Patents

Literature

78results about How to "Improve puncture ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

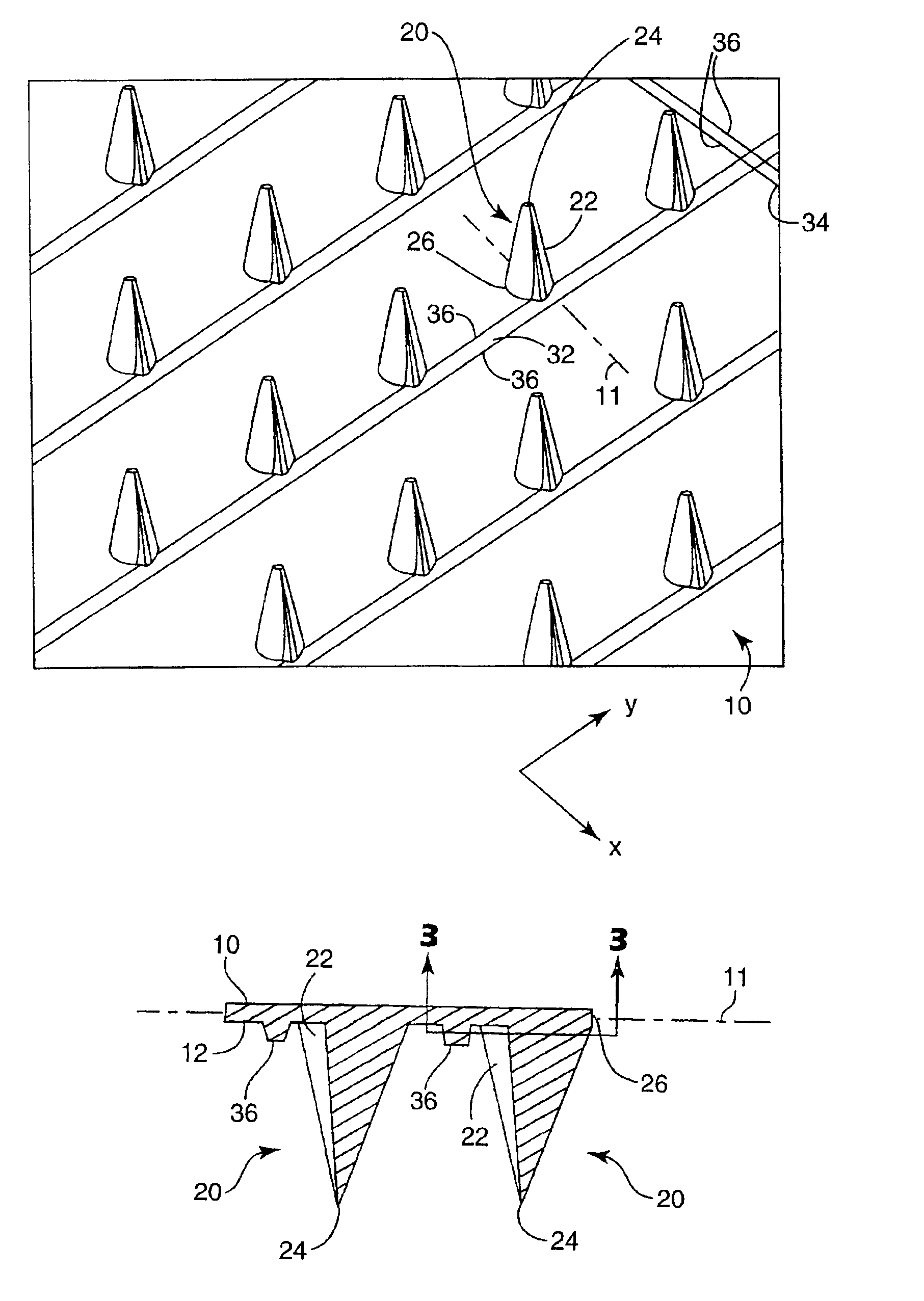

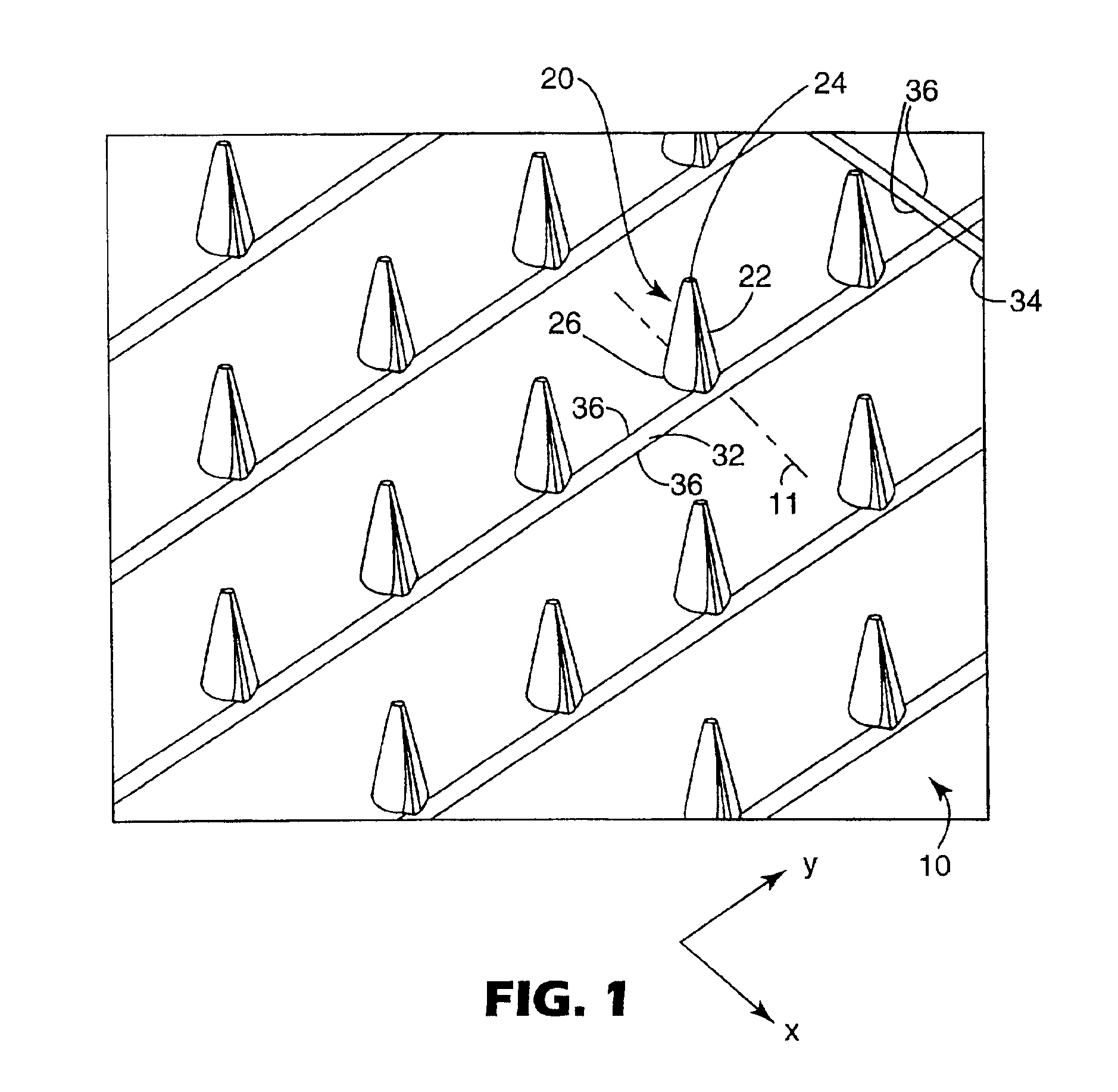

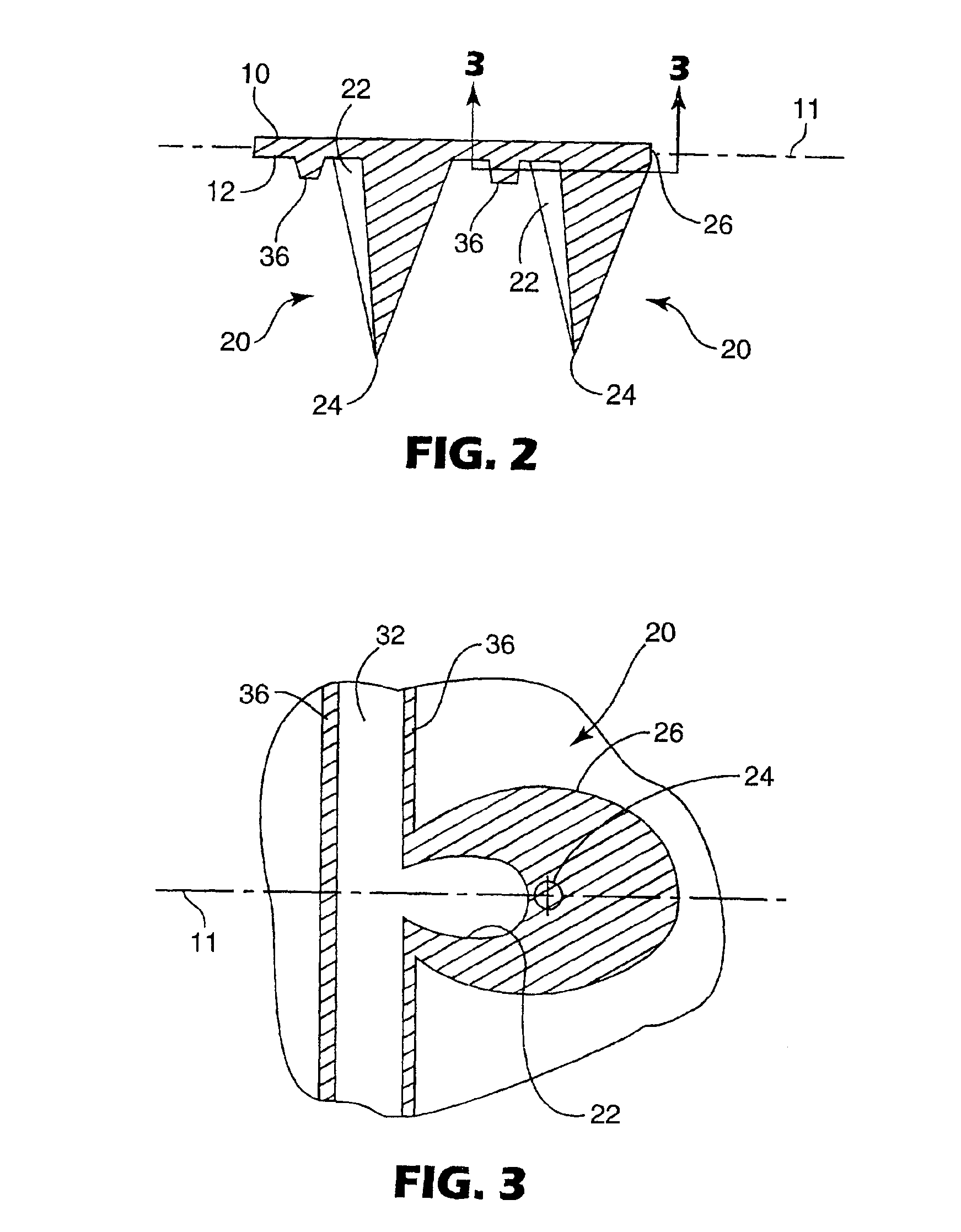

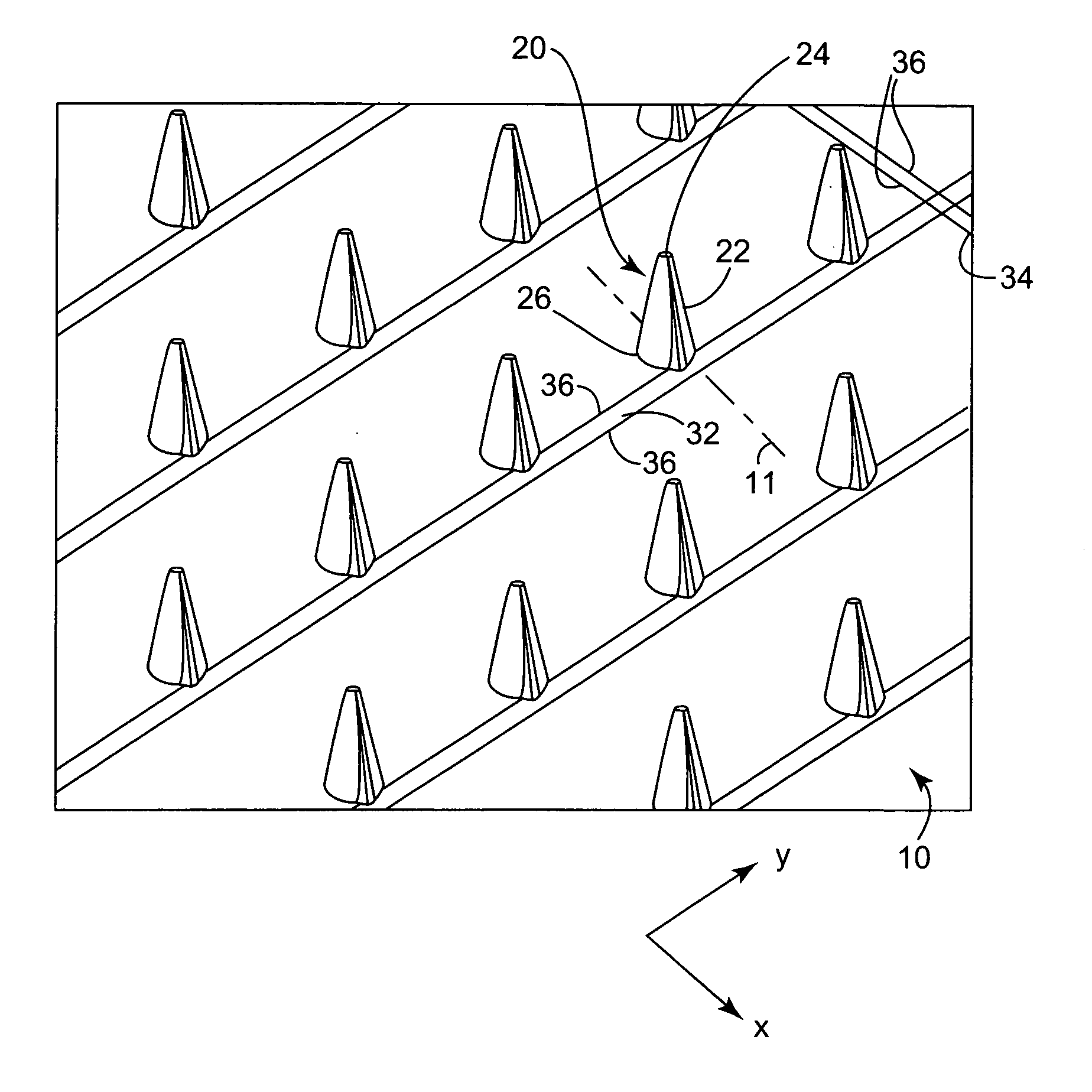

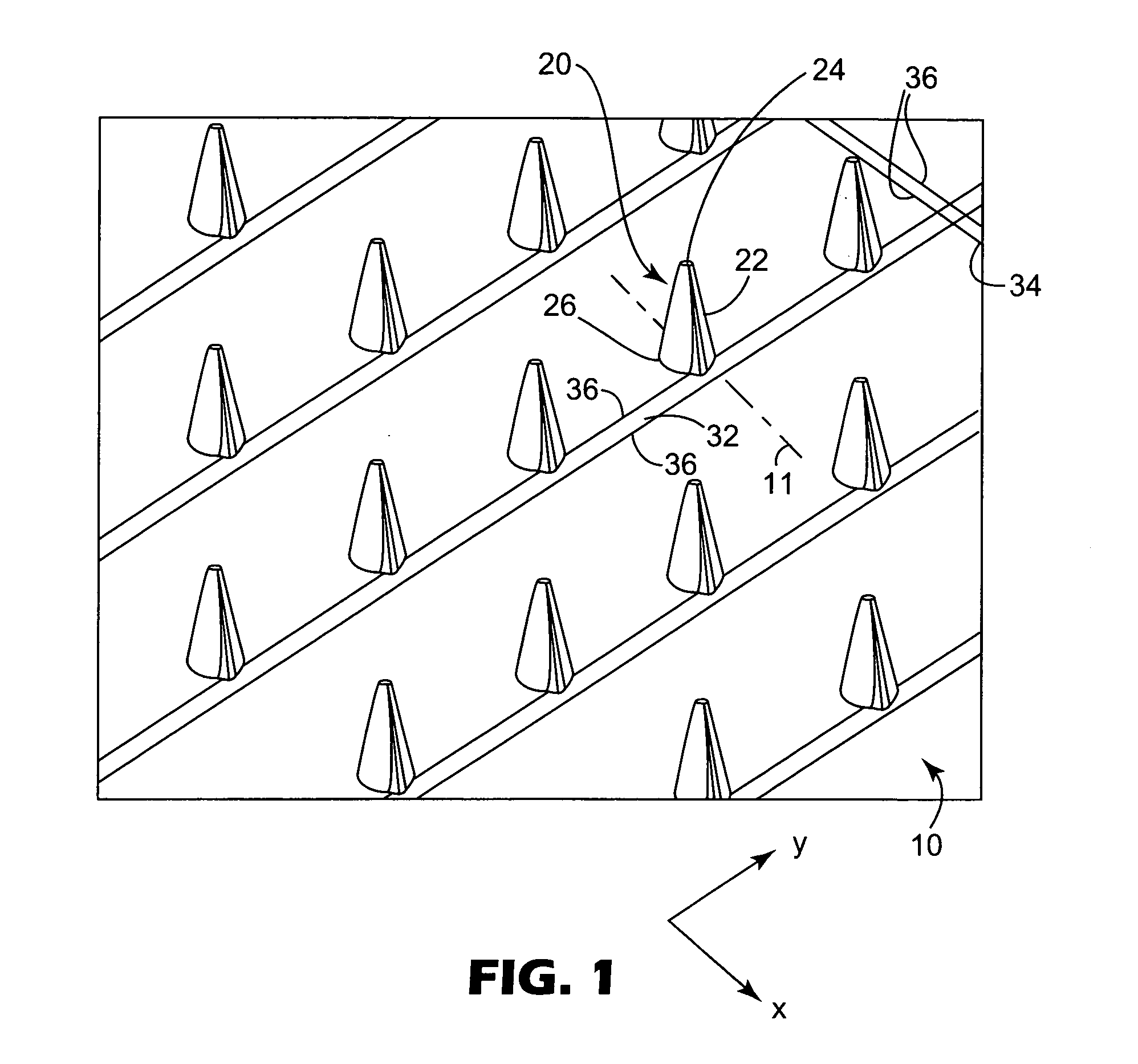

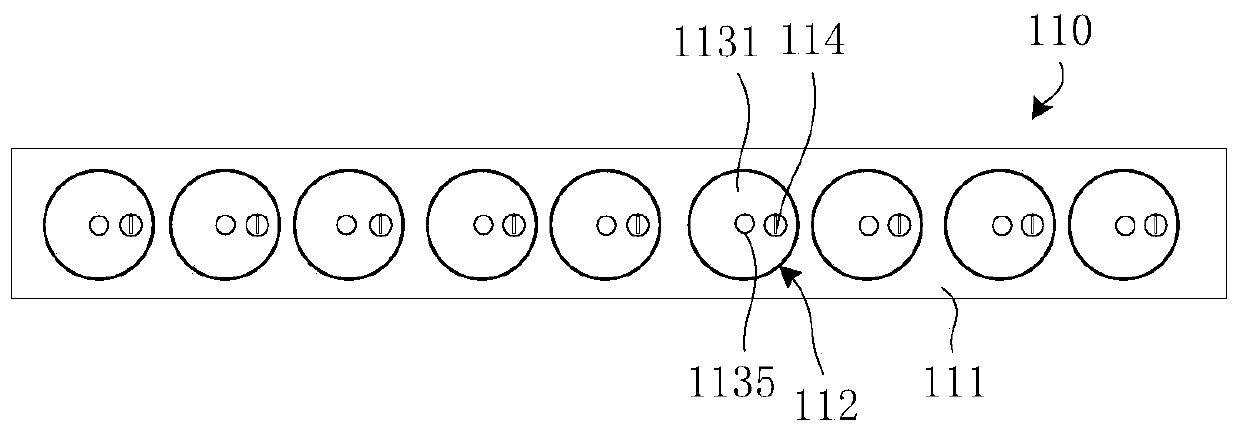

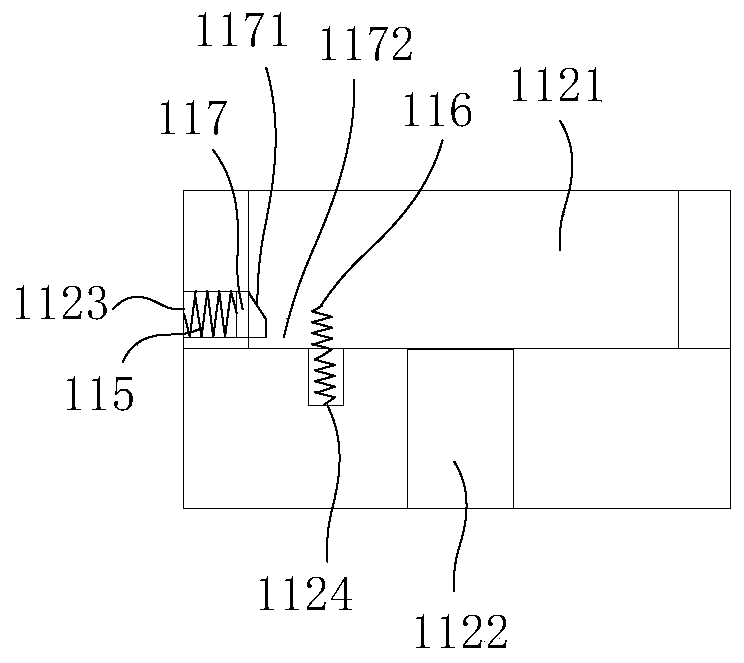

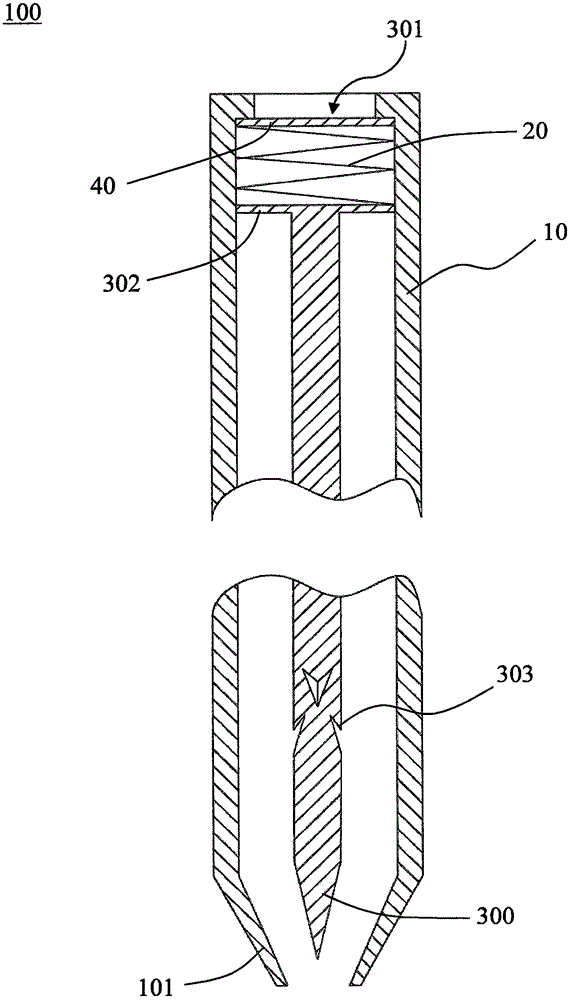

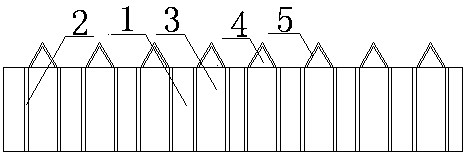

Microneedle arrays and methods of manufacturing the same

InactiveUS6881203B2Additional rigidity and structural integrityImprove puncture abilitySurgeryMicroneedlesCatheterMicro-needle

Microneedle arrays, methods of manufacturing microneedles and methods of using microneedle arrays. The microneedles in the microneedle arrays may be in the form of tapered structures that include at least one channel formed in the outside surface of each microneedle. The microneedles may have bases that are elongated in one direction. The channels in microneedles with elongated bases may extend from one of the ends of the elongated bases towards the tips of the microneedles. The channels formed along the sides of the microneedles may optionally be terminated short of the tips of the microneedles. The microneedle arrays may also include conduit structures formed on the surface of the substrate on which the microneedle array is located. The channels in the microneedles may be in fluid communication with the conduit structures. One manner of using microneedle arrays of the present invention is in methods involving the penetration of skin to deliver medicaments or other substances and / or extract blood or tissue.

Owner:3M INNOVATIVE PROPERTIES CO

Microneedle arrays and methods of manufacturing the same

InactiveUS20050143713A1Additional rigidity and structural integrityImprove puncture abilityAutomatic syringesMicroneedlesCatheterTissue skin

Microneedle arrays, methods of manufacturing microneedles and methods of using microneedle arrays. The microneedles in the microneedle arrays may be in the form of tapered structures that include at least one channel formed in the outside surface of each microneedle. The microneedles may have bases that are elongated in one direction. The channels in microneedles with elongated bases may extend from one of the ends of the elongated bases towards the tips of the microneedles. The channels formed along the sides of the microneedles may optionally be terminated short of the tips of the microneedles. The microneedle arrays may also include conduit structures formed on the surface of the substrate on which the microneedle array is located. The channels in the microneedles may be in fluid communication with the conduit structures. One manner of using microneedle arrays of the present invention is in methods involving the penetration of skin to deliver medicaments or other substances and / or extract blood or tissue.

Owner:3M INNOVATIVE PROPERTIES CO

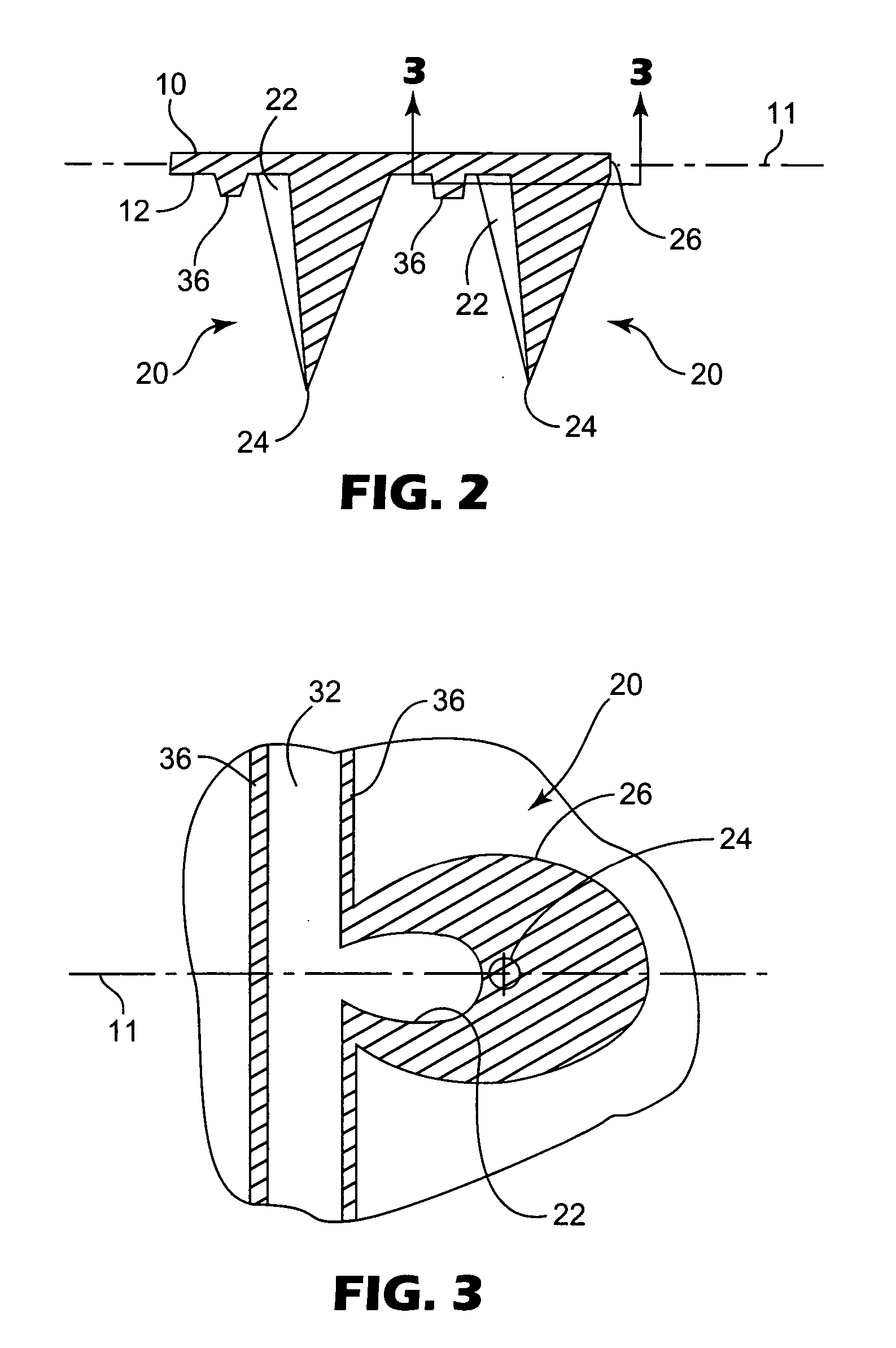

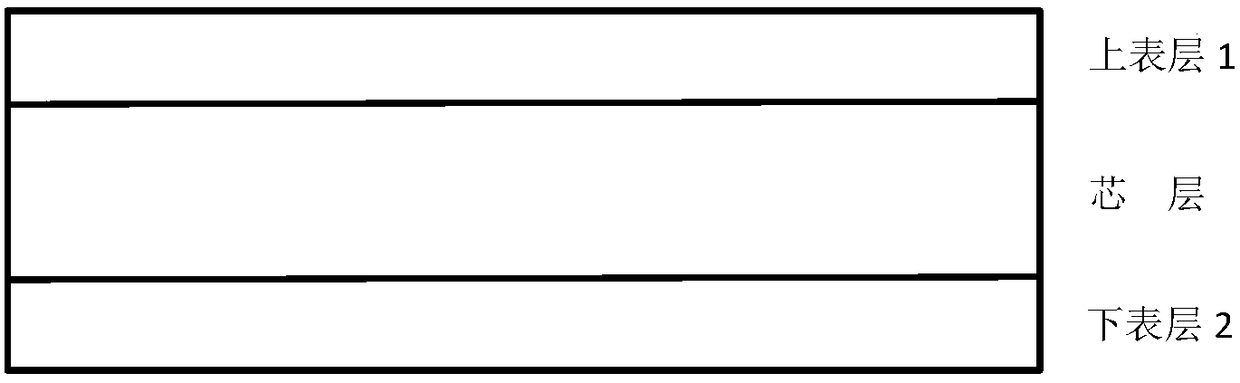

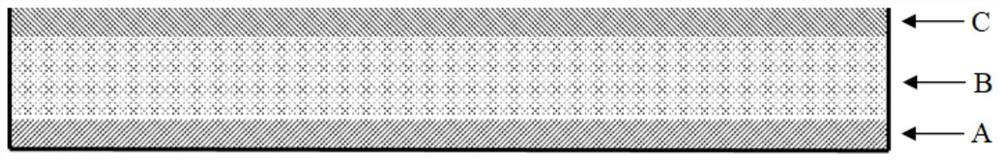

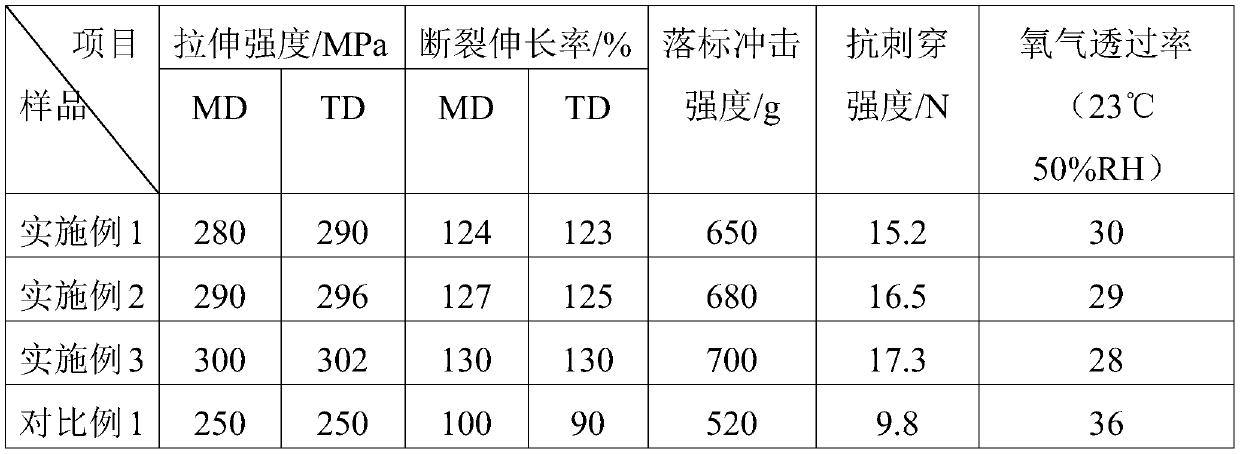

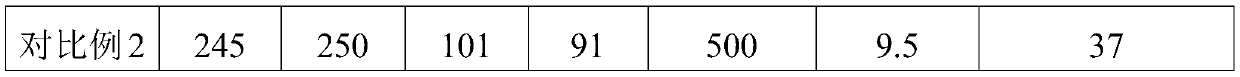

Puncture-resistant two-way stretching nylon film of three-layer structure and preparation method thereof

ActiveCN108515762AImprove barrier propertiesImprove puncture resistanceFlexible coversWrappersSurface layerMetallurgy

The invention relates to a puncture-resistant two-way stretching nylon film of a three-layer structure and a preparation method thereof. The puncture-resistant two-way stretching nylon film of the three-layer structure consists of an upper surface layer 1, a core layer and a lower surface layer 2, wherein the raw material formula of the upper surface layer 1 comprises the following materials in percentage by mass: 10 to 30 percent of copolymerized nylon, 68.4 to 89.8 percent of nylon resin, 0.1 to 0.8 percent of anti-bonding agents and 0.1 to 0.8 percent of slipping agents; the raw material formula of the core layer is prepared from 100 percent of additives in percentage by mass; the raw material formula of the lower surface layer 2 comprises the following materials in percentage by mass:10 to 30 percent of copolymerized nylon, 68.4 to 89.8 percent of nylon resin, 0.1 to 0.8 percent of anti-bonding agents and 0.1 to 0.8 percent of slipping agents. The invention also provides the preparation method of the puncture-resistant two-way stretching nylon film of the three-layer structure. The film prepared by using the method has the characteristics of excellent puncture-resistant performance and the like, and is particularly suitable for being used as packages of commodities with edges and corners such as sharp bones and fishbone, heavy objects and the like.

Owner:厦门长塑实业有限公司

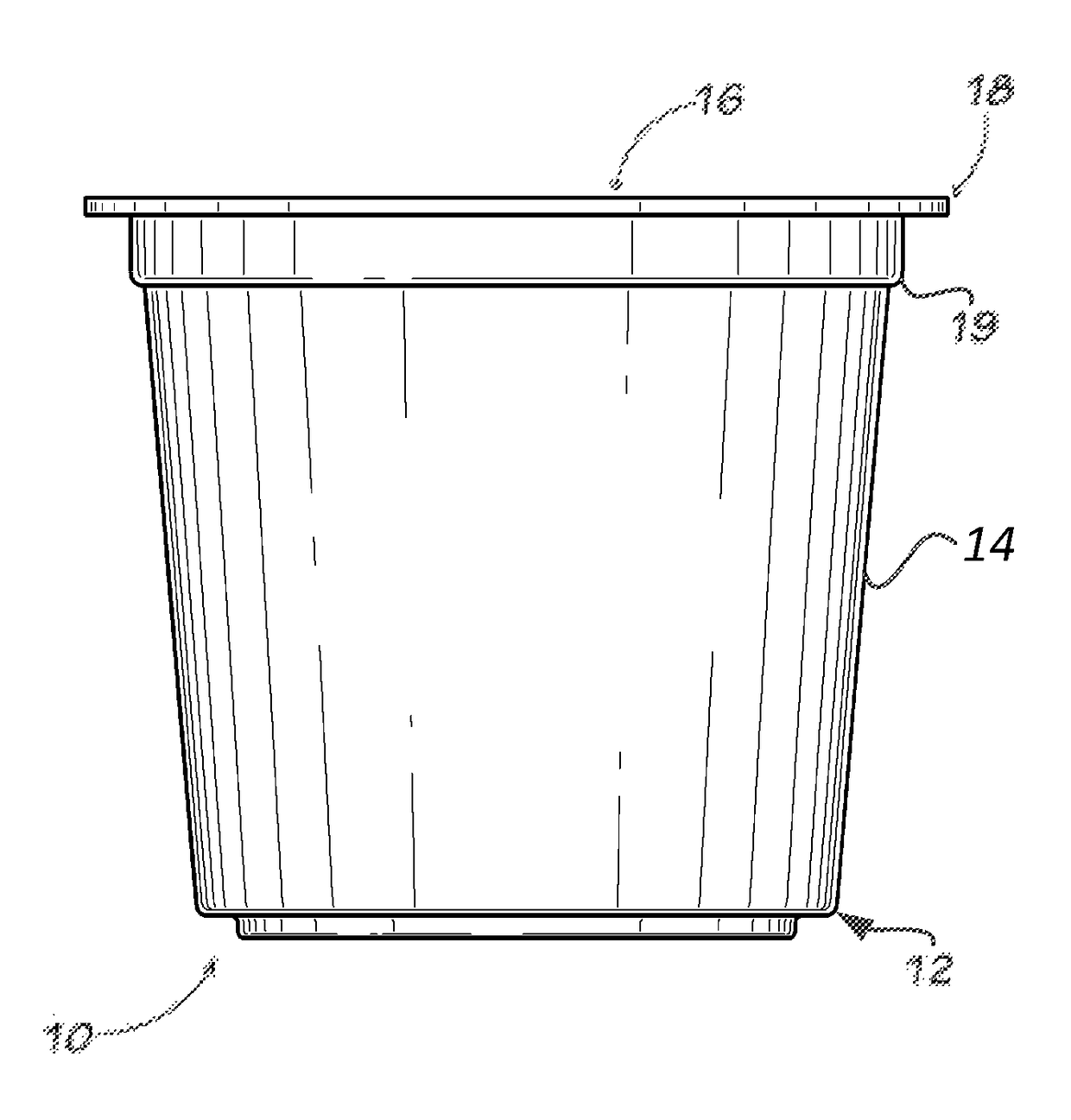

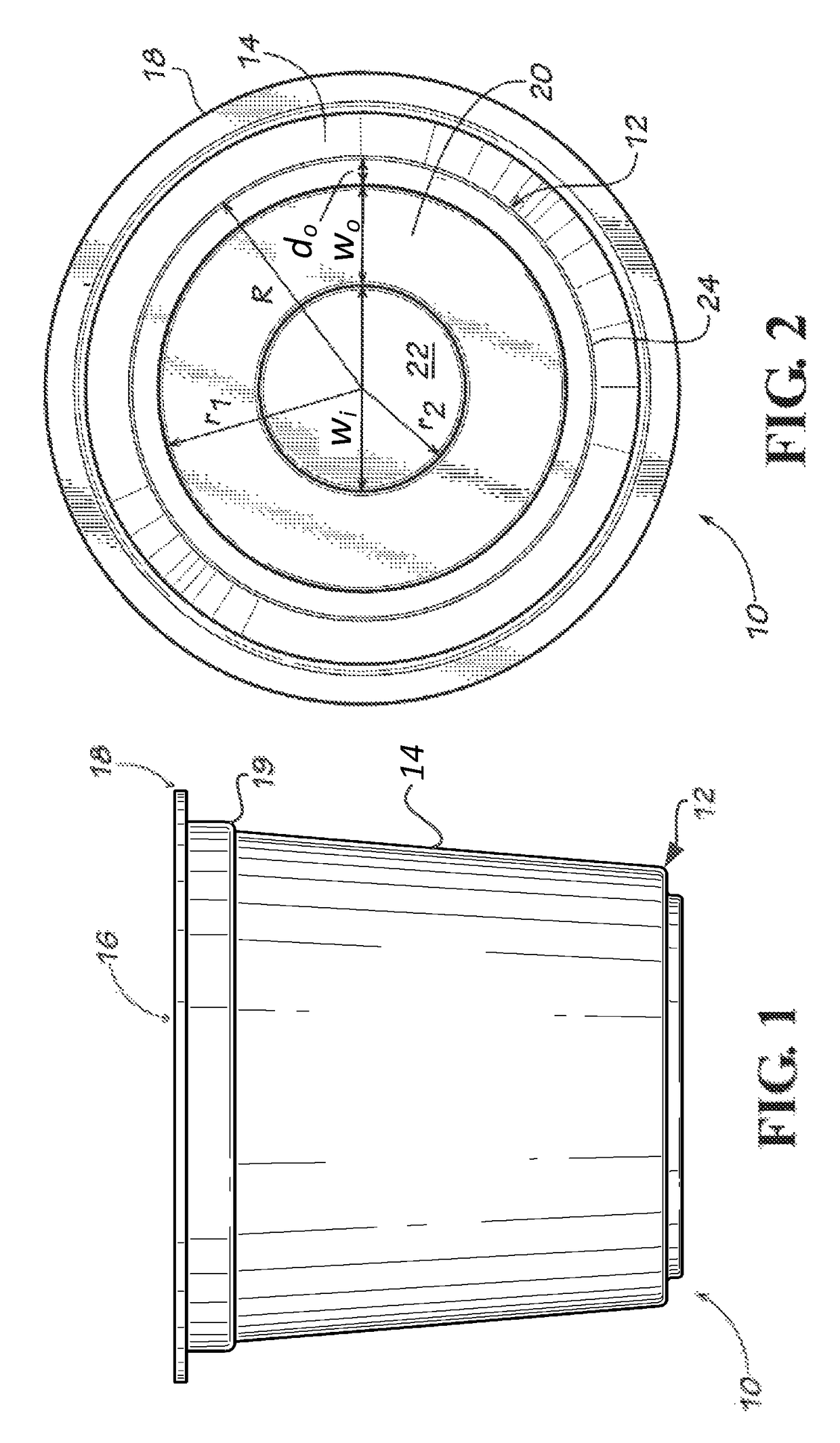

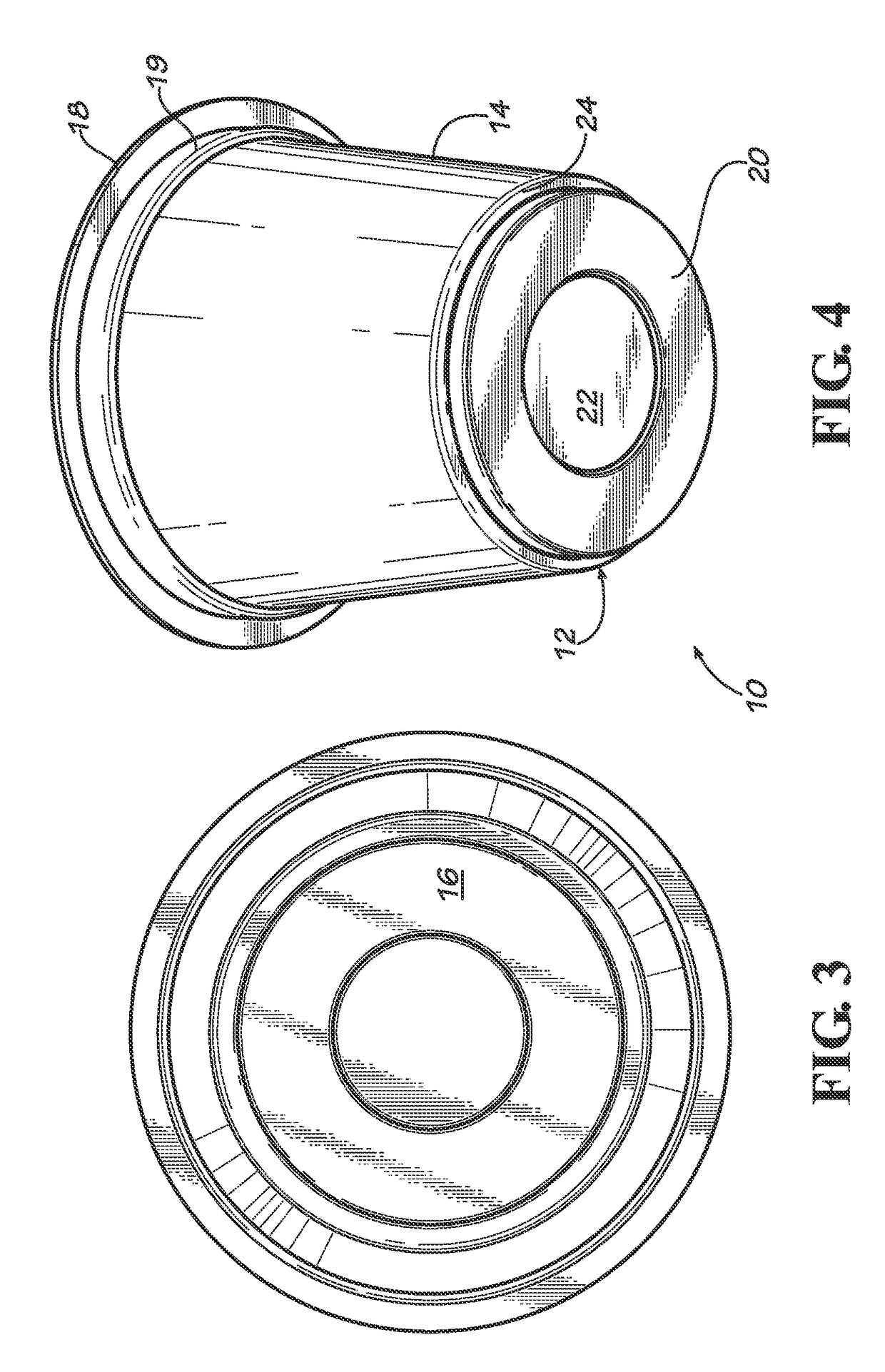

Containers and materials with improved punctureability

ActiveUS9657155B2Improve puncture abilityThin material handlingRigid containersEngineeringThermoplastic materials

The present description includes containers having an improved puncture design that can be punctured without substantial deformation of the container. Such containers are particularly suitable for use in preparing beverages using automatic machines, particularly those used for preparation of single serve beverages. Also provided are thermoplastic materials having improved punctureability for use in containers, containers for preparation of a beverage, and methods for preparing a beverage using such containers.

Owner:PRINTPACK ILLINOIS

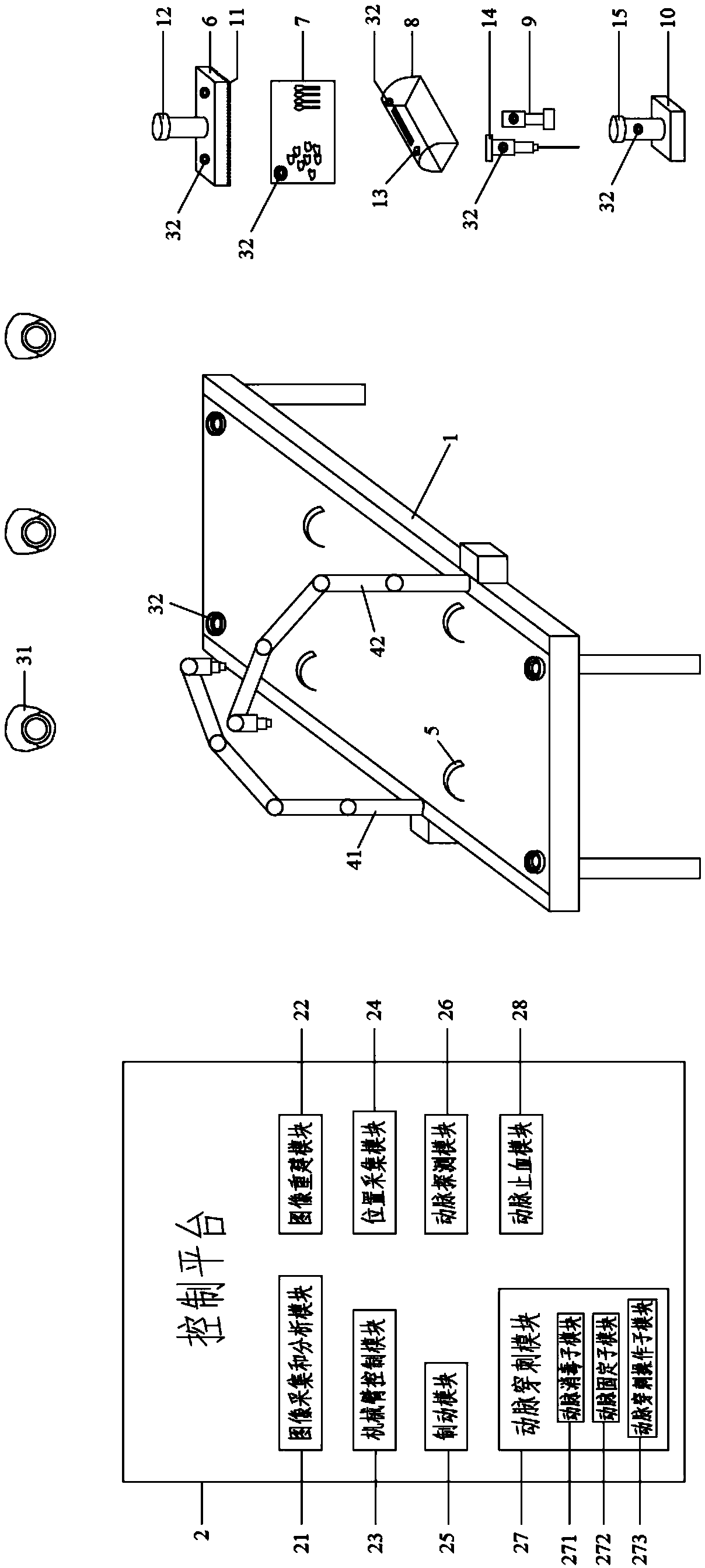

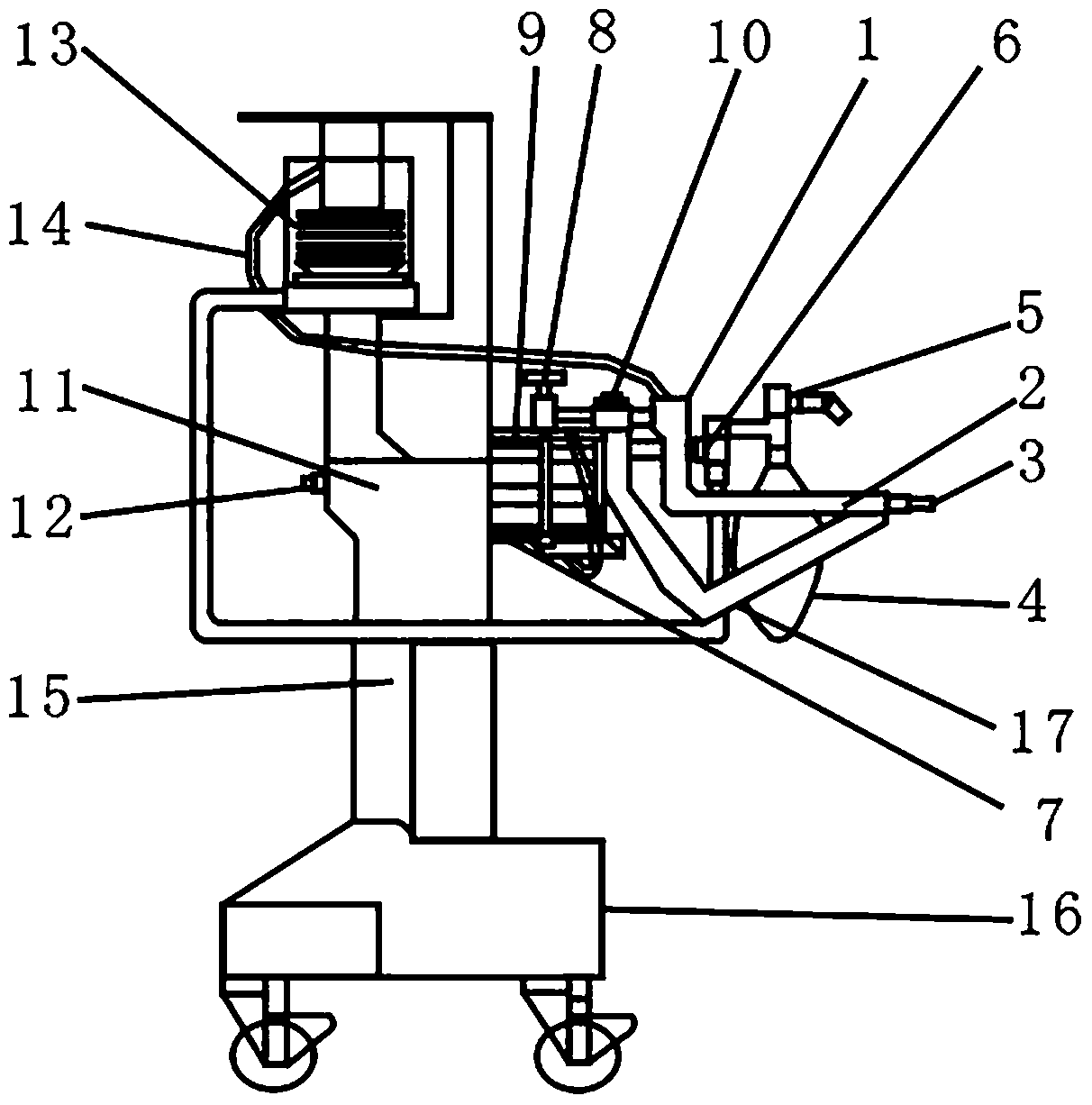

Arterial puncture system and method for determining arterial puncture position

ActiveCN109044498AOperableSave medical resourcesSurgical needlesSurgical navigation systemsOperabilityPulse wave

The invention relates to an arterial puncture system and a method for determining an arterial puncture position. The arterial puncture system is provided with a surgical bed, mechanical arms, a braking device, an arterial detection device, a skin disinfection device, an arterial fixation device, a puncture needle operation device, an arterial pressing device and a control platform, and the controlplatform includes an image acquisition and analysis module, an image reconstruction module, a mechanical arm control module, a position collection module, a braking module, an arterial detection module, an arterial puncture module and an arterial hemostasis module. The method for determining the arterial puncture position is completed by using the arterial puncture system. Human body imaging, human body contour recognition, pulse-induced skin pressure change and the like are organically combined, a relationship between pulse wave conduction velocity and blood vessel wall hardness is utilizedto eliminate arterial diseases, and the complete fully-automated precise positioning arterial puncture system with practical operability is constructed.

Owner:ZHONGSHAN HOSPITAL FUDAN UNIV

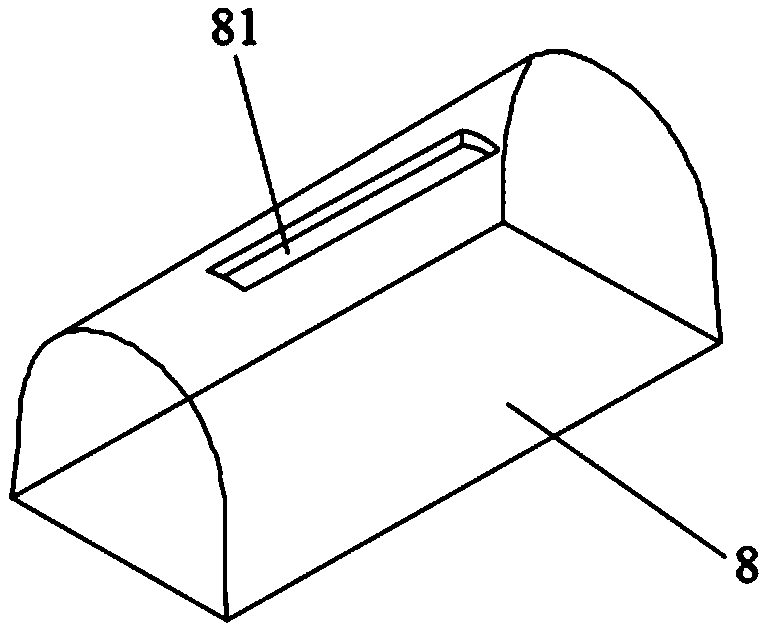

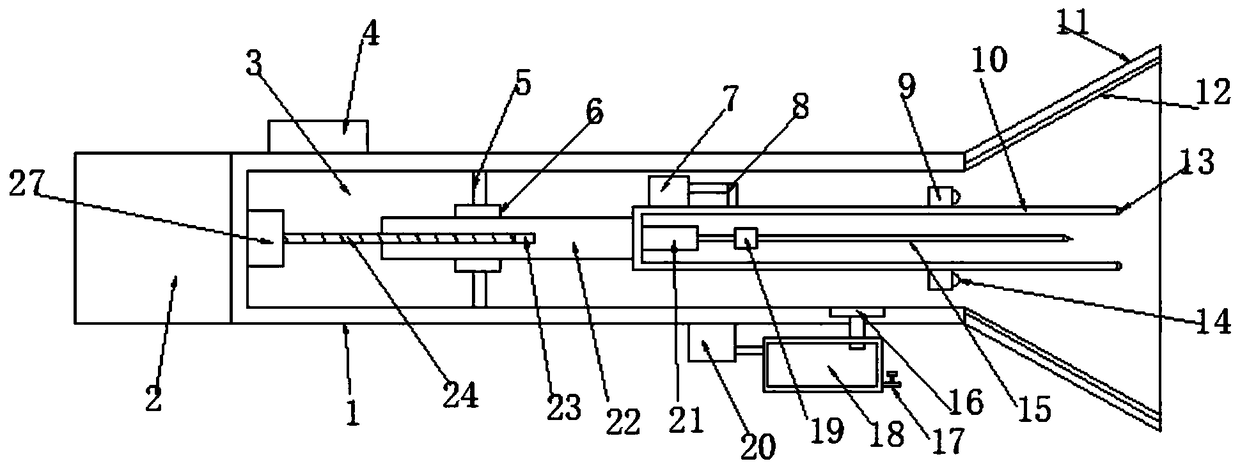

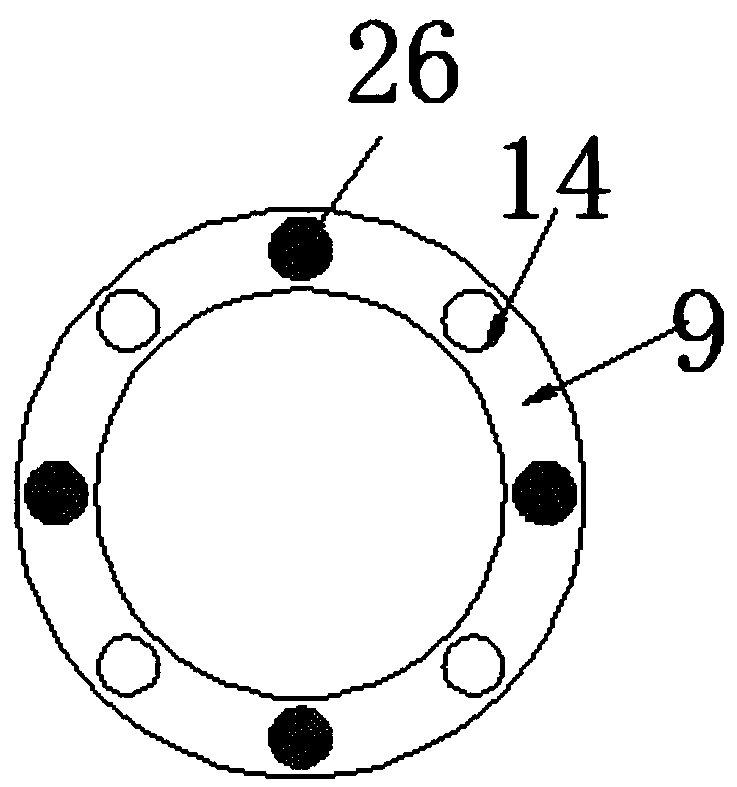

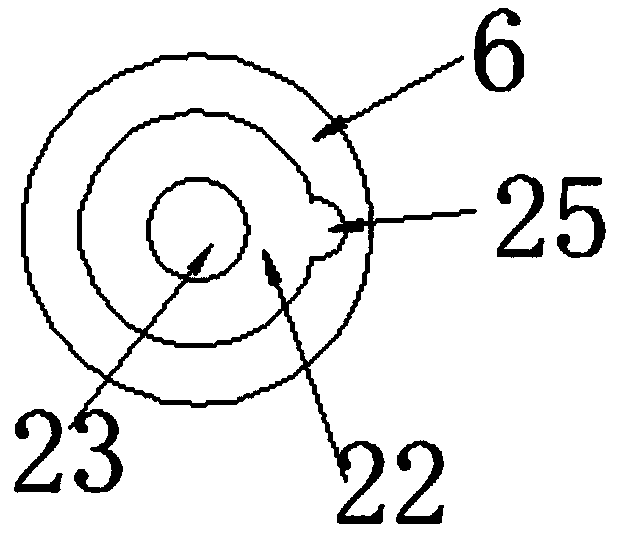

Membrane rupture device for obstetrics department

InactiveCN108938062ASimple structureReasonable structureObstetrical instrumentsObstetric historyLight reflection

The invention discloses a membrane rupture device. The device comprises a cylinder body, a mounting cavity is formed in the cylinder body, and a suction cup is arranged at an opening of the right endof the mounting cavity and is of a conical structure; a light reflection layer is arranged on the inner wall of the suction cup, a retractable rod is arranged in the cylinder body, and a puncture mechanism is arranged at the right end of the retractable rod; a guide sleeve slidingly sleeves the outer side of the retractable rod and is fixedly connected with the inner wall of the mounting cavity through a positioning rod, and a rotation limit mechanism is arranged between the guide sleeve and the retractable rod and comprises a limit groove formed in the inner wall of the guide sleeve and a limit protrusion located at the outer side of the retractable rod; a transmission screw hole is formed in the left end of the retractable rod. The membrane rupture device is simple and reasonable in structure, through a rotation motor, a puncture needle can pierce into through a rotation mode, and the puncture effect is improved. By adopting a mode that part of membrane is sucked in an auxiliary extrusion cylinder for puncture, the hidden safety dangers during direct puncture are avoided, the safety of the device is improved, and the practicability is high.

Owner:THE WEST CHINA SECOND UNIV HOSPITAL OF SICHUAN

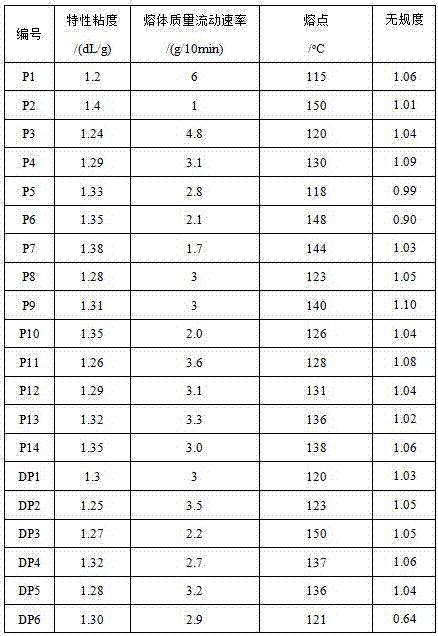

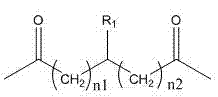

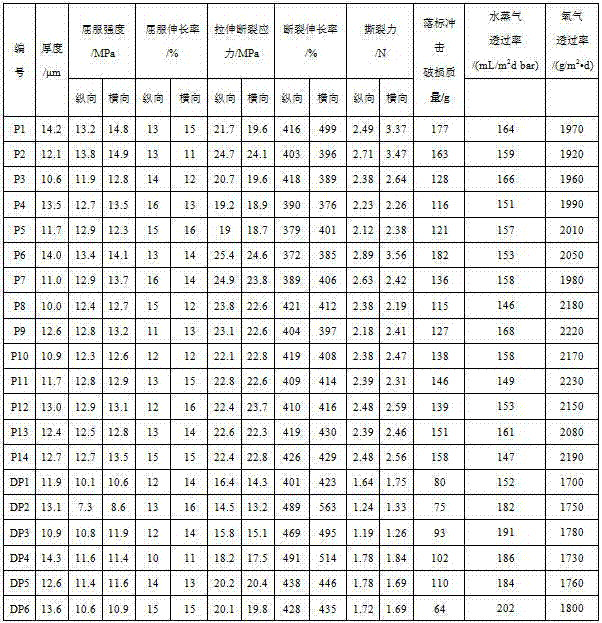

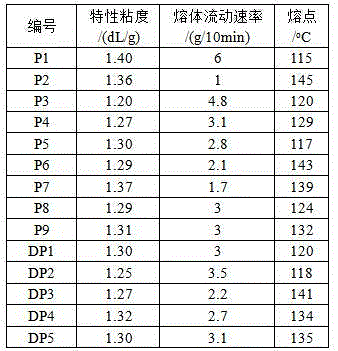

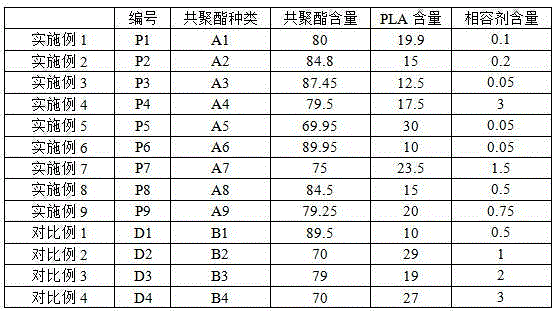

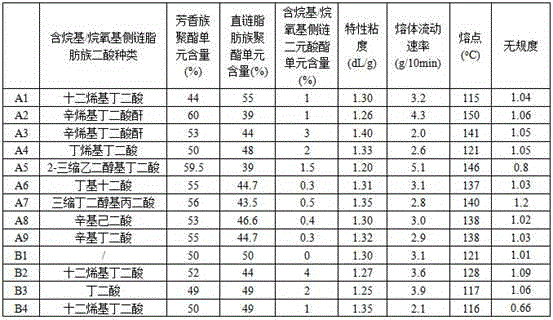

Biodegradable aliphatic-aromatic copolyester and application thereof

InactiveCN104497293AHigh yield strengthImprove puncture abilityClimate change adaptationPlant protective coveringsPolymer sciencePlastic mulch

The invention discloses a biodegradable aliphatic-aromatic copolyester and application thereof. The biodegradable aliphatic-aromatic copolyester comprises the following components: component 1: an aromatic polyester unit comprising 45-60 mol% of aromatic diacid residues A1 and dihydroxy compound residues B; component 2: a linear aliphatic polyester unit comprising 37-54.7 mol% of linear aliphatic diacid residues A2 and the dihydroxy compound residues B; and component 3: an alkyl-containing side chain aliphatic polyester unit comprising 0.3-3 mol% of alkyl-containing side chain aliphatic diacid residues A3 and the dihydroxy compound residues B. As the biodegradable aliphatic-aromatic copolyester disclosed by the invention comprises the alkyl-containing side chain aliphatic polyester unit, the yield strength of a thin film prepared from the biodegradable aliphatic-aromatic copolyester is improved, thereby being favorable for improving the performance of tolerating puncture of crops and weeds of an agricultural plastic mulching film and reducing the probability of causing a hole breaking phenomenon; and the oxygen transmission rate is improved, the water vapor transmission rate is reduced, and when the prepared thin film is used as the agricultural plastic mulching film, better heat preservation and moisture preservation effects are realized.

Owner:KINGFA SCI & TECH CO LTD

Self-repairing anti-root-penetrating concrete waterproof structure and construction method thereof

InactiveCN102817445AImprove puncture abilityExtended service lifeRoof improvementClimate change adaptationPlant rootsStructural engineering

The invention relates to a self-repairing anti-root-penetrating concrete waterproof structure and a construction method thereof. The self-repairing anti-root-penetrating concrete waterproof structure is characterized by comprising a self-repairing rigid waterproof layer and a root barrier layer. The root barrier layer is formed by coating a root repellent layer on the self-repairing rigid waterproof layer. The self-repairing rigid waterproof layer comprises, by weight, 1 part of cement, 1.2-1.8 parts of sand, 3-4 parts of fine aggregate, 0.37-0.48 part of water and 0.008-0.015 part of cement-based capillary crystalline waterproofing agent. The root barrier layer has a function of root penetrating prevention and is formed by coating 0.3-0.8 kg / m<2> the root repellent layer on the self-repairing rigid waterproof layer. Under synergistic effect of the self-repairing rigid waterproof layer and the root barrier layer, the self-repairing anti-root-penetrating concrete waterproof structure is capable of effectively preventing penetrating of plant roots, leakage of a green plant roof is avoided, and the service life of the green plant roof is prolonged.

Owner:HUATAI CONSTR GROUP

Strip-shaped traditional Chinese medicinal material cutting device and system and cutting method

InactiveCN111823301AReduce reaction forceReduce sharpnessMetal working apparatusStructural engineeringKnife blades

The invention discloses a strip-shaped traditional Chinese medicinal material cutting device and system and a cutting method. The cutting device comprises a shell, a first driving device is arranged on the shell, the lower end of the first driving device is connected with a connecting plate positioned in the shell, the first driving device is used for driving the connecting plate to move in the vertical direction, and the lower surface of the connecting plate is provided with an extrusion mechanism and a pre-cutting mechanism; when the connecting plate vertically moves downwards, the extrudingmechanism makes contact with strip-shaped Chinese medicinal materials earlier than the pre-cutting mechanism, the connecting plate continuously moves downwards after making contact, the length of theextruding mechanism is shortened, the strip-shaped Chinese medicinal materials are extruded, and meanwhile the pre-cutting mechanism penetrates and / or cuts the outer skin of the strip-shaped Chinesemedicinal materials. According to the strip-shaped traditional Chinese medicinal material cutting device and system and the cutting method, a plurality of puncture holes and / or cutting lines are formed in the outer skin through the pre-cutting mechanism so as to damage the integrity of the outer skin, the resistance of the outer skin and the inner core to a blade tends to be consistent, the bladeshaking caused by uneven stress is remarkably reduced, the cutting quality is improved, and the blade and a driving mechanism are protected.

Owner:黄小霞

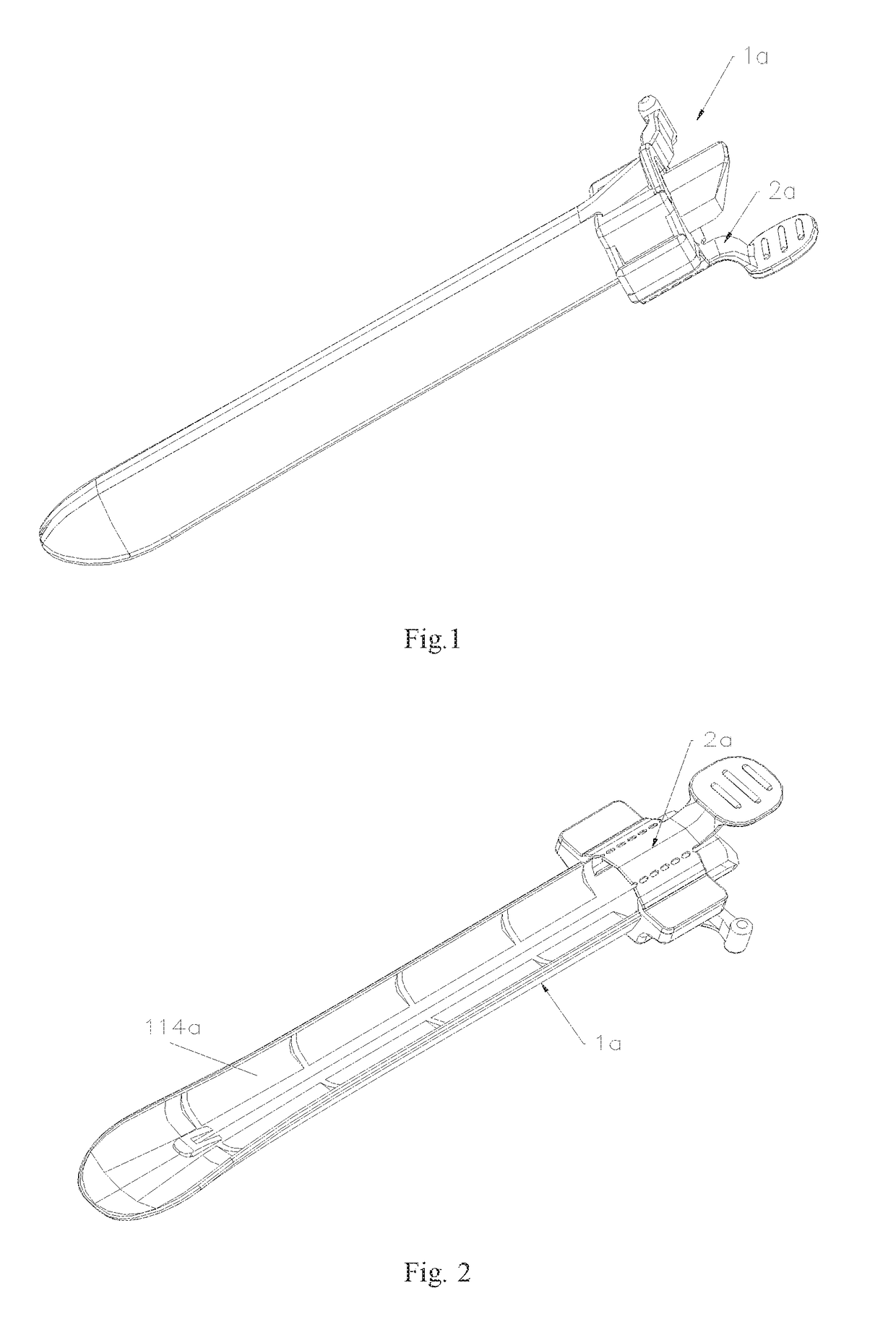

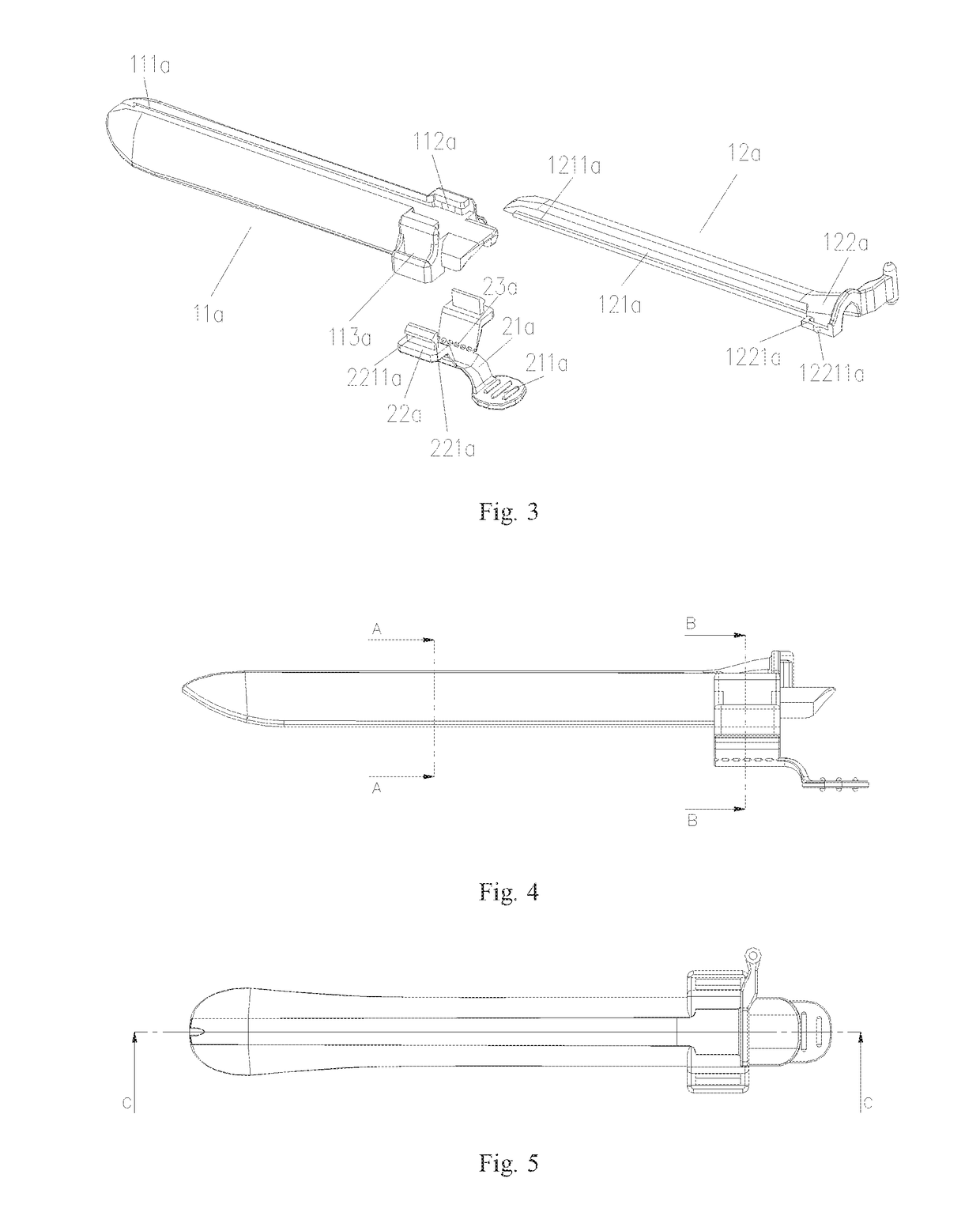

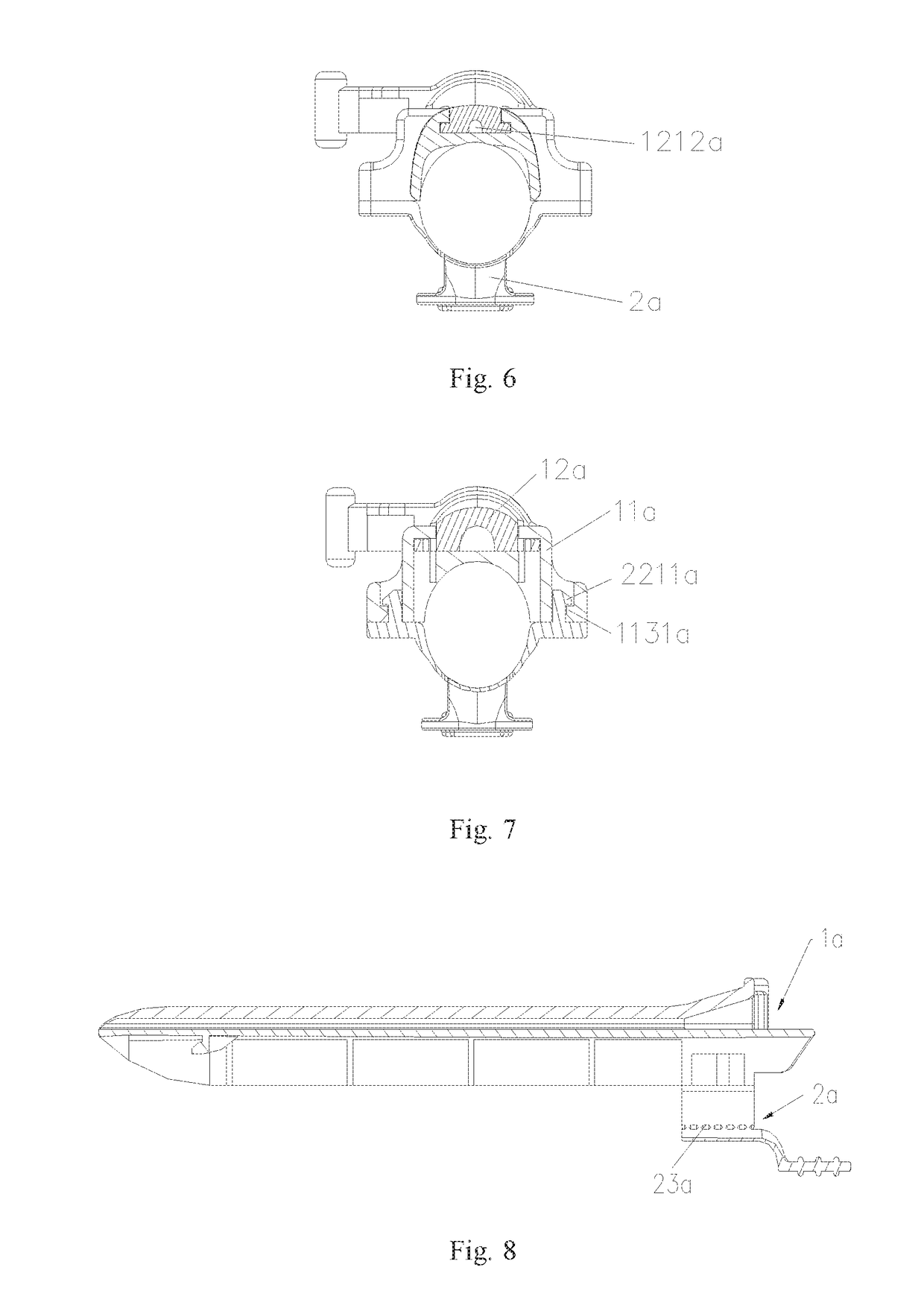

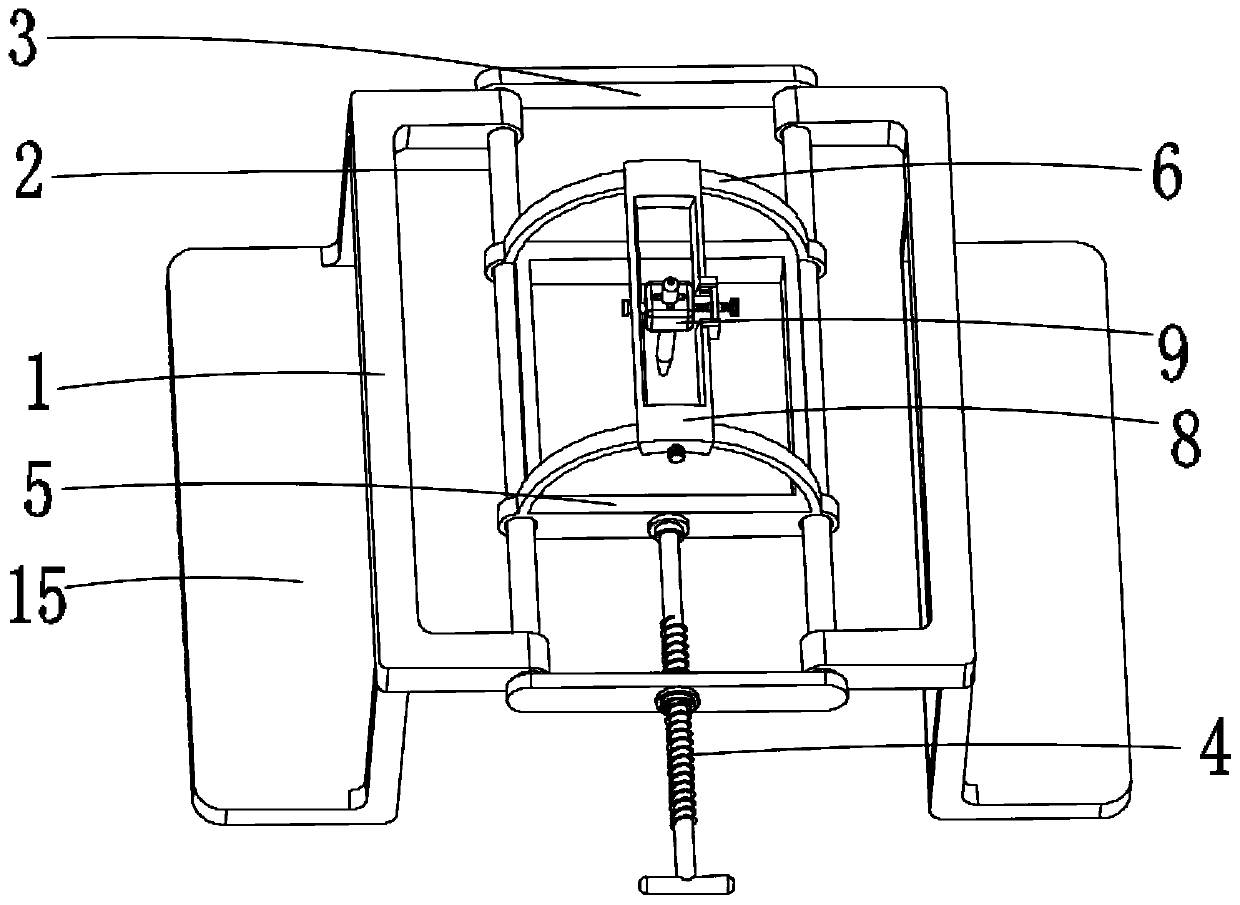

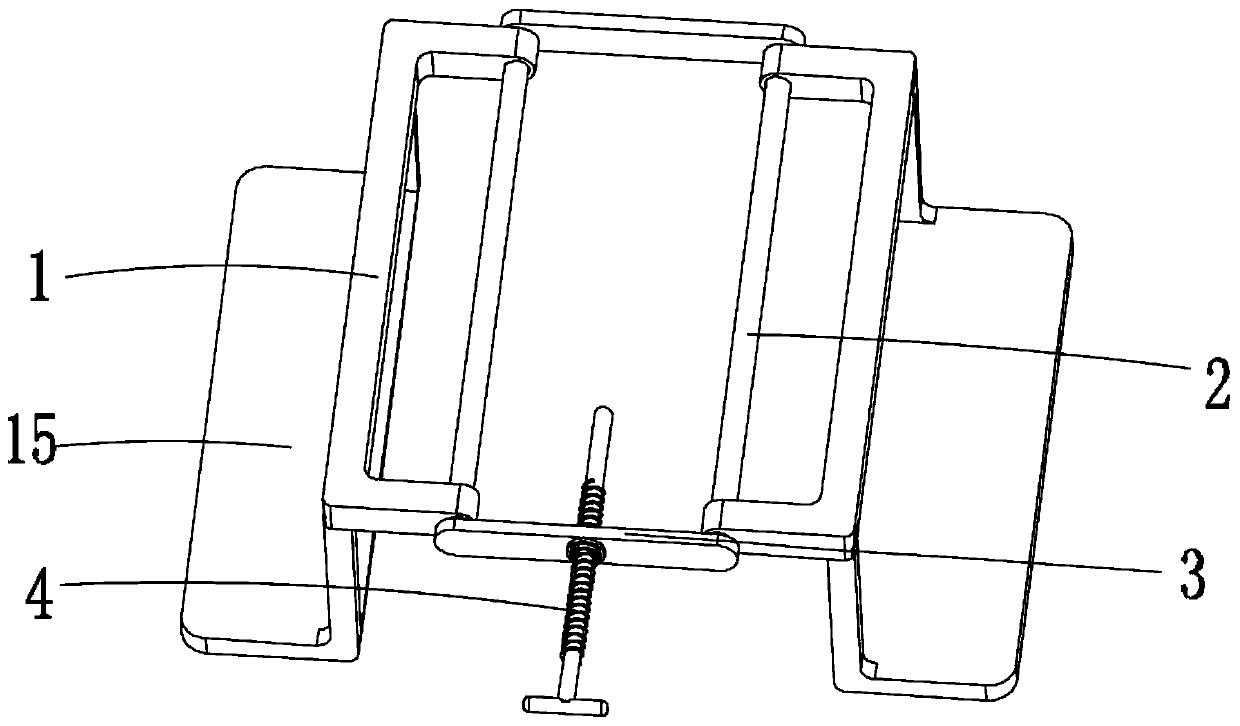

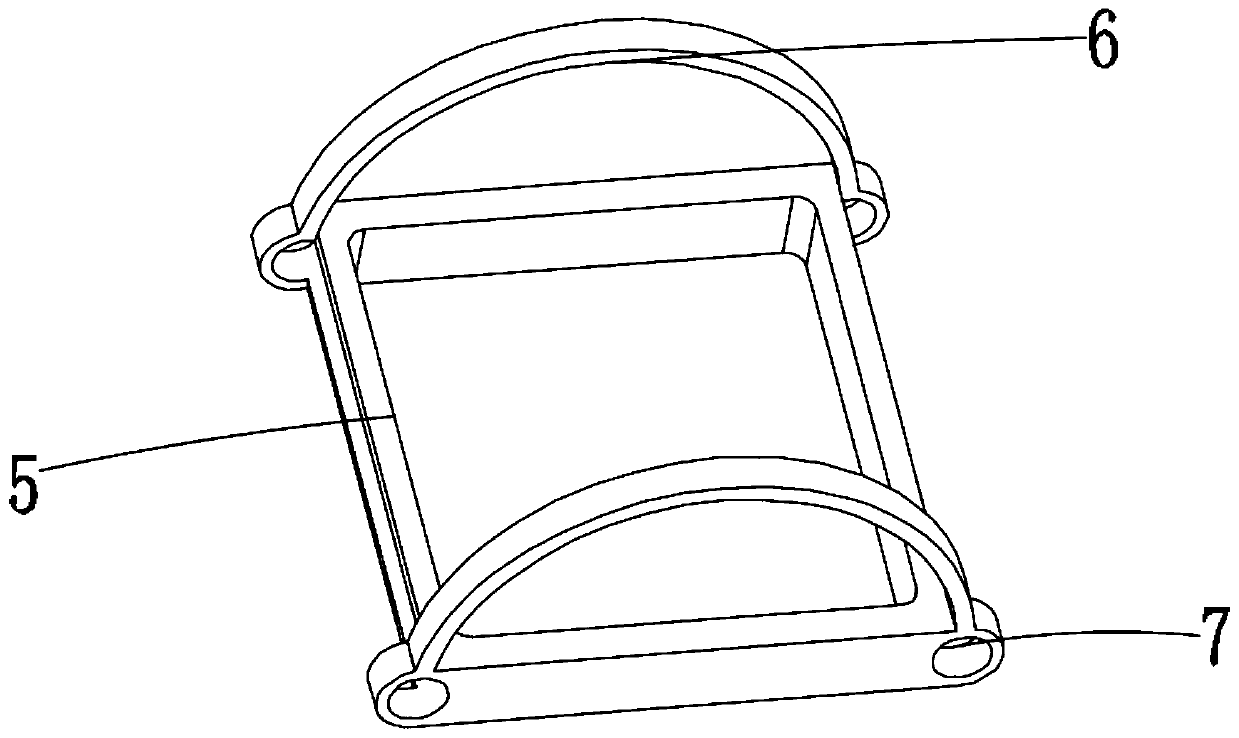

Paracentesis needle frame

ActiveUS20190069923A1Conveniently and accurately adjustConvenient and efficient installationUltrasonic/sonic/infrasonic diagnosticsCannulasParacentesisFixed frame

A needle guide holder, which is used for a fixing medical puncture needle and a ultrasonic probe, comprises a holder body (1a, 1b) and a fixing device (2a, 2b) used in cooperation with the holder body (1a, 1b). The fixing device (2a, 2b) is mounted onto the holder body (1a, 1b) and provided with a weakening portion (23a, 23b). The needle guide holder is designed to be disposable, thereby avoiding the possibility of cross-infection caused by using the same needle guide holder on different patients. The needle guide holder can be used on one and same patient to perform a number of treatments just through the replacement of a sliding frame and without replacing the fixing device and a fixing frame. In a treatment process, the puncture needle is left in the body for a subsequent treatment, while the needle guide holder and the ultrasonic probe can be removed from the human body.

Owner:WANG QIN

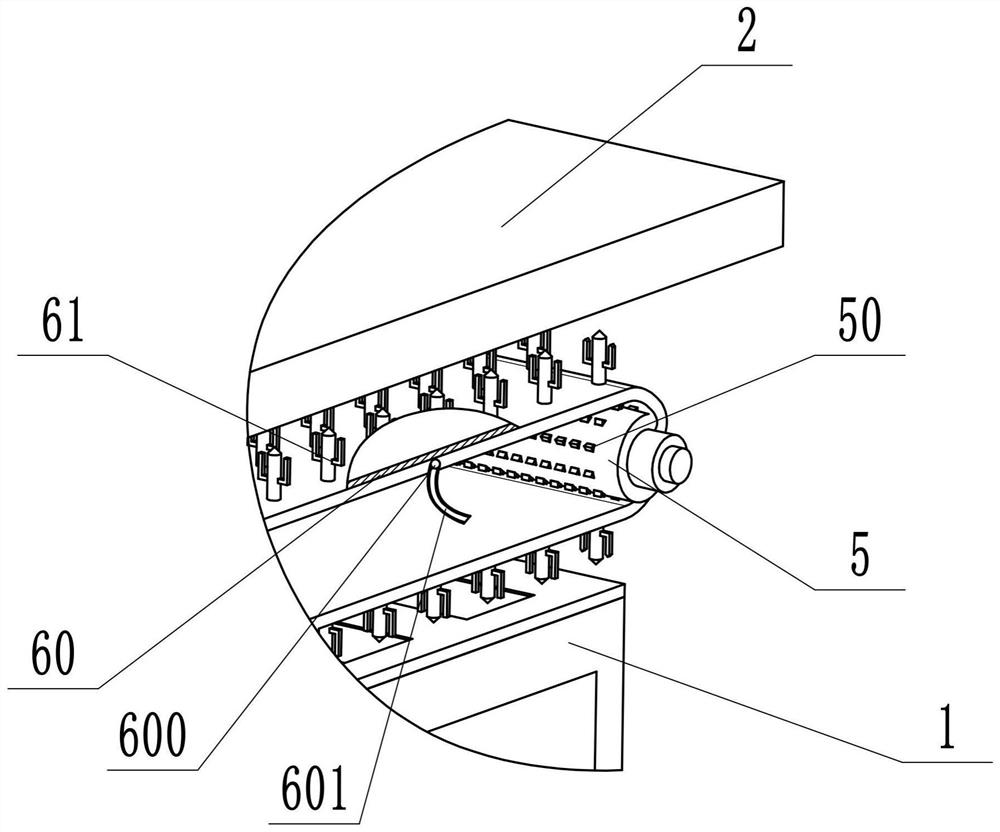

Needle machine

InactiveCN109722793AExtended service lifeHigh strengthNeedling machinesEngineeringUltimate tensile strength

The invention provides a needle machine, and belongs to the field of textile machinery. The needle machine comprises a needle. The needle comprises a working section and a needle point section locatedon the lower side of the working section. The working section comprises a body. Two or more groove parts are circumferentially formed in the body and extend in the axial direction of the body. Everytwo adjacent groove parts are separated by a side wall part. The working section further comprises a plurality of barbs. The barbs are concavely arranged on the side wall parts. Openings of the barbsface the needle point section. The depth of the groove parts is larger than the depth of the barbs. The two sides of an arbitrary barb are each connected with a reinforcing part. The reinforcing partsare located in the groove parts. By means of the needle machine, the two sides of the arbitrary barb are each connected with one reinforcing part, the reinforcing parts are located in the groove parts, the intensity of the barbs on the needle are enhanced, and therefore the service life of the needle is prolonged.

Owner:HAIAN KEHAO TEXTILE CO LTD

Cyclone with rubber liner, and production method of rubber liner

InactiveCN104549792AExtended service lifeImprove wear resistanceReversed direction vortexRubber materialHigh resistance

The invention relates to a cyclone with a rubber liner, and a production method of the rubber liner, and relates to a cyclone in separating and grading equipment. The rubber liner is arranged in the cyclone. The production method of the rubber line comprises the following steps: forming a skeleton by using aramid glass fibers and nylon fibers, and then mixing special corrosion-resistant rubber as a base material with the aramid glass fibers and nylon fibers; filling high-wear-resistant materials such as zirconium carbide micro powder, alumina micro powder, silicon oxide micro powder and elemental silicon micro powder in an assistant manner in the mixing process, thus obtaining a rubber material with high strength, good wear resistance, good erosion resistance and good puncture resistance, wherein a layer of wear resistant ceramic wafers is adhered to the surface of the rubber material so as to further enhance the wear resistance, the erosion resistance and the puncture resistance, and then the rubber material is taken as a liner material. The rubber liner has very high wear resistance, erosion resistance and puncture resistance, and also has certain resilience and flexibility, so that the service life of the cyclone is greatly prolonged.

Owner:平顶山华瑞锦橡耐磨材料有限公司

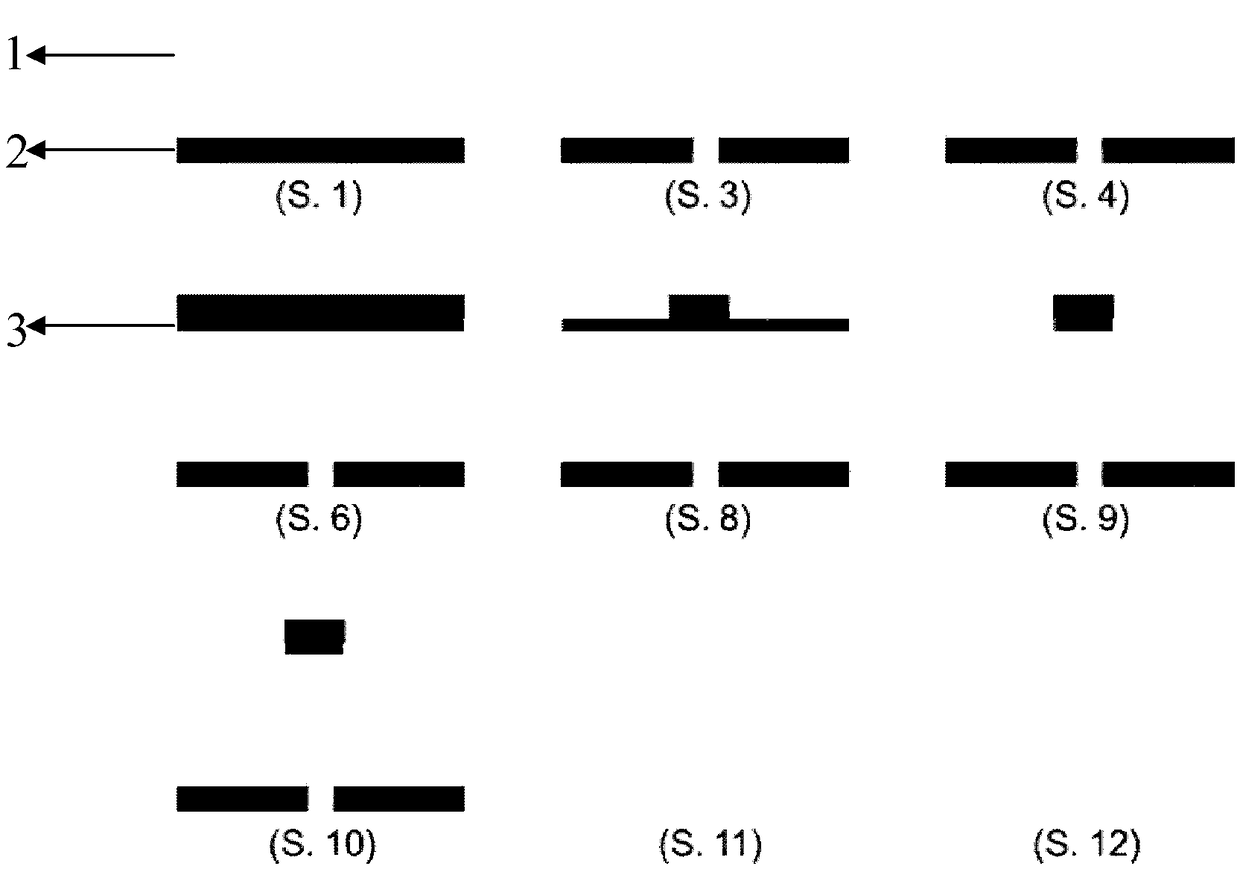

A preparation method of a silicon-based microneedle array patch

ActiveCN108751120AImprove puncture abilityEasy piercingDecorative surface effectsChemical vapor deposition coatingEvaporationSilicon etching

A preparation method of a silicon-based microneedle array patch is disclosed. The method includes S.1) coating the back of a silicon wafer with a photoresist; S.2) baking the silicon wafer; S.3) photoetching, exposing, and developing to prepare a hole array; S.4) performing deep silicon etching to form deep holes in the silicon wafer; S.5) covering the front surface of the silicon wafer with an aluminum film layer through electron beam evaporation; S.6) coating the front surface of the silicon wafer with the photoresist; S.7) baking the silicon wafer; S.8) photoetching, exposing, and developing to prepare a photoresist cylinder array; S.9) immersing the silicon wafer into an aluminum corrosive liquid to remove the excess aluminum film, and rinsing; S.10) performing deep silicon etching toobtain a silicon needle tip blank array, with aluminum being adopted as an etching template; S.11) removing the photoresist and the aluminum film; and S.12) immersing the silicon wafer into a corrosive liquid to obtain a silicon-based microneedle array. Beneficial effects of the method are that (1) a preparation process is greatly simplified and processing is simple; (2) micropores deviate from the centers of needle tips and piecing capability is enhanced; and (3) subsequent secondary processing can be performed conveniently.

Owner:上海揽微医学科技有限公司

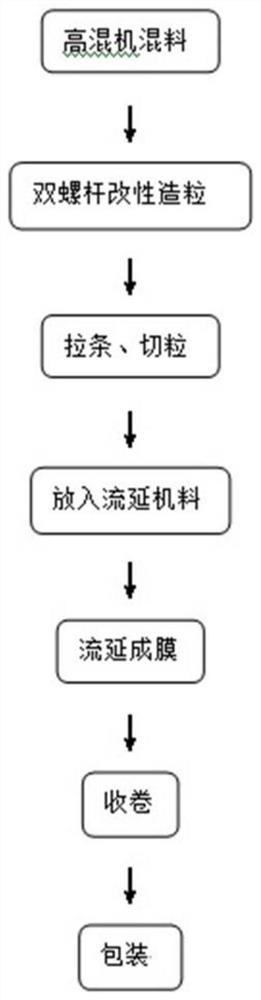

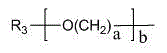

Resin modification and preparation method for producing wrapping film from biodegradable material

The invention aims to provide a resin modification and preparation method for producing a wrapping film from a biodegradable material. An industrially applied degradable wrapping film is produced from a biodegradable material, so that the technical problem and the production process problem for producing a wrapping film from a full biodegradable material are solved, and meanwhile, the problem that the environment is polluted by using a wrapping film is also solved. The invention relates to a resin modification and preparation method for producing a wrapping film from a biodegradable material. The used materials comprise the following components in parts by weight: 2-10 parts of polylactic acid (PLA); 90-98 parts of poly (butylene adipate-co-terephthalate) (PBAT); 2-5 parts of nano calcium carbonate; 0.2-0.5 parts of octadecyl acrylate-maleic anhydride; 0.2-0.6 parts of a chain extender; 0.2-0.8 parts of an antioxidant; and 0.2-0.5 parts of a lubricant. The method has the beneficial effects that firstly, the raw materials are fully biodegradable materials and are environment-friendly; and secondly, part of materials are modified, PBAT on the inner side does not need to be modified again and is directly produced, and damage to the molecular structures of the raw materials can be reduced.

Owner:生刚

Curbstone foot cleaning device

InactiveCN112323699APrevent affecting the appearance of the cityPrevent affecting drainagePaving gutters/kerbsRoad cleaningMechanical engineeringSanitation

The invention provides a curbstone foot cleaning device, and relates to the technical field of urban environmental sanitation. The curbstone foot cleaning device comprises a connecting frame, a firstcleaning mechanism, a connecting rod, a connecting block, a second cleaning mechanism and a storage box, the storage box is arranged at the bottom end of the connecting frame, the top end of the storage box is fixedly connected with the bottom end of the connecting frame, the first cleaning mechanism is arranged at the right end of the storage box, and the connecting rod is arranged above the right end of the first cleaning mechanism; the connecting rod is fixedly connected with the top end of the first cleaning mechanism, the connecting block is arranged at the right end of the connecting rod, the connecting block is fixedly connected with the connecting rod, and the second cleaning mechanism is arranged at the right end of the connecting block. Through the second cleaning mechanism, theposition around thecurbstone foot is cleaned, and the second cleaning mechanism is rotatably connected with a connecting block. The problems that dust and garbage at the included angle between the curbstone and the ground, fallen leaves in autumn and winter are attached to the included angle between the curbstone and the ground, and the ground near the curbstone is inconvenient to clean are solved.

Owner:周茂正

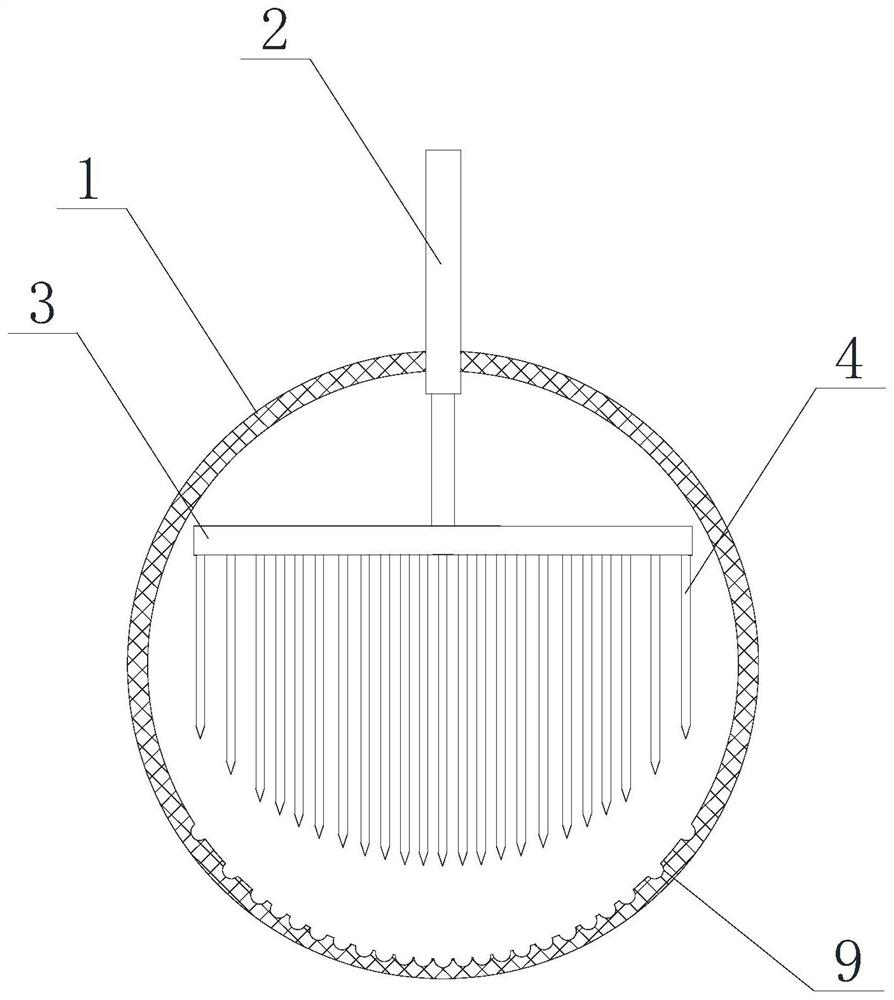

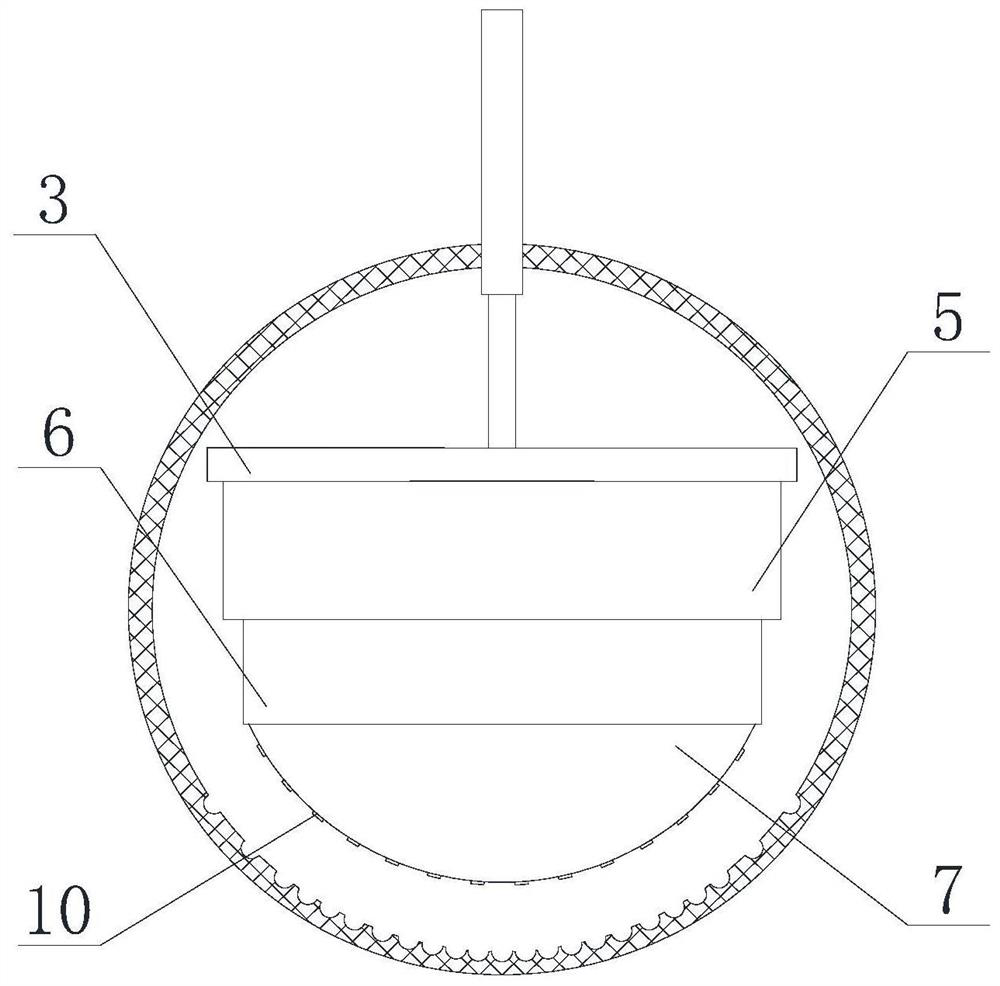

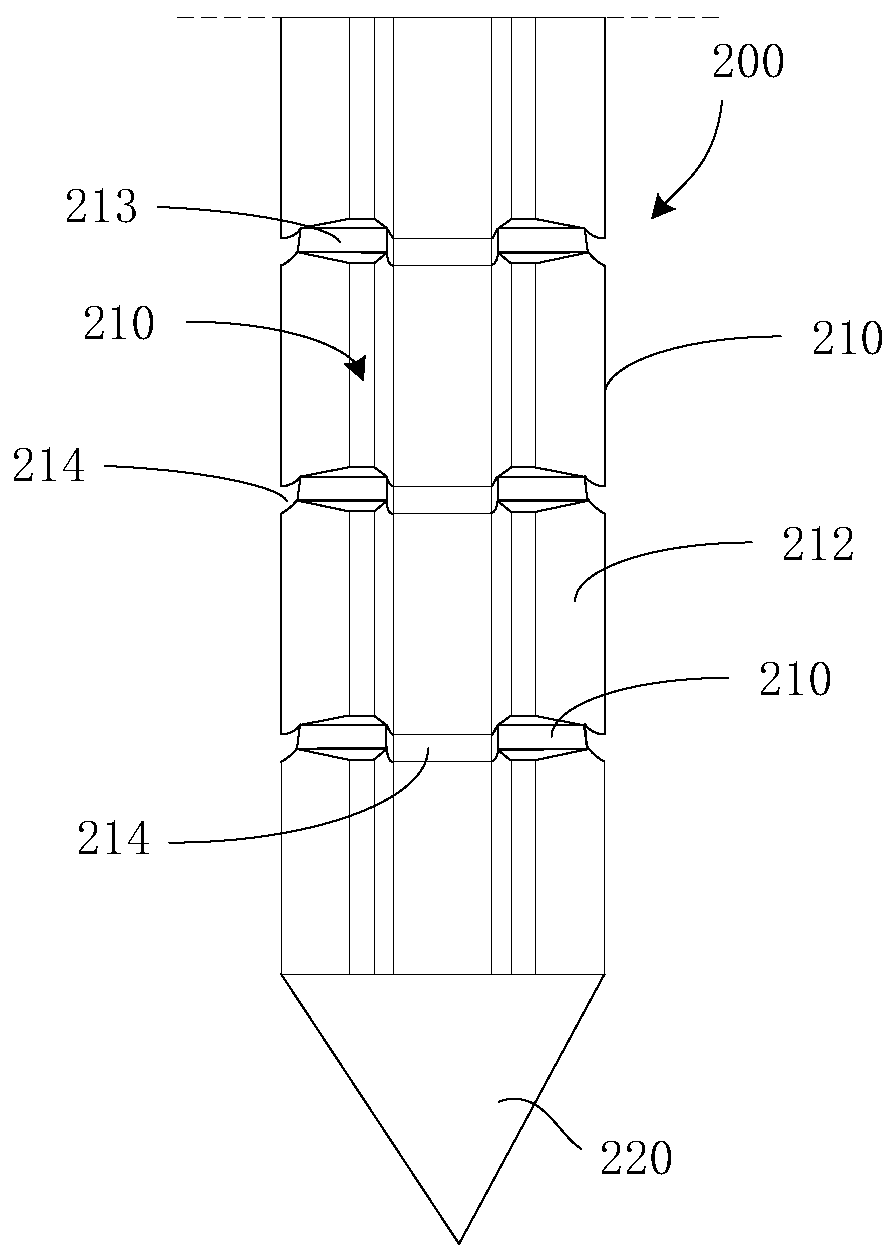

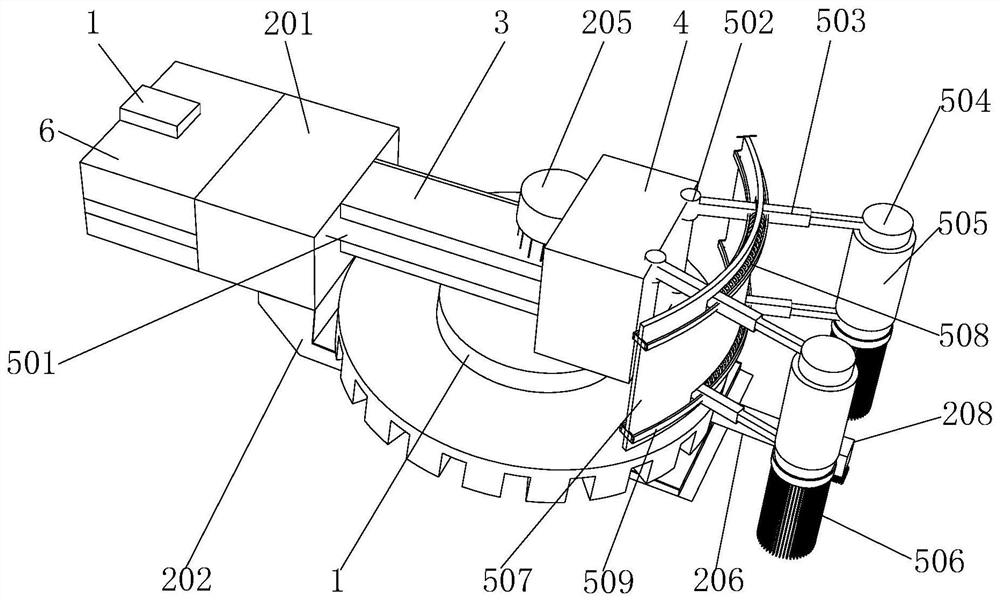

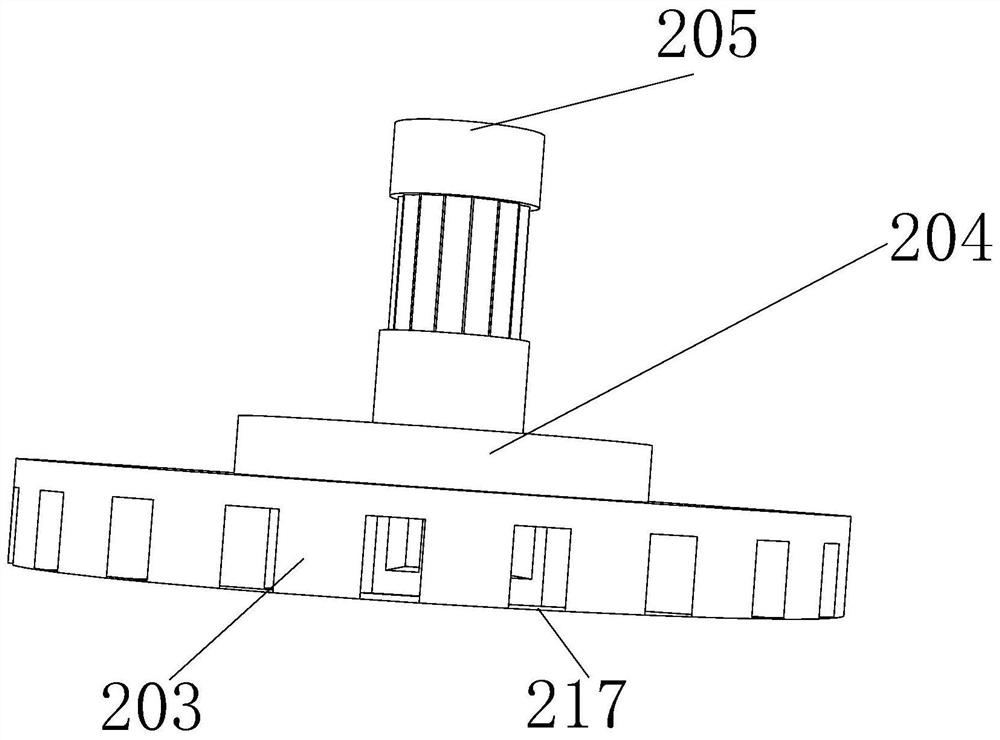

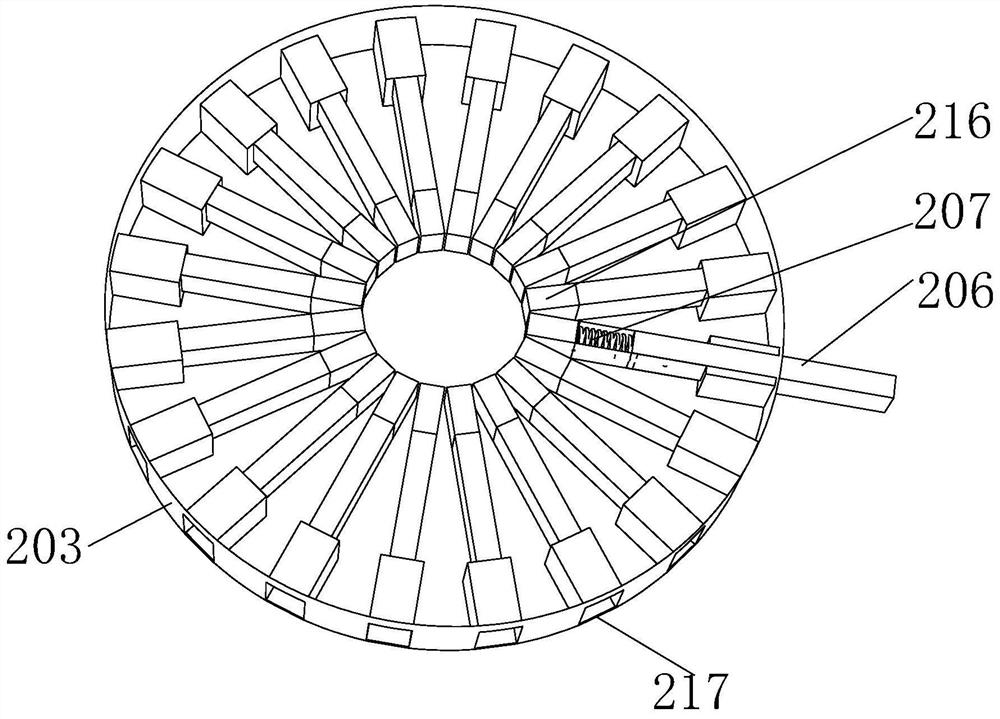

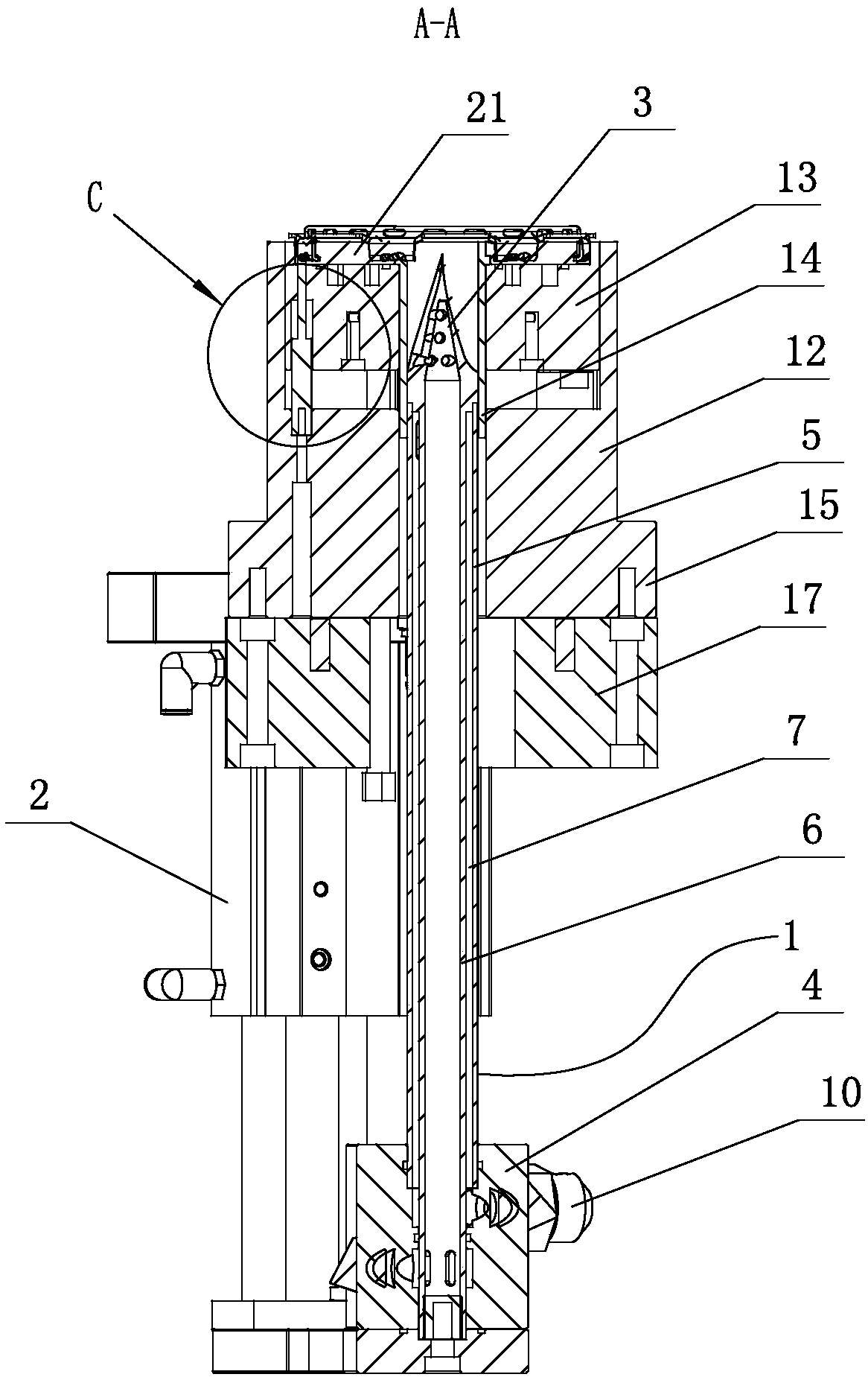

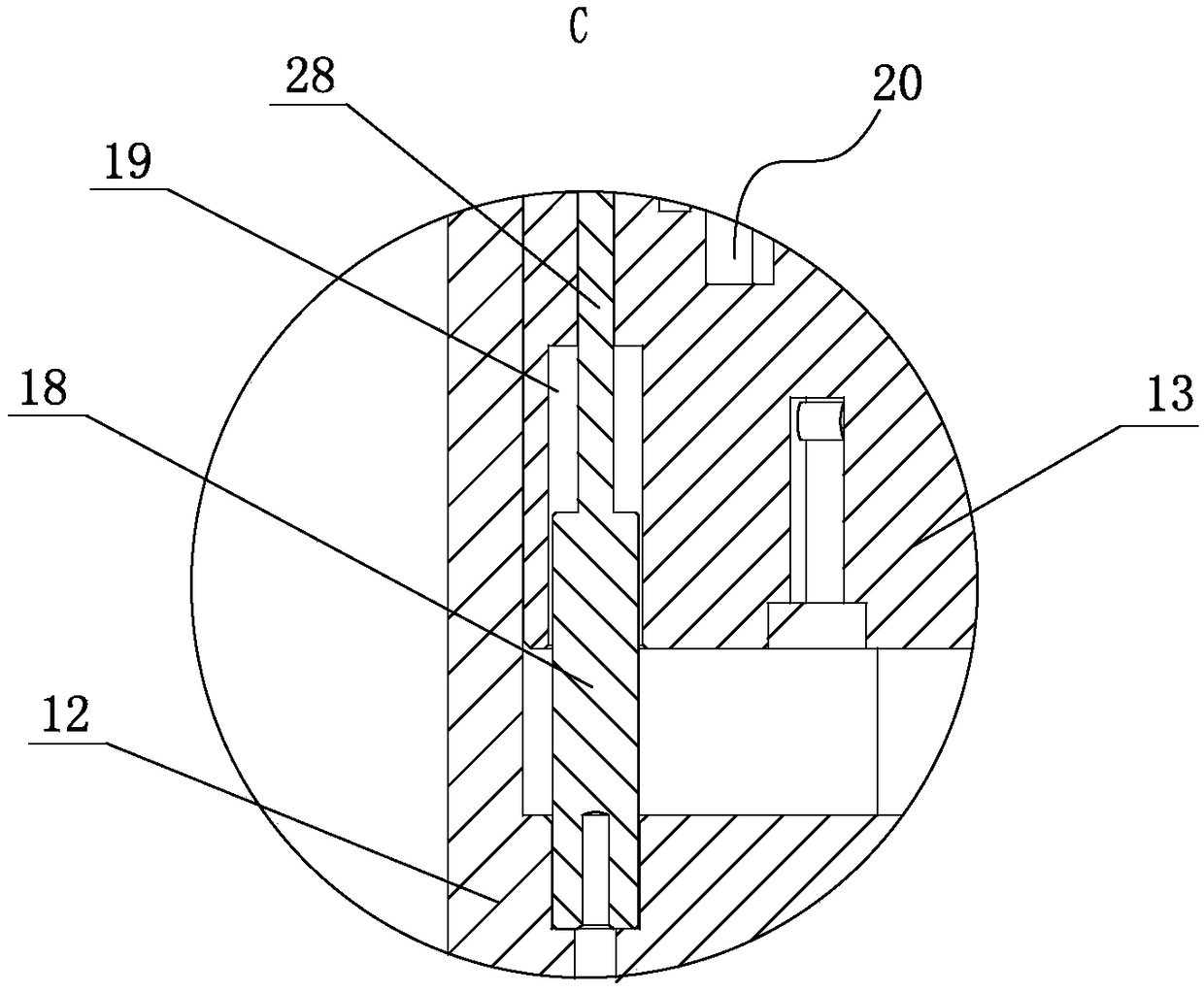

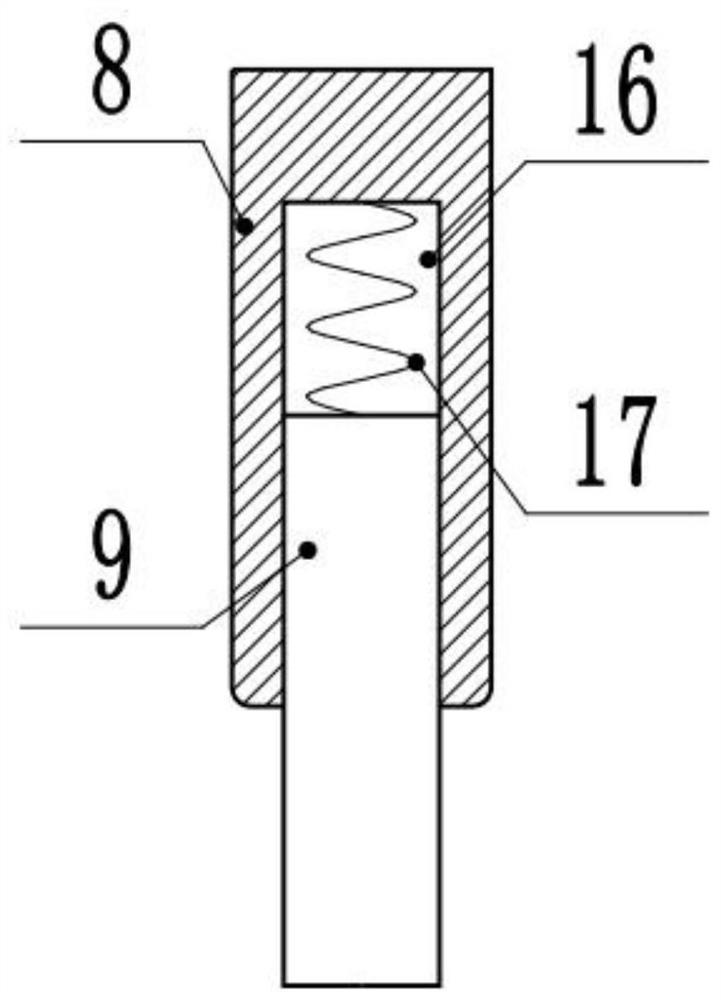

Puncture needle mechanism for manufacturing composite carbon fiber prefabricated part

InactiveCN104963103AAchieve punctureImprove production efficiencyNeedling machinesElastic componentCarbon fibers

The invention discloses a puncture needle mechanism for manufacturing a composite carbon fiber prefabricated part. The puncture needle mechanism comprises a hollow barrel, a thimble which is arranged inside the barrel and connected with the barrel through an elastic component, and a first gasket. A conical part is arranged at one end of the barrel, a through hole is formed in the other end of the barrel, and the first gasket abuts against the edge of the barrel. The thimble can make longitudinal motion in the barrel and movably stretch out of the conical part, and the thimble is connected with the elastic component through a second gasket. A spine part is arranged at the other end of the thimble, and a plurality of barb parts are arranged between the spine part and the second gasket. According to the puncture needle mechanism for manufacturing the composite carbon fiber prefabricated part, due to the arrangement of the barrel with the conical part, carbon fiber layers can be punctured, and fiber gaps can be widened; then through the arrangement of the thimble with the spine part, the carbon fiber layers are ejected into the back face of a carbon fiber mesh tire through a puncture needle, hence, the puncture effect is improved, and the manufacturing efficiency of the composite carbon fiber prefabricated part is improved as well.

Owner:宜兴市飞舟高新科技材料有限公司

Kidney puncture sampling device

InactiveCN108852427AEasy to locateAvoid damageSurgical needlesVaccination/ovulation diagnosticsBiopsyProthrombin time

The invention relates to the field of medical equipment, and particularly relates to a kidney puncture sampling device. The kidney puncture sampling device comprises a puncture device; the puncture device comprises a ring-shaped biopsy needle fixing frame; a puncture needle is arranged inside the biopsy needle fixing frame; a hand pressing airbag is arranged behind the biopsy needle fixing frame;a pressure reducing valve is arranged at the top of the hand pressing airbag, and the pressure reducing valve is connected with a puncture point positioning device; a test device is arranged at one side of the puncture point positioning device, and the test device comprises a platelet counter and a prothrombin time tester; the platelet counter is directly connected with the prothrombin time tester, and the platelet counter is connected with a blood pressure monitor; the prothrombin time tester is connected with a B-mode ultrasound detector; an ultrasonic probe is arranged on the surface of theB-mode ultrasound detector; an anaesthetic vaporizing tank is arranged at the top of the B-mode ultrasound detector. The device is simple in structure and has a good working effect.

Owner:罗生金

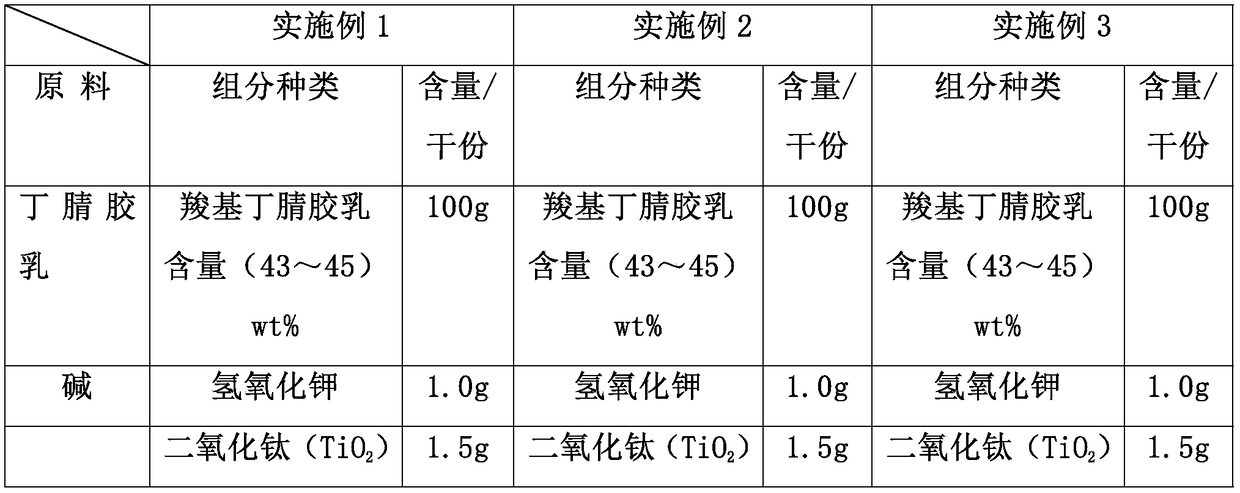

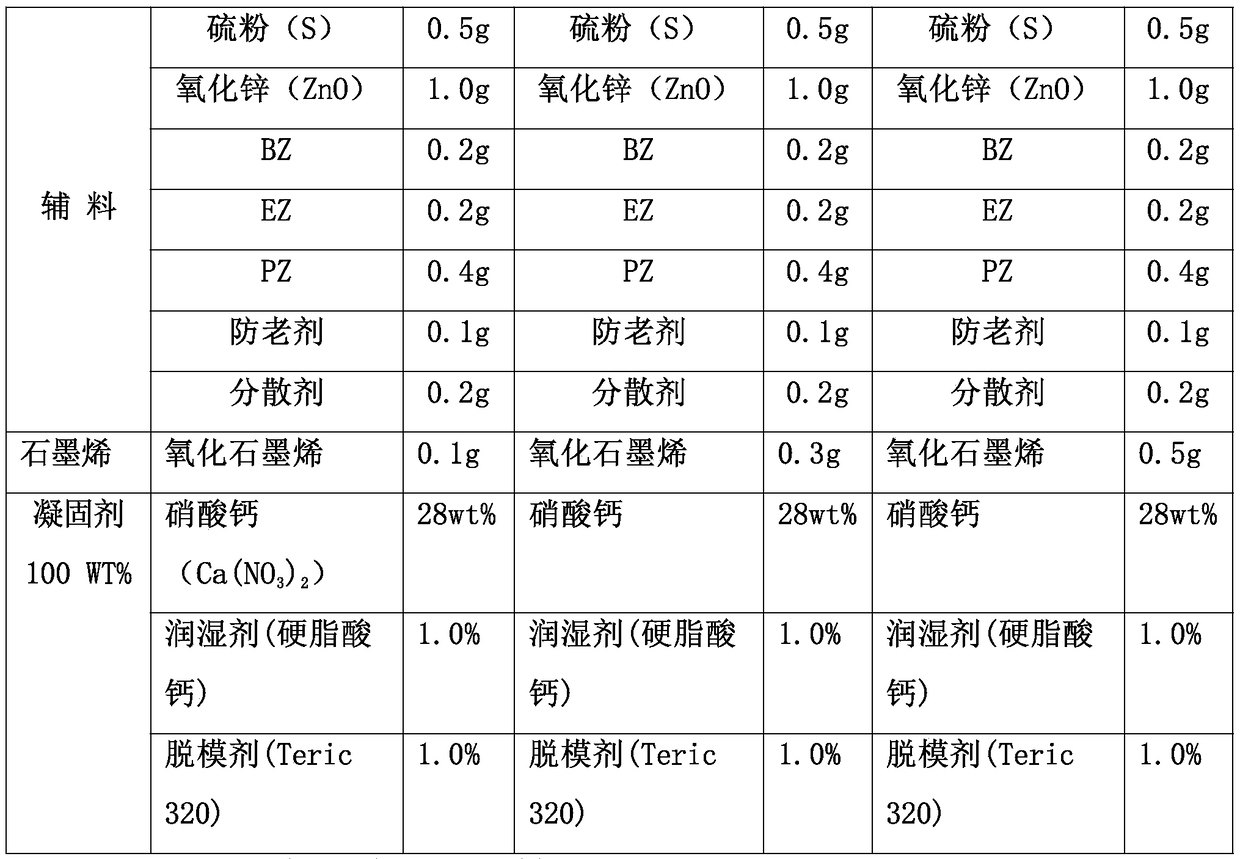

Method for producing graphene functionalized nitrile flocked gloves

InactiveCN108948386AStrong tensile properties and wear resistanceLong-lasting anti-acid and anti-alkaline propertiesGlovesProtective garmentCvd grapheneWater soluble

The invention discloses a method for producing graphene functionalized nitrile flocked gloves. Highly-water-soluble graphene oxide is adopted, and is organically modified, the specially treated graphene oxide is uniformly dispersed in nitrile butadiene latex, a graphene oxide reducing agent is added into the latex, and the co-action of heat reduction of the graphene oxide and reduction of the reducing agent in the high-temperature vulcanization molding of the nitrile butadiene latex makes the performances of reduced graphene maximally shown in the latex gloves. Test data of the graphene functionalized nitrile flocked gloves show that the mechanical property tensile strength is improved by 65%, and reaches 43 MPa; the elongation at break is increased by 38% or above, and reaches 360% or above; the antibacterial performance reaches 100%, and the chemical resistance is grade 5; and the wear resistance, the cutting resistance and the puncture performance of the gloves are greatly improved.

Owner:NANTONG QIANGSHENG SAFETY PROTECTION TECHNOLOGY CO LTD

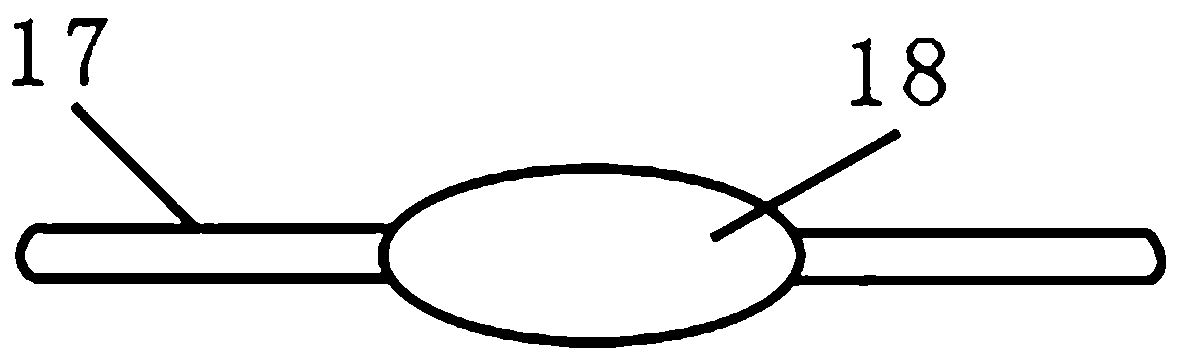

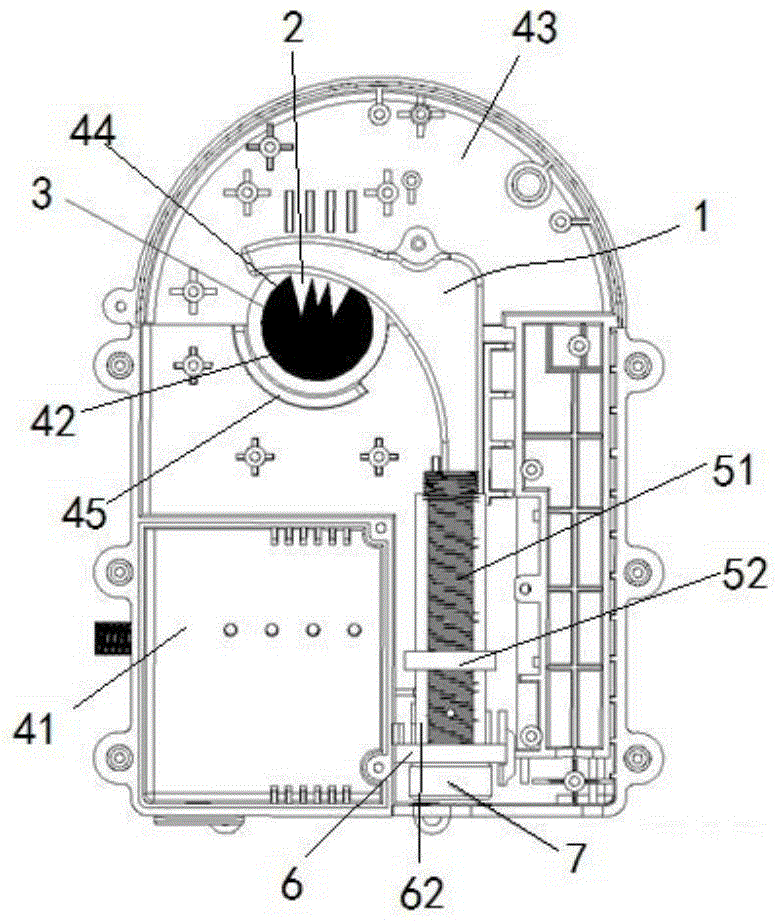

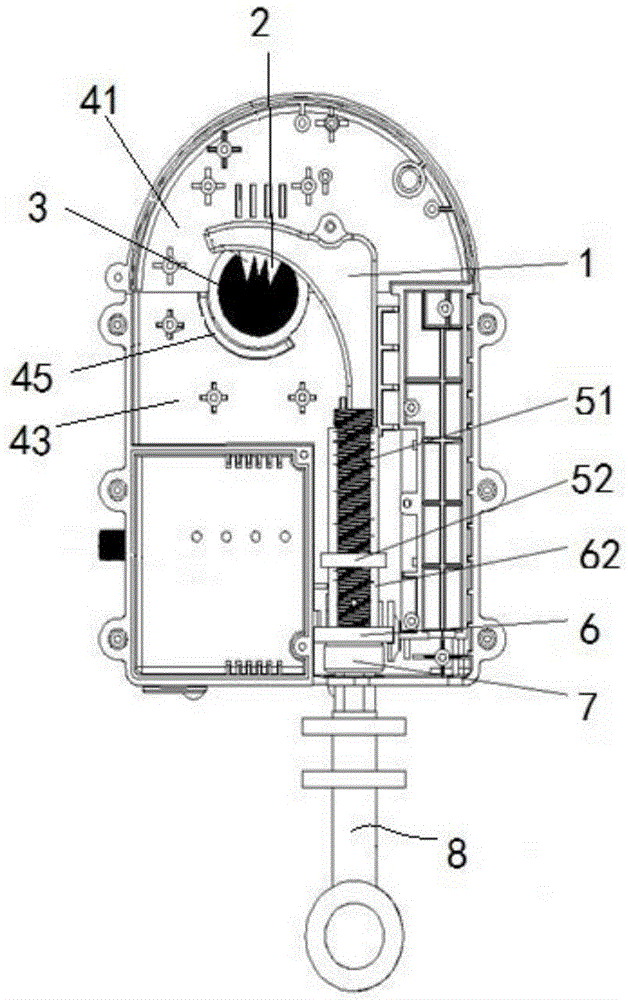

Puncture electricity-taking device and electric equipment equipped with the same

ActiveCN105576400AHigh power electric energyEasy to installContact members penetrating/cutting insulation/cable strandsApparatus for overhead lines/cablesElectricityElectrical wiring

The invention provides a puncture electricity-taking device and electric equipment equipped with the same. The puncture electricity-taking device includes a puncture electricity-taking piece (1) which is suitable for being electrically connected with electric equipment and has at least one tooth (2), and the teeth (2) can penetrate through an insulating jacket of a power transmission line (3) to be in contact with and electrically connected with the power transmission line (3), thereby supplying power to the electric equipment. The puncture electricity-taking device provided by the invention can stably provide high-power electric energy for the electric equipment for a long time, is rapid and convenient to install, and in addition, can realize live-line installation, and power supply is not influenced during installation.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

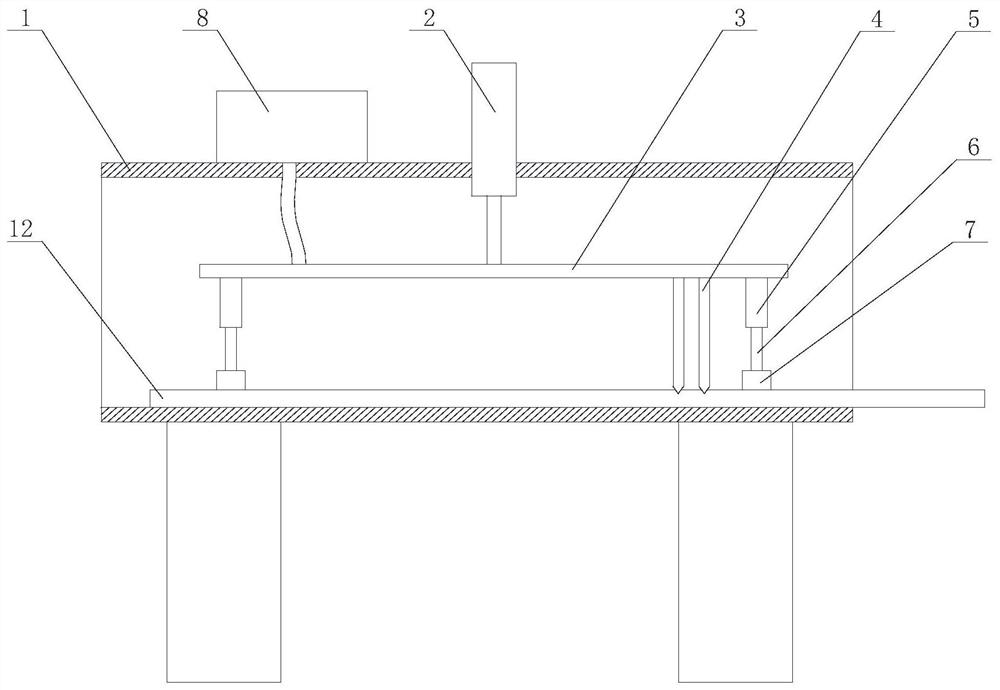

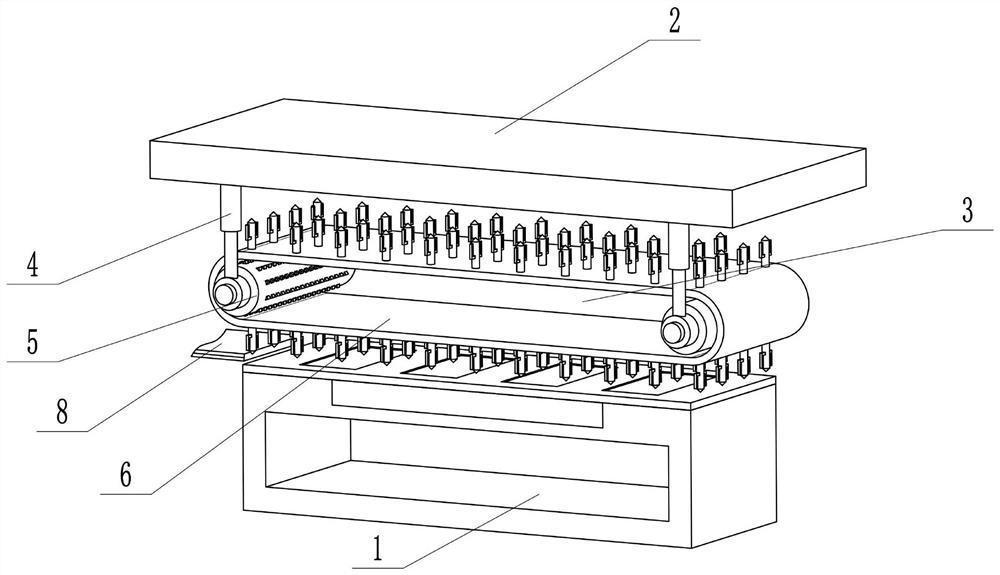

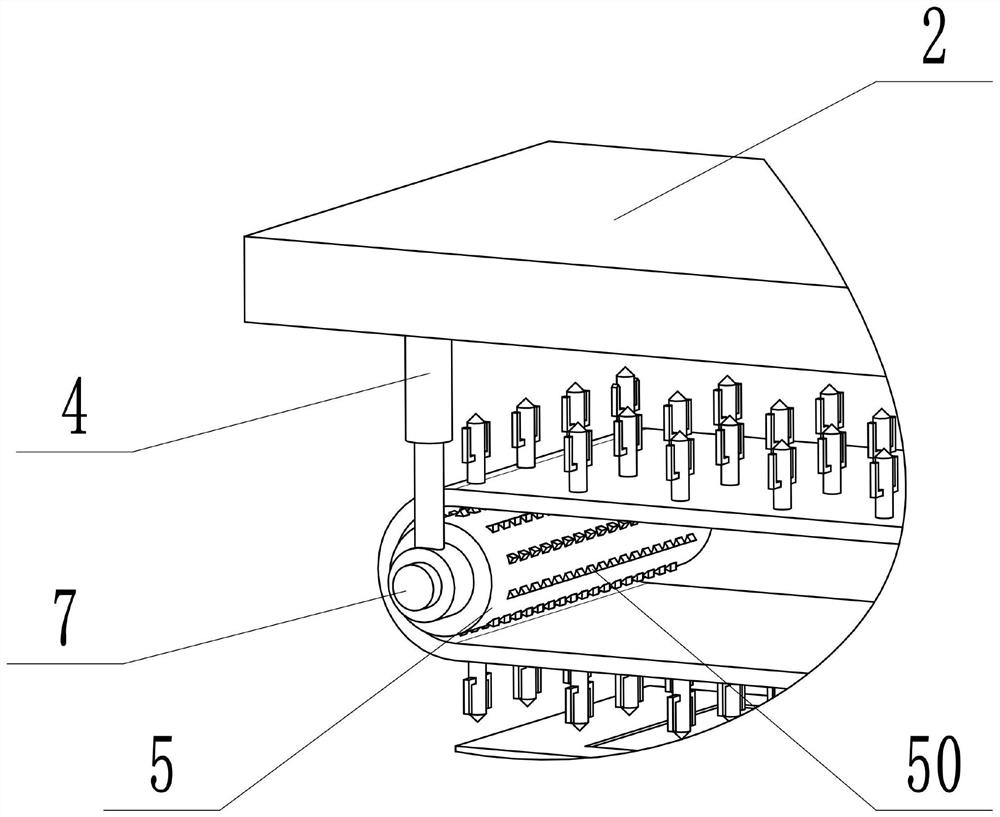

Non-woven fabric with good air permeability and preparation process

ActiveCN113265771AReduce fluffinessImprove puncture abilityNeedling machinesHeating arrangementNonwoven fabricMechanical engineering

The invention discloses a non-woven fabric with good air permeability and a preparation process, and aims to provide the non-woven fabric with good air permeability and the preparation process, and the non-woven fabric is good in needling reinforcement and cloth forming effect. The non-woven fabric is formed by superposing multiple layers of fiber webs; a preparation device for the non-woven fabric with good air permeability comprises a base and a top plate; the top plate is arranged above the base; a processing assembly is arranged between the base and the top plate; the lower surface of the top plate is connected with telescopic rods; the processing assembly is provided with two supporting roller shafts; the supporting roller shafts are sleeved with a processing belt capable of rolling; and the telescopic rods are connected with the supporting roller shafts. The invention has the beneficial effects that water discharged from water outlets in the centers of fixed needles can humidify multilayer fibers, so that the fluffy effect of the multilayer fibers is reduced, and the multilayer fibers are easily reinforced to form cloth; movable needles are matched with stop blocks, and the stop blocks can swing through vertical movement of the movable needles, so that water discharge and closing of the water outlets are controlled; the movable needles are connected with springs, so that the puncture effect of the movable needles is stronger, and the reinforcing effect is better; and a heat conducting plate can heat the processed non-woven fabric to obtain the dry non-woven fabric with good air permeability.

Owner:浙江巴来腾科技股份有限公司

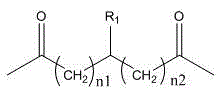

Biodegradable aliphatic-aromatic copolyester and application thereof

ActiveCN104479120AHigh yield strengthImprove puncture abilityClimate change adaptationPlant protective coveringsPolymer scienceSide chain

The invention discloses a biodegradable aliphatic-aromatic copolyester and an application thereof. The biodegradable aliphatic-aromatic copolyester comprises the following components: component 1: an aliphatic polyester unit composed of 45-60mol% of aromatic diacid residue A1 and dihydroxyl compound residue B; component 2: a linear aliphatic polyester unit composed of 37-54.7 mol% of linear aliphatic diacid residue A2 and dihydroxyl compound residue B; component 3: a polyether-containing side-chain aliphatic polyester unit composed of 0.3-3mol% of polyether-containing side-chain aliphatic diacid residue A3 and dihydroxyl compound residue B. According to the biodegradable aliphatic-aromatic copolyester disclosed by the invention, because the polyether-containing side-chain aliphatic polyester unit is contained, the yield strength of the prepared film is increased, the improvement of the puncture resistance of the agricultural mulch film to crops and weeds is promoted, and the probability of the occurrences of a hole breaking phenomenon is reduced; moreover, the anti-tear strength and the dart-drop-impact breakage quality are improved, and the prevention of hole breakage of the film during a use process is promoted.

Owner:KINGFA SCI & TECH CO LTD

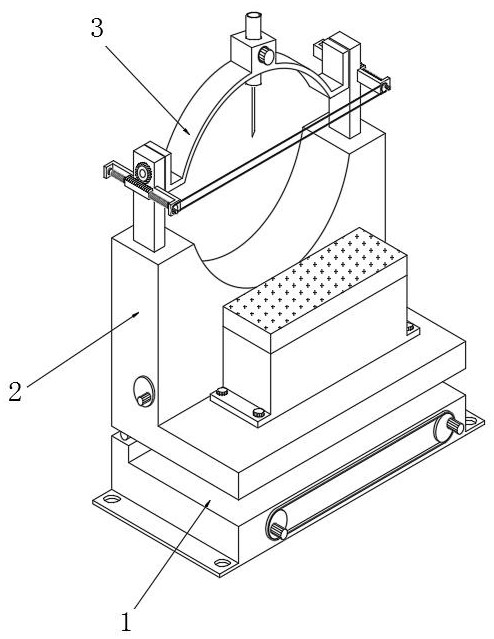

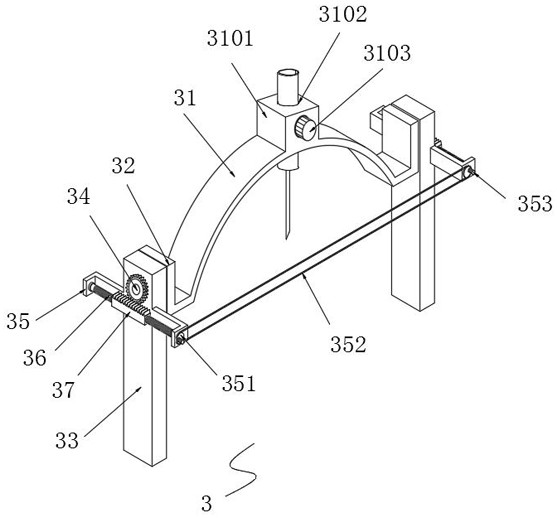

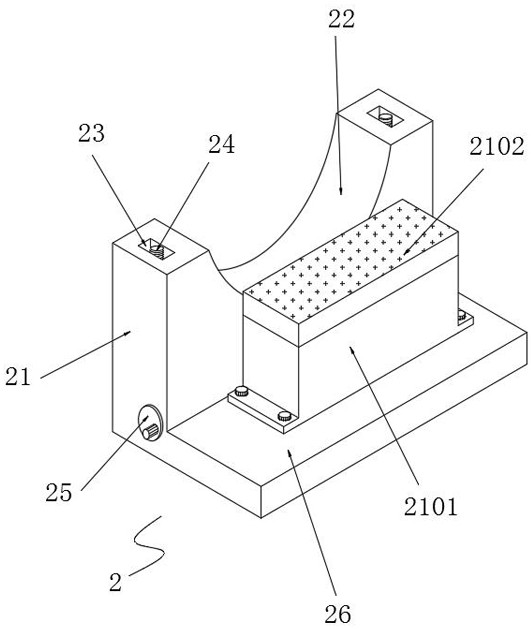

A disposable thyroid puncture positioning device

ActiveCN112244967BPrecise positioningIncrease success rateSurgical needlesVaccination/ovulation diagnosticsSurgeryThyroid

The invention discloses a positioning device for a disposable thyroid puncture device, which includes a base mechanism, a support mechanism is rotatably installed on one side of the upper surface of the base mechanism, an adjustment mechanism is arranged on the upper surface of the support mechanism, and the adjustment mechanism includes There are arc-shaped plates, and both ends of the arc-shaped plates are provided with L-shaped blocks, and the back sides of the two L-shaped blocks are vertically rotated and connected with vertical rods, and the upper ends of the two vertical rods are embedded in the back side The rotation is fitted with gears. The invention relates to the technical field of thyroid puncture. The disposable thyroid puncturer positioning device is provided with an adjustment mechanism and a support mechanism. Under the mutual cooperation of the adjustment mechanism and the support mechanism, when the patient's thyroid is punctured, the puncturer can It plays a good positioning role, and can conveniently adjust the puncture angle, without manually supporting the puncture device by hand, so that the puncture device is more stable during the puncture process.

Owner:武孟孟

Filling material for extrusion recombination

The present invention discloses one kind of stuffing for extrusion compounding and aims at reducing plastic consumption. The stuffing has the basic plastic components maintained, and added pellet comprising mechanically ground calcium carbonate powder as main component and small amount of LDPE, coupling agent and dispersant in certain proportion. The stuffing is applied in extruding soft plastic packing material for food, etc. and has raised physical performance, lowered production cost and saving in energy.

Owner:许锦才 +1

Carding plate

InactiveCN103526343ASimple structureEasy to assembleCarding machinesBiomedical engineeringEngineering

The invention relates to the technical field of textile machinery, in particular to a carding plate. The carding plate comprises a framework, threaded holes, needle bodies, needle tips and non-stick layers. Each threaded hole is formed in the framework, each needle body provided with the needle tip is disposed in the threaded hole, and each non-stick layer is coated on the needle tip. The carding plate has the advantages that the carding plate is simple, compact and reasonable in structure, convenient and fast to assemble, reliable in connection and easy to use and popularize, each needle tip is sharp and high in puncture capability, carding effect can be increased, nep is reduced, fiber damage is reduced, yield is increased, working reliability of the carding plate is increased greatly, each carding needle is connected with the framework in a threaded manner and can be replaced independently, and service life of the carding plate is prolonged.

Owner:CHONGQING YUBI TEXTILE

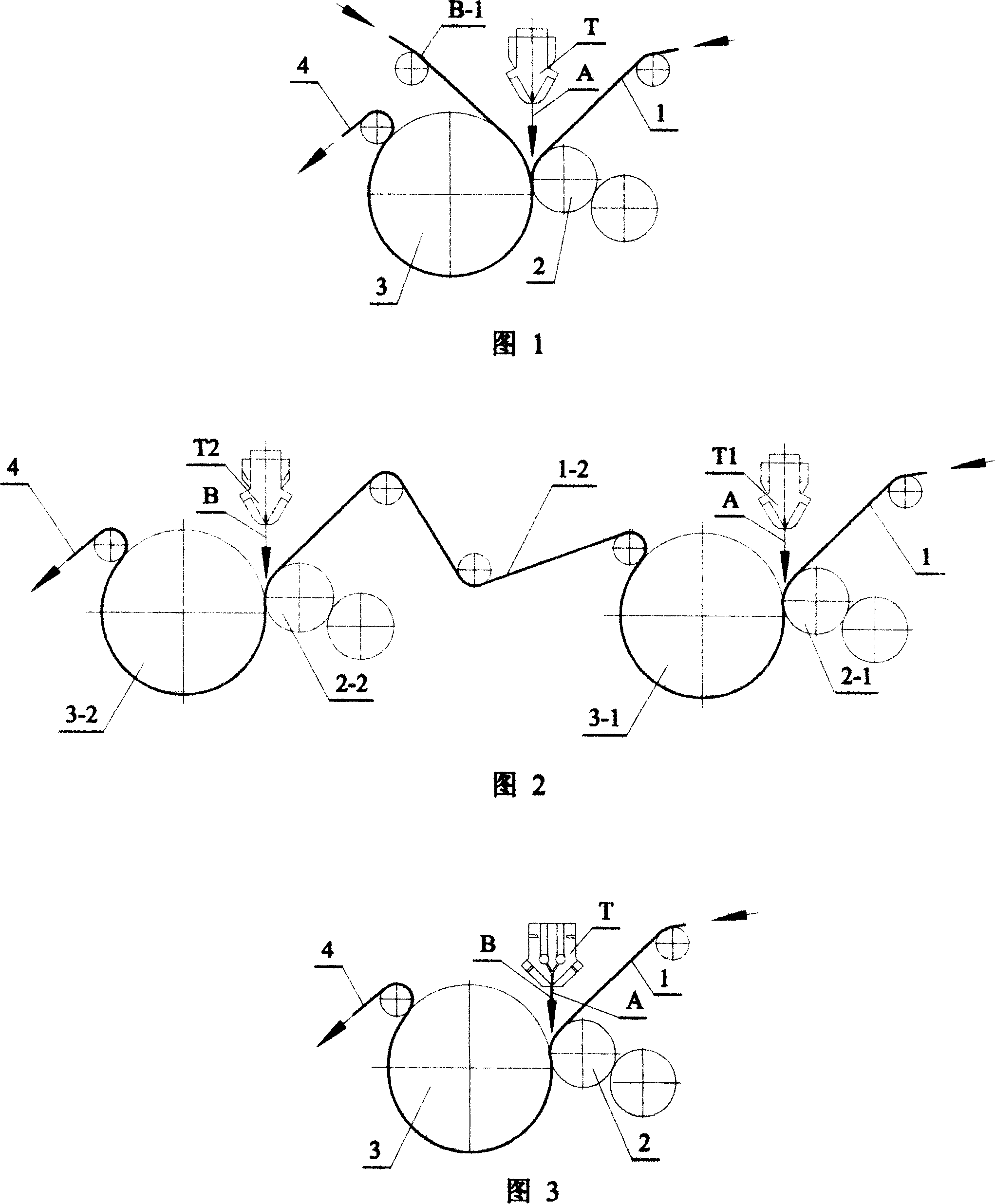

Kirschner wire locator for orthopaedics

InactiveCN111067612AEasy to punctureImprove puncture abilityAnti-corrosive paintsOsteosynthesis devicesEngineeringSurgery

The invention relates to the field of medical apparatuses, in particular to a Kirschner wire locator for orthopaedics. The Kirschner wire locator comprises a supporting seat assembly and a regulatingmechanism, wherein the supporting seat assembly comprises concaved frames which are arranged from left to right and sliding rods which are fixedly arranged between notches in each group of the concaved frame; the front ends of the two groups of the sliding rods and the rear ends of the two groups of the sliding rods are separately connected through connecting pieces; an adjusting screw rod is in threaded connection to the middle part of the connecting piece in the front side in a penetrating manner; the regulating mechanism comprises a moving assembly and an angle regulating assembly; the moving assembly comprises a moving frame and arc-shaped guide rails which are symmetrically arranged at the front part and the rear part of the upper side of the moving frame; sliding sleeves which are insleeving connection with the sliding rods for cooperation are arranged at four corners of the moving frame; and the front side of the moving frame is rotatably connected with the rear end of the adjusting screw rod through spherical hinging. The Kirschner wire locator disclosed by the invention is simple in structure; and through rotating the adjusting screw rod and the angle screw rod and movinga rectangular framework, different piercing inclined angles between the Kirschner wire pipe and the bone part of a patient are realized, so that the Kirschner wire can be pierced into the bone part of the patient in a stable sloping angle, and the piercing effect of the Kirschner wire is improved.

Owner:CHONGQING MEDICAL & PHARMA COLLEGE

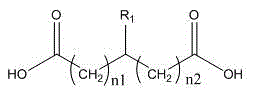

Biodegradable aliphatic-aromatic copolyester composition and application thereof

The invention discloses a biodegradable aliphatic-aromatic copolyester composition. The biodegradable aliphatic-aromatic copolyester composition contains the following ingredients in percentage by mass: A: 69.95-89.95% of alkyl / alkoxy side chain-containing aliphatic-aromatic copolyester, B: 10-30% of polylactic acid and C: 0.05-3% of compatibilizer, wherein the A contains the following ingredients in percentage by mass: A1: 44-60% of aromatic polyester unit, A2: 39-55% of straight-chain aliphatic polyester unit and A3: 0.3-3% of alkyl / alkoxy side chain-containing aliphatic dibasic acid ester unit. According to the biodegradable aliphatic-aromatic copolyester composition disclosed by the invention, the alkyl / alkoxy side chain-containing aliphatic dibasic acid ester unit of a specific proportioning ratio is added, so that the yield strength of manufactured films is improved, the improvement of crop and weed puncture resistance of agricultural mulching films is facilitated, and the probability of occurrence of a hole breaking phenomenon is reduced; the oxygen gas permeability is improved, and the water vapor permeability is lowered, so that the manufactured films have better heat preserving and moisture preserving effects as the agricultural mulching films.

Owner:KINGFA SCI & TECH CO LTD

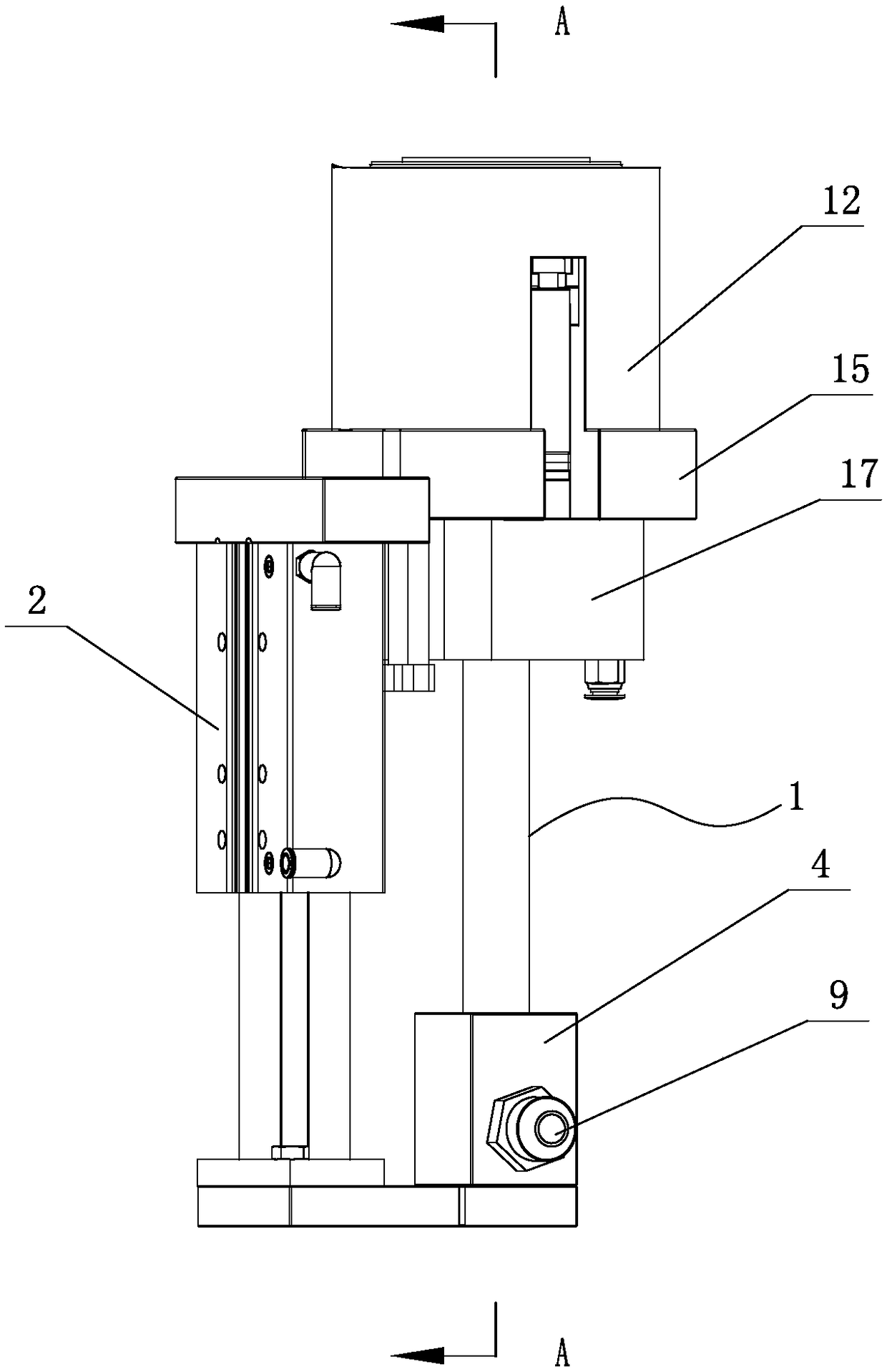

Blowing needle mechanism for single blowing hole of blowing mold

A blowing needle mechanism for a single blowing hole of a blowing mold comprises a blowing needle (1) connected with an air source, a push-pull air cylinder (2) fixed on a mold rack and a blowing needle guide mechanism, wherein a needle body comprises an outer pipe (5) and an inner pipe (6); the inner pipe (6) is located in the outer pipe (5); the inner wall of the outer pipe (5) and the outer wall of the inner pipe (6) form a channel (7); the upper end of the inner pipe (6) is connected and communicated with a needle head (3); the upper end of the outer pipe (5) is hermetically connected withthe needle head (3); at least one air hole (8) is formed in the outer peripheral surface of the upper end of the outer pipe (5); the lower end of the outer pipe (5) is connected with a needle seat (4); a first pipe connector (9) is communicated with the inner pipe (5); a second pipe connector (10) is communicated with the channel (7); and a plurality of air blowing holes (11) is formed in the needle head (3). Compared with the prior art, the blowing needle mechanism has the characteristics that the volume is relatively small, the production cycle can be shortened, the preparation cost is relatively low and the maintenance is relatively simple and convenient.

Owner:NINGBO FANGZHENG TOOL

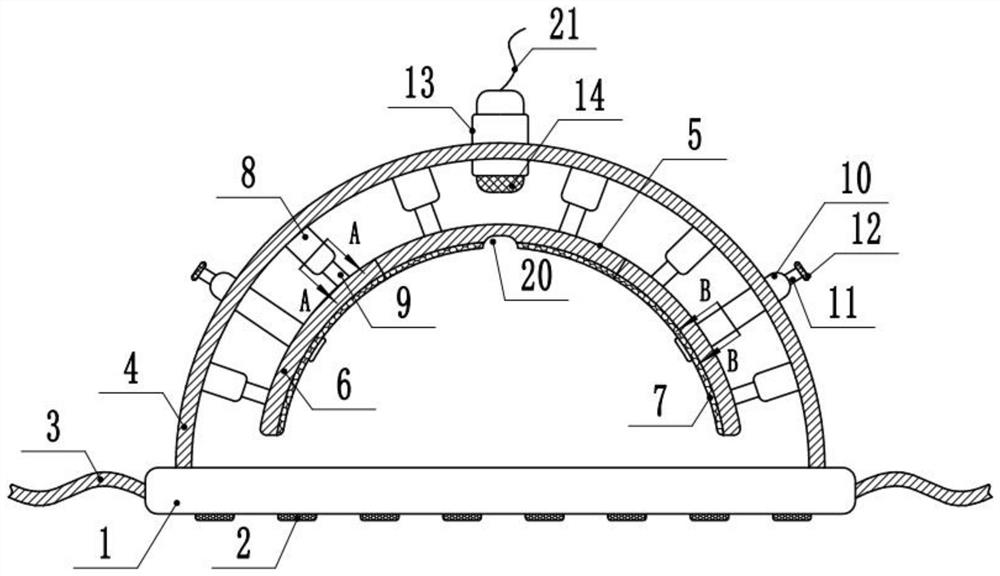

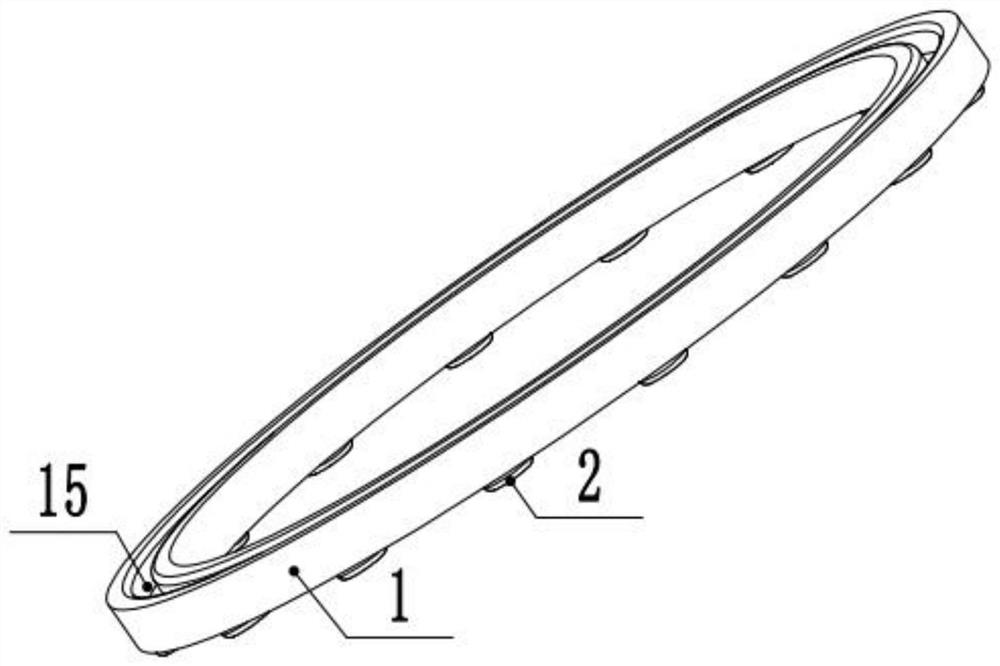

Ultrasonic-guided mammary gland puncture device

InactiveCN112401991AGood fixed effectRelieve painSurgical needlesVaccination/ovulation diagnosticsHuman Mammary GlandsBiomedical engineering

The invention discloses an ultrasonic-guided mammary gland puncture device. The ultrasonic-guided mammary gland puncture device comprises an outer ring, an inner ring and a fixed disc; the outer ringand the inner ring are semicircular structures; the inner ring is composed of an upper inner ring body and a side inner ring body; furthermore, the upper inner ring body and the side inner ring body are spliced to form a semicircular structure; the periphery of the surface of the inner wall of the outer ring is fixedly connected with a fixed base; a sliding groove is arranged in the other end of the fixed base; the bottom in the sliding groove is fixedly connected with a first spring; the other end of the first spring is fixedly connected with a connecting rod; the side surface of the connecting rod is in contact connection with the side surface of the sliding groove; furthermore, the other end of the connecting rod is fixedly connected with the outer walls of the upper inner ring body andthe side inner ring body respectively; a puncture cylinder is installed between the side inner ring body and the outer ring; and the outer surface of one end of the inner side of the puncture cylinder is in contact connection with the inside of the side inner ring body. The ultrasonic-guided mammary gland puncture device disclosed by the invention has a better breast fixing effect, is more beneficial to subsequent mammary gland puncture, and can effectively reduce the pain of a patient caused by mammary gland puncture.

Owner:王明辉

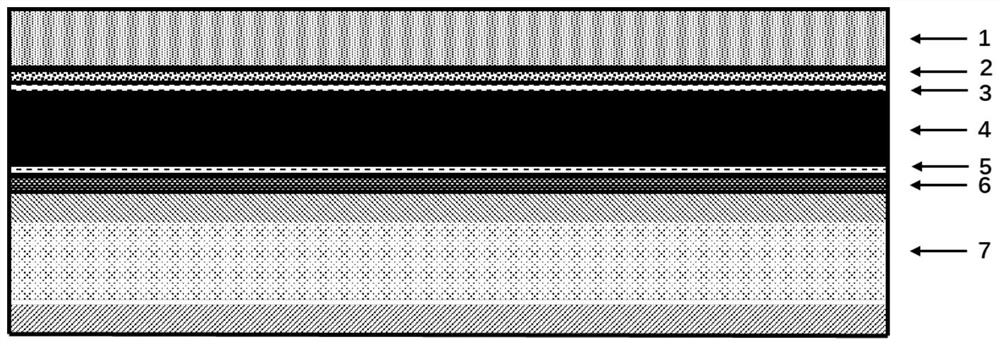

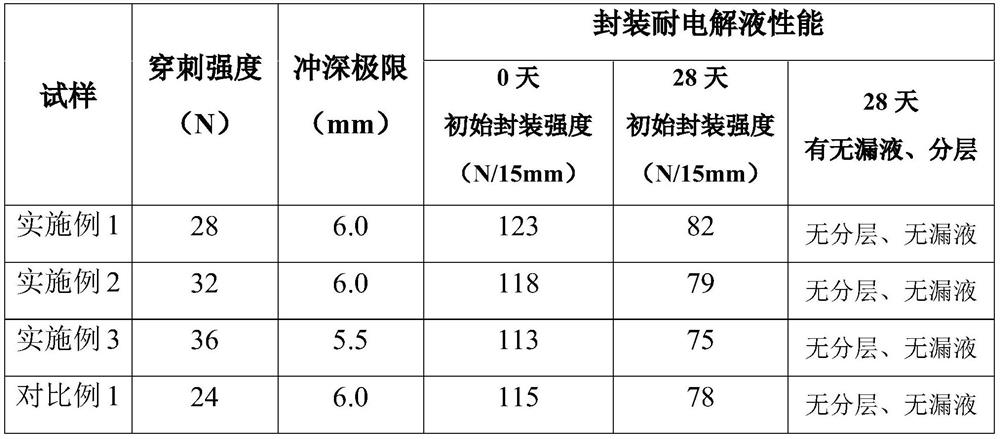

Puncture-resistant electrolyte-resistant casting polypropylene film, aluminum-plastic film and application of puncture-resistant electrolyte-resistant casting polypropylene film and aluminum-plastic film

PendingCN114142170AHigh crystallinityHigh strengthSynthetic resin layered productsCell component detailsElectrolytic agentPolymer science

The invention relates to a puncture-resistant electrolyte-resistant casting polypropylene film, an aluminum-plastic film and application of the puncture-resistant electrolyte-resistant casting polypropylene film and the aluminum-plastic film. The puncture-resistant electrolyte-resistant casting polypropylene film comprises a heat-sealing base layer, a core layer and a corona layer which are sequentially distributed in an overlapped mode, the corona layer is polypropylene random copolymer, and the core layer comprises polypropylene random copolymer and nano silicon nitride. According to the puncture-resistant electrolyte-resistant casting polypropylene film disclosed by the invention, nano silicon nitride is introduced into the core layer, so that the core layer polypropylene with higher nano hardness shows higher wear resistance; in addition, the nano silicon carbide can also be used as a nucleating agent to improve the crystallization property of polypropylene so as to enhance the mechanical property; besides, due to the addition of the nano silicon nitride, the heat sealing performance of the heat sealing layer of the aluminum-plastic film and the bonding performance between the corona layer and glue are not influenced, and the core layer with high puncture strength and the complete corona layer structure can still be kept while the CPP puncture performance is improved, so that the core layer has high puncture strength under the condition that the core layer is punctured and worn by burrs in a battery cell for many times, and the service life of the core layer is prolonged. And a relatively complete electrolyte-resistant casting polypropylene structure can still be kept.

Owner:浙江华正能源材料有限公司

Puncture-resistant BOPET film for aluminizing and preparation method thereof

InactiveCN110920195AImprove toughnessHigh strengthSynthetic resin layered productsMasterbatchPolymer science

The invention discloses a puncture-resistant BOPET film for aluminizing and a preparation method thereof. The film is composed of an upper surface layer, a core layer and a lower surface layer. The core layer is prepared from the following raw materials by mass percent: 60%-80% of PET polyester chips and 20%-40% of ENBA copolymerization modified PET polyester chips, wherein the upper surface layeris prepared from the following raw materials: 5% to 10% of PET polyester chips, 10% to 20% of ENBA copolymerized modified PET polyester chips, and 70% to 85% of PET polyester anti-stick master batch.The lower surface layer is prepared from the following raw materials: 30 to 35 percent of PET polyester chips and 65 to 70 percent of PET polyester anti-sticking master batch. The BOPET film has excellent strength, breaking nominal strain, puncture resistance and the like, and a produced product has more advantages in the aspects of performance, production cost, environmental protection, energy consumption and the like.

Owner:ANHUI GUOFENG PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com