Sound insulation and noise reduction composite waved plate tile and production process thereof

A composite, corrugated board technology, applied in the field of corrugated boards, can solve the problems of unsatisfactory flame retardancy, poor impact resistance, insufficient sound insulation and noise reduction, etc., to improve interface compatibility, improve heat resistance, and improve The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

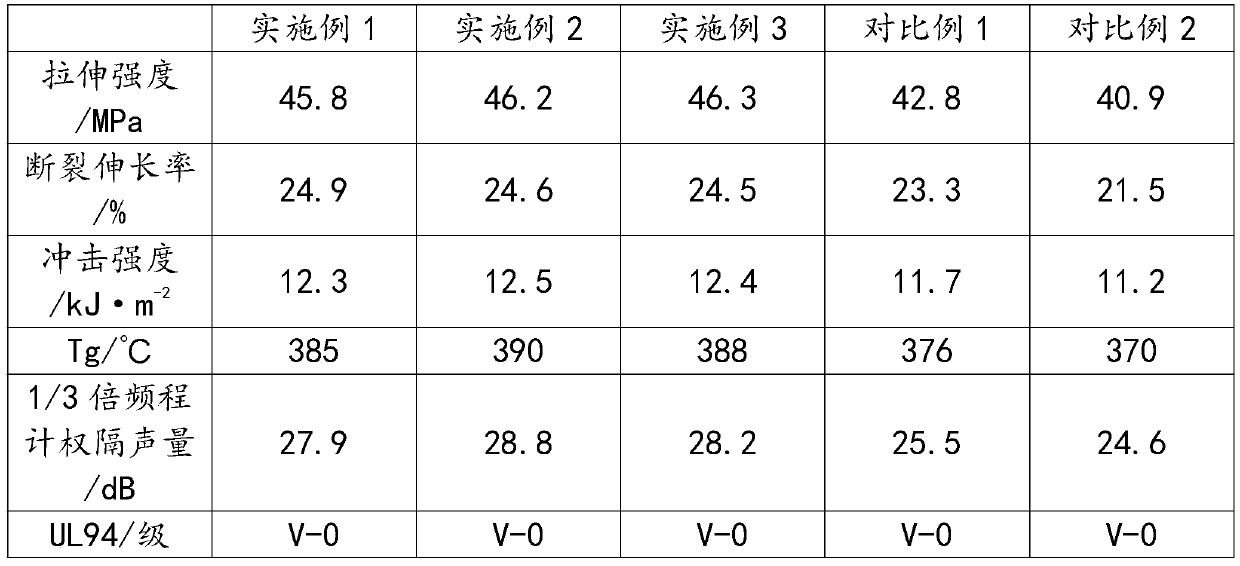

Embodiment 1

[0055] The PC layer is made of the following raw materials in parts by weight: 60 parts of PC resin, 15 parts of polyacrylonitrile-butadiene-styrene copolymer, 0.8 part of ultraviolet absorber, 2 parts of composite filler, and 0.5 part of compound flame retardant .

Embodiment 2

[0057] The PC layer is made of the following raw materials in parts by weight: 65 parts of PC resin, 18 parts of polyacrylonitrile-butadiene-styrene copolymer, 0.9 part of ultraviolet absorber, 2.5 parts of composite filler, 0.6 part of compound flame retardant .

Embodiment 3

[0059] The PC layer is made of the following raw materials in parts by weight: 70 parts of PC resin, 20 parts of polyacrylonitrile-butadiene-styrene copolymer, 1 part of ultraviolet absorber, 3 parts of composite filler, 0.7 part of compound flame retardant .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com