Patents

Literature

771results about How to "Avoid scorching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pre-passivation process for a continuous reforming apparatus, and passivation process for a continuous reforming apparatus during the initial reacation

ActiveUS20100282645A1Reduce operational riskReduce contentThermal non-catalytic crackingPhysical/chemical process catalystsLiquid productReaction temperature

The present invention relates to a pre-passivation process for a continuous reforming apparatus prior to the reaction, or a passivation process for a continuous reforming apparatus during the initial reaction, comprising loading a reforming catalyst into the continuous reforming apparatus, starting the gas circulation and raising the temperature of a reactor, injecting sulfide into the gas at a reactor temperature ranging from 100-650° C., controlling the sulfur amount in the recycle gas within a range of 0.5-100×10−6 L / L so as to passivate the apparatus.The process of the present invention may also comprise the following steps:(1) loading a reforming catalyst into the continuous reforming apparatus, starting the gas circulation and raising the temperature of a reactor, feeding the reforming feedstock into the reaction system when the temperature of the reactor is increased to 300-460° C., introducing sulfide into the reaction system while or after the reforming feedstock is fed, controlling the ratio of the total sulfur amount introduced into the system to the reforming feedstock within the range of 0.5 μg / g-50 μg / g, reducing the content of sulfide introduced into the system when hydrogen sulfide concentration in the recycle gas reaches to 2.0 μL / L˜30 μL / L; and(2) maintaining the reforming reactor at a temperature of 460-490° C., controlling the ratio of the total sulfur amount introduced into the system to the reforming feedstock within the range of 0.2 μg / g-0.5 μg / g, adjusting the amount of the reforming feedstock to the design value of the apparatus, increasing the reforming reaction temperature to 490-545° C. according to the requirements on the octane number of the liquid product, and letting the reforming apparatus run under normal operating conditions.

Owner:CHINA PETROCHEMICAL CORP +1

Process for desulfurizing hydrocarbon fuels and fuel components

InactiveUS20050098478A1Substantial sulfur removalLow costCatalytic crackingHydrocarbon oils refiningHydrodesulfurizationSorbent

Processes are disclosed for removing sulfur, including cyclic and polycyclic organic sulfur components such as thiophenes and benzothiophenes, from a hydrocarbon feedstock including fuels and fuel components. The feedstock is contacted with a regenerable sorbent material capable of selectively adsorbing the sulfur compounds present in the hydrocarbon feedstock in the absence of a hydrodesulfurization catalyst. In one embodiment, the sorbent can be an active metal oxide sulfur sorbent in combination with a refractory inorganic oxide cracking catalyst support. In another embodiment, the sorbent can be a metal-substituted refractory inorganic oxide cracking catalyst wherein the metal is a metal which is capable in its oxide form, of adsorption of reduced sulfur compounds by conversion of the metal oxide to a metal sulfide. The processes are preferably carried out in a transport bed reactor.

Owner:RES TRIANGLE INST

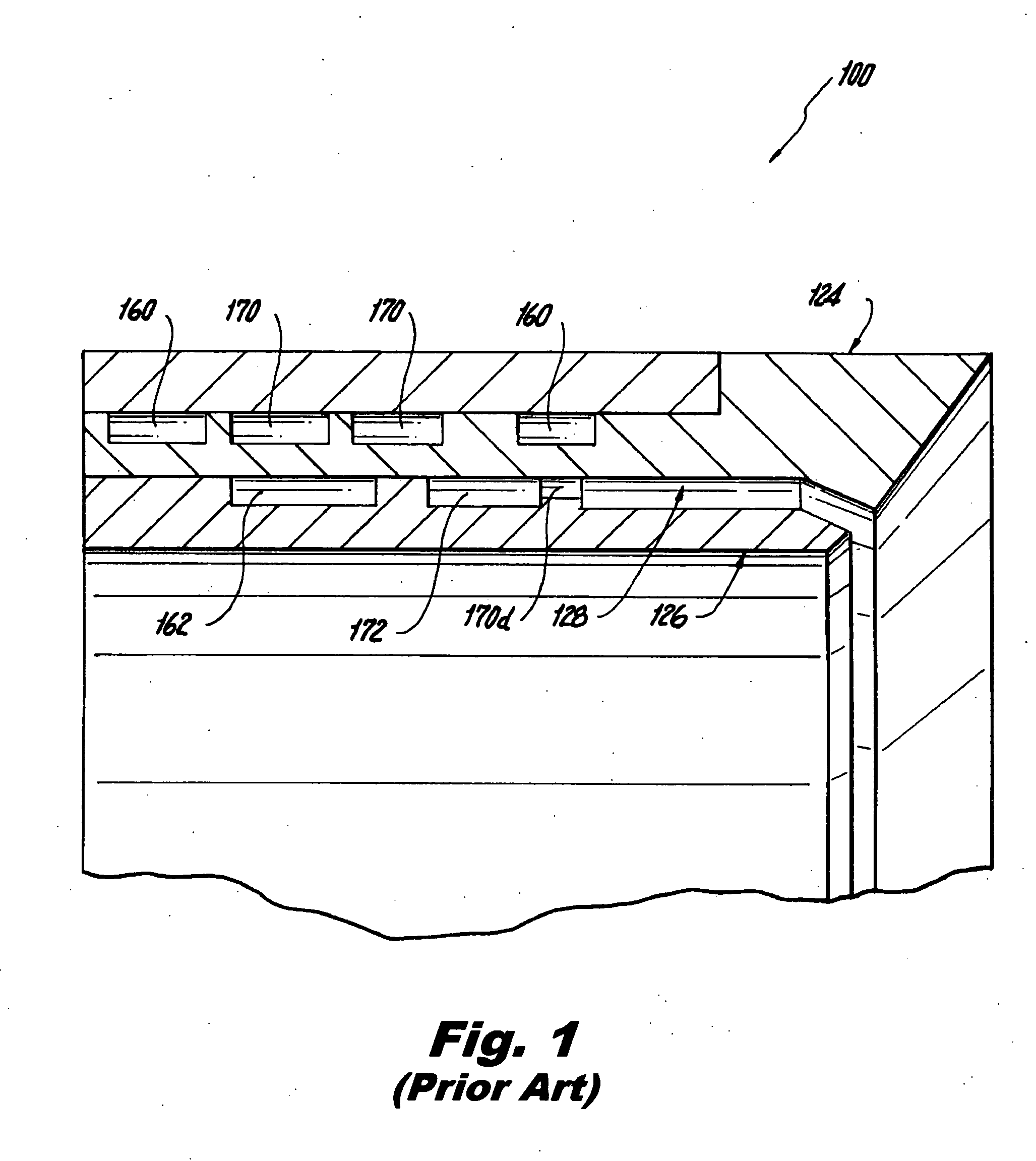

Exhaust gas purification catalyst with improved hydrocarbon conversion

InactiveUS6080375AImprove hydrocarbon suppressionImprove stabilityNitrogen compoundsInternal combustion piston enginesHydrogen compoundsExhaust gas

An exhaust gas purification catalyst with improved hydrocarbon conversion is disclosed, which contains metals from the platinum group as its catalytically active components. Two superposed functional layers are applied to one support. The catalyst has a first functional layer with a mixture of a first catalyst with at least one zeolite and the second functional layer applied to the first functional layer which contains a mixture of a second catalyst and at least one zeolite. The zeolites exhibit a molar ratio of silicon dioxide / aluminum oxide of more than 40 and in that at least palladium and rhodium are present as the platinum group metals and are each contained separately from one another in only one of the two catalysts. The catalyst is distinguished by particularly good suppression of hydrocarbon emissions during cold-starting and exhibits particularly good long-term stability.

Owner:DMC2 DEGUSSA METALS +1

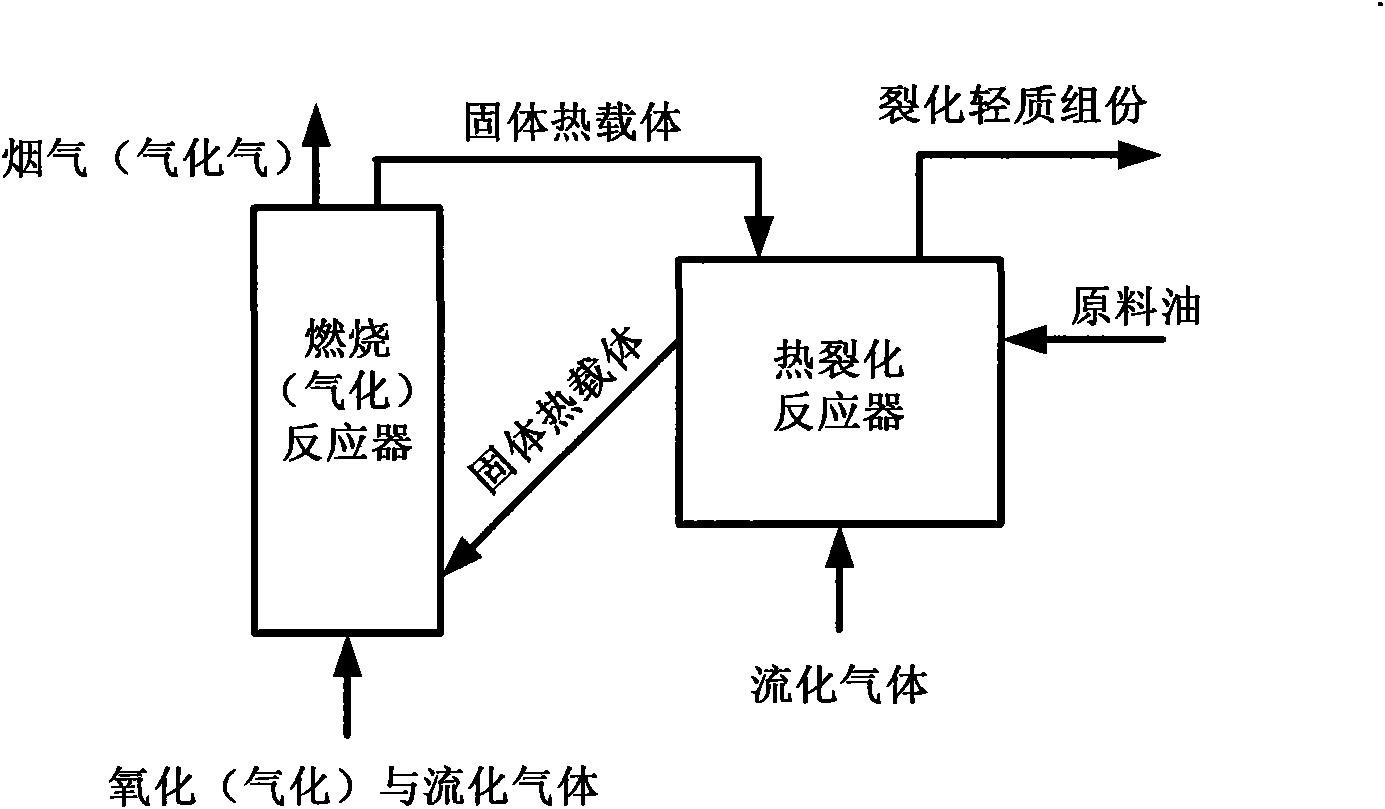

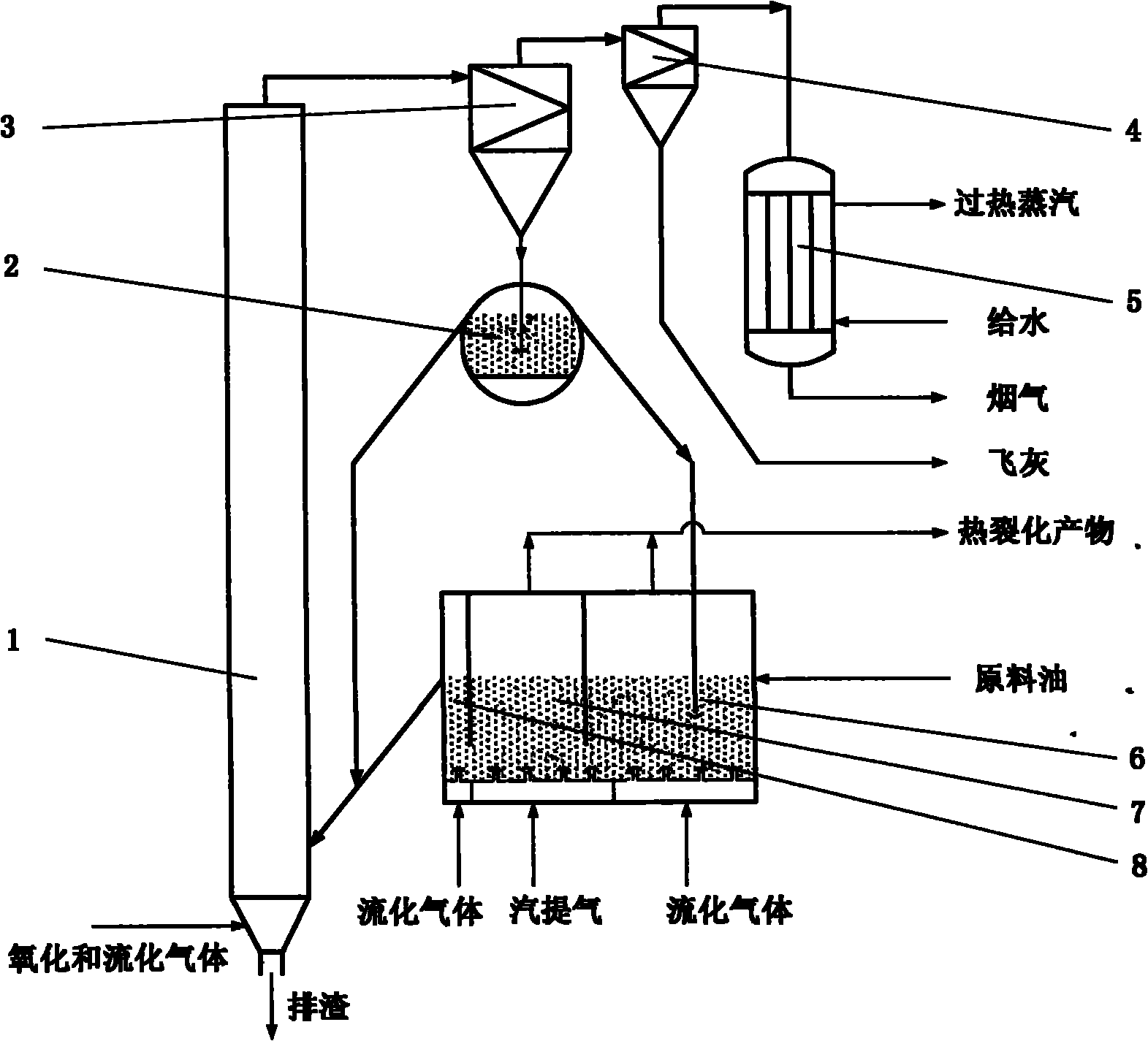

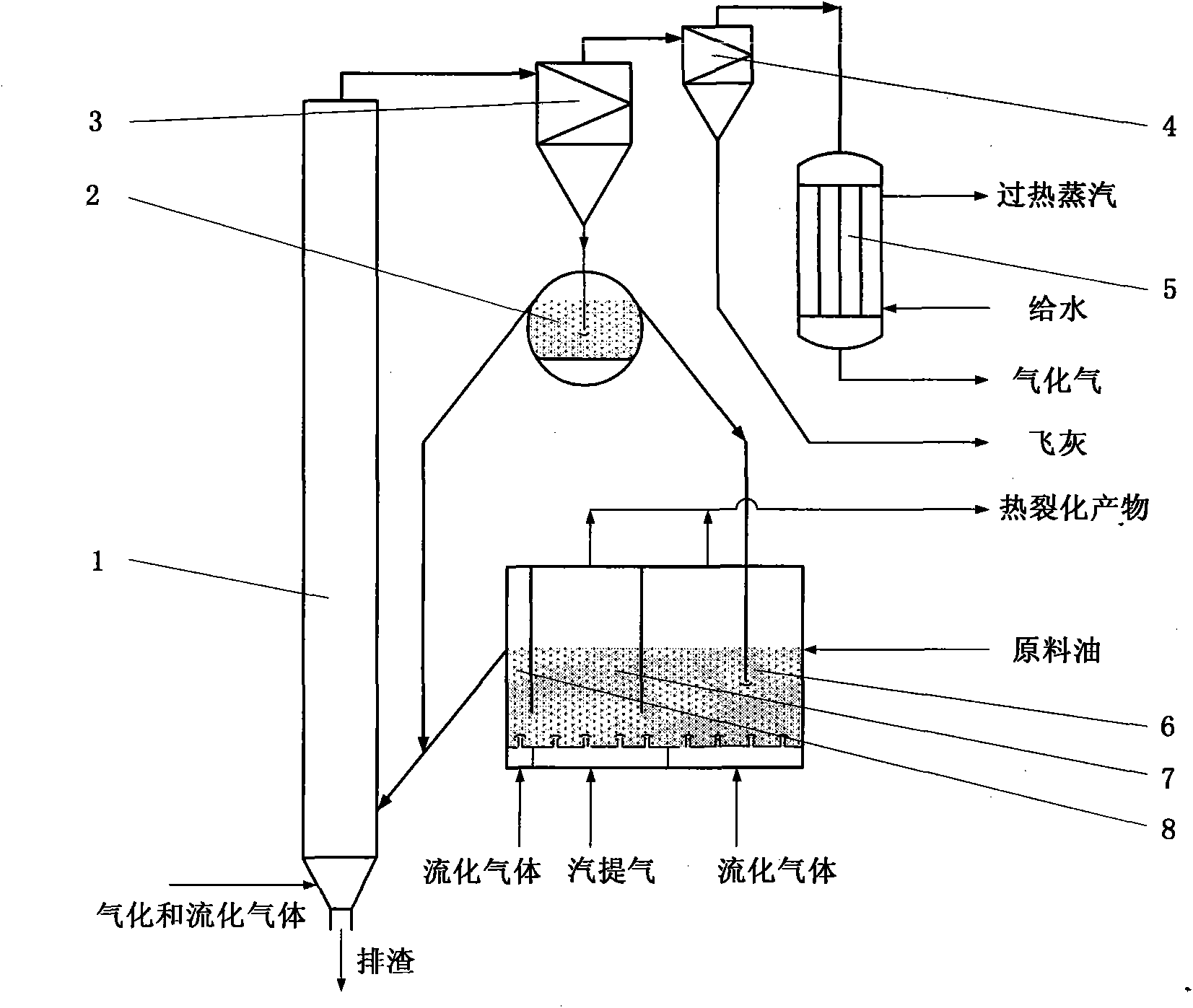

Heavy oil lightening method and device

InactiveCN102115675AAchieve conversionEfficient conversionThermal non-catalytic crackingEnergy inputHeat carrierCombustion

The invention relates to a heavy oil lightening method and technique. The method comprises steps as follows: raw oil is introduced into a thermal cracking reactor through a feed system, and mixed with a high-temperature solid heat carrier from a combustion (gasifying) reactor, so that the raw oil is subjected to fluidizing heat exchange with the solid heat carrier and carries out thermal cracking reaction on the surface of the solid heat carrier; the cracking gas generated by the thermal cracking reaction and a light component product are subjected to steam stripping by fluidizing medium gas and enter a subsequent absorption and stabilization system and a purification and separation system, heavy coke (petroleum coke) is attached to the surface of the solid heat carrier and enters the combustion (gasifying) reactor via a material returning valve, and an oxidizing (gasifying) and fluidizing gas is introduced to realize combustion (gasifying) reaction in the fluidization elevation process of the petroleum coke; and after the reaction product (fume or gasified gas) and the solid heat carrier are separated by a gas-solid separator, the fume (gasified gas) is led into a waste heat recovery system and a gas purification system, the high-temperature solid heat carrier is distributed by a distribution valve and respectively enters the thermal cracking reactor and the combustion (gasifying) reactor for cyclic use, and the collected fly ash can be used after further processing, thereby complete high-value conversion and use of the heavy oil.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

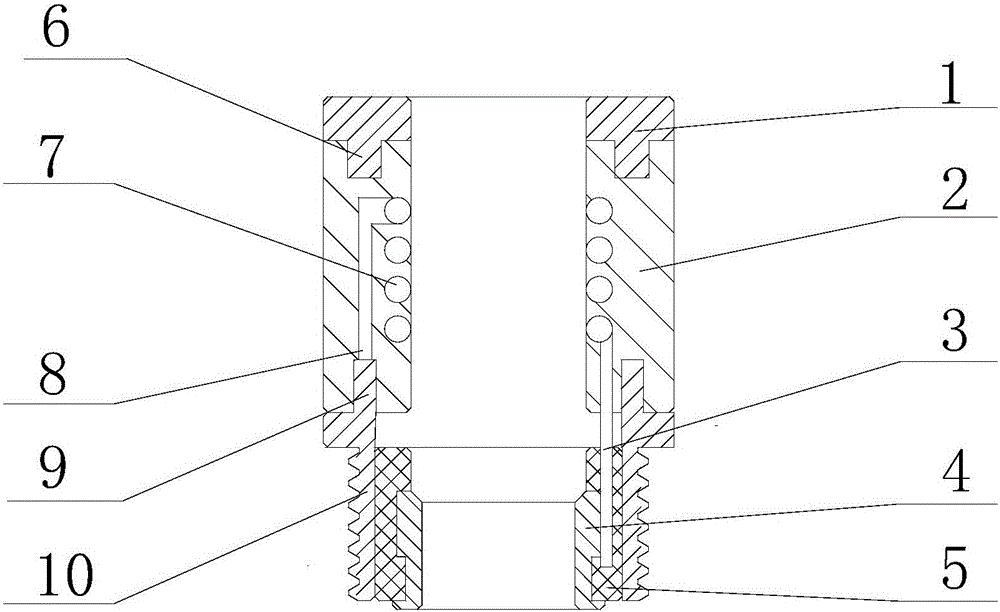

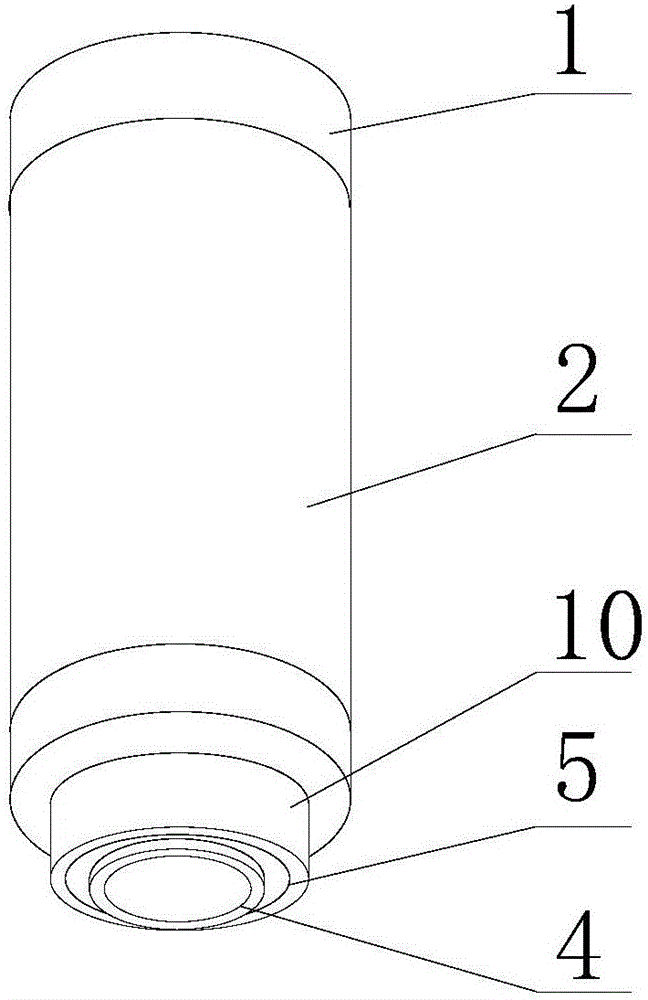

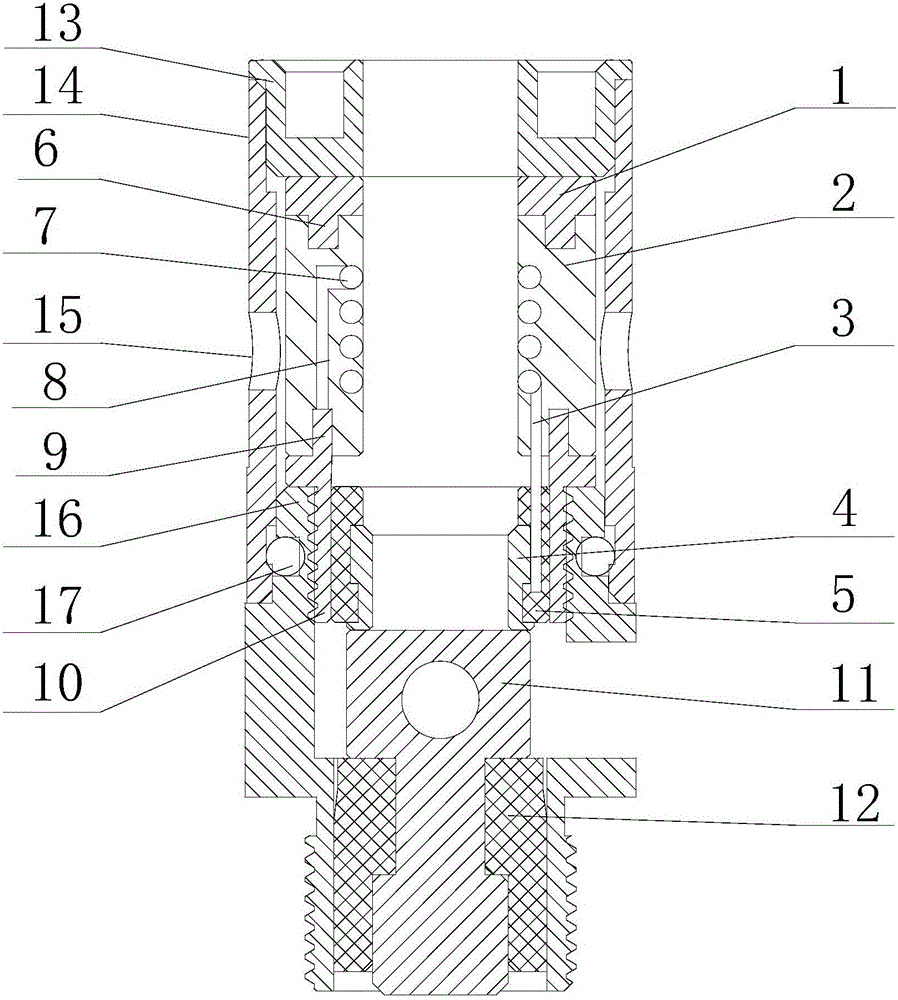

Ceramic composite electronic cigarette heating pipe and electronic cigarette atomizing core employing same

The invention discloses a ceramic composite electronic cigarette heating pipe which comprises an electric heating wire and a micro-porous ceramic pipe; a main body part of the electric heating wire is pre-embedded in the pipe wall of the micro-porous ceramic pipe; the electric heating wire is led out of the outside of the micro-porous ceramic pipe through connecting pins. A compact connecting piece is arranged at each of the upper and lower ends of the micro-porous ceramic pipe. The two connecting pins of the electric heating wire are lead out from the lower end of the micro-porous ceramic pipe; the compact connecting piece at the lower end is a metal connecting ring; a connecting pile protruding into the pipe wall of the micro-porous ceramic pipe is arranged on the upper side of the metal connecting ring. A double-electrode conductive connecting ring consists of an inner ring electrode and an outer ring electrode and is arranged on the lower side of the metal connecting ring; the outer ring electrode is electrically connected or integrally formed with the metal connecting ring; an insulating ring is arranged between the outer ring electrode and the inner ring electrode. The inner ring electrode and the outer ring electrode of the double-electrode connecting ring are respectively electrically connected with the two connecting pins of the electrical heating wire. When the heating pipe disclosed by the invention is in use, the double-electrode conductive connecting ring and a double-electrode conductive connecting column of an atomizing core are designed to be in threaded connection for realization.

Owner:INNOKIN TECH

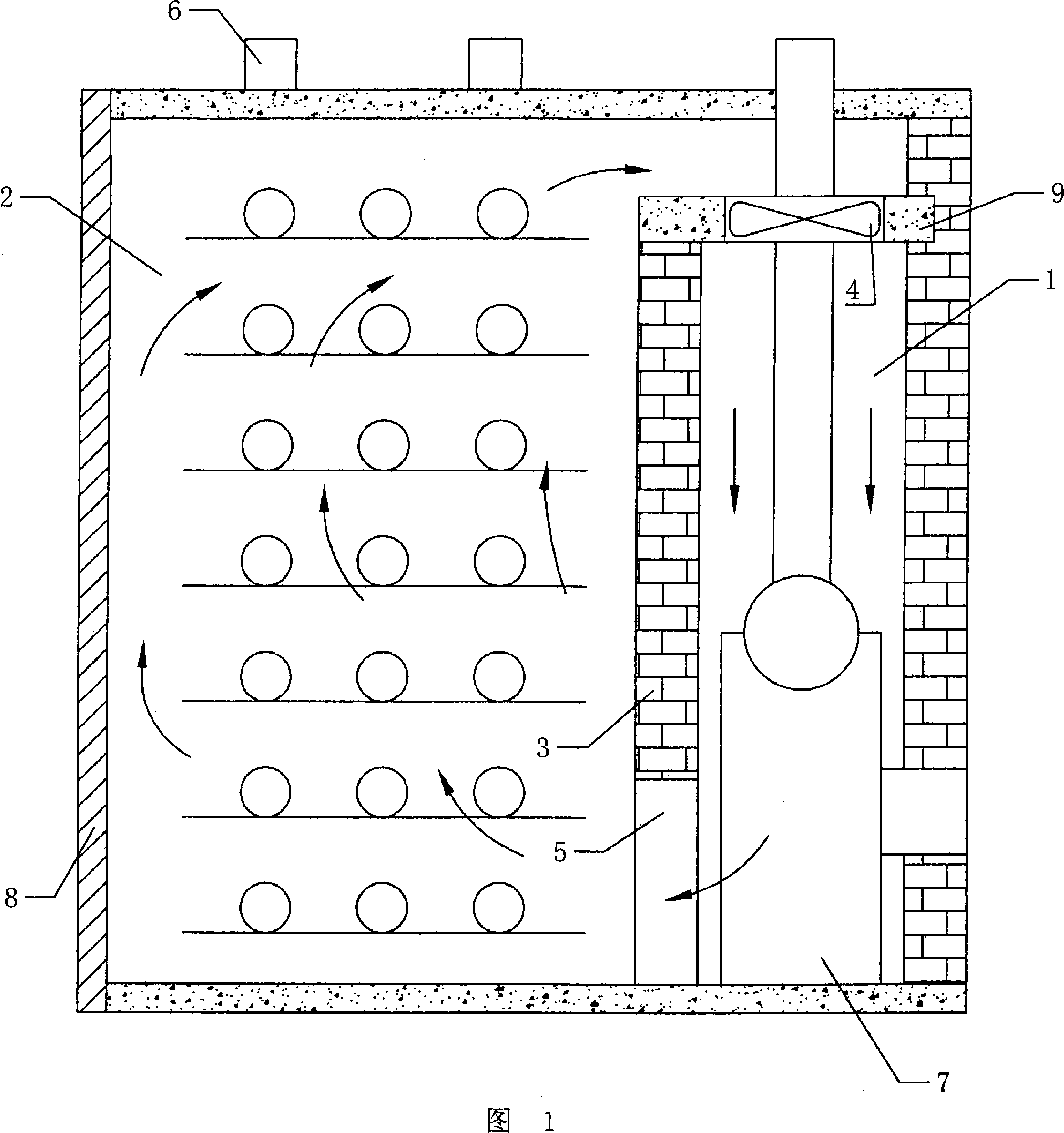

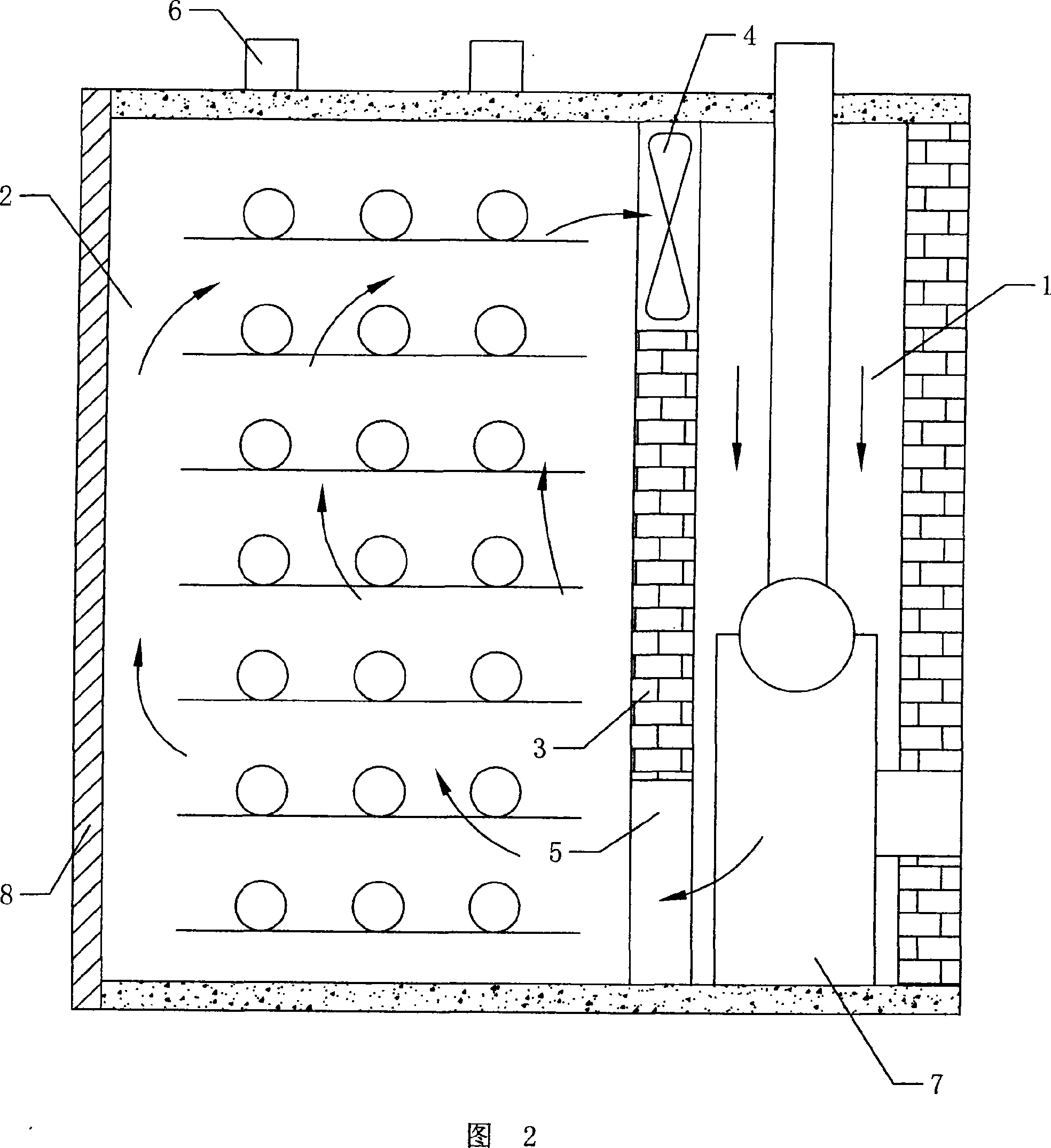

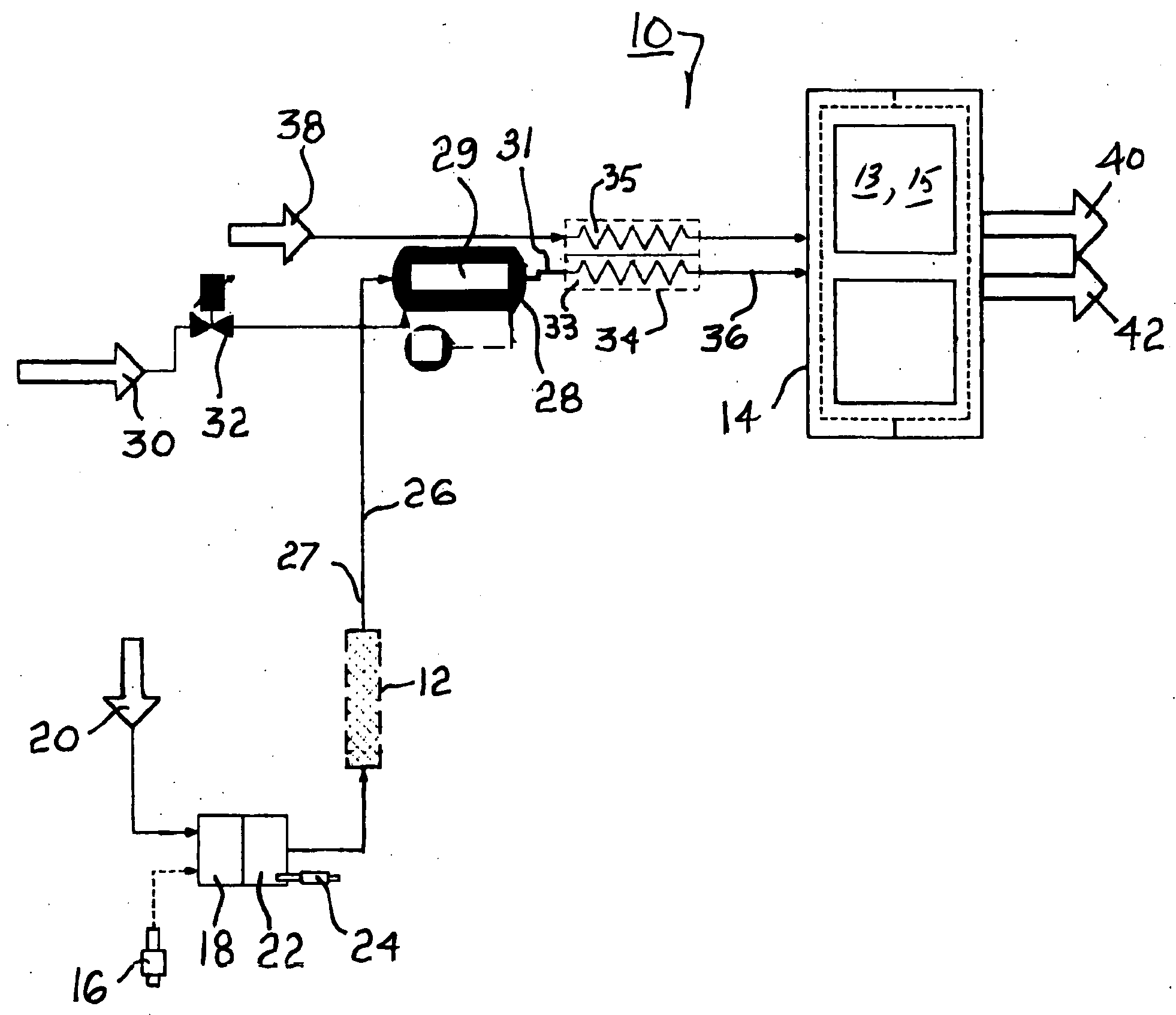

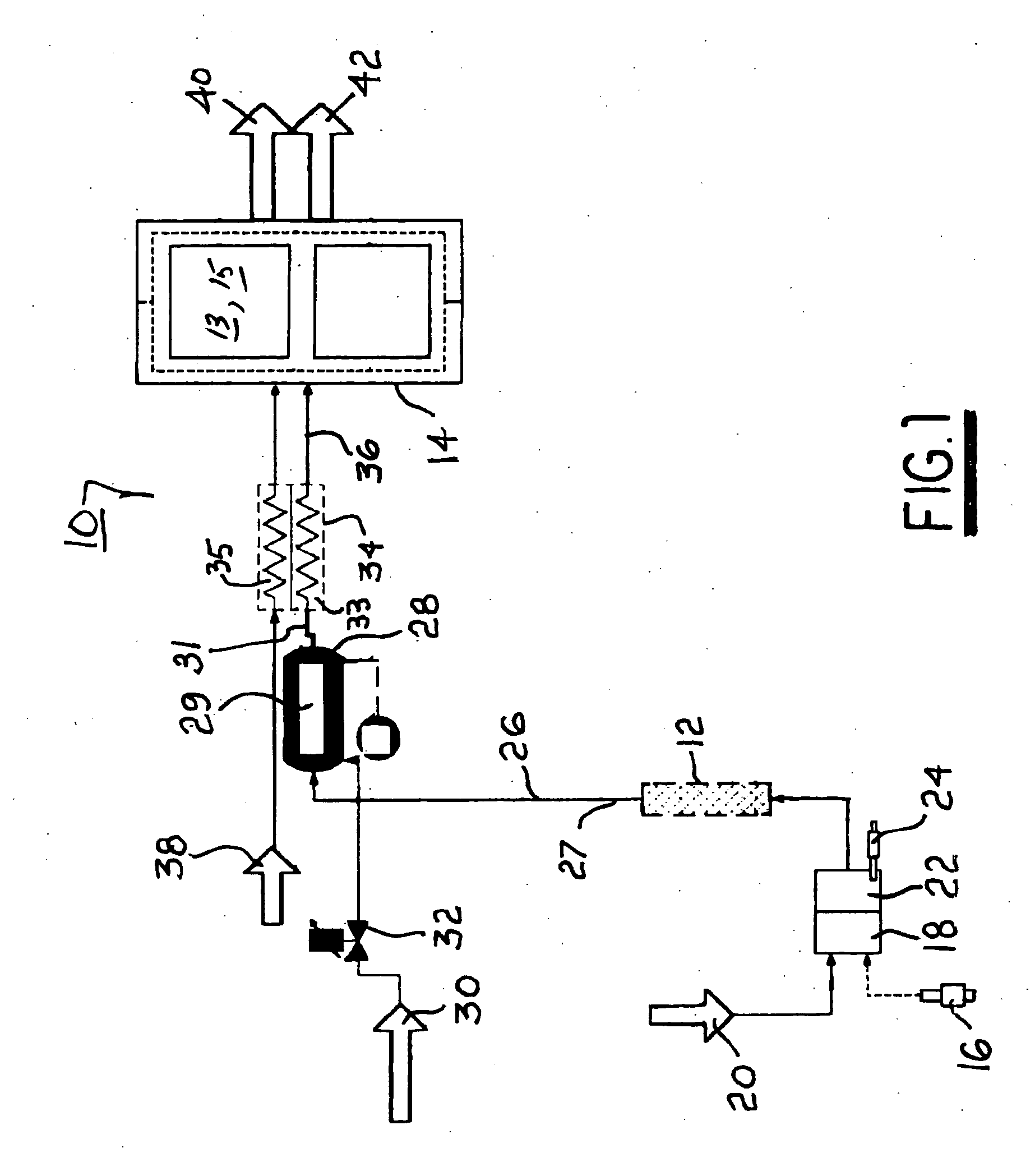

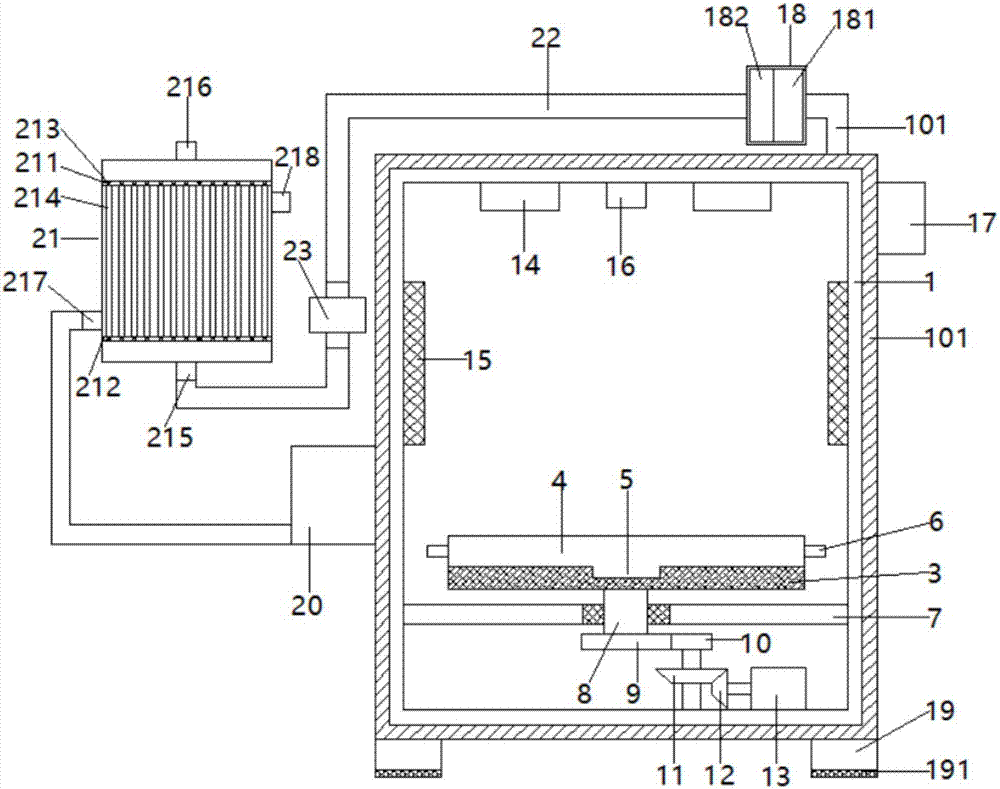

Lumber drying kiln

InactiveCN101144681AHigh thermal efficiencySmooth and even circulationDrying solid materials with heatDrying gas arrangementsEngineeringCombustion

The invention discloses a lumber drying kiln. An isolation wall is arranged between the bottom part and the top part in the drying kiln, the isolation wall divides the space in the kiln into an air heating room used for installing a drying furnace, and a lumber drying room; wherein, an upper ventilation opening is arranged at the upper part of the isolation wall, a lower ventilation opening is arranged at the lower part of the isolation wall, a fan used for blowing air to the air heating room from the lumber drying room is arranged between the air heating room and the lumber drying room; an air exhaust passage is arranged at the top part corresponding to the lumber drying room; because the fan is arranged at the position of the upper ventilation opening, the fan sucks the hot air from the lumber drying room to blow into a lumber heating room, the back flow does not happen, thereby leading the heated air circulation to be smoother, therefore the drying quality to be improved. Because the isolation wall is arranged between the air heating room and the lumber drying room, the charring of the lumber close to a combustion furnace because of over high temperature is avoided, the lumber far away the combustion furnace does not have the drying phenomenon, to lead the drying to be evener.

Owner:李祥文

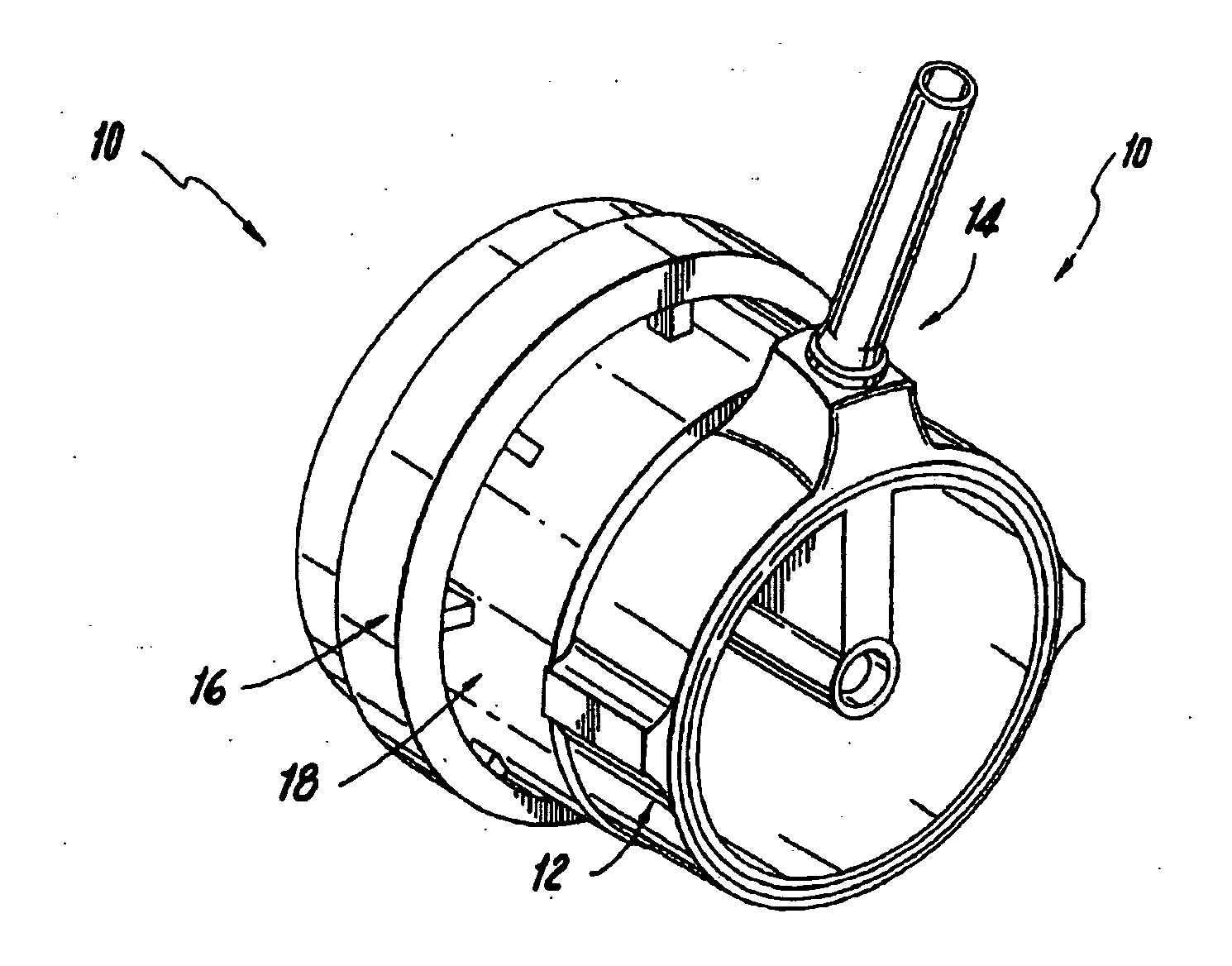

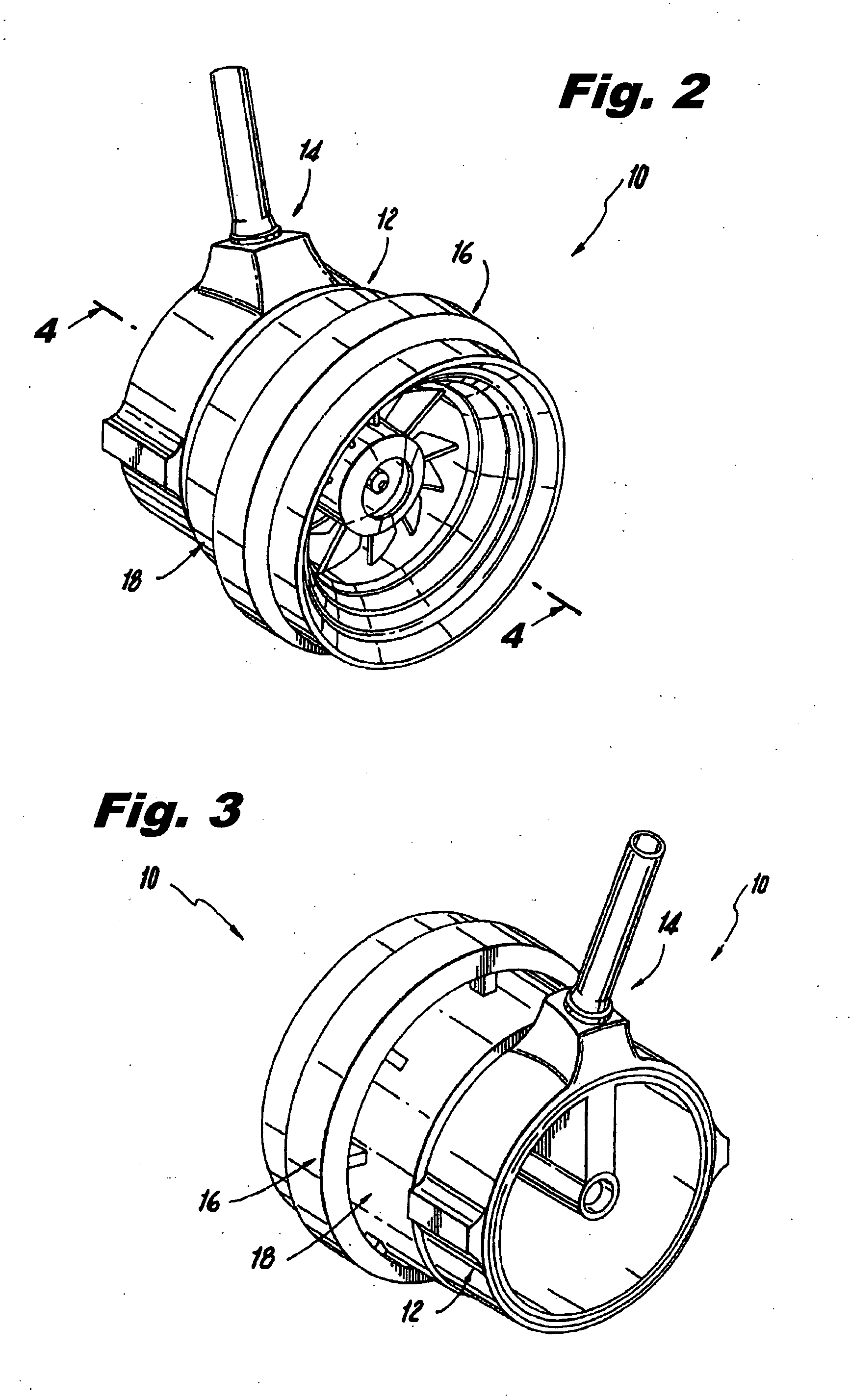

Systems and method for cooling a staged airblast fuel injector

ActiveUS20120228397A1High engine powerAvoid scorchingBurnersContinuous combustion chamberInjectorEngine power

The present invention is directed to a staged fuel injector that includes, inter alia, a main fuel circuit for delivering fuel to a main fuel atomizer and a pilot fuel circuit for delivering fuel to a pilot fuel atomizer which is located radially inward of the main fuel atomizer. The main fuel atomizer includes a radially outer prefilmer and a radially inner fuel swirler. Portions of the main fuel circuit are formed in the prefilmer and portions of the pilot fuel circuit are formed in the prefilmer and the fuel swirler and are positioned proximate to and in thermal contact with fuel exit ports associated with the main fuel circuit and formed in the prefilmer. As a result, the pilot fuel circuit cools the stagnant fuel located in main fuel circuit, including the exit ports, even when performing at engine power levels of up to 60% of the maximum take-off thrust.

Owner:ROLLS ROYCE PLC

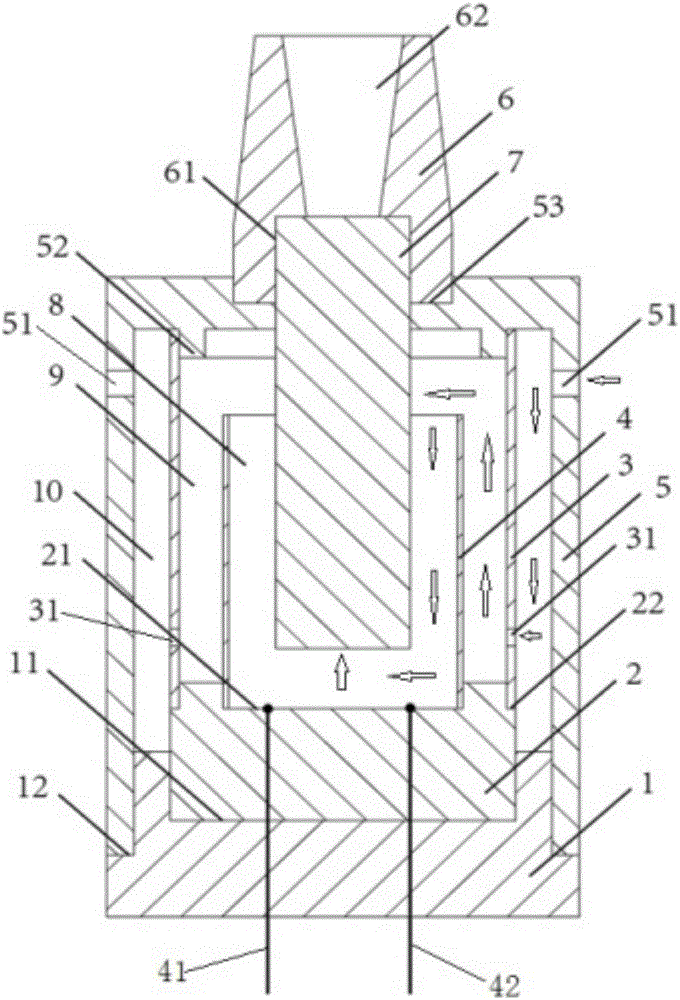

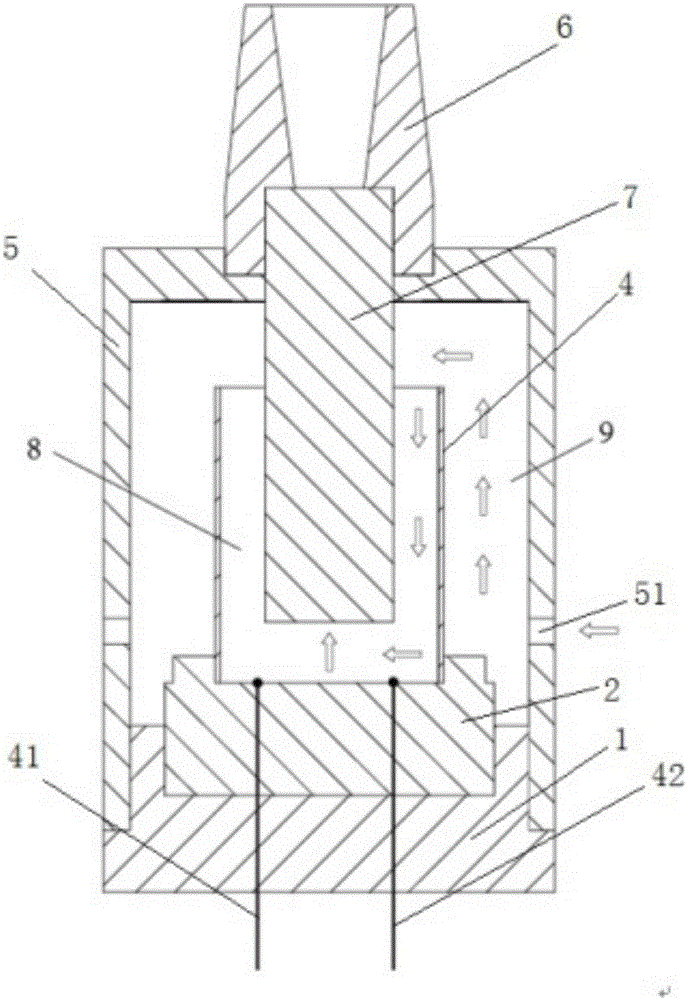

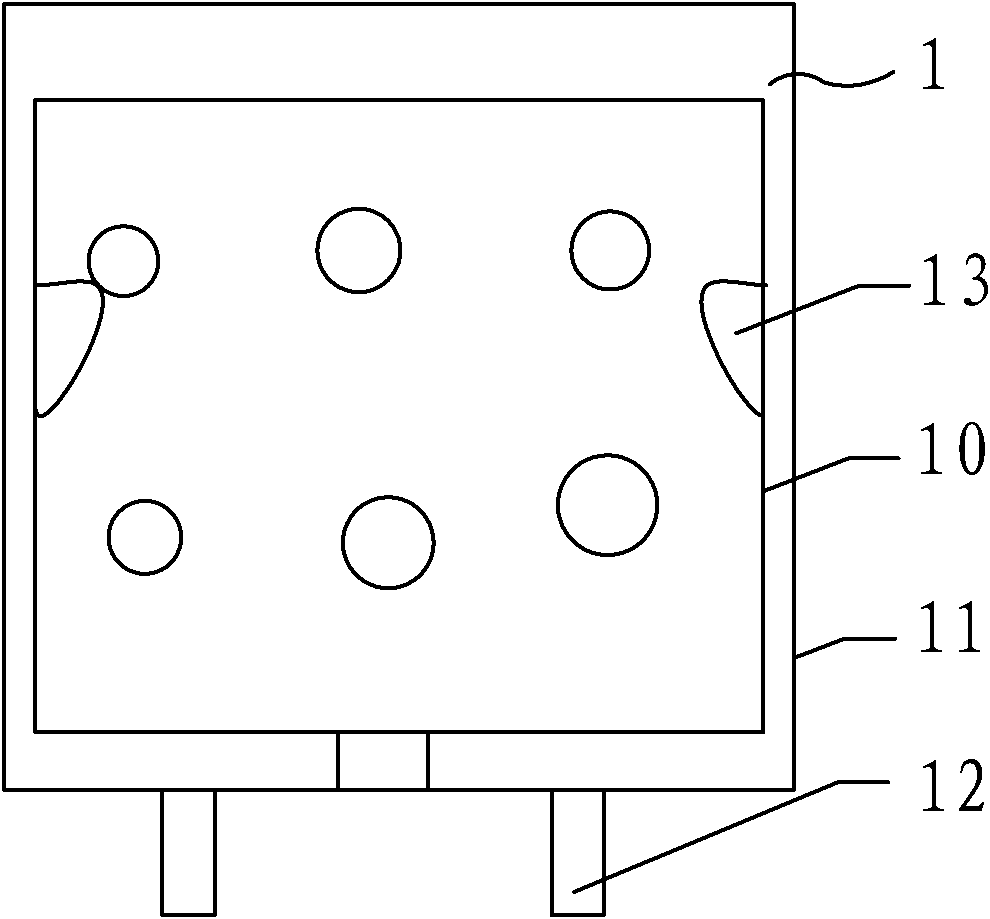

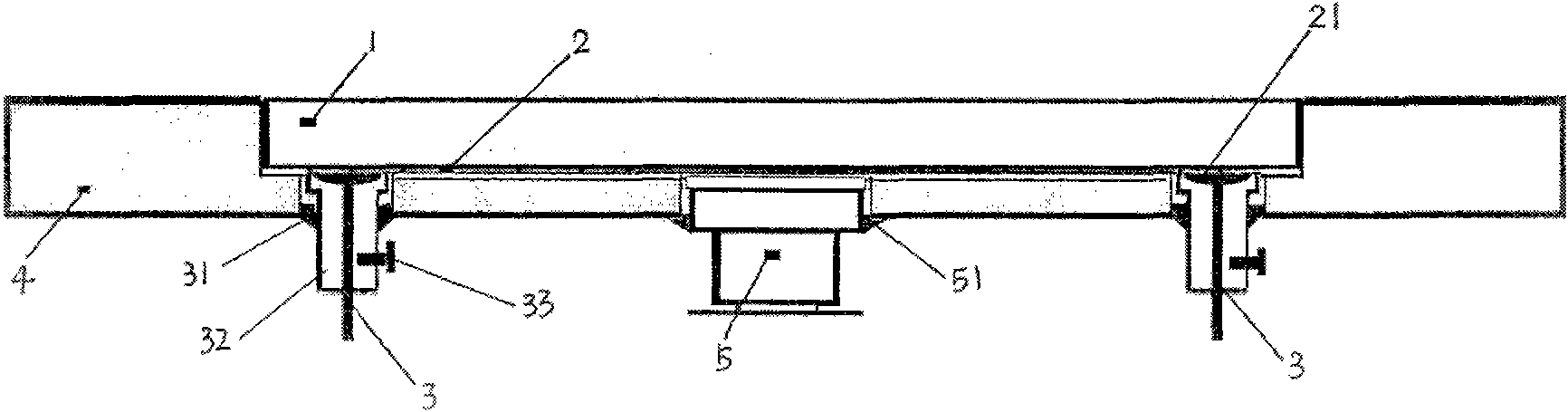

Low temperature tobacco smoking set heated by hot air

A low temperature tobacco smoking set heated by hot air comprises a base (1), an insulating seat (2), a tubular heating element (4), a strip top plate and a shell (5), wherein the base (1) is provided with a first outer ring bearing platform (12) and a first upper part center groove (11); the insulating seat (2) is mounted in a first round center groove; a second upper part round center groove (21) is arranged at the upper part of the insulating seat (2); the tubular heating element (4) is mounted in the second upper part round center groove (21); the strip top plate is located on the first outer ring bearing platform (12); a round bearing platform (53) is formed in the center of the top of the shell (5); a suction nozzle (6) provided with a gas guide channel (62) in the center is mounted on the round bearing platform in an insertion manner; an insertion hole, into which a cylindrical tobacco material (7) can be inserted, is formed in the center of the bottom of the suction nozzle; and a positive electrode (41) and a negative electrode (42) of the heating element respectively penetrate through the insulating seat and are connected with a power supply device. The smoking set has the advantages that the heating uniformity of the tobacco material can be improved, aroma components are promoted to be uniformly and fully released, the suction experience feeling is improved, and charring of the tobacco material is avoided, so as to reduce the generation of harmful substances.

Owner:云南拓宝科技有限公司

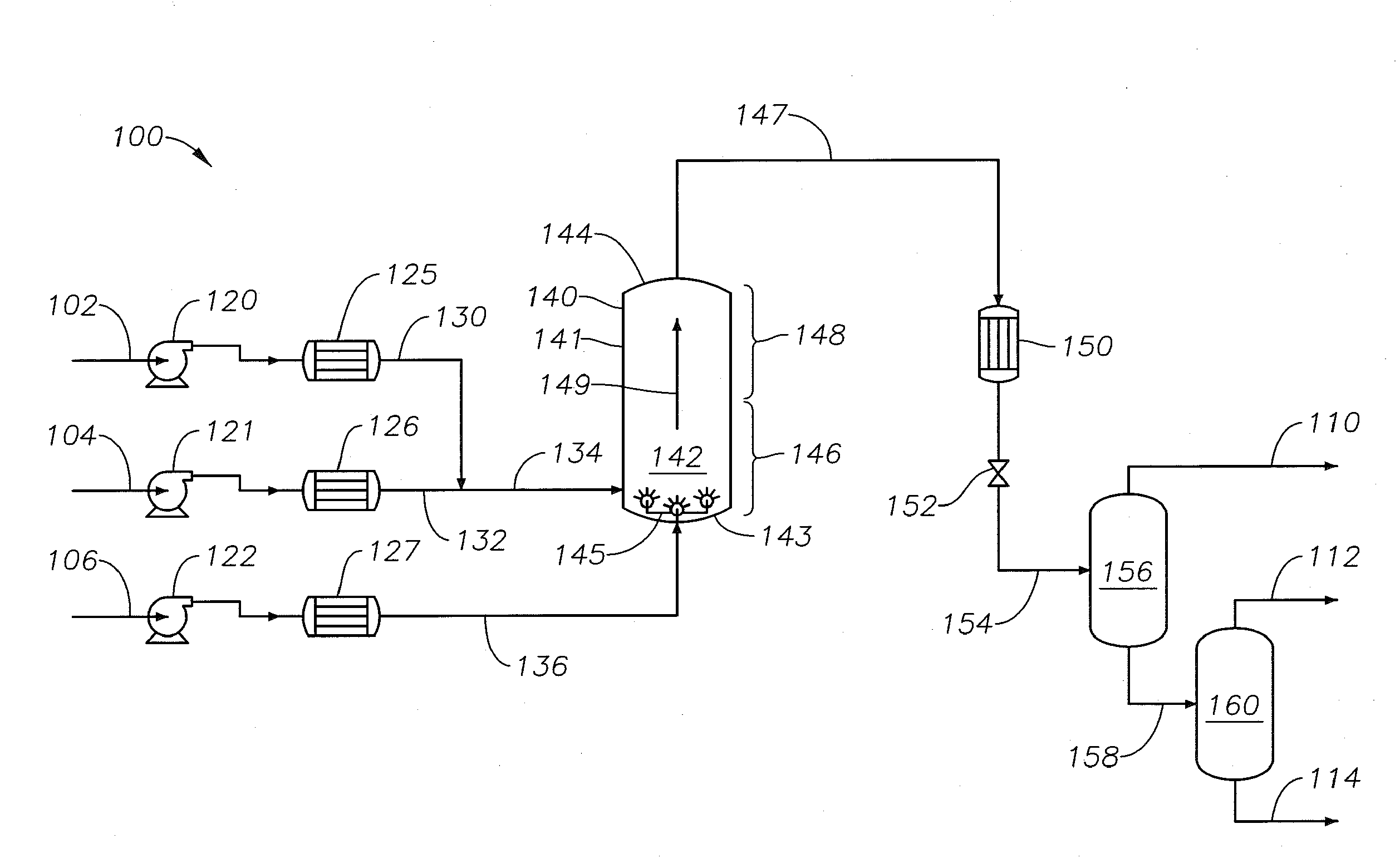

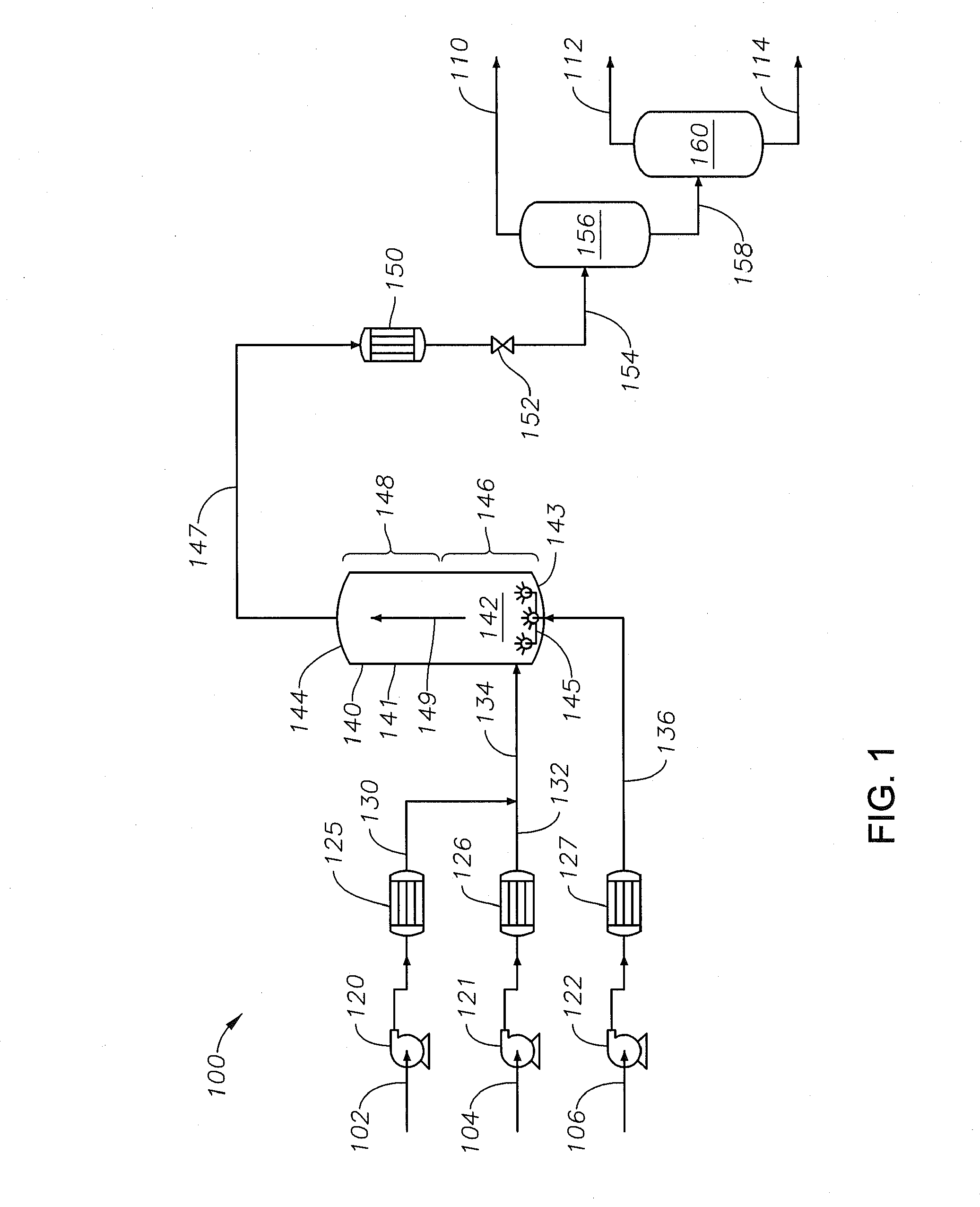

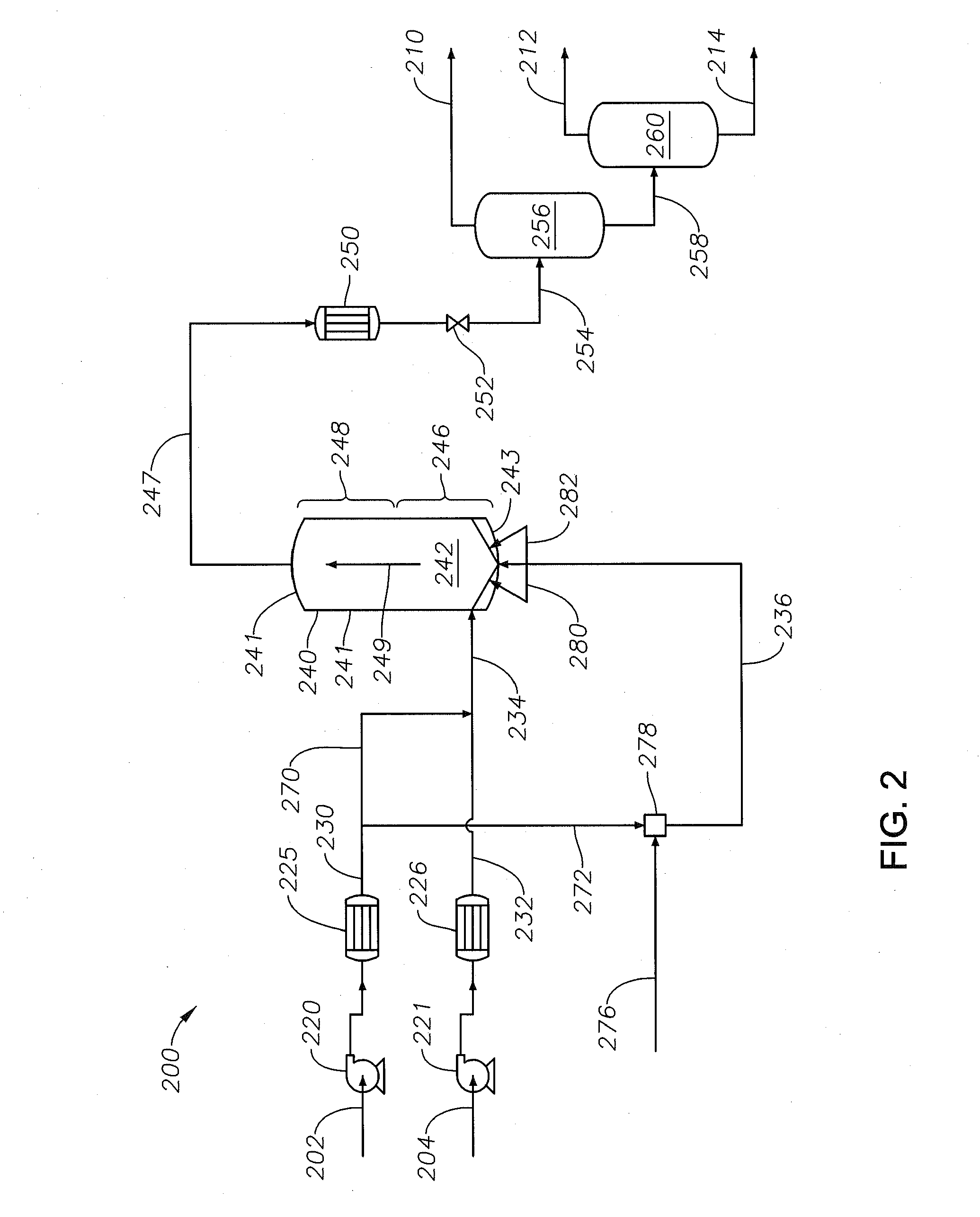

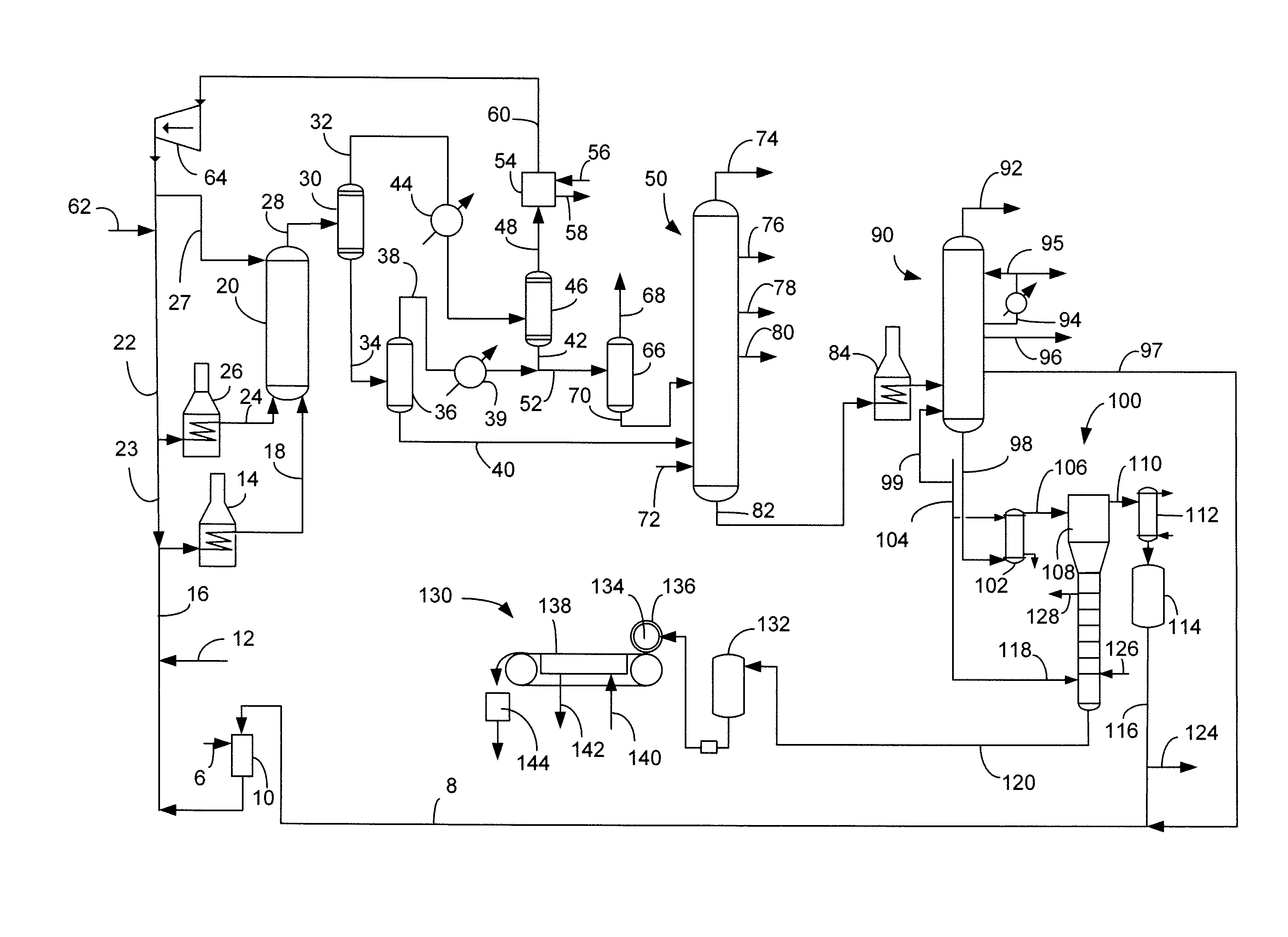

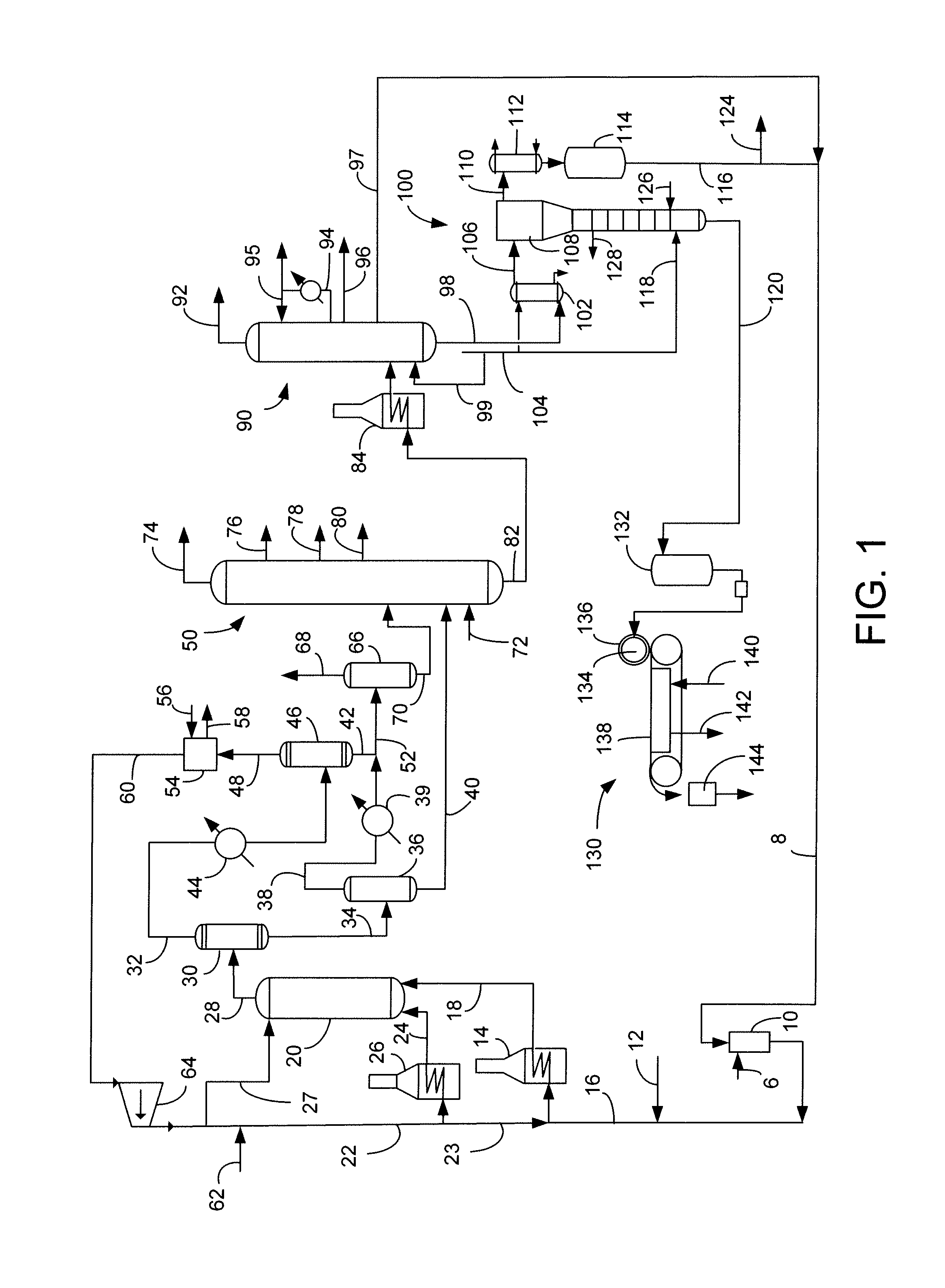

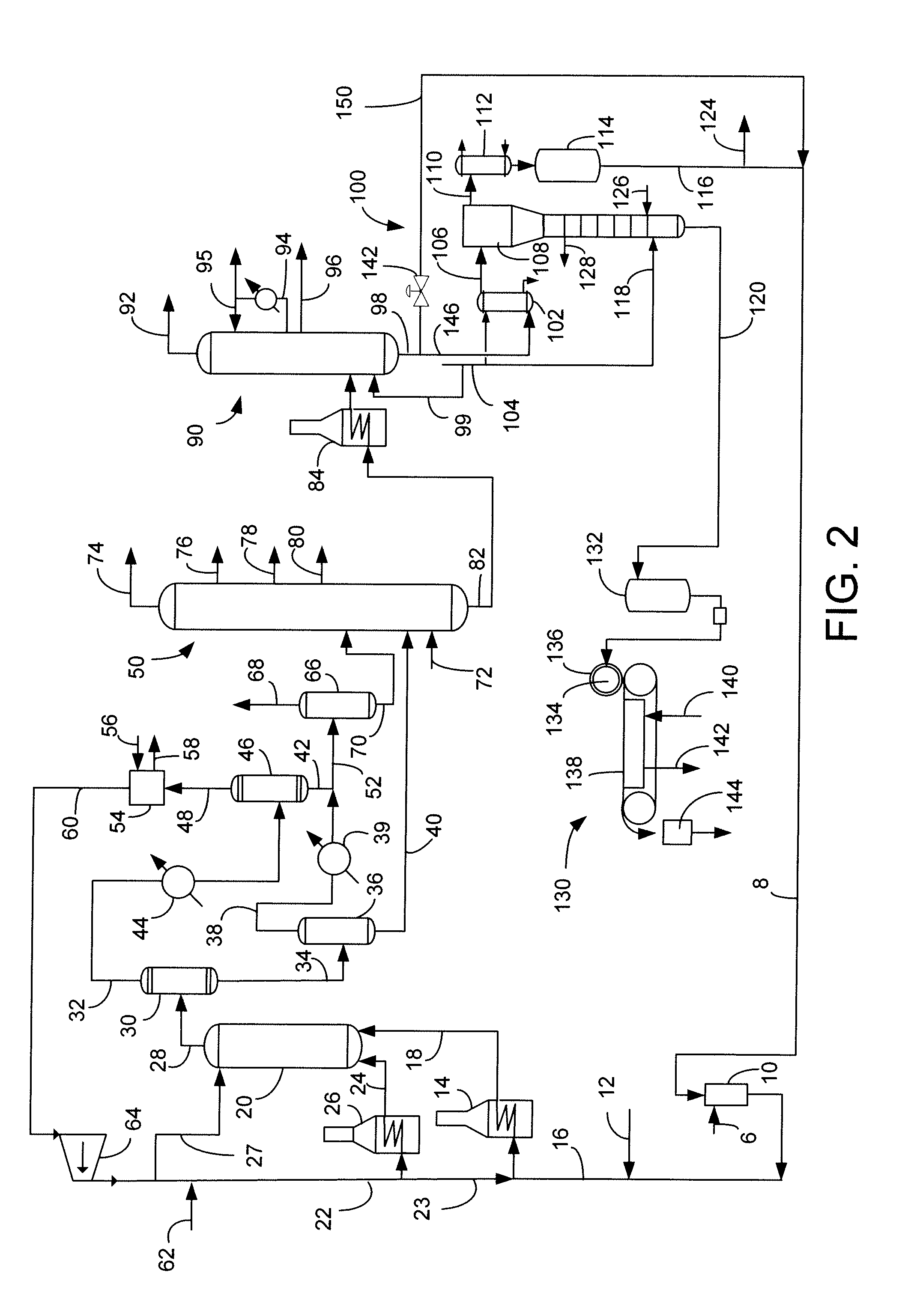

Production of upgraded petroleum by supercritical water

ActiveUS20160312129A1Long residence timeLong exposureSolvent extractionHydrocarbon oil crackingPetroleumPetroleum engineering

A method for upgrading a petroleum feedstock using a supercritical water petroleum upgrading system includes introducing the petroleum feedstock, water and an auxiliary feedstock. The method includes operating the system to combine the petroleum feedstock and the water to form a mixed petroleum feedstock and introducing separately and simultaneously into a lower portion of an upflowing supercritical water reactor. The auxiliary feedstock is introduced such that a portion of a fluid contained within the upflowing reactor located proximate to the bottom does not lack fluid momentum. An embodiment of the method includes operating the supercritical water petroleum upgrading system such that the upflowing reactor product fluid is introduced into an upper portion of a downflowing supercritical water reactor. The supercritical water petroleum upgrading system includes the upflowing supercritical water reactor and optionally a downflowing supercritical water reactor.

Owner:SAUDI ARABIAN OIL CO

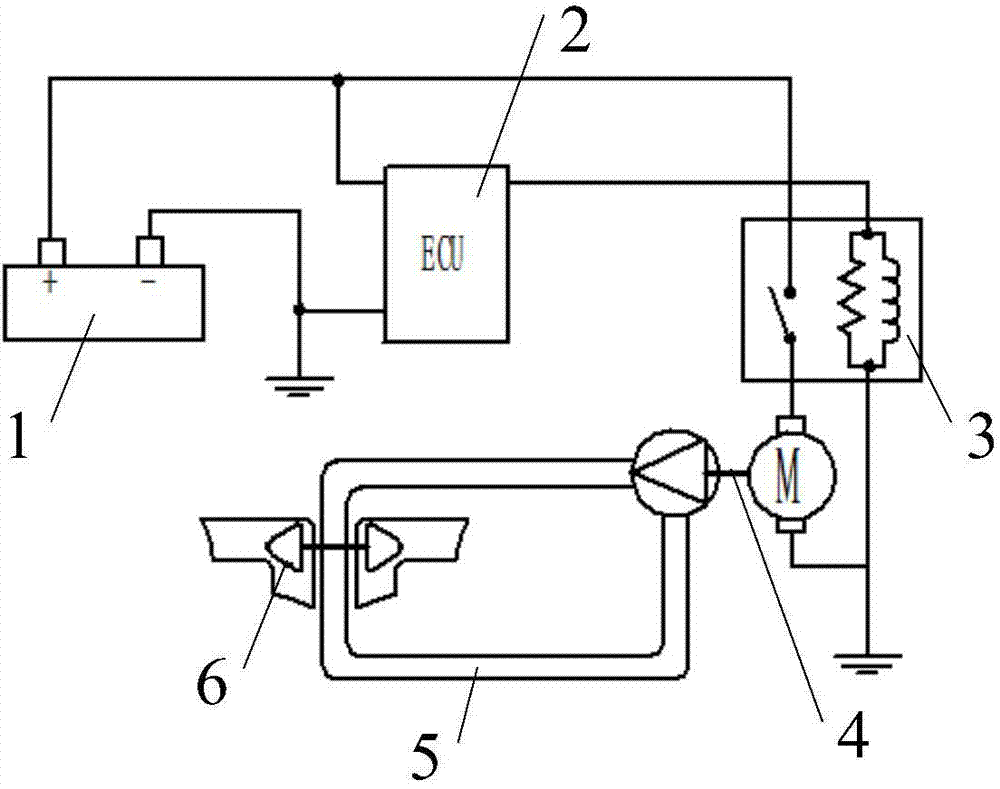

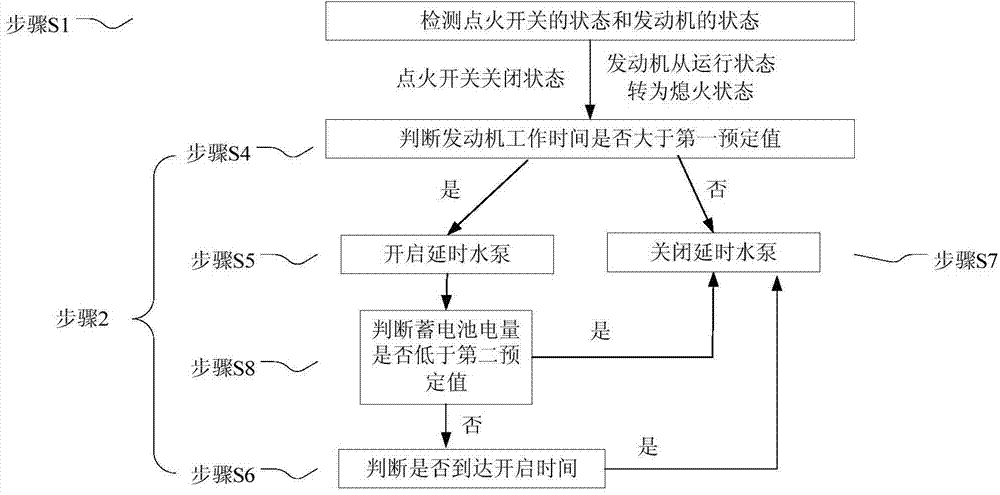

Time delay water cooling device and control method thereof

InactiveCN104763519AExtended service lifeAvoid scorchingMachines/enginesEngine componentsStopped workTime delays

The invention belongs to the technical field of automobile components, and provides a time delay water cooling device and a control method thereof. The time delay water cooling device comprises a controller, a time delay water pump connected with the controller and a cooling water loop used to cool a supercharger, wherein the time delay water pump is connected with the cooling water loop, and a storage battery, an ignition switch and an engine are respectively connected with the controller. When the controller detects that the ignition switch is in a closing state and the engine turns into an extinction state from a running state, the controller controls the time delay water pump to start, and the time delay water pump drives the cooling water loop to circulate. According to the time delay water cooling device, the cooling water loop and the time delay water pump are added in the existing supercharger, the time delay water pump is started after the engine stops work, the cooling water loop is driven by the time delay water pump to circulate so as to reduce temperature in the supercharger as quickly as possible, engine oil is prevented from coking, the supercharger is protected, and therefore normal running of a whole car is guaranteed.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

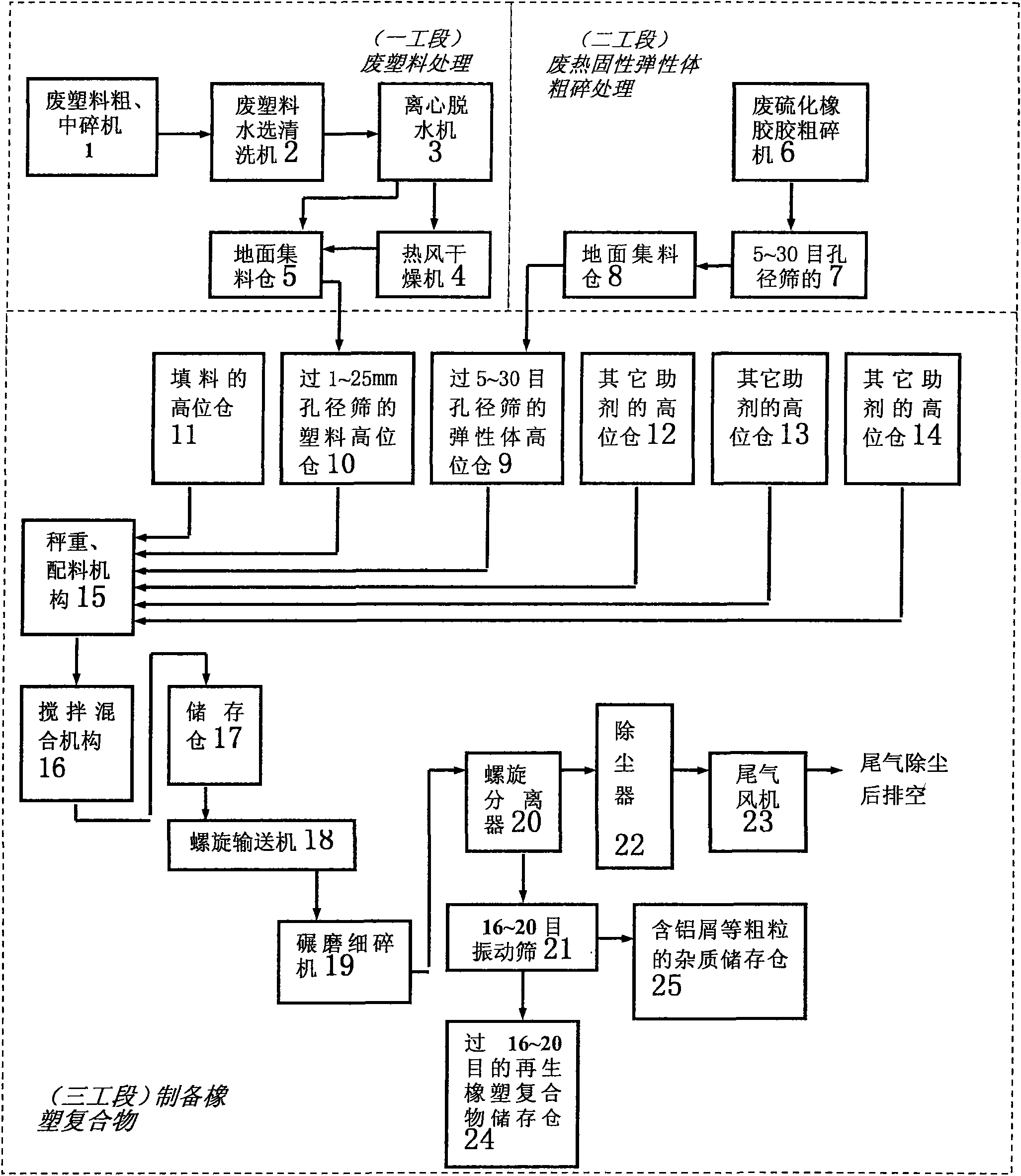

Method for preparing rubber-plastic compound

InactiveCN101665627AAvoid scorchingAvoid smokingPlastic recyclingCocoaElastomerThermoplastic elastomer

The invention provides a method for preparing a rubber-plastic compound. A composite device containing normal-temperature millstone-type elastomer fine crushing machineries is utilized to carry out crushing treatment on a mixture containing formulas of thermosetting elastomer and plastic or / and thermoplastic elastomer, and the mixture comprises the following components in weight ratio: thermosetting elastomer sieved by a sieve with the aperture of 5-40 meshes: plastic sieved by a sieve with the aperture of 1-5mm or / and thermoplastic elastomer sieved by a sieve with the aperture of 1-5 meshes:filler: other adjuvants = 40-90:60-10:0-200:0-10. The invention comprises a method, the composite device for implementing the method, and rubber-plastic compound products produced by the method, wherein a regeneration rubber-plastic compound is included. The invention not only can enable the absorb filler operation to become clean, continuous, normal-temperature and energy saving in the process of preparing new rubber-plastic composite material, but also can enable mixed waste plastic difficult to be reused by the prior art to be conveniently used for high-valued recycling.

Owner:上海橡源驰晨环保科技发展有限公司

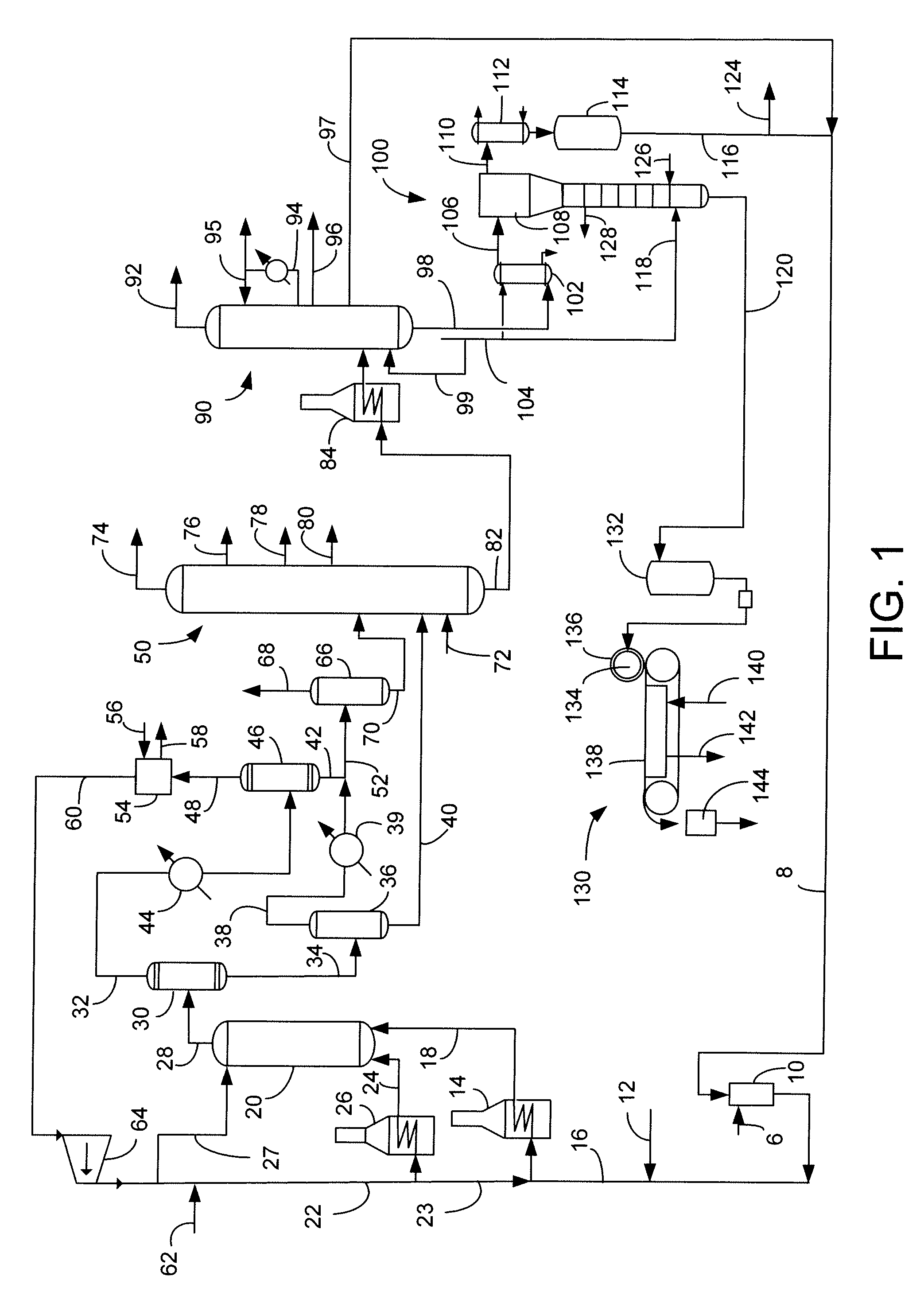

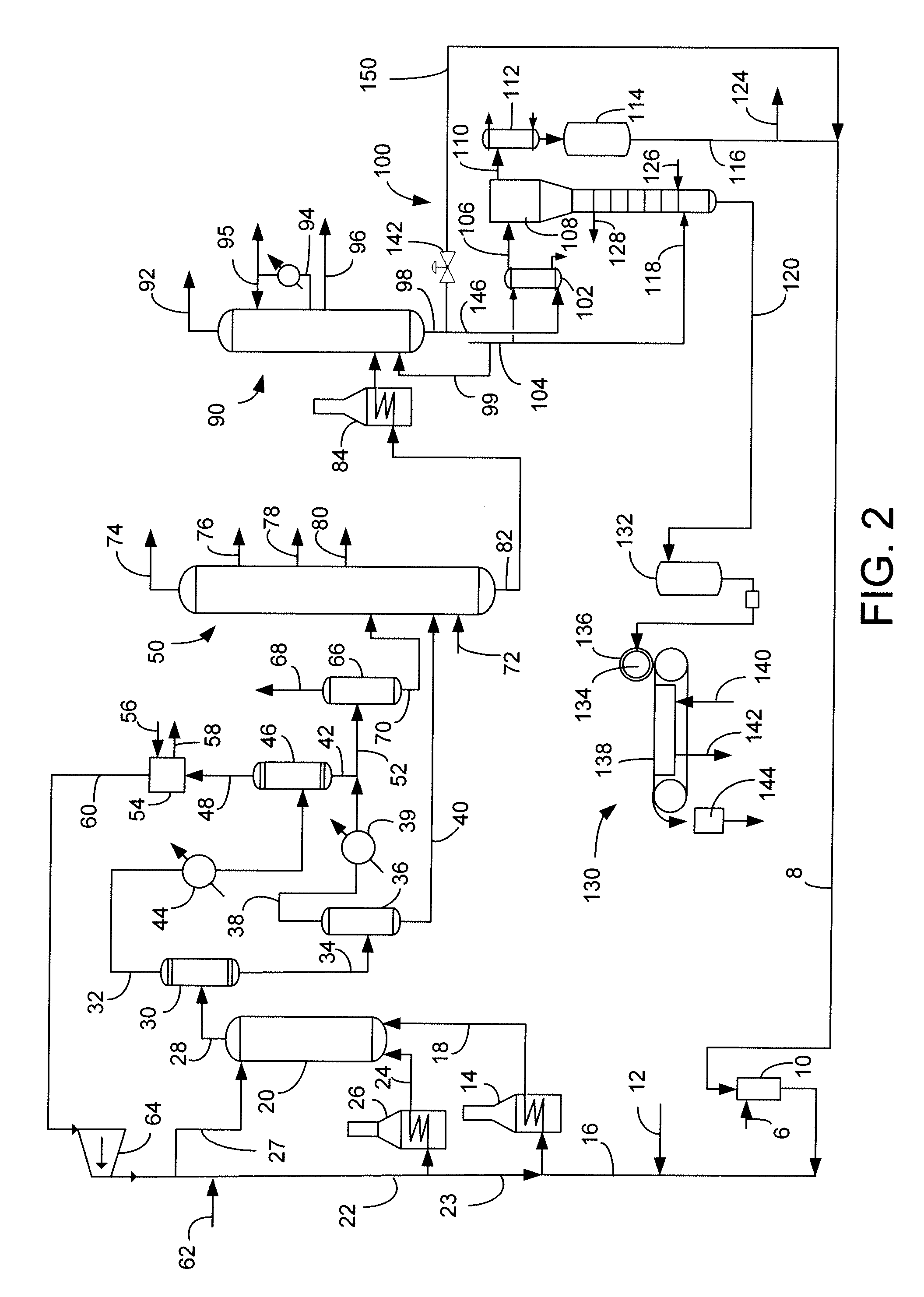

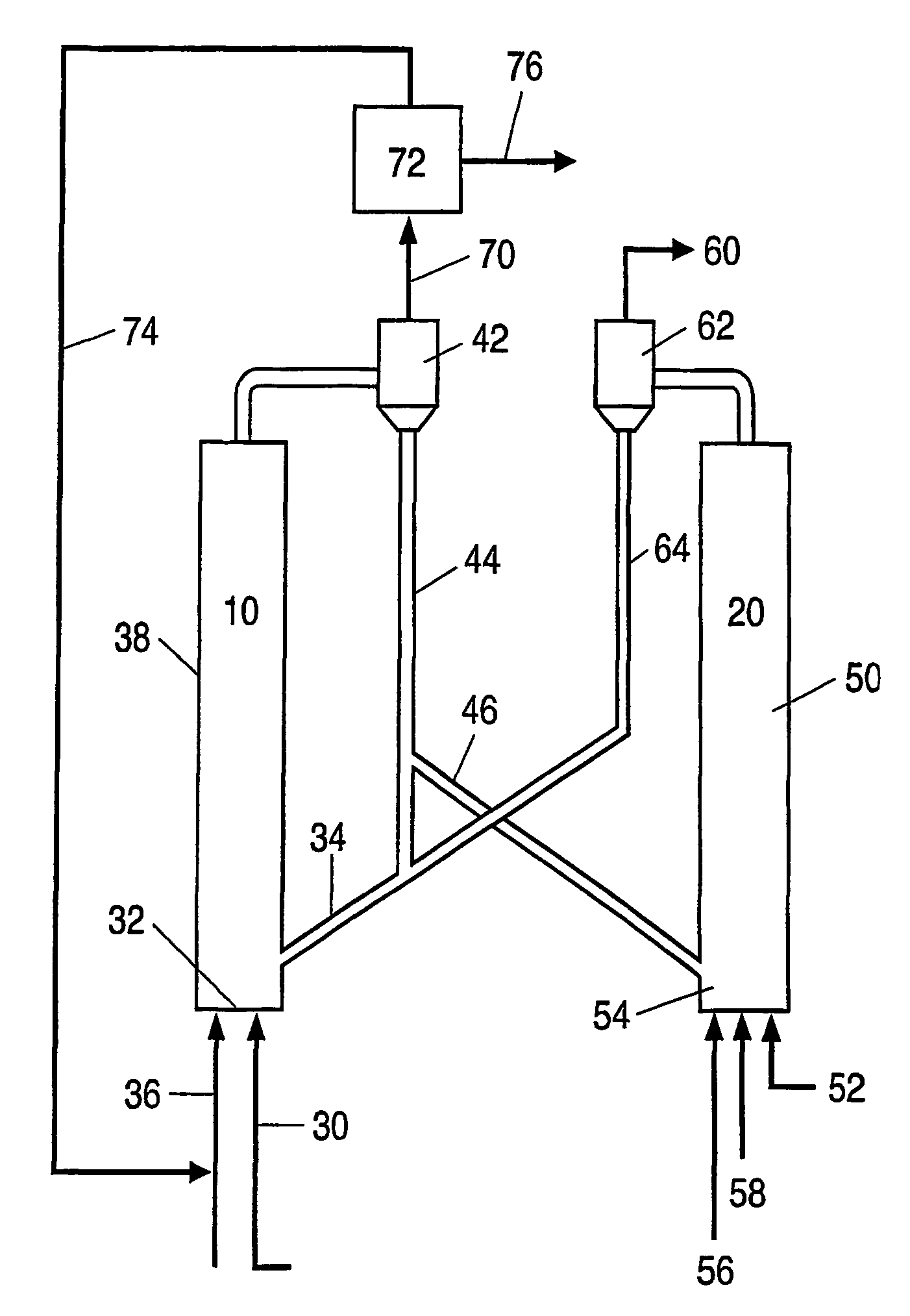

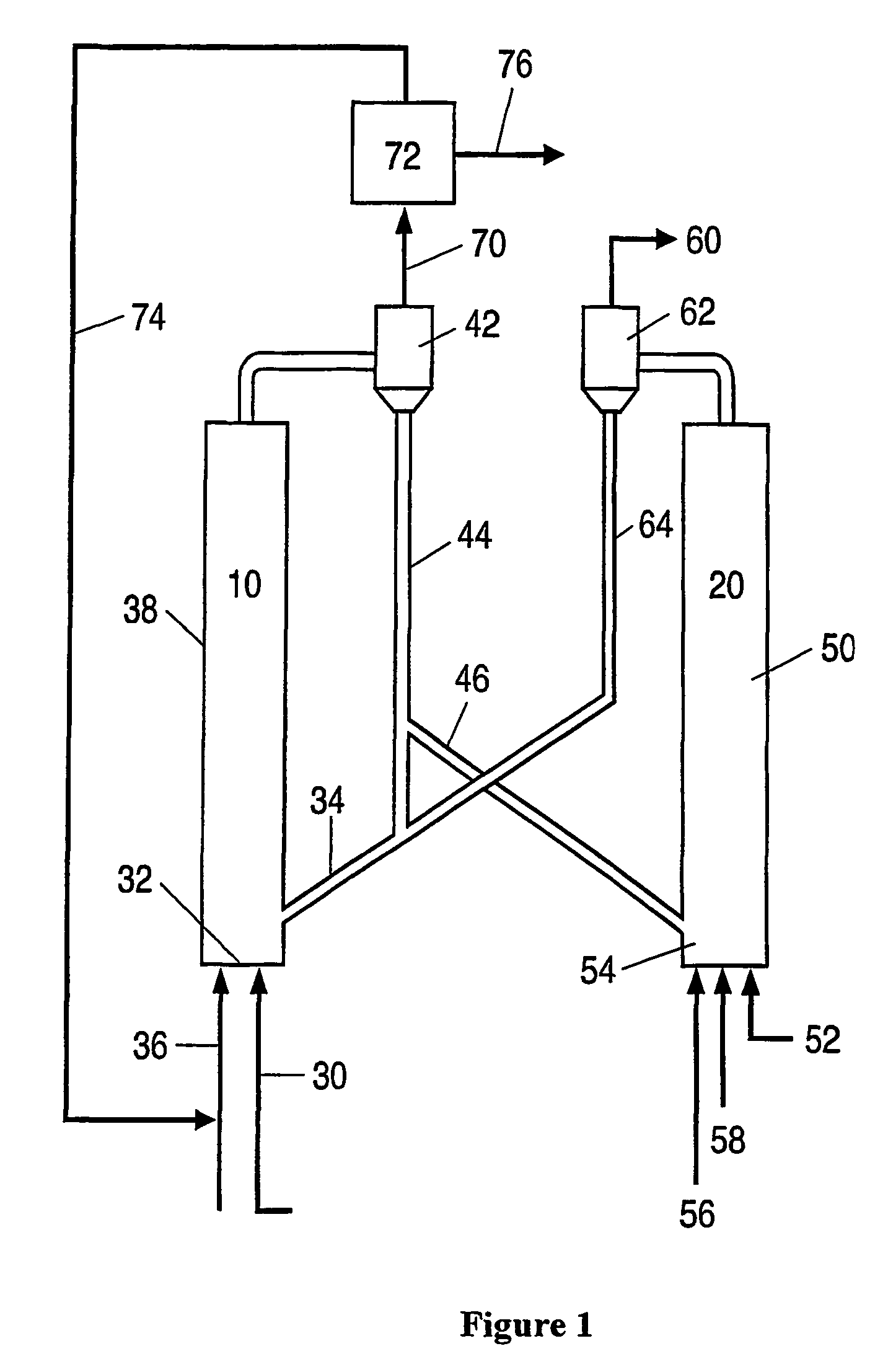

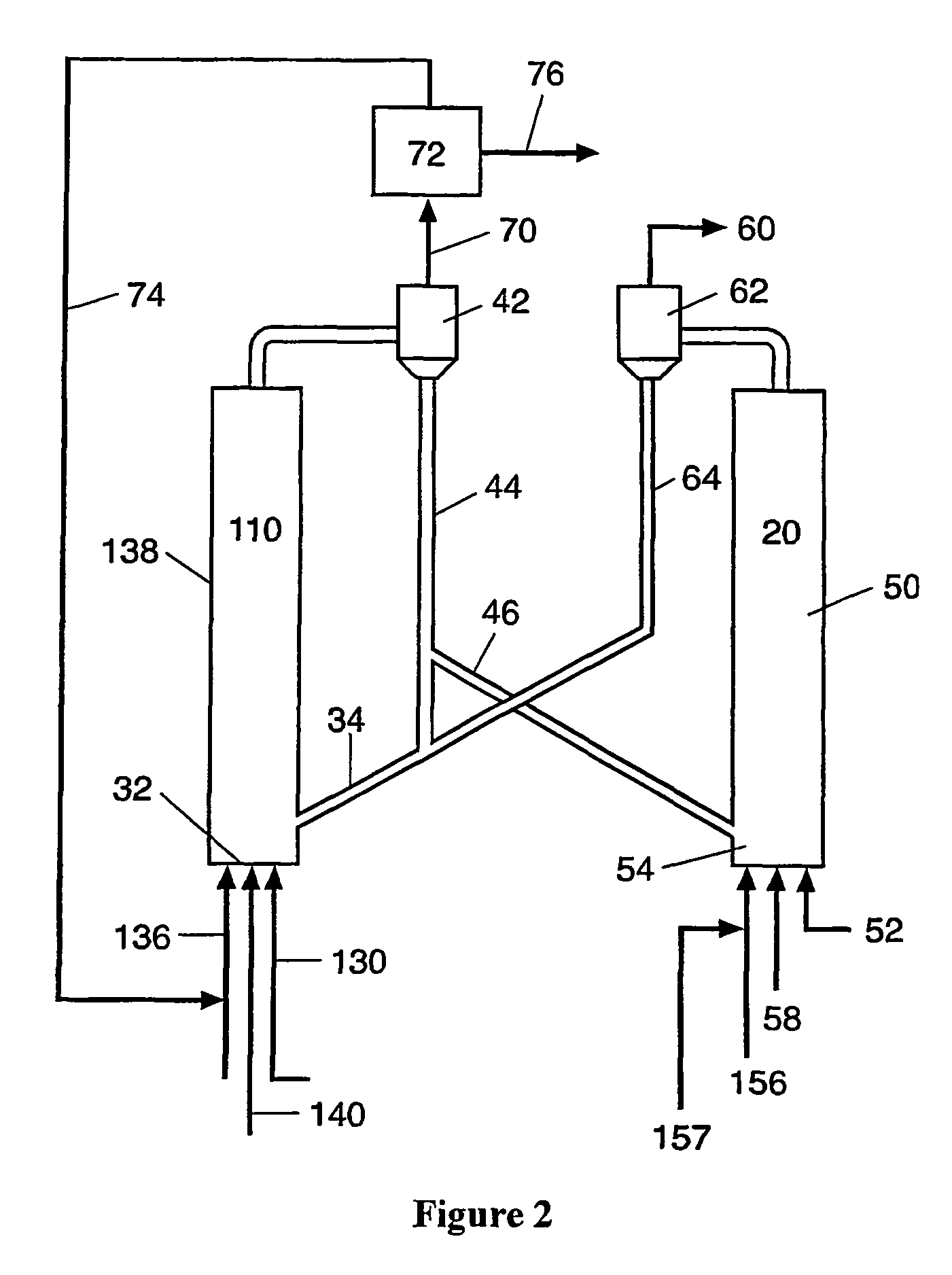

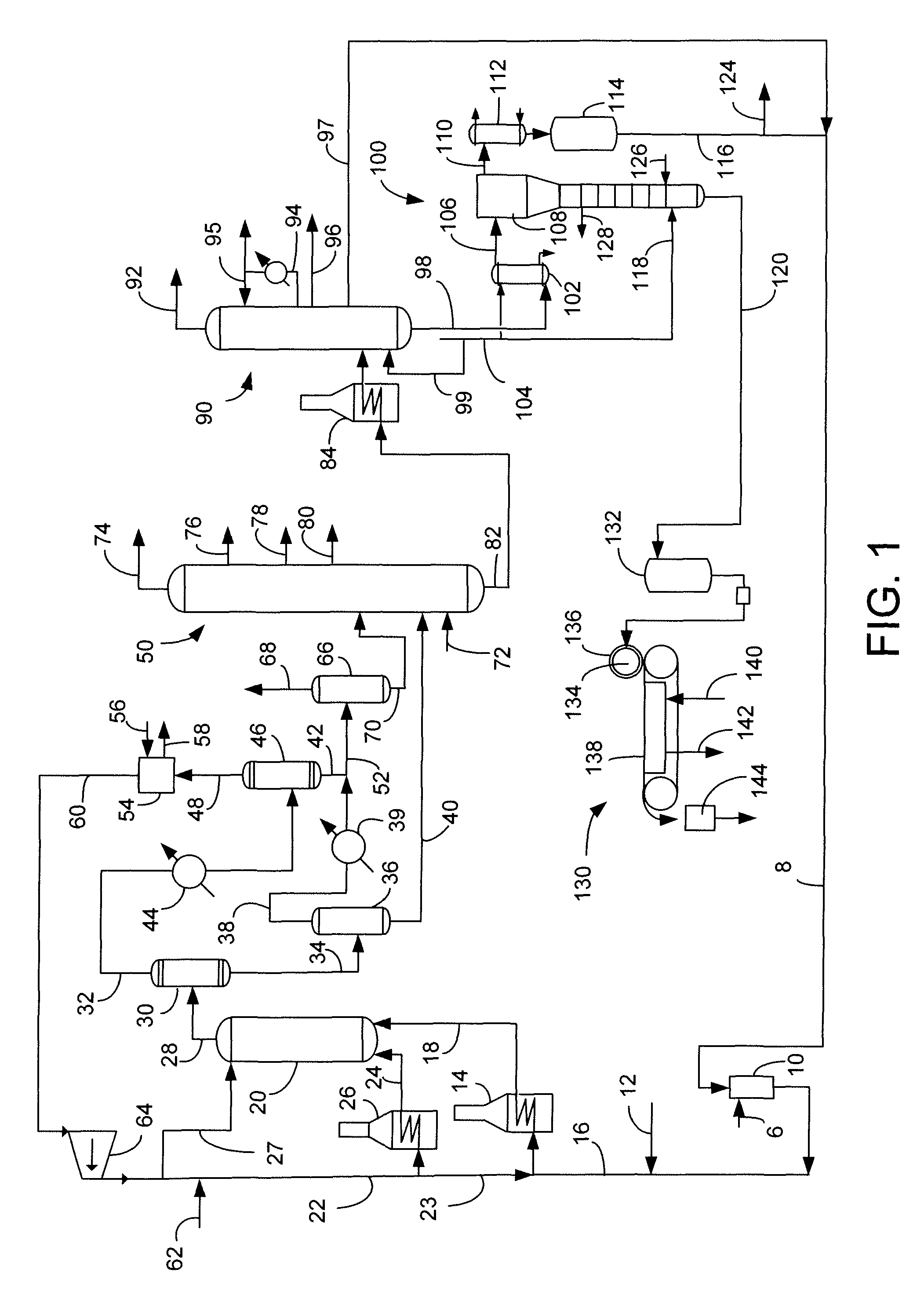

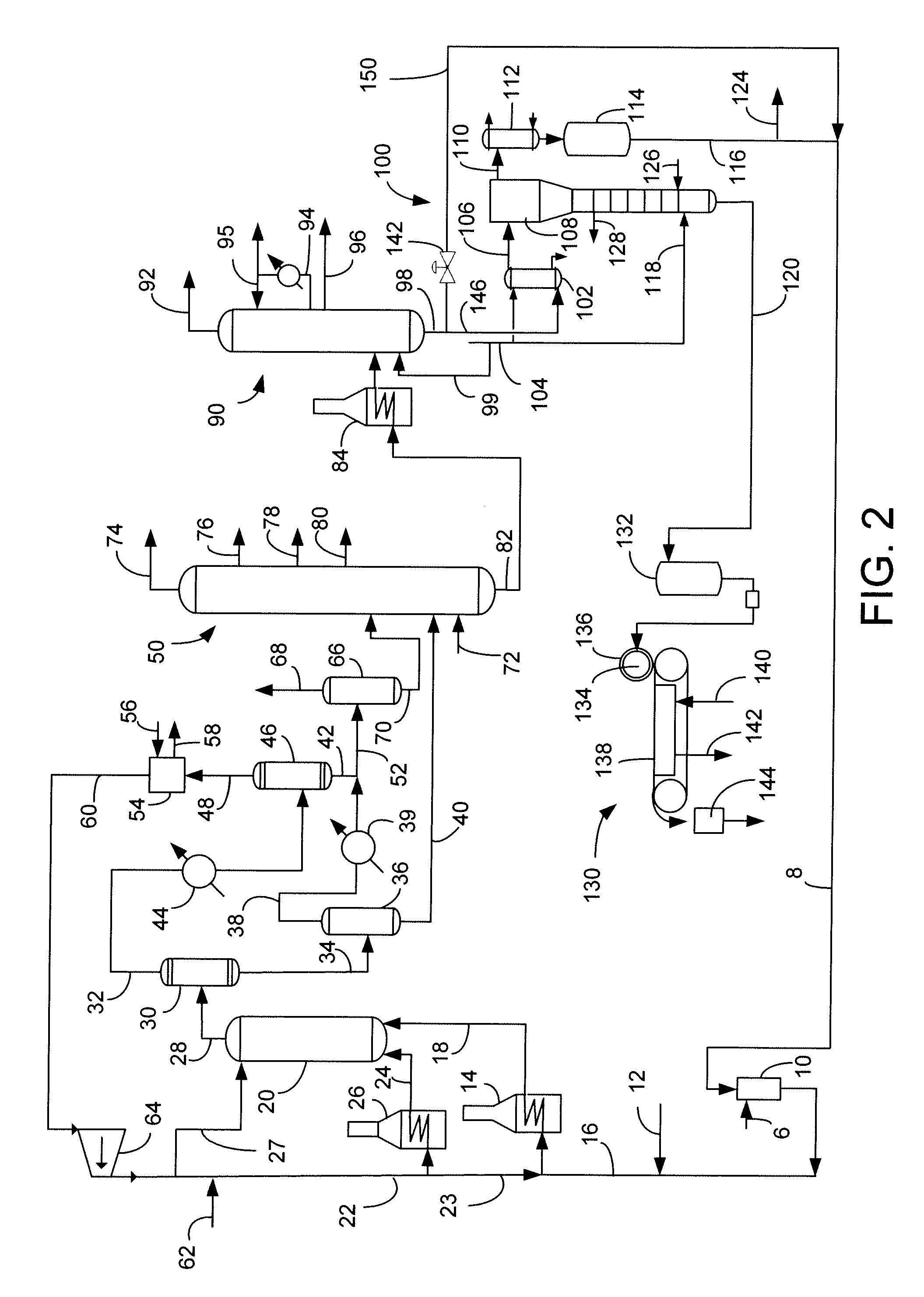

Process for Separating Pitch from Slurry Hydrocracked Vacuum Gas Oil

InactiveUS20100326887A1Easy to manageLess stickyWorking-up pitch/asphalt/bitumen by distillationHydrocarbon oil crackingParticulatesSlurry

A process is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a particulate solid material to form a heavy hydrocarbon slurry and hydrocracked in a slurry hydrocracking unit to produce vacuum gas oil (VGO) and pitch. A first vacuum column separates VGO from pitch, and a second vacuum column further separates VGO from pitch. As much as 15 wt-% of VGO can be recovered by the second vacuum column and recycled to the slurry hydrocracking unit. A pitch composition is obtained which can be made into particles and transported without sticking together.

Owner:UOP LLC

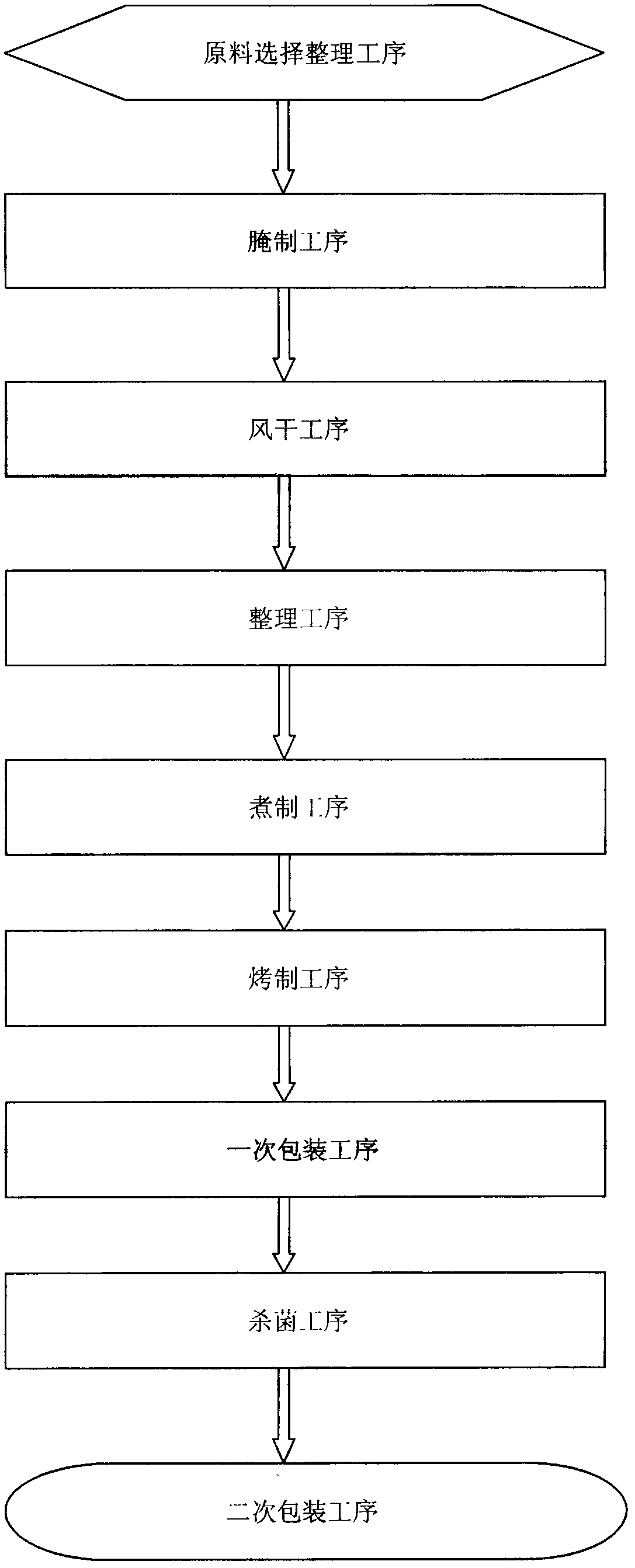

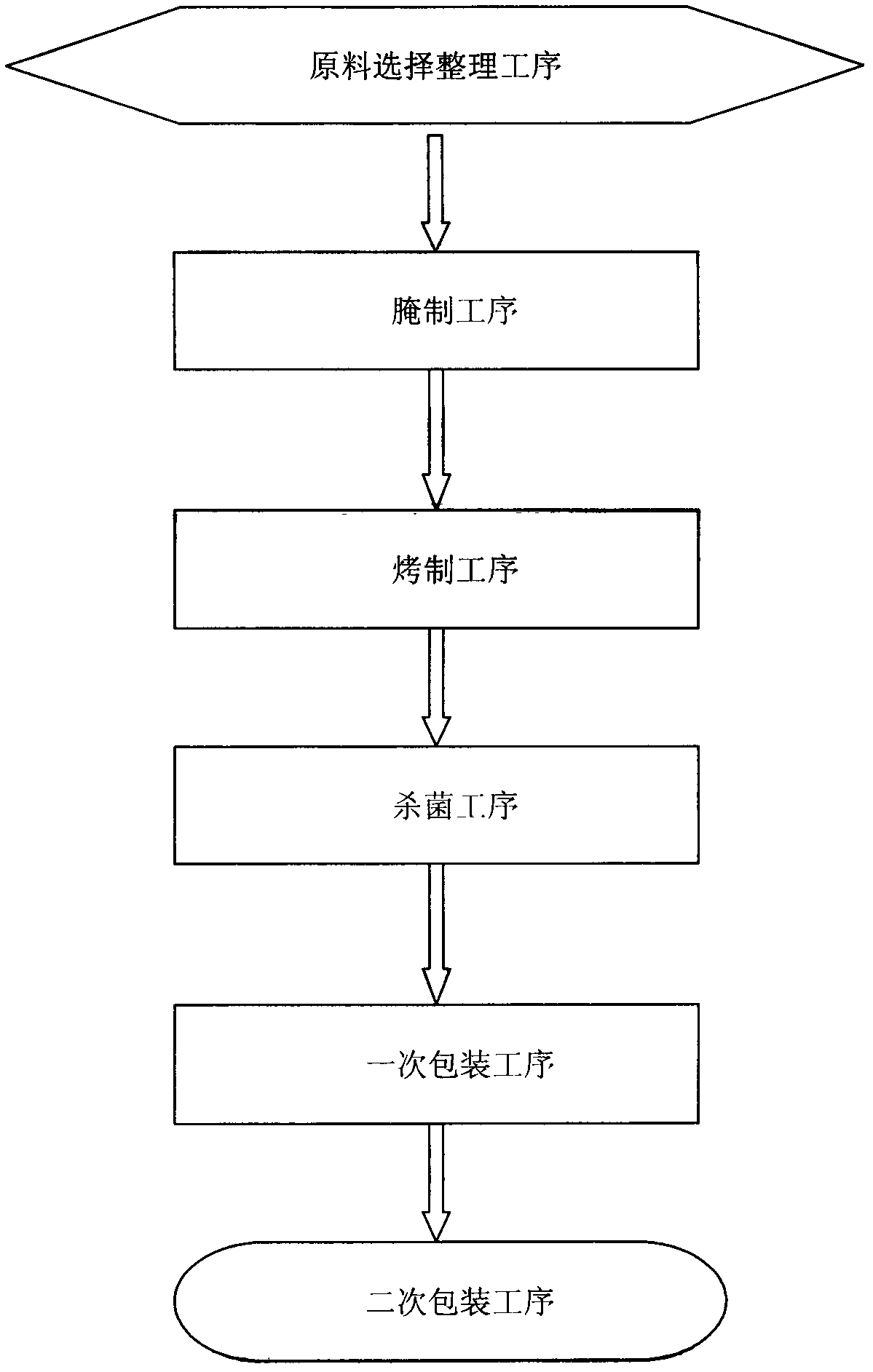

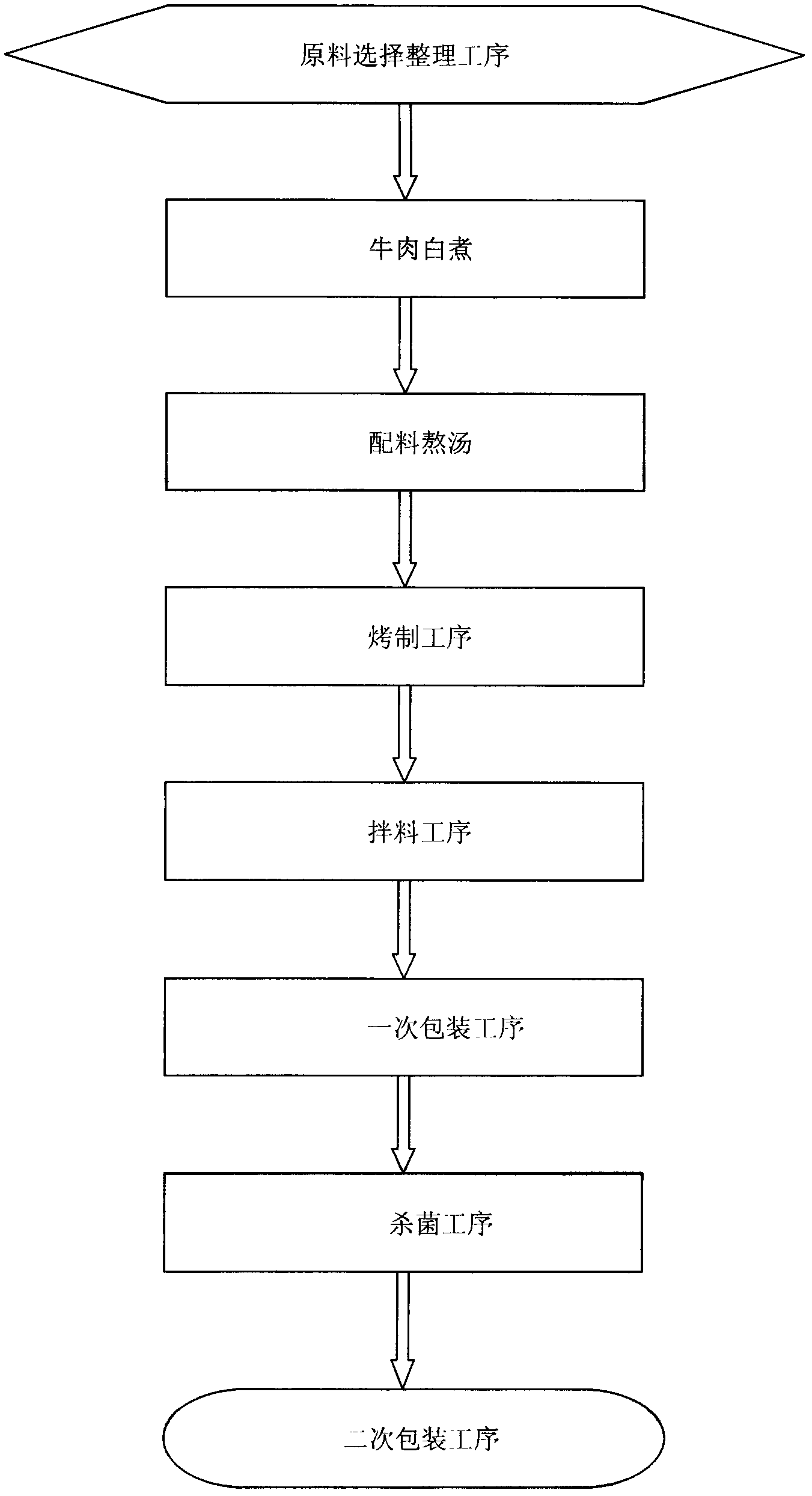

Auxiliary material and method for preparing sliced dried beef by aid of auxiliary material

An auxiliary material and a method for preparing sliced dried beef by the aid of the auxiliary material relate to the technical field of meat processing. The auxiliary material comprises galangal, myrcia, anise, black pepper, wild pepper, spicy pepper, cinnamon, fennel, glycyrrhiza, myristica fragrans, amomum tsao-ko, lemongrass and chilli. The method for preparing sliced dried beef by the aid of the auxiliary material includes raw material selecting and neatening; a curing procedure; an air drying procedure; a neatening procedure; a cooking procedure; a baking procedure; a primary packaging procedure; a sterilizing procedure; and a secondary packaging procedure. A traditional production process including salting and natural air drying is combined with an industrial production process including microwave drying and sterilizing and high-temperature and high-pressure sterilization in the method for preparing the sliced dried beef, advantages of the traditional production process and the industrial production process are complemented, so that moistures of different layers of the sliced dried beef are distributed uniformly, production energy consumption is reduced effectively, color, fragrance, taste and nutritional substances of the sliced dried beef are kept well, a sterilizing effect is realized, storage and quality guarantee of the sliced dried beef are facilitated, a non-fried baking process is adopted, the original nutritional substances of beef are kept effectively, protein loss is reduced, coking is stopped, carbohydrate is avoided, and needs of different people groups are met to the greatest extent.

Owner:燕凤兰

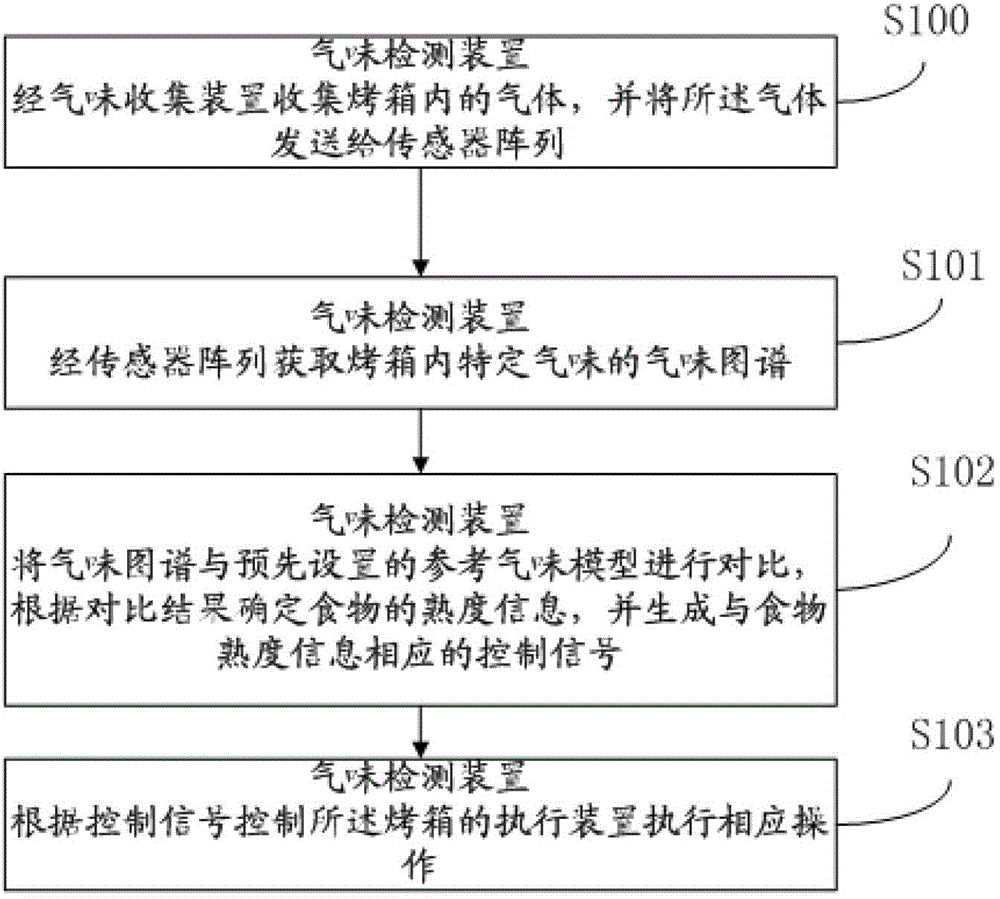

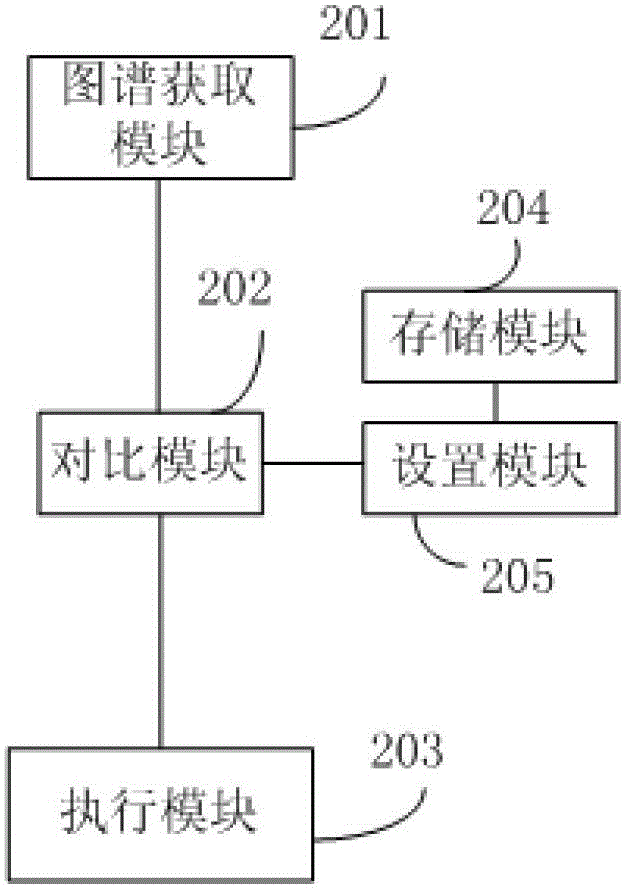

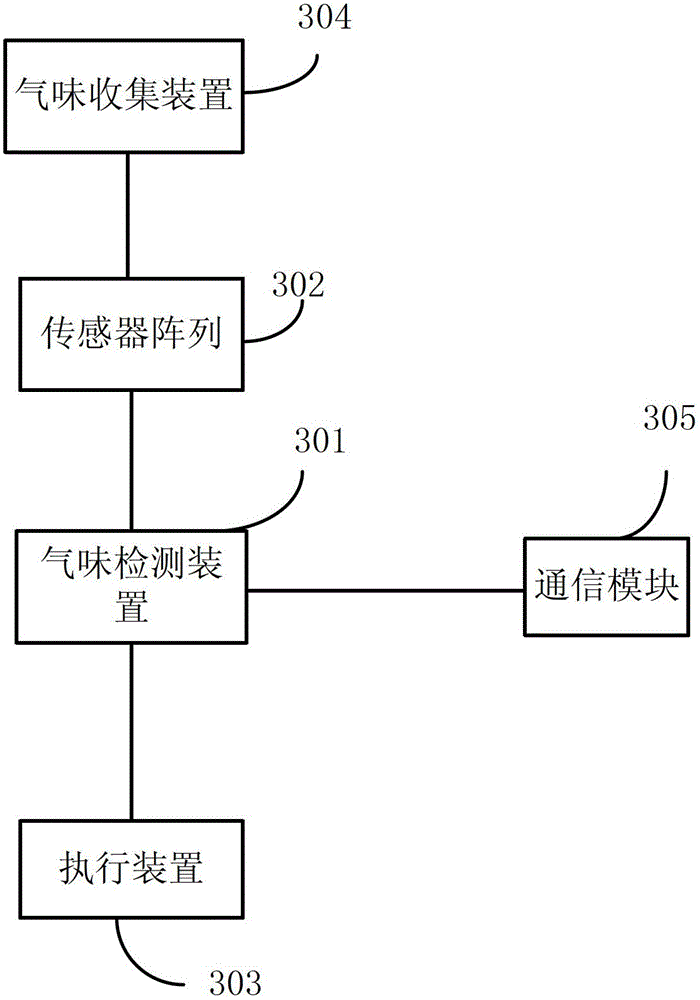

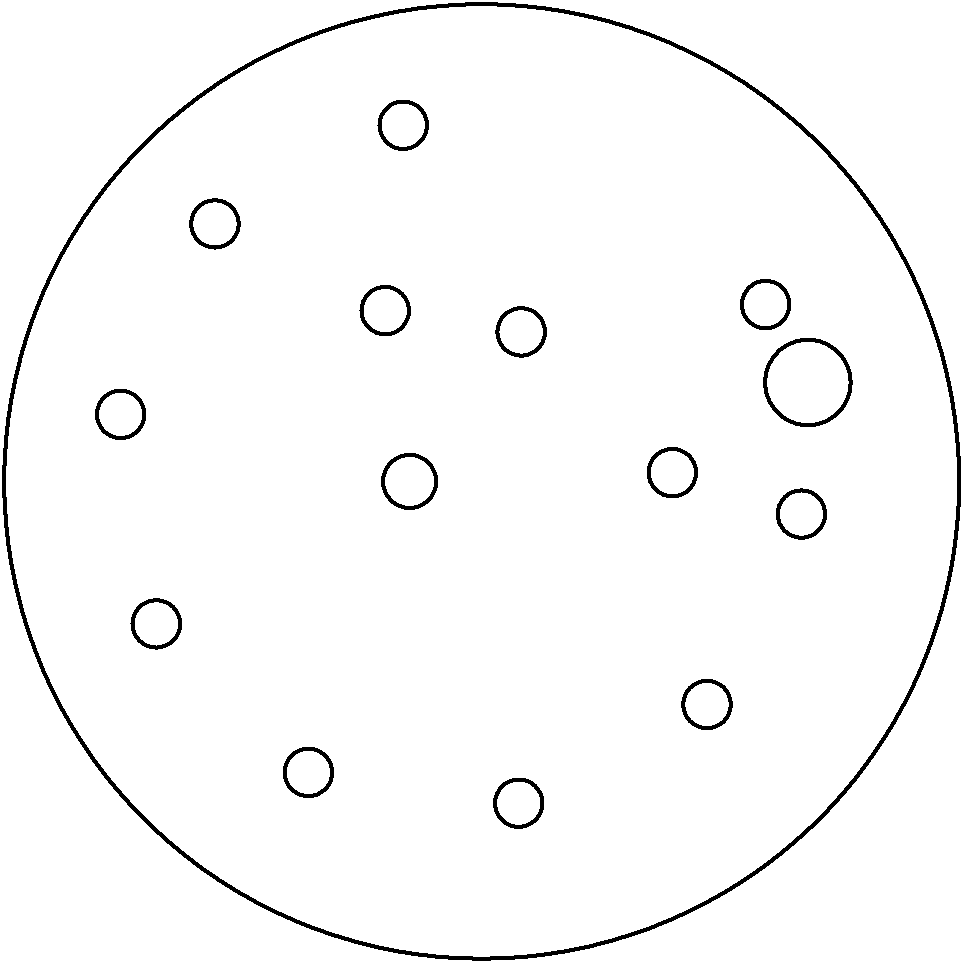

Smell detection method, device, baking box and detection system

InactiveCN103940971AAvoid scorchingMeet the needs of intelligenceRoasters/grillsTesting foodSensor arrayCooking & baking

The invention provides a smell detection method, a device, a baking box and a detection system. According to the method, the smell detection device obtains a smell spectrum of a specific smell in the baking box through a sensor array; the smell detection device compares the smell spectrum with a preset reference smell model, determines the cooked degree of food according to the comparison results, and generates a control signal corresponding to the cooked degree information of the food; the smell detection device controls an executive device according to the control signal so as to execute corresponding operation; and the executive device executes the corresponding operation according to the corresponding control signal, thus protecting food from being burned during baking, and satisfying intelligentizing requirements of people for household appliances.

Owner:HAIER GRP CORP +1

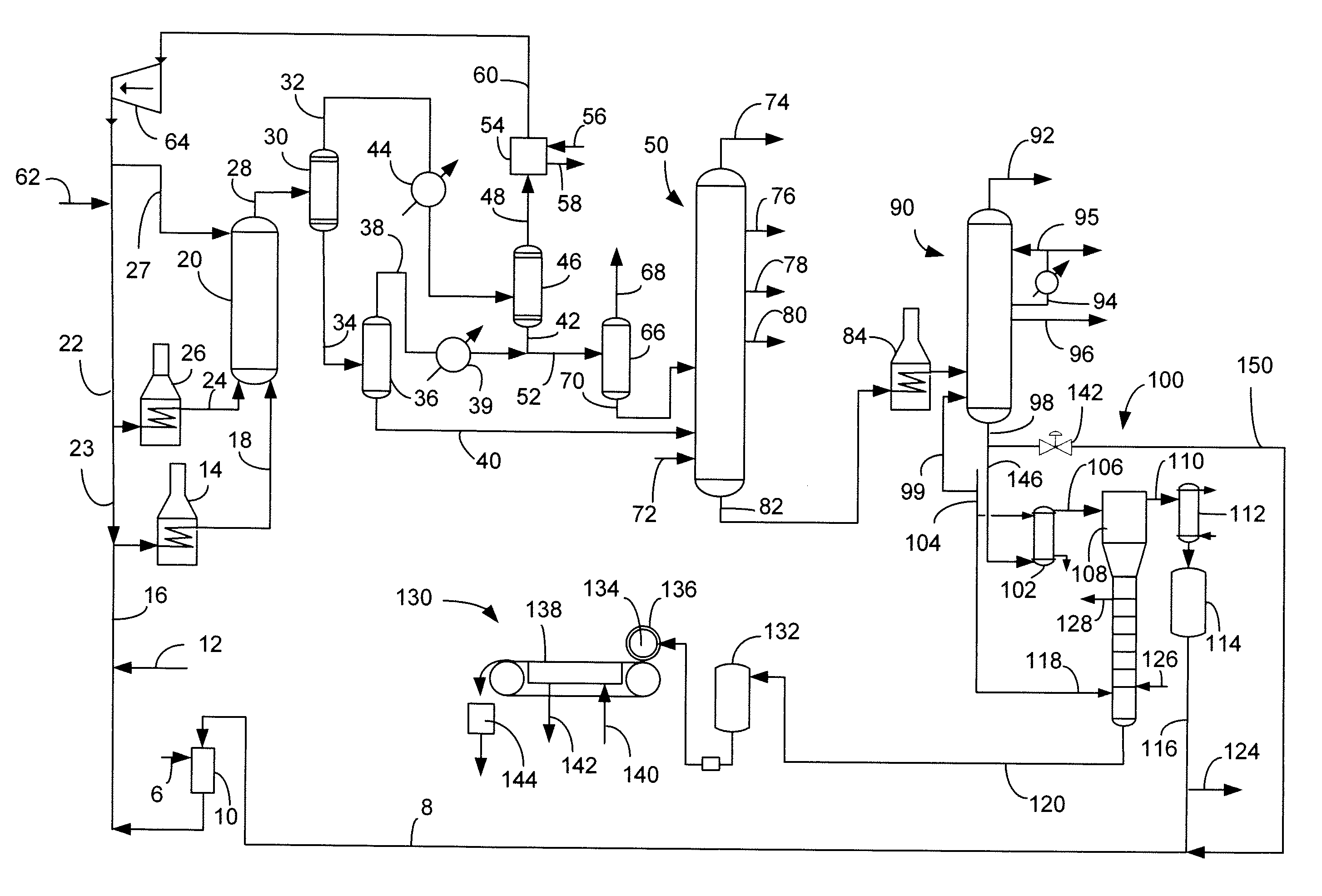

Apparatus for Separating Pitch from Slurry Hydrocracked Vacuum Gas Oil

ActiveUS20100329935A1Reduces coke and crack concernEasily manageHydrocarbon by hydrogenationHydrocarbon distillationChemistrySlurry

An apparatus is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a particulate solid material to form a heavy hydrocarbon slurry and hydrocracked in a slurry hydrocracking unit to produce vacuum gas oil (VGO) and pitch. A first vacuum column separates VGO from pitch, and a second vacuum column further separates VGO from pitch. As much as 15 wt-% of VGO can be recovered by the second vacuum column and recycled to the slurry hydrocracking unit. A pitch composition is obtained which can be made into particles and transported without sticking together.

Owner:UOP LLC

Solid-oxide fuel cell system having an upstream reformate combustor

ActiveUS20060024541A1Avoid scorchingAssisting in overall heatingHydrogenFuel cell auxillariesCombustorFuel cells

A solid-oxide fuel cell system wherein a reformate combustor is disposed in the reformate flow path between a hydrocarbon reformer and a fuel cell stack. At system start-up, reformate is partially burned within the combustor by admitting combustion air, and the partially-burned reformate is passed through the anode chambers of the stack to warm the anodes. In addition, reformate is passed through a cathode-air heat exchanger to warm combustion air entering the cathode chambers of the stack. The combustor may continue to be supplied with a low level of air during steady-state operation of the SOFC, thereby providing a moist environment within the anode chambers to prevent coking of the anodes and providing additional heat to the reformate. The combustor decouples the reformer from the stack thermodynamically, permitting the reformer and the stack each to run in its own optimal temperature range.

Owner:APTIV TECH LTD

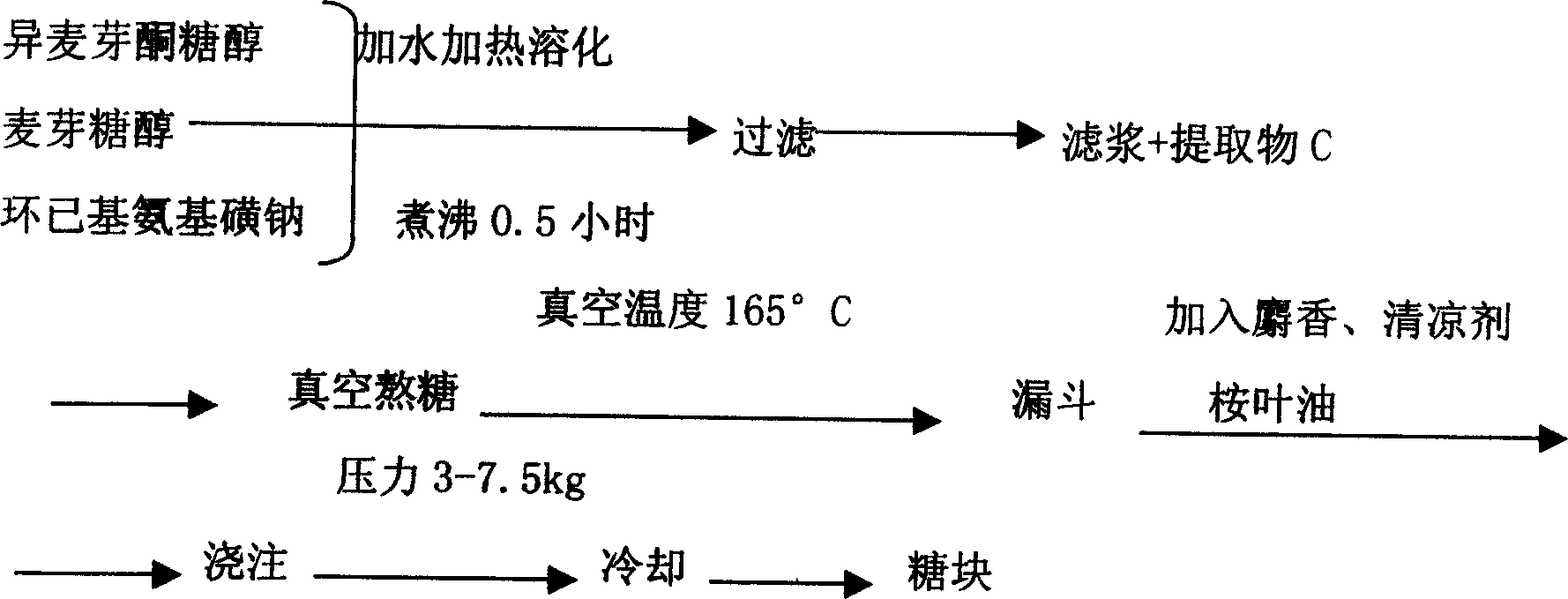

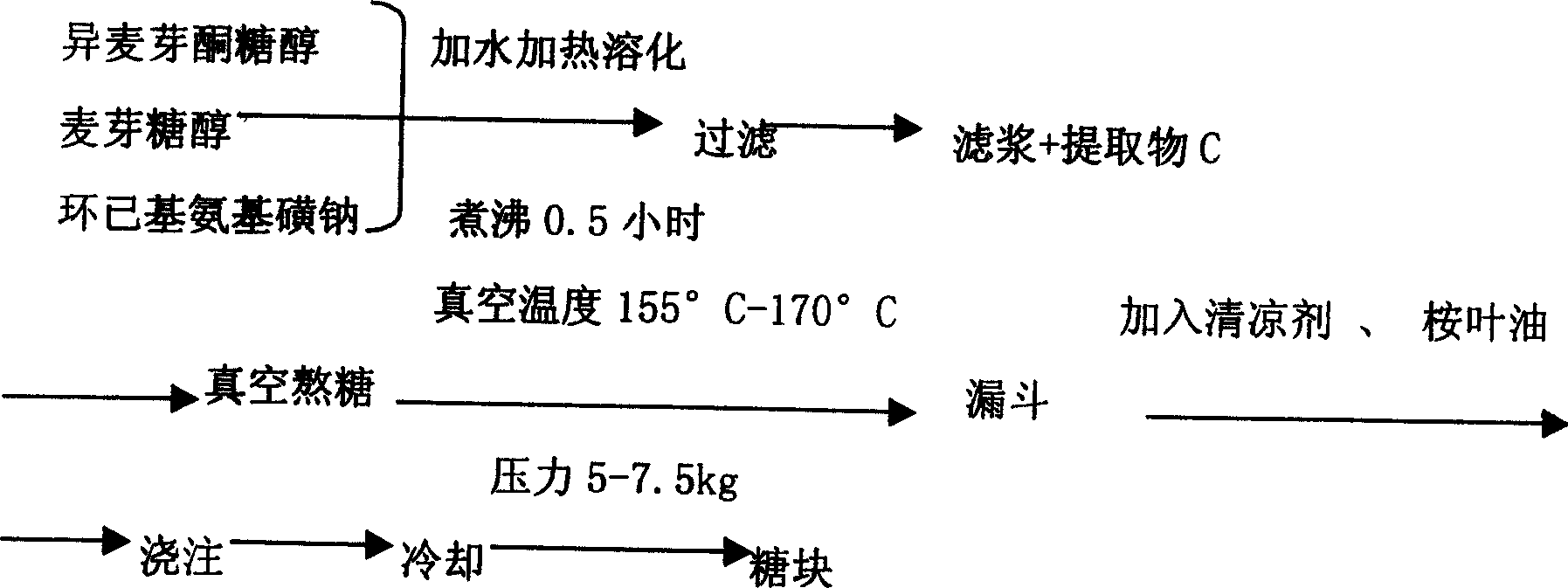

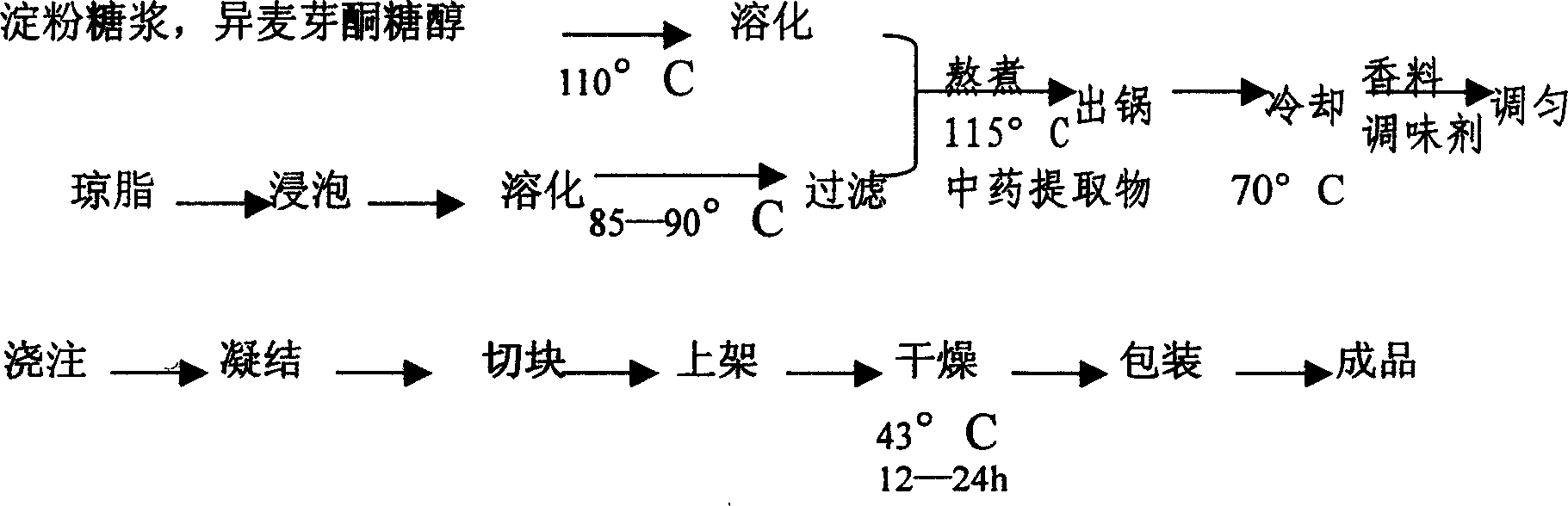

Solid prepn. with functions of clearing and moistening throat, and its prodn. technique

InactiveCN1513381AImprove thermal stabilityPromote withdrawalUnknown materialsRespiratory disorderThroatIsomalt

Owner:JIANGZHONG PHARMA

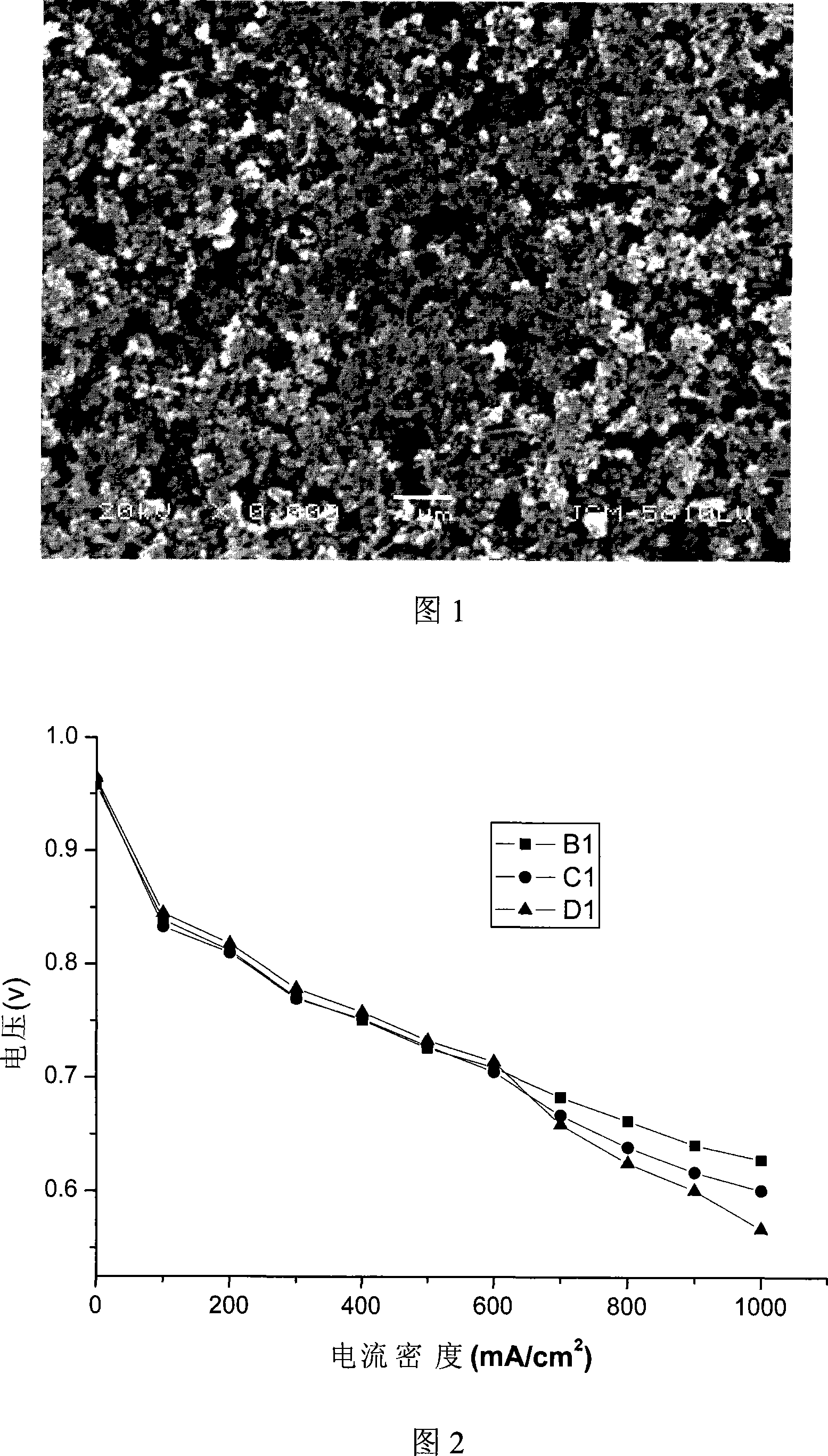

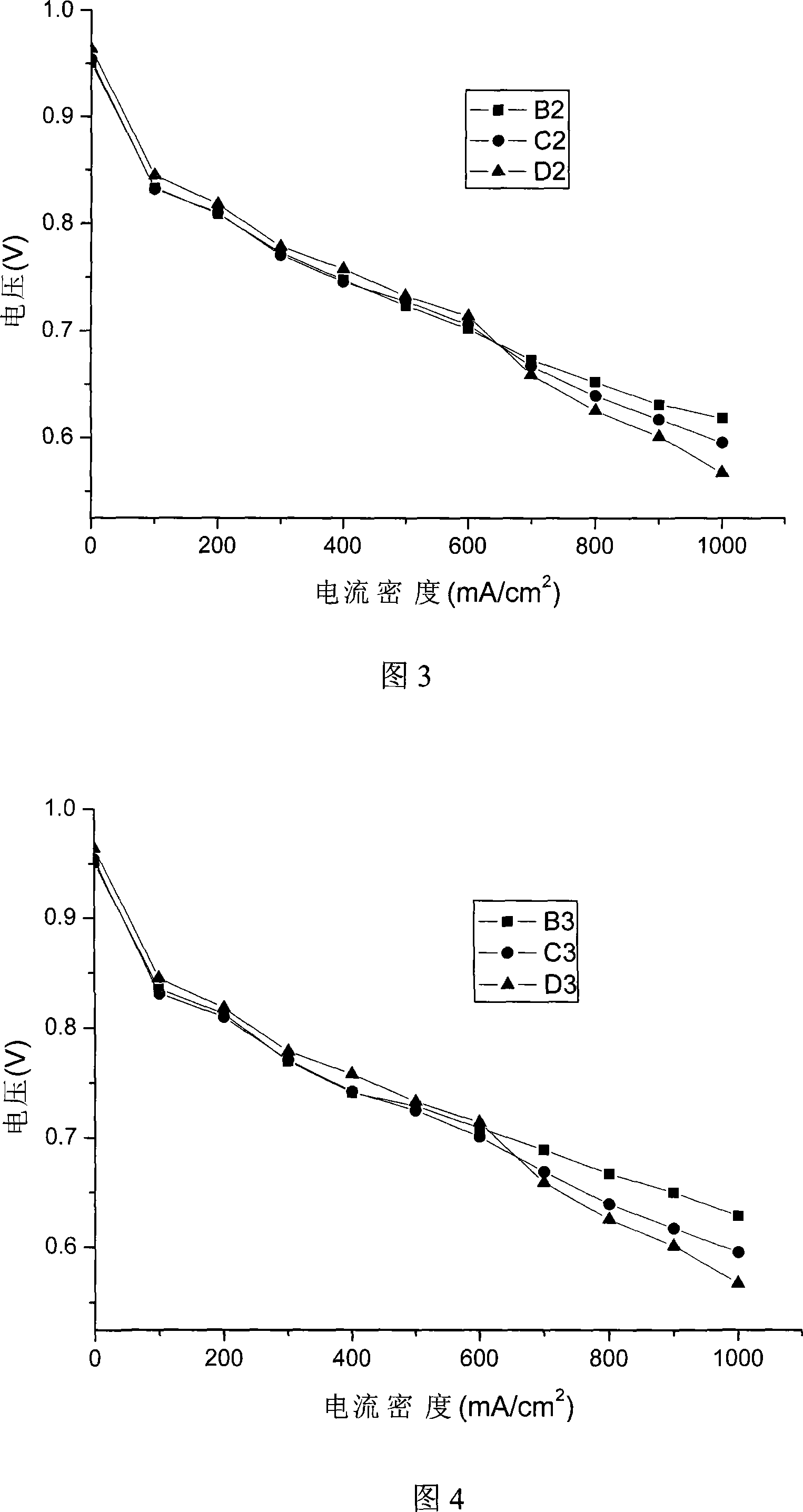

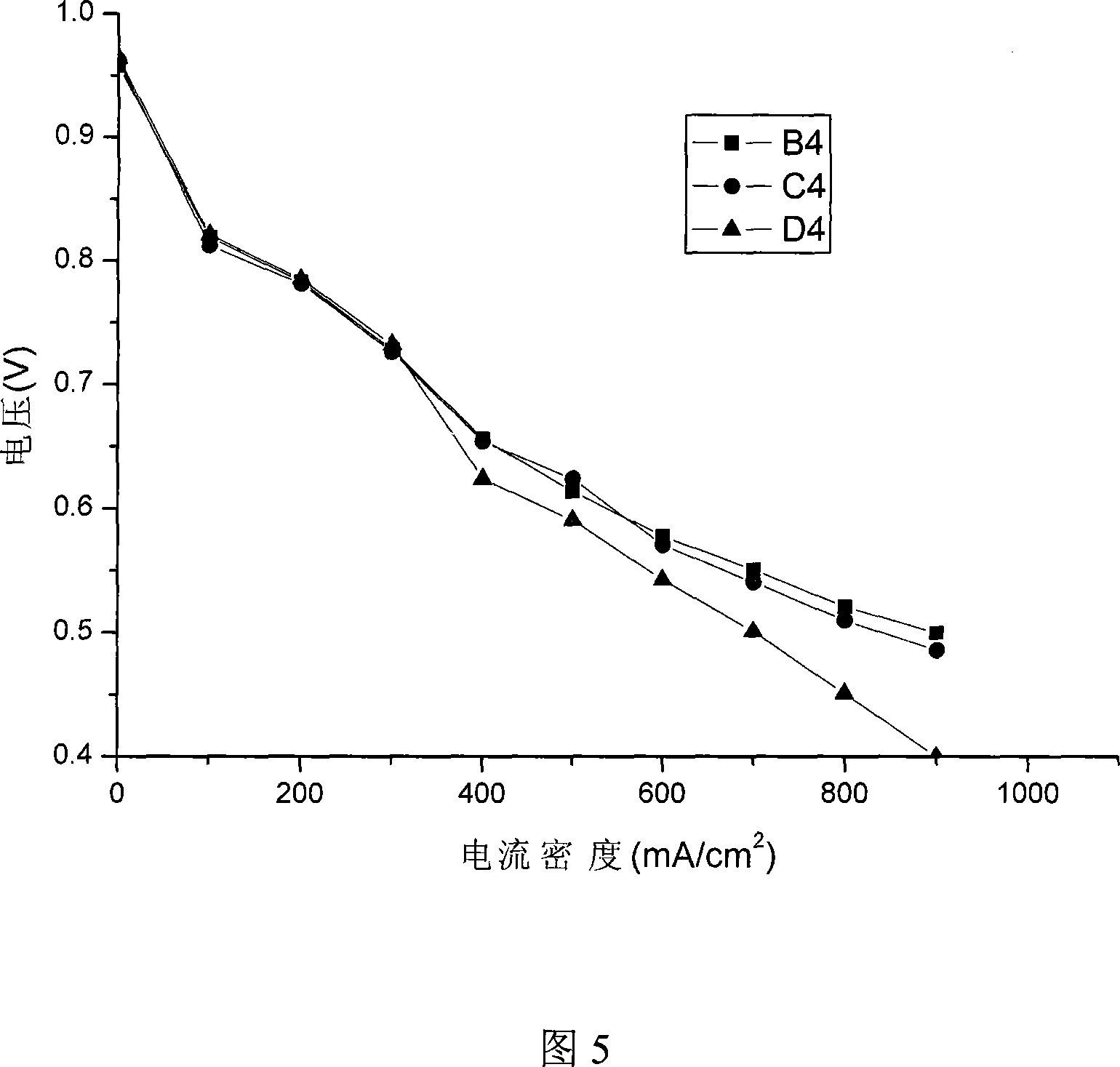

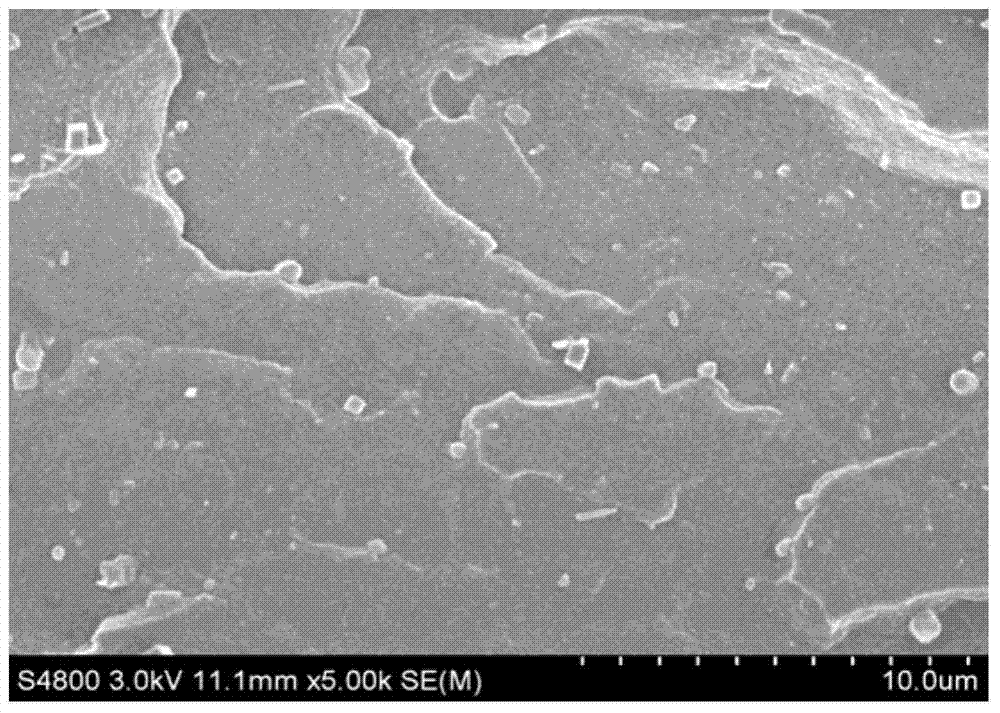

Fuel cell membrane electrode using polymer superbhort fiber as hydrophobic agent and its preparing method

InactiveCN101071874AImprove drainageWell Reactive Gas Diffusion ChannelsCell electrodesFuel cell detailsFiberPolymer electrolytes

A fuel cell membrane electrode using polymer ultra-short fiber as water repellent and it's the preparation method, in which the catalyst layer is dopped with polymer ultra-short fiber. The preparation method is that: coat the catalyst pulp containing load-type catalyst, solid polymer electrolyte, polymer ultra short fiber and the solvent on to gas diffusion layer surface to get a gas diffusion layer electrode, hot press this electrode and the proton exchange membrane to prepare the membrane electrode; Or transfer solidified catalyst onto two sides of the proton exchange membrane to prepare the catalyst / membrane central assembly. Advantages : raised water discharge function comparing with grain-like polymer water repellent, having good reaction gas dispersion path, raised structure and catalyst size stability and simple preparation process of membrane electrode.

Owner:WUHAN UNIV OF TECH

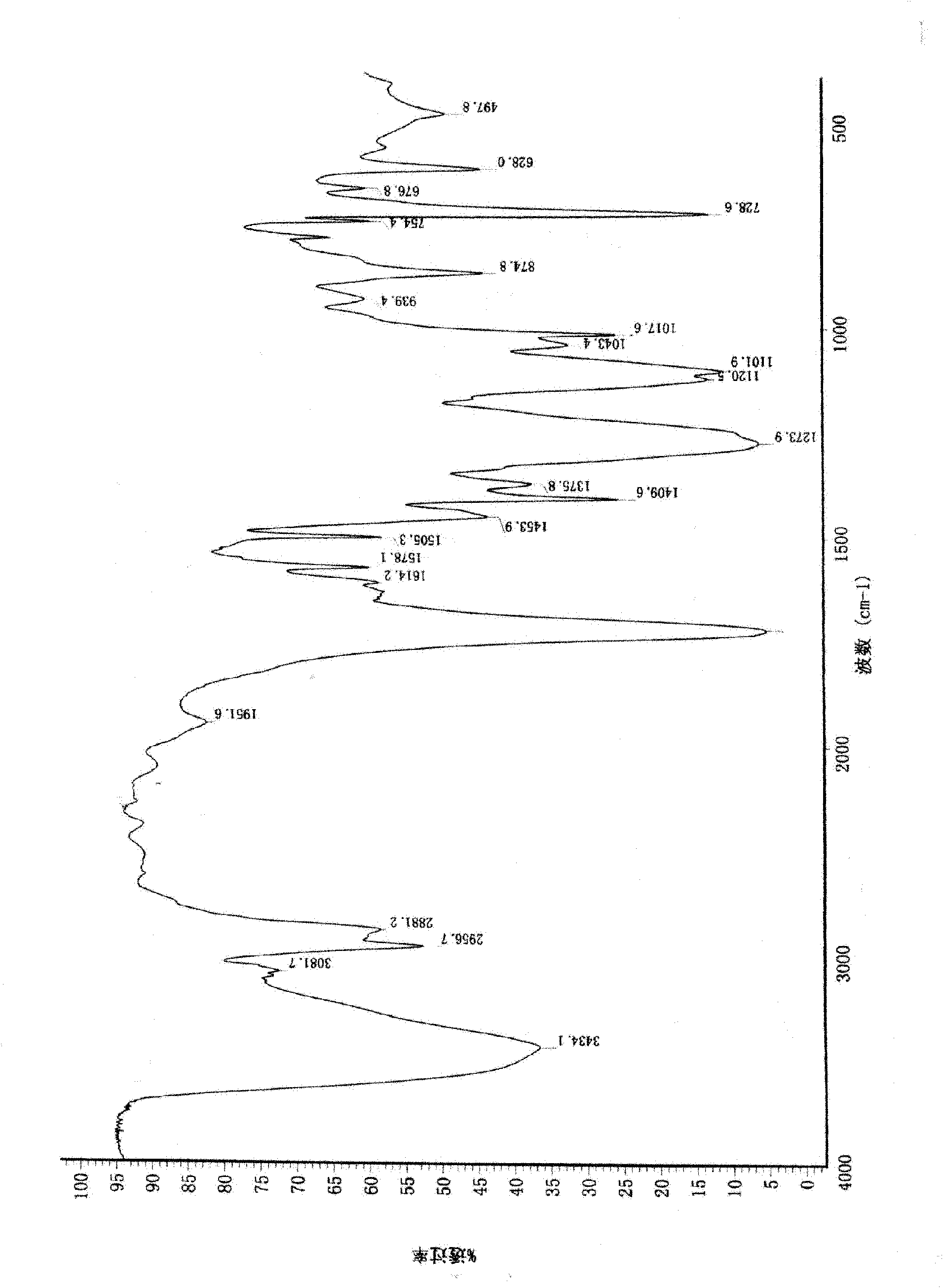

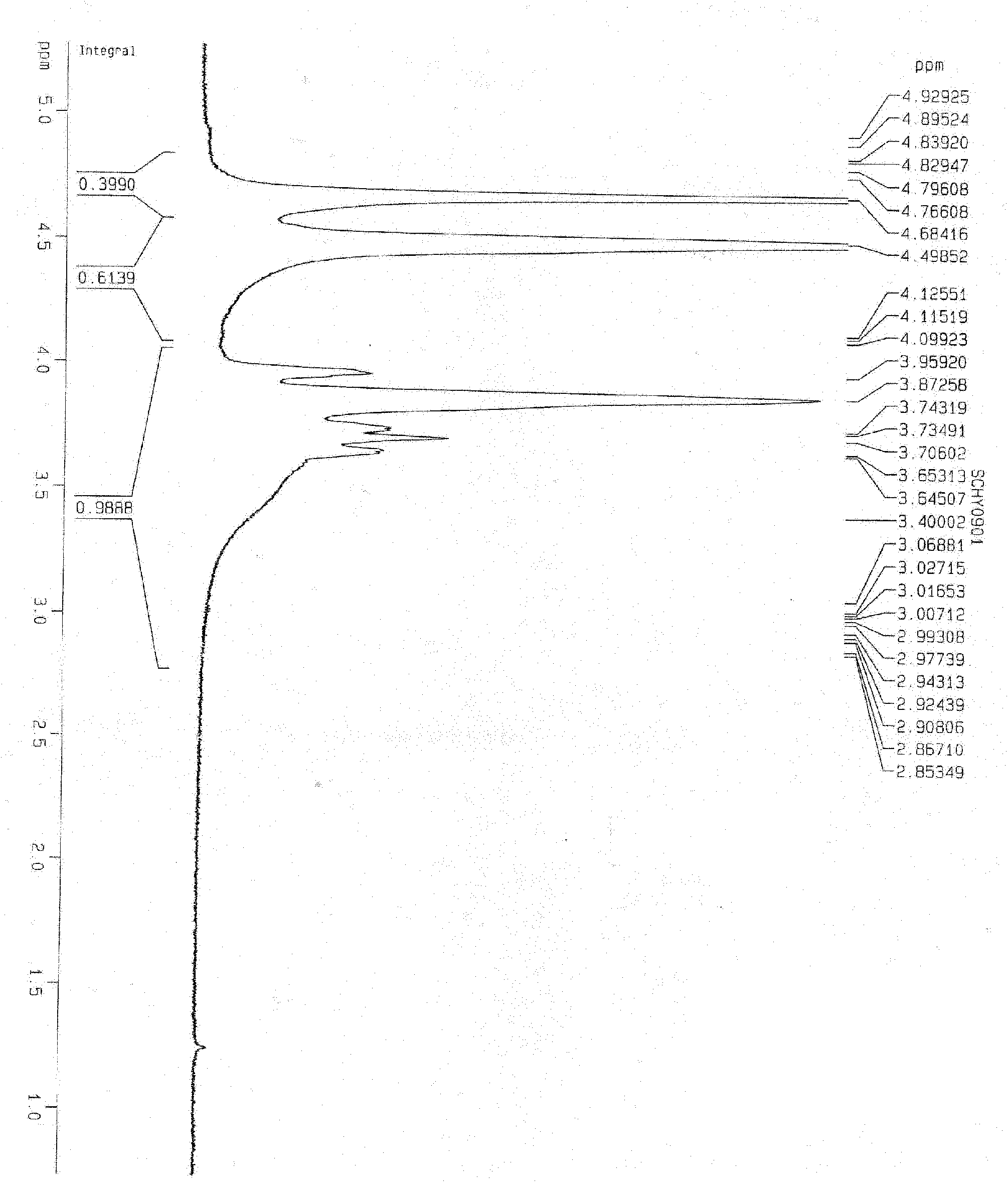

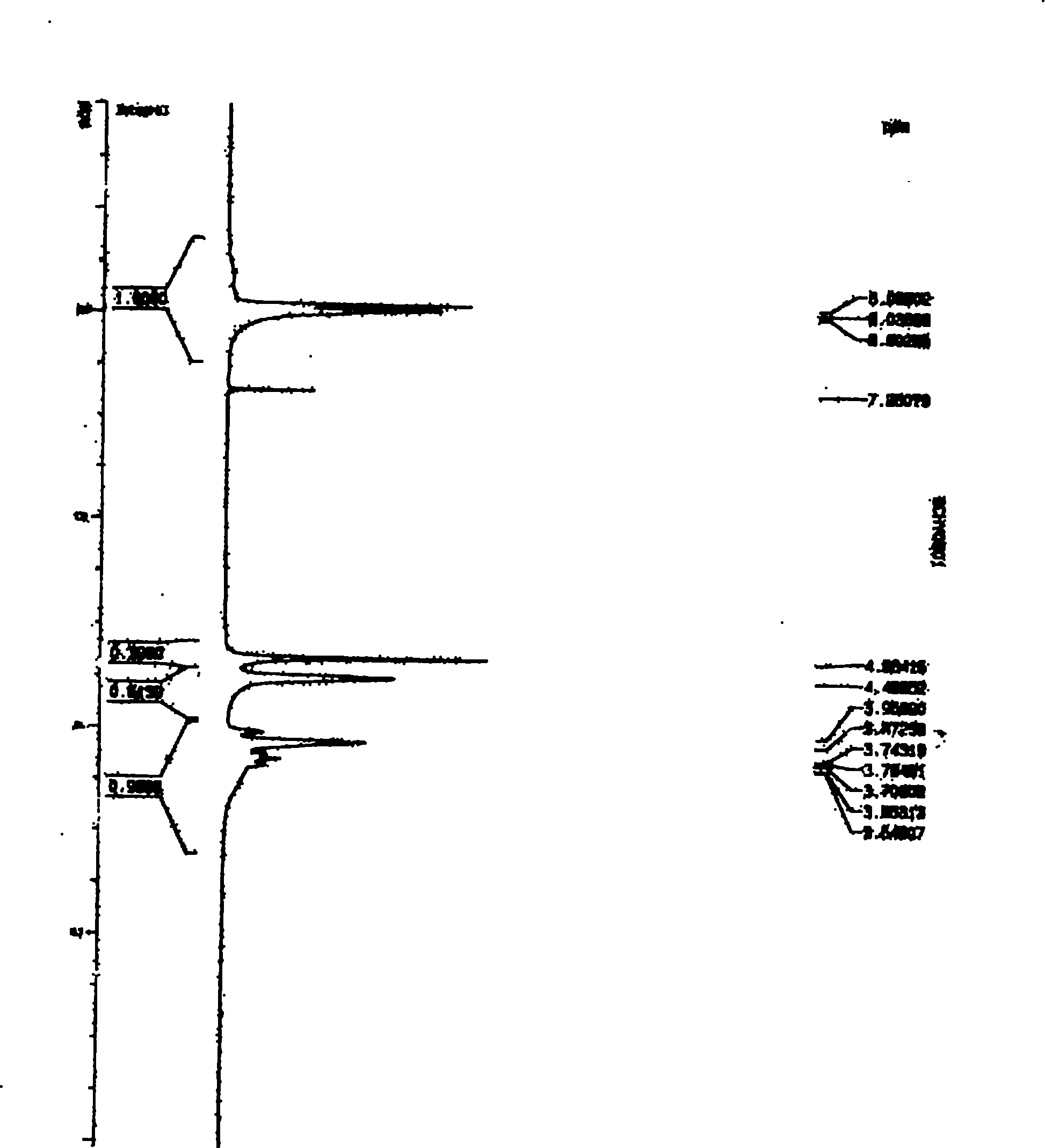

Water-soluble polyester slurry prepared from waste polyester plastics and preparation method thereof

The invention discloses a method for preparing water-soluble polyester slurry from waste polyester plastics through a one-step method, belonging to the technical field of processing and recycling of waste polyester plastic bottles and pieces. The preparation method comprises the following step of carrying out modification and polycondensation on waste polyester scraps, 1,2-propanediol, diglycol, a waterborne polyester modifying agent A, a composite stabilizing agent and a catalyst in the same reaction kettle so as to ensure that when the polyester slurry is polymerized, a macromolecular main chain not only contains ester groups, but also contains water-soluble groups and is hydrophilic and soluble in water. By adopting an ester exchange polycondensation one-step method to prepare the water-soluble polyester slurry, the invention solves the technical problems of complicated processes, long time, and the like of the traditional two-step method for preparing the water-soluble polyester and has the advantages of low raw material cost, simple and convenient operation, short time and low energy consumption.

Owner:SICHUAN HONGYANG HIGH POLYMER TECH

Seal ring rubber material and mixing method thereof

InactiveCN102010553AAvoid bloomingPrevent blooming and scorching of rubberEngine sealsRubber materialCalcium hydroxide

The invention relates to a seal ring rubber material and a mixing method thereof. The mixing method comprises the following steps: carrying out crude rubber laminating and roller covering: adding 1-1.5 parts of aflux-42 serving as a processing agent and 1.5-2 parts of TM-80 serving as a mould release agent into 100 parts of fluororubber serving as crude rubber; mixing the above components of the rubber material for about 1 minute at the roller temperature of 40-45 DEG C, and adding 4-6 parts of activated magnesia serving as an acceptor; evenly mixing, adding 30-40 parts of a reinforcing agent which contains aramid pulp fiber; evenly mixing once again, adding 1-1.5 parts of bisphenol AF serving as a vulcanizing agent and 1-0.5 part of tert-butyl peroxypivalate (BPP) serving as an accelerator; and finally adding 5-7 parts of calcium hydroxide, packaging into a cornucopla for three or four times after all compounding ingredients are consumed up under the roller temperature of below 55 DEG C, adjusting the roller distance to be less than 0.55mm, rolling the dropped rubber for five or six times, and discharging. The seal ring rubber material has the advantages of rapid vulcanization speed of fluororubber, high production efficiency and low rejection rate.

Owner:广东天诚密封件股份有限公司

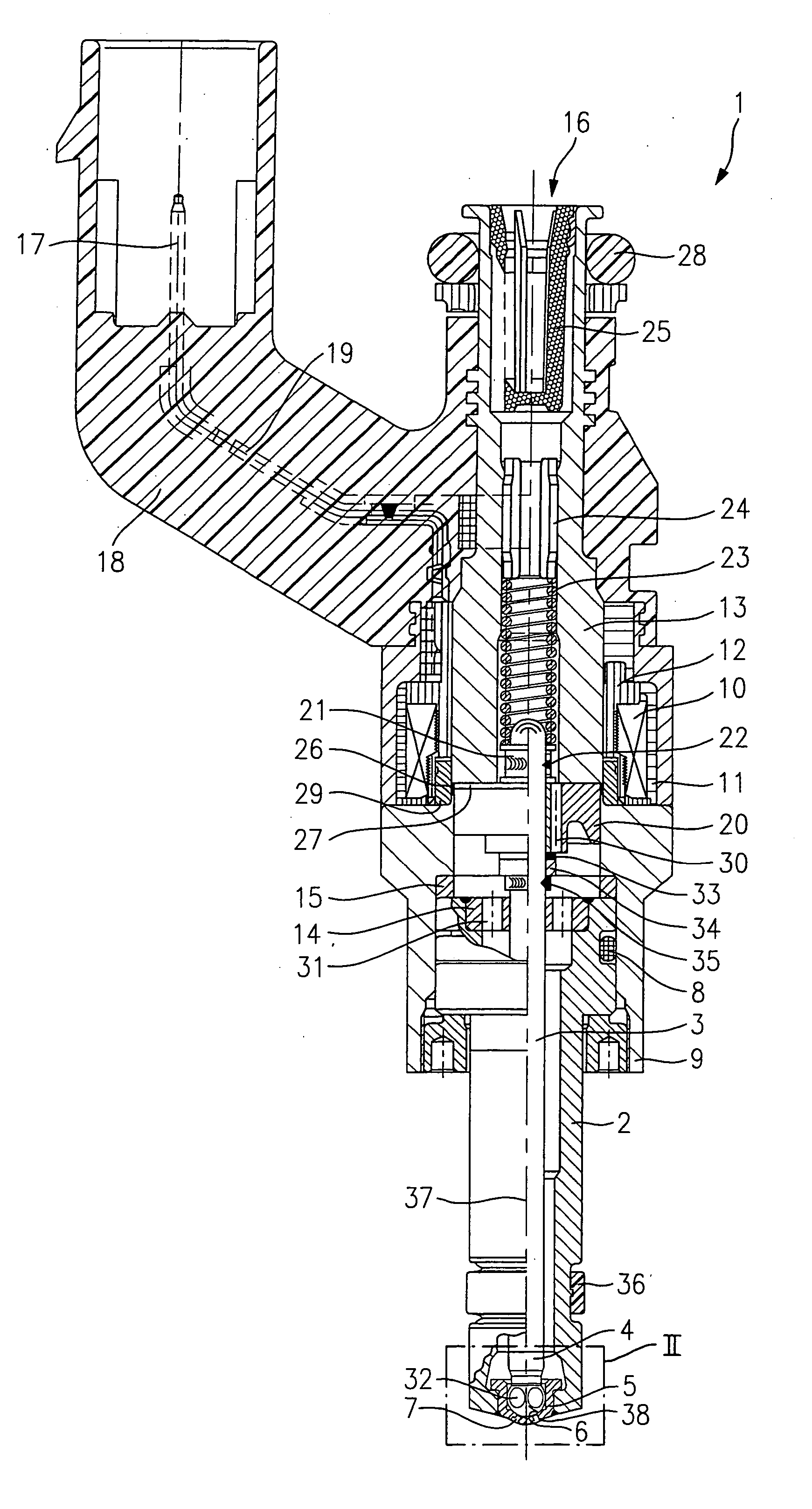

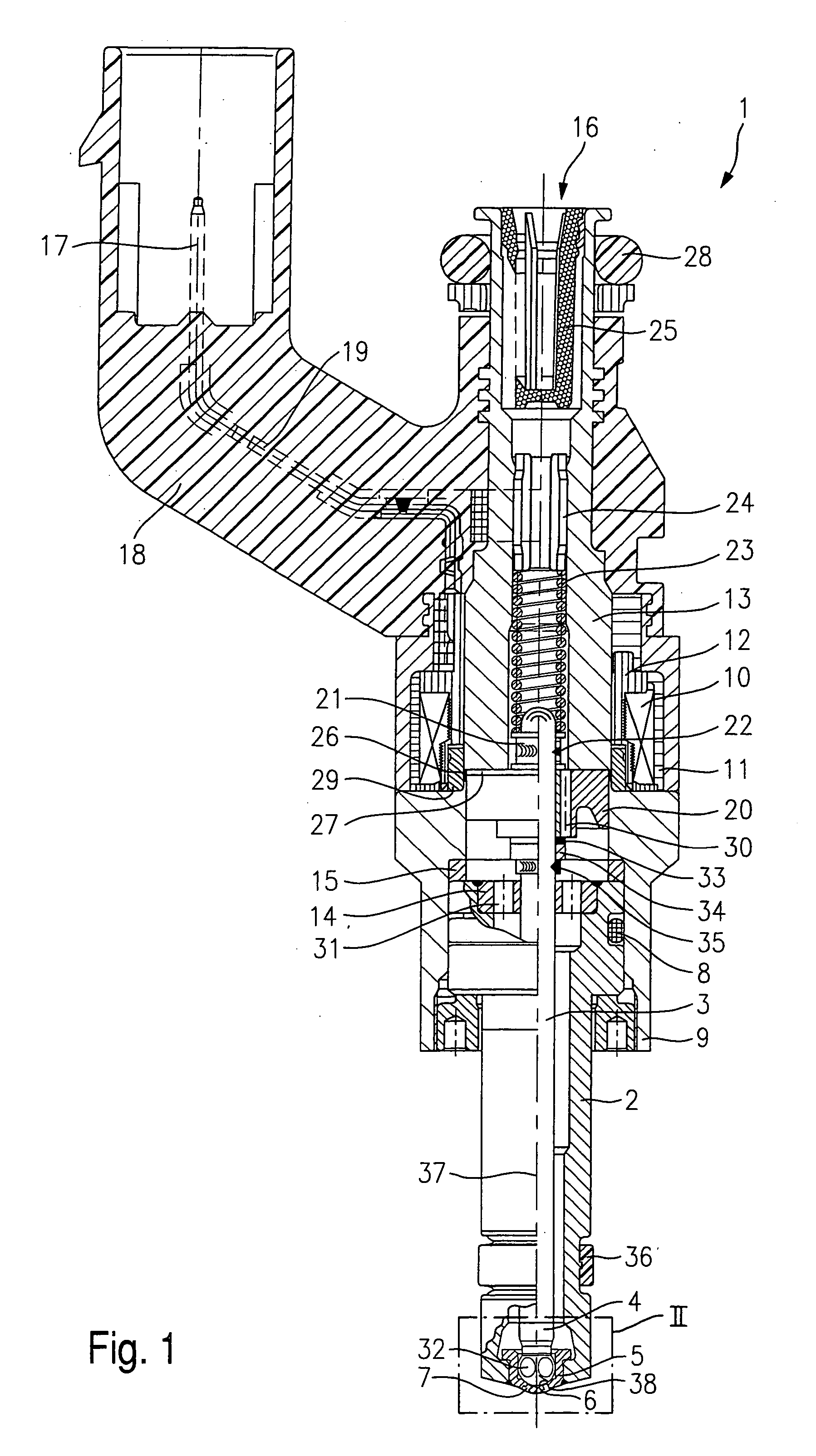

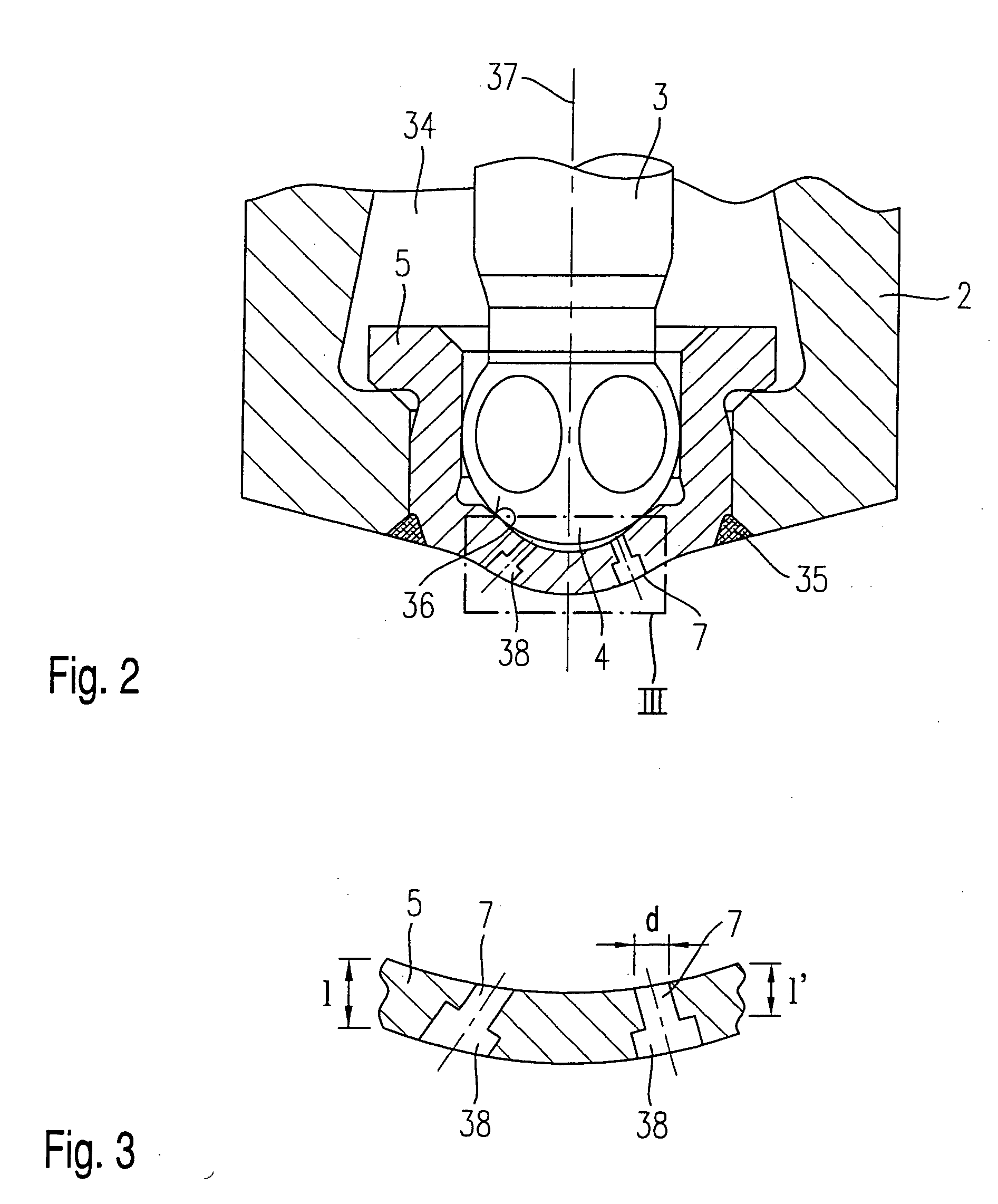

Fuel injection valve

InactiveUS20070012805A1Reduced service lifeAvoid scorchingSpray nozzlesFire rescueCombustion chamberInternal combustion engine

A fuel injector for the direct injection of fuel into a combustion chamber of an internal combustion engine includes an energizable actuator, a valve needle, which is in operative connection with the actuator and acted upon by a restoring spring in a closing direction to actuate a valve-closure member, which forms a sealing seat together with a valve-seat surface formed at a valve-seat body. The valve-seat body includes at least two spray-discharge orifices. The pressure of the fuel flowing through the fuel injector is greater than 10 bar.

Owner:ROBERT BOSCH GMBH

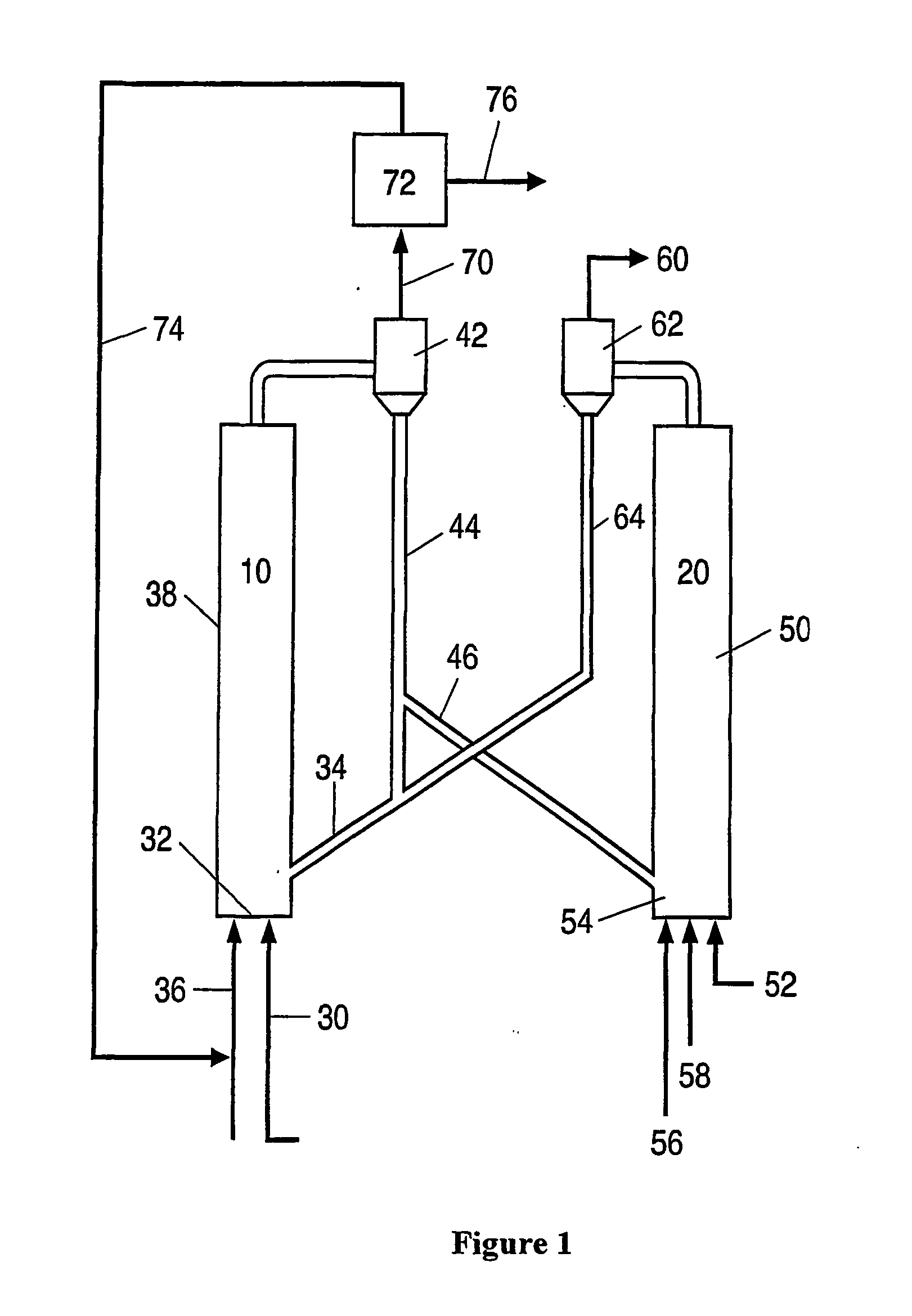

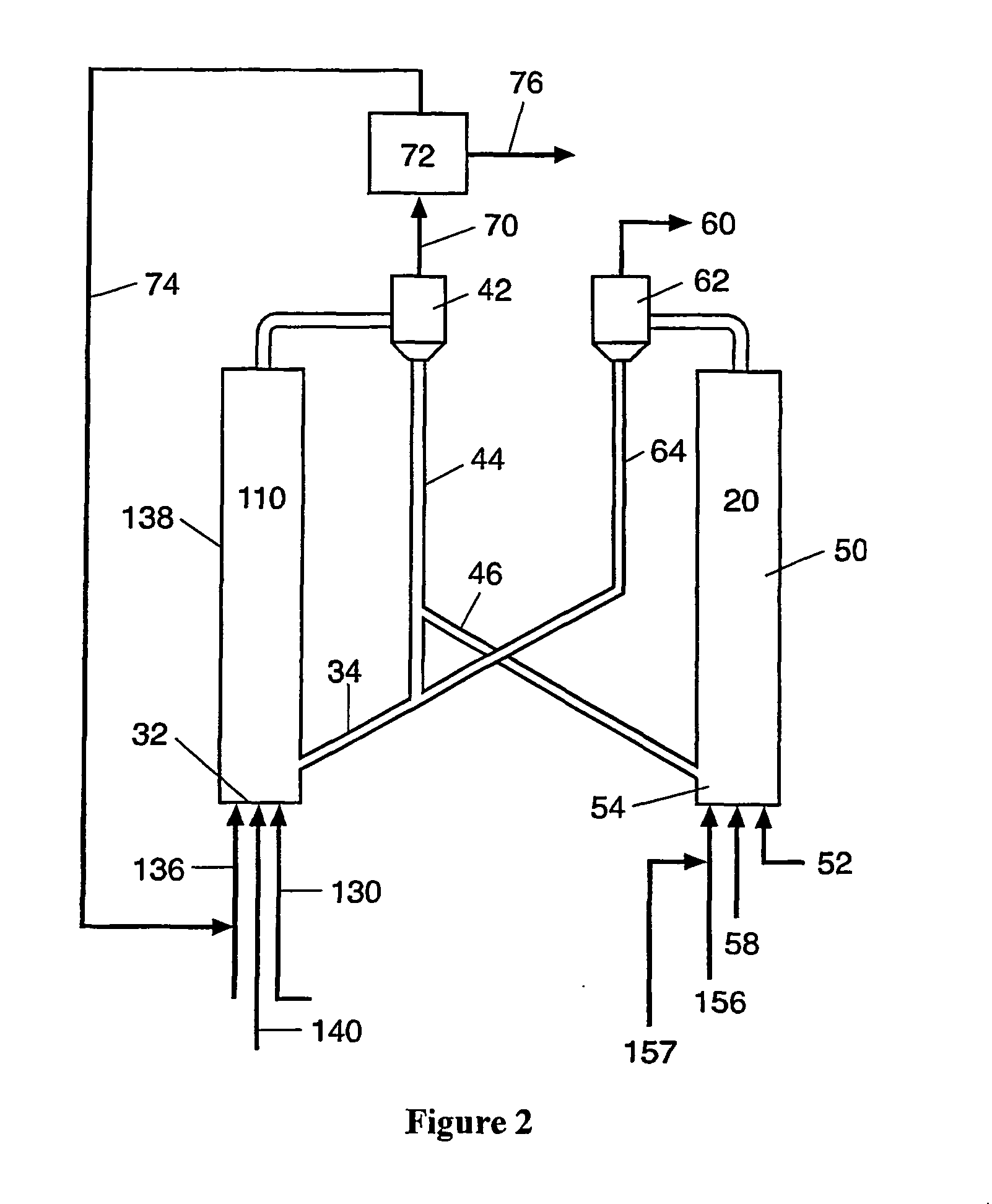

Process for desulfurizing hydrocarbon fuels and fuel components

InactiveUS7291259B2Low costSubstantial sulfur removalCatalytic crackingHydrocarbon oils refiningSorbentHydrodesulfurization

Processes are disclosed for removing sulfur, including cyclic and polycyclic organic sulfur components such as thiophenes and benzothiophenes, from a hydrocarbon feedstock including fuels and fuel components. The feedstock is contacted with a regenerable sorbent material capable of selectively adsorbing the sulfur compounds present in the hydrocarbon feedstock in the absence of a hydrodesulfurization catalyst. In one embodiment, the sorbent can be an active metal oxide sulfur sorbent in combination with a refractory inorganic oxide cracking catalyst support. In another embodiment, the sorbent can be a metal-substituted refractory inorganic oxide cracking catalyst wherein the metal is a metal which is capable in its oxide form, of adsorption of reduced sulfur compounds by conversion of the metal oxide to a metal sulfide. The processes are preferably carried out in a transport bed reactor.

Owner:RES TRIANGLE INST

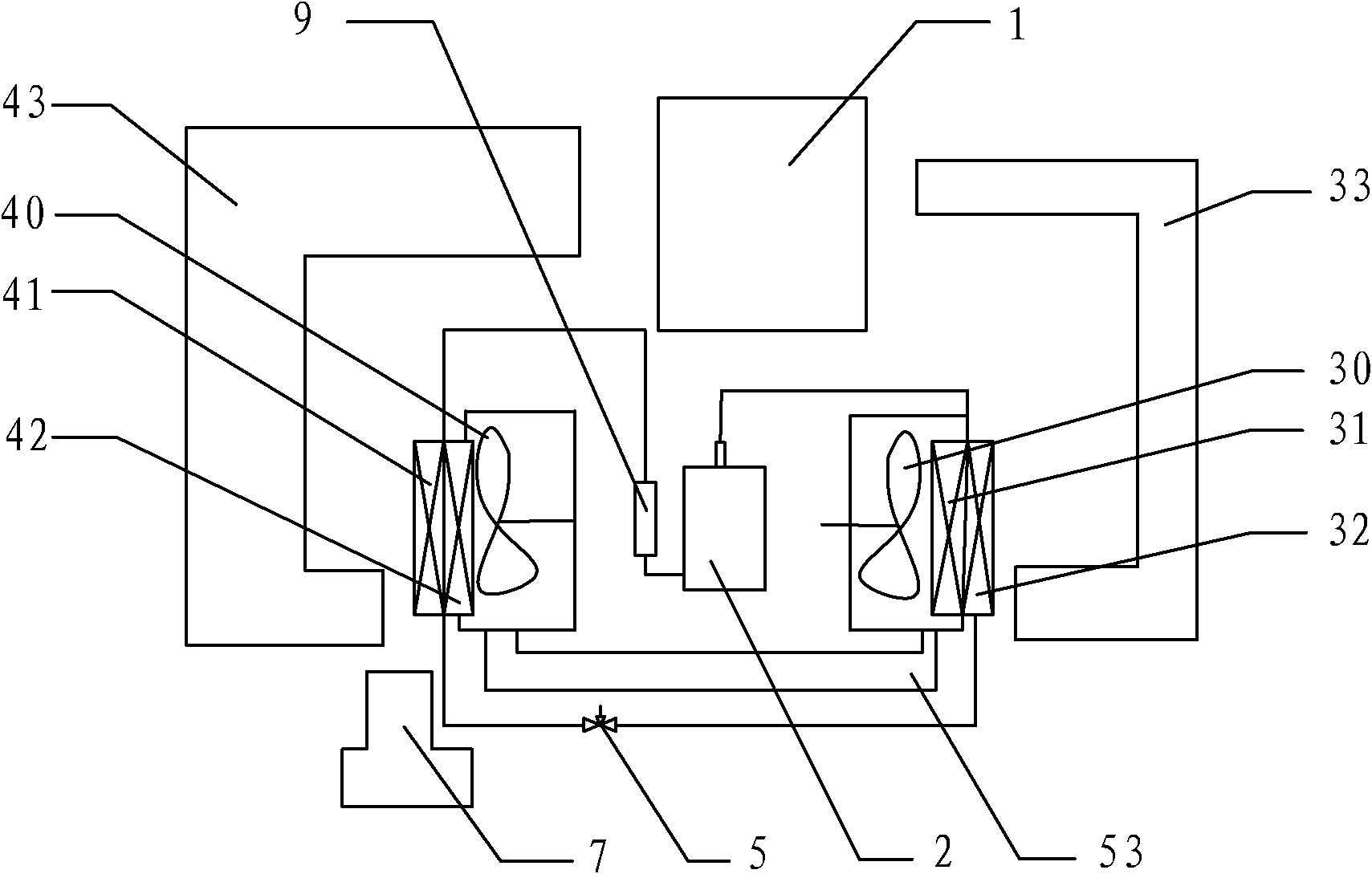

Heat pump type clothes dryer

ActiveCN102002843AReduce power consumptionAvoid scorchingTextiles and paperLaundry driersControl systemProcess engineering

The invention relates to a heat pump type clothes dryer which comprises a control system, a refrigeration system and an air circulation system, wherein the refrigeration system consists of a compressor, a condenser, an evaporator and a throttle valve, the air circulation system consists of a clothes drying barrel, an evaporator, an evaporator fan, a condenser, a condenser fan, a humid heat air flow passage, a low-temperature dry air flow passage and a dry air flow passage, the humid heat air flow passage is arranged between the clothes drying barrel and the evaporator, the low-temperature dry air flow passage is arranged between the evaporator and the condenser, the dry air flow passage is arranged between the condenser and the clothes drying barrel, the compressor is a variable-frequency compressor and comprise a first condenser and a second condenser group which are connected in series, and the output end of the first condenser is also provided with a by-pass pipeline so that refrigerants can selectively flow to the throttle valve through the by-pass pipeline. The heat pump type clothes dryer can be used for high temperature dehumidification in high moisture content, can be used for medium temperature dehumidification in low moisture content and has obvious energy saving effect.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

Polyurethane foam

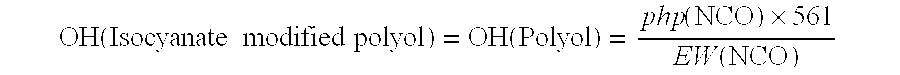

InactiveUS20100227151A1Low olfactory detection limitEliminate odorIsocyanic acid derivatives preparationOrganic compound preparationPolymer sciencePolyol

A method of making a polyurethane foam from a mixture of isocyanate modified polyol and foam-forming ingredients, wherein the isocyanate modified polyol is made by reacting at least one polyol with at least one multifunctional isocyanate, wherein the isocyanate modified polyol is a non-foamed polyol polymer having available OH groups, wherein the foam forming ingredients comprise at least a multifunctional isocyanate and a foaming agent, preferably water, and characterised in that (i) the at least one polyol from which the isocyanate modified polyol is made comprises at least one lipid-based polyol which has undergone reaction with the isocyanate in the presence of a PU gelation catalyst, and / or (ii) the isocyanate modified polyol is mixed with a lipid-based polyol prior to, or at the same time as, foaming.

Owner:GREEN URETHANES

Preparation method of crosslinked low density polyethylene (LDPE)

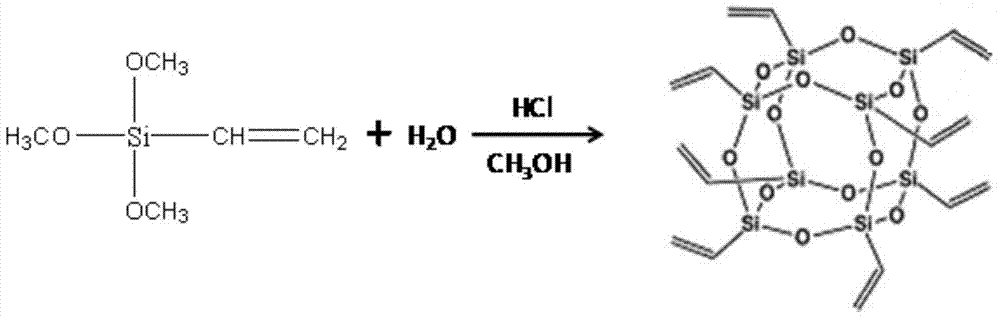

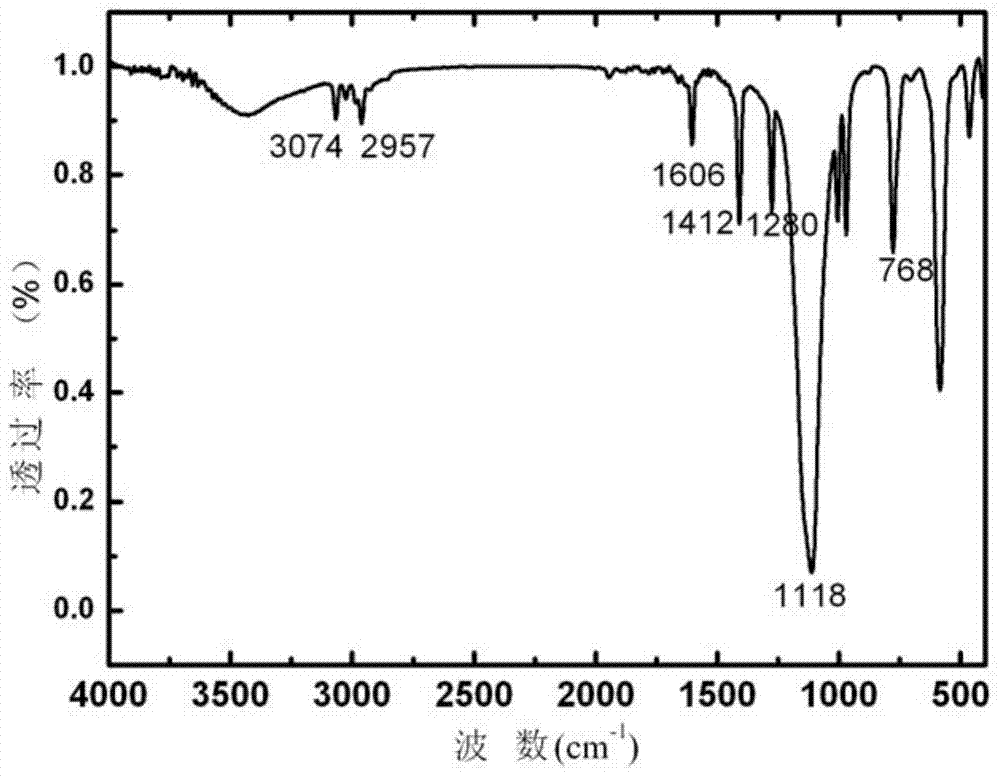

ActiveCN104277182ASimple processing technologyEasy to operatePlastic/resin/waxes insulatorsDecompositionPerformance requirement

The invention discloses a preparation method of crosslinked low density polyethylene (LDPE), which comprises the following step: under the condition of a free-radical initiator, carrying out crosslinking reaction on octafunctional cage-type oligomer silsesquioxane and LDPE to obtain the crosslinked LDPE. The crosslinked low density polyethylene is prepared from the following raw materials in percentage by mass: 98.5-99.6% of LDPE, 0.2-1% of octafunctional cage-type oligomer silsesquioxane and 0.2-0.5% of initiator. The functional group of the octafunctional cage-type oligomer silsesquioxane contains vinyl group. The invention also discloses a crosslinked LDPE prepared by the method and application thereof. By using the octafunctional cage-type oligomer silsesquioxane as the crosslinking agent, the peroxide crosslinking agent content in the traditional method is effectively lowered, thereby reducing the pores generated by chain-breaking reaction and peroxide decomposition. The prepared crosslinked LDPE has excellent mechanical properties and dielectric properties, and can satisfy the performance requirements for high-voltage cable materials.

Owner:ZHEJIANG UNIV

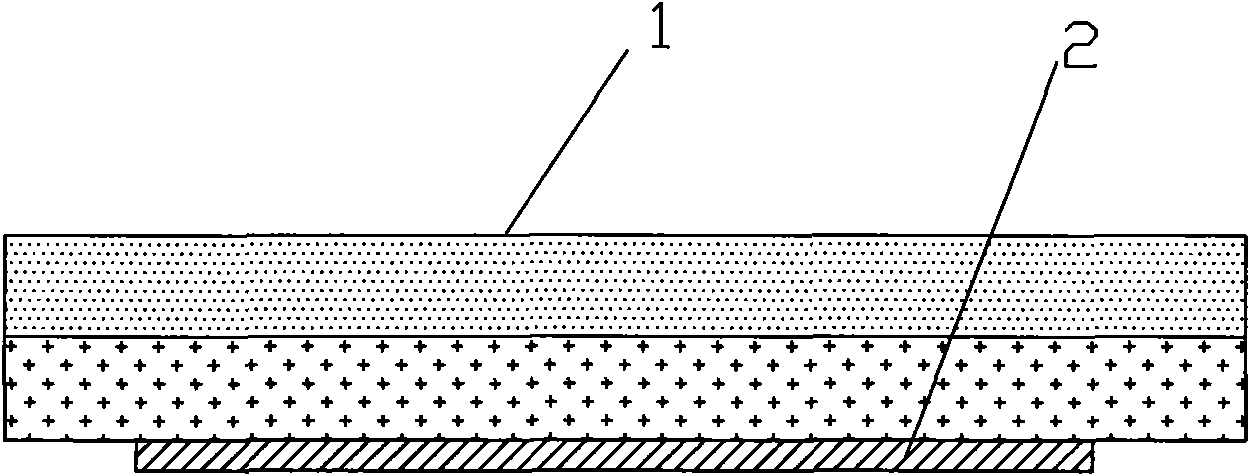

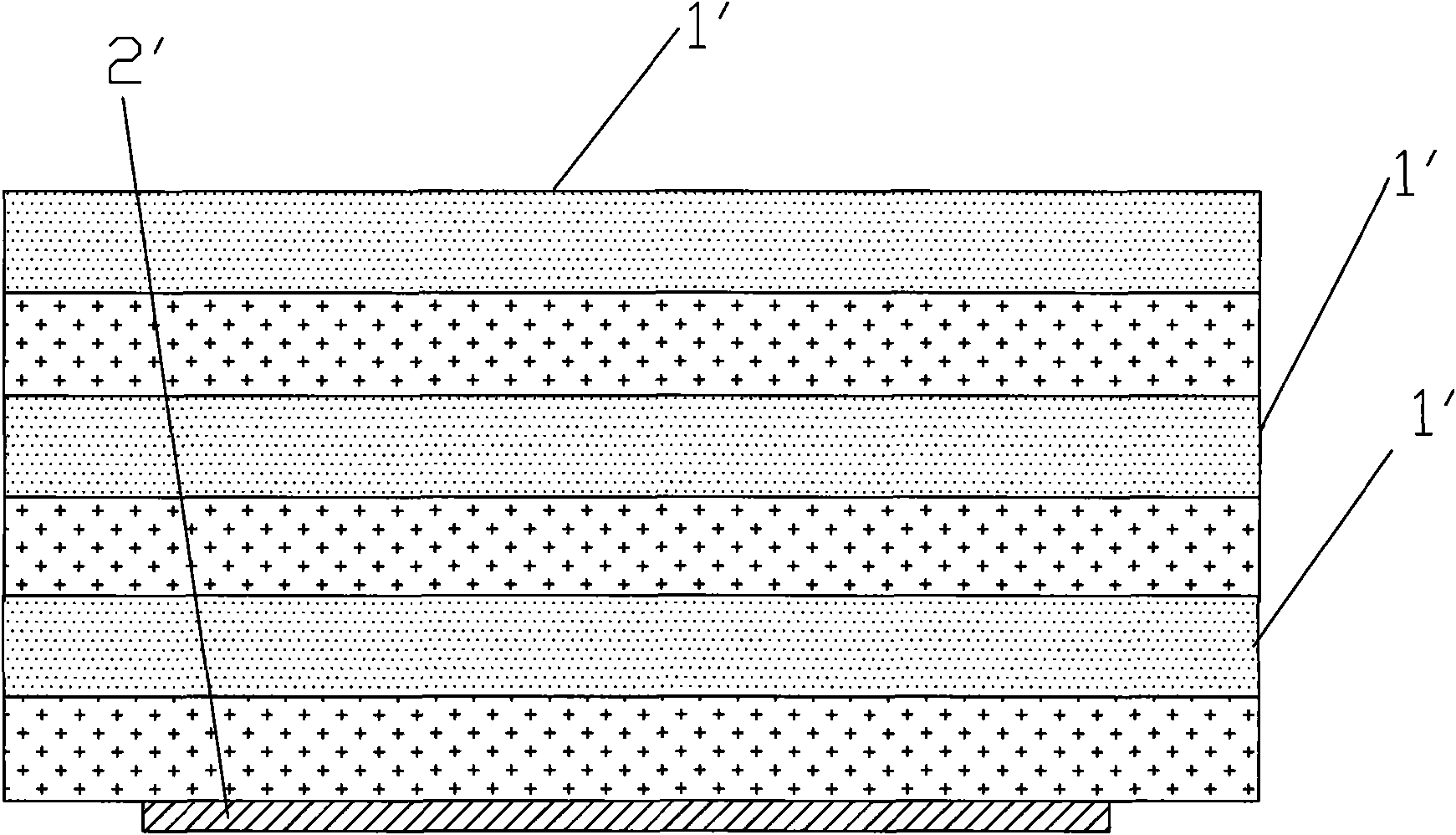

Novel electrical heating unit

InactiveCN102045900AGood thermal conductivityImprove heat utilizationOhmic-resistance heatingHeating filmAlumina ceramic

The invention relates to a novel electrical heating unit which at least comprises a substrate and an electrical heating film attached to the substrate, wherein the at least one substrate is made of aluminum oxide ceramics; the aluminum oxide ceramic substrate is in a plane-shaped structure; and at least one electrical heating film is attached to at least one surface of the aluminum oxide ceramic substrate. Thus, the electrical heating films can generate heat on one surface of the substrate, on which the electrical heating film is arranged, and the heat is evenly generated from the attached surface and transmitted through the aluminum oxide ceramic substrate so as to generate uniform heating effect.

Owner:潘洁英

Process for separating pitch from slurry hydrocracked vacuum gas oil

InactiveUS8540870B2Easy to manageLess stickyWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by solidifying/disintegratingParticulatesSlurry

A process is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a particulate solid material to form a heavy hydrocarbon slurry and hydrocracked in a slurry hydrocracking unit to produce vacuum gas oil (VGO) and pitch. A first vacuum column separates VGO from pitch, and a second vacuum column further separates VGO from pitch. As much as 15 wt-% of VGO can be recovered by the second vacuum column and recycled to the slurry hydrocracking unit. A pitch composition is obtained which can be made into particles and transported without sticking together.

Owner:UOP LLC

High-strength tear-resistant modified cable material and preparation method thereof

The invention discloses a high-strength tear-resistant modified cable material. The high-strength tear-resistant modified cable material comprises the following raw materials in part by weight: 36-42 parts of polyurethane rubber, 52-56 parts of butadiene-vinylpyridine rubber, 6-9 parts of hydrogenated nitrile rubber, 10-13 parts of nano-cellulose whisker, 1.8-2.2 parts of silane coupling agent A-151, 2-2.5 parts of sulphur, 1.1-1.4 parts of accelerant TMTD (tetramethyl thiuram disulfide), 1.5-1.8 parts of accelerant AC, 7-8 parts of light calcium carbonate, 5-6 parts of modified graphene, 24-28 parts of hard clay, 20-23 parts of mica powder, 2-3 parts of diethyl phthalate DEP, 3-5 parts of epoxy butyl oleate, 2-3 parts of pentaerythritol fatty acid ester, 2.3-2.6 parts of melamine phosphate, 8-11 parts of microencapsulated red phosphorus, 11-14 parts of zinc borate, 1.5-1.8 parts of anti-aging agent ODA and 0.9-1.2 parts of anti-aging agent DFC-34. The invention discloses a preparation method of the high-strength tear-resistant modified cable material.

Owner:ANHUI ELECTRIC GRP SHARES

Domestic intelligent electric oven

InactiveCN106943034AImprove the baking effectImprove job stabilityRoasters/grillsAutomatic controlEngineering

The invention discloses a household intelligent electric oven, which comprises a box body, an insulation layer is arranged on the outer wall of the box body, and a partition board is horizontally arranged on the lower side inside the box body, and the partition board divides the box body into a baking cavity on the upper side and a baking chamber on the upper side. In the installation cavity on the lower side, a turntable is horizontally arranged at the center of the lower side of the box body, and a circular groove is opened at the center of the upper surface of the turntable. The limiting protrusion of the household electric oven of the present invention can effectively eliminate oil fume and reduce pollution during the baking process, can automatically control the baking temperature, improve the baking effect, and drive the food to rotate at a uniform speed during baking, so that The food is baked more evenly. Infrared heating and hot air are used for baking, which improves the baking efficiency, effectively reduces shock, improves stability, and improves the efficiency of heat use, avoids heat loss, and saves energy.

Owner:湖南鸣腾智能科技有限公司

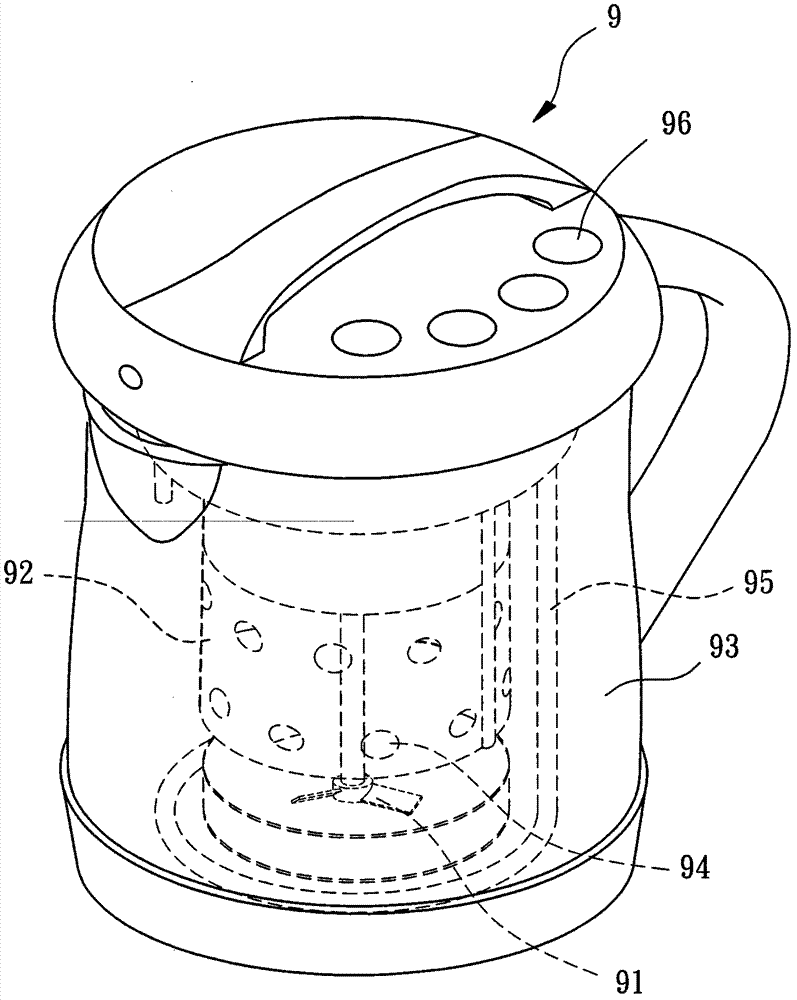

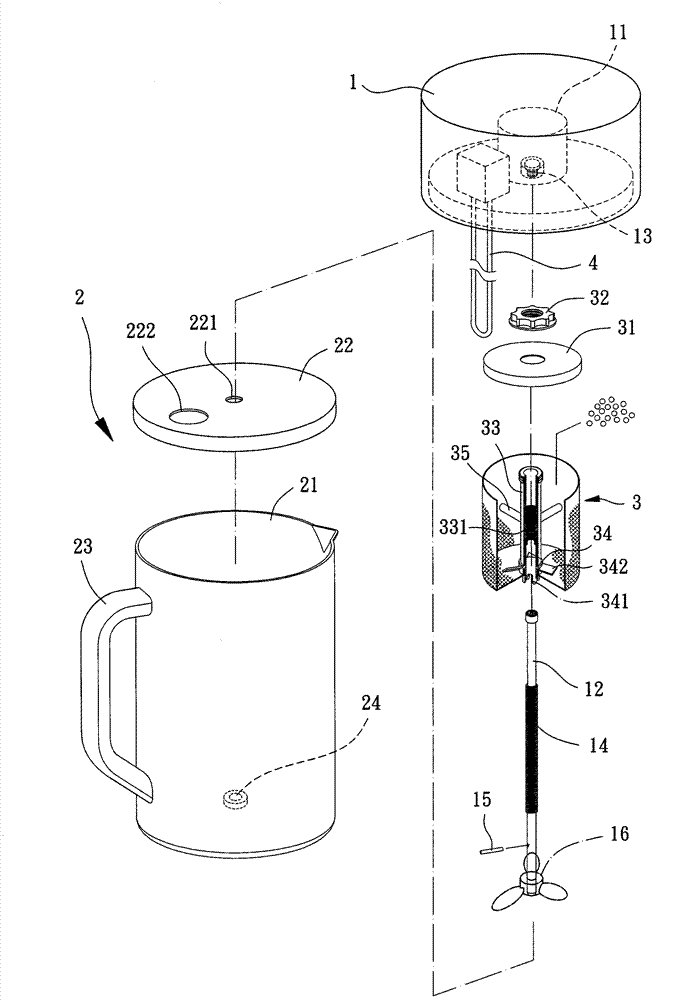

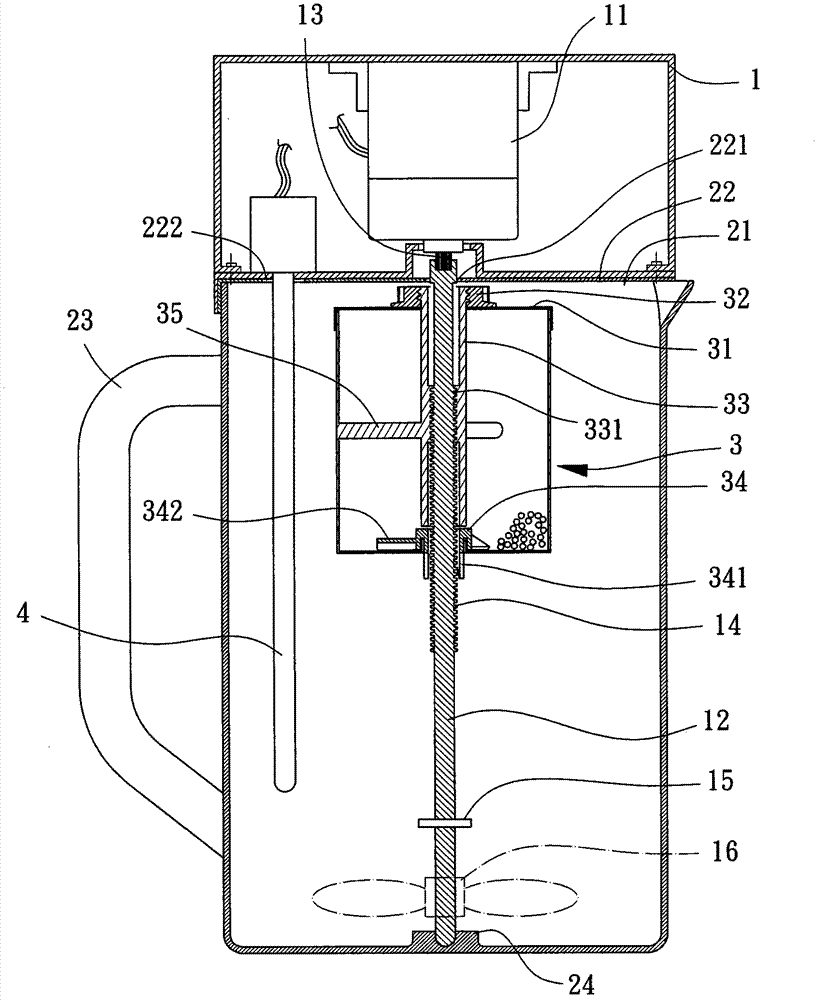

Scum juice separator and food ingredient processing method

A scum juice separator comprises a base, a container and a scum collecting member, wherein the base is provided with a power element to drive a rotating shaft to rotate, and a threaded part and a driving part are arranged on the rotating shaft; the container is provided with an opening jointed with the base, and the container is capable of holding or collecting liquid or juice; the scum collecting member is made of a liquid permeable material, and is provided with a shaft tube and a rotary member; the shaft tube is provided with internal threads so as to be screwed down with or detached from the threaded part of the rotating shaft; and the rotary member is capable of rotating in relation to the rotating shaft, or the rotary member is engaged with the driving part through an engagement part to form synchronous rotation. A method for using the device comprises a crushing step of crushing food ingredients to generate crushed pieces, and a displacement step of moving the crushed pieces of the food ingredients in the scum juice separator to obtain processed food ingredients. With the scum juice separator, solid-liquid separation of the food ingredients and subsequent processing of the food ingredients can be realized; and the effect of finishing the processing of the food ingredients in predetermined time can be achieved.

Owner:陈建荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com