Method for preparing rubber-plastic compound

A mixture and plastic technology, applied in food science, plastic recycling, grain processing, etc., can solve problems such as poor product quality, environmental pollution, and prolonged contact with materials at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] With the known pulverizer of normal temperature disc type finely crushing waste thermosetting elastomer, process a group of formula mixture as follows:

[0088] Recipe Component:\Recipe Number:

1

2

3

4

5

6

Those that pass through a 3.5mm aperture sieve will be collected by the papermaking enterprise

The paper-plastic composite film removes most of the pulp and discharges it

Discarded impurity-containing composite plastic film (water content 50%)

10

15

20

30

45

60

Tire rubber powder particles passed through a 18-mesh aperture sieve

90

85

80

70

55

40

Dry wood flour through a 100-mesh sieve

/

/

15

/

/

10

Fly ash passed through a 400-mesh sieve

/

150

/

/

/

150

Salt sludge (water content 50%) discarded by salt ...

Embodiment 2

[0096] Use the new method described in the present invention to process new plastics and thermosetting elastomers with grinding and crushing to mix and eat powder operation

[0097] A set of formulation mixtures containing plastics and thermoset elastomers is processed using a disc-type pulverizer for finely pulverizing vulcanized rubber:

[0098] Recipe Component:\Recipe Number:

1

2

PP particles passing through a 3.5mm sieve

20

50

Thermosetting EPDM vulcanized rubber particles with a tensile strength greater than 10 MPa passing through a 20-mesh sieve

80

50

Red clay powder

20

50

Mixed short-staple fiber materials of fibers and rubber powder particles discarded by reclaimed rubber and rubber powder manufacturers

5

/

Peanut shell powder passed through a 100-mesh sieve

30

30

Lubricants such as: stearic acid

1

2

Coupling agent such as: maleic...

Embodiment 3

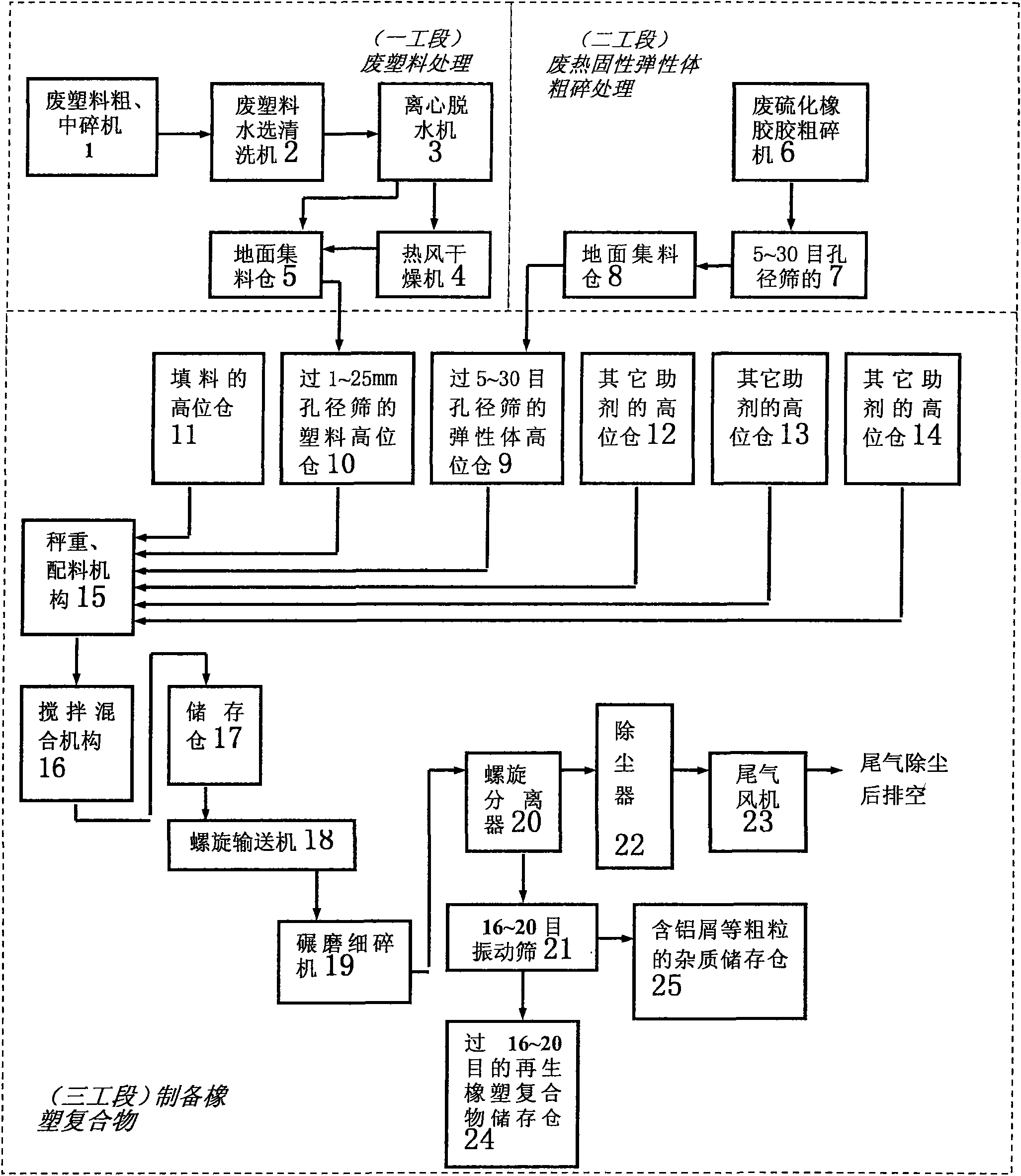

[0107] Combination device for carrying out the novel method of the present invention

[0108] Examples are attached figure 1 As shown, it is a schematic block diagram of the combination device described in this embodiment, and 19 in the figure is the normal temperature thermosetting elastomer fine shredder equipment set in the combination device according to the present invention; in the figure 1 - waste plastics coarse and medium crushing Machine, 2-waste plastic water sorting and cleaning machine, 3-centrifugal dehydrator, 4-hot air dryer, 5-ground collection bin, which (one section) is combined to form the fine crushing unit machine for thermosetting elastomer at room temperature according to the present invention Before the equipment, add coarse and medium crushing machines that can crush plastic particles that pass through a sieve with an aperture of 1 to 5 mm, add washing and sorting of waste plastics, a centrifugal dehydrator, and hot air drying equipment to remove heav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com