Loose fill insulation product having phase change material therein

a technology of phase change material and loose fill insulation, which is applied in the direction of heat-proofing, light and heating equipment, weaving, etc., can solve the problems of not being able to improve the insulation properties of loose fill insulation, and achieve the effects of less energy consumption, less flammability of phase change material, and optimized performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

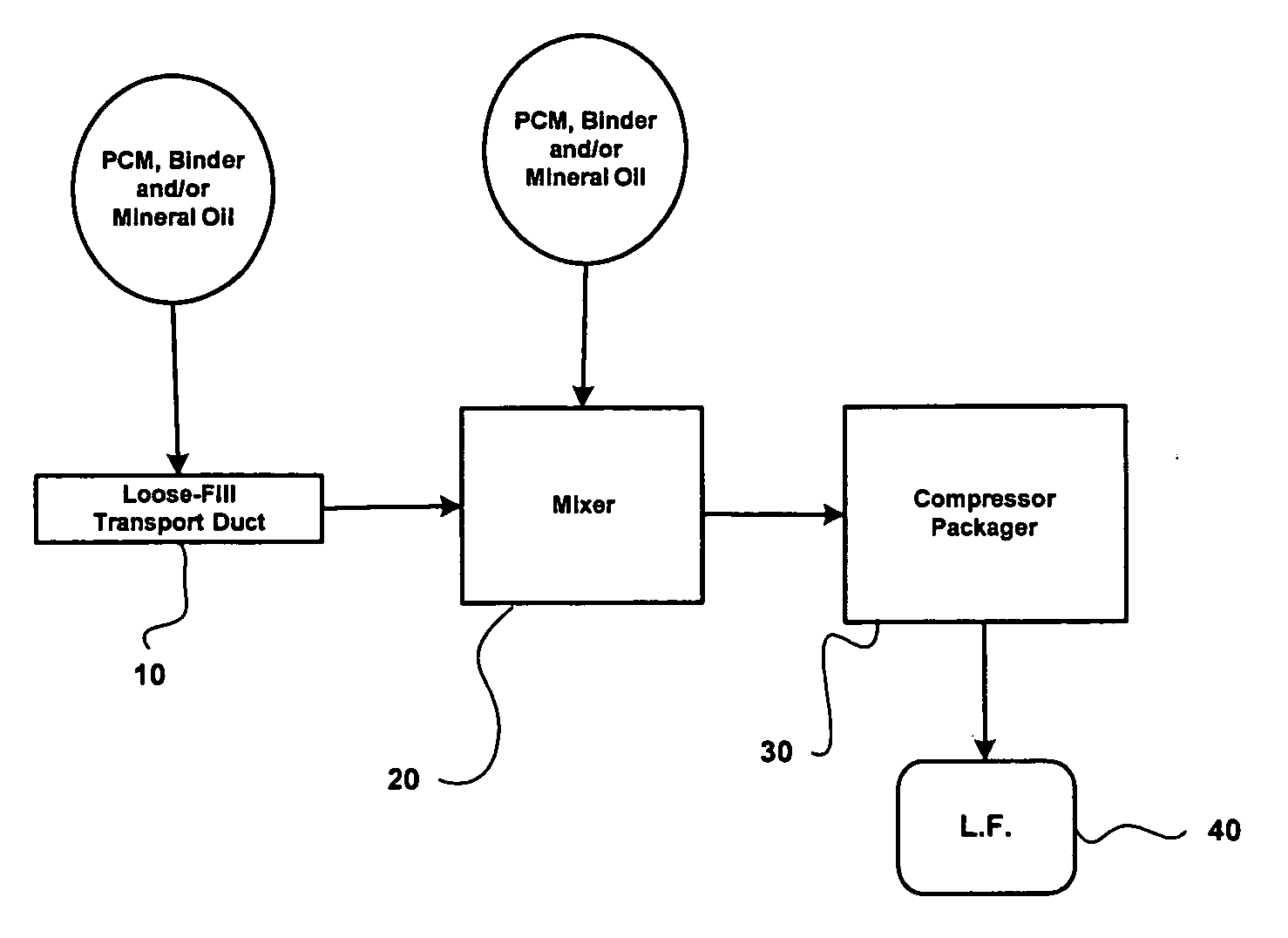

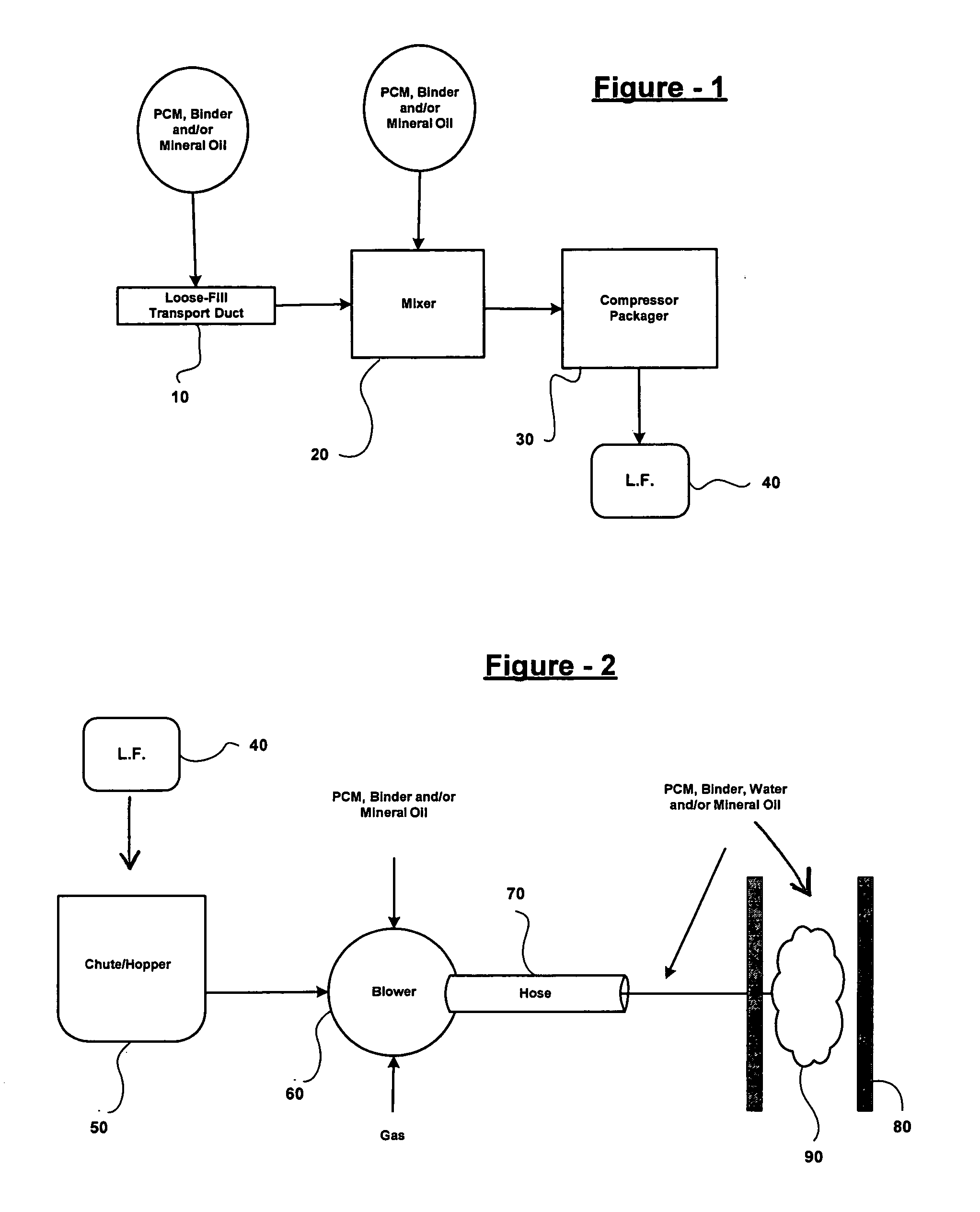

Method used

Image

Examples

Embodiment Construction

[0011] As used herein, “phase change material” (PCM) means a “latent” thermal storage material, such as one that uses inter molecular physical bonds to store and release heat. The thermal energy transfer of a phase change material occurs when the material changes from a solid to a liquid, or from a liquid to a solid form, although with some PCMs thermal energy transfer occurs when the material changes from a solid to a softer solid and vice versa. Initially, the solid-liquid PCM performs like a conventional storage material in that its temperature rises as it absorbs heat. Unlike a conventional storage material, when a PCM reaches the temperature at which it changes phase (its melting point), it absorbs large amounts of heat without getting hotter. When the ambient temperature in the space around the PCM material drops, the PCM solidifies, releasing its stored latent heat. A PCM absorbs and emits heat while maintaining a constant temperature. Within the human comfort range of 68°-86...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com