Patents

Literature

80results about How to "Good elasticity recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

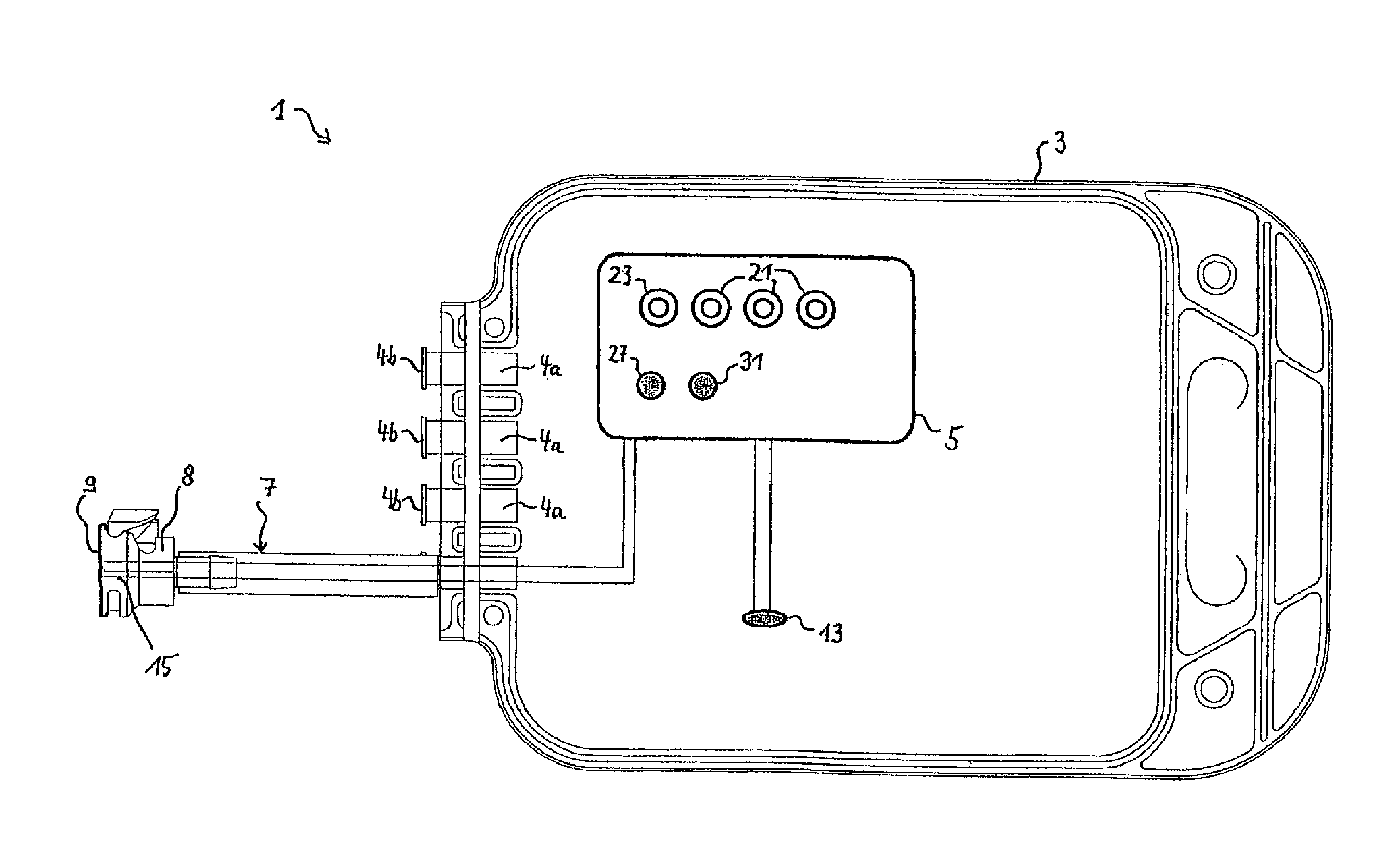

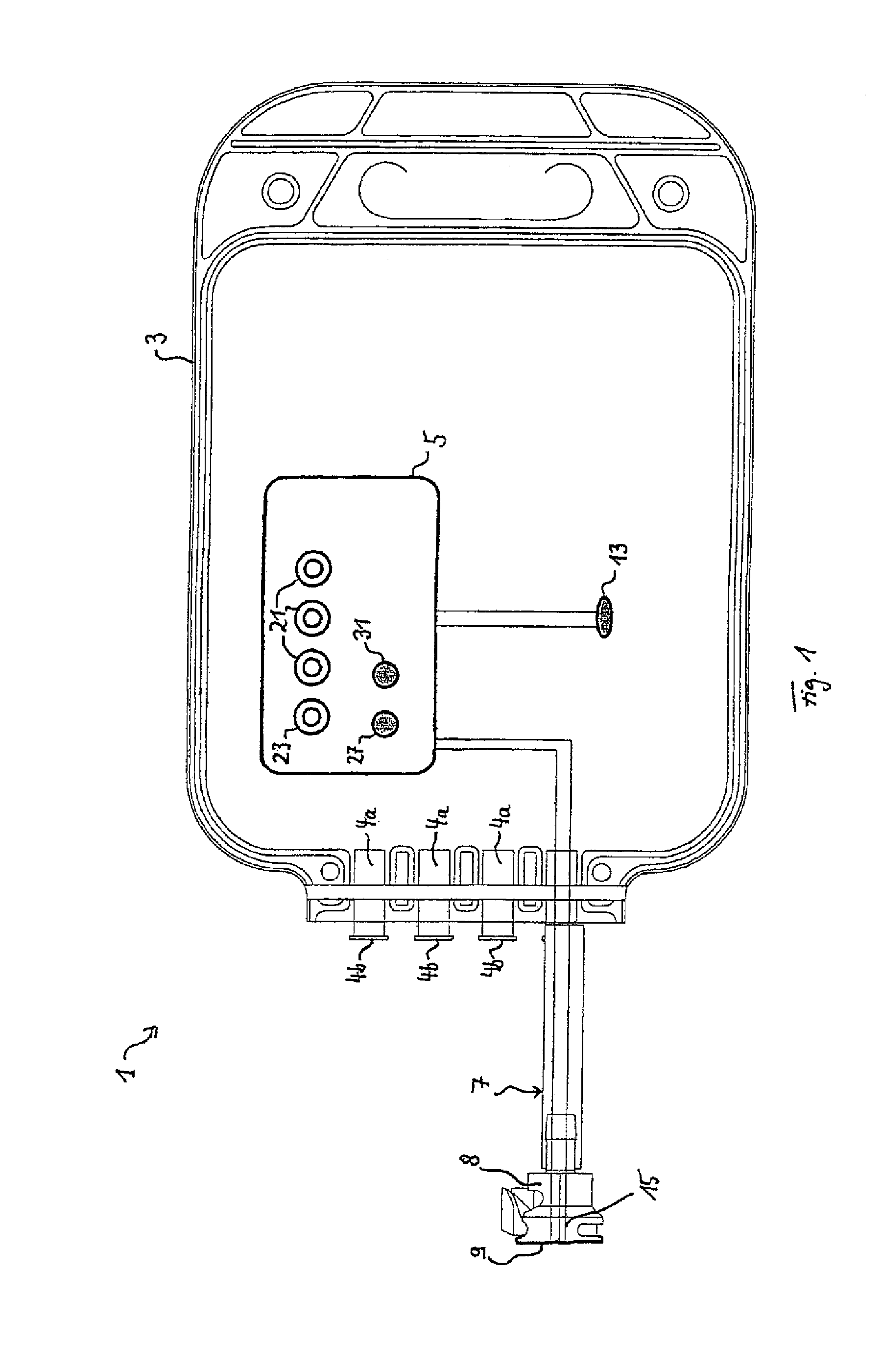

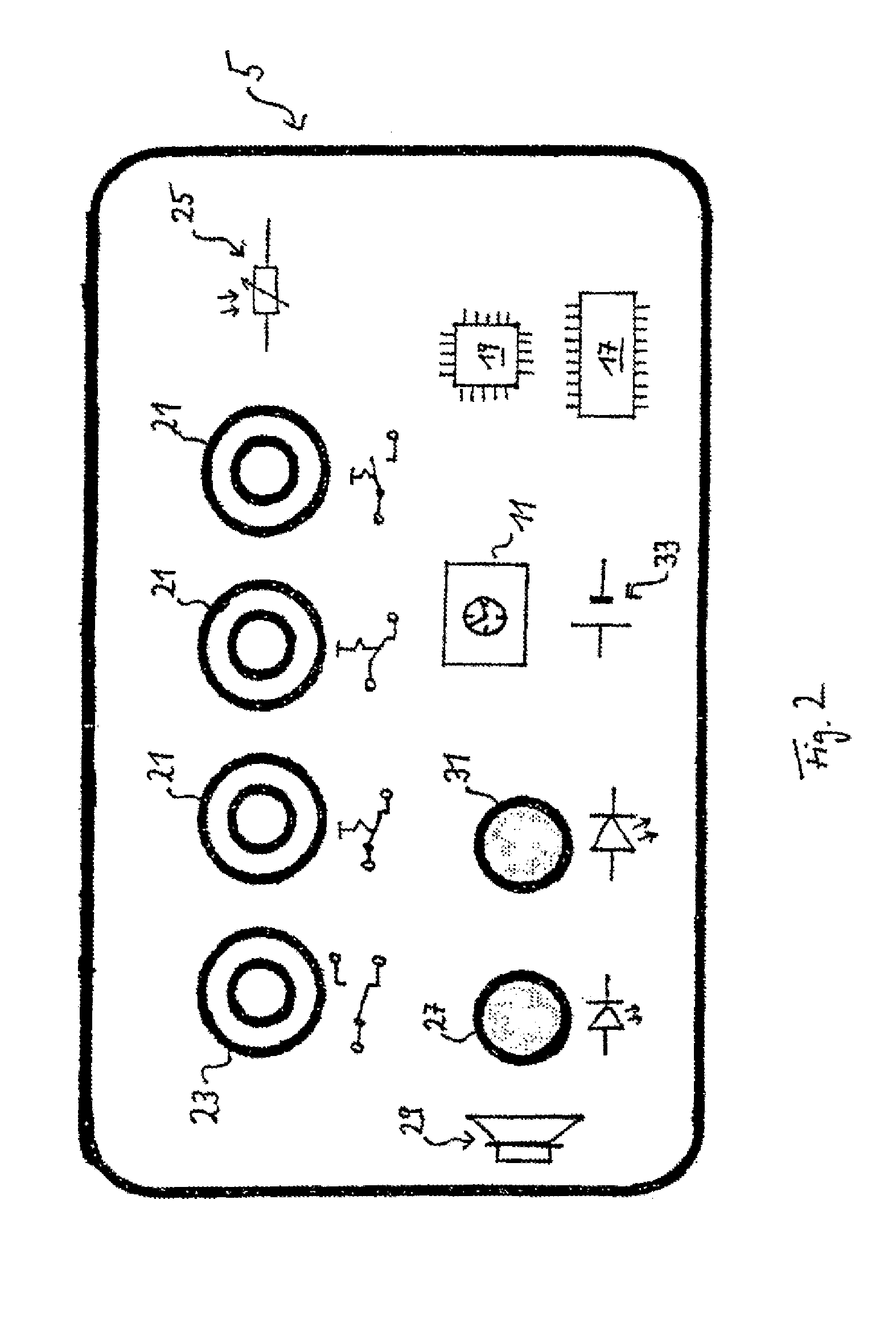

Container having a computer product

ActiveUS20110198255A1The process parameters are simpleSimple processReagent containersPharmaceutical containersDocumentation procedureComputer science

A storage and / or reaction container system for fluids, includes a container and an electronic documentation device connected to the container. The documentation device further includes a timing device for capturing a point in time, at least one sensor, at least one input device for capturing inputs, and a storage device to store for readout at least one measured value captured by the at least one sensor device and / or an input captured by the at least one input device. The at least one measured value and / or the at least one input is associated by the timing device with the point in time of the capture.

Owner:SARTORIUS STEDIM BIOTECH GMBH

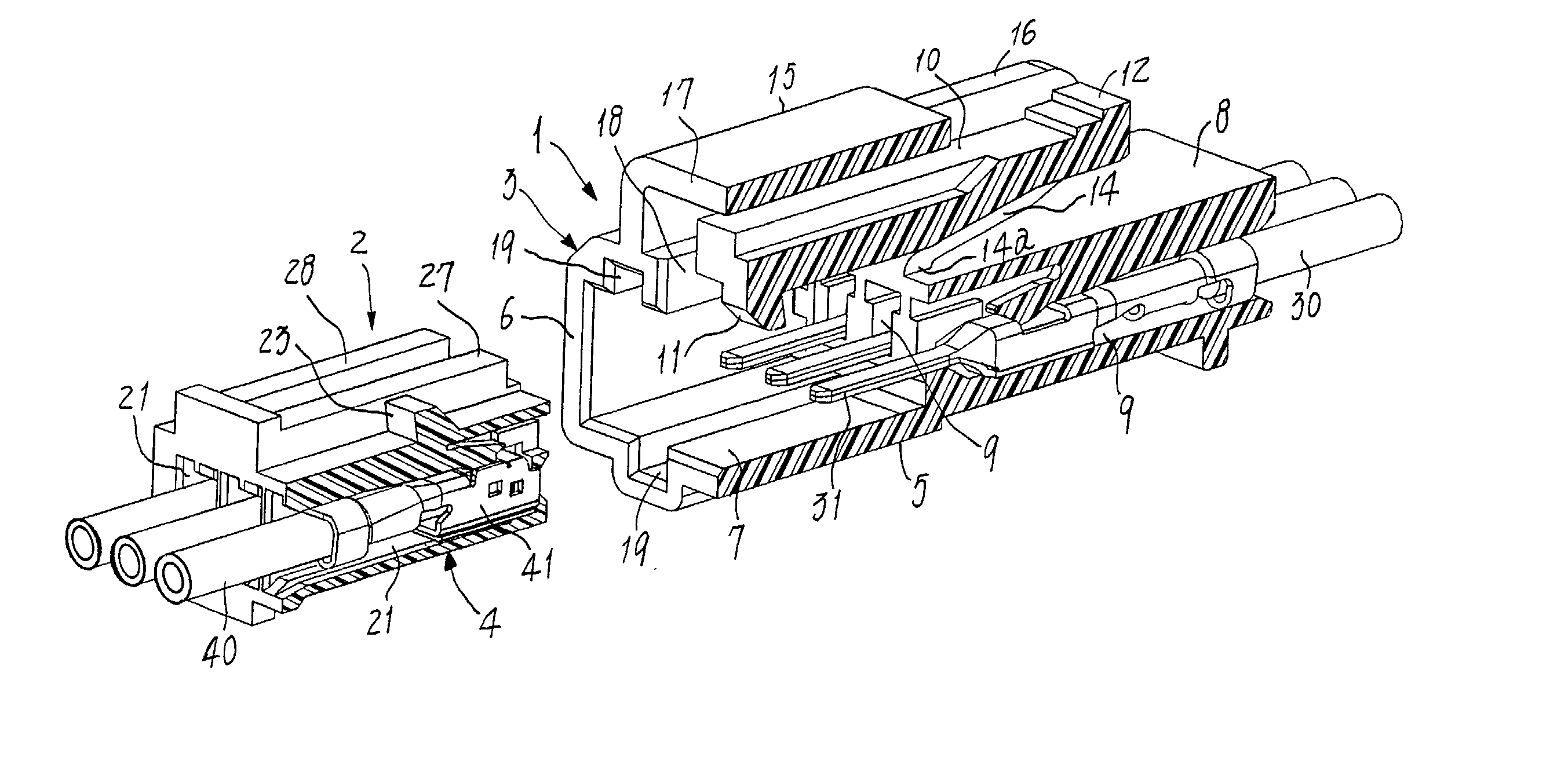

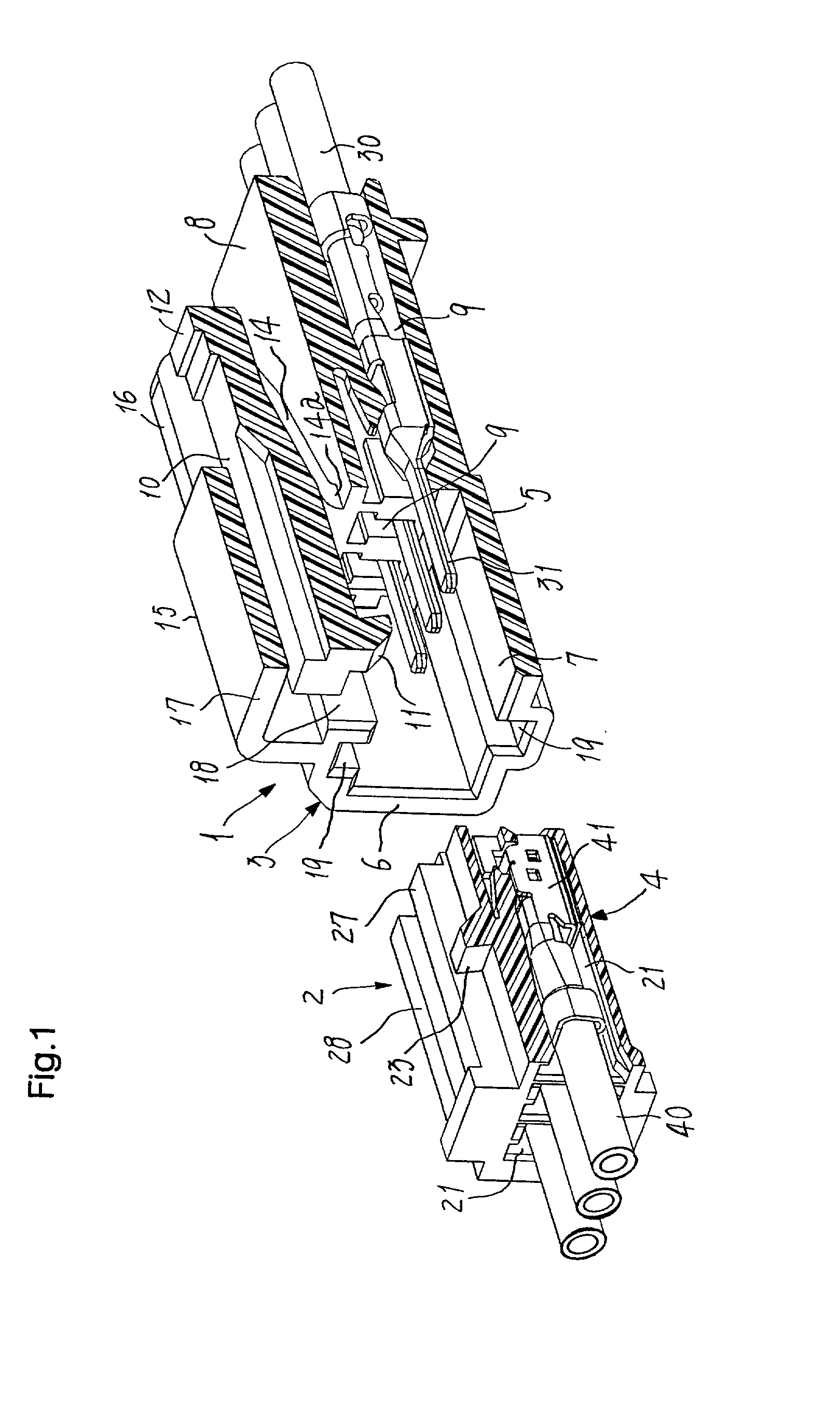

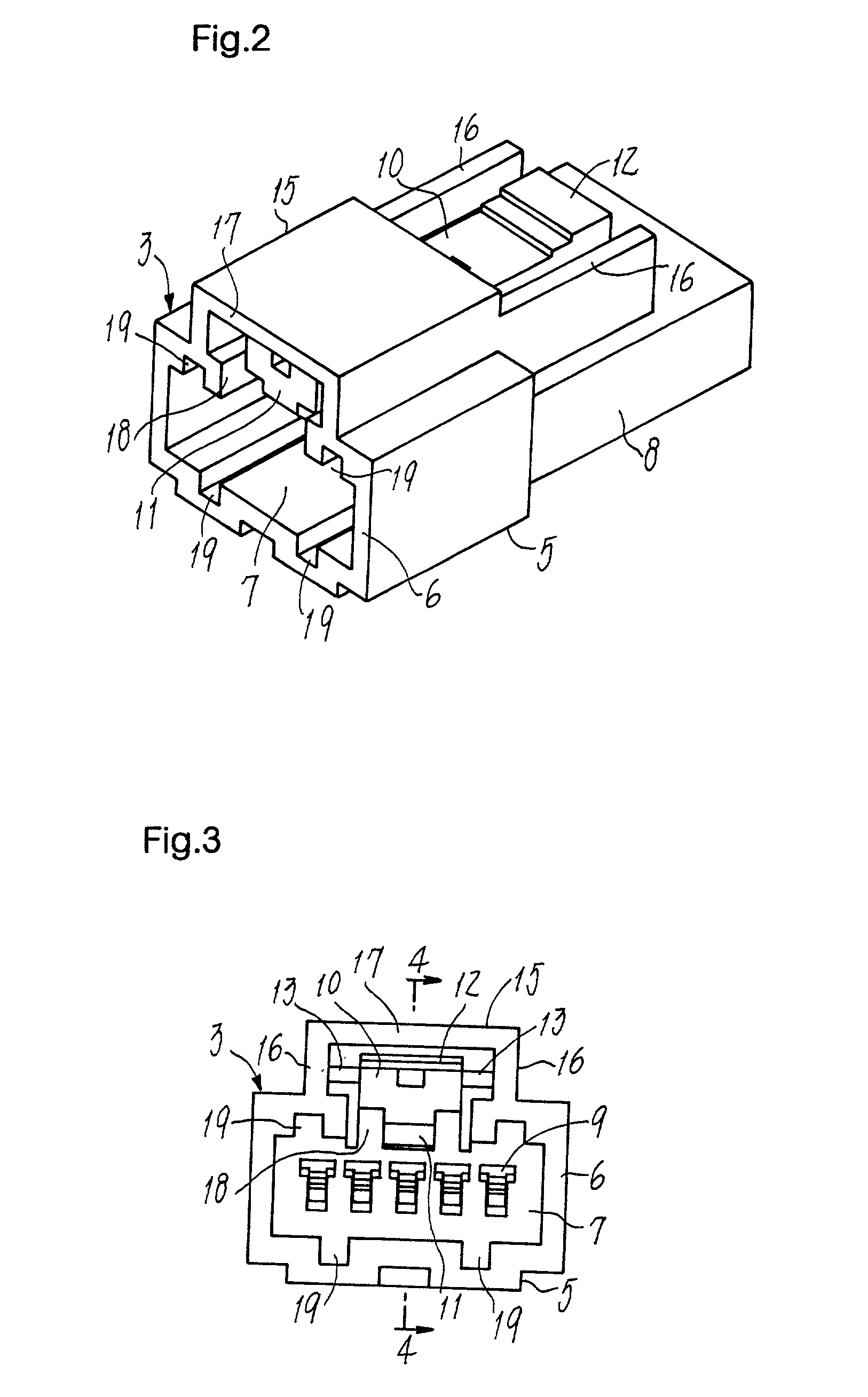

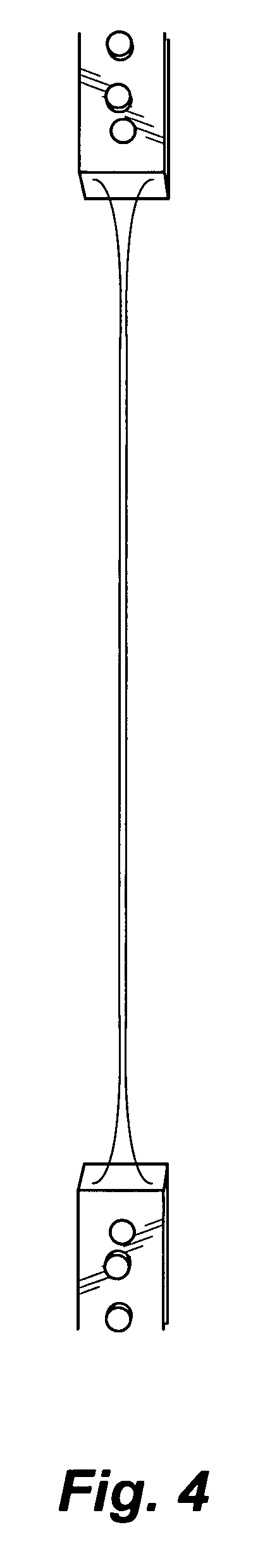

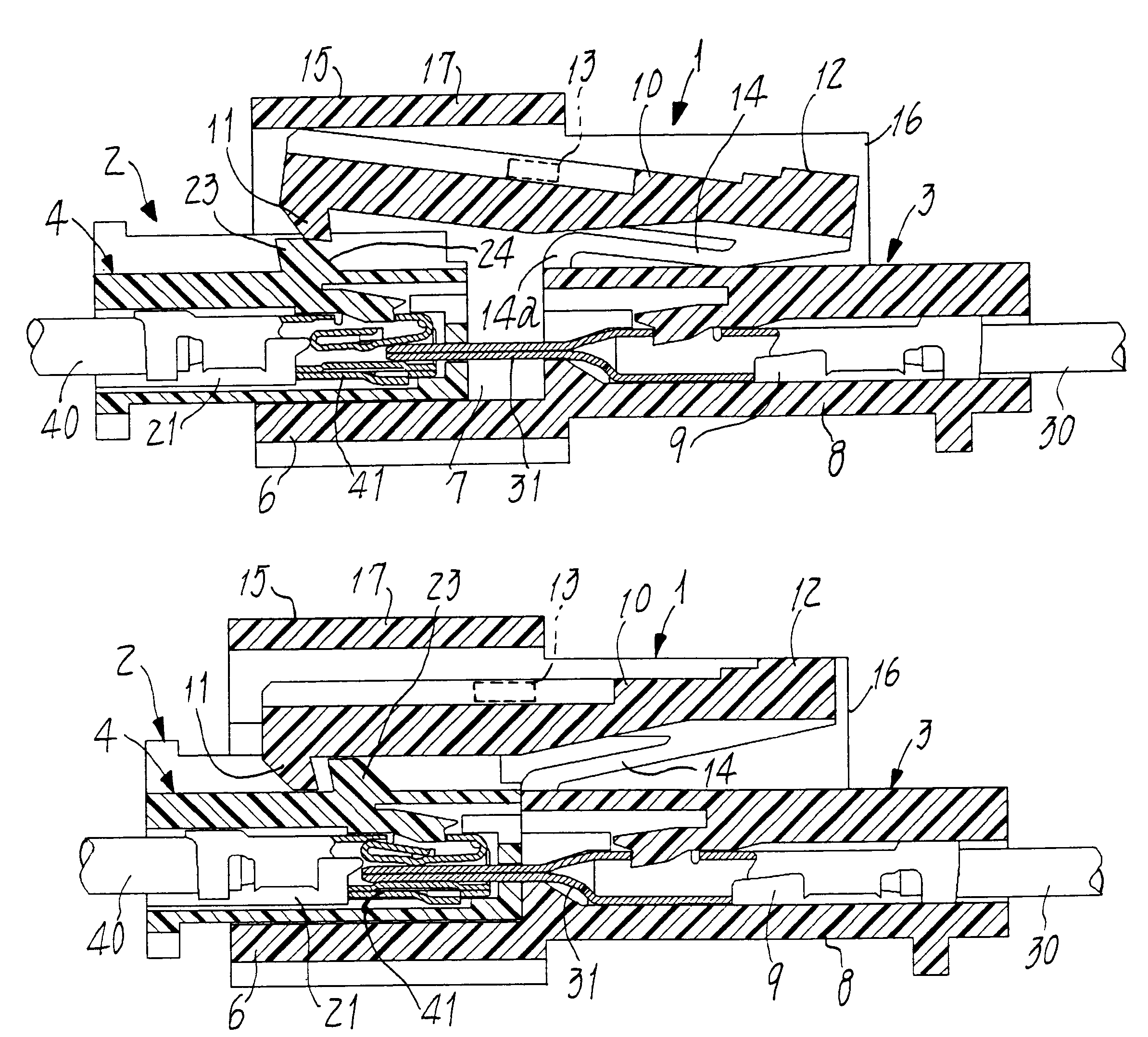

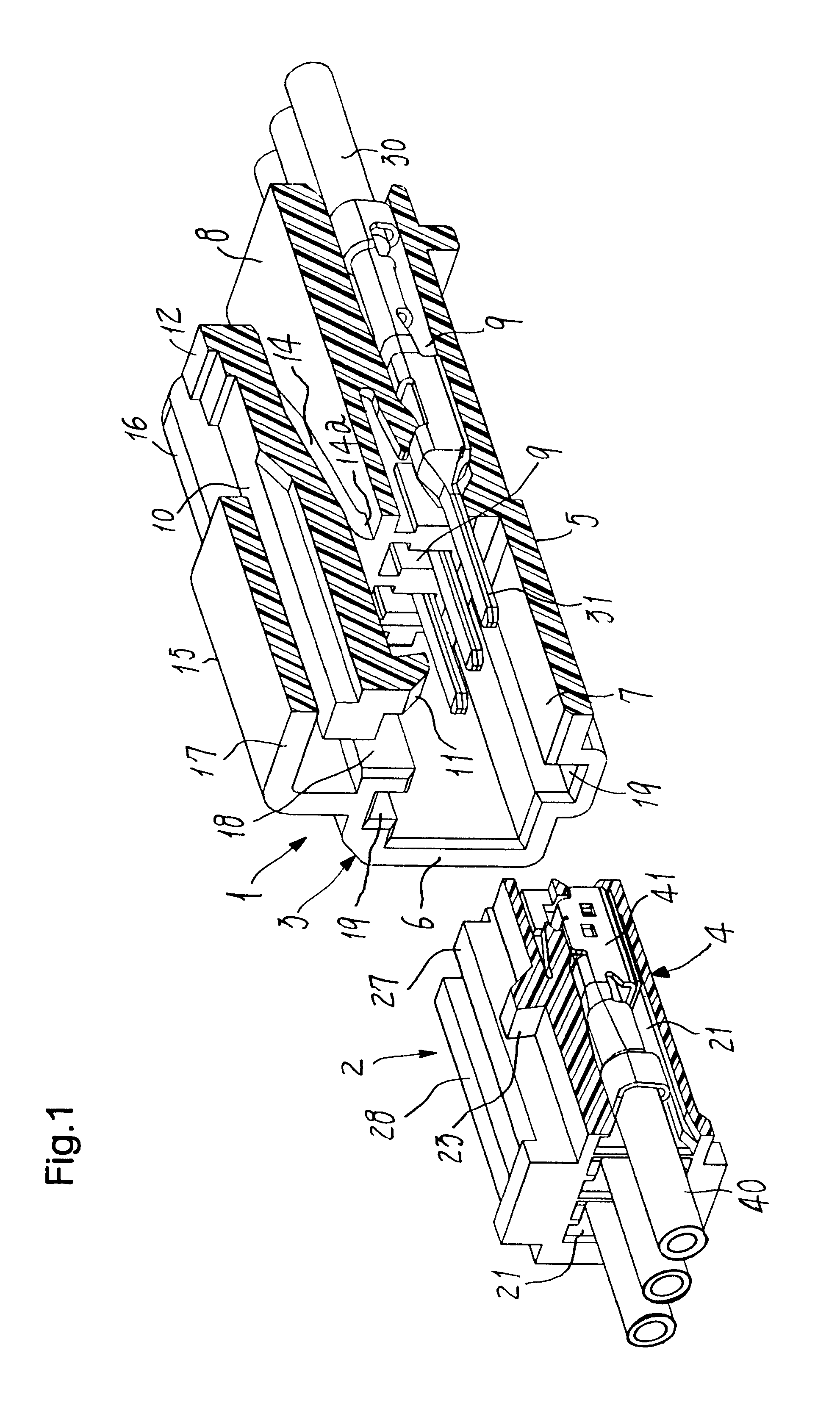

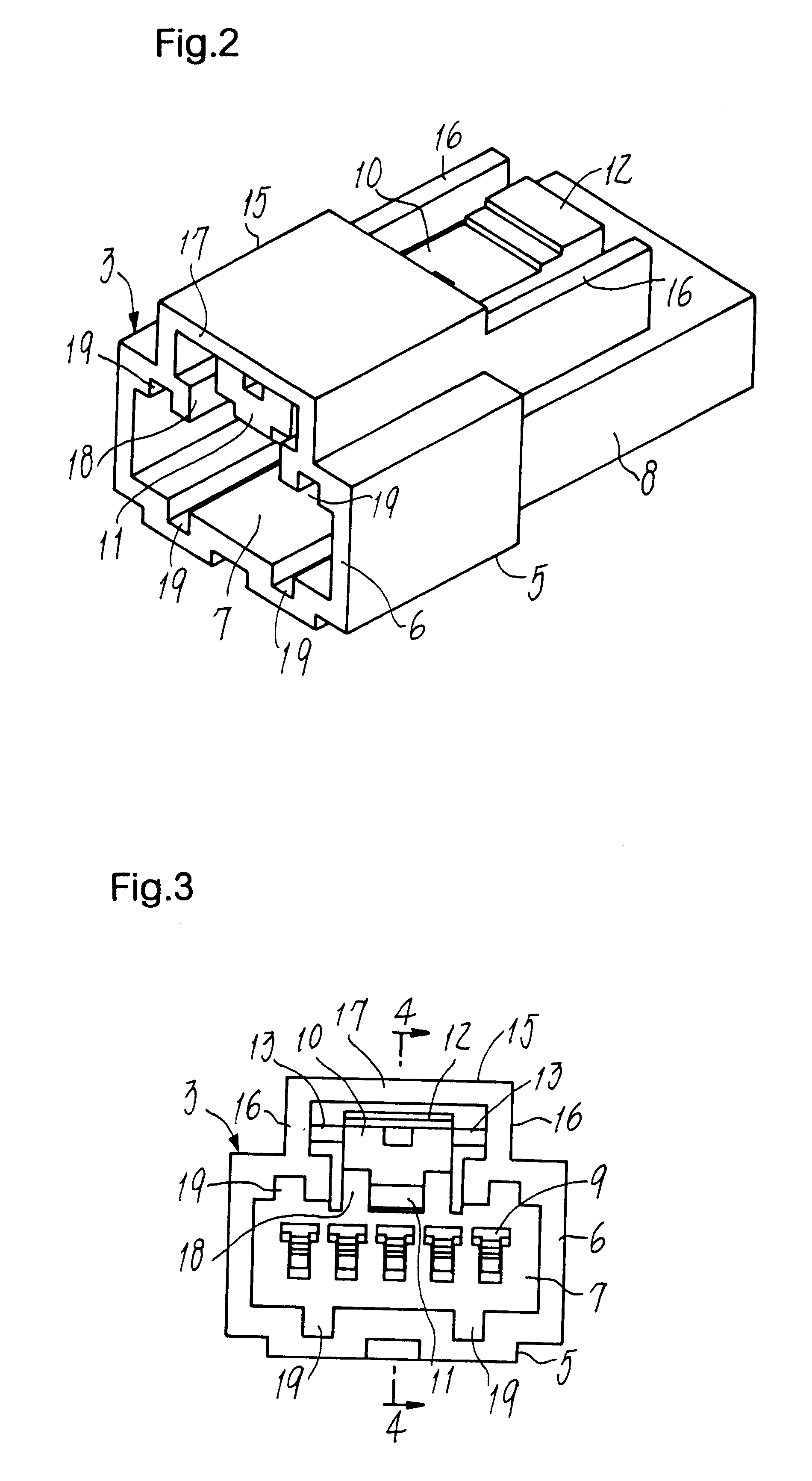

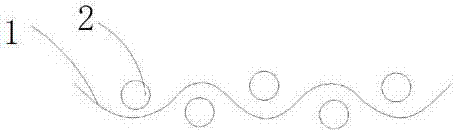

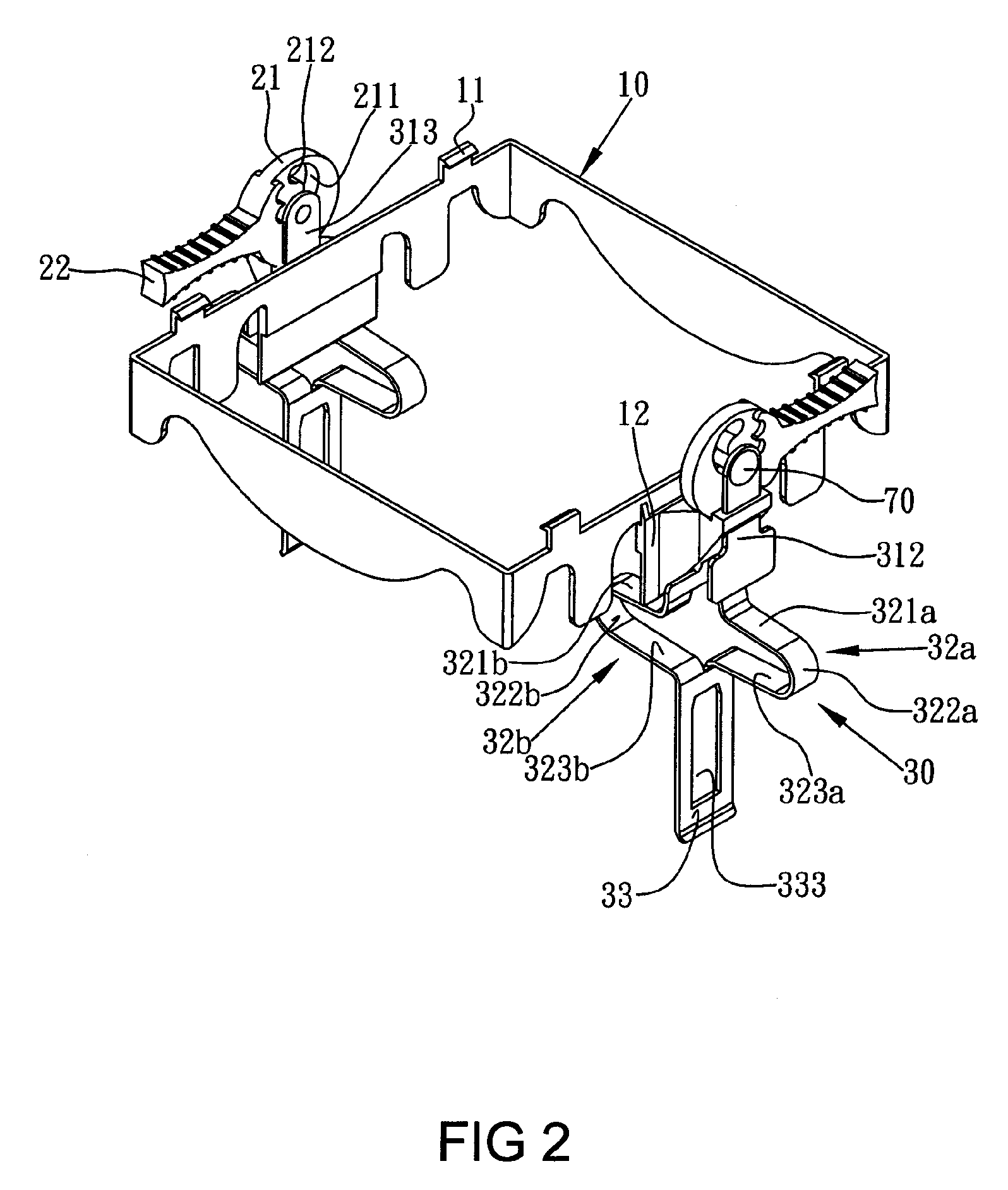

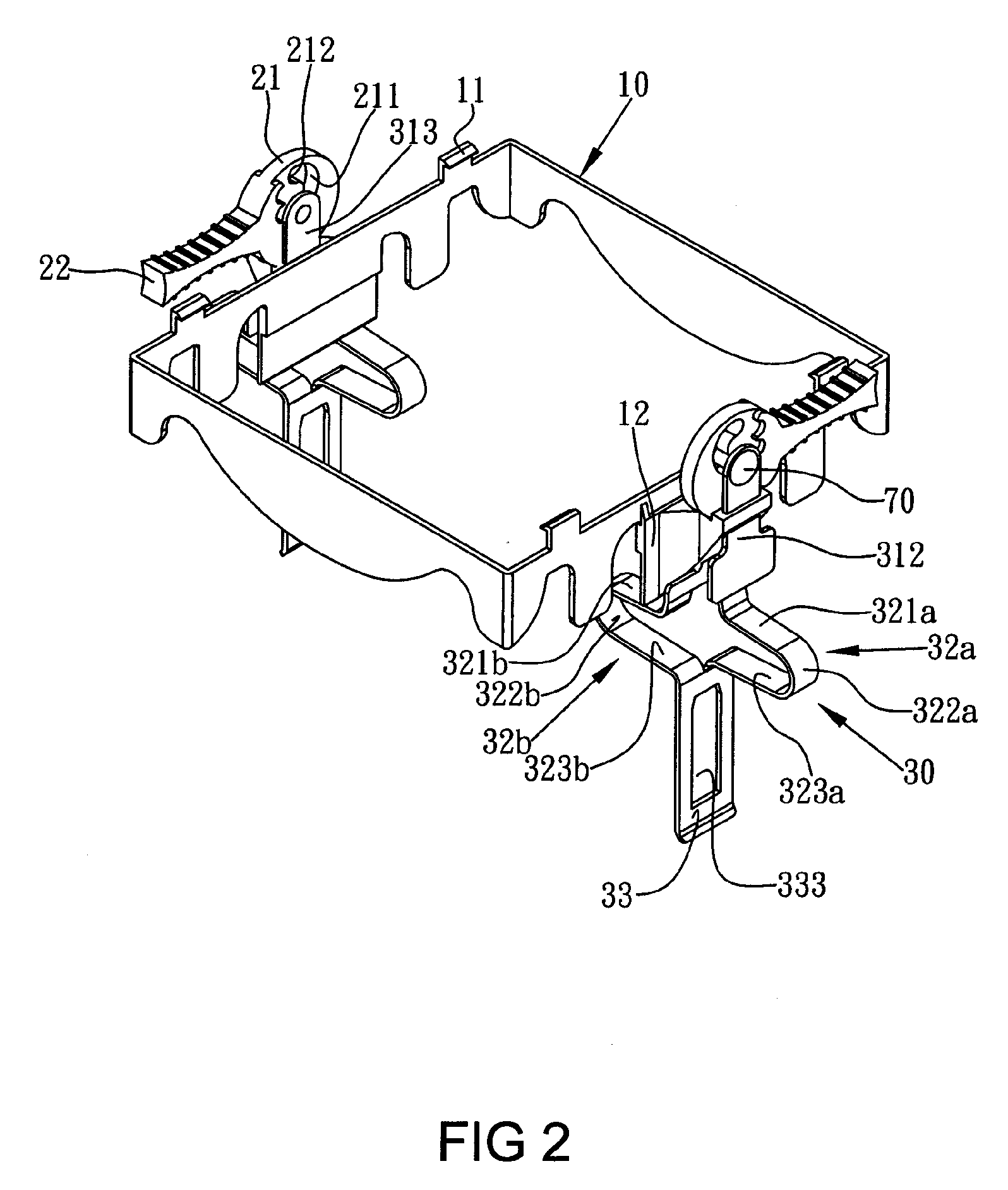

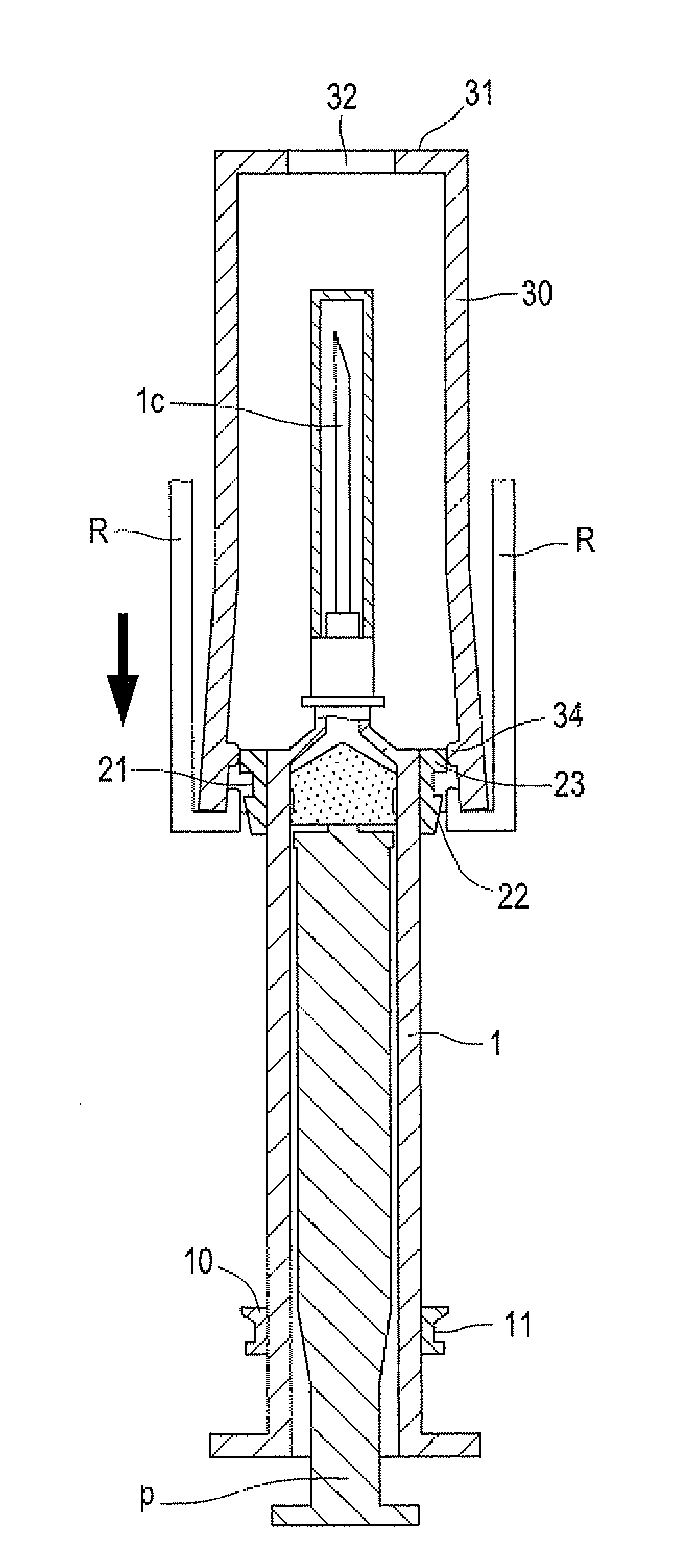

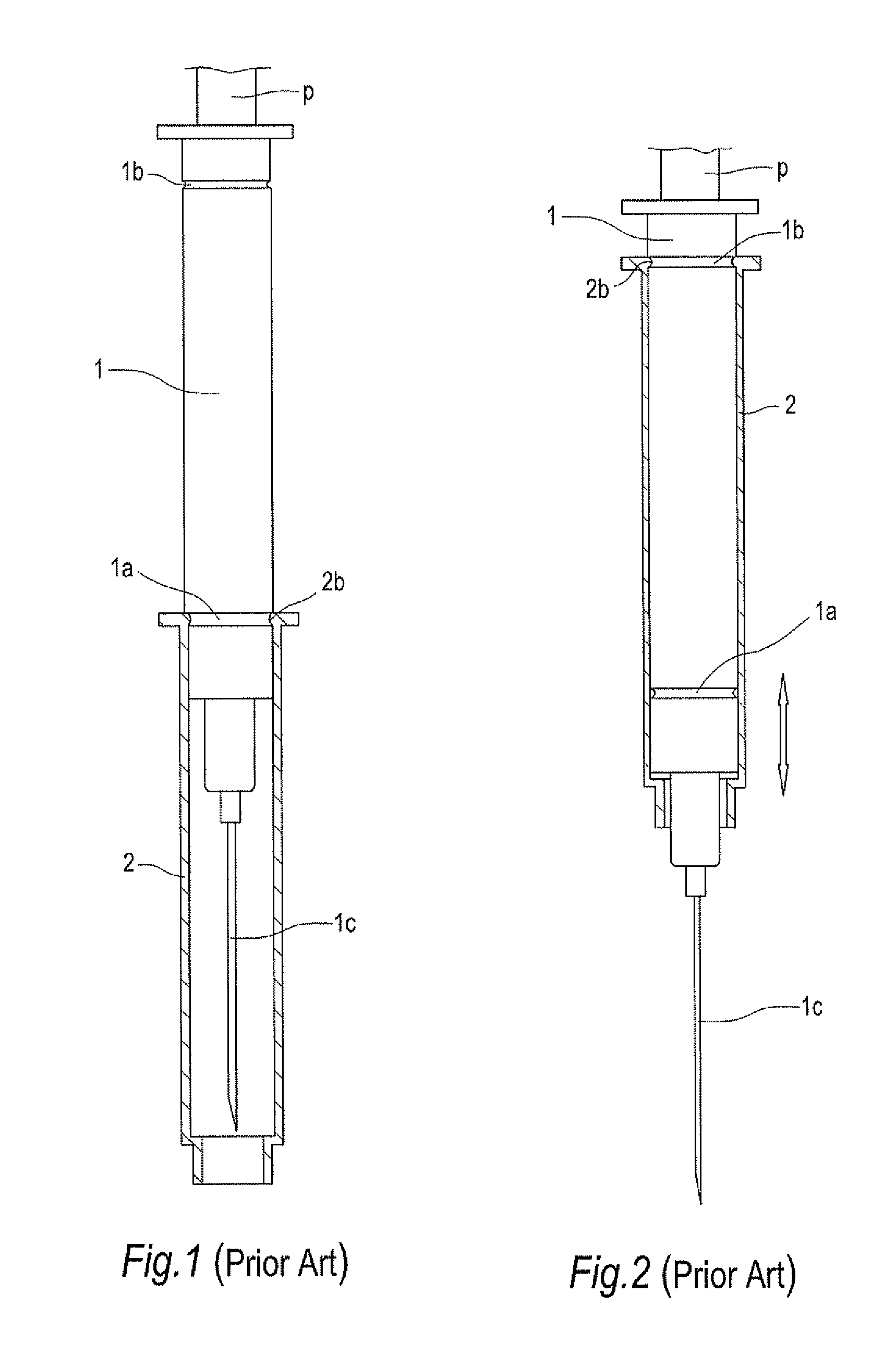

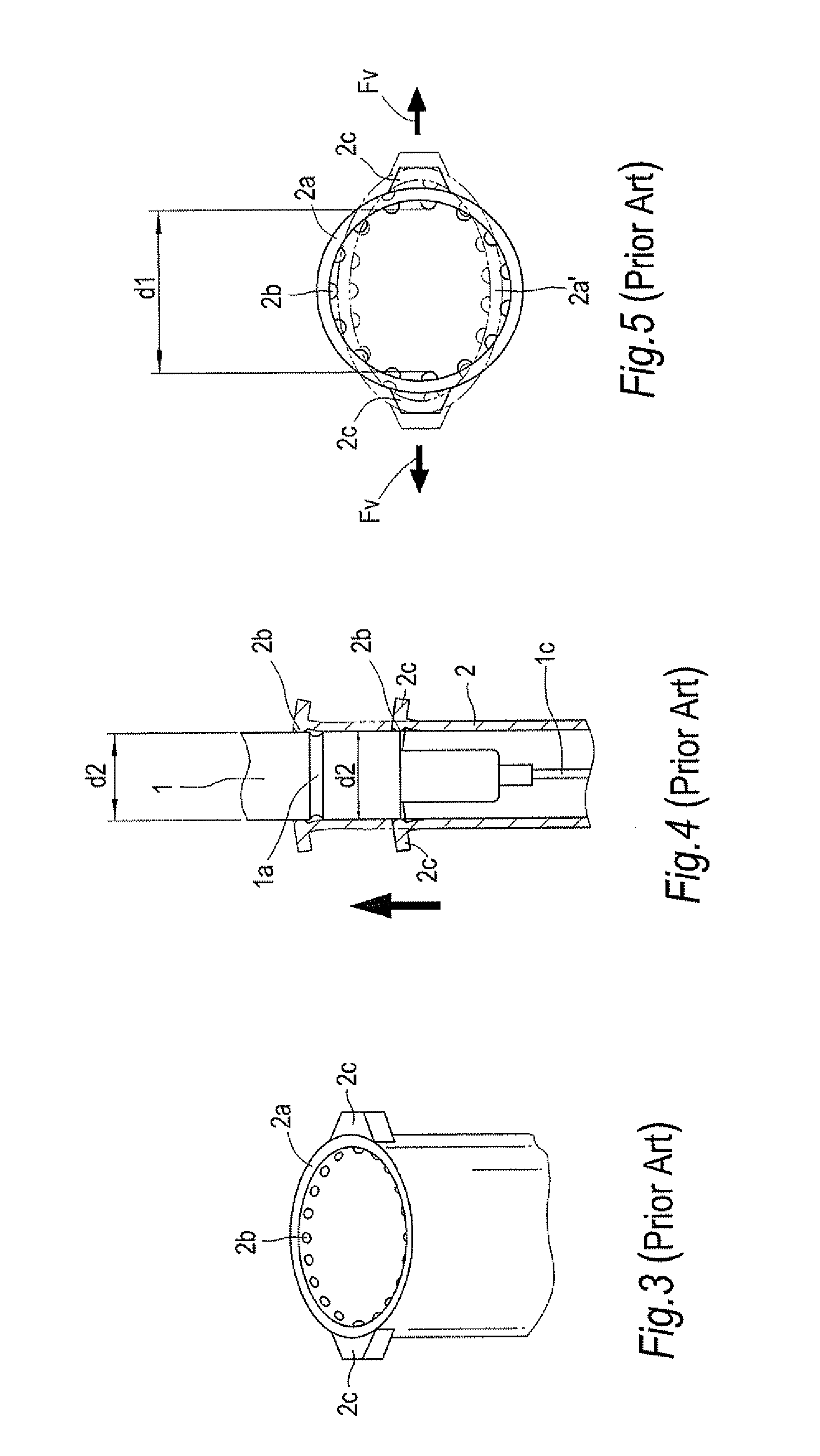

Connector assembly having a latching mechanism

InactiveUS20020119693A1Feel goodImprove rigidityIncorrect coupling preventionMechanical engineeringCable harness

A connector assembly has a male connector (1) engaging with a female connector (2), and a latching mechanism is composed of a lockable lug (23) formed on a female housing (4) and a lock arm (10) formed on a male housing (3). Elastically deforming hinge-shaped feet (13) have each one end integral with the male housing and the other end continuing from the lock arm, whose pawl (11) corresponds to the lug (23), so that the lock arm (10) rocks about the feet to engage the pawl with the lug. A push lever (12) has lateral ends integral with the lock arm's rear end disposed in rear of the feet (13). A supplementary resilient arm (14) continues from the rear end to be inclined down and forwards. Its fore end is fixed on the outer surface of male housing (3), such that the housings are firmly locked together to give a stronger "click' feeling for detection of engagement, with wire ends from any foreign harness never catching the push lever.

Owner:JST MFG CO LTD

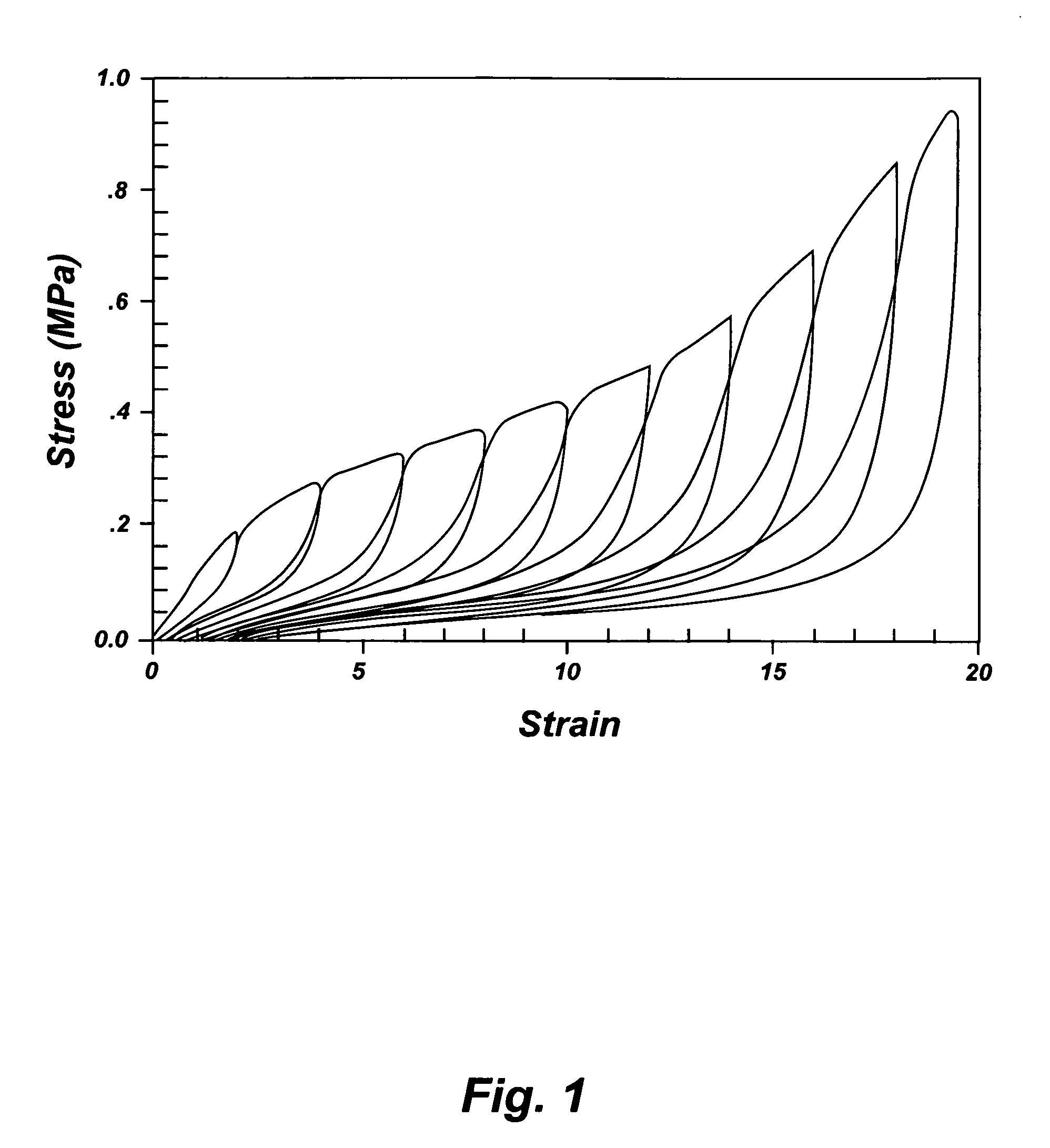

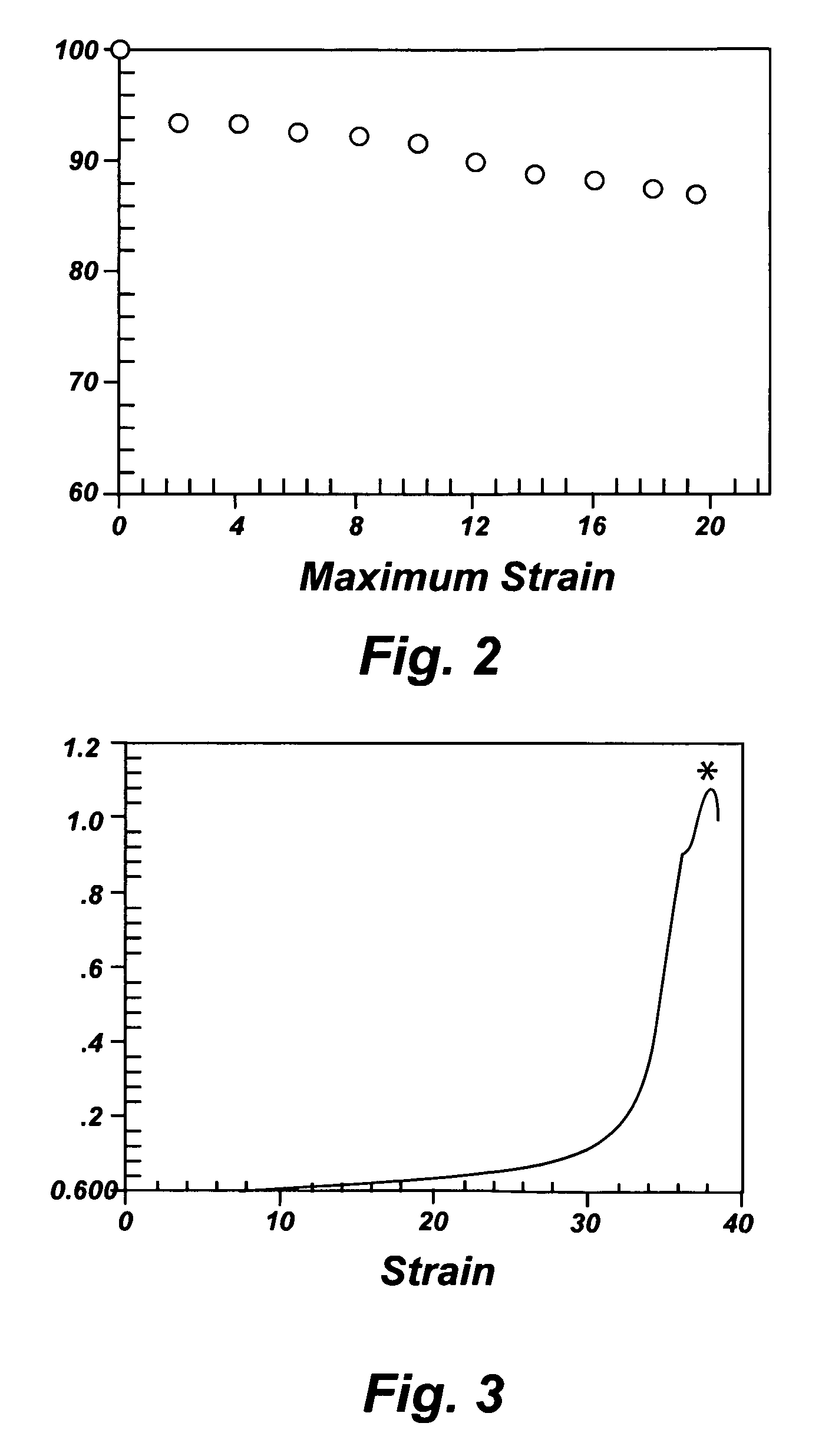

Soft and strong elastomeric compositions from semicrystalline-amorphous polyolefin block copolymers

ActiveUS20080319116A1Remarkable mechanical propertyExcellent elastic recoveryMixingCeramic shaping apparatusPolyolefinThermomechanical processing

Polyolefin block and graft copolymers comprised of two or more semicrystalline polyolefin blocks or grafts and one or more amorphous polyolefin blocks can be blended with a low molecular weight fluid diluent that preferentially locates within and swells the amorphous domains of the block or graft copolymer, while preserving the crystallinity of the semicrystalline block domains. After mechanical or thermomechanical processing, such compositions combine softness with high strength and high recoverable elasticity. Compositions are also disclosed whereby the diluent species is removed from the composition, either before or after the mechanical or thermomechanical processing, in order to create a strong elastic material with an ultra-low entanglement density within the amorphous domains.

Owner:RGT UNIV OF CALIFORNIA

Connector assembly having a latching mechanism

InactiveUS6561834B2Feel goodImprove rigidityIncorrect coupling preventionMechanical engineeringCable harness

A connector assembly has a male connector (1) engaging with a female connector (2), and a latching mechanism is composed of a lockable lug (23) formed on a female housing (4) and a lock arm (10) formed on a male housing (3). Elastically deforming hinge-shaped feet (13) have each one end integral with the male housing and the other end continuing from the lock arm, whose pawl (11) corresponds to the lug (23), so that the lock arm (10) rocks about the feet to engage the pawl with the lug. A push lever (12) has lateral ends integral with the lock arm's rear end disposed in rear of the feet (13). A supplementary resilient arm (14) continues from the rear end to be inclined down and forwards. Its fore end is fixed on the outer surface of male housing (3), such that the housings are firmly locked together to give a stronger "click' feeling for detection of engagement, with wire ends from any foreign harness never catching the push lever.

Owner:JST MFG CO LTD

Elastic fiber fabric and preparation method thereof

The invention relates to an elastic fiber fabric, in particular to an elastic fiber fabric and a preparation method thereof. Warps and wefts are respectively 150D or75D PTS elastic yarns. The elastic fiber fabric is prepared through the steps of winding, twisting, sectional warping, healding, weaving, blank inspection, unrolling and flattening, pre-shrinking treatment, presetting, dyeing, reduction clearing and finishing. The elastic fiber fabric and a preparation method thereof have the advantages as follows: the structure is simple, the chemical fiber differentiation is promoted, the added value is increased, the preparation steps are scientific and reasonable and conform to the basic state policy of energy conservation and emission reduction, and the fabric feels like nylon, has a bright and pure color, is far lower than spandex in price and is a preferred garment material.

Owner:杭州宏海纺织有限公司 +1

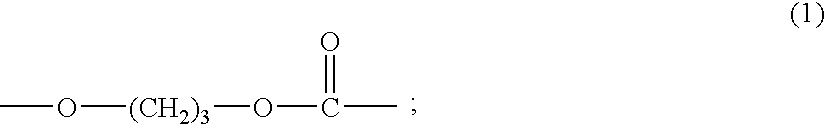

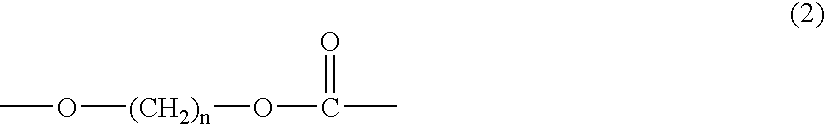

Copolycarbonate diol and thermoplastic polyurethane obtained therefrom

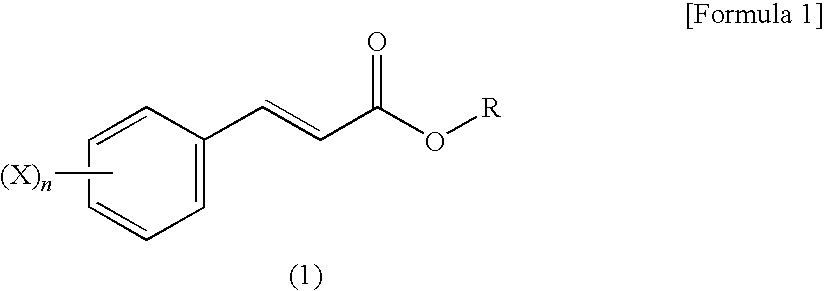

InactiveUS6872797B2Excellent resistance to hydrolysis , lightExcellent low temperature propertyOrganic chemistryOther chemical processesIsocyanateDiol

A copolycarbonate diol comprising:(a) recurring units each represented by the following formula (1): (b) recurring units each independently represented by the following formula (2): wherein n is 4, 5 or 6; and(c) terminal hydroxyl groups, wherein the copolycarbonate diol has a number average molecular weight of from 300 to 20,000, and wherein the amount of the recurring units (a) is from 10 to 90% by mole, based on the total molar amount of the recurring units (a) and (b). A thermoplastic polyurethane obtained by copolymerizing the above-mentioned copolycarbonate diol with a polyisocyanate.

Owner:ASAHI KASEI KOGYO KK

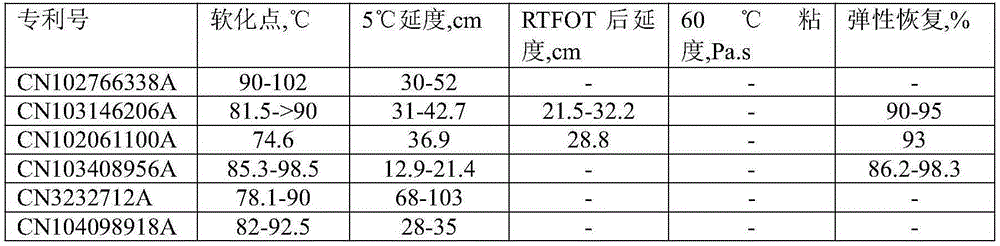

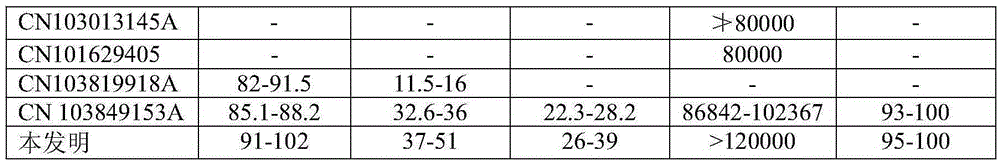

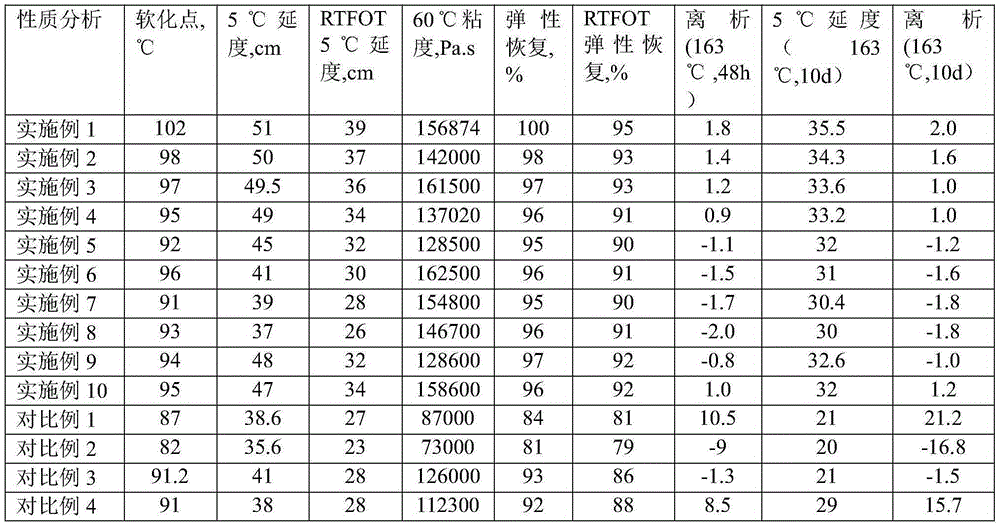

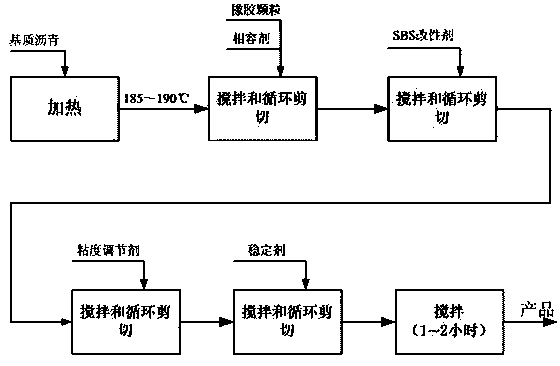

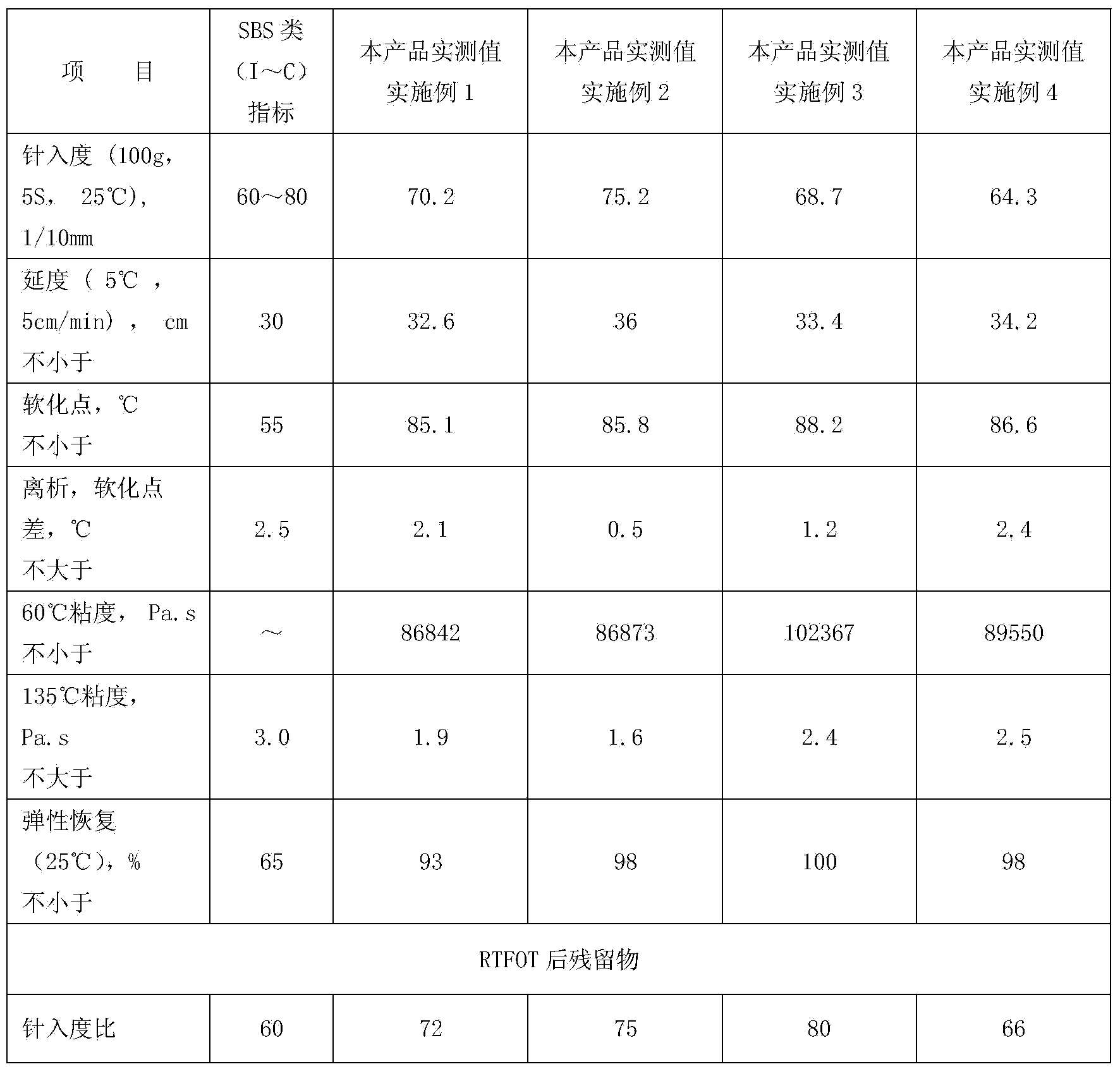

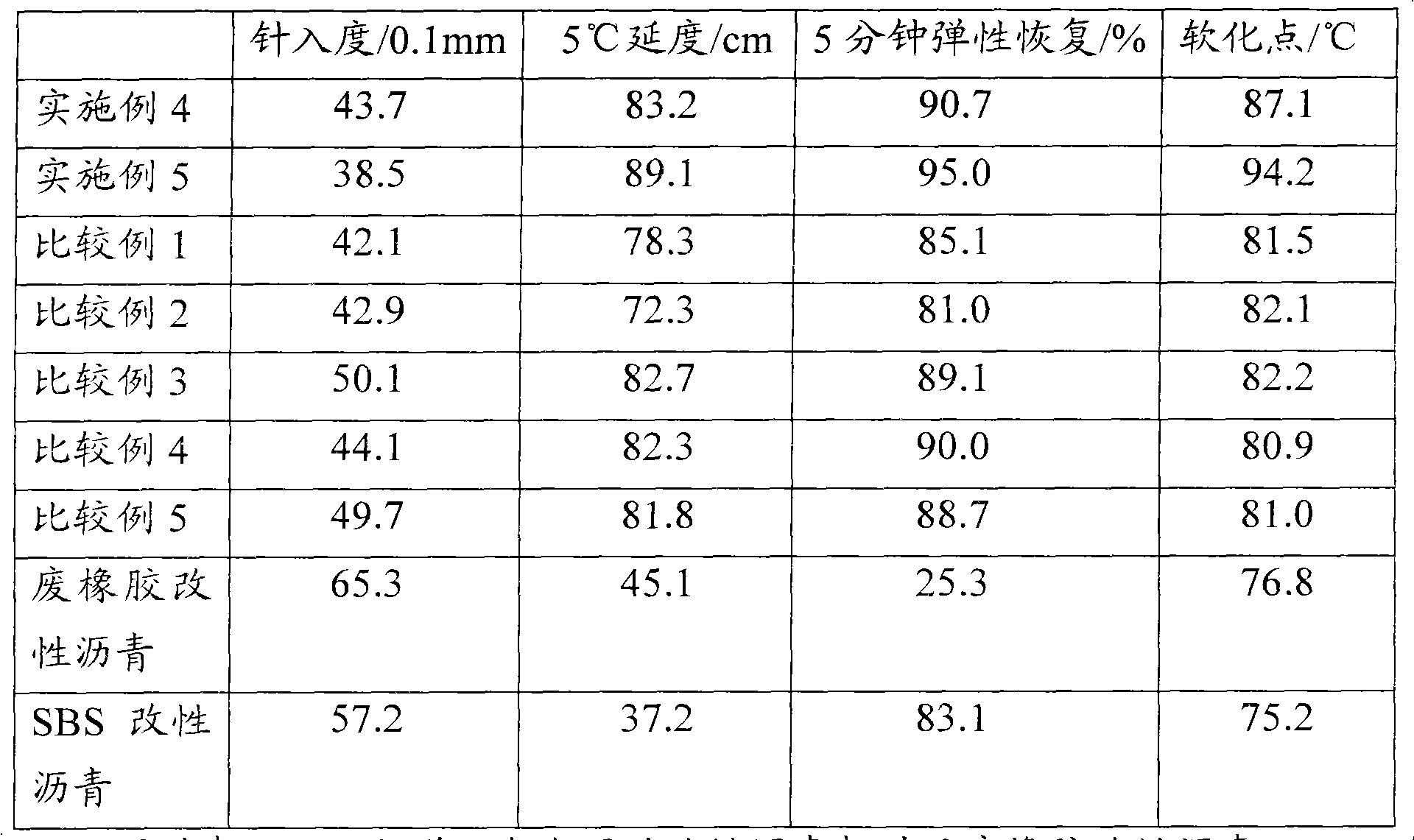

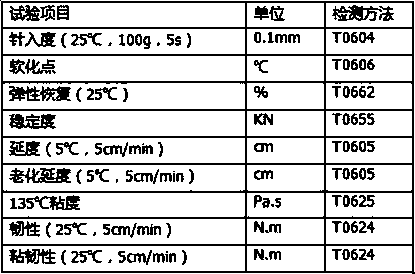

High temperature storable high viscosity and high elasticity modified asphalt and preparation method thereof

ActiveCN106800787AWide variety of sourcesEasy to promote and applyBuilding insulationsWaste rubberAging resistance

Owner:PETROCHINA CO LTD

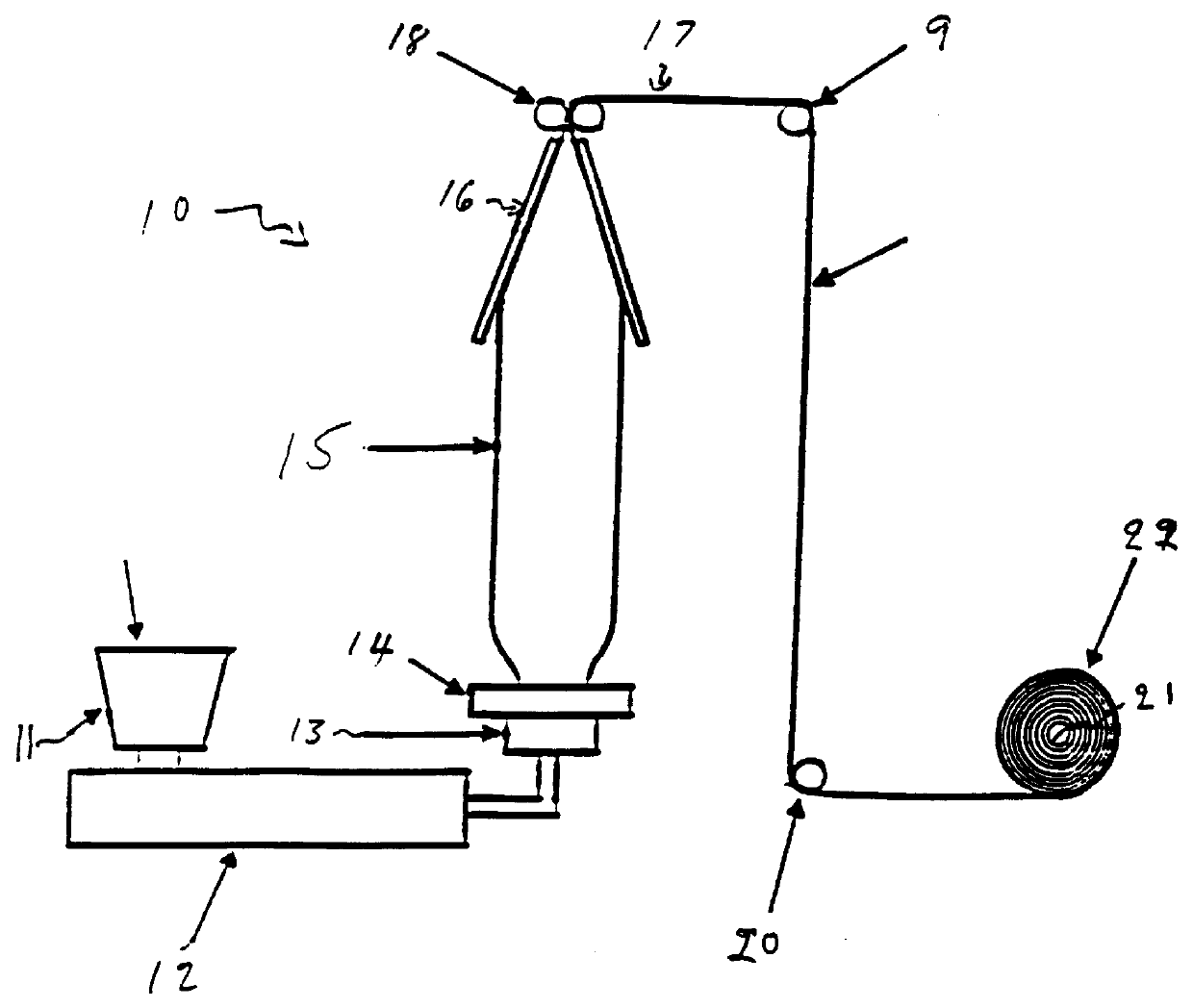

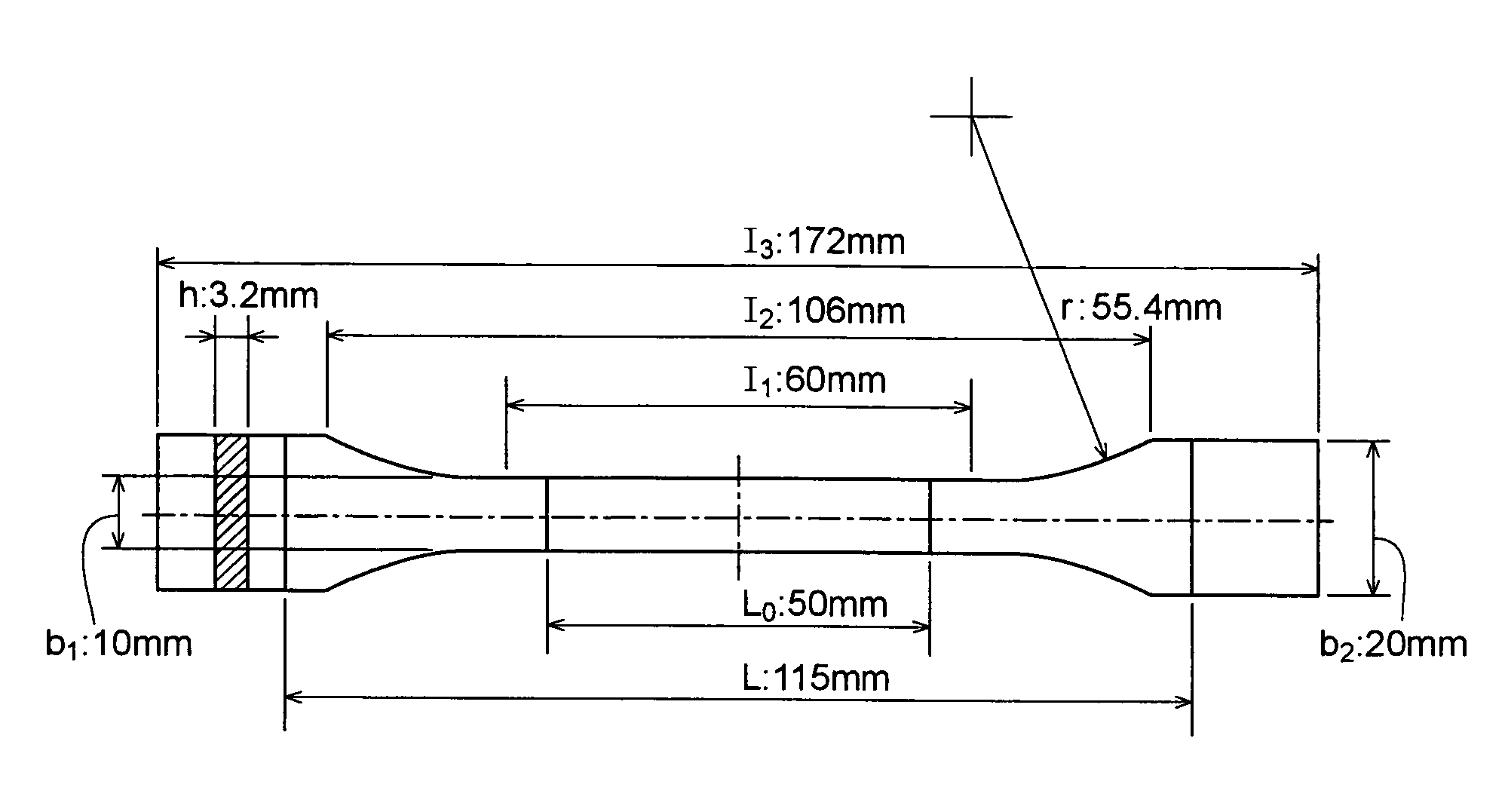

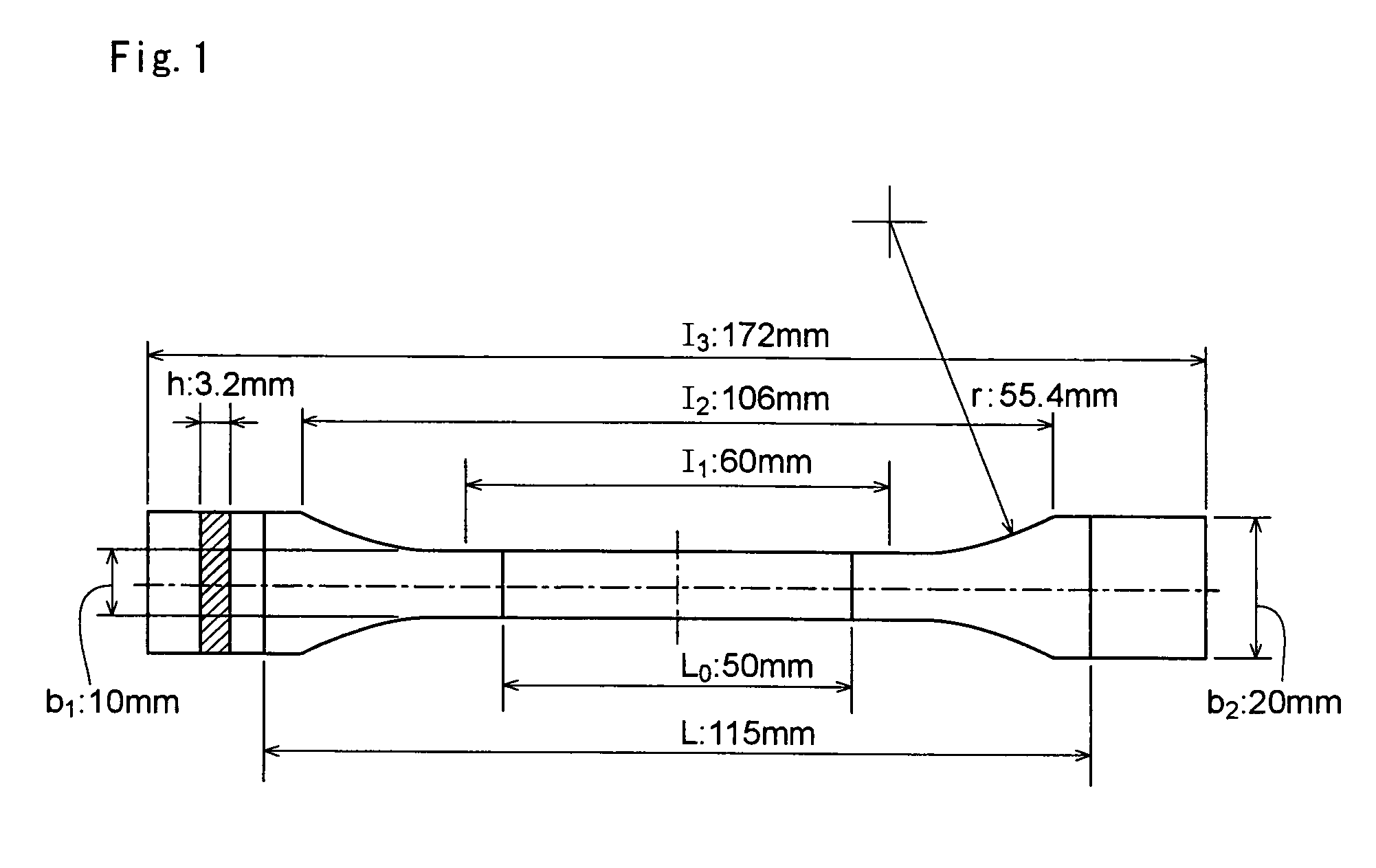

Method for producing polypropylene elastic fiber and polypropylene elastic fiber

InactiveUS20110236683A1Good elasticity recoveryHigh strengthMonocomponent polypropylene artificial filamentConjugated synthetic polymer artificial filamentsFiberPolymer science

Provided are a method of producing an elastic fiber, including the steps of: subjecting a raw material to melt extrusion with a spinning nozzle at 100 to 300° C.; cooling the fiber after the melt extrusion in a water bath at 0 to 50° C.; and winding the cooled fiber, in which a specific low-crystalline polypropylene is used as the raw material, and an elastic fiber having a core-sheath bicomponent structure, which is obtained by using a specific low-crystalline polypropylene.

Owner:IDEMITSU KOSAN CO LTD

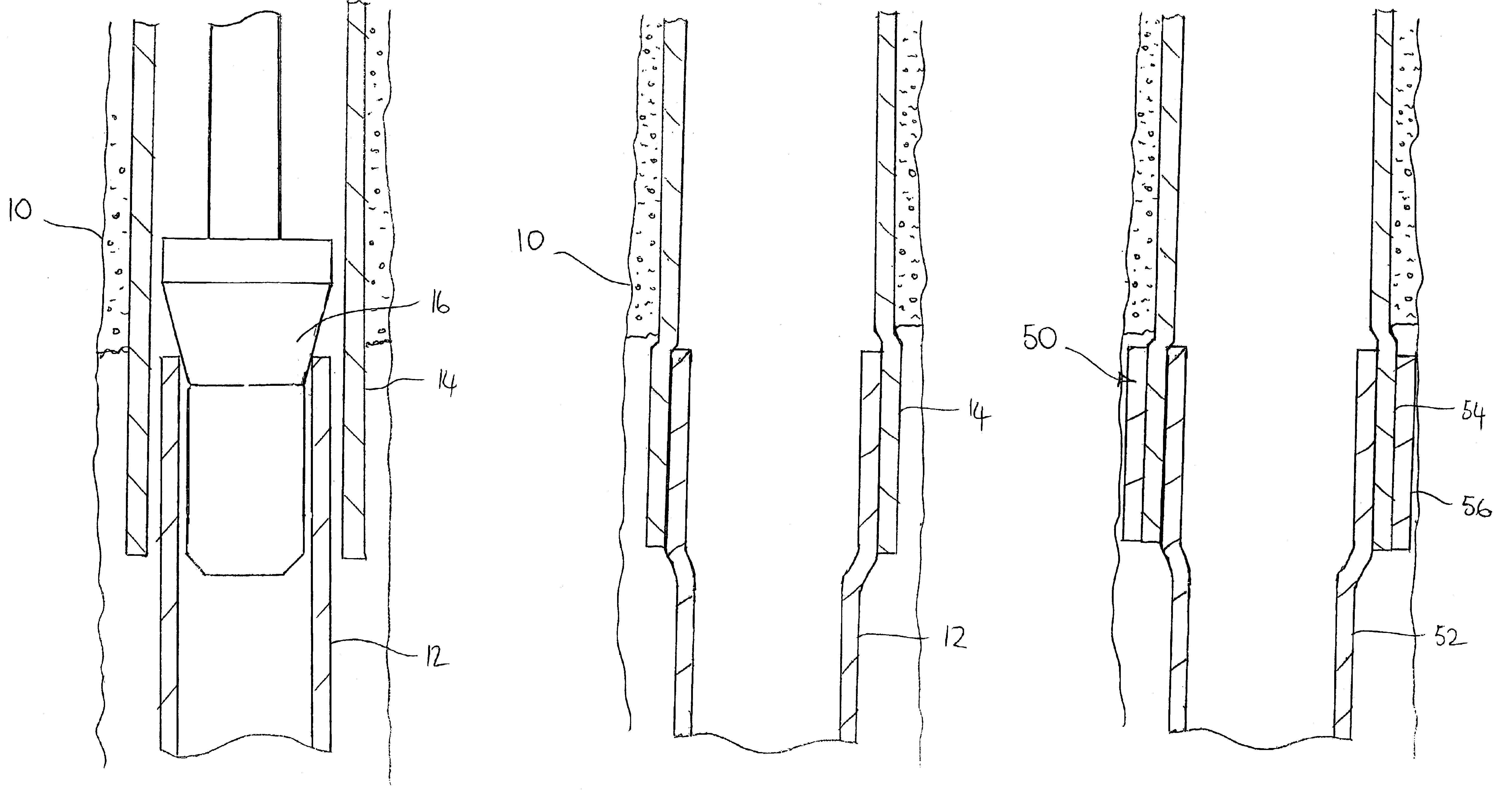

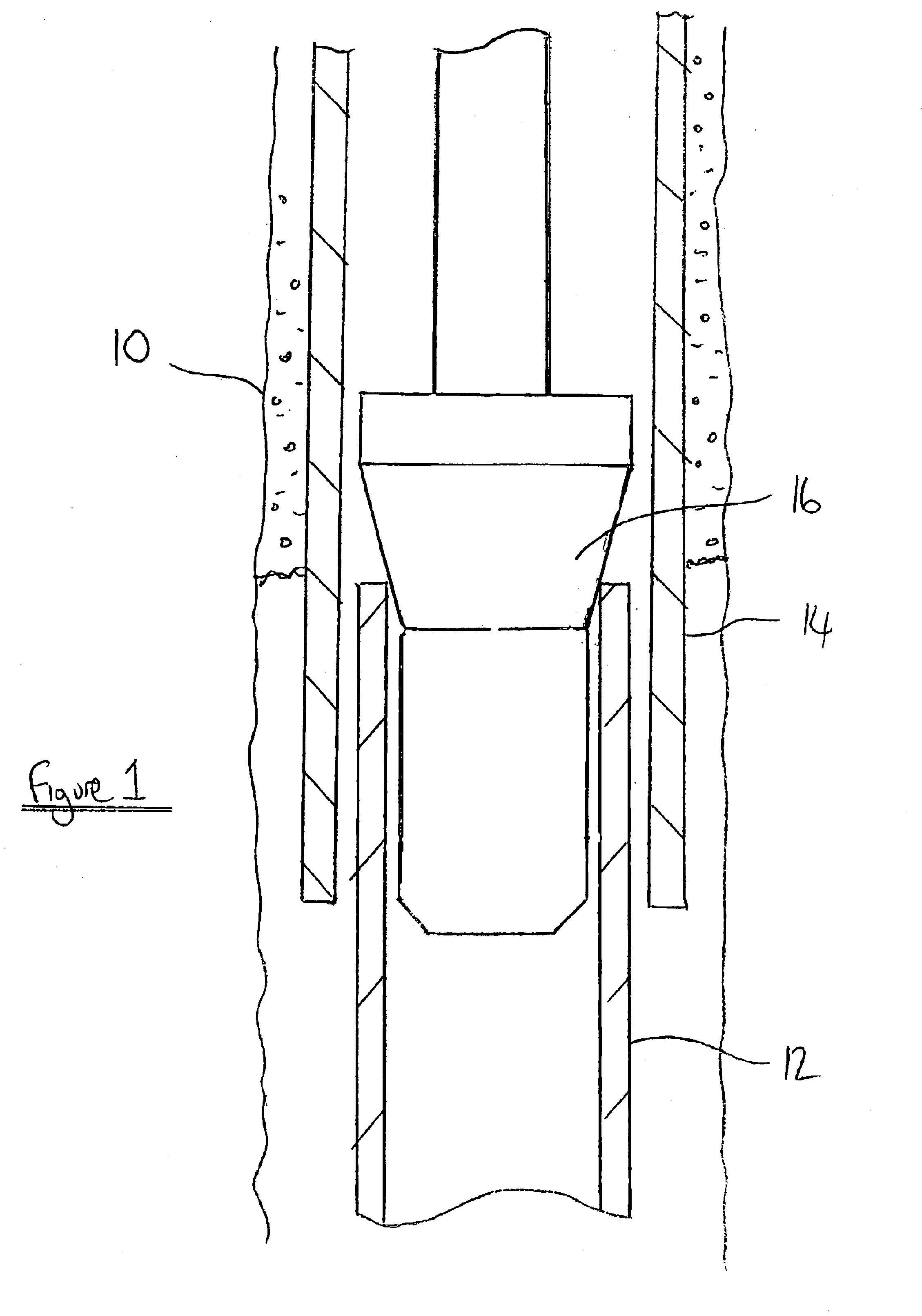

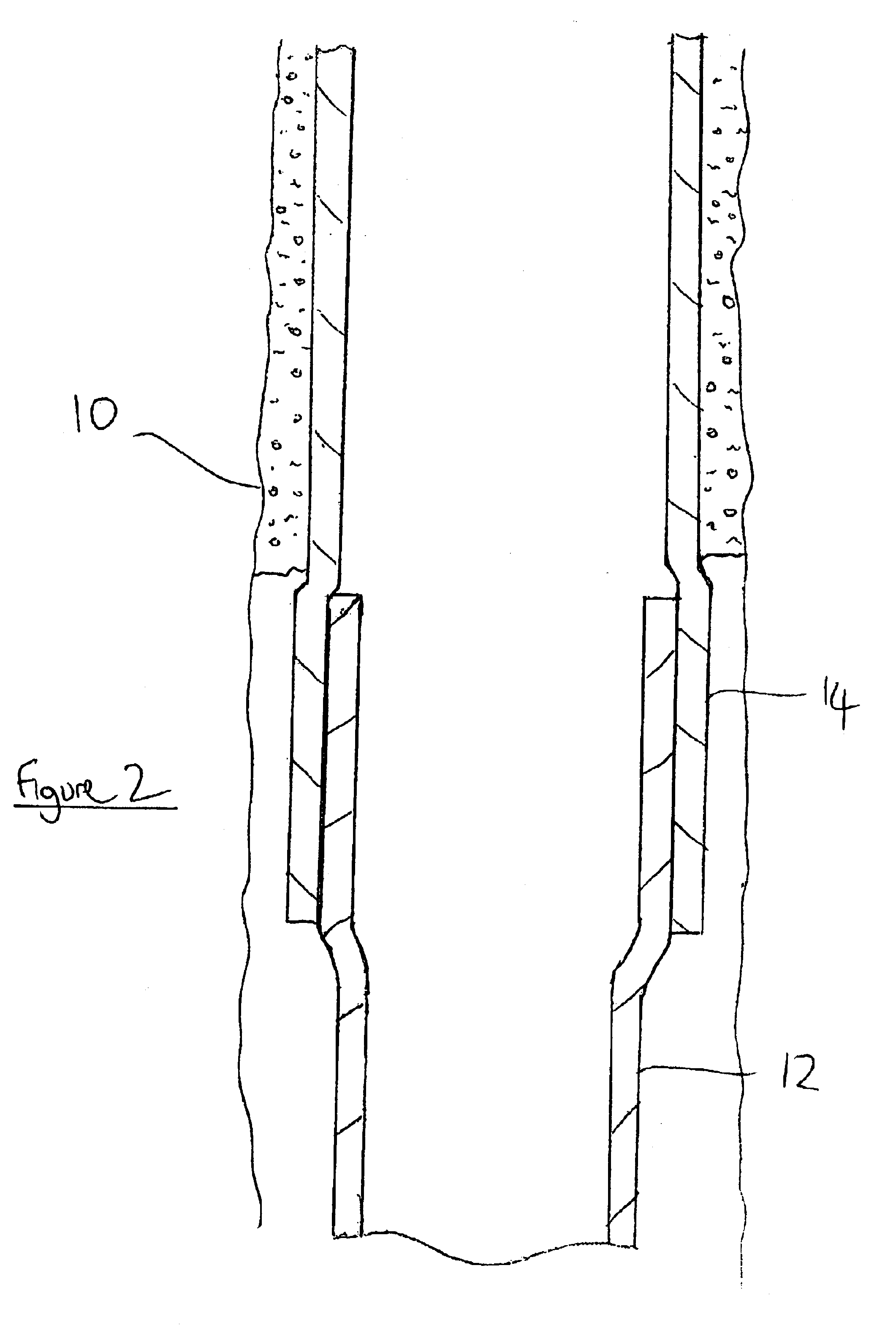

Tubing expansion

InactiveUS6942029B2To offer comfortGood elasticity recoveryDrilling rodsFluid removalEngineeringUltimate tensile strength

A method of coupling first and second tubulars (12,14) comprises providing a first tubular having a first yield strength and a second tubular having a higher second yield strength. A portion of the first tubular is located within and overlapping a portion of the second tubular and the first tubular is expanded sufficient to expand the second tubular, at least the first tubular being expanded beyond its yield point. Following expansion, a degree of elastic contraction of the tubulars is permitted, sufficient to provide interference between the tubulars.

Owner:WEATHERFORD TECH HLDG LLC

Method of forming molded foam and molded foam

InactiveUS20090029143A1Uniform diameterUniform shapeLayered productsDomestic articlesElastomerPolymer science

A method of molding a foam-molded product is provided which includes foam-molding a thermoplastic elastomer composition with a gas or a supercritical fluid, the composition containing 10 to 93 parts by mass of (1) an ethylene / α-olefin copolymer, 3 to 30 parts by mass of (2) a crystalline polyethylene resin, 3 to 30 parts by mass of (3) a hydrogenated block copolymer formed by hydrogenating a specific block copolymer, and 1 to 30 parts by mass (4) an α-olefin resin having three or more carbon atoms (provided that the total amount of the components (1), (2), (3), and (4) is 100 parts by mass), and having a melt flow rate at a temperature of 230° C. and a load of 10 kg of 5 g / 10 min or more and a melt tension at a temperature of 210° C. and a take-up speed of 2 m / min of less than 3.0 cN. A foam-molded product is provided which exhibits excellent closed-cell properties, a uniform cell shape, a small cell diameter, excellent elastic recovery, excellent flexibility, excellent surface appearance, produces no odor, and exhibits excellent recyclability and an excellent cushion feel.

Owner:JSR CORPORATIOON

Thermoplastic elastomer copolymer films

InactiveUSH2096H1Low ethyleneIncrease elasticityAbsorbent padsFlat articlesElastomerThermoplastic elastomer

Disclosed are (1) a thermoplastic elastomeric film comprised of an elastomeric arene-diene block copolymer and particular ethylene / .beta.-olefin copolymers having low ethylene crystallinity and (2) the process of preparing films thereof. The disclosed films have superior strength and elasticity characteristics which render them particularly useful in apparel and healthcare items such as disposable diapers.

Owner:EXXON CHEM PAT INC

High-viscosity high-elasticity pitch and preparation method thereof

ActiveCN103849153AEasy constructionImprove workabilityBuilding insulationsViscosityMaterials science

The invention discloses high-viscosity high-elastic pitch and a preparation method thereof. The high-viscosity high-elasticity pitch prepared according to the invention has high viscosity and high elasticity as well as excellent workability, and meets the requirements of deformation resistance, fatigue resistance and long service life of large-span bridges, and with the high-viscosity high-elasticity pitch, the problem of poor workability of the existing high-viscosity high-elasticity pitch is solved; the viscosity of the pitch at 60 DEG C is larger than 80000 Pa.s, the viscosity at 135 DEG C is smaller than 3 Pa.s, the softening point reaches up to 85 DEG C above, and the cost is 20% lower than that of the common similar high-viscosity high-elasticity pitch in China at present.

Owner:CNPC JIANGSU FUEL ASPHALT

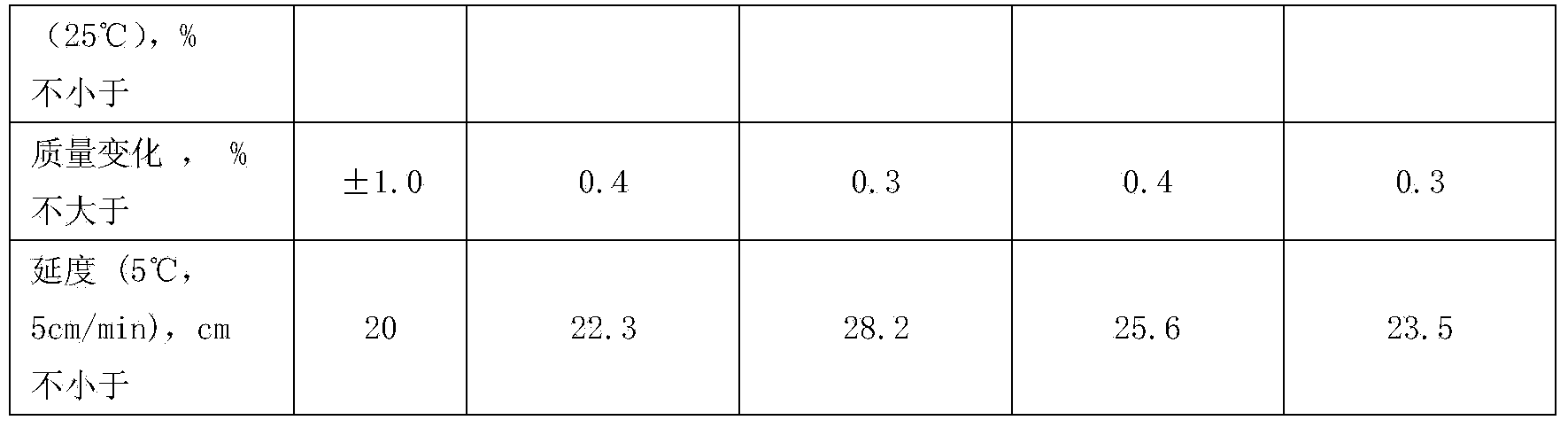

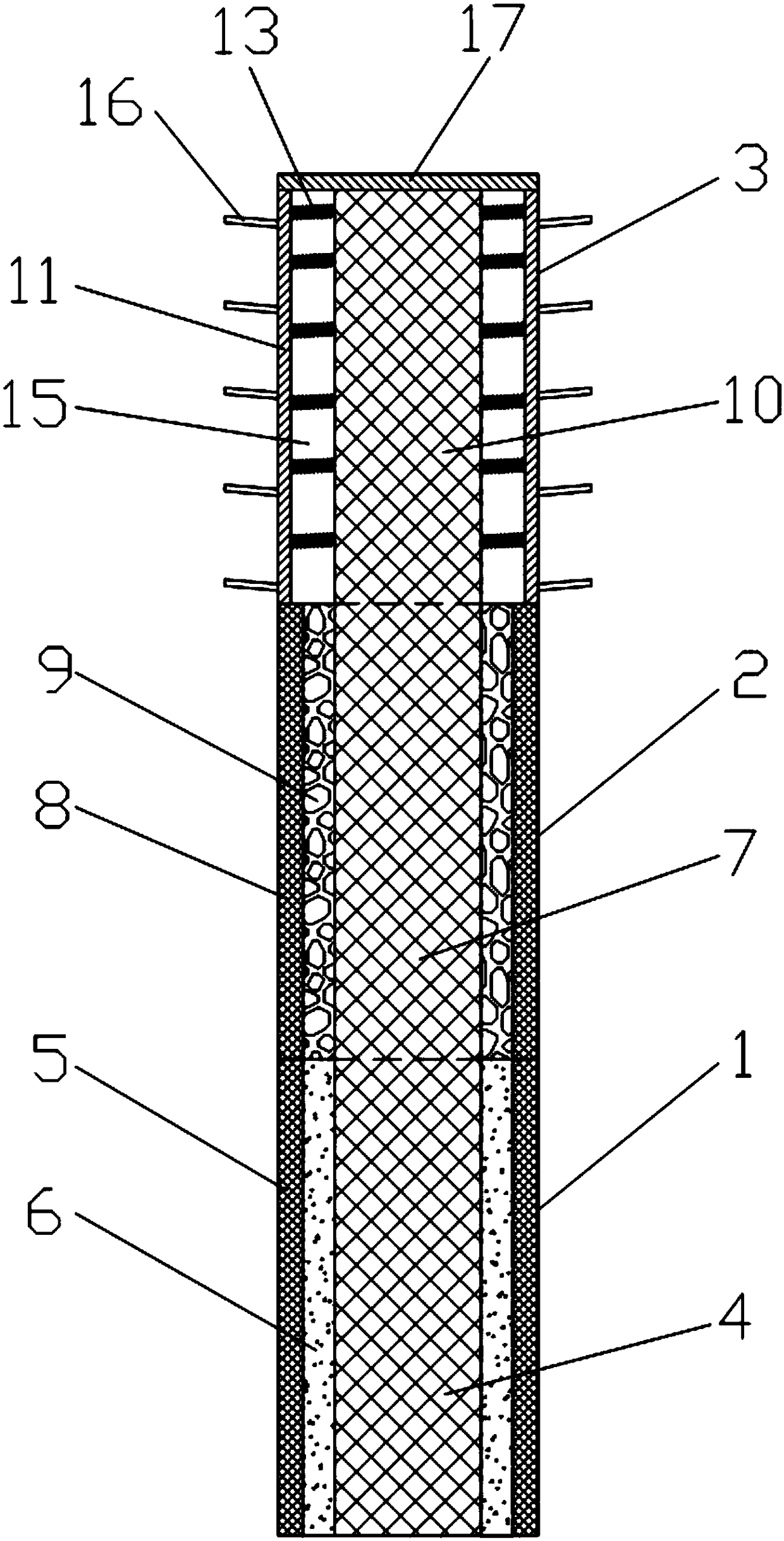

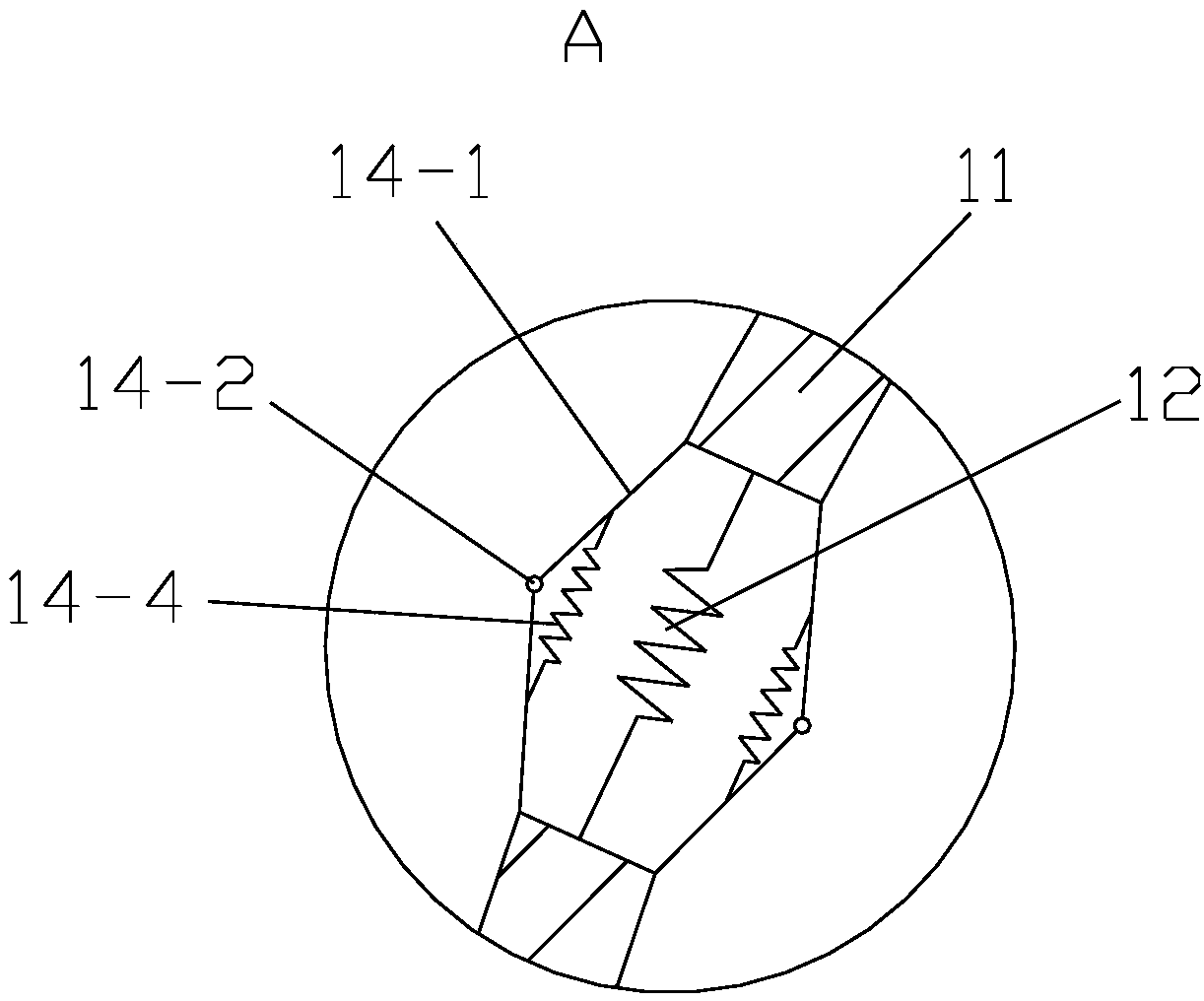

Deformation self-adaptive drainage anti-slide pile for expansive soil side slope and construction method

ActiveCN109137942AReduce infiltrationTo preventExcavationsSoil preservationWater storageSurface layer

The invention discloses a deformation self-adaptive drainage anti-slide pile for an expansive soil side slope and a construction method. The deformation self-adaptive drainage anti-slide pile for theexpansive soil side slope comprises an embedment section, a water storage section and an elastic section. The embedment section comprises a first reinforced concrete precast pile and a first reinforced concrete retaining wall, and concrete is poured between the first reinforced concrete precast pile and the first reinforced concrete retaining wall. The water storage section comprises a second reinforced concrete precast pile and a second reinforced concrete retaining wall, and the space between the second reinforced concrete precast pile and the second reinforced concrete retaining wall is filled with rubble. The elastic section comprises a third reinforced concrete precast pile and a concrete pile, and the concrete pile is formed by a plurality of arc-shaped concrete precast parts in a splicing mode. The deformation self-adaptive drainage anti-slide pile is divided into the elastic section, the water storage section and the embedment section, expansion and contraction deformation of expansive soil in the process of experiencing the dry-wet cycle can be coordinated through deformation of the elastic section, generation of vertical tension cracks can be effectively avoided, and therefore infiltration of the rainwater on the surface layer is remarkably reduced, and the coordination control over expansion and contraction deformation of the expansive soil is achieved as the anti-slide capacity is brought into full play.

Owner:XIAN UNIV OF SCI & TECH

Preparation method for water-based wet-process microfiber leather

InactiveCN108823679AFully contractedEliminate needle stick stressGrip property fibresConjugated synthetic polymer artificial filamentsWater basedPolyester

The invention provides a preparation method for a water-leatherd wet-process microfiber leather. The preparation method comprises the following steps of preparing non-woven leather cloth; carrying outwater-soluble polyester pre-shrinking treatment on the non-woven leather cloth; carrying out waterborne polyurethane wet-process impregnation treatment; carrying out extruding; carrying out wet-process solidification; carrying out splitting and reduction; and carrying out post-processing. The preparation method has the advantages that the key of the method lies in how to avoid using an organic solvent in the whole producing and manufacturing processes, a water-leatherd wet process is adopted, so that all process materials are environmentally-friendly, and the prepared leather can achieve thestructural characteristics of leatherette; and a figured sea-island short fiber leather material is used, ultrafine fibers with the fineness of 0.05 D can be obtained after sea components are dissolved away, and prepared leather is soft in hand feeling, good in drapability, attractive and good in air permeability, is similar to real leather in strength, folding resistance and other performances, is superior to natural leather in water resistance and anti-mildew and antibacterial performance and is a novel material with vitality in the industry of artificial leather and synthetic leather.

Owner:LANZHOU SCISKY AQUEOUS POLYMER MATERIAL CO LTD

Modified asphalt, and preparation method and use thereof

InactiveCN102492302AHigh softening pointHigh elongationBuilding insulationsPolymer scienceRoad surface

The invention provides modified asphalt. The modified asphalt comprises base asphalt, a modifying agent, a lignin stabilizing agent, maleic acid mono-lauryl La, rubber powder and a mineral filler, wherein the modifying agent is obtained by taking a styrene-butadiene-methyl methacrylate polymer as a base material and the lignin stabilizing agent is extracted by adopting an alcoholic solvent with high boiling point; and the modifying agent is prepared through the following method: under the action of a thermal polymerization initiator, the styrene-butadiene-methyl methacrylate polymer and reactive monomers are polymerized in a solvent, and then, the modifying agent is obtained. The modified asphalt has the advantages of high softening point, high extension degree, excellent elastic recovery, long storage time and high stability, when the modified asphalt is used in the process of road construction, the maintenance engineering for expressways of our country can be improved, the service lives of the expressways are prolonged, and the road level of service is improved.

Owner:SHANDONG UNIV OF SCI & TECH +1

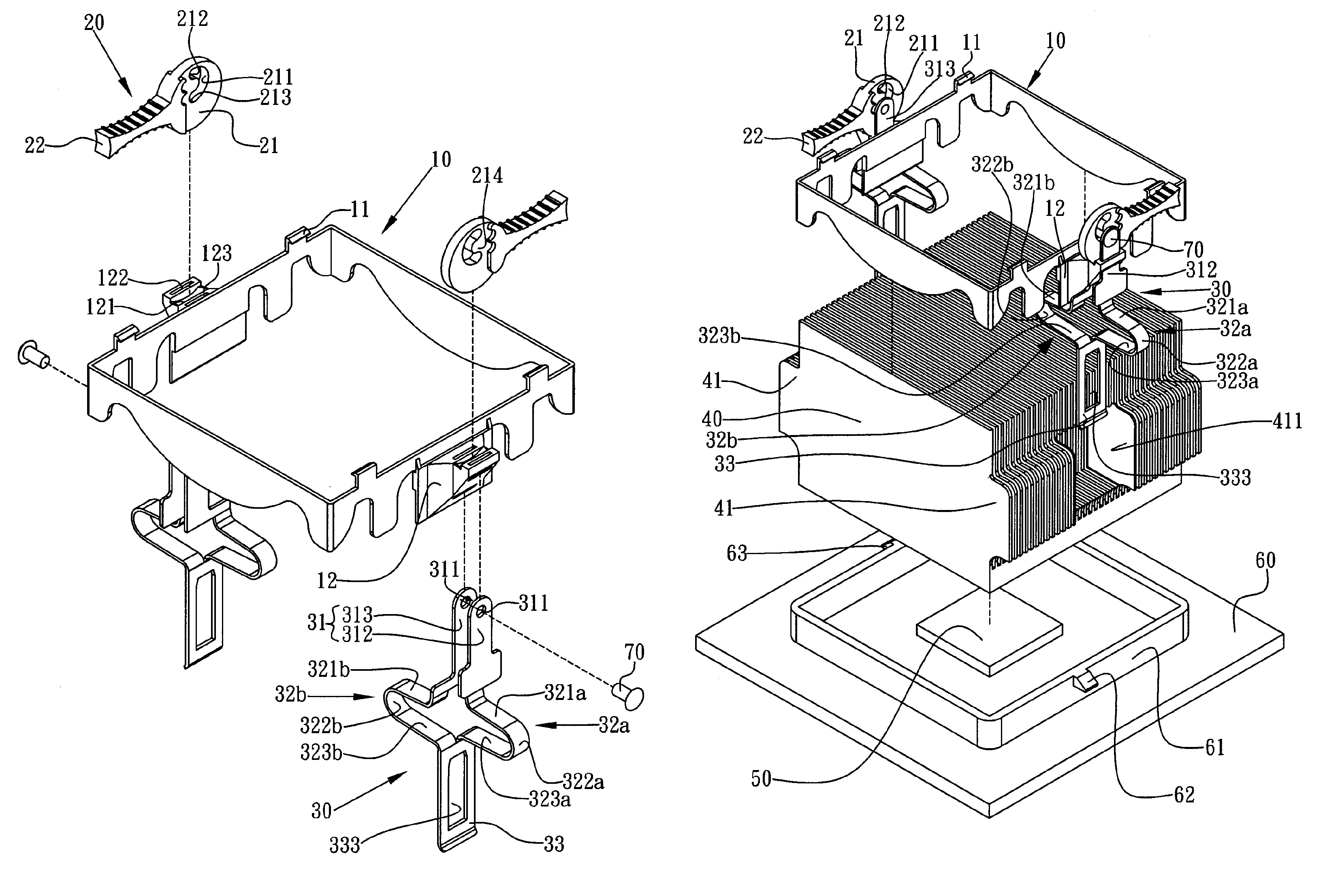

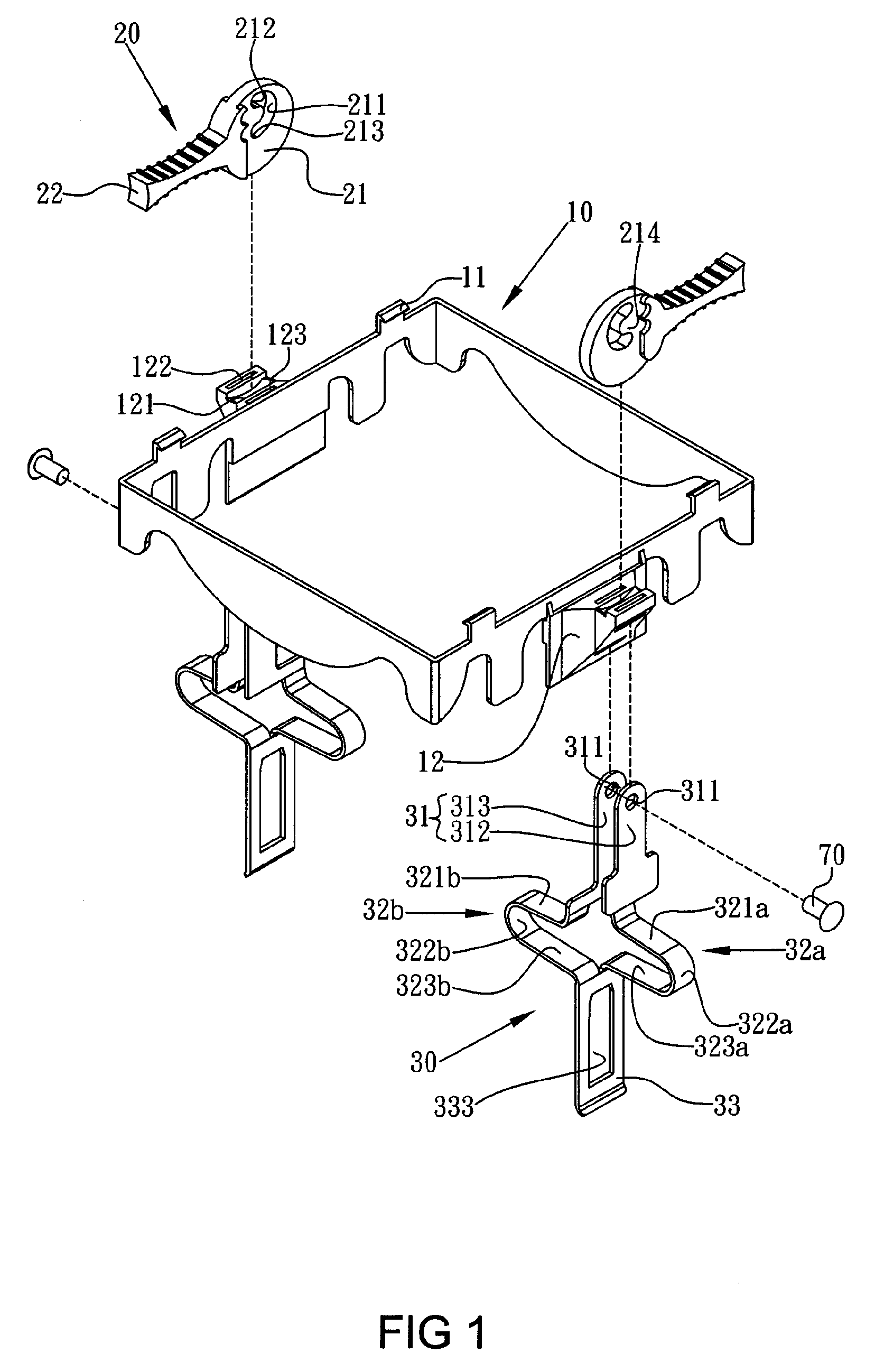

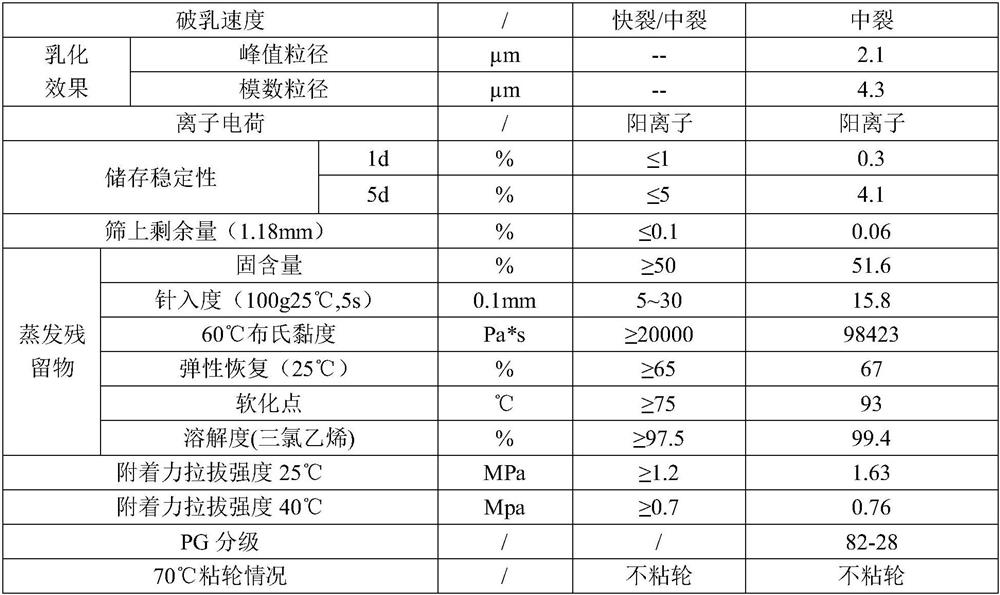

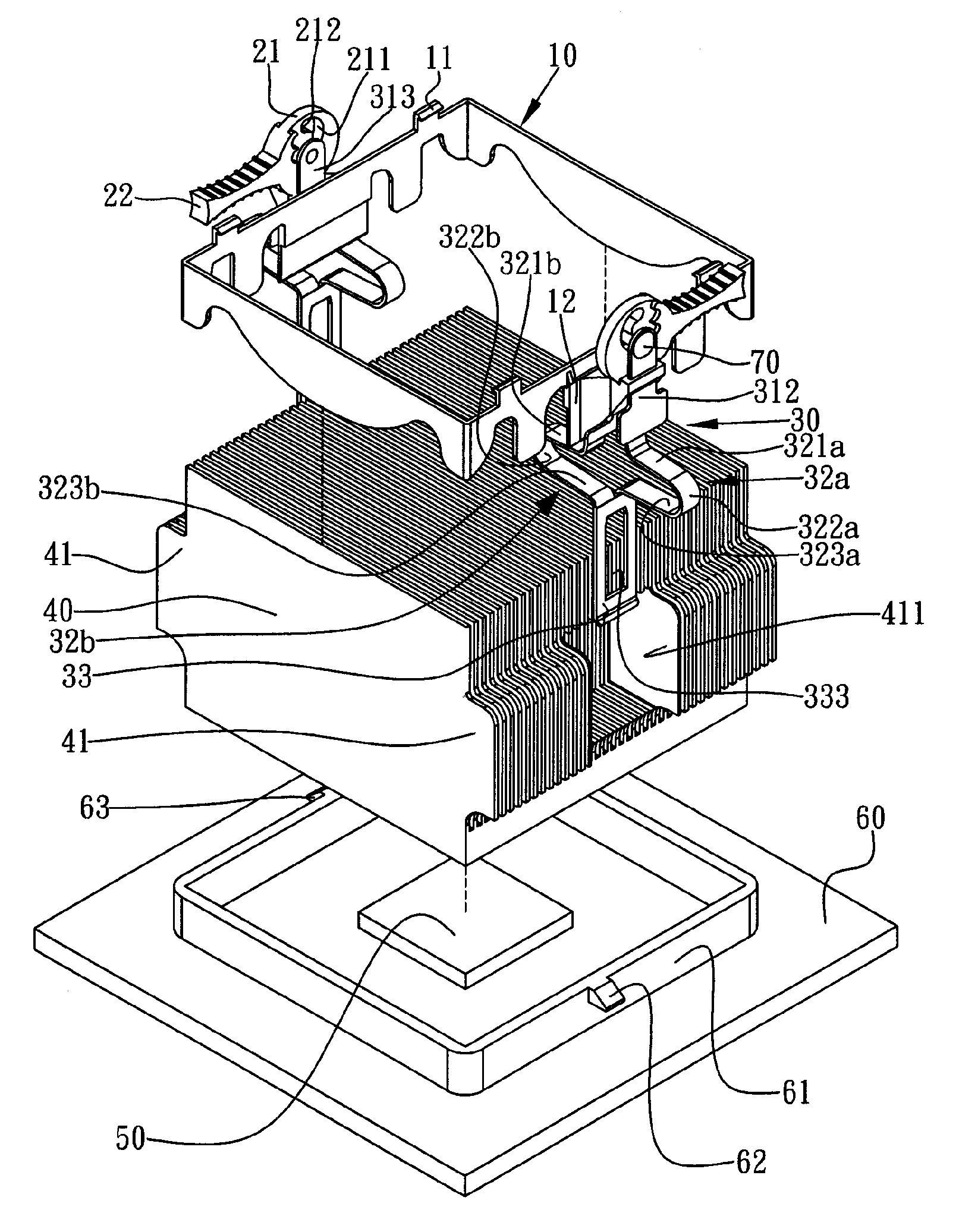

Retaining tool for a heat sink

ActiveUS7558067B2Reduce the possibilityEasy to controlSnap fastenersDigital data processing detailsEngineeringHeat spreader

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

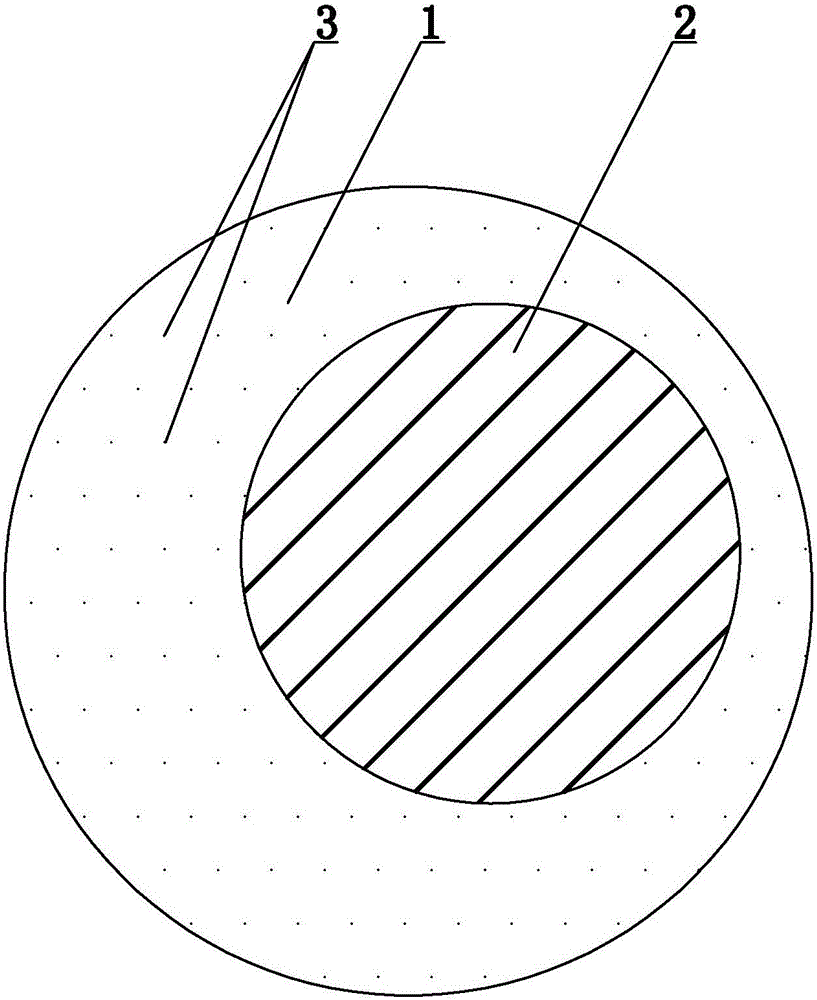

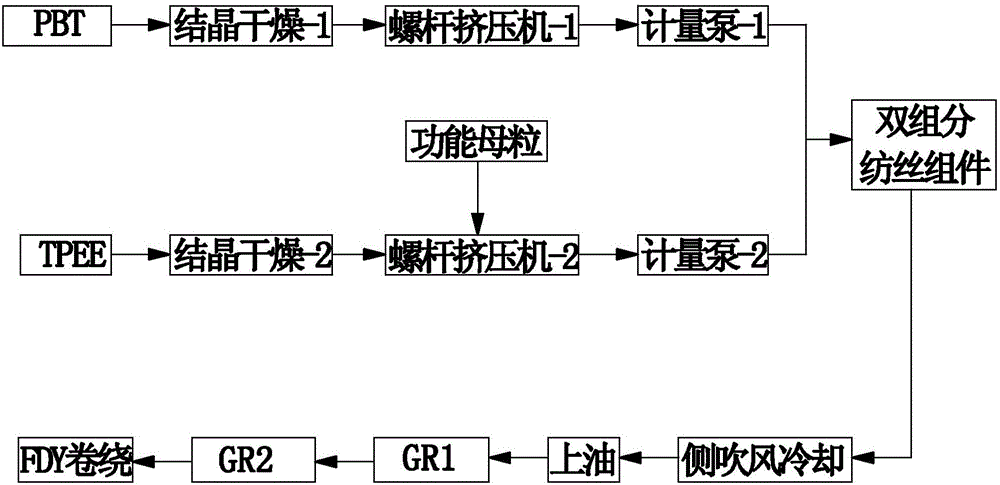

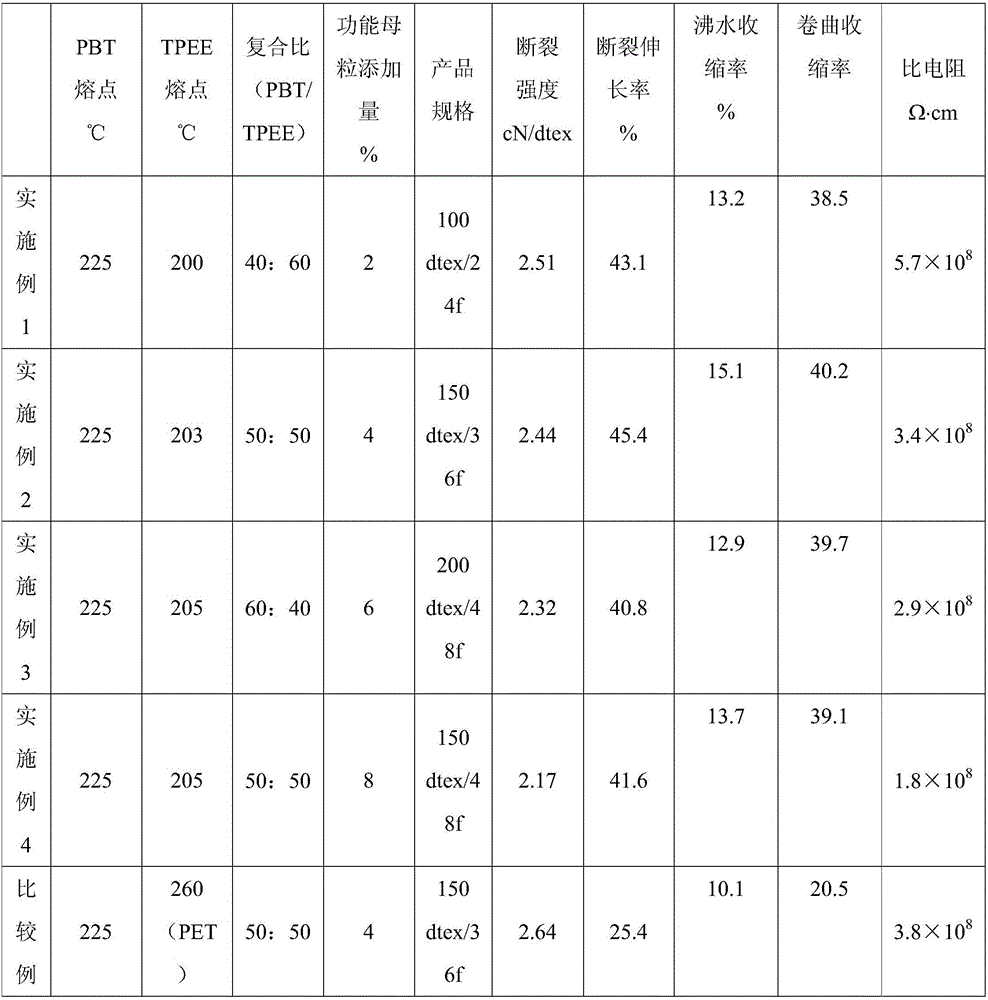

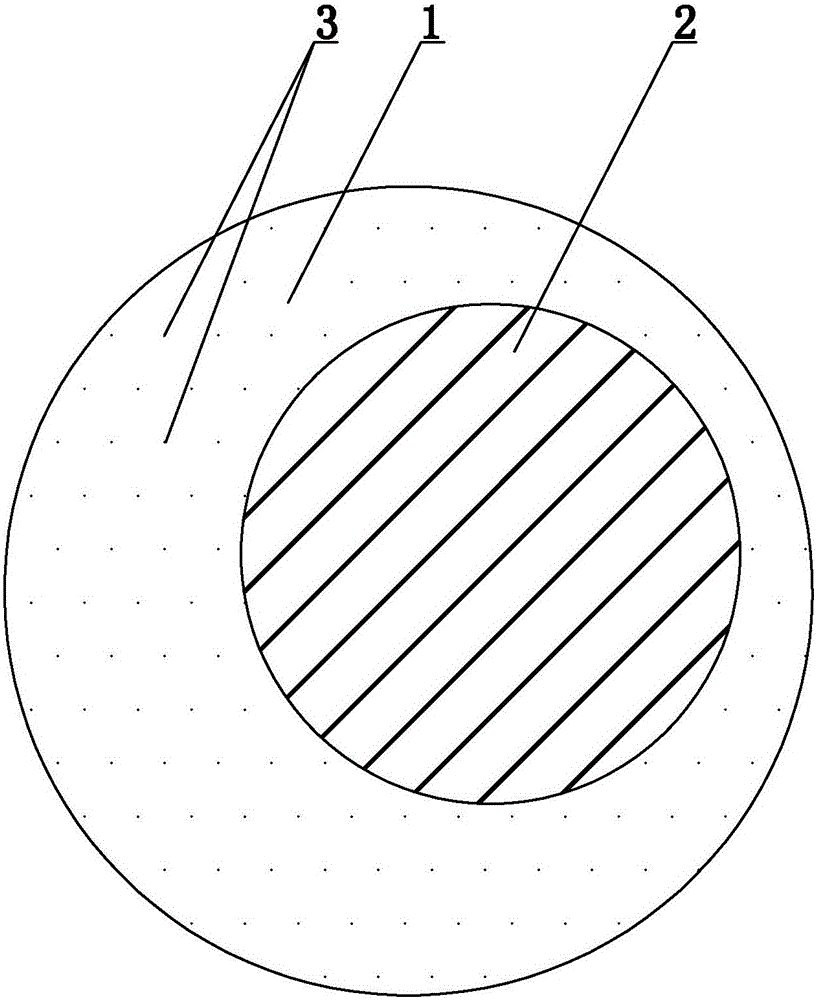

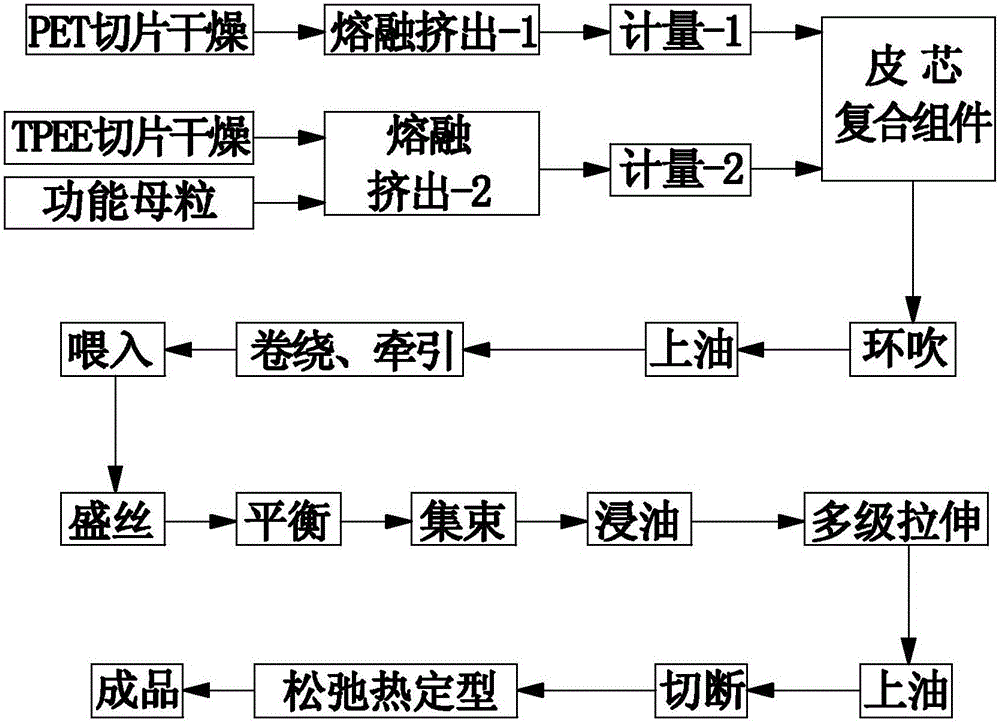

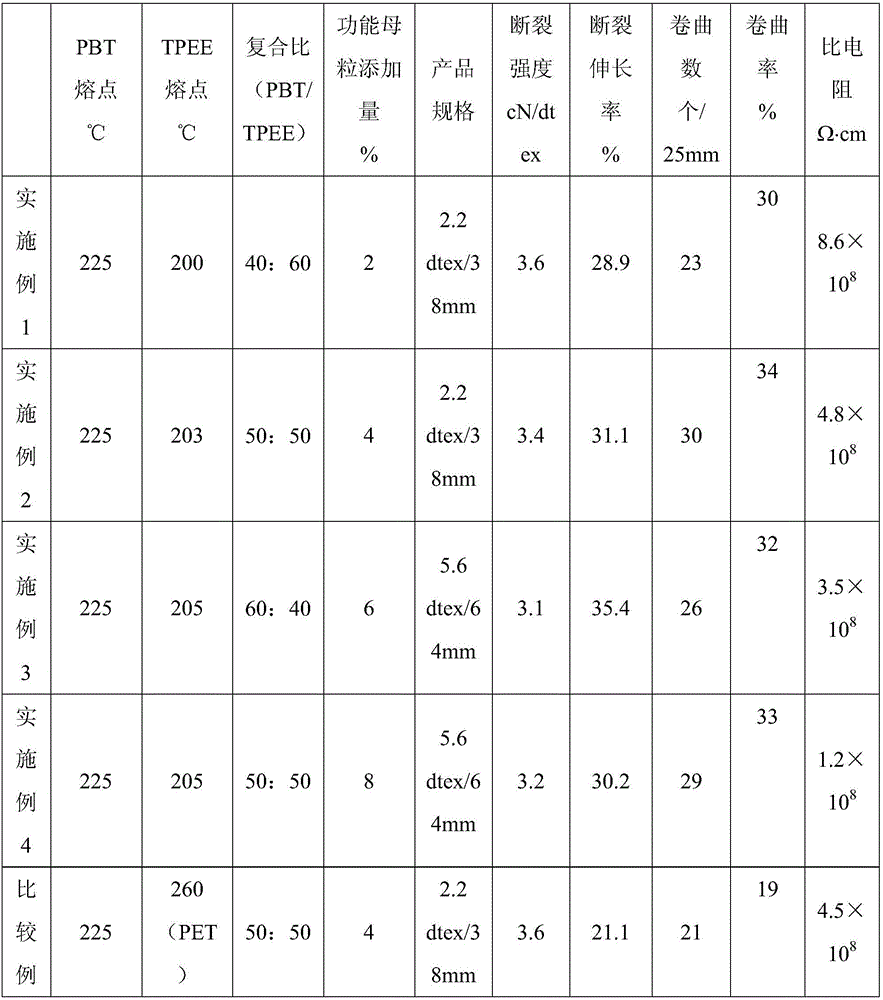

Self-crimping composite filament and processing process thereof

InactiveCN105926062AFunctionalWith curl propertiesElectroconductive/antistatic filament manufactureMelt spinning methodsPolytetramethylene terephthalateElastomer

The invention relates to a self-crimping composite filament and a processing process thereof and belongs to the technical field of fiber production. PBT (polybutylene terephthalate) and a polymer, to which master batches with a composite function are added, are taken as skin layer components, a PBT TPEE (thermoplastic polyester elastomer) is taken as a core layer component, the components are subjected to melt extrusion by a screw extruder respectively, an extruded product enters dual-component composite spinning equipment and skin-core eccentrically composited spinning holes, the sprayed melt is subjected to cooling, oiling, heat setting and winding, and the self-crimping composite filament with ultraviolet-resistant, antistatic and antibacterial combined functions is prepared. The self-crimping composite filament is applied to fields of top-grade elastic fabric, home textile products and the like, and a composite filament product has advantages of good self-crimping property, optimal elastic elongation and elastic recovery performance and the like.

Owner:ZHEJIANG SCI-TECH UNIV

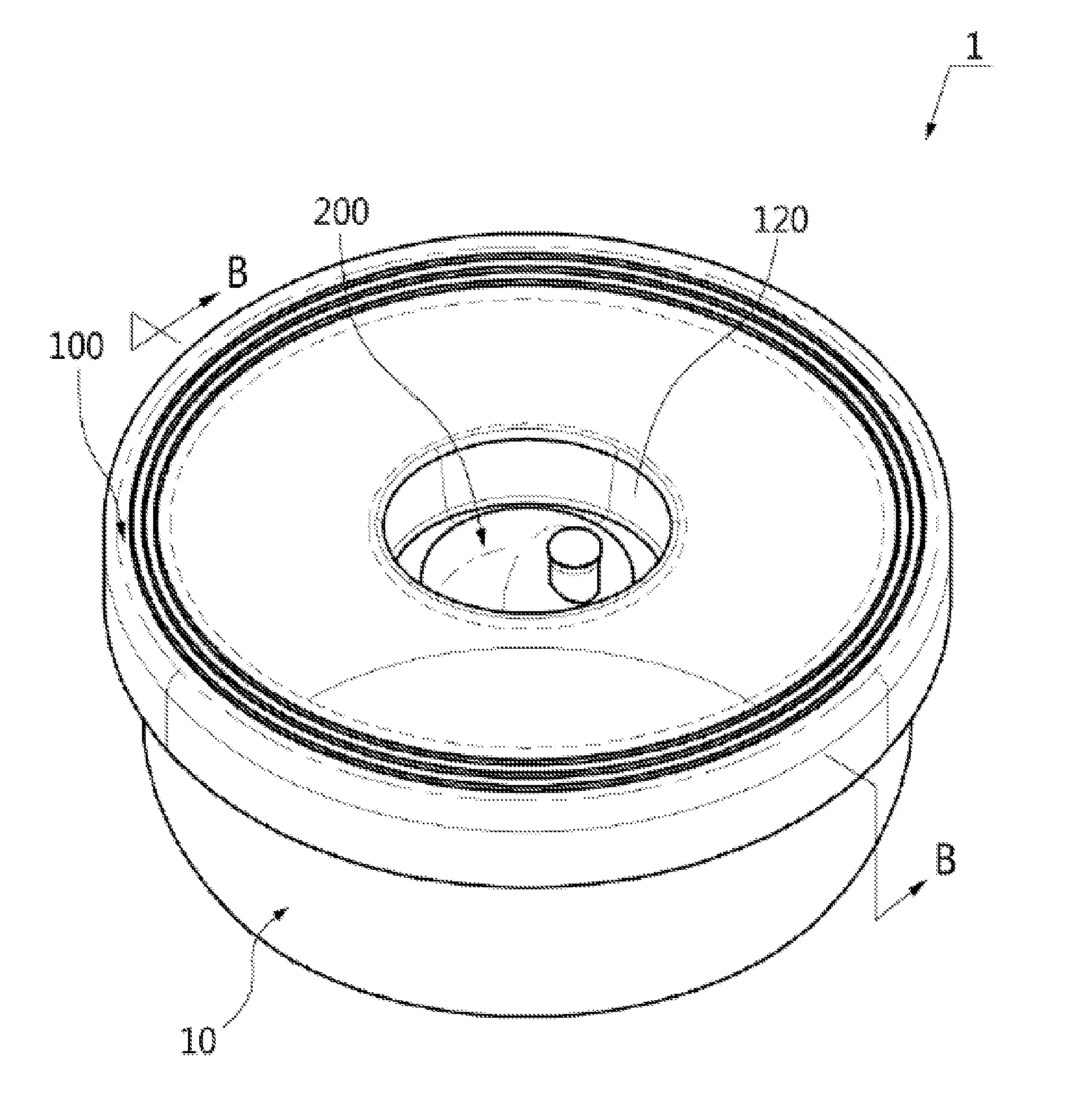

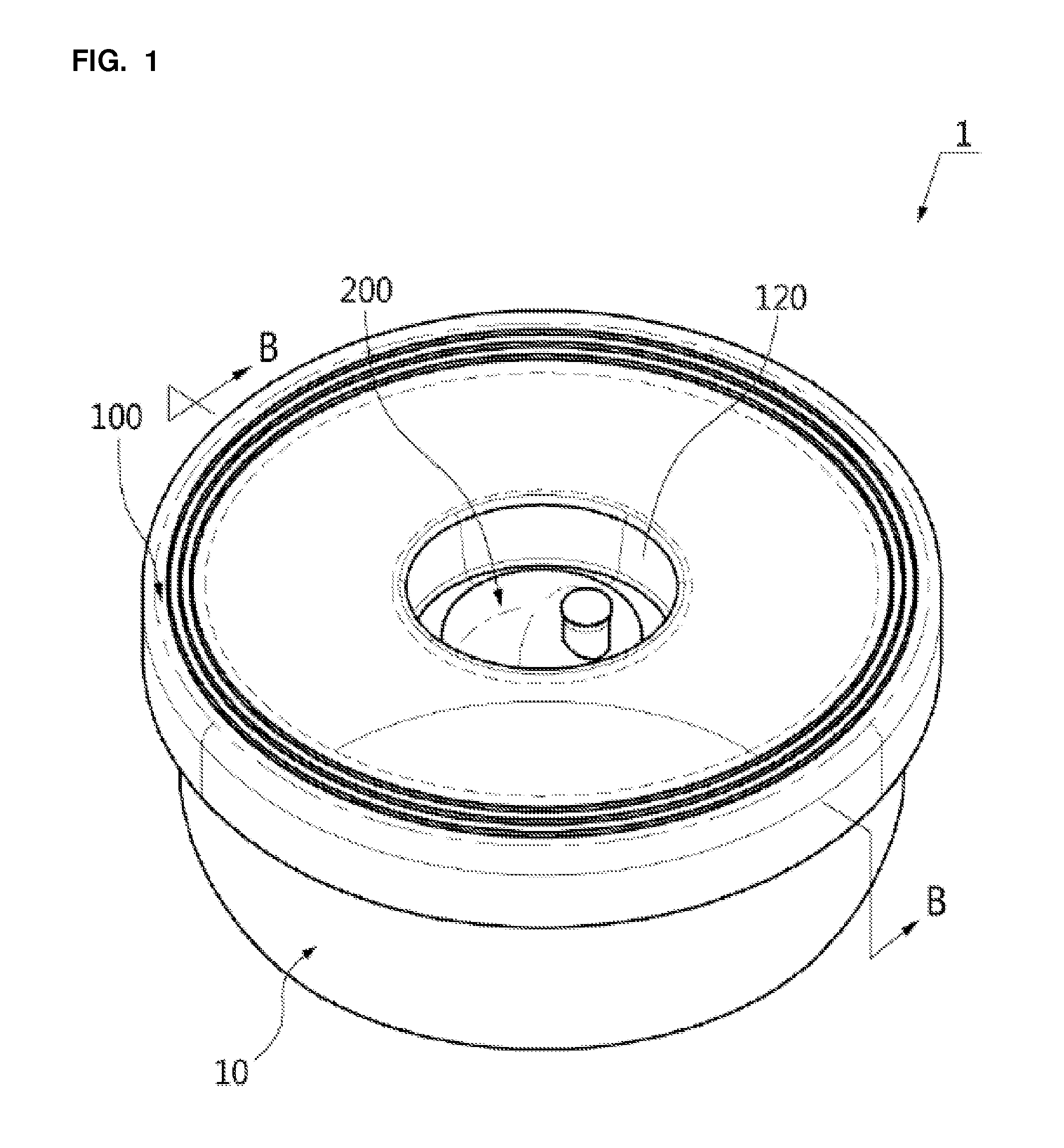

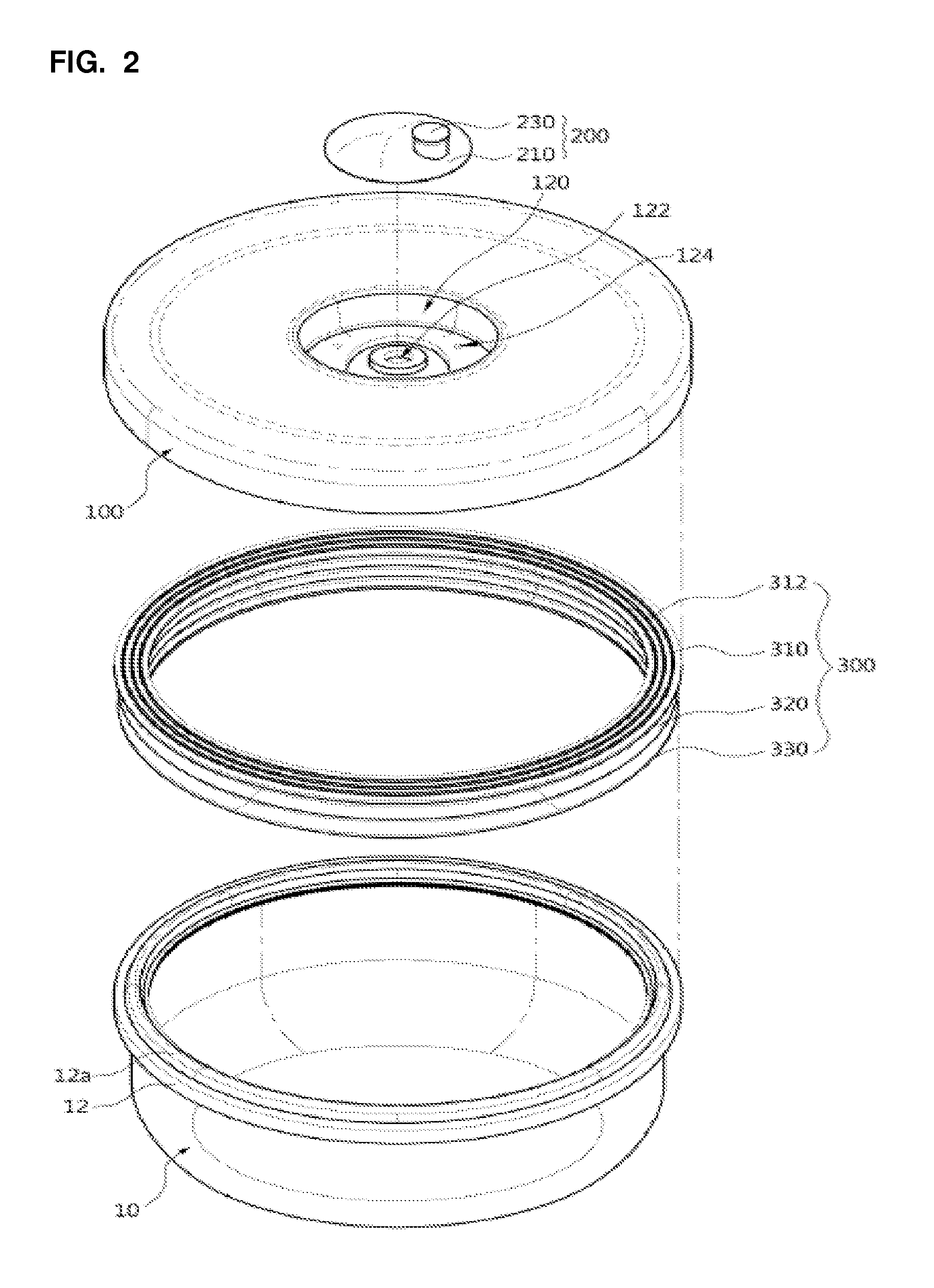

Vacuum receptacle lid for easy sealing

InactiveUS20120273488A1Improve sealingIncrease vacuumEngine sealsRemovable lids/coversEVACUATED CONTAINEREngineering

A vacuum receptacle lid for easy sealing includes a lid body that closes and opens an inlet portion of a receptacle body provided with a space containing contents, and includes a valve installation hole formed at a part thereof, at least one air vent hole, and a packing installation groove which is opened downwardly in a C shape inside a rim thereof, a check valve that is provided a combining projection at a bottom surface of a body portion enclosing the air vent hole, is inserted into and combined with the valve installation hole, and exhausts air of the inside of the receptacle body via the air vent hole and blocks inflow of external air by enclosing, opening and closing the air vent hole, and a packing that is accommodated and installed at the packing installation groove, and includes an upper contact portion coming into contact with an upper surface of the packing installation groove, a lower contact portion coming into contact with the receptacle body, and an intermediate contact portion of which ends are connected to at least a part of the upper contact portion and the lower contact portion and which has a cross-section of a zigzag shape.

Owner:KODAECS

Terylene low elastic interlaced yarn carpet and production method thereof

InactiveCN101476208AGood clusteringReduce bulkWarp knittingHeating/cooling textile fabricsYarnTouch Senses

The invention provides a terylene low elastic net yarn target and a manufacturing method thereof which relates to a terylene low elastic net yarn target knitted on a double neilsbed raschel tricot machine, and a corresponding manufacturing method thereof. The method includes steps as follows: using 1-6D terylene yarn as a felted yarn raw material and 100-500d terylene FDY as a bottom yarn for knitting on the double raschel tricot machine, thermal finalization; terylene dyeing or printing; treating and back spraying or coating skidproof glue, then drying. The terylene low elastic net yarn manufactured by the method is knitted directly without spinning that leads to little producing procedure, short producing period, more reasonable and effective producing procedure and low cost; the produced fabric has better filling power, elastic recovery and stand property, and comfortable touch sense; the terylene low elastic net yarn target weights 1000g / m(2) per centiare that can compare beautiful with other carpet 2000g / m(2). The carpet can better serve market requirement.

Owner:SUZHOU YUNYING TEXTILES

Hindered phenol/montmorillonoid/nitrile rubber composite damping material for car and preparing method thereof

The invention discloses a hindered phenol / montmorillonoid / nitrile rubber composite damping material for a car. The hindered phenol / montmorillonoid / nitrile rubber composite damping material comprises raw materials including, by weight, 40-60 parts of nitrile rubber, 30-40 parts of chlorinated butyl rubber, 128-160 parts of tetrahydrofuran, 42-61 parts of maleic anhydride, 2-6 parts of benzoyl peroxide, an appropriate amount of ethyl alcohol, 1-3 parts of hydroxide sodium hypophosphite, an appropriate amount of xylene, 24-33 parts of softwood celluloses, 1-2 parts of stearic acid, 2-7 parts of carbon black, 1-2 parts of sulphur, 4-7 parts of montmorillonoid, 2-4 parts of hindered phenol HP1098, an appropriate number of calcium chloride solution and an appropriate amount of deionized water. According to the hindered phenol / montmorillonoid / nitrile rubber composite damping material, the maleic anhydride and the nitrile rubber are grafted, and are then grafted with the softwood celluloses for compounding; on one hand, internal friction resistance of rubber molecular chain activity is strengthened, and the damping performance of the material is strengthened; and on the other hand, the character of the softwood celluloses is used for improving the sound absorption and noise lowering performance of the damping material, and the nitrile rubber damping material which is excellent in sound absorption and noise lowering performance is prepared.

Owner:WUHU HONGKUN AUTO PARTS

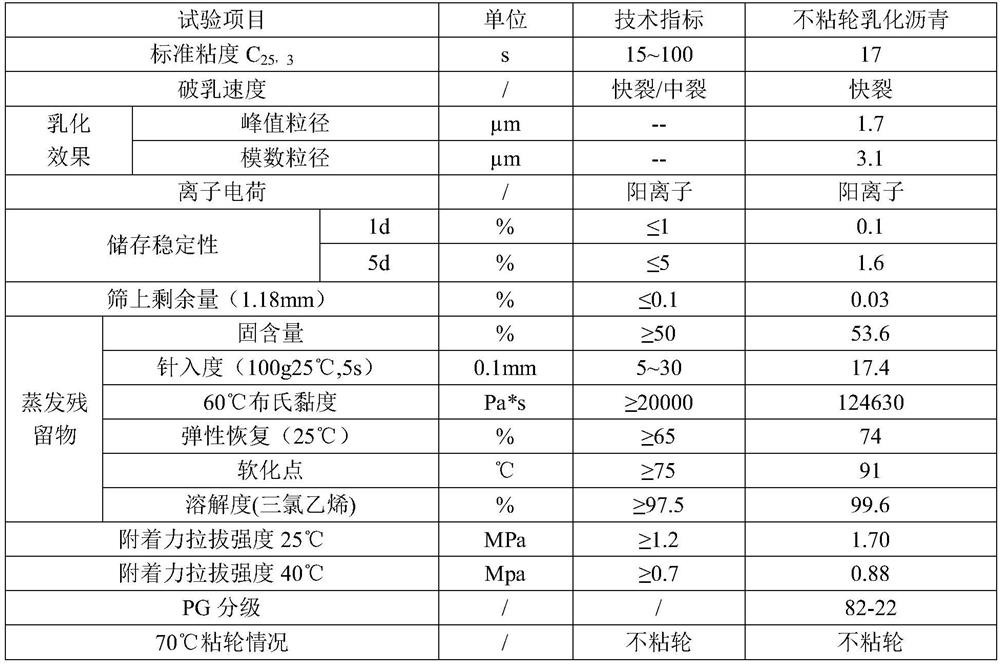

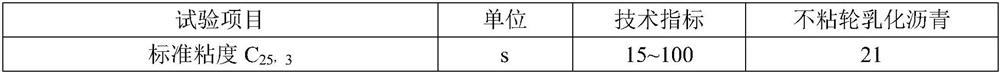

Preparation method of wheel-sticking-free emulsified asphalt for adhesive layer

InactiveCN111777770AHigh softening pointHigh and low temperature gradeBuilding insulationsElastomerPolymer science

The invention discloses a preparation method of wheel-sticking-free emulsified asphalt for an adhesive layer. The preparation method comprises the following steps: preparing parent asphalt, preparingmodified asphalt, preparing liquid soap, mixing the liquid soap and the modified asphalt, grinding and emulsifying. High-proportion thermoplastic elastomer is used as a modifier for adjusting the low-temperature performance of asphalt, the softening point of the evaporation residues of the prepared wheel-sticking-free emulsified asphalt is as high as 90 DEG C or above, and the PG grade and the binding power at 60 DEG C of the evaporation residues of the emulsified asphalt can be improved.

Owner:江苏创为交通科技发展有限公司

High-temperature-stable type modified asphalt and preparation method thereof

The invention provides high-temperature-stable type modified asphalt. The high-temperature-stable type modified asphalt is prepared from the following components: matrix asphalt, rubber powder, natural rubber, aromatic lightweight oil, polyester fibers, polyethylene and sulfur; a preparation method comprises the following steps: (1) heating the matrix asphalt to 200 to 210 DEG C; then adding the matrix asphalt into a stirring tank; adding the rubber powder and the natural rubber into the stirring tank, and continually stirring for 30 to 40min to obtain a mixture I; (2) adding the aromatic lightweight oil, the polyester fibers and the polyethylene into the stirring tank respectively and carrying out primary stirring; when the temperature in the stirring tank is 150 to 160 DEG C, adding thesulfur and carrying out secondary stirring to obtain a mixture II; (3) pumping the mixture II into a development tank, wherein the fermentation time is 45 to 55min; cooling to obtain the high-temperature stable type modified asphalt. The high-temperature stable type modified asphalt provided by the invention has the advantages of high stability and good elastic recovery; the preparation method issimple, has an easy-to-control process and is applicable to popularization and application.

Owner:SHANDONG XINGHUO SCI TECH INSTITYTE

Retaining tool for a heat sink

ActiveUS20080273309A1Reduce the possibilityEasy to controlSnap fastenersDigital data processing detailsEngineeringHeat spreader

A retaining tool for a heat sink includes a frame, at least an operation member and at least an engaging member. The frame is attached to an upper portion of the heat sink with a projection at two opposite sides thereof and the projection has a contact face. The operation member provides a main operation part and a stir part. The main operation part is disposed on top of the contact face and the stir part is angularly lifted for the main operation part being capable of moving relative to the contact face. The engaging member further has a follower part piercing the projection with an end of the follower part connecting with the main operation part pivotally and another end of the follower part being joined to a first elastic part and a second elastic part respectively. The first elastic part extends curvedly a circular bend outward the heat sink and the second elastic part extending curvedly another bend inward the heat sink and free ends of both the elastic parts are joined to two opposite lateral sides of an engaging part for controlling the engaging force evenly and decreasing plastic deformation.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

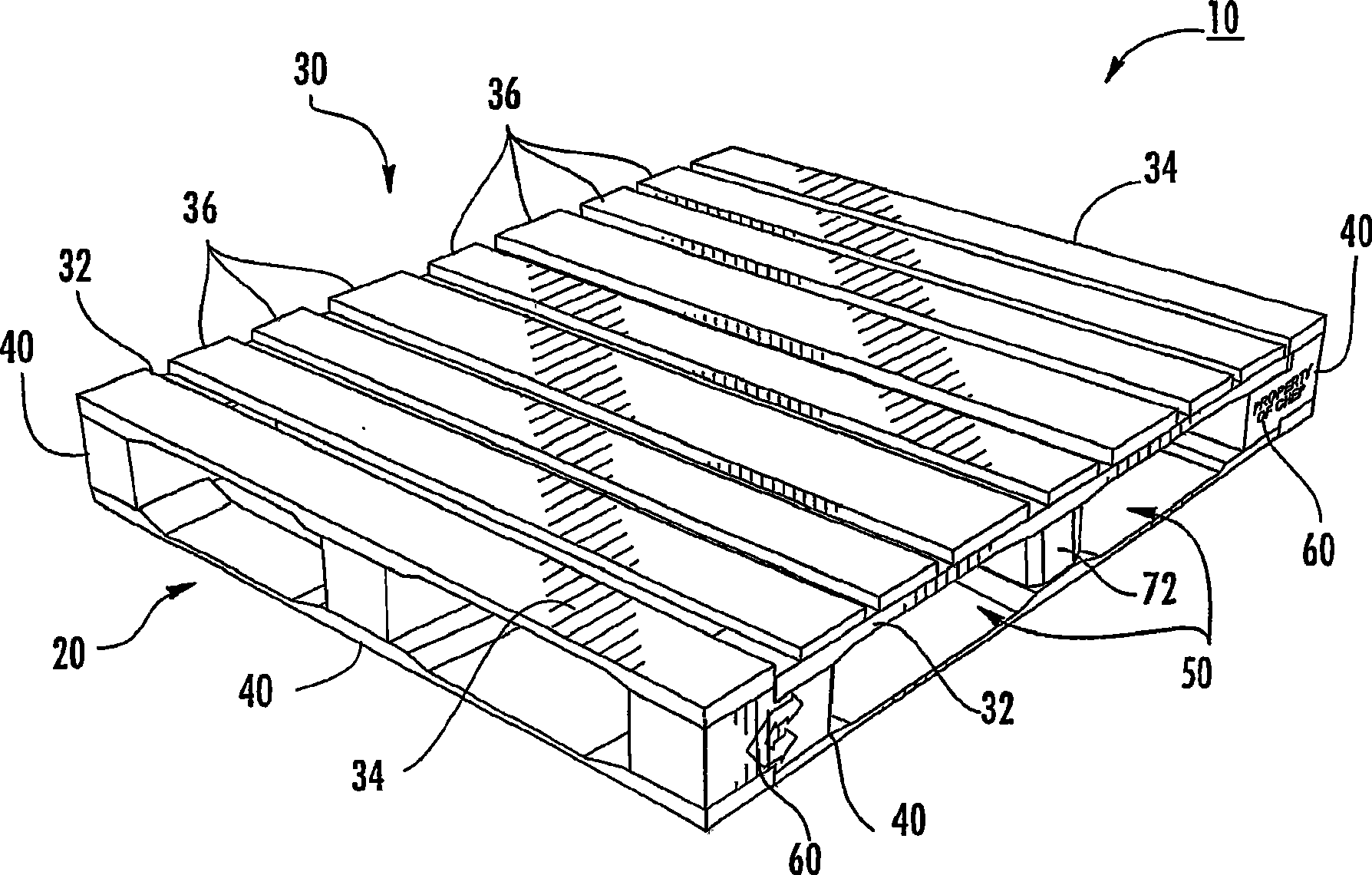

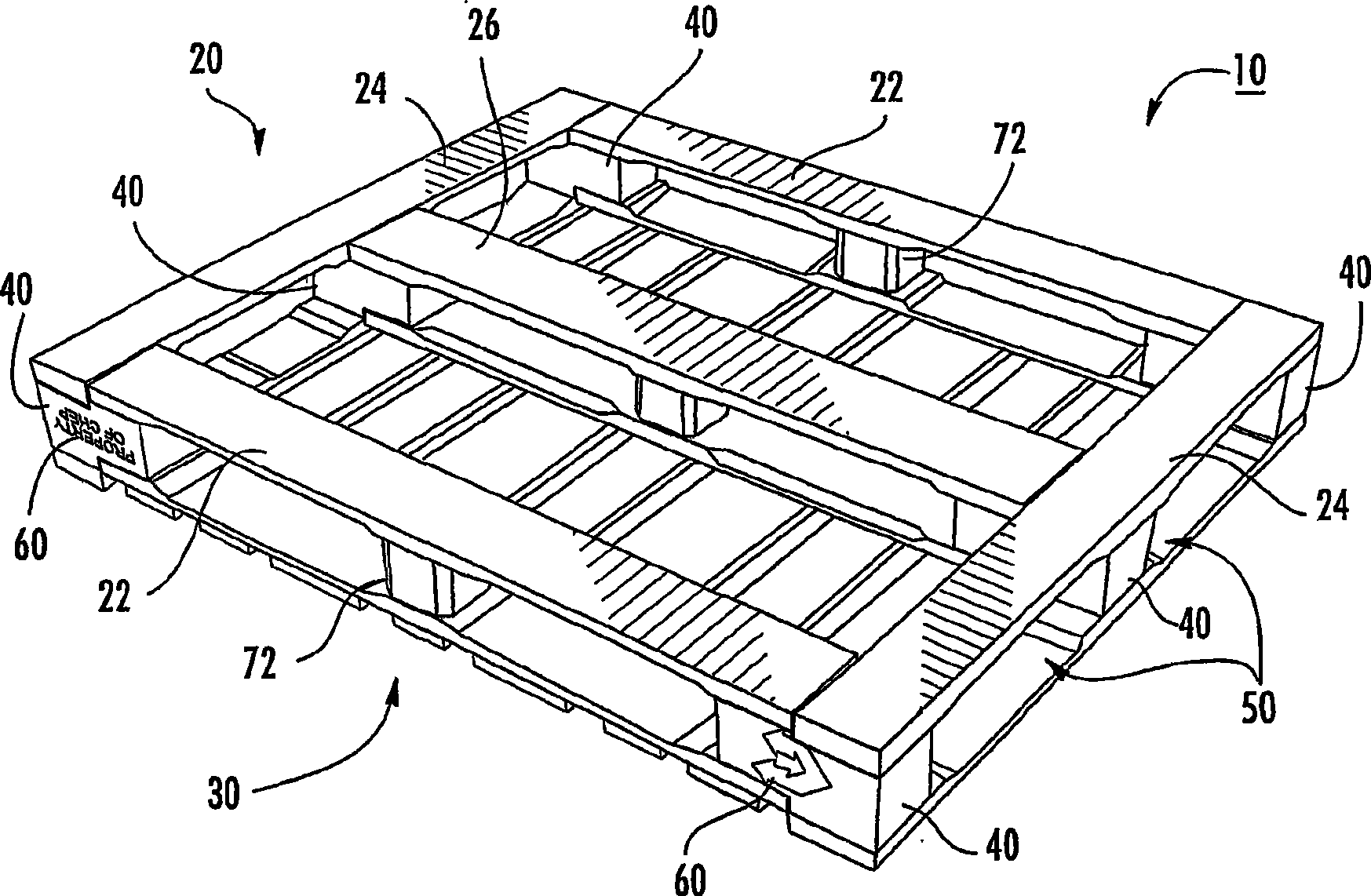

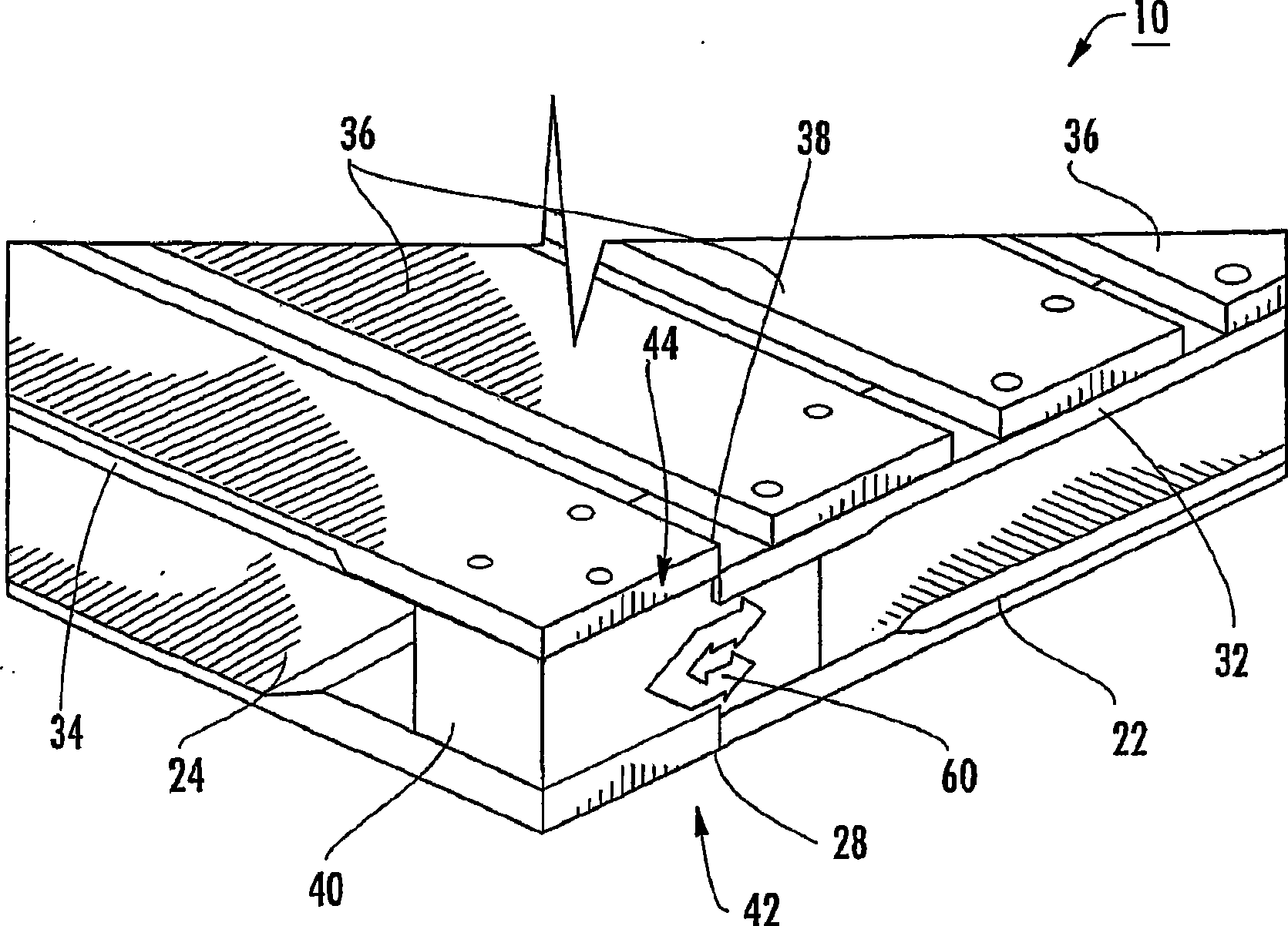

Pallet with stepped support blocks and related methods

The invention relates to a pallet with stepladder-like support plates and method of manufacturing the same. The pallet includes a cargo layer and a base layer. The base layer includes a pair of spaced apart end deck boards, and a pair of spaced apart connector boards orthogonal to the pair of spaced apart end deck boards. Spaced apart support blocks are between the base and cargo layers, and form a gap therebetween for receiving a lifting member. In addition, each supports block includes a stepladder-like top surface which is provided with a first horizontal plane for accommodating a terminal cover panel and a second horizontal plane for accommodating a connector panel.

Owner:CHEP TECH PTY LTD

Emulsified asphalt with high viscosity and high elasticity and preparation method of emulsified asphalt

PendingCN109912987AAging ductility improvementIn-degree improvementBuilding insulationsPolymer scienceReaction temperature

The invention discloses emulsified asphalt with high viscosity and high elasticity and a preparation method of the emulsified asphalt. The emulsified asphalt is prepared from asphalt stock, waste tirerubber powder, a tackifier, an emulsifier, a thermoplastic elastomer, water, carbon black, an antiaging agent, modified calcium carbonate and a surfactant; the emulsified asphalt with high viscosityand high elasticity is prepared by steps as follows: the waste tire rubber powder pulverized by a pulverizer, the tackifier, the emulsifier, the thermoplastic elastomer, water, carbon black, the antiaging agent, modified calcium carbonate and the surfactant are added to the molten asphalt stock. Through the adoption of the method, reaction temperature can be reduced, asphalt aging is prevented, release of toxic gas is reduced, resource saving and environment protection are realized, and operation is simple; the prepared modified asphalt mixture has higher bend resistance, break resistance, high-temperature resistance and the like, and the application range of the modified asphalt is enlarged.

Owner:肖剑

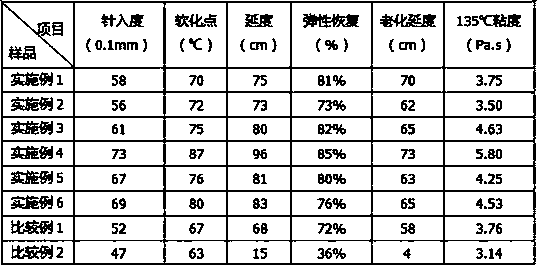

Safety sheath for hypodermic syringe needle

InactiveUS20120022463A1Facilitate subsequent sleeving processImprove tightnessMedical devicesInfusion needlesHypodermic needleEngineering

The present invention provides a safety sheath for hypodermic syringe needle comprising a proximal mounting ring, a distal mounting ring and a shielding sheath. The shielding sheath includes two symmetrical slits, two symmetrical semicircular aprons and an inward annular fillet, which is bisected into two symmetrical curved segments with crescent thickness, namely marginal thickness is less than central thickness. During sleeving the shielding sheath over the distal mounting ring and proximal mounting ring, both symmetrical semicircular aprons are outwardly hauled by outwards forces such that the bore profile of the inward annular fillet is dilated into circular shape, which will not only facilitate subsequent sleeving process without difficulty but also enhance the tightness for the latch of the shielding sheath with the distal mounting ring in locked manner without any possibility of mutually slipping displacement so that medical personnel in handling can prevent from accidental pricks by hypodermic needle.

Owner:WU KUO CHENG

Elastic short fiber and processing process thereof

InactiveCN105839225AFunctionalWith curl propertiesElectroconductive/antistatic filament manufactureArtificial filament heat treatmentPolytetramethylene terephthalateTextile production

The invention relates to an elastic short fiber and a processing process thereof and belongs to the technical field of fiber generation. Polybutylene terephthalate and a polymer where complex function master batches are added to serve as a skin layer component, poly butylene tertephehalate ester thermoplastic elastomer serves as a core layer component, the skin layer component and the core layer component are respectively subject to melting extrusion through a screw extruder and enter a dual-component composite spinning device and a skin-core core shift composite spinneret orifice, melt sprayed out is subject to a spinning postprocessing process of cooling, oiling, bundling, drafting, cutoff and heat setting, so that the elastic short fiber which has complex functions of ultraviolet resistance, statistic resistance and bacterial resistance is obtained. The elastic short fiber is applied to the fields such as high-grade elastic fabrics and home textile productions and the like, and the products have the advantages of being self-curled and good in elastic elongation ratio and elastic recovery.

Owner:杭州栋华实业有限公司

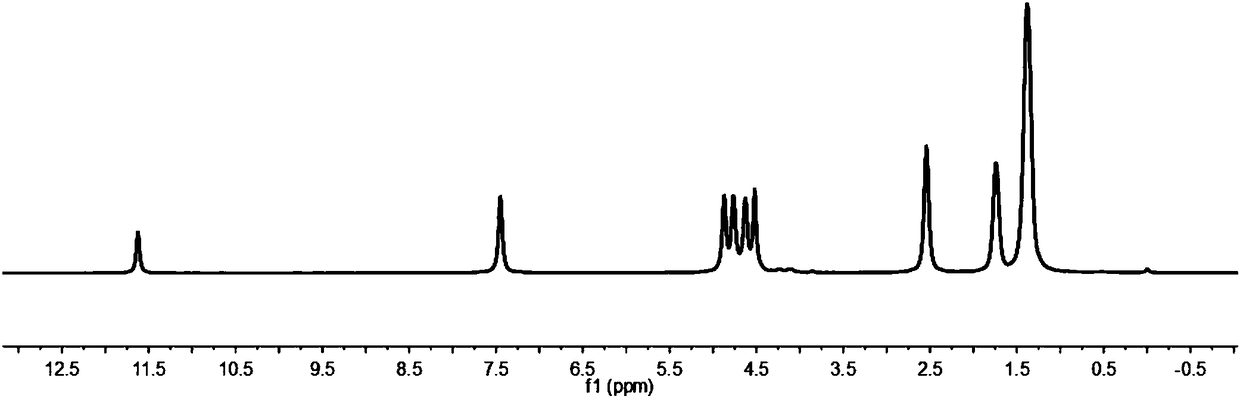

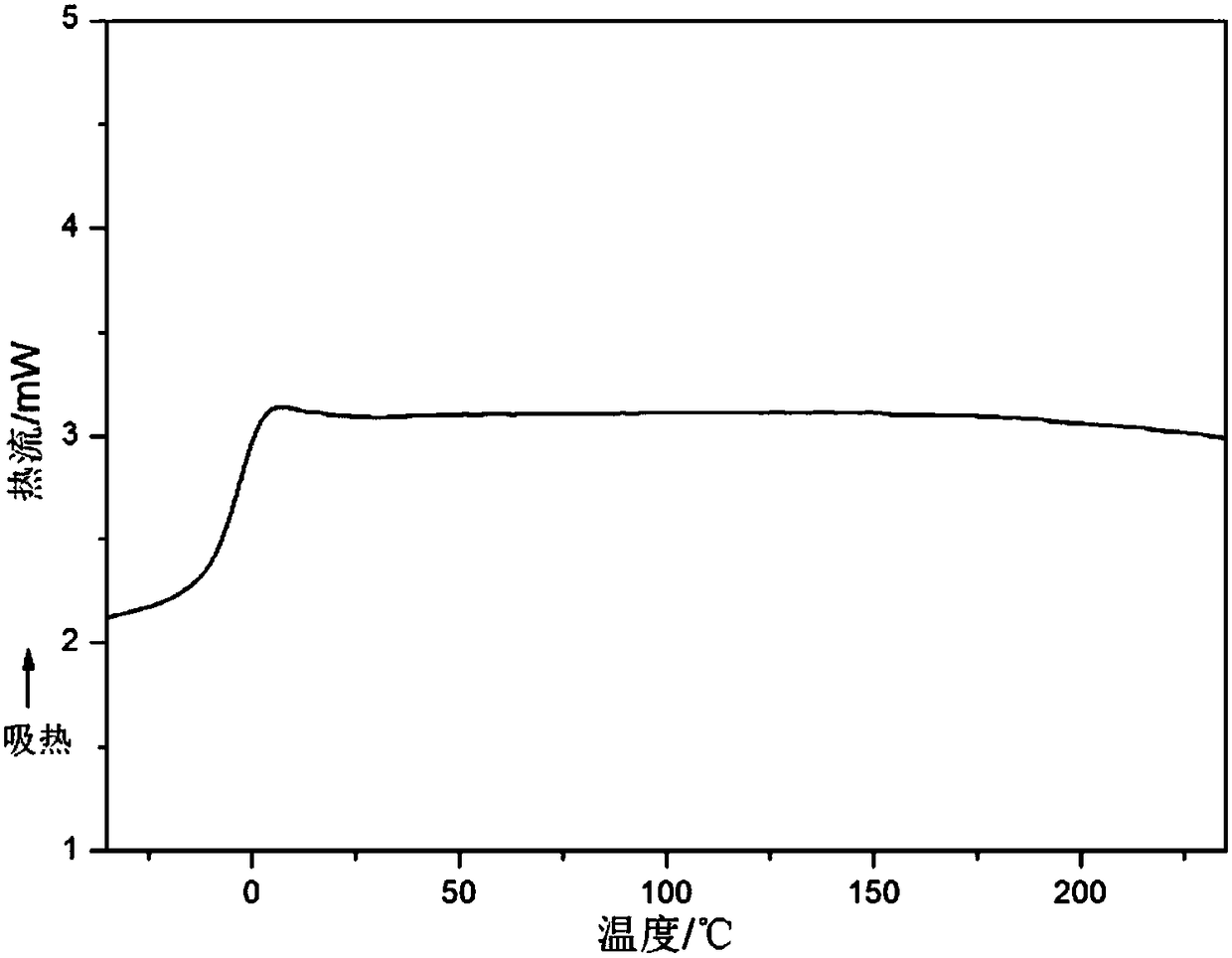

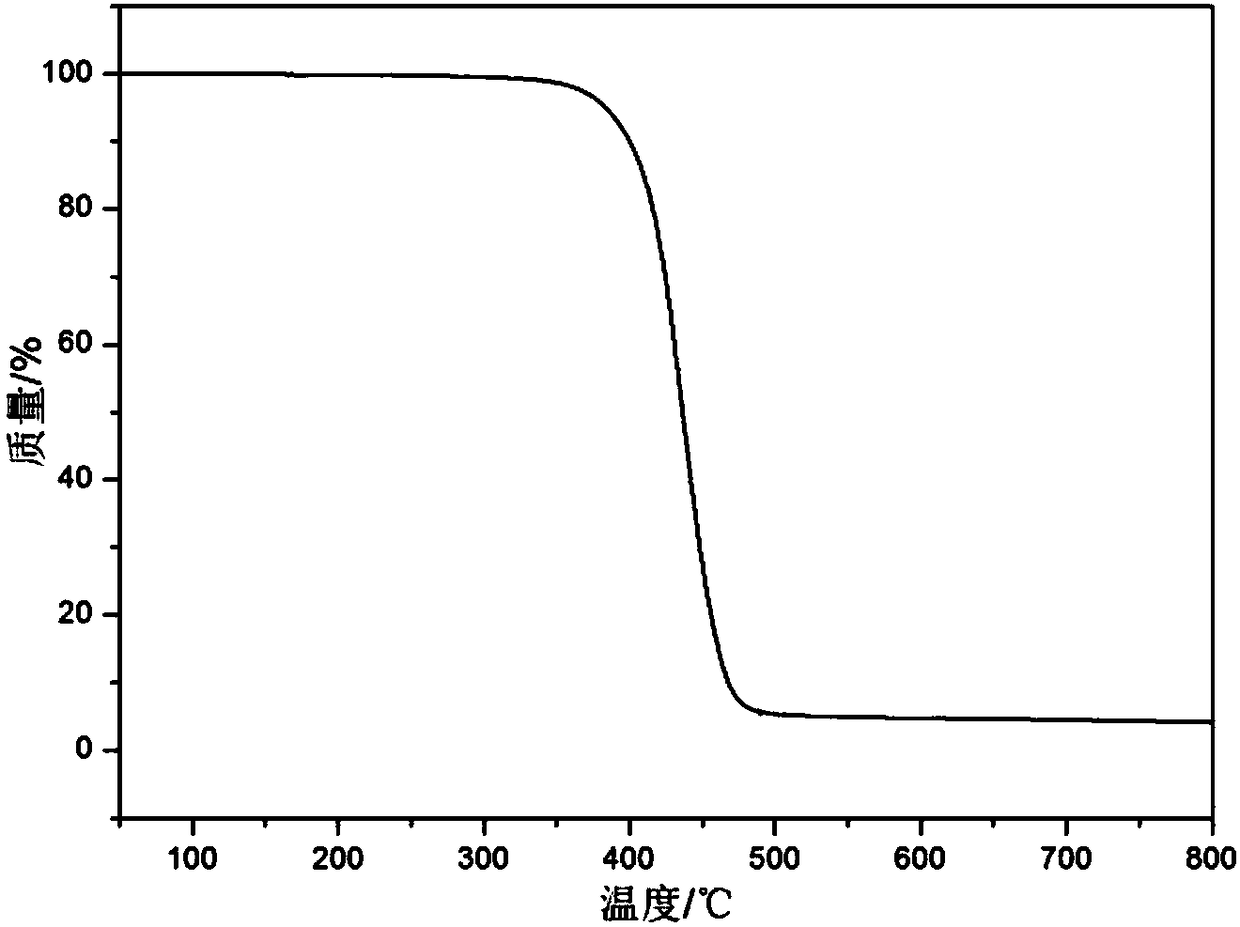

Thermoplastic polyester elastomer as well as preparation and application thereof

The invention relates to a thermoplastic polyester elastomer as well as preparation and application thereof. Specifically, the thermoplastic polyester elastomer is prepared according to a preparationmethod as follows: a component (a) of furandicarboxylic acid and / or an esterified product thereof, a component (b) of aliphatic dibasic acid and / or the esterified product thereof and a component (c) of dibasic alcohol are subjected to polycondensation to obtain the thermoplastic polyester elastomer, wherein the molar amount of the component (a) to (the molar amount of the component (a) plus the molar amount of the component (b)) is 0.3 to 0.7, and the thermoplastic polyester elastomer has a 500% elastic recovery ratio of being equal to or greater than 70%. The invention further discloses the preparation and the application of the thermoplastic polyester elastomer. The thermoplastic polyester elastomer combines excellent toughness, thermal stability, elastic recovery and elongation at break. The method has the characteristics of simple process, low cost, safety, environmental friendliness and the like. The thermoplastic polyester elastomer can be widely used in the fields of automobileparts, toys, textiles and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

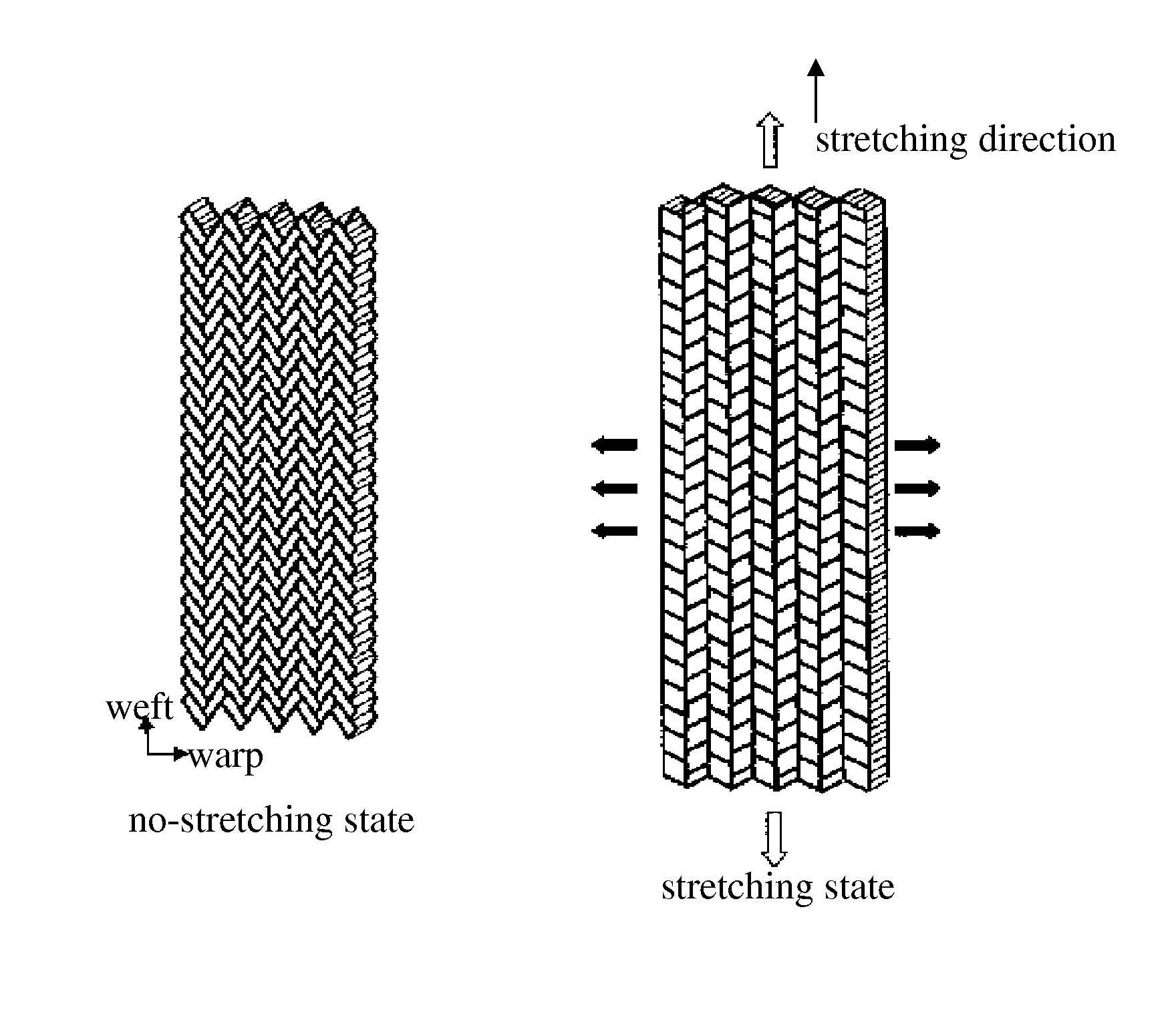

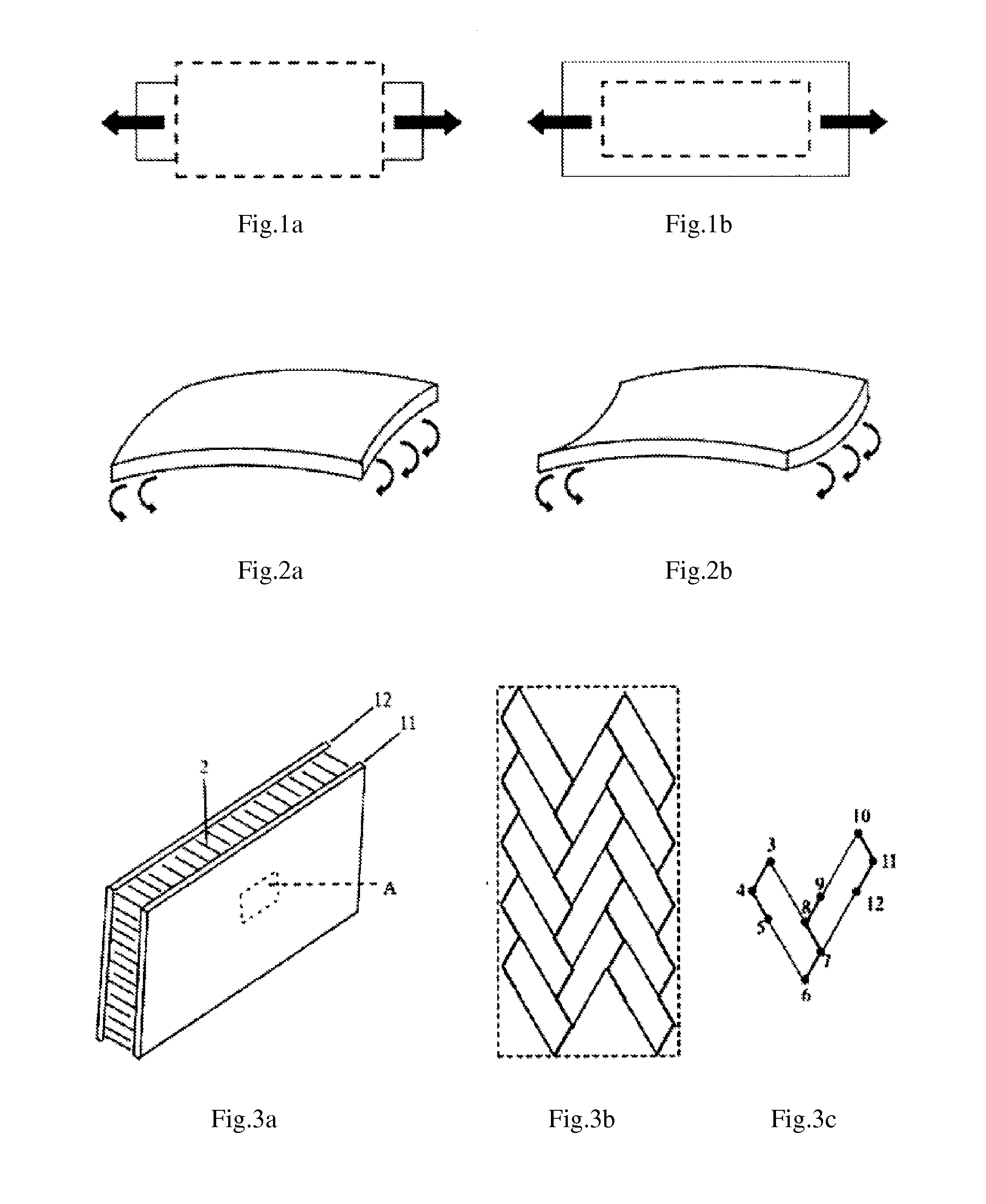

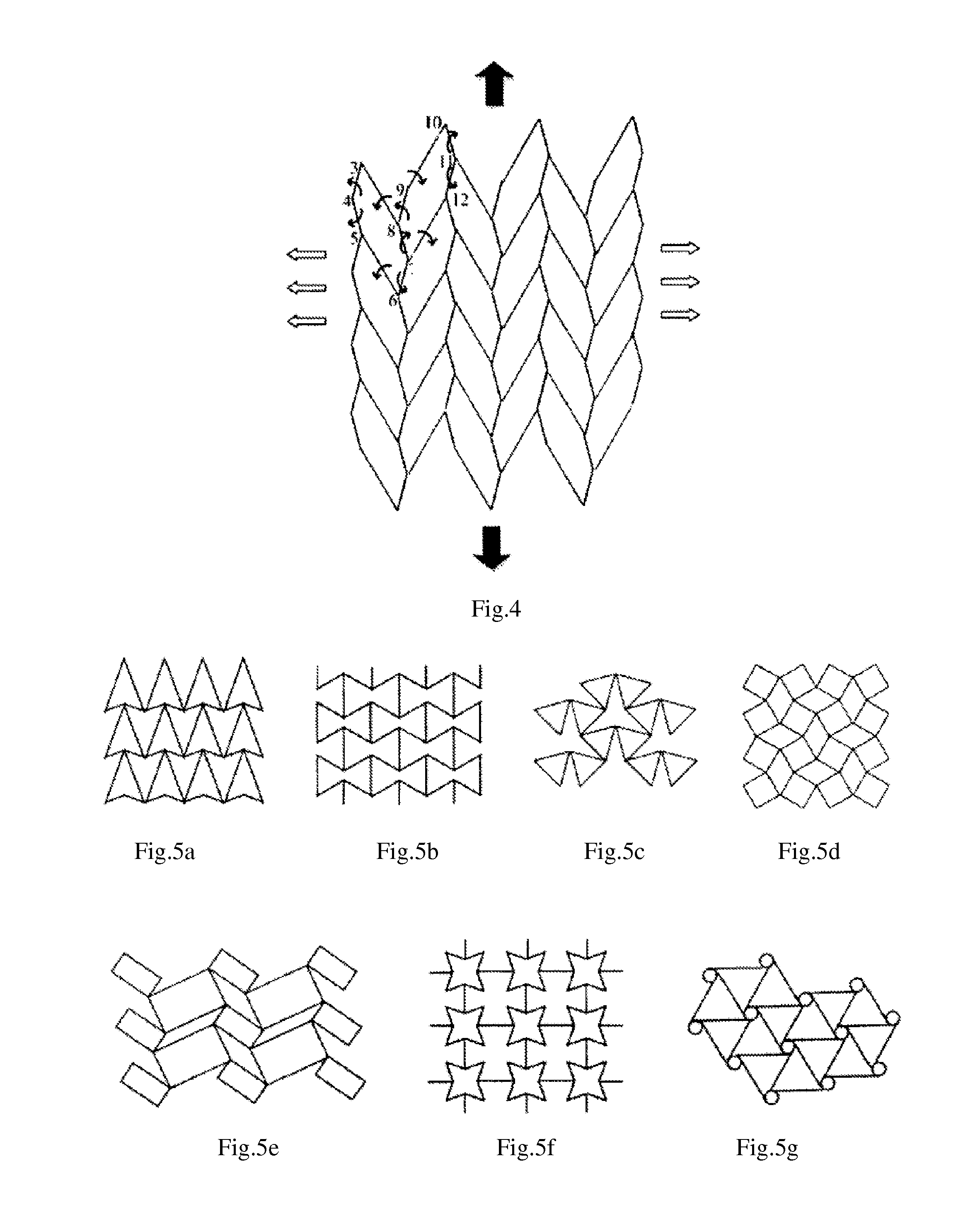

Three dimensional negative poisson'S ratio spacer knitted fabric and method for making the same

ActiveUS9475257B2Simple processGood elasticity recoveryOrnamental textile articlesLayered productsYarnSurface layer

This present application relates to a three dimensional negative Poisson's ratio spacer knitted fabric and a method for making the same; the fabric includes a first surface layer fabric, a second surface layer fabric, and a spacer yarn layer connecting the first surface layer fabric with the second surface layer fabric, both the first surface layer fabric and the second surface layer fabric are bi-dimensional structures having the negative Poisson's ratio effects; the method is to compress and / or stretch a three dimensional mesh spacer knitted base fabric along one or two plane directions to form a structures having the negative Poisson's ratio effects. The advantages of the present application include low making cost, simple operation method, significant negative Poisson's ratio effects, good elastic recovery, and high practical application value.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

Polylactic acid composition

InactiveUS7585910B2High-level drawabilityHigh-level flexibilitySpecial tyresEmulsion paintsResidual deformationPlasticizer

A polylactic acid composition containing polylactic acid and ester-based plasticizer, wherein a content of the ester-based plasticizer is 16 to 33 wt %, and when the composition is highly deformed by stress loading as the relation between the stress and the deformation deviates from linear viscoelastic behavior and thereafter the stress is released, residual deformation measured after the stress is released is not less than 66.0% after 0.2 minute of the stress release, and is not more than 34.0% after 240 hours of the stress release.

Owner:TOYOTA CENT RES & DEV LAB INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com