Filling material for extrusion recombination

A technology of extrusion compounding and filling materials, which is applied in the field of improvement of extrusion compound materials, can solve the problems of high production cost, rising price of petroleum by-products, waste of energy, etc., and achieves easy material acquisition, good social and economic benefits, and improved Effect of shading performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

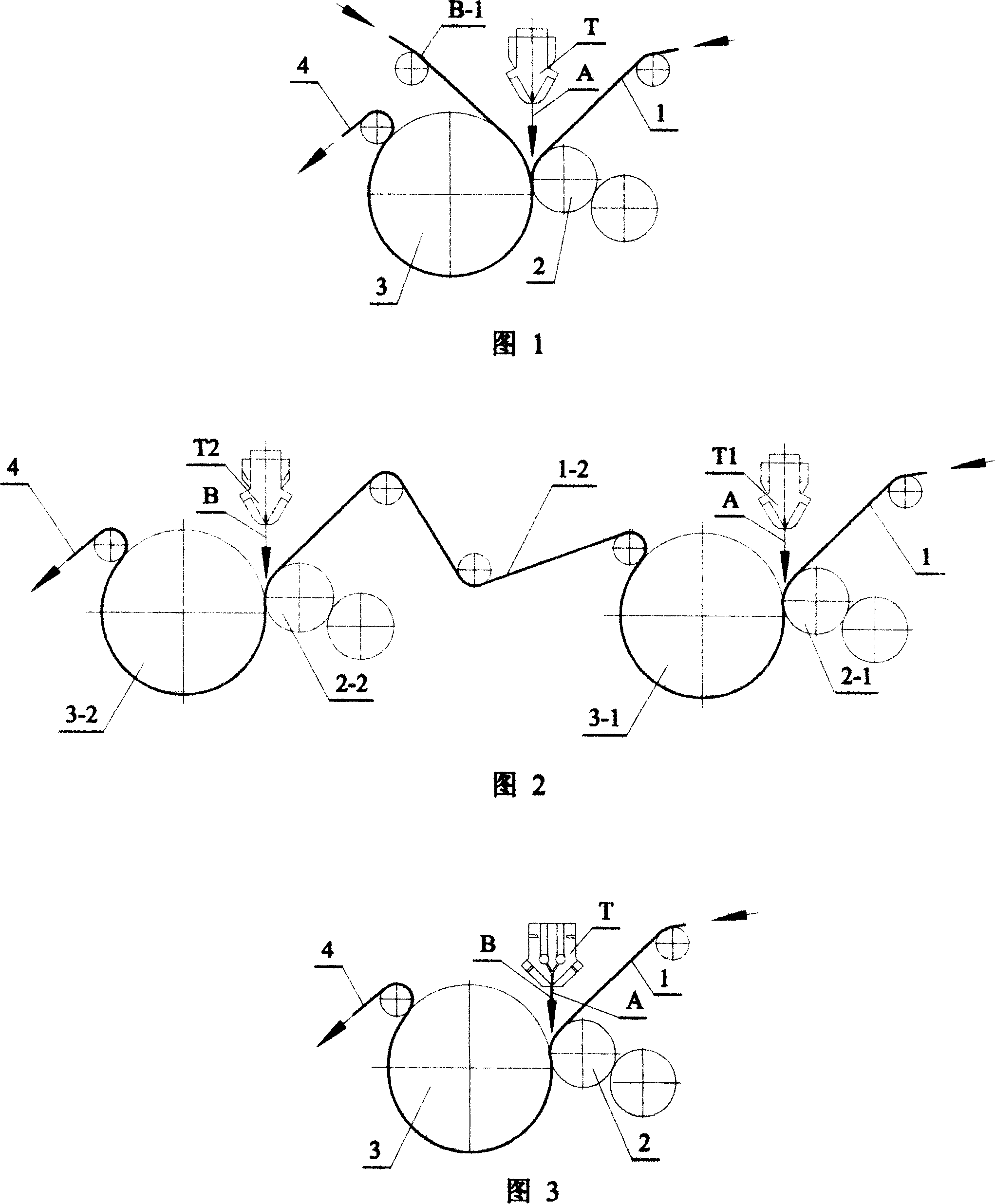

[0009] Principle of the present invention will be further described below in conjunction with accompanying drawing and embodiment:

[0010] The present invention properly reduces the amount of plastic pellets on the basis of retaining the basic components of plastic pellets, the compound material used for extrusion, and adds non-plastic substances in an appropriate amount, that is, plastic pellets and non-plastic substances constitute the filler of the present invention. The non-plastic material is granular, with calcium carbonate CaCo formed by mechanical grinding 3 As the main component, a small amount of LDPE, coupling agent and dispersant are added, and they are pre-mixed with plastic pellets in a certain proportion and extruded by extrusion equipment.

[0011] The present invention works like this in the extrusion equipment: after the extrusion equipment stirs the filler of the present invention with the plastic pellets to be used such as LDPE or PP in a certain proportio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com