Polymer cement-based modified mortar

A cement-based, modified sand technology, applied in the field of building decoration, can solve the problems of poor toughness, high brittleness, unsatisfactory cohesion, frost resistance and impermeability, and achieves improved flexibility, good early strength, The effect of improving the thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

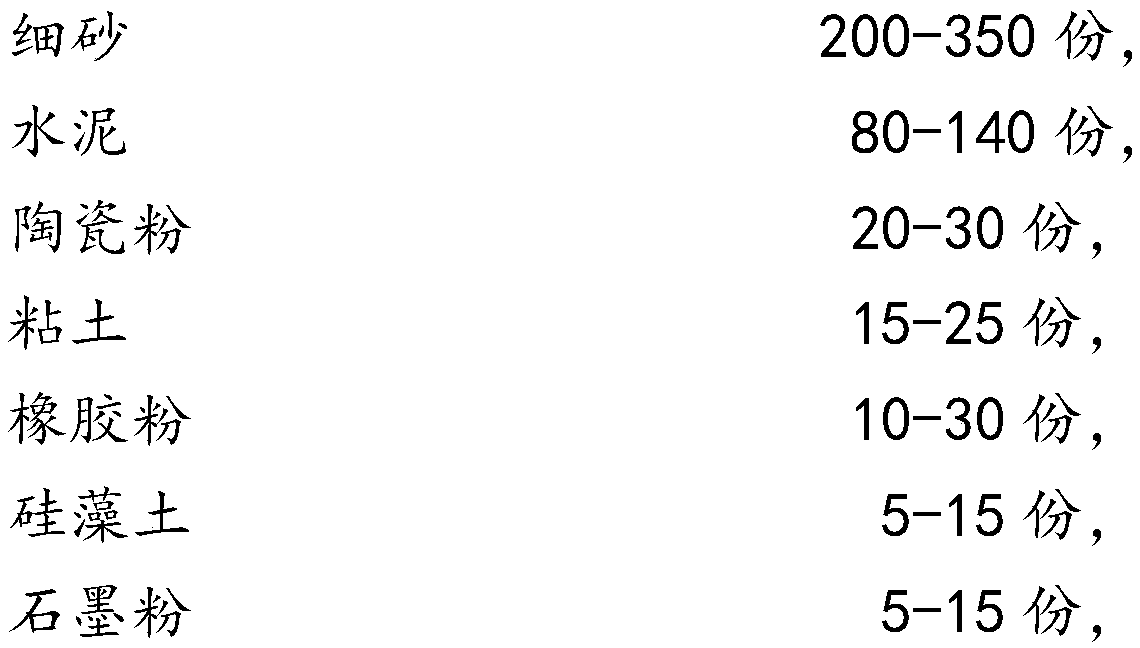

[0015] This embodiment discloses a polymer cement-based modified mortar, including the following raw materials measured in parts by mass:

[0016]

[0017]

Embodiment 2

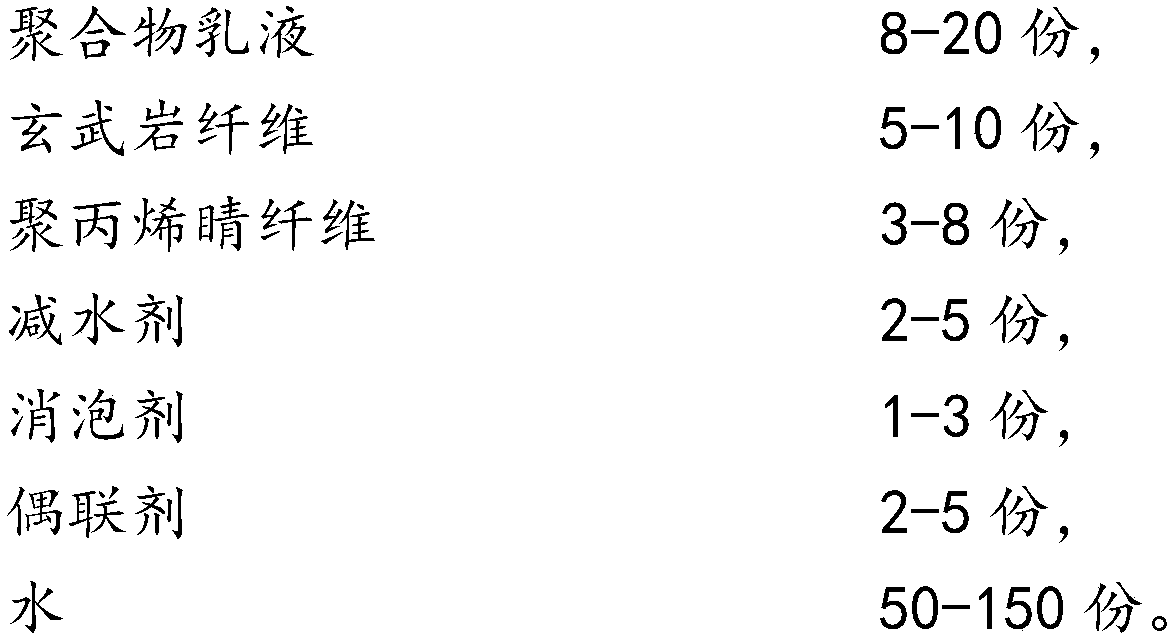

[0019] This embodiment discloses a polymer cement-based modified mortar, including the following raw materials measured in parts by mass:

[0020]

Embodiment 3

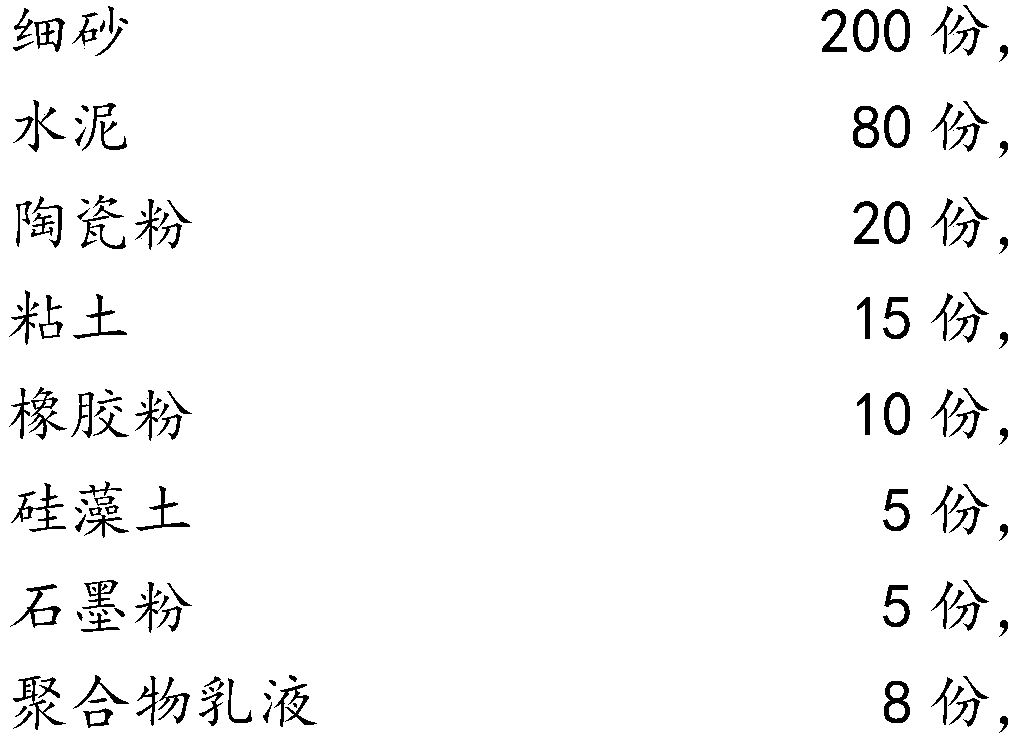

[0022] This embodiment discloses a polymer cement-based modified mortar, including the following raw materials measured in parts by mass:

[0023]

[0024]

[0025] Among them, the cement is a mixture of aluminate cement and Portland cement; the mass ratio of aluminate cement to Portland cement is 2:1. Sulphoaluminate cement undergoes hydration reaction after being mixed with water, and produces high early strength after hardening, and the strength increases steadily in the later period. When combined with Portland cement, the early strength of the mortar is good, and the frost resistance and waterproof performance are good. The polymer emulsion is polyacrylate emulsion and ethylene-vinyl acetate copolymer emulsion; the mass ratio of polyacrylate emulsion to ethylene-vinyl acetate copolymer emulsion is 1:1. Polyacrylate emulsion has good performance improvement in anti-seepage and waterproof, and ethylene-vinyl acetate copolymer emulsion has good performance improvement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com