Patents

Literature

517 results about "Plastic compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compounding consists of preparing plastic formulations by mixing or/and blending polymers and additives in a molten state, these blends are automatically dosed with fixed setpoints usually through feeders/hoppers.

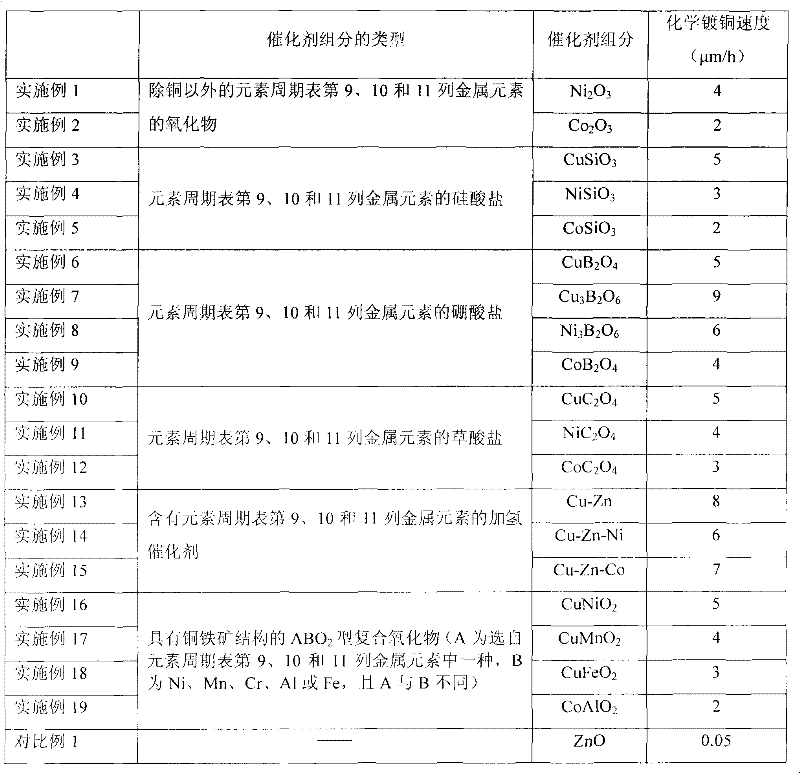

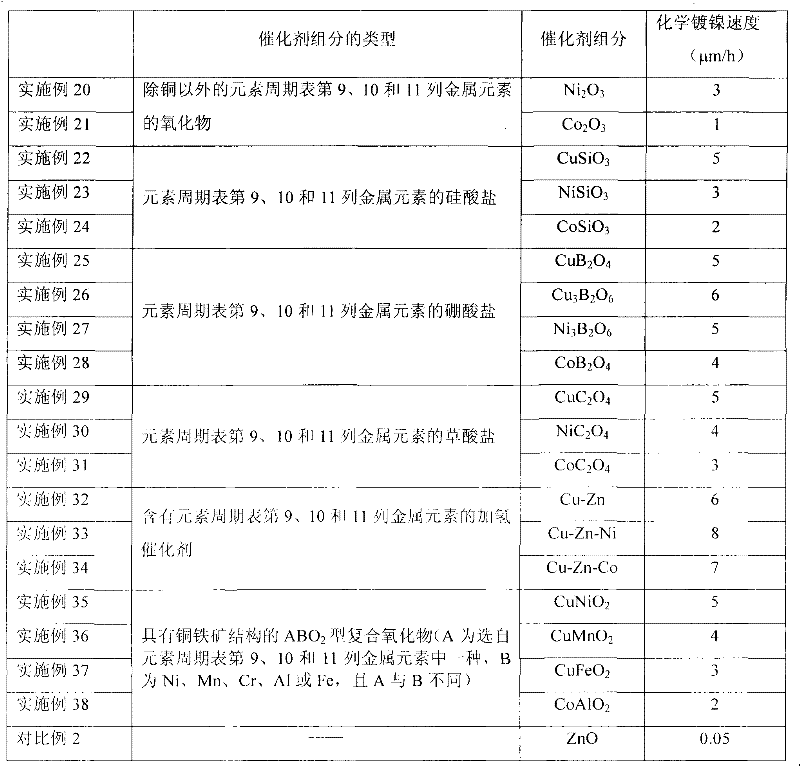

Plastic compound, application thereof and method of selective metallization of plastic surface

ActiveCN101747650AFacilitates electroless copper platingReduced stabilityLiquid/solution decomposition chemical coatingOxalateCopper

The invention provides a plastic compound, which comprises a plastic substrate component and a catalyst component, wherein the catalyst component is selected from one kind or two or more kinds of oxides of the metal elements in the ninth line, the tenth line and the eleventh line of the periodic table of elements except copper, silicates, borates and oxalates of the metal elements in the ninth line, the tenth line and the eleventh line of the periodic table of elements, hydrogenation catalysts with the metal elements in the ninth line, the tenth line and the eleventh line of the periodic table of elements and ABO2 type compound oxides with a delafossite structure; A is selected from one kind of the metal elements in the ninth line, the tenth line and the eleventh line of the periodic table of elements, B is Ni, Mn, Cr, Al or Fe, and A and B are different from each other. The invention also relates to application of the plastic compound in the selective metallization of a plastic surface. Moreover, the invention provides a method of the selective metallization of the plastic surface. When the method is applied, the circuit can be further easily formed.

Owner:BYD CO LTD

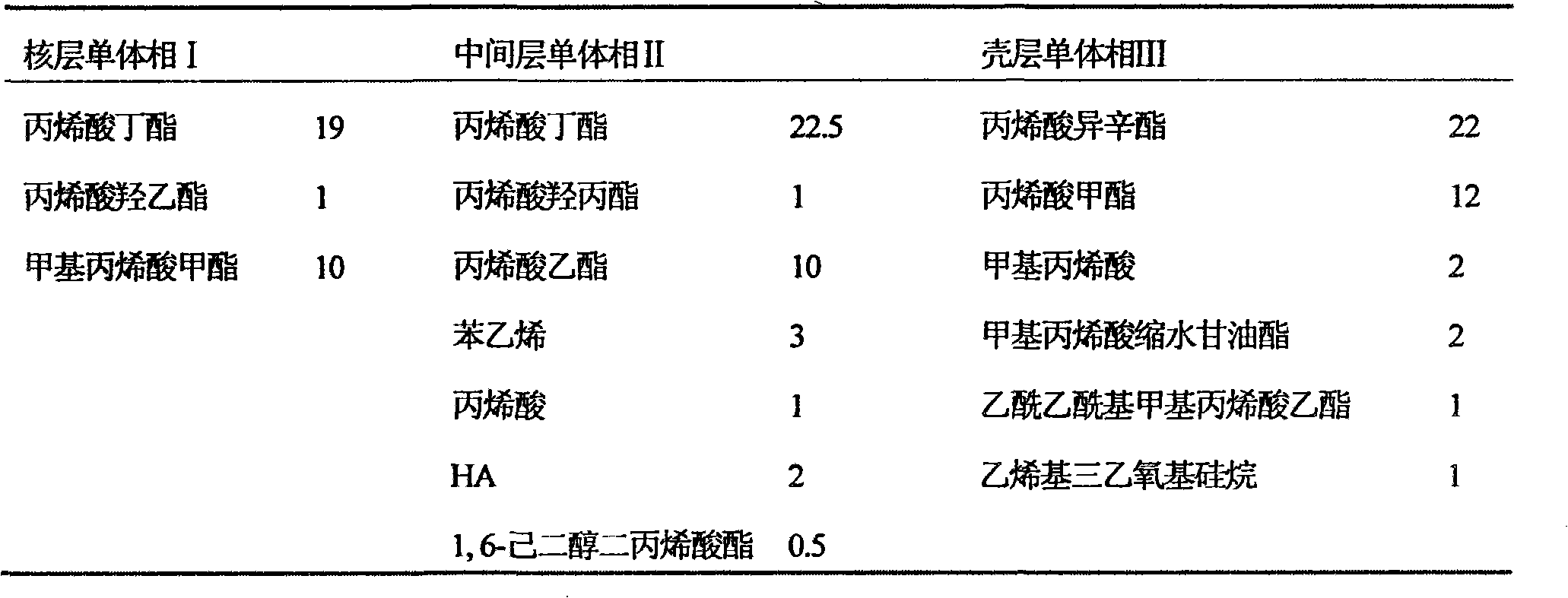

Single-component low temperature self-crossing emulsion adhesive for paper and plastic compounds and preparing method thereof

InactiveCN101928534ALess slagHigh affinityNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceAdhesive

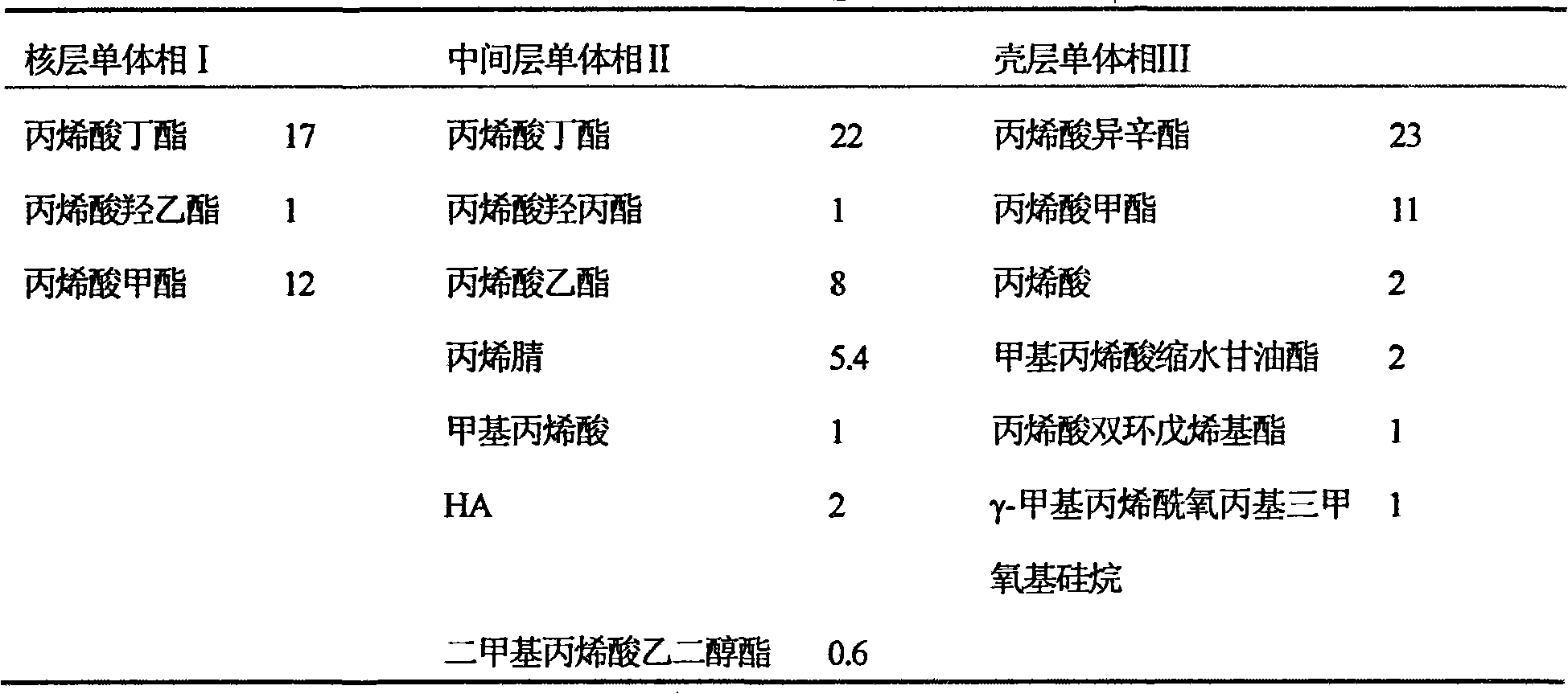

The invention discloses a single-component low temperature self-crossing emulsion adhesive for paper and plastic compounds and a preparing method thereof. The raw materials of the self-crossing emulsion adhesive comprise the following components in part by weight: 100-150 parts of de-ionized water, 0.8-3.0 parts of emulsifier, 20-40 parts of nuclear layer monomer, 30-50 parts of interlayer monomer, 20-40 parts of shell layer monomer, and 0.2-0.6 part of initiator. The invention uses a small amount of anionic emulsifier to prepare nuclear emulsion, uses polymerisable emulsifier to prepare interlayer and shell layer pre-emulsion, and adopts semi-continuous seeded low emulsion polymerization process to prepare emulsion particles that have a three-layer core-shell microstructure to obtain the exquisite and stable emulsion. The product has no organic solvent, and does not release methanal, contains no APEO and no phthalate; the film coating has high transparency, high water resistance and high heat and humidity resistance; and the emulsion adhesive is applied to plastic and paper compounds, has high adhesive strength, peel strength and permanent adhesion, is also compatible to oil and ink and has high oil / ink transferring rate.

Owner:SOUTH CHINA UNIV OF TECH

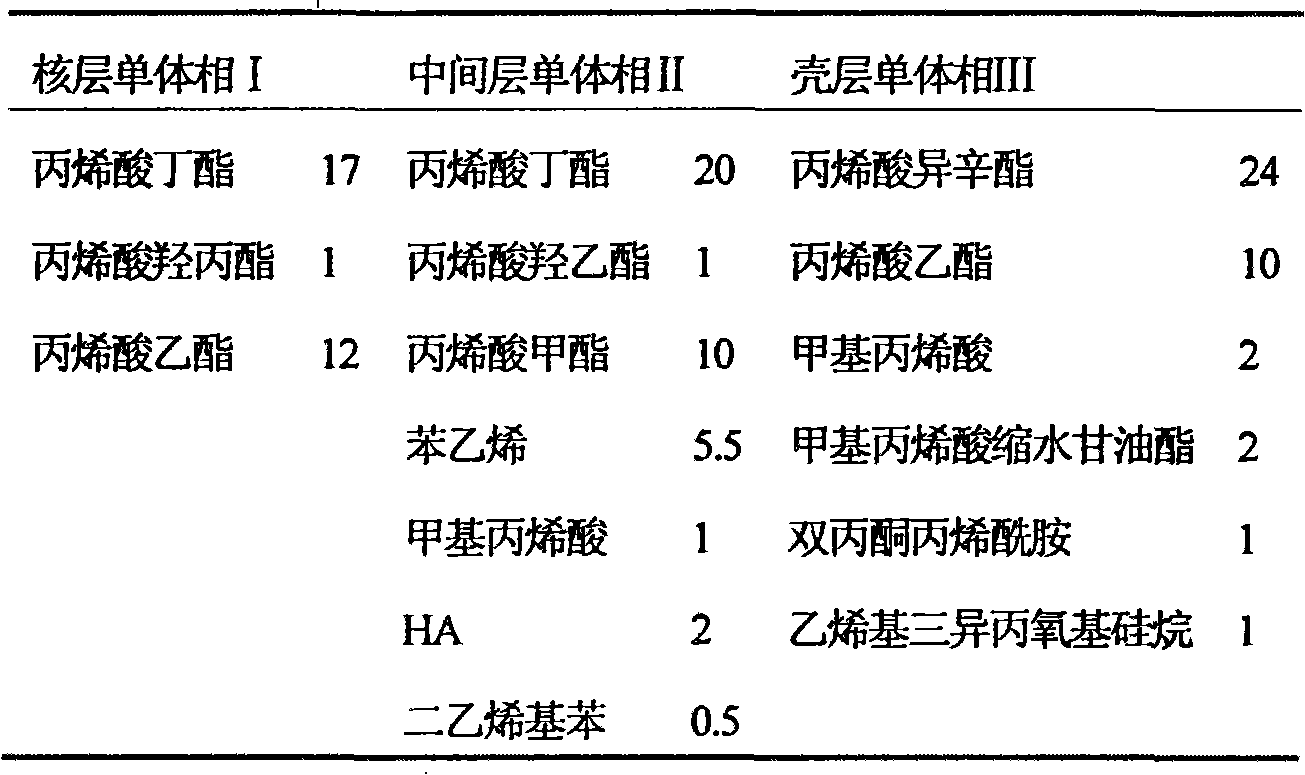

Water-based plastic-plastic compound adhesive for food and drug flexible package and preparation method thereof

ActiveCN103059784AHigh bonding strengthImprove stabilityEster polymer adhesivesWater basedPolyurethane adhesive

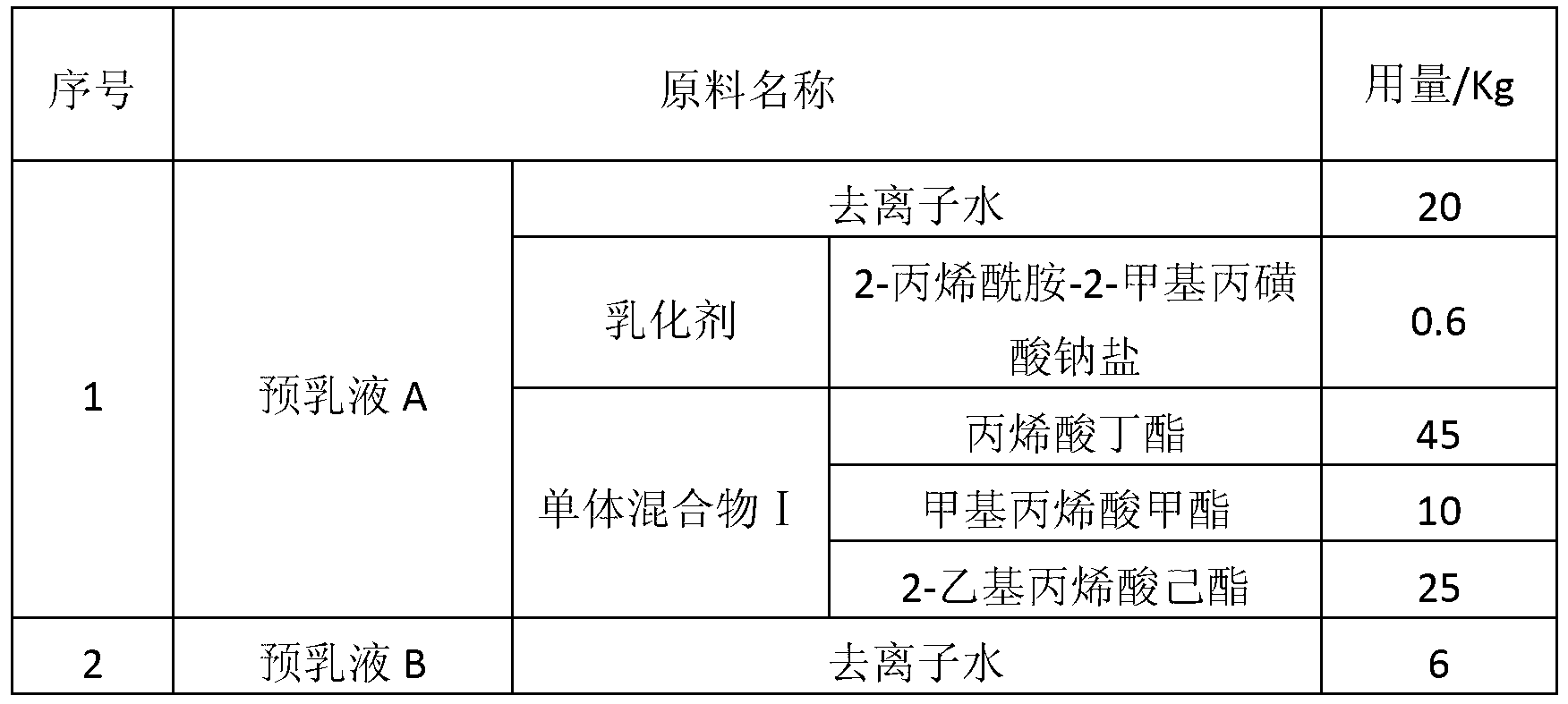

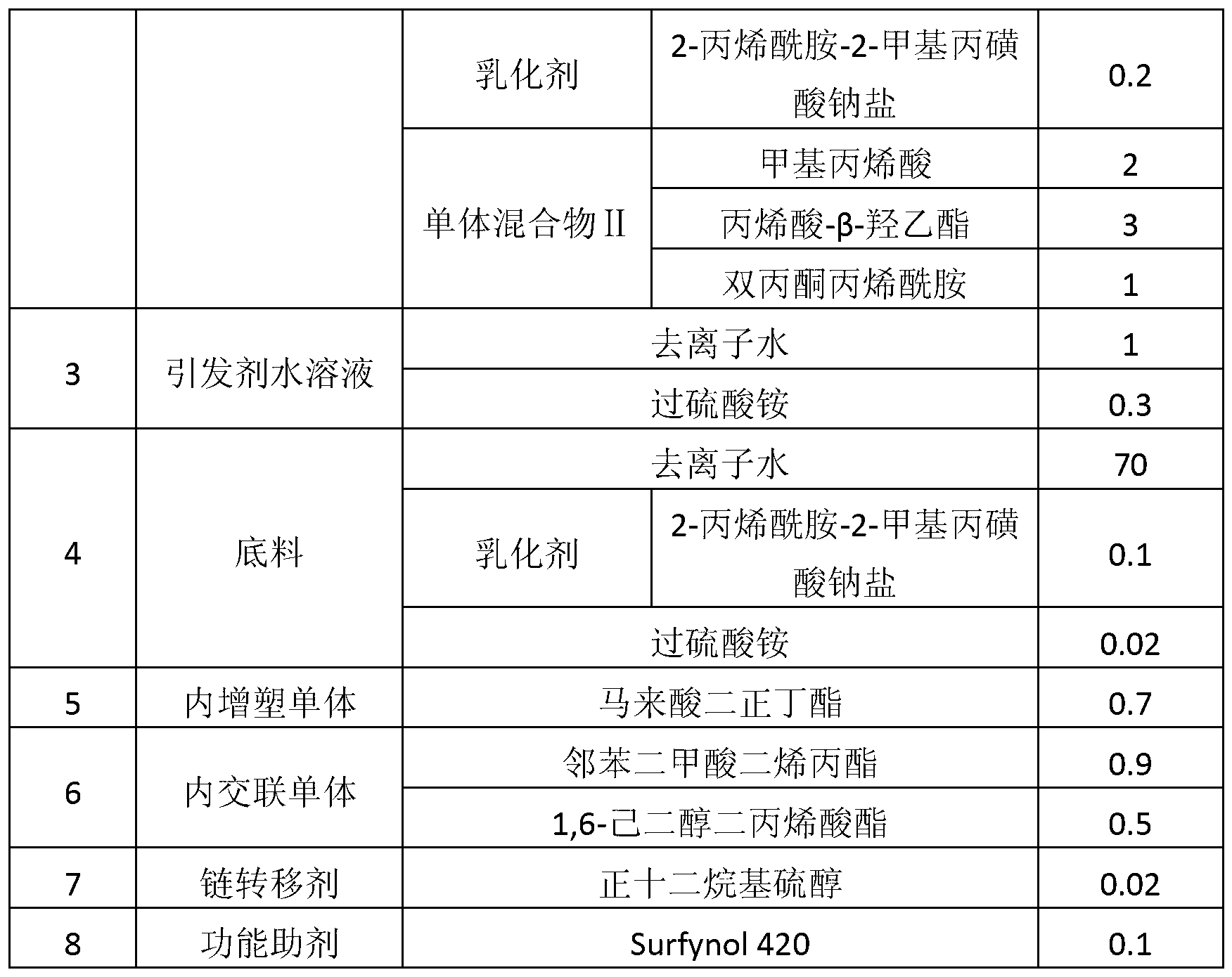

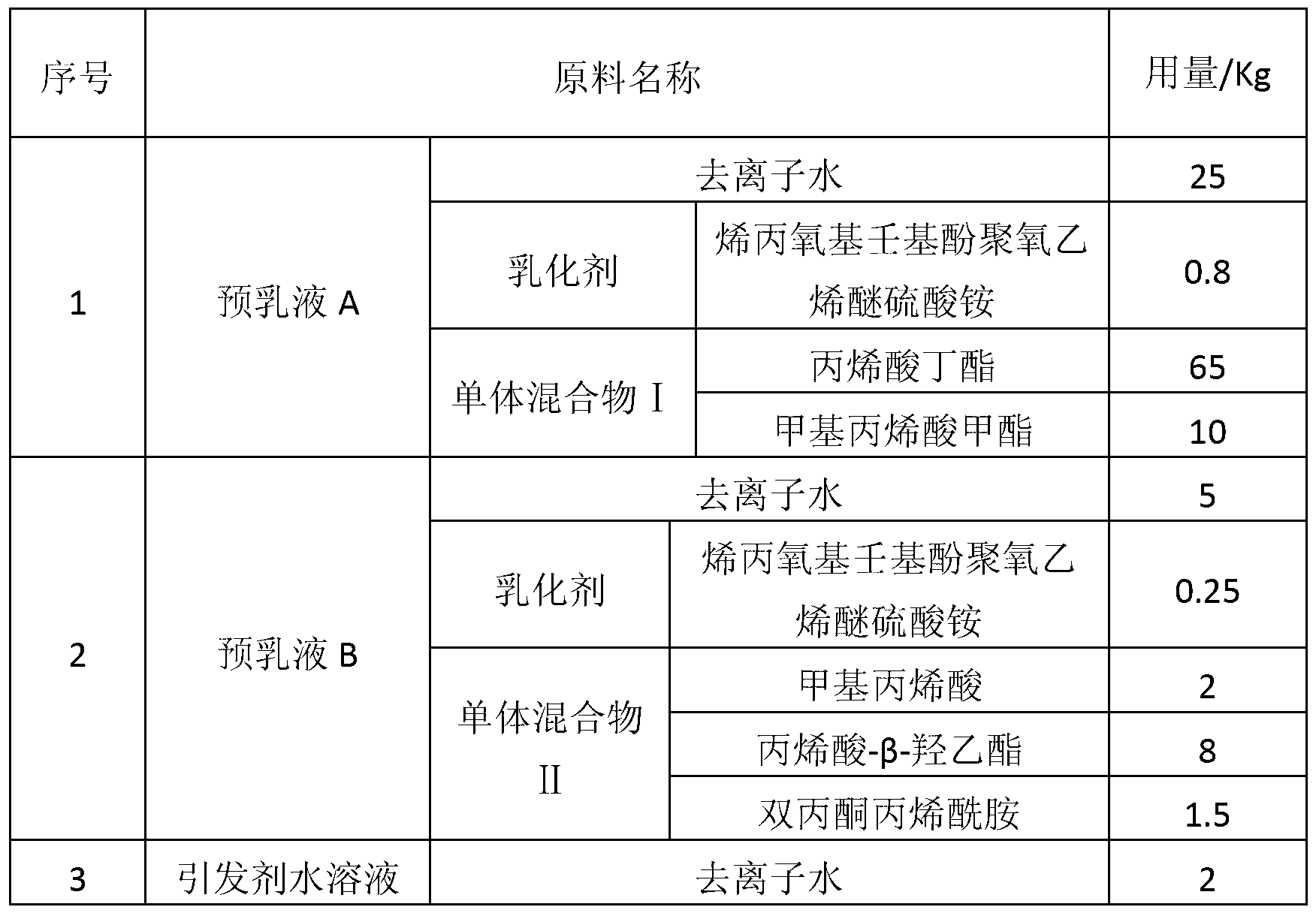

The invention discloses a water-based plastic-plastic compound adhesive for food and drug flexible packages and a preparation method thereof. The preparation method comprises the following steps of: carrying out pre-emulsification by using 20-30 parts by weight of deionized water, 0.4-1.0 part by weight of emulsifying agents and 75-90 parts by weight of monomer mixtures to obtain a pre-emulsion A; then carrying out the pre-emulsification by using 5-8 parts by weight of the deionized water, 0.2-0.3 part of the emulsifying agents and 3-20 parts by weight of the monomer mixtures to obtain a pre-emulsion B; preparing an initiator water solution C by using 1-3 parts by weight of the deionized water and 0.2-0.8 part by weight of initiators; and dropping the monomer mixture I with lower polarity and the monomer mixture II with higher polarity step by step by adopting a pre-emulsification seed emulsion polymerization process to obtain the water-based plastic-plastic compound adhesive for the food and drug flexible packages. The water-based plastic-plastic compound adhesive disclosed by the invention has the advantages of no organic solvent, no formaldehyde release, good adhesivity and high stripping strength and permanent adhesion and can be applied to a flexible package industry and substitute for a solvent type two-component polyurethane adhesive maturely applied to the present market.

Owner:DONGGUAN STAR COSM POLYMER

Moulding-grade wood-plastic composite and processing process

InactiveCN101024709AImprove high temperature fluidityExcellent formabilityCoatingsMoulding gradeStearic acid

The invention relates to an injection moulding wood plastic compound material and the process technology. It is made up from recycled P or HDPE or PVC 100 portions, wood flour 80-130 portions, chlorinated polyethylene 5-10 portions, polyethylene wax 0.5-5.0 portions, geoceric acid or stearate 1.0-5.0 portions, nanometer reinforcing agent 4.0-8.0 portions, organic esters flexibilizer 5.0-15.0 portions, and PE grafted by maleic anhydride 5.0-20 portions. Mixing the materials at low speed (300-600round / min), high speed (1500-2500 round / min), low speed (300-600 round / min) for 5-10min, 25-40min, and 5-10min, the premixed material would be gained. After being extruded from extruder, the moulding wood plastic compound material would be gained. It could be widely used in producing complex shaped products.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Polyethylene wood plastic and preparation method thereof

The invention relates to a polyethylene wood plastic and a preparation method thereof and belongs to the technical field of plastic compound modifying processing. The invention provides a formula of the polyethylene wood plastic and a preparation method for a section bar; extruding temperature and extruding speed are increased; a polyethylene wood plastic section bar produced according to the preparation method has excellent high-temperature resistance; and according to the technical scheme, the polyethylene wood plastic comprises the following raw materials in parts by weight: 30-40 parts of polyethylene, 50-70 parts of wood flour, 0.5-2 parts of maleic anhydride grafted polyethylene, 0.8-1.5 parts of polyethylene wax, 1-3 parts of zinc stearate, 2-6 parts of toner, 0.5-1 part of antioxidant, 0.4-0.9 part of anti-ultraviolet light absorber UV-531 and 0.5-1.2 parts of stearic acids. The preparation method provided by the invention is suitable for the extruding molding of the polyethylene wood plastic section bar.

Owner:山西峰岩新型建材股份有限公司

Room-temperature self-crosslinking water-soluble polyurethane acrylic resin and preparation method and application thereof

InactiveCN101544738ALow viscosityImprove conversion ratePolyureas/polyurethane adhesivesInksPolymer scienceAcrylic resin

The invention discloses a room-temperature self-crosslinking water-soluble polyurethane acrylic resin and a preparation method and an application thereof. The preparation method adopts an in-situ emulsion polymerization method and improves the prior preparation method, introduces tetramethyl benzene dimethylene diisocyanate or 2, 4 methyl cyclohexyl diisocyanate, and dipropylene glycol or neopentyl glycol functioning as chain extendor in raw materials, thereby lowering the viscosity of polyurethane prepolymer, and achieving the purpose of performing the synthetic reaction without organic solvent; oil-soluble evocating agent and water-soluble evocating agent are adopted to together evocate radical copolymerization so that oil-soluble monomer and water-soluble monomer can more effectively perform the radical copolymerization, thereby improving the reaction conversion rate. In addition, the combination of the two evocating agents also leads emulsion in the reaction to keep stable without easily jellifying and layering. The resin can be used for preparing plastics, aluminum foil package compound gel, paper-plastics compound gel, water color ink, water oil polish, water wooden ware paint or water plastic paint.

Owner:SUN YAT SEN UNIV

Preparation method of wood-plastic compound material with improved strength

InactiveCN102108213AStrong mechanical propertiesImprove mechanical propertiesFiberUltimate tensile strength

The invention discloses a preparation method of a wood-plastic compound material with improved strength. The wood-plastic compound material with improved strength comprises the following used raw materials by weight percent: 40-70% of plant fiber, 1-3% of reinforced fiber, 4-6% of lubricant and the balance of plastic. The preparation method comprises the following steps: fully mixing the raw materials through melt blending; and carrying out extrusion molding to obtain the wood-plastic compound material. In the technical scheme of the invention, the mechanical property of the whole wood-plastic compound material is enhanced by using the reinforced fiber, and the binding strength of the phase interface between wood powder and plastic is also improved. Simultaneously, specific additives are selected and used. For example, a coupling agent generates strong interface binding between the surfaces of wood powder and the plastic and can reduce water absorption property of the wood powder and improve the compatability and dispersibility between the wood powder and the plastic, therefore the mechanical property of the compound material is greatly improved; in addition, the flowability of a melt and the surface quality of an extrued product are improved by adding the lubricant, thereby obtaining the wood-plastic compound material with good mechanical property and excellent surface quality.

Owner:SHANGHAI BESTON PLASTICS

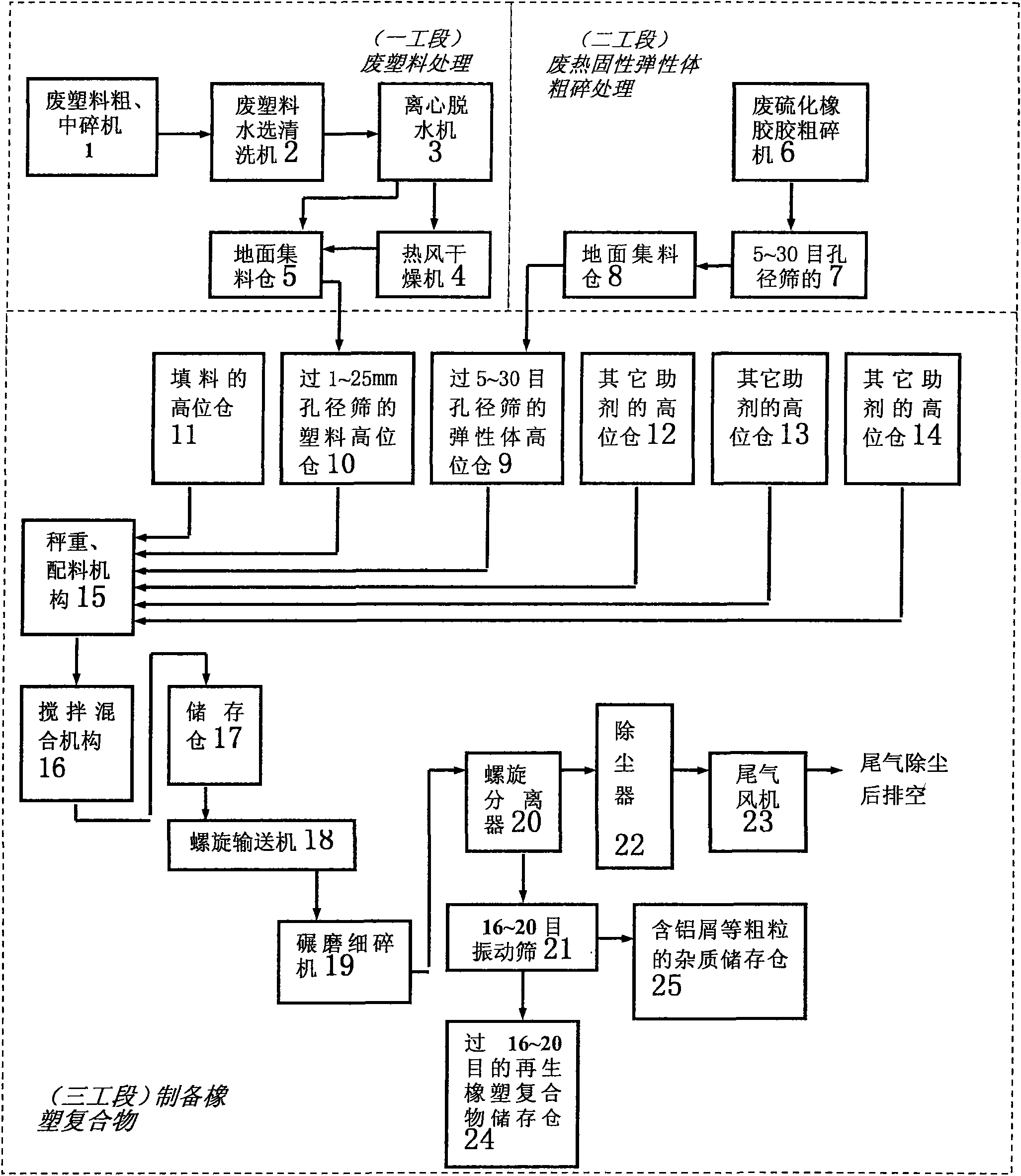

Method for preparing rubber-plastic compound

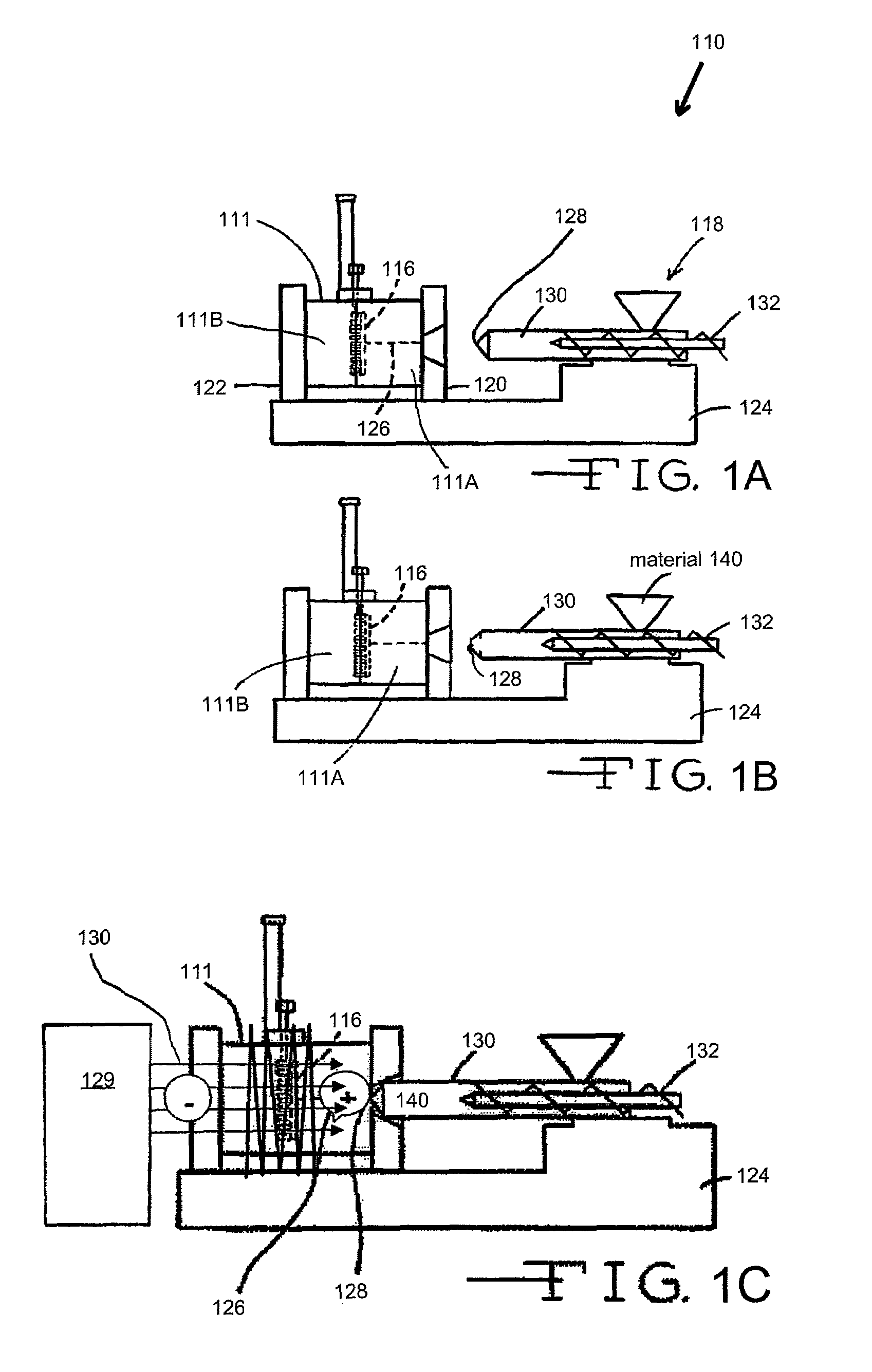

InactiveCN101665627AAvoid scorchingAvoid smokingPlastic recyclingCocoaElastomerThermoplastic elastomer

The invention provides a method for preparing a rubber-plastic compound. A composite device containing normal-temperature millstone-type elastomer fine crushing machineries is utilized to carry out crushing treatment on a mixture containing formulas of thermosetting elastomer and plastic or / and thermoplastic elastomer, and the mixture comprises the following components in weight ratio: thermosetting elastomer sieved by a sieve with the aperture of 5-40 meshes: plastic sieved by a sieve with the aperture of 1-5mm or / and thermoplastic elastomer sieved by a sieve with the aperture of 1-5 meshes:filler: other adjuvants = 40-90:60-10:0-200:0-10. The invention comprises a method, the composite device for implementing the method, and rubber-plastic compound products produced by the method, wherein a regeneration rubber-plastic compound is included. The invention not only can enable the absorb filler operation to become clean, continuous, normal-temperature and energy saving in the process of preparing new rubber-plastic composite material, but also can enable mixed waste plastic difficult to be reused by the prior art to be conveniently used for high-valued recycling.

Owner:上海橡源驰晨环保科技发展有限公司

PVC (polyvinyl chloride)-based wood plastic and preparation method thereof

Owner:山西峰岩新型建材股份有限公司

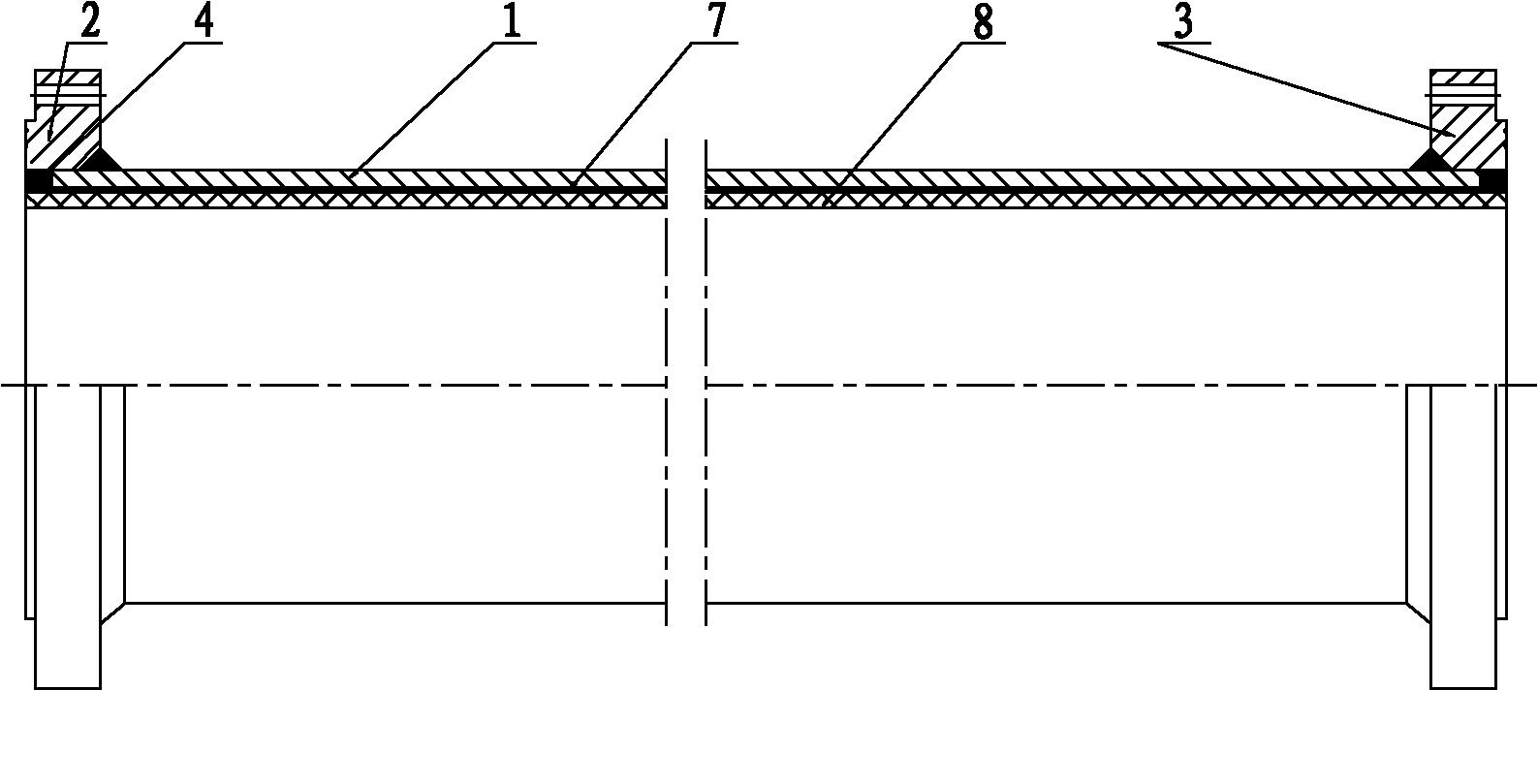

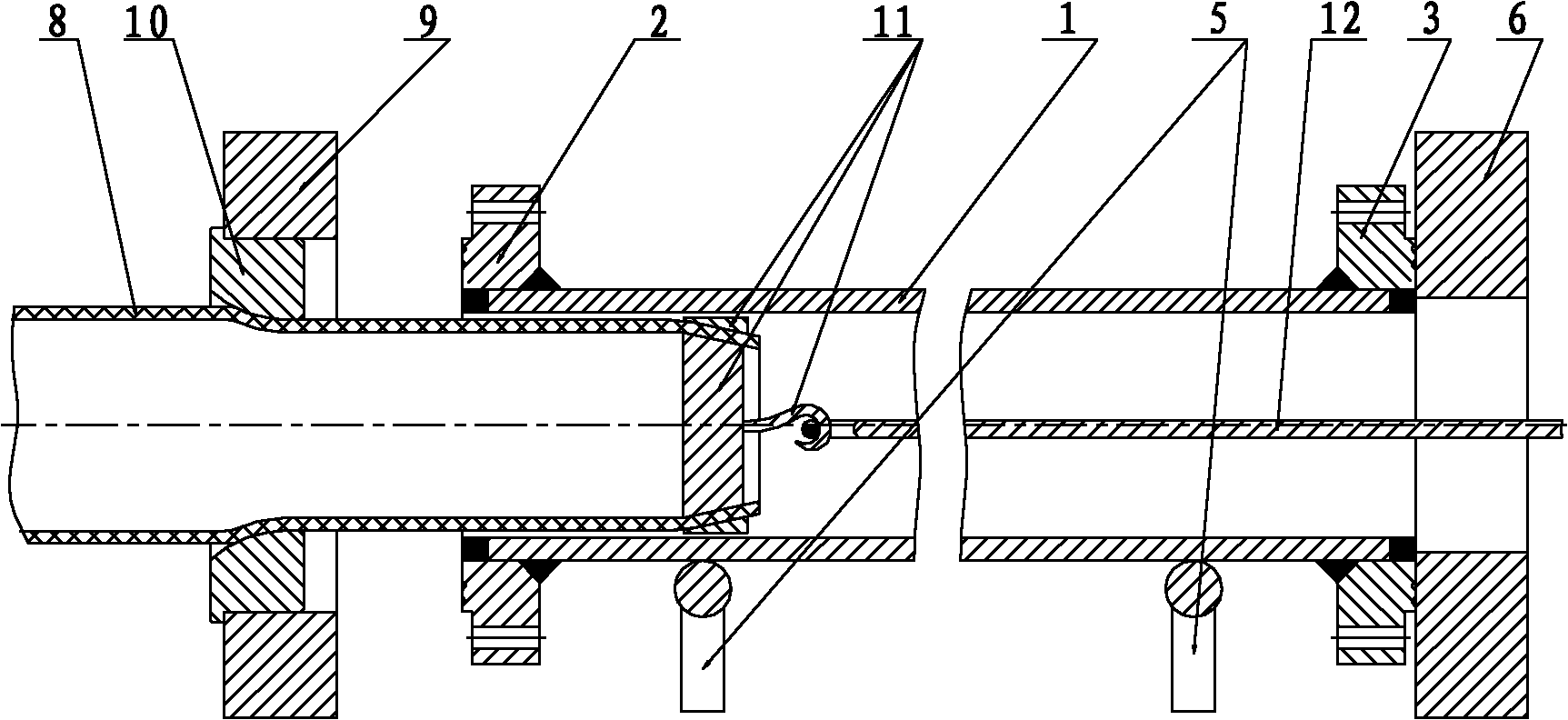

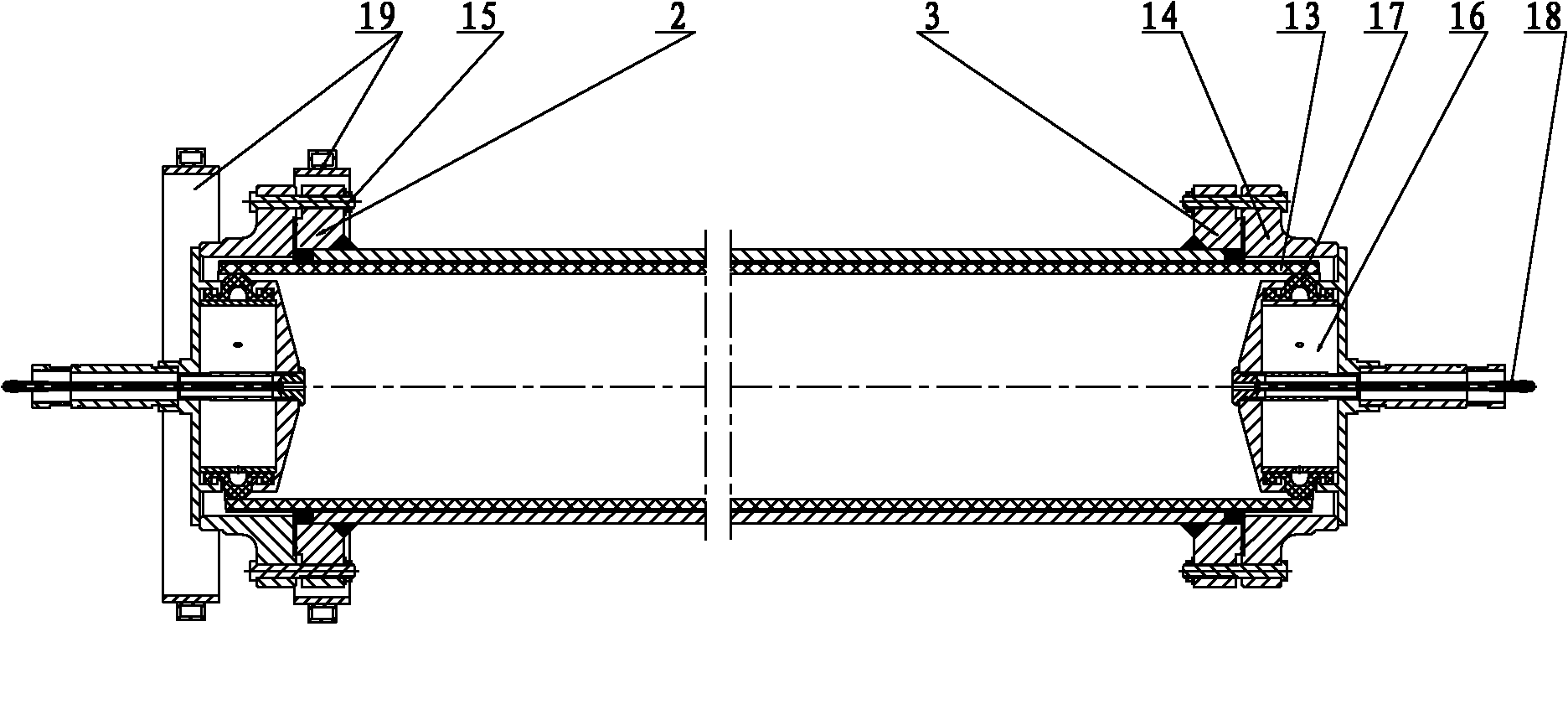

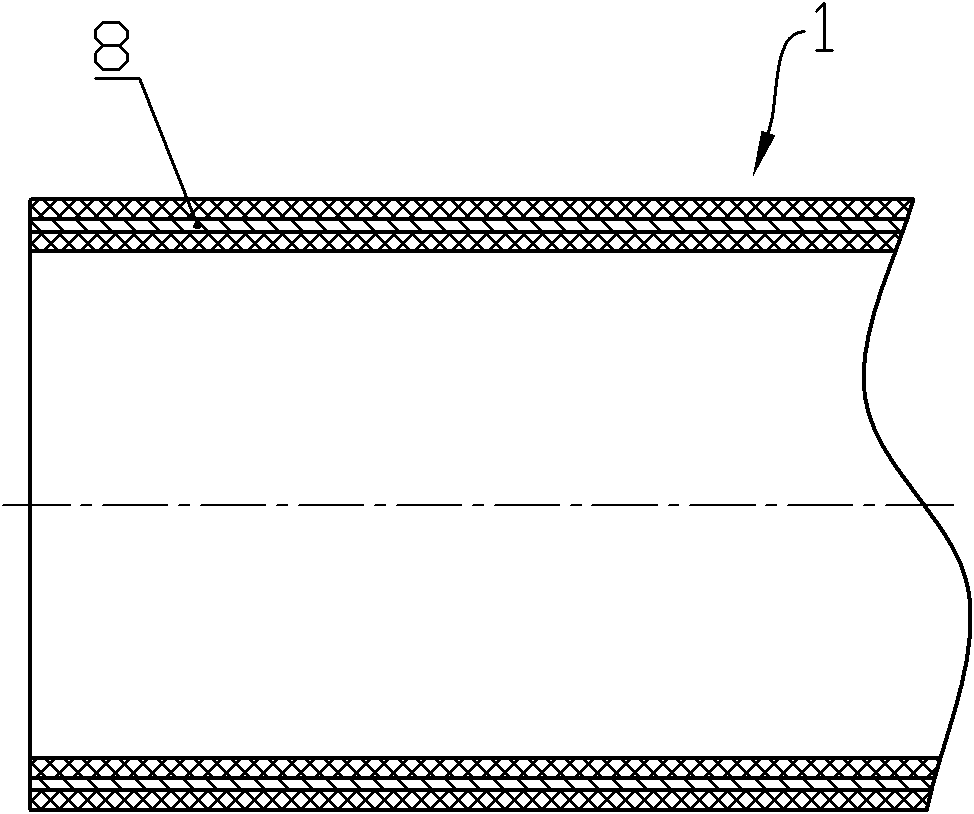

Method and equipment for producing flange type lining plastic compound steel pipe

ActiveCN101839375AFit tightlyAvoid delaminationLaminationLamination apparatusInterference fitMetallurgy

The invention discloses a method and equipment for producing a lining plastic compound steel pipe, and in particular relates to a method and equipment for producing a flange type lining plastic compound steel pipe. The technical problem to be solved by the invention is to provide the method and the equipment for producing the flange type lining plastic compound steel pipe which enables the inner walls of a plastic pipe and a steel pipe to be compounded into a whole through a hot melt adhesive, ensures no separation and delamination phenomena occurred between steel and plastics and has stable and reliable product quality, the plastic pipe is towed to penetrate into the steel pipe through a towing device, the plastic pipe clings to the steel pipe through compressed air, and then the hot melt adhesive on the outer wall of the plastic pipe is molten and bonded with the steel pipe through an electromagnetic induction heating device. The inside of the plastic pipe is pressurized by adopting compressed air, so that the plastic pipe is expanded to enable the plastic pipe and the steel pipe to be in the state of interference fit, and then the steel pipe is heated at the moment by adopting an induction heating ring, so that the plastic pipe and the steel pipe are compounded into a whole, the steel and plastic materials in the pipes are more tightly bonded, and the separation and delamination phenomena between the steel and the plastics can not occur.

Owner:成都共同制管有限公司

Wood composite alloy composition having a compatibilizer that improves the ability to process and compress cellulosic fiber

A crystalline polyamide 6 in a compounding extrusion process to make wood flour-polyolefin composite. The wood plastic composite pellet and can be post-blended with reinforced polyolefin pellets in an injection molding step to produce hybrid fibrous composites. The resulting compatibilization in the hybrid fibrous composites gives molded parts having enhanced mechanical properties at greatly reduced temperatures. There is wide variety of molded parts that can be made by varying the blend ratio of the wood plastic compounded product with or without and glass fiber reinforced pellets in the injection molding step.

Owner:INNOVATIVE PLASTICS & MOLDING +1

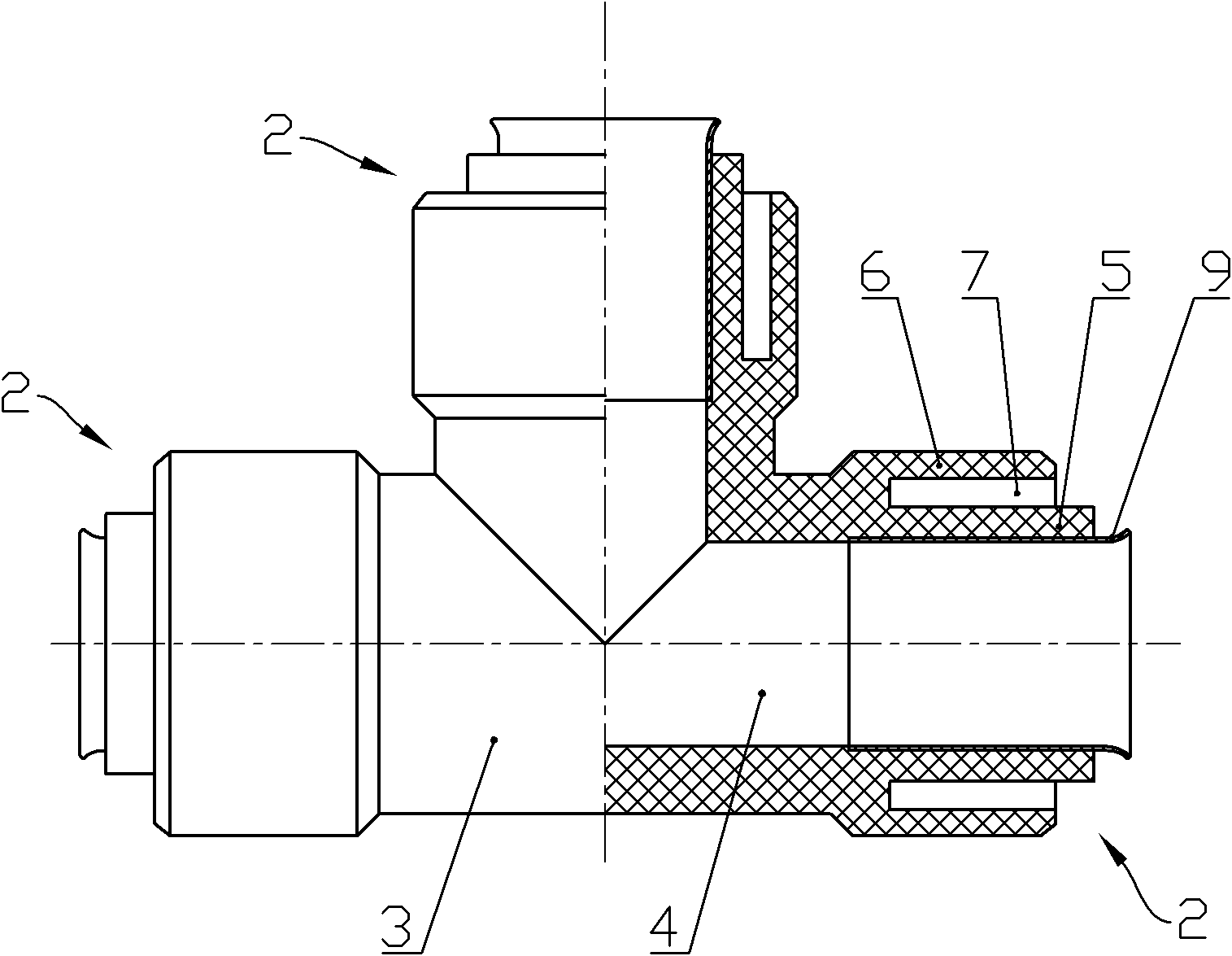

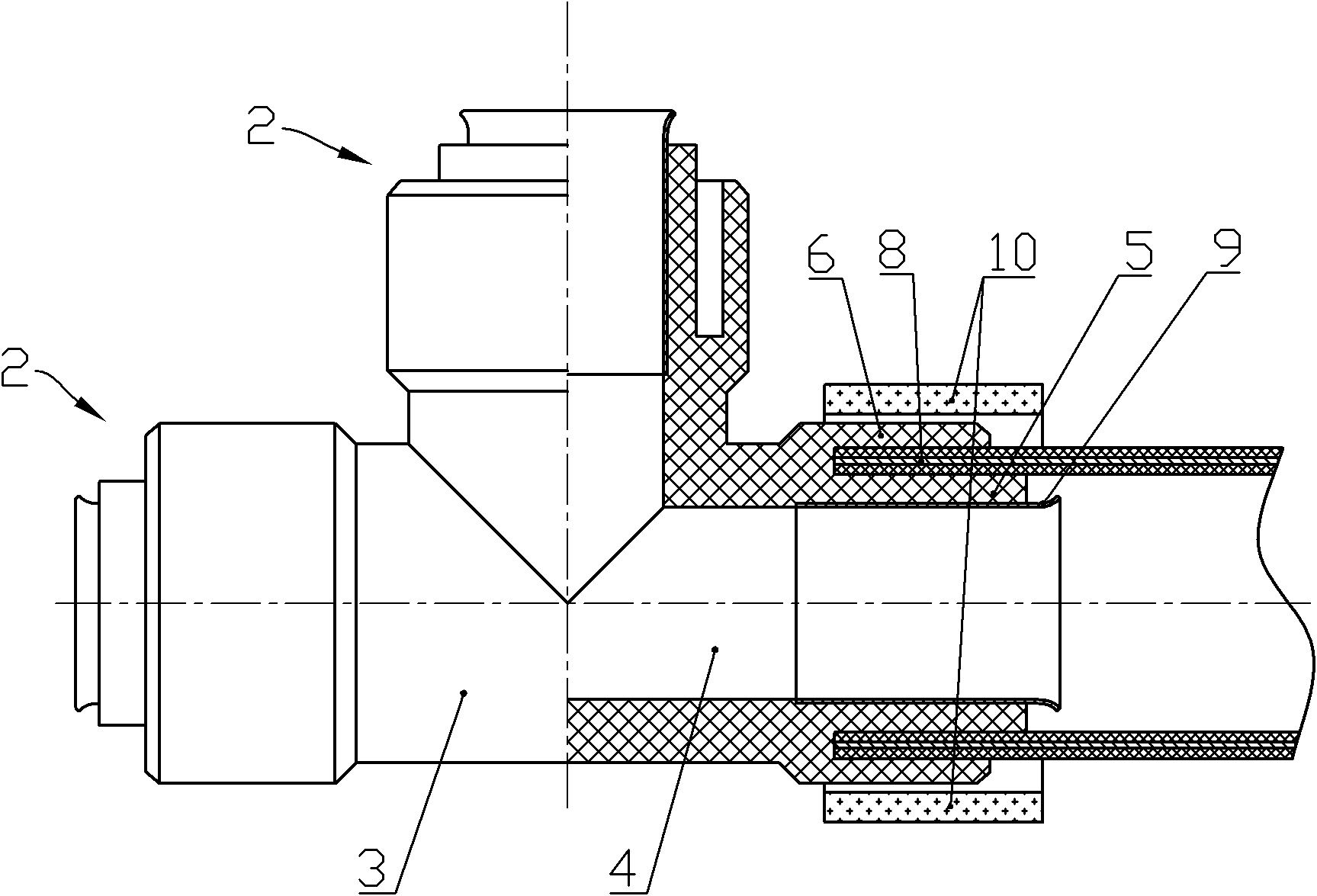

Electromagnetic inductive welding method of steel-plastic compound pipe

InactiveCN101852323AEasy to implementSuitable for weldingPipe connection arrangementsPipe fittingWater leak

The invention discloses an electromagnetic inductive welding method of a steel-plastic compound pipe, which belongs to a pipeline connecting method. The traditional methods can not realize welding of steel-plastic compound pipes of all specifications. In the method, firstly, the steel-plastic compound pipe is inserted into a connecting port of a pipe fitting; secondly, a steel pipe layer of the steel-plastic compound pipe in the inserting position is heated by an electromagnetic inductive heater to fuse plastics on both sides of the steel pipe layer; and finally, the plastics are cooled to realize welding of the steel-plastic compound pipe and the pipe fitting. Because the steel-plastic compound pipe is inserted into the connecting port of the pipe fitting at first, and then the inserting position is heated for welding, the method is easy. The structures of the pipe fitting and the pipe are not changed, and thus the pipe is easy to be manufactured. The method is suitable for welding of steel-plastic compound pipes of all specifications and the pipe fitting, and is easy to realize double-face seal. In case of water leak or water seepage caused by bad welding quality, the inserting part can be heated again for improvement.

Owner:中科华飞管业(东莞)有限公司

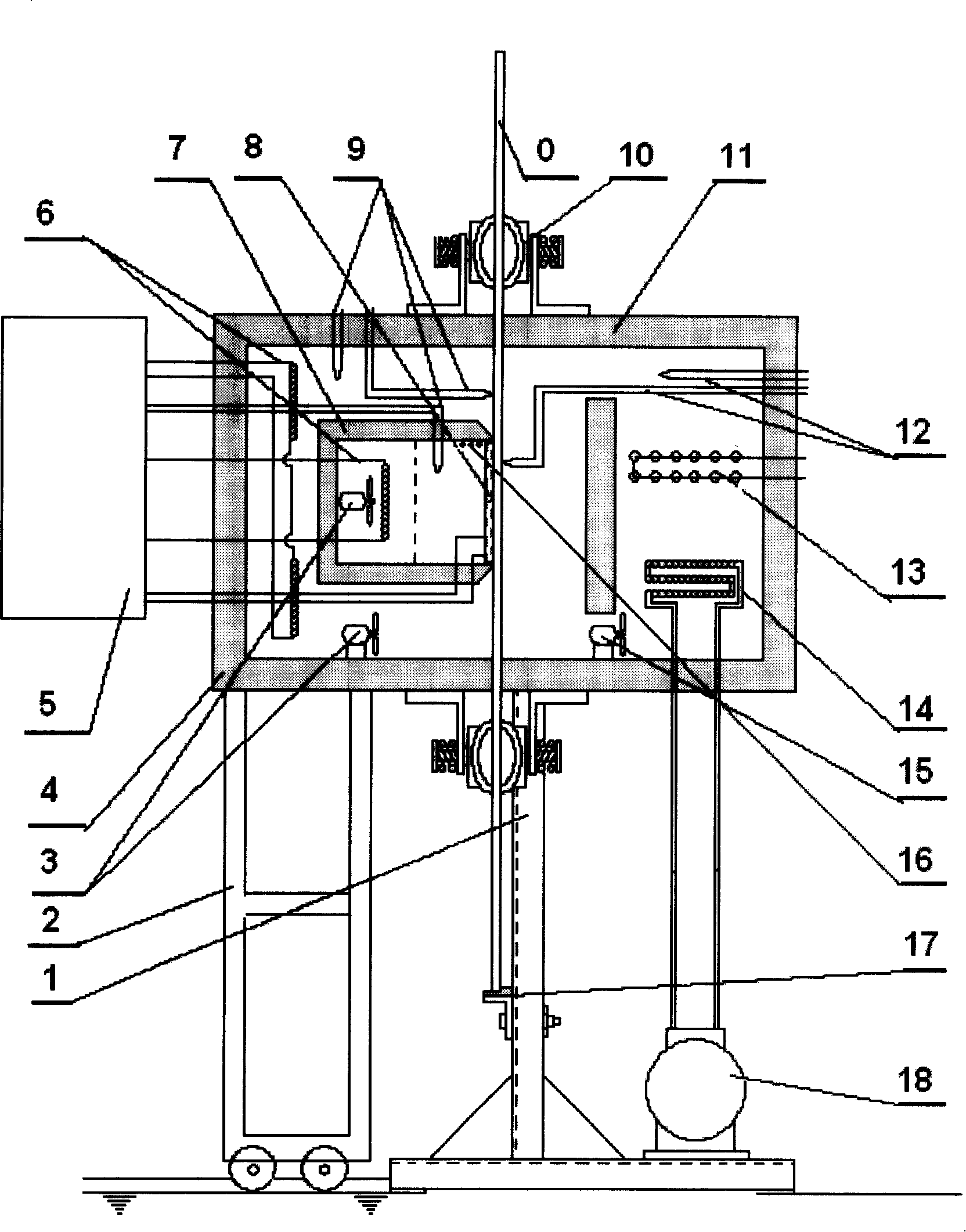

Building glass steady state heat resistance measuring equipment

InactiveCN101241091AHigh precisionUniform temperatureMaterial thermal conductivityMaterial heat developmentHot boxProcess systems

A device special for determining stable state thermal resistance of architecture glass which is a necessary determining device for quality control and product acceptance in energy-saving architecture glass produce is provided. The present invention comprises of heat flux sensor, internal and external guarding heat-box, cold-box (including refrigerating unit), precision temperature measurement and computer data collecting process system, and frame mounted rise-and-fall glass carrying stage and vacuum acetabula glass fixation mechanism. The present invention is not only used for detecting state thermal resistance of energy-saving architecture glass such as vacuum glass, hollow glass, and so on, but also used for detecting heat insulation and heat preservation capacity of other plate architecture material such as polystyrene board, steel (aluminium) plastic compound heat preserving board and so on.

Owner:BEIJING QINRUN GLASS

Aqueous plastic compound ink

The water-thinned plastic composite printing ink consists of anionic polyurethane dispersing liquid, acrylic ester emulsion, pigment, dispersant, defoaming agent, polyethylene wax, water and small amount of isopropanol. The self made acrylic ester emulsion well compatible with the anionic polyurethane dispersing liquid results in good comprehensive performance and low cost of the water-thinned printing ink. The addition of crosslinking agent raises the wear resistance, attaching strength and stripping strength of ink layer. The trial water-thinned printing ink has a printing speed on a processed bi-directional polypropylene film of 30-50 m / min and stripping strength after compounding of 180 N / in. The water-thinned printing ink has fast drying speed and high wear resistance, and is especially suitable for printing on polypropylene, polyester film and other soft food packing material.

Owner:SUN YAT SEN UNIV

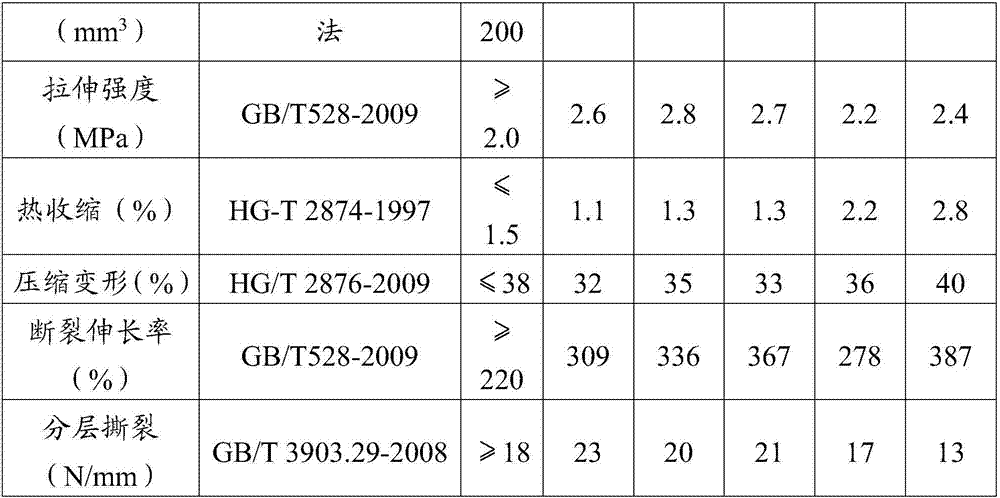

Rubber-plastic compound foaming material, and preparation method and application thereof

The invention provides a rubber-plastic compound foaming material, and a preparation method and application thereof. The material is prepared by mixing and foaming raw materials, wherein the raw materials comprise 35-50 parts by mass of EVA (ethylene-vinyl acetate), 15-35 parts by mass of thermoplastic elastomer, 10-20 parts by mass of ethylene propylene diene monomer rubber, 10-20 parts by mass of polyolefin block copolymer, 5-15 parts by mass of anti-wear agent, 4-6 parts by mass of filler, 2-5 parts by mass of activator, 0.7-1.2 parts by mass of crosslinking agent, 2.5-3.5 parts by mass of foaming agent and 0-10 parts by mass of additive; the thermoplastic elastomer is prepared by performing melt blending on polyurethane elastomer, cis-1,4-polybutadiene rubber and modification substances; and the modification substances comprise styrene elastomer and / or polyolefin elastomer. Under the combined action of the above components, the material is soft and comfortable, has excellent cushioning and resilience properties, excellent abrasion resistance and favorable recoverability, and can satisfy the performance requirements of sports shoe soles.

Owner:ANTA CHINA

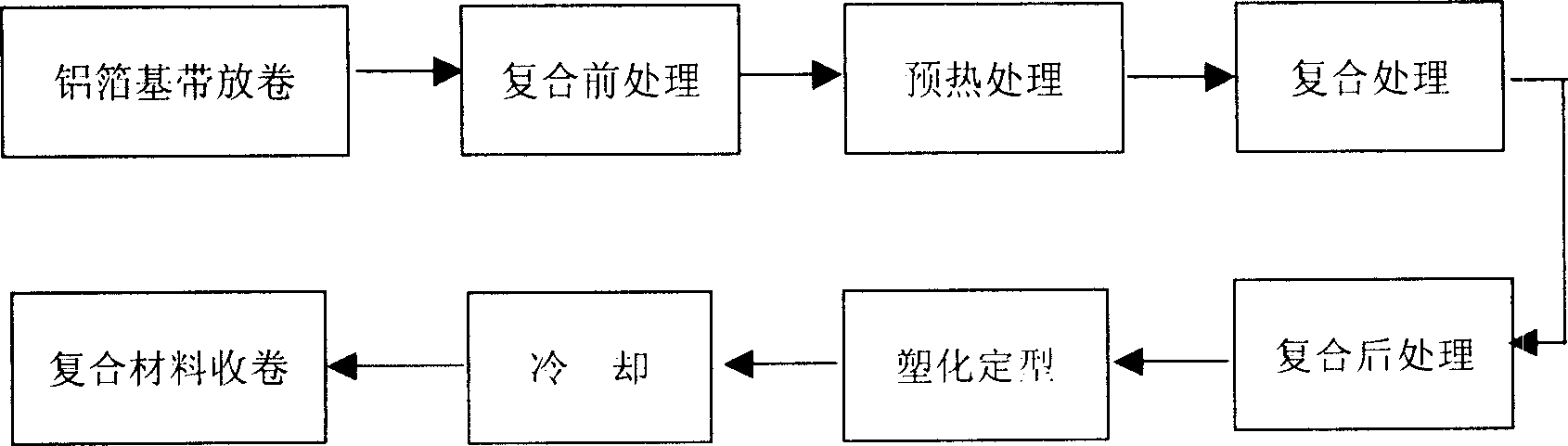

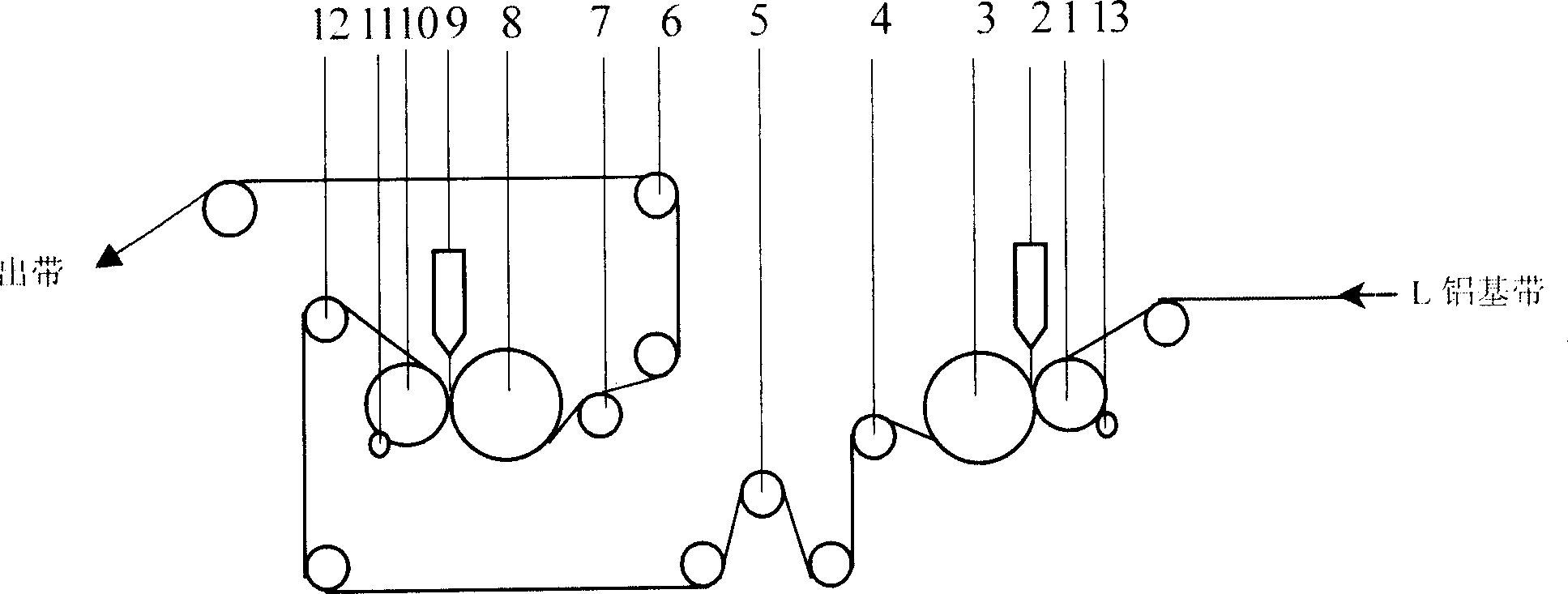

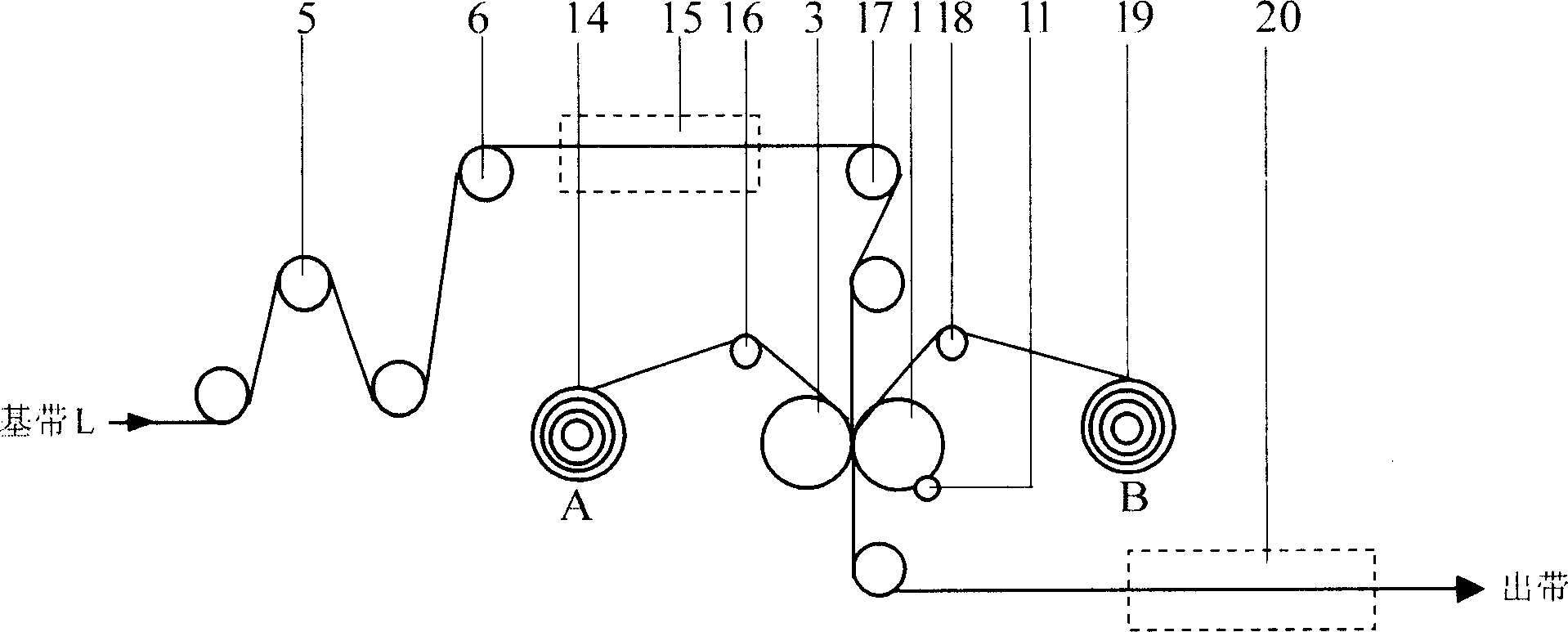

Method for mfg. sub light smooth type aluminium plastic compound band

ActiveCN1792605AReduce weightSave materialSynthetic resin layered productsBeltsPlastic filmAluminum foil

A process for preparing the dull and smooth aluminum-plastic band includes such steps as choosing an aluminum foil as basic band, pre-treating, extruding out at least one plastic film layer onto one or two surfaces of basic band, rolling while heating, and heat-treating by controlling the temp between Vicat softening point and fusion point for obtain dull and smooth surface. It can be used for optical cable or electric cable for high moisture tight effect.

Owner:上海网讯新材料科技股份有限公司

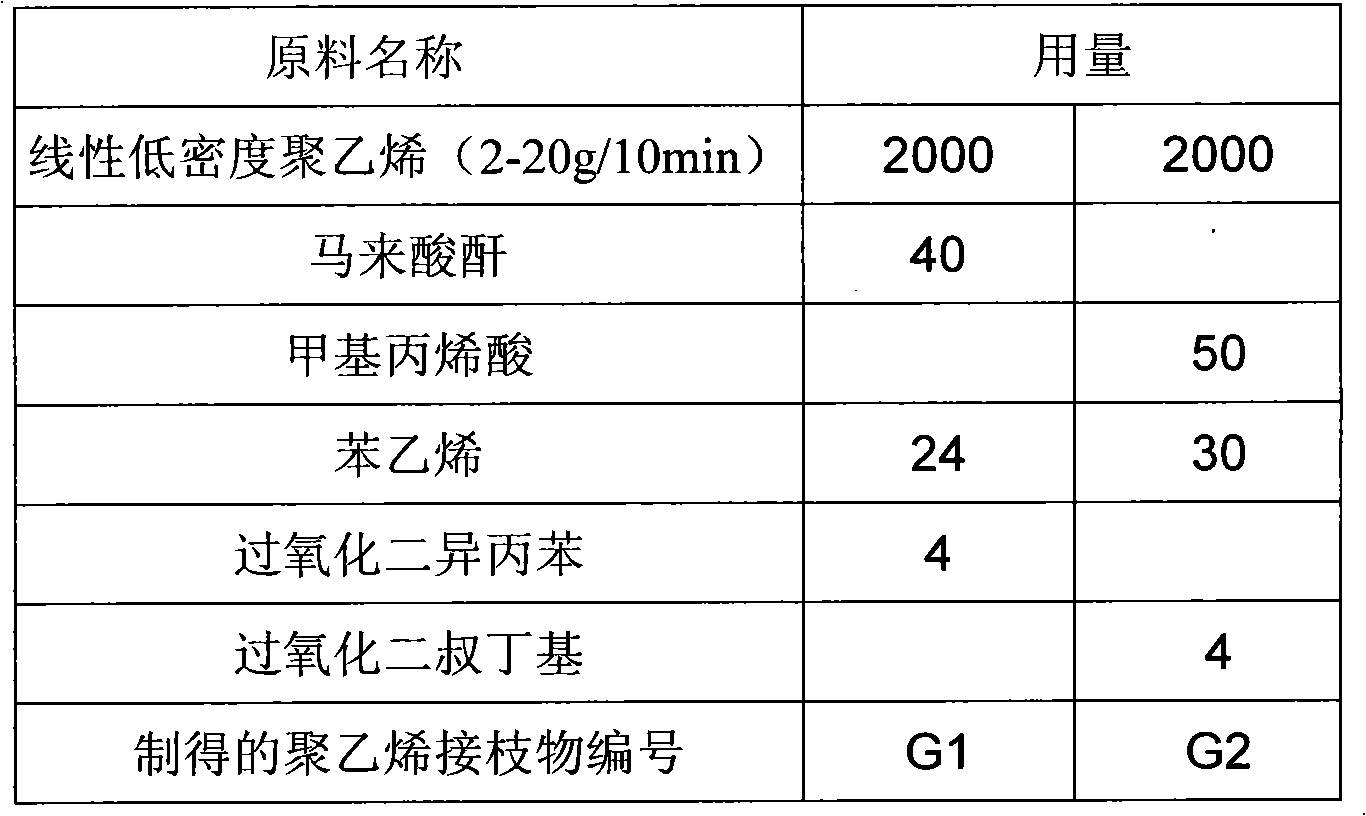

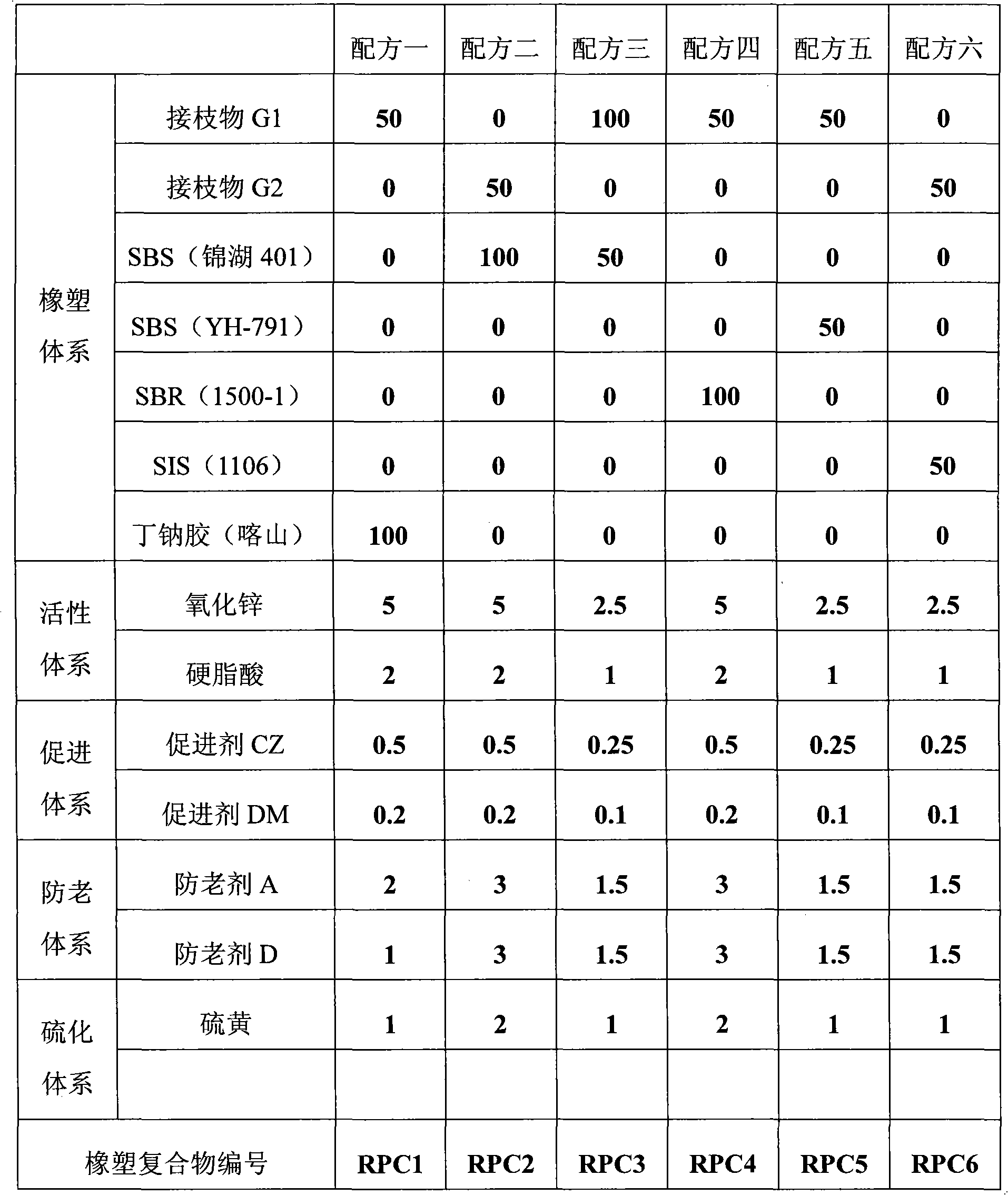

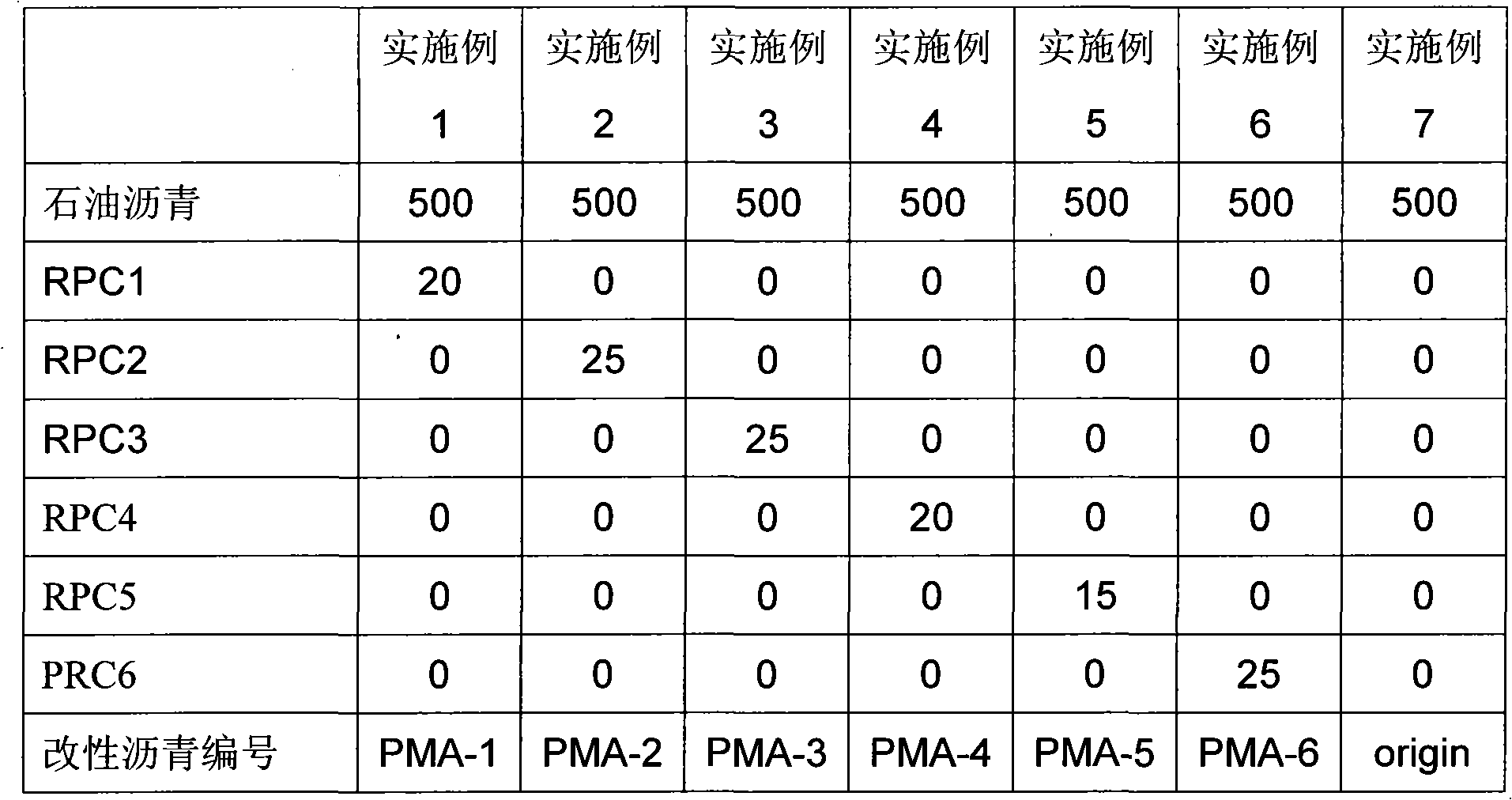

Preparation method of rubber and plastic compound modified asphalt with stable heat storage

InactiveCN102020860AReduce the amount addedViscosity does not increase significantlyBuilding insulationsLinear low-density polyethylenePolymer science

The invention discloses a preparation method of a rubber and plastic compound modified asphalt with stable heat storage, comprising the following steps: preparing linear low-density polyethylene graft on a double-screw extruder; on an open mill or an internal rubber mixer, preparing accessory ingredients, such as the polyethylene graft, rubber, an accelerator, an activator, a vulcanizing agent and the like into the rubber and plastic compound by warming, wherein the rubber and plastic compound is a thermoplastic elastomer; heating 100 parts of petroleum asphalt to 150-200 DEG C; adding 3-5 parts of prepared rubber and plastic compound; intensely shearing at high speed by a high-speed emulsification dispersion machine dedicated for preparing the polymer modified asphalt; completely meltingand shearing the rubber and plastic compound; and evenly dispersing asphalt to obtain the rubber and plastic compound modified asphalt. The preparation method is easy to prepare the modified asphalt and only needs to charge once. The prepared modified asphalt consumes a small quantity of vulcanizing agent, has good compatibility of the rubber and plastic compound and the asphalt, stable heat storage, good high-temperature stability and good low-temperature crack resistance and can be used for road paving, buildings, waterproof materials and the like.

Owner:SOUTH CHINA UNIV OF TECH

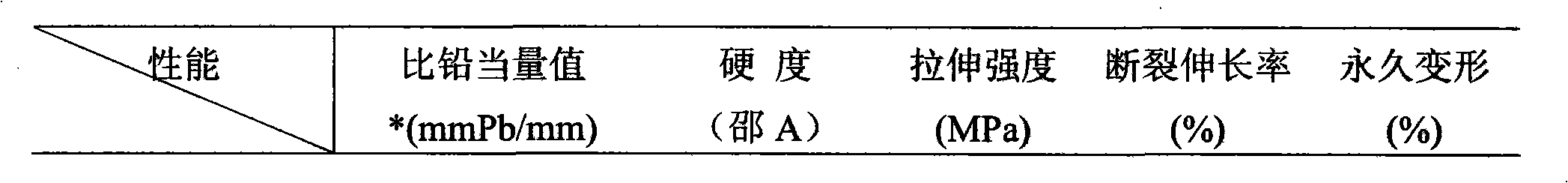

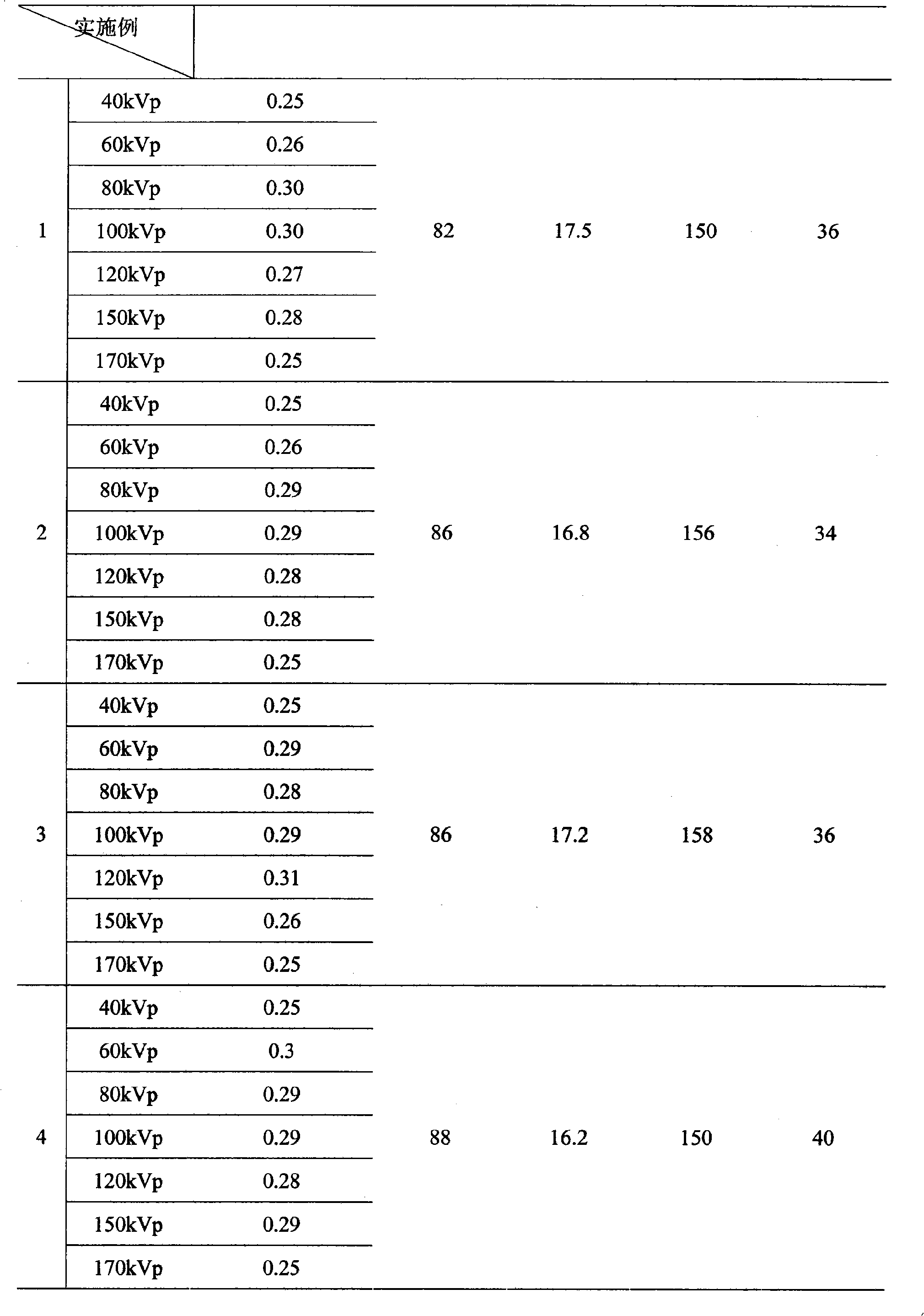

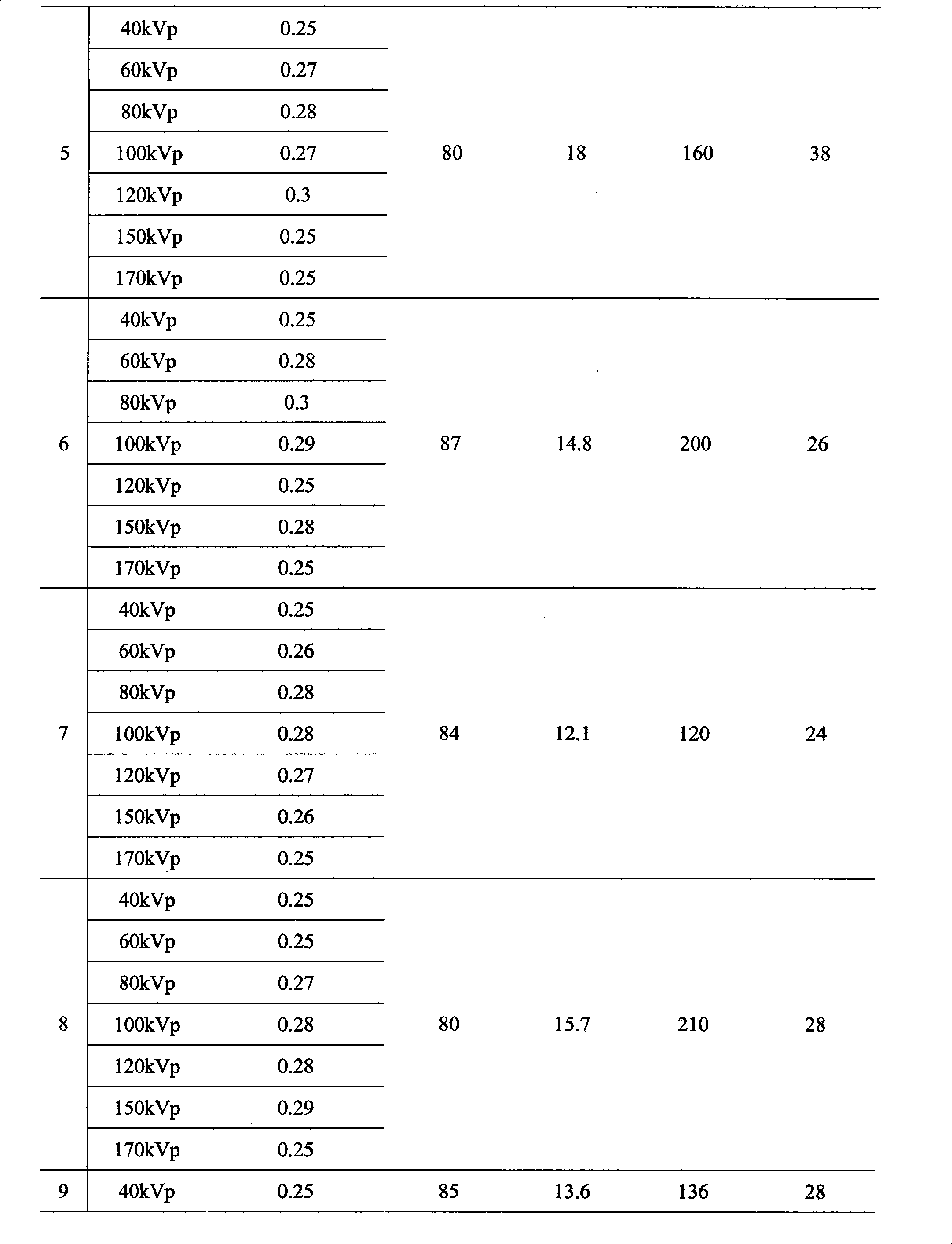

Overall lead-free X-ray shielding plastic compound material

InactiveCN101572129AEvenly distributedExcellent conventional physical and mechanical propertiesShieldingCoatingsX-ray shieldInorganic compound

The invention relates to an overall lead-free X-ray shielding plastic compound material. The overall lead-free X-ray shielding plastic compound material uses rare earth mixture to replace lead, simultaneously adds metal tin and compounds thereof, metal tungsten and the compounds thereof and bismuth and the compounds thereof as shielding main materials and is further compounded with plastic to prepare the compound material which can realize the overall shielding and the complete lead-free property within the energy range of 40-170kVp. When in use of rare earth and bismuth materials, the way of combined use of the two metal element inorganic compounds and unsaturated organic complexes is adopted, and the in-situ reaction and the compounding with a polymer matrix are carried out, thereby leading the shielding element disperse phase to form nano-micro-level dispersed particles. The prepared material combines the X-ray shielding performance of shielding elements and the good conventional physical mechanical performance of matrix polymer material and can be widely used in medical diagnostic X-ray machines, X-ray diffraction instruments and occasions accompanied with X-ray generation for ray protection for working staff.

Owner:BEIJING UNIV OF CHEM TECH

Jute and plastic compound material plank stuff and manufacturing method thereof

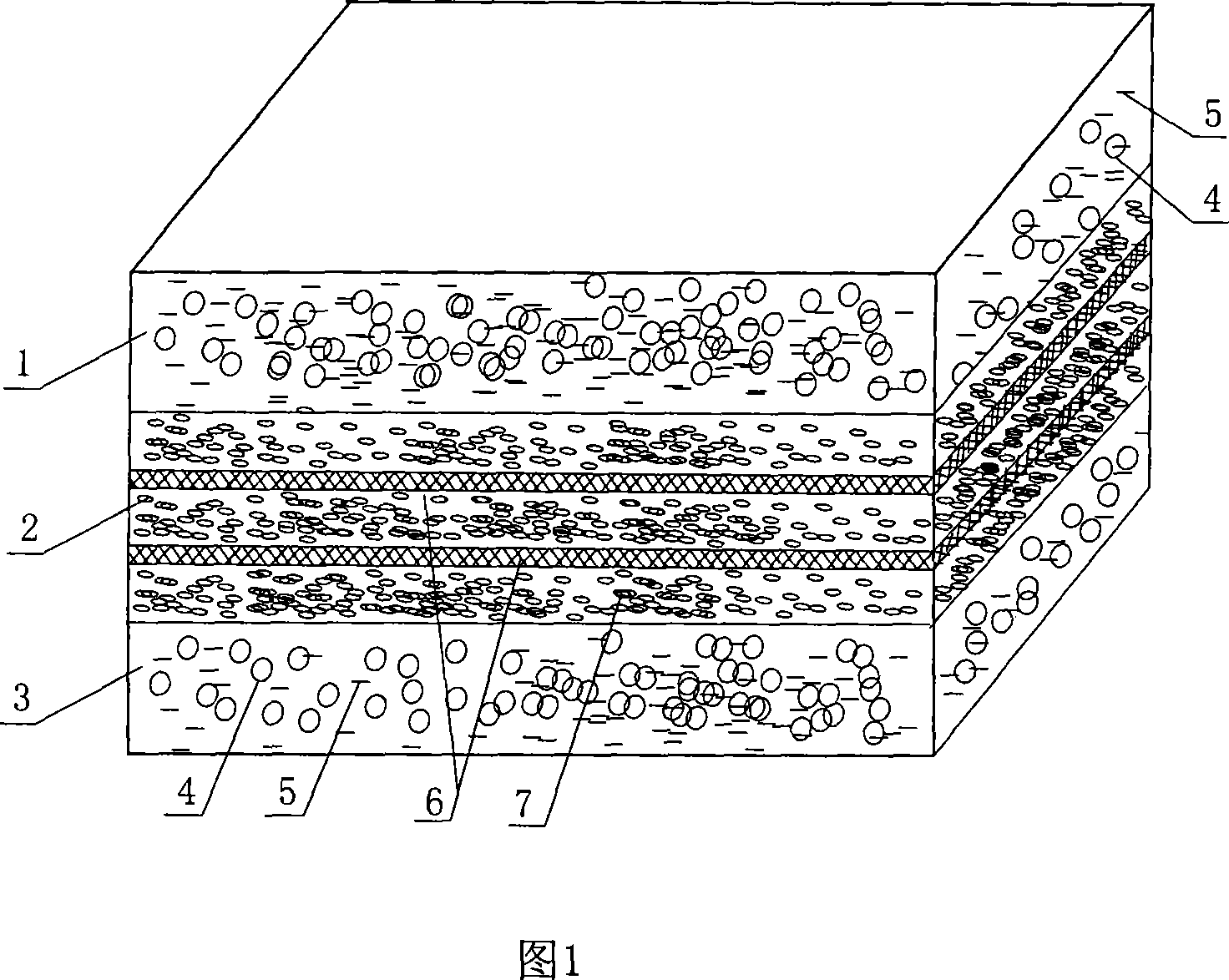

InactiveCN101229700AReasonable designSimple structureSynthetic resin layered productsCellulosic plastic layered productsFiberEngineering

The invention relates to a linen-plastic compound material plate and a preparation method thereof, in particular to a compound material and an environment-friendly material and a preparation method thereof. The material is preferably used for manufacturing goods shelf plates, door panels, etc. of vehicles such as cars, planes, etc. in traffic field, manufacturing decorative boards, palisades, rails, etc. in architecture field as well as manufacturing trays, goods shelves, etc. in packaging field. The linen-plastic compound material plates consist of two layers of linen fiber modification plastic layers and a linen fiber cloth enhancement plastic layer; the linen fiber cloth enhancement plastic layer is molded and pressed between the two layers of linen fiber modification plastic layers; modification plastic particles, linen fiber and interface compatilizer are mixed and calendered to form the linen fiber modification plastic layers; the plastic particle and a plurality of layers of fiber linen cloth processed by silane coupling agent are molded and pressed to form the linen fiber cloth enhancement plastic layer.

Owner:NANJING FORESTRY UNIV

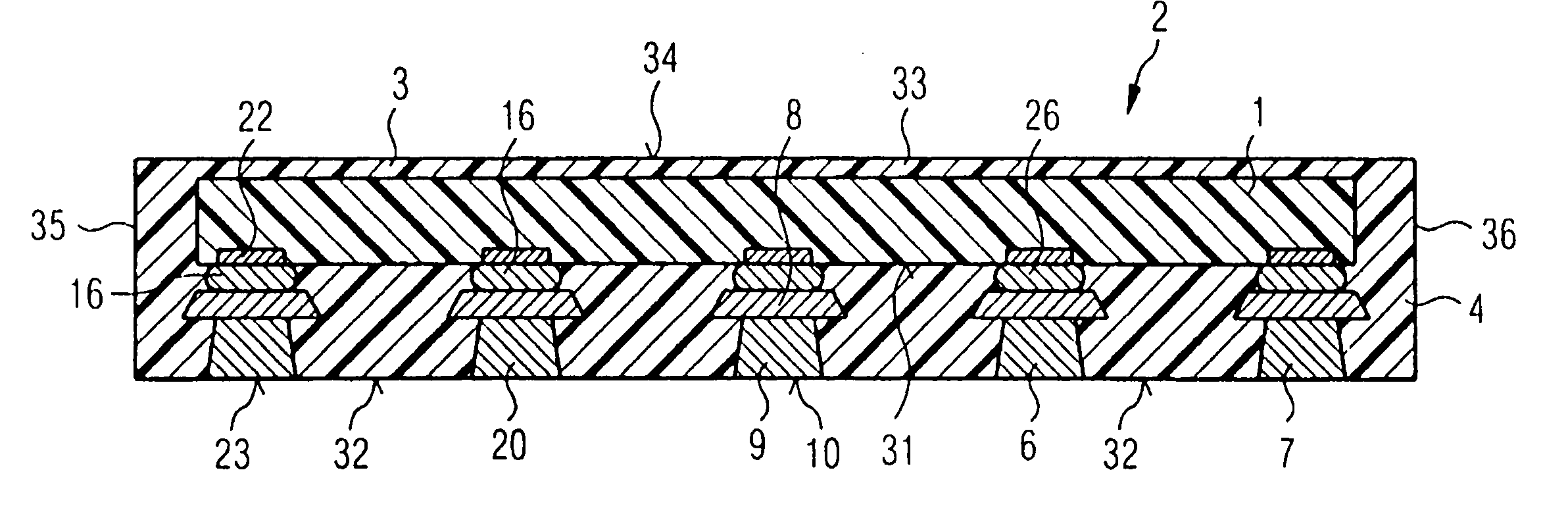

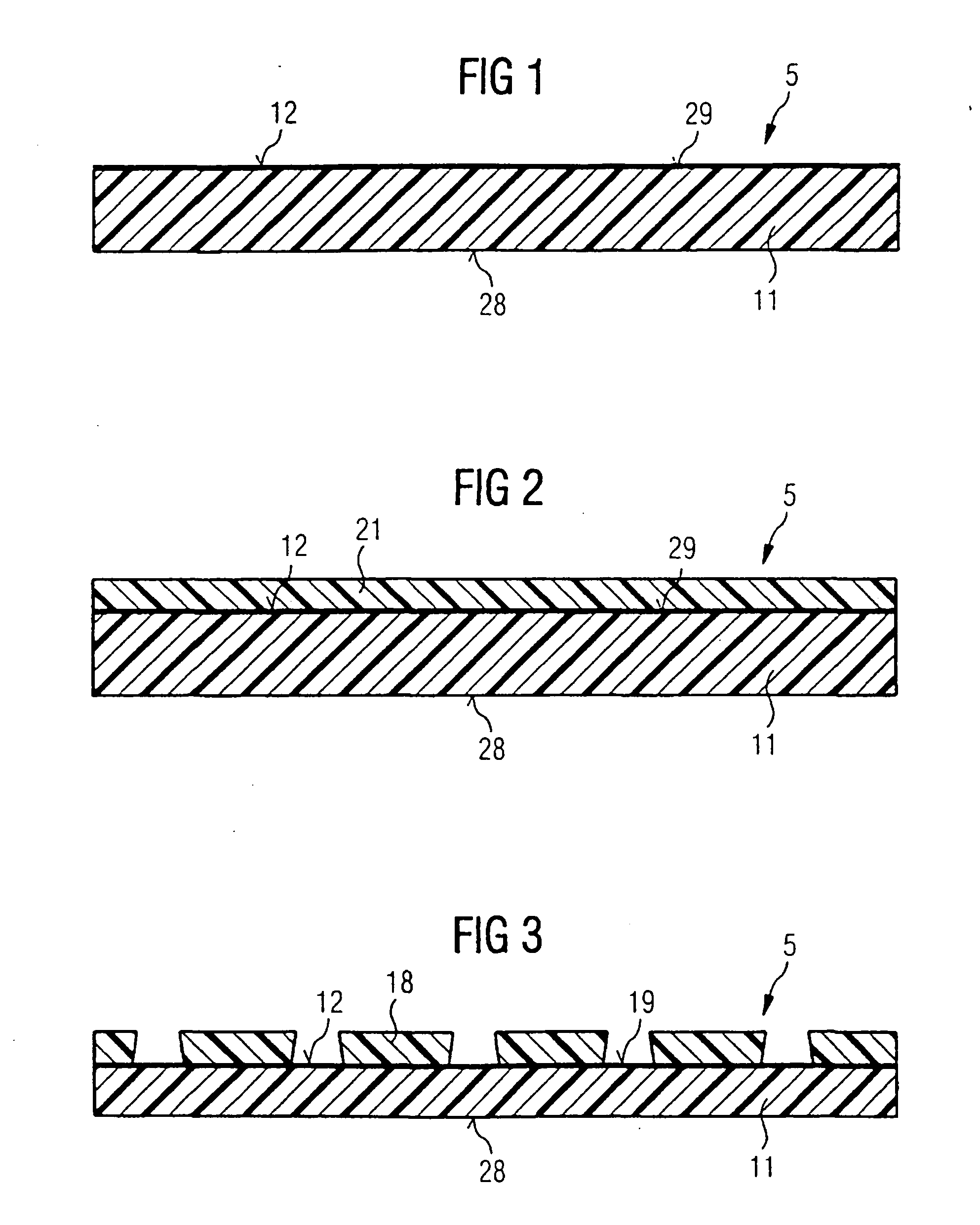

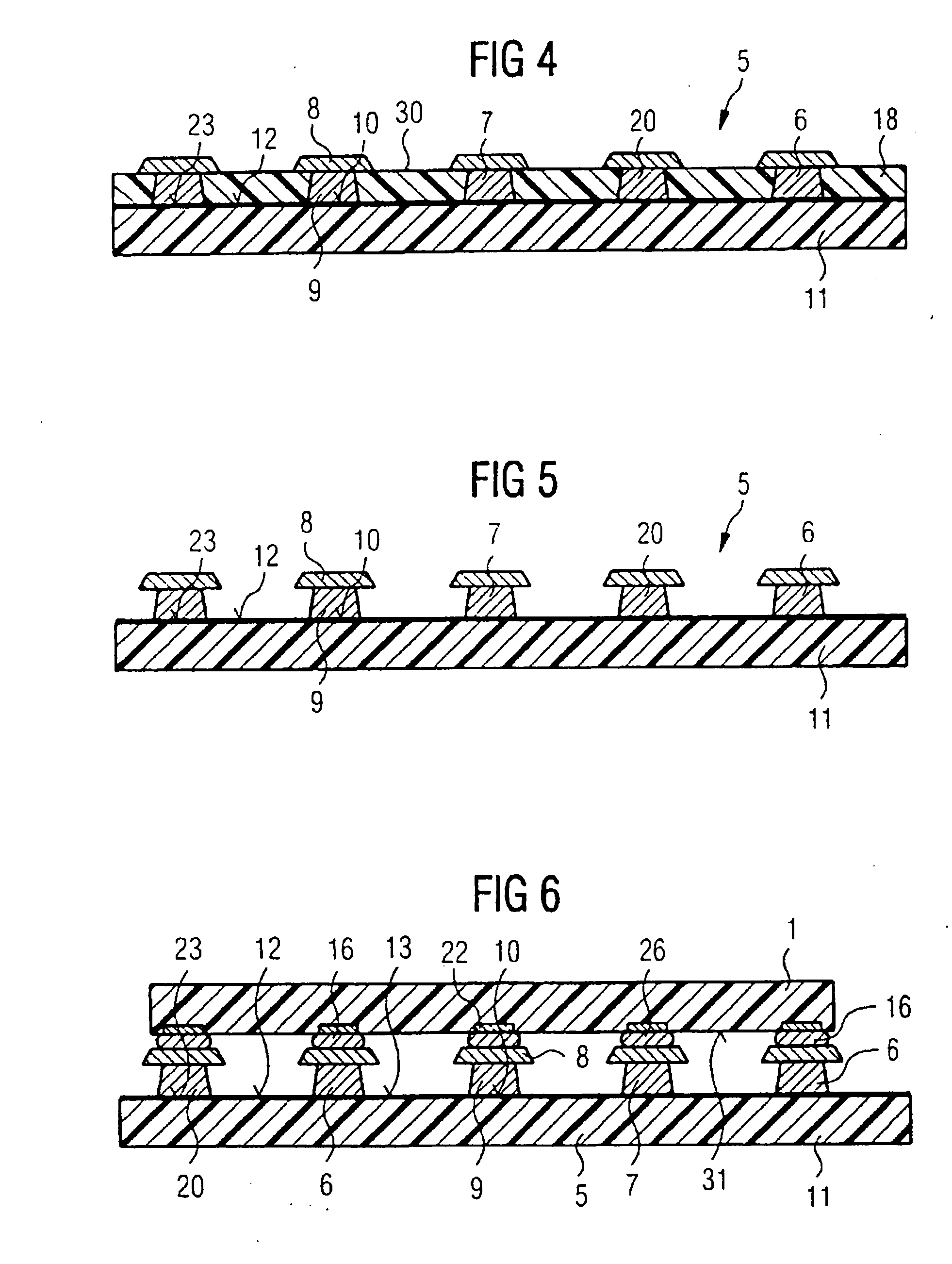

Production methods for a leadframe and electronic devices

InactiveUS20060060981A1Semiconductor/solid-state device detailsSolid-state devicesFoot regionSemiconductor chip

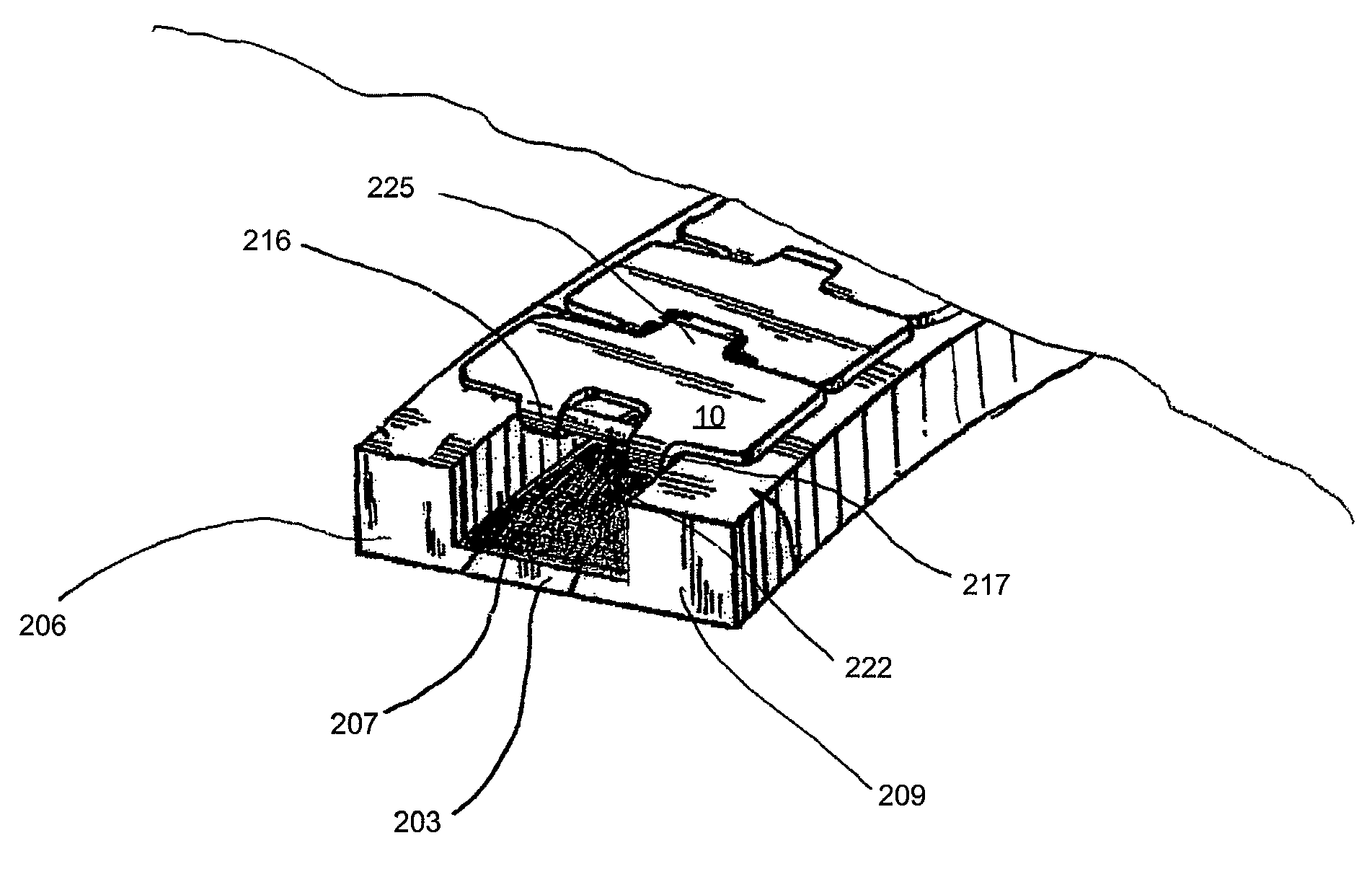

A leadframe for semiconductor chips and electronic devices produced on the leadframe includes providing the leadframe with a basic substrate, on which are disposed external contact elements exhibiting a rivet-shaped cross-section with a rivet head region, a rivet shank region, and a rivet foot region, as a result of which, the external contact elements are securely anchored in the housing made of a plastics compound.

Owner:INFINEON TECH AG

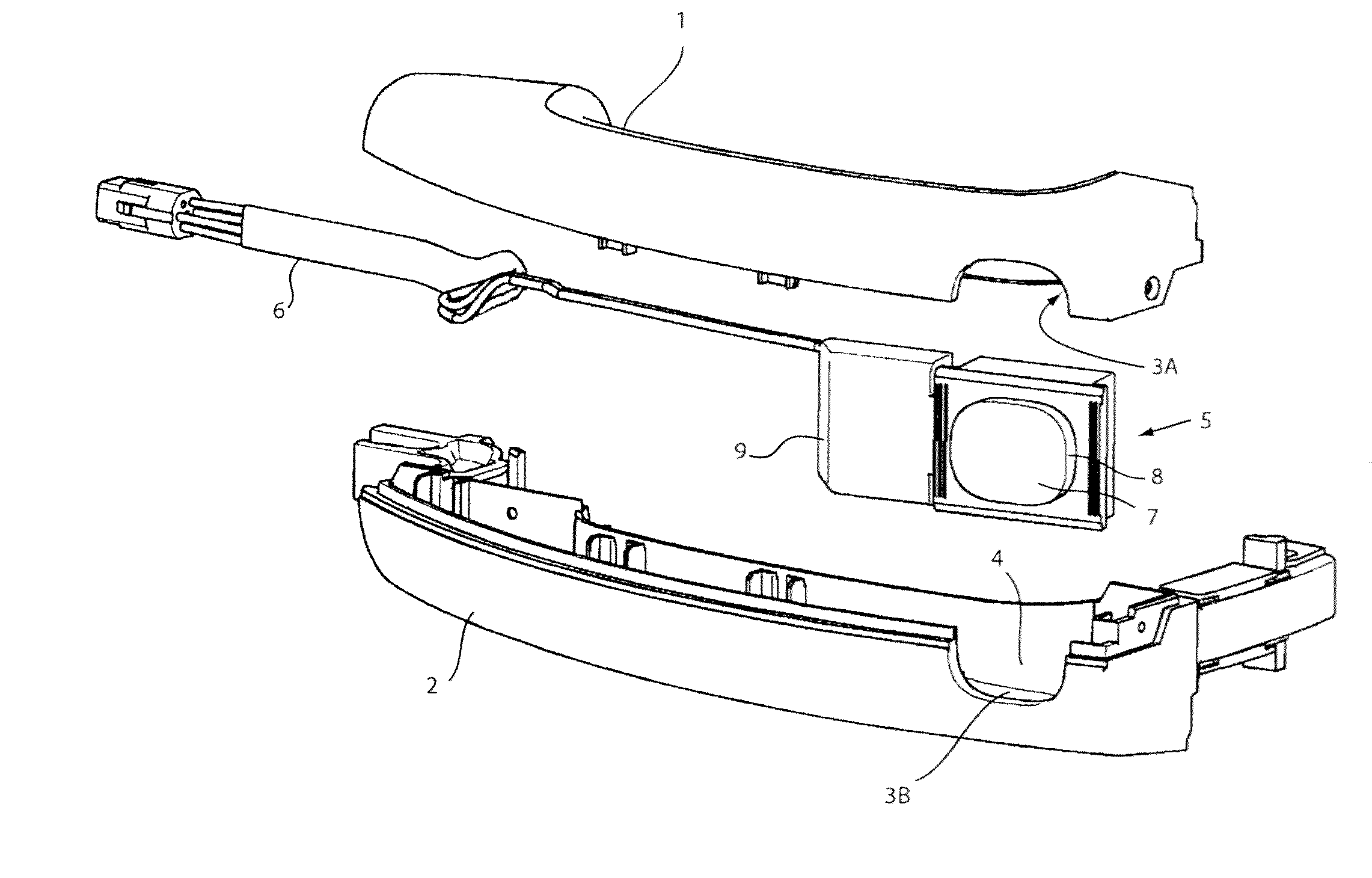

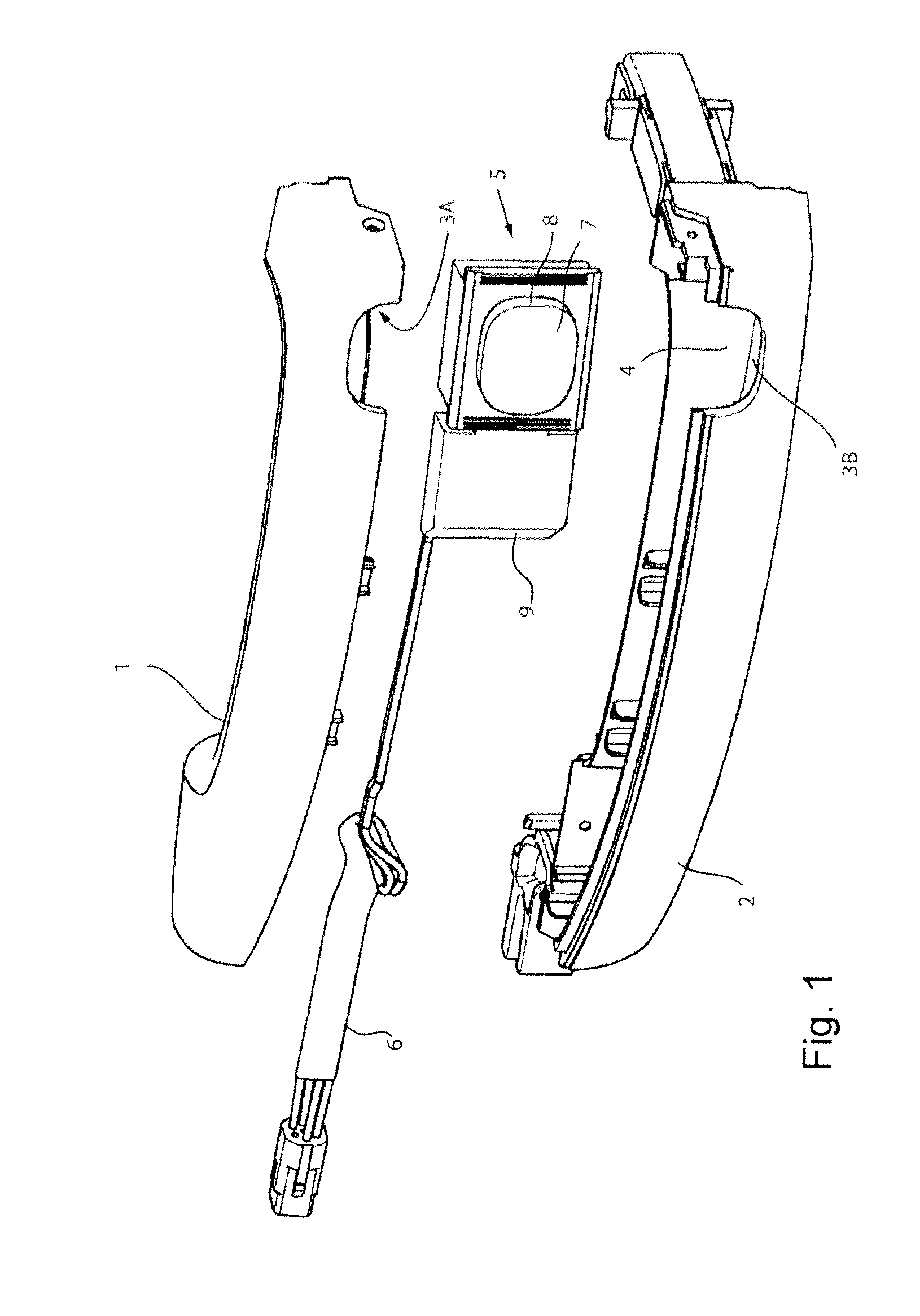

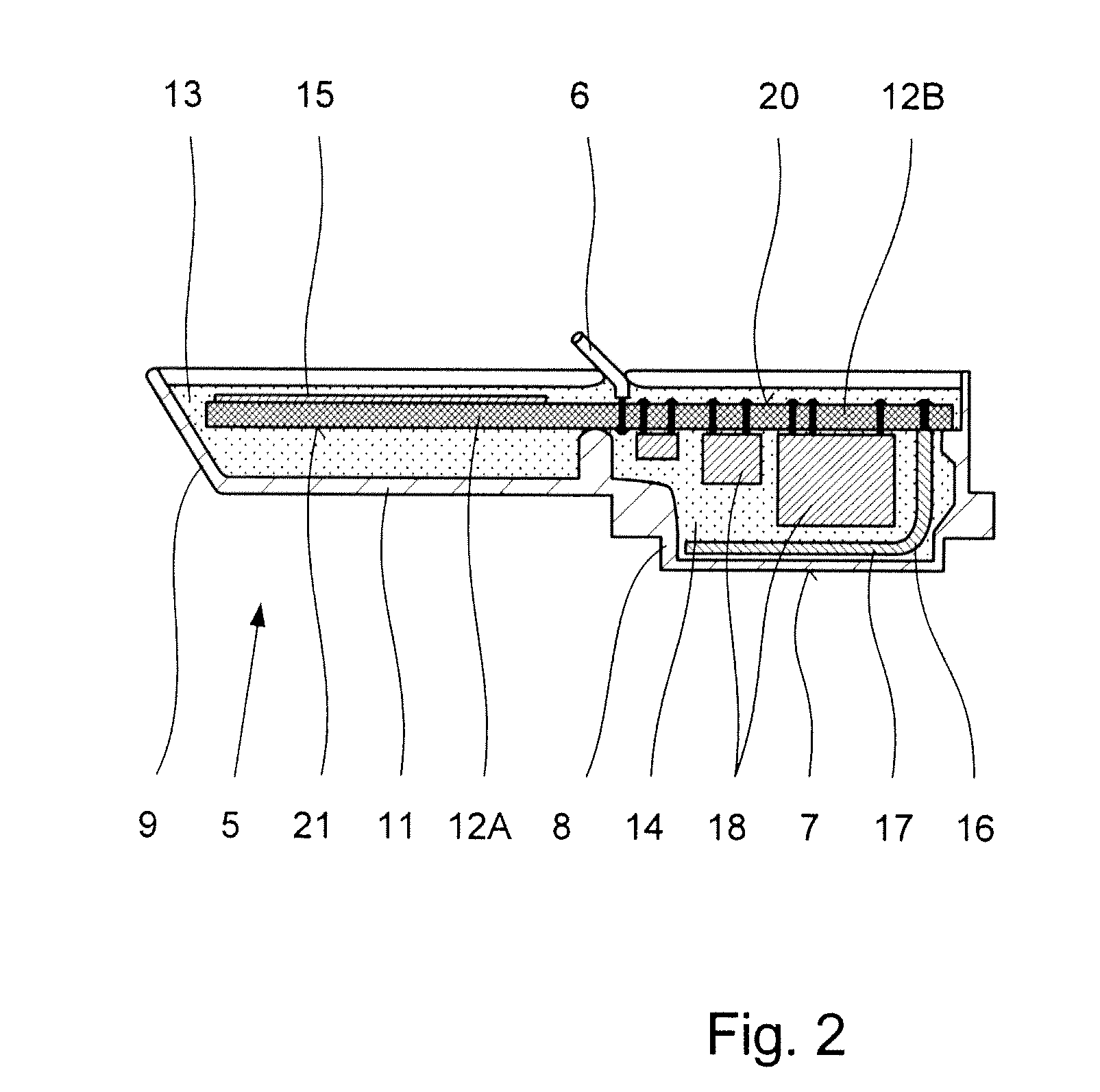

Motor vehicle outside door handle with a sensor module

ActiveUS20110025522A1Improve reliabilityEasy to manufactureLock applicationsDigital data processing detailsInterior spaceEngineering

A motor vehicle outside door handle with a wall surrounding an interior space (4), a first sensor electrode (15) of a first capacitive sensor for triggering a final locking operation, a second sensor electrode of a second capacitive sensor for triggering a locking operation, and an evaluation circuit, which is connected to the first sensor electrode and the second sensor electrode and is arranged in the interior space (4), is characterized in that the first sensor electrode, the second sensor electrode and the evaluation circuit are accommodated in a single sensor module (5) which can be inserted into the interior space (4). The sensor module (5) has a flat plastic trough (9) which has a bottom wall and is open on one side. A printed circuit board provided with connecting cables (6) is placed into the plastic trough (9). The plastic trough (9) is filled with a plastics compound. The sensor electrodes are formed by metal-coated layers of the printed circuit hoard or by metal bodies mounted on the printed circuit board.

Owner:HUF HULSBECK & FURST GMBH & CO KG

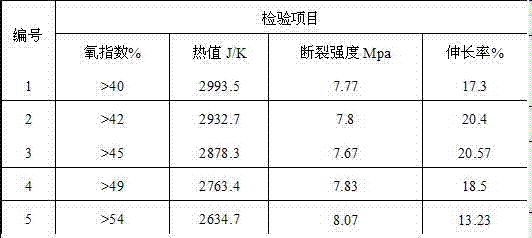

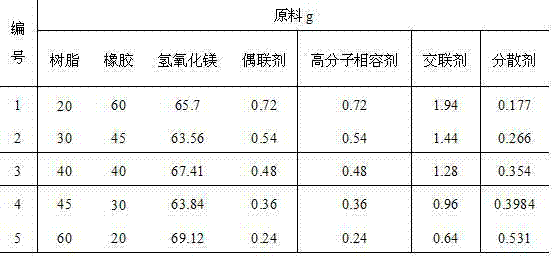

Material special for level-A fire-proof aluminum-plastic board core and preparation method thereof

The invention relates to an aluminum-plastic compound board sandwich layer material, in particular to a material special for a level-A fire-proof aluminum-plastic board core and a preparation method thereof. An inorganic flame retardant, i.e., magnesium hydroxide is taken as a flame retardant, and a high filling technology is adopted. Aids such as a coupling agent, a dispersing agent, a high-molecular compatilizer and the like are used for performing modification pretreatment on magnesium hydrate, so that the magnesium hydrate flame retardant has superior performance, the filling amount of the flame retardant in a substrate is up to 80-90 percent by weight, which is much higher than the adding amount of a flame retardant of the same type of products, the oxygen index of the product is remarkably increased in comparison to that of the same type of products, and the flame-retarding environmental protection performance is improved remarkably. An aluminum-plastic board core material prepared by adopting the method has the characteristics of freeness from halogen, low thermal value, low smoke, flame retardance, drop resistance, nontoxicity and freeness from pollution.

Owner:大连亚泰科技新材料股份有限公司

Plastic compound and preparation process

The invention relates to a plastic compound comprising at least one polyolefin and a biological entity that degrades said polyolefin. The invention further relates to a process for preparing a plastic article wherein at least one polyolefin and one biological entity that degrades said polyolefin are mixed at a temperature at which the polyolefin is in a partially or totally molten state.

Owner:CARBIOS +2

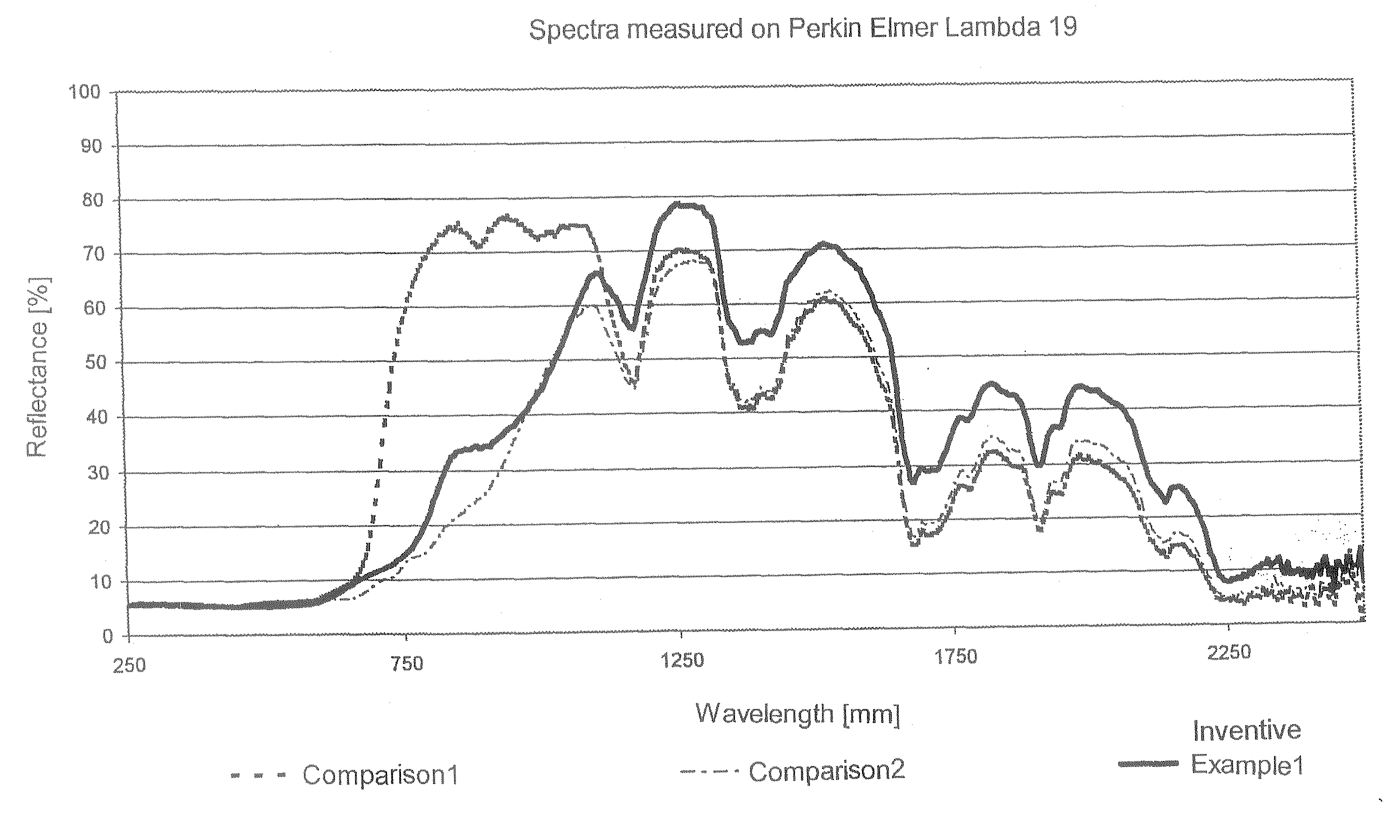

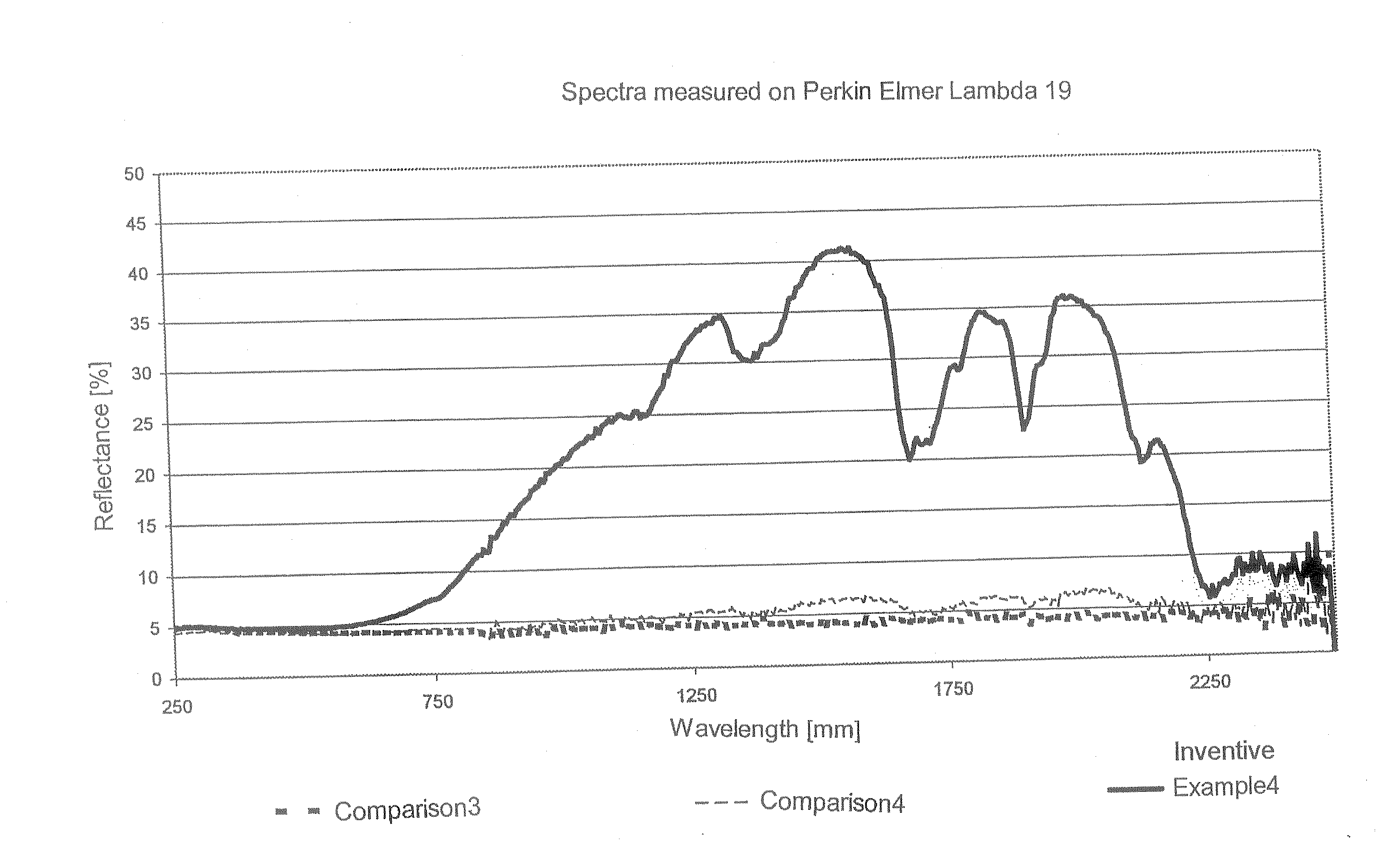

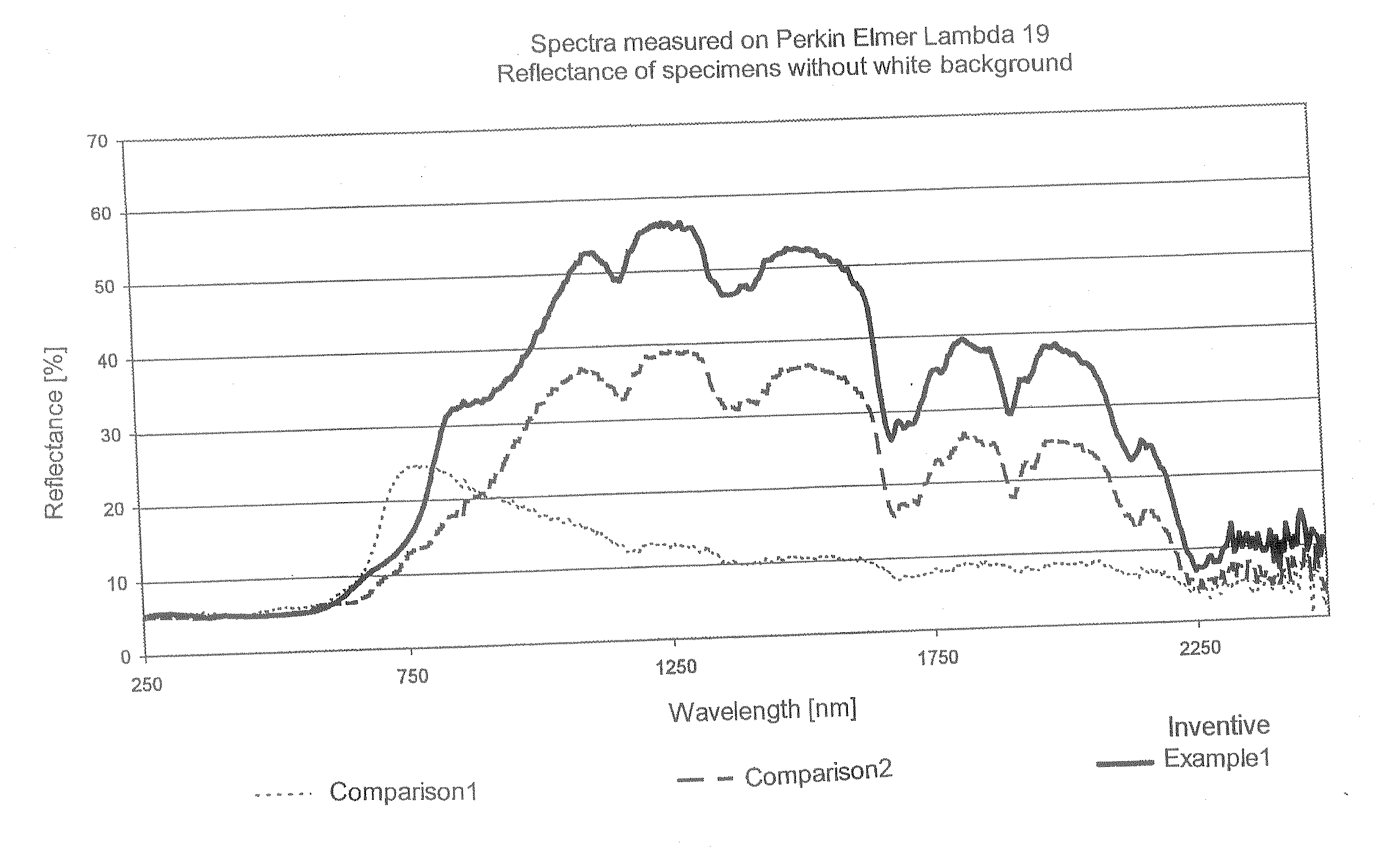

Subduedly colored, infrared reflecting plastic compound

The invention relates to subduedly colored (brown, gray, black, green), infrared reflecting PMMA compounds which can be applied to other plastic compounds as an IR barrier layer

Owner:EVONIK ROEHM GMBH

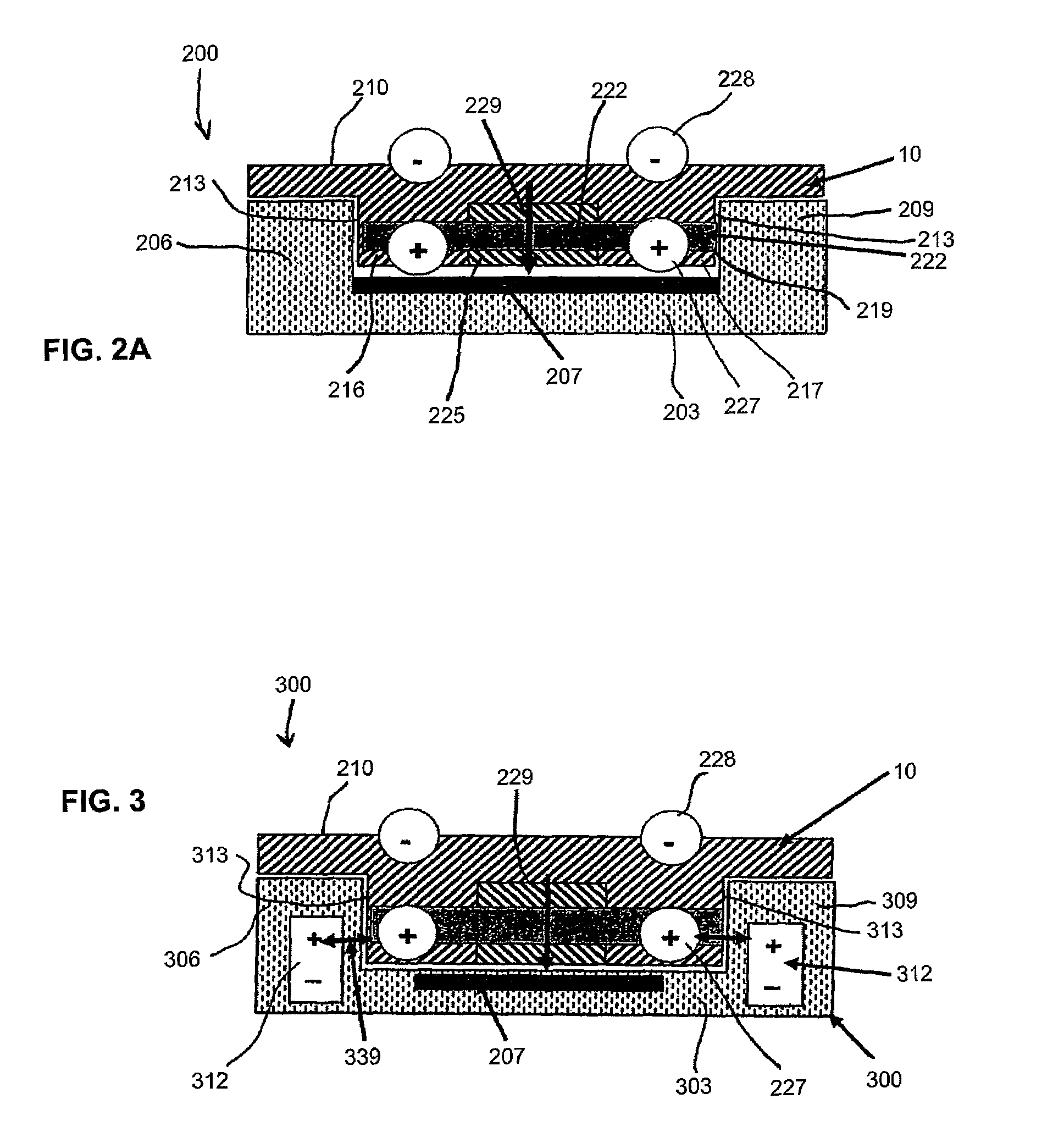

Belt module with magnetic properties

A module for chains or belts that is molded from a plastic compound containing a magnetizable element. The molding may be performed in a standard injection molding machine equipped with a device that produces an electromagnetic or permanent magnetic field. The field lines are directed in such a way as to penetrate the mold cavities and the molded part in the desired axis, in order to electrically charge the magnetizable particles and orient them to form a permanently magnetized plastic body. After discharge of the mold, the plastic part has magnetic properties with opposite charges at opposite poles.

Owner:HABASIT AG

Molding compound for sheet tantalum capacitor

InactiveCN1546566AMeet the requirements of production molding process parametersImprove product qualityCapacitorsEpoxyCombustion

The invention discloses a molded plastic compound for sheet tantalum capacitor, which is an epoxy resin compound and belongs to the field of special-purpose plastic encapsulating material in electronic industry. The molded plastic uses epoxy resin as the main block resin and phenolic resins as curing agent, prepared by adding solidification accelerating agent, filling material, releasing agent, combustion inhibitor, coloring agent, coupling agent, toughening agent and modifier though the steps of disintegrating, mixing, pugging, cooling down, disintegrating, batch mixing, pre-forming and packaging.

Owner:WUXI RES & DESIGN INST OF CHEM IND

Compositions Comprising Placental Collagen for Use in Wound Healing

Provided herein is a topical wound dressing that comprises a collagen and a flexible paste. Also provided is a wound dressing with a first layer of a sterilized mixture of collagen and a second adhesive layer effective to adhere to surrounding skin and to keep the first layer in contact with the wound. In addition there is provided a wound dressing foil that comprises collagen and a plastic compound that can provide a foil shape. Furthermore, methods of dressing wounds utilizing the wound dressings and wound dressing foil are provided herein.

Owner:MAM HLDG OF WEST FLORIDA L L C

A-level fire-protection energy-saving rubber-plastic compound building insulation material and preparation method thereof

ActiveCN102786740AImprove insulation effectMeet Class A flame retardant requirementsLow-density polyethyleneStearic acid

A preparation method for A-level fire-protection energy-saving rubber-plastic thermal-insulating compound foam comprises the following steps: adding polypropylene powder resin, methyl vinyl base silicone rubber, ceramic powder, a fire retardant, glass fiber powder, an antioxidant, white carbon black and polyethylene wax in a high-speed mixer for kneading at a normal temperature, discharging the kneaded materials to an internal mixer so as to obtain material groups through internal mixing, discharging the material groups to a single-screw extrusion pelletizer so as to obtain a basic material A through melting, plasticizing and granulation; adding low-density polyethylene resin in a high mixing machine, then adding an AC blowing agent, talc powder, a lubricating agent and zinc stearate for kneading at the normal temperature, and then discharging the kneaded materials into a single-screw extruder so as to obtain a foaming masterbatch B through granulation; adding the basic material A, the foaming masterbatch B and the polyethylene wax into the high-speed mixer for kneading at the normal temperature, and then discharging the kneaded materials into the single-screw extruder so as to obtain sheets through extruding; carrying out irradiation crosslinking and foaming; grooving on the surface of the prepared foam; and embedding fire-protection filler in the grooves of the foam, immersing in a fire retardant solution and baking so as to obtain the compound building foam.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

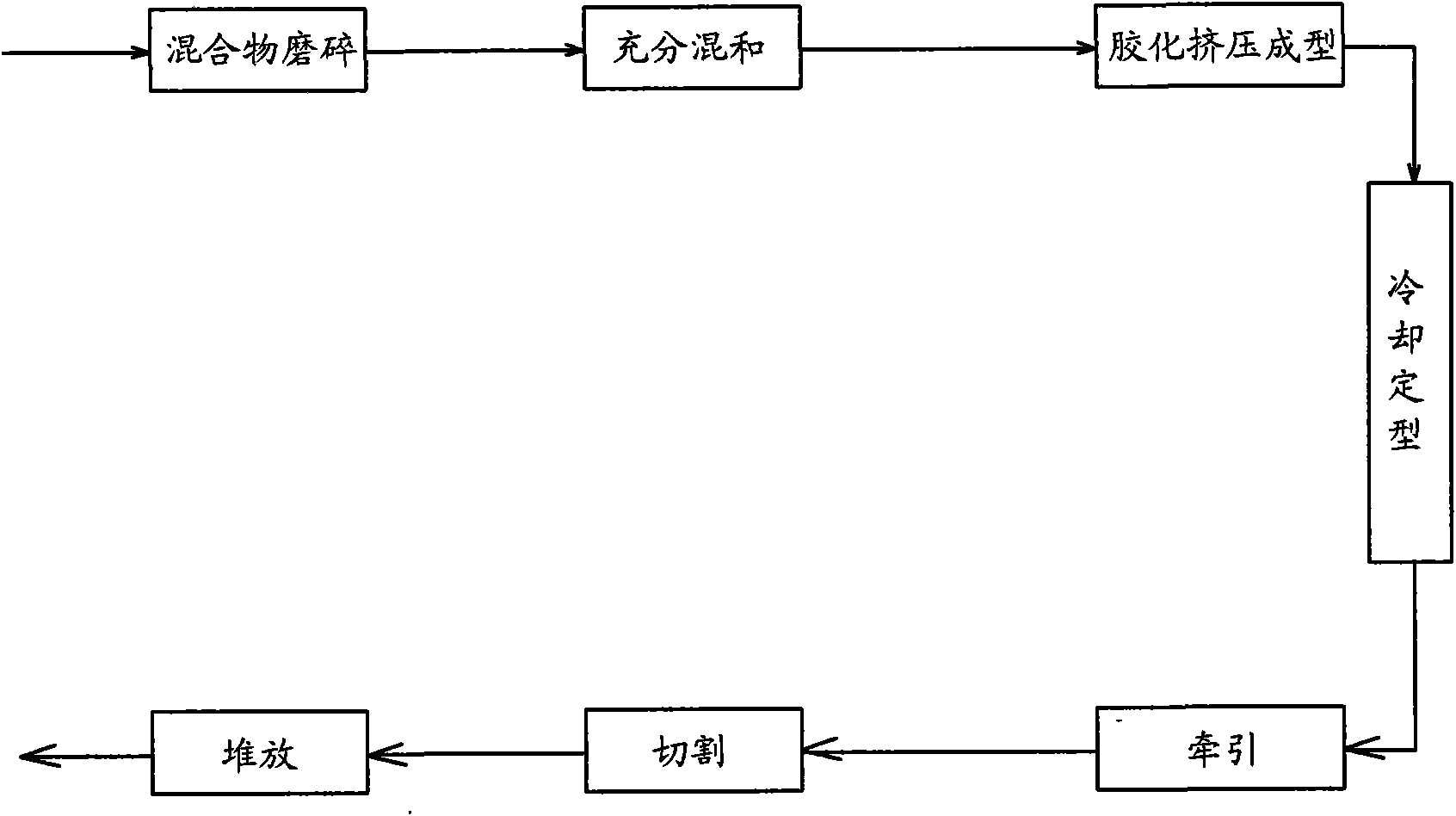

Manufacturing method of a regenesis wood plastic compound structures sectional materials

InactiveCN101550278AReduce carbonizationCarbonization achievedComposite constructionMaterials processing

The present invention discloses manufacturing method of a regenesis wood plastic compound structures sectional materials, belonging to polymer material processing technology field, mixing mixture containing wood fiber, polyethylene resin, calcium carbonate, plasticizer, geoceric acid, epoxy oil, tranquilizer, slipping agent, coupling agent and industry whiteruss sufficiently in mixing machine; adding the mixture into extrusion molding machine for gelatination; squashing into moulds for molding; cooling the moulded product in moulds by cooling water for shaping; pulling out the shaped products by tractor and cutting into completed product. The wood plastic compound structures sectional materials produced by using the raw stuff recipe of the invention have more excellent physical chemistry character and appearance quality than other similar products.

Owner:广东贤林家居用品有限公司

Polyvinyl chloride hot-dipping plastic compounded product, and its production and use

The present invention relates to a kind of PVC heat soaking plastic product and its producing method and application. It's produced by the technics steps of preparing coal paste, preparing materials, adjusting viscosity, pumping into vacuum and placed according to proportions of these materials: PVC resin powder, DOP, epoxy soybean oil, DOS, DIDG, fire retarder, stabilizing agent, meteorological method hydration silicon dioxide, carbon black and viscosity reducing agent; and its products are used in cable golden implement accessories as cable preventing tube. The compound layer has such performances as combining firmly with substrate surface, anti-corrosive, anti-aging, good insulating property, fire retarding, waterproofing and antimagnetic. It's surface compound layer material preferred by metal products.

Owner:BAOYUAN ELECTRIC ENG GEZHOU CITY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com