High-performance polyglycolic acid-based composite material and preparation method thereof

A technology of polyglycolic acid and composite materials, applied in the field of polymer processing, can solve the problems such as improvement of toughness and heat resistance that are not mentioned, and achieve the effects of improving interfacial interaction force, good crystallization, and promoting crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

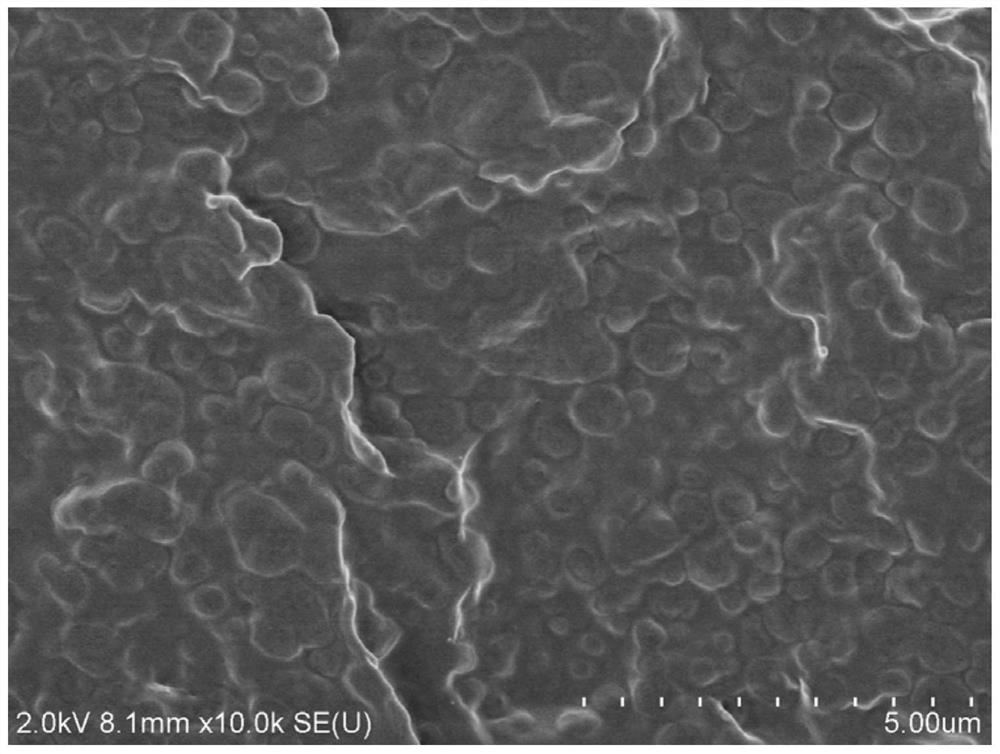

Image

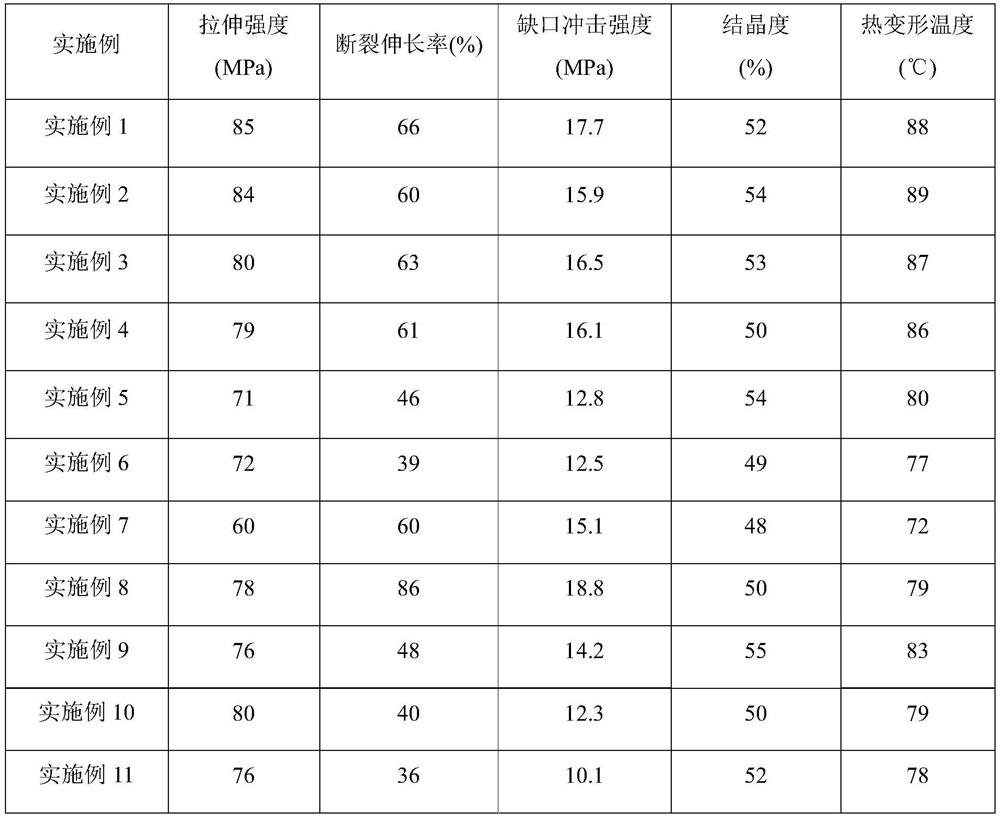

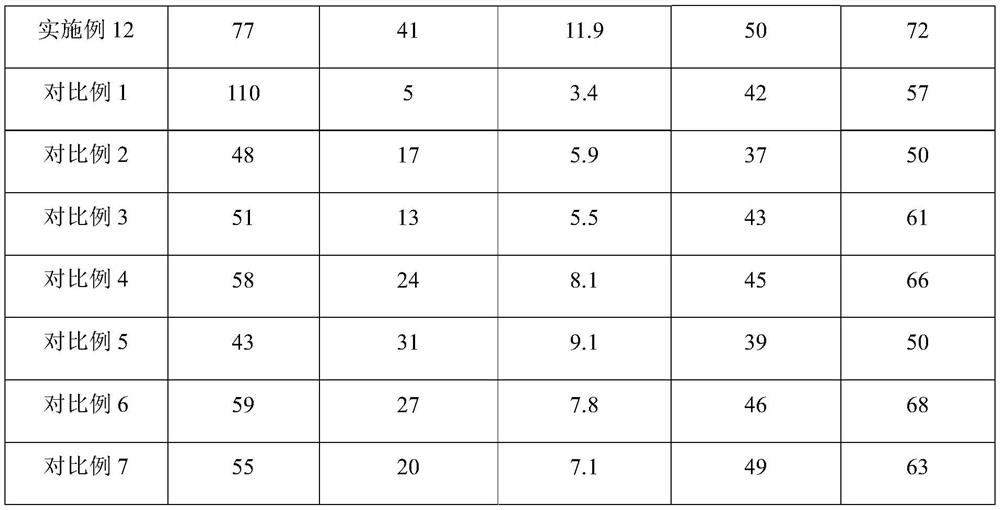

Examples

Embodiment 1

[0038] 20 parts of polyadipate / butylene terephthalate, 3 parts of ethylene-vinyl acetate-glycidyl methacrylate copolymer (glycidyl methacrylate mass content is 8%) were pre-prepared at room temperature. Mix evenly, add to an internal mixer and blend for 4 minutes (blending temperature is 190°C) to obtain a blend masterbatch;

[0039] 80 parts of polyglycolic acid, 23 parts of the above-mentioned blending masterbatch, 0.1 part of chain extender ADR4370, 20 parts of talcum powder activated by silane coupling agent KH550, 0.5 parts of polyethylene wax, tetrakis [β-(3,5-di 0.3 parts of tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester, premixed evenly at room temperature, then the premixed material was added into the twin-screw extruder from the main feeding port, and passed through continuous melt extrusion, granulation (The temperature of the screw is 230° C., the rotational speed of the screw is 200 rpm), and a high-performance polyglycolic acid-based composite ma...

Embodiment 2

[0042] 20 parts of polyadipate / butylene terephthalate, 1 part of ethylene-vinyl acetate-glycidyl methacrylate copolymer (glycidyl methacrylate mass content is 8%) were pre-prepared at room temperature. Mix evenly, add to an internal mixer and blend for 4 minutes (blending temperature is 190°C) to obtain a blend masterbatch;

[0043] 80 parts of polyglycolic acid, 23 parts of the above-mentioned blending masterbatch, 0.1 part of chain extender ADR4370, 20 parts of talcum powder activated by silane coupling agent KH550, 0.5 parts of polyethylene wax, tetrakis [β-(3,5-di 0.3 parts of tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester, premixed evenly at room temperature, then the premixed material was added into the twin-screw extruder from the main feeding port, and passed through continuous melt extrusion, granulation (The temperature of the screw is 230° C., the rotational speed of the screw is 200 rpm), and a high-performance polyglycolic acid-based composite mat...

Embodiment 3

[0046] Premix 20 parts of polyadipic acid / butylene terephthalate, 3 parts of ethylene-vinyl acetate-glycidyl methacrylate copolymer (glycidyl methacrylate mass content is 8%) at room temperature Evenly, add to the internal mixer and blend for 6 minutes (the blending temperature is 190°C) to obtain a blending masterbatch;

[0047] 80 parts of polyglycolic acid, 23 parts of the above-mentioned blending masterbatch, 0.1 part of chain extender ADR4370, 20 parts of talcum powder activated by silane coupling agent KH550, 0.5 parts of polyethylene wax, tetrakis [β-(3,5-di 0.3 parts of tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester, premixed evenly at room temperature, then the premixed material was added into the twin-screw extruder from the main feeding port, and passed through continuous melt extrusion, granulation (The temperature of the screw is 230° C., the rotational speed of the screw is 200 rpm), and a high-performance polyglycolic acid-based composite materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com