Patents

Literature

85 results about "Loose fill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Loose fill materials are used to fill empty spaces in packages that contain lightweight, non-fragile items. An example of loose fill material is Expanded Polystyrene Peanuts.

Air filtration media

A glass fiber composite air filtration media is fabricated from glass fibers and plastic-containing boding fibers. The glass fibers may be virgin rotary fibers, loose-fill blowing wool insulation, bindered glass fibers such as batting insulation, or scrap rotary fibers.

Owner:CERTAINTEED CORP

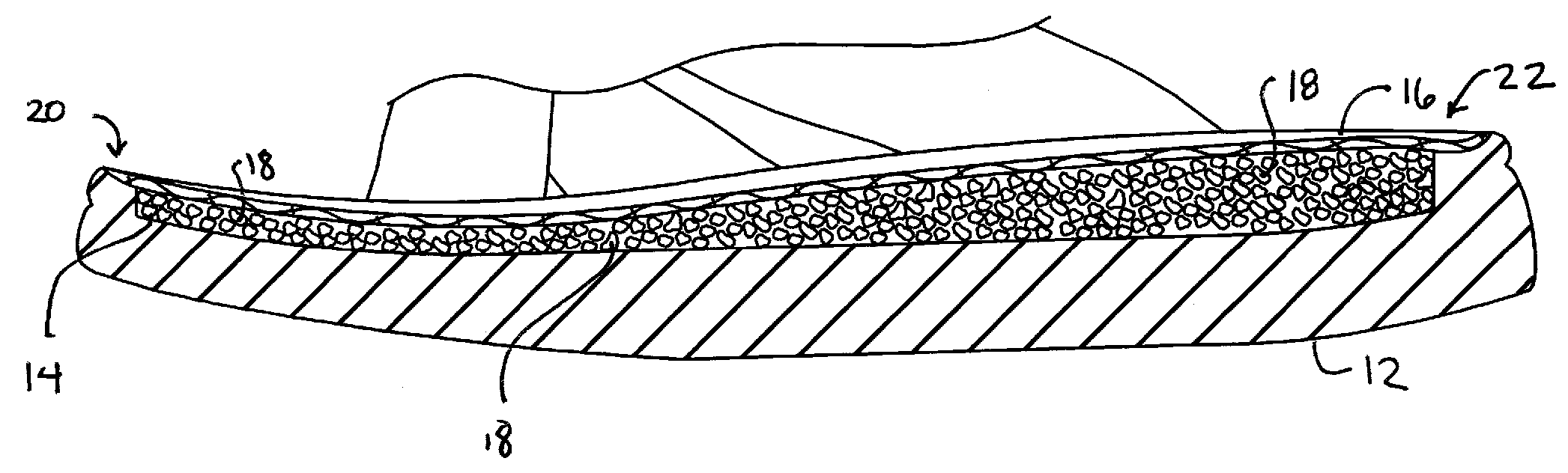

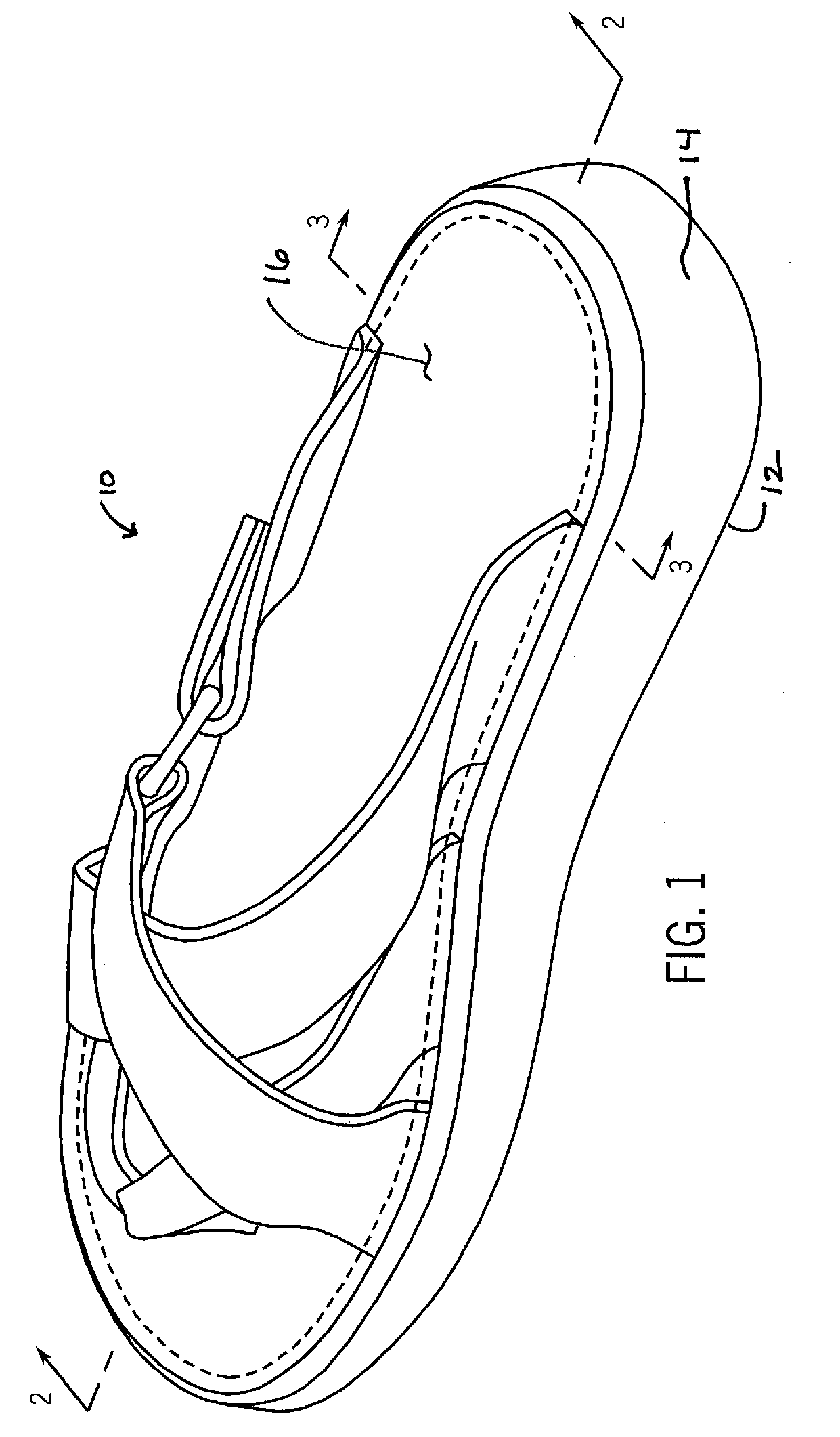

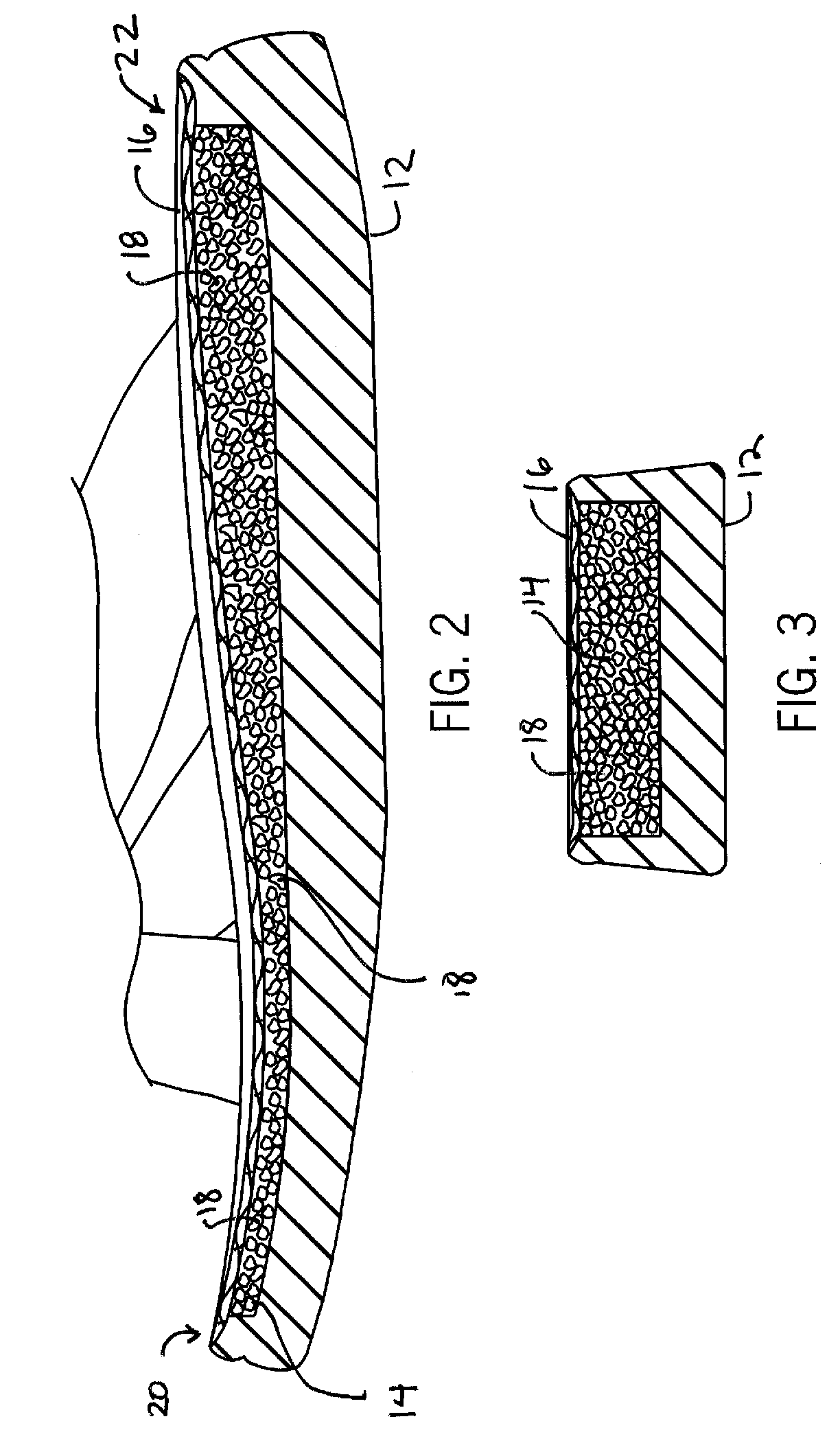

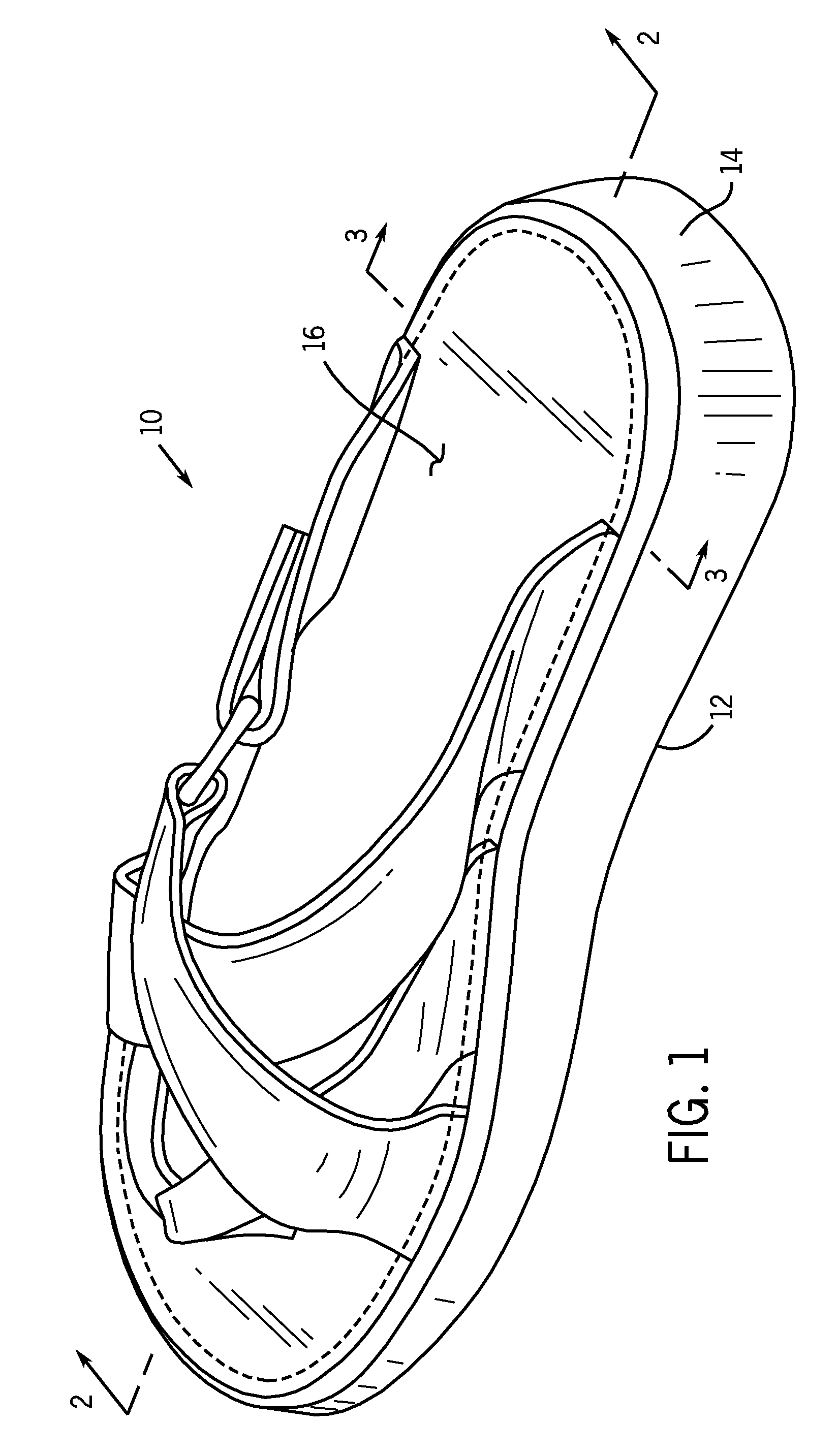

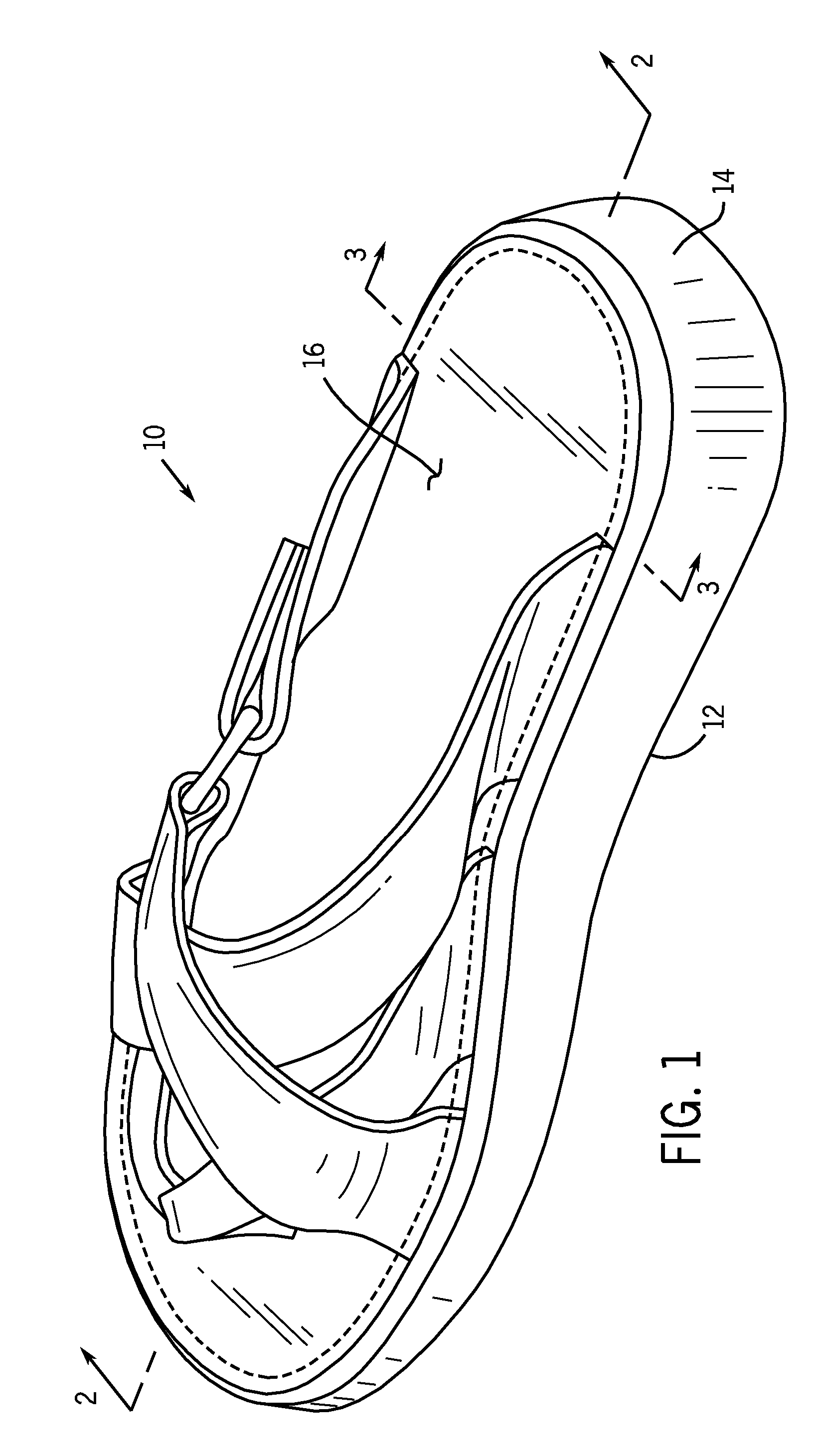

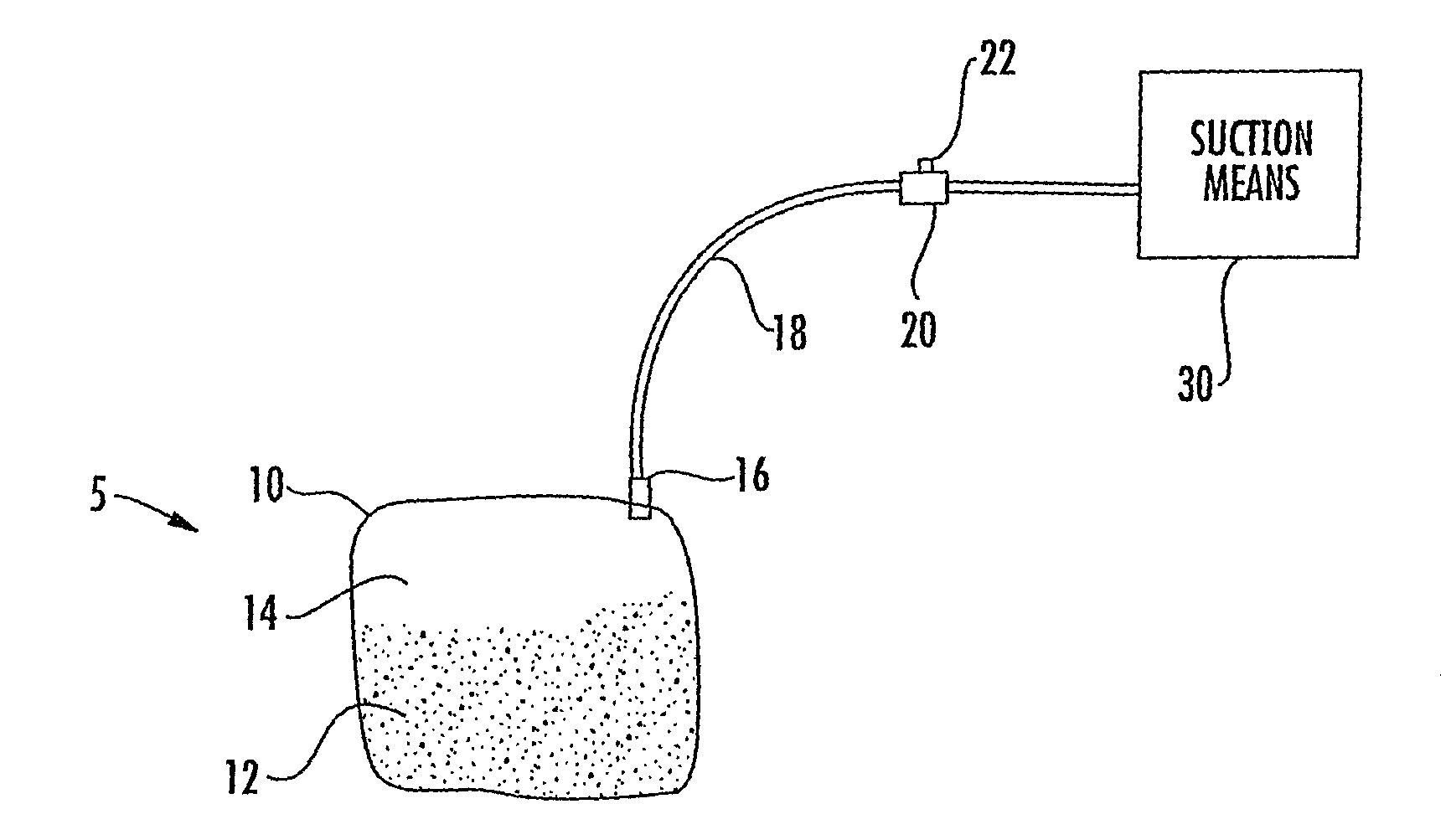

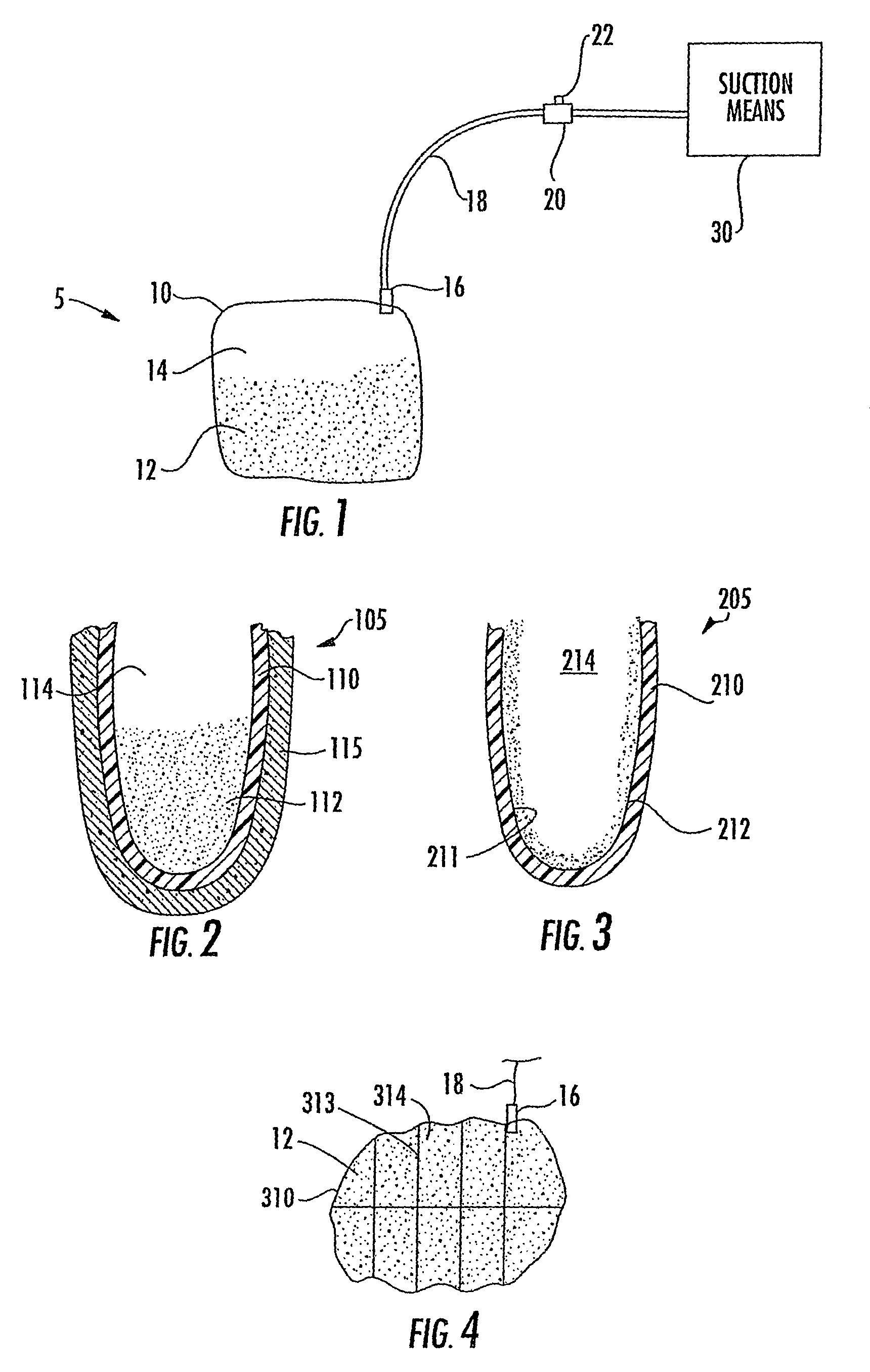

Shoe sole with a loose fill comfort support system

InactiveUS20060130363A1Cushion forceSolesTextile/flexible product manufactureSupporting systemFilling materials

A shoe is provided with an outsole which contacts the ground, an insole upon which a foot rests, and a midsole located between the outsole and the insole, wherein the midsole absorbs impact by providing a loose fill material throughout the midsole of the shoe to cushion any force exerted upon the shoe, wherein the midsole is divided into at least two compartments and each of the compartments is filled with the loose fill material.

Owner:GRAVITY GRP

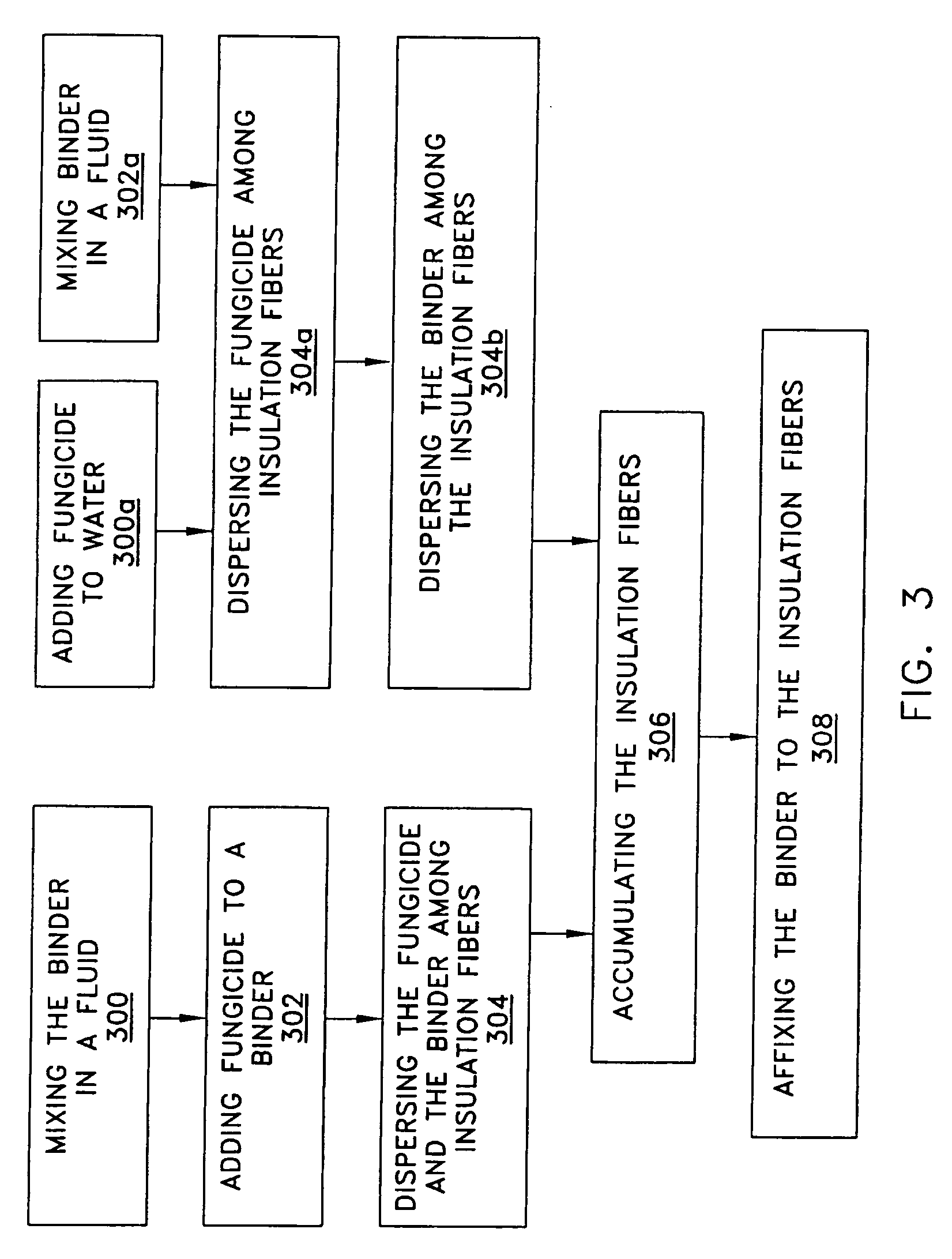

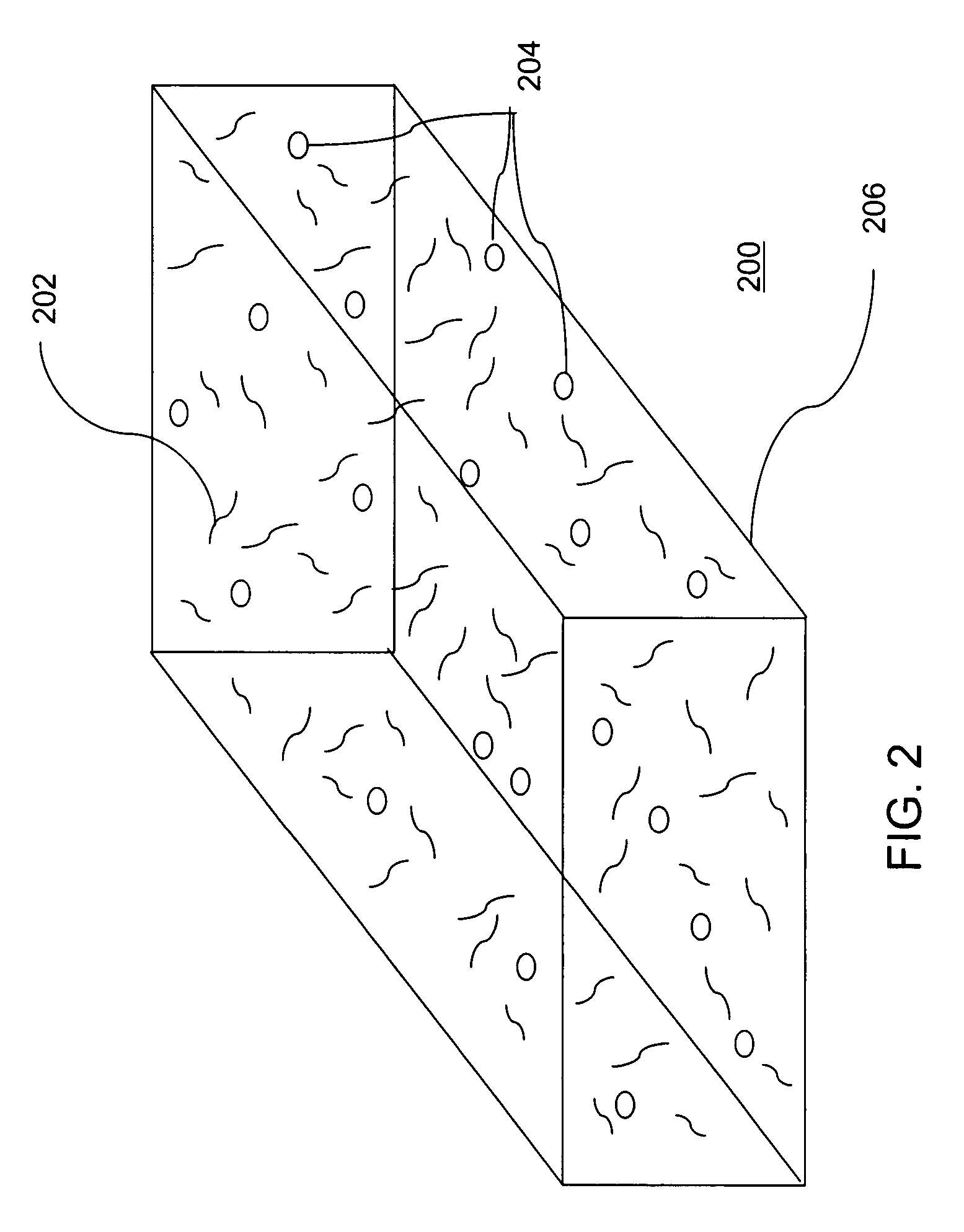

Fibrous insulation with fungicide

InactiveUS20060078720A1Improve anti-mold performanceNon-fibrous pulp additionNatural cellulose pulp/paperFungicideFiber

A fibrous insulation has insulation fibers (104) with a fungicide in a dispersed additive affixed to the fibers (104), and a method of making a fibrous insulation by dispersing a fungicide and a dispersed additive on the fibers (104) followed by affixing the dispersed additive on the fibers (104). The method produces thermal, acoustic, duct liner or board insulation either as loose fill insulation or as an insulation mat.

Owner:CERTAINTEED CORP

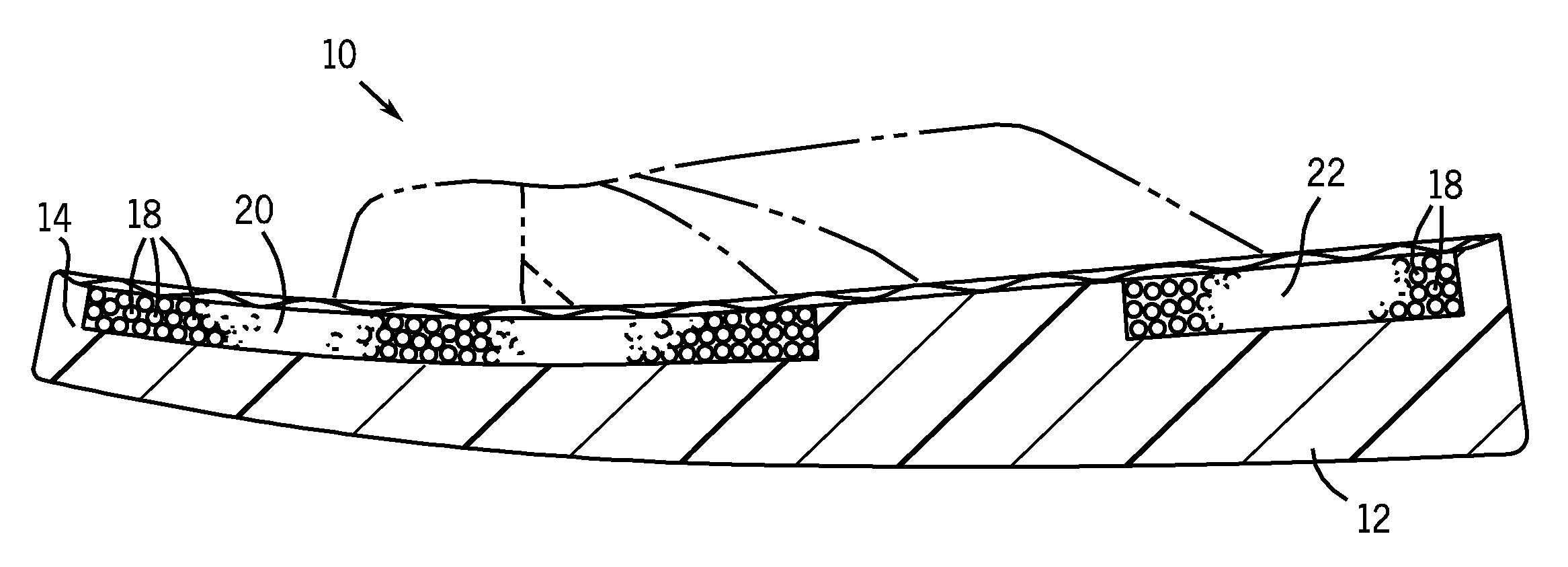

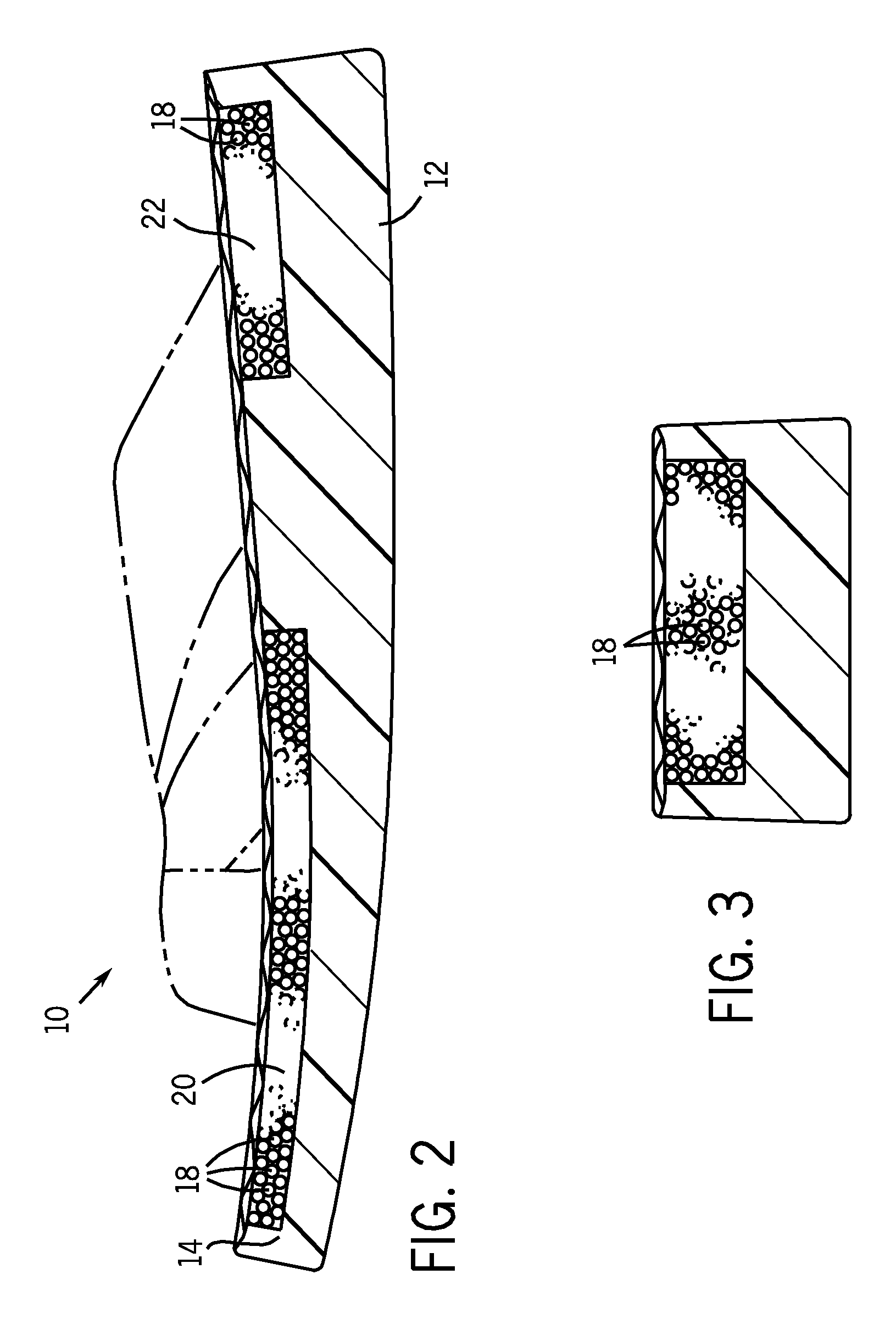

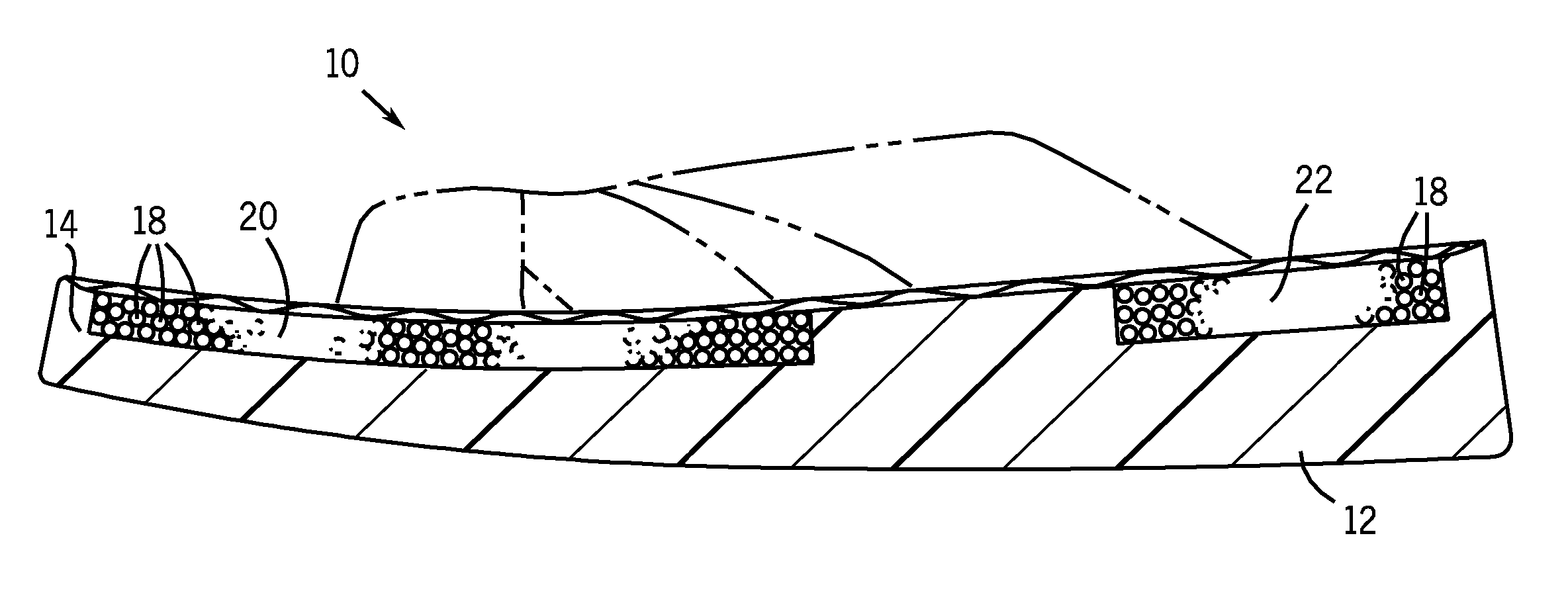

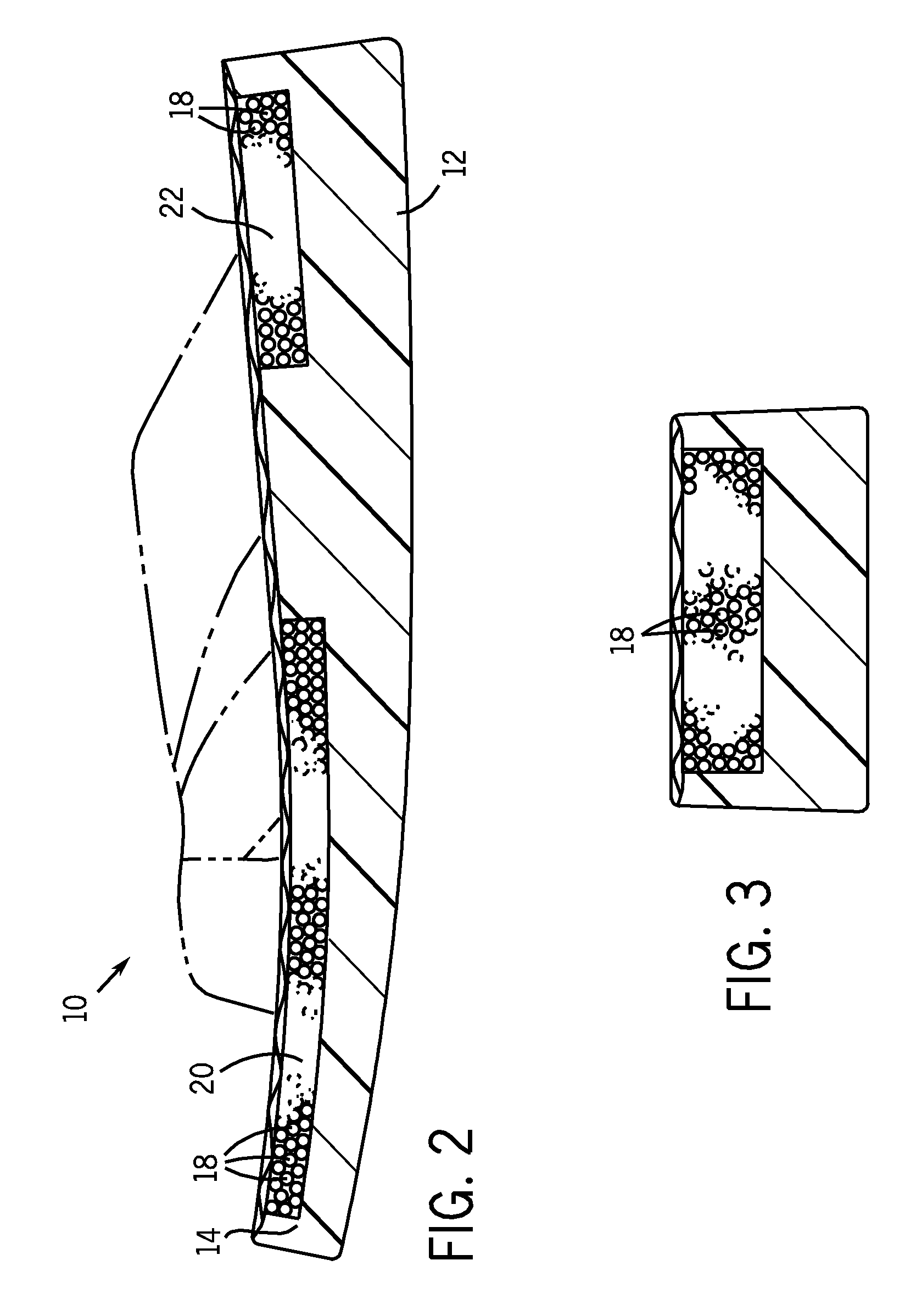

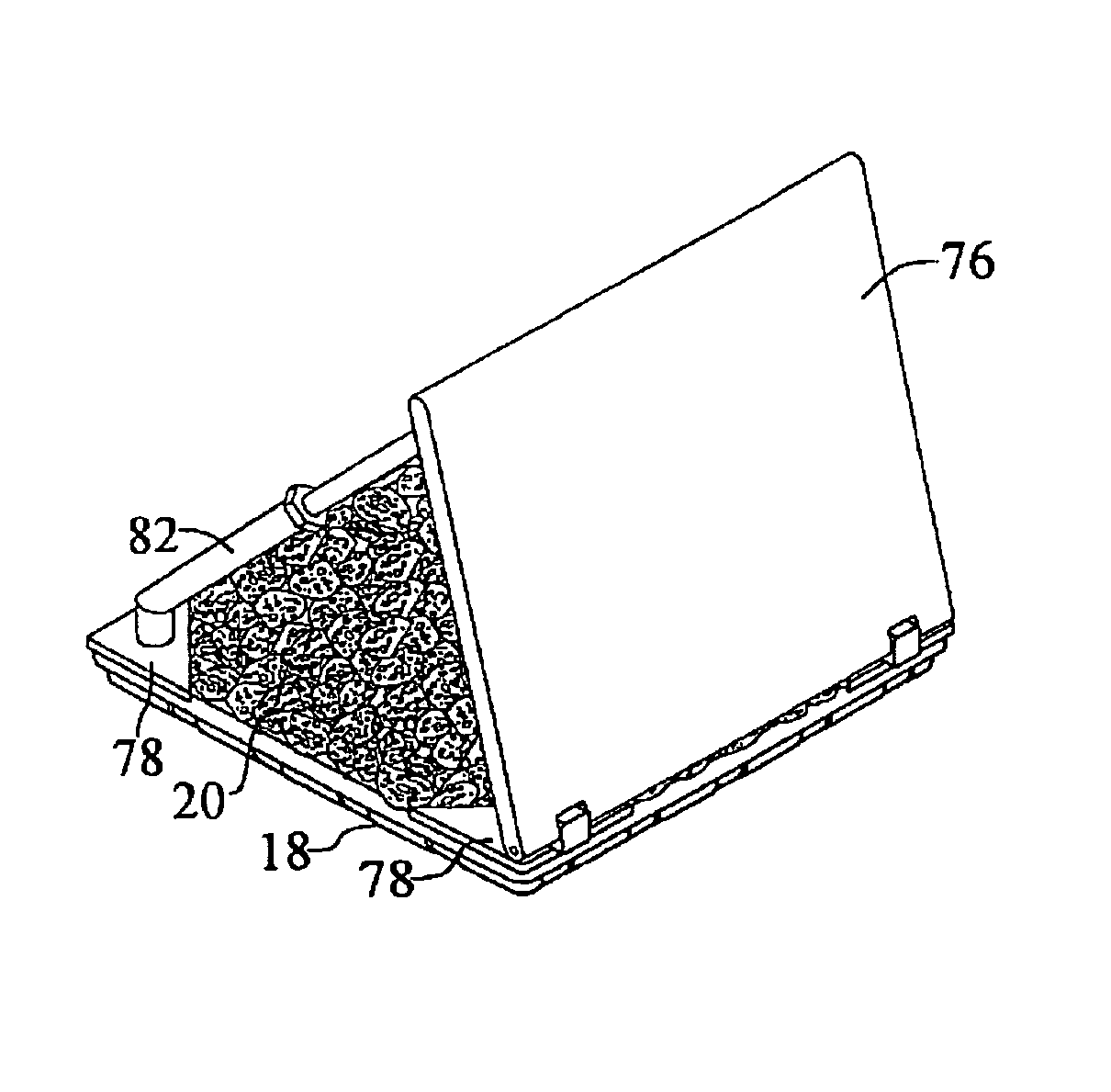

Shoe sole with loose fill compartments seperated by arch support

InactiveUS20080060221A1Superior comfort and performance and stabilityImprove stabilitySolesTextile/flexible product manufactureFilling materialsHeel strike

A shoe is provided with an outsole that contacts the ground, an insole upon which a foot rests, and a midsole located between the outsole and the insole. The midsole cushions the wearer's foot by providing a loose fill material in a front compartment on which the toes and ball of the foot of the wearer rest and a heel compartment on which the heel of the wearer rests. The front compartment is divided into at least two sub compartments to keep the loose fill evenly distributed. The front compartment and the heel compartment are separated by an arch support section of the midsole, which provides relatively rigid support for the arch of the wearer's foot.

Owner:GRAVITY GRP

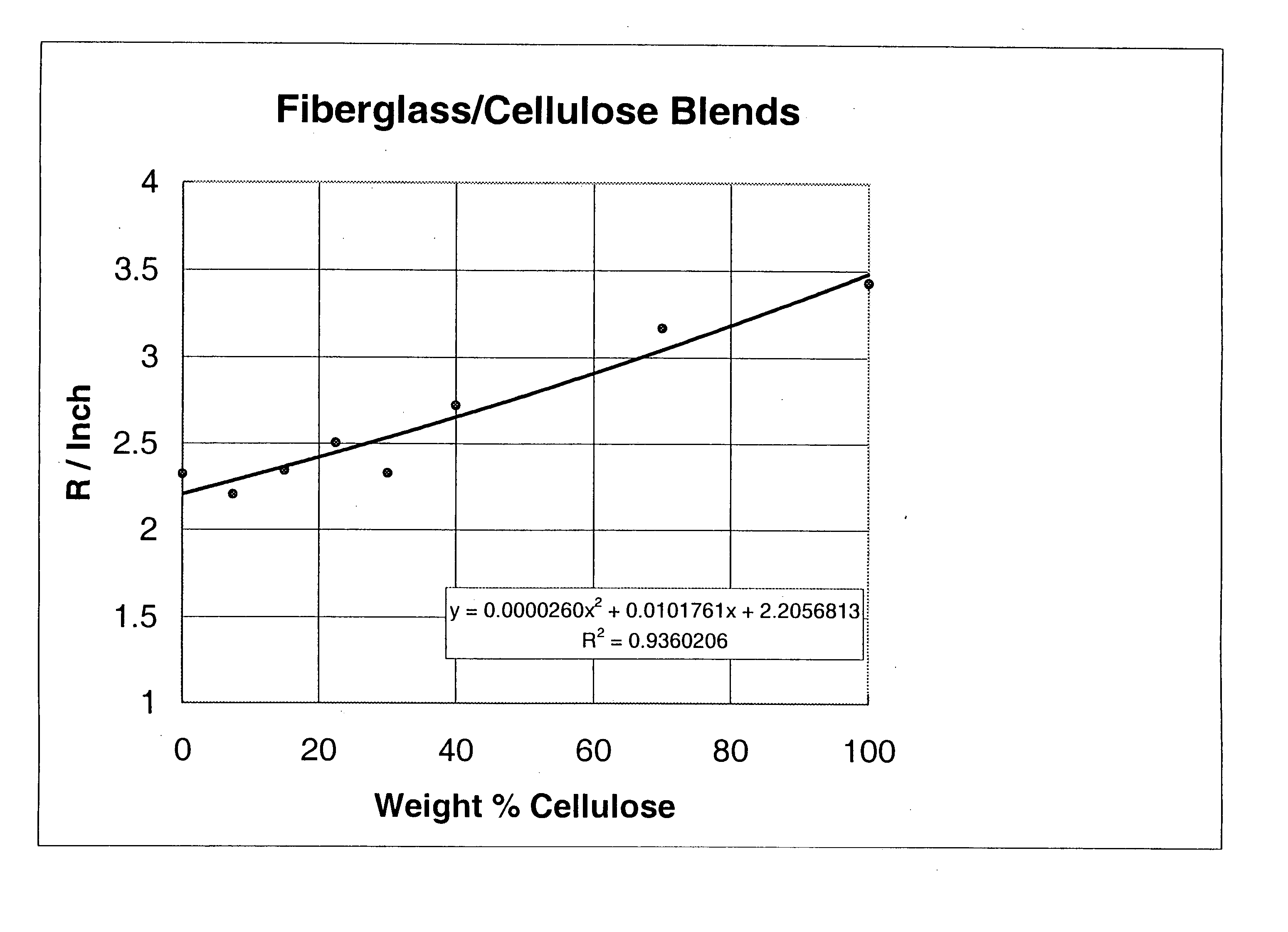

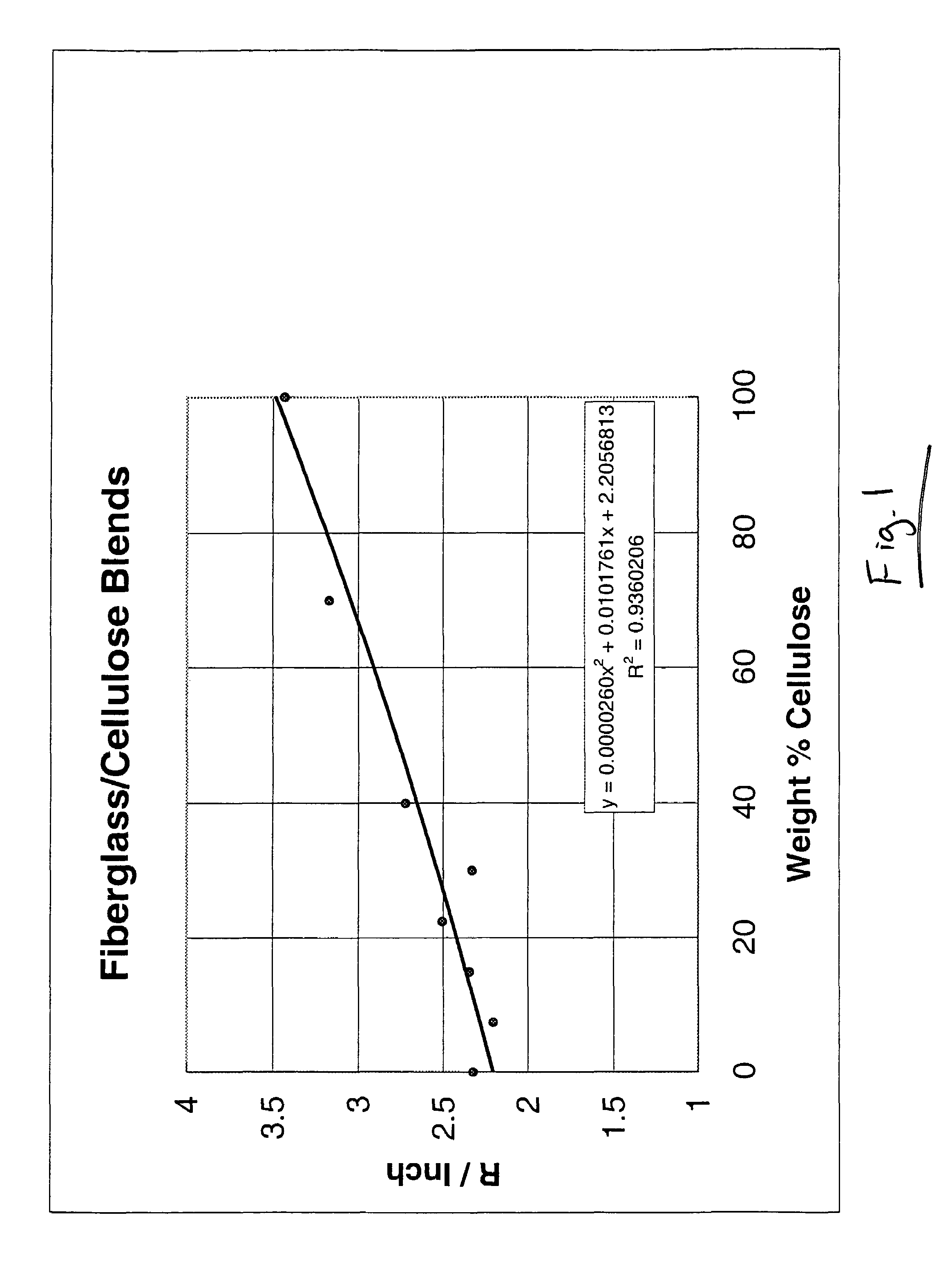

Insulation with mixture of fiberglass and cellulose

InactiveUS20050279963A1Improve propertiesNon-fibrous pulp additionNatural cellulose pulp/paperCelluloseGlass fiber

Certain example embodiments of this invention relate to insulation (e.g., loose-fill insulation which may be blown into attics, wall cavities, or the like) including a mixture of fiberglass and cellulose. In certain example embodiments, the insulation mixture comprises from 15-60% cellulose, more preferably from 20-50% cellulose, and most preferably from 25-45% cellulose (with substantially the remainder of the insulation be made up of fiberglass). Example advantages include improved radiant barrier properties and thus improve R-values / inch.

Owner:KNAUF INSULATION LLC

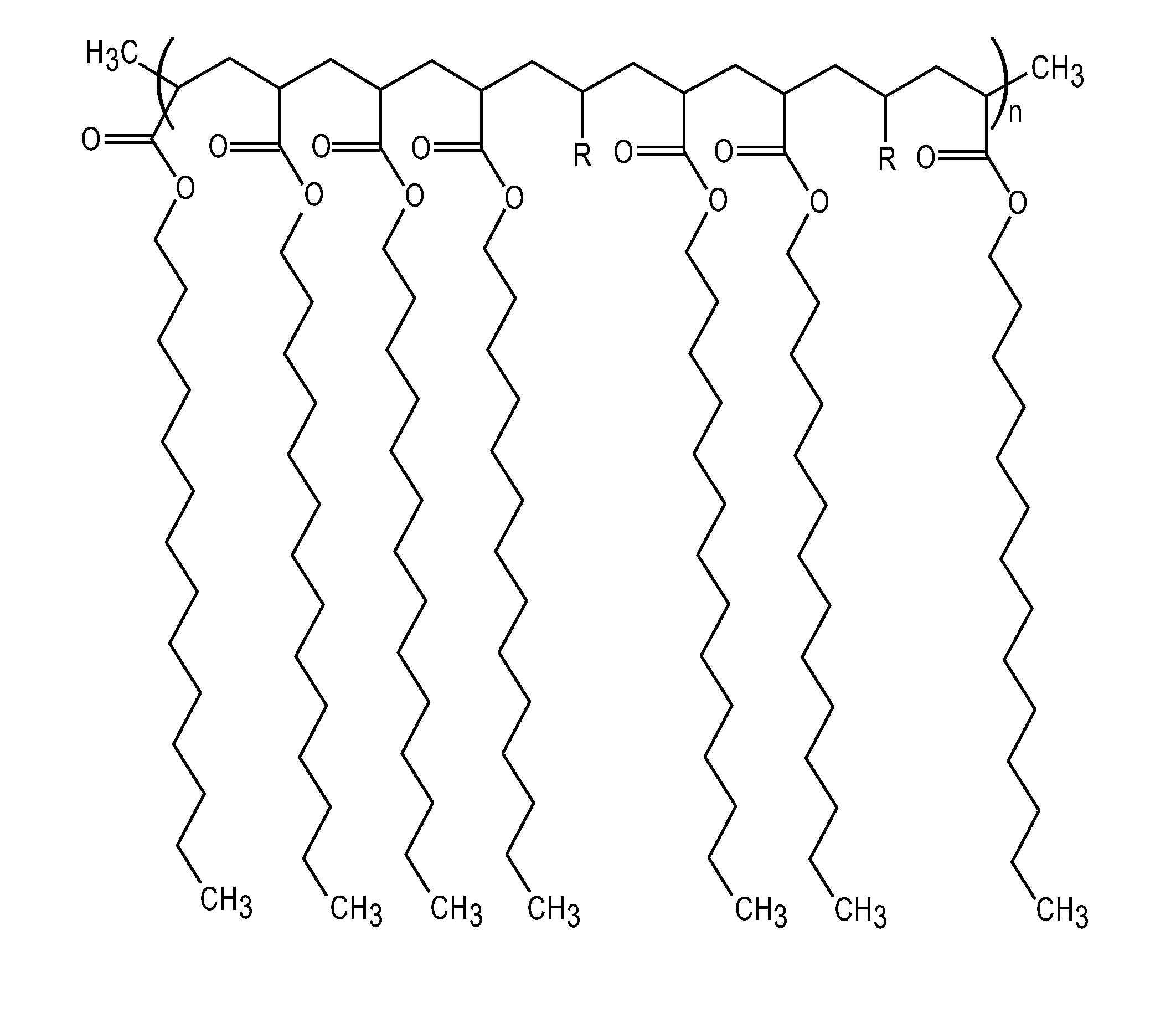

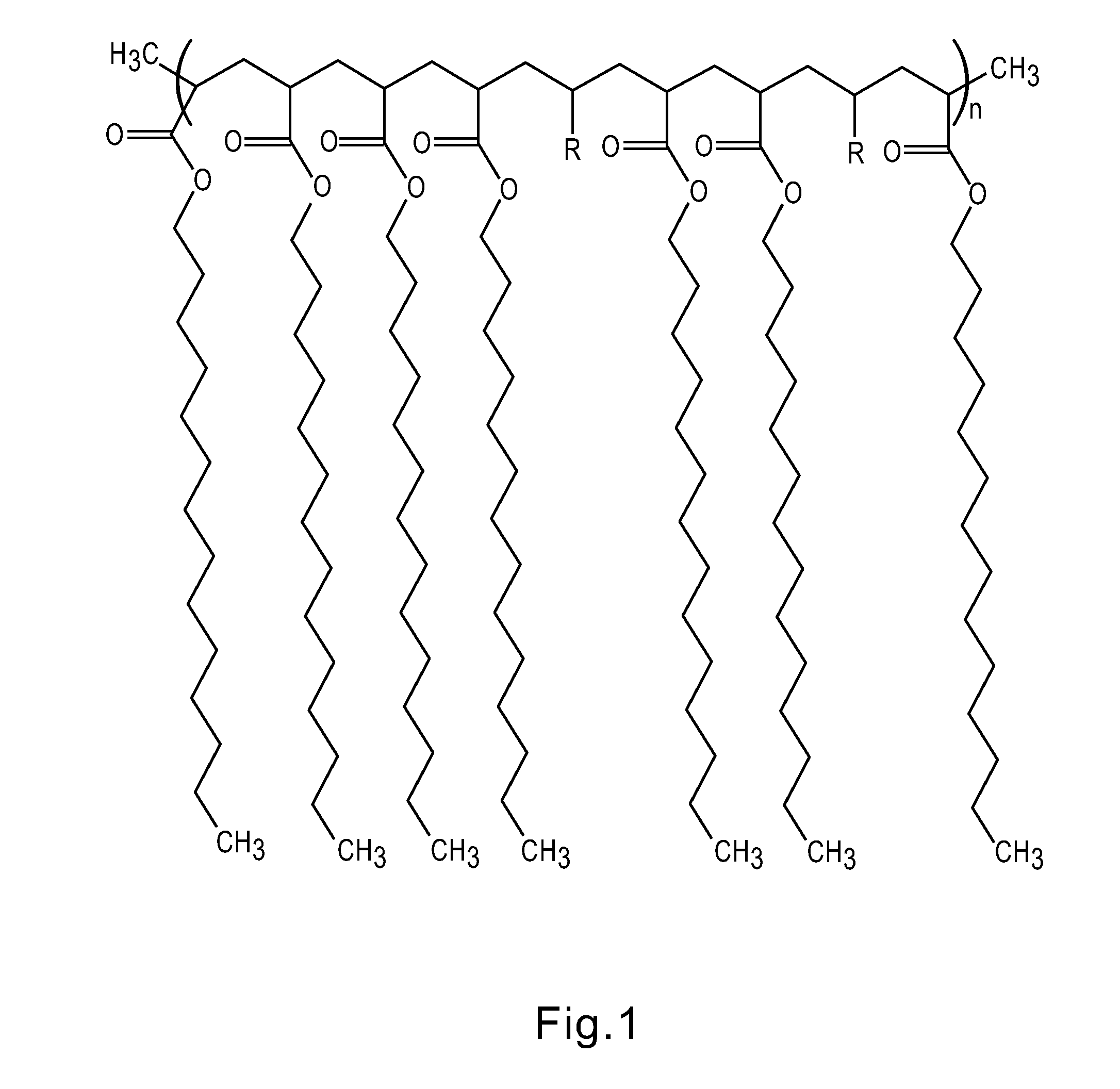

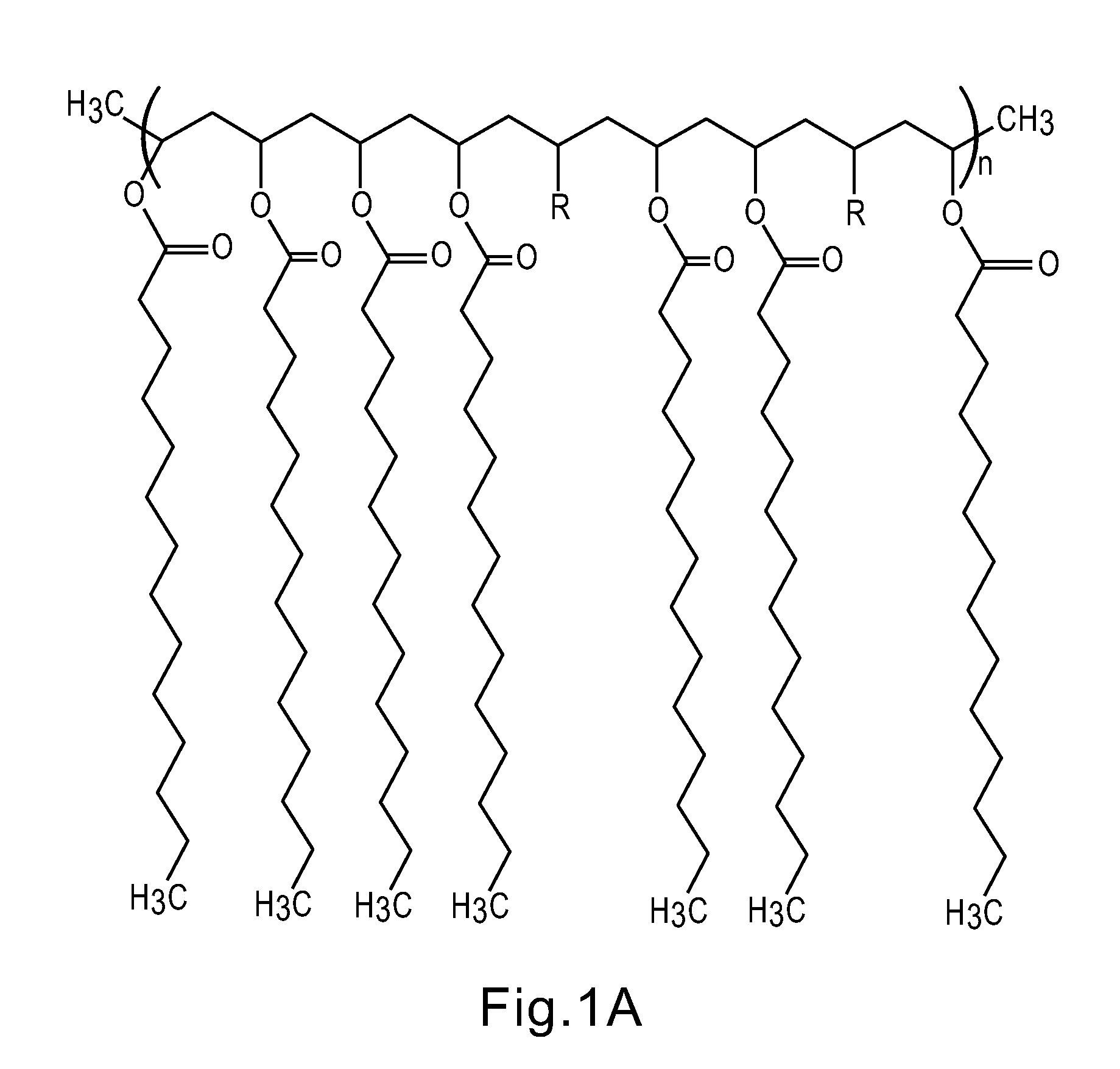

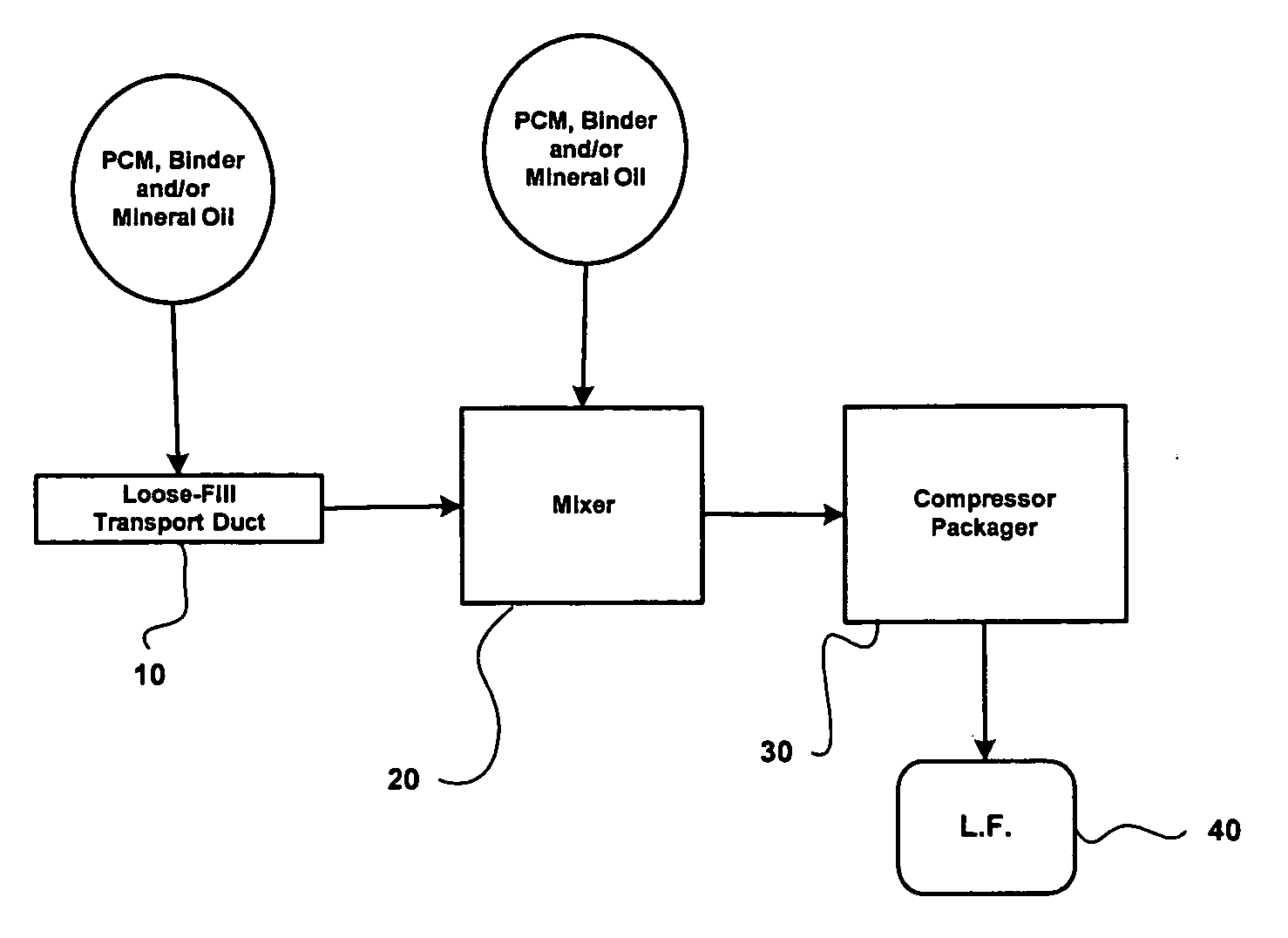

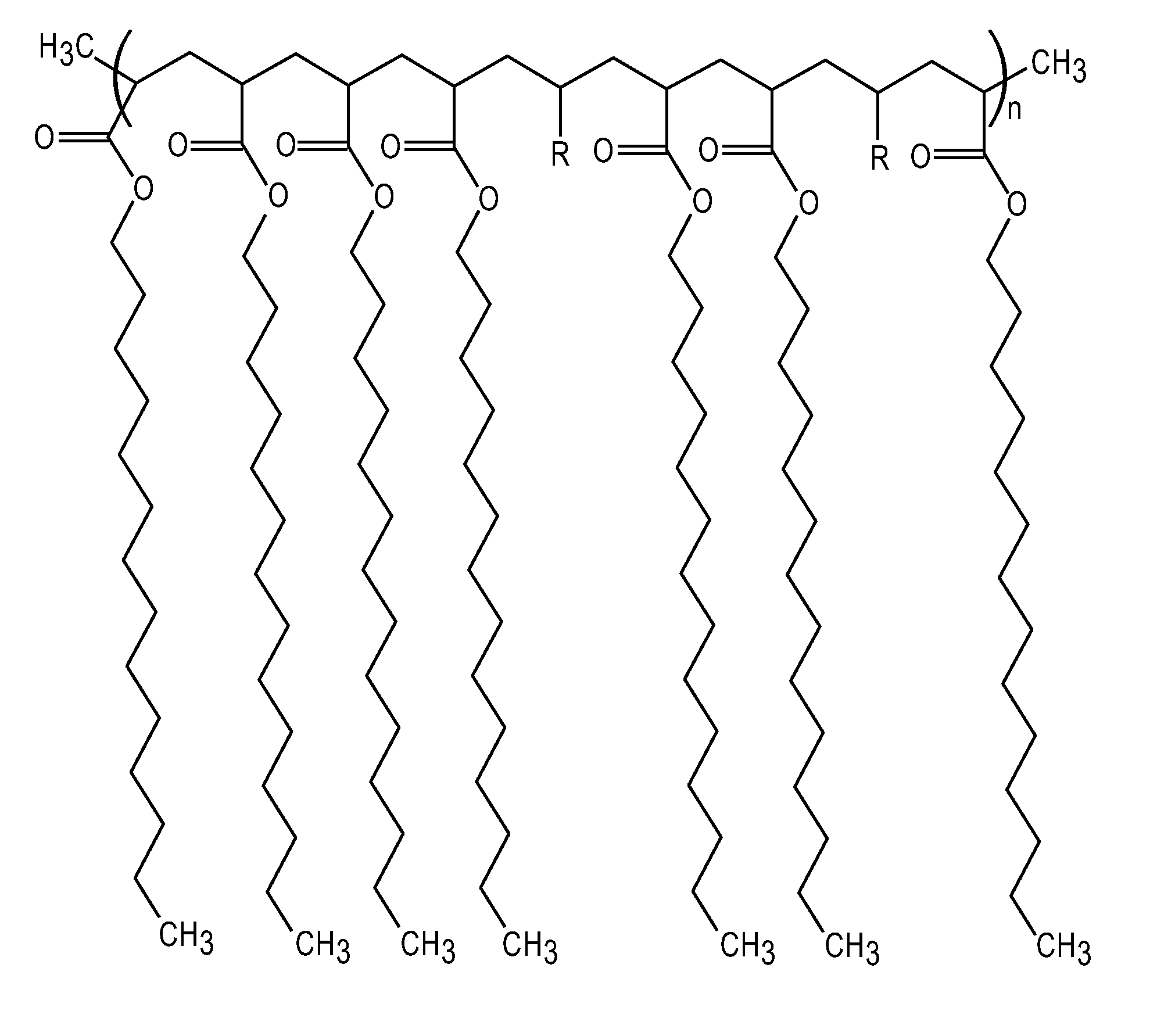

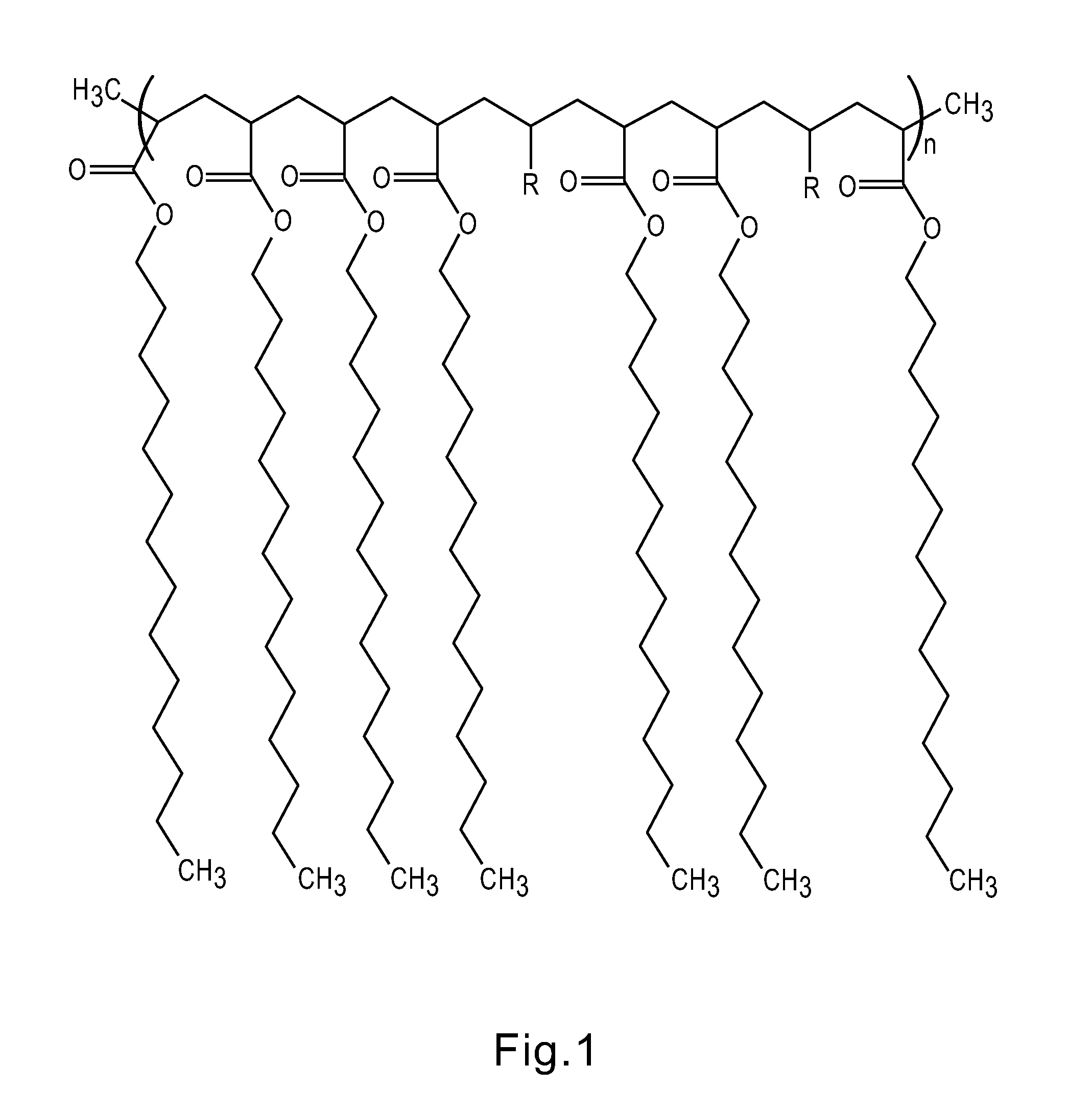

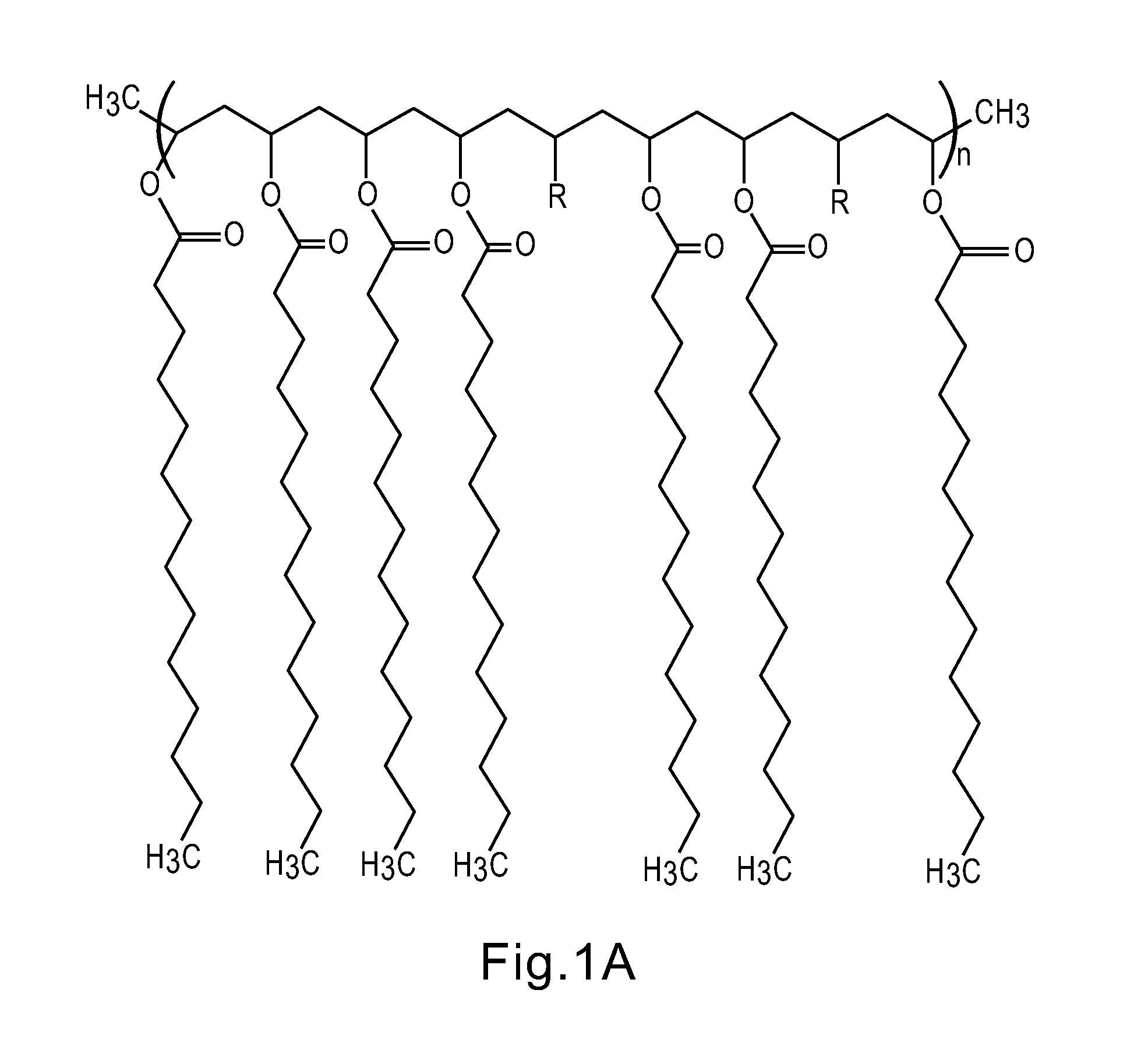

Thermal regulating building materials and other construction components containing polymeric phase change materials

In accordance with one aspect, a thermally regulating construction material comprises a base material and a polymeric phase change material bound to the base material, wherein the base material provides reversible temperature regulation properties to the building construction material. In accordance with another aspect, an insulation material for use in building construction comprises a base material and a polymeric phase change material bound to the base material, wherein the base material provides reversible temperature regulation properties to the insulation material. The base material may be selected from the group consisting of foam insulation, loose fill insulation, and batted insulation.

Owner:LATENT HEAT SOLUTIONS LLC

Antimicrobial activated carbon and use thereof

InactiveUS20070199890A1Excellent and long-lived antimicrobial propertyReduce surface tensionBiocideCarbon active ingredientsActivated carbonControlled release

Antimicrobial activated carbon having controlled release of the antimicrobial active agent are provided comprising activated carbon and an antimicrobial coating applied to at least a portion of its exposed outer surface wherein the antimicrobial coating comprises a binder and an antimicrobial water soluble glass or an inorganic ion exchange type antimicrobial agent. The antimicrobial coatings to be applied to the activated carbon materials are curable liquids or ultra-fine thermoplastic powder coatings. The antimicrobial activated carbon materials may be employed in filters as a loose fill or in sintered filters.

Owner:SCIESSENT LLC

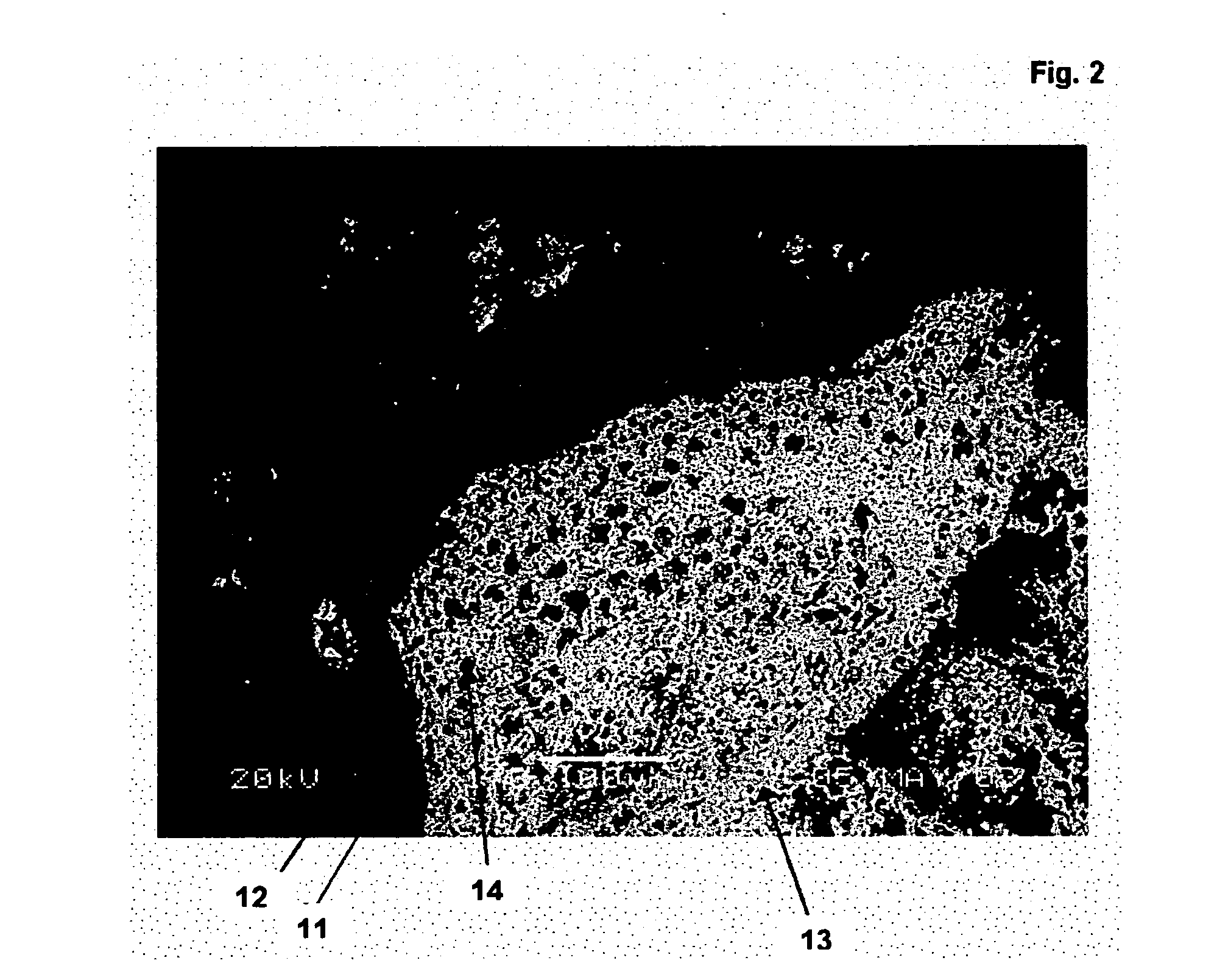

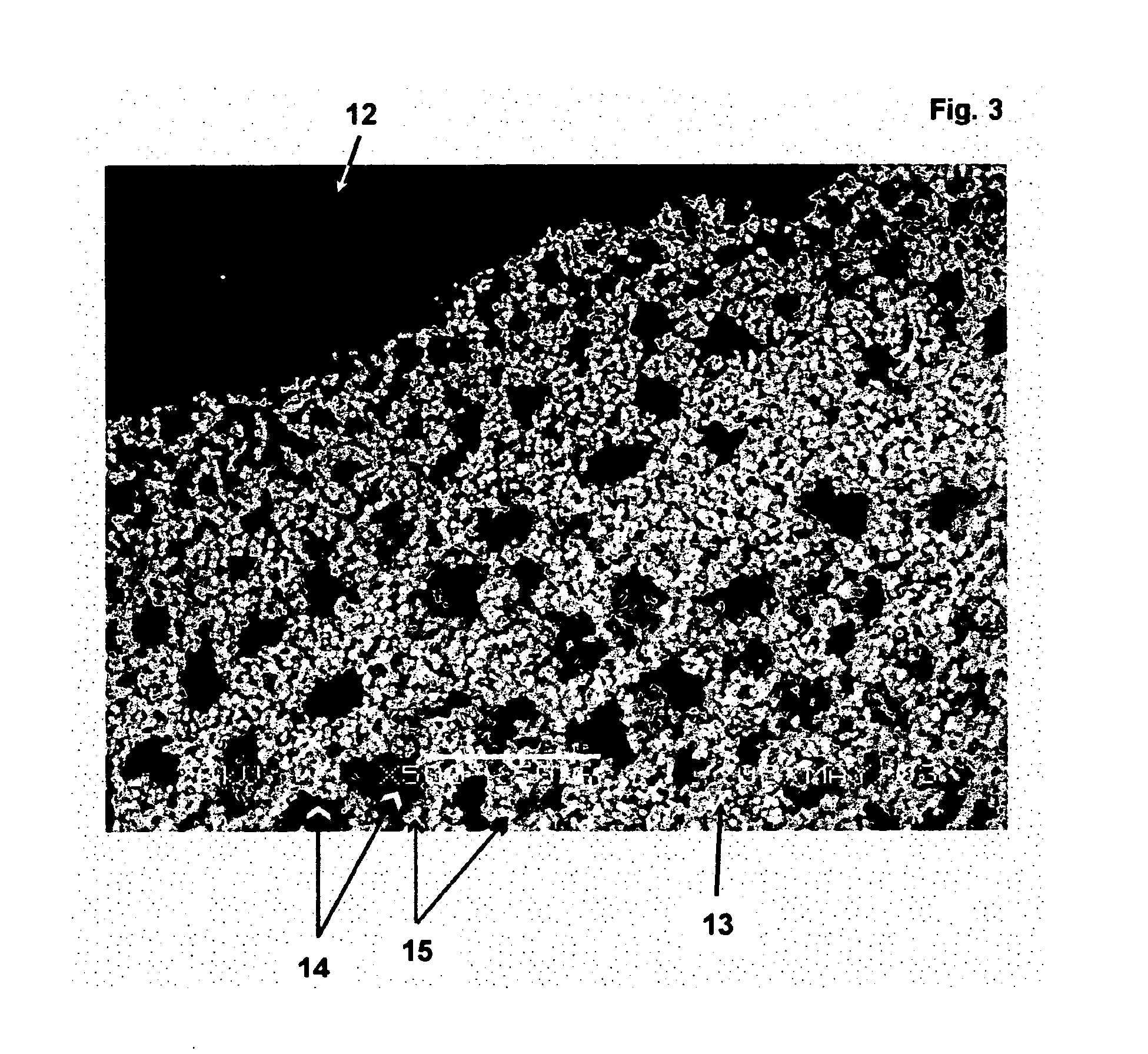

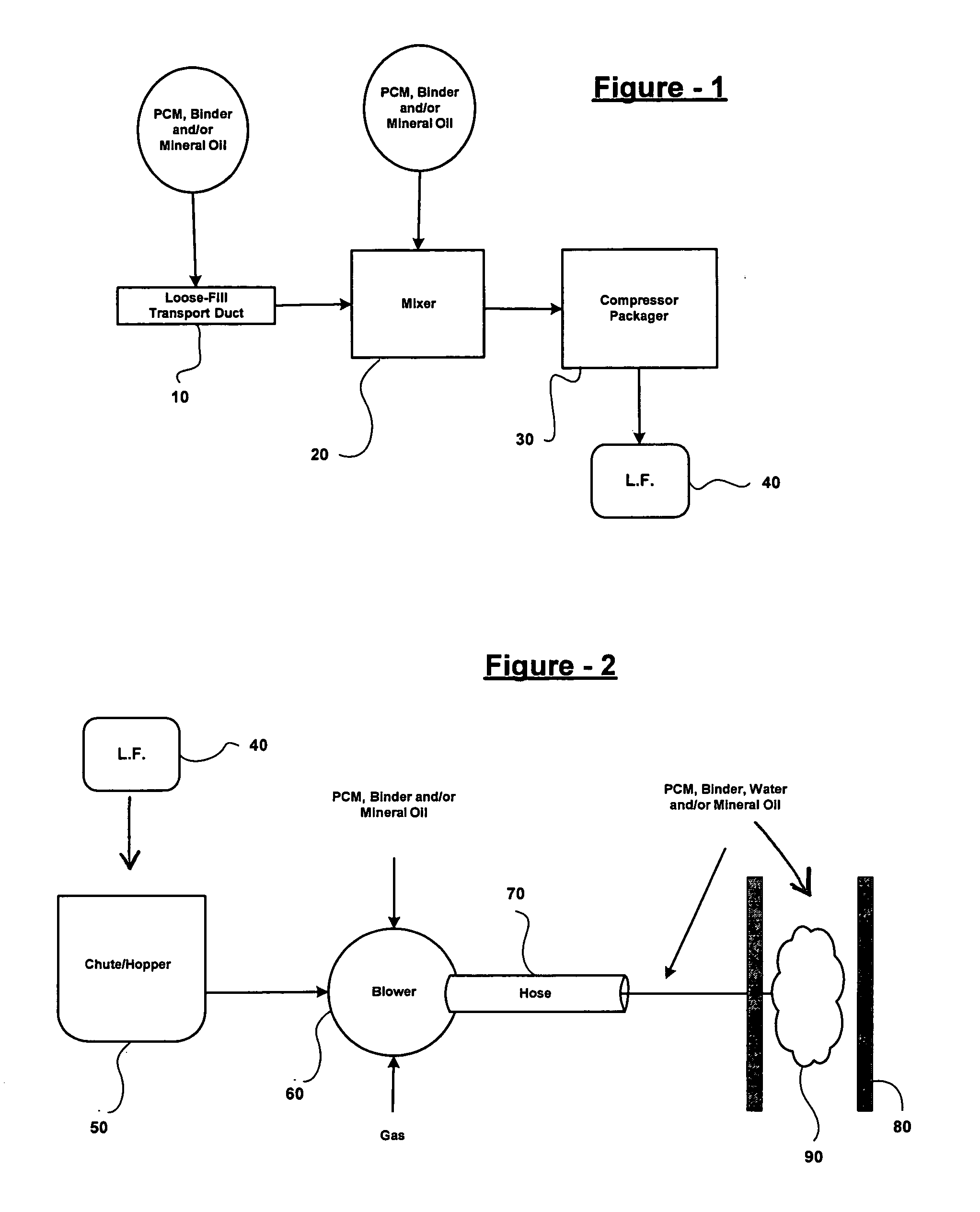

Loose fill insulation product having phase change material therein

InactiveUS20050281979A1Improve performanceReduce needThermal insulationLayered productsThermal insulationPhase-change material

A thermal insulation product is provided comprising a loose fill insulation for insulating an interior of a hollow or open space in a structure and at least one phase change material dispersed in the loose fill insulation.

Owner:CERTAINTEED CORP

Shoe sole comfort and support system containing blends of loose fill material

InactiveUS20080066341A1Superior comfort and performance and stabilitySolesTextile/flexible product manufactureSupporting systemEngineering

A shoe is provided with an outsole that contacts the ground, an insole upon which a foot rests, and a midsole located between the outsole and the insole. The midsole cushions the wearer's foot by providing a loose fill having a size between −2 and −80 mesh, in a front compartment on which the toes and ball of the foot of the wearer rest and a heel compartment on which the heel of the wearer rests. The front compartment is divided into at least two sub compartments to keep the loose fill evenly distributed. The front compartment and the heel compartment are separated by an arch support section of the midsole. A blend of two or more mesh sizes of fill may also be used for the loose fill.

Owner:GRAVITY GRP

Lightweight wall construction

InactiveUS6907708B2High viscosityImprove suppression propertiesConstruction materialWallsCement boardLoose fill

A low or no fines lightweight concrete mixture. The mixture comprises one part by volume of a cementitious binder, 2-10 parts inert coarse aggregate, a cement additive in an amount of 0.05 to 0.3% by weight of the cementitious binder and an effective amount of water, the additive including 40-99% of a viscosity enhancing agent, which in water either dissolves or forms colloidal dispersions, and 1-60% of an air entrainment agent / surfactant adapted to entrain air when mixed with water and / or pumped. The mixture is particularly suitable for constructing a building panel where a frame is prepared, the front and rear faces being covered by fibre reinforced cementitious sheets and the cavity there between at least partially filled with the lightweight concrete mixture which flows in a manner similar to loose fill.

Owner:JAMES HARDIE TECH LTD

Degradable plastics possessing a microbe-inhibiting quality

InactiveUS6756428B2Altering biodegradabilityOvercomes shortcomingBiocideAntifouling/underwater paintsMicroorganismPolymer science

A microbe-inhibiting (MI) compound is incorporated into a biodegradable polymer composition most preferably, a starch-based polymer, to inhibit microbial growth and to attenuate the biodegradation of the polymer composition. Such a composition is used to manufacture any of a number of articles, particularly those that come in contact with foods such as foam containers and fruit shock absorber nets as well as packing materials such as loose fill pellets.

Owner:ANIMAL MAJESTY

Modular ballast system for membrane roofs

ActiveUS20100325975A1Reduce evaporationPredictable and relatively large volumePhotovoltaic supportsSolar heating energyTime segmentEnvironmental engineering

Owner:WESTON SOLUTIONS

Thermal regulating building materials and other construction components containing polymeric phase change materials

Owner:LATENT HEAT SOLUTIONS LLC

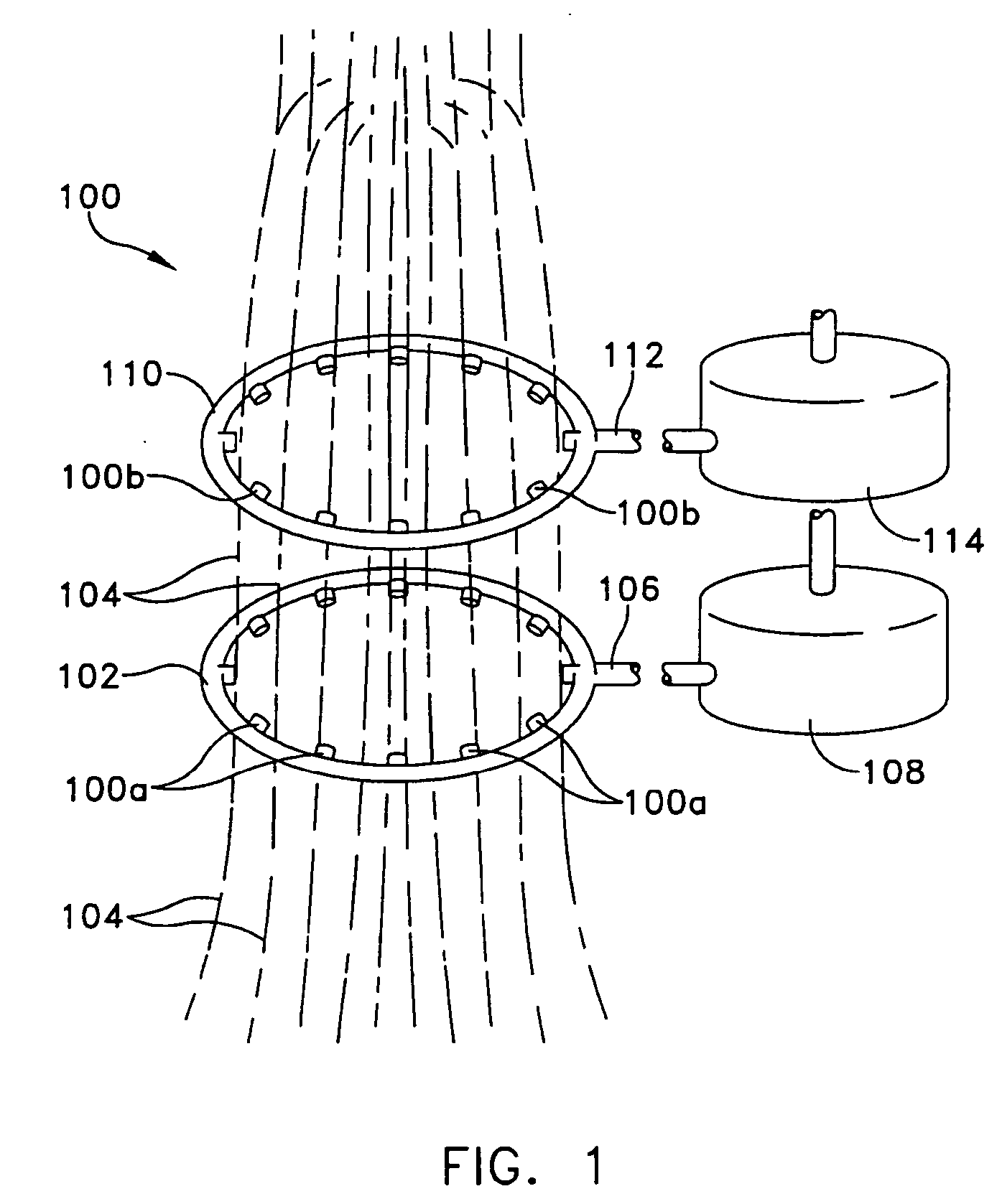

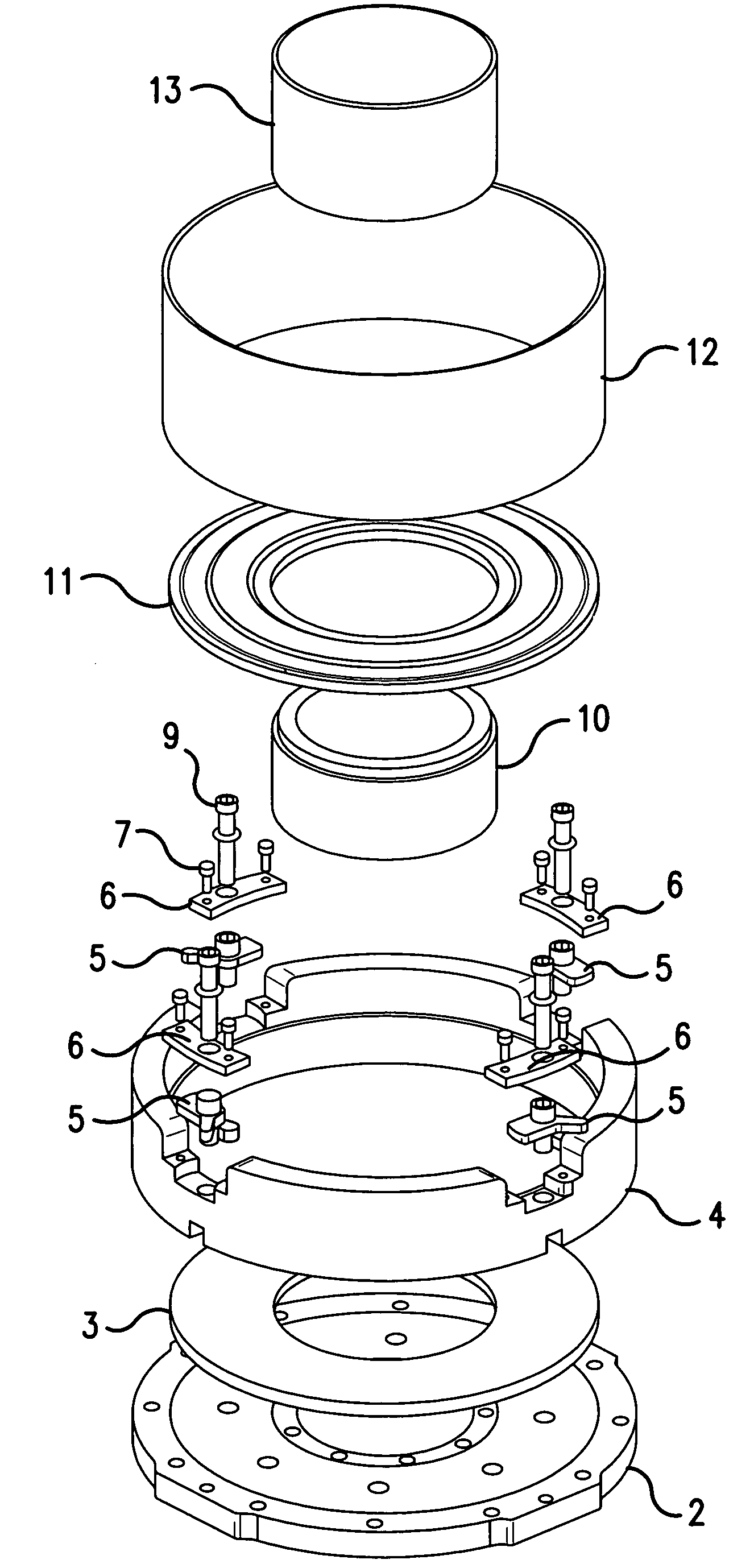

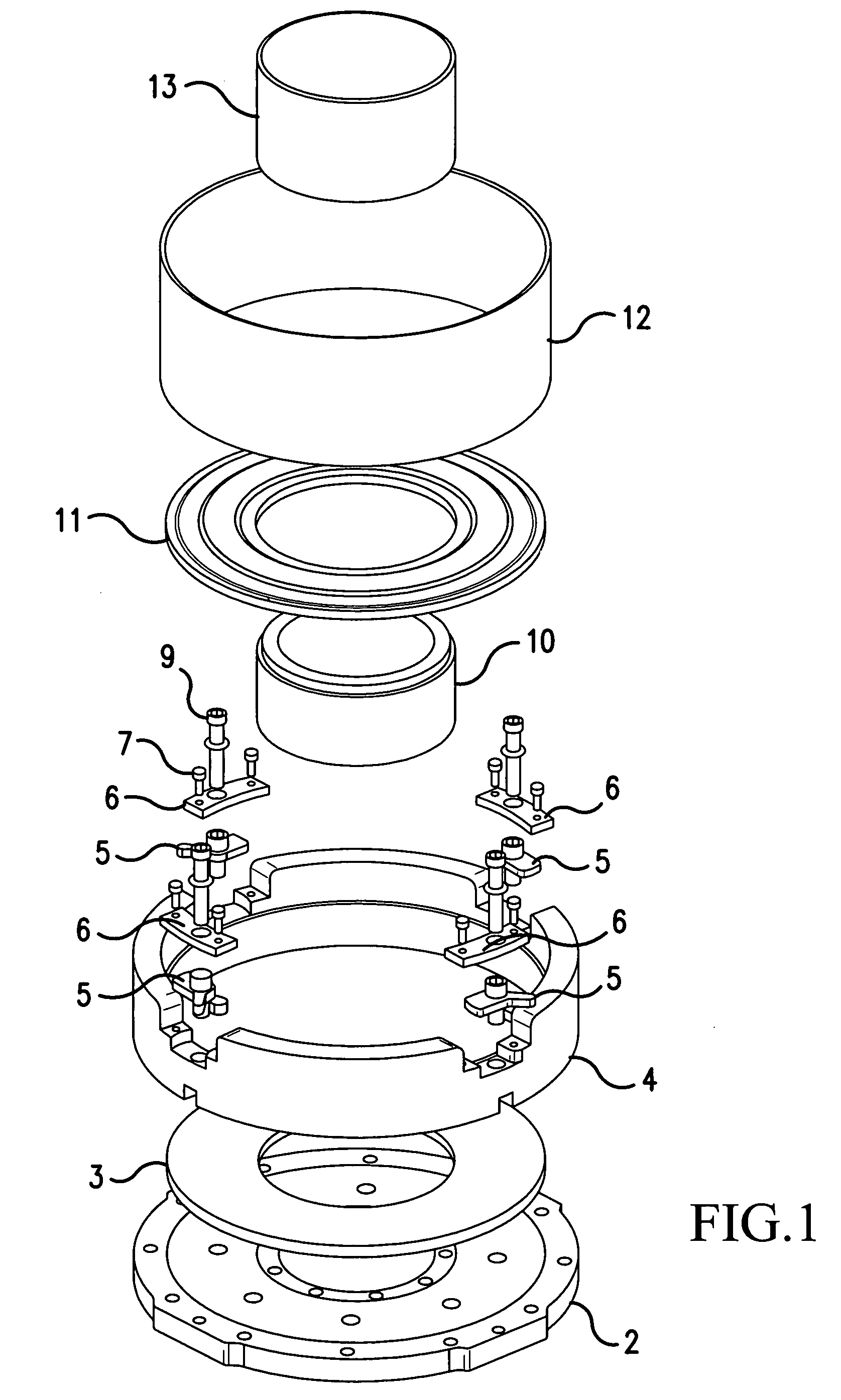

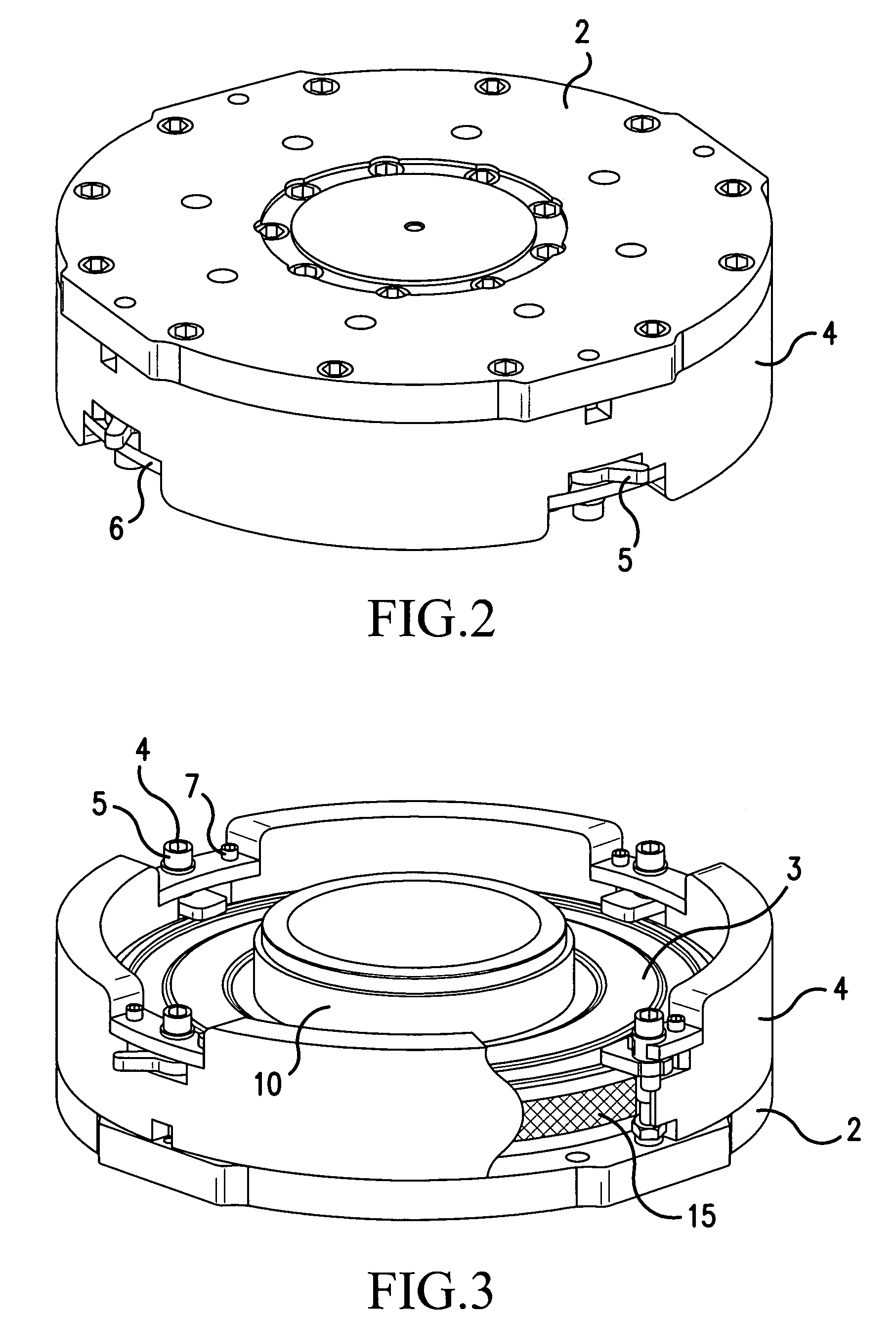

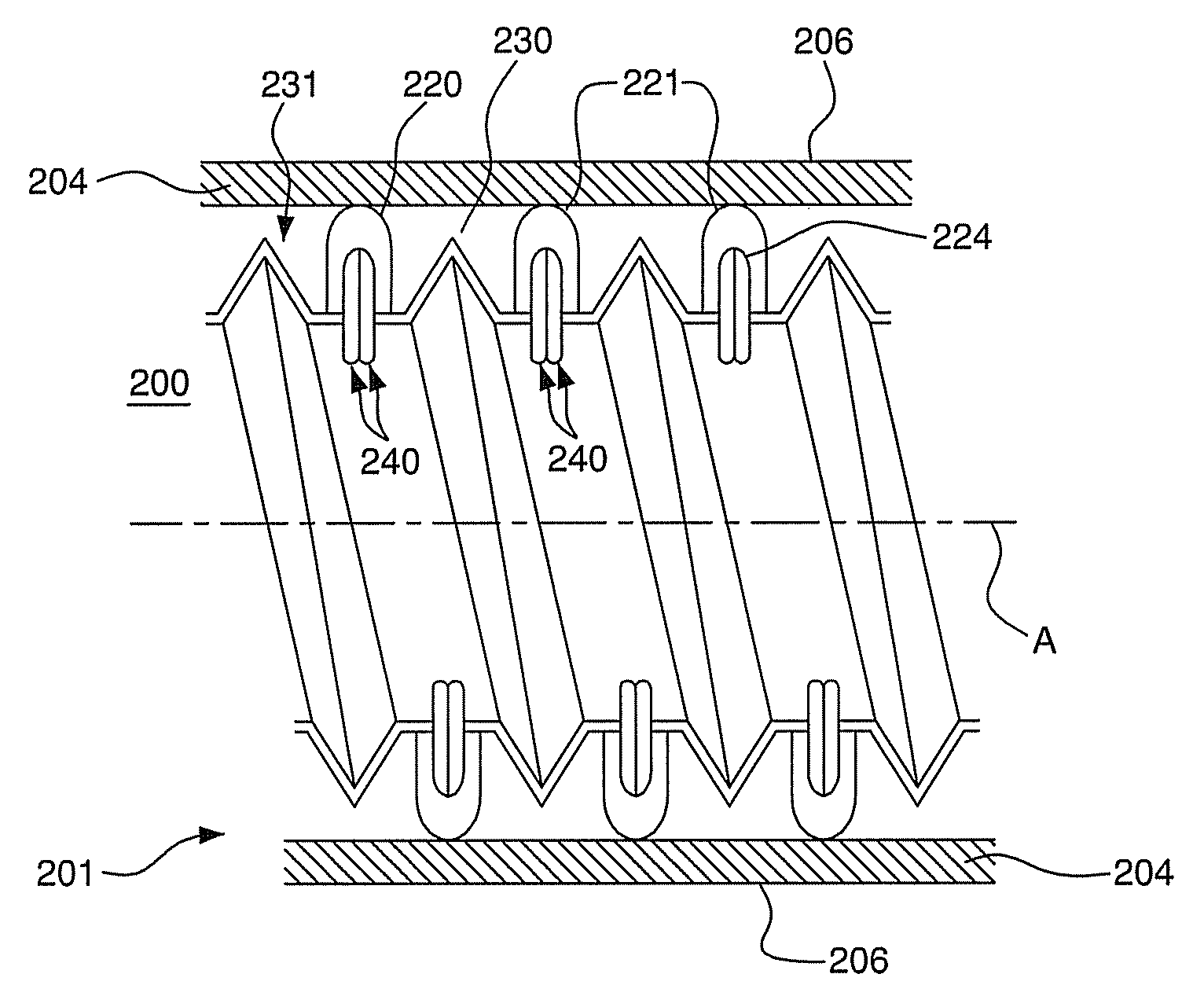

Binderless preform manufacture

The present invention makes use of loose fibrous material (for instance, chopped fibers) as reinforcement matrix material in the manufacture of carbon-carbon composites. In accordance with this invention, a constraint fixture is provided which can be separated from the mold. The constraint fixture has an internal shape corresponding to the shape of a desired preform component, with the internal shape being defined by a bottom plate (2), an annular ejector plate (3, 3′), a inner wall (10), an outer wall (4), and an annular top plate (11, 11′). The constraint fixture is normally made of metal, porous ceramic, or carbon material. The constraint fixture of the mold holds the loose matrix materials (fibers, along with any fillers and / or additives). The mold assembly itself is segmented, so that the constraint, fixture and the loose fill materials in the fixture can be removed and subjected to further processing as a unit. Such further processing may include Chemical Vapor Deposition or resin or pitch infiltration or Resin Transfer Molding. The preform matrix may remain in the constraint fixture through such processing steps as densification and until it is removed therefrom for final machining.

Owner:PURDUE RES FOUND INC +1

Modular ballast system for membrane roofs

ActiveUS8122682B2Reduce evaporationImplemented cost-effectivelyPhotovoltaic supportsSolar heating energyModularityEnvironmental engineering

Owner:WESTON SOLUTIONS

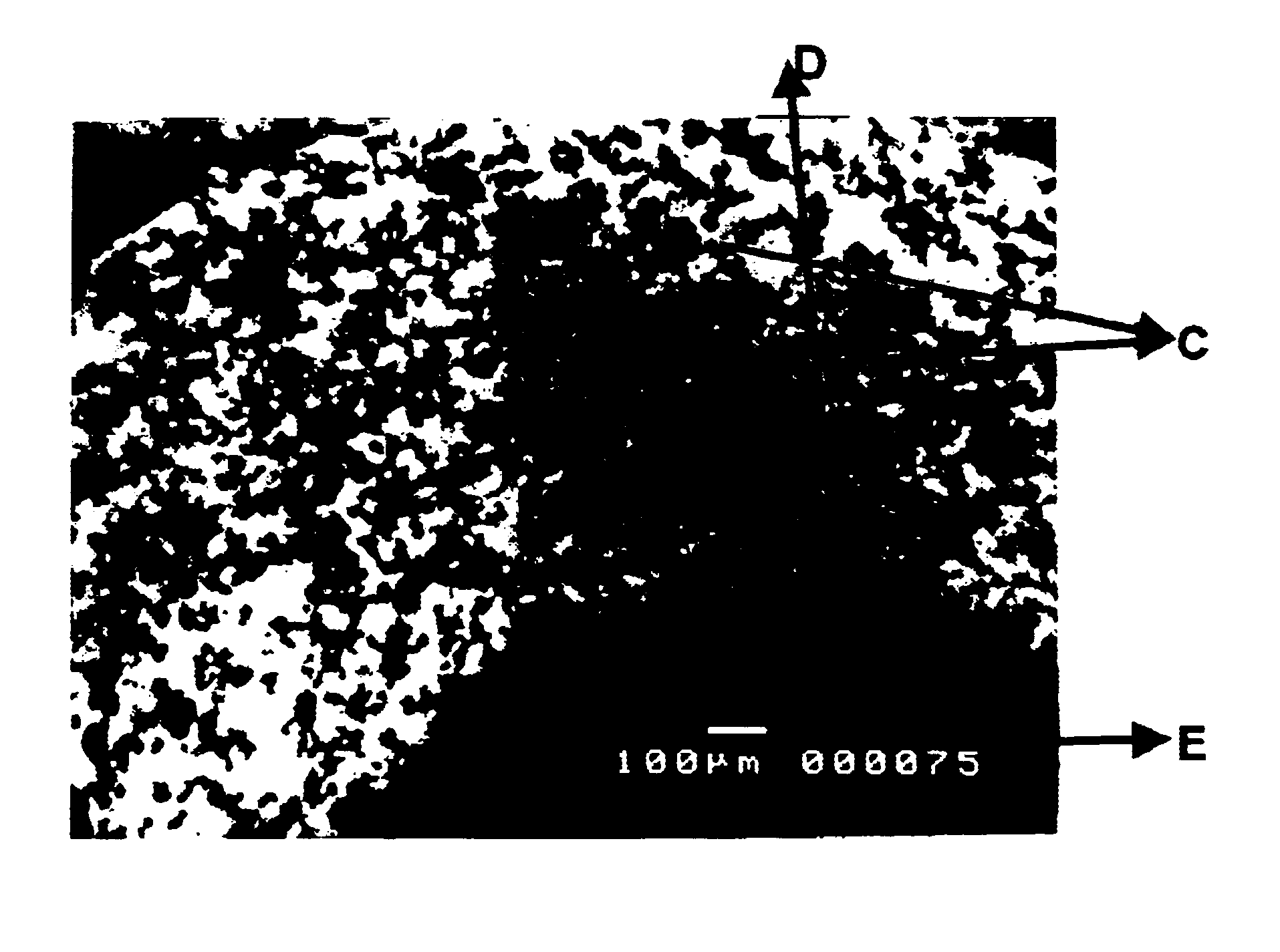

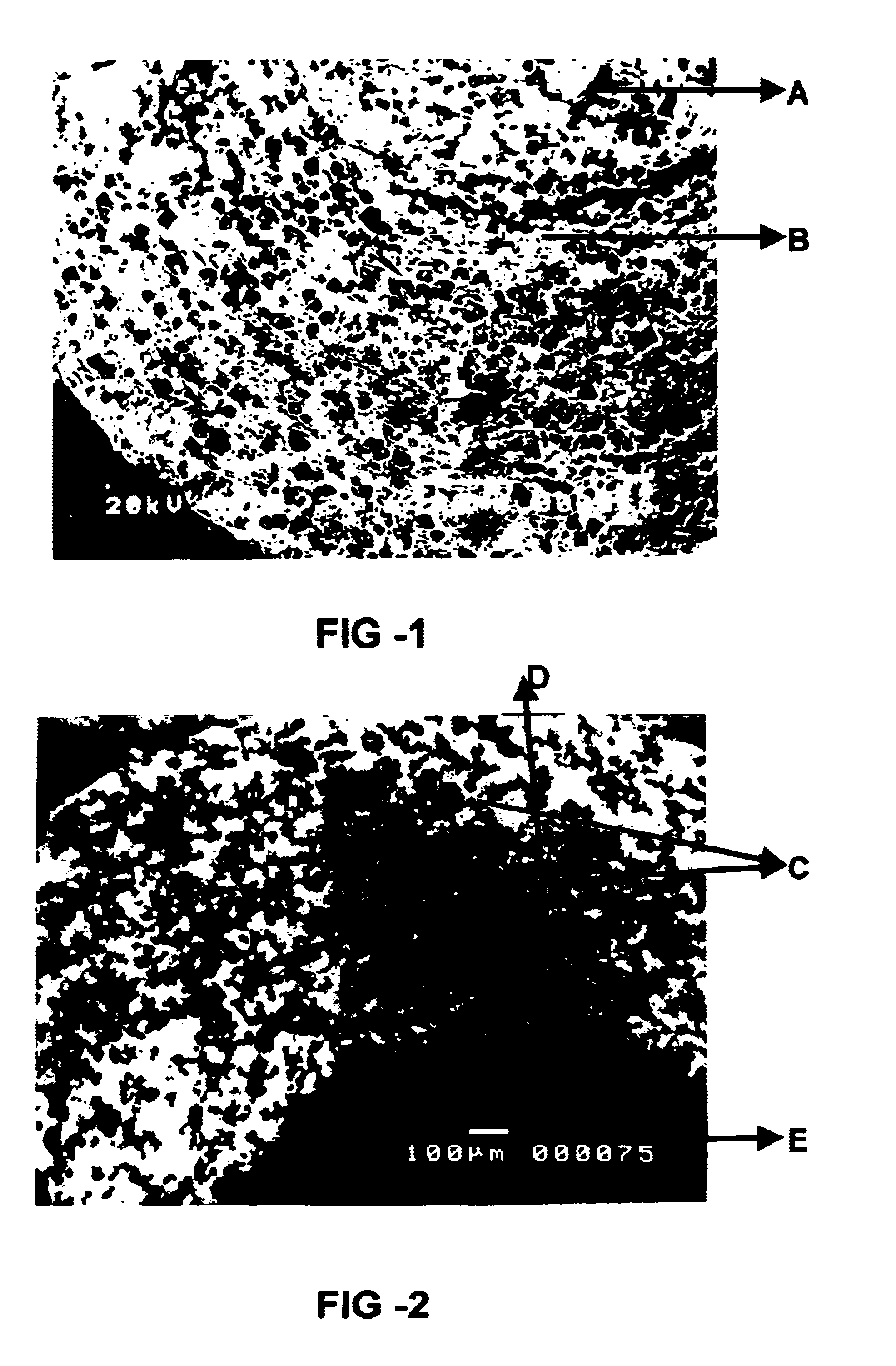

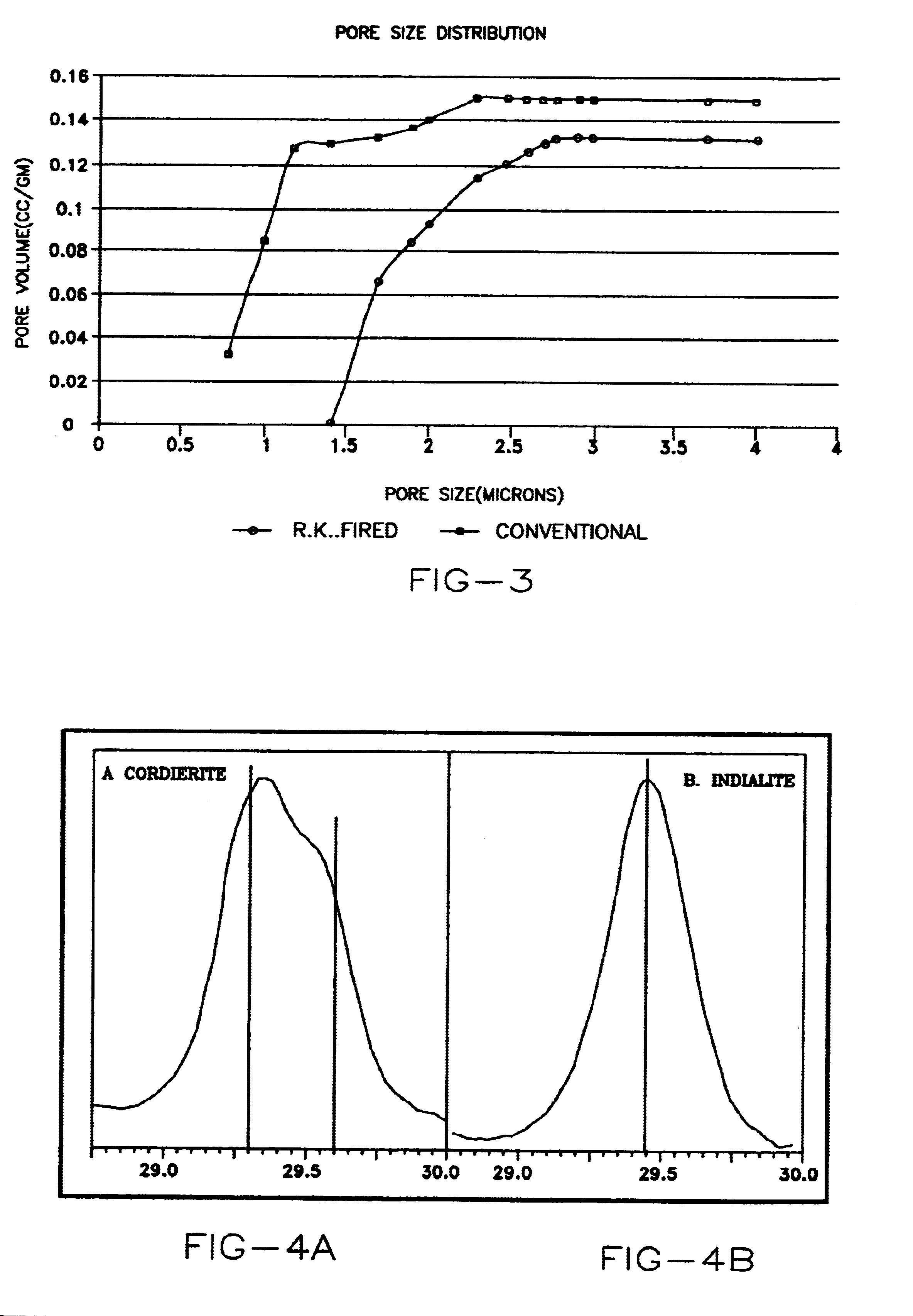

Process for making macro porous ceramic spheres

InactiveUS6616873B1High compressive strengthUniform heat treatmentCeramic shaping apparatusCeramicwareBrickCooling down

Process for making thermally stable macro porous spheres with or without central core cavity includes steps of homogenizing dry pulverized selective constituents with or without burnable core particles and with <25% combustibles; sprinkling over pan pelletizer wetted with PVA aqua sol binder and rolling to form spheres having <25% moisture and dry compacting in pelletizer before oven drying at 90-100° C. until moisture and core particles are partially destroyed and sintering under rotary motion of the spheres for 45-60 minutes at 1350-1380° C. before being rapidly cooled down to ambient temperature and sieving and recovering therefrom low-to-high temperatures >90% loose fill macro porous spheres for catalyst and moulded bricks / monoliths forming refractory insulation applications.

Owner:THE ASSOC CEMENT CO LTD

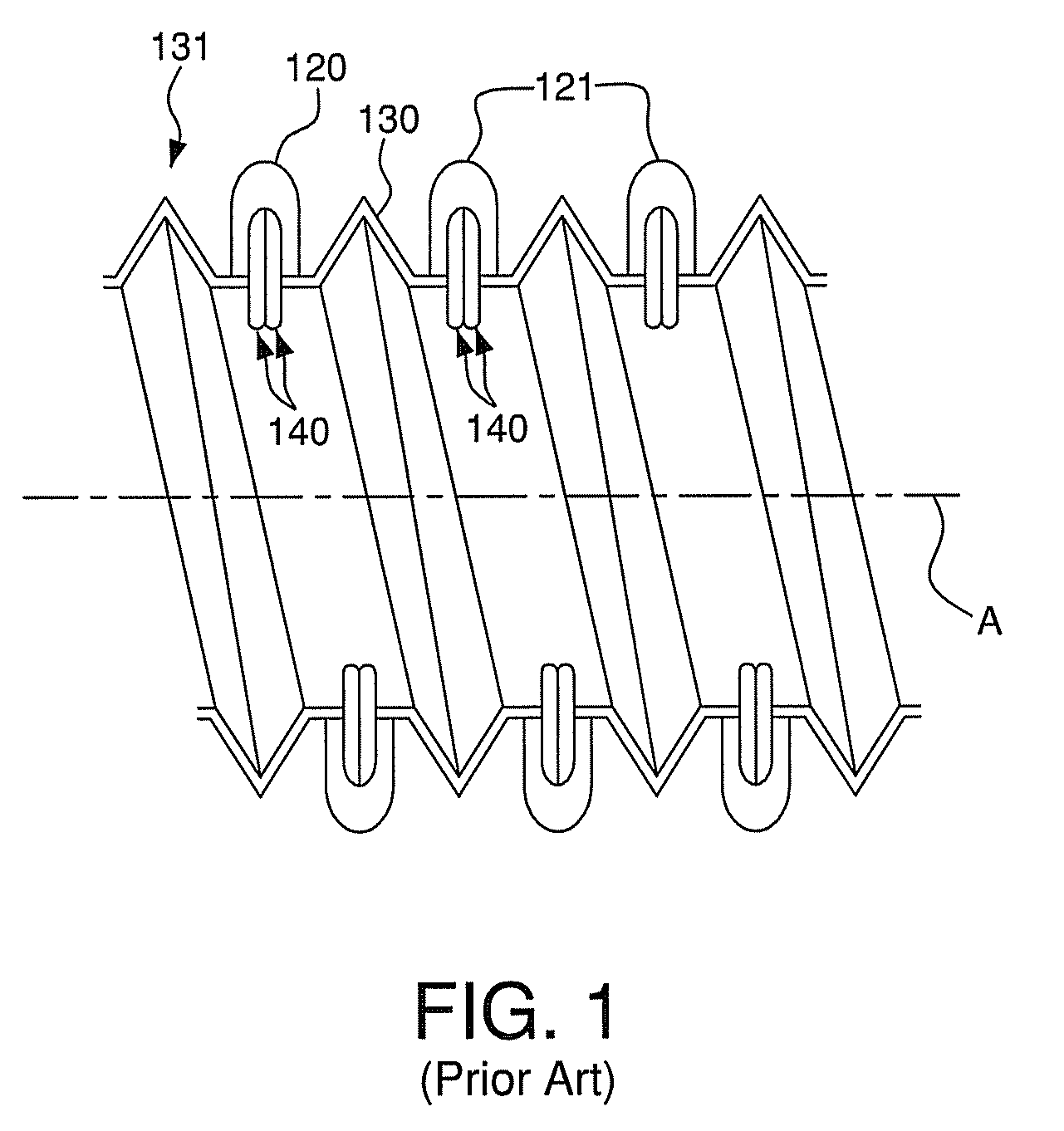

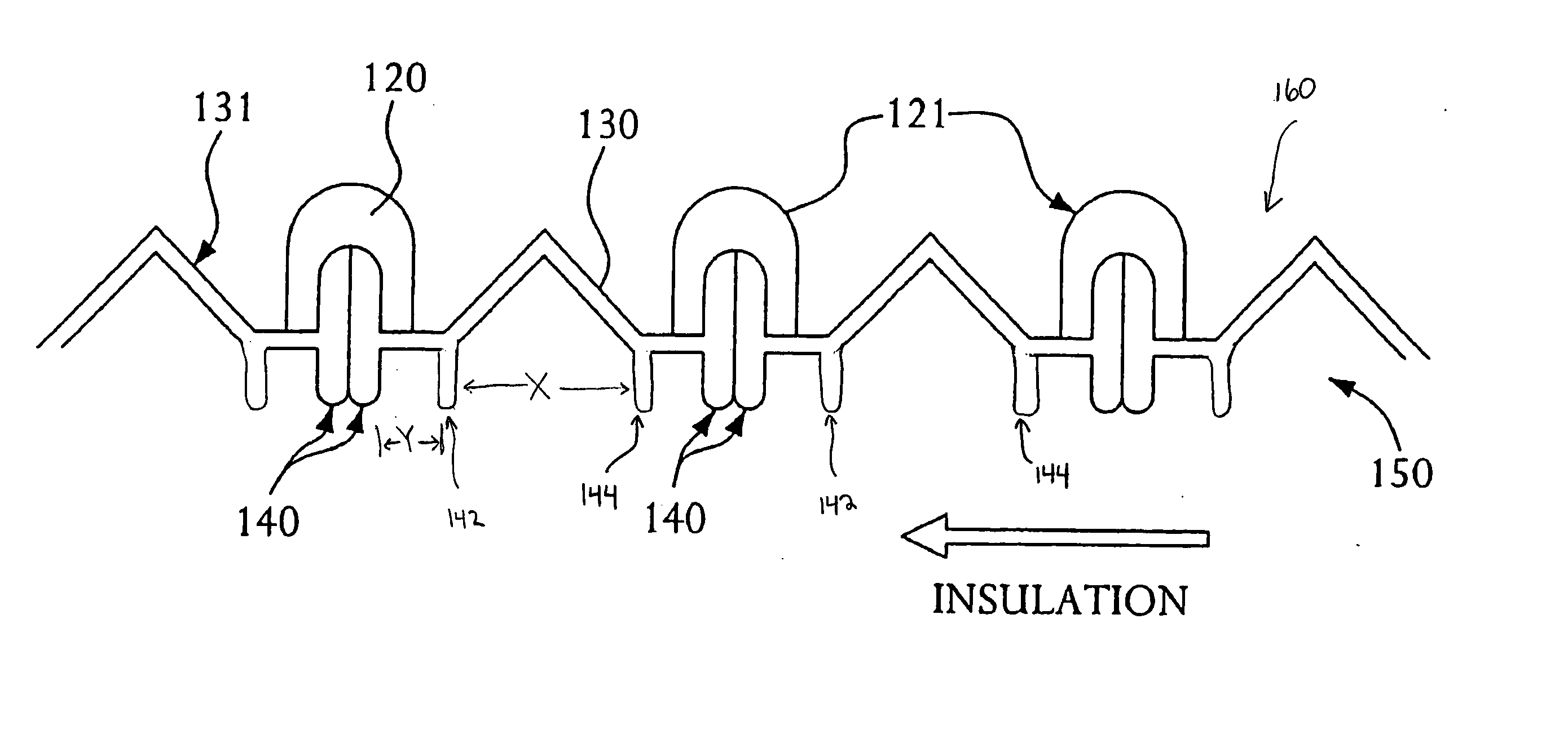

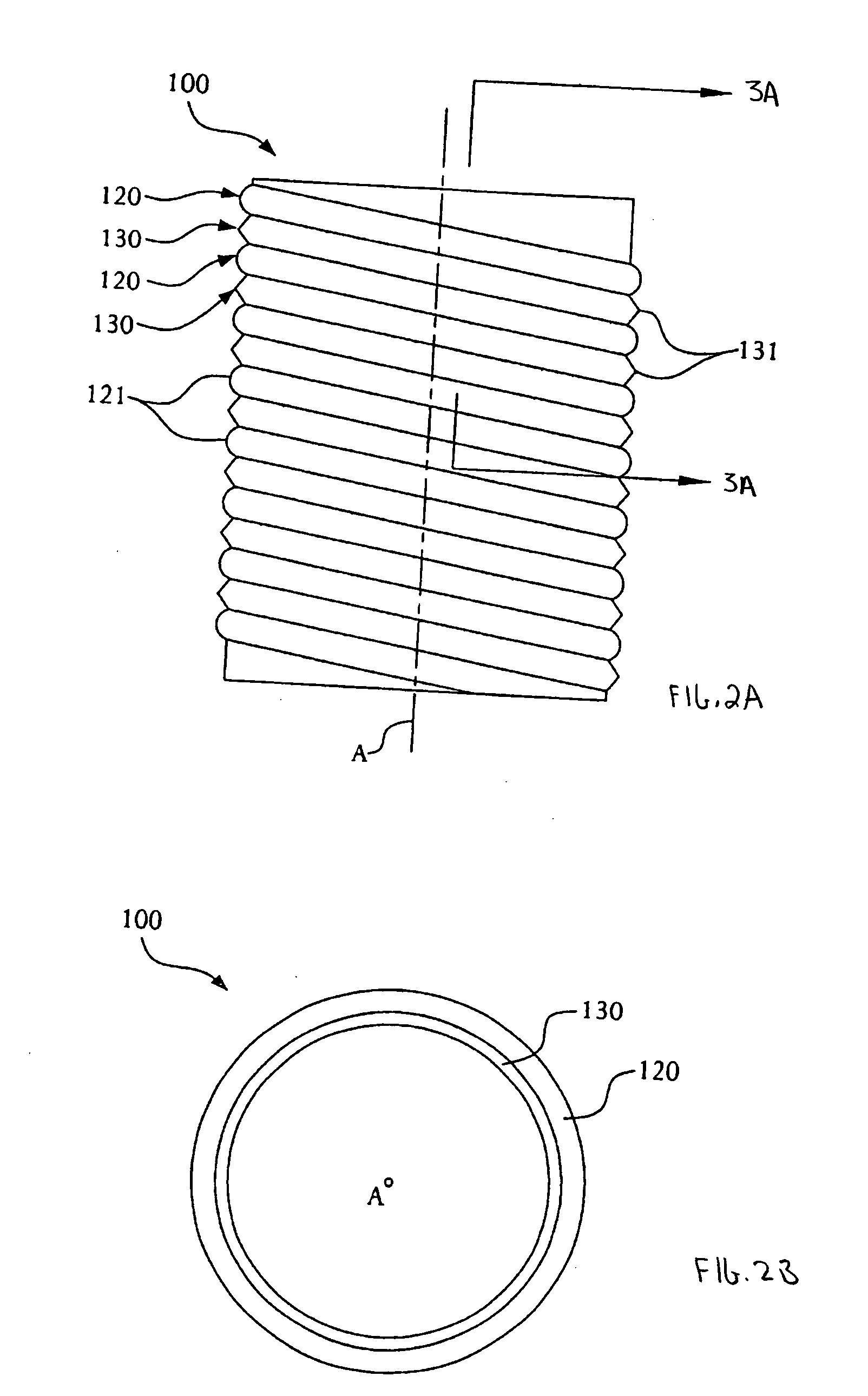

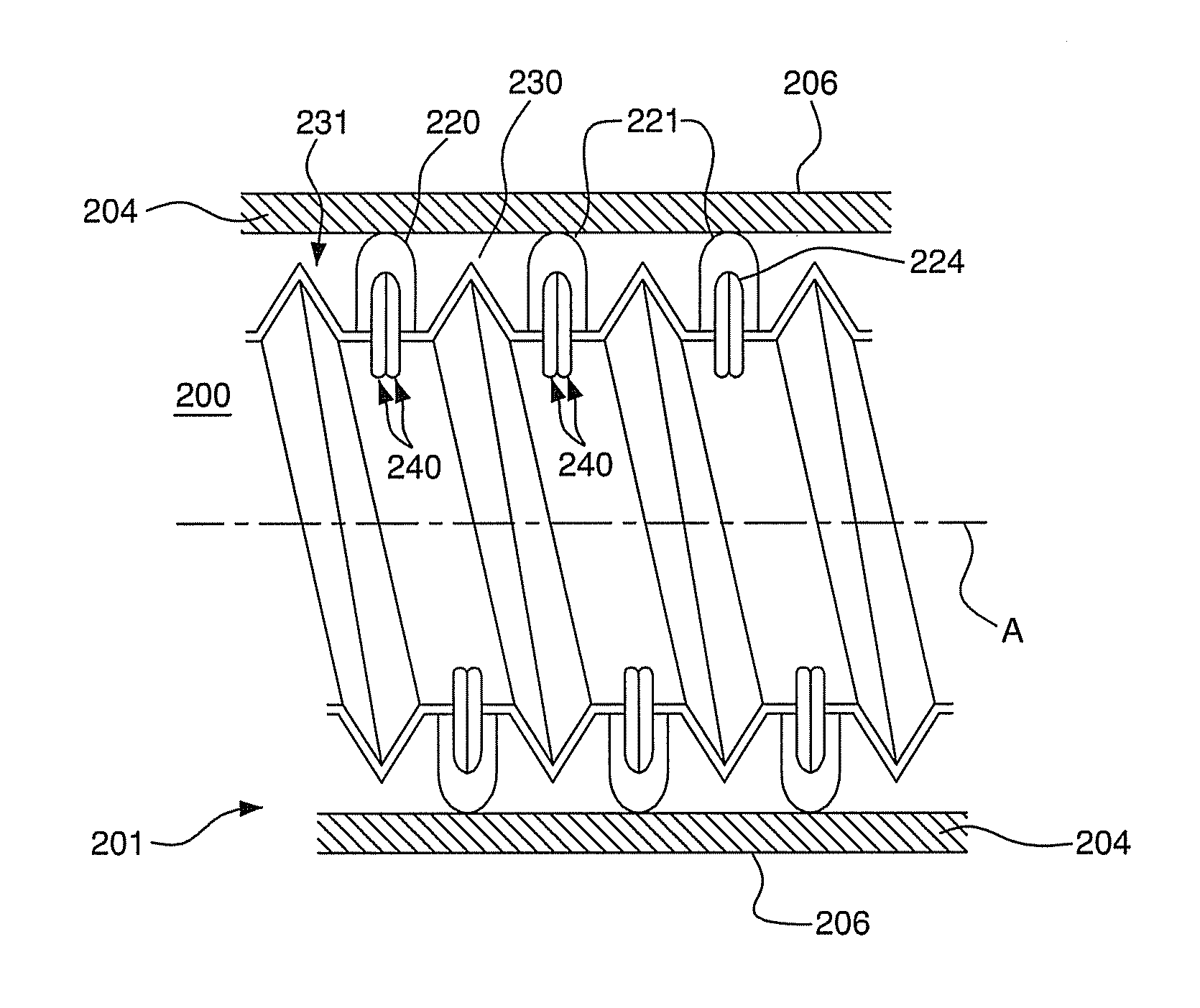

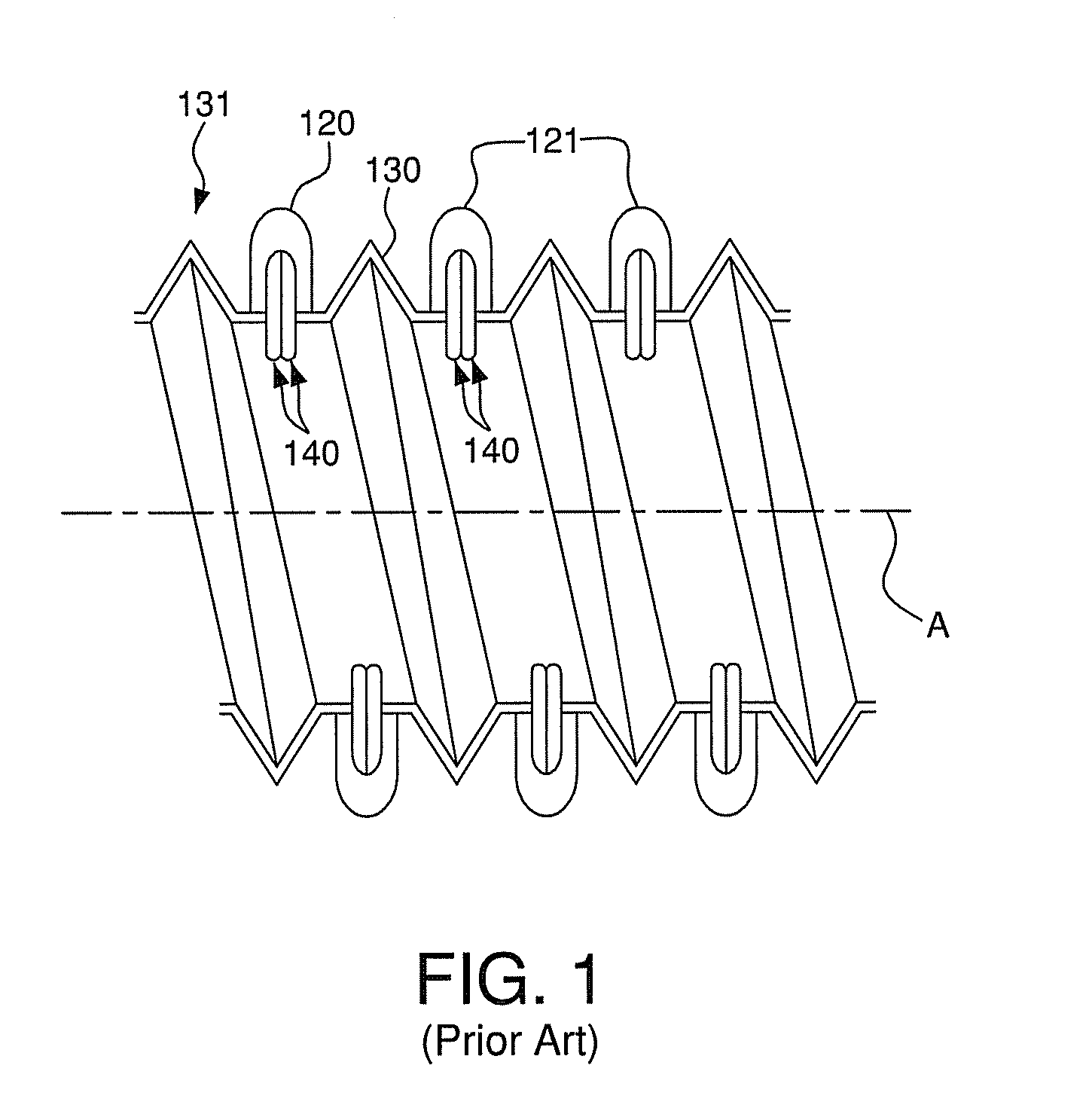

Corrugated hose with non-conforming outer layer for dispensing loose-fill insulation

A hose assembly comprises: a flexible corrugated inner hose suitable for conveying and dispensing loose-fill insulation material, and a non-conforming outer hose snugly fitted about the inner hose, the outer hose having a substantially cylindrical outer surface that is substantially free of corrugations.

Owner:CERTAINTEED CORP

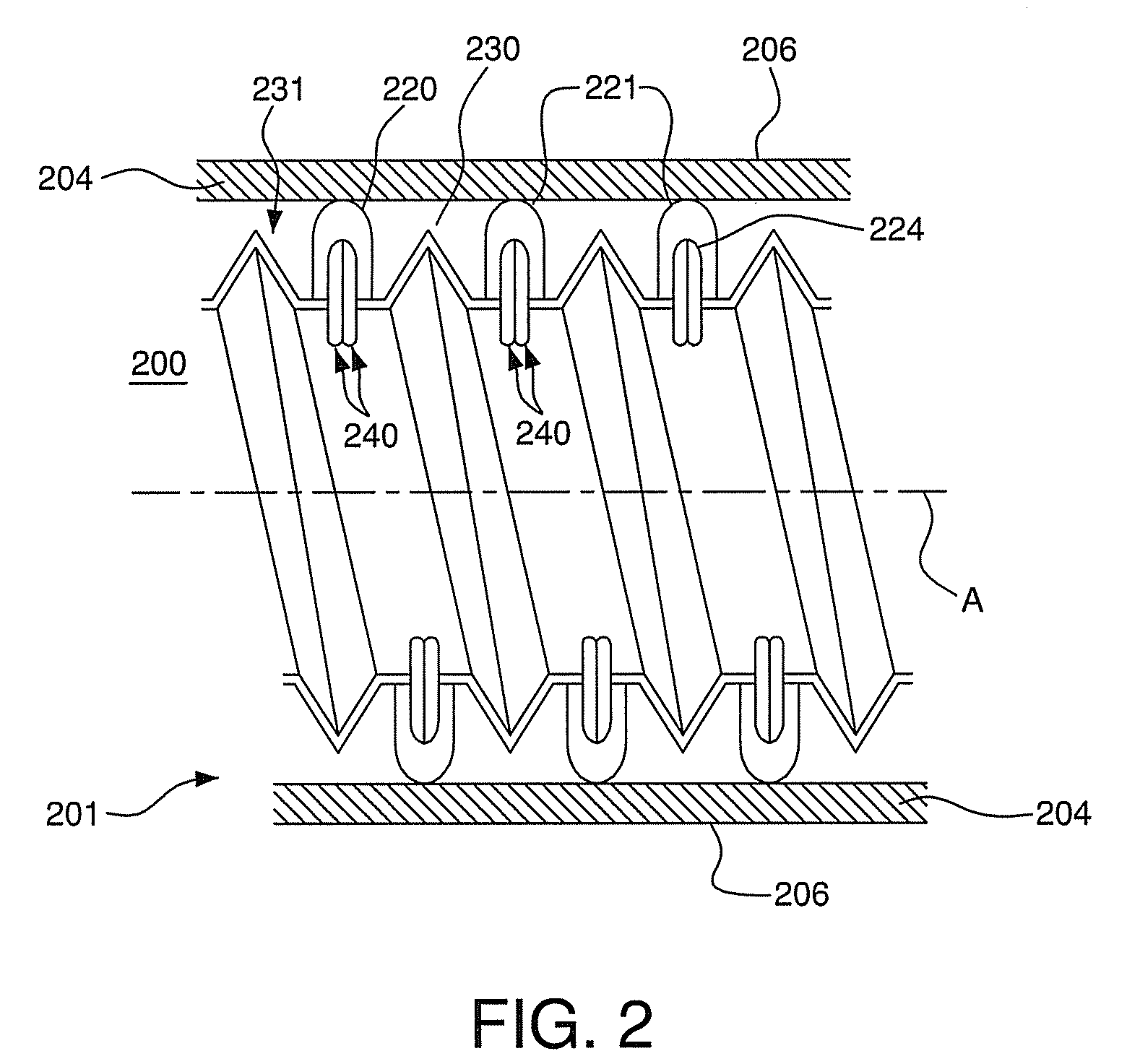

Intra-corporeal surgical retractor

An intra-corporeal surgical retractor for holding tissues and organs in place is provided, including a sealed container, made from a flexible material, having an interior containing a granular substance and a fluid. At least one tube may be provided with one end attached to the container in communication with the interior of the container and the other end connected to a suction mechanism. When the fluid is evacuated from the container, the container constricts around the granular substance and becomes relatively rigid. An absorbent sleeve or layer may be provided surrounding the container. The granular substance may be provided as loose fill or as a layer over at least a portion of the inner wall. Alternatively, the inner walls of the container may be provided with a very rough surface. Further, the outer surface of the bottom of the pouch is enhanced frictionally.

Owner:BODENSTEIN LAWRENCE

Hose for installing loose fill insulation

The present invention provides tubes for, in an exemplary embodiment, dispensing loose fill insulation. The tube comprises an inner web formed in a tubular shape and having a plurality of spaced helical projections disposed along an inner surface thereof and extending towards a central longitudinal axis of the inner web, the inner surface of the inner web also forming an inner surface of the tube. A cap is disposed around an outer periphery of the inner web. The helical projections serve to condition the insulation as the insulation passes through the tube.

Owner:CERTAINTEED CORP

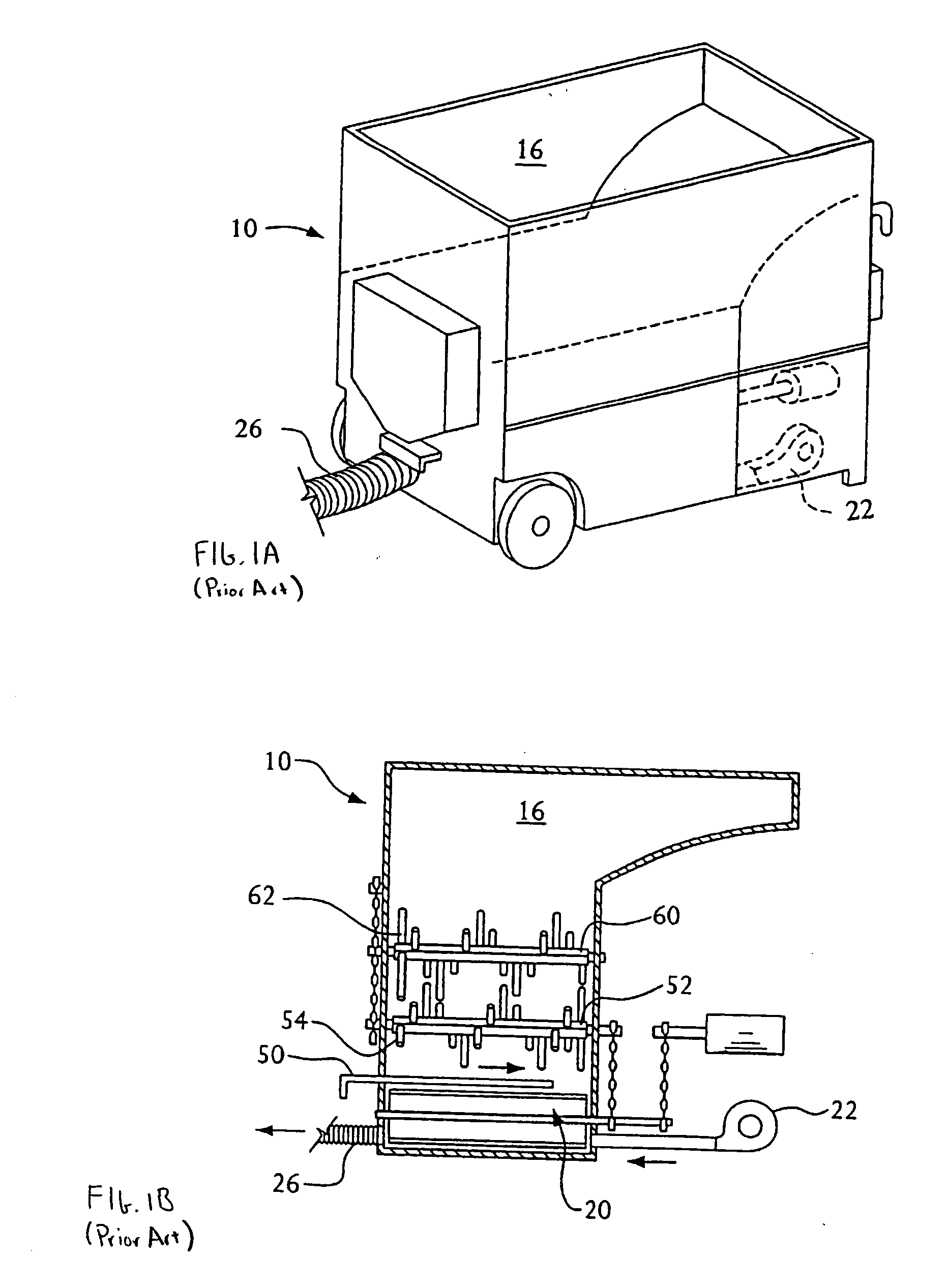

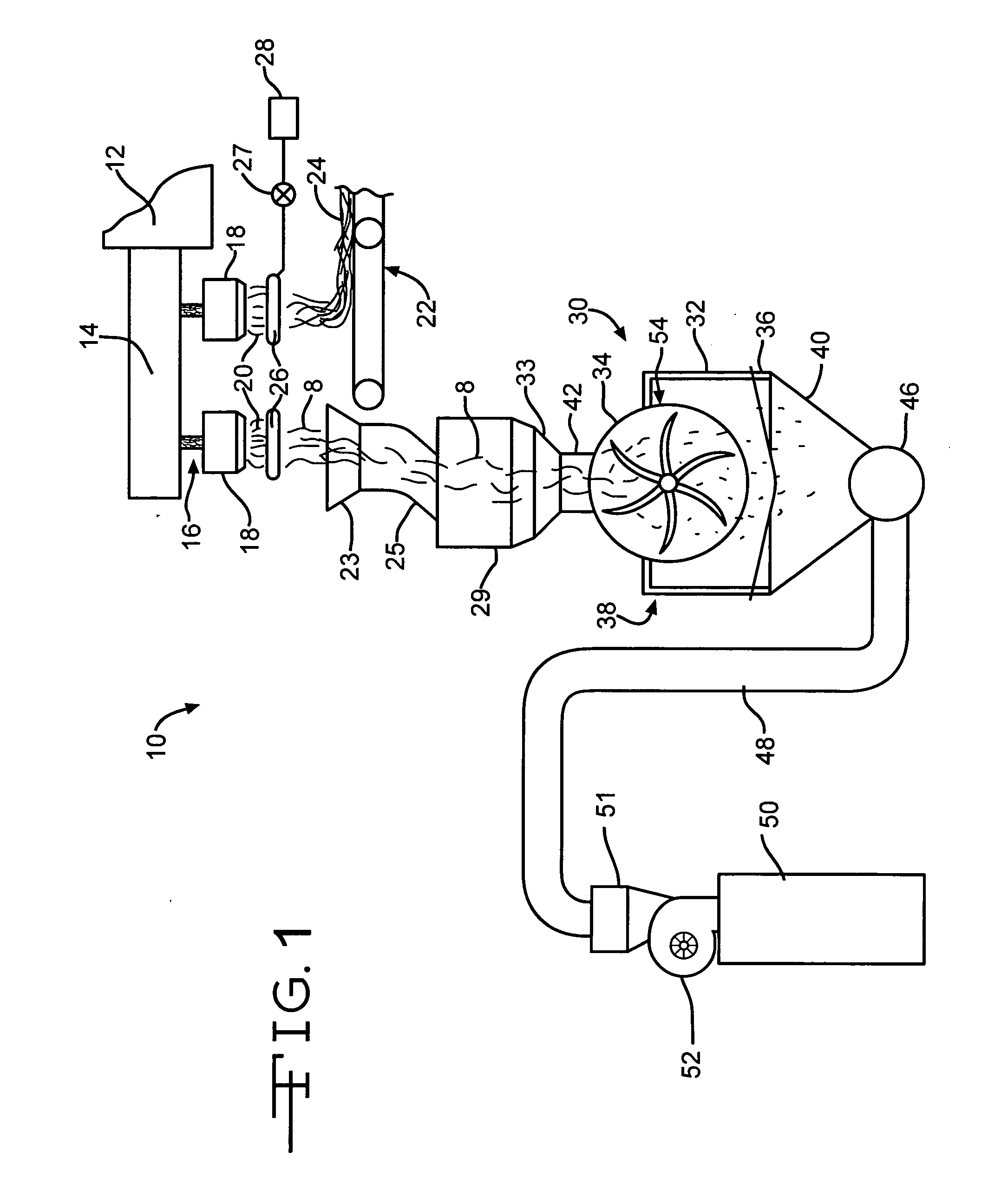

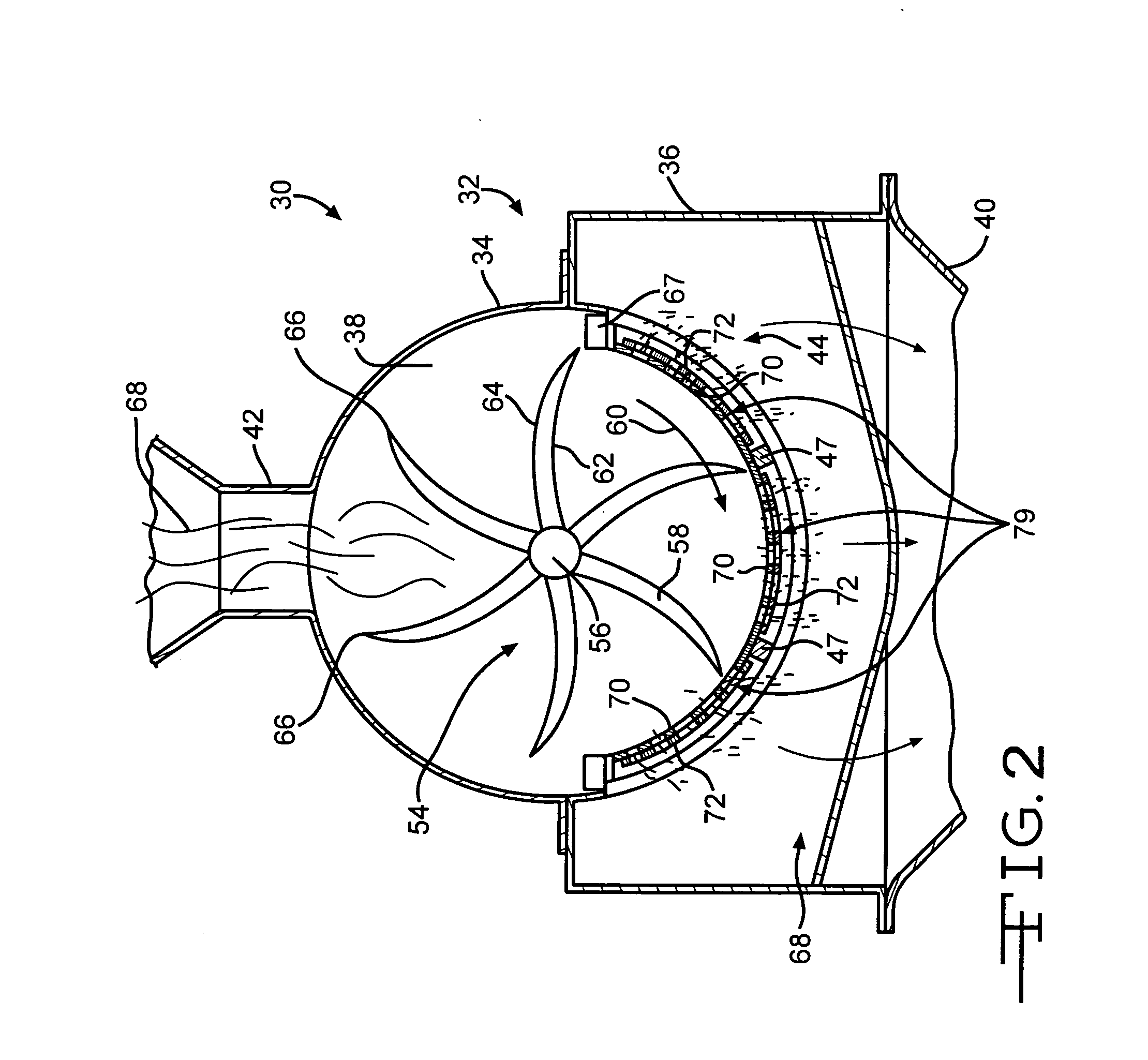

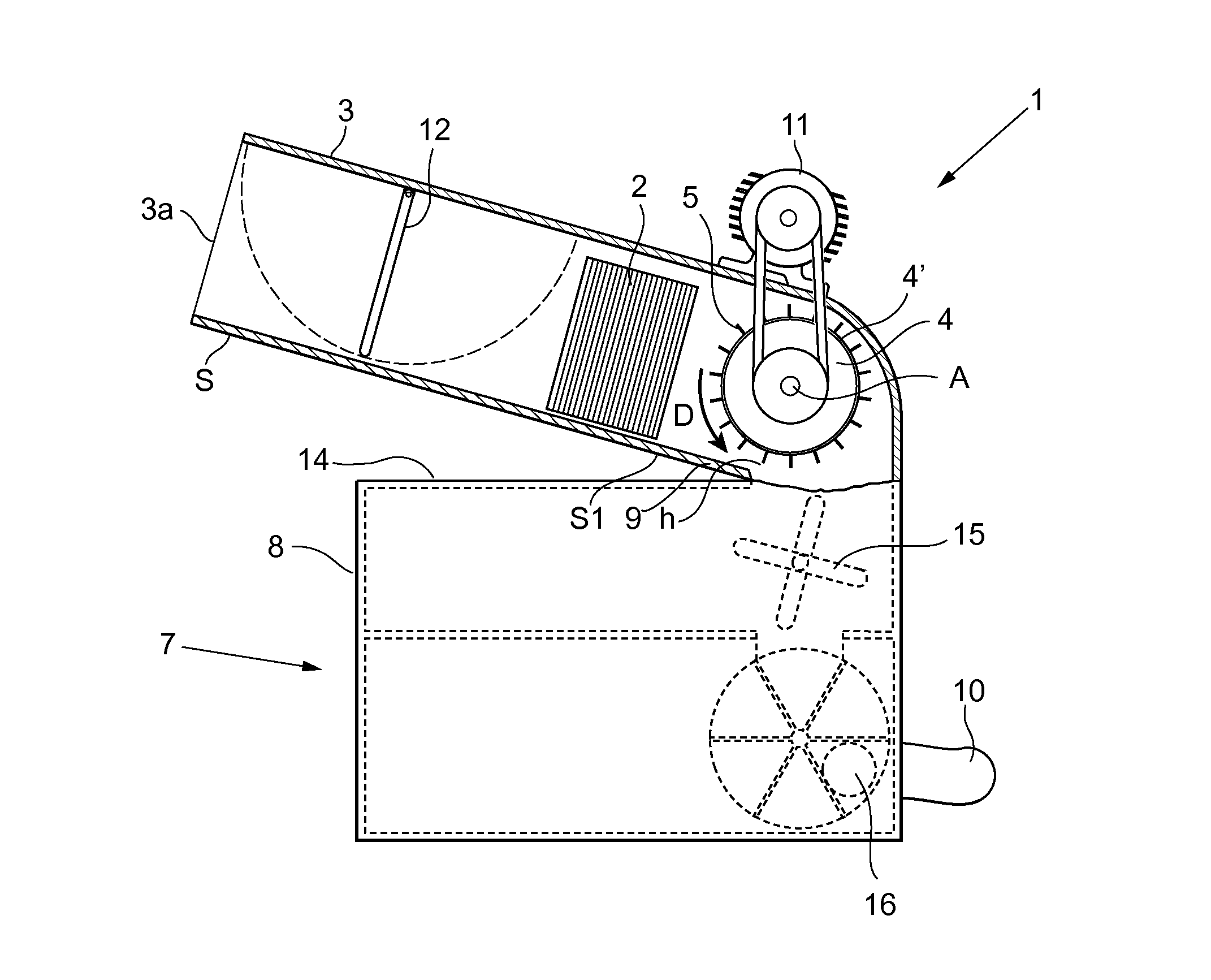

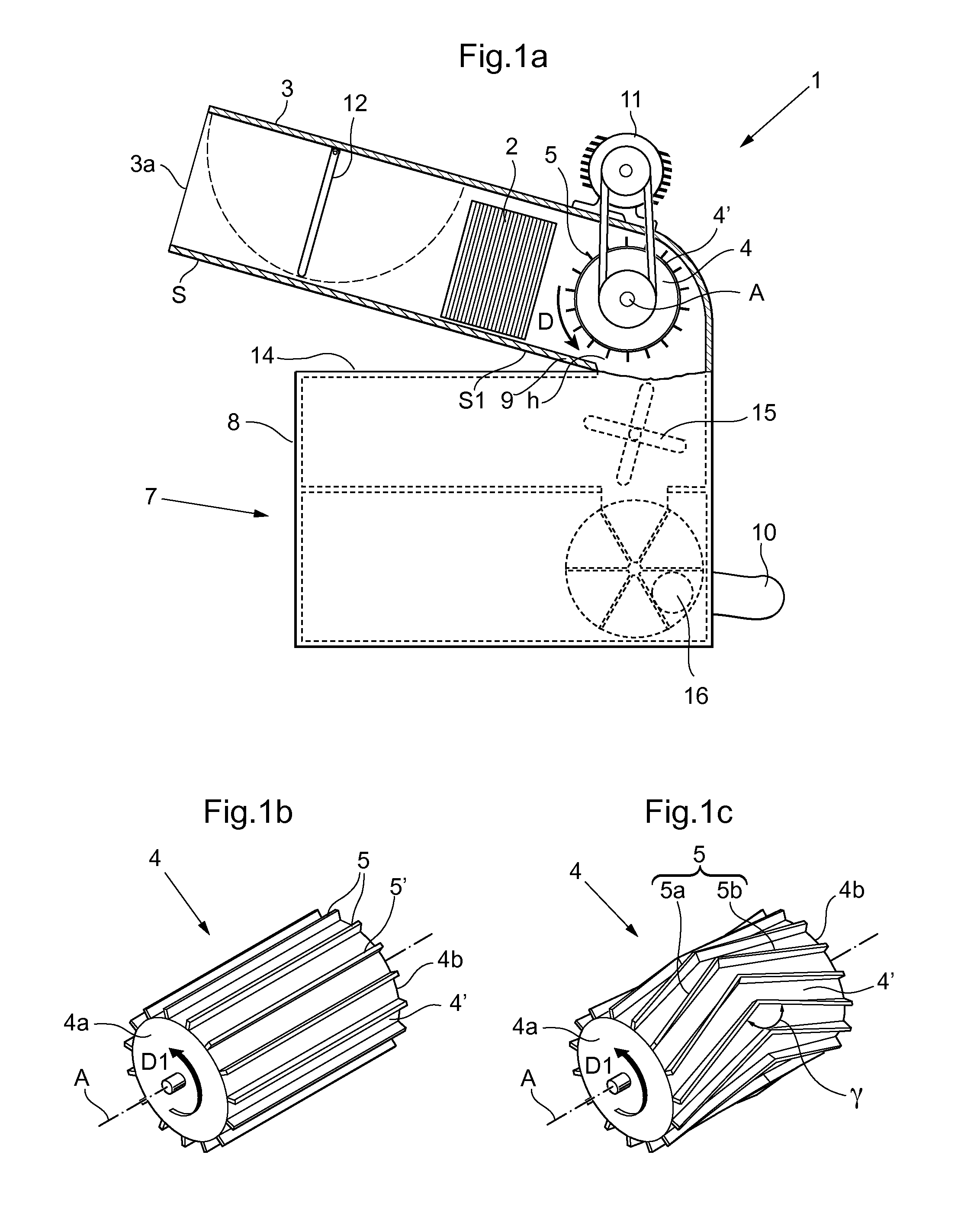

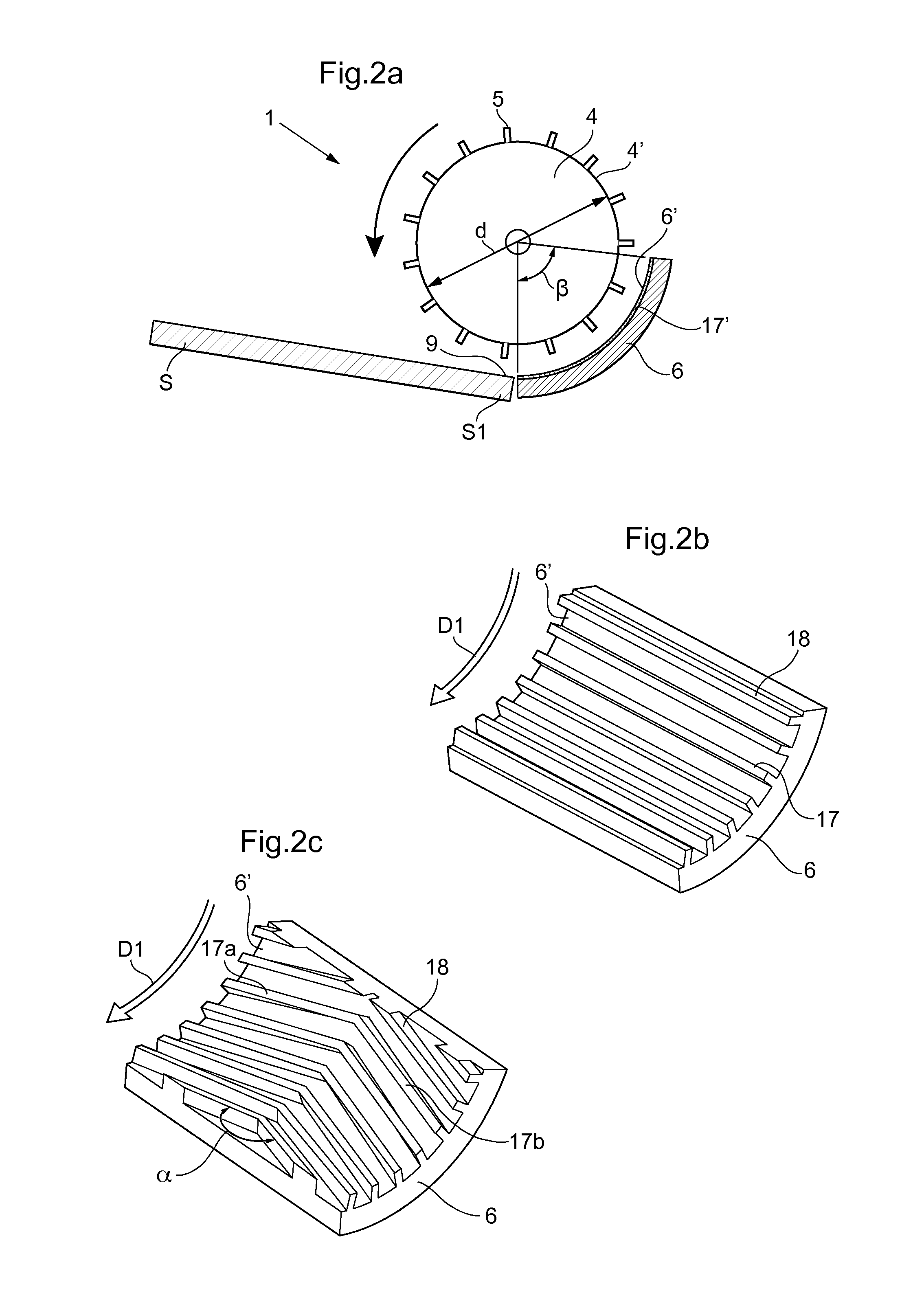

Adjustable screen for loose fill fibrous insulation machine

InactiveUS20070063080A1Effective opening sizeSame sizeSortingGrain treatmentsMechanical engineeringLoose fill

A rotary mill is configured to cut fibrous insulation material into tufts of loosefil insulation. A housing of the mill has a rotary cutter assembly mounted therein having a plurality of radially outwardly extending vanes extending to the housing and being configured to sweep along the housing in a machine direction. A screen having a plurality of screen openings is positioned in the housing, each screen opening having an effective opening size. The screen comprises an inner plate having a plurality of inner openings formed therethrough and an outer plate having a plurality of outer openings formed therethrough. The inner openings correspond with the outer openings to define the screen openings, and the screen openings have an effective cutting edge oriented transversely to the machine direction. The inner and outer plates are mounted for movement relative to each other so the effective opening size of the screen openings can be changed. The length of the effective cutting edges of the screen openings are kept substantially constant regardless of any change in the size of the screen openings.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Corrugated hose with non-conforming outer layer for dispensing loose-fill insulation

A hose assembly comprises: a flexible corrugated inner hose suitable for conveying and dispensing loose-fill insulation material, and a non-conforming outer hose snugly fitted about the inner hose, the outer hose having a substantially cylindrical outer surface that is substantially free of corrugations.

Owner:CERTAINTEED CORP

Loose fill insulation packaged with additive

Owner:CERTAINTEED CORP

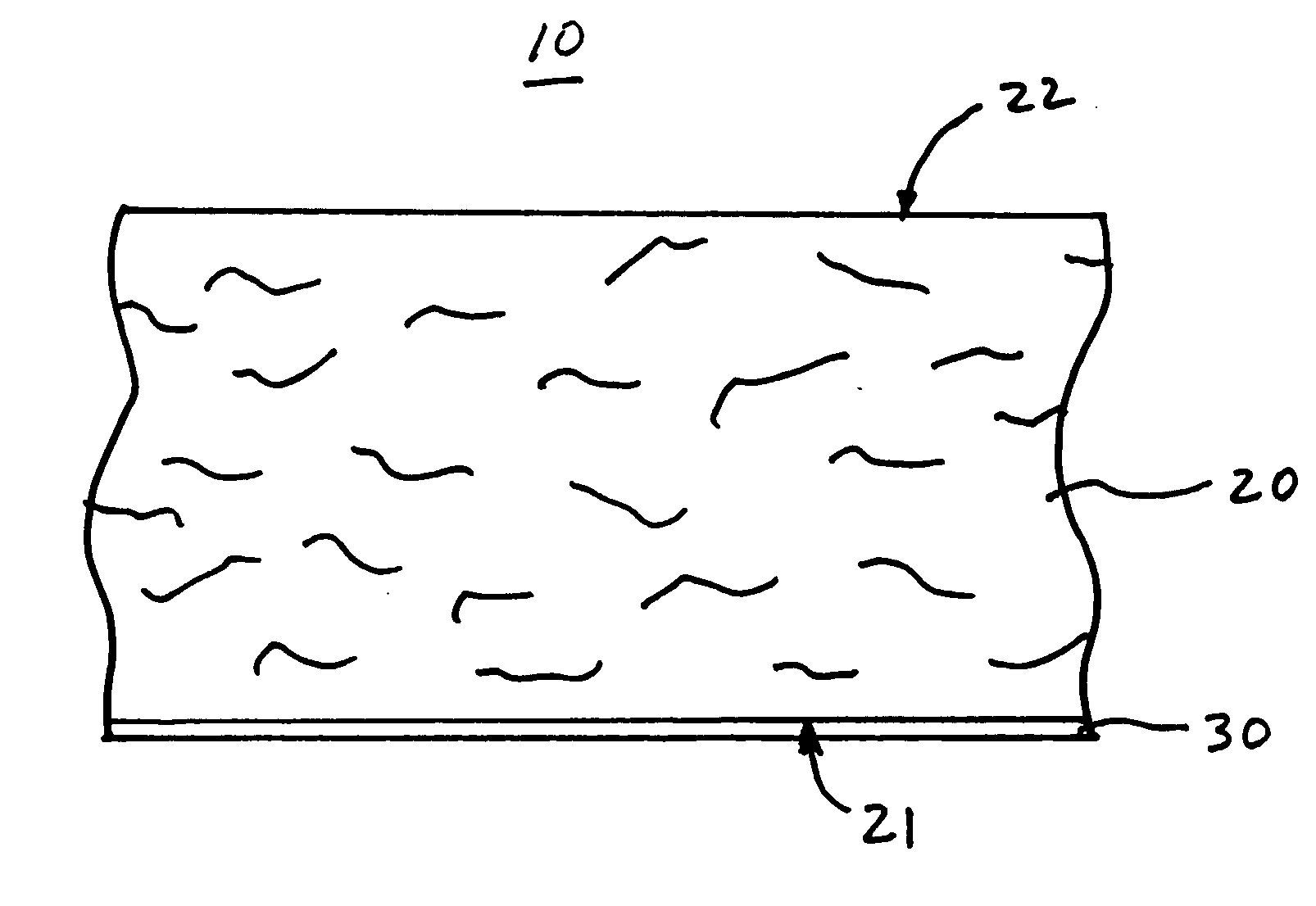

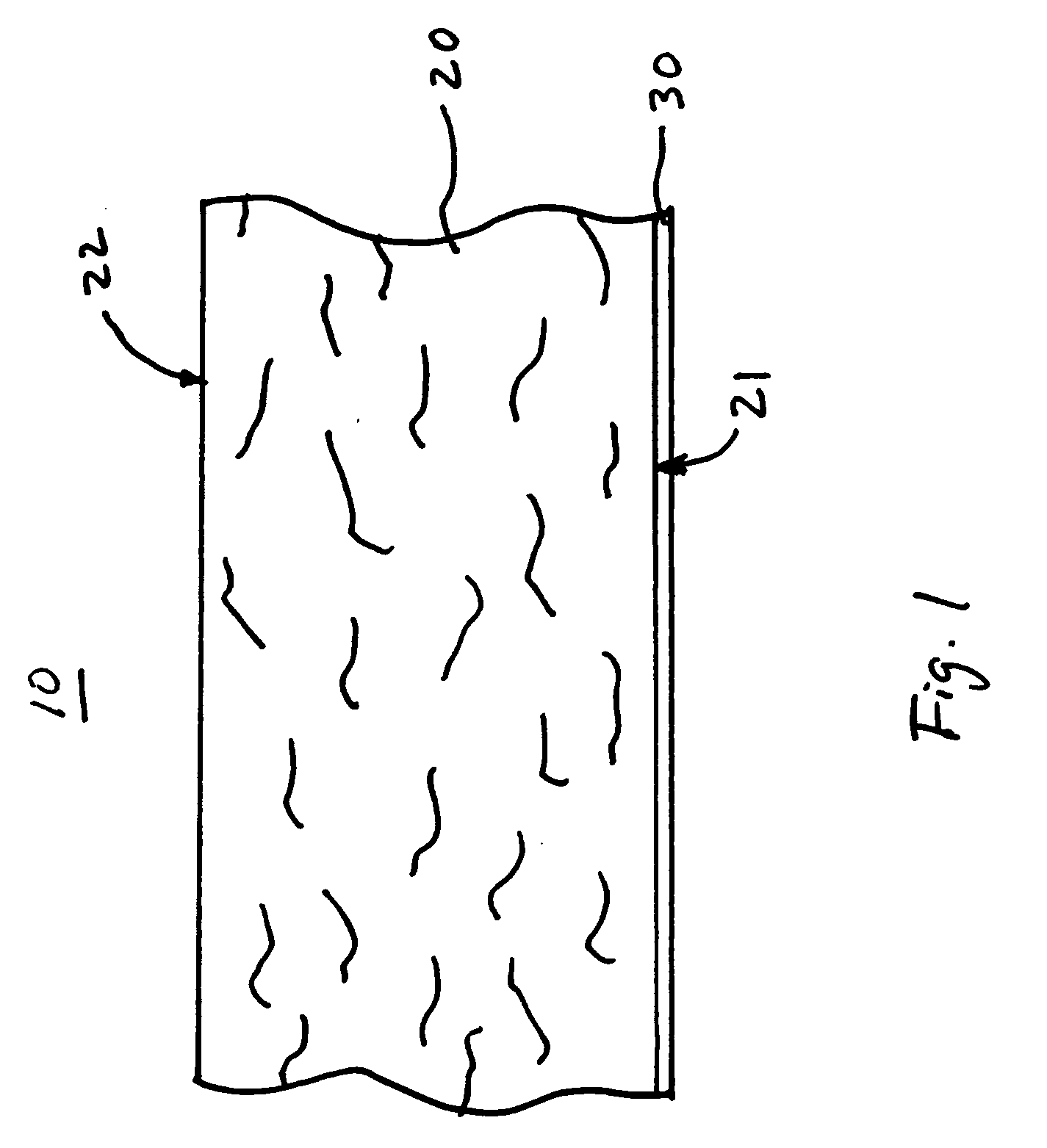

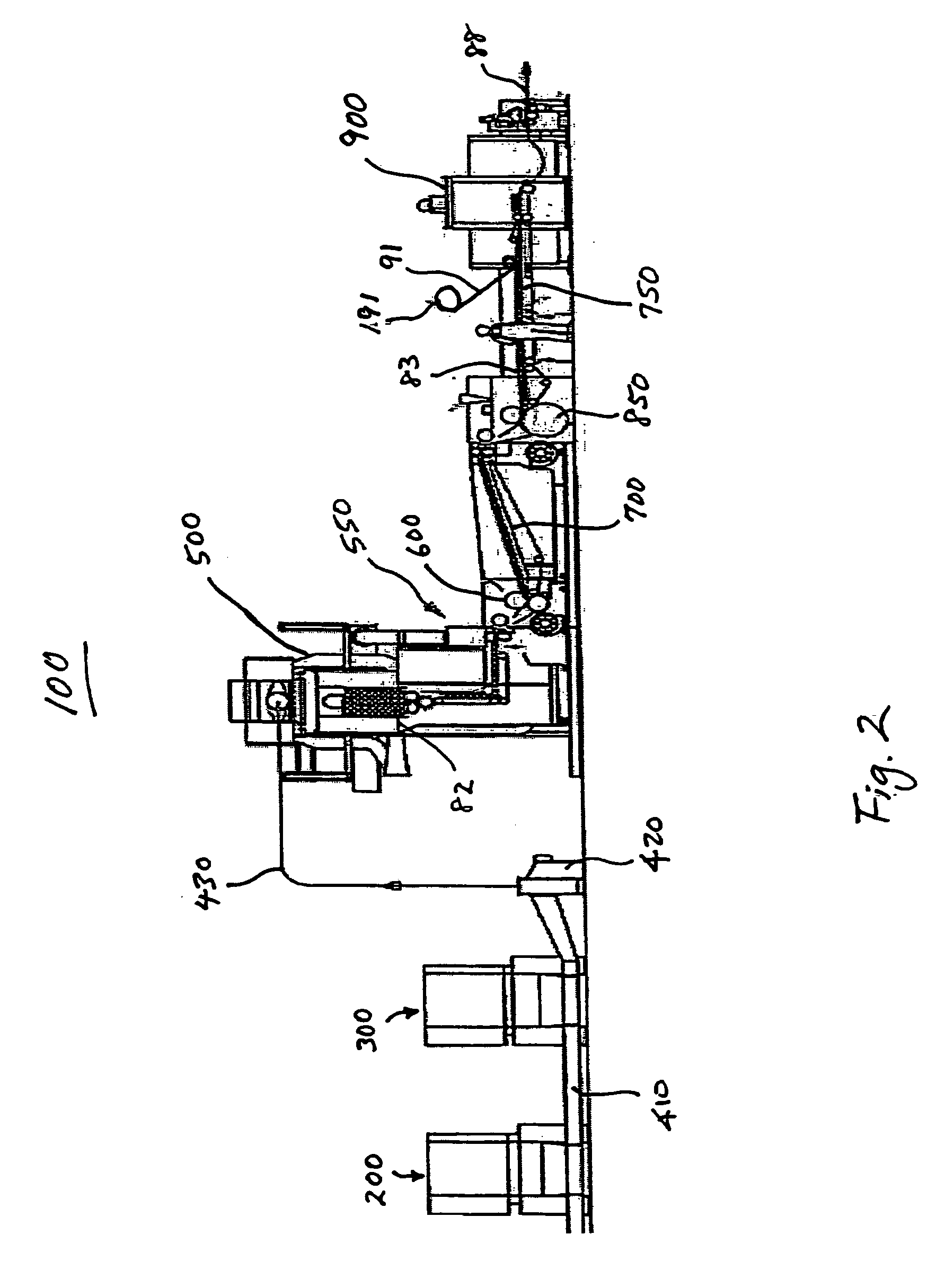

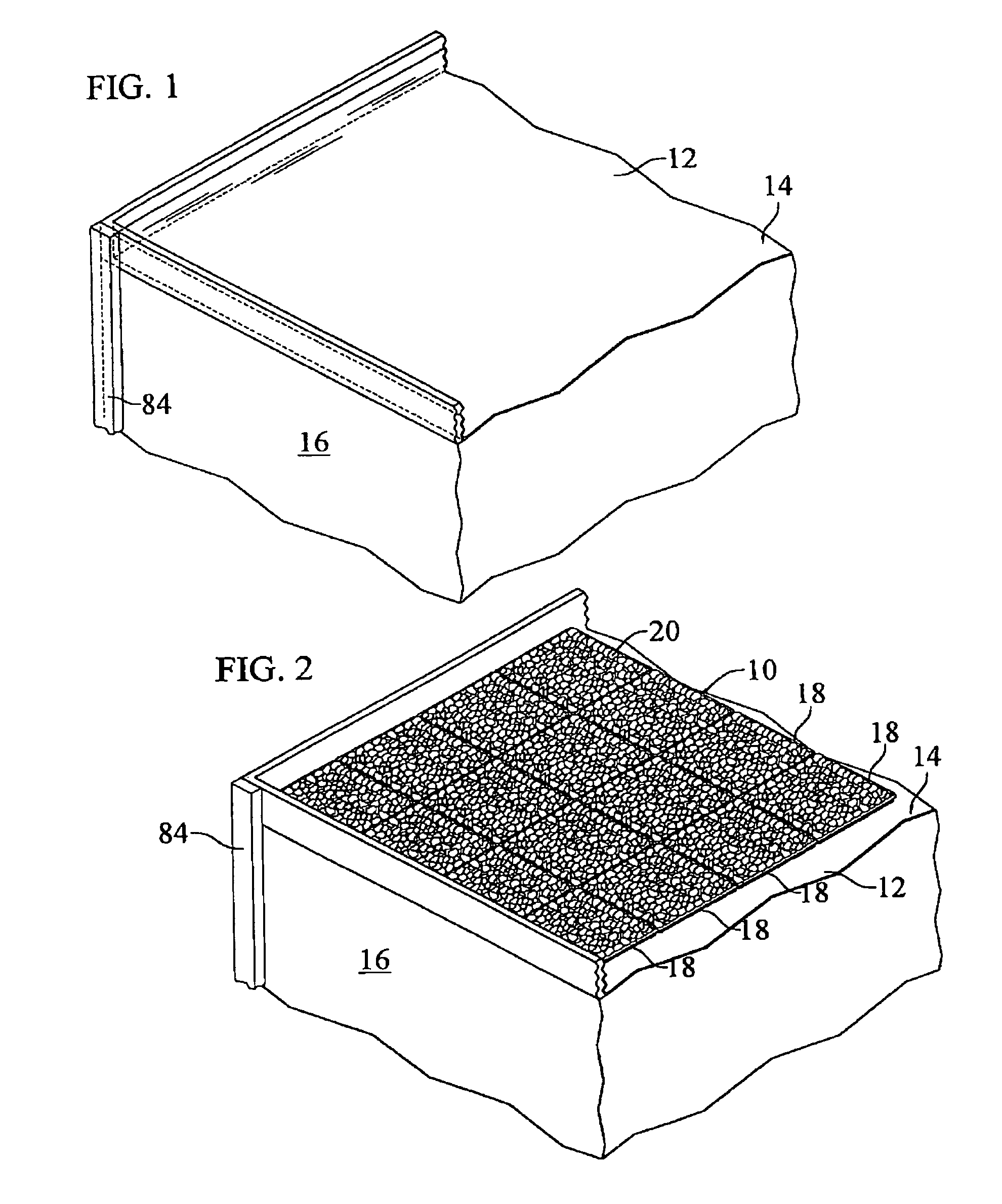

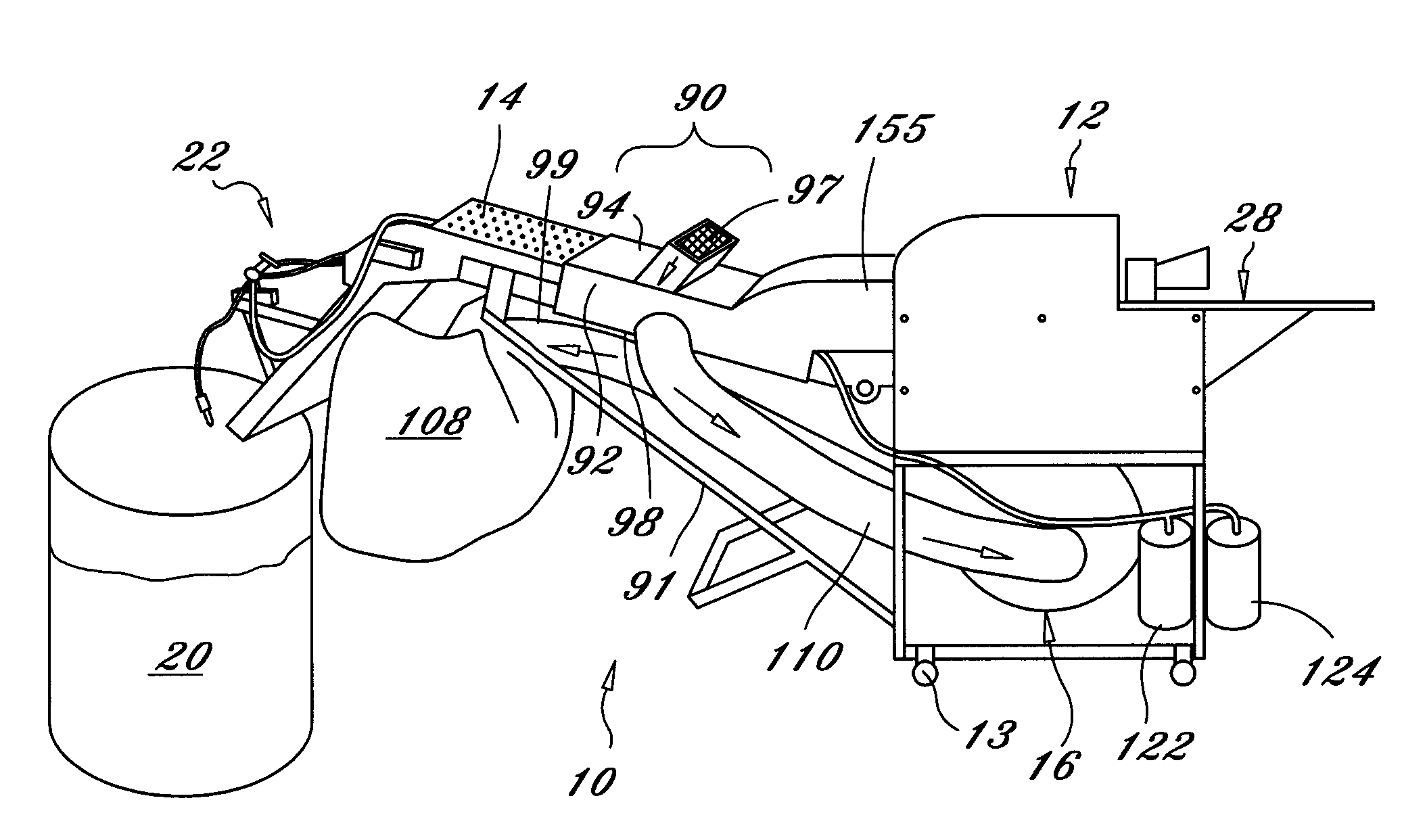

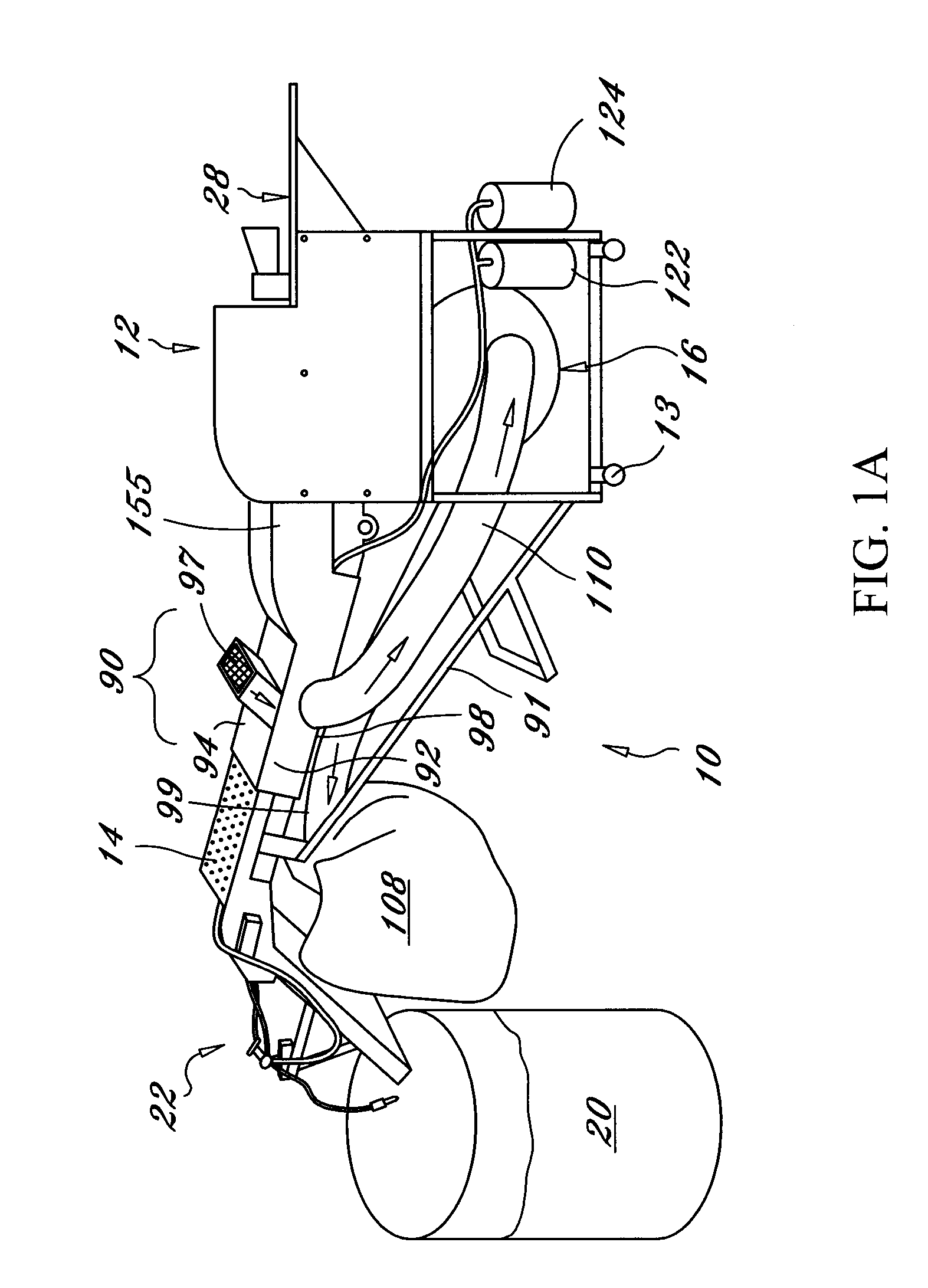

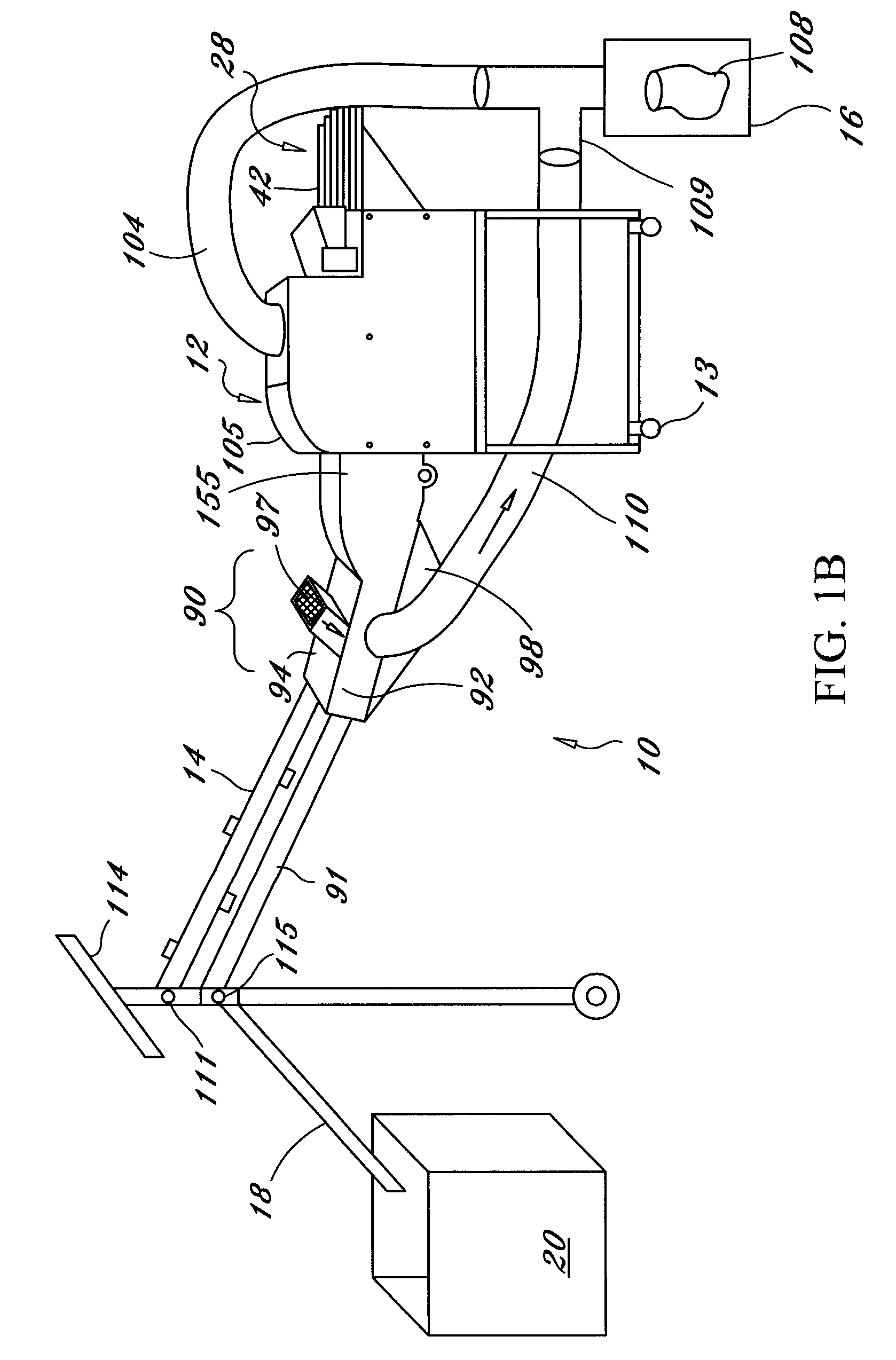

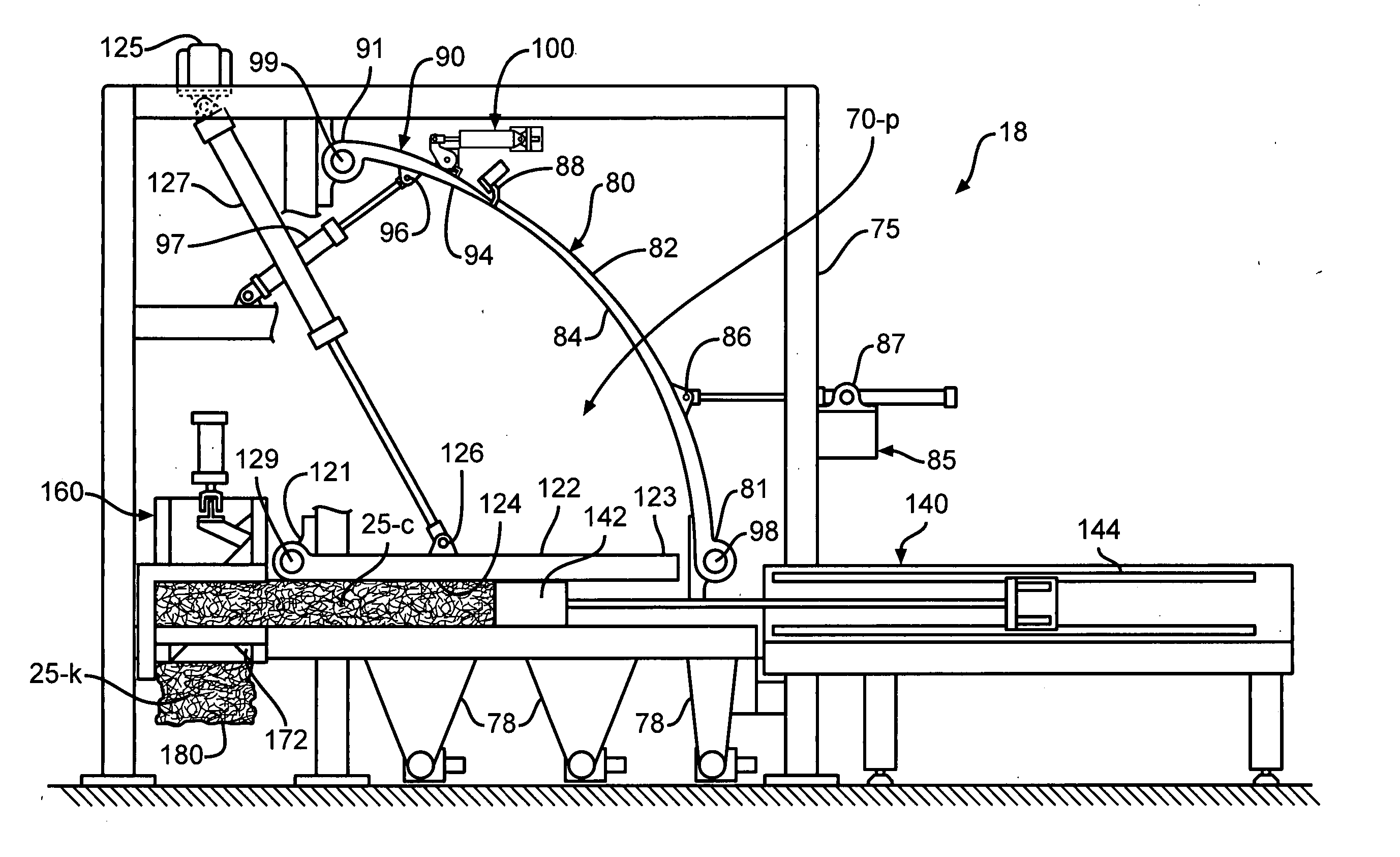

Loose fill packing material and apparatus for manufacturing same

ActiveUS7410454B1Easily biodegradableEfficient preparationMechanical working/deformationPaper/cardboard articlesCardboardDisinfectant

This invention forms a loose fill packing material comprising clean, elongated strips of paper formed from corrugated cardboard having internal fluting formatted to expand in height, improving the ability of the strips to lattice. A vertical slitter divides cardboard into blanks of a predetermined width generally with the grain of corrugation. The blanks are fed into a shredding device that cuts the blanks with a scissor motion across the width of the blank. The strips pass onto a cleated perforated conveyor and into an enclosed suction housing. Inside the suction housing is a vortex box enhancing air flow for cleaning the strips. Strips are centered on the conveyor. The strips move from the conveyor to an angled, vibrating sifter plate into a collector. Strips are sprayed with a liquid material having microbicidal, sanitizing, insect repellant, disinfectant and / or deodorizing properties.

Owner:LEVINE NORMAN D

Low profile packaging assembly for loose fill insulation material

InactiveUS20070193224A1Equally distributedSolid materialLiquid materialMechanical engineeringLoose fill

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

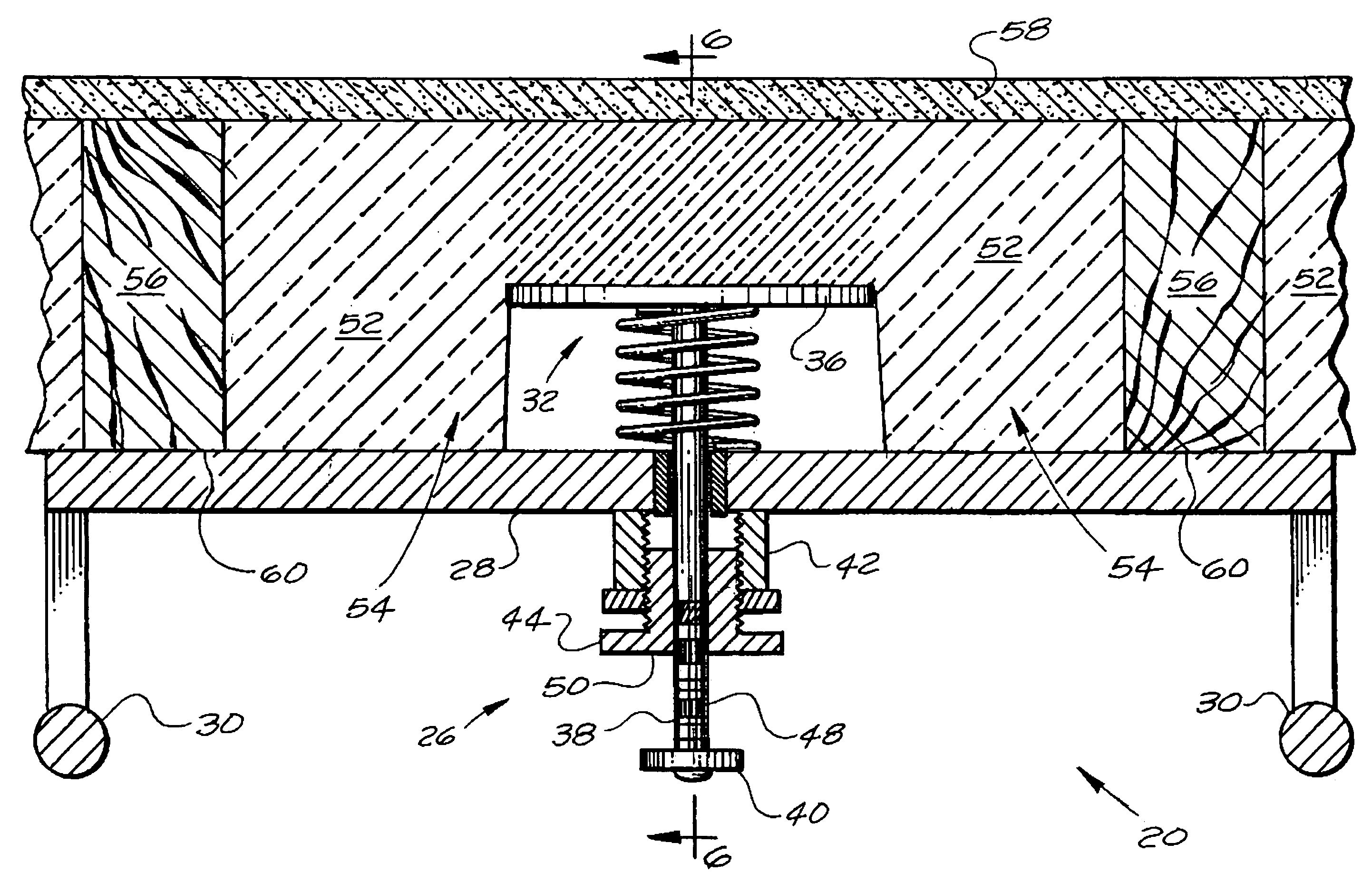

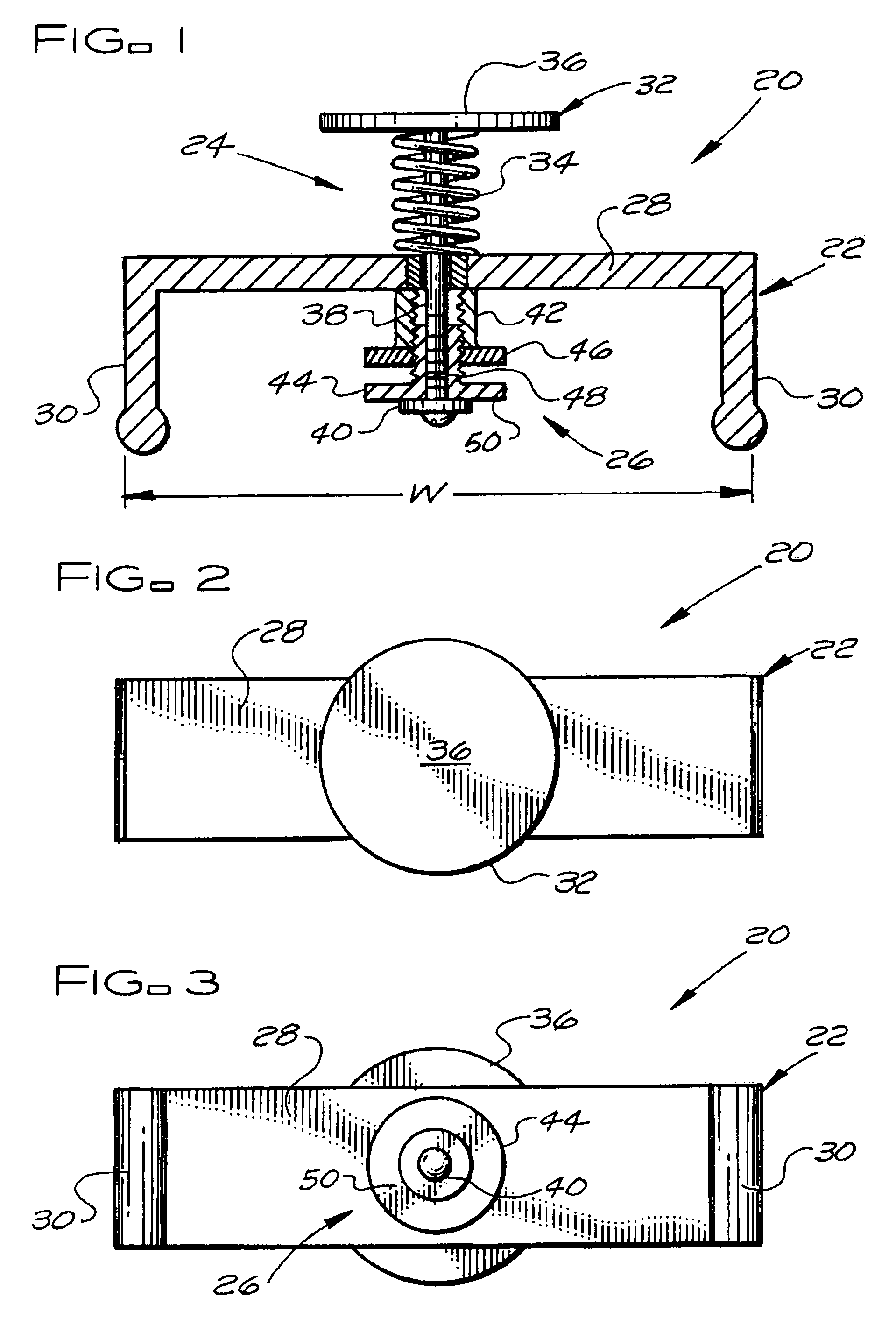

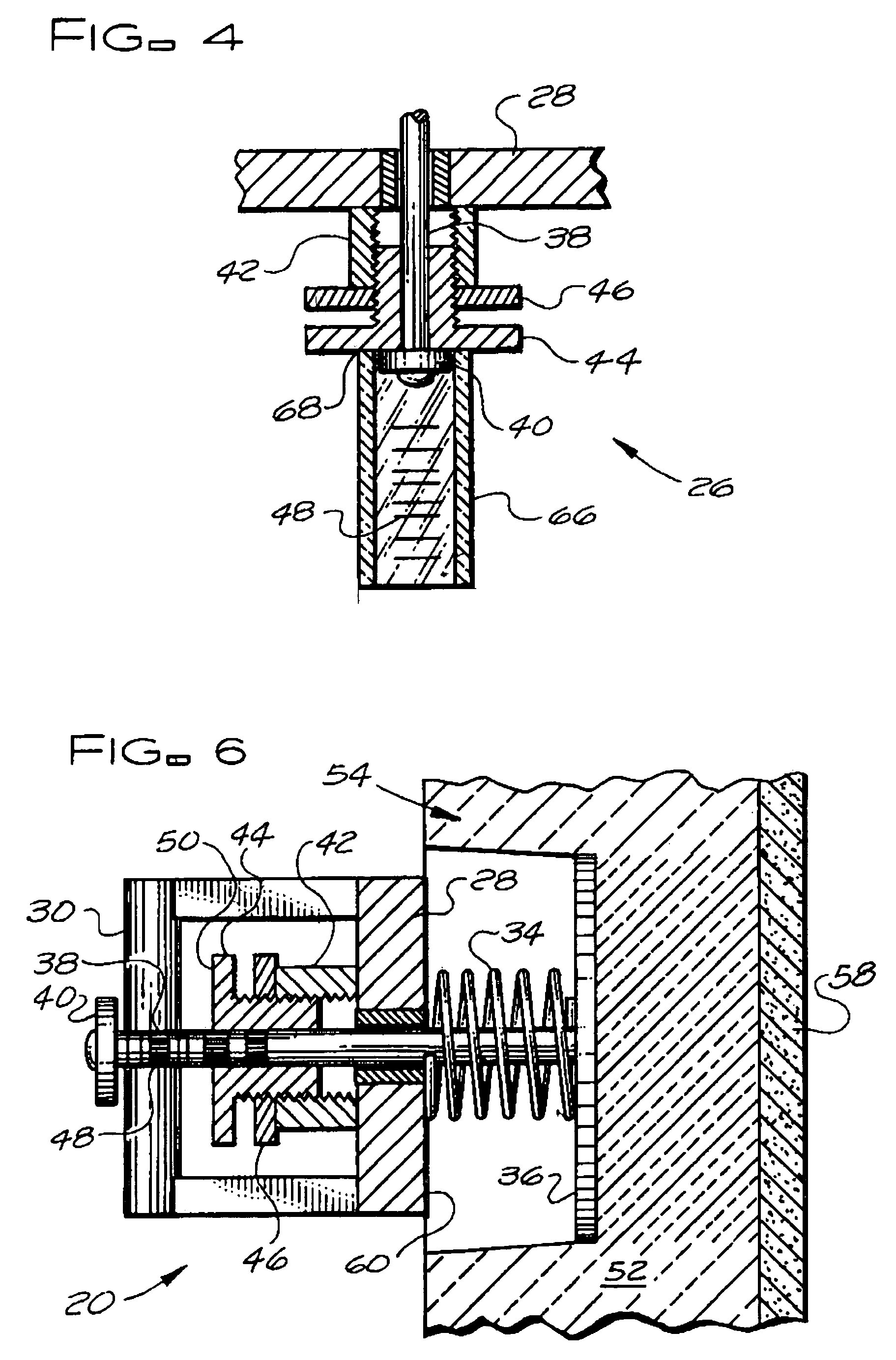

Gauge and method for indicating one or more properties of a loose-fill insulation

A portable gauge and method are used to determine an as installed property of a loose-fill insulation in a building cavity wherein the cavity has a given depth, an open front, a rear surface, and sidewalls defined by spaced apart framing members. The gauge includes a frame for extending between and overlapping front surfaces of the framing members to position the gauge for determining an as installed property of the insulation; a plunger assembly mounted on the frame for compressing a portion of the insulation in the cavity to a compressed density sufficiently dense to prevent plunger creep and to a compressed thickness less than the as installed thickness of the insulation; and a readout assembly calibrated to indicate an as installed property of the insulation based on the compressed thickness of the insulation.

Owner:JOHNS MANVILLE CORP

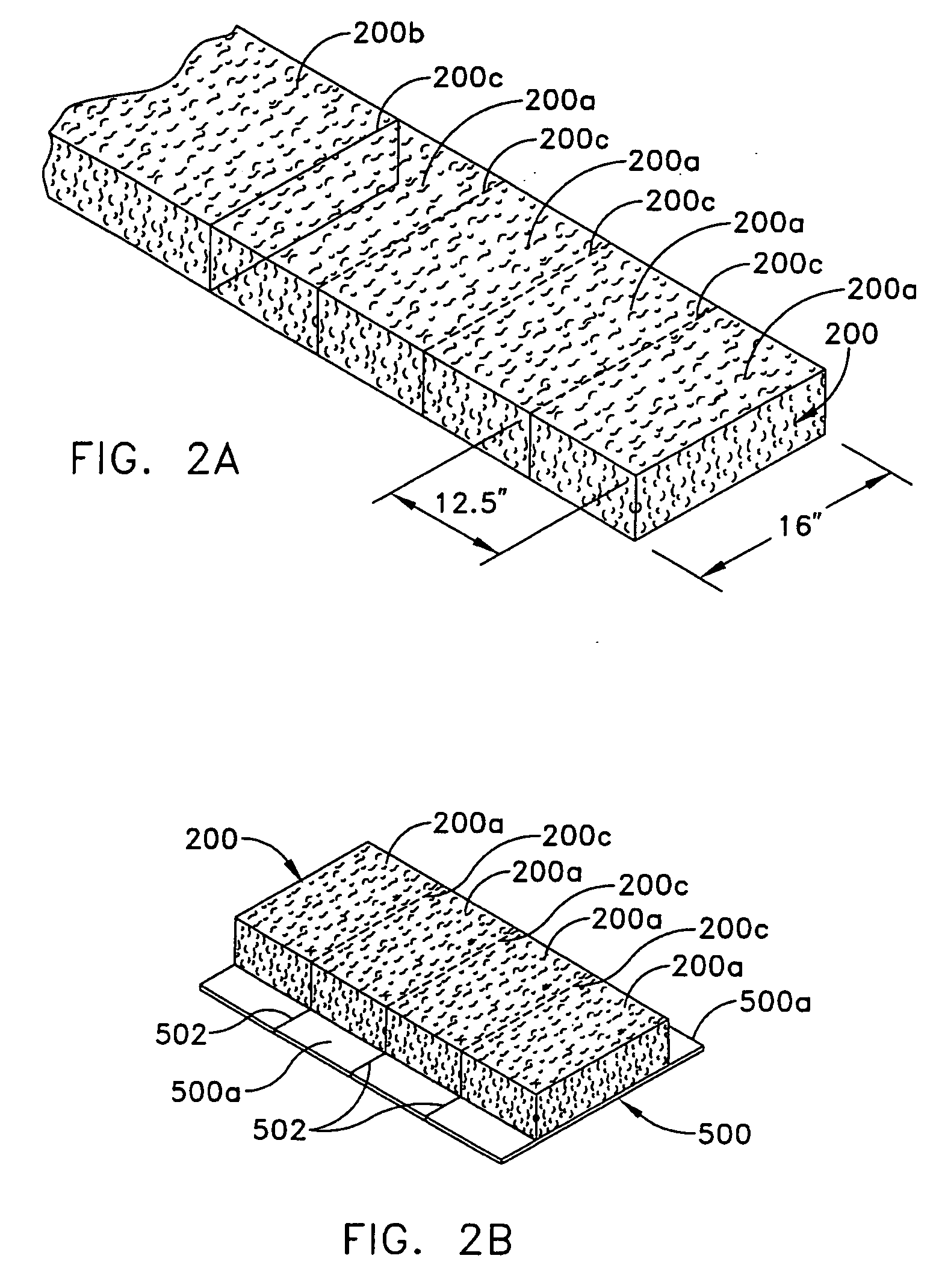

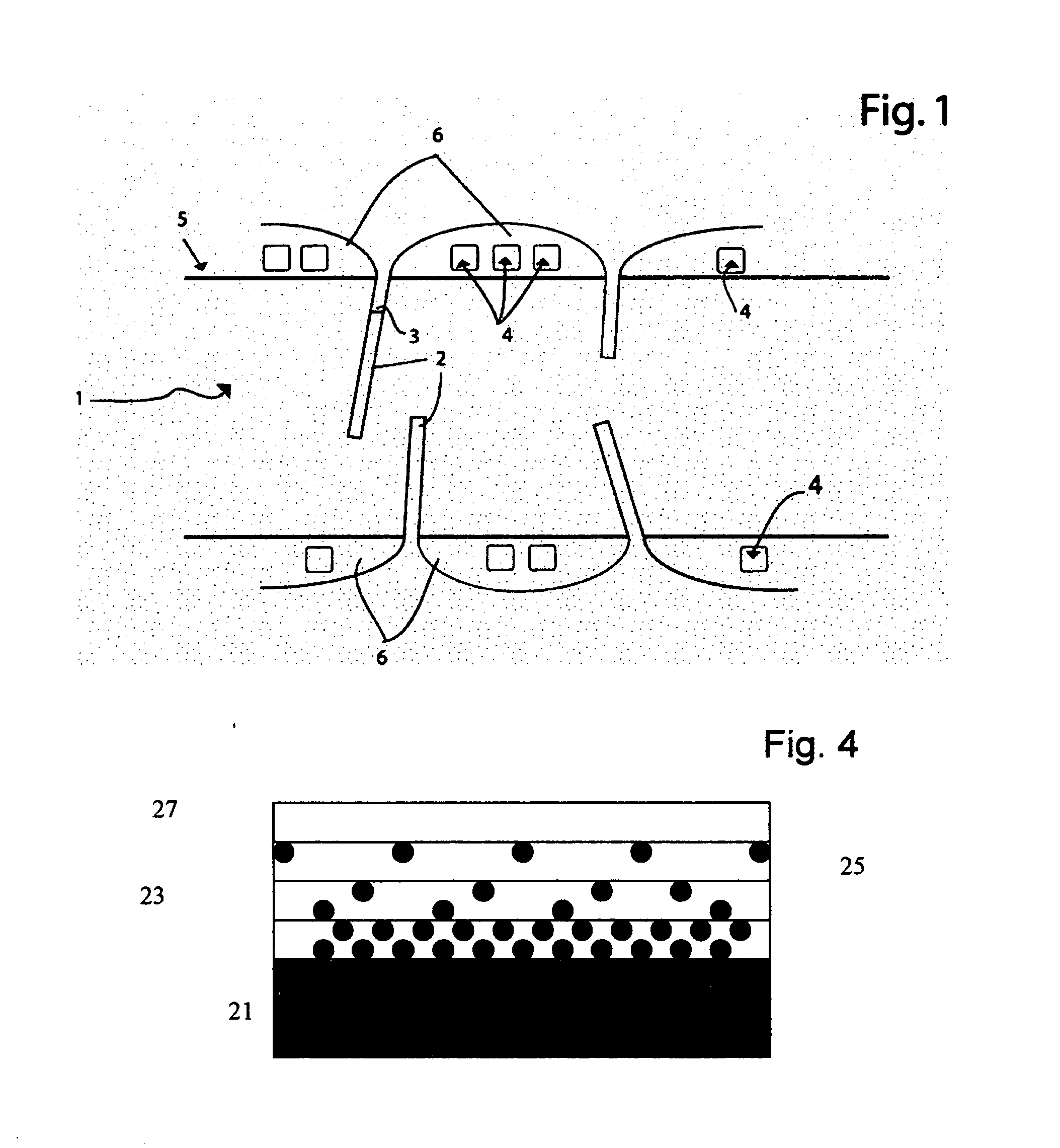

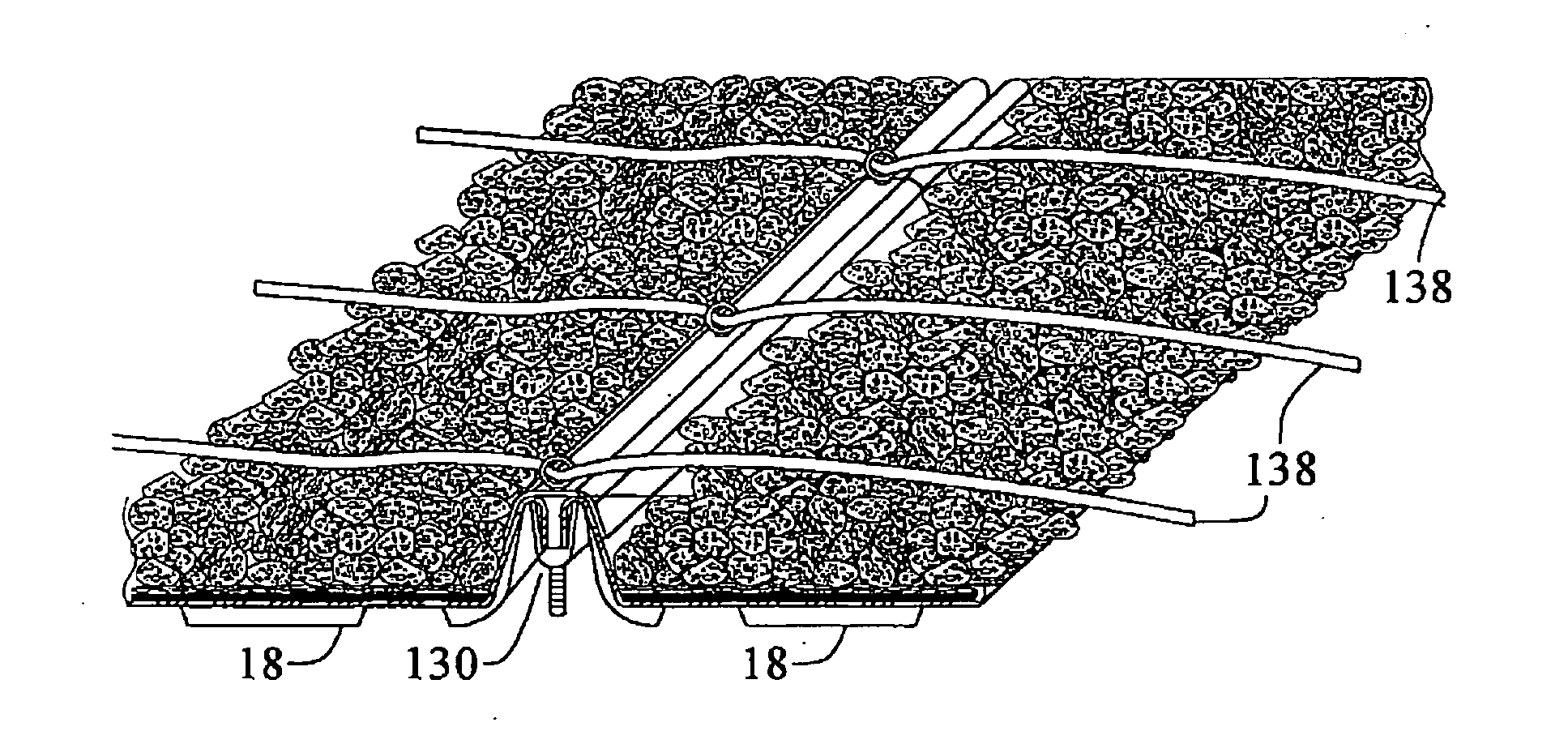

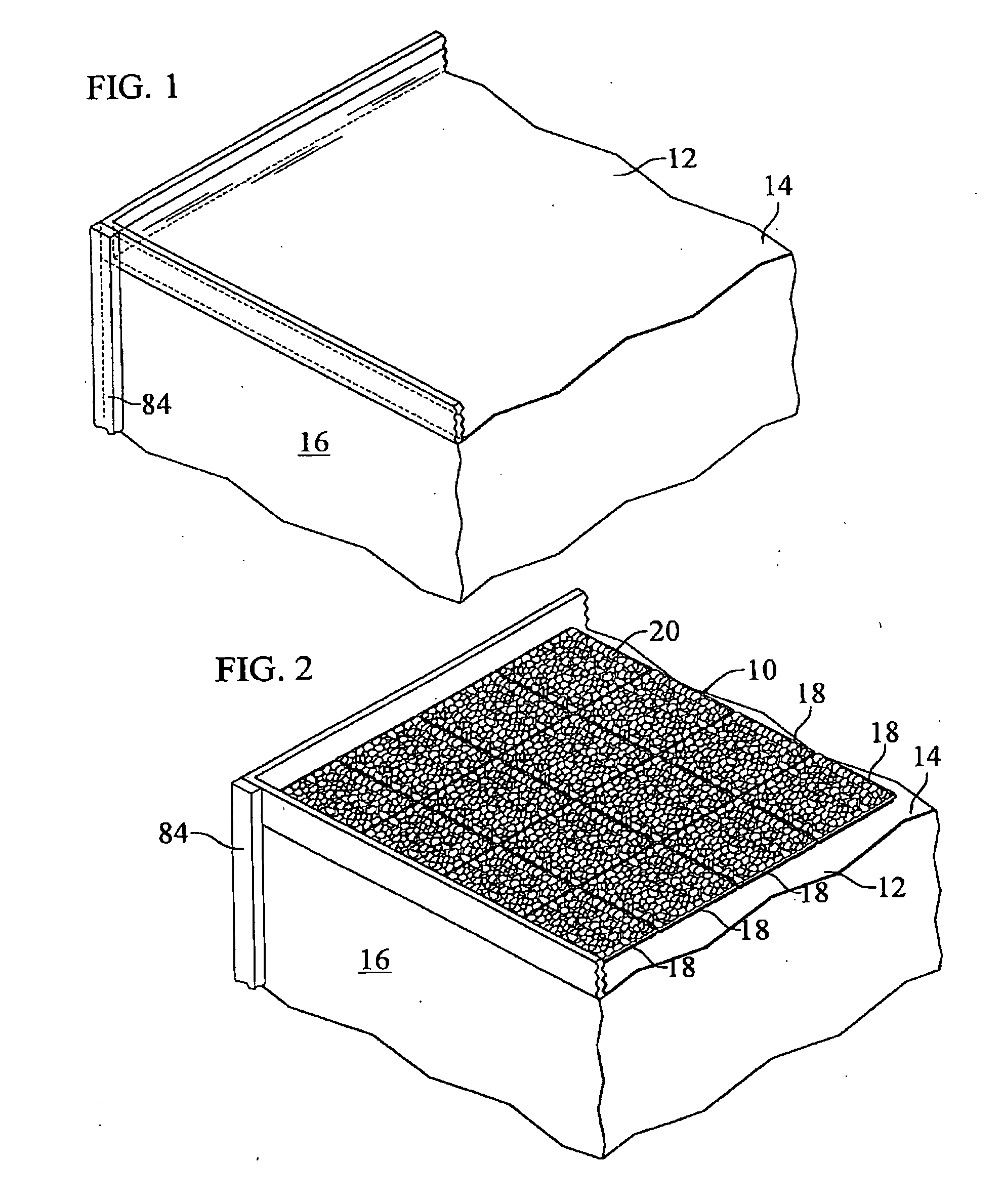

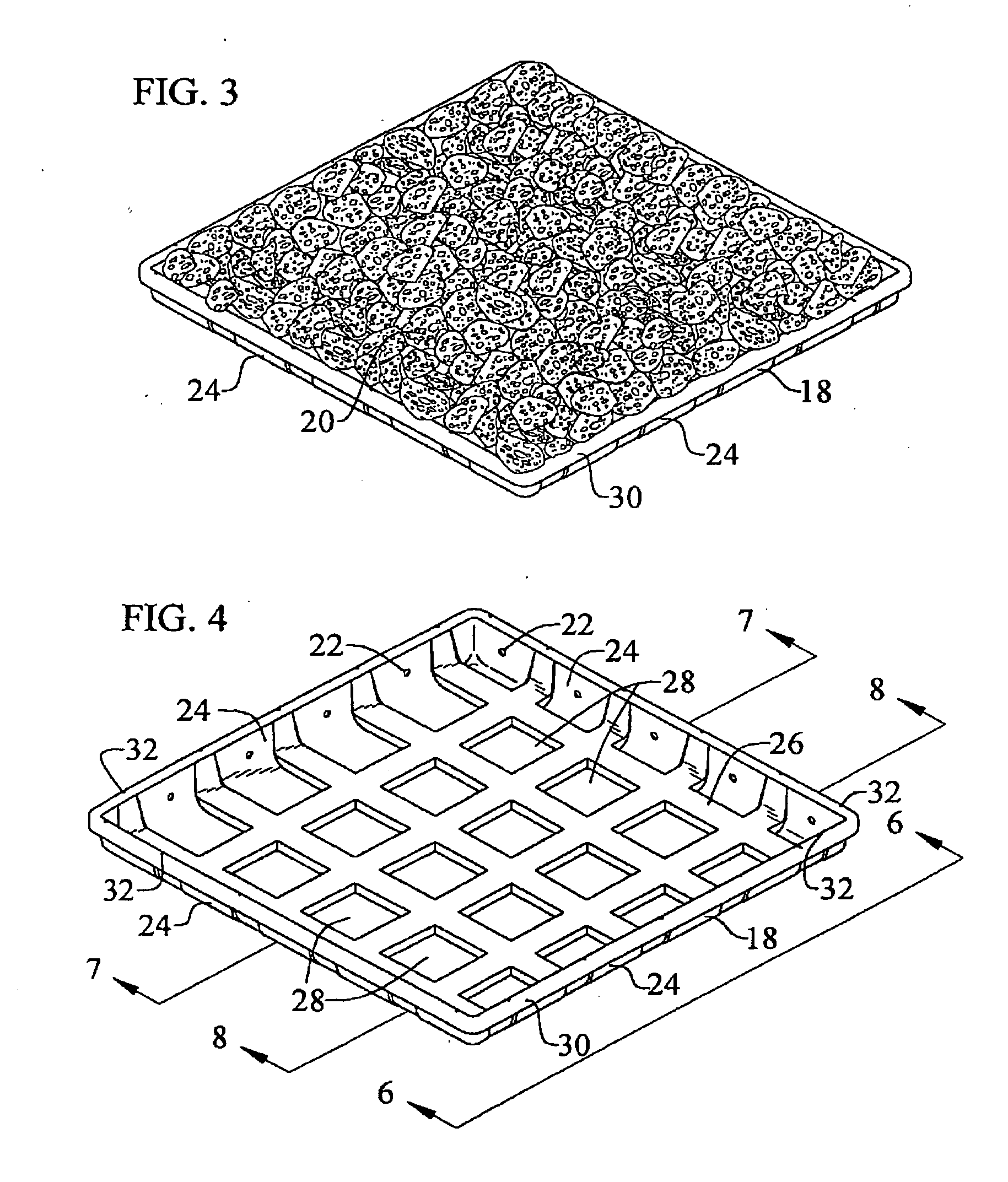

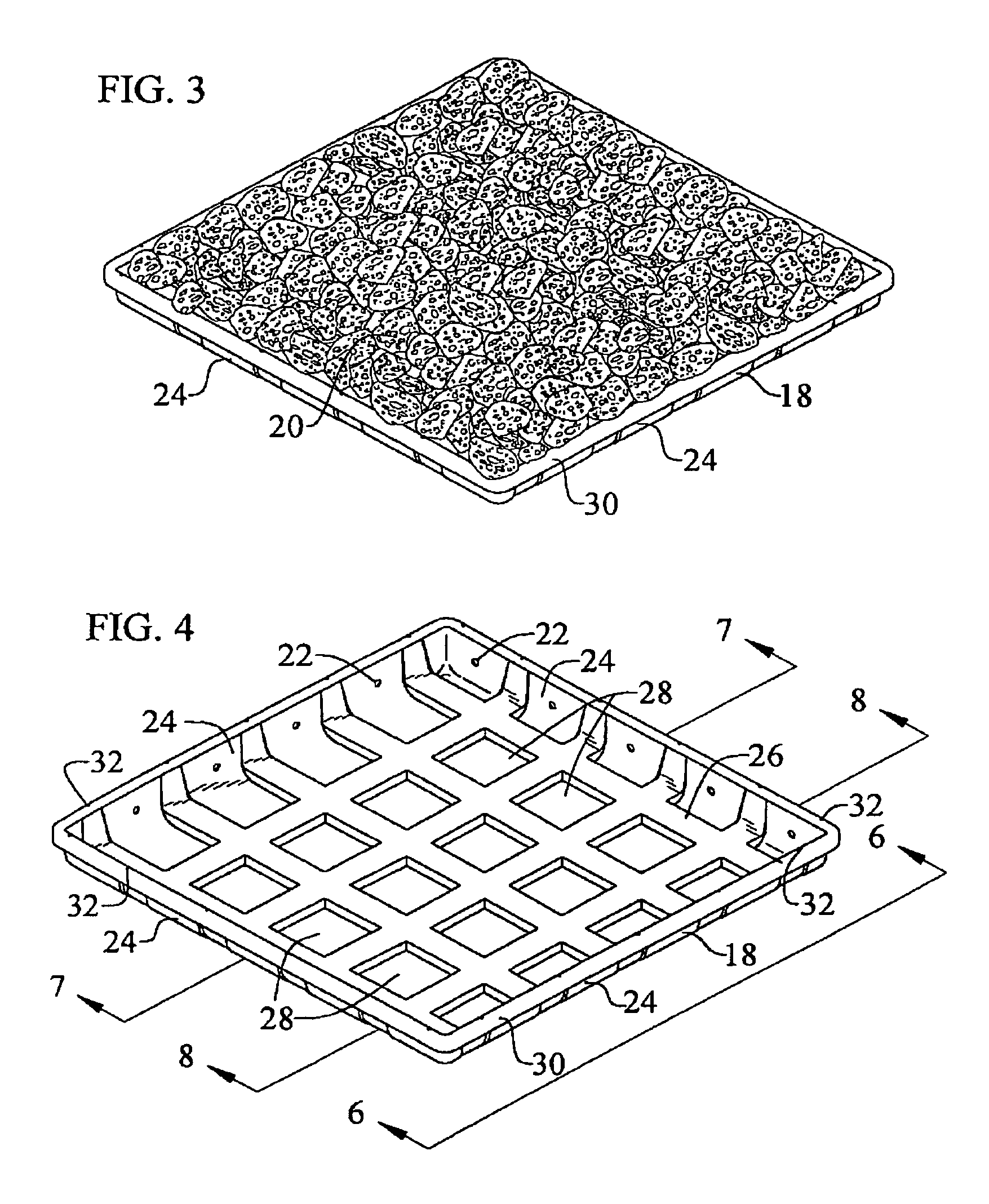

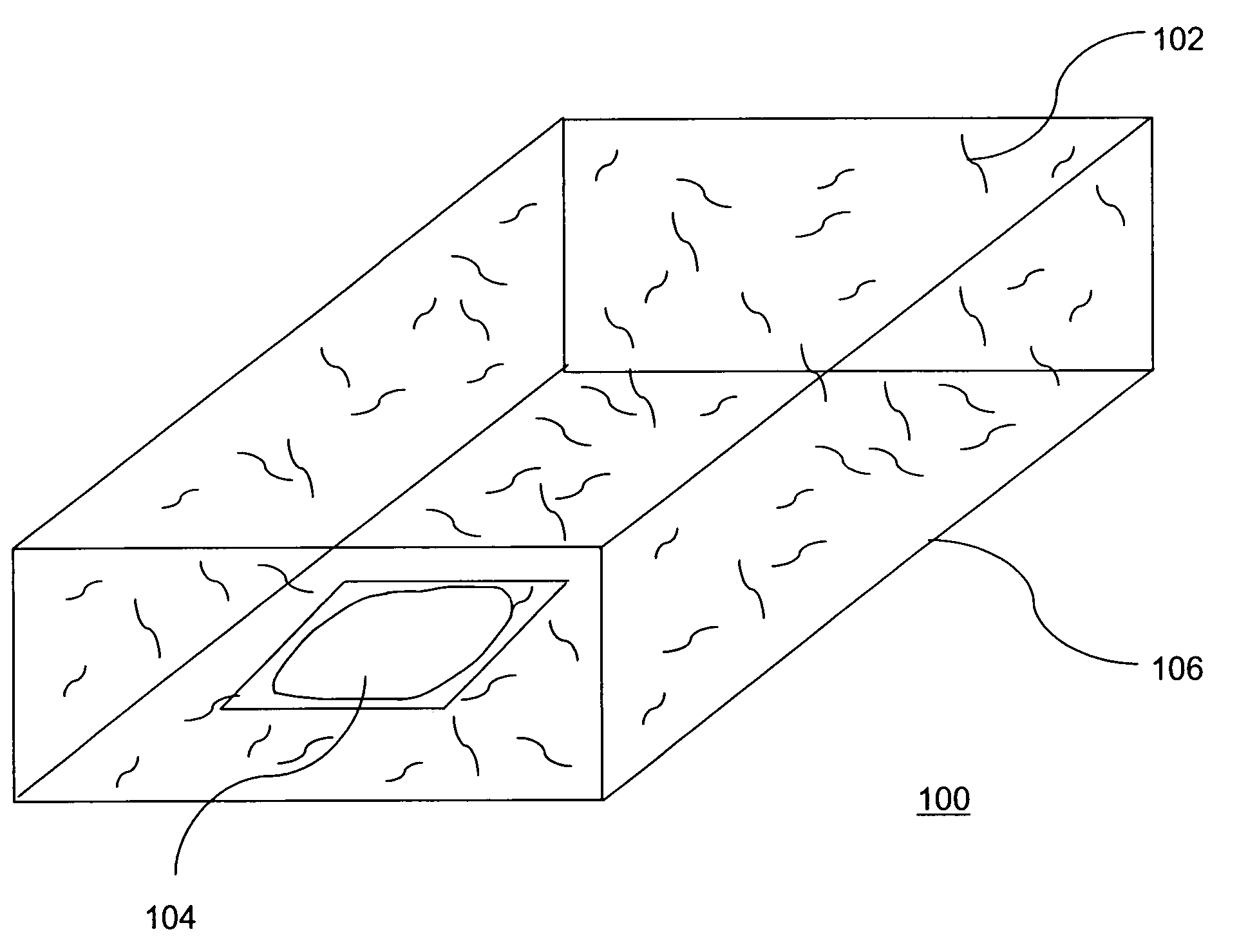

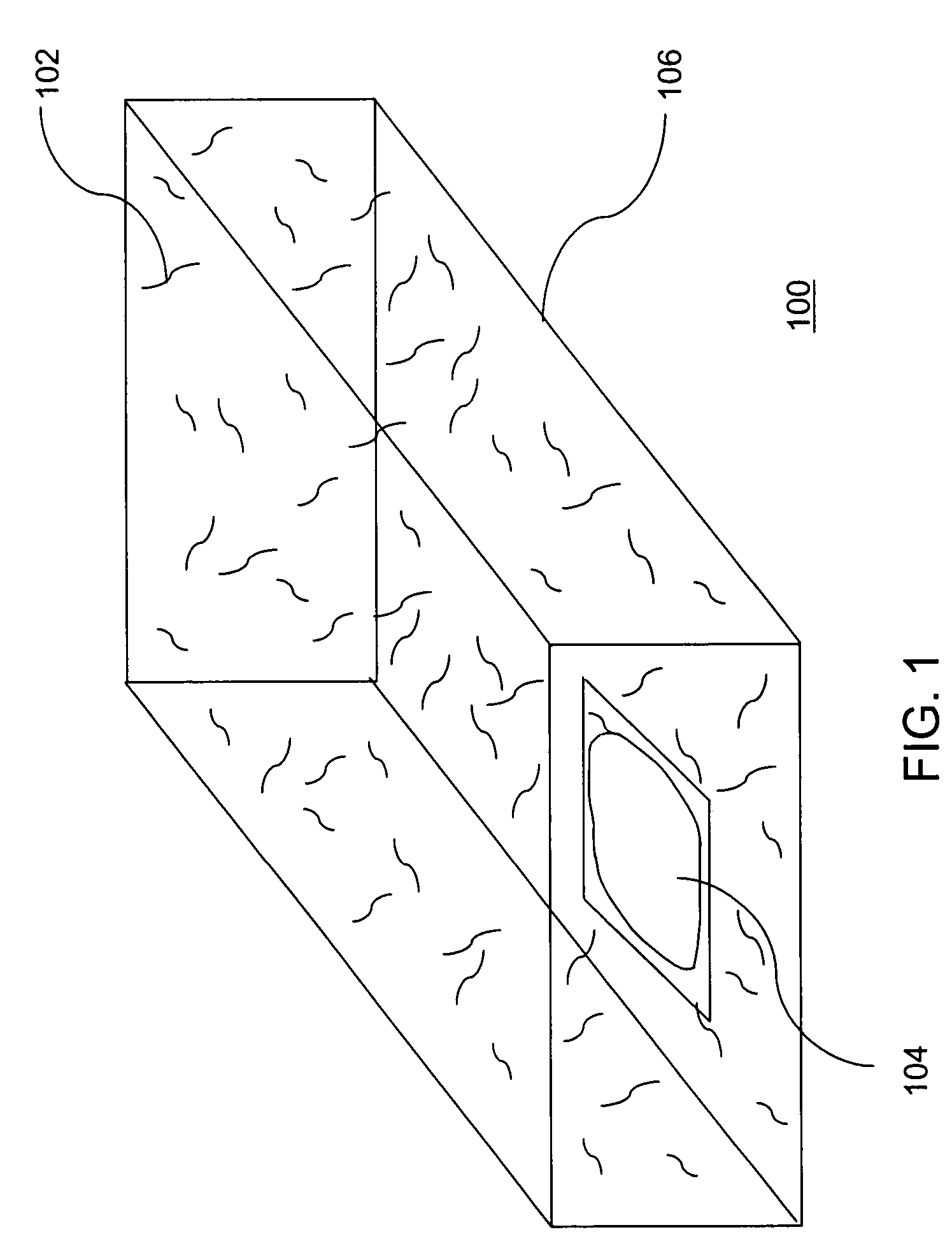

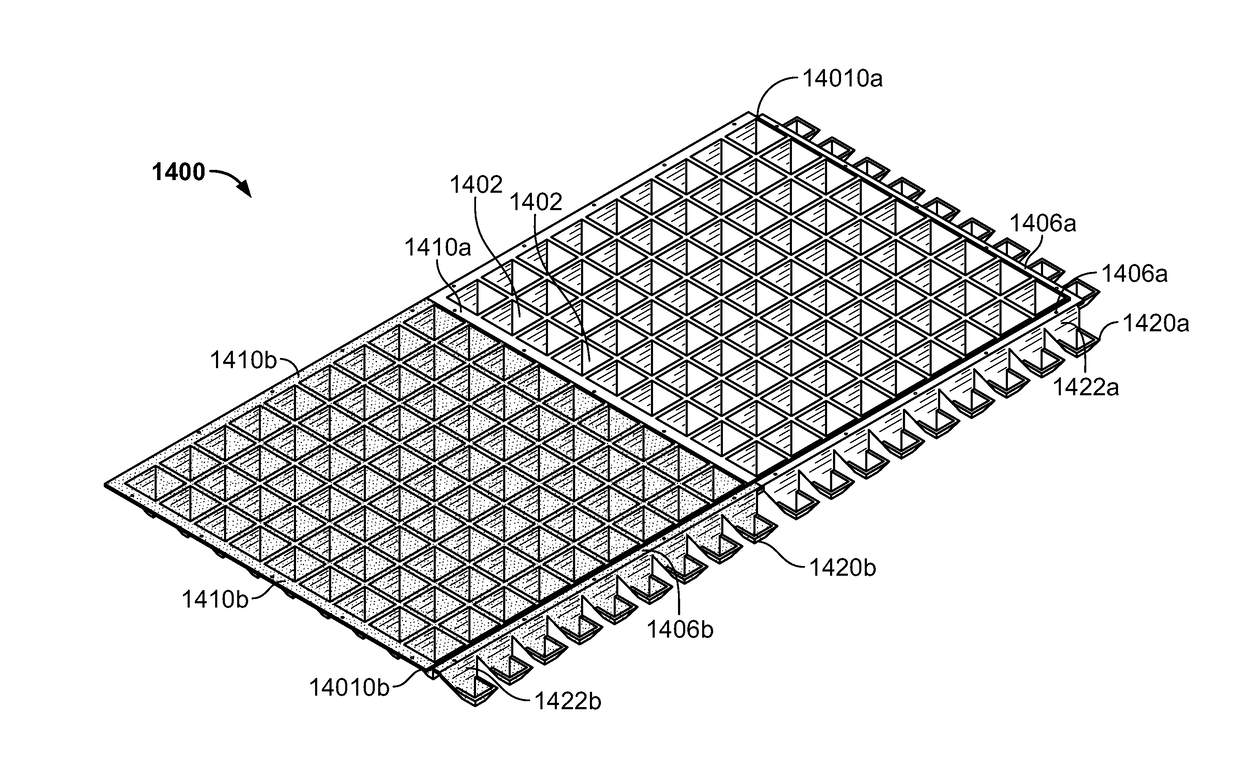

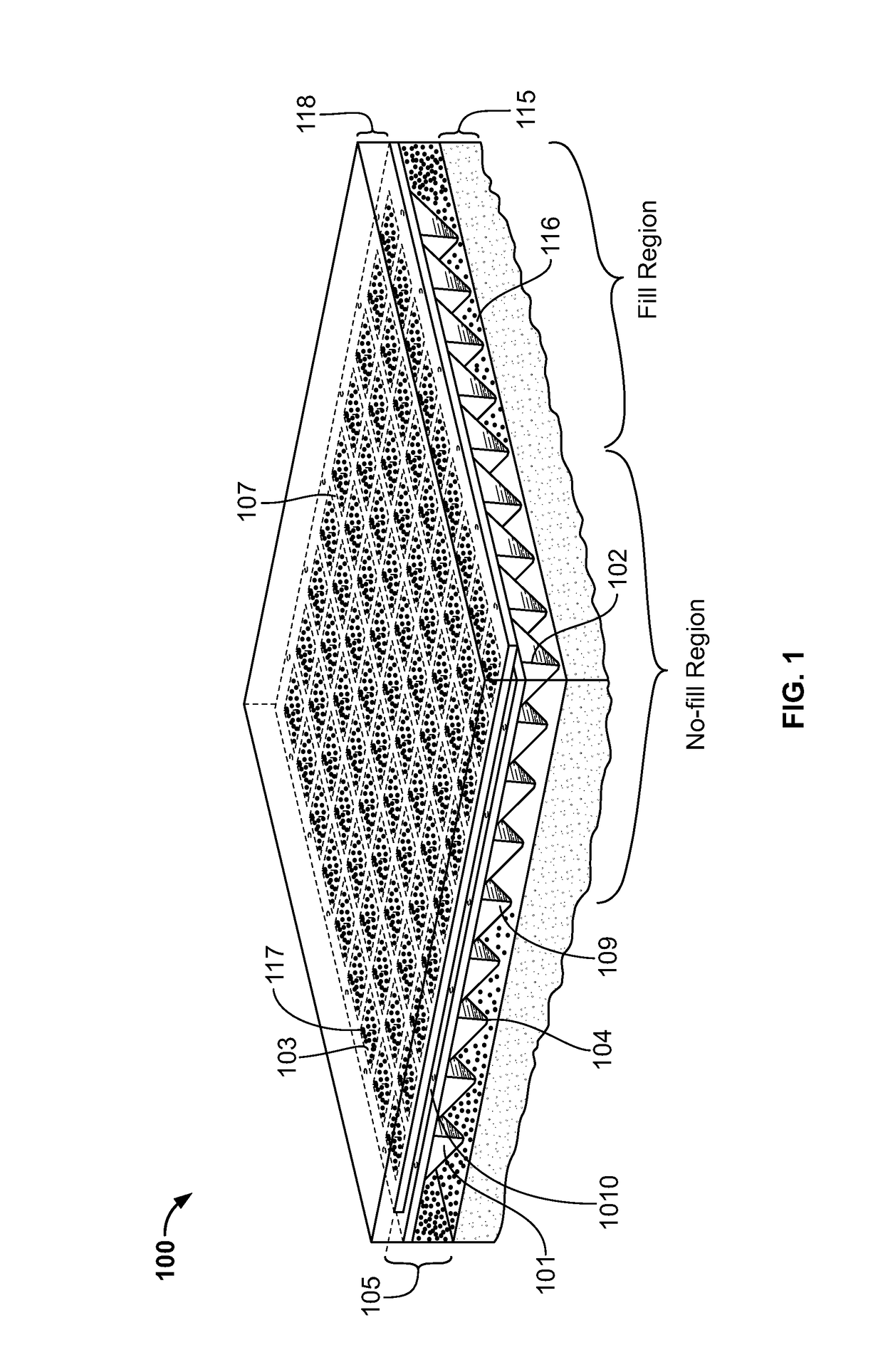

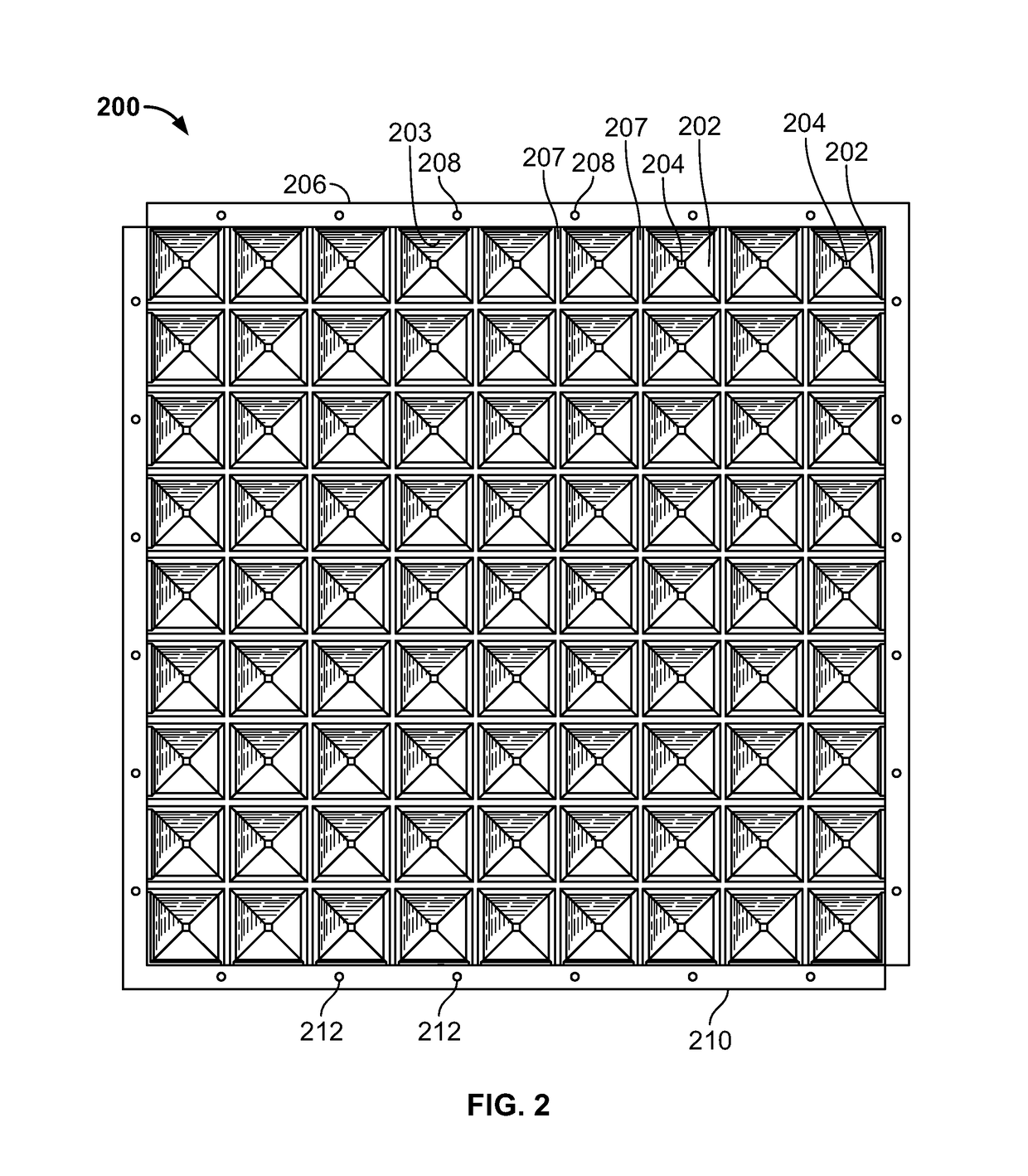

Safety surface with engineered shock-absorbing base

A safety surface with an engineered shock-absorbing base. The base may include one or more engineered resilient mats. The mats may be fabricated of repurposed tire rubber. The mats may be adjoined edgewise. Adjoined mats may be coupled together. The base may overlay a surface. The base may include upward-facing pockets. Interiors of the pockets may receive loose fill. An upper layer may cover the base. The upper layer may bond to the base. The upper layer may seal the loose fill within the safety surface. The upper layer may include poured-in-place surfacing. The upper layer may be textured. The upper layer may include synthetic turf. Impact upon the upper layer may be attenuated by flexion of the base. Mats may be coupled without hardware fasteners. Exterior surfaces of pockets of one mat may be nested into complementarily contoured features of an adjoining mat.

Owner:PLAYSAFER SURFACING LLC A DIV OF RUBBERECYCLE

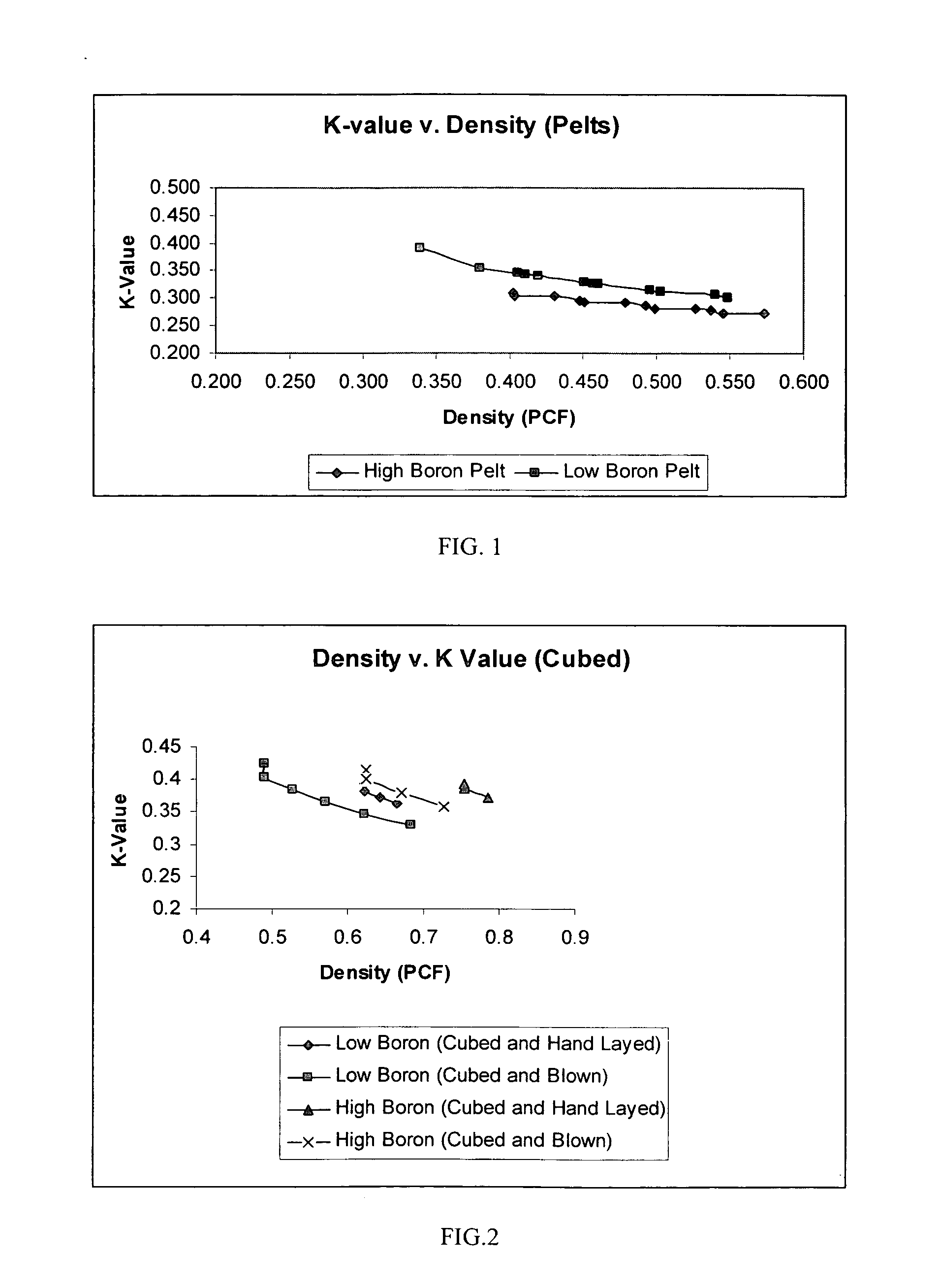

Low boron glass composition for loose-fill fiberglass insulation

ActiveUS20060148634A1Improve furnace lifeReduce the amount of solutionLayered productsThin material handlingGlass fiberVolumetric Mass Density

The present invention relates to fiberglass loose-fill insulation that is insensitive to the content of boron in the composition of the glass. It has been discovered that the level of boron in the glass used for the manufacture of loose-fill glass wool can be substantially reduced without degrading thermal performance. The lowered amount of boron provides for a lower cost batch composition and increased furnace life. The glass composition of the present invention includes a substantially reduced content of boron and preferably an increased amount of sodium dioxide. The primary phase of these glass compositions is typically devitrite (Na2Ca3Si6O16). The glass of the present invention provides a glass fiber blowing wool that does not require an increase in pack density to compensate for the reduced boron content while achieving the similar thermal conductivity. The glass of the present invention is also suitable for use in acoustic insulation.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Insulation with mixture of fiberglass and cellulose

InactiveUS7449125B2Improve propertiesNon-fibrous pulp additionNatural cellulose pulp/paperGlass fiberCellulose

Certain example embodiments of this invention relate to insulation (e.g., loose-fill insulation which may be blown into attics, wall cavities, or the like) including a mixture of fiberglass and cellulose. In certain example embodiments, the insulation mixture comprises from 15-60% cellulose, more preferably from 20-50% cellulose, and most preferably from 25-45% cellulose (with substantially the remainder of the insulation be made up of fiberglass). Example advantages include improved radiant barrier properties and thus improve R-values / inch.

Owner:KNAUF INSULATION LLC

Low profile packaging assembly for loose fill insulation material

InactiveUS20070180797A1Equally distributedSolid materialLiquid materialEngineeringMechanical engineering

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

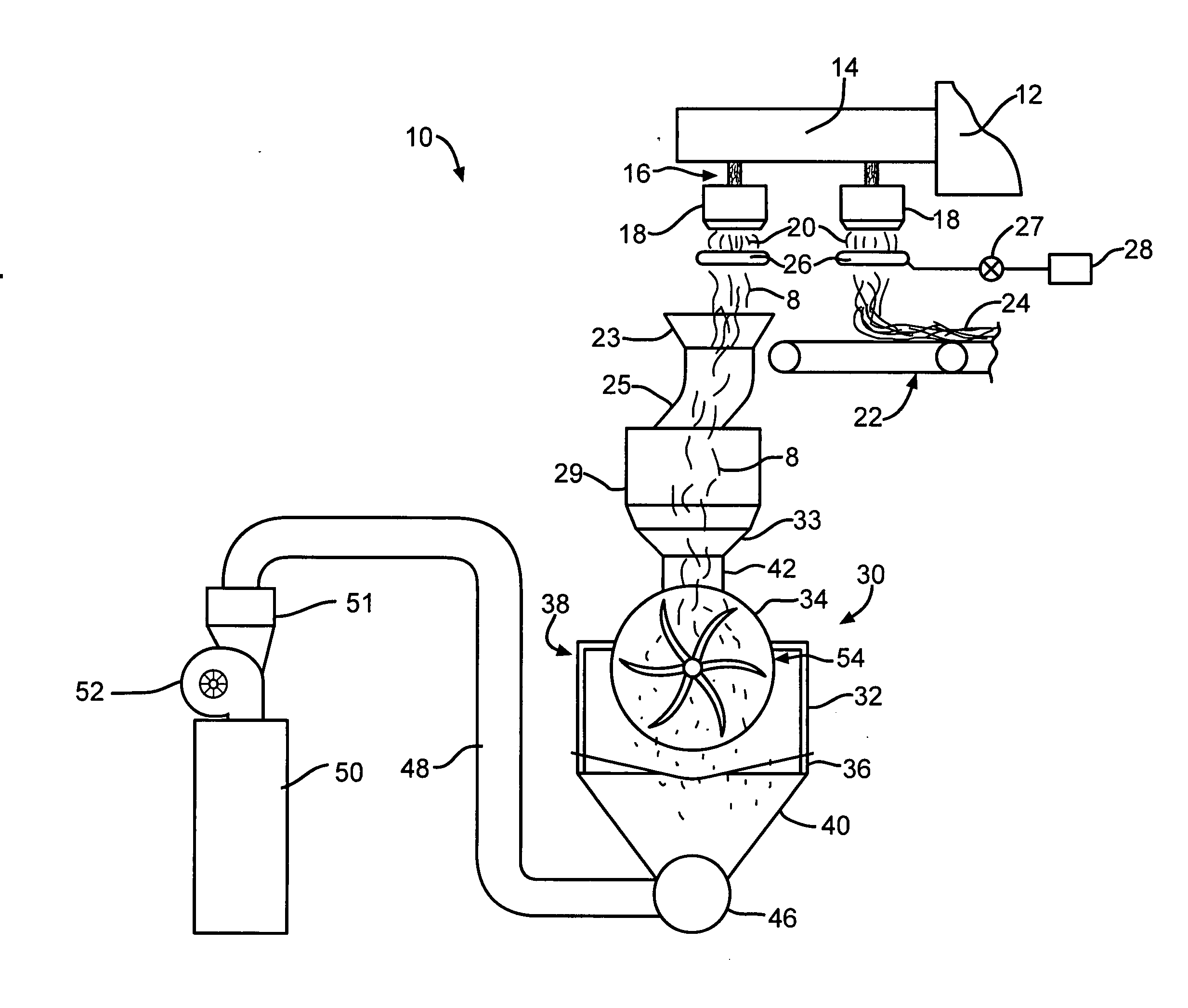

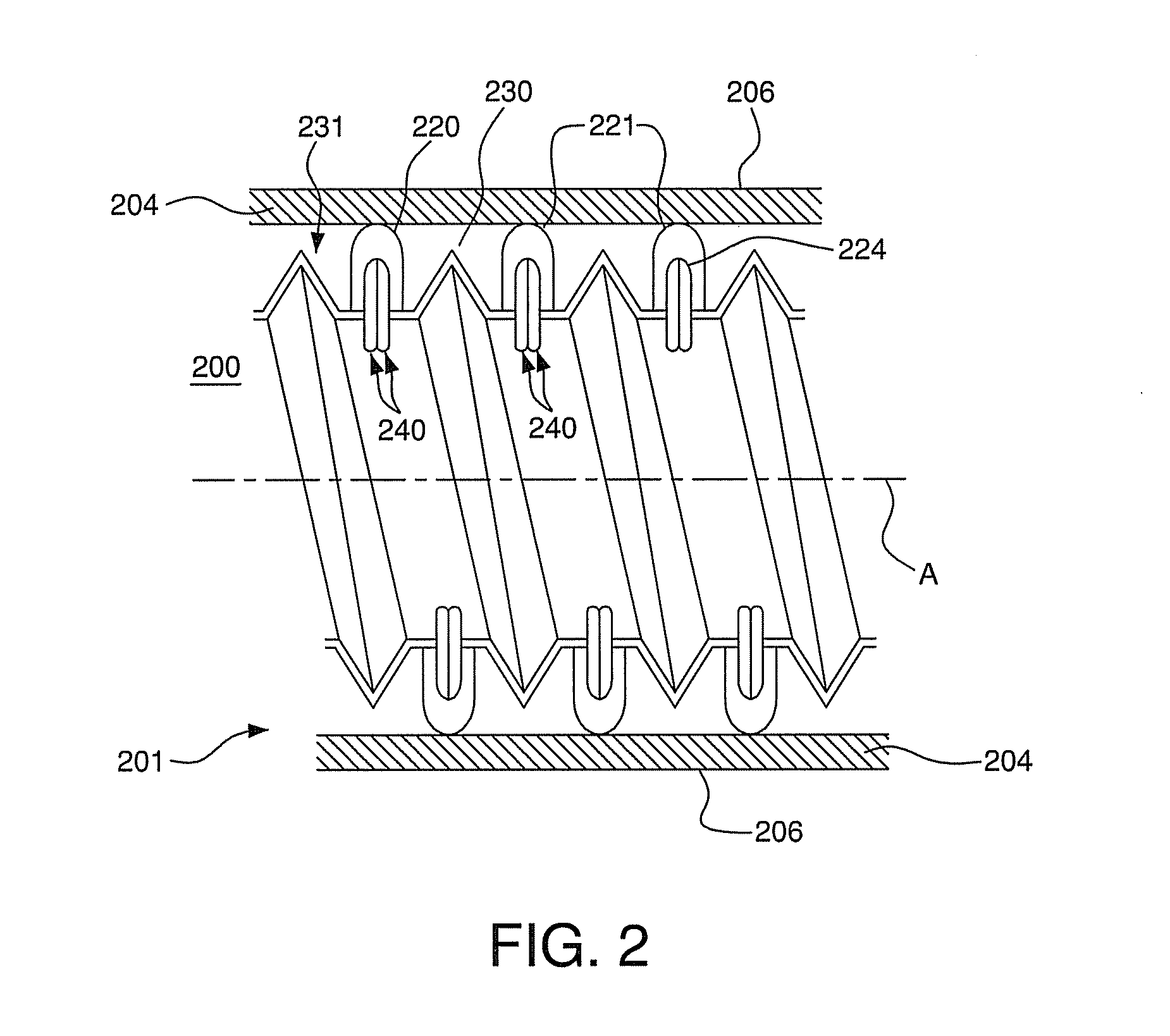

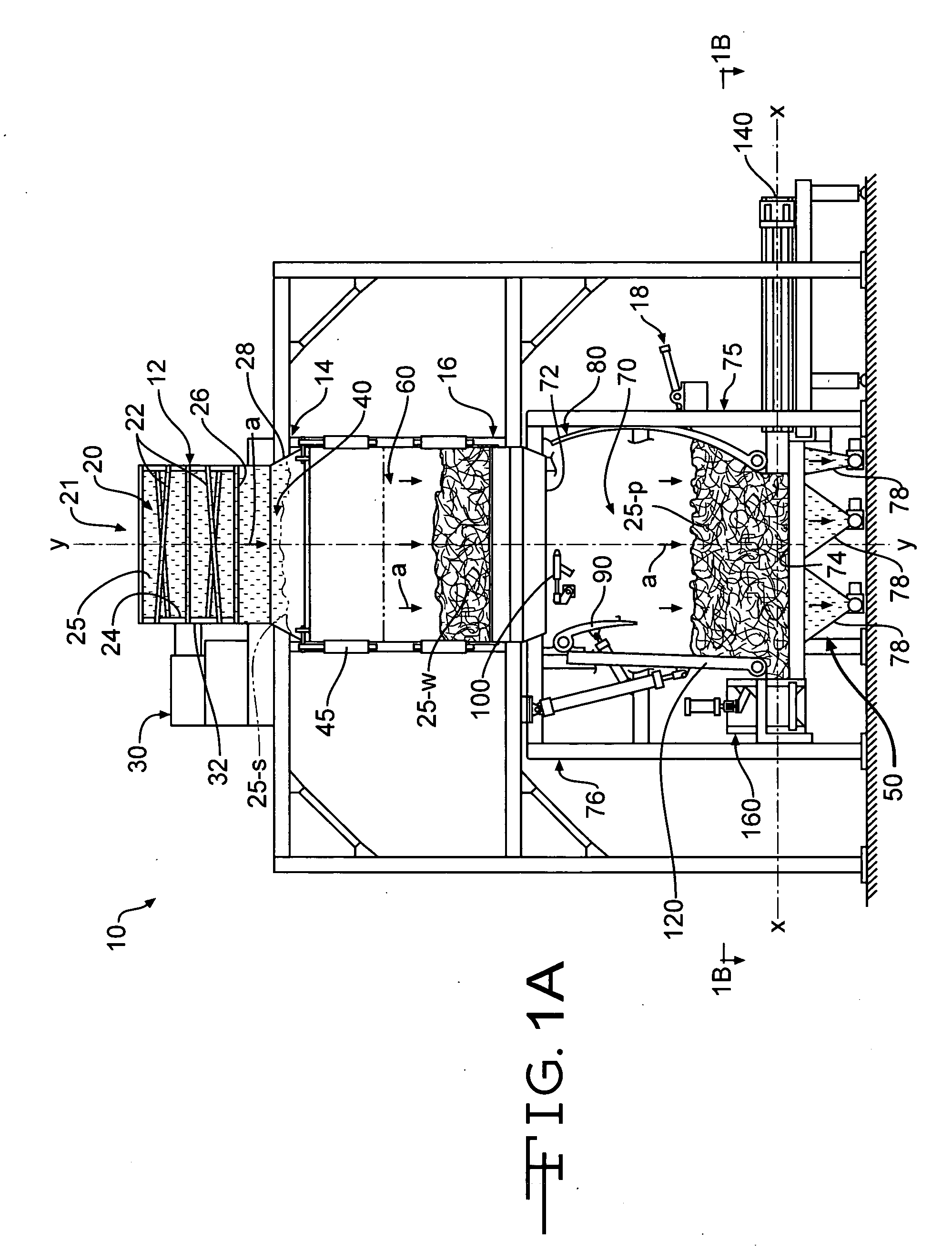

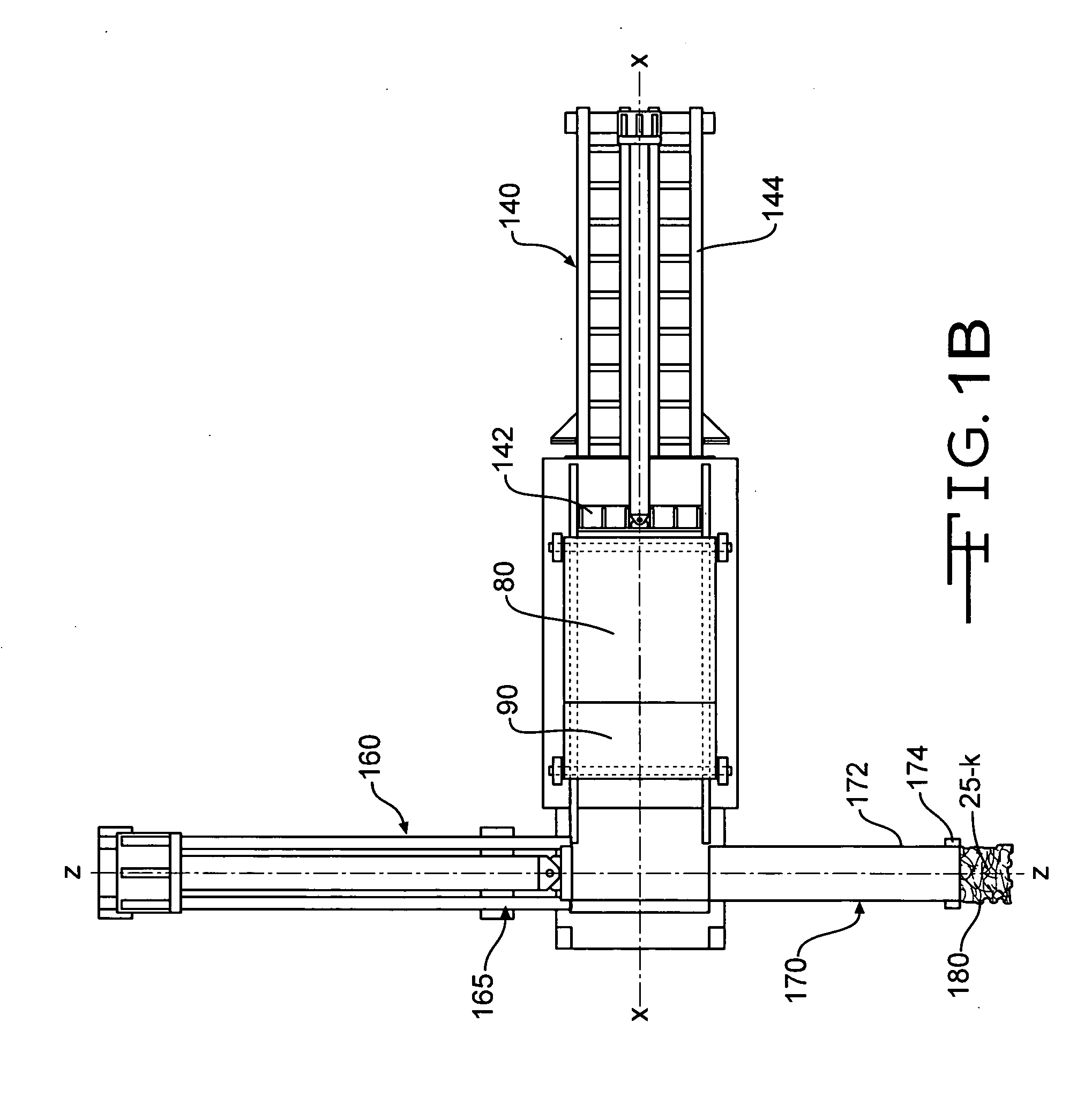

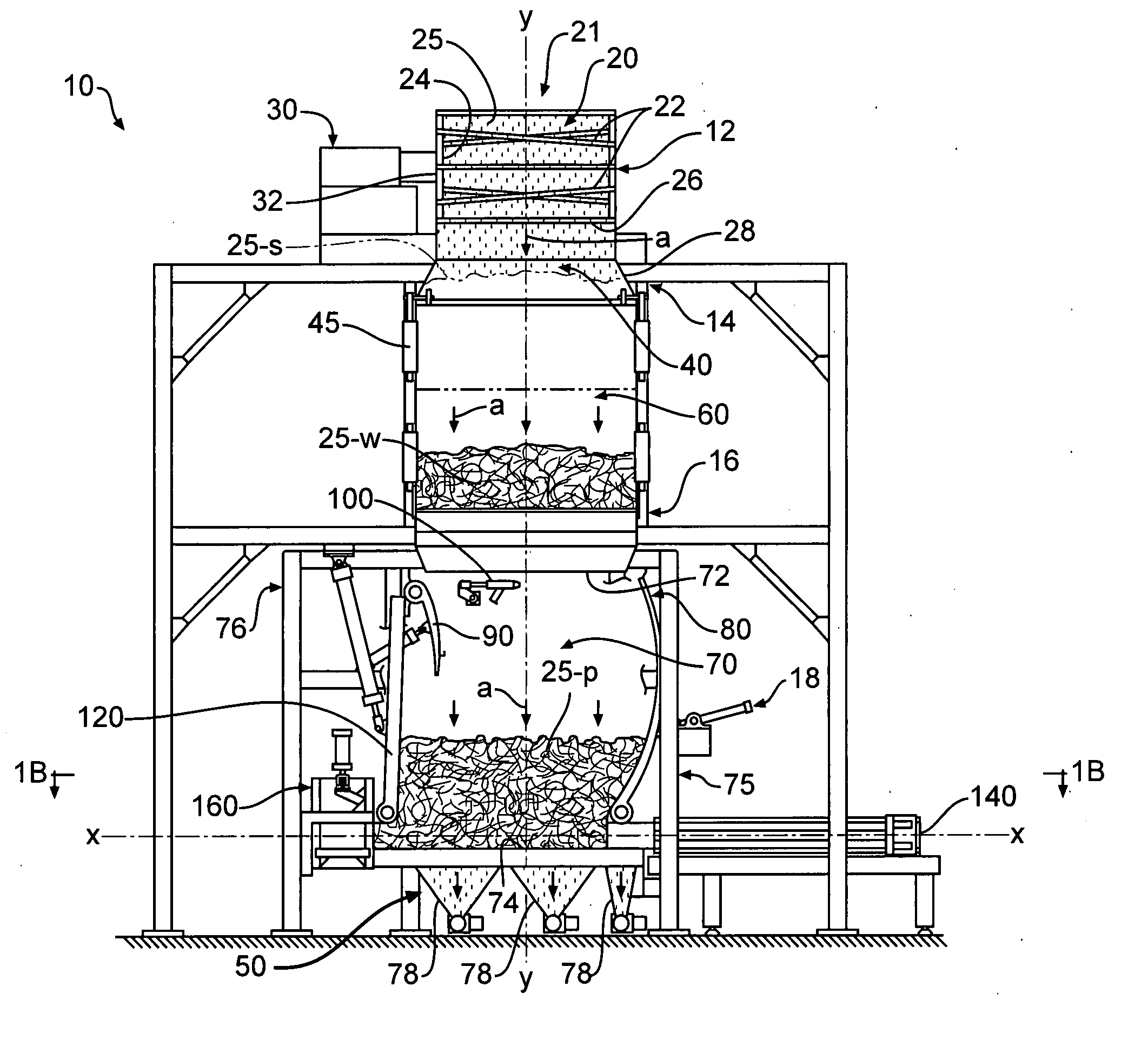

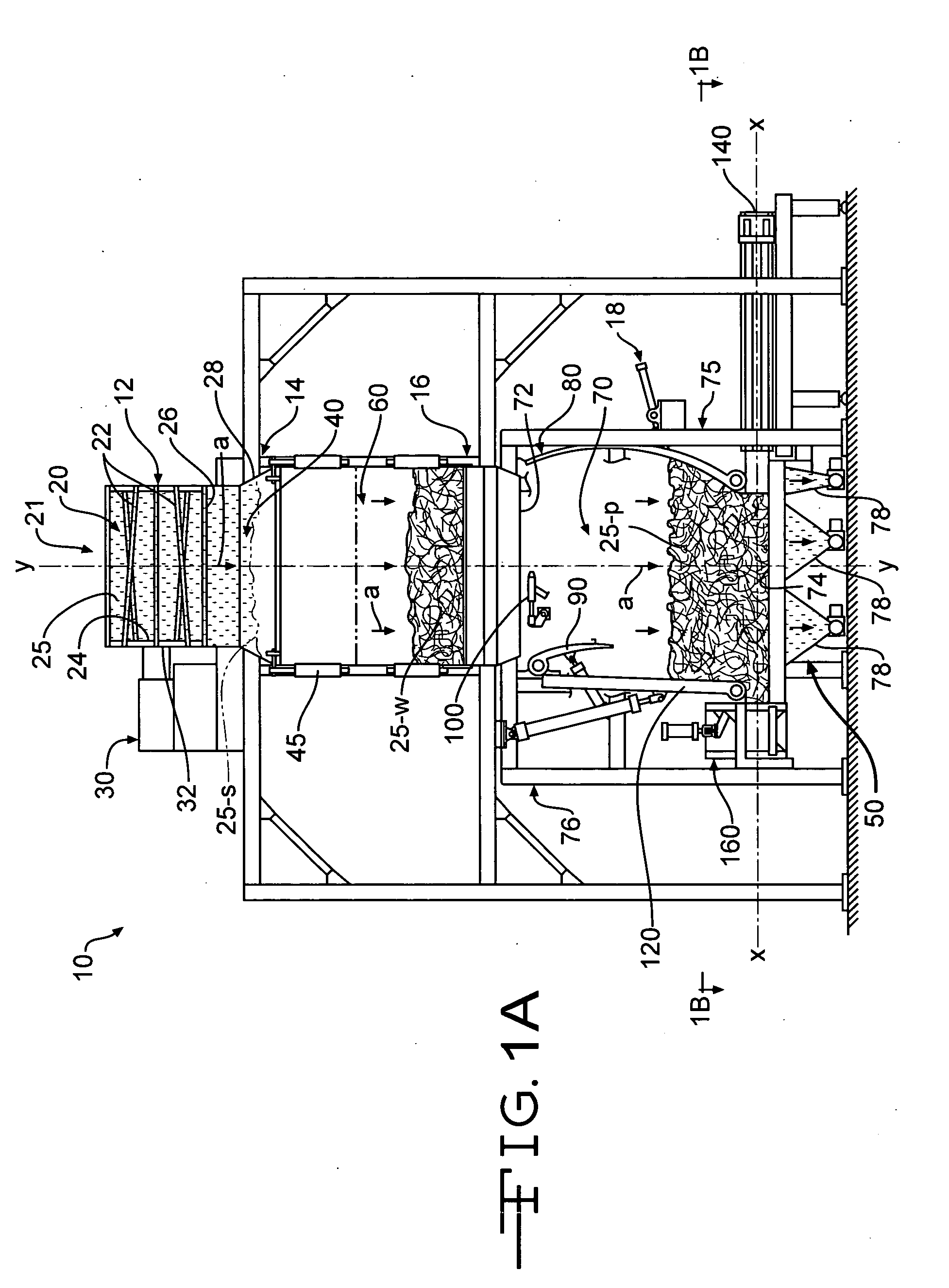

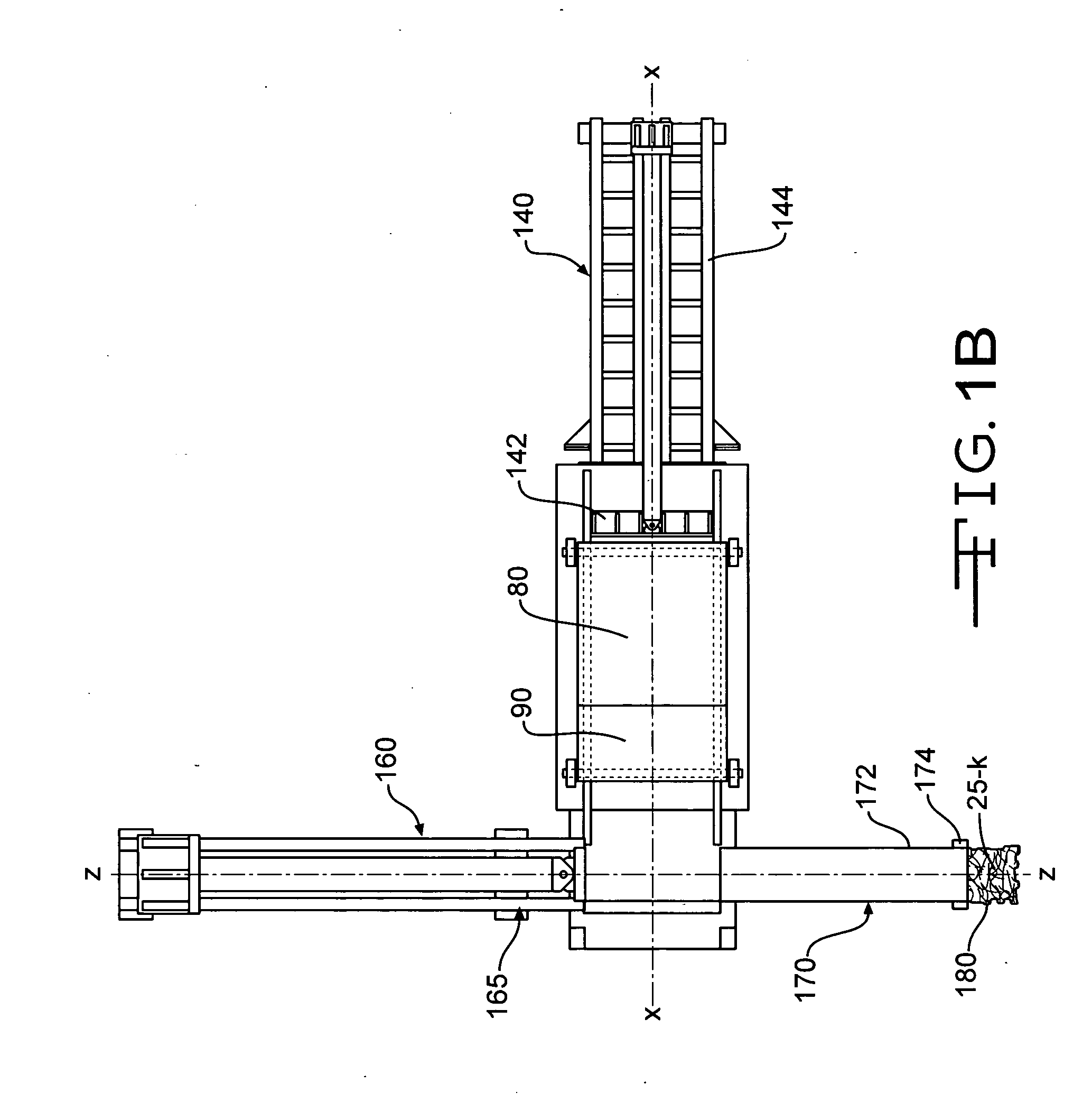

Device for dissolving compressed blocks of insulation, a loose fill insulation apparatus and a method for dissolving compressed blocks of insulation

ActiveUS20150102143A1High densityLow densityReed/straw treatmentCocoaThermal insulationHorizontal axis

The invention relates to a device for dissolving compressed blocks of loose-fill cellulose thermal insulation material. The device comprises a support surface for the compressed blocks of insulation and a cylinder with protruding members arranged on the cylinder mantel surface. Said cylinder is rotatable around a substantially horizontal axis in order to process and dissolve the compressed blocks of insulation between the protruding members and a processing zone arranged by an edge of said support surface. The invention is characterized in that said protruding members arranged on the cylinder mantel surface are elongated protrusions extending substantially parallel to the horizontal axis. The invention is further characterized in that the cylinder is arranged to rotate inside of an arc-shaped surface partly covering the cylinder mantel surface and prolonging the milling zone in a peripheral direction of the cylinder. Further, the invention relates to a loose fill insulation apparatus and a method for dissolving loose-fill cellulose thermal insulation material compressed into a block.

Owner:CELLULOSE INSULATION PRODION SCANDINAVIA CPS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com