Preparation method of rubber and plastic compound modified asphalt with stable heat storage

A heat storage stable, modified asphalt technology, applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of low temperature ductility of modified asphalt, long production cycle, etc., to increase the utilization rate and Effects of reaction speed, increased compatibility, and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

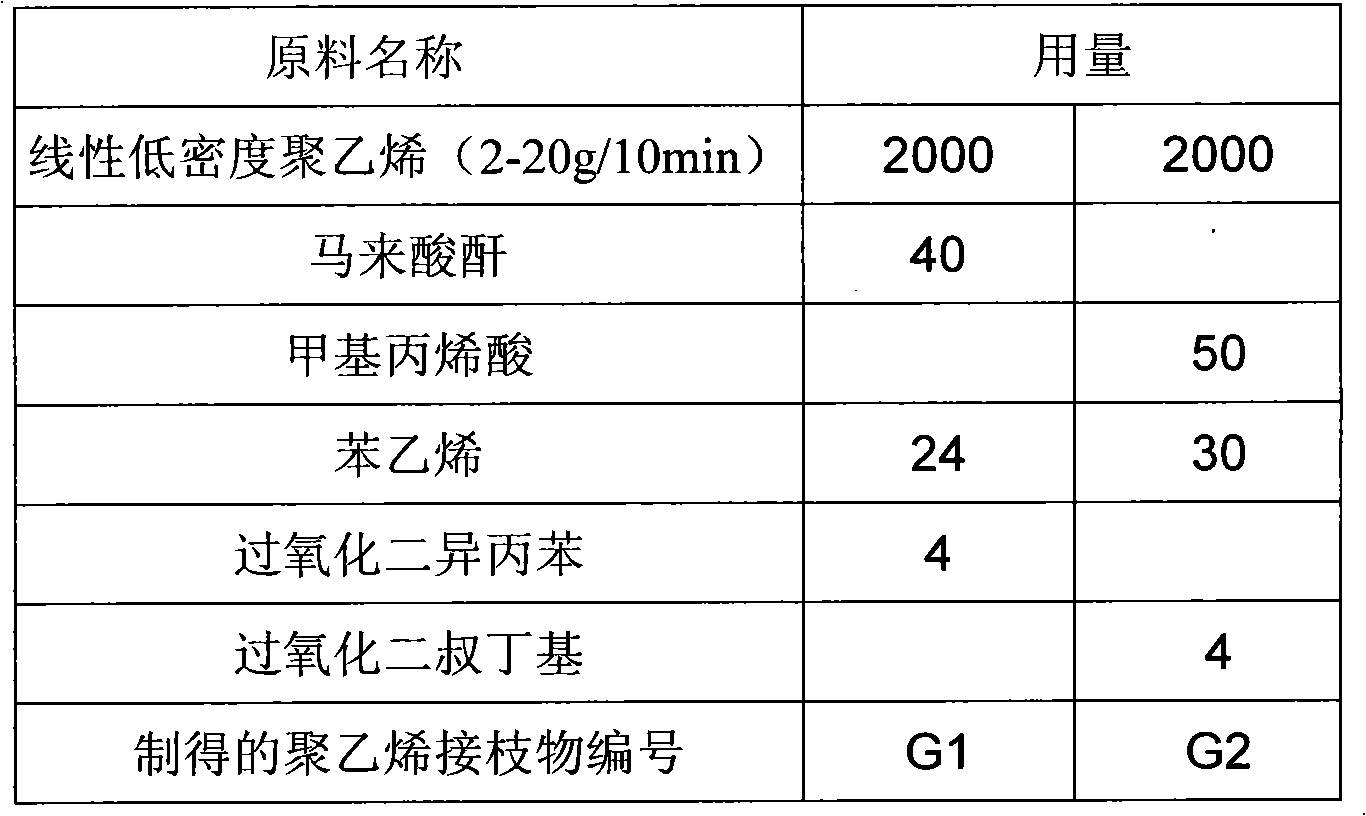

[0066] In a small mixer of 3 liters, according to the formula in Table 1, add 2000 g of linear low density polyethylene and 40 g of maleic anhydride, and mix evenly at a low speed. 4 g of dicumyl peroxide were dissolved in 24 g of styrene and added to the mixture of linear low density polyethylene and maleic anhydride. Mix on high speed for 3-5 minutes to obtain a mixture.

[0067] The mixture is added into the feed hopper of the twin-screw extruder, extruded and pelletized in a twin-screw extruder with a screw length-to-diameter ratio of 40:1 and a screw diameter of 20mm, and the host of the twin-screw extruder The rotation speed is 300 rpm, the feeding speed is 40 rpm, and the temperature of each section of the extruder (including 6 sections in total) is 170°C, 180°C, 185°C, 185°C, 180°C, 180°C, Finally, dry the polyethylene graft G1. The graft ratio of graft G1 was 1.39 mmol / 100 g.

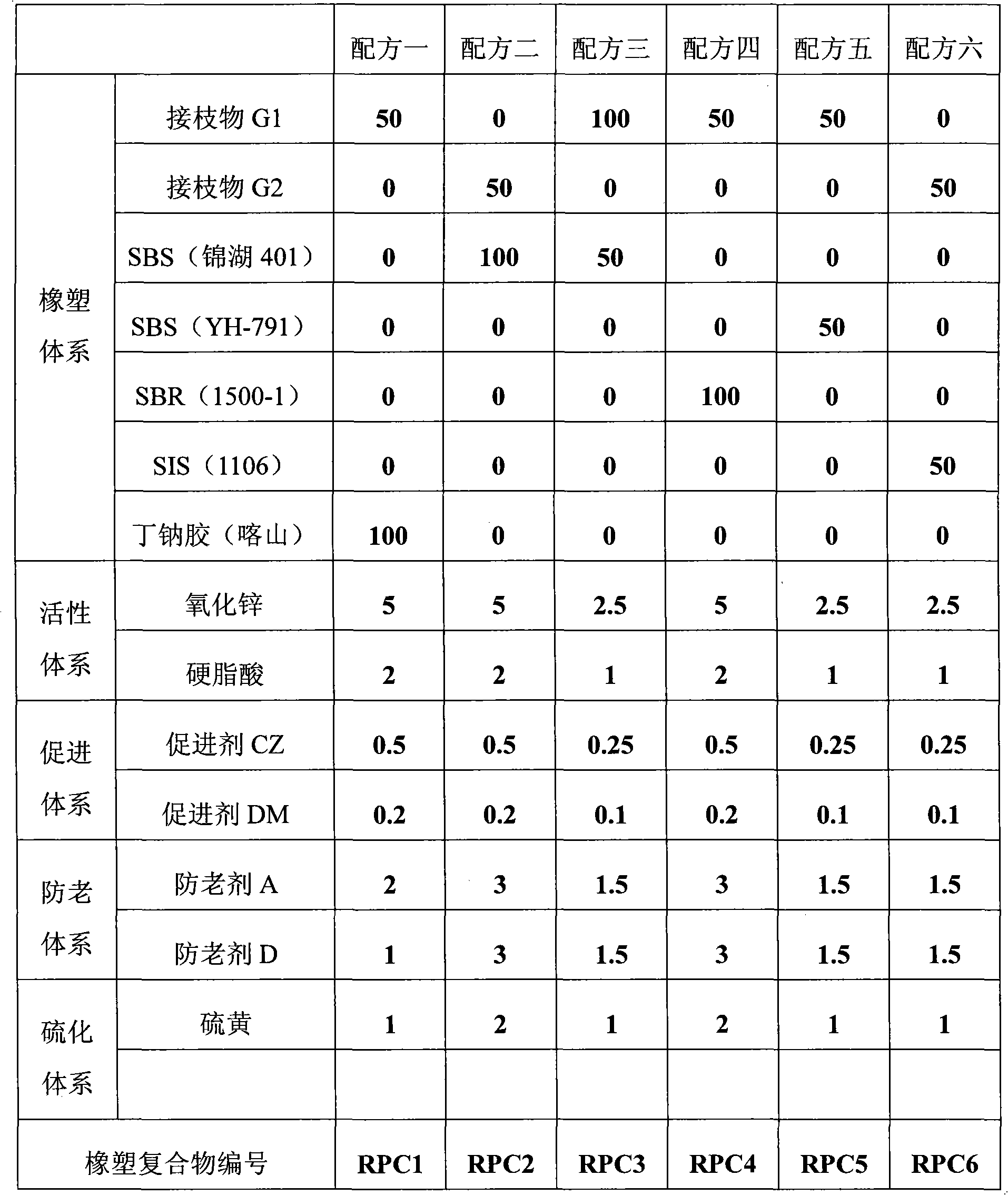

[0068] According to formula 1 in Table 2, the temperature of the open mill is first rais...

Embodiment 2

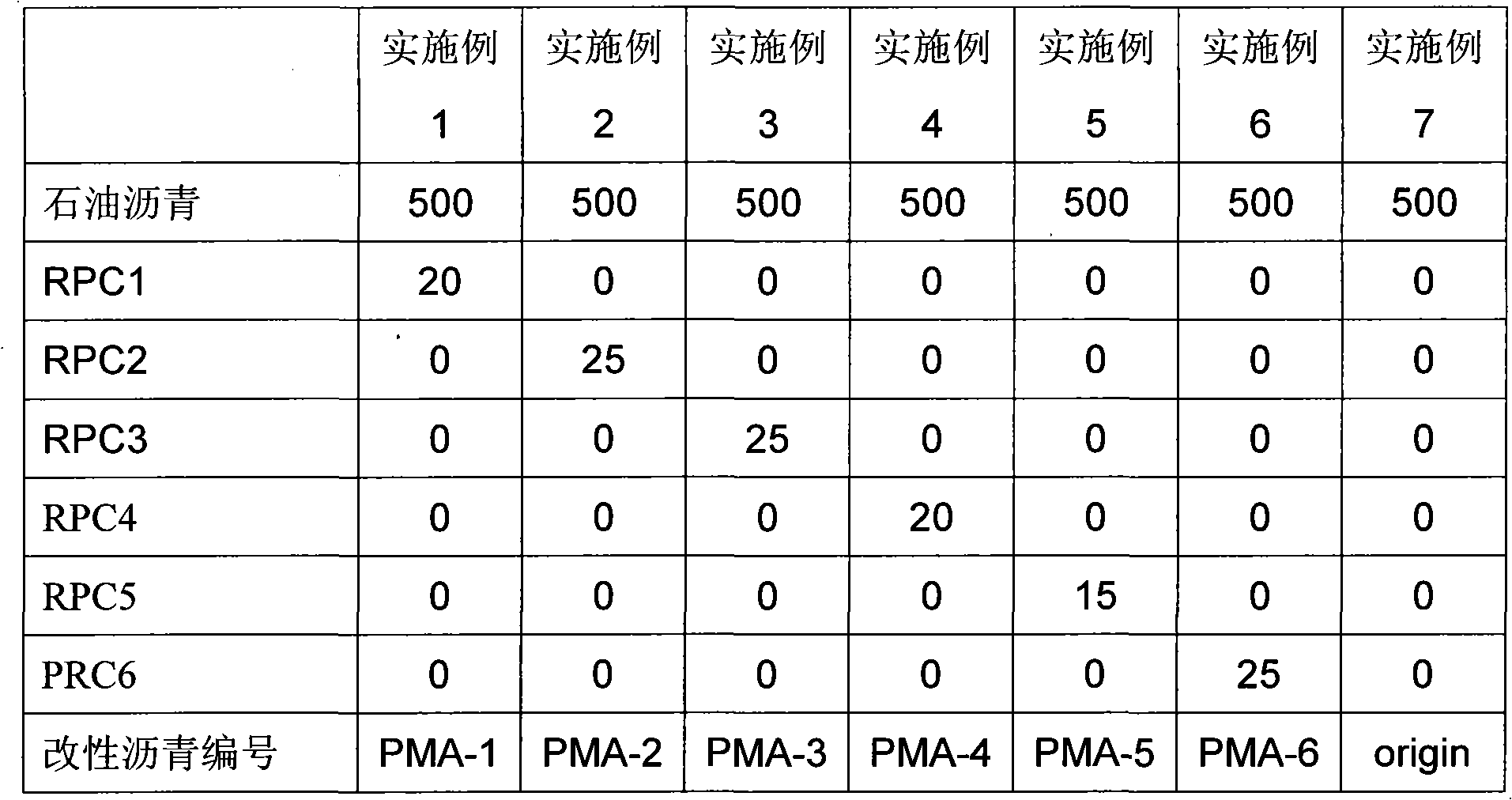

[0071] According to the same processing conditions of Example 1, the graft G2 was prepared according to the formula in Table 1, and the grafting rate of G2 was 1.56mmol / 100g. Different from Example 1, the process of the twin-screw extruder is: the rotating speed of the main engine is 300 rpm, the feeding speed is 60 rpm, and the temperature of each section of the extruder (including 6 sections of the head) is sequentially It is 170°C, 185°C, 190°C, 190°C, 180°C, 175°C. According to the ratio of formula 2 in Table 2, the rubber-plastic composite numbered RPC2 was obtained, and the rubber-plastic composite modified asphalt PMA-2 was obtained according to the ratio of Example 2 in Table 3. The performance test method of modified asphalt is the same as that of Example 1, and the performance of PMA-2 is listed in Table 4.

[0072] Table 1 Formula for the preparation of polyolefin grafts in Examples 1 to 6 (unit: gram)

[0073]

Embodiment 3

[0075] According to the same processing conditions as in Example 1, the graft G1 was obtained according to the formula in Table 1, and the rubber-plastic composite numbered RPC3 was obtained according to the proportion of Formulation 3 in Table 2, and it was prepared according to the proportion of Example 3 in Table 3. Rubber-plastic compound modified asphalt PMA-3. The performance test method of modified asphalt is the same as that of Example 1, and the performance of PMA-3 is listed in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com