Patents

Literature

432results about "Reagent containers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Accurate and timely body fluid analysis

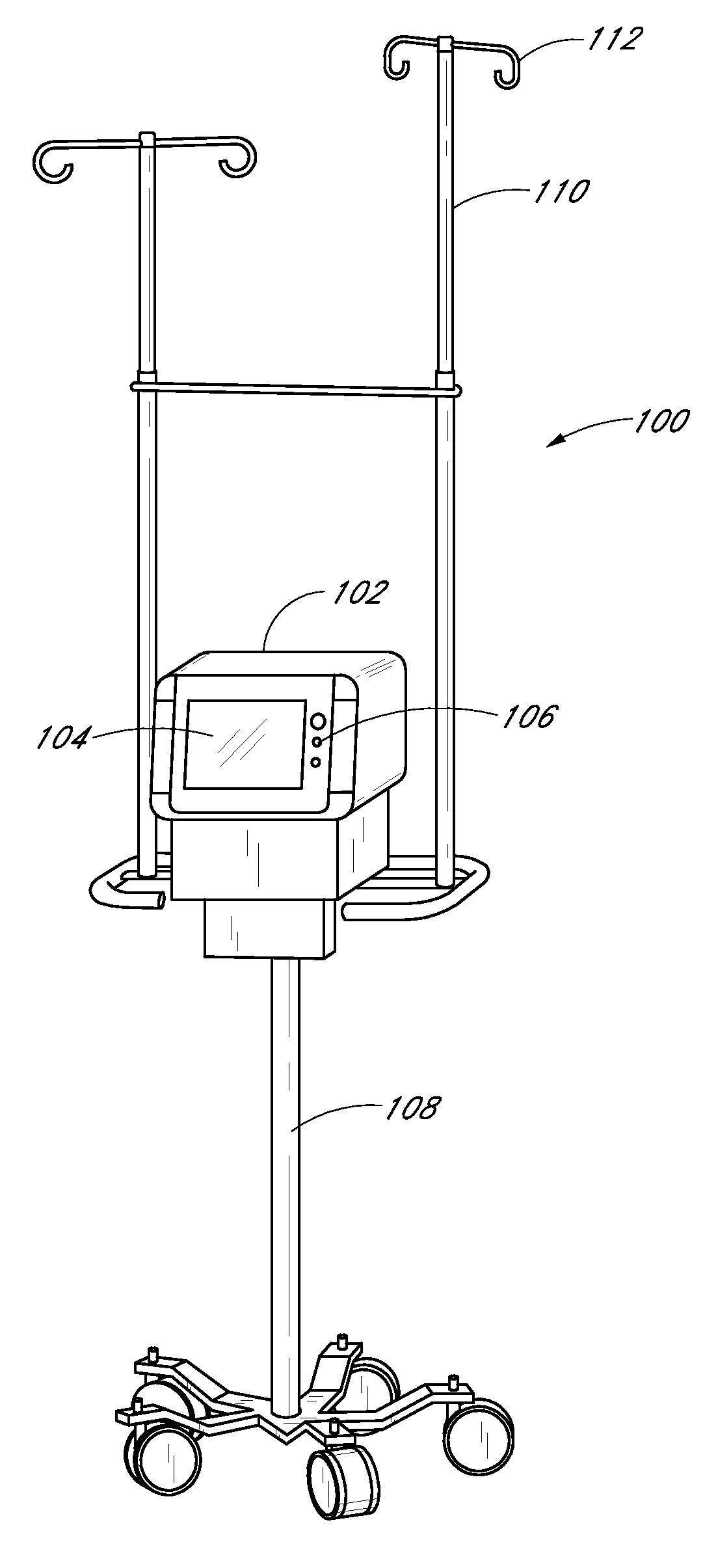

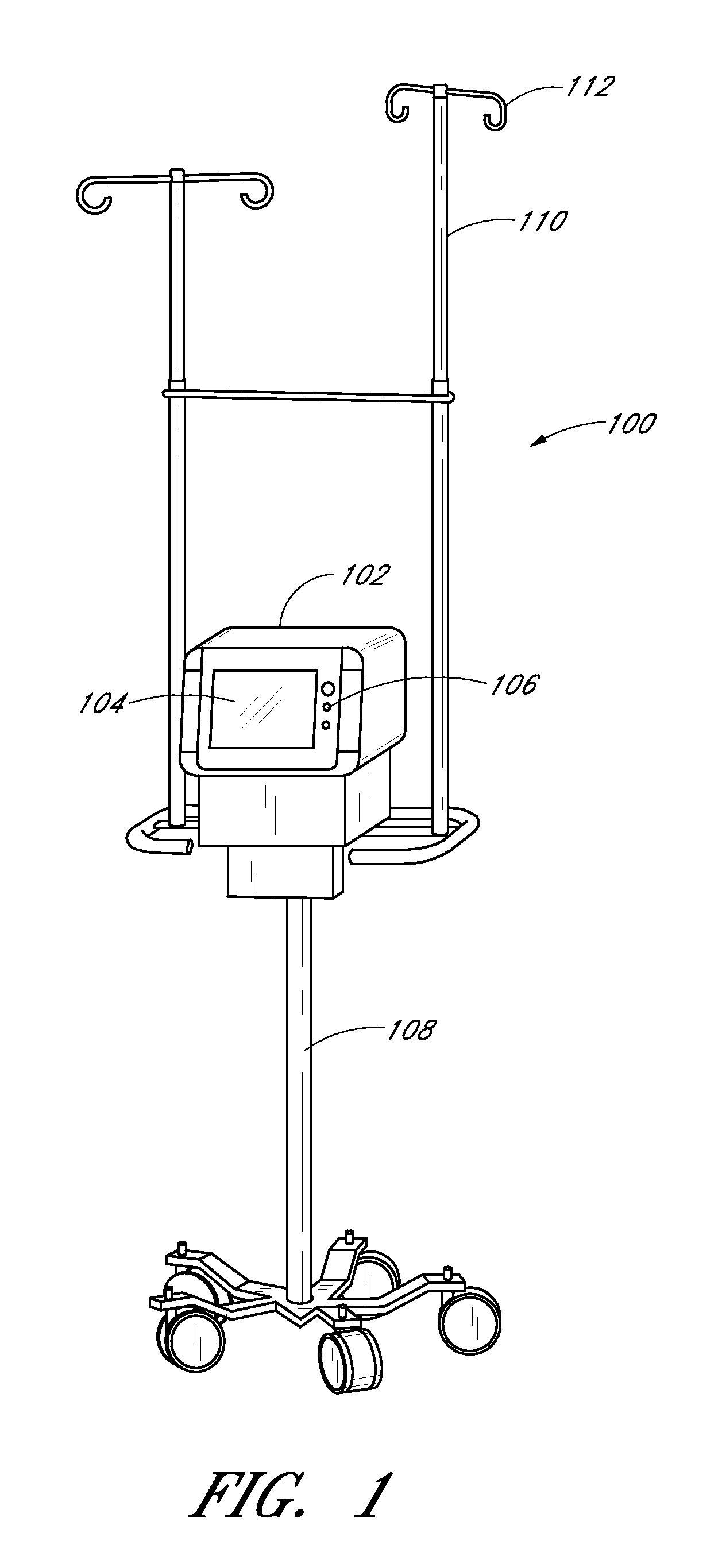

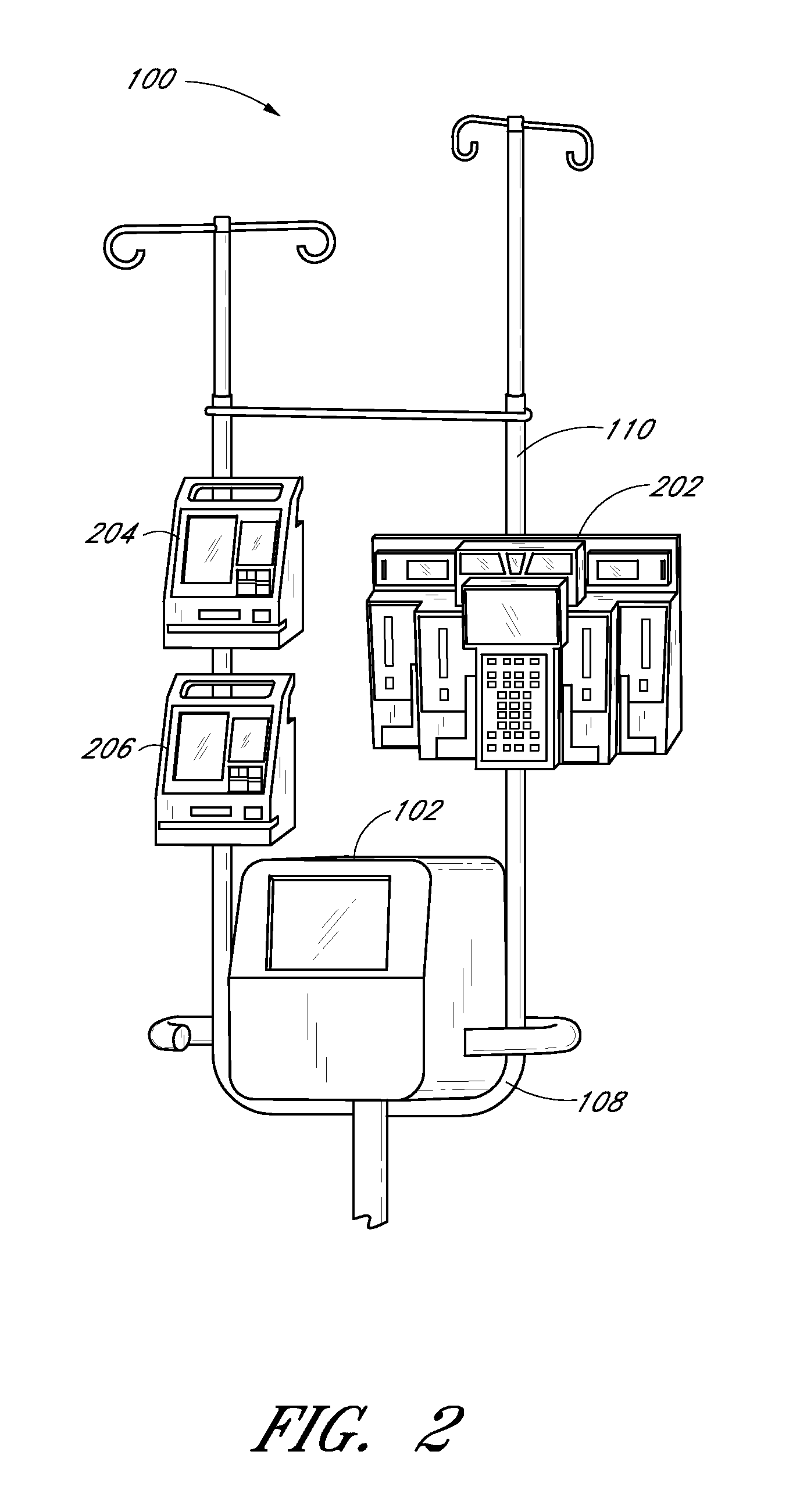

InactiveUS20080072663A1Specific gravity using centrifugal effectsMedical devicesPoint of careAnalyte

A method of extracting and analyzing bodily fluids from a patient at the point of care for the patient is provided. The method comprises establishing fluid communication between an analyte detection system and a bodily fluid in the patient. A portion of the bodily fluid is drawn from the patient. A first component of the bodily fluid is separated from the drawn portion, while the analyte detection system remains in fluid communication with the patient. The analyte detection system analyzes the first component to measure a concentration of an analyte in an accurate and timely manner.

Owner:OPTISCAN BIOMEDICAL

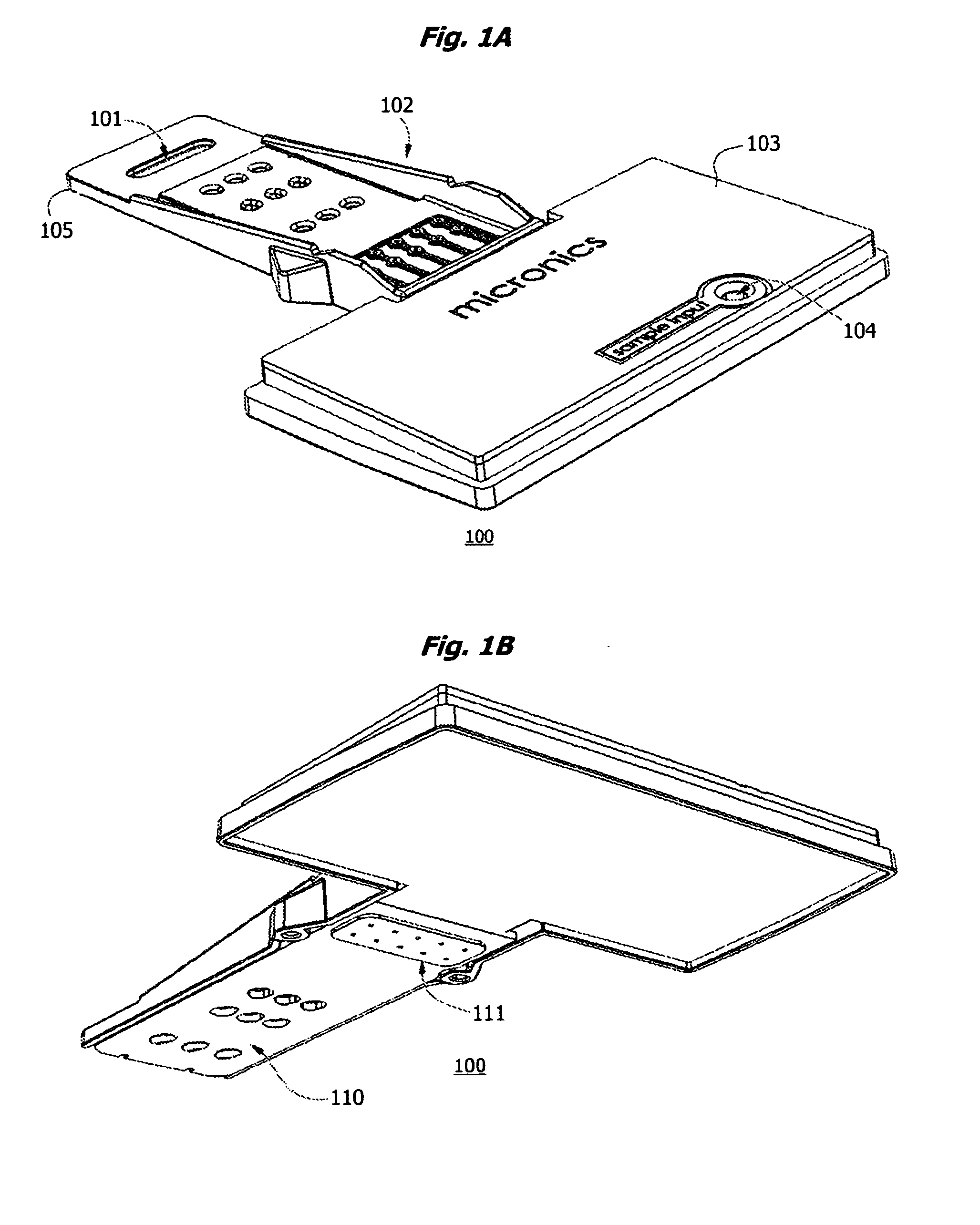

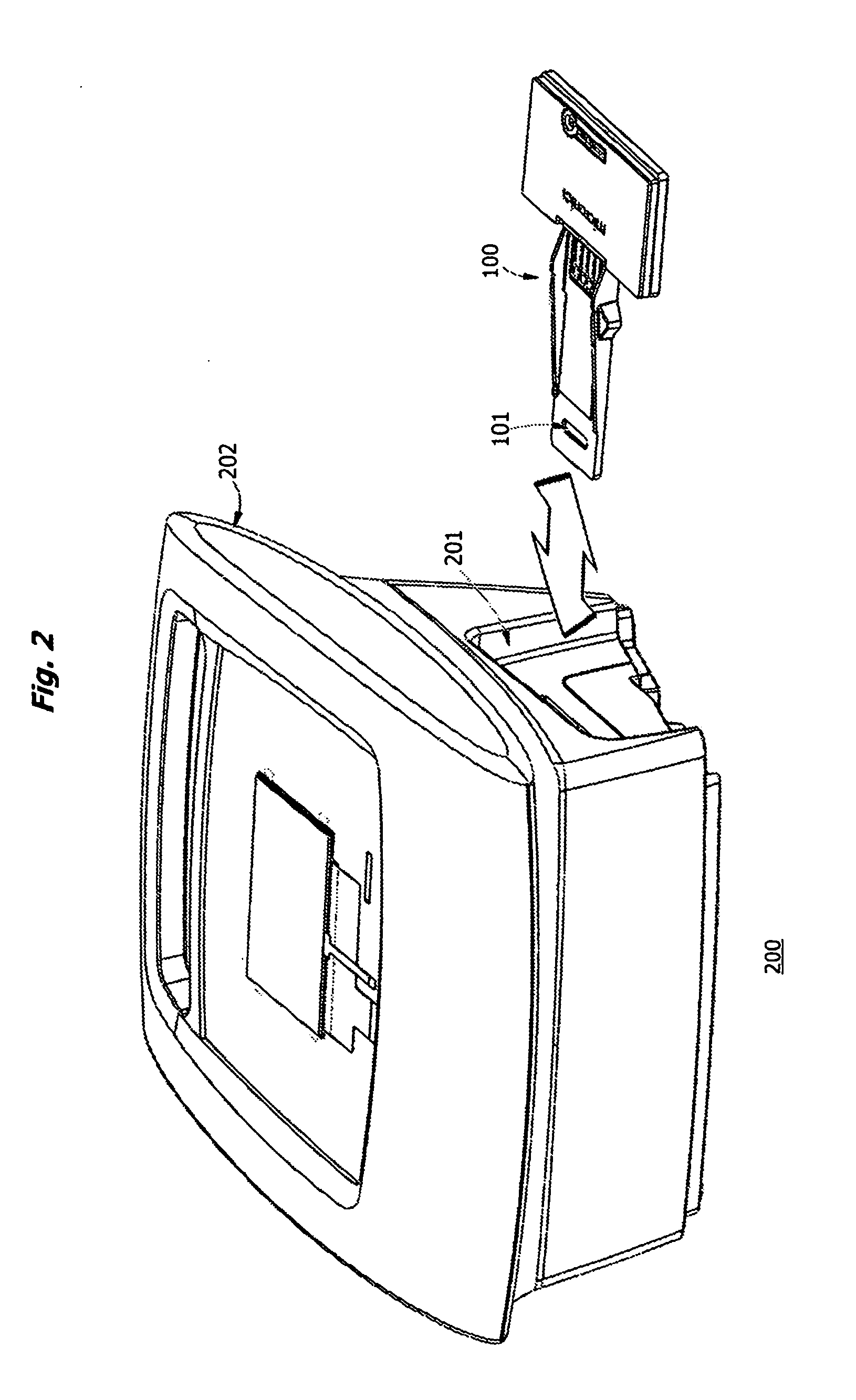

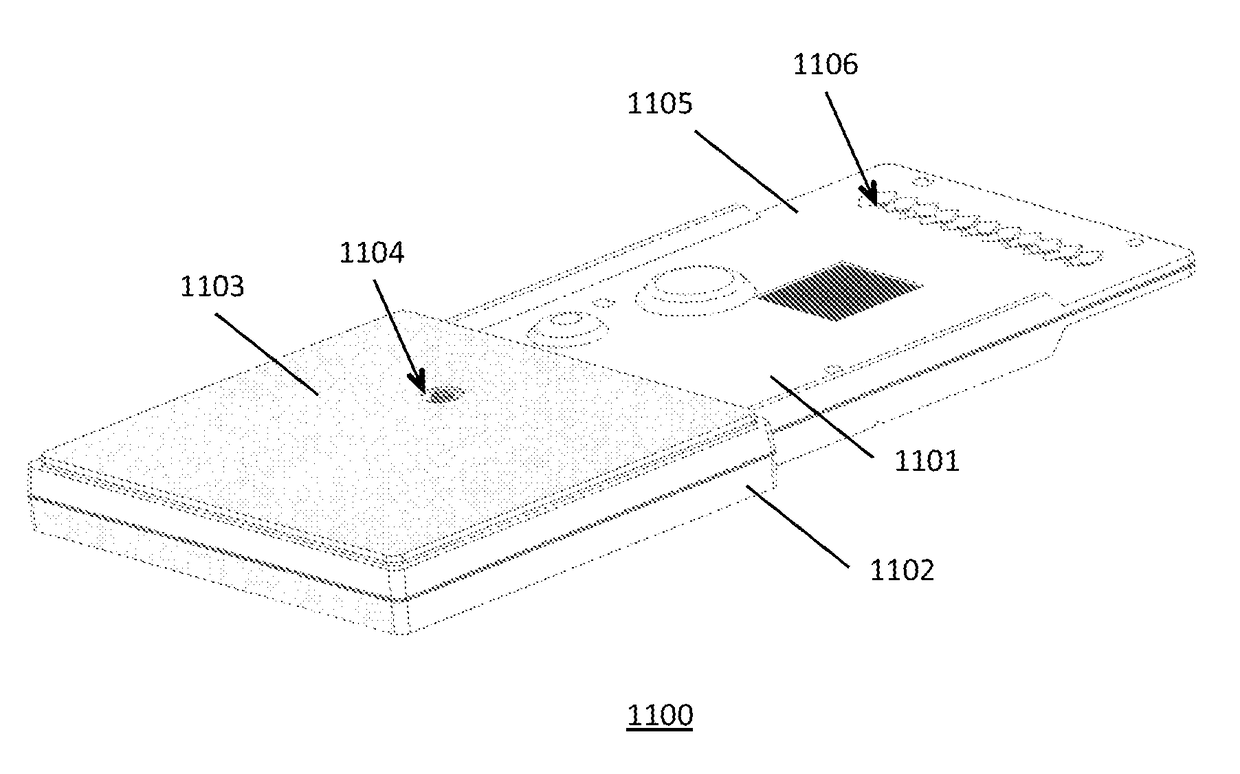

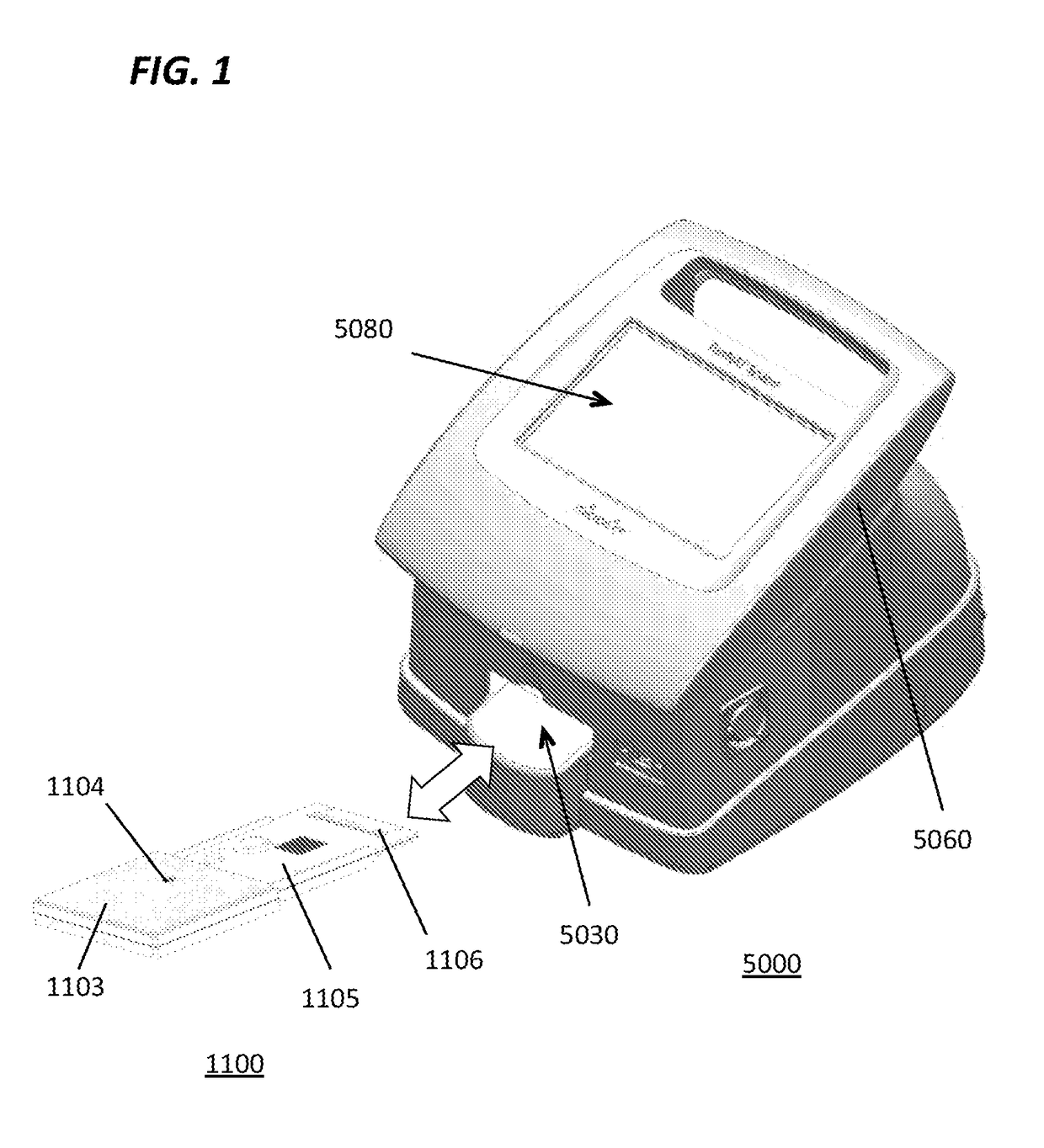

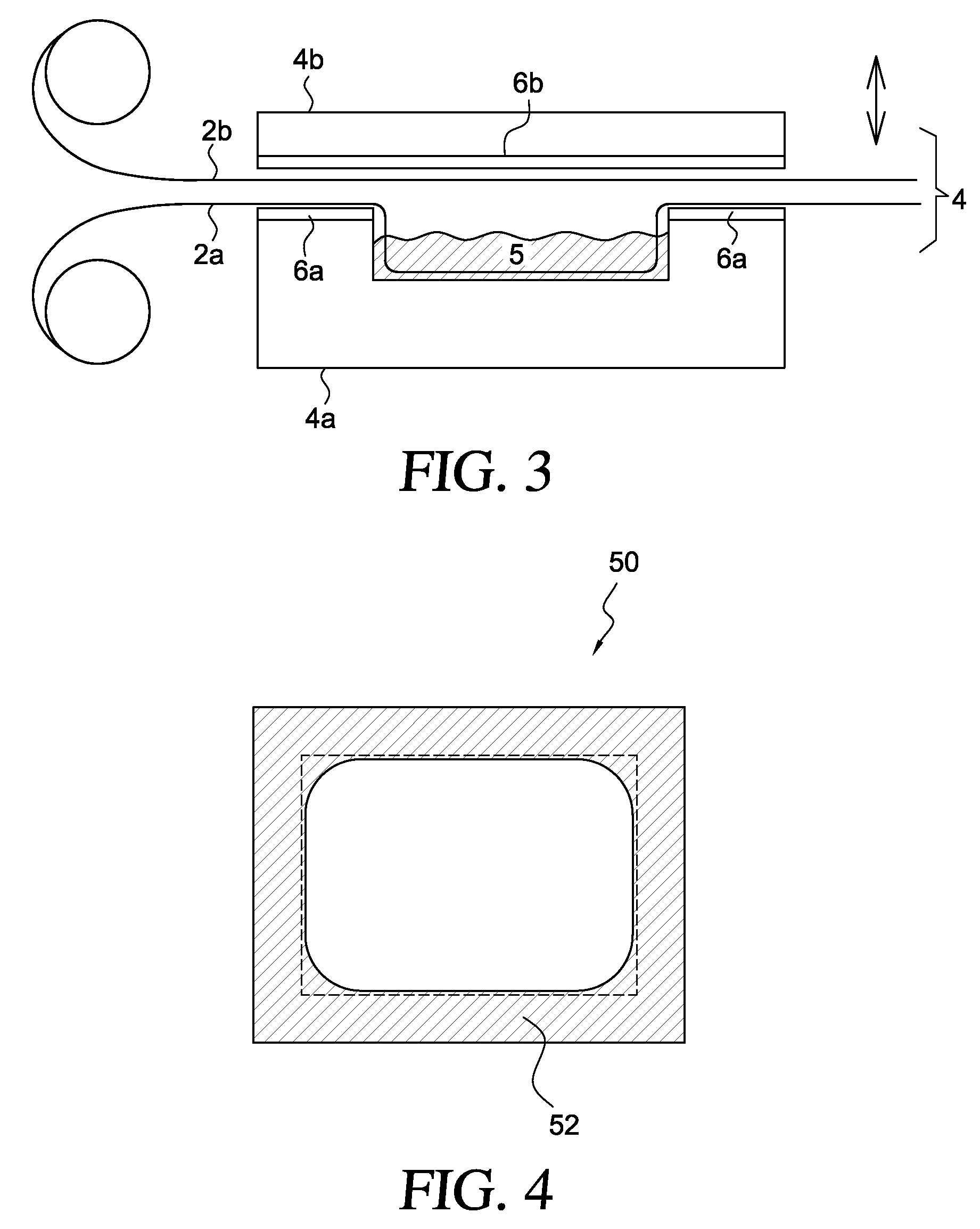

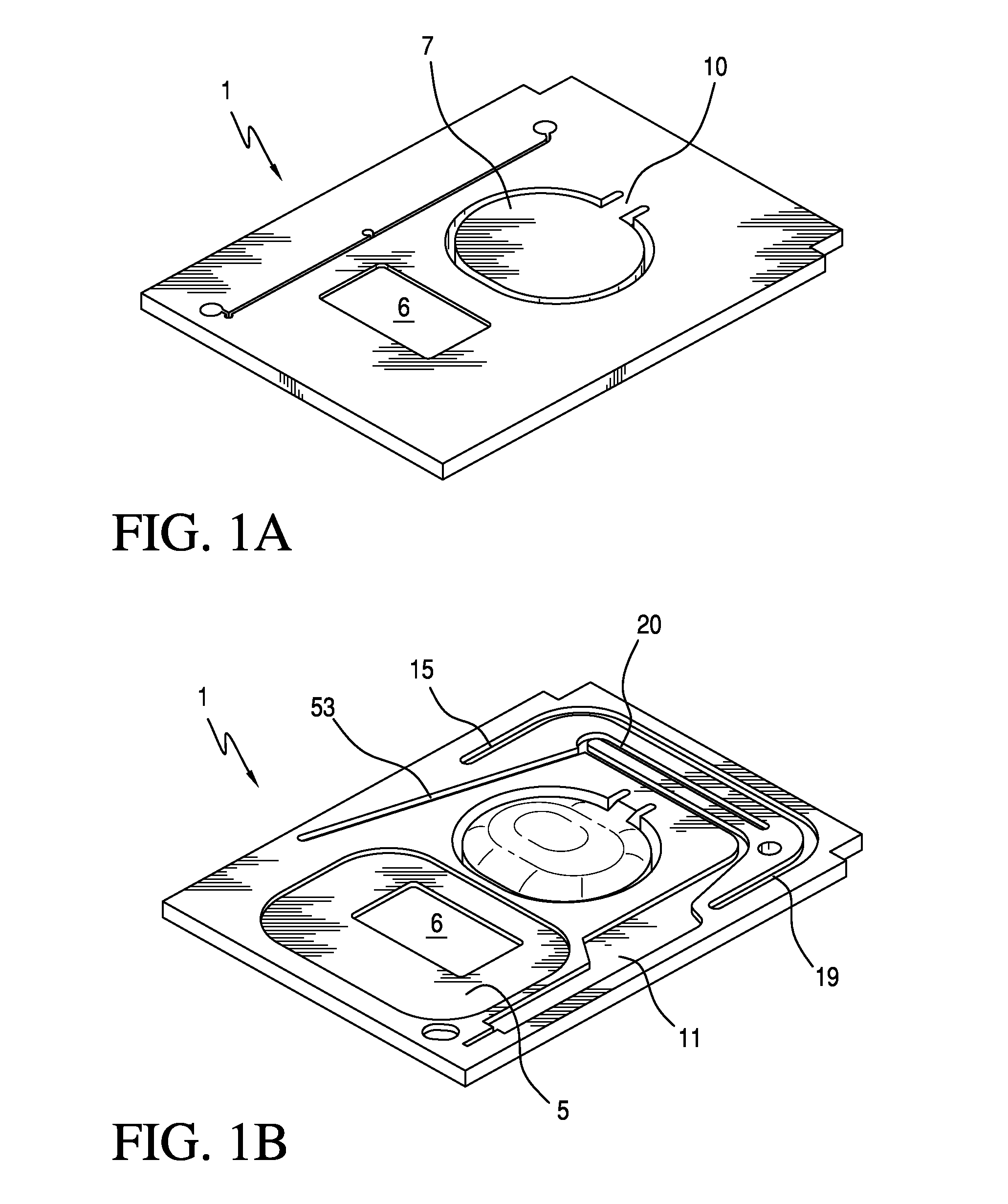

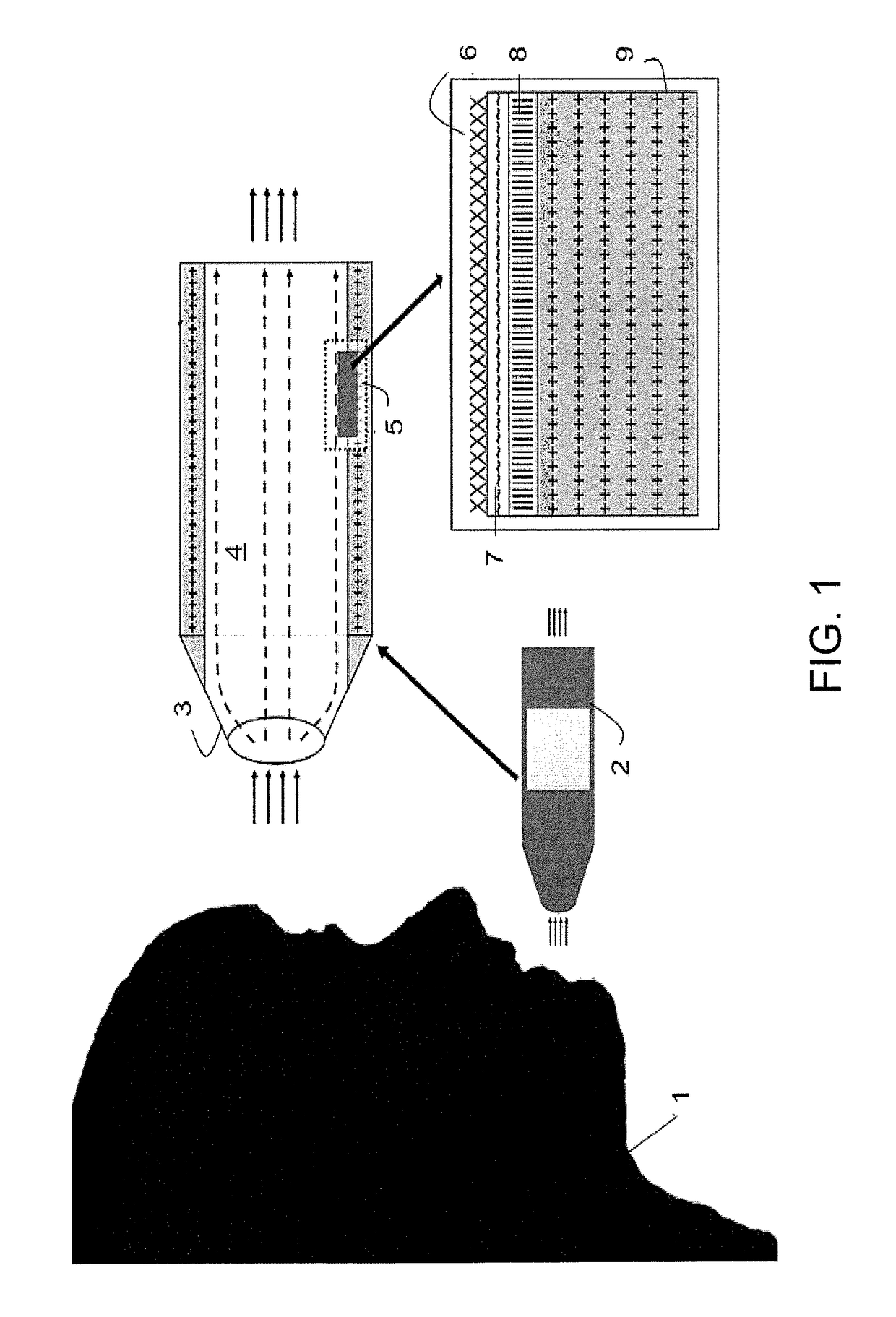

Sample-to-answer microfluidic cartridge

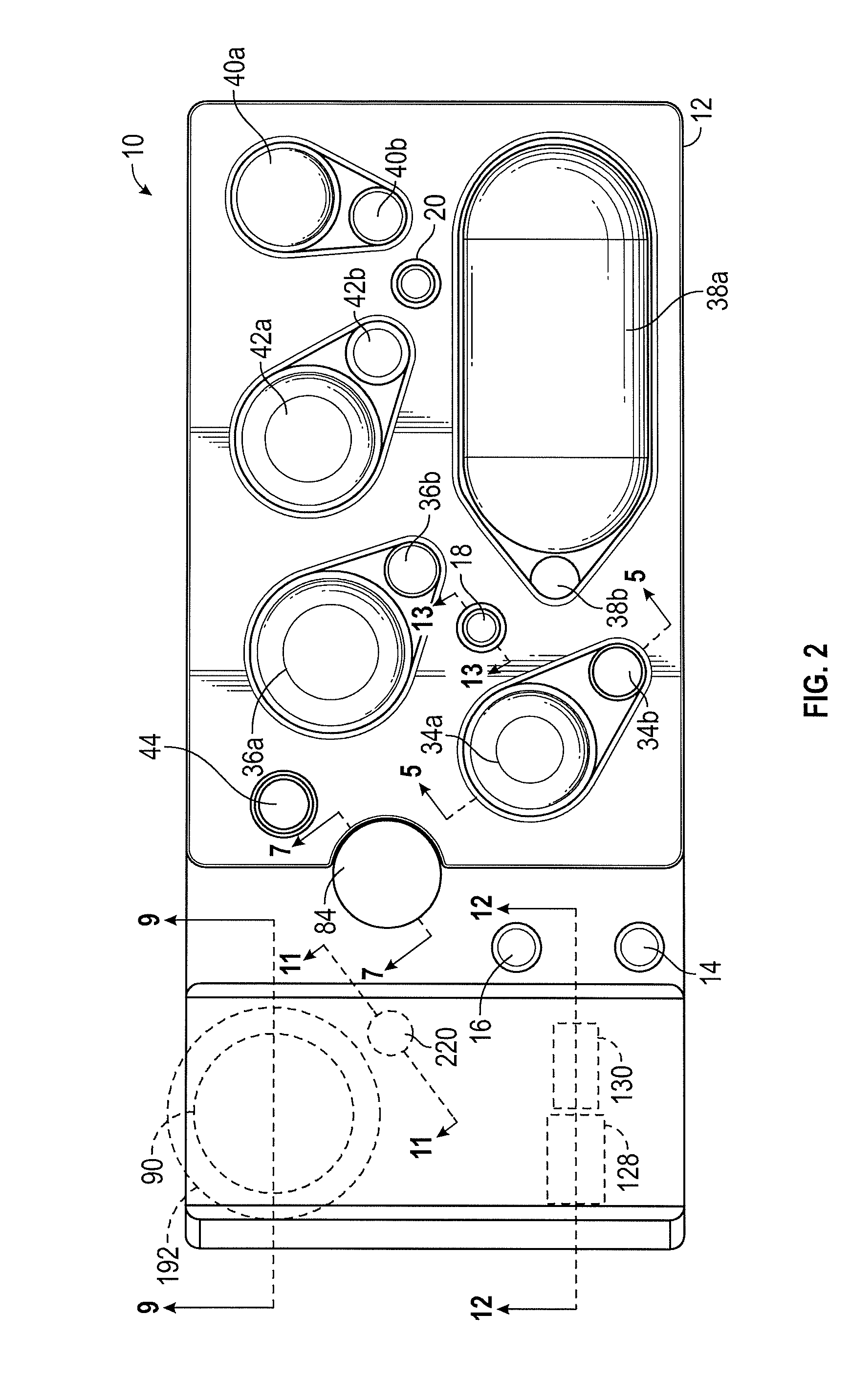

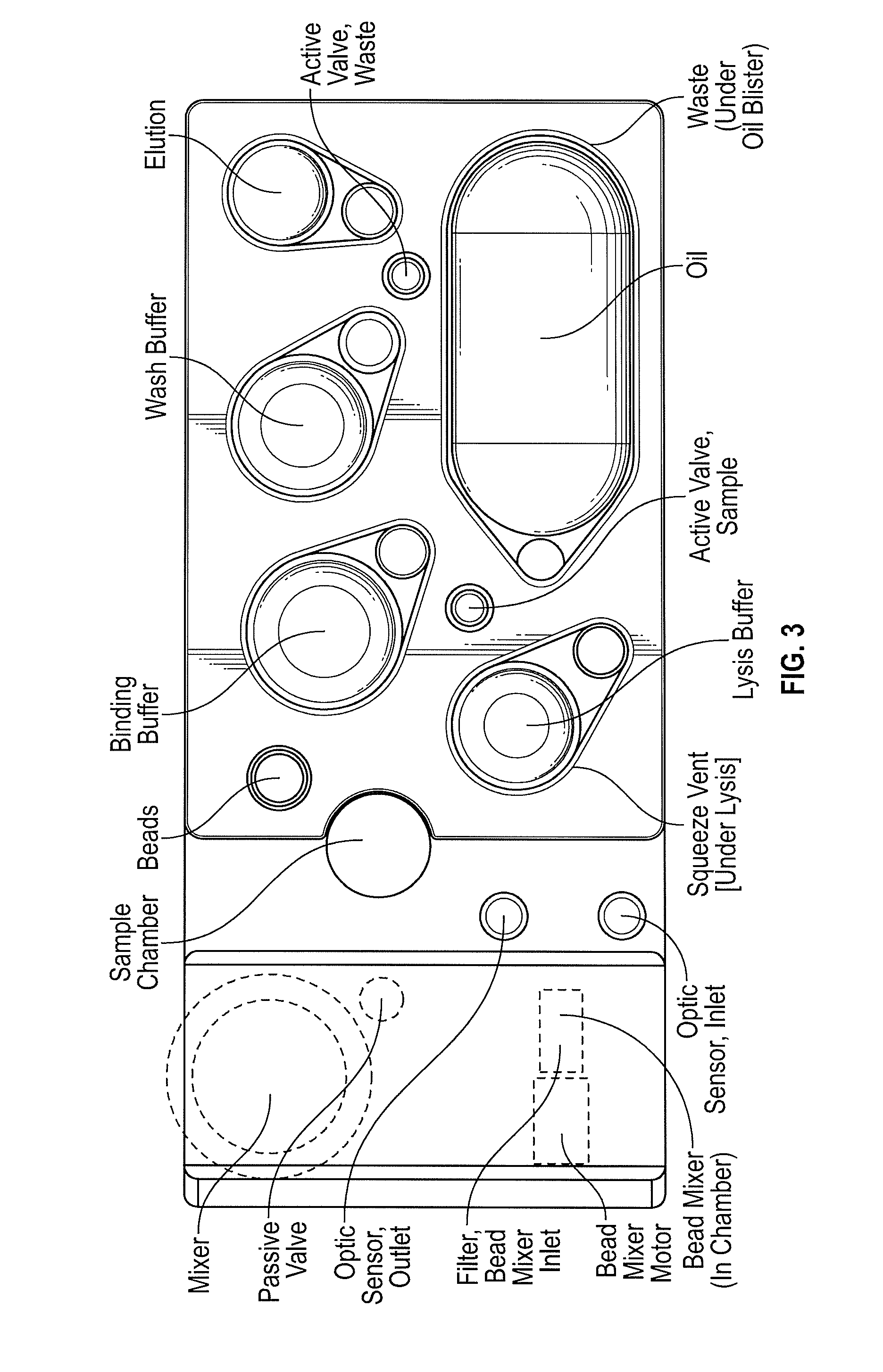

ActiveUS20130130262A1Reduce distractionsLimit parasitic heat capacitanceBioreactor/fermenter combinationsBiological substance pretreatmentsReagentAnalytical chemistry

A microfluidic cartridge and methods for performing a diagnostic, molecular or biochemical assay thereon, where all dried and / or liquid reagents necessary for the assay are contained in the cartridge and the assay requires only the addition of sample. Pneumohydraulic features, chamber and diaphragm technologies are introduced for overcoming the problems of bubble interference and reagent washout during operation of a microfluidic cartridge. The cartridges are inserted into a host instrument for performance of an assay and the cartridge is supplied as a consumable.

Owner:PERKINELMER HEALTH SCIENCES INC

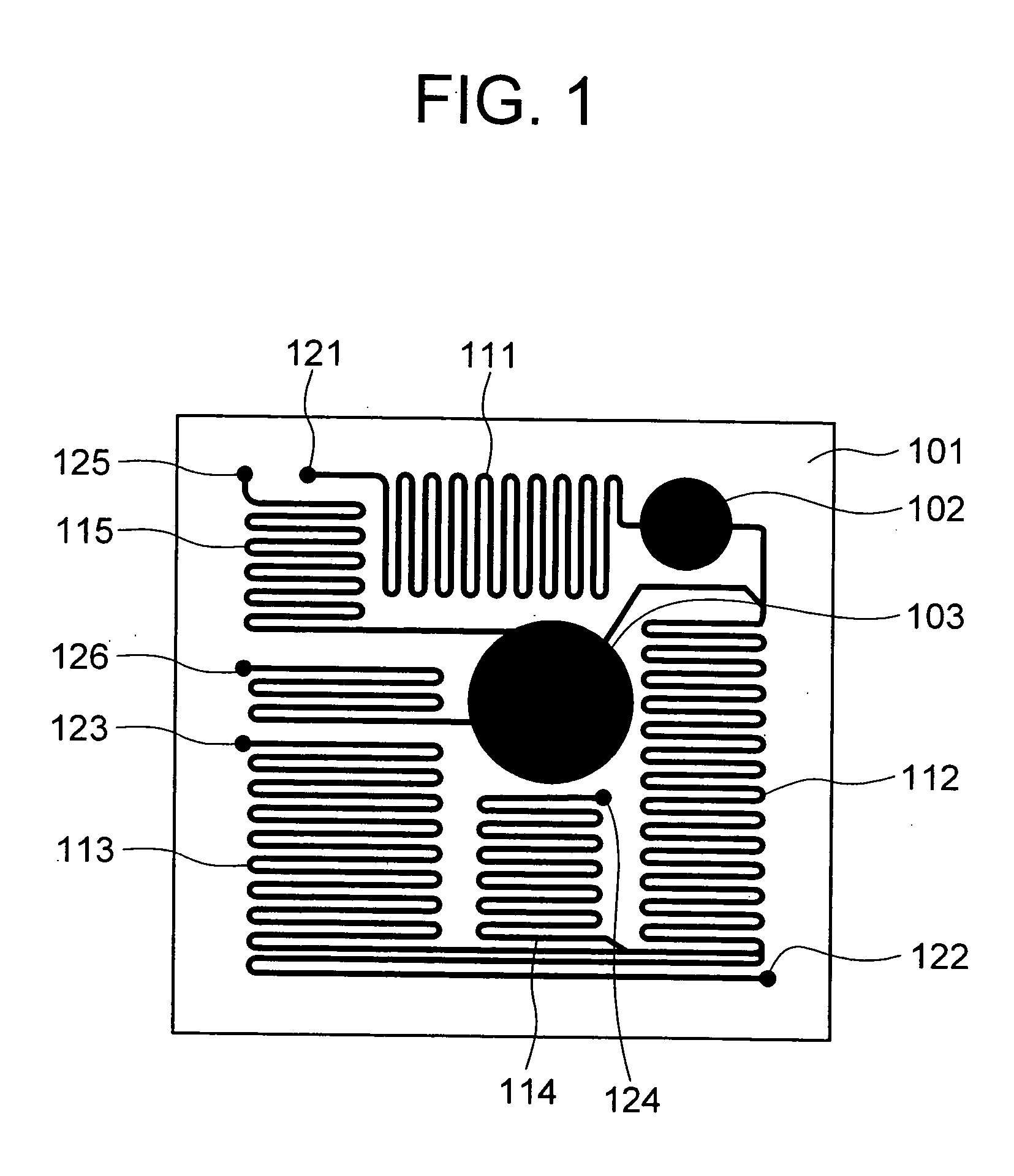

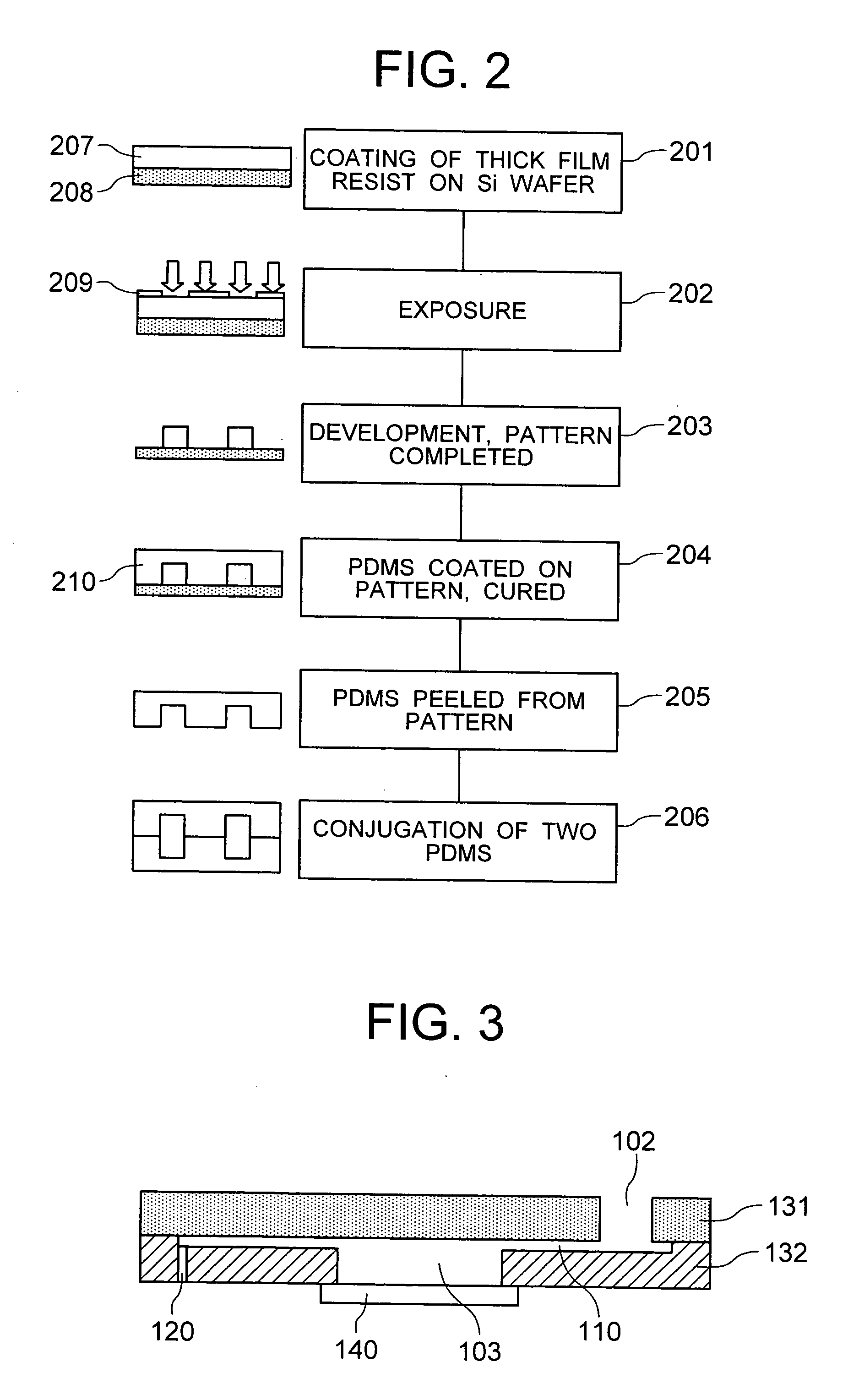

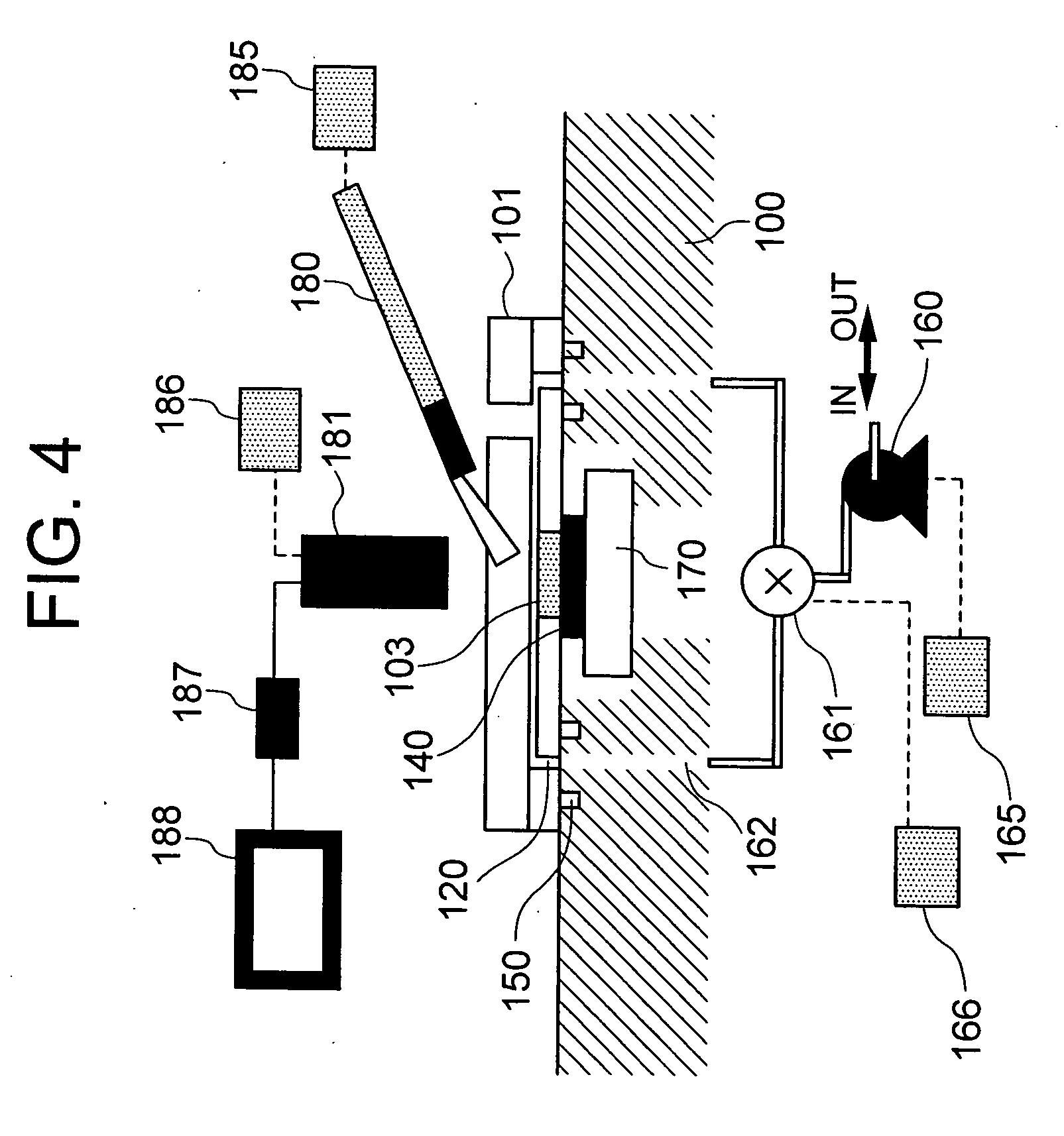

Chip for processing of gene and apparatus for processing of gene

InactiveUS20050048540A1Short processBioreactor/fermenter combinationsHeating or cooling apparatusInjection portGene

The present invention provides an analytical chip that is easy to handle, inexpensive, and for which the extraction of gene from a sample and analysis thereof can be automated to one process, and a small-sized and portable analytical apparatus equipped therewith. The chip for processing of gene that is equipped with an injection port into which a sample containing gene is delivered, a gene extraction part into which a solution containing said sample is introduced and which has a gene-binding carrier that binds to said gene, a washing solution-storing part that stores the washing solution to be introduced into said gene extraction part, and a reaction part into which said gene captured in said extraction part is introduced, wherein a fluid channel through which said washing solution is introduced from said washing solution-storing part has been connected to a region more remote from said injection port than from a region into which a solution containing said sample is introduced in said gene extraction part is obtained.

Owner:HITACHI LTD

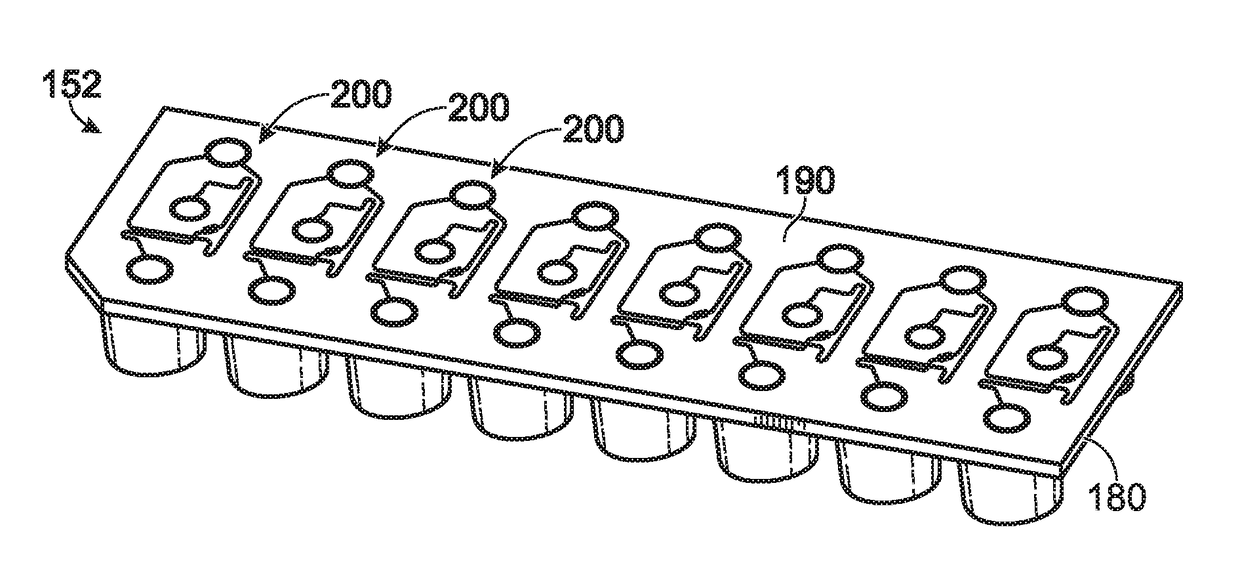

Fluidic devices and systems for sample preparation or autonomous analysis

ActiveUS20130309679A1Bioreactor/fermenter combinationsHeating or cooling apparatusBiospecimenAnalytical chemistry

The present invention relates to fluidic devices for preparing, processing, storing, preserving, and / or analyzing samples. In particular, the devices and related systems and methods allow for preparing and / or analyzing samples (e.g., biospecimen samples) by using one or more of capture regions and / or automated analysis.

Owner:TALIS BIOMEDICAL CORP +1

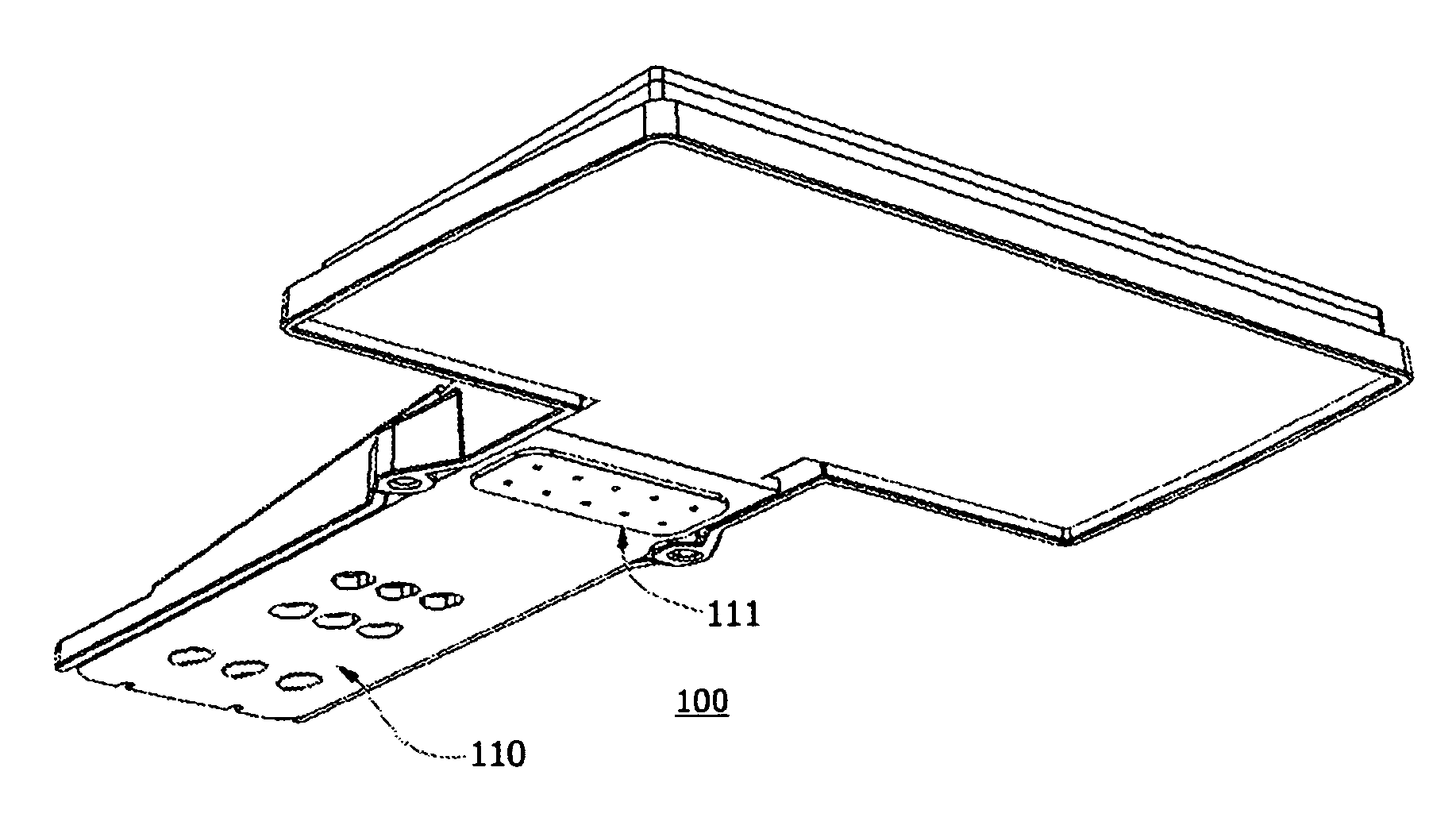

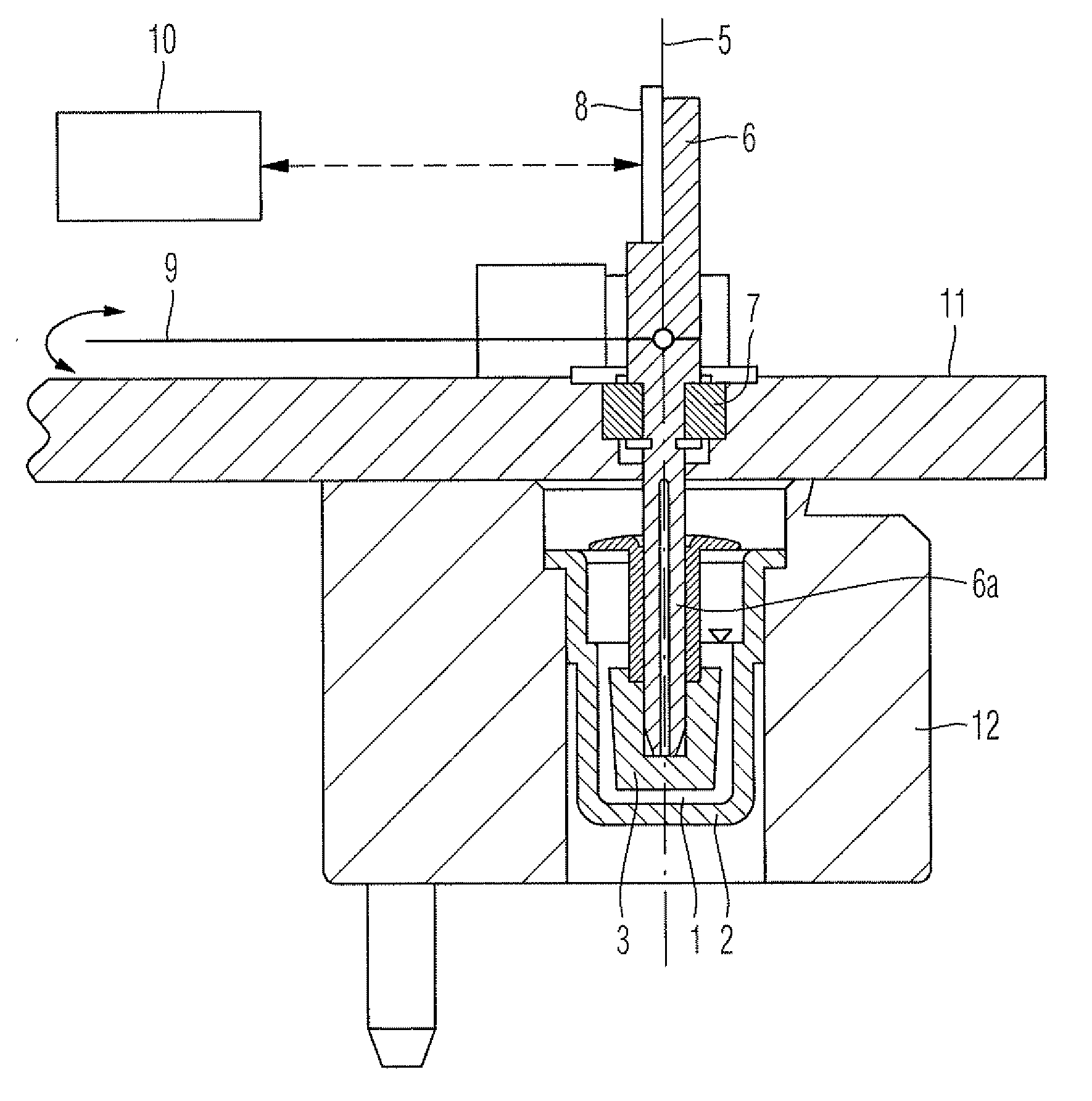

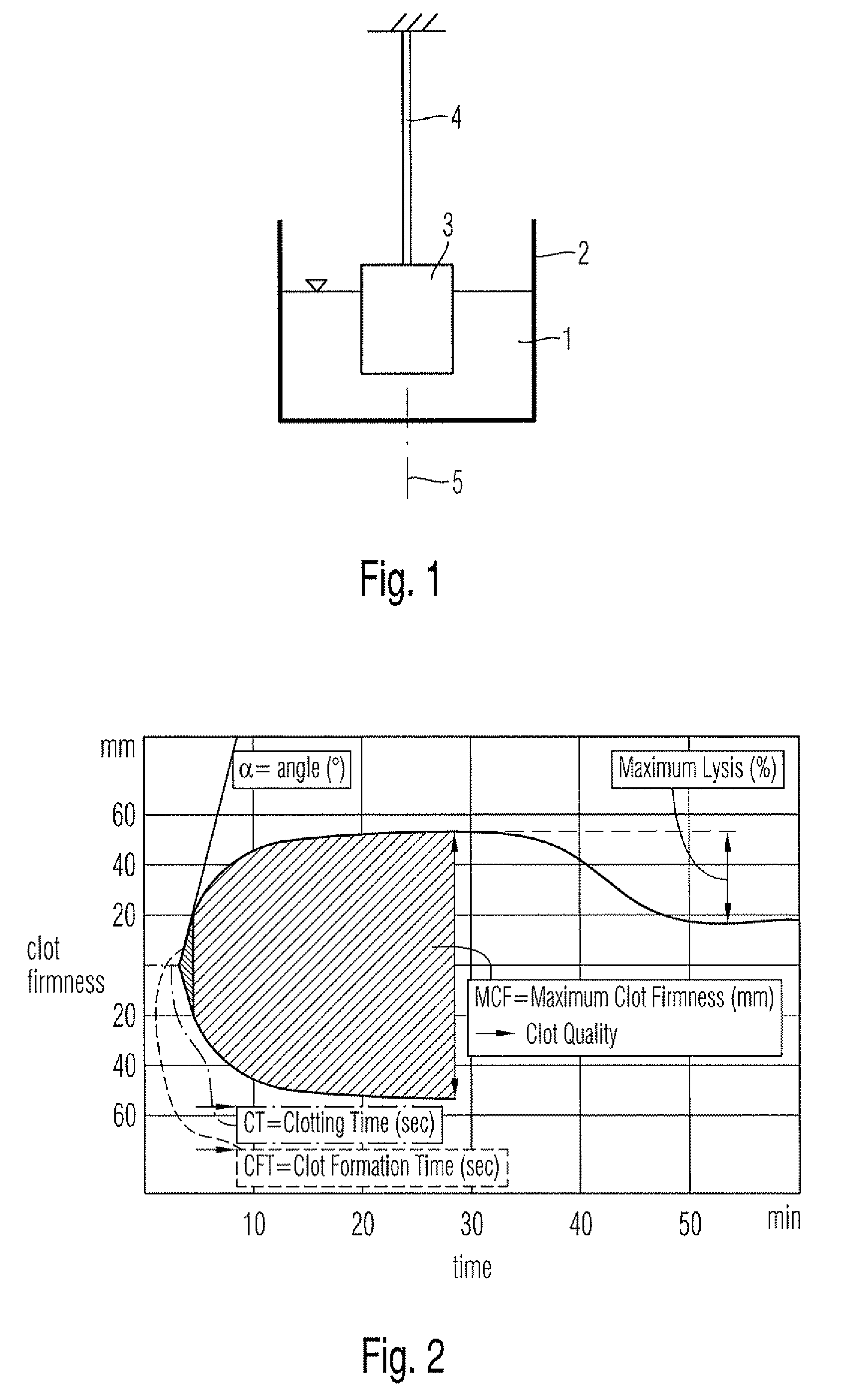

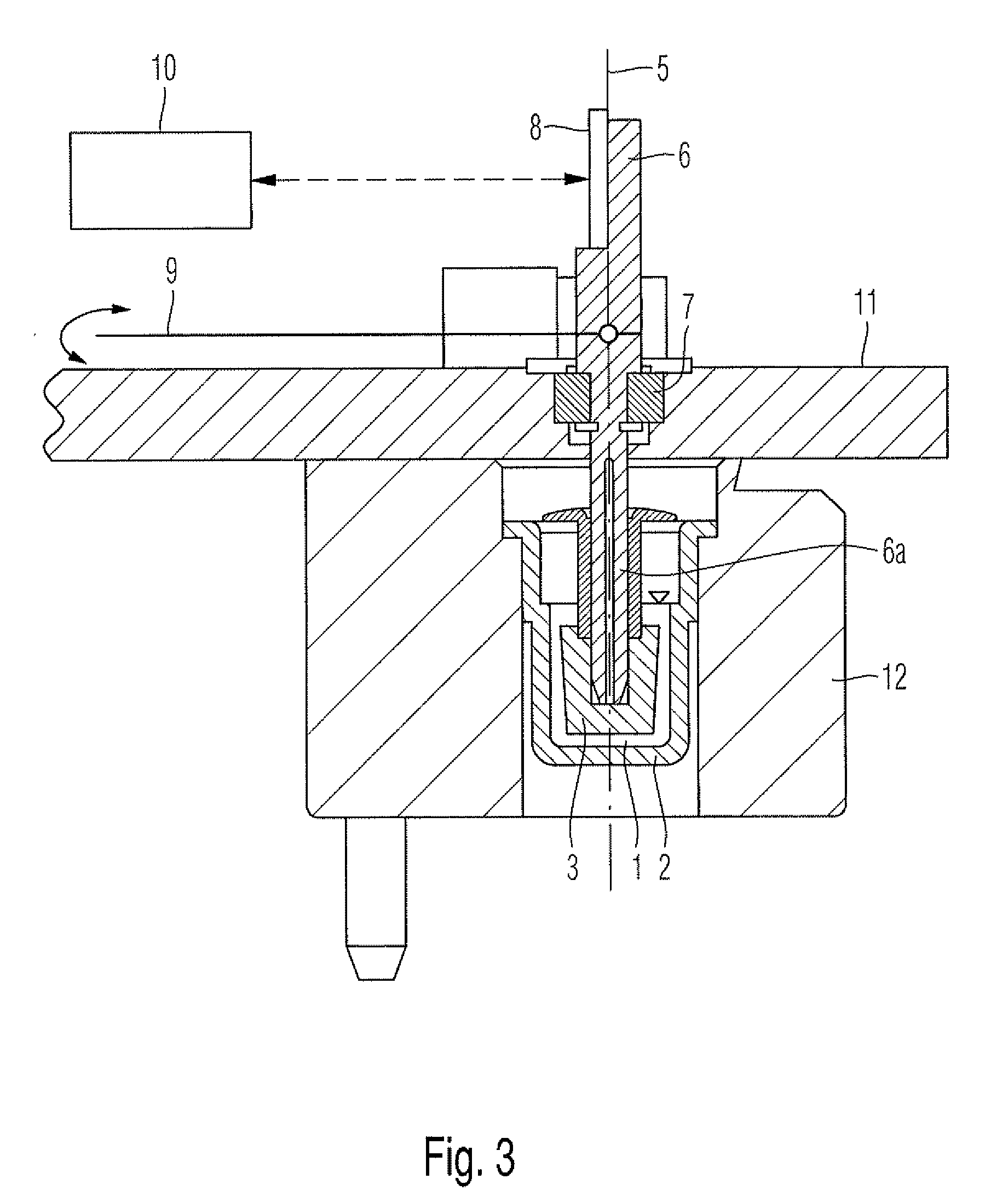

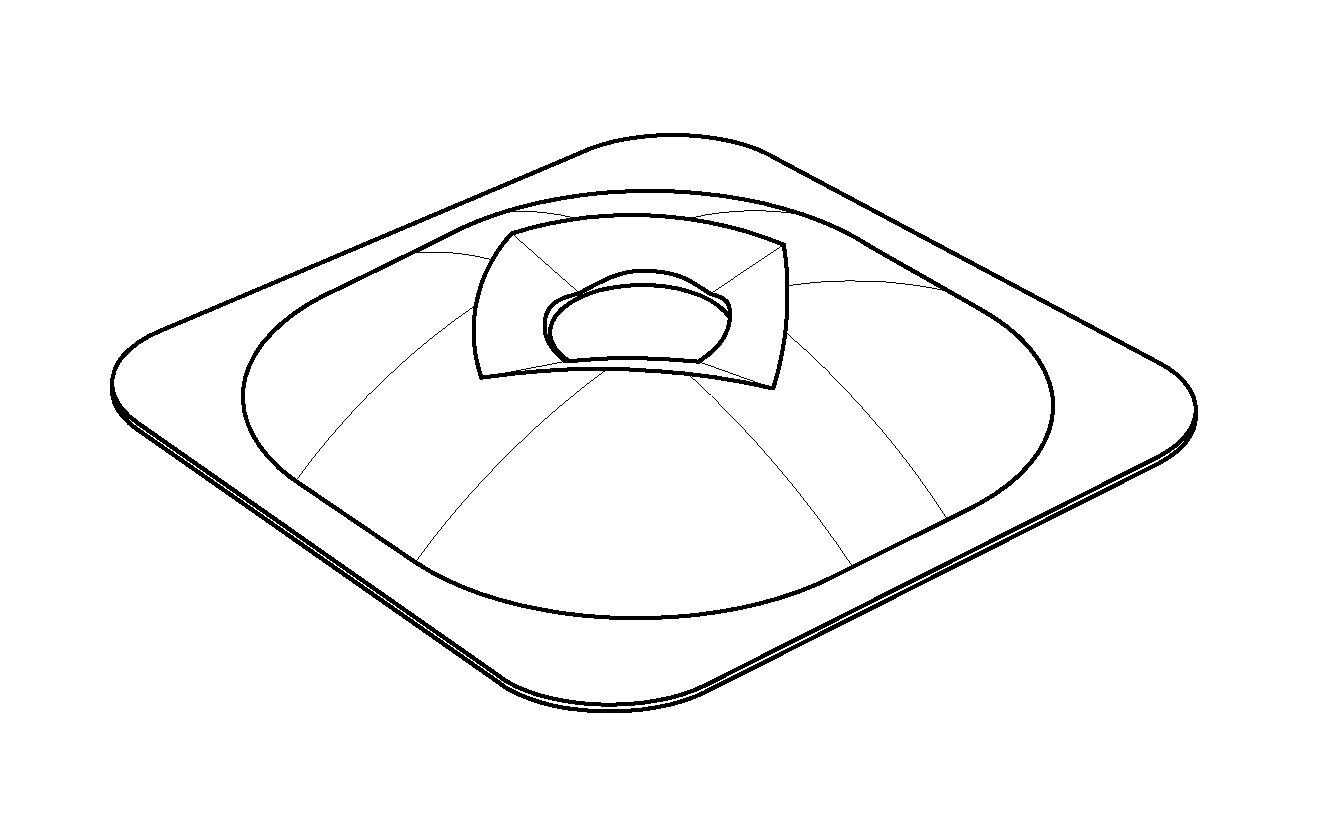

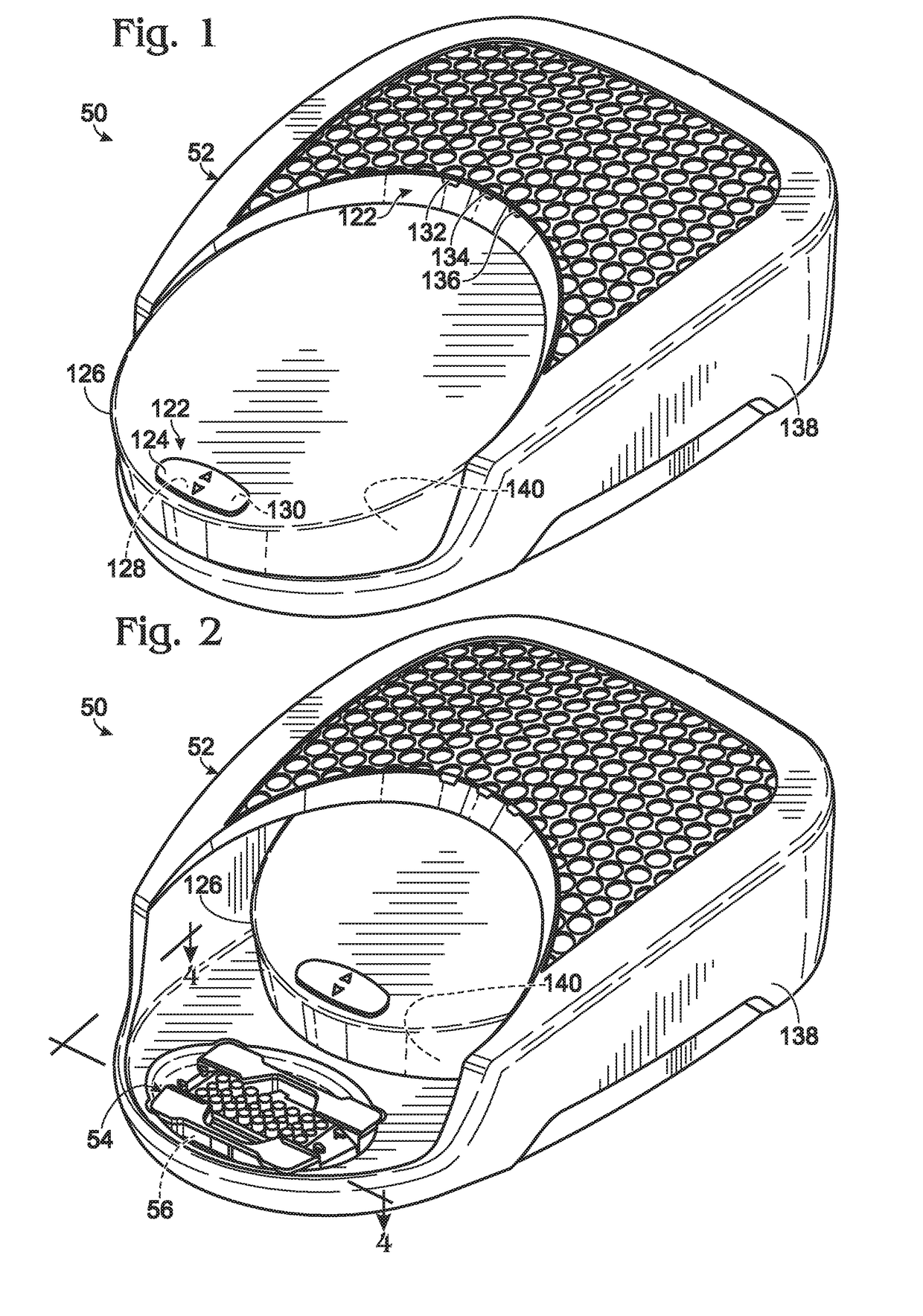

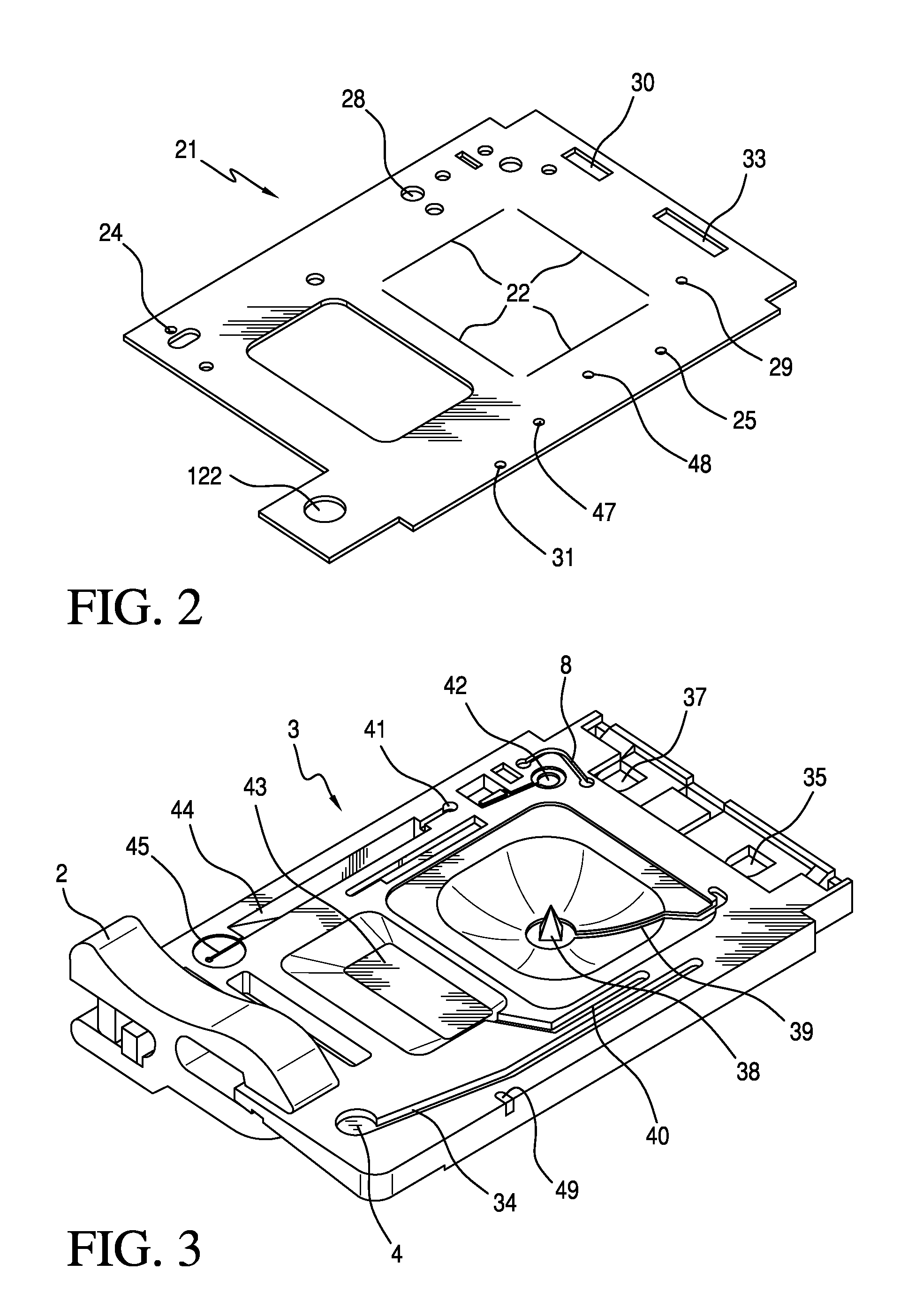

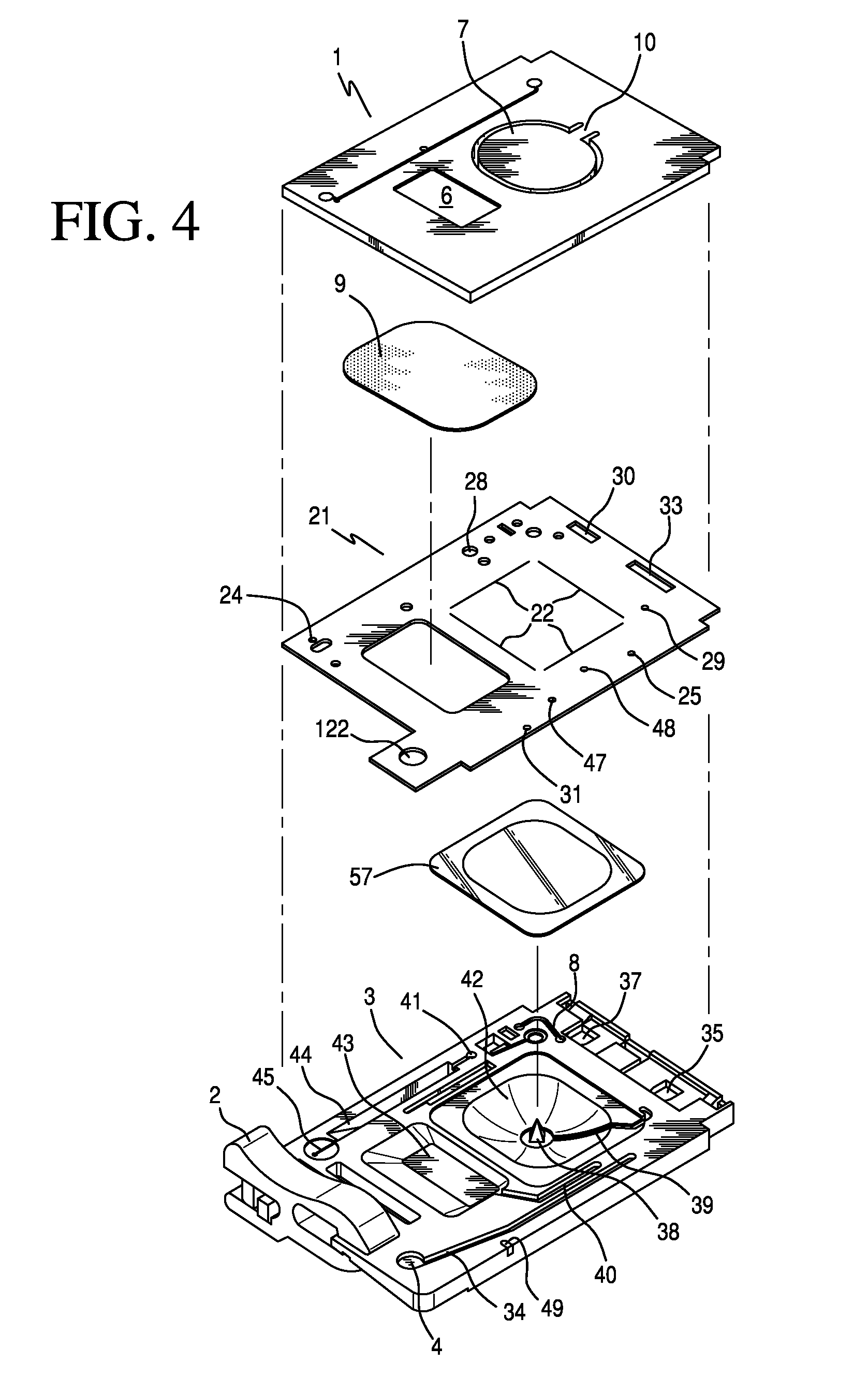

Cartridge device for a measuring system for measuring viscoelastic characteristics of a sample liquid, a corresponding measuring system, and a corresponding method

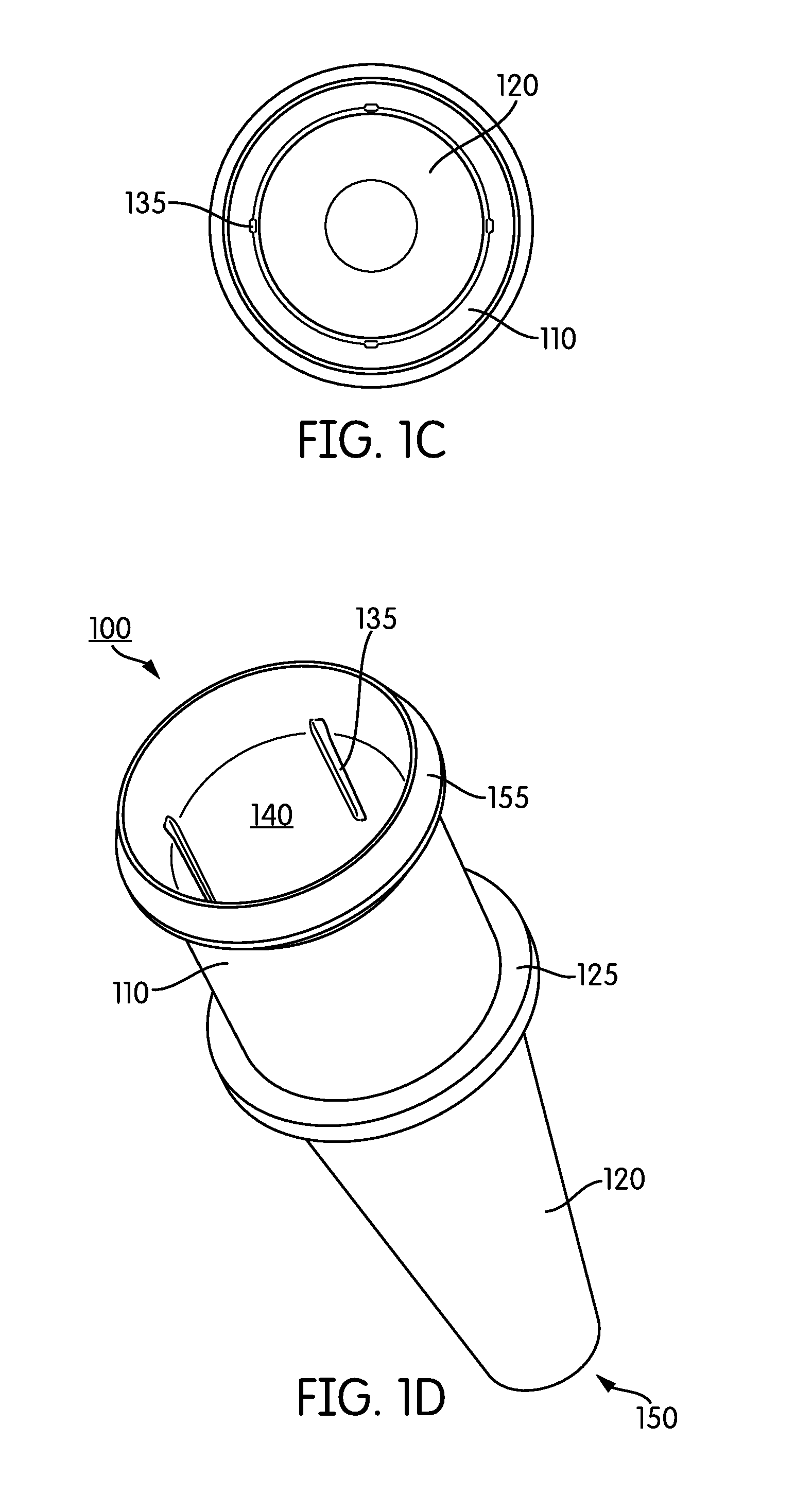

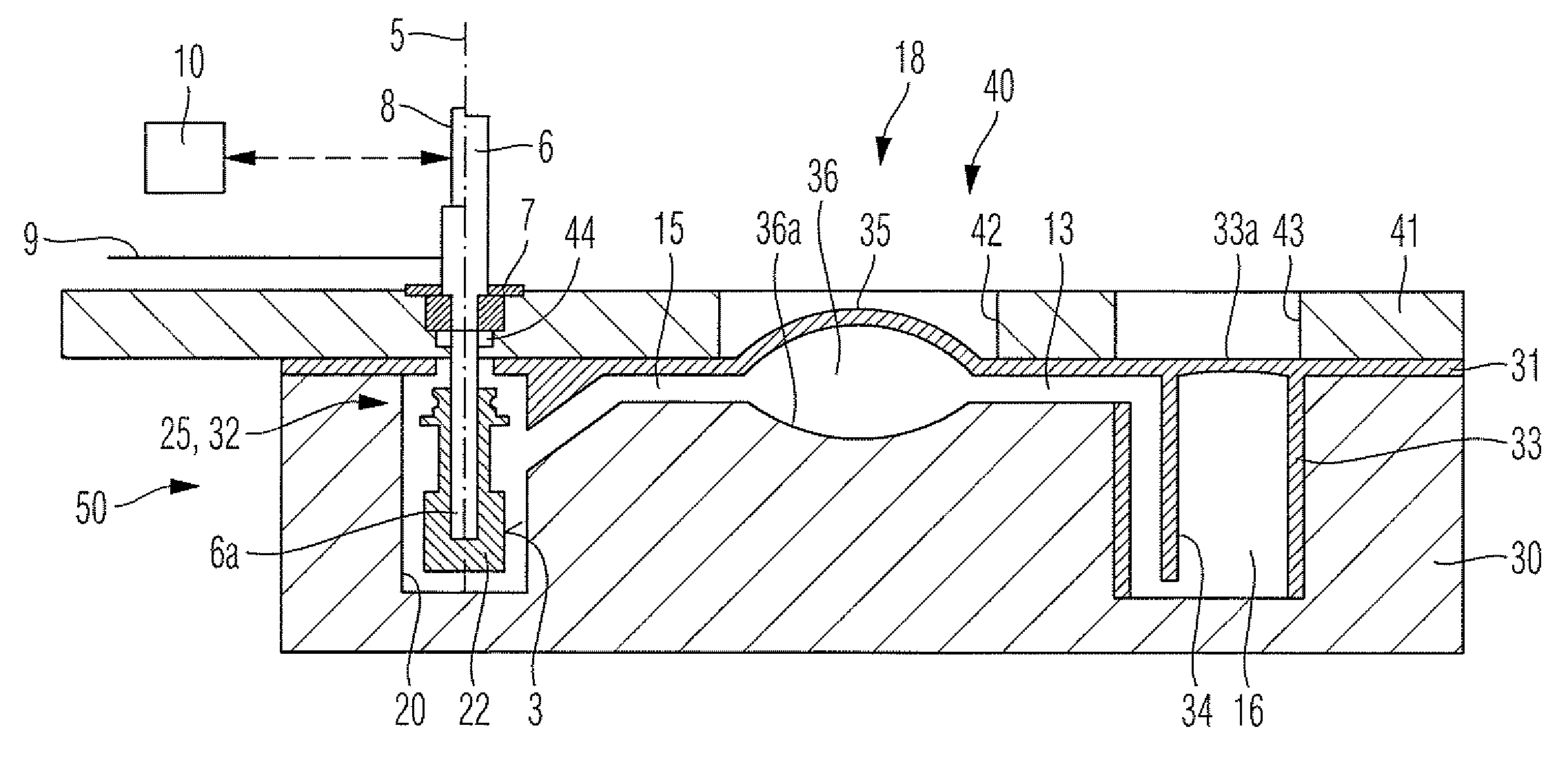

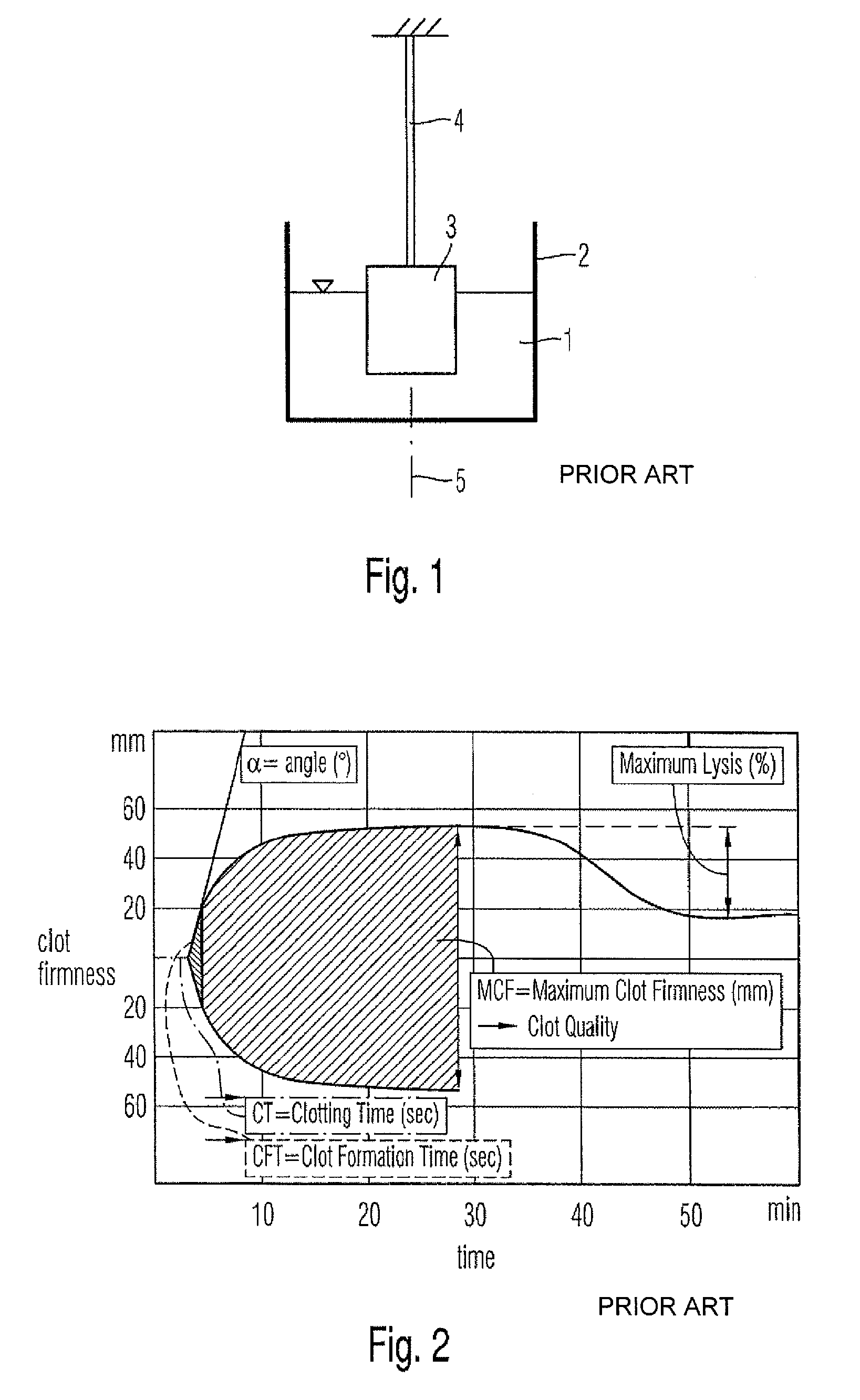

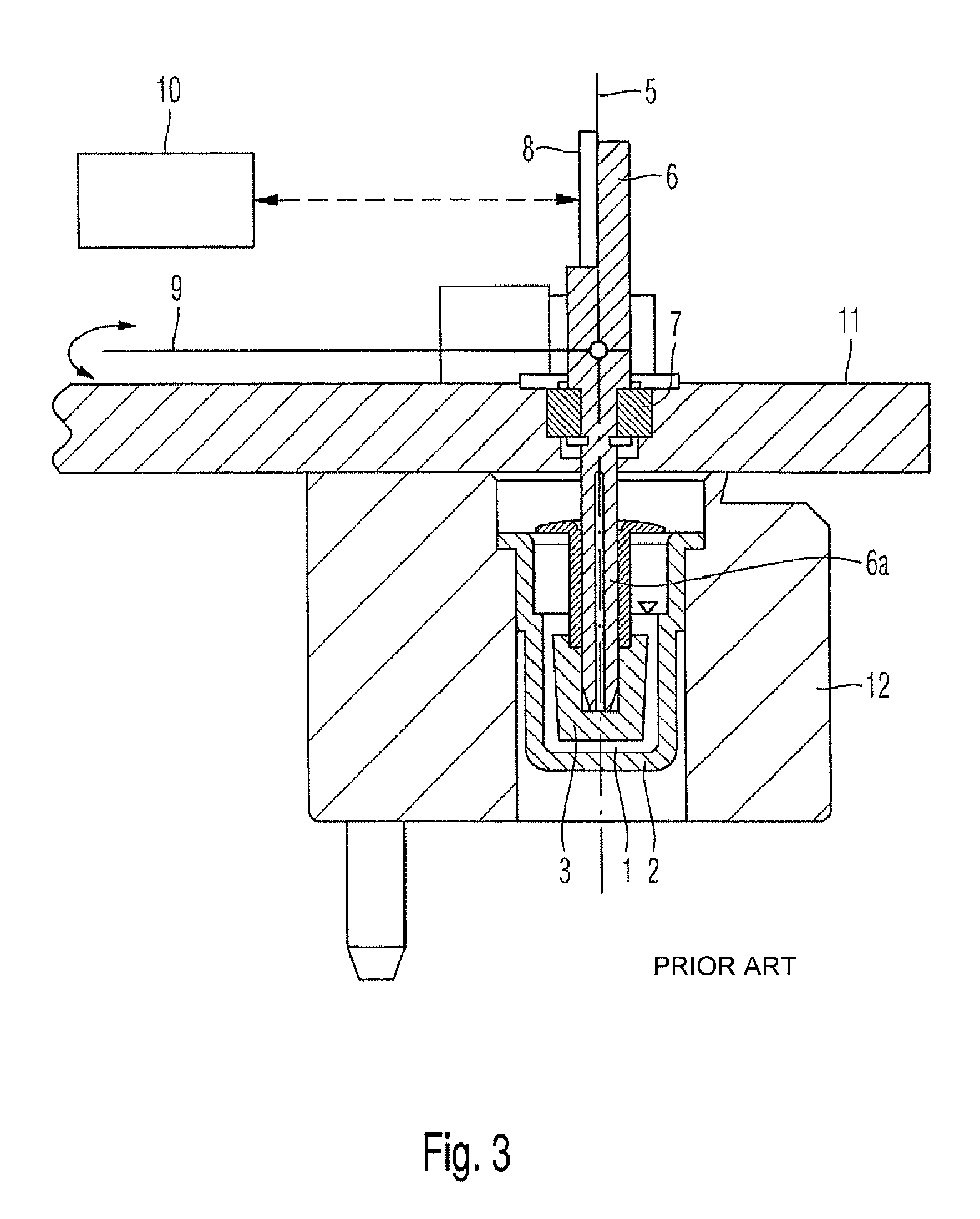

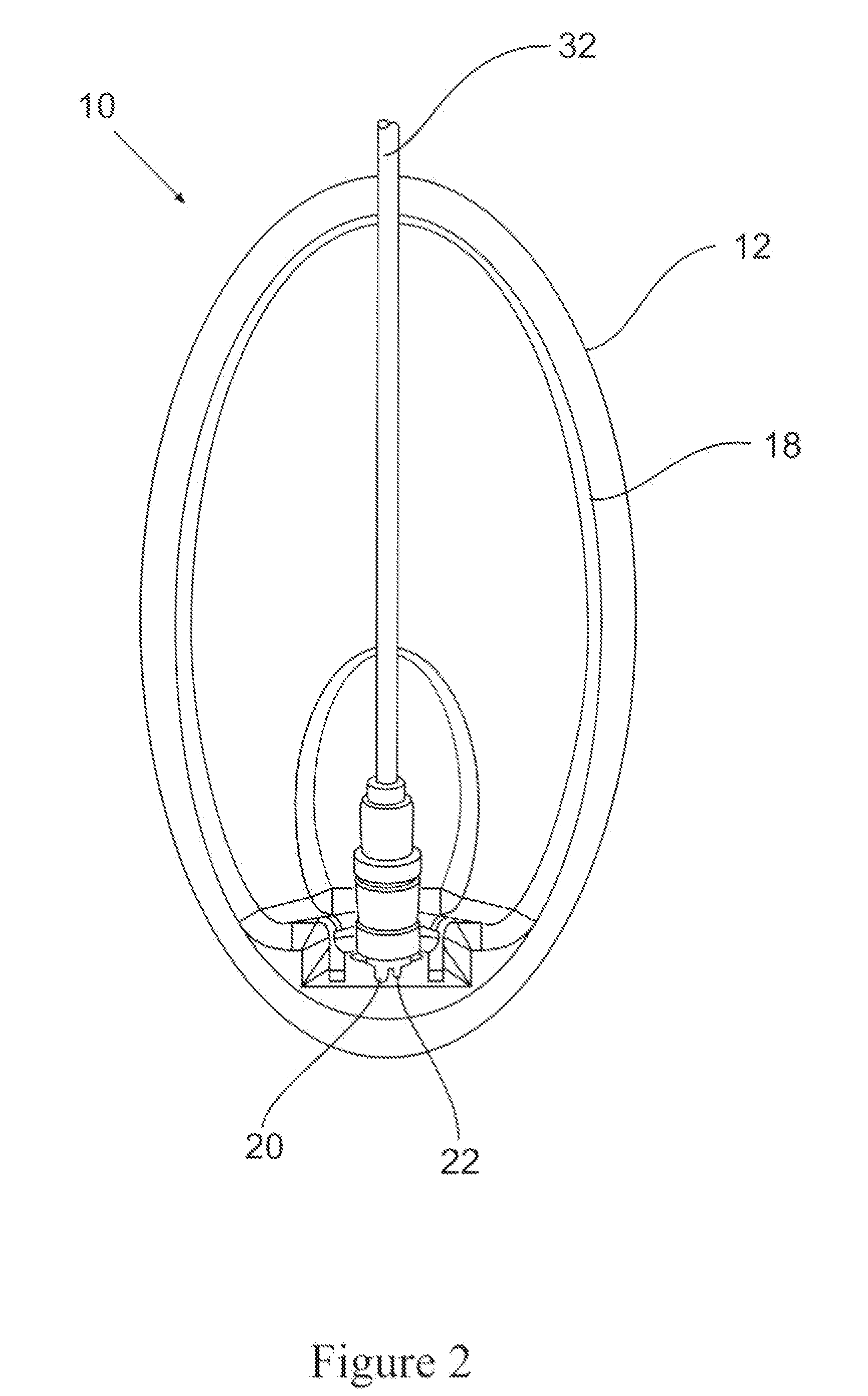

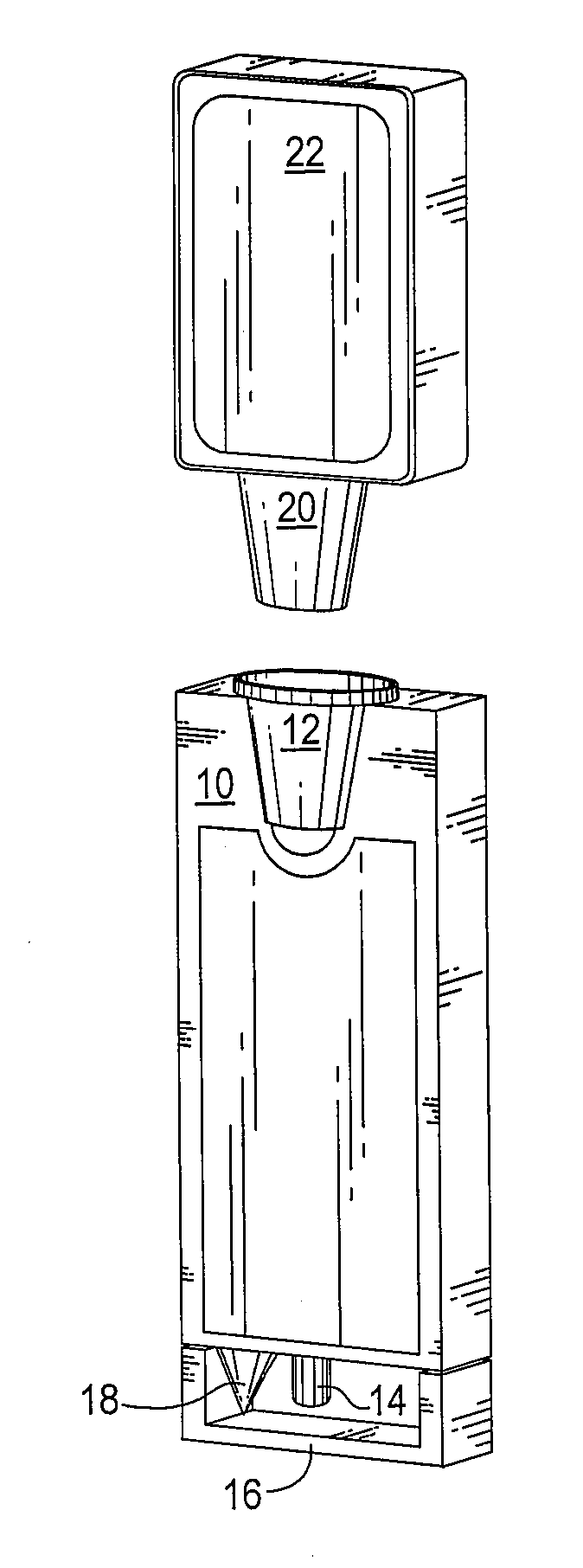

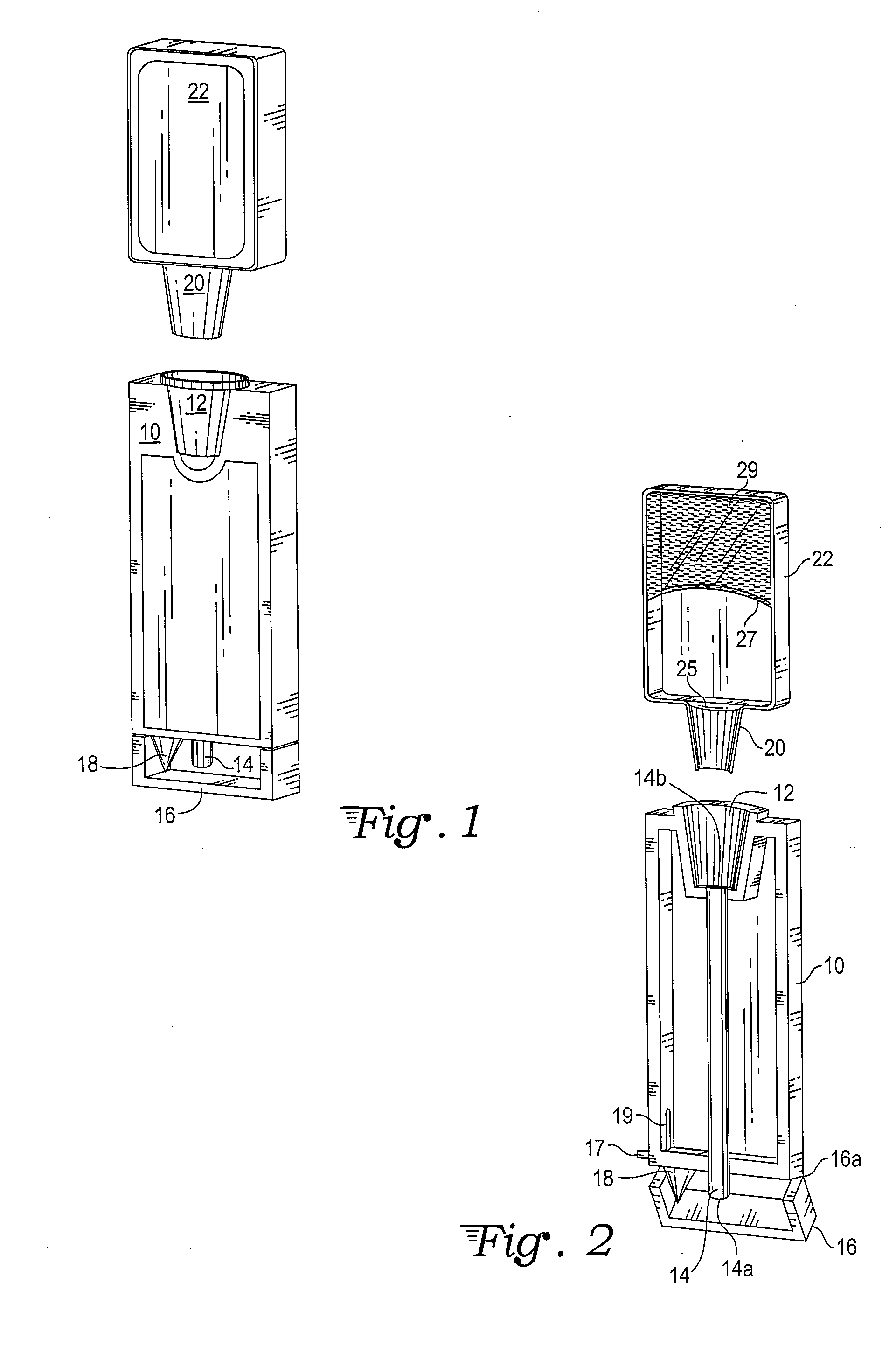

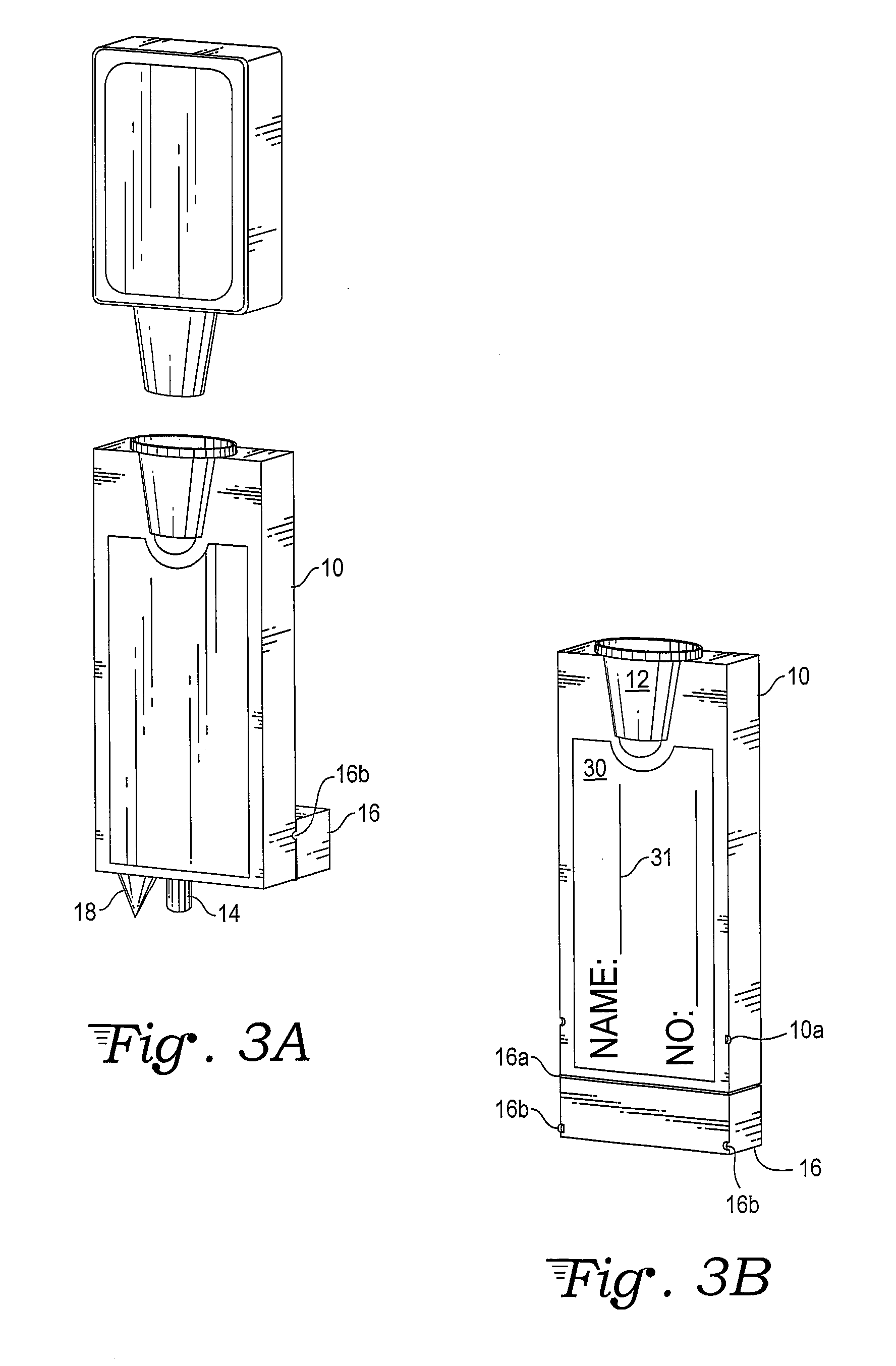

ActiveUS20100154520A1Facilitates of partConnection securityReagent containersFlow propertiesBiomedical engineeringCartridge device

The present invention is directed to a cartridge device for a measuring system for measuring viscoelastic characteristics of a sample liquid, in particular a blood sample, comprising a cartridge body having at least one measurement cavity formed therein and having at least one probe element arranged in said at least one measurement cavity for performing a test on said sample liquid; and a cover being attachable on said cartridge body; wherein said cover covers at least partially said at least one measurement cavity and forms a retaining element for retaining said probe element in a predetermined position within said at least one measurement cavity. The invention is directed to a measurement system and a method for measuring viscoelastic characteristics of a sample liquid.

Owner:C A CASYSO

Test box

Owner:BECKMAN COULTER INC

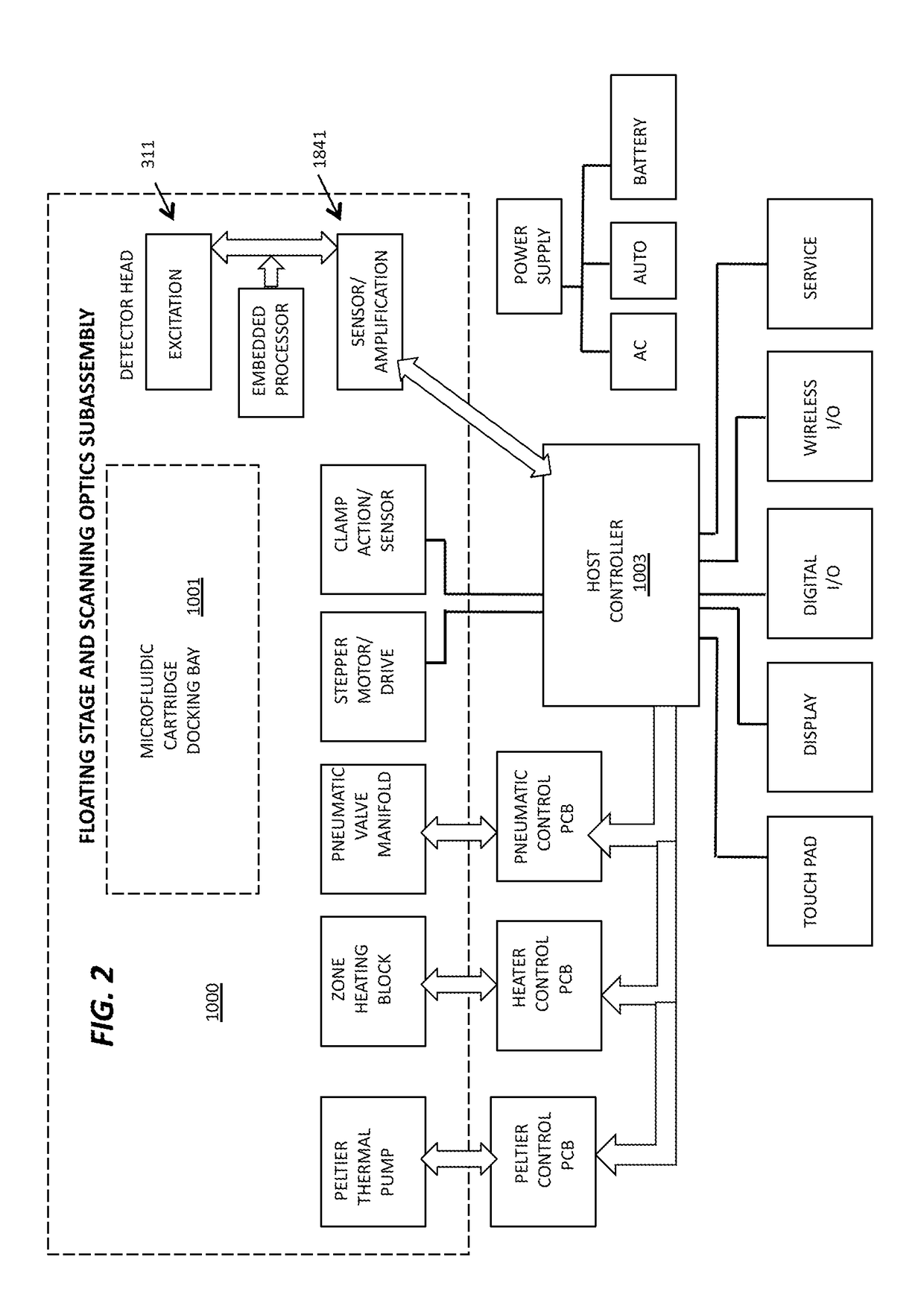

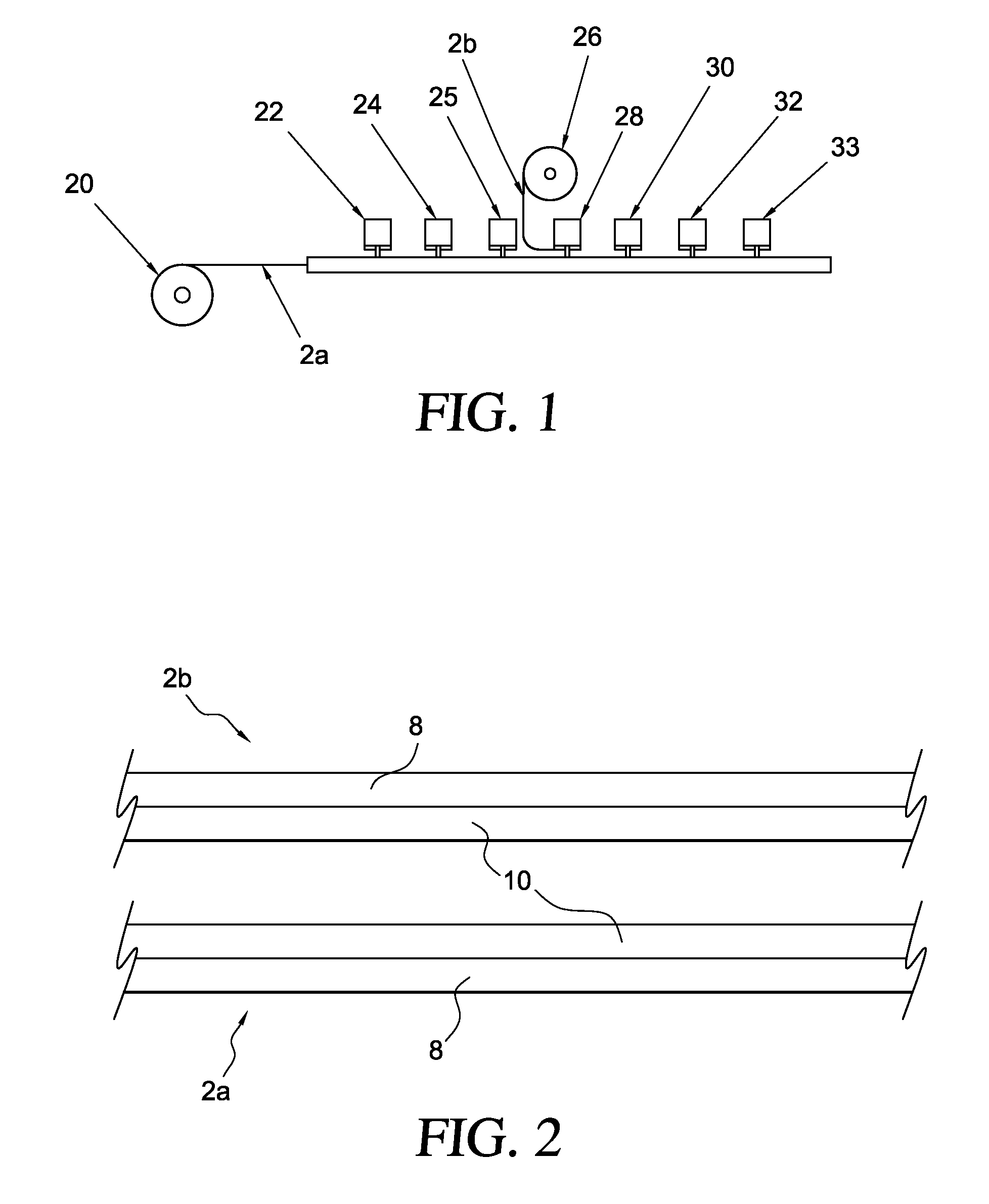

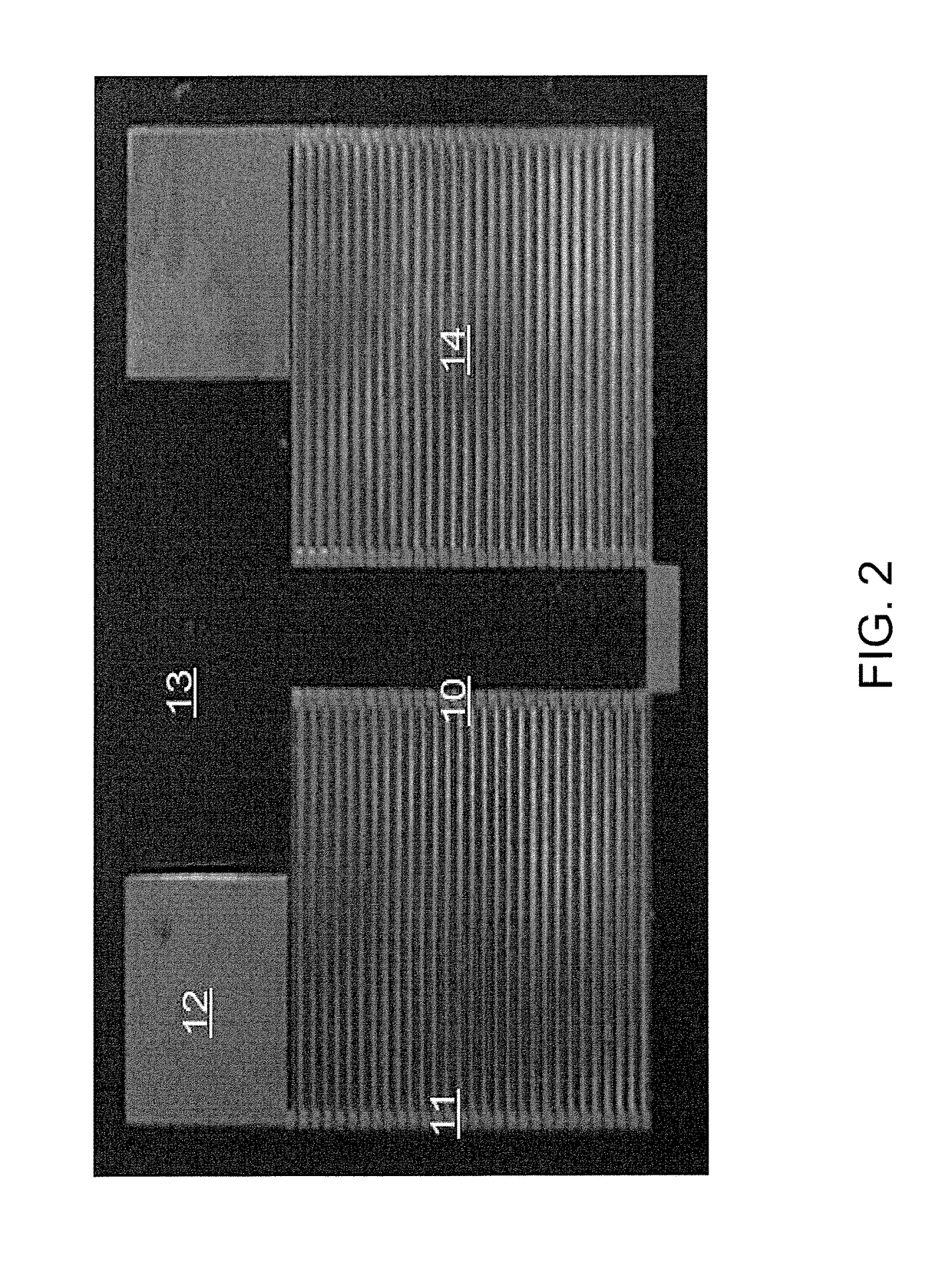

Microfluidic cartridges and apparatus with integrated assay controls for analysis of nucleic acids

InactiveUS20170113221A1Eliminate needAccurate methodReagent containersHeating or cooling apparatusAnalyteMicro assay

Disclosed is a microassay testing system, including a microfluidic cartridge and a compact microprocessor-controlled instrument for fluorometric assays in liquid samples, the cartridge having integrated process controls and positive and negative assay controls. The instrument has a scanning detector head incorporating multiple optical channels. In a preferred configuration, the assay is validated using dual channel optics for monitoring a first fluorophore associated with a target analyte and a second fluorophore associated with a process control. Integrated positive and negative assay controls provide enhanced assay validation capabilities and facilitate analysis of test results. Applications include molecular biological assays based on PCR amplification of target nucleic acids and fluorometric assays in general.

Owner:PERKINELMER HEALTH SCIENCES INC

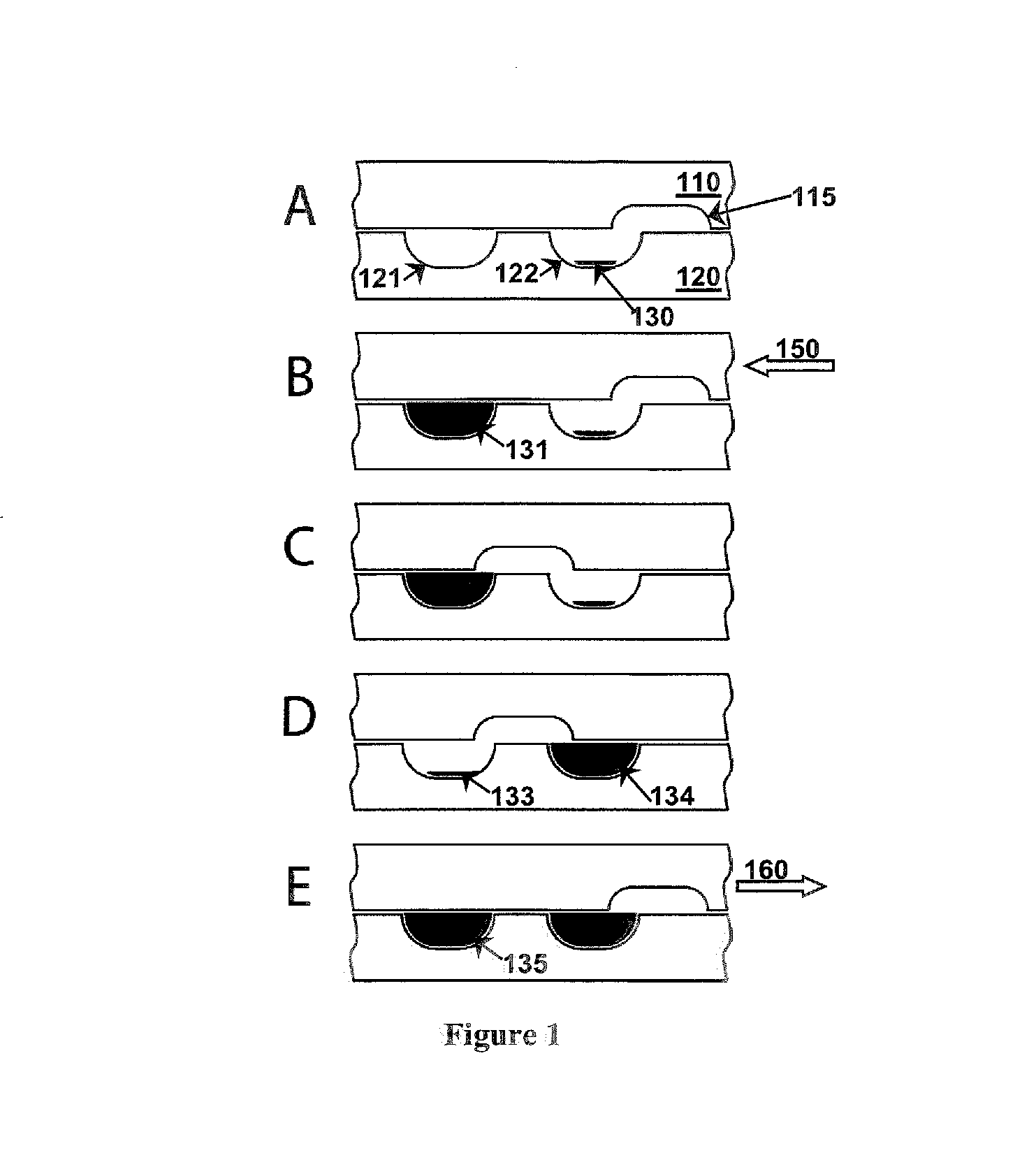

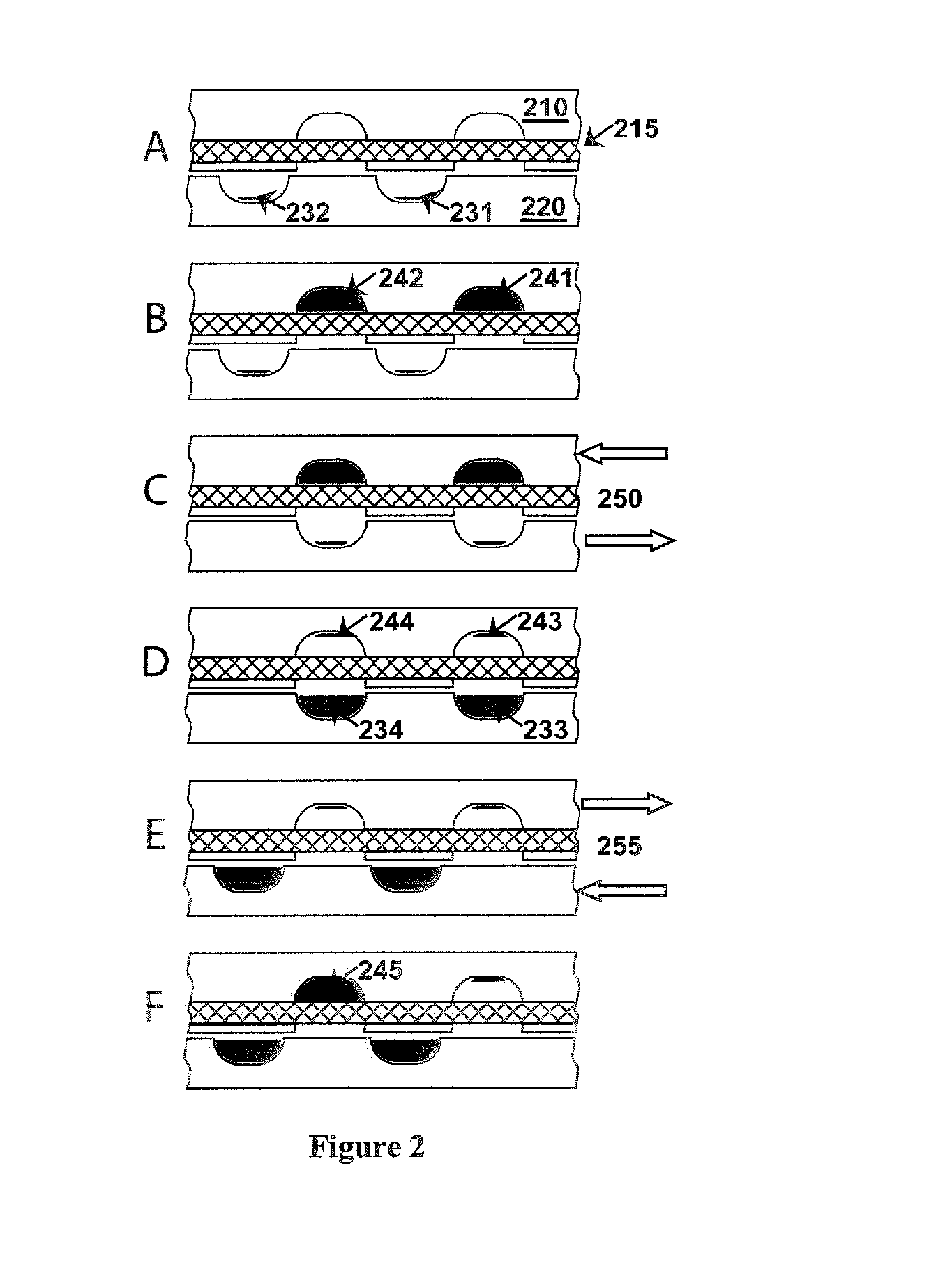

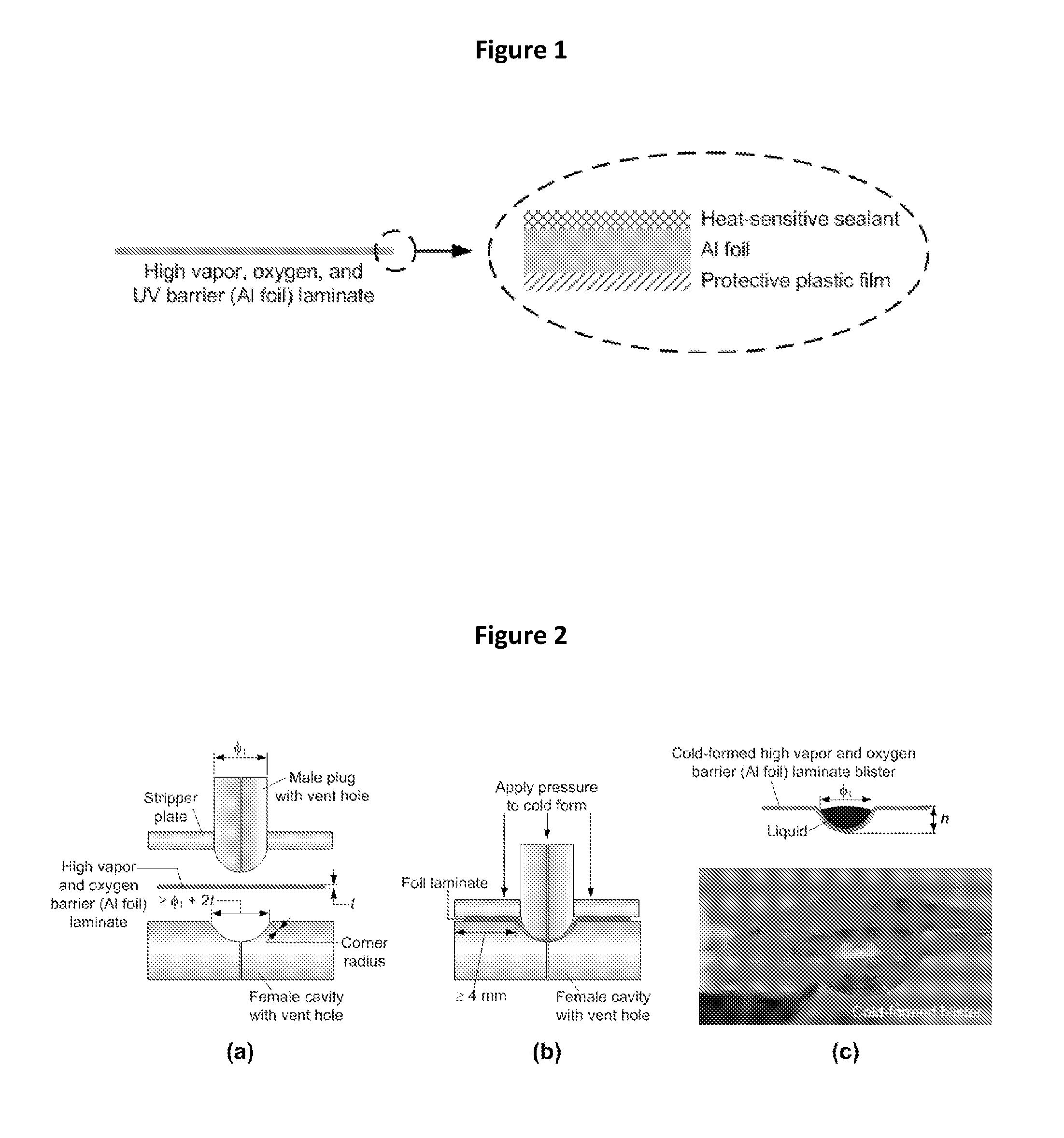

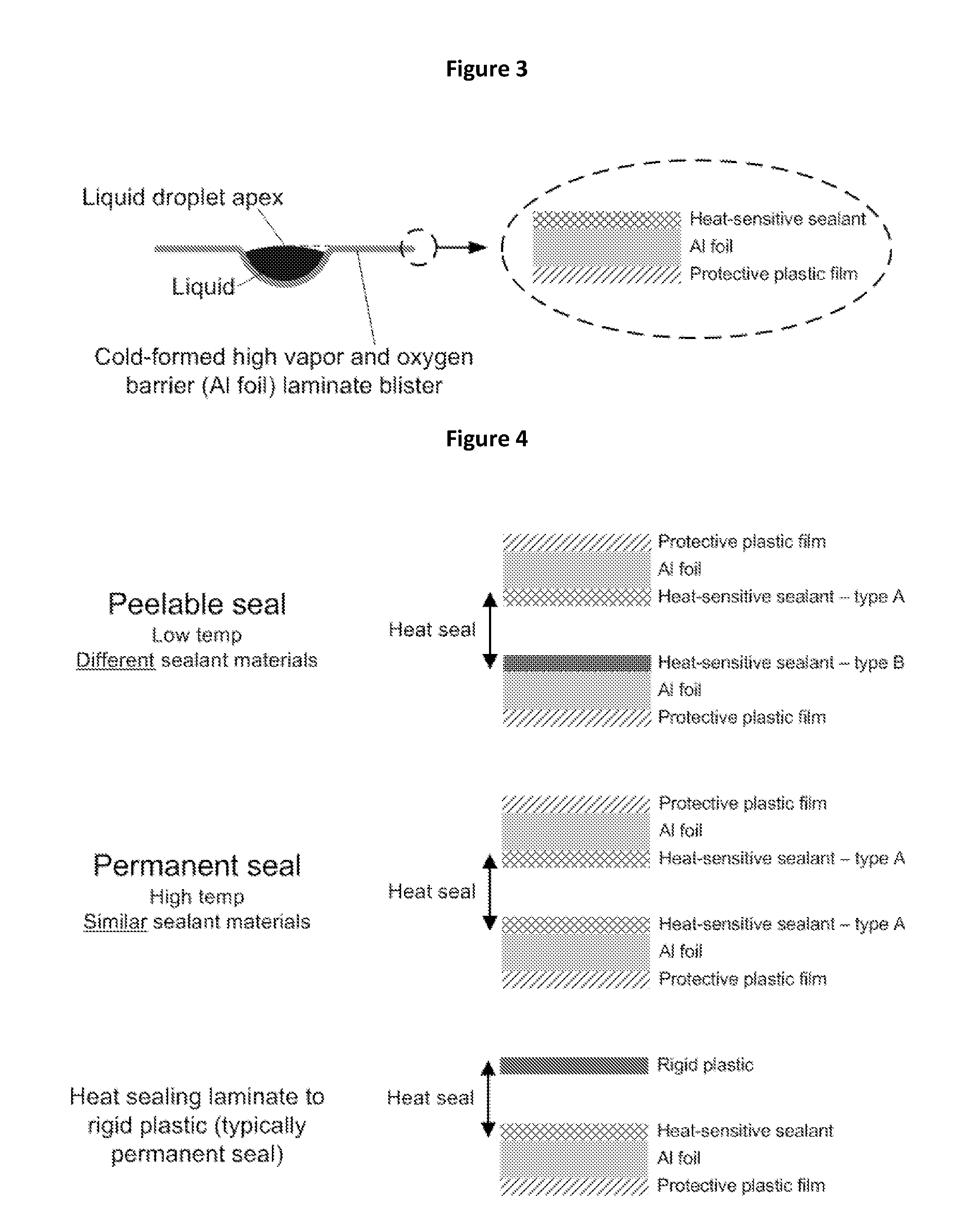

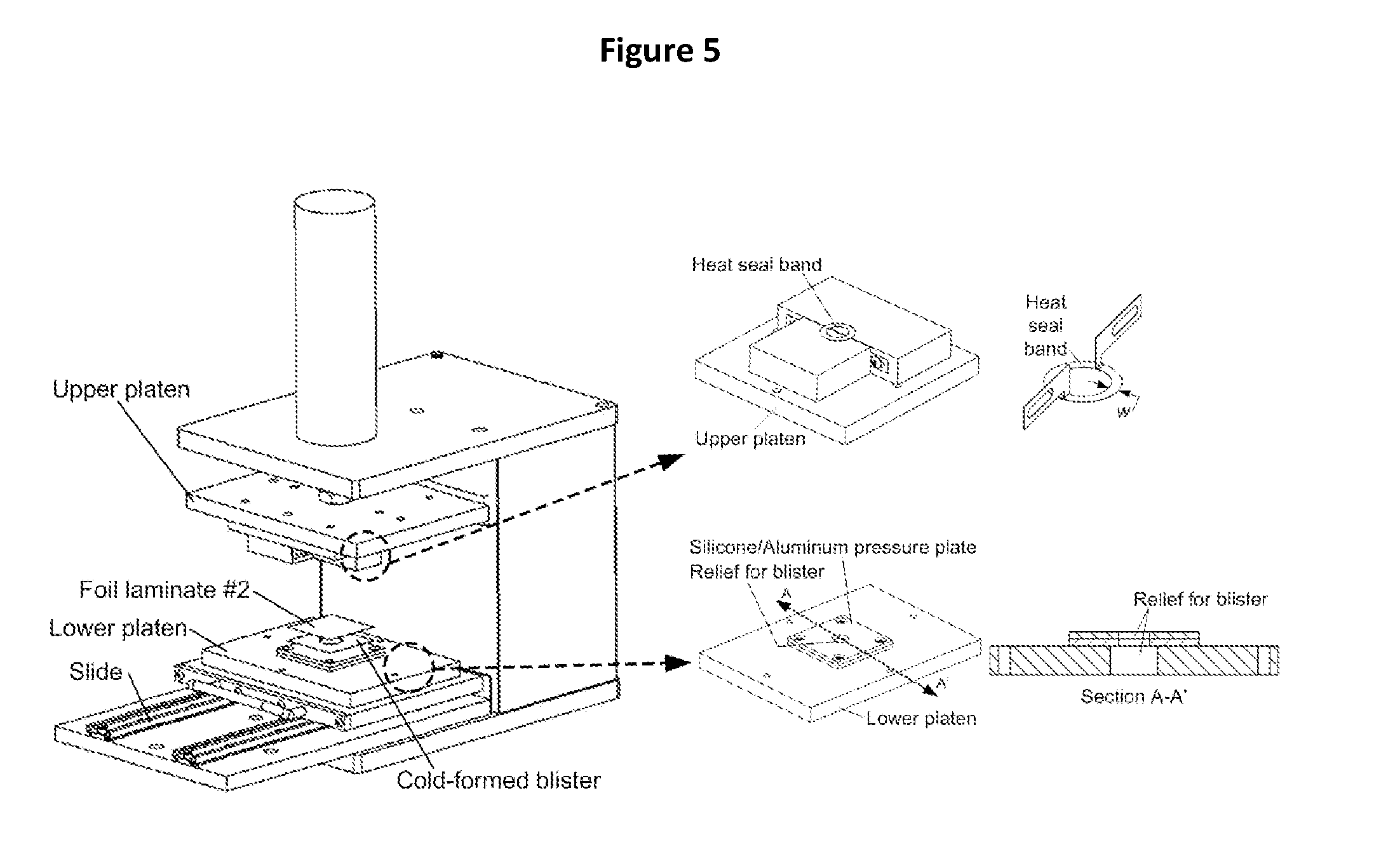

Burstable liquid packaging and uses thereof

InactiveUS20120107811A1Bioreactor/fermenter combinationsHeating or cooling apparatusChemical reactionPhotochemistry

Owner:NORTHWESTERN UNIV

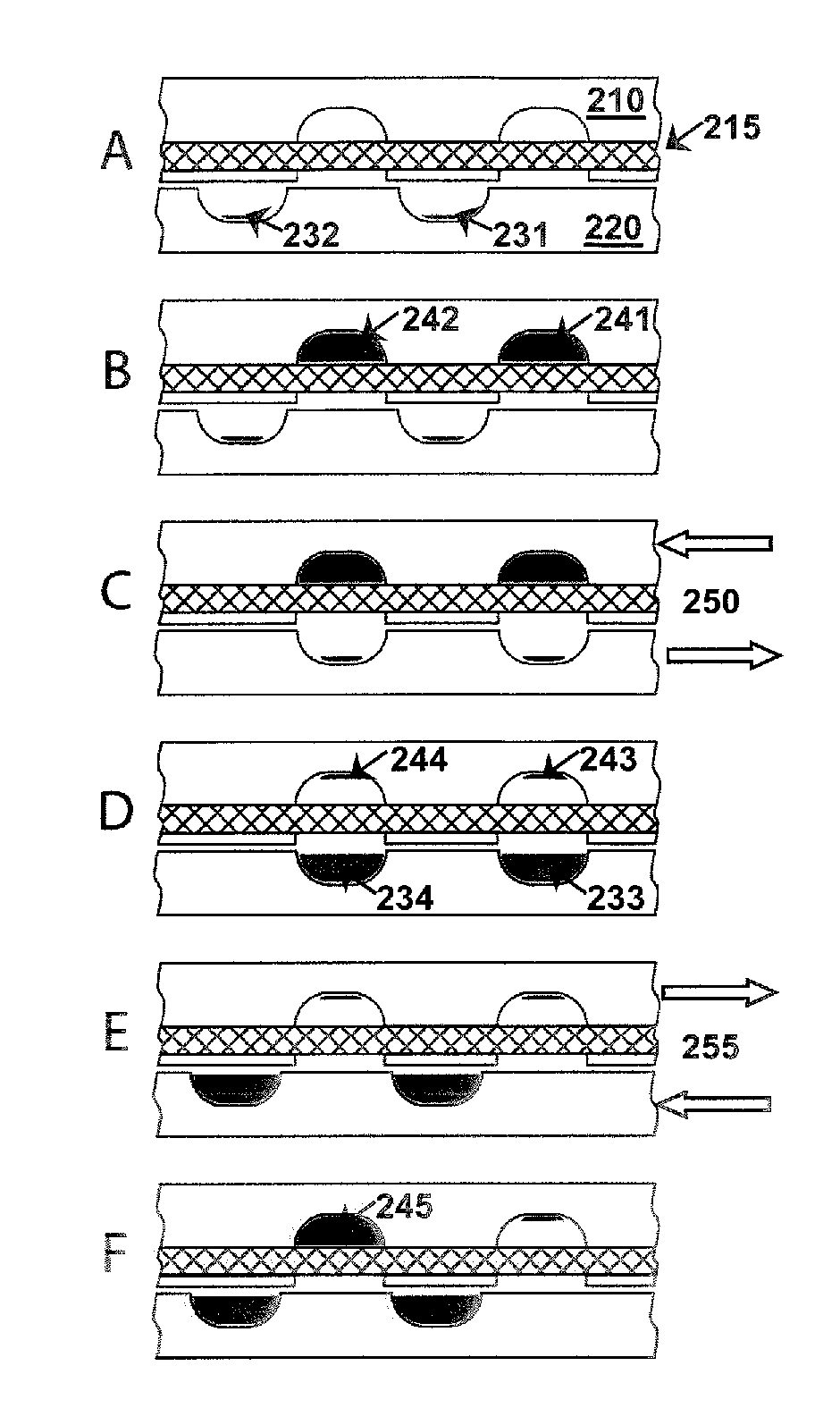

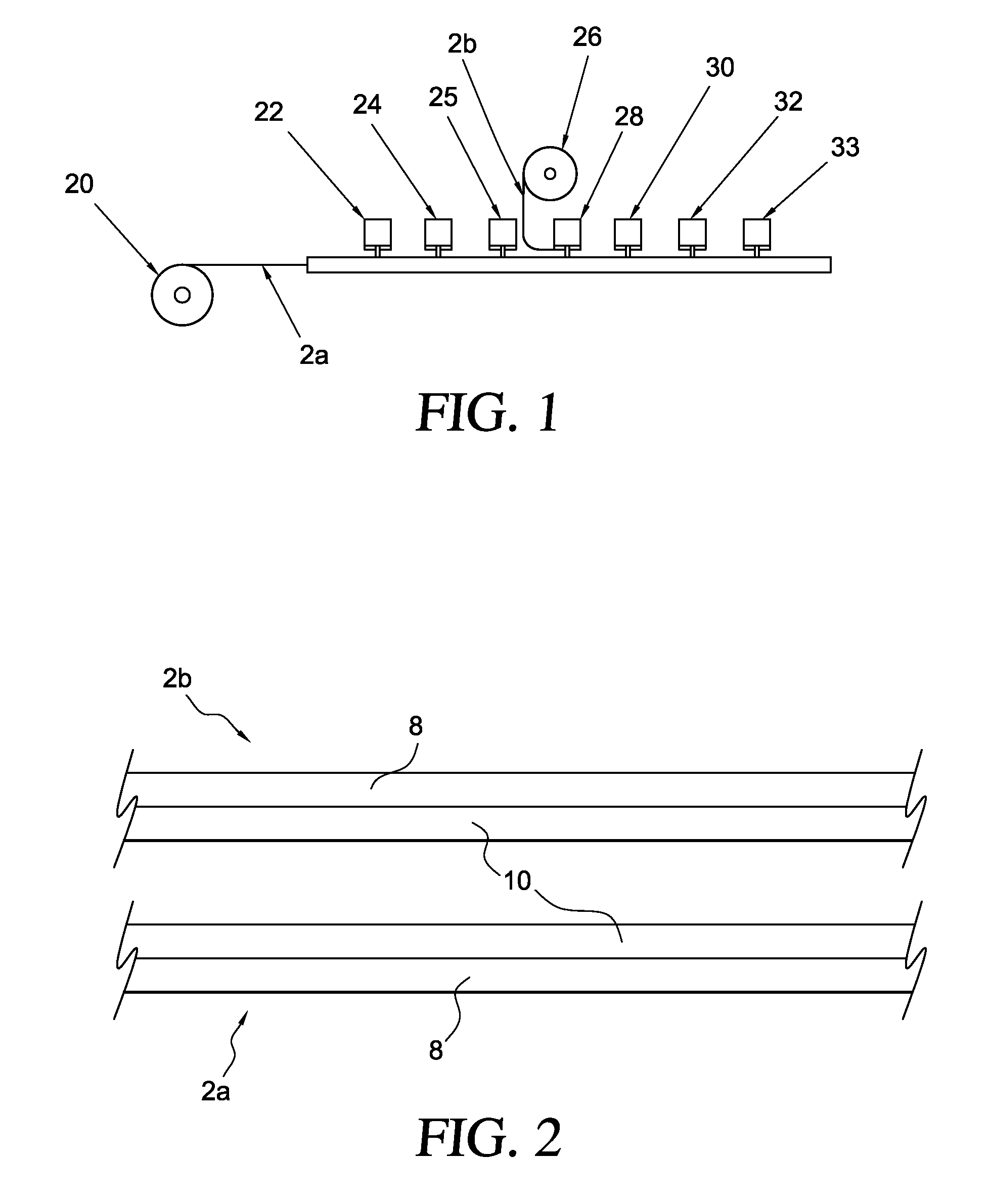

Fluid-containing pouches with reduced gas exchange and methods for making same

ActiveUS8216529B2Reduce penetrationReduce solubilityReagent containersClosure using stoppersUltrasonic weldingProduct gas

Owner:ABBOTT POINT CARE

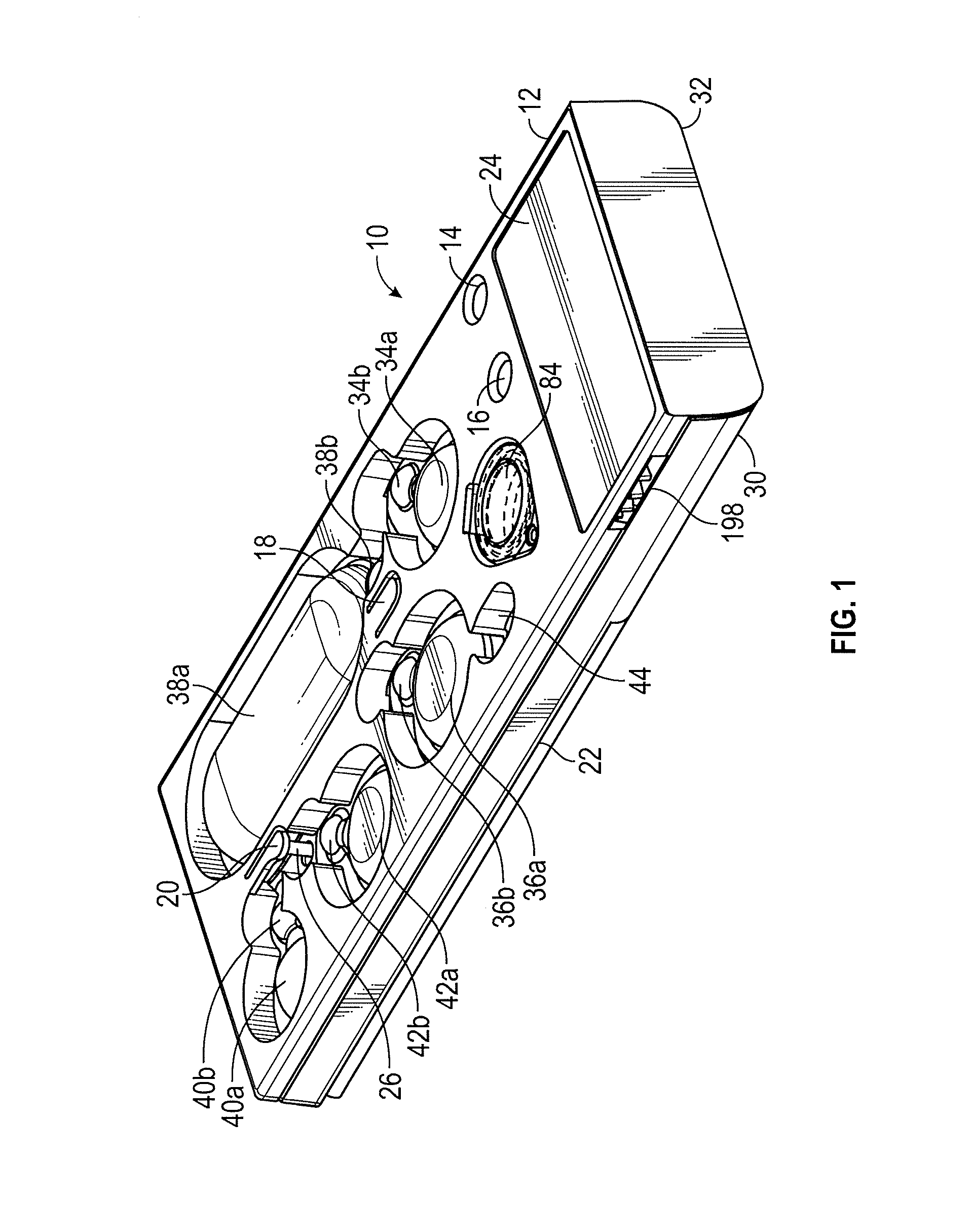

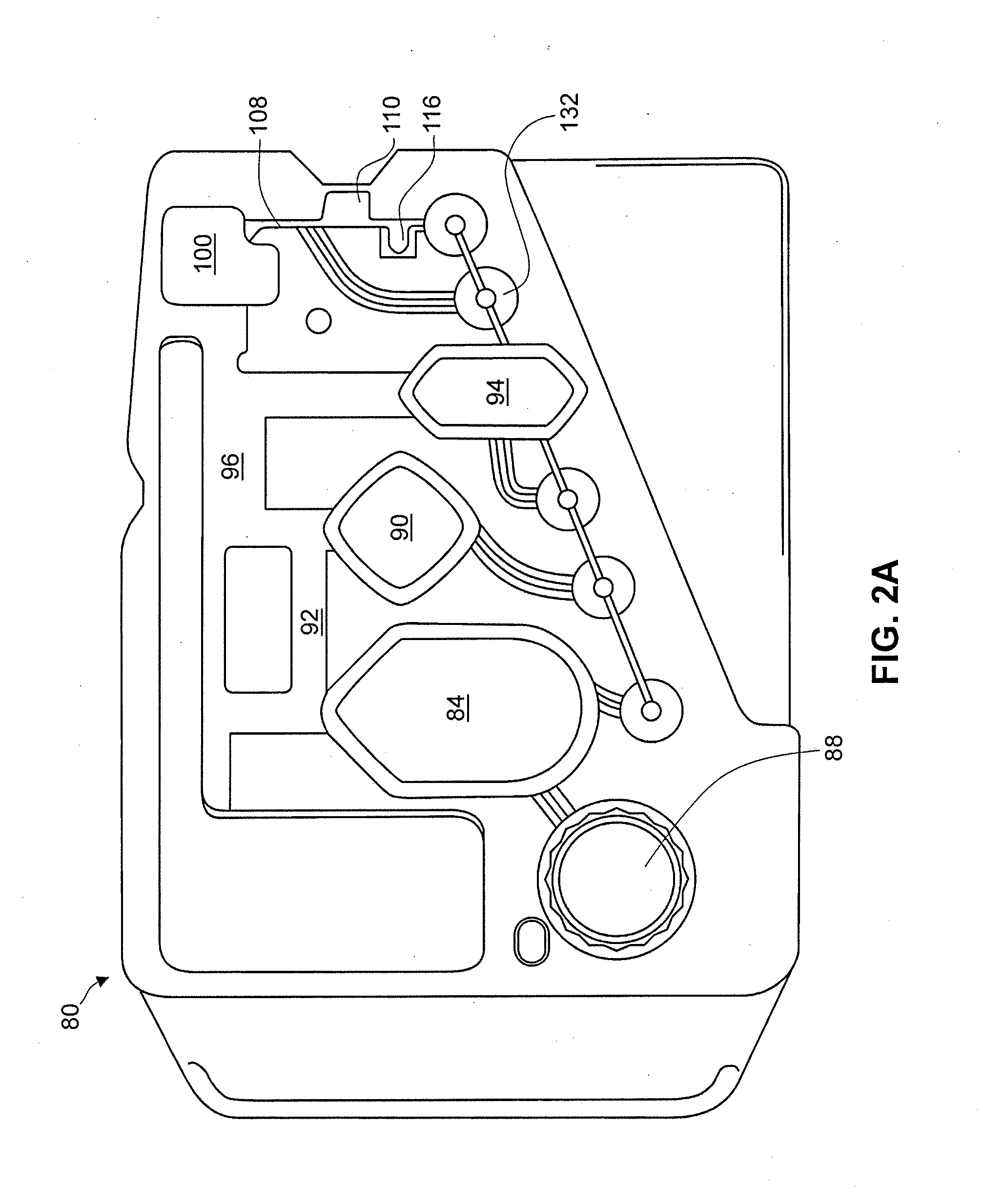

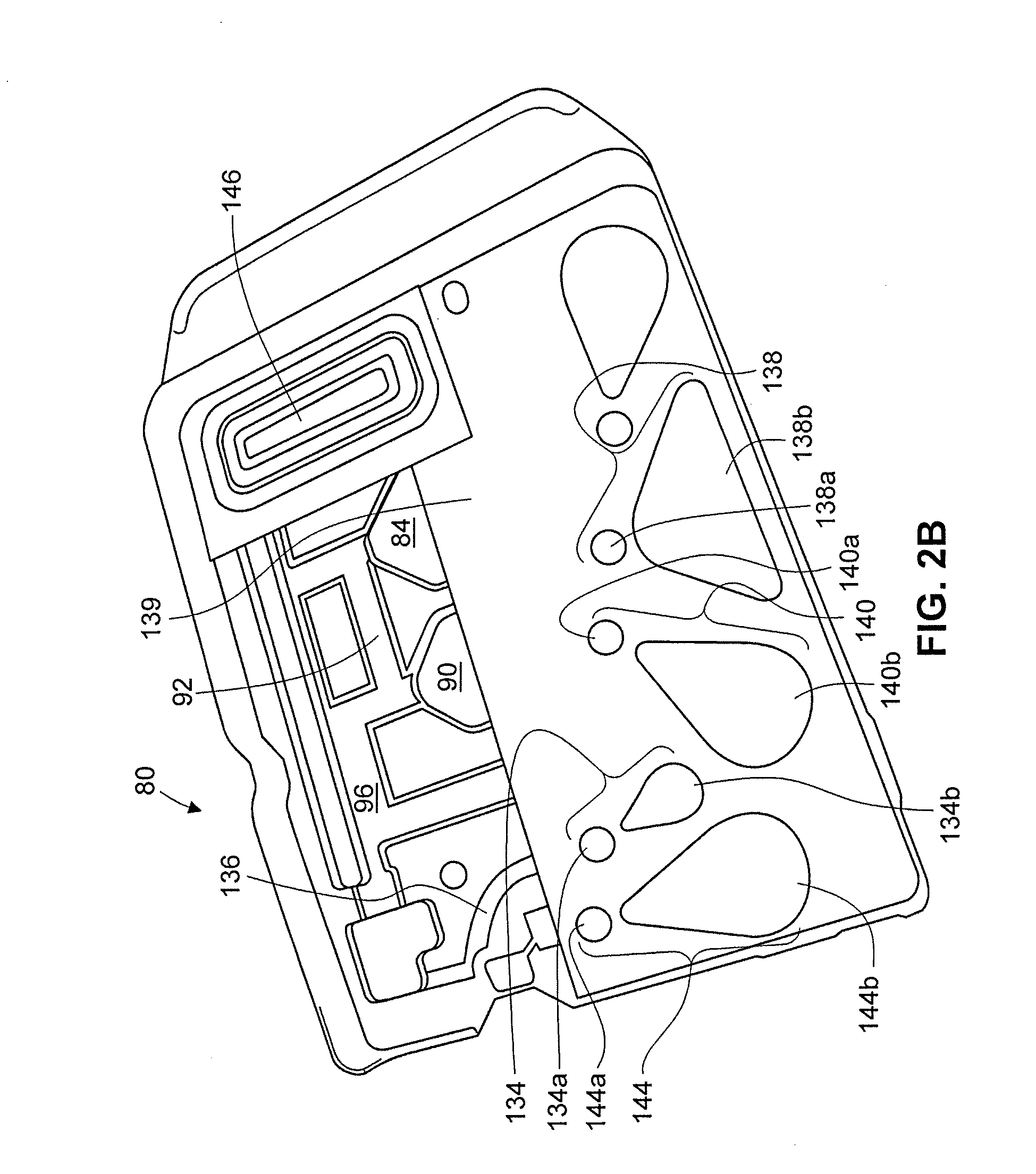

Instrument and cartridge for performing assays in a closed sample preparation and reaction system employing electrowetting fluid manipulation

ActiveUS20160129437A1Ease and rapidityCellsFatty/oily/floating substances removal devicesElectricityThermal energy

In one embodiment, a multiplex fluid processing cartridge includes a sample well, a deformable fluid chamber, a mixing well with a mixer disposed therein, a lysis chamber including a lysis mixer, an electrowetting grid for microdroplet manipulation, and electrosensor arrays configured to detect analytes of interest. An instrument for processing the cartridge is configured to receive the cartridge and to selectively apply thermal energy, magnetic force, and electrical connections to one or more discrete locations on the cartridge and is further configured to compress the deformable chamber(s) in a specified sequence.

Owner:ROCHE MOLECULAR SYST INC +1

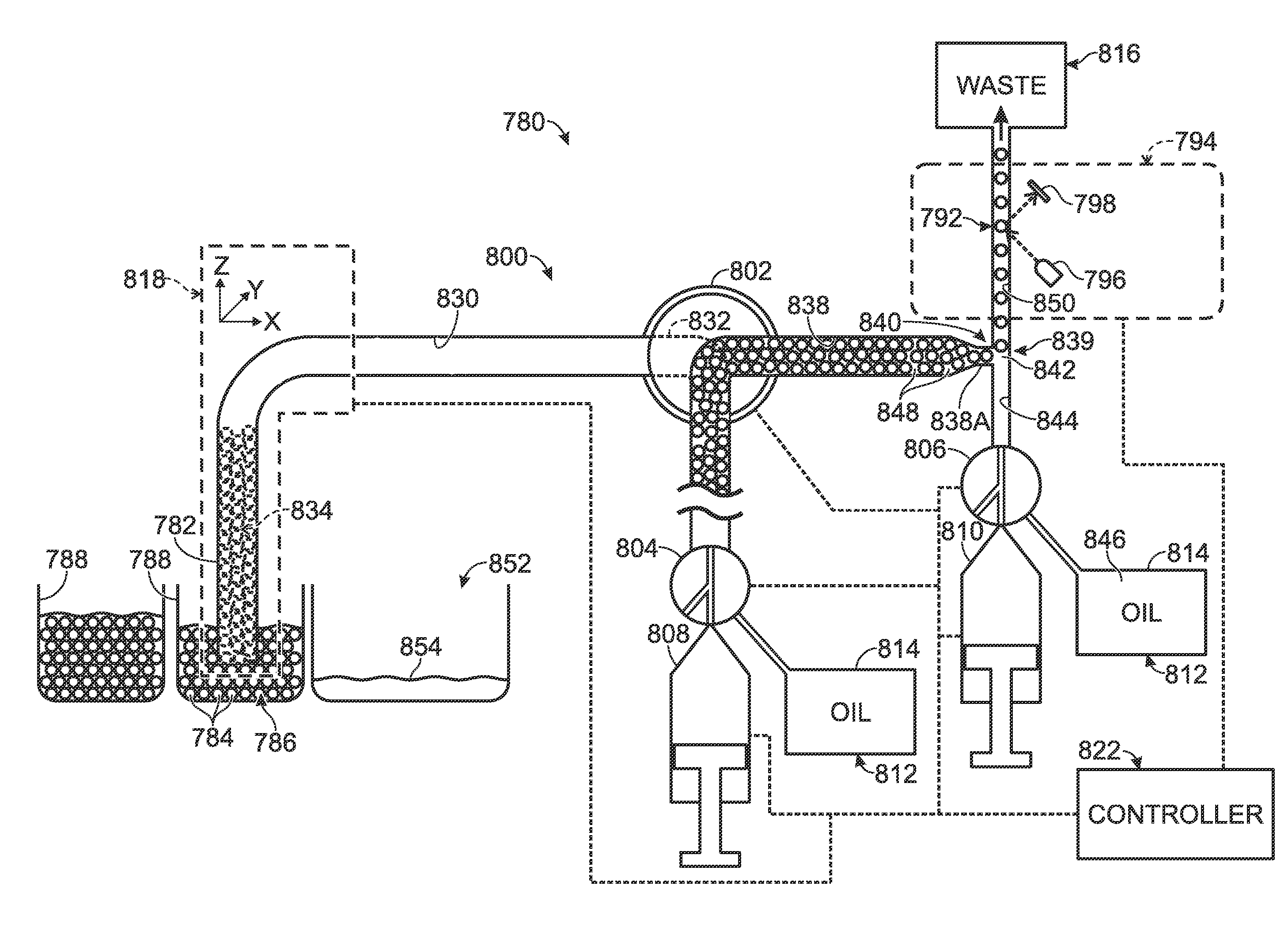

System for generating droplets with pressure monitoring

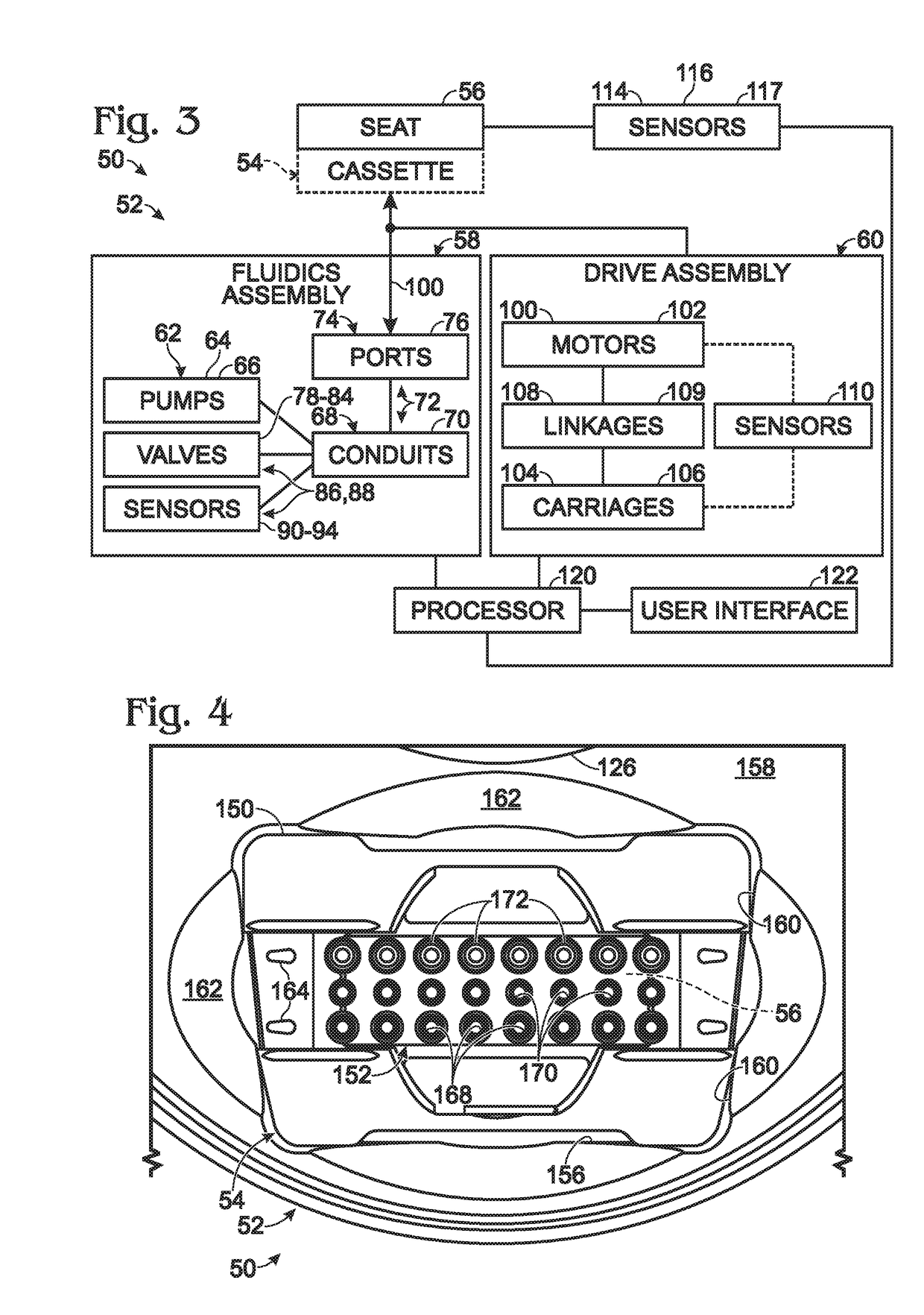

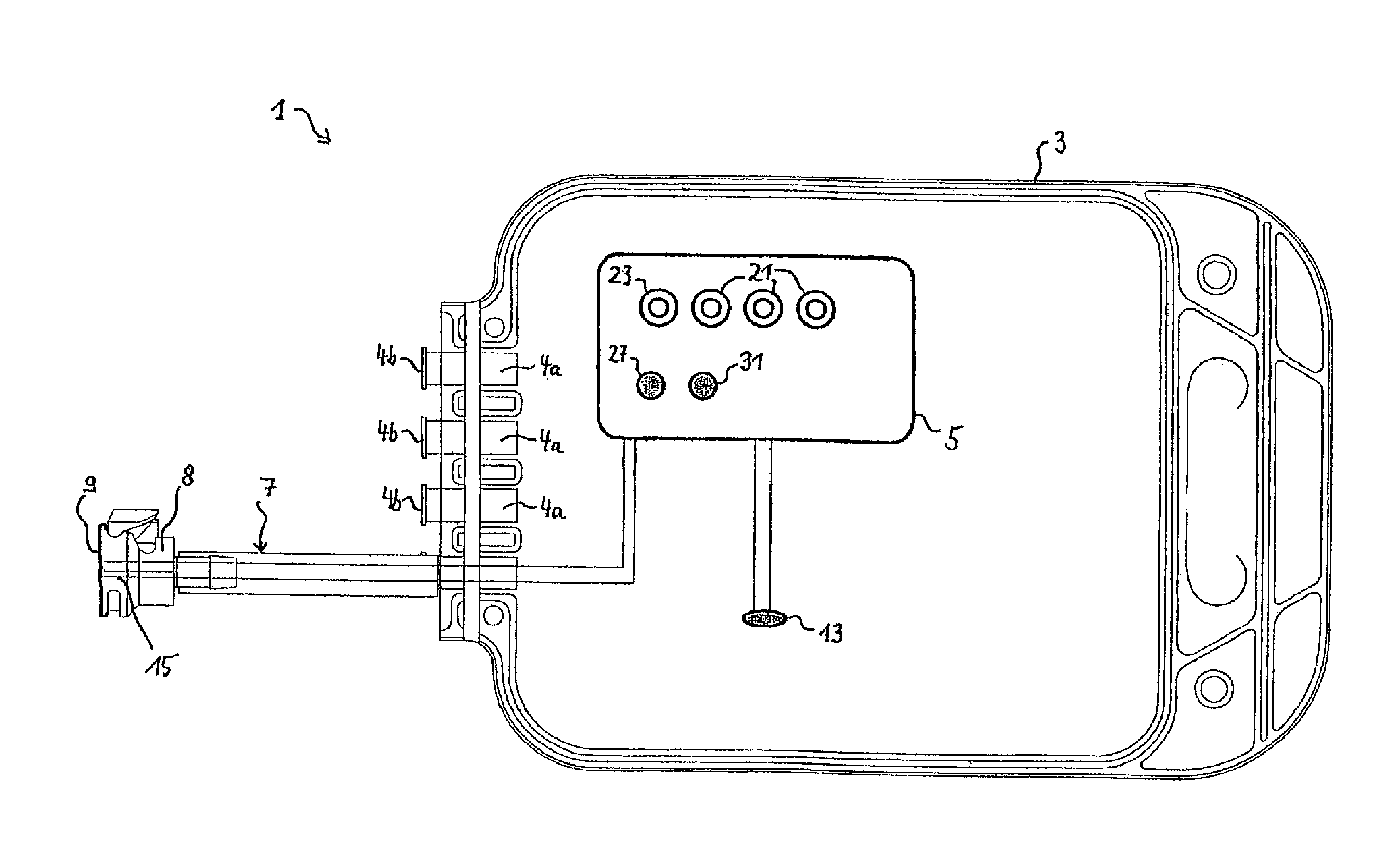

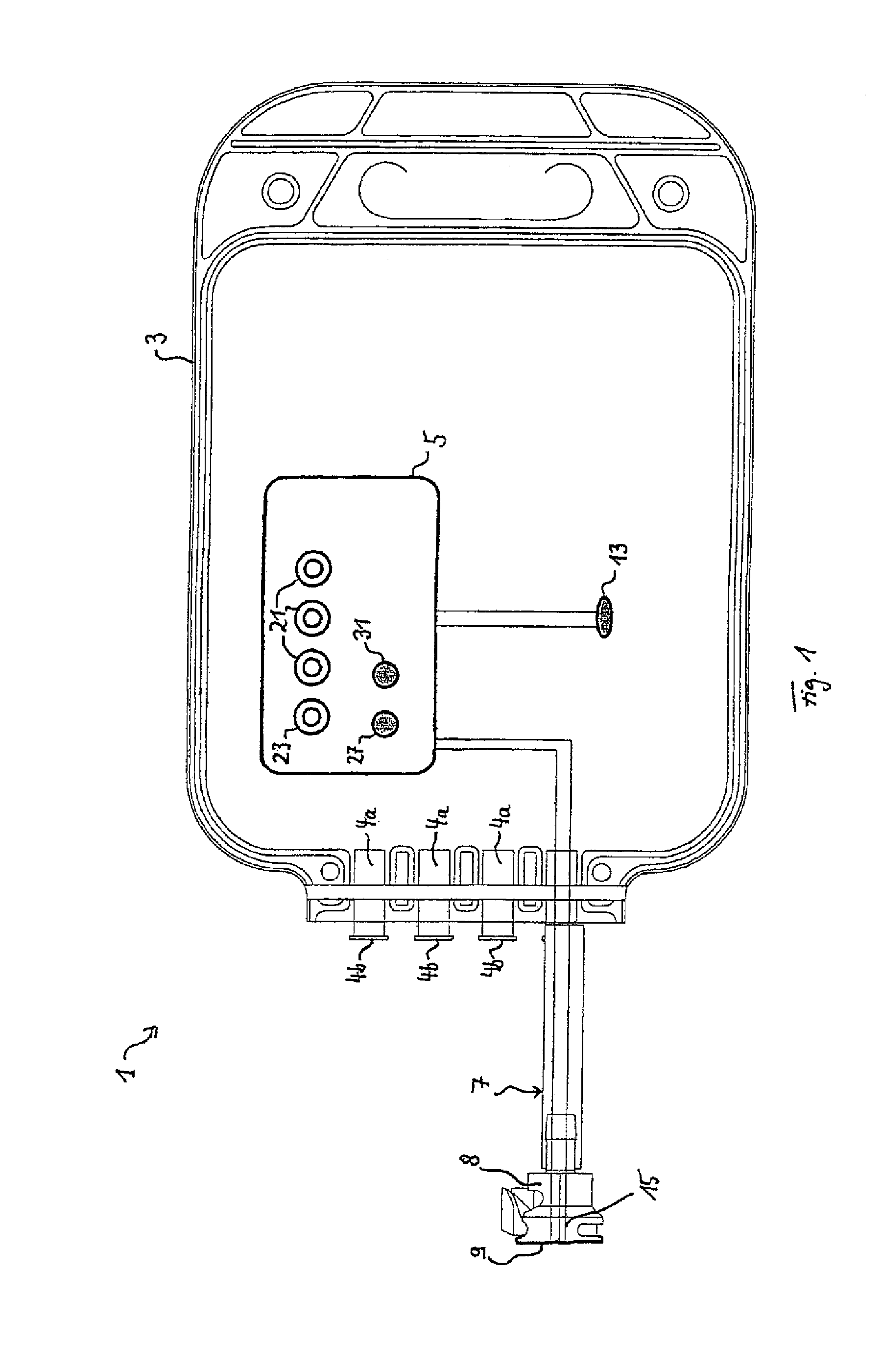

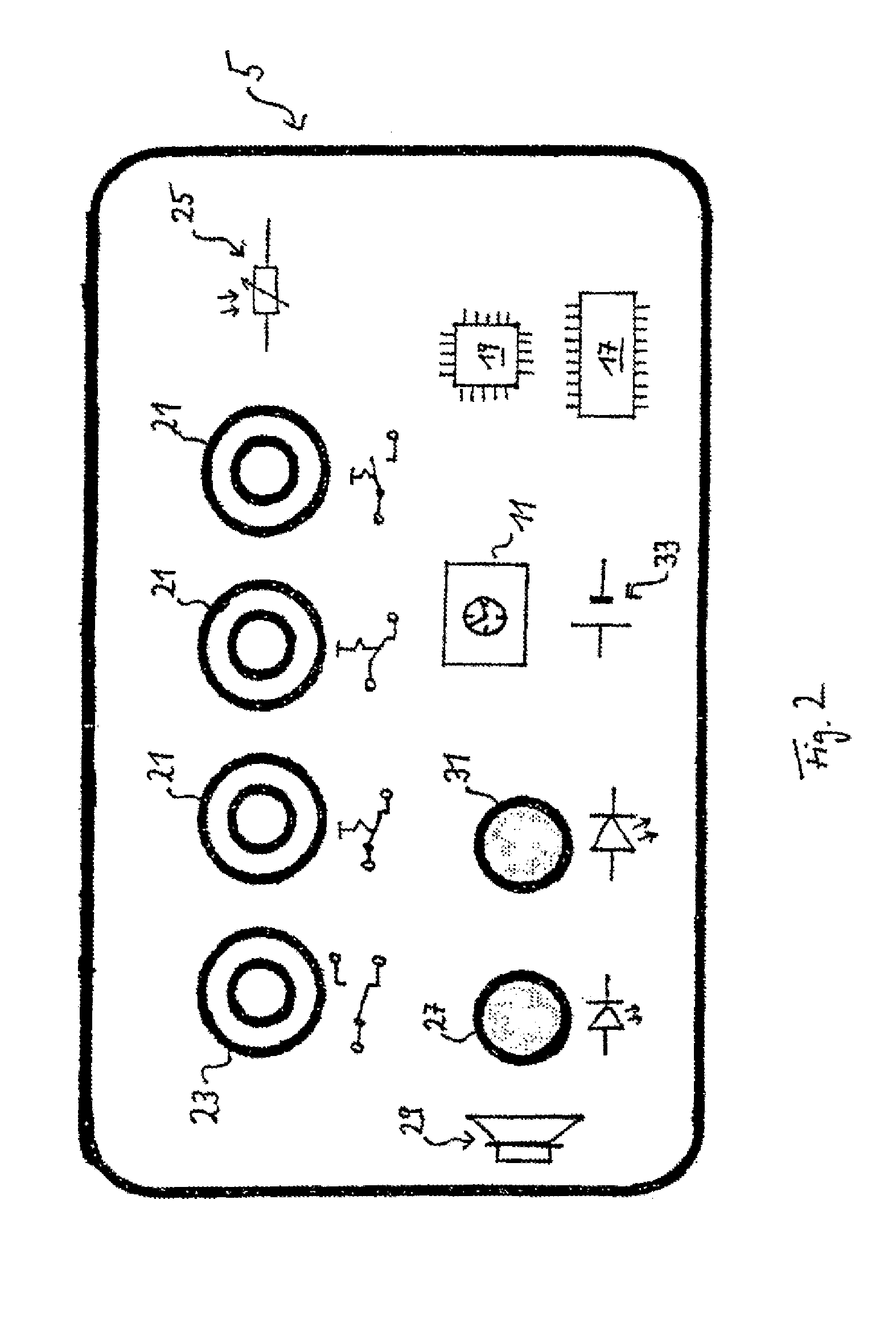

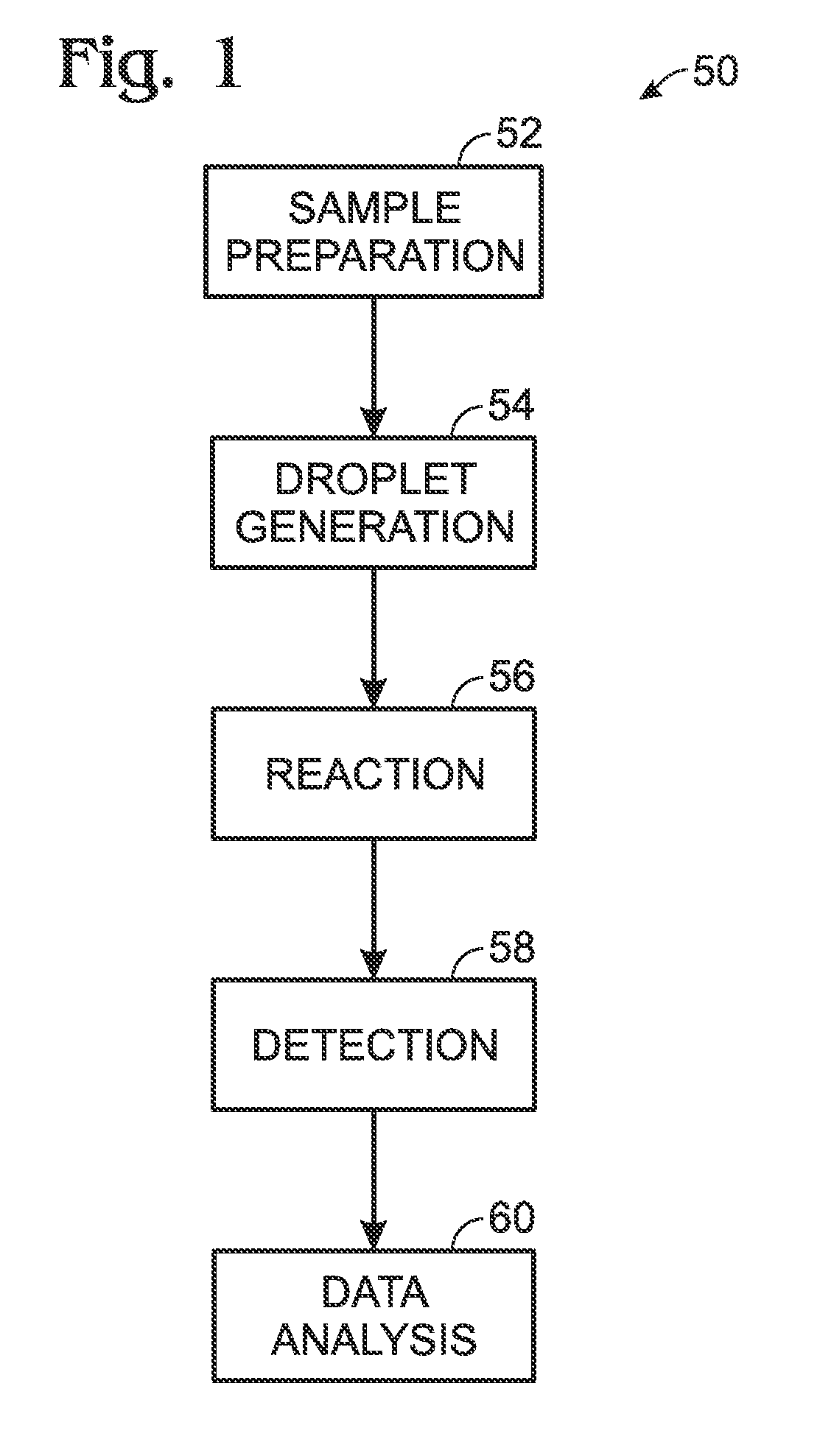

System, including methods, apparatus, and kits, for forming emulsions. In an exemplary method of generating droplets, a device may be selected that includes a plurality of emulsion-formation units each including a sample well, a continuous-phase well, a droplet well, and a channel network that fluidically interconnects the wells and creates a droplet-generation region. A discrete volume of sample-containing fluid may be placed into the sample well of each emulsion-formation unit, and a discrete volume of continuous-phase fluid into the continuous-phase well of each emulsion-formation unit. Pressure may be applied to the device with a fluidics assembly after the step of placing, such that the plurality of emulsion-formation units generate droplets in parallel with one another. A pressure signal may be detected from the fluidics assembly. Application of the pressure may be stopped when the pressure signal indicates that a sample well is empty.

Owner:BIO RAD LAB INC

Container having a computer product

ActiveUS20110198255A1The process parameters are simpleSimple processReagent containersPharmaceutical containersDocumentation procedureComputer science

A storage and / or reaction container system for fluids, includes a container and an electronic documentation device connected to the container. The documentation device further includes a timing device for capturing a point in time, at least one sensor, at least one input device for capturing inputs, and a storage device to store for readout at least one measured value captured by the at least one sensor device and / or an input captured by the at least one input device. The at least one measured value and / or the at least one input is associated by the timing device with the point in time of the capture.

Owner:SARTORIUS STEDIM BIOTECH GMBH

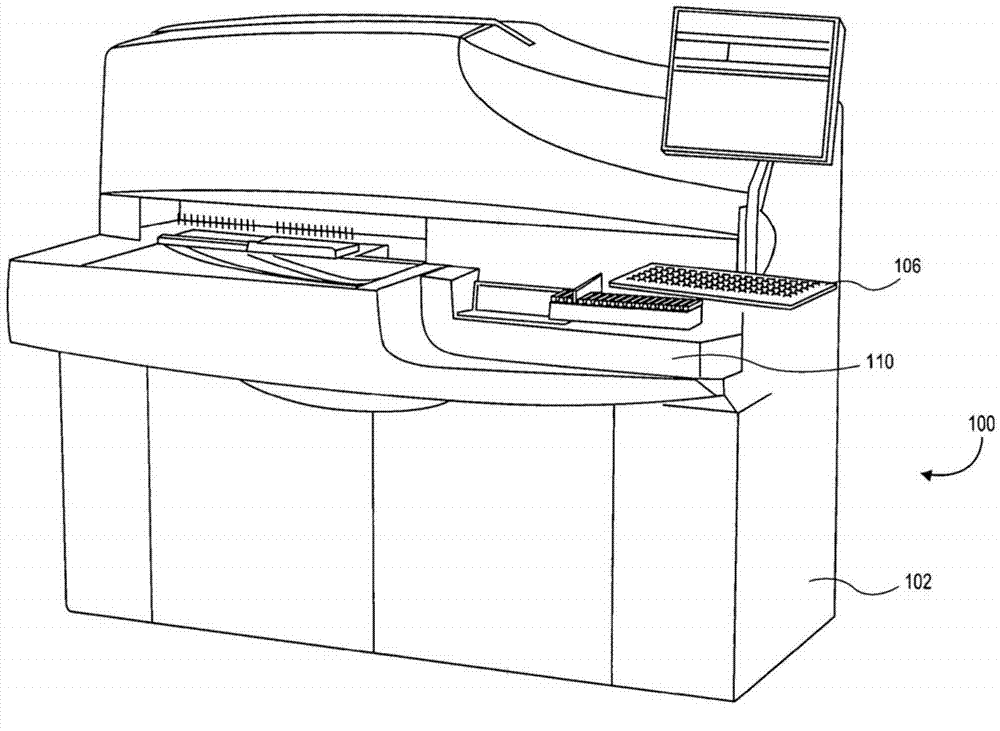

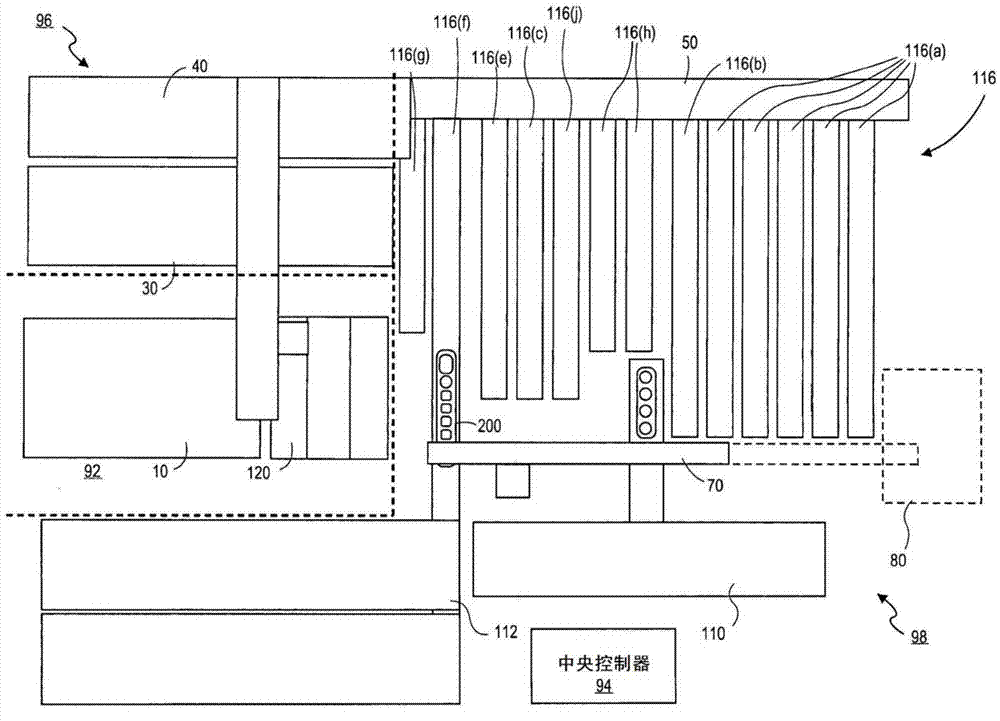

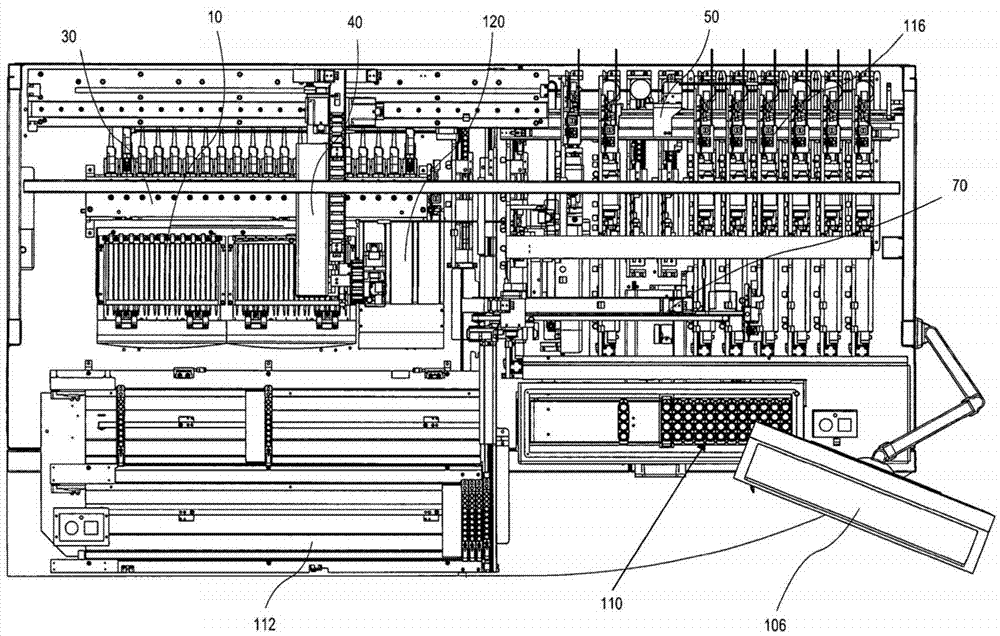

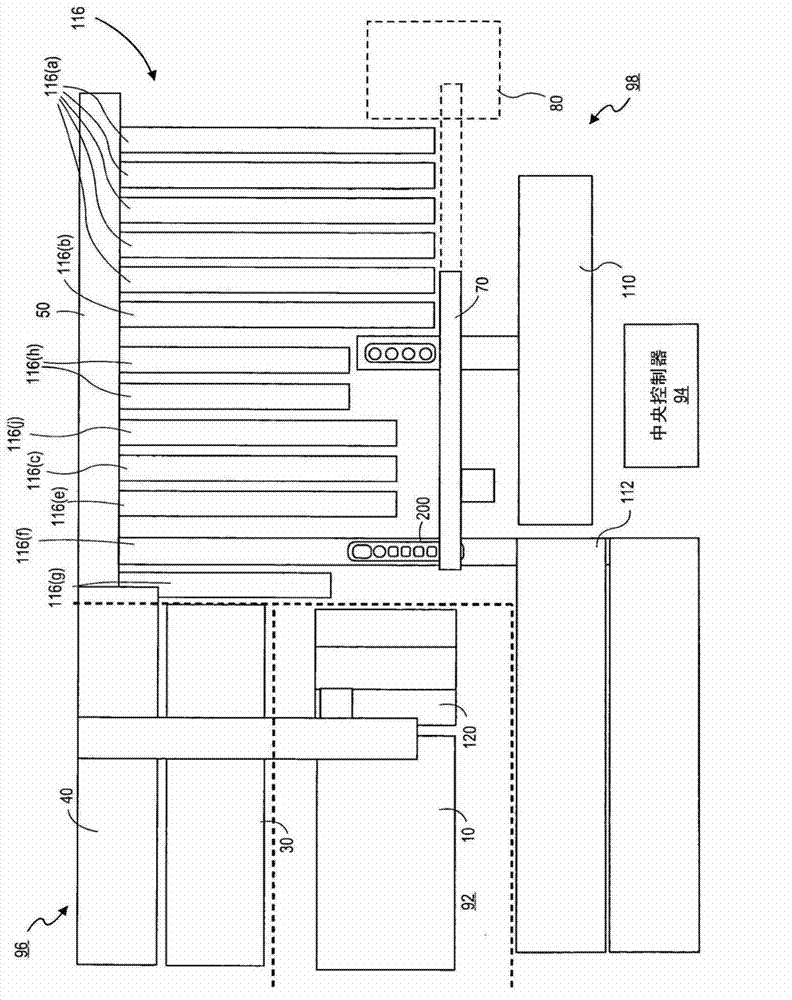

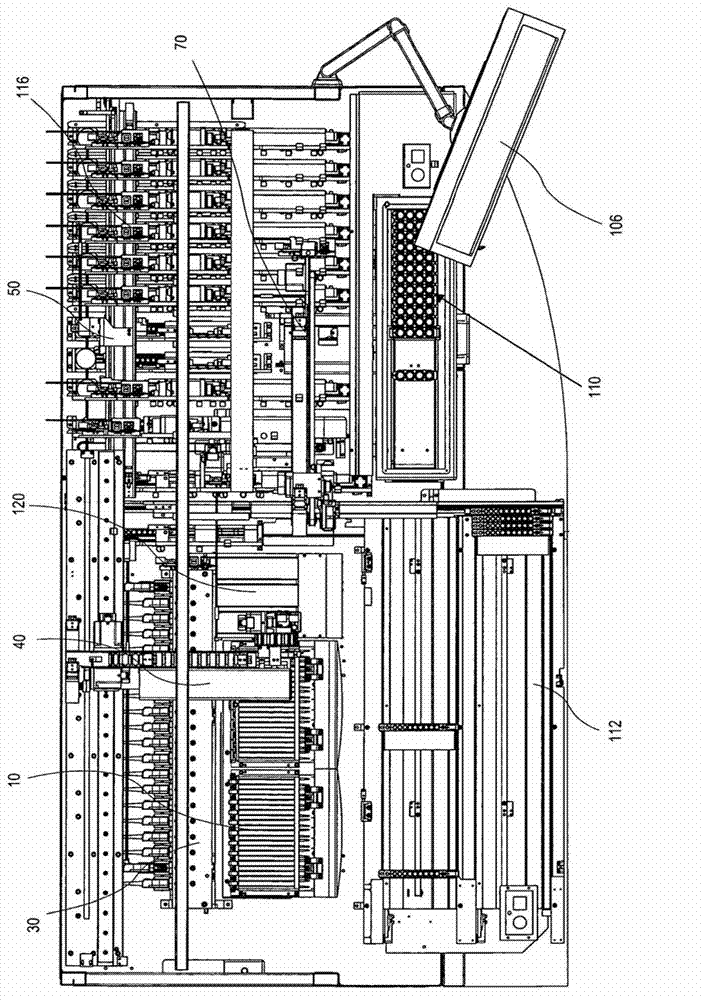

System and method including analytical units

InactiveCN103119451ASimple structureHeating or cooling apparatusReagent containersAssayPhysical chemistry

Systems and methods for processing and analyzing samples are disclosed. The system may process samples, such as biological fluids, using assay cartridges which can be processed at different processing locations. In some cases, the system can be used for PCR processing. The different processing locations may include a preparation location where samples can be prepared and an analysis location where samples can be analyzed. To assist with the preparation of samples, the system may also include a number of processing stations which may include processing lanes. During the analysis of samples, in some cases, thermal cycler modules and an appropriate optical detection system can be used to detect the presence or absence of certain nucleic acid sequences in the samples. The system can be used to accurately and rapidly process samples.

Owner:BECKMAN COULTER INC

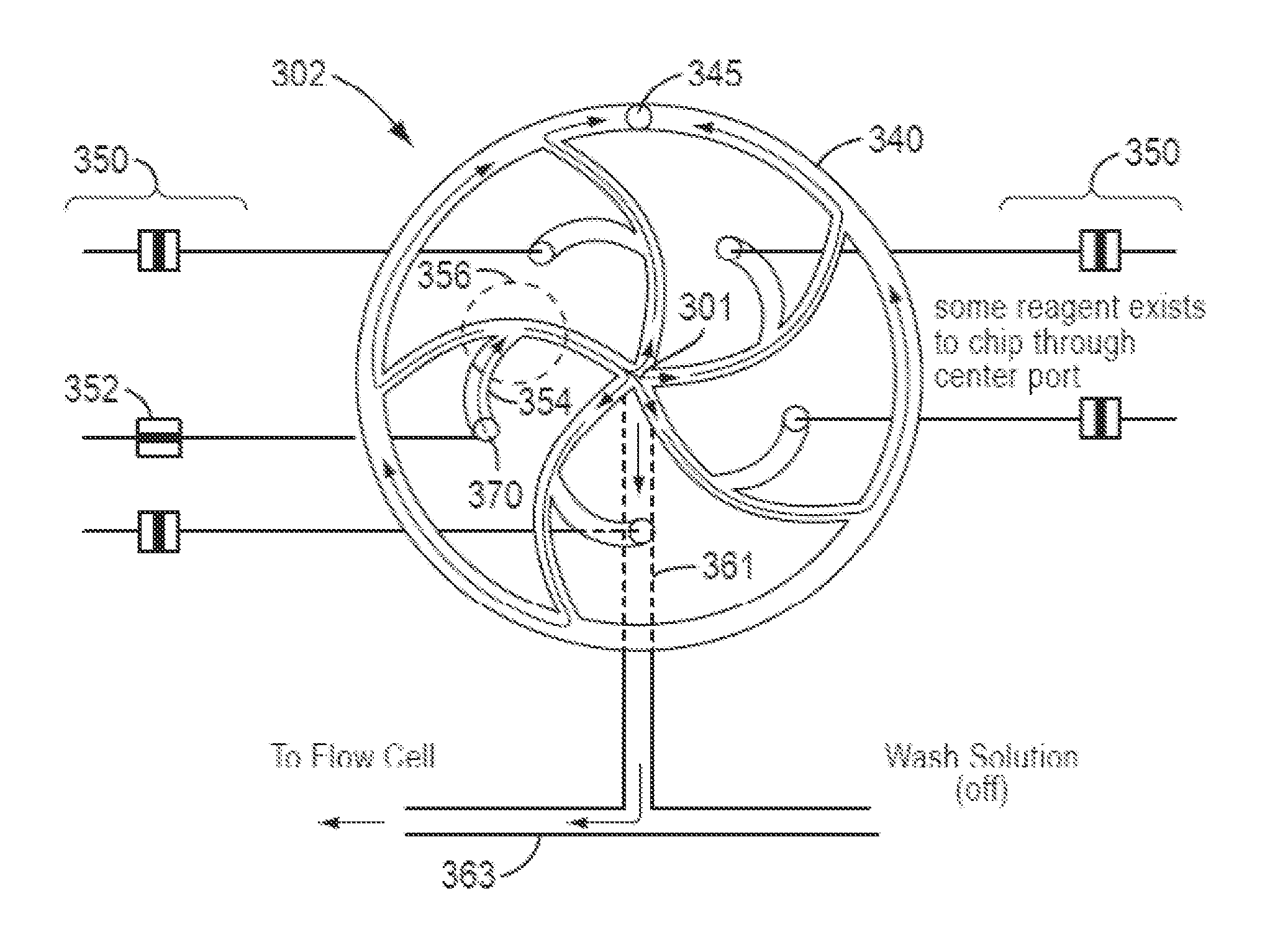

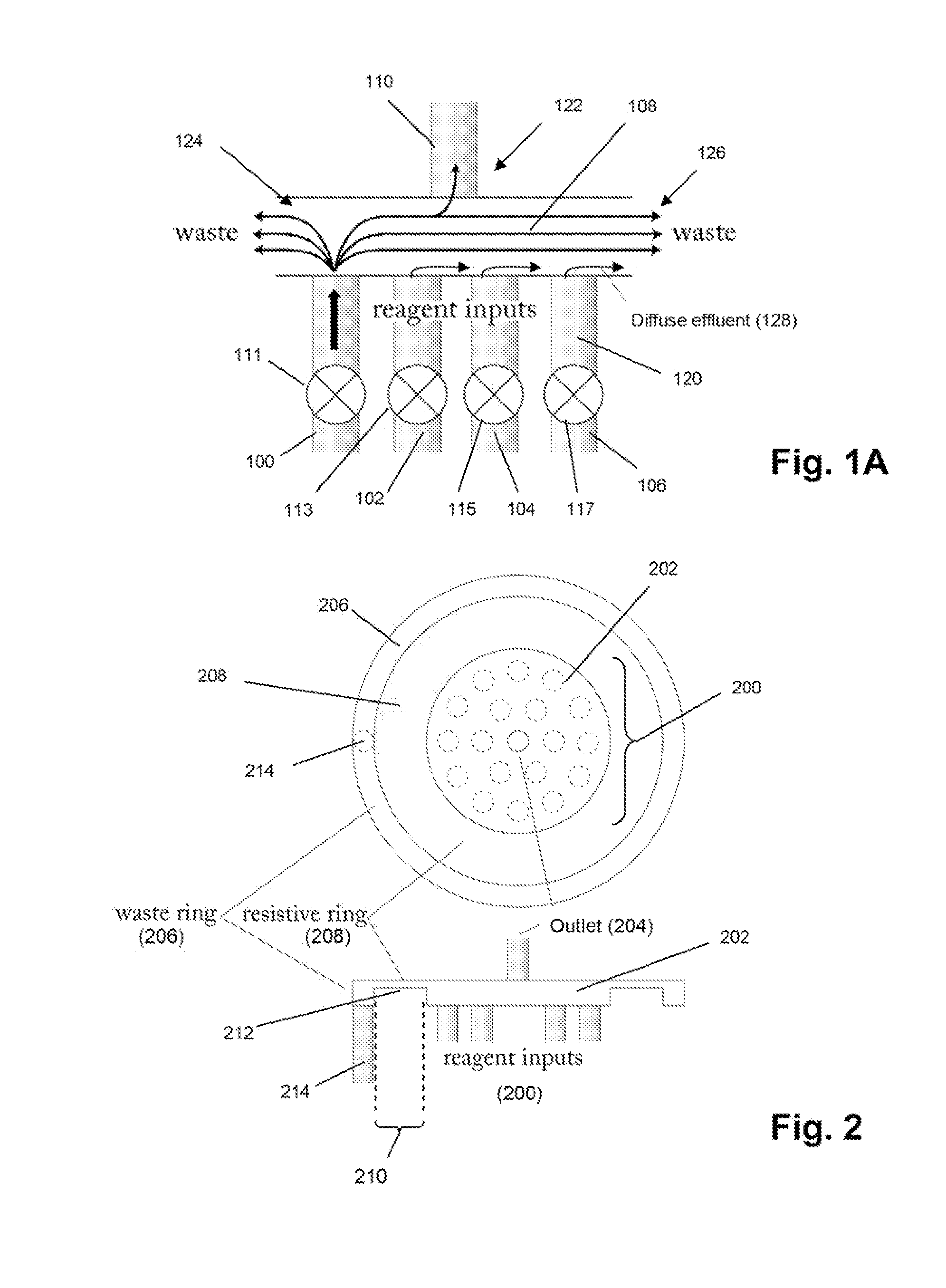

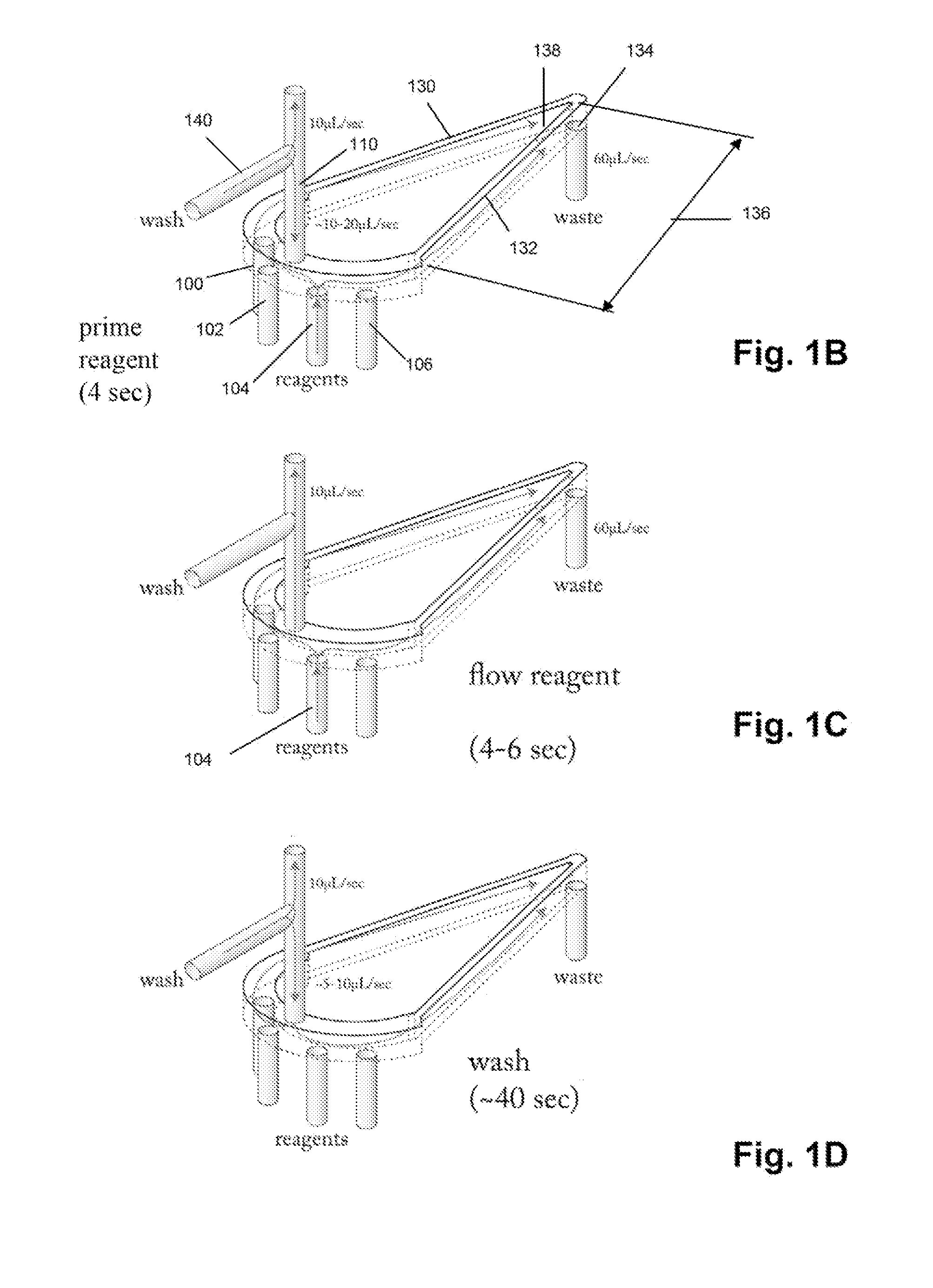

Fluidics system for sequential delivery of reagents

ActiveUS20120073667A1MiniaturizationProcess can be usedReagent containersMicrobiological testing/measurementFluidicsFlow cell

The invention provides a passive fluidics circuit for directing different fluids to a common volume, such as a reaction chamber or flow cell, without intermixing or cross contamination. The direction and rate of flow through junctions, nodes and passages of the fluidics circuit are controlled by the states of upstream valves (e.g. opened or closed), differential fluid pressures at circuit inlets or upstream reservoirs, flow path resistances, and the like. Free diffusion or leakage of fluids from unselected inlets into the common outlet or other inlets at junctions or nodes is prevented by the flow of the selected inlet fluid, a portion of which sweeps by the inlets of unselected fluids and exits the fluidics circuit by waste ports, thereby creating a barrier against undesired intermixing with the outlet flow through leakage or diffusion. The invention is particularly advantageous in apparatus for performing sensitive multistep reactions, such as pH-based DNA sequencing reactions.

Owner:LIFE TECH CORP

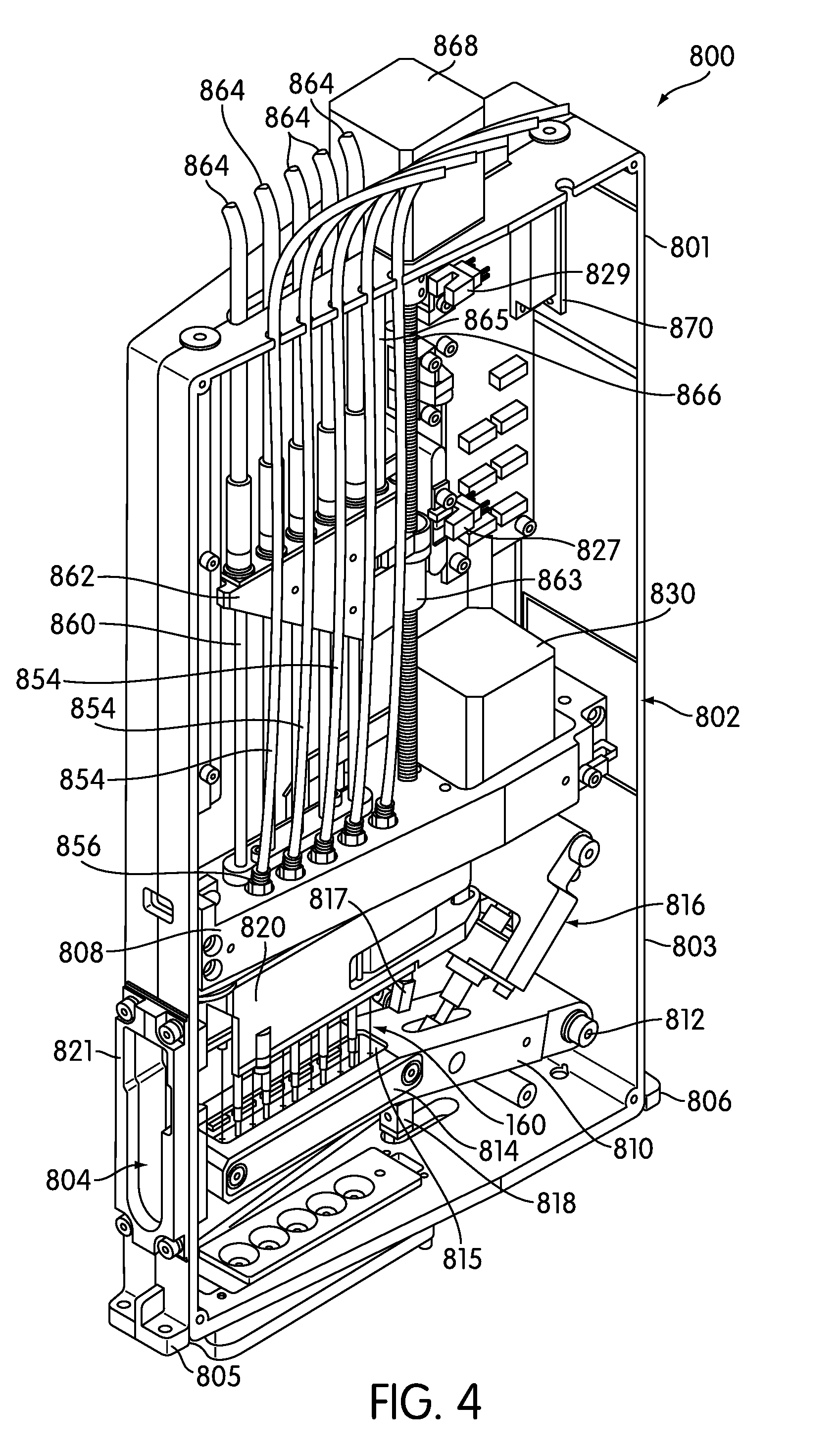

Method and Apparatus for Effecting Automated Movement of a Magnet in an Instrument for Performing a Magnetic Separation Procedure

Methods, systems, and apparatus are provided for automated isolation of selected analytes, to which magnetically-responsive solid supports are bound, from other components of a sample. An apparatus for performing an automated magnetic separation procedure includes a mechanism for effecting linear movement of a magnet between operative and non-operative positions with respect to a receptacle device. A receptacle holding station within which a receptacle device may be temporarily stored prior to moving the receptacle to the apparatus for performing magnetic separation includes magnets for applying a magnetic field to the receptacle device held therein, thereby drawing at least a proton of the magnetically-responsive solid supports out of suspension before the receptacle device is moved to the magnetic separation station. An automated receptacle transport mechanism moves the receptacle devices between the apparatus for performing magnetic separation and the receptacle holding station.

Owner:GEN PROBE INC

Fluid-containing pouches with reduced gas exchange and methods for making same

ActiveUS20100068097A1Reduce penetrationReduce solubilityHollow inflatable ballsHollow non-inflatable ballsUltrasonic weldingEngineering

The invention is directed to fluid-containing pouches and to methods for forming fluid-containing pouches. In one embodiment, the invention is to a fluid-containing pouch, comprising first and second opposing sheets, and a fluid (e.g., a calibrant fluid, a reactant fluid or a wash fluid) disposed between the first and second opposing sheets. The first sheet and the second sheet have a substantially liquid and gas impermeable perimeter seal. The sheets may be sealed, for example, by one or more of heat crimping, pressure crimping, heat and pressure crimping, ultrasonic welding, metal-to-metal welding or laser welding. Fluid-containing pouches sealed according to the disclosed methods and apparatuses show substantially improvement in terms of reduced gas exchange, notably CO2 pressurization levels.

Owner:ABBOTT POINT CARE

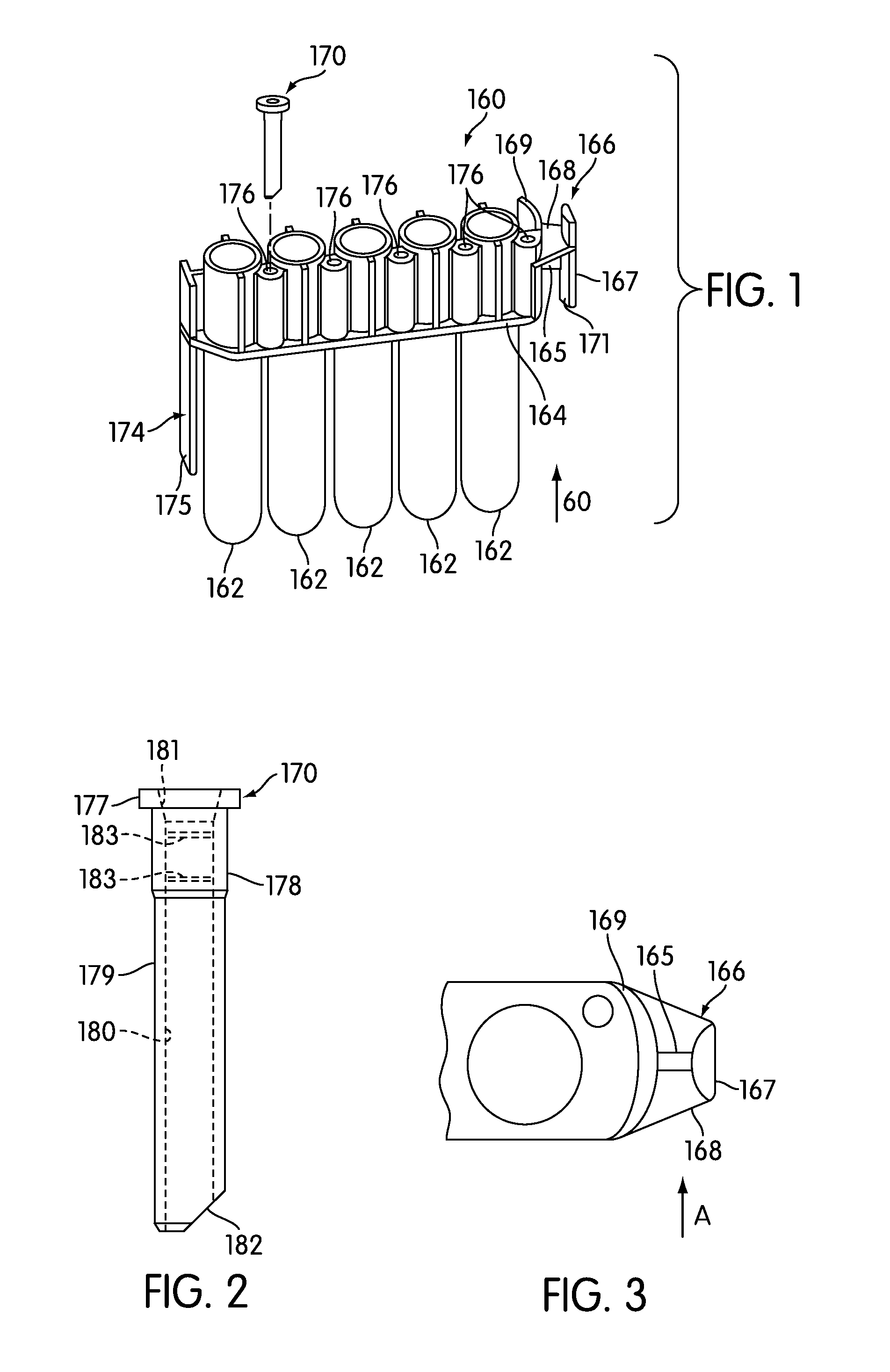

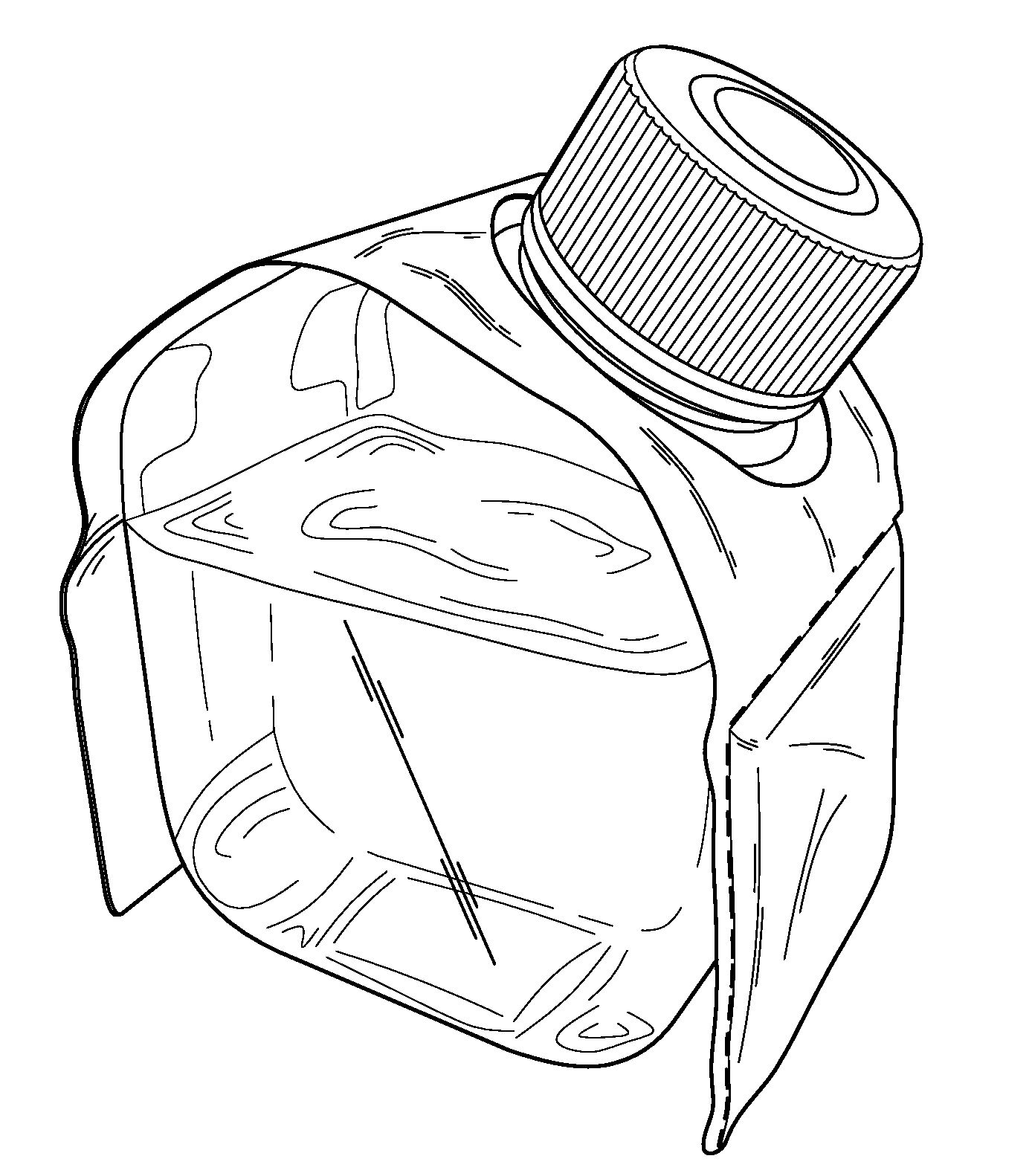

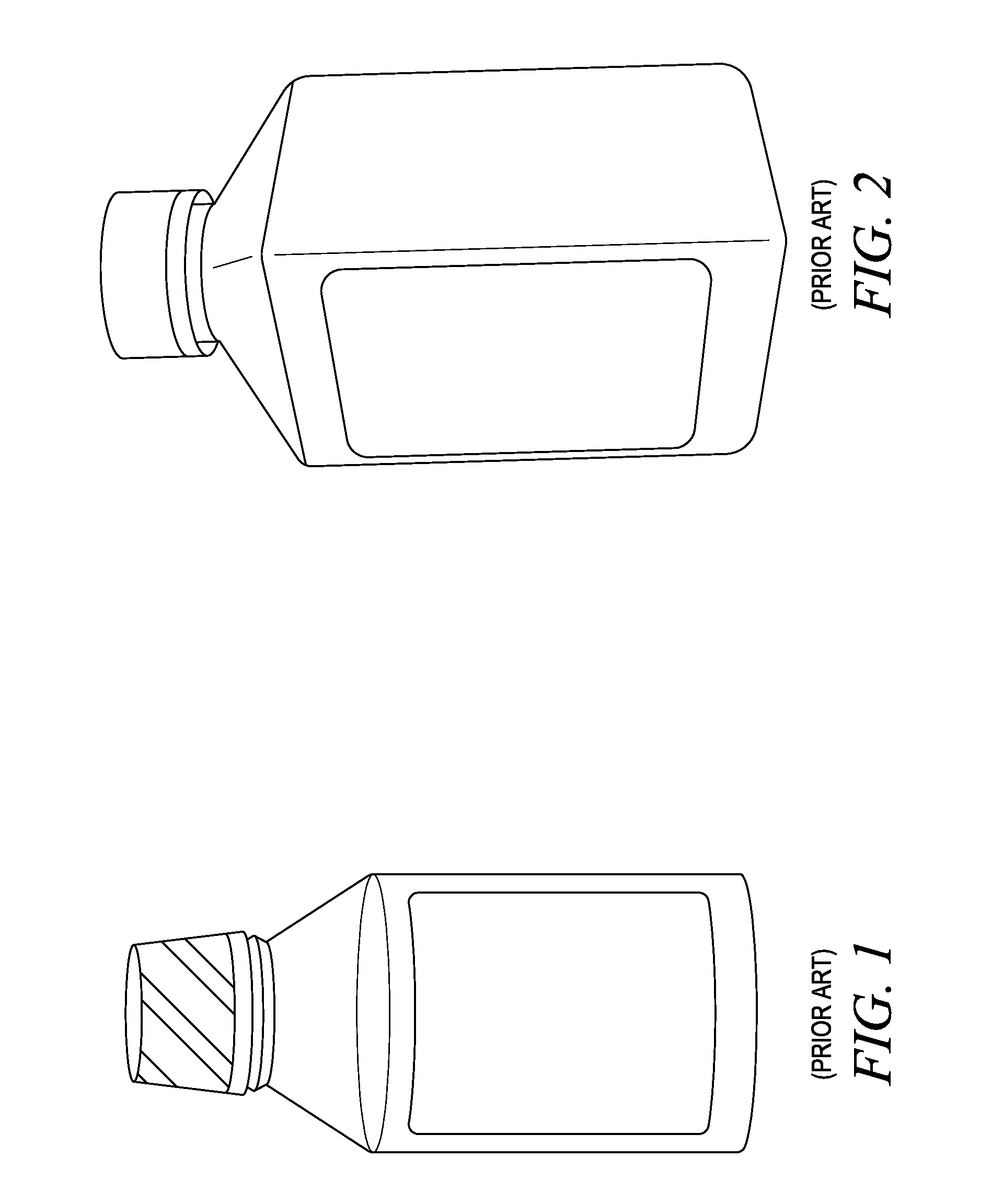

Labels, containers, system and method for providing reagents

InactiveUS20100059533A1Avoid trafficStop the flowContainer decorationsLevel indicationsAlphanumericLaboratory facility

The invention relates to systems and methods for marketing and using products such as liquid materials, especially liquid reagents for use in microbiological and cellular biological laboratory settings include the use of unique color and simple numeric or alphanumeric identifiers to quickly and easily identify any product from a catalog list of products. Methods of marketing, advertising and producing such products are also disclosed. Particular embodiments include products, product packaging and product labeling. The invention also relates to collars and sleeves for containers, flexible stabilizers for containers, as well as related methods of use.

Owner:LIFE TECH CORP

Sample Metering Device and Assay Device with Integrated Sample Dilution

InactiveUS20120142020A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteDiluent

In one embodiment, the invention is to a sample metering device, comprising a sample holding chamber oriented between a sample entry port and a sample extraction unit, wherein a portion of said extraction unit defines a metered volume of a sample. A diluent may be transported over and / or through the extraction unit to form a diluted sample for sample analysis. In another embodiment, the invention is to an apparatus and method for rapid determination of analytes in liquid samples by various assays including immunoassays incorporating a sample dilution feature, capable of being used in the point-of-care diagnostic field is provided. The devices and methods of the invention preferably are well-suited for high range sample dilution.

Owner:ABBOTT POINT CARE

Interlocking cap and receptacle with detent feature and method and apparatus for separating interlocked cap and receptacle

ActiveUS20140260118A1Increasing the thicknessAccurate identificationBottle/container closureReagent containersDetentEngineering

Owner:GEN PROBE INC

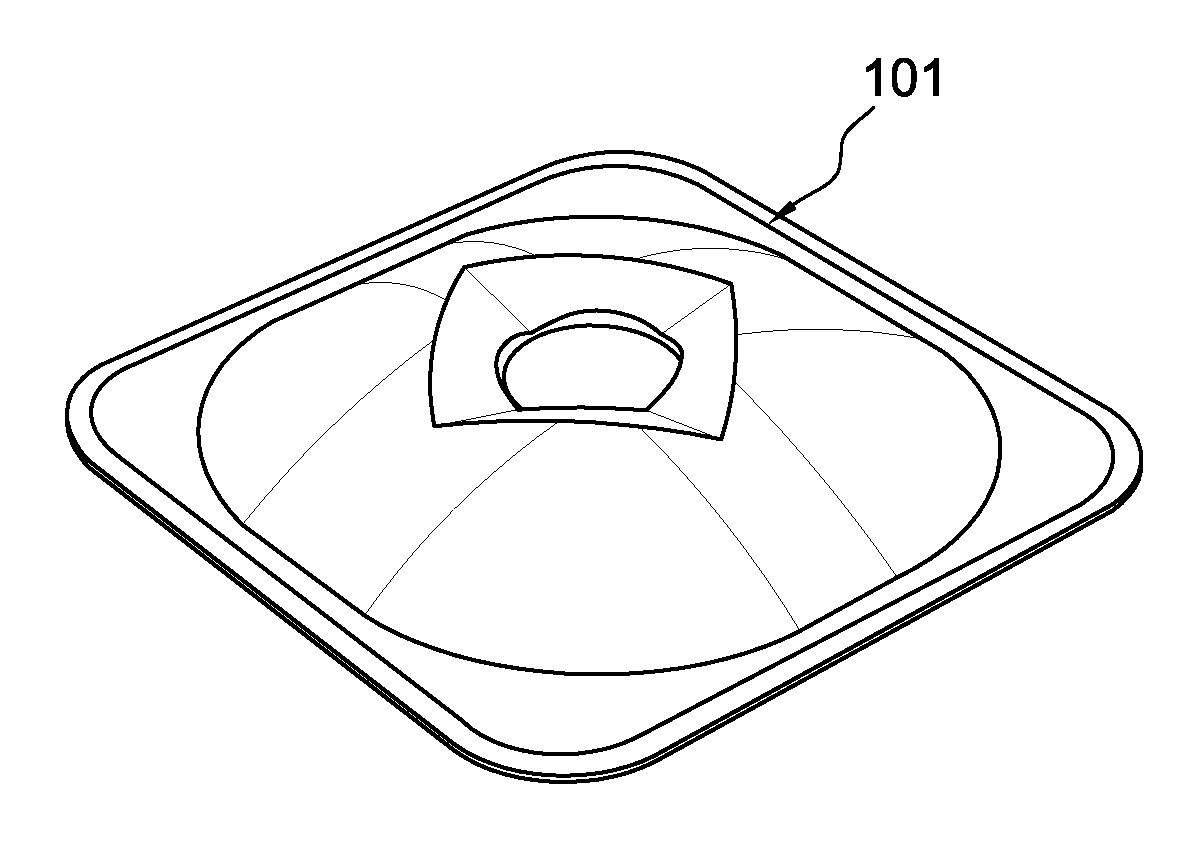

Cartridge device for a measuring system for measuring viscoelastic characteristics of a sample liquid, a corresponding measuring system, and a corresponding method

ActiveUS8448499B2Facilitates of partConnection securityMaterial analysis using sonic/ultrasonic/infrasonic wavesReagent containersBiomedical engineeringCartridge device

The present invention is directed to a cartridge device for a measuring system for measuring viscoelastic characteristics of a sample liquid, in particular a blood sample, comprising a cartridge body having at least one measurement cavity formed therein and having at least one probe element arranged in said at least one measurement cavity for performing a test on said sample liquid; and a cover being attachable on said cartridge body; wherein said cover covers at least partially said at least one measurement cavity and forms a retaining element for retaining said probe element in a predetermined position within said at least one measurement cavity. The invention is directed to a measurement system and a method for measuring viscoelastic characteristics of a sample liquid.

Owner:C A CASYSO

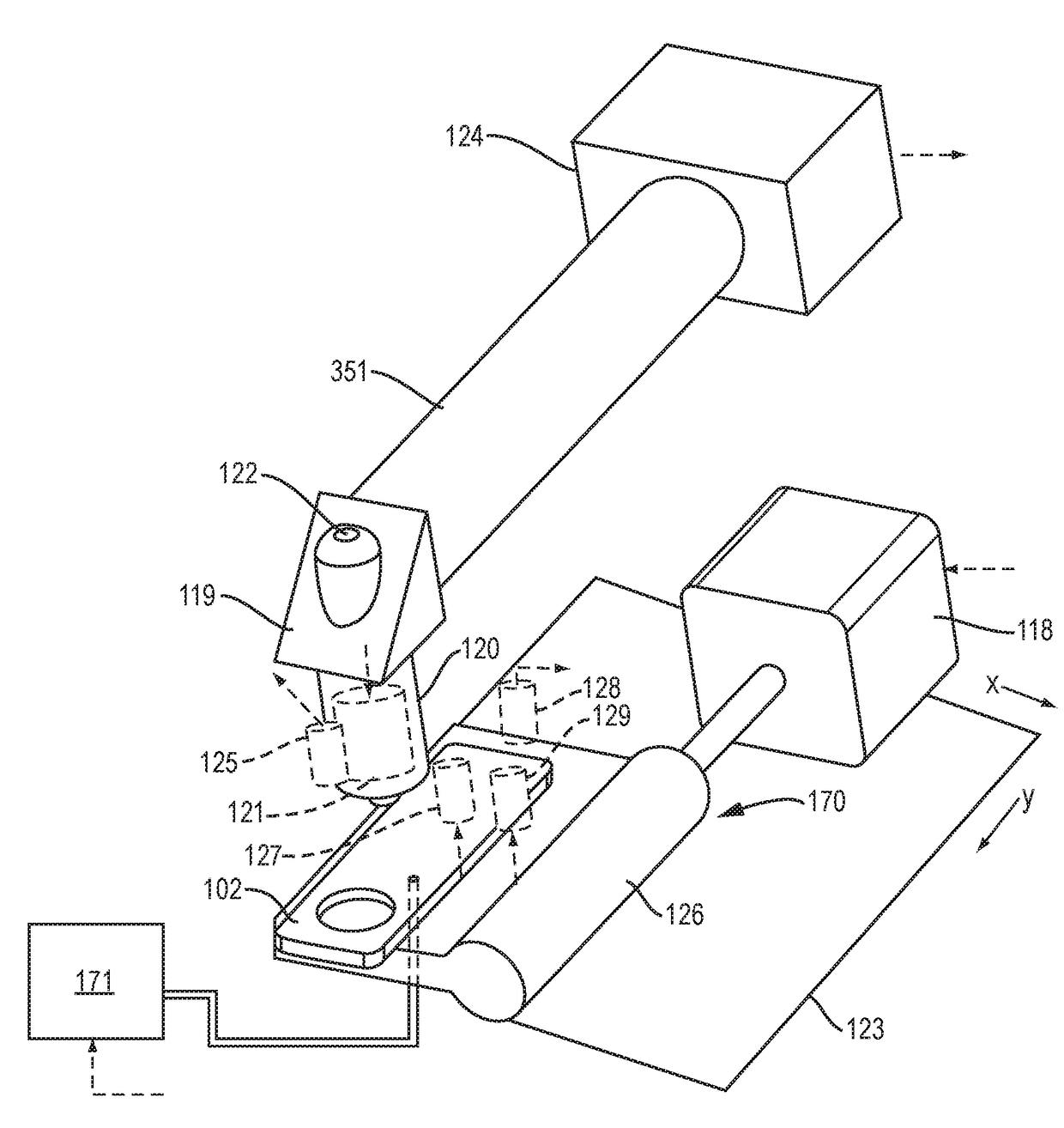

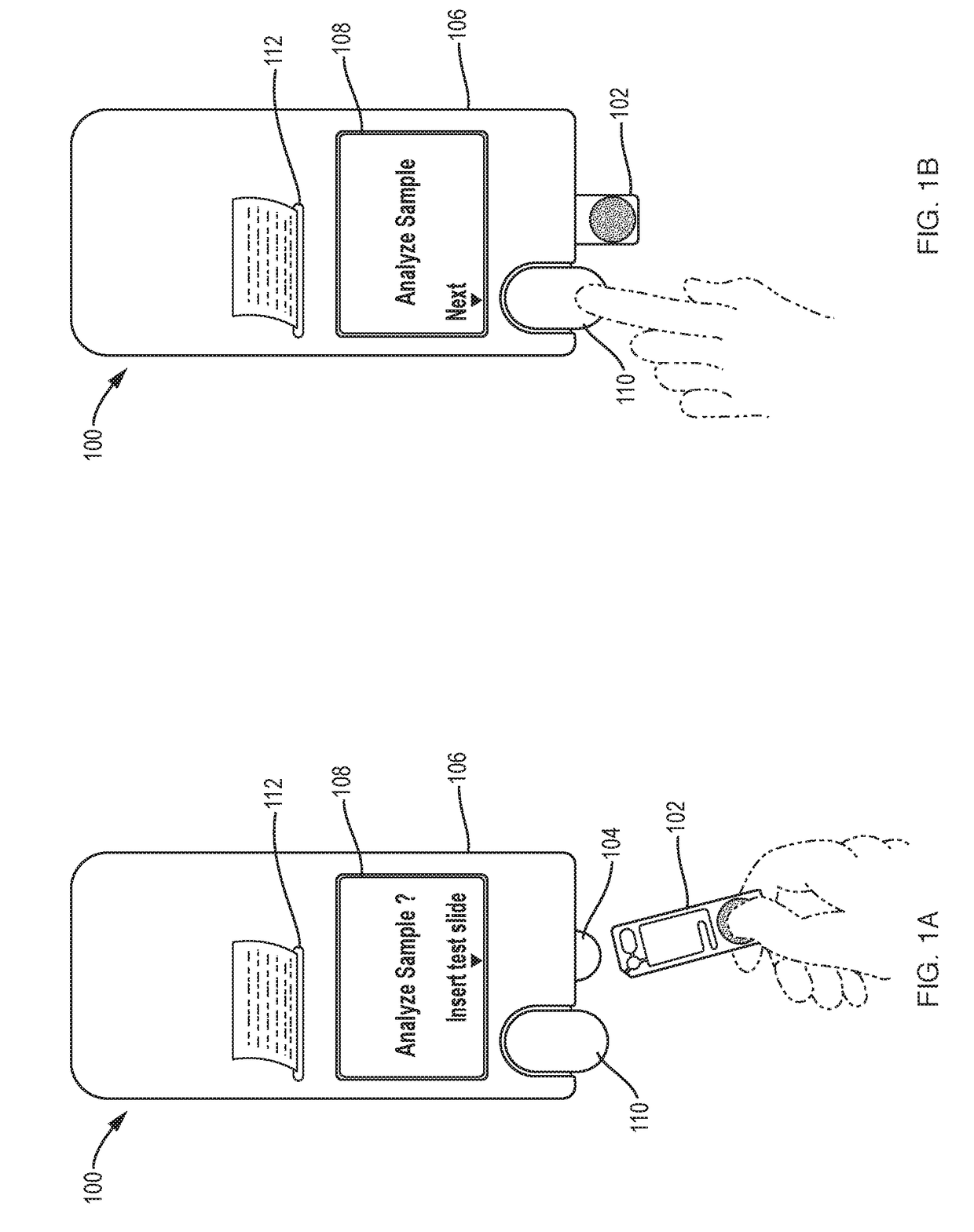

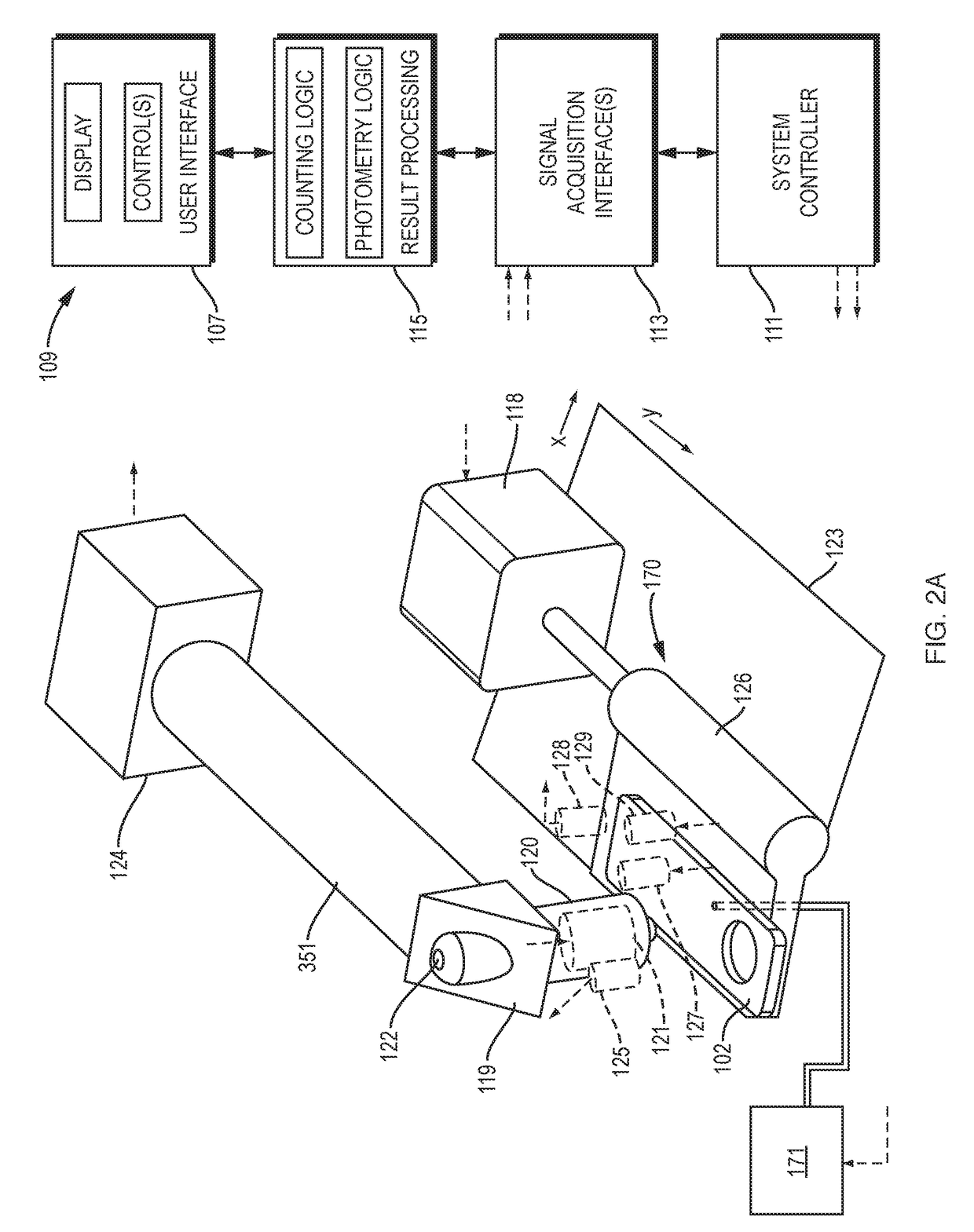

Automated microscopic cell analysis

InactiveUS20170328924A1Eliminate Bubble ProblemsSolve insufficient capacityReagent containersPreparing sample for investigationWhite blood cellRed blood cell

Disclosed in one aspect is a method for performing a complete blood count (CBC) on a sample of whole blood by metering a predetermined amount of the whole blood and mixing it with a predetermined amount of diluent and stain and transferring a portion thereof to an imaging chamber of fixed dimensions and utilizing an automated microscope with digital camera and cell counting and recognition software to count every white blood cell and red blood corpuscle and platelet in the sample diluent / stain mixture to determine the number of red cells, white cells, and platelets per unit volume, and analyzing the white cells with cell recognition software to classify them.

Owner:MEDICA CORP

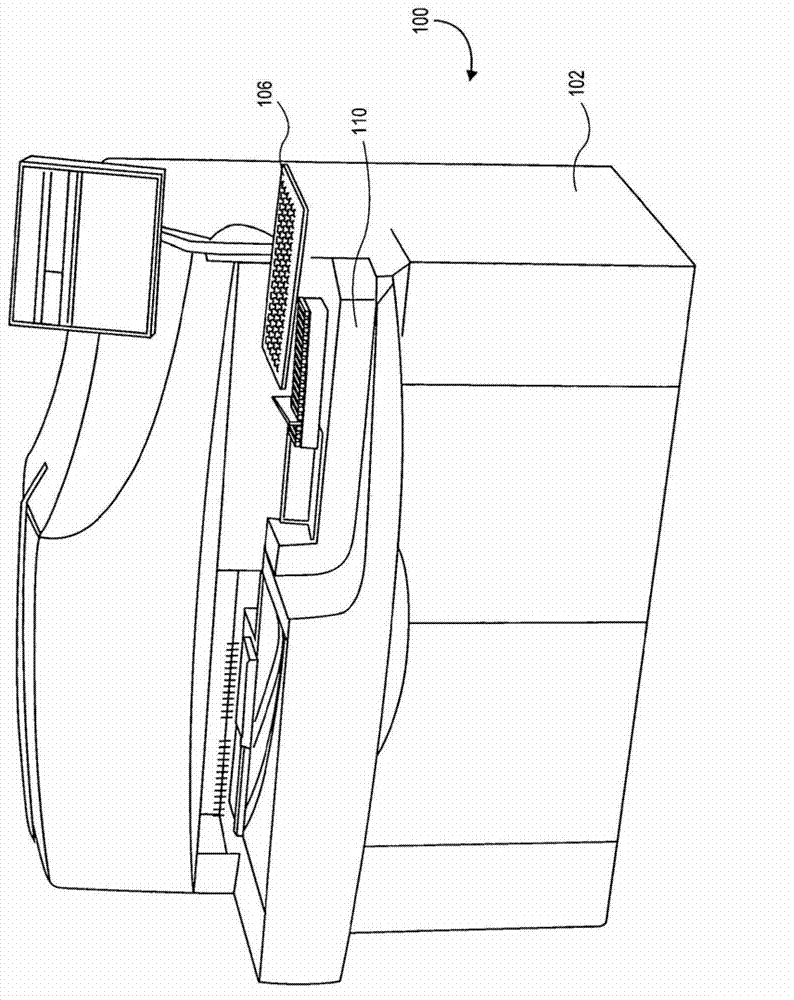

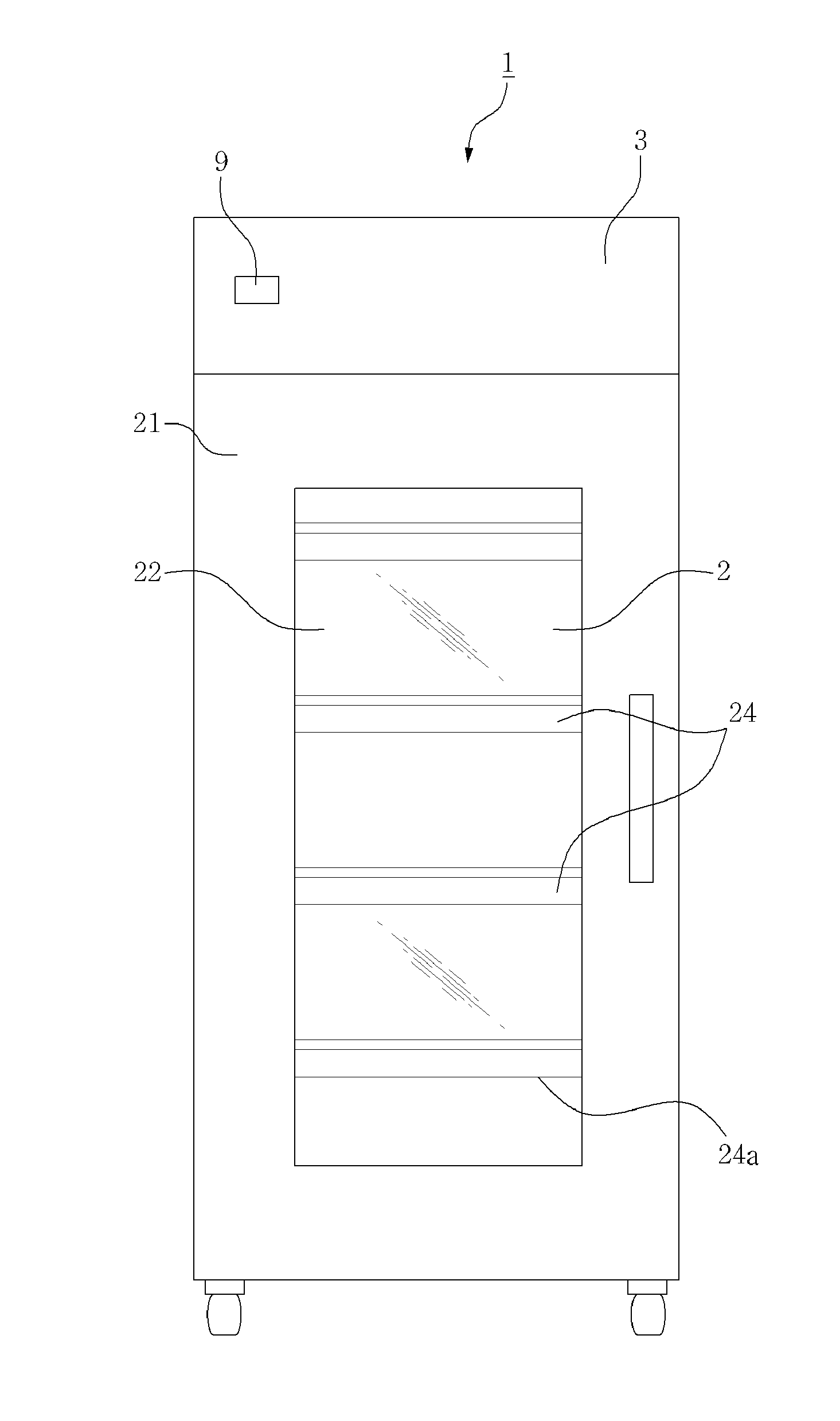

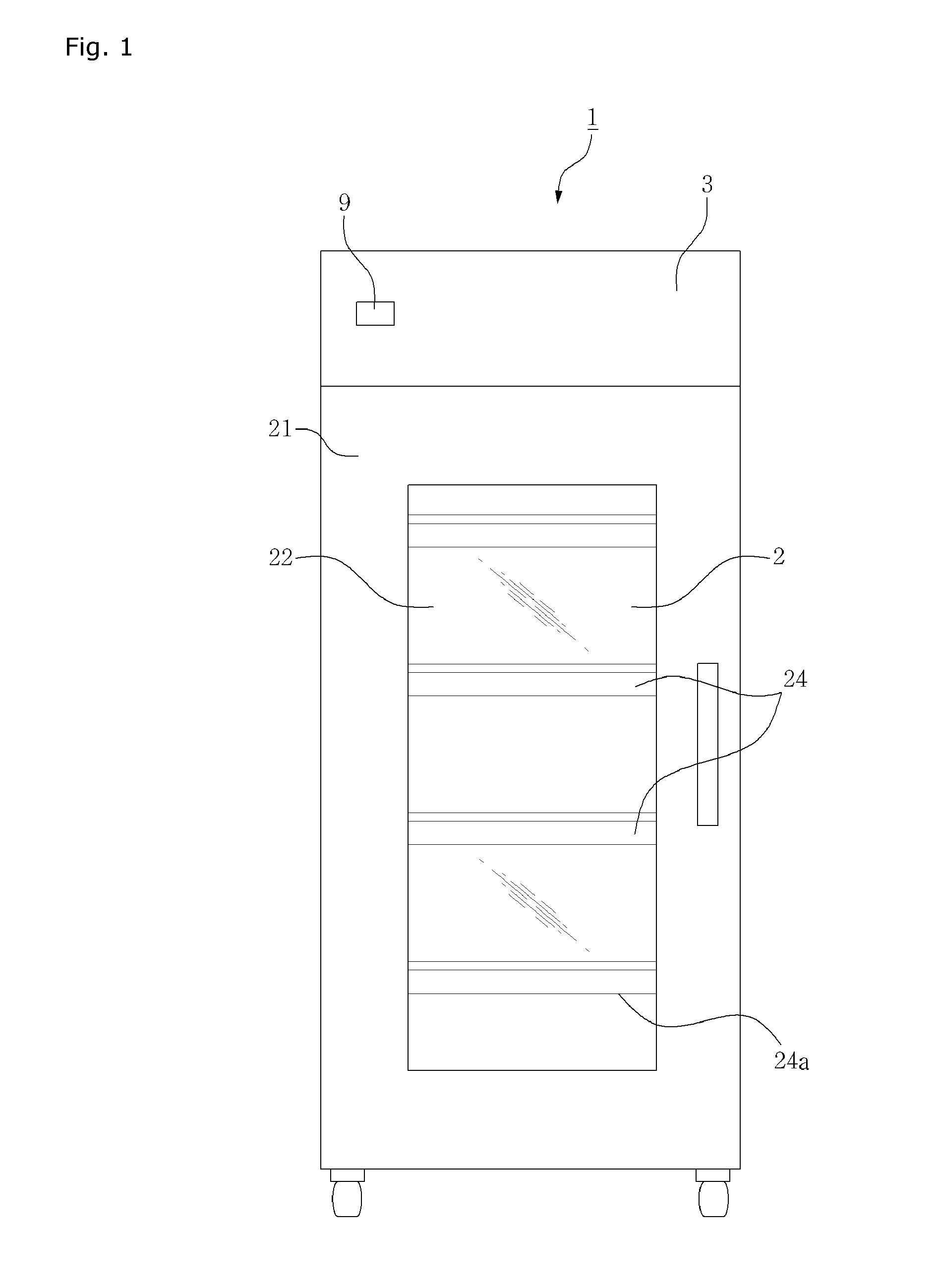

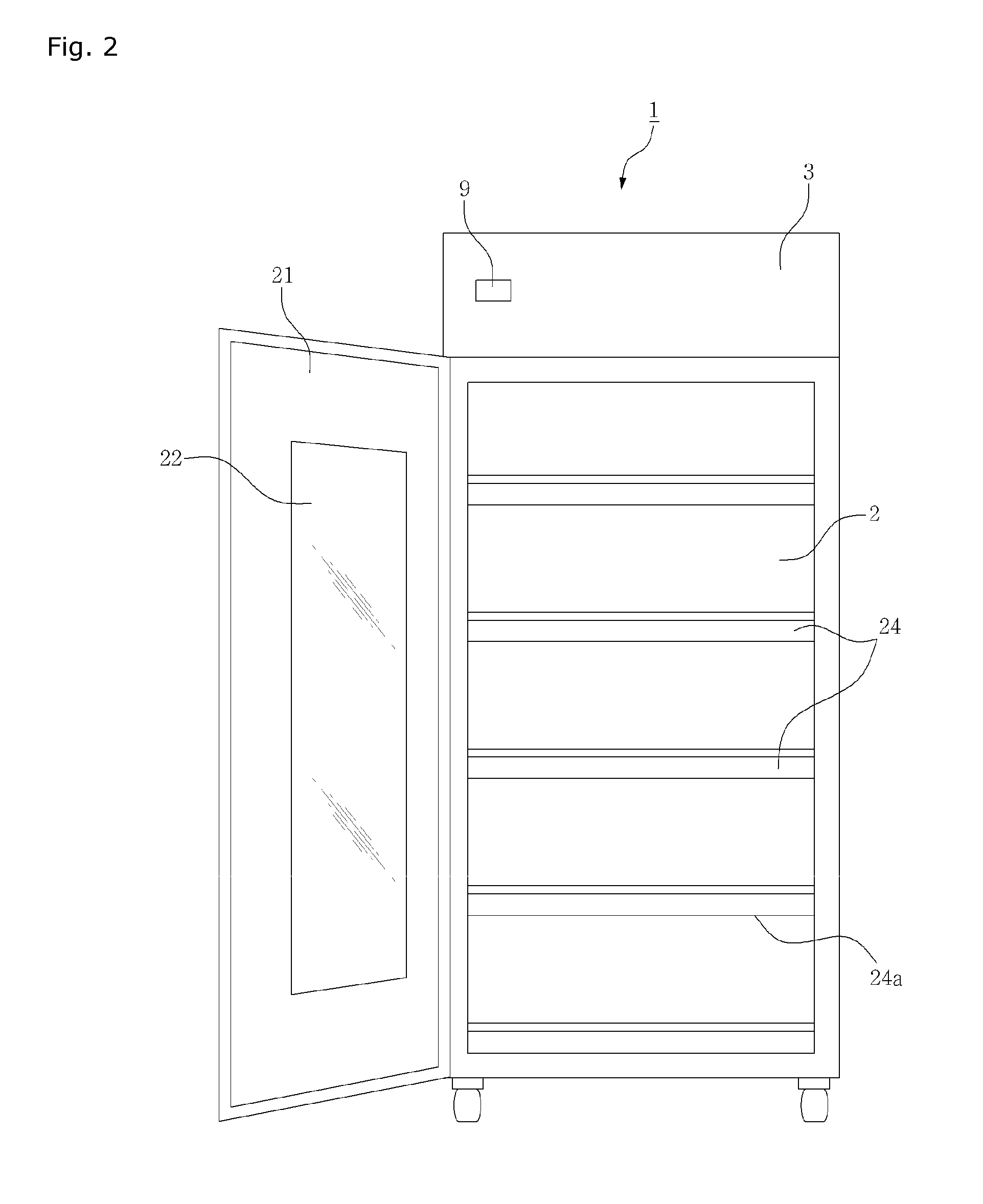

Reagent refrigerator

ActiveUS20130036755A1Decrease of qualityDecrease of titerReagent containersLighting and heating apparatusAutomatic controlRemote control

The present invention relates to a reagent refrigerator which comprises a reagent refrigerator compartment including reagent storing trays; an upper housing a cooling equipment compartment and a cooling purification compartment; a side duct defined by a side partition having a through hole at the side of the reagent refrigerator; one each of a second side duct, separately defined by a side partition having a through hole at the other side thereof, and a rear duct, separately defined by a rear partition having a through hole at the rear side thereof; and an upper duct having one end communication with the upper portion of the second side or rear side, and the other end communicating with the cooling purification compartment. Accordingly, refrigeration temperature of the reagent refrigerator can be controlled, and circulation flow in the reagent refrigerator is improved, to thereby purify the air therein and minimize deviations from refrigerator temperature values. In addition, since the reagent refrigerator is based on a closed circulation type structure, impurities are prevented from being introduced to the reagent refrigerator to thereby increase the service life of the filter and reduce energy consumption. Moreover, even when the door of the reagent refrigerator is opened, negative pressure distribution in the reagent refrigerator is relatively even, thereby preventing the emission of noxious gas and an offensive smell from the reagent refrigerator compartment to the indoor space. More particularly, the reagent refrigerator may be modified to have a partial opening circulation structure without a heater to thereby prevent explosions and to perform a defrosting / dehumidifying operation so that safety and economic feasibility can be improved. In addition, the reagent refrigerator can be automatically controlled and the internal condition of the reagent refrigerator compartment can be monitored in real time. Furthermore, not only can on-site / real-time control be executed, but remote control as well.

Owner:GT SCIEN CO LTD

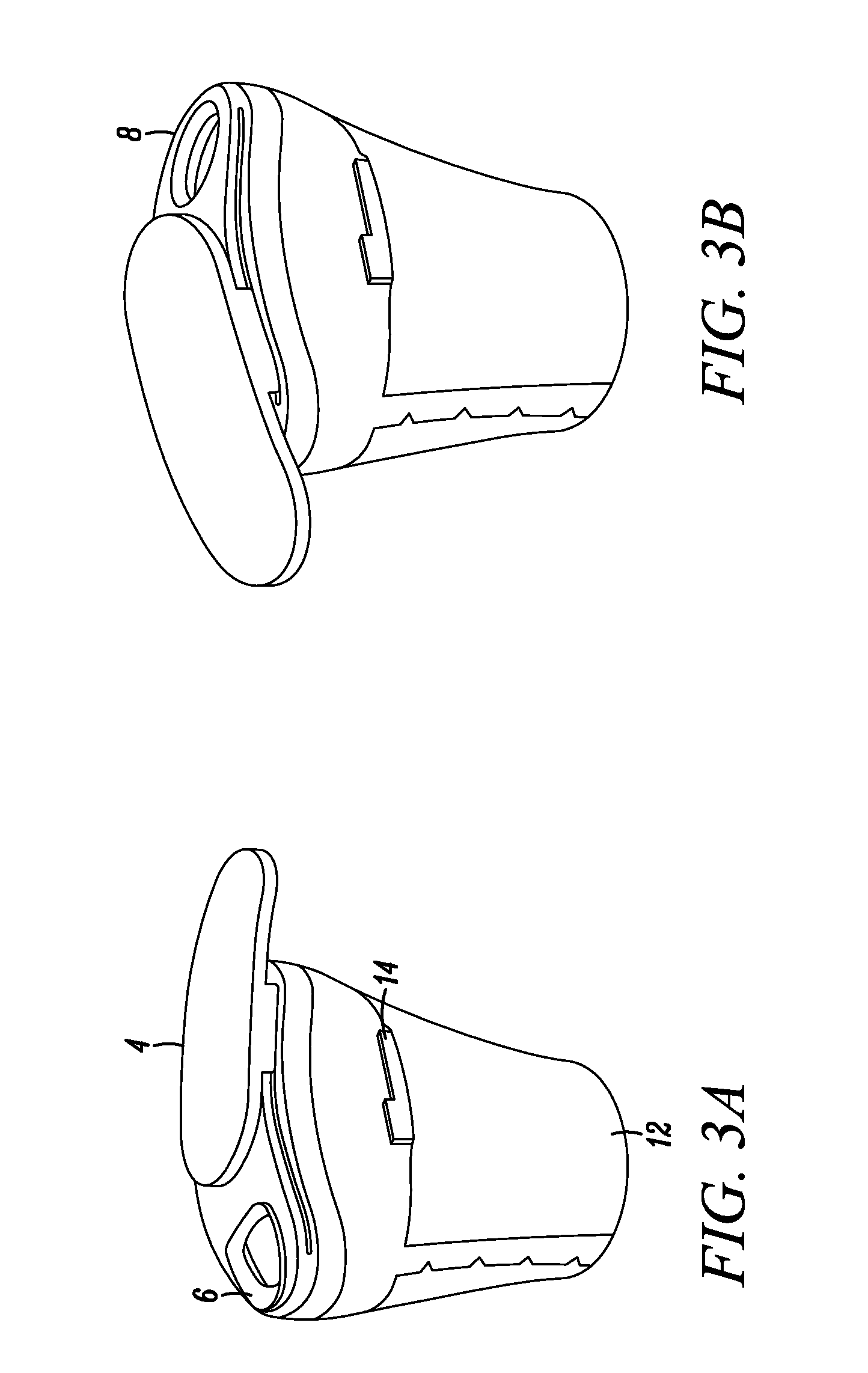

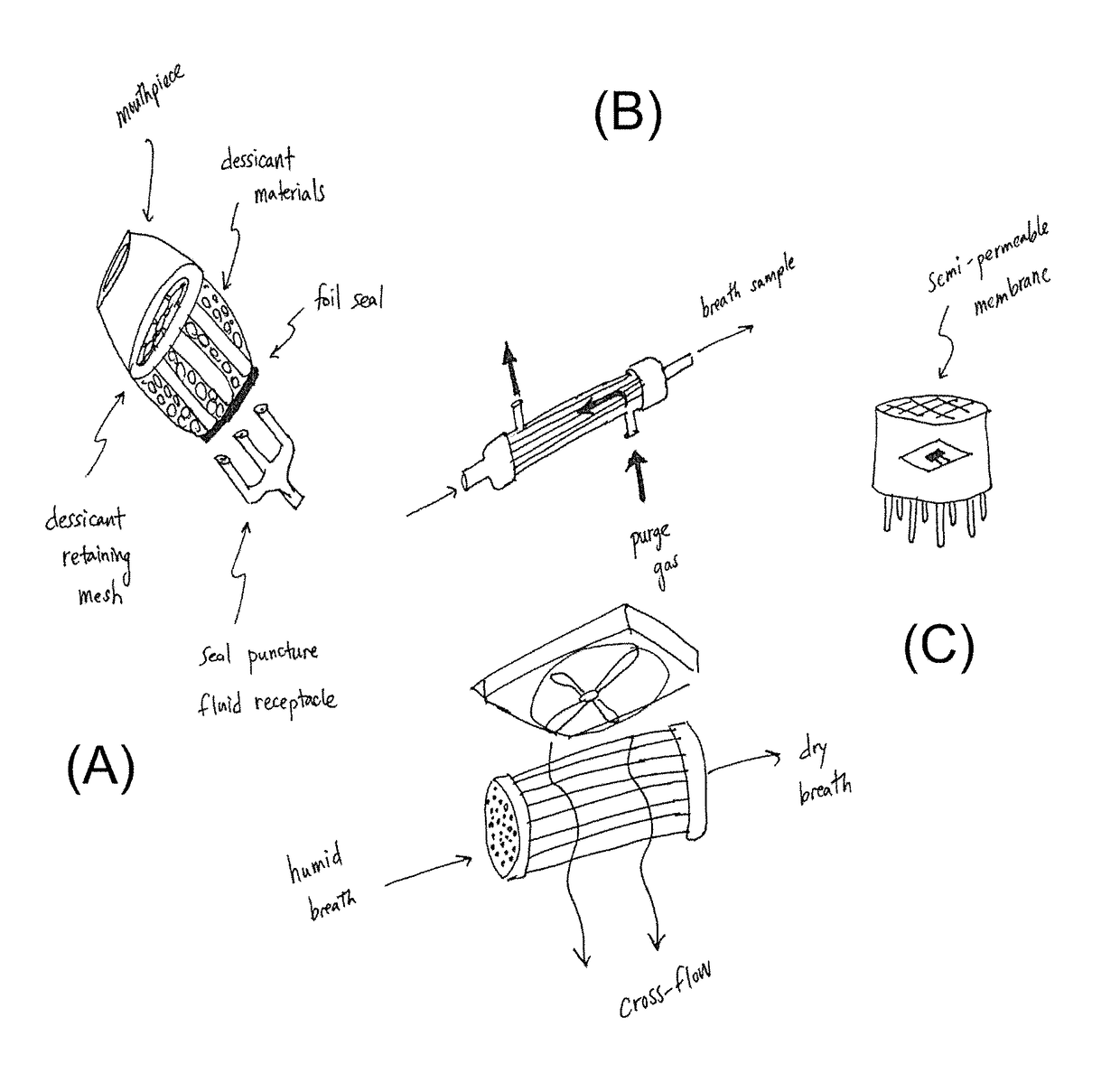

Breath analysis system, device and method employing nanoparticle-based sensor

According to one aspect of the invention, the apparatus comprises a fluid collecting device configured to receive a sample of breath; a conditioning device coupled to the fluid collecting device and configured to receive the sample of breath and condition the sample with respect to at least one of temperature, flow rate, pressure, humidity, and concentration; and a sensing device coupled to the conditioning device and configured to receive the conditioned sample, wherein the sensing device includes a nanoparticle-based sensor and further whereby the analyte interacts with the sensing device to cause a change that is sensed by the sensing device and wherein the change comprises information useful in characterizing the analyte. Preferably, the apparatus is hand-held and characterizing the analyte is useful for health monitoring.

Owner:INVOY HLDG INC

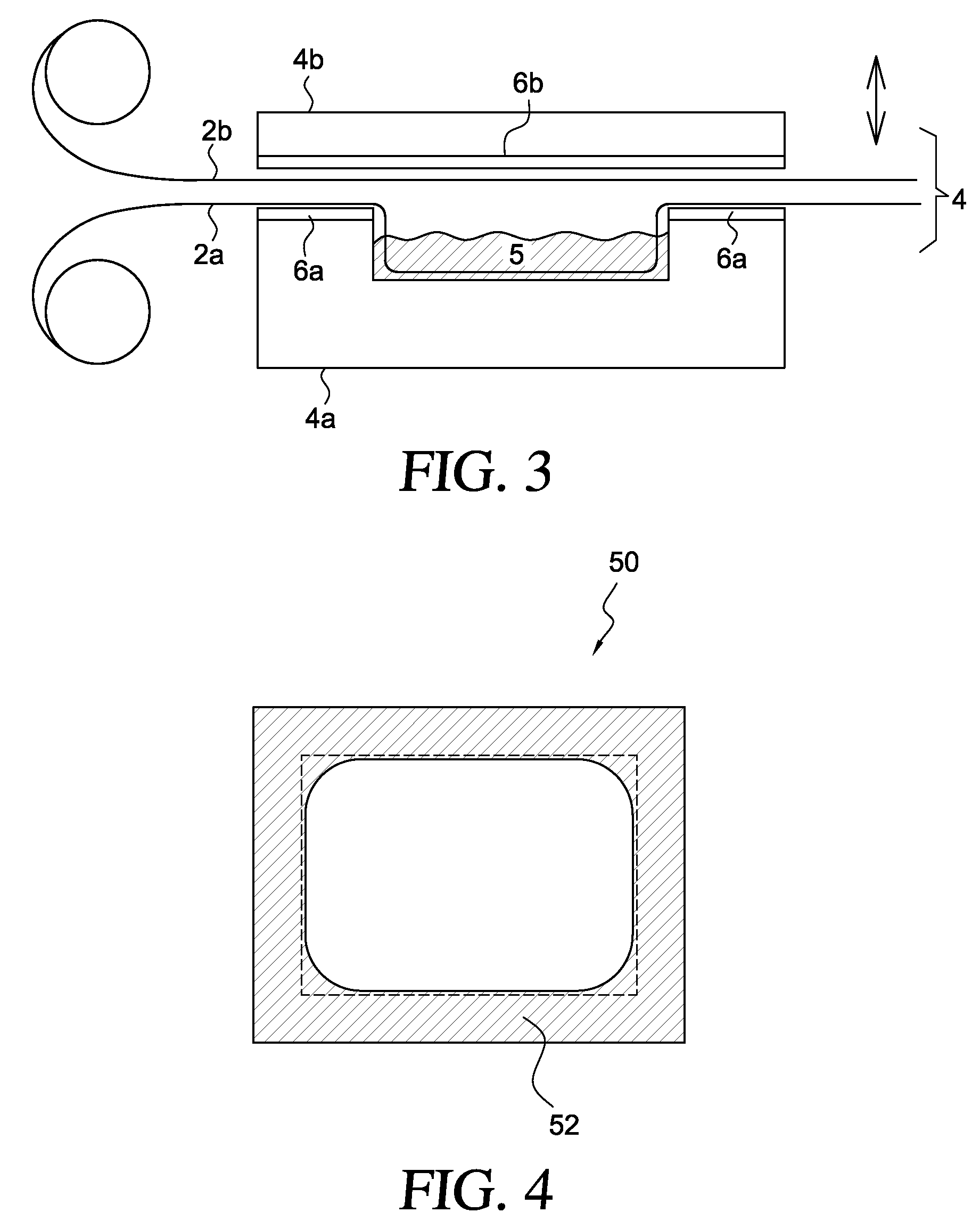

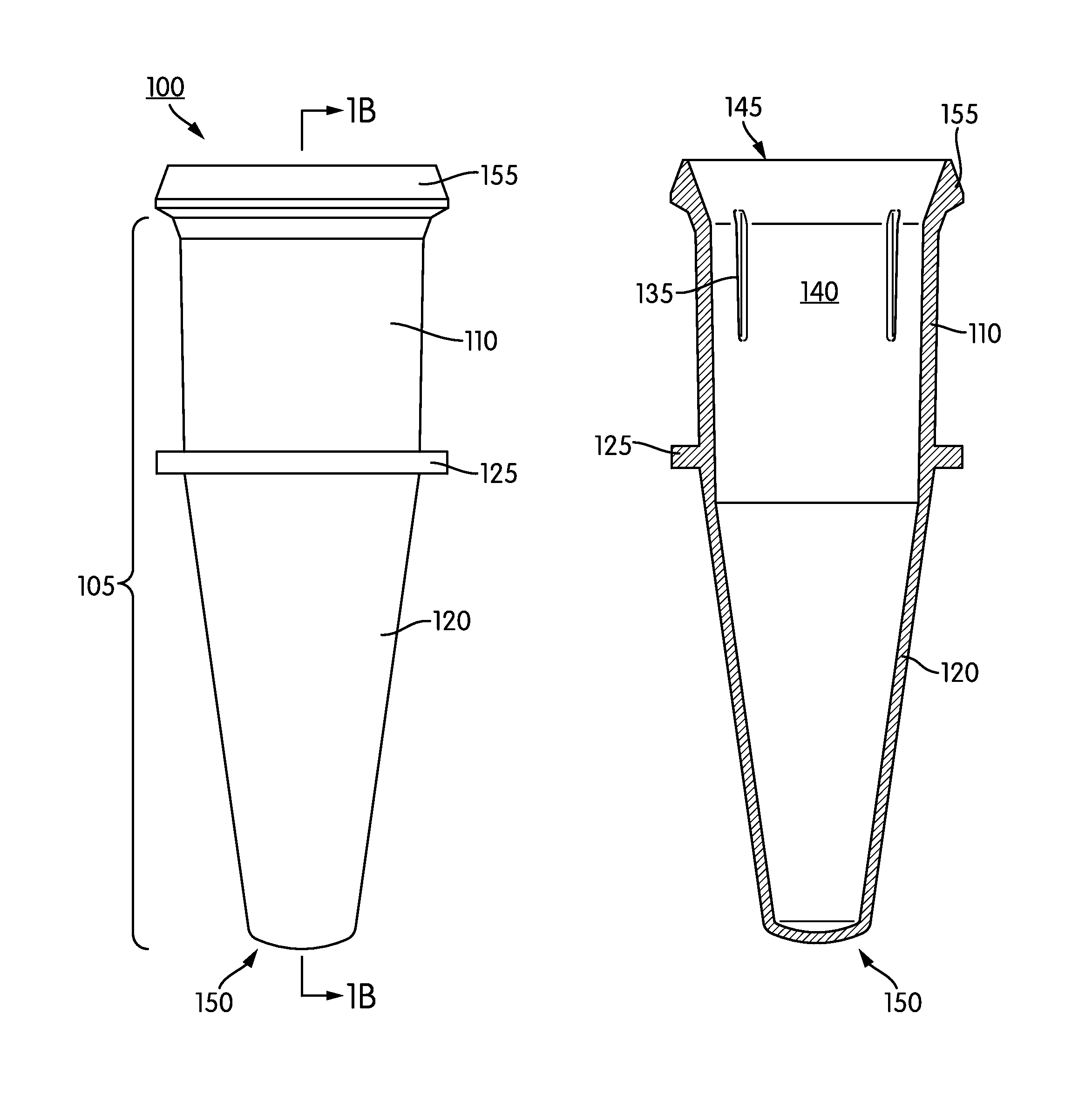

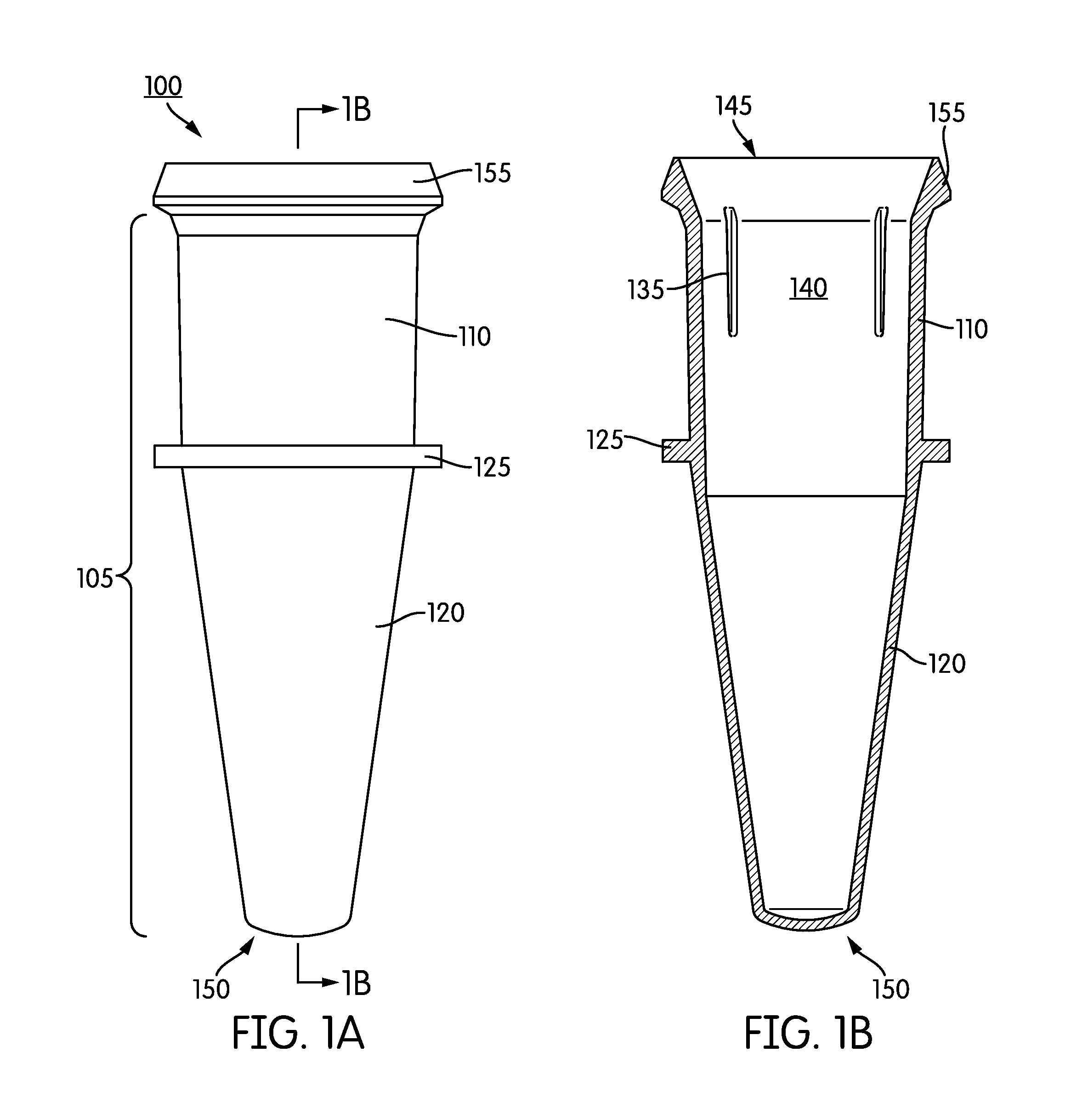

Dual chamber liquid packaging system

InactiveUS20140255275A1Improve puncture abilityReagent containersFluid controllersAnalyteEngineering

A packaging system with a dual chamber configuration is described. The packaging system is comprised of a primary chamber and a secondary chamber, where the primary chamber and the secondary chamber are in or capable of being in fluidic communication by a channel. The secondary chamber has an upper layer and a lower layer, wherein the lower layer is of a material that opens in response to an applied force that the upper layer is able to withstand, whereupon a fluid, preferably a liquid, in the primary chamber can be dispensed from the packaging system. In one embodiment, the packaging system is integrated with a planar cartridge having one or more chambers for processing a sample for detection of an analyte.

Owner:QUIDEL

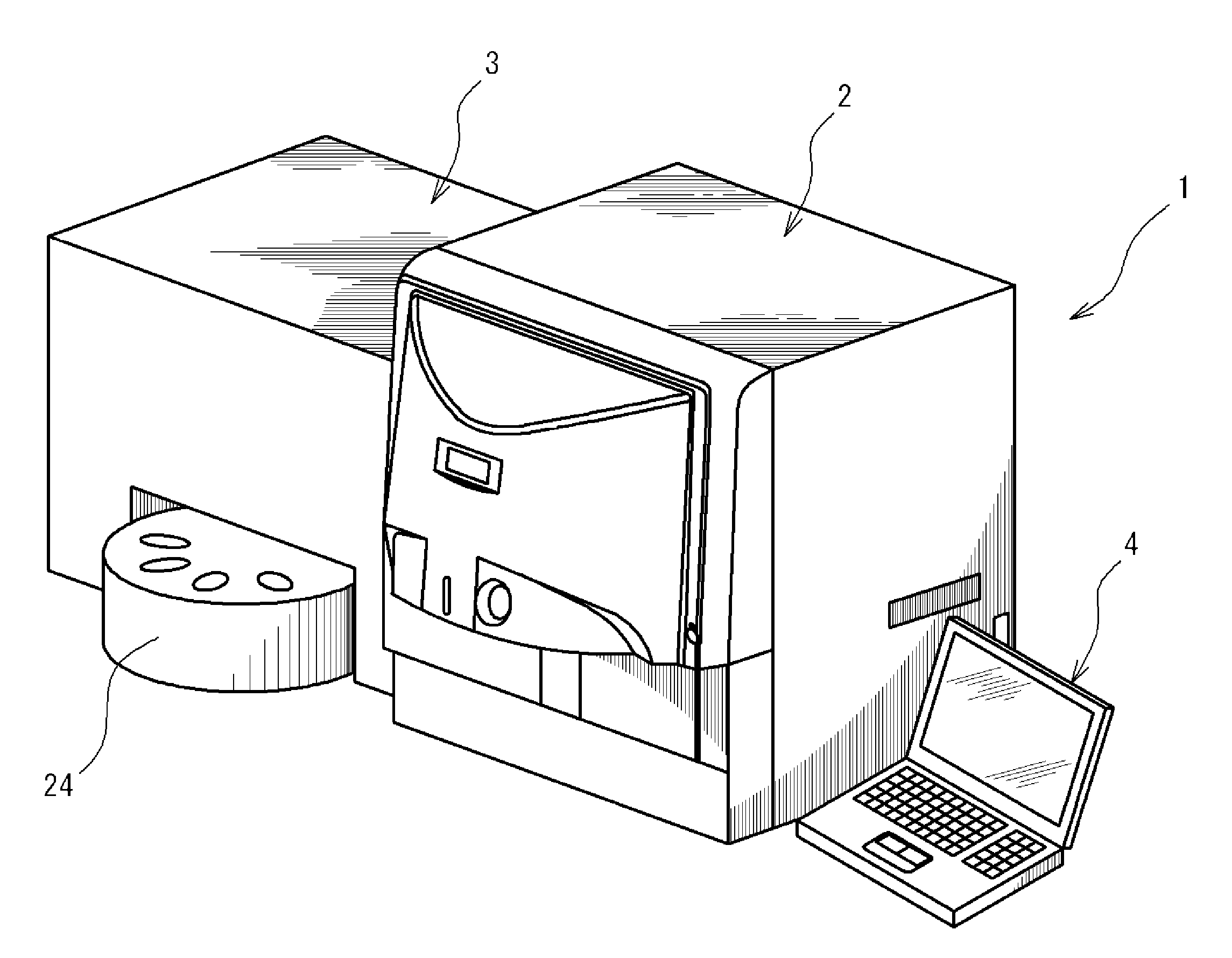

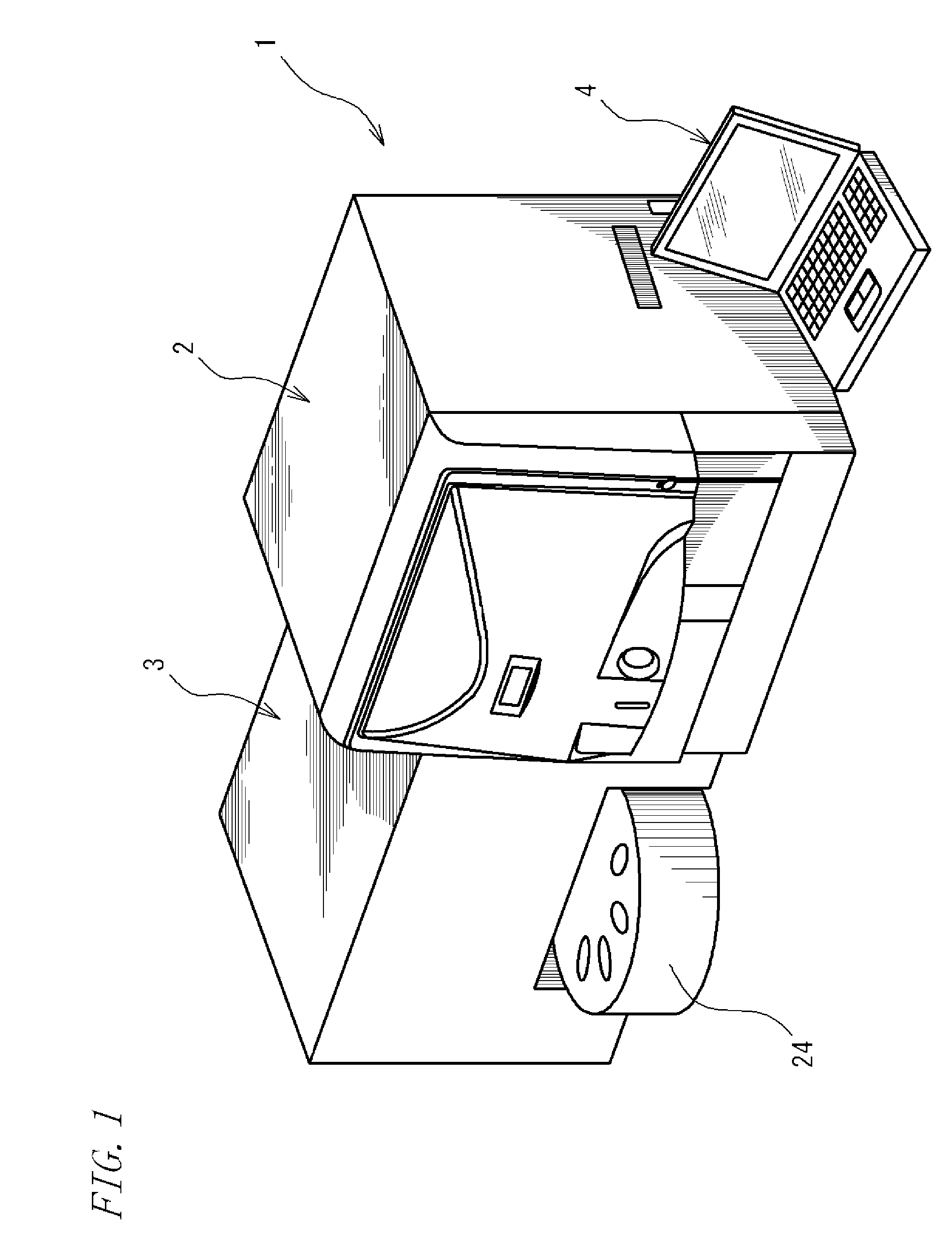

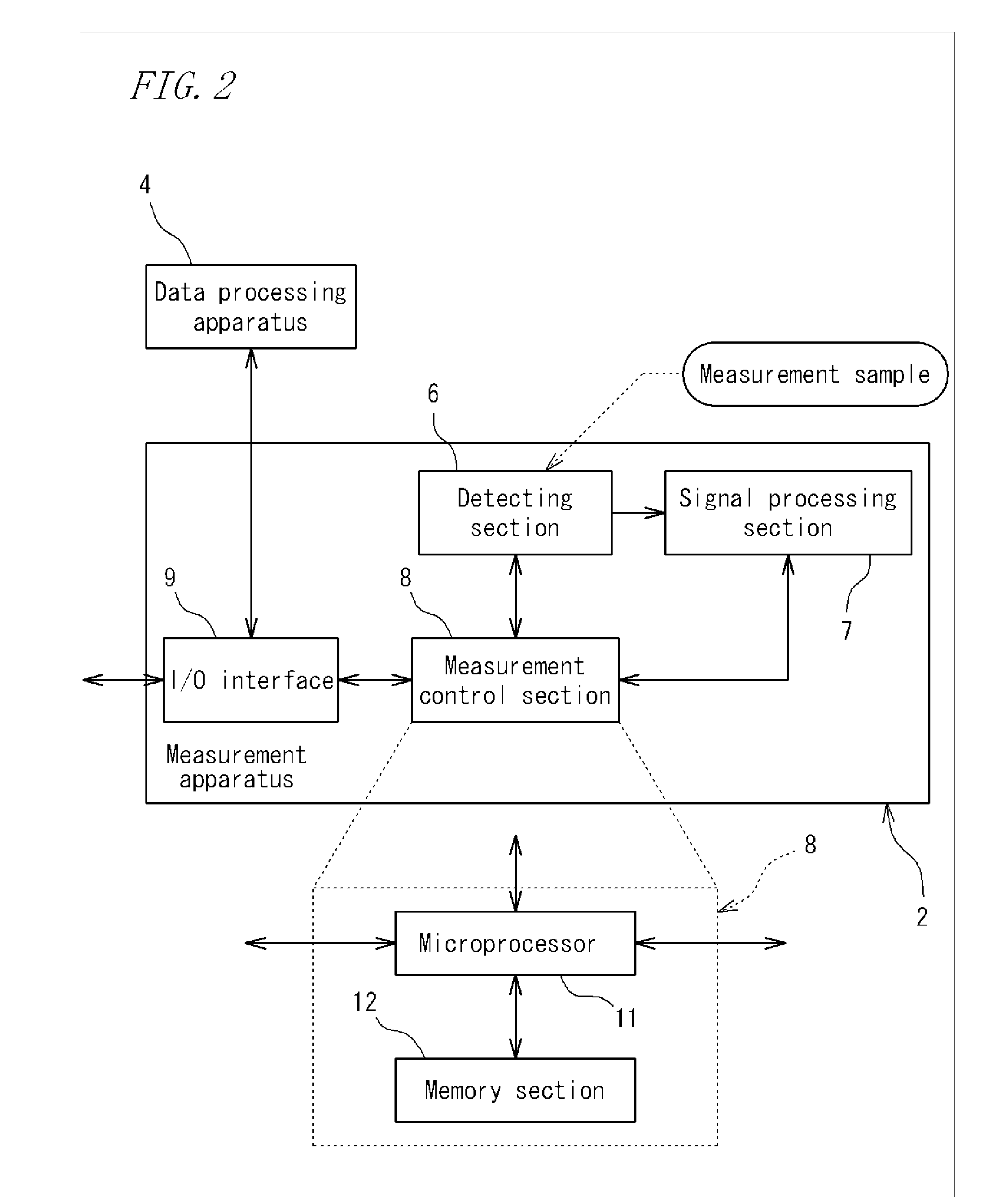

Sample preparation apparatus and cell analyzer

ActiveUS20110076755A1Increase concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationAnalytical chemistry

A sample preparation apparatus comprising: a storage chamber that can store therein a liquid sample including an analysis target to be analyzed; a concentrated sample storage chamber that is provided to communicate with the storage chamber and that stores therein concentrated liquid having an analysis target having a higher concentration than that of the liquid sample; and an analysis target transportation section for transporting the analysis target included in the liquid sample stored in the storage chamber to the concentrated sample storage chamber. A cell analyzer is also disclosed.

Owner:SYSMEX CORP

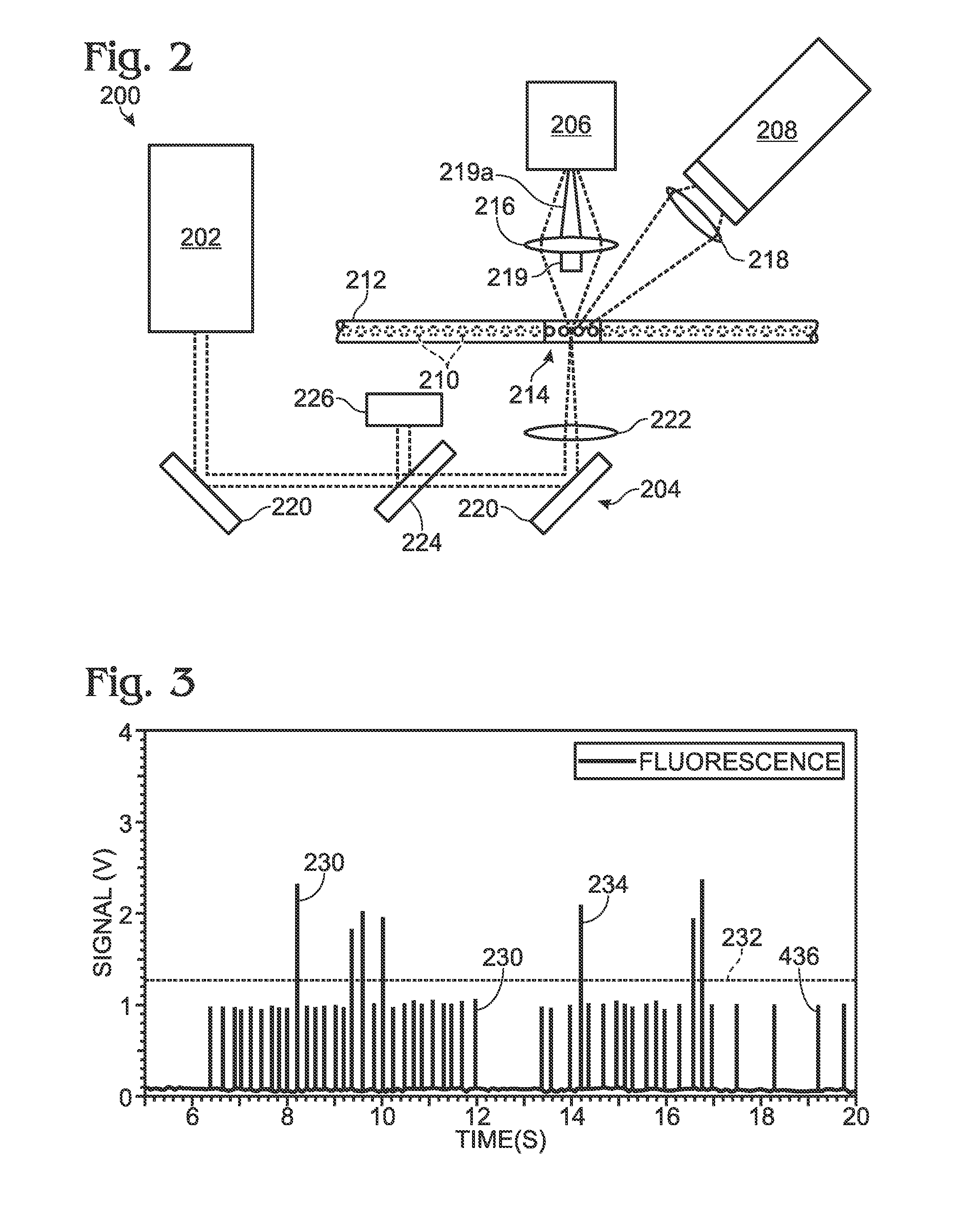

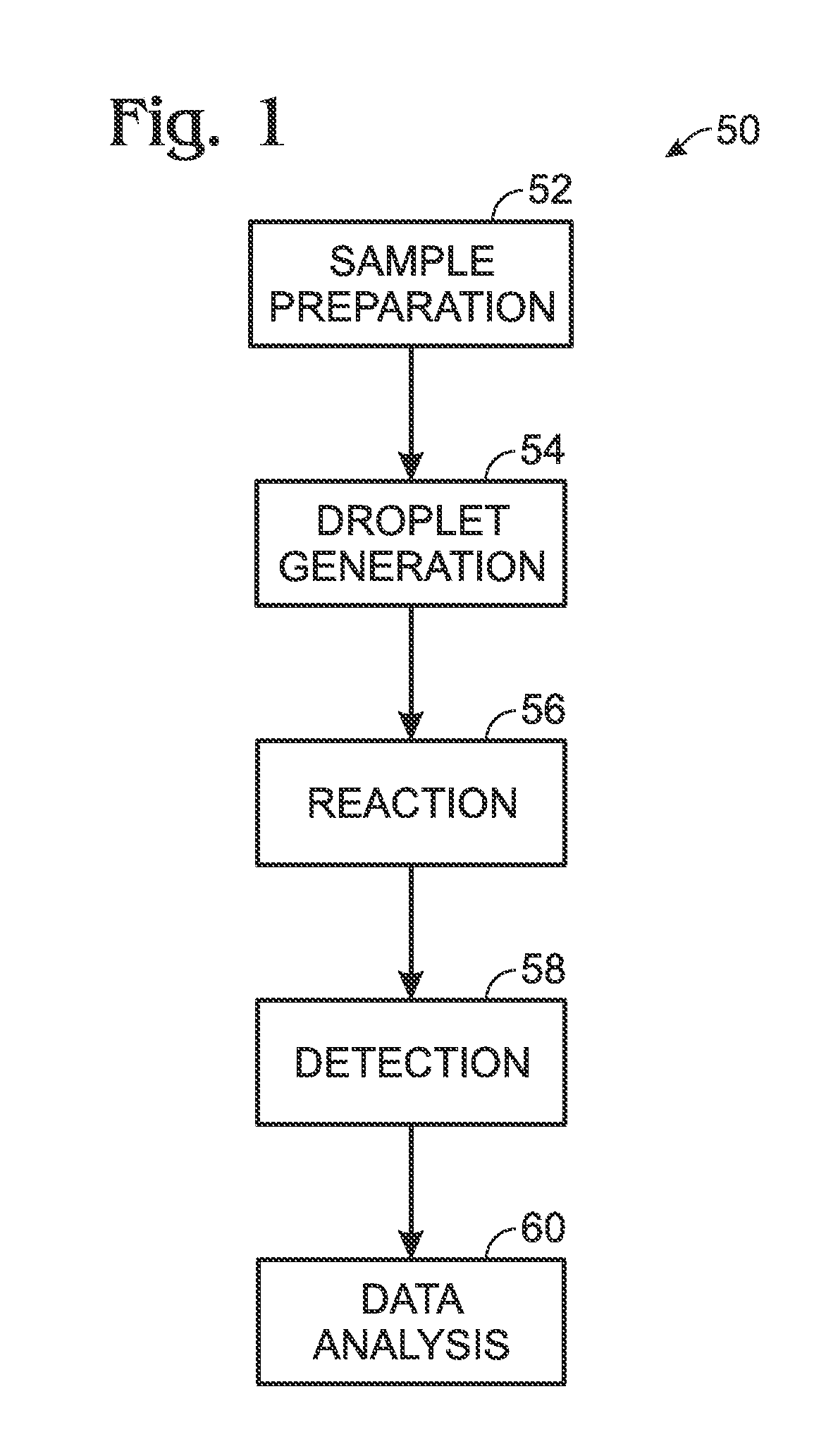

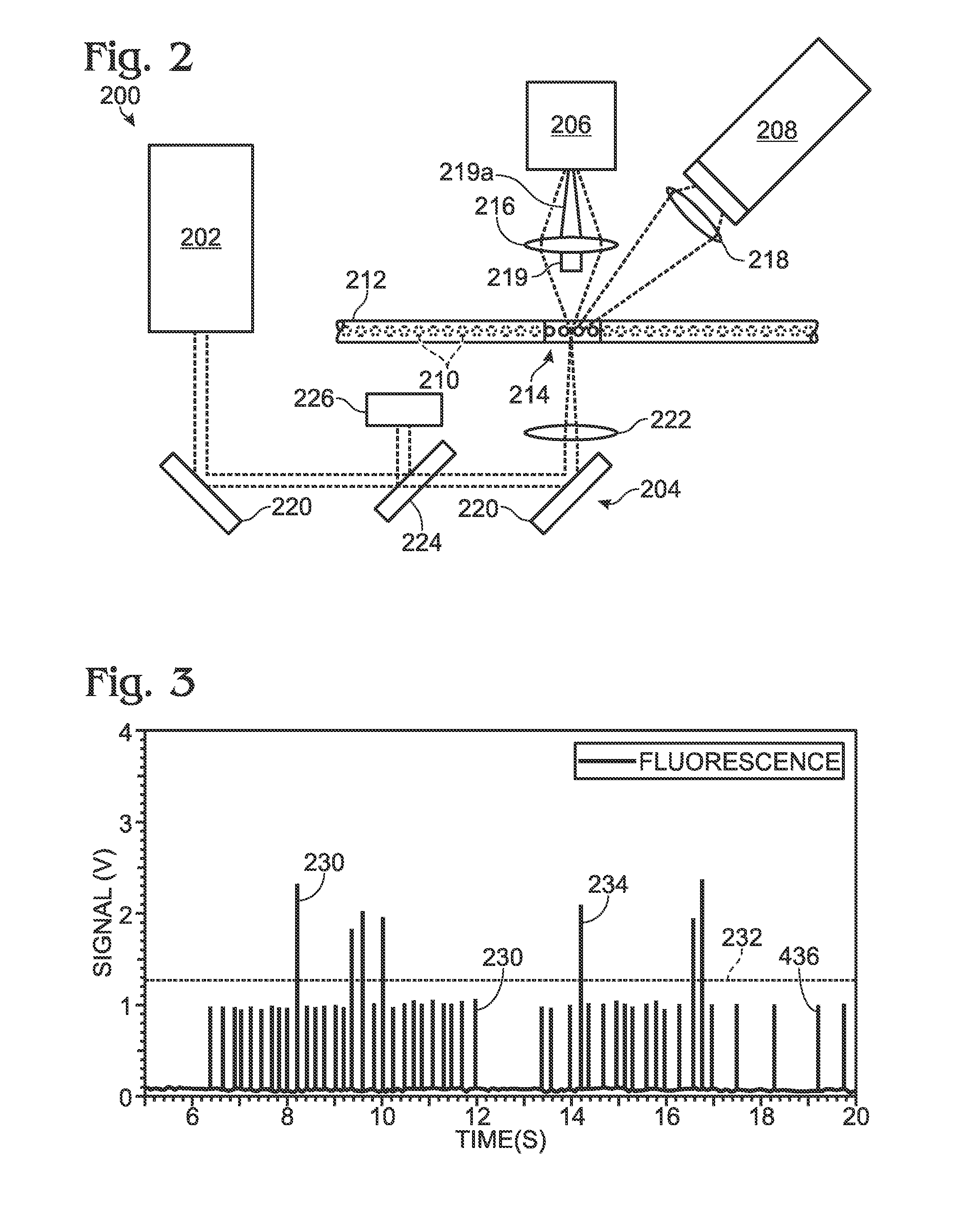

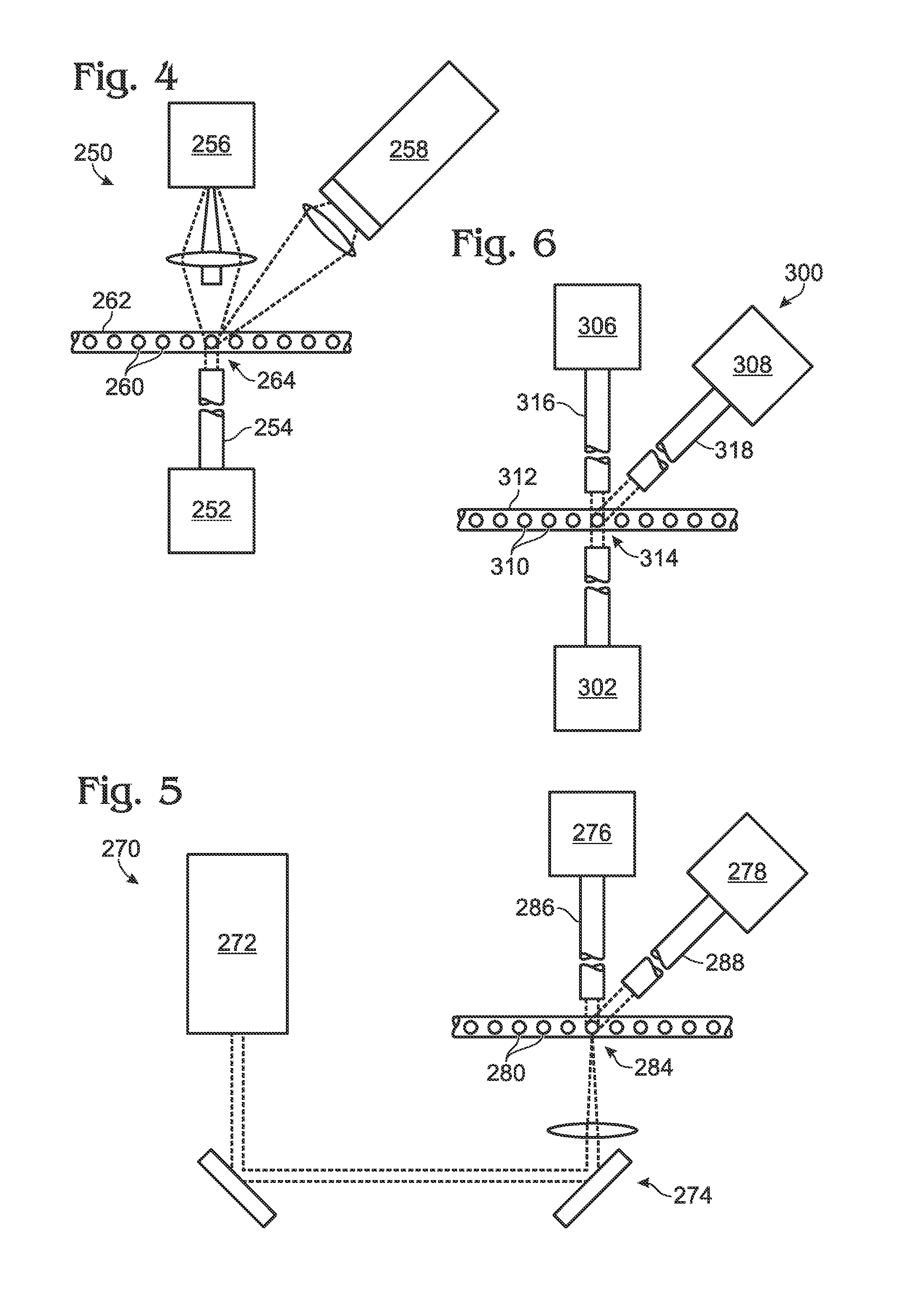

System for detection of spaced droplets

ActiveUS9492797B2High-confidence resultLower the volumeHeating or cooling apparatusReagent containersInlet channelEmulsion

Method of detection for droplet-based assays. In an exemplary method, an open end of a channel network may be placed into an emulsion. Droplets of the emulsion may be driven along a flow path from the open end, through a confluence region where a dilution fluid is introduced into the flow path from at least one dilution inlet channel to increase an average distance between droplets, and through an examination region disposed downstream of the confluence region. Light may be detected from the examination region as droplets pass through. The channel network may include a droplet inlet channel that meets the at least one dilution inlet channel at the confluence region. The droplet inlet channel may form a tapered region that is sized such that droplets leave the tapered region in single file.

Owner:BIO RAD LAB INC

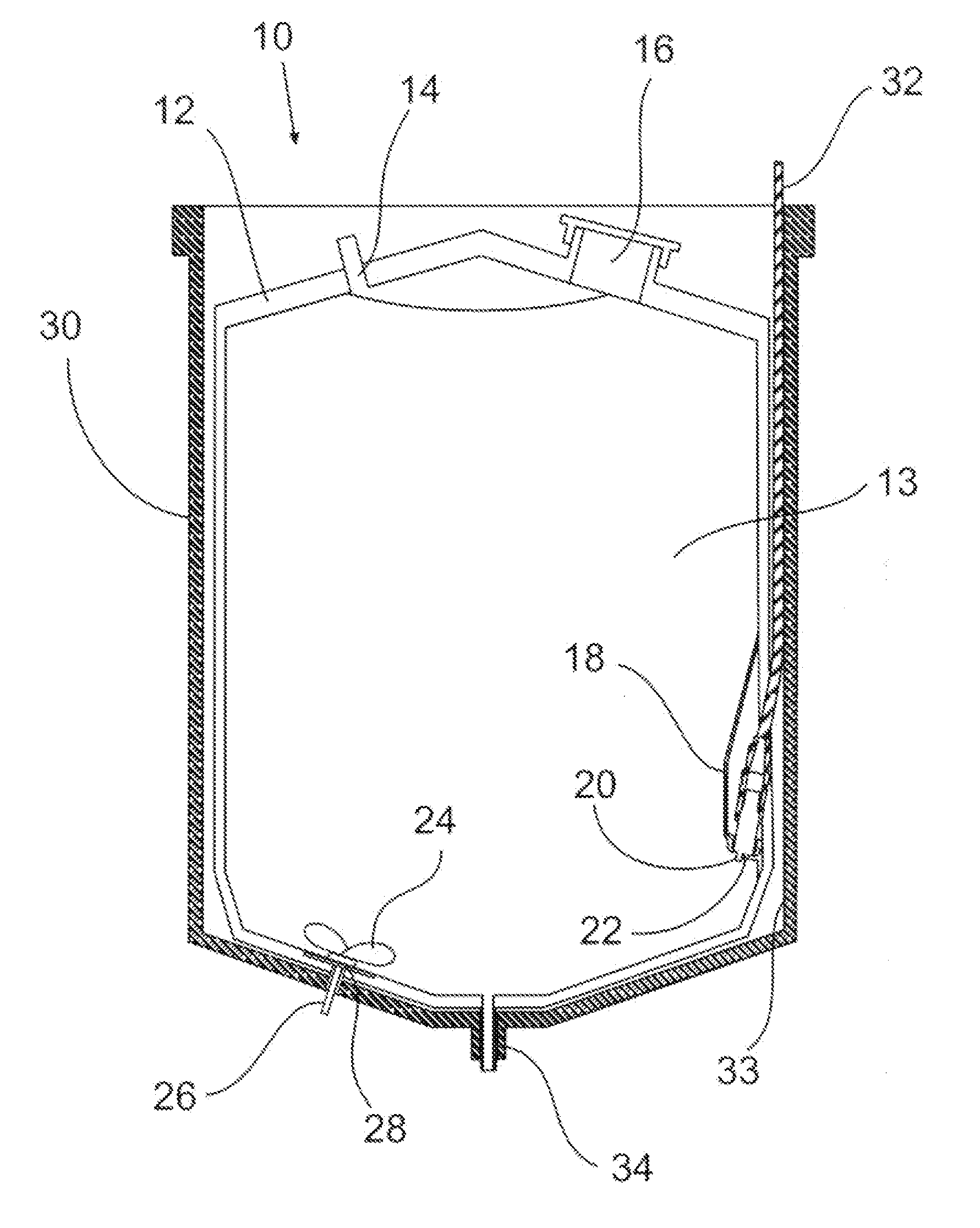

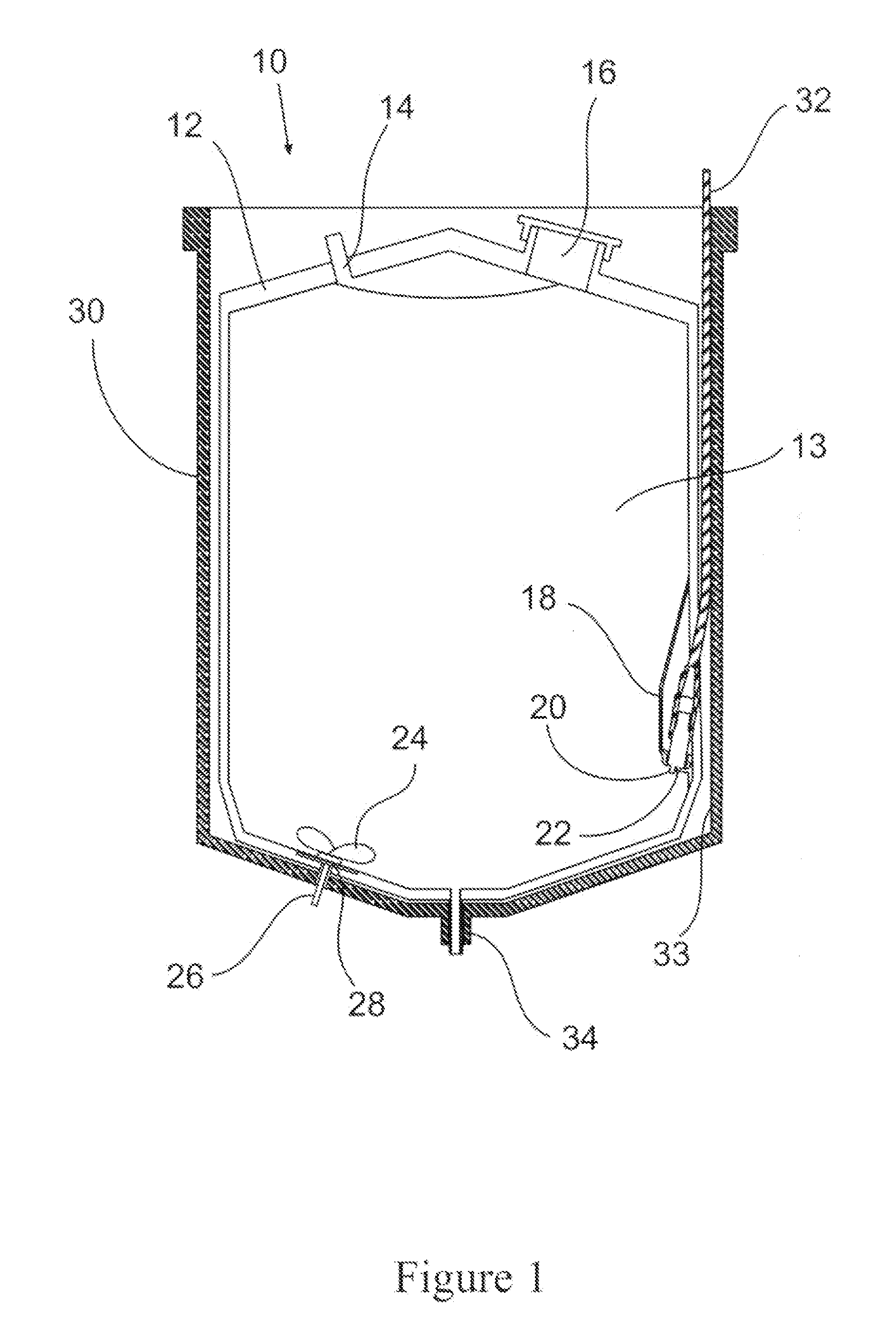

Process bag container with sensors

ActiveUS20110249526A1Affecting its functionReagent containersRotary stirring mixersEngineeringData transmission

A process bag container is provided comprising a flexible bag, at least one inlet sealed to the bag, and an outlet. A probe housing for a probe construction is sealed to the bag. Preferably, the probe housing extends at least partway into the bag interior and is connected to a cable for power and data transmission that runs along the outer surface of the bag to the top of the bag or its support container. The probe construction is adapted to monitor the composition of a reagent in the bag as well as the environment within the bag. A mixer is positioned within the bag to effect mixing of reagents in the bag.

Owner:MILLIPORE CORP

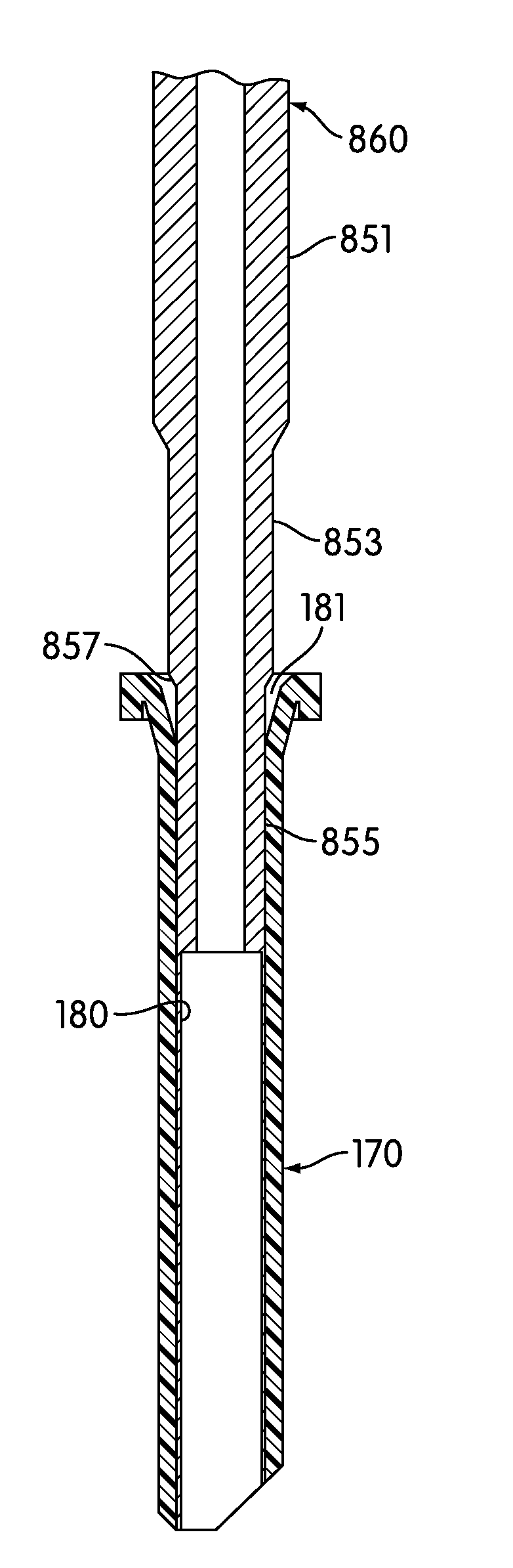

Apparatus and method for preparation of small volume of samples

A method and device for sample preparation. A capillary having adherent internal desiccated reagent is held by a housing, with one capillary end extending from the housing. A dock on the housing allows a dispense module to be docked onto the housing and dispense the contents of the capillary.

Owner:INOVX

System for detection of spaced droplets

ActiveUS20140200164A1High-confidence resultLower the volumeHeating or cooling apparatusMixing methodsComputational physics

Owner:BIO RAD LAB INC

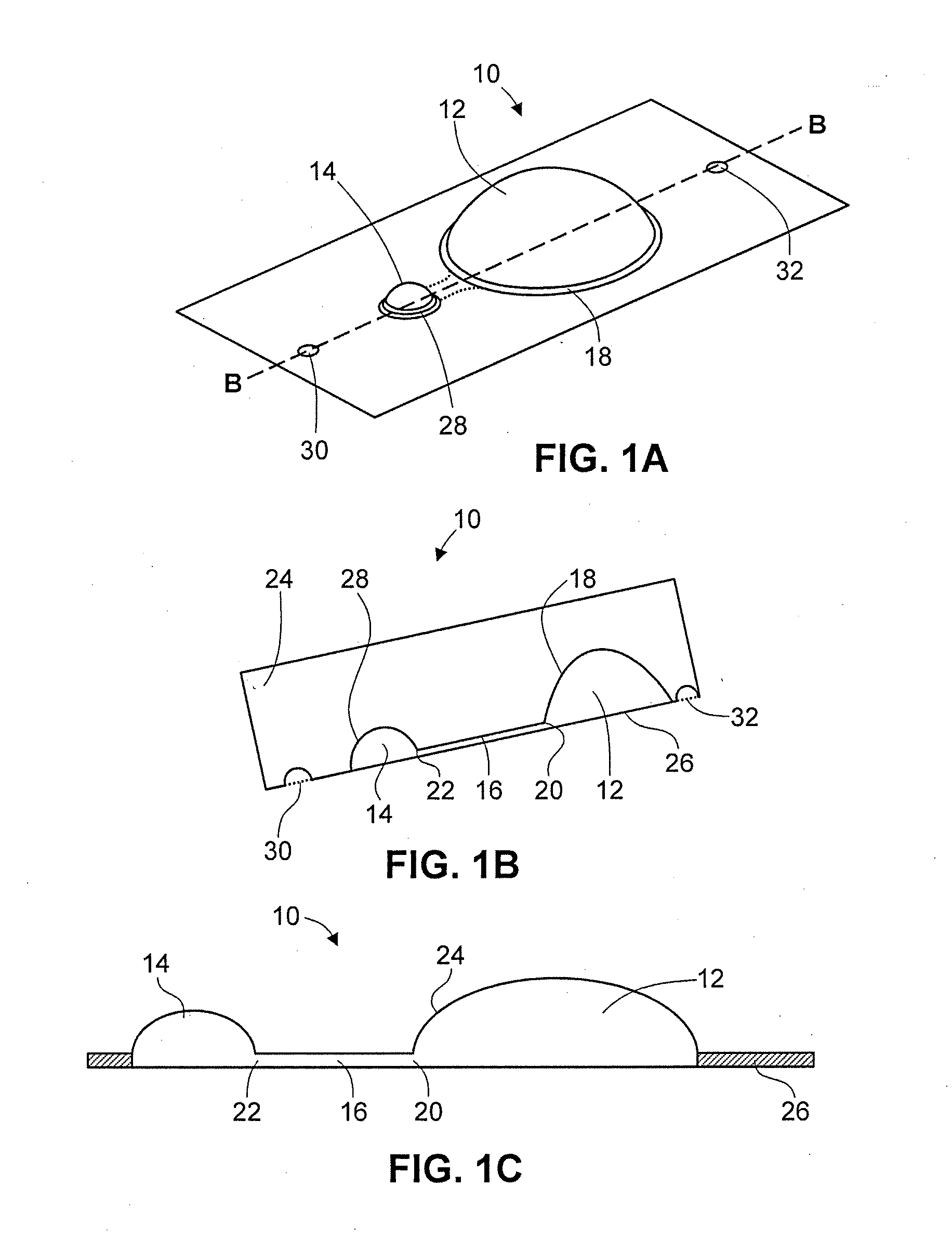

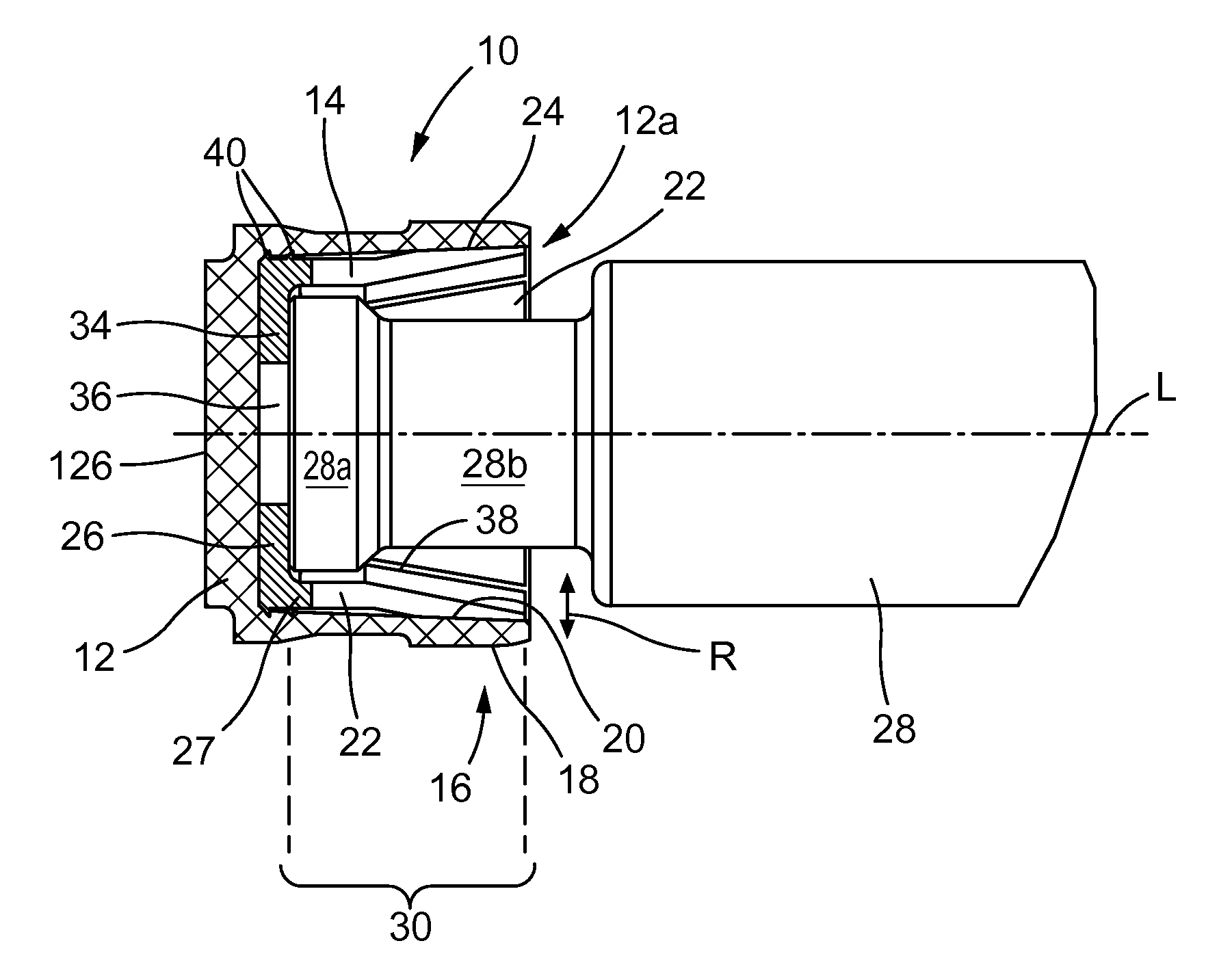

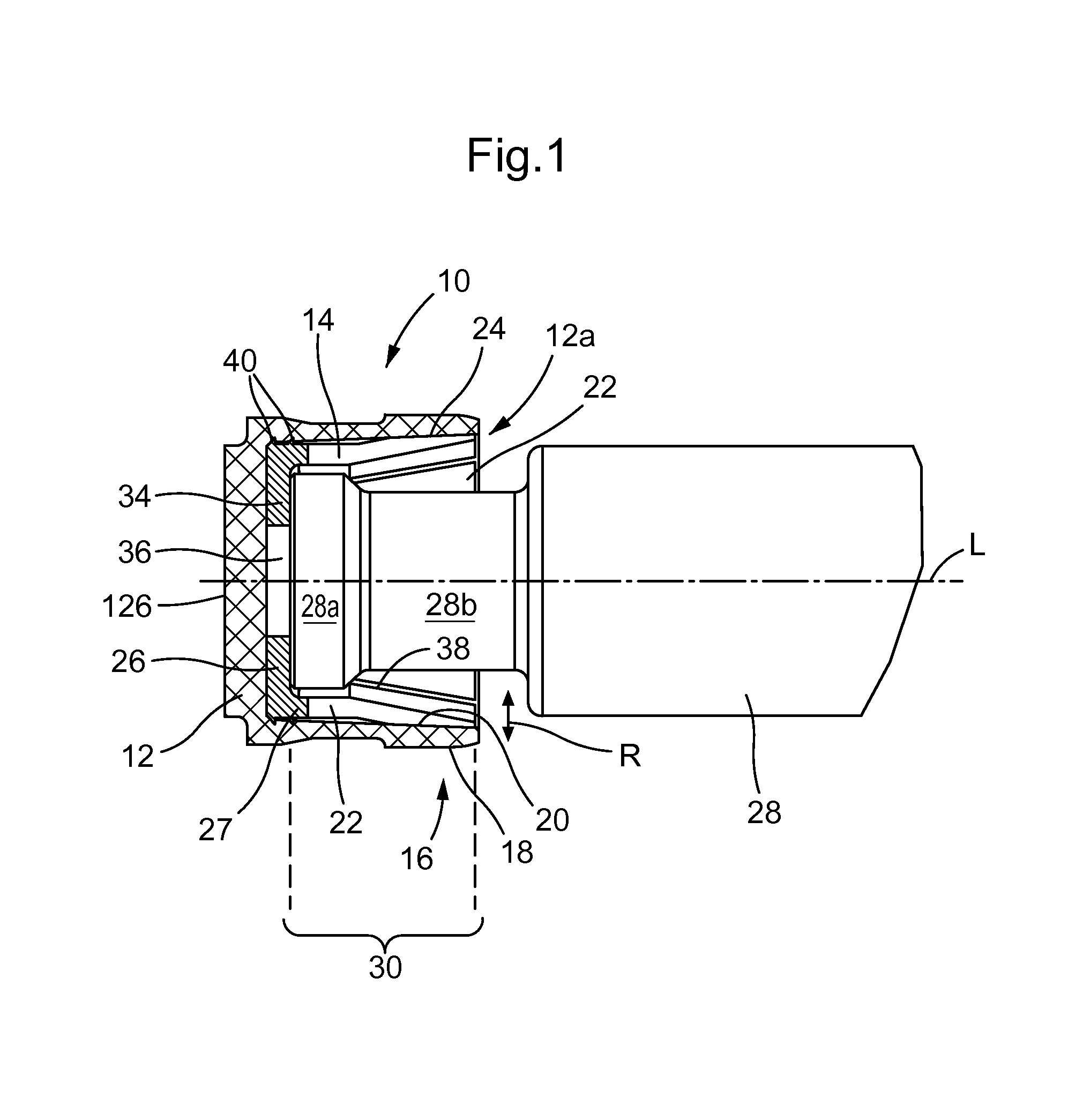

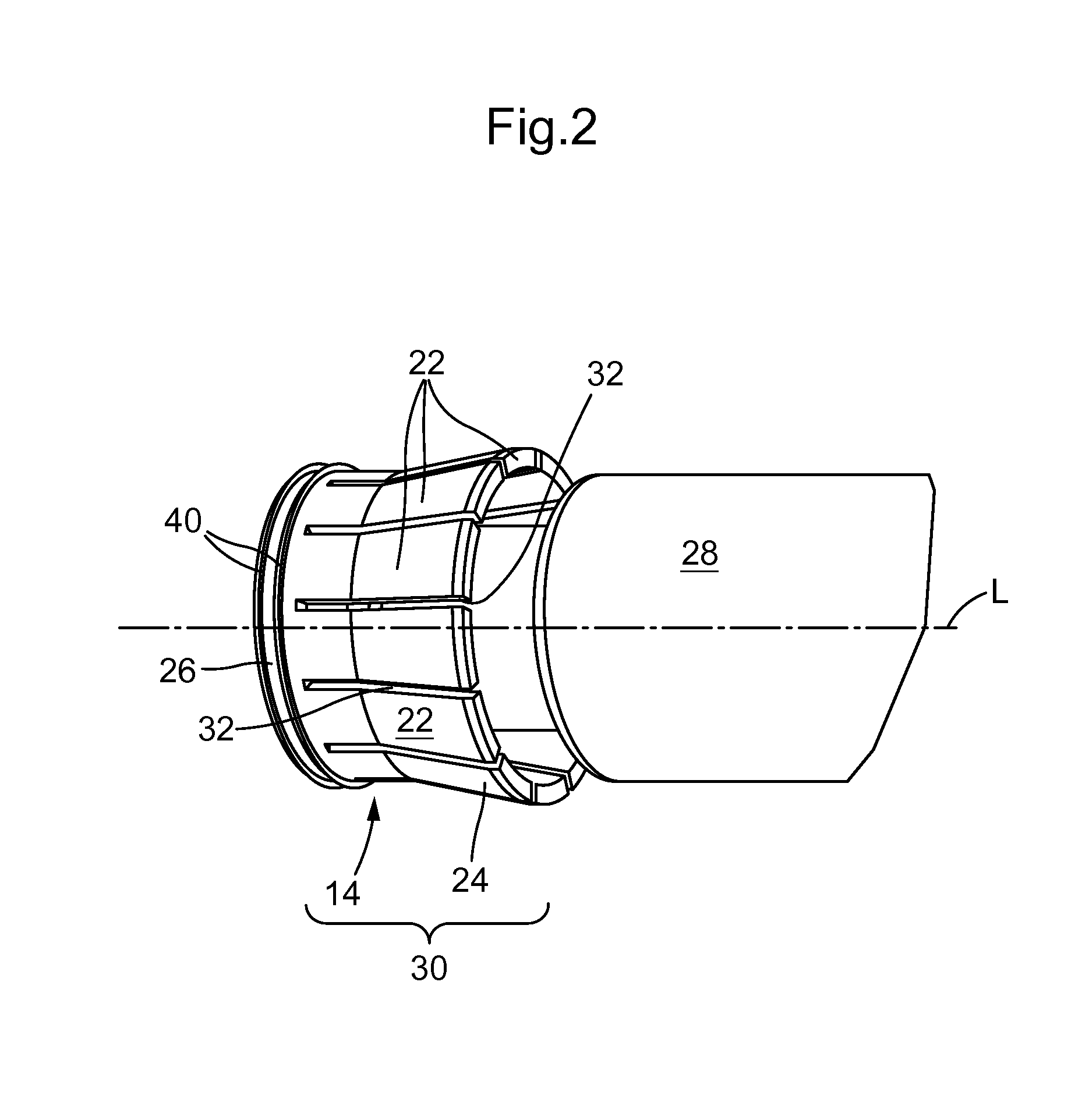

Radial sliding seal component for metering devices and metering device having such a radial sliding seal component

ActiveUS8557197B2Optimization definitionSmall geometryEngine sealsPiston ringsContact formationEngineering

The invention relates to a radial sliding seal component (10), particularly for use in metering devices, such as syringes, pipetting piston-cylinder arrangements, and the like, comprising a sealing component (12) working together with at least one pretensioning component (14), wherein the sealing component (12) comprises a sealing segment (16) extending in the axial direction and in the circumferential direction, preferably running in the circumferential direction, on which a sealing surface (18) facing in a first radial direction for sealing and sliding contact in at least the axial direction is formed on a working surface extending in the axial direction and in the circumferential direction, preferably running in the circumferential direction, and on which a pretensioning surface (20) extending in a second radial direction opposite to the first is formed for engaging with the pretensioning component (14) for transferring the radial pretensioning force, wherein the pretensioning component (14) comprises a spring carrier (26) and a plurality of separately formed radial spring segments (22) compliantly supported at least in the radial direction on the spring carrier (26).

Owner:HAMILTON BONADUZ AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com