Emulsified asphalt with high viscosity and high elasticity and preparation method of emulsified asphalt

An emulsified asphalt, high-elasticity technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of reduced asphalt strength and water resistance, arduous tasks of road maintenance, poor asphalt toughness and viscous toughness, etc. Achieve the effect of aging ductility improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

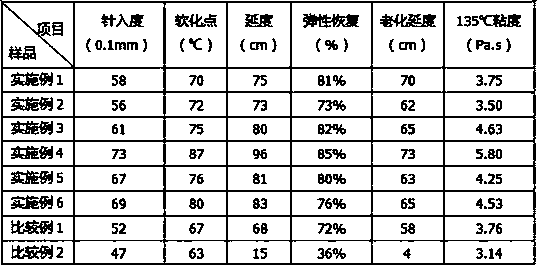

Embodiment 1

[0043] Select 80 parts of 40# base asphalt, recycle 10 parts of old tire rubber powder, 3 parts of tackifier (2.75 parts of styrene-butadiene-styrene block copolymer, 0.15 parts of maleic anhydride), polyethylene 5 parts of pyrrolidone, 5 parts of styrene-butadiene block copolymer, 0.5 part of carbon black, 0.05 part of asphaltene peptizer, 0.1 part of modified calcium carbonate, and 0.1 part of sorbitan trioleate 2 parts, water is 20 parts.

[0044] A method for preparing high-viscosity and high-elasticity emulsified asphalt, the method for preparing high-viscosity and high-elasticity emulsified asphalt comprises the following steps:

[0045] (1) Select 80 parts of 40# matrix asphalt, and remove the waste soil and stone inclusions in the asphalt raw material;

[0046] (2) Dry the asphalt raw material in step (1) in an oven at 80°C for 3 hours for later use;

[0047] (3) After pulverizing the asphalt raw material in step (2) with a pulverizer, sieve it with a 50-mesh stainle...

Embodiment 2

[0059] Select 96 parts of 110# base asphalt, 24 parts of recovered asphalt, 20 parts of styrene-butadiene block copolymer rubber powder, 10 parts of tackifier (3 parts of acrylic acid, hydrogenated styrene-butadiene block copolymer 7 parts), cetyltrimethylammonium bromide is 10 parts, ethylene-isoprene block copolymer is 10 parts, carbon black is 2 parts, lime is 2 parts, modified calcium carbonate It is 3 parts, polyoxyethylene sorbitol beeswax derivative is 8 parts, and water is 60 parts.

[0060] A method for preparing high-viscosity and high-elasticity emulsified asphalt, the method for preparing high-viscosity and high-elasticity emulsified asphalt comprises the following steps:

[0061] (1) Select 96 parts of 110# matrix asphalt, recover 24 parts of asphalt, and remove waste soil and stone inclusions in the asphalt raw materials;

[0062] (2) Dry the asphalt raw material in step (1) in an oven at 100°C for 5 hours for later use;

[0063] (3) After pulverizing the aspha...

Embodiment 3

[0075] Select 80 parts of 70# matrix asphalt, 20 parts of recovered asphalt, 15 parts of styrene-acrylonitrile-butadiene graft copolymer rubber powder, 6.5 parts of tackifier (5.36 parts of styrene-butadiene block copolymer , isocyanate 1.14 parts), sodium lauryl sulfate, polyethylene glycol is 7.5 parts, styrene-butadiene block copolymer, ethylene-isoprene block copolymer is 7.5 parts, carbon black is 1.3 parts, 1.02 parts of asphaltene peptizer and lime, 1.55 parts of modified calcium carbonate, 5 parts of sorbitan tristearate, and 40 parts of water.

[0076] A method for preparing high-viscosity and high-elasticity emulsified asphalt, the method for preparing high-viscosity and high-elasticity emulsified asphalt comprises the following steps:

[0077] (1) Select 80 parts of 70# matrix asphalt, recover 20 parts of asphalt, and remove the waste soil and stone inclusions in the asphalt raw materials;

[0078] (2) Dry the asphalt raw material in step (1) in an oven at 90°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com