Patents

Literature

220 results about "Reflective crack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Reflective crack is a type of failure in asphalt pavement, one of the most popular road surface types. Asphalt pavement is impacted by traffic and thermal loading. Due to loading, cracks can appear on pavement surface that can reduce the Pavement Condition Index(PCI) dramatically.

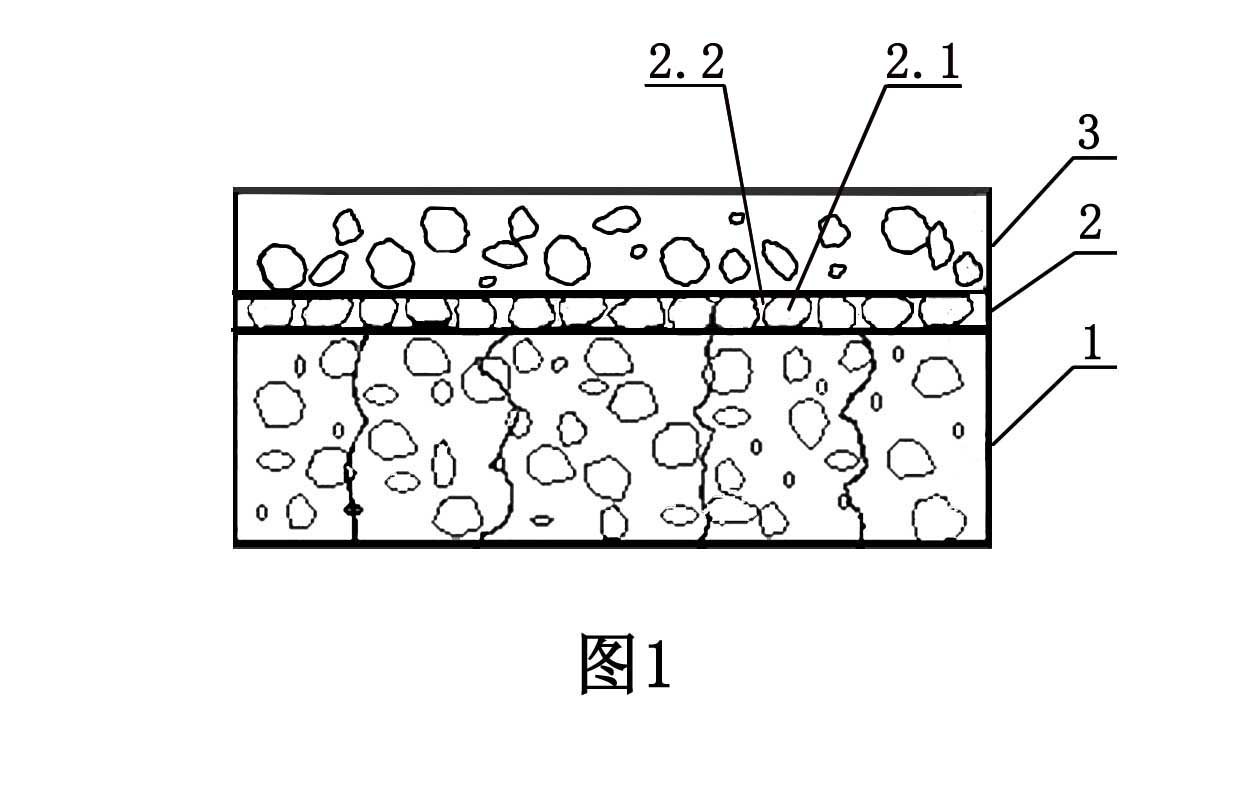

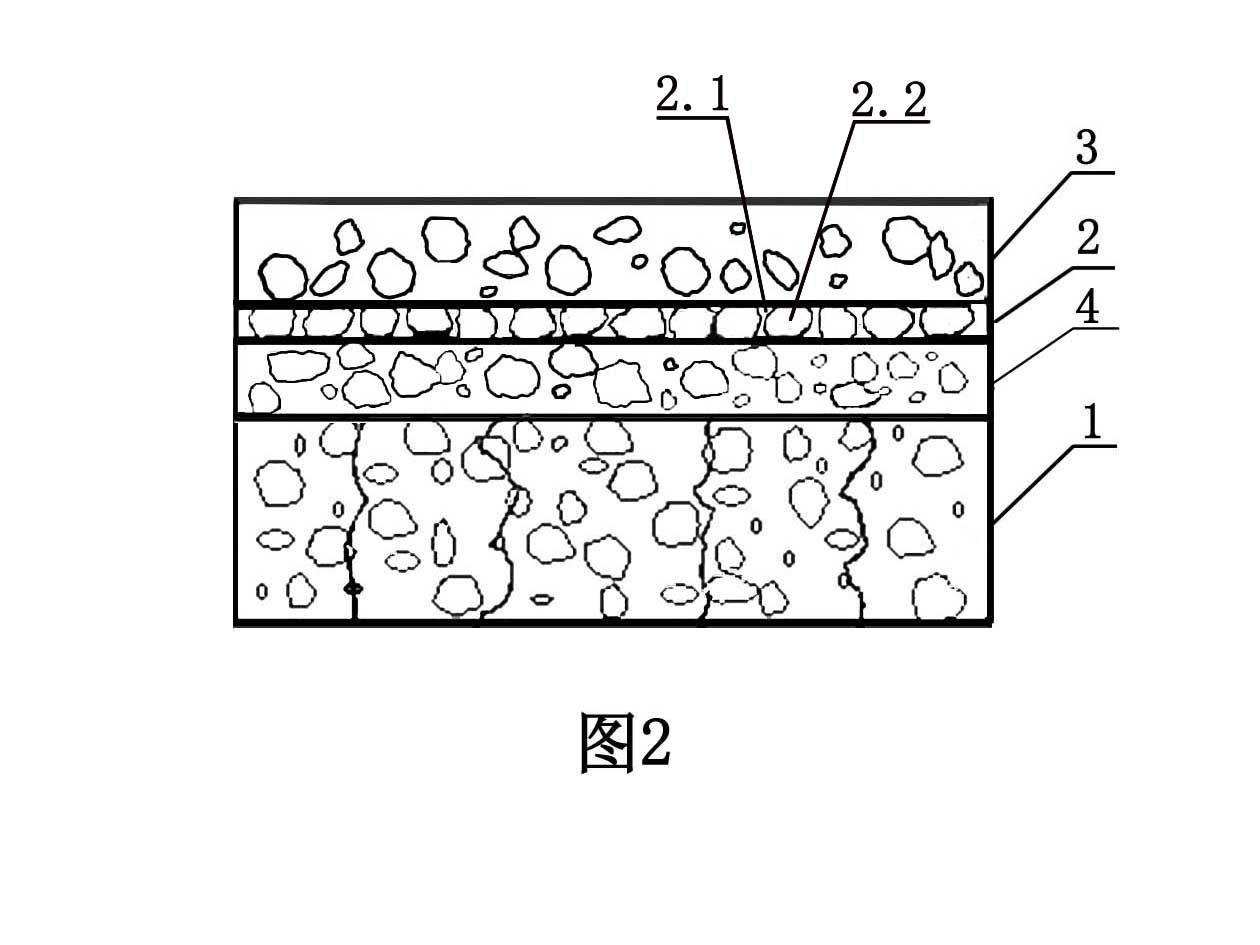

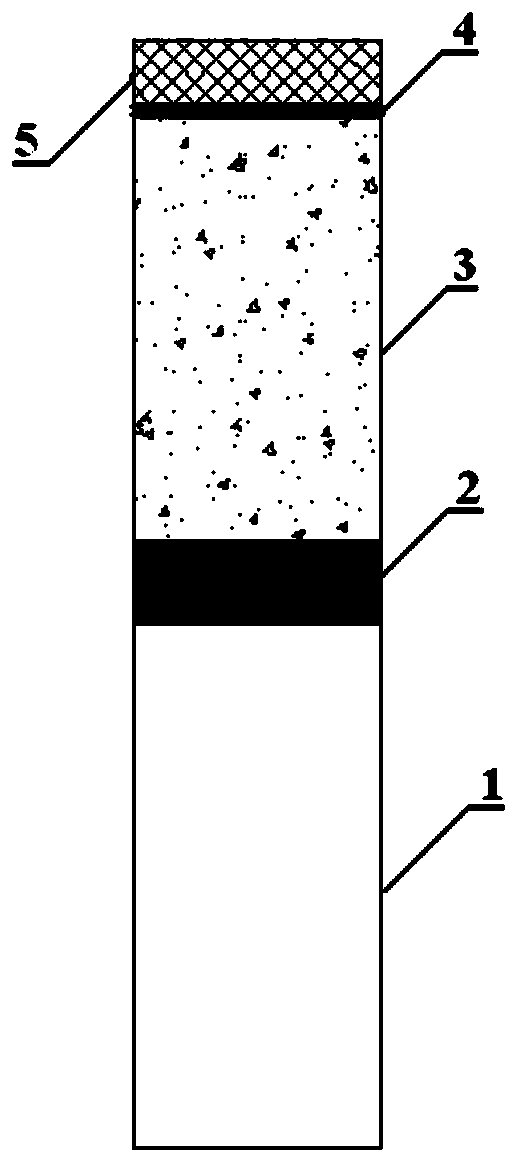

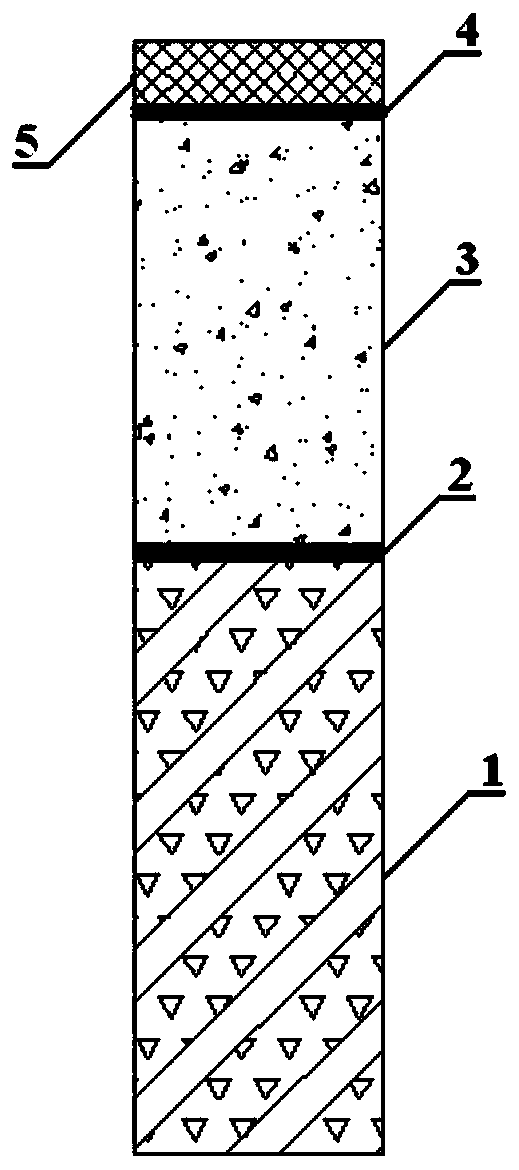

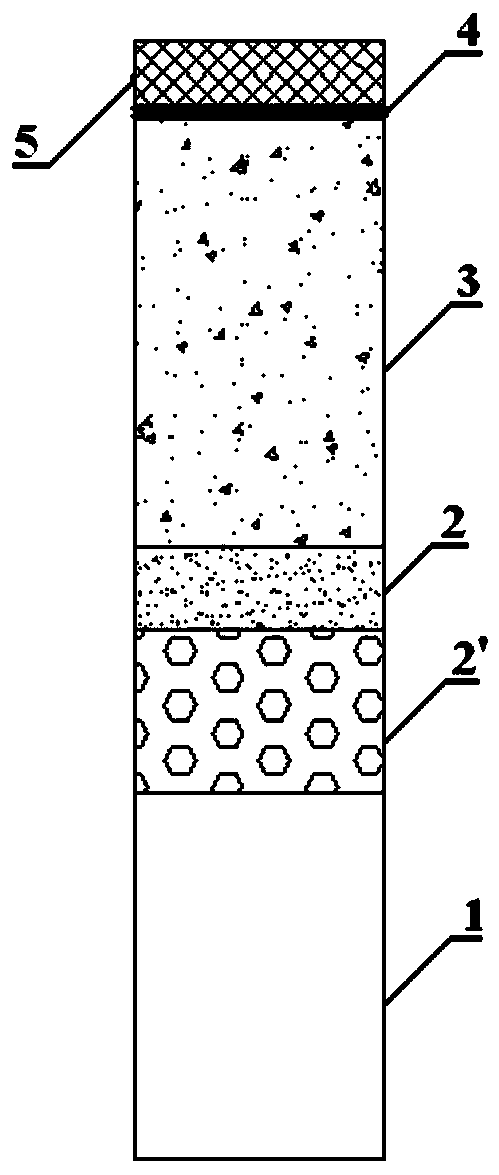

Asphalt macadam stress absorption layer and construction method thereof

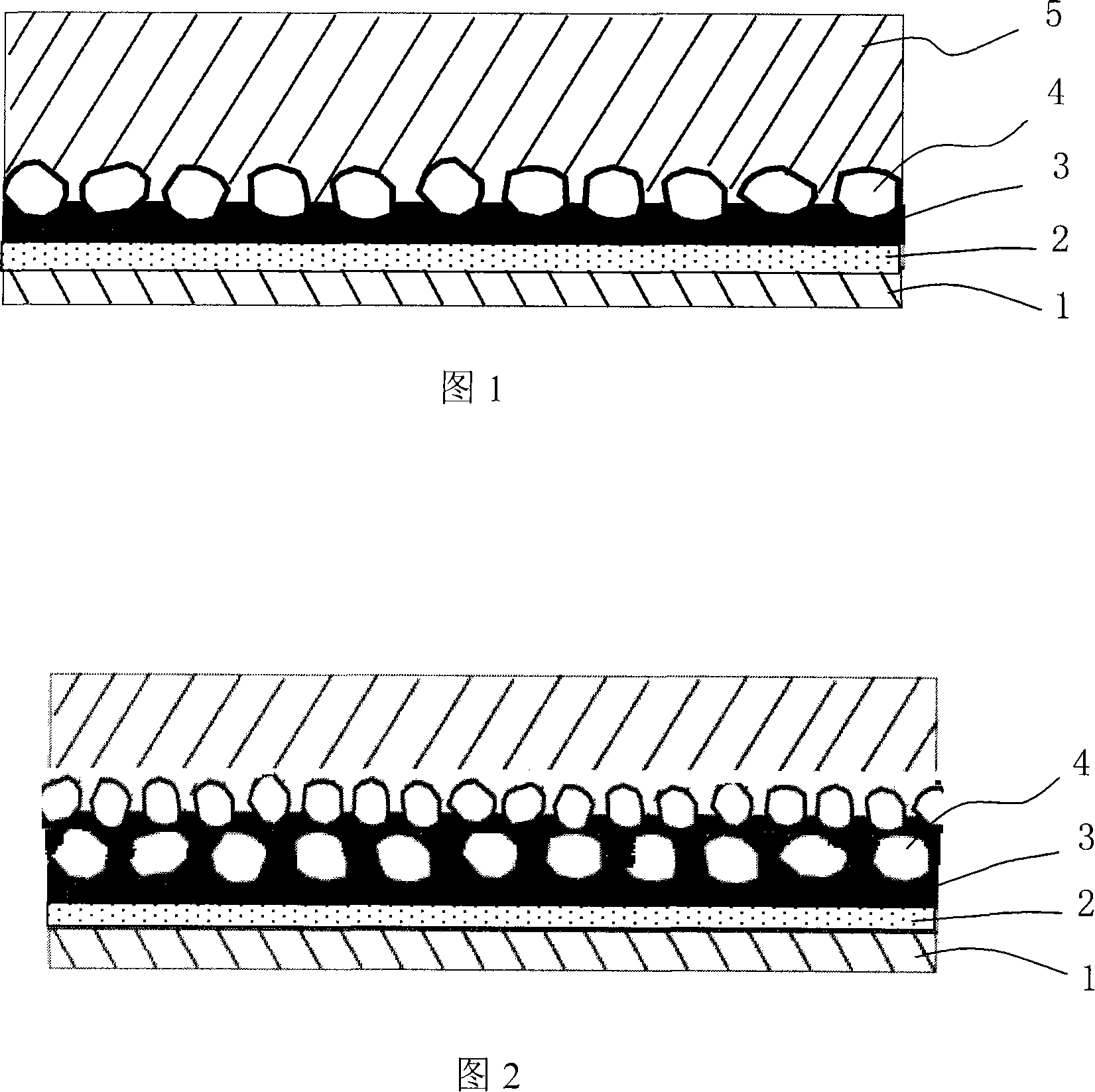

InactiveCN101148856AStress Absorption and ReductionEasy to useIn situ pavingsPolymer modifiedChipseal

The present invention relates to asphalt road engineering, and is especially one stress absorbing asphalt macadam layer and its construction process. The stress absorbing asphalt macadam layer can absorb and reduce the stress of asphalt road surface or composite road surface and weaken the transmission of cracks to the surface asphalt layer. It consists of one macadam layer, one stress absorbing and binding layer and one connecting layer from top to bottom. Its construction process includes the steps of spreading connecting layer material onto the base layer, spreading the stress absorbing and binding layer and spreading the macadam layer. The stress absorbing and binding layer has material of polymer modified emulsified asphalt, high viscosity emulsified asphalt, hot SBS modified asphalt or rubber modified asphalt; and the connecting layer has material of kerosene diluted asphalt, high permeability emulsified asphalt, concrete interface adhesive, polymer modified emulsified asphalt or hot modified asphalt.

Owner:徐培华

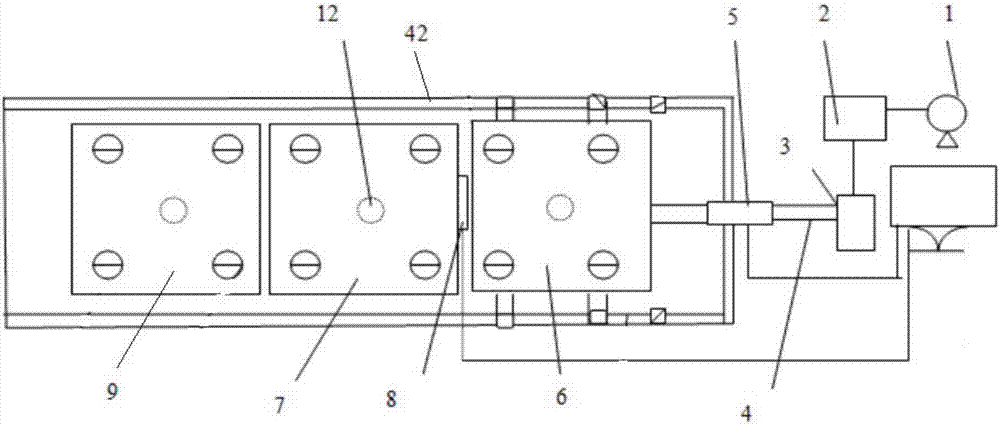

Asphalt pavement reflection crack propagation analog experiment device

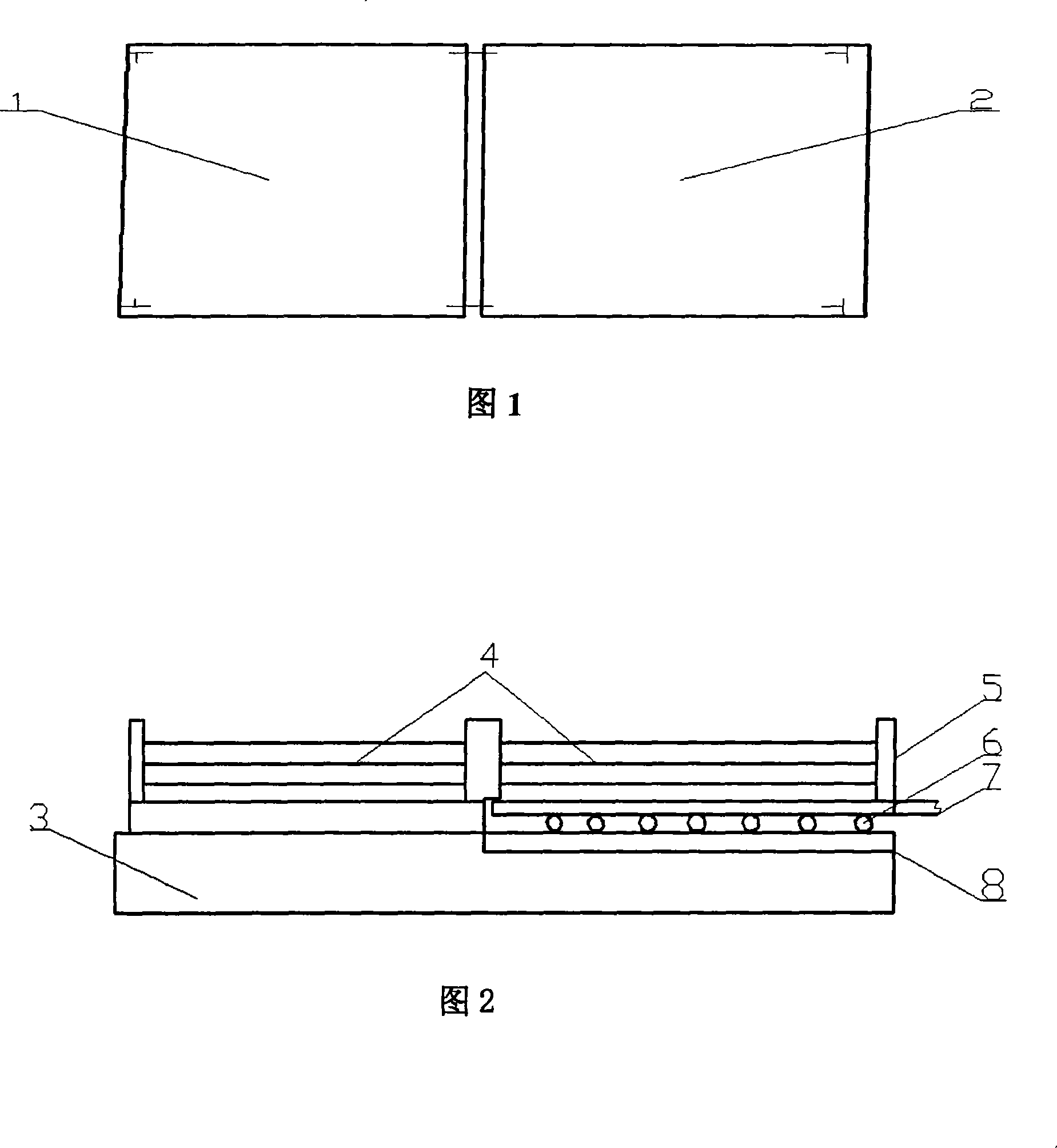

InactiveCN101178340AGuaranteed molding effectEasy to study crack resistanceMaterial testing goodsStrength propertiesMicrocomputerTester device

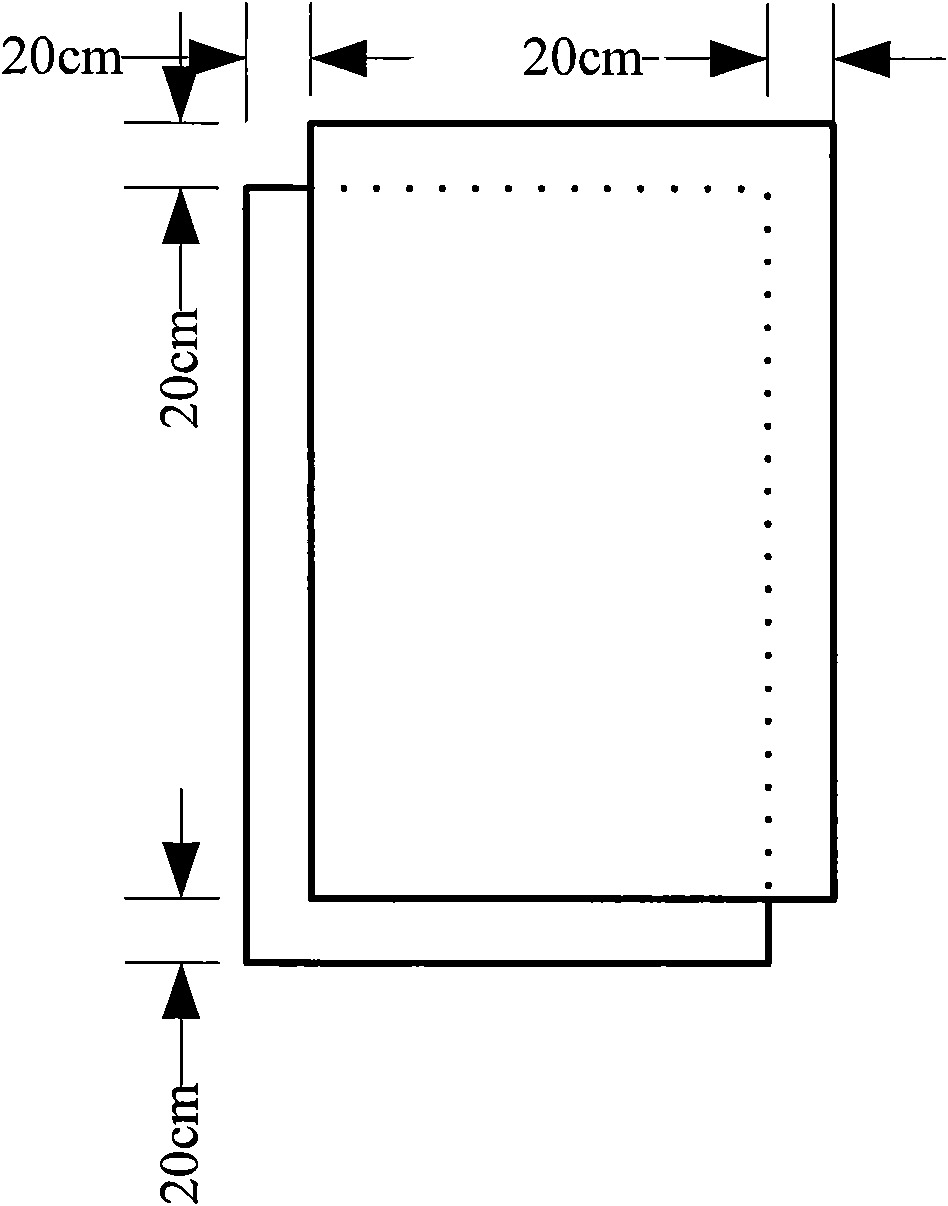

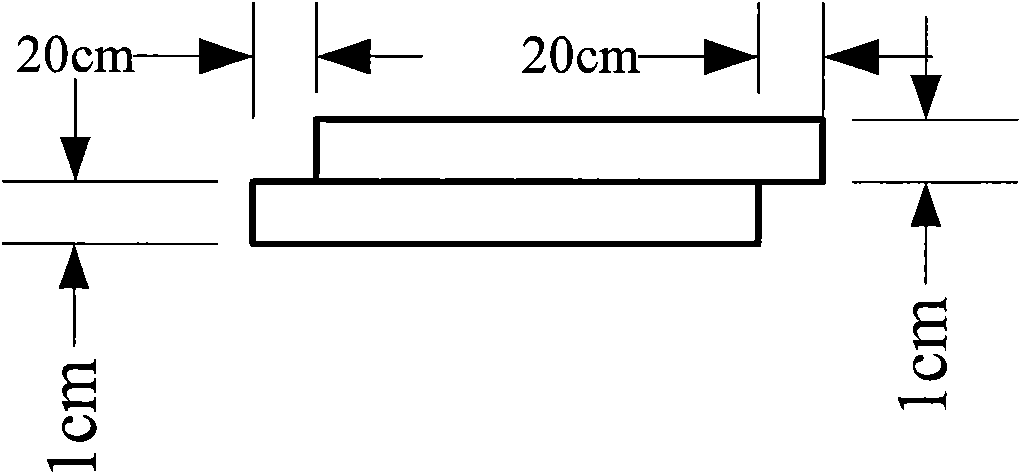

The invention discloses a blacktop reflecting crack propagation analog experiment device which includes an environment box and a blacktop simulative platform and a reflecting crack propagation tester arranged in the environment box. The reflecting crack propagation tester includes a horizontal pulling fatigue test part, a vertical cutting fatigue test part and a data collecting part controlled by a microcomputer. The blacktop simulative platform includes a fixed testing vehicle (1) and a skip car frame (3) welded as a whole, and an active testing skip car (2) that can move horizontally on the skip car frame (3). The device can carry through pulling type and cutting type reflecting crack propagation expanding large scale dimension road structure experiment, analyze and compare the anti-crack effects of different blacktop structures or materials, acquire relevant calculating parameters and verify a theoretical calculating result, and provide a reliable testing basis for the blacktop structure design.

Owner:CHANGAN UNIV

Polymer modified asphalt emulsions for treatment of road surfaces

InactiveUS20030215286A1Low costIncrease flexibilityIn situ pavingsPaving detailsPolymer modifiedPolymer science

A composition for rejuvenating asphalt pavement according to the present invention comprises an asphalt binder, water, a cationic surfactant, a recycling agent, and a cationic, co-agglomerated styrene butadiene rubber latex, which includes sulfur and a vulcanizing agent. The composition is also useful as a scrub seal, fog seal, sand seal as well as for crack filling and the prevention of reflective cracking. The inventive composition may be used in emulsions with different setup times. The invention also includes a method for treatment of aged and cracked asphalt by application of the disclosed compositions.

Owner:WESTERN EMULSIONS

Construction method of stress absorbing layer for road repairing

InactiveCN102535299AImprove low temperature ductilityImprove deformation abilityIn situ pavingsReflective crackCost (economic)

The invention relates to the technical field of road engineering, and discloses a construction method of a stress absorbing layer for road repairing. The construction method comprises the following steps of: carrying out high-speed shearing on substrate asphalt, a modifying agent and a stabilizing agent after being mixed uniformly to prepare modified asphalt; mixing coarse aggregate, fine aggregate, stuffing and the modified asphalt to prepare a stress absorbing mixture; paving the stress absorbing mixture on a road surface to be repaired, wherein the road surface to be repaired is subjected to purification treatment; and rolling to form the stress absorbing layer. The construction method disclosed by the invention has the advantages of mechanized operation, simplicity and convenience in construction process and low economic cost; the formed stress absorbing layer has the characteristics of high flexibility and high deformation restoring capacity, and can be used for effectively absorbing interlaminar stress produced during the paving of an asphalt surface layer on an old cement concrete road surface as well as weakening and delaying the transfer of contraction cracks and reflection cracks on the cement concrete road surface to the asphalt surface layer; and therefore road performance of the asphalt surface layer is improved, and service life of the asphalt surface layer is prolonged.

Owner:中国人民武装警察部队交通指挥部

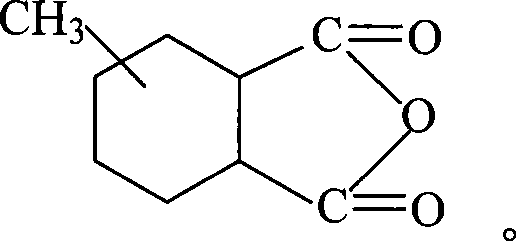

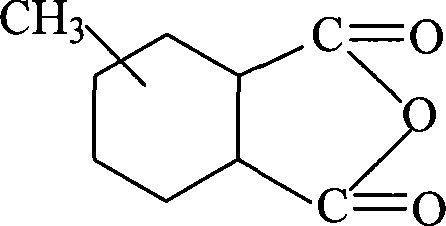

Asphalt modified by epoxy resin and rubber powder

InactiveCN101085871AGood high temperature resistance to fluidityImprove ductilityBuilding insulationsEpoxyPolymer science

The invention discloses a kind of modified asphalt with epoxy resin and rubber powder and solidifying agent. The weight proportion of said components is as follows: asphalt 100 units, rubber powder 3- 20 units, epoxy resin 1- 5 units, solidifying agent is 15% of that of epoxy resin. The penetration, softening point, low- temperature extension and torsional elasticity are better than that of normal asphalt. The modified asphalt is sticking material, and the flowability at high temperature and extension at low temperature is good. It can be used to repair asphalt concrete road surface and slow down the reflective crack generation, and increase life length for asphalt road.

Owner:GUANGDONG UNIV OF TECH

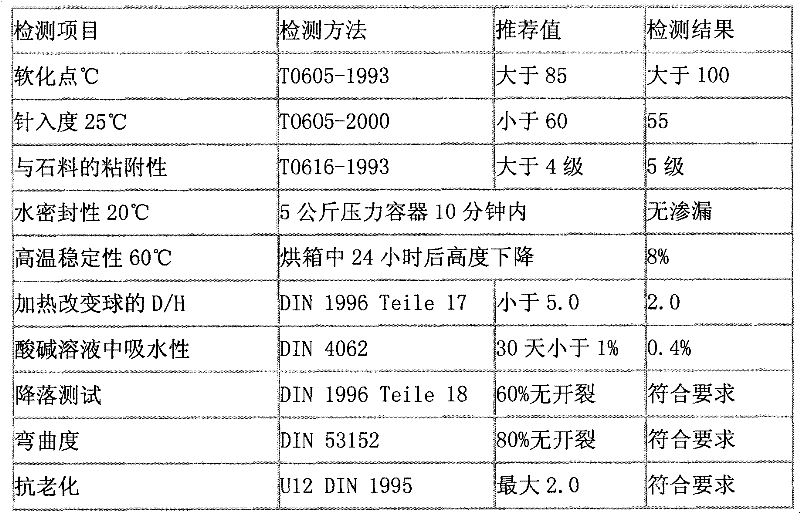

High-molecular polymer asphalt for road crack repair, manufacturing method and crack-bonding belt

The invention discloses high-molecular polymer asphalt for road crack repair, a manufacturing method and a crack-bonding belt. The high-molecular polymer asphalt for road crack repair comprises the following components by mass: 80-85% of AH-70A road petroleum asphalt; 6-8% of liquid star-shaped SBS asphalt modifier; 1-2% of diatomite; 0.3%-1.0% of polyacrylates; 0.8-1.2% of liquid rosin; 1.5-2.5% of C-5 petroleum resin; 0.9-1.5% of wood fiber; 2-3.5% of calcium hydroxide; 0.5-2.0% of asphalt anti-stripping agents. The high-molecular polymer asphalt of the invention is applicable to the treatment of various cracks of highways and urban roads including reflection cracks, and is also applicable to crack treatment before construction of seal coat overlay and the like; the crack treatment does not require heating, and the asphalt is self-adhered; the crack treatment is environment-friendly, requires no special equipment, no crack enlargement, and the asphalt can be stored at normal temperature.

Owner:DONGGUAN CHAOYI BUILDING MATERIAL CO LTD +1

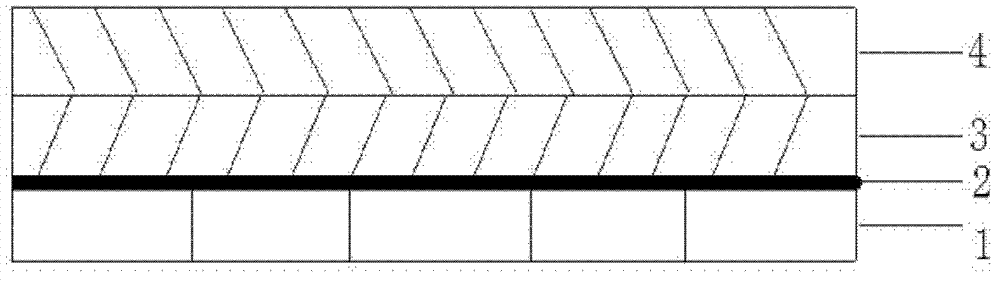

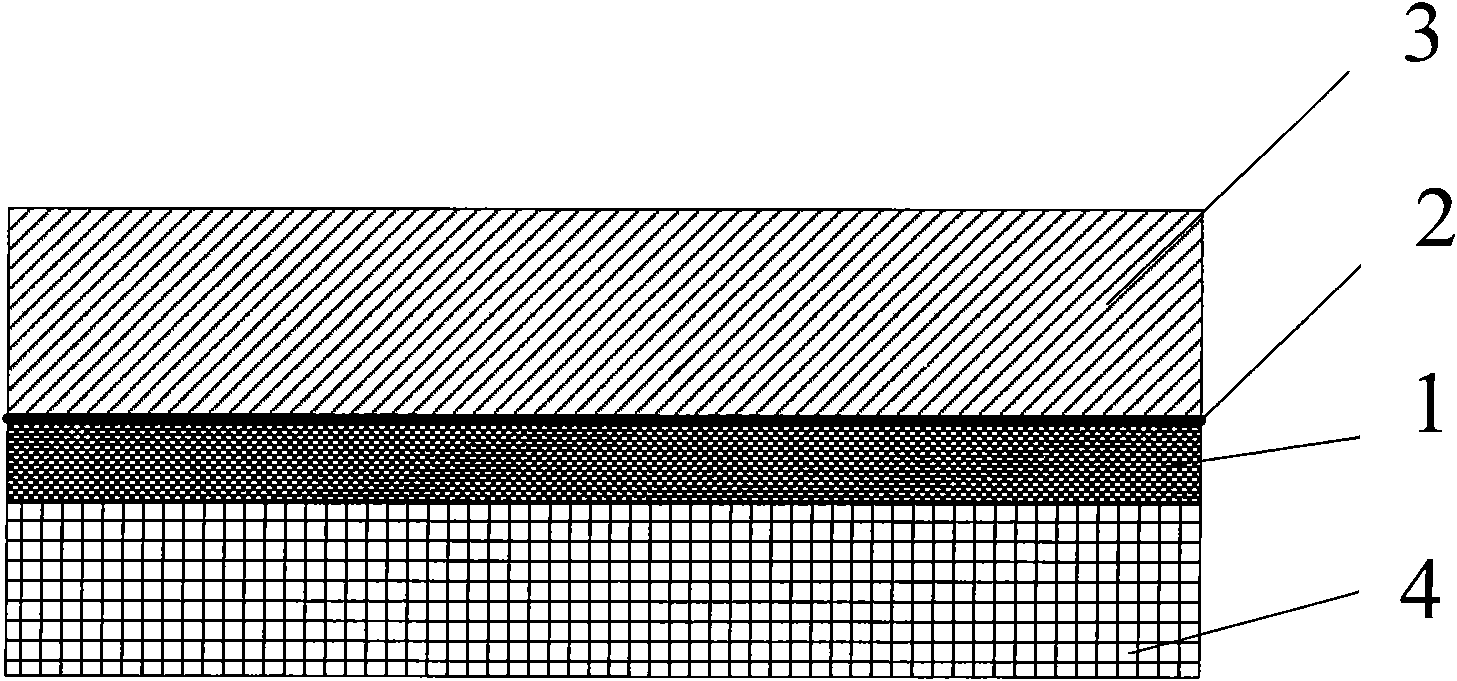

Double-layer rubber asphalt concrete structure for inhibiting reflection cracks of pavement and pavement method

ActiveCN102733284AGuaranteed against ruttingGuaranteed fatigue and other permanent deformation problemsIn situ pavingsCement boardRoad surface

The invention discloses a double-layer rubber asphalt concrete structure for inhibiting reflection cracks of a pavement, from the bottom up comprising a treated old cement concrete pavement, an anti-cracking tack coat, a lower surface adopting a special modified asphalt mixture, and an upper surface adopting a rubber asphalt mixture. The invention simultaneously discloses a pavement method of the double-layer rubber asphalt concrete structure, comprising the following steps: (a) firstly pasting an anti-cracking belt on the junction of adjacent cement boards, and then spraying modified emulsified asphalt tack coat oil with the thickness of 0.8-1.0 mm to form the anti-cracking tack coat; (b) then paving the special modified asphalt mixture with the paving thickness of 4-8 cm to form the lower surface; and (c) finally paving the rubber asphalt mixture to form the upper surface. According to the invention, the generation and extension of the reflection cracks can be effectively inhibited, and the service life and service condition of the pavement structure can be improved.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

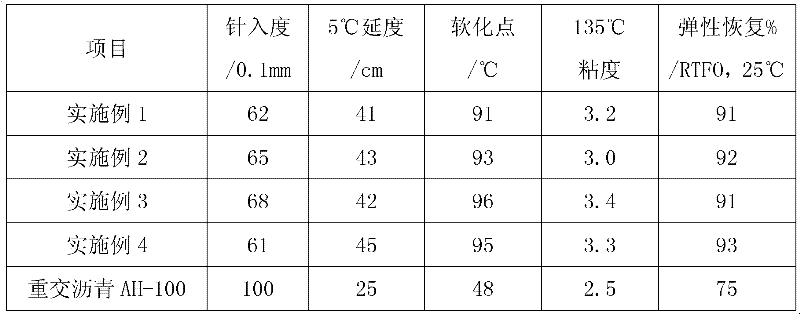

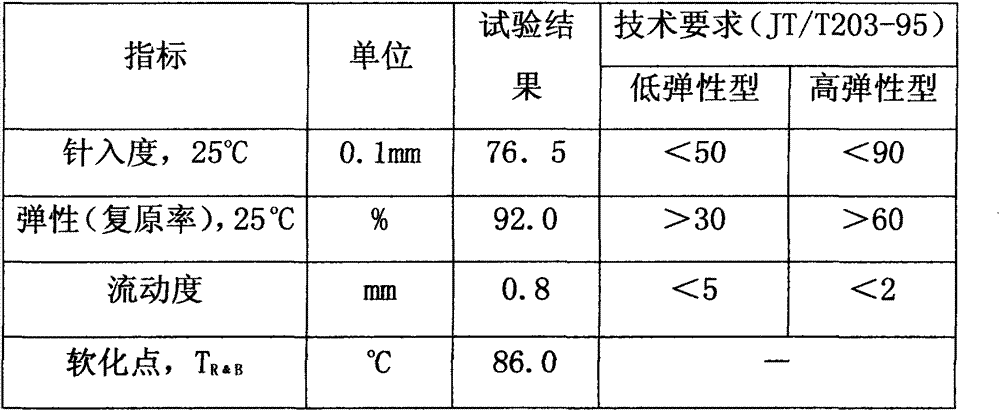

High-viscosity high-elasticity asphalt and preparation method thereof

ActiveCN101560332AImprove featuresSolve the problem of reflection crack diseaseBuilding insulationsPolymer scienceAsphalt

The invention discloses high-viscosity high-elasticity asphalt and a preparation method thereof. The high-viscosity high-elasticity asphalt is prepared from the following components by mass portion: 50 to 92 portions of asphalt matrix; 8 to 40 portions of additives and 0.1 to 12 portions of crosslinking agent, wherein the additives are rubber powder and styrene-butadiene-styrene block copolymer; the mass ratio of the rubber powder to the rubber powder and styrene-butadiene-styrene block copolymer is (0.5-35):(3-12); and the crosslinking agent is sulfur and natural asphalt; the mass ratio of the sulfur to the natural asphalt is 1:(0.1-20). The dynamic viscosity of the high-viscosity high-elasticity asphalt is 20,000 to 40,000 Pa.S at 60 DEG C; and the elastic recovery of the high-viscosity high-elasticity asphalt is greater than 90 percent at 25 DEG C. The modified asphalt can be used as a transition layer between a cracking structural layer and an asphalt surface coat / asphalt overlay to achieve the aims of dispersing and absorbing concentrated stress at crack tips, thereby solving the problem of reflection crack diseases.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Hot-distribution rubber bituminous pavement and construction method thereof

InactiveCN101982610AImprove adhesionAvoid enteringIn situ pavingsSolid waste managementInter layerChipseal

The invention discloses hot-distribution rubber bituminous pavement and a construction method thereof. The construction method comprises the following steps: 1, cleaning a lower bearing layer; 2, preparing rubber asphalt; 3, distributing the rubber asphalt, namely, uniformly distributing a rubber asphalt layer on the lower bearing layer, wherein the distribution amount of the rubber asphalt is 2.2 to 2.6 kg / m<2>, and the distribution temperature is 180 to 190 DEG C; 4, distributing broken stone with an amount which is 60 to 70 percent based on the distribution area of the rubber asphalt, wherein the distribution temperature of the broken stone is not lower than 80 DEG C; and 5, rolling and forming, namely, rolling and forming a rubber asphalt waterproof adhesive layer by a rubber-tire pavement roller following a broken stone distribution vehicle, wherein the rubber-wire pavement roller rolls the pavement once to twice back and forth. The construction method of the invention can enhance the inter-layer adhesive performance, prevent water penetration, effectively absorb and eliminate inter-layer stress and reduce reflection cracks caused by the conventional bituminous pavement, and can be applied to the projects of building and rebuilding bituminous pavement, pavement of bituminous concrete bridge floor, bituminous overlaying of cement concrete pavement and the like.

Owner:BEIJING ROAD & BRIDGE CONSTR GROUP +2

Composite type pavement structure and pavement method thereof

ActiveCN101597878AImprove fatigue resistanceIncrease stiffnessIn situ pavingsBridge structural detailsSheet steelRoad engineering

The invention discloses a composite type pavement structure and a pavement method, and relates to a road engineering structure and a construction method thereof. In the invention, the thermal expansion coefficient, the cement concrete and the fiber-reinforced composite material substrate which performance is near to the steel plate are adopted to reinforce for the bottom surface of the asphalt layer; thus improving the performance of anti-fatigue and anti-reflecting crack of the asphalt surface course, effectively preventing the lower bearing layer from being eroded due to infiltration of the rain water from the asphalt surface course, avoiding bonding problem between the asphalt surface course and the cement concrete or the steel plate, increasing stiffness of the steel bridge surface, and particularly reinforcing the steel bridge surface the steel plate of which has insufficient thickness, so as to reduce the thickness of the asphalt surface course, avoid the damages, such as cracking and falling of the asphalt pavement layer caused by the insufficient thickness of the steel bridge surface and the like.

Owner:广州大象超薄路面技术开发有限公司

Large grain diameter water permeability asphalt mixture novel pavement structure and laying method thereof

InactiveCN101250845AImprove high temperature stabilityObvious resistance to permanent deformationIn situ pavingsMining engineeringRoad surface

The invention discloses a novel road surface structure with large particle diameter water permeability bitumen mixture and a method for laying thereof, which solves diseases such as problems of reflection crevice, pit groove and pump mud and the like which are brought from that current express-way only adopts a semi-rigid basal layer and a traditional bitumen layer, and has the advantages of simple structure, good water permeability, thereby being not easy to occur breakage of early water and being capable of efficiently increasing life time of the road surface and the like. The novel road surface structure comprises a basal layer which is consecutively provided with a large particle diameter water permeability bitumen mixture layer and at least a bitumen layer, wherein the large particle diameter water permeability bitumen mixture layer is made of one-stone coarse aggregates with the particle diameter of 25mm-62mm to form a frame and be mixed with a proper quantity of filling fine aggregates with the particle diameter of 0-4.75mm and bituminous cement to form the frame type bitumen mixture, and the thickness of each bitumen layer is not above the thickness of the large particle diameter water permeability bitumen mixture layer.

Owner:山东省交通厅公路局 +2

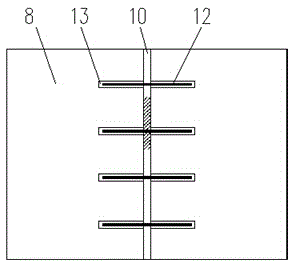

Joint construction method for preventing reflection cracks generated during spreading of asphalt on old concrete pavement

The invention relates to a joint construction method for preventing reflection cracks generated during spreading of asphalt on an old concrete pavement. The method comprises the following steps: firstly determining the inter-panel deflection difference of old concrete panels to be jointed for reinforcing; after qualification, cutting across the joints at the joints of the two old concrete panels to obtain equal-distance stripe-type grooves and then vertically drilling the end parts of the stripe-type grooves by using an impact drill; bending a reinforcing steel bar according to the hole depth, the length of the grooves and the width of the inter-panel joint and finishing forming of a horseshoe rib; after transplanting the horseshoe ribs into the stripe-type grooves and the vertical holes in the end parts, pouring epoxy resin embedded steel bar glue into the cleaned drilling holes; mixing concrete and broken stone concrete, pouring into the grooves to form an embedded steel bar protective layer; and sequentially spreading layers of protective covering surfaces on the upper layers of the two waste concrete panels from bottom to top. The method provided by the invention has the advantages that the relative vertical displacement at two sides of the old panel joint, the reflection cracks are prevented to generate and develop so as to reduce or stop reflection cracks generated during spreading of asphalt on an old concrete pavement.

Owner:SHANGHAI SHISHEN IND & TRADE CO LTD

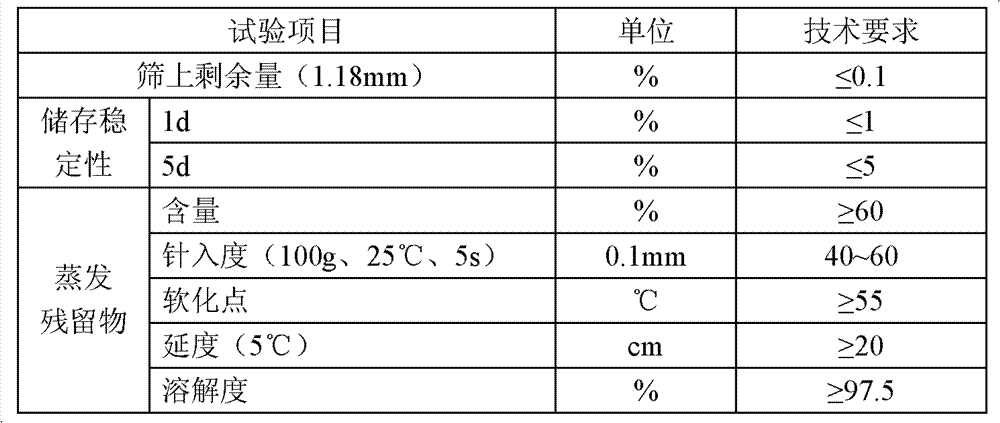

Operation method for confirming cold regeneration mix mixing proportion of emulsified asphalt

The invention relates to a working method for determining the combining ratios of cold recycled mixtures of emulsified asphalts and comprises the following aspects: (1) the performance evaluation of old asphalt mixtures; (2) the design of the combining ratio of cold recycled mixtures of the emulsified asphalts; (3) the performance tests of the performance of the cold recycled mixtures of the emulsified asphalts. The working method has the advantages of releasing the unavoidable reflective cracking problem of a semi-rigid base, improving the water temperature environment, reducing the tensile stress at the bottom of the semi-rigid base and prolonging the service life of the semi-rigid base asphalt pavement, thus providing effective measure of settlement for newly built pavements, more particularly for the maintenance and transformation of old roads; the working method can save a plurality of construction and maintenance funds as well as reducing the resource waste and environmental destruction.

Owner:TIANJIN GUOSHENG CONSTR COST CONSULTATIVE

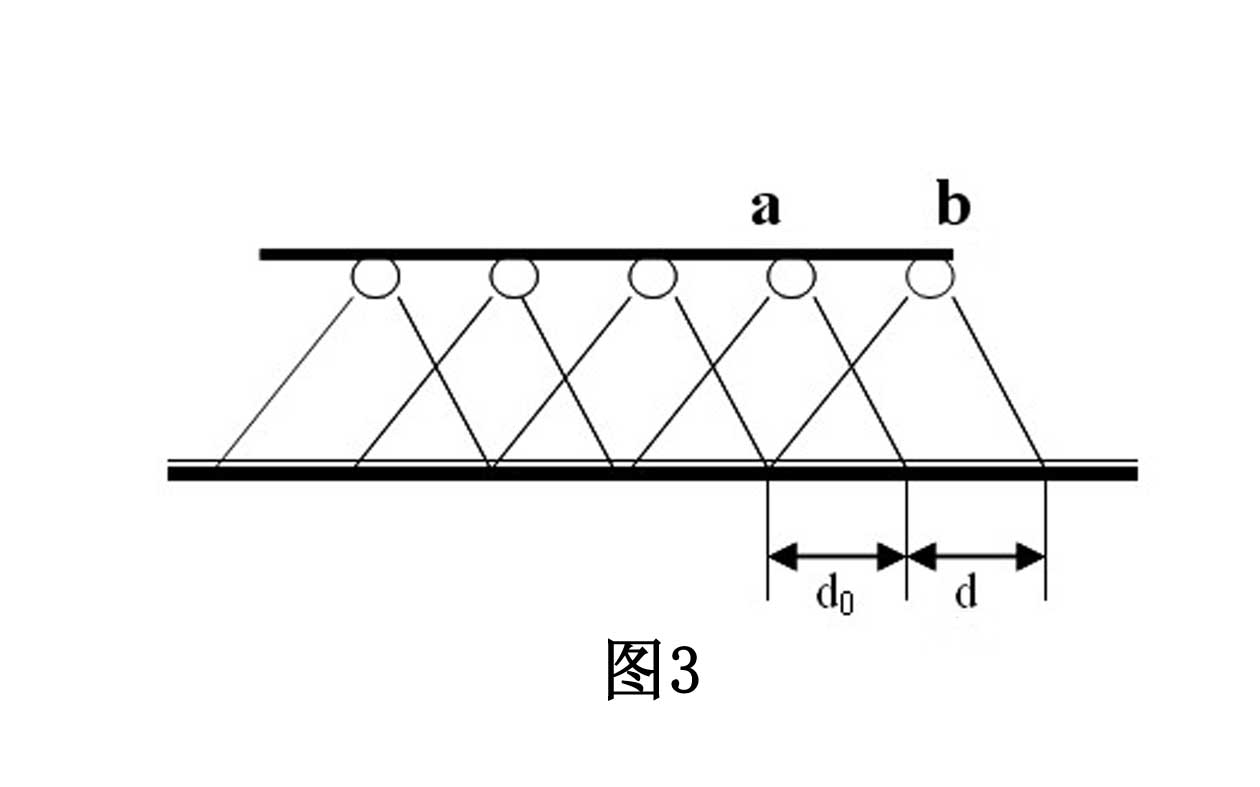

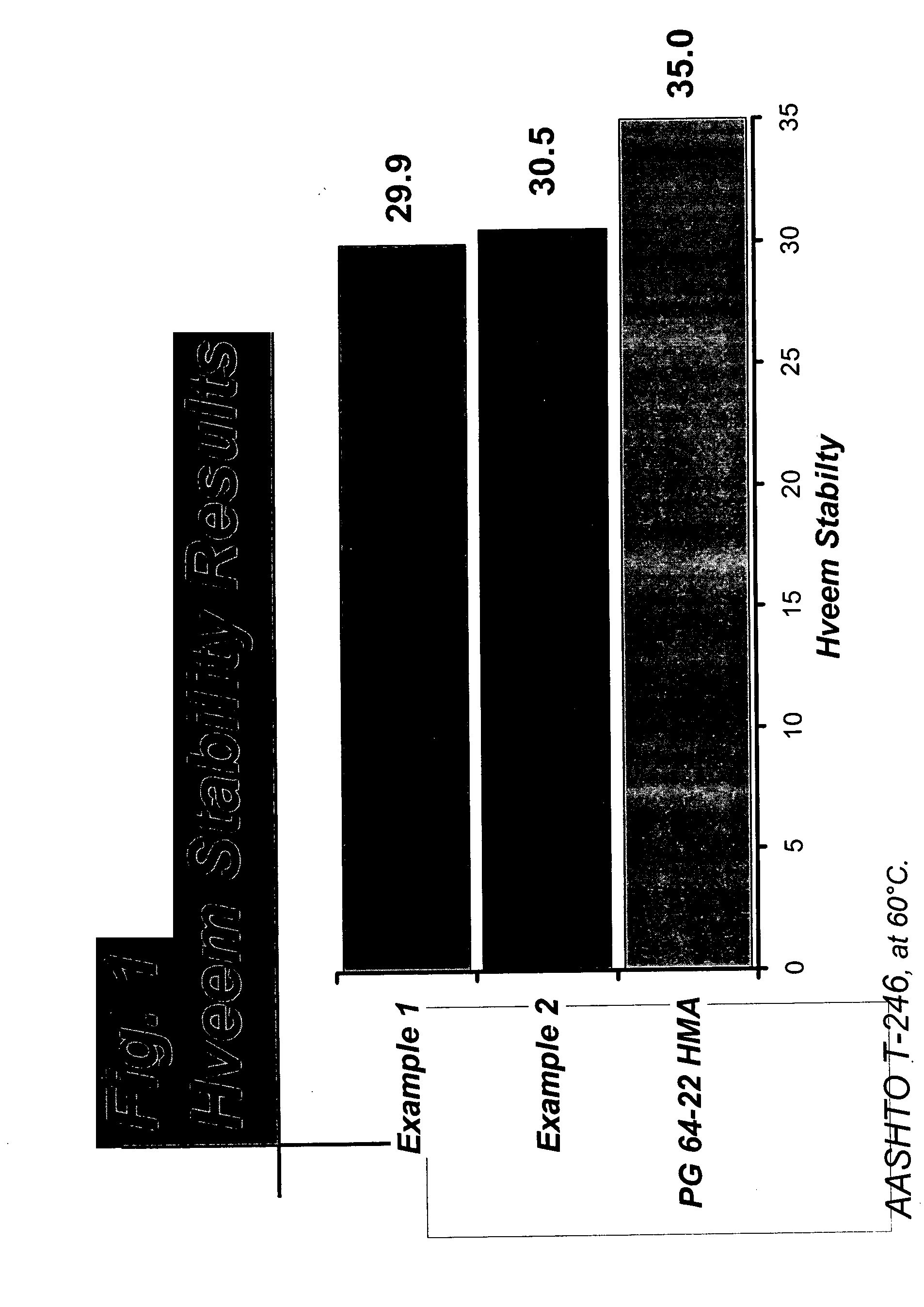

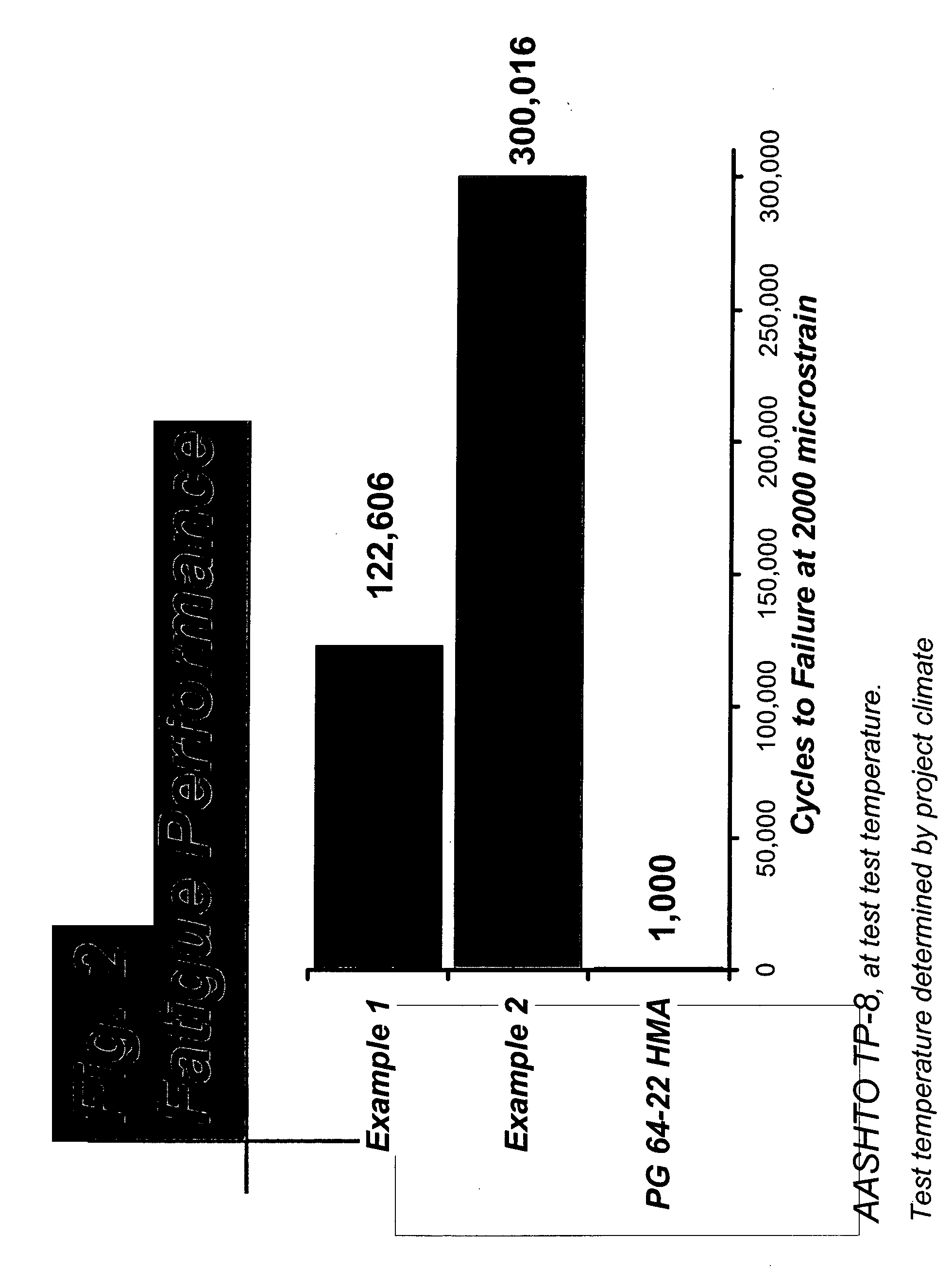

Reflective crack relief pavement interlayer with improved load bearing capacity and method for designing interlayer

ActiveUS20050022696A1Prevent moistureSlow deteriorationIn situ pavingsSingle unit pavingsPolymer modifiedRoad surface

A highly strain tolerant, substantially moisture impermeable, reflective crack relief interlayer is provided. The interlayer includes a polymer modified asphalt binder mixed with a dense fine aggregate mixture containing a substantial amount of manufactured sand. The interlayer mix is designed using a fatigue test and a stability test. Preferably, a hot mix asphalt overlay that is compatible with the interlayer, as well as the demands of local traffic and climate, is placed over the interlayer so that a protected, smooth paved surface is provided. The interlayer may delay the first appearance of cracks and the severity of cracks for several years compared with traditional hot mix overlays and extend pavement service life.

Owner:ARRMAZ PROD INC

Fiber-reinforced rubber asphalt stress absorbing layer and construction method thereof

The invention provides a fiber-reinforced rubber asphalt stress absorbing layer and a construction method thereof. The fiber-reinforced rubber asphalt stress absorbing layer per square meter comprises the following components: 0.2-1.0 kg of SBS (styrene butadiene styrene) modified emulsified asphalt, 70-150 g of glass fibers, 1.5-3.0 kg of rubber asphalt and 10-20 kg of broken stones. The construction method comprises the following steps of: spraying an SBS modified emulsified asphalt layer and spreading the glass fibers sequentially on the clean and dry surface of a lower supporting layer; after the SBS modified emulsified asphalt breaks emulsion, spraying the rubber asphalt and spreading the broken stones; and finally, rolling a road surface, and controlling the time from the spraying of the rubber asphalt to the completion of the rolling within 10-20 minutes. The rubber asphalt stress absorbing layer prepared by the invention is firmly adhered to the lower supporting layer, can prevent the oil bleeding phenomenon of an asphalt surface layer and the generation of the reflection crack of the asphalt surface layer, improves the anti-cracking performance of the rubber asphalt stress absorbing layer, and prolongs the service life of the road surface.

Owner:广州大象超薄路面技术开发有限公司

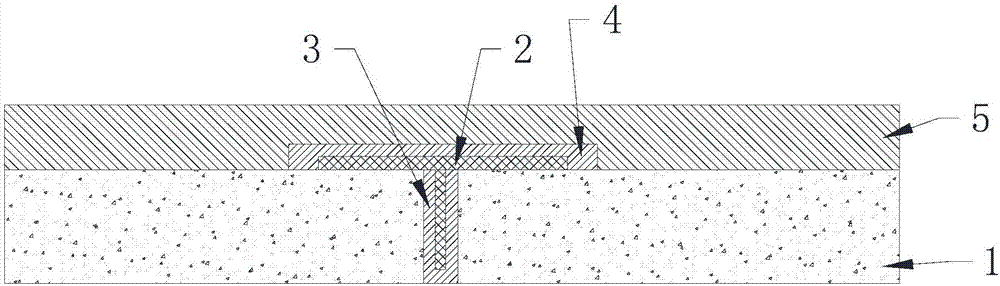

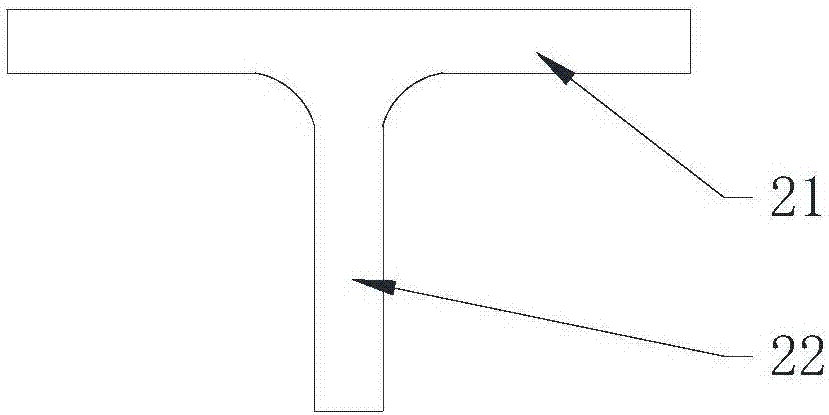

Anti-reflection crack asphalt pavement structure and construction method thereof

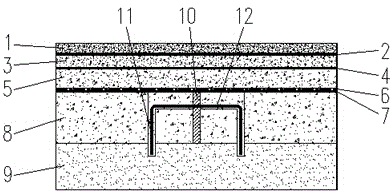

The invention discloses an anti-reflection crack asphalt pavement structure and a construction method thereof. The anti-reflection crack asphalt pavement structure is paved on the surface of a roadbase with cracks. The anti-reflection crack asphalt pavement structure comprises a T-shaped reinforcing part and an asphalt joint sealing material layer filling the cracks. The T-shaped reinforcing part comprises a transverse plate piece and a vertical plate piece arranged in the middle along the width direction of the lower surface of the transverse plate piece; the vertical plate piece of the T-shaped reinforcing part is embedded into and fixed in the asphalt joint sealing material layer and the lower surface of the transverse plate piece is adhered and fixed to the surface of each roadbase on each side of the crack; the asphalt pavement structure also comprises an asphalt coating and an asphalt concrete surface layer covering the asphalt coating. The asphalt coating coats the surface of a combination formed by adhering the roadbase and the T-shaped reinforcing piece. The structure disclosed by the invention has the advantages of good stability and high anti-reflection crack ability and the service life of the pavement can be prolonged effectively.

Owner:广东金长成桥梁隧道科技有限公司

Asphalt concrete pavement reflection crack treatment method

ActiveCN104343077AImprove bearing capacityImprove the compression and crack resistance coefficientIn situ pavingsRoads maintainenceGlass fiberPortland cement

The invention relates to an asphalt concrete pavement reflection crack treatment method. The asphalt concrete pavement reflection crack treatment method comprises the following steps: removing asphalt concrete pavement sections with local cracks; detecting the crack conditions of the basement layer after the asphalt concrete cutting operation is finished, removing partial loose basement layer in the basement layer, and eliminating the removed basement layer wastes; longitudinally forming injected holes along the cracks of the basement layer structure, wherein the injected holes are formed along the middle of the cracks; preparing injecting paste material slurry, namely mixing and stirring ordinary Portland cement and water, thereby obtaining pure cement grout; restoring the cracked asphalt concrete pavement, laying anti-crack stickers and glass fiber grids on the asphalt structure layer in a layered mode, performing reinforcing treatment, and performing layered packing compaction on the cracks from bottom to top after the pavement structure layer is restored, wherein the compaction degree refers to the original design requirement; and monitoring, detecting and inspecting the pavement. The method disclosed by the invention is high in treatment effect, short in construction period, low in cost, safe in construction and high in working efficiency and has high application values, and the pavement crack treatment is restored in place.

Owner:CHINA MCC20 GRP CORP

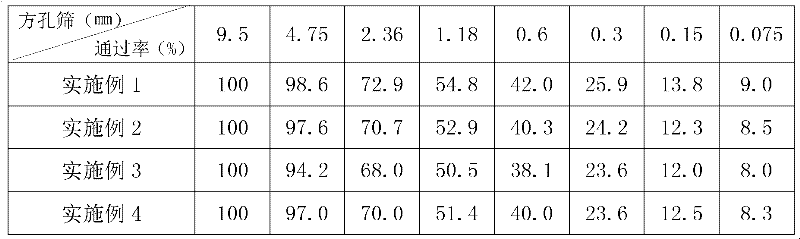

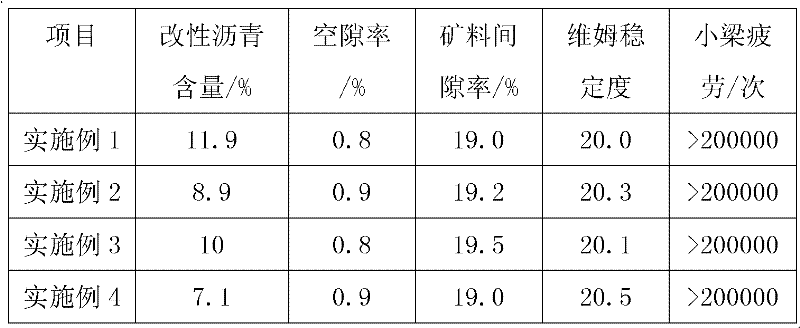

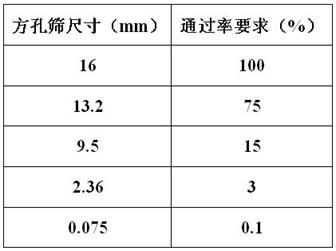

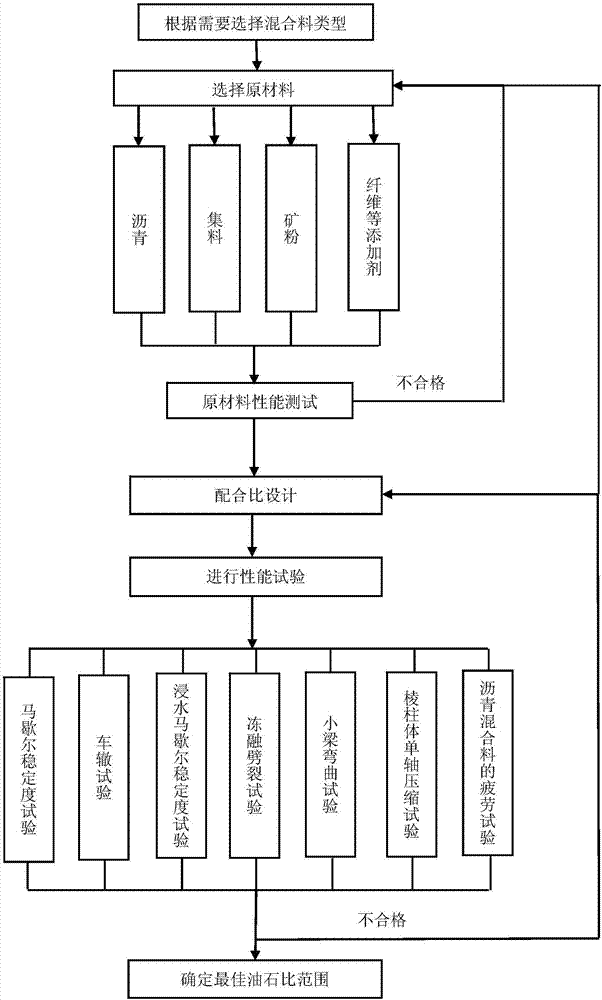

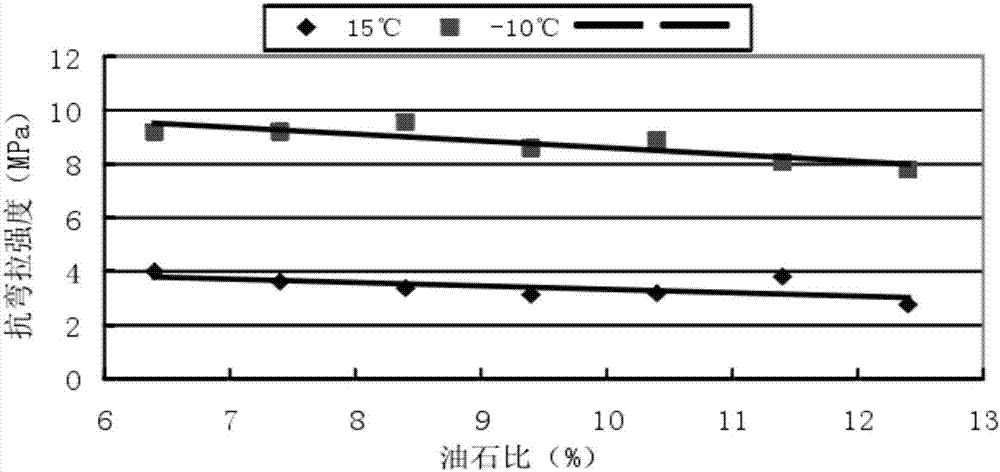

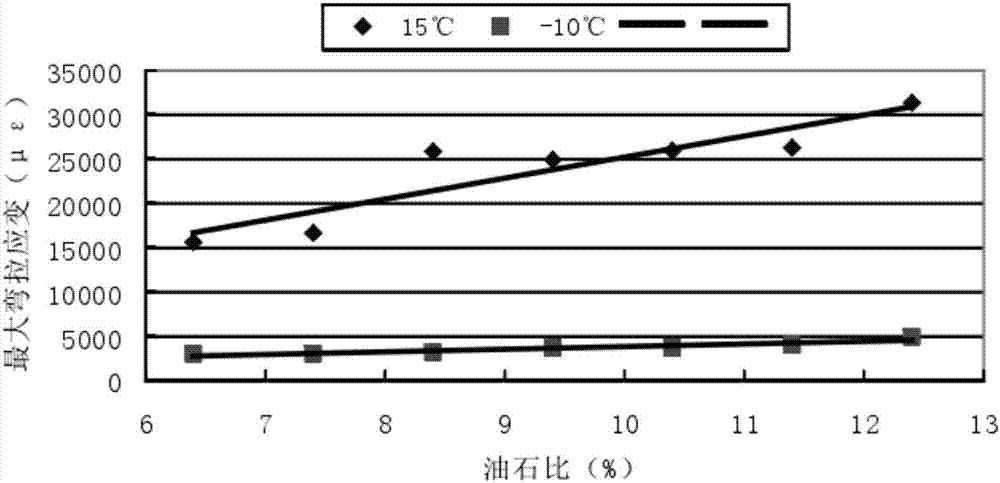

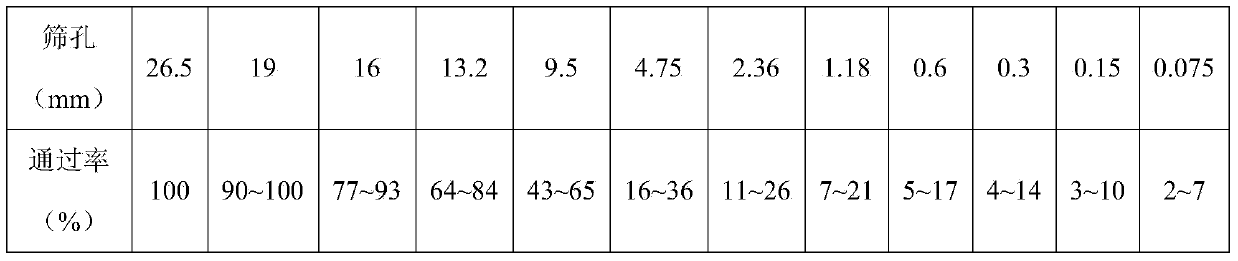

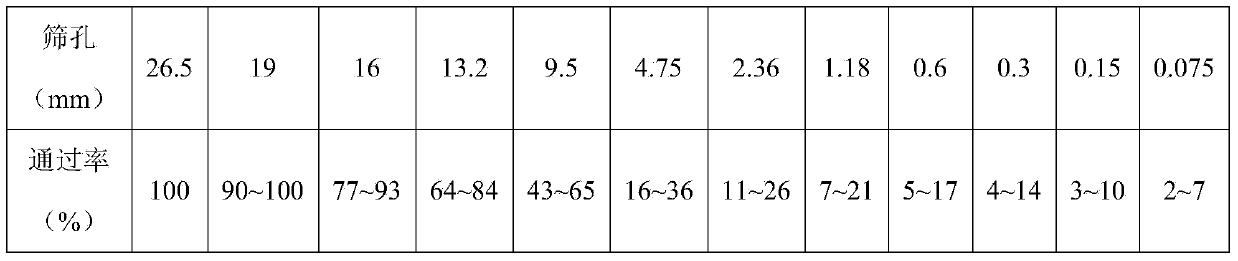

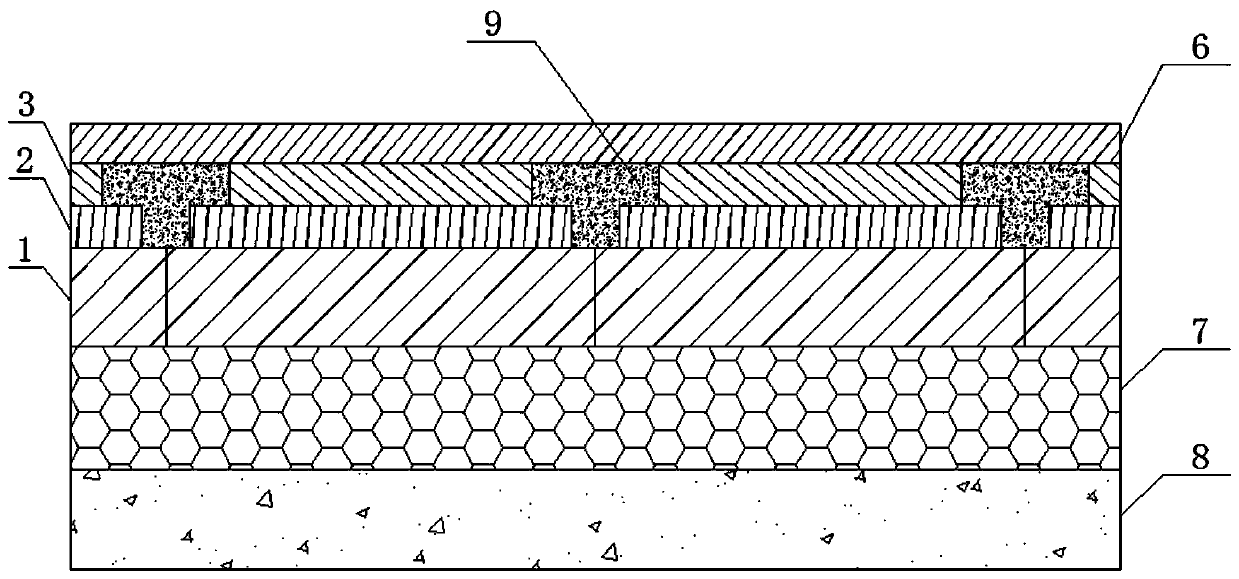

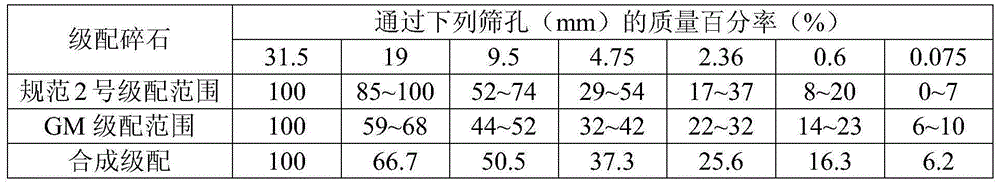

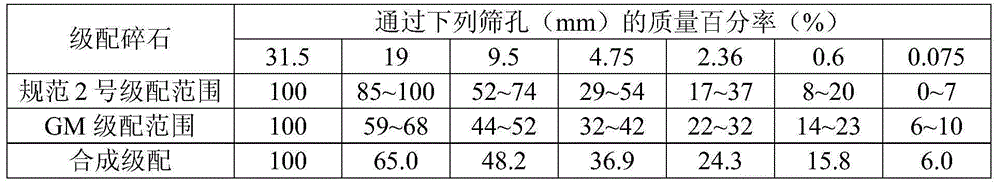

Coarse grain type stress absorption structure layer asphalt mixture and design method thereof

ActiveCN107129196AGuaranteed high temperature stabilityWaterproofGeometric CADSpecial data processing applicationsCrack resistancePerformance index

The invention discloses a coarse grain type stress absorption structure layer asphalt mixture and a design method thereof. The design method comprises the following steps: (1) selecting the type of an asphalt mixture according to engineering requirements; (2) selecting raw materials and carrying out performance detection experiments on the raw materials; (3) determining a reasonable asphalt aggregate ratio range by adopting a large asphalt aggregate ratio; designing gradation of mineral aggregate according to each selected asphalt aggregate ratio; (4) detecting performance of the asphalt mixture; (5) when all performance indexes in step (4) meet requirements, finishing a mixing proportion design; if the performance indexes do not meet the requirements, returning back to design the mixture again until the requirements are met; (6) analyzing results of performance detection and determining optimal asphalt aggregate ratio range and gradation range of the asphalt mixture. The coarse grain type stress absorption structure layer asphalt mixture disclosed by the invention has an effect of a stress absorption structure layer and has various functions of water resistance and cracking resistance, fatigue resistance, prevention and control of reflection cracks and the like.

Owner:广西桂海高速公路有限公司

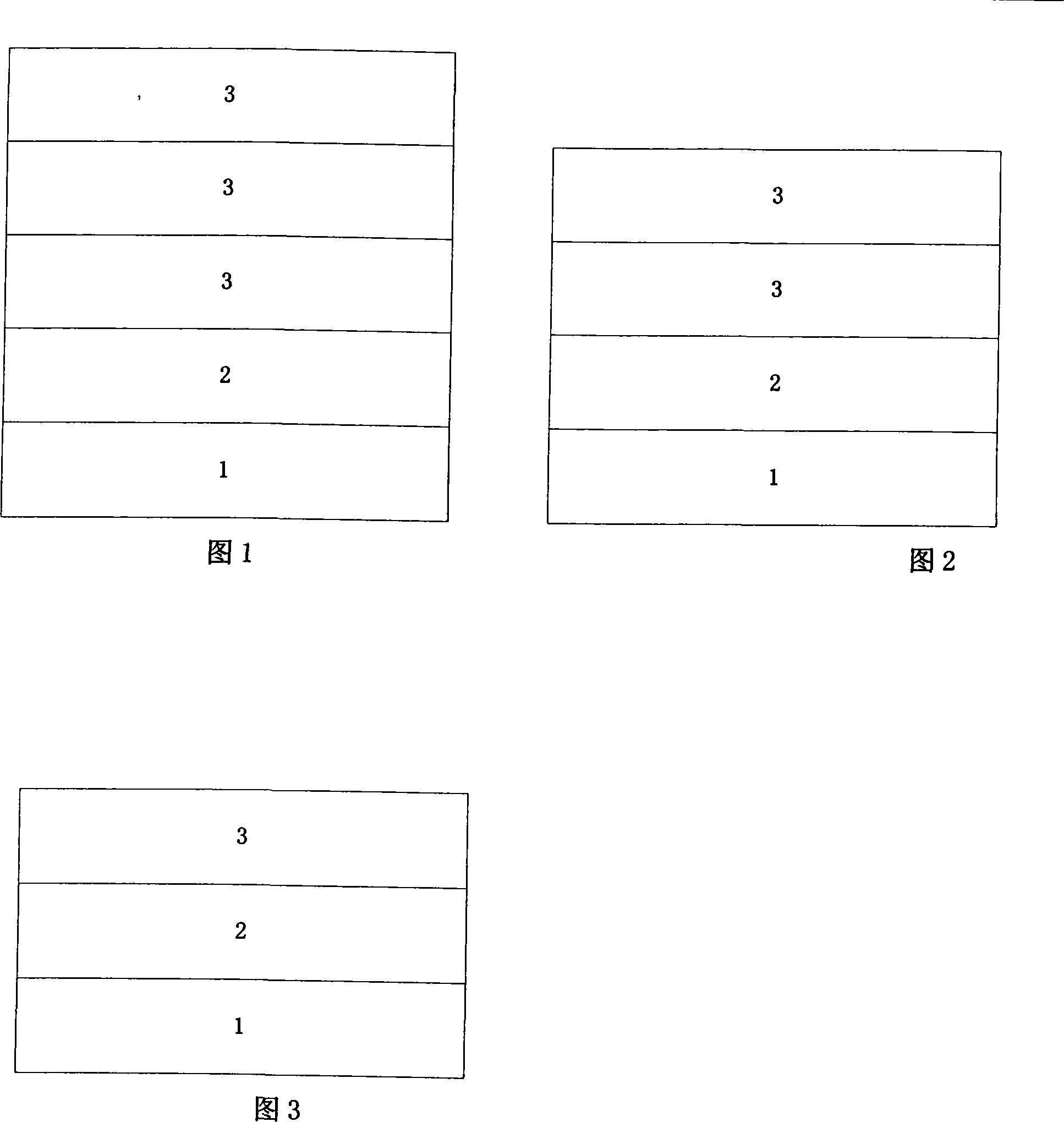

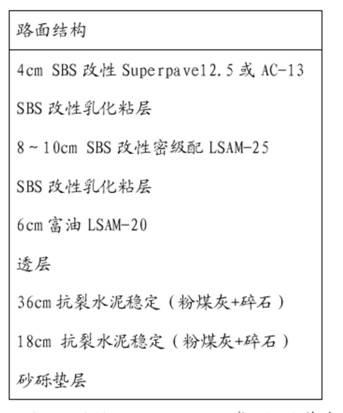

Structure of asphalt pavement applicable to very heavy traffic

InactiveCN102433815AIncreased durabilityReduce reflective cracksIn situ pavingsEngineeringStructural engineering

The invention discloses a structure of an asphalt pavement applicable to very heavy traffic. A wearing layer of the structure adopts 4cm of SBS (styrene butadiene styrene) modified Superpave 12.5 type or AC-13 type modified asphalt concrete; a middle layer of the structure adopts 8-10cm of SBS modified dense gradation LSAM (large stone asphalt mixture)-25; an anti-fatigue layer of the structure adopts 6cm of rich oil LSAM-20 asphalt concrete; a base layer of the structure adopts 36cm of anti-crack stabilized cement; and a subbase layer of the structure adopts treated original cement concrete pavement and treated original asphalt pavement or 18cm of anti-crack stabilized cement. The asphalt pavement structure resists the breaking such as penetrating, cracking, loosing, deforming and the like, resists high-temperature permanent deformation, resists fatigue loading damage, disperses the load, and slows down the reflection crack, so that the problems of rutting deformation resistance and the durability of the very heavy traffic asphalt pavement can be solved, and the service life of the asphalt pavement can be prolonged.

Owner:SHANXI PROVINCIAL RES INST OF COMM

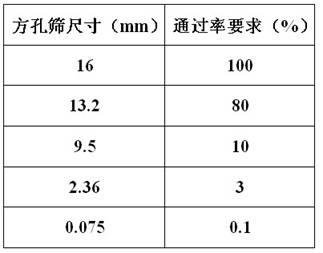

Asphalt mixture capable of suppressing reflection cracks in road surface, and preparation method and application of asphalt mixture

The invention relates to an asphalt mixture capable of suppressing reflection cracks in a road surface, and a preparation method and application of the asphalt mixture. The mixture comprises aggregates, a filler, a fiber stabilizing agent and a high-viscosity asphalt binding material, wherein the aggregates comprise coarse aggregates and fine aggregates; the nominal maximum particle size of the aggregates is 19 mm; limestone is adopted for both the coarse and fine aggregates; the mixing amount of the high-viscosity asphalt binding material is 5.5 to 6.9 percent based on the mass of the asphalt mixture; the high-viscosity asphalt binding material consists of 12 to 19 weight percent of 60 to 80-mesh rubber powder, 0.1 to 0.3 weight percent of a cross-linking agent, 4.0 to 8.0 weight percent of a modifying agent, 3.8 to 7.6 weight percent of a viscosity reducer and the balance of 70# matrix asphalt; the asphalt mixer is a gap semi-open gradation asphalt mixture, and has porosity of 8 to 12 percent. The reflection cracks in the road surface can be effectively suppressed, and the asphalt mixture is low in preparation cost, and has good economic benefits and environmental benefits.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

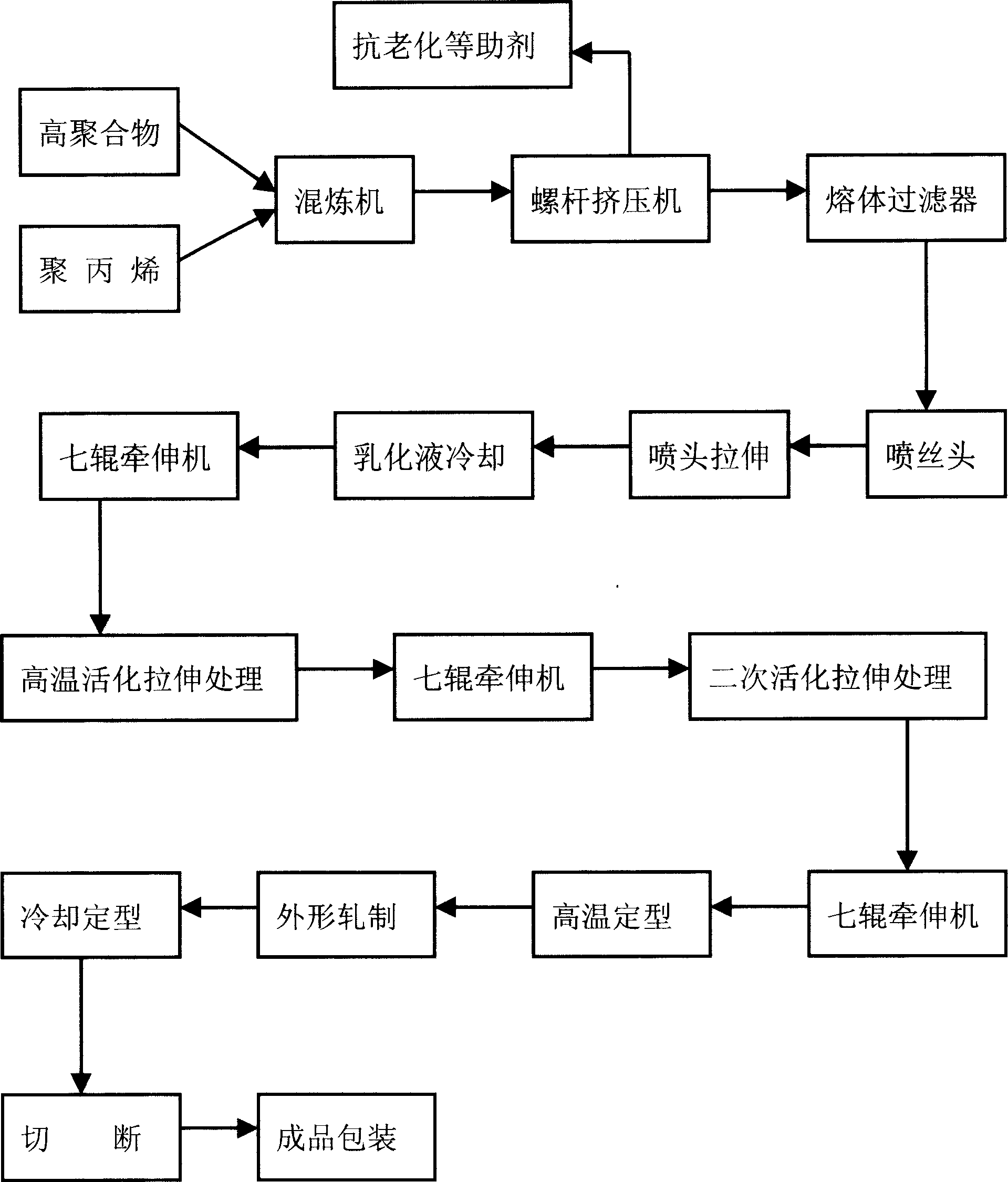

Process for production of special-shaped high polymer plastic-steel fabric

InactiveCN1632191AImprove antistatic performanceGood dispersionIn situ pavingsFilament/thread formingPolyesterPlastic fiber

The invention relates to a high polymer used for controlling concrete cracks in building cement concrete engineering, effectively improving the toughness, impact resistance, bending resistance, bending resistance and impermeability of concrete, and inhibiting the cracking of the middle layer of asphalt roads and the generation of reflection cracks, etc. The production method of special-shaped plastic steel fiber. It uses polypropylene, polyethylene, polyester and other copolymers as the main raw materials, through advanced production technology and special treatment of fiber structure, to obtain rough surface, five-lobed, six-lobed and multi-lobed cross-section, and a cross-section of Concave-convex, wavy, zigzag shaped fibers. The fiber has high tensile strength, large elastic modulus, acid and alkali resistance, aging resistance, easy dispersion, light specific gravity, and firm combination with cement concrete and asphalt concrete.

Owner:NINGBO DACHENG ADVANCED MATERIAL

Process for quickly repairing semi-rigid substrate damage of asphalt pavement

InactiveCN102251454AImprove high temperature stabilityImprove water stabilityIn situ pavingsRoads maintainenceCrack resistanceRoad surface

The invention discloses a process for quickly repairing semi-rigid substrate damage of an asphalt pavement, which comprises the following steps: milling and planing an asphalt topping and a loose substrate at normal temperature, leveling a roadbed, spreading gravels having a thickness of 10-20cm, spreading large stone asphalt mixtures of 25-40cm at twice, paving glass fiber grids, spreading coarse graded asphalt, cooling before opening to traffic for 2-3 days, and finally spreading topping asphalt concrete, thus finishing the quick repair of the semi-rigid substrate damage of an asphalt pavement. The invention can resist high plastic and shear deformation and bear heavy-duty traffic action, has fine rutting resistance, improves the high-temperature stability and water stability of the asphalt pavement, and has fine drainability; the on-site construction process is simple and feasible, and the operation time is short; the reflection crack resistance and pavement deformation resistance of the pavement are improved; the bonding property with the asphalt topping is fine, and the pavement structure can be stressed more evenly, thereby having high lasting quality; and by increasing large stone aggregate and reducing powdered ore, the construction cost is lowered.

Owner:杭州市市政设施监管中心 +1

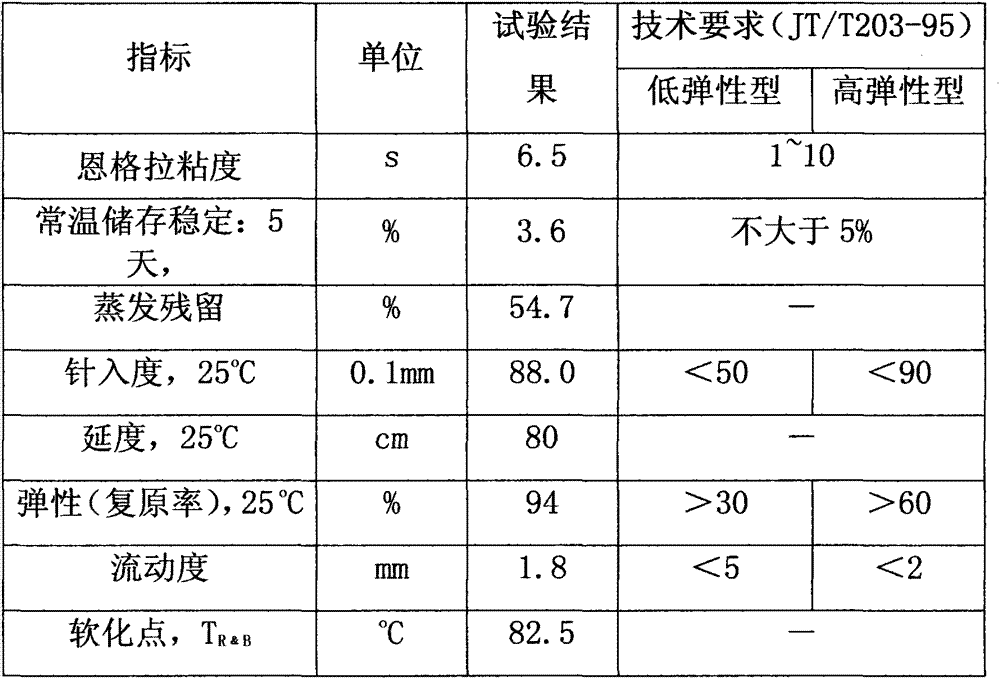

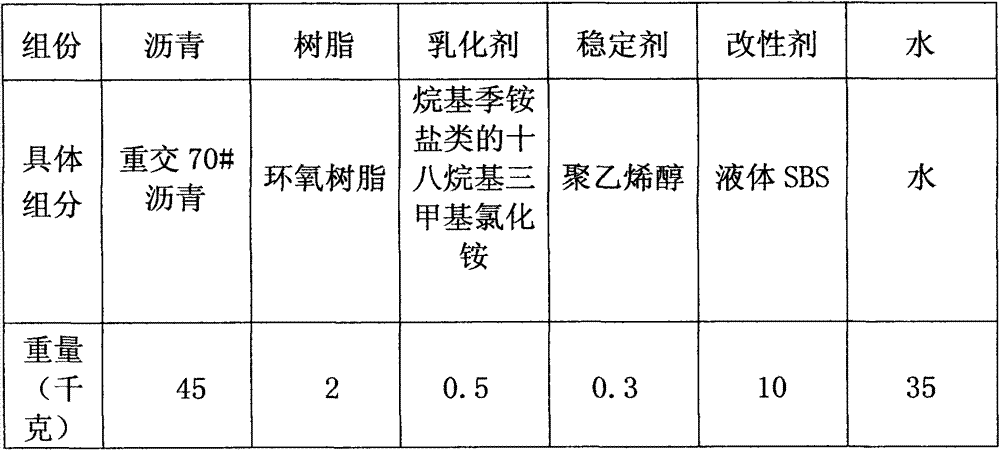

Road sealant for use at normal temperature and preparation method thereof

InactiveCN103497729AAvoid destructionGood fluidityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesFrostRoad surface

The invention belongs to the technical field of road sealants and in particular relates to a road sealant for use at a normal temperature and a preparation method thereof. The road sealant is prepared from the following raw materials in parts by weight: 45-65 parts of pitch, 2-6 parts of resin, 0.5-1.5 parts of emulsifier, 0.3-0.6 part of stabilizer, 10-20 parts of modifier and 35-45 parts of water. The road sealant can be used at the normal temperature, and is capable of treating pavement frost boiling distress caused by reflection cracks for pressure crack pouring of the underneath layer and the base layer of the pavement.

Owner:河南交投交通建设集团有限公司

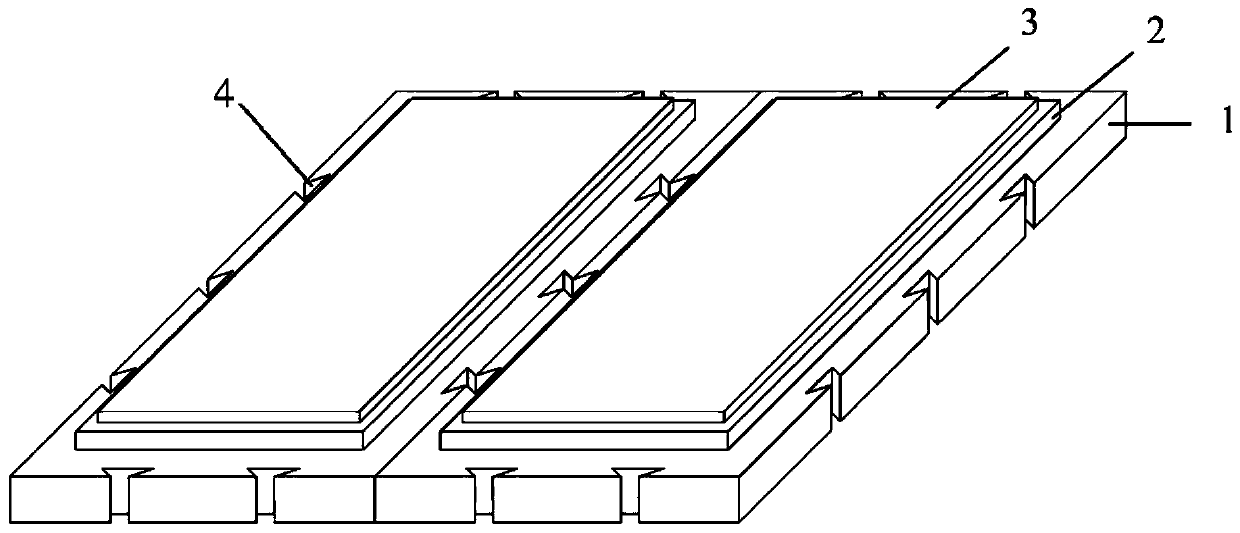

Composite fabricated cement concrete pavement structure and construction method thereof

The invention provides a composite fabricated cement concrete pavement structure. The composite fabricated cement concrete pavement structure comprises a base layer, a leveling layer laid on the baselayer, a fabricated prefabricated concrete slab laid on the leveling layer, a rubber modified asphalt synchronous gravel sealing layer laid on the fabricated prefabricated concrete slab, and rubber modified asphalt concrete laid on the rubber modified asphalt synchronous gravel sealing layer. Compared with the prior art, the composite fabricated cement concrete pavement structure is formed by combining specific functional layers under specific connection relationship, the functional layers have good interaction, and the cooperation of layer structures is realized, so that the whole composite fabricated cement concrete pavement structure has high strength and good driving comfort, and reflective cracks and rutting can be reduced, and the service life of the pavement is prolonged. The experimental results show that the pavement damage index PCI of the composite fabricated cement concrete pavement structure is 92.3-95.5, and the pavement service condition is excellent.

Owner:CCCC THIRD HIGHWAY ENG

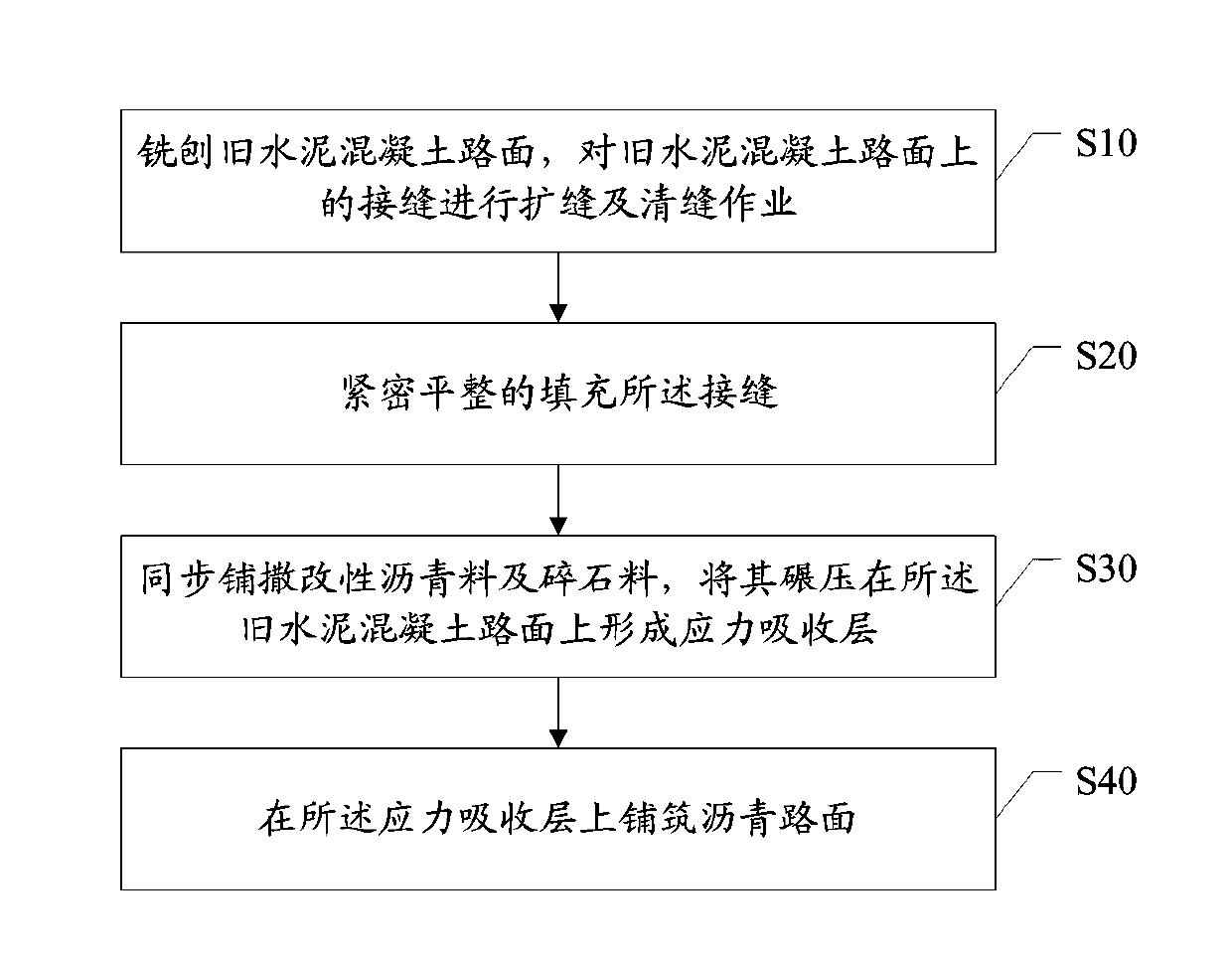

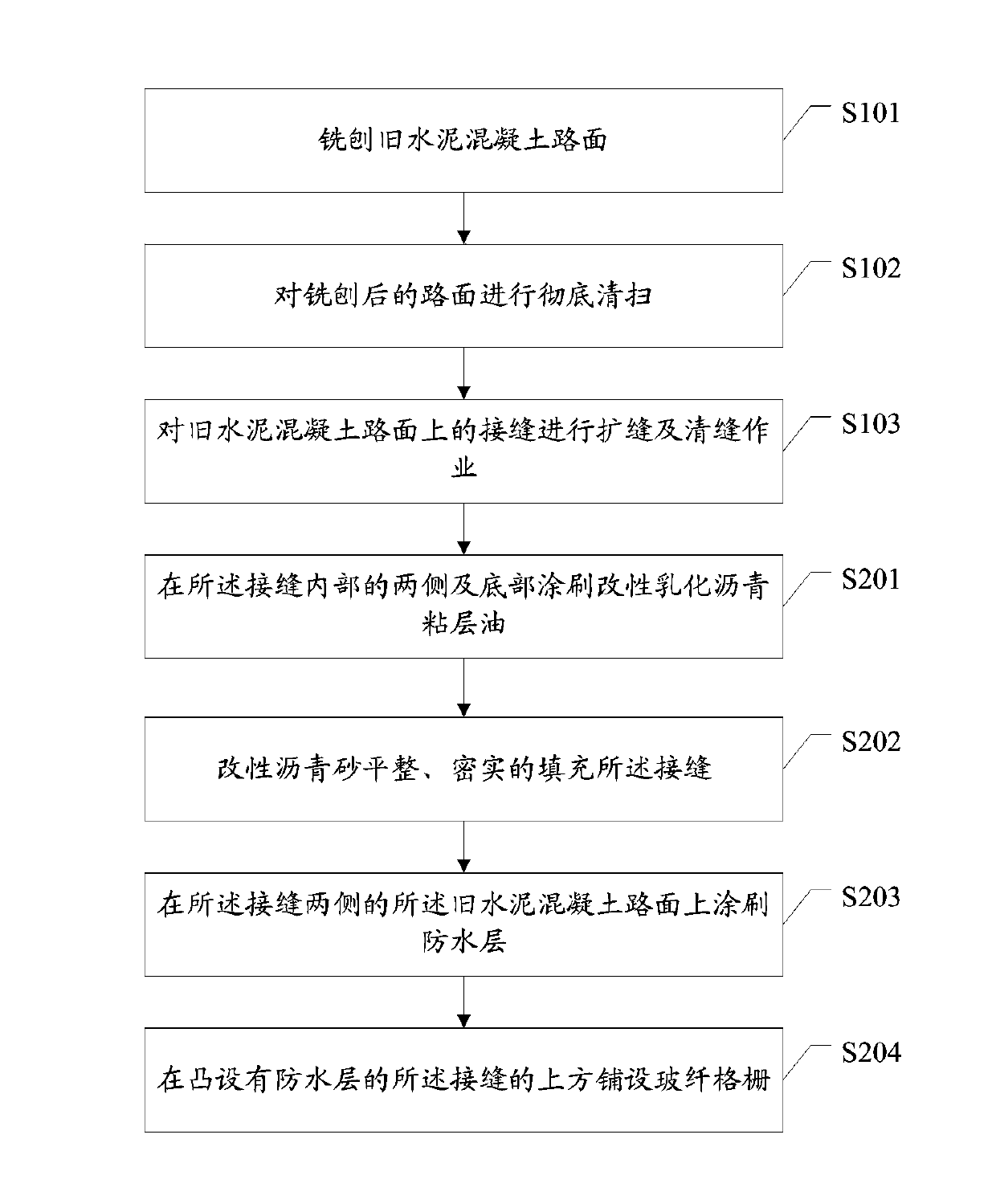

Repairing and transforming method of old cement concrete pavement

InactiveCN103132420AEasy to useMake the most of remaining strengthIn situ pavingsPaving detailsTemperature stressCrushed stone

The invention discloses a repairing and transforming method of an old cement concrete pavement. The repairing and transforming method comprises the following steps: milling and digging the old cement concrete pavement, and expanding and cleaning seams in the old cement concrete pavement; compactly and flatly filling the joint seams; synchronously paving and spreading modified asphalt and road metal; grinding the modified asphalt and the road metal on the old cement concrete pavement so as to form a stress absorbing layer; and paving an asphalt pavement on the stress absorbing layer. By utilizing the repairing and transforming method of the old cement concrete pavement, the joint seams and cracks in the old cement concrete pavement can be treated, so that the problem that reflection cracks is easy to occur when the asphalt pavement is paved on the old cement concrete pavement is solved, the pavement can resist the inhomogeneous deformation caused by temperature stress, and the service life of the paved asphalt pavement is prolonged.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST +1

Continuous prefabricated asphalt pavement and construction method thereof

ActiveCN110863404AGuaranteed flatnessGuaranteed integrityIn situ pavingsSingle unit pavingsArchitectural engineeringBitumen emulsion

The invention discloses a continuous prefabricated asphalt pavement and a construction method thereof, and relates to a prefabricated asphalt pavement and an installation method thereof. The continuous prefabricated asphalt pavement and the construction method thereof aim to solve the problems that an existing prefabricated asphalt pavement slab is prone to generate a reflection crack and is low in construction efficiency. The prefabricated asphalt pavement is composed of a prefabricated asphalt pavement slab, an upper surface layer, a cushion layer and a soil foundation; and the prefabricatedasphalt pavement slab is arranged on the upper surface of the cushion layer, the upper surface layer is arranged on the upper surface of the prefabricated asphalt pavement slab and the upper surfacelayer and the prefabricated asphalt pavement slab are bonded through emulsified asphalt adhesive, and a gap between adjacent lower surface layers and a T-shaped joint between adjacent middle surface layers are filled with asphalt mixture. The method comprises the following steps of manufacturing prefabricated slab units and dual-tenon joint blocks in a prefabricated field, paving the soil foundation on a construction site, laying the cushion layer on the soil foundation, assembling the prefabricated asphalt pavement slab, and paving the upper surface layer. The continuous prefabricated asphaltpavement has good flatness, integrity and continuity, the reflection crack is reduced, the durability is good, and the construction period is short; and the continuous prefabricated asphalt pavementand the construction method thereof are suitable for asphalt pavement paving.

Owner:HARBIN INST OF TECH

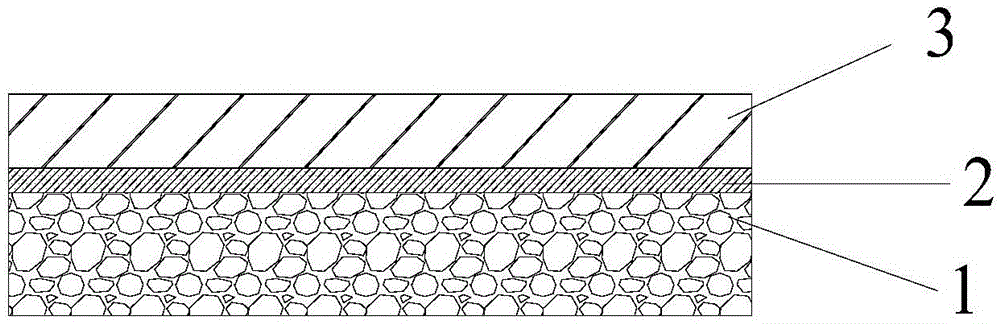

Reflection crack resistant asphalt pavement structure and construction method thereof

ActiveCN105019328AImprove structural strengthImprove road performanceIn situ pavingsChipsealSurface layer

The invention belongs to the technical field of road design and construction and discloses a reflection crack resistant asphalt pavement structure and a construction method thereof. The pavement structure sequentially comprises a high-performance graded broken stone base layer, a modified emulsified asphalt adhesive layer and a rock asphalt layer from bottom to top. The construction method comprises the following steps: clearing the surface of a lower supporting layer; mixing, spreading and rolling the raw material of high-performance graded broken stone; spraying the modified emulsified asphalt adhesive layer onto the surface of the high-performance graded broken stone base layer; spreading a rock asphalt modified asphalt mixture on the surface of the modified emulsified asphalt adhesive layer by using an asphalt mixture spreading machine; and then rolling by using a double-drum vibratory roller and a tyre roller. The reflection crack resistant asphalt pavement structure has the advantages that the performance advantages of all structural layers are fully exerted, the generation and development of reflective cracks of pavements are reduced and delayed, the blocking property and waterproof property between the asphalt surface layer and the base layer are increased, the asphalt pavement structure strength is increased, and the asphalt pavement performance is improved.

Owner:SOUTH CHINA UNIV OF TECH

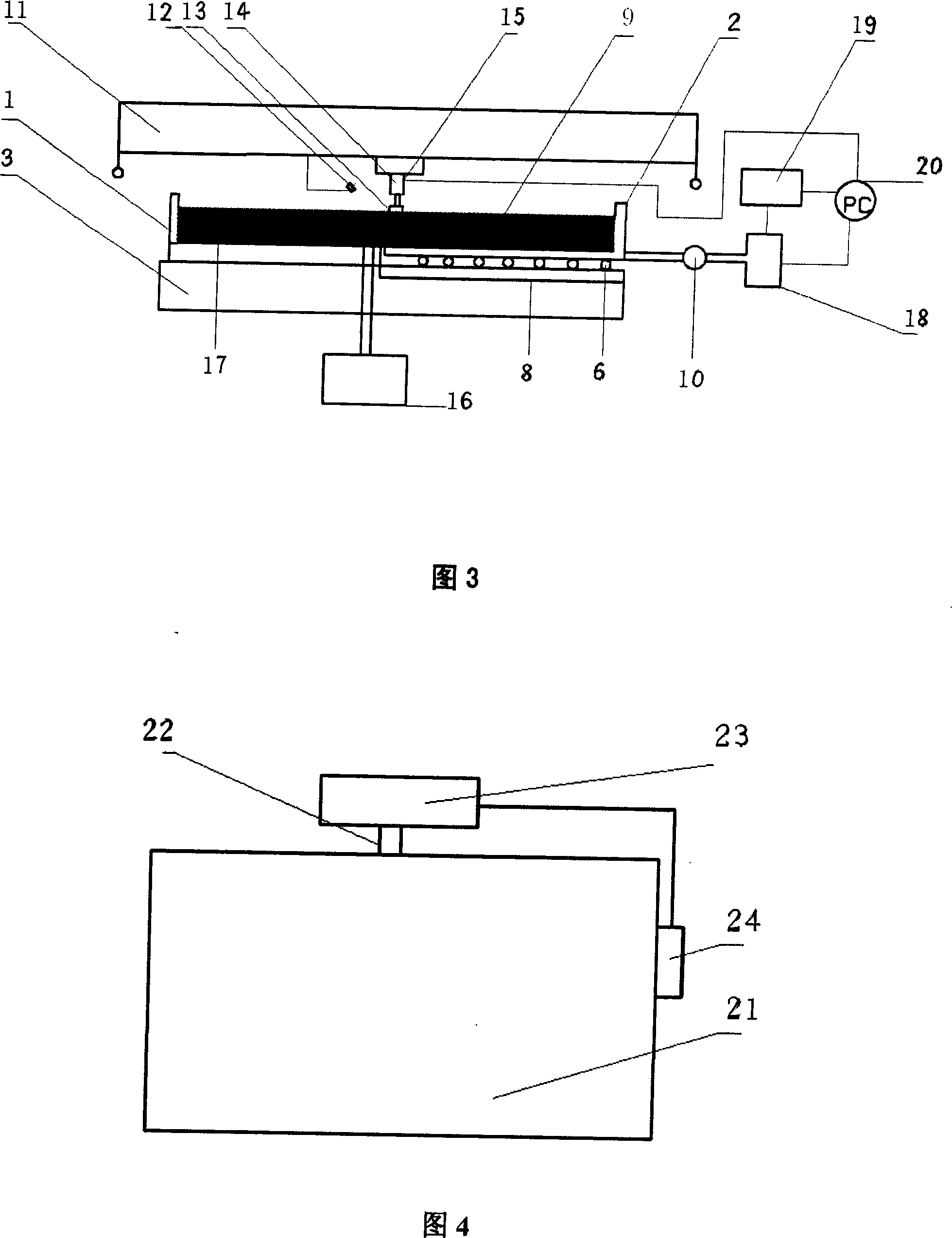

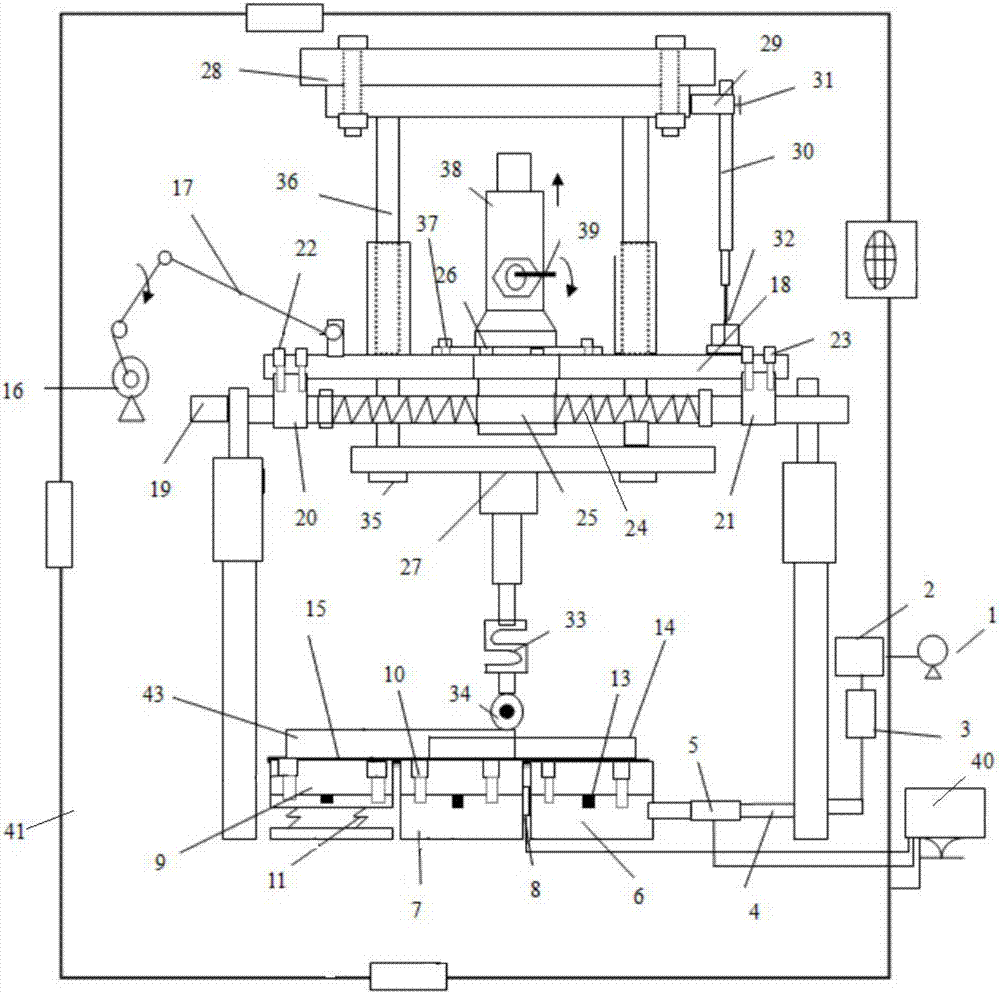

Device and method for simulating propagation of reflective cracks of semi-rigid-base asphalt pavement

PendingCN106896029ACrack Resistance EvaluationMaterial strength using steady shearing forcesMaterial strength using repeated/pulsating forcesControl systemStructural engineering

The invention discloses a device and a method for simulating propagation of reflective cracks of a semi-rigid-base asphalt pavement. The device comprises an environmental cabinet, a reflective crack simulating platform, a reflective crack testing system and an acquisition control system, wherein a pedestal is arranged at the bottom of the environmental cabinet; and the reflective crack testing system comprises a horizontal open-type reflective crack testing module and a vertical shear-type reflective crack testing module. The device not only can simulate open-type reflective cracks in the horizontal direction, but also can simulate shear-type reflective cracks in the vertical direction, and can really simulate occurrence and the propagation of the actual reflective cracks of the semi-rigid-base asphalt pavement, so that a reference basis is provided for selecting an anti-cracking material and an anti-cracking structure in pavement structure design.

Owner:青海省交通规划设计研究院有限公司 +2

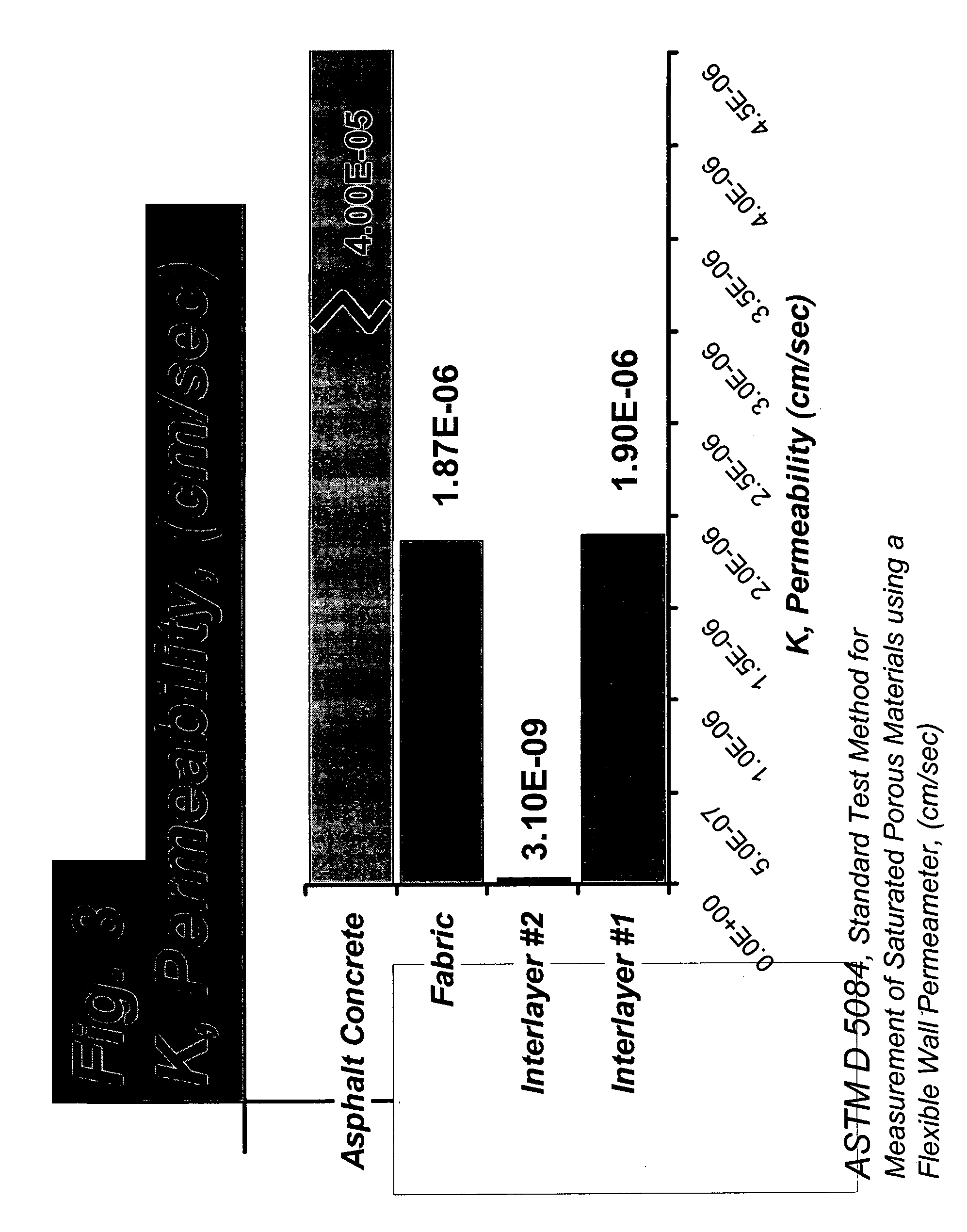

Reflective crack relief layer that is permeable

ActiveUS7479185B2Improve breathabilityAvoid formingSynthetic resin layered productsCellulosic plastic layered productsRoad surfaceReflective crack

A design method for making a bituminous mixture that is used to form a vapor-permeable layer of pavement is provided. This design procedure includes preparing one or more bituminous mixture test specimens, measuring the performance of these specimens, and selecting a desirable bituminous mixture for paving that is vapor-permeable based on the performance of the specimens. Another aspect of the present invention is the selected bituminous mixture, which includes aggregate and a bituminous binder. The aggregate should be selected such that no more than about 5% by mass of the aggregate and preferably no more than about 3.5% by mass of the aggregate is able to pass through a 75 μm sieve. The selected bituminous mixture should have an Air Permeability Value that is at least about 8 cm2 so as to reduce its propensity for blistering during and after construction. Still further, the selected bituminous mixture should have desirable fatigue resistance and should be substantially water-impermeable.

Owner:ROAD SCI

Reflective crack relief layer that is permeable

ActiveUS20070028802A1Improve breathabilityAvoid blistersSynthetic resin layered productsCellulosic plastic layered productsRoad surfaceReflective crack

A design method for making a bituminous mixture that is used to form a vapor-permeable layer of pavement is provided. This design procedure includes preparing one or more bituminous mixture test specimens, measuring the performance of these specimens, and selecting a desirable bituminous mixture for paving that is vapor-permeable based on the performance of the specimens. Another aspect of the present invention is the selected bituminous mixture, which includes aggregate and a bituminous binder. The aggregate should be selected such that no more than about 5% by mass of the aggregate and preferably no more than about 3.5% by mass of the aggregate is able to pass through a 75 μm sieve. The selected bituminous mixture should have an Air Permeability Value that is at least about 8 cm2 so as to reduce its propensity for blistering during and after construction. Still further, the selected bituminous mixture should have desirable fatigue resistance and should be substantially water-impermeable.

Owner:ROAD SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com