Double-layer rubber asphalt concrete structure for inhibiting reflection cracks of pavement and pavement method

A technology of concrete structure and rubber asphalt, which is applied in the direction of roads, roads, on-site paved cohesive pavements, etc., can solve the problems such as the effect is not outstanding, and achieve the effect of suppressing reflection cracks and dissipating concentrated stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

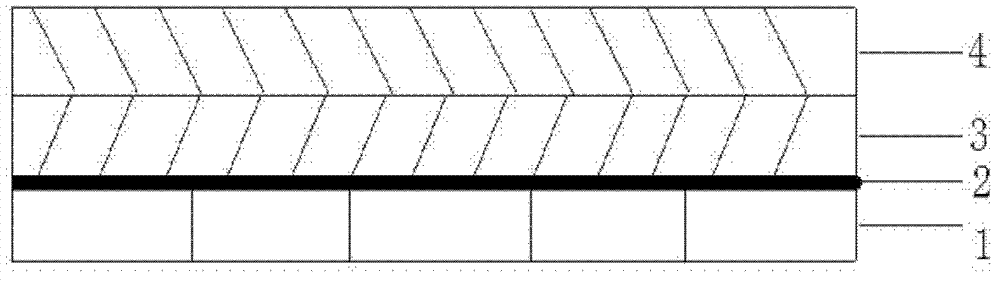

[0031] Example 1: First, stabilize the old cement slabs, then paste SBS self-adhesive anti-cracking stickers on the junction of adjacent cement slabs, and then spread 0.8mm-1.0mm modified emulsified asphalt sticky layer oil to form anti-cracking Adhesive course; then pave SDG-20 asphalt mixture with a paving thickness of 6cm to form the lower layer; finally pave rubber asphalt mixture with a gradation of SMA-13 and pave with a thickness of 4cm to form the upper layer.

Embodiment 2

[0032] Embodiment 2: First, paste SBS self-adhesive anti-cracking paste at the junction of adjacent old cement plates, and then spread 0.8mm-1.0mm modified emulsified asphalt adhesive layer oil to form an anti-cracking adhesive layer; then pave SDG -13 asphalt mixture, the paving thickness is 4cm to form the lower layer; finally, the rubber asphalt mixture with a gradation of SMA-10 is paved, and the paving thickness is 3cm to form the upper layer.

Embodiment 3

[0033] Embodiment 3: First, paste SBS self-adhesive anti-cracking paste at the junction of adjacent old cement plates, and then spread 0.8mm-1.0mm modified emulsified asphalt adhesive layer oil to form an anti-cracking adhesive layer; then pave SDG -16 asphalt mixture, the paving thickness is 5.5cm to form the lower layer; finally, the rubber asphalt mixture with a gradation of SMA-13 is paved, and the paving thickness is 5cm to form the upper layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com