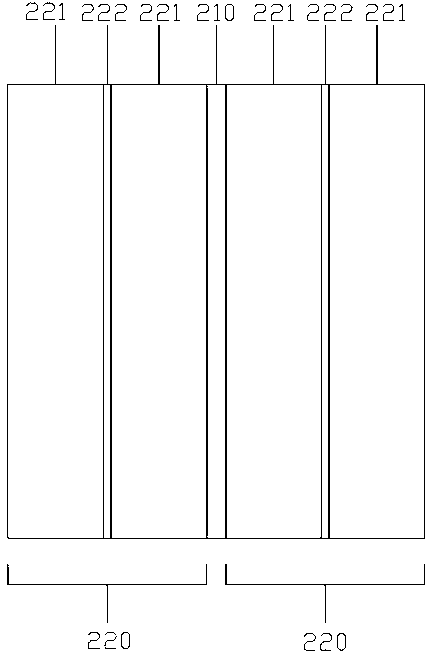

Lithium ion secondary battery and preparation method thereof

ActiveCN102709592AImprove charge and discharge efficiencyImprove securityCell electrodesFinal product manufactureMetallic lithiumDischarge efficiency

The invention discloses a lithium ion secondary battery and a preparation method thereof, and belongs to the field of lithium ion secondary batteries. The anode layer of the lithium ion secondary battery has a layered structure, and comprises an anode current collector. An anode material layer consisting of two outer hard carbon material layers and a lithium metal layer between the two hard carbon material layers is adhered to one or two surfaces of the anode current collector, wherein the lithium metal layer is plated on the hard carbon material layers by adopting an ion sputtering method. An irreversible capacity compensation layer of the lithium ion secondary battery is the lithium metal layer sandwiched between the hard carbon material layers, is uniformly distributed, and can avoid the risk that a diaphragm is pierced by lithium metal or lithium dendrites, wherein the lithium ion secondary battery has the advantages of high charging and discharging efficiency, high safety and the like.

Owner:DONGFANG ELECTRIC CORP LTD

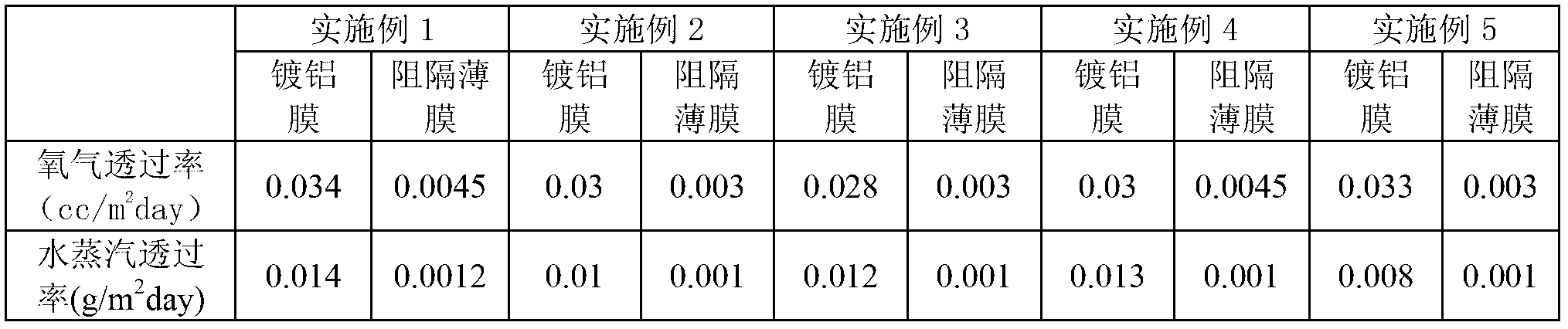

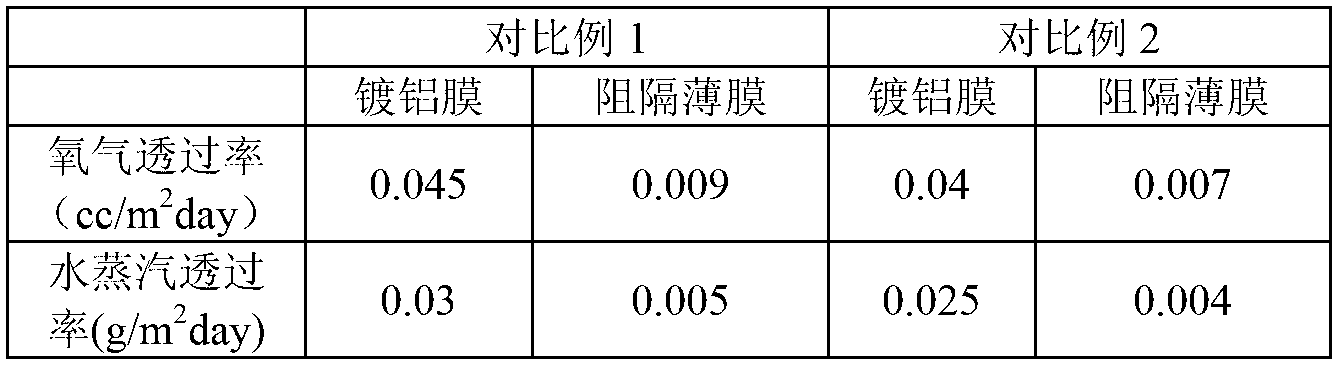

Barrier film and vacuum insulating board adopting same

ActiveCN103057212AHigh gas barrierHigh barrierVacuum evaporation coatingSputtering coatingPolyethylene terephthalateSurface layer

The invention provides a barrier film and a vacuum insulating board compounded by utilizing the barrier film. The barrier film is formed by adhering a surface layer, a gas barrier layer and a heat seal layer, wherein the gas barrier layer consists of at least one aluminum-plated polyethylene terephthalate (PET) film layer. The preparation process of the aluminum-plated PET film comprises the following of: (1) arranging a PET substrate film in an aluminum-plating chamber for performing vacuum aluminum plating, and forming an aluminum-plating layer on the surface of the PET substrate film; and (2) introducing nitrogen into the aluminum-plating chamber in stages after aluminum plating is ended, introducing the nitrogen until the nitrogen pressure is 800-1200pa at the first time, maintaining for 8-12 hours, introducing the nitrogen until the nitrogen pressure is 1300-1500pa, maintaining for at least 12 hours, and obtaining the aluminum-plated PET film. Compared with the conventional aluminum-plated film prepared by the prior art, the aluminum-plated film has the advantages that the overall barrier performance of the barrier film can be effectively improved, so that the requirements can be met in occasions with strict barrier performance requirement.

Owner:中亨新型材料科技有限公司

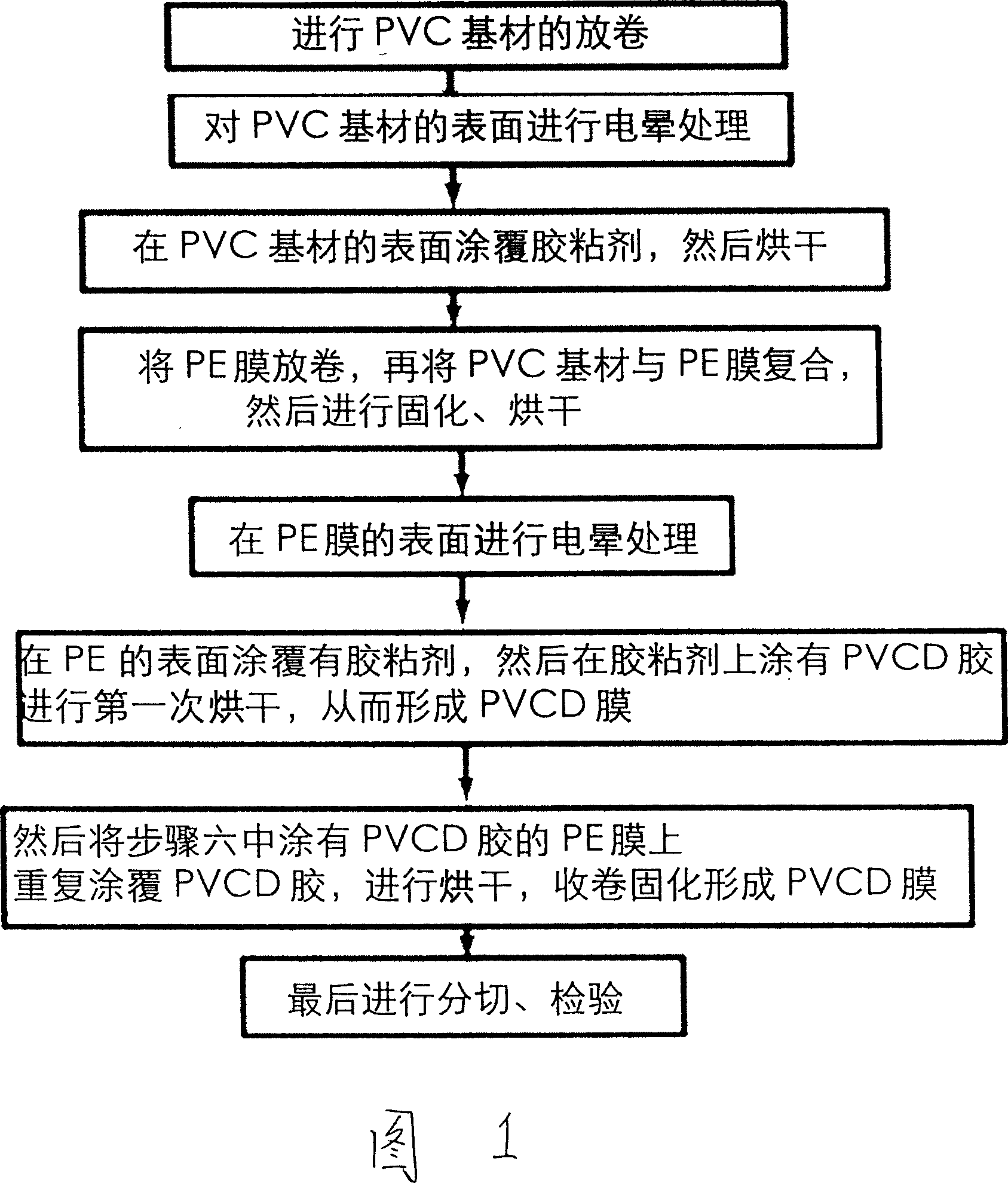

Technology for preparing high-separation, low solvent residue and low resolving-out matter PVC/PE/PVCD solid medicinal composite hard sheet

InactiveCN101024325ASolvent resistantUV resistantLamination ancillary operationsSynthetic resin layered productsManufacturing technologyAdhesive

The invention discloses PVC / PE / PVCD solid medicine using composite hard sheet manufacturing technology. It includes the following steps: unreeling for PVC basis material; corona treatment for its surface; coating adhesive; drying; unreeling for PE film; compositing the PVE basis material and PE film; solidifying; dying; corona treatment for the PE film surface; coating adhesive; coating PVCD glue; drying to form PVCD film; repeating coating the PVCD glue on the PE film; drying; rolling, solidifying to form PVCD film again; patting cut and detecting.

Owner:徐小圣

Nano aqueous interior wall heat insulation paint and preparation method thereof

InactiveCN101948653AImprove insulation effectLow VOC contentRadiation-absorbing paintsLow speedSolvent

The invention provides a nano aqueous interior wall heat insulation paint and a preparation method thereof, which belong to the technical field of production of aqueous paint. The nano aqueous interior wall heat insulation paint comprises the following components in percentage by weight: 20 to 35 percent of emulsion, 20 to 30 percent of nano calcium carbonate, 8 to 16 percent of nano oxide composition, 0.2 to 2 percent of thickening agent, 0.5 to 2 percent of wetting and dispersing agent, 0.1 to 0.5 percent of antifoaming agent, 0.5 to 2 percent of anti-freezing agent and the balance of water. The preparation process comprises the following steps of: uniformly stirring the water, the dispersing agent, glycol and half the antifoaming agent at a low speed, sequentially adding the nano calcium carbonate and the nano oxide composition with stirring; uniformly stirring the nano calcium carbonate and the nano oxide composition and uniformly dispersing the mixture by shearing the mixture on a multifunctional disperser at a high speed; slowly adding the emulsion dropwise at a low stirring speed; subsequently adding the remaining antifoaming agent and the thickening agent; and uniformly stirring and mixing the mixture at the low speed. The heat insulation paint of the invention comprises the water serving as a solvent, does not contain an organic solvent, and has the advantages of low VOC content, simple preparation process and wide application.

Owner:CHINA MCC17 GRP

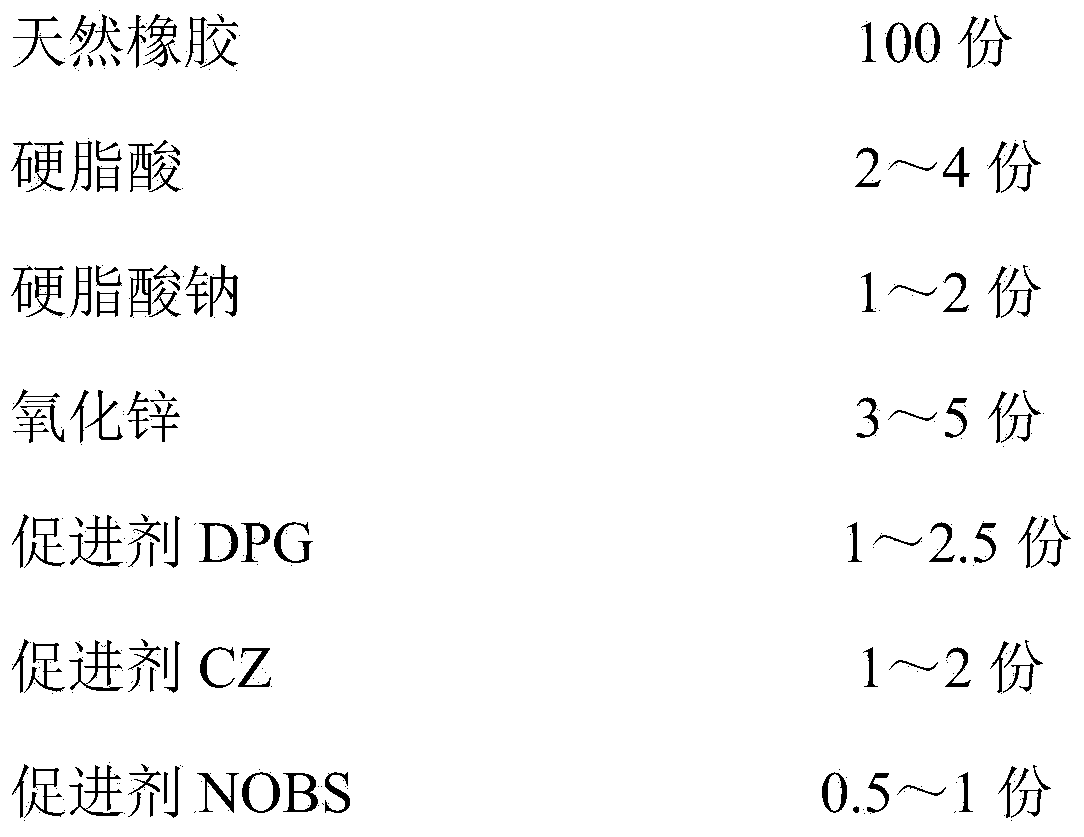

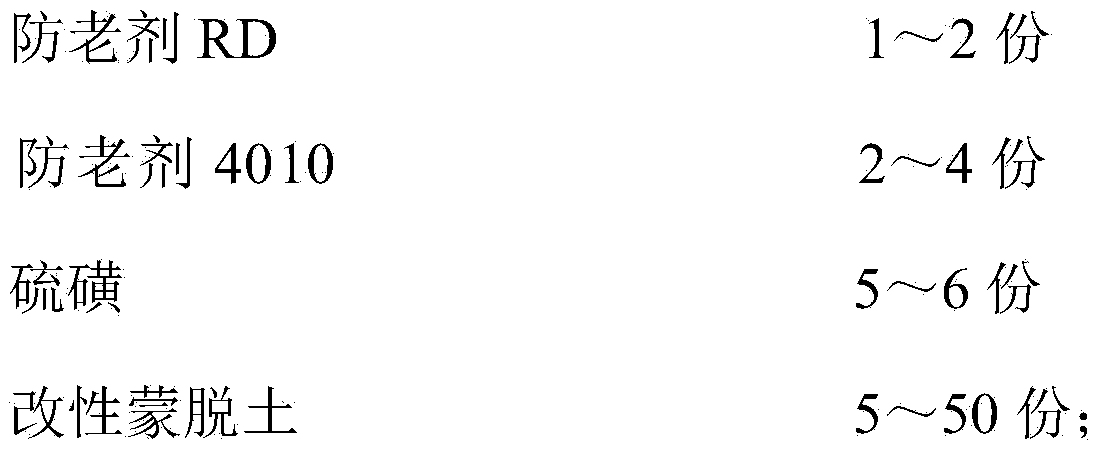

Imvite/natural rubber composite and preparation method thereof

The invention discloses an imvite / natural rubber composite and a preparation method thereof. 100 parts of imvite / natural rubber comprise 5-50 parts of modified imvite by weight, wherein the modified imvite comprises the following components in parts by weight: 100 parts of organic imvite, 5-20 parts of graphene, and 0.5-2 parts of coupling agent. The imvite is dispersed in the natural rubber by a lamellar structure, thus improving both the property of the rubber composite and barrier property of the rubber material, and remarkably lowering the production cost of the rubber. The preparation method is simple and efficient, and expands the application range of the natural rubber.

Owner:SHANGHAI UNIV OF ENG SCI

High obstructing degradable medical multilayer composite packing film and manufacture method thereof

InactiveCN101016099AHigh barrierImprove performanceFlexible coversWrappersTemperature resistancePolyolefin

A degradable medical multilayer composite packing film uses modified polyester, modified polyamide, and polyvinyl alcohol as baffle layer, adds optical degrade agent and biological degrade agent into polyolefin to control degradation. The invention is characterized in that the film comprises 10-12 layers, which uses nanometer nontoxic modified molecule material and degradable PVA resin as baffle layer. The inventive product has high insulation, degradable property, nontoxic property, high temperature resistance or the like.

Owner:程慧荣 +1

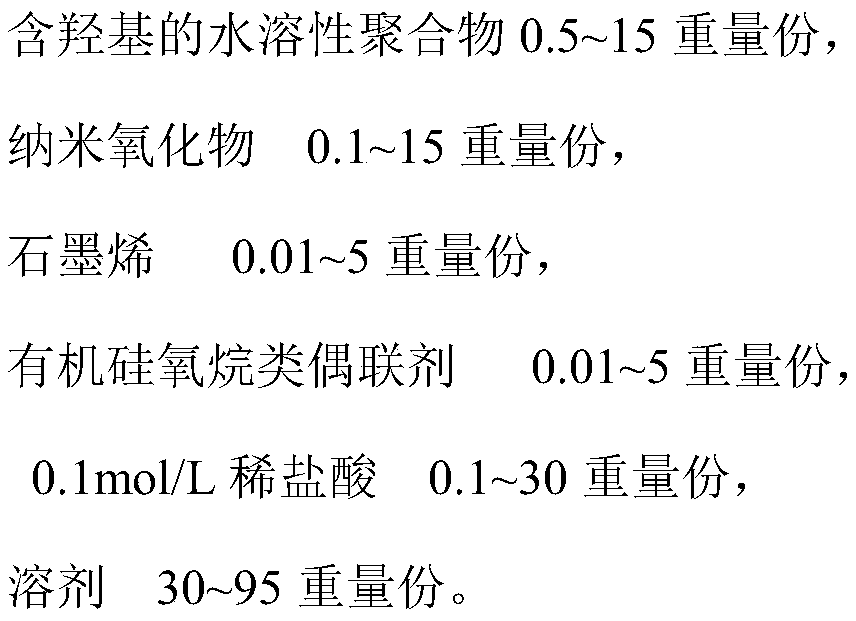

Water-based high-barrier coating liquid and production method thereof

The invention discloses water-based high-barrier coating liquid and a production method thereof. The water-based high-barrier coating liquid comprises 0.5-15 parts of a hydroxy group-containing water-soluble polymer, 0.1-15 parts of a nanometer oxide, 0.01-10 parts of graphene, 0.01-5 parts of an organic siloxane coupling agent, 0.1-30 parts of 0.1-mol / L diluted hydrochloric acid and 30-95 parts of a solvent. According to the water-based high-barrier coating liquid and the production method thereof, nanometer oxide particles produced through a sol-gel method are used as a small-size polymerization inhibitor, and are loaded onto the surfaces of the graphene by means of physical adsorption, and polymerization among the graphene can be inhibited, so that the problem of poor dispersity of thegraphene is solved; and by using cross linking of the nanometer oxide and the water-soluble polymer, the synergistic enhanced barrier action of the graphene / polymer on gas is given full play to. Moreover, a process of the production method of the water-based high-barrier coating liquid is simple and easy to implement, and a produced film material has good mechanical performance and package printing performance at the same time, and can be applied to a wide variety of fields of medicines, food, electronic product packaging, encapsulation and the like.

Owner:CHINA LUCKY FILM CORP

Modified PVA paint and its prepn process

InactiveCN1847334APrevent penetrationImprove densification performanceCoatingsPolymer scienceUltraviolet

The present invention discloses one kind of modified PVA paint, which consists of PVA, regulator, inorganic matter, tackifier and water. The tackifier is polyethylene imine and / or polyoxyethylene; the inorganic matter is clay and / or nanometer titania or the mixture of clay, nanometer silica and nanometer titania. The preparation process includes mixing PVA, regulator, inorganic matter, and water through stirring, heating to and maintaining at 90-95 deg.c to dissolve PVA completely, cooling to normal temperature, and adding tackifier through stirring. The product of the present invention has excellent machinability, and the formed coating has high water resistance, excellent ultraviolet ray and infrared ray reflecting property, high wear resistance and other excellent performance.

Owner:刘建林

Gas barrier easy-demolding fully biodegradable beverage bottle production method

ActiveCN106366588AImprove oxygen resistanceHigh barrierBio-packagingBottlesPlasticizerBlowing bottles

The invention provides a gas barrier easy-demolding fully biodegradable beverage bottle production method which includes the steps: raw material modification: adding plastic additives into fully biodegradable materials, mixing the plastic additives and the fully biodegradable materials according to a certain proportion, and performing granulation for the mixture; processing plastic master batches: uniformly mixing the mixture, and processing the mixture into the plastic master batches; blowing bottles; performing surface treatment of the bottles. The plastic additives are at least one in chain extenders, nucleating agents, plasticizers and plastic expansion microspheres, the fully biodegradable materials include powder biodegradable materials which are at least four in PLA (polylactic acid), PBS (poly butylene succinate), PHA (polyhydroxyalkanoate), PBSA poly(butylene succinate adipate), PBAT (poly butylene adipate-co-terephthalate) and starch, and blowing bottles include blowing the bottles by extrusion and blowing the bottles by injection molding.

Owner:ZHEJIANG BILI PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com