Fuel cell membrane electrode using polymer superbhort fiber as hydrophobic agent and its preparing method

A fuel cell membrane and fuel cell technology, applied in the direction of fuel cells, battery electrodes, fuel cell components, etc., can solve the problems of reducing the three-phase reaction interface of the catalyst layer, increasing the resistance of the membrane electrode, reducing the life of the membrane electrode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

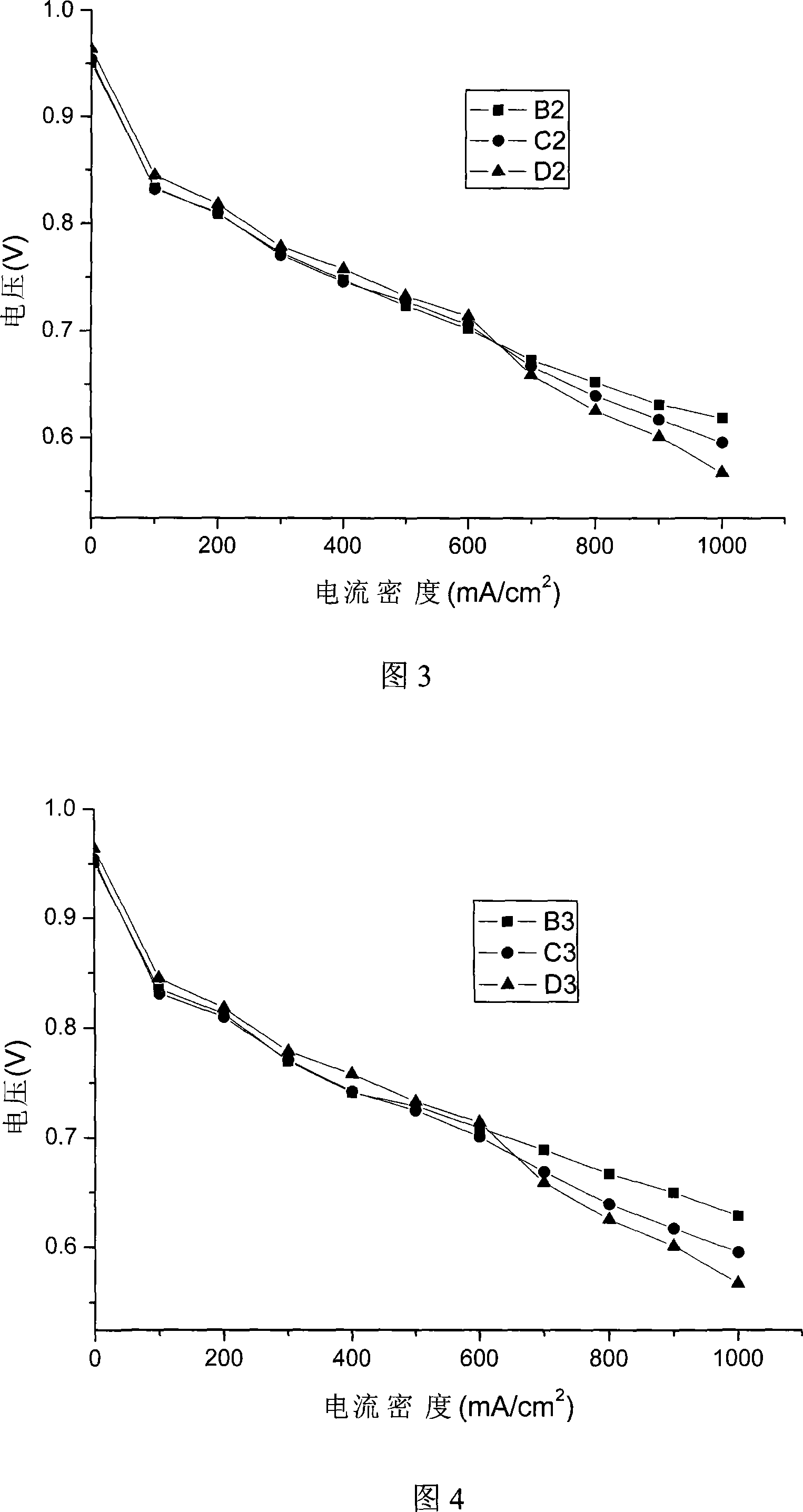

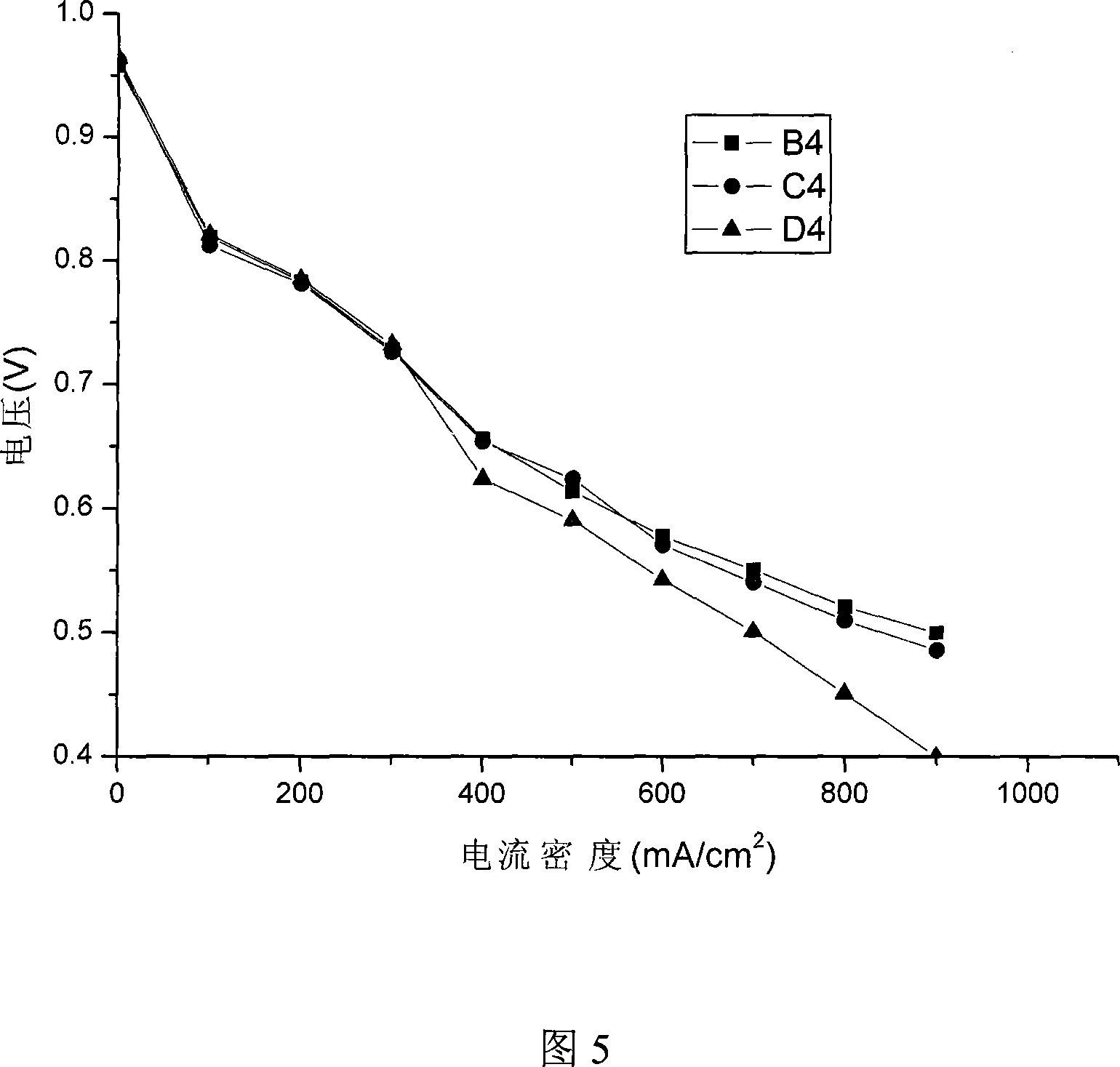

[0036] Preparation of Fuel Cell Membrane Electrode with PTFE Ultrashort Fiber as Hydrophobic Agent

[0037] The preparation steps are:

[0038] 1) Disperse 3 grams of Pt / C (40wt%) catalyst in 10 grams of deionized water, add 20 grams of 5wt% perfluorosulfonic acid tree finger (Nafion ®, produced by U.S. Du Pont Company) solution, use under vacuum condition Disperse with a high-speed mixer (10,000 rpm) for 50 minutes to prepare a catalyst-electrolyte dispersion;

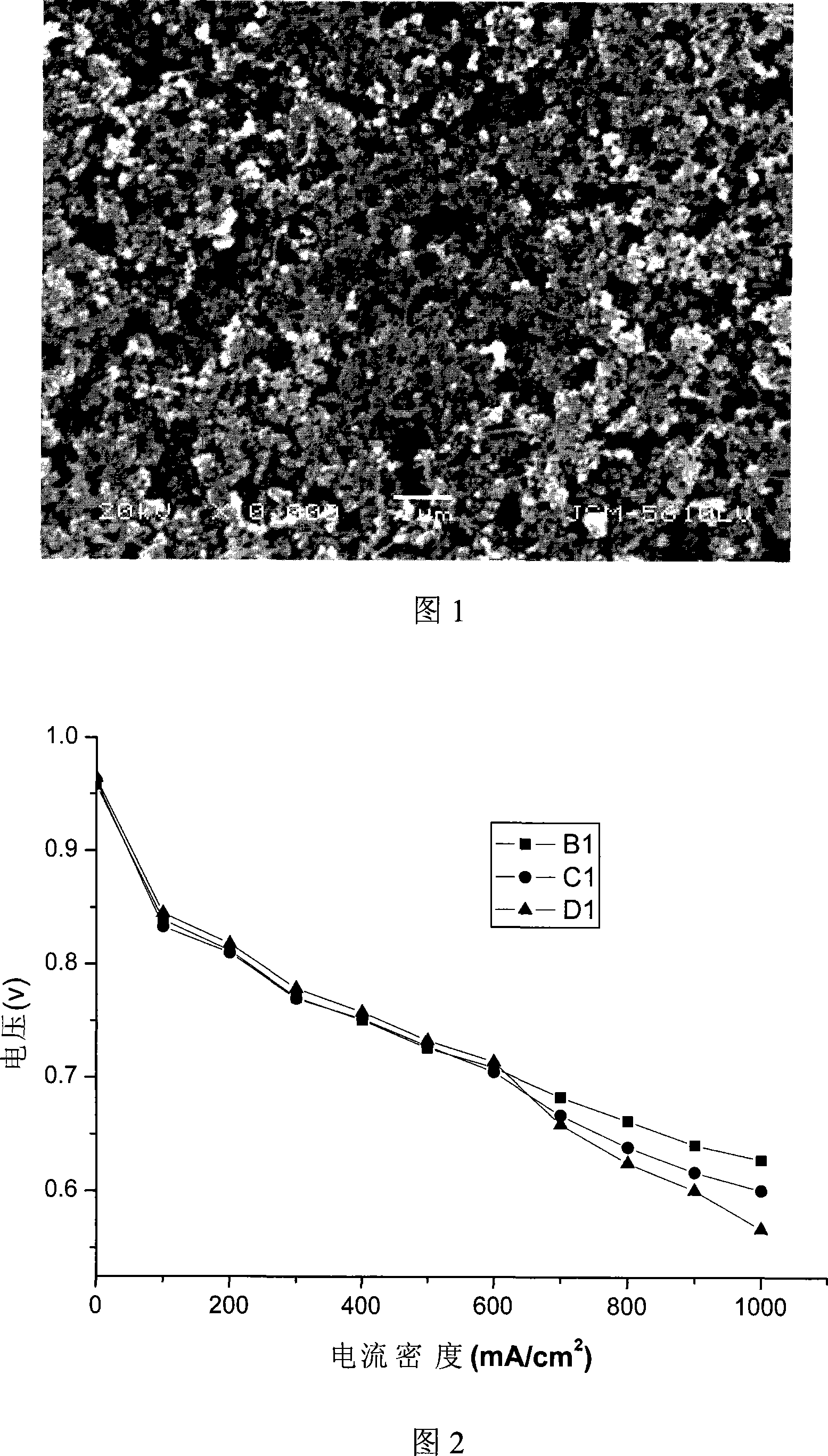

[0039] 2) 0.3 gram of PTFE ultra-short fiber is added to 3 grams of deionized water, 30 mg of sodium polyphosphate dispersant is added, and a high-speed mixer is used to disperse (10,000 rpm) for 30 minutes to obtain a PTFE ultra-short fiber dispersion, super The diameter of short fibers is 0.05-0.1 microns, and the fiber length is 25-50 microns;

[0040] 3) adding the prepared PTFE ultra-short fiber dispersion into the catalyst-electrolyte dispersion, and dispersing (10,000 rpm) in a high-speed mixer under vacuum f...

Embodiment 2

[0046] Preparation of Fuel Cell Membrane Electrode with PP Ultrashort Fiber as Hydrophobic Agent

[0047] The preparation steps are:

[0048] 1) Disperse 3 grams of Pt / C (40wt%) catalyst in 40 grams of isopropanol, add 30 grams of 5wt% perfluorosulfonic acid resin solution (Nafion ®, produced by U.S. Du Pont Company), and use Disperse with a high-speed mixer (10,000 rpm) for 55 minutes to obtain a catalyst-electrolyte dispersion;

[0049] 2) Add 0.15 g of PP ultra-short fibers to 7.5 g of isopropanol, add 45 mg of sodium polyacrylate dispersant and disperse with a high-speed mixer (10,000 rpm) for 30 minutes to obtain a polymer ultra-short fiber dispersion, The diameter of the ultra-short fiber is 0.1-1 micron, and the fiber length is 100-500 micron;

[0050] 3) Add the prepared PP ultra-short fiber dispersion to the catalyst-electrolyte dispersion, and disperse it with a high-speed mixer (10,000 rpm) for 30 minutes under vacuum conditions to prepare a catalyst slurry;

[0...

Embodiment 3

[0056] Preparation of Fuel Cell Membrane Electrode Using PET Ultrashort Fiber as Hydrophobic Agent

[0057] The preparation steps are:

[0058] 1), the preparation of the catalyst-electrolyte dispersion is the same as in Example 1, except that the solvent is an aqueous alcohol solution, the mass ratio of alcohol to water is 1:100, and the catalyst is PtCr / C (Pt:Cr=1:1);

[0059] 2), 0.3 grams of PET ultra-short fibers were added to 15 grams of deionized water, 90 mg of 30% sodium polyphosphate + 70% sodium polyacrylate compound was added, and a high-speed mixer was used to disperse (10,000 rpm) for 40 minutes. A polymer ultra-short fiber dispersion is prepared; the diameter of the ultra-short fiber is 0.01-0.05 microns, and the fiber length is 1-26 microns;

[0060] 3), adding the prepared PET ultra-short fiber dispersion into the catalyst-electrolyte dispersion, and dispersing (10,000 rpm) in a high-speed mixer under vacuum for 30 minutes to prepare a catalyst slurry;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com