Jute and plastic compound material plank stuff and manufacturing method thereof

A composite material and sheet technology, applied in chemical instruments and methods, synthetic resin layered products, cellulose plastic layered products, etc., can solve problems such as mechanical properties decline, and achieve strong creep resistance and short production cycle. , high stretch effect

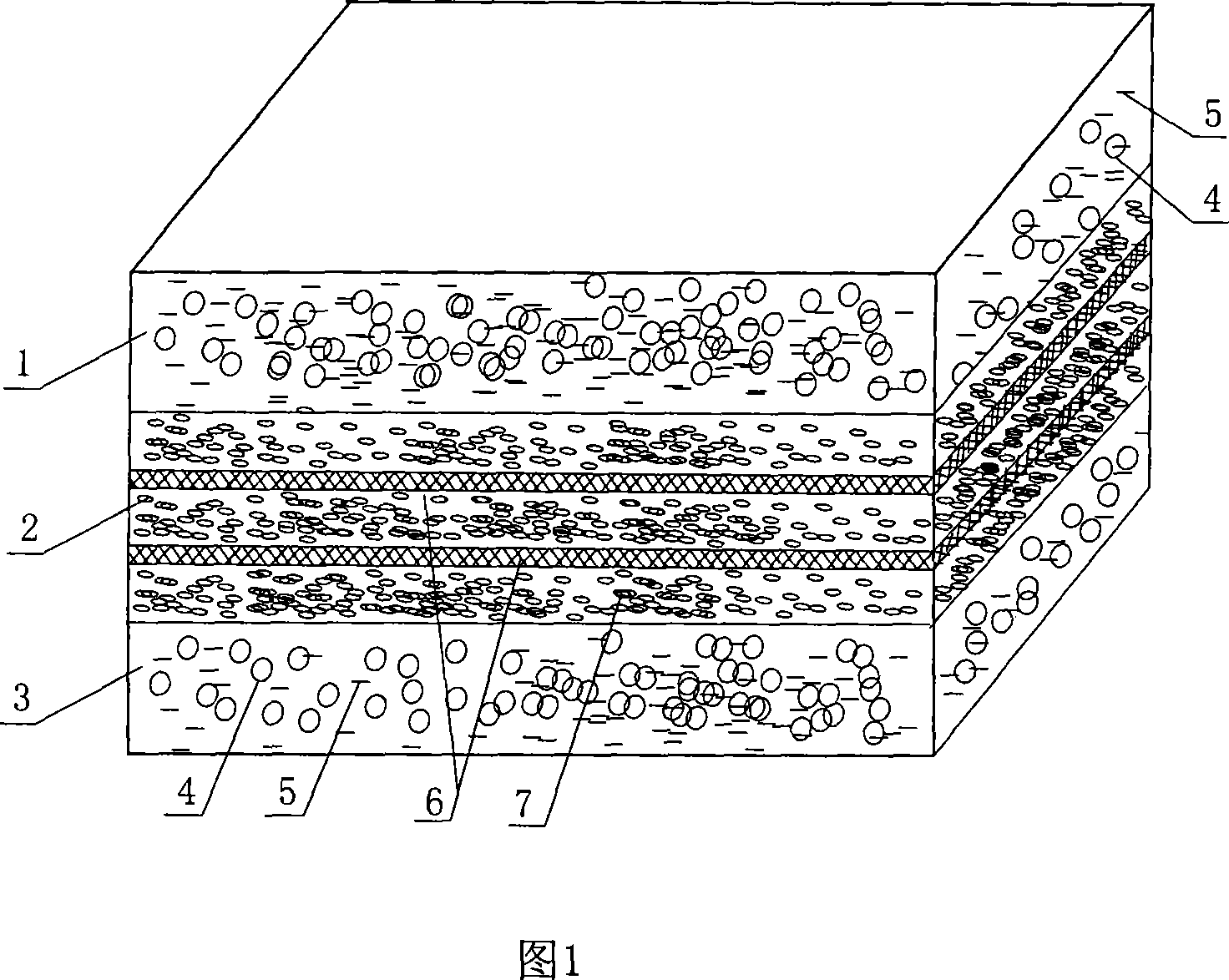

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: a kind of preparation method of hemp-plastic composite material plate, its preparation process is:

[0037] (1) Mix the silane coupling agent and water in a mass ratio of 1:1, weigh 1 g of the silane coupling agent and 1 g of water, and mix evenly, wherein water is the solvent; the silane coupling agent uses γ-(methacryloyl Oxy)propyltrimethoxysilane;

[0038] (2) Nano-titanium dioxide and the diluted silane coupling agent are in a mass ratio of 100: 2, weigh 0.1 kg of nano-titanium dioxide and 0.002 kg of the above-mentioned diluted silane coupling agent, mix uniformly, and dry in vacuum for 6 hours at a temperature of 40° C. Modified nano-titanium dioxide particles are made; the silane coupling agent adopts γ-(methacryloyloxy)propyltrimethoxysilane;

[0039] (3) According to the mass ratio of hemp fiber cloth and silane coupling agent 100:1, weigh 0.01kg of silane coupling agent, dilute the silane coupling agent with water, and the amount of water shall...

Embodiment 2

[0045] Embodiment 2: a kind of preparation method of hemp-plastic composite material plate, its preparation process is:

[0046] (1) Mix the silane coupling agent and water at a mass ratio of 1:5, weigh 5 g of the silane coupling agent and 25 g of water, and mix evenly, wherein water is the solvent; the silane coupling agent uses γ-(methacryloyl Oxy)propyltrimethoxysilane;

[0047] (2) Mix nano-titanium dioxide and diluted silane coupling agent in a mass ratio of 100:6, weigh 0.5 kg of nano-titanium dioxide and 0.03 kg of the diluted silane coupling agent, and dry in vacuum for 3 hours at a temperature of 80° C. to prepare Forming modified nano titanium dioxide particles; the silane coupling agent adopts γ-(methacryloyloxy)propyltrimethoxysilane;

[0048] (3) According to the mass ratio of hemp fiber cloth and silane coupling agent 100:5, weigh 0.25 kg of silane coupling agent, dilute the silane coupling agent with water, and the amount of water shall be based on immersing th...

Embodiment 3

[0054] Embodiment 3: a kind of preparation method of hemp-plastic composite material plate, its preparation process is:

[0055] (1) Mix the silane coupling agent and water in a mass ratio of 1:1, weigh 5 g of the silane coupling agent and 5 g of water, and mix evenly, wherein water is the solvent; the silane coupling agent uses γ-(methacryloyl Oxy)propyltrimethoxysilane;

[0056] (2) Nano-titanium dioxide and the diluted silane coupling agent are in a mass ratio of 100: 2, weigh 0.5 kg of nano-titanium dioxide and 0.01 kg of the above-mentioned diluted silane coupling agent and mix evenly, and dry in vacuum for 6 hours at a temperature of 40° C. Modified nano-titanium dioxide particles are made; the silane coupling agent adopts γ-(methacryloyloxy)propyltrimethoxysilane;

[0057] (3) According to the mass ratio of hemp fiber cloth and silane coupling agent 100:1, weigh 0.05kg of silane coupling agent, dilute the silane coupling agent with water, and the amount of water shall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com