Rubber-plastic compound foaming material, and preparation method and application thereof

A composite foaming, rubber-plastic technology, applied in applications, clothing, footwear, etc., can solve the problems of poor cushioning, rebound performance, poor cushioning performance, and poor fatigue resistance of materials, and achieve good recovery performance , Excellent rebound performance, and the effect of meeting the performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047]The preparation material of the rubber-plastic composite foaming material described in the present application includes 10-20 parts by mass of EPDM rubber, preferably 12-15 parts by mass of EPDM rubber. In the present application, the hardness of the EPDM rubber is preferably 60A-70A. In the embodiment of the present application, the type of the EPDM rubber may be one or more of IP3745, EPDM8800 and EPDM9500.

[0048] In parts by mass, the material includes 10-20 parts by mass of polyolefin block copolymer, preferably 11-18 parts by mass of polyolefin block copolymer. In the present application, the hardness of the polyolefin block copolymer is preferably 60A-90A. In the embodiment of the present application, the model of the polyolefin block copolymer may be one or more of Infuse9100, Infuse9107, Infuse9500 and Infuse9507. In a preferred embodiment of the present application, the hardness of the EPDM rubber is 60A-70A, and the hardness of the polyolefin block copolyme...

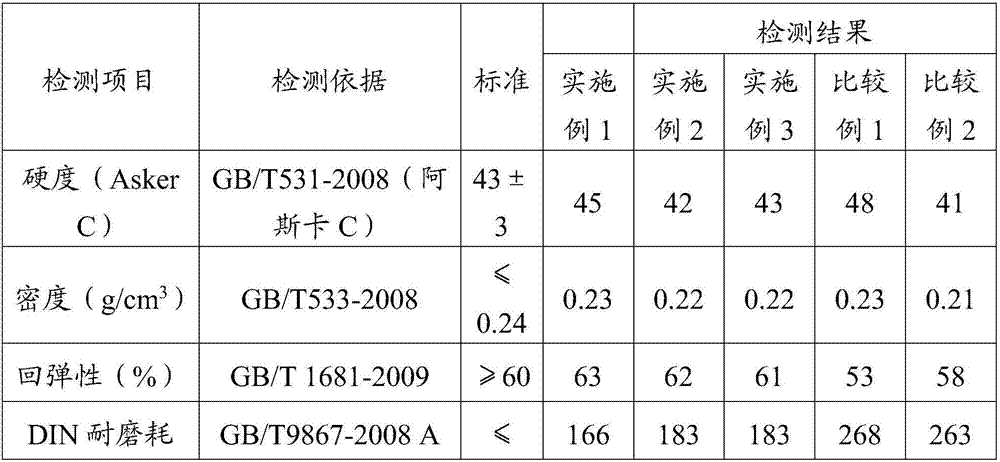

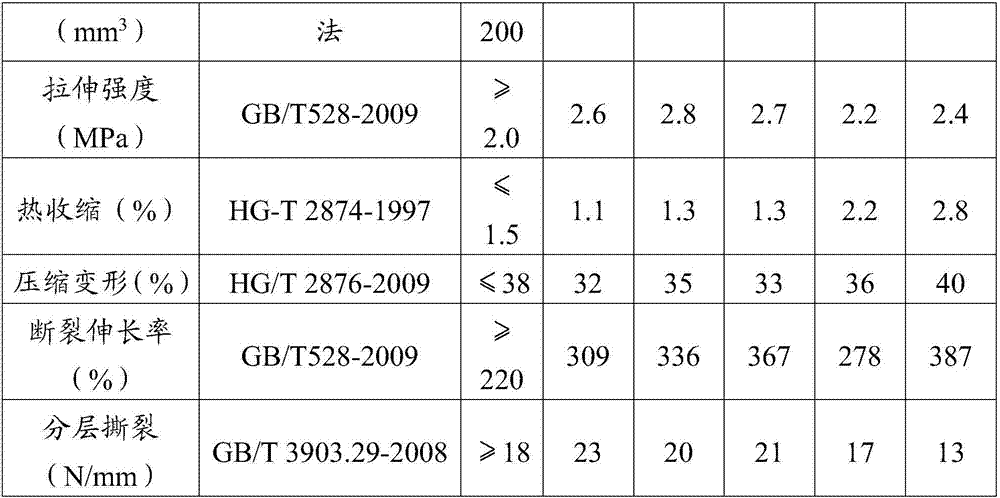

Embodiment 1

[0072] A soft, high-elastic and wear-resistant rubber-plastic composite foaming material for sports shoe soles is formulated as follows:

[0073] Ethylene-vinyl acetate copolymer: 42 parts by mass;

[0074] Thermoplastic elastomer: 30 parts by mass;

[0075] EPDM rubber: 13 parts by mass;

[0076] Polyolefin block copolymer: 15 parts by mass;

[0077] Wear-resistant agent: 8 parts by mass;

[0078] Anti-shrinkage agent: 1.5 parts by mass;

[0079] Talcum powder: 5 parts by mass;

[0080] Zinc oxide ZnO: 2.0 parts by mass;

[0081] Stearic acid St: 0.5 parts by mass;

[0082] Zinc stearate ZnSt: 1.0 parts by mass;

[0083] Cross-linking auxiliary agent: 0.1 parts by mass;

[0084] Crosslinking agent: 1.0 parts by mass;

[0085] Foaming agent: 3.1 parts by mass;

[0086] Titanium dioxide: 2.5 parts by mass.

[0087]Among them, the model of ethylene-vinyl acetate copolymer is 7470M, produced by Formosa Plastics Corporation; the thermoplastic elastomer consists of 15 pa...

Embodiment 2

[0092] A soft, high-elastic and wear-resistant rubber-plastic composite foaming material for sports shoe soles is formulated as follows:

[0093] Ethylene-vinyl acetate copolymer: 50 parts by mass;

[0094] Thermoplastic elastomer: 25 parts by mass;

[0095] EPDM rubber: 15 parts by mass;

[0096] Polyolefin block copolymer: 10 parts by mass;

[0097] Wear-resistant agent: 10 parts by mass;

[0098] Anti-shrinkage agent: 2.5 parts by mass;

[0099] Talcum powder: 5 parts by mass;

[0100] Zinc oxide ZnO: 2.0 parts by mass;

[0101] Stearic acid St: 0.5 parts by mass;

[0102] Zinc stearate ZnSt: 0.8 parts by mass;

[0103] Cross-linking auxiliary agent: 0.17 parts by mass;

[0104] Crosslinking agent: 1.0 parts by mass;

[0105] Foaming agent: 3.0 parts by mass;

[0106] Titanium dioxide: 2.5 parts by mass.

[0107] Among them, the ethylene-vinyl acetate copolymer models are 265 and 40L, the mass ratio is 2:1, produced by DuPont; the thermoplastic elastomer is made ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com