Patents

Literature

208results about How to "Improve furnace life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sorbent containing engineered fuel feed stock

ActiveUS20110099890A1Less-harmful emissionEmission reductionSolid fuel pretreatmentBiofuelsPower stationCombustion

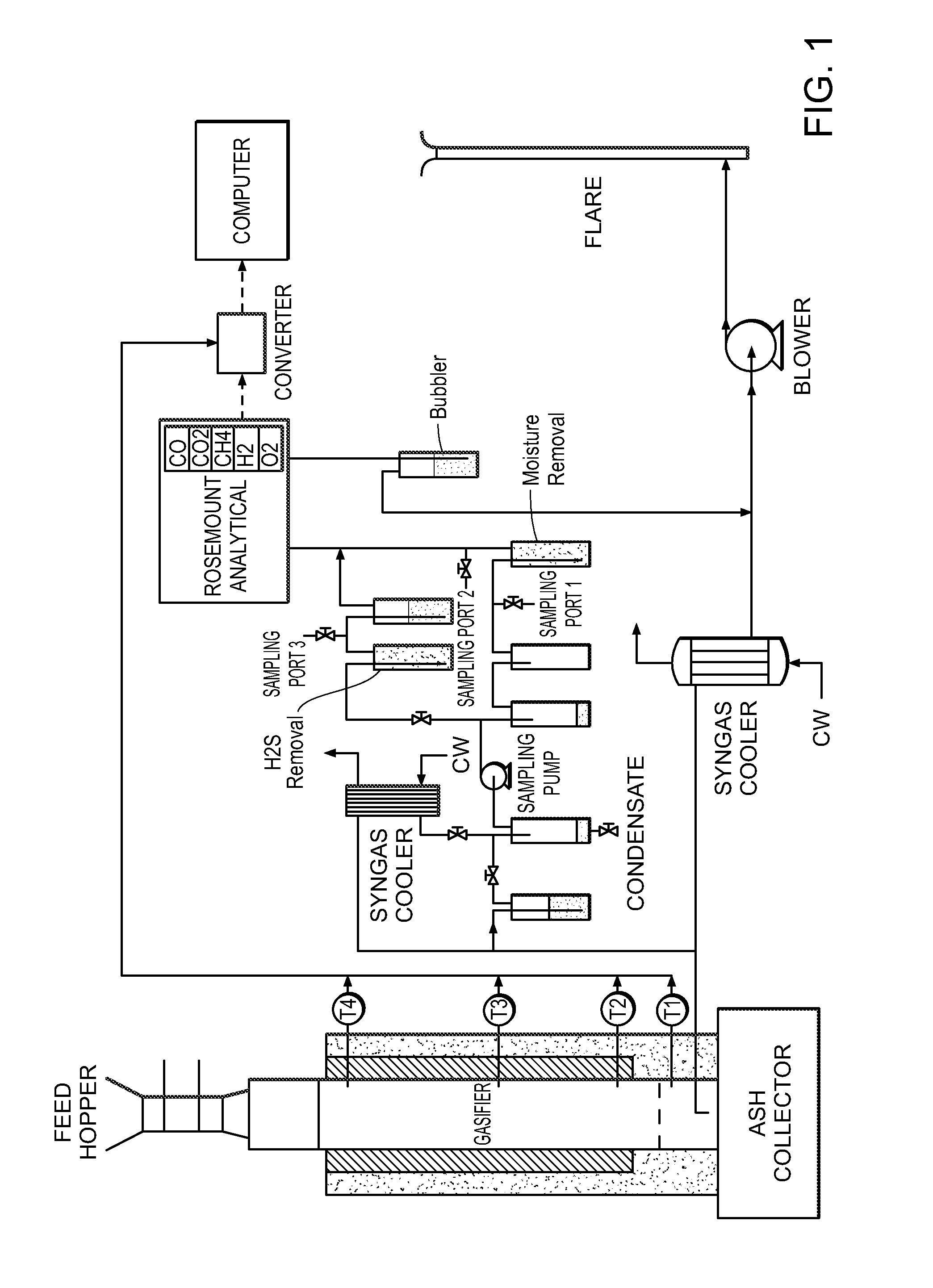

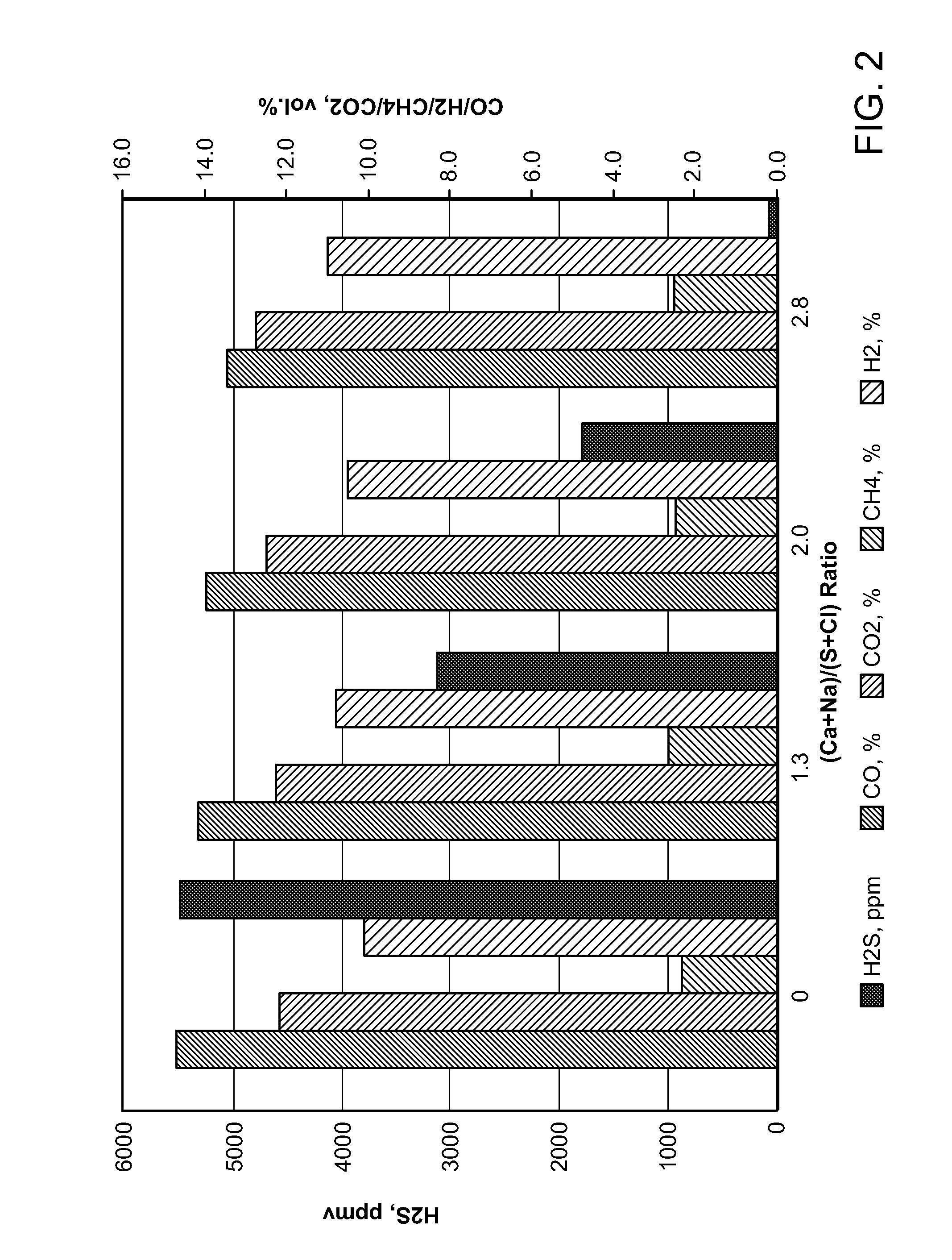

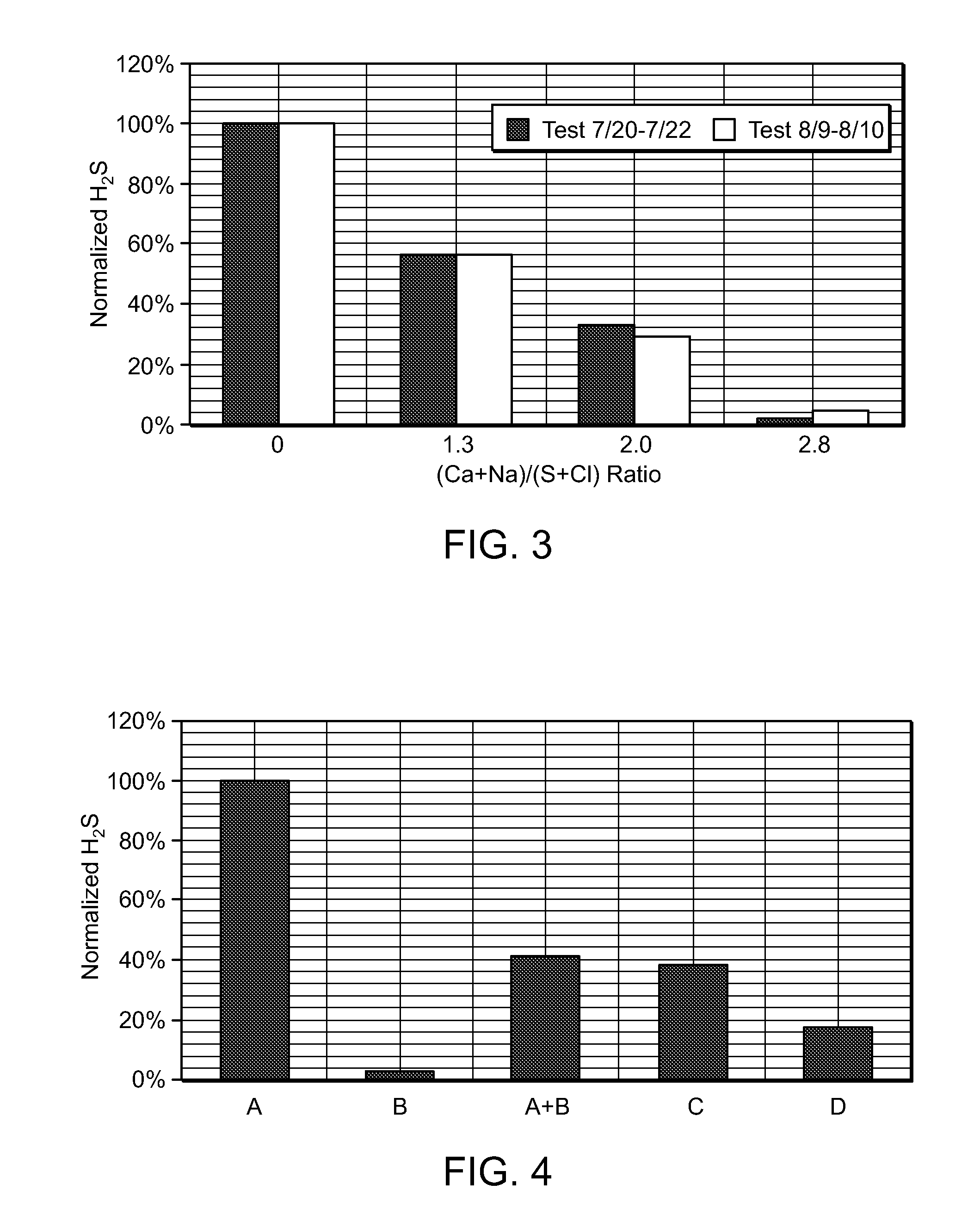

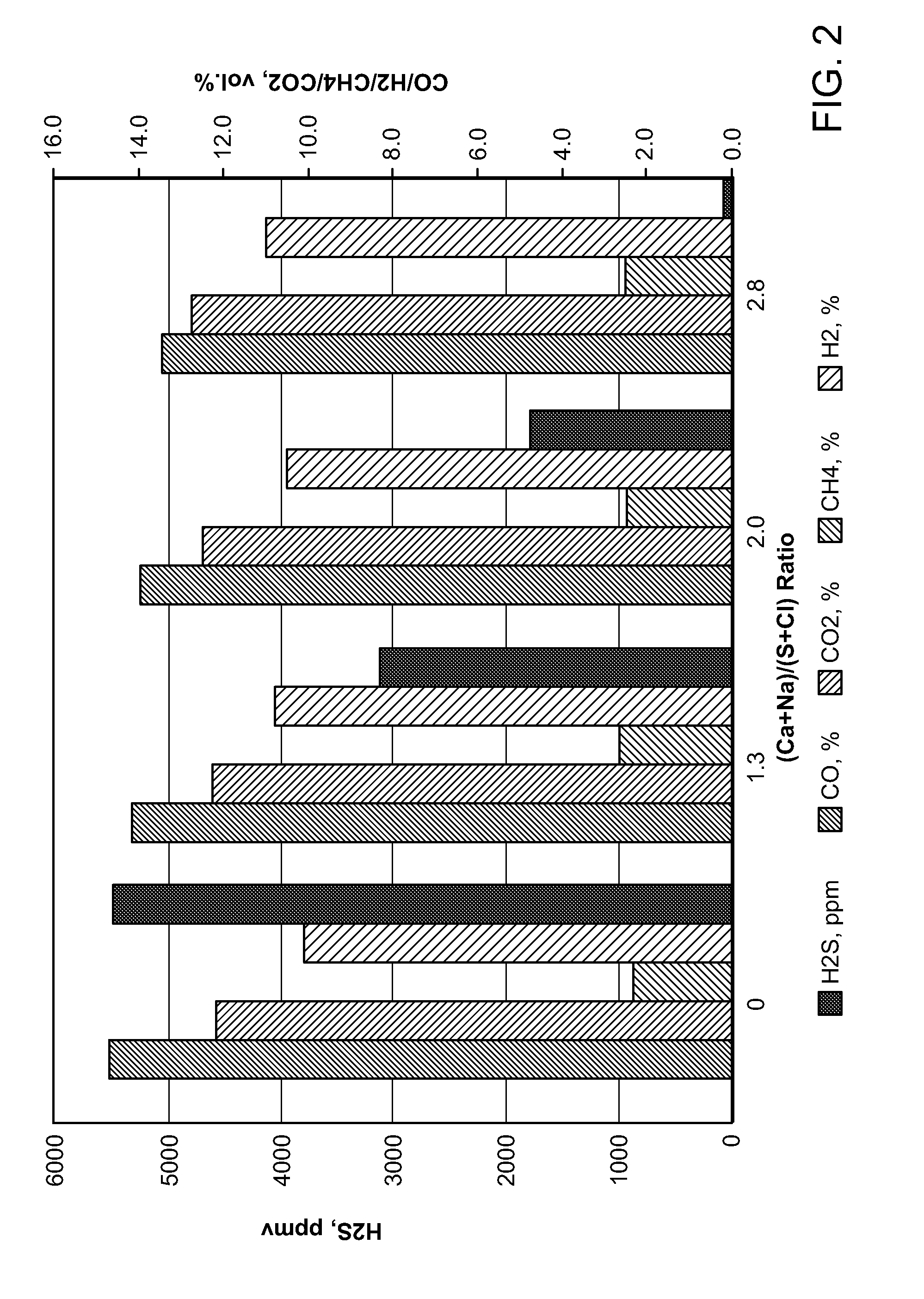

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, methods of making the fuel feed stocks, methods of producing energy from the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles and contain a sorbent. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels. In addition, one or more sorbents can be added to the feed stocks in order to reduce the amount of a variety of pollutants present in traditional fuel and feed stocks, including, but not limited, sulfur and chlorine. Further, these feed stocks with added sorbent can mitigate corrosion, improve fuel conversion, extend power generating plant lifetime, reduce ash slagging, and reduced operating temperature.

Owner:REPOWER IP LLC

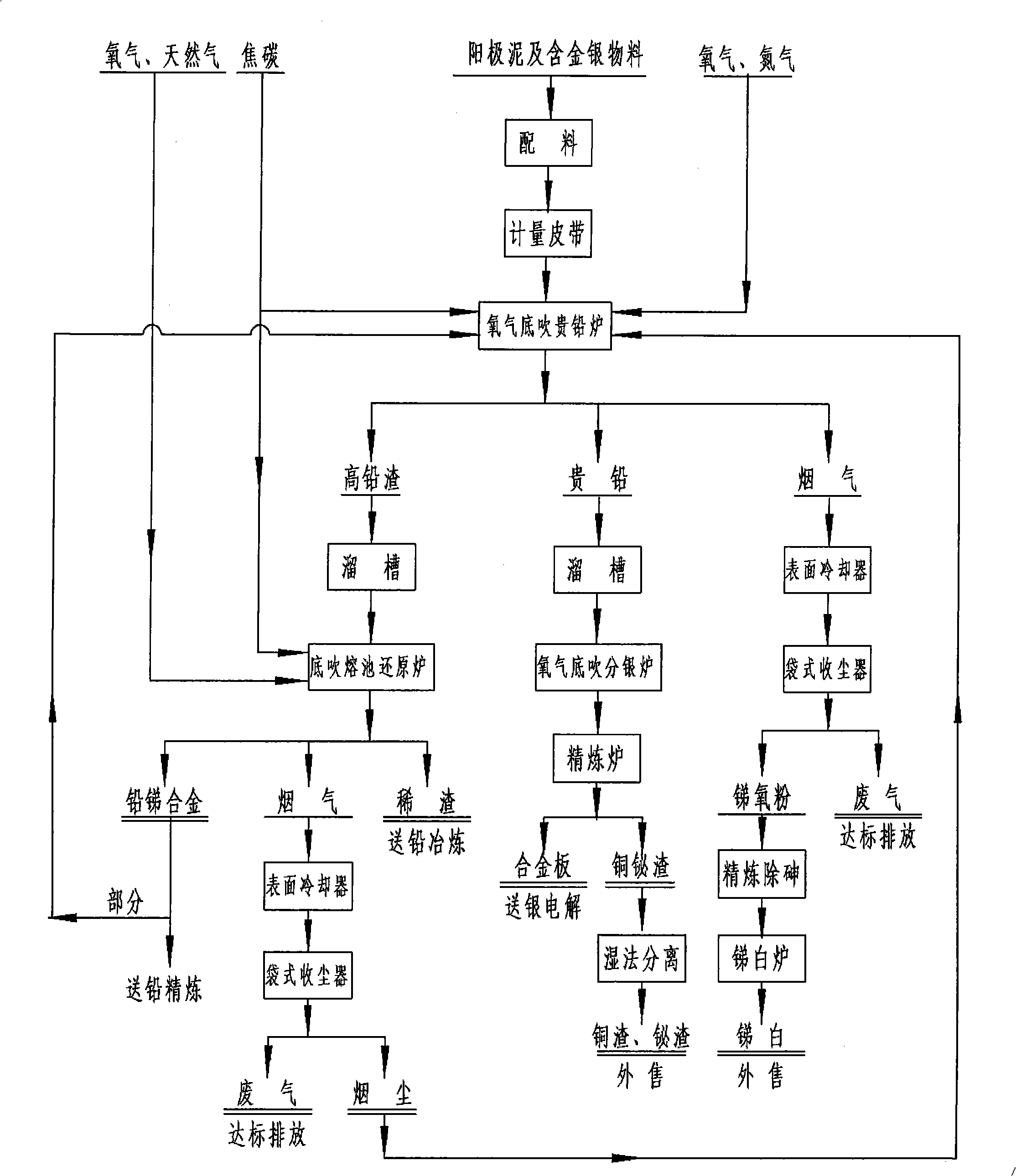

Smelting method for separating value metals from anode mud by firing process and device thereof

The present invention relates to a smelting method for separating and extracting noble and base metals during anode mud pyrogenic attack process and the device thereof, belonging to the field of nonferrous metallurgical industry. The smelting compositions only includes anode mud and nut coke, continuous oxidation-reduction smelting is carried out on the anode mud by oxygen bottom blown smelting method, gold, silver, copper and bismuth are enriched, arsenic and stibium are volatilized, silicon and lead are slagged, the smelting process is divided into two processes: one is the process of bottom oxidative slagging of oxygen and noble lead or bottom lead; the other is the process of reducing volatilization of coke on the slag surface, the two processes are two continuous combined cycle smelting processes finished in a same furnace and during the same time, the smelting process is non-alkali low-silicon high-lead-slag type, the mass ratio of the SiO2 to PbO is 0.2 to 0.5. The invention has the advantages of low cost, large handling capacity, low energy comsuption, long using period of refractory lining, high direct recovery rate of gold, silver, copper, stibium and bismuth, strong adaptability to raw materials, high automation level, etc.

Owner:HENAN YUGUANG GOLD & LEAD

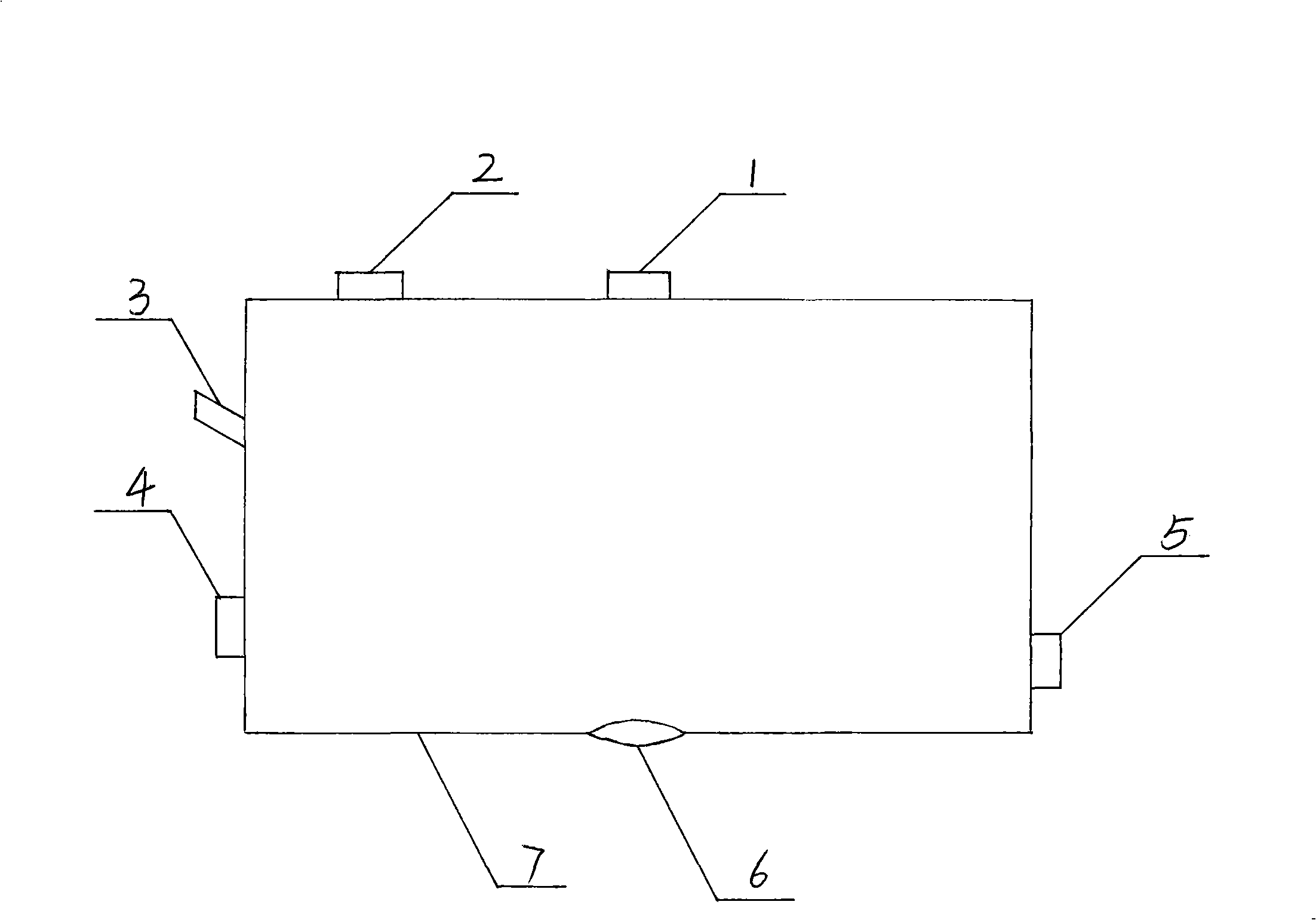

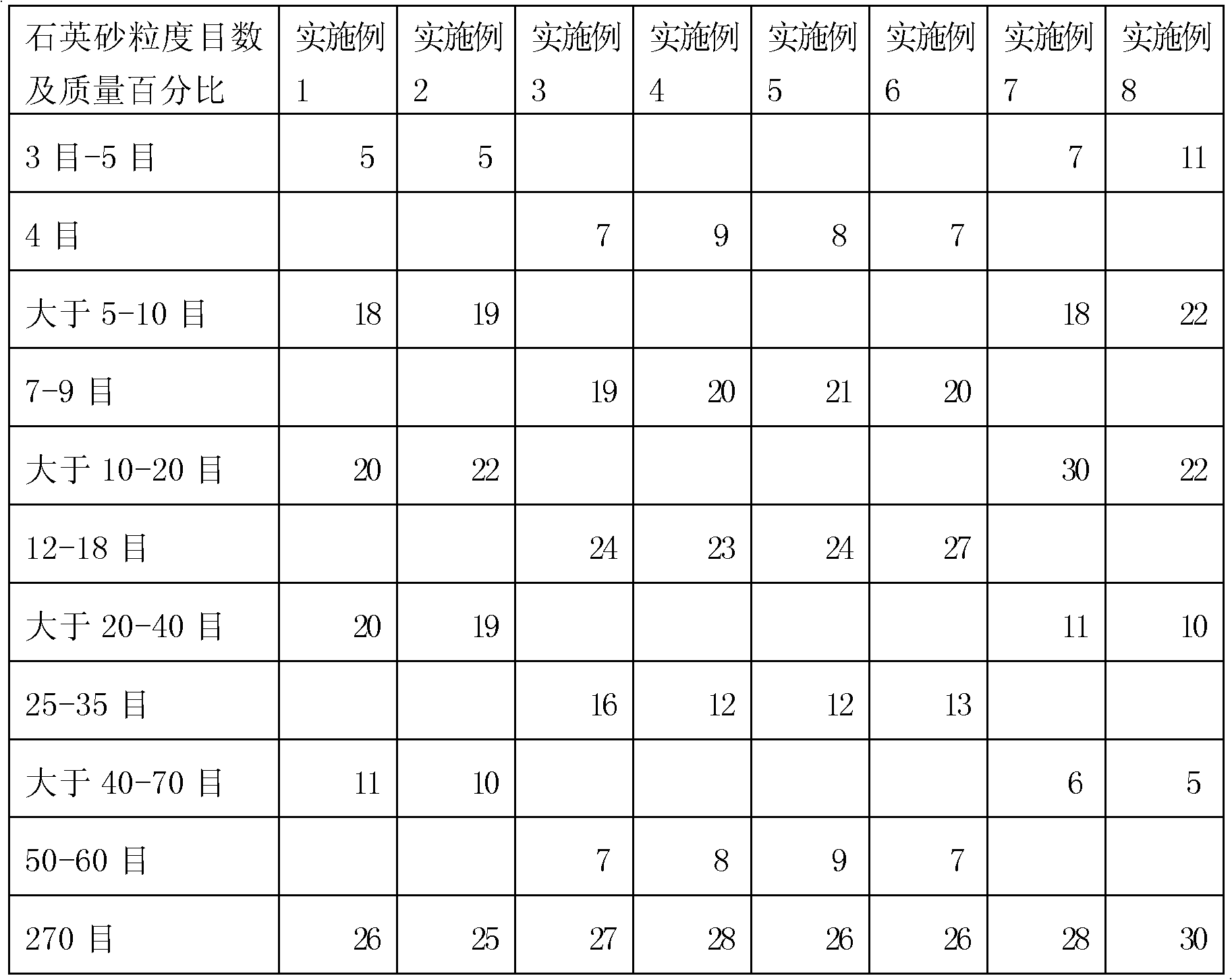

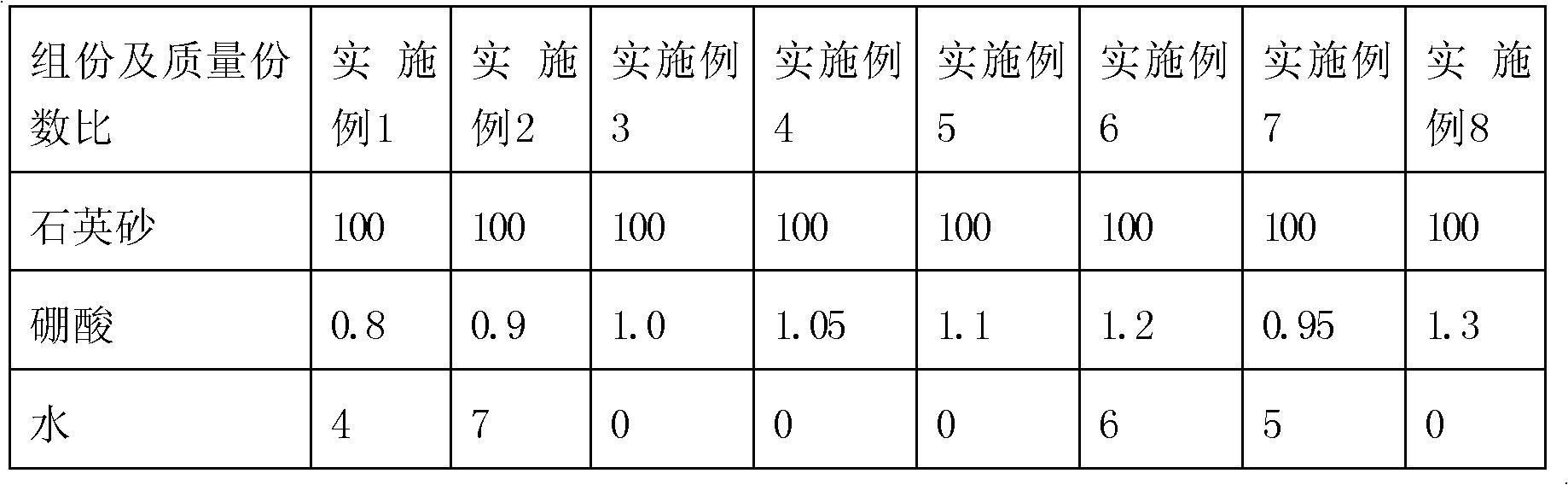

Acid lining material of medium-frequency induction furnace and furnace building method thereof

ActiveCN102617164ACounteract bad effectsCounteracts boric acid to reduce adverse effectsLinings repairCooking & bakingGranularity

The invention relates to an acid lining material of a medium-frequency induction furnace and a furnace building method thereof. Components of a furnace body lining material comprise that proportion of quartz sand and boric acid is 100: 0.8-1.3 by mass percentage. The quartz sand comprises 5% to 11% of quartz sand with granularity of 3-5 meshes, 18% to 22% of quartz sand with granularity larger than 5-10 meshes, 20% to 30% of quartz sand with granularity larger than 10-20 meshes, 10% to 20% of quartz sand with granularity larger than 20-40 meshes, 5% to 11% of quartz sand with granularity larger than 40-70 meshes and 25% to 30% of quartz sand with granularity of 270 meshes by weight. Materials of a furnace collar and a furnace nozzle comprise 5% to 20% of quartz sand with granularity of 6-10 meshes, 30% to 50% of quartz sand with granularity larger than 10-20 meshes, 30% to 50% of fire clay and 4% to 7% of water glass. The acid lining material and the furnace building method can prolong effective service life of an acid lining and shorten furnace baking time by improving the lining material and the furnace building process.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Steelmaking and slagging method

The invention provides a steelmaking and slagging method. The method comprises the following steps of: adding semisteel from which vanadium is extracted into a steel refining furnace; blowing oxygen into the steel refining furnace and blowing; in two minutes after the blowing is started, adding 9 to 11kg of lime, 9 to 11kg of high-magnesium lime, 3 to 8kg of fluxing agent, and 11 to 14kg of acid composite slag into the steel refining furnace based on one ton of semisteel from which vanadium is extracted; and in 9 minutes after the first slag is formed and blowing is started, adding 9 to 11kg of lime and 9 to 11kg of high-magnesium lime into the steel refining furnace based on one ton of semisteel from which vanadium is extracted, and continuously blowing to obtain molten steel and final slag. The fluxing agent is refined steel slag. Slagging is performed by the method, the slag can be formed quickly, the consumption of an iron and steel material is reduced, smelting time is shortened and steelmaking cost is saved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

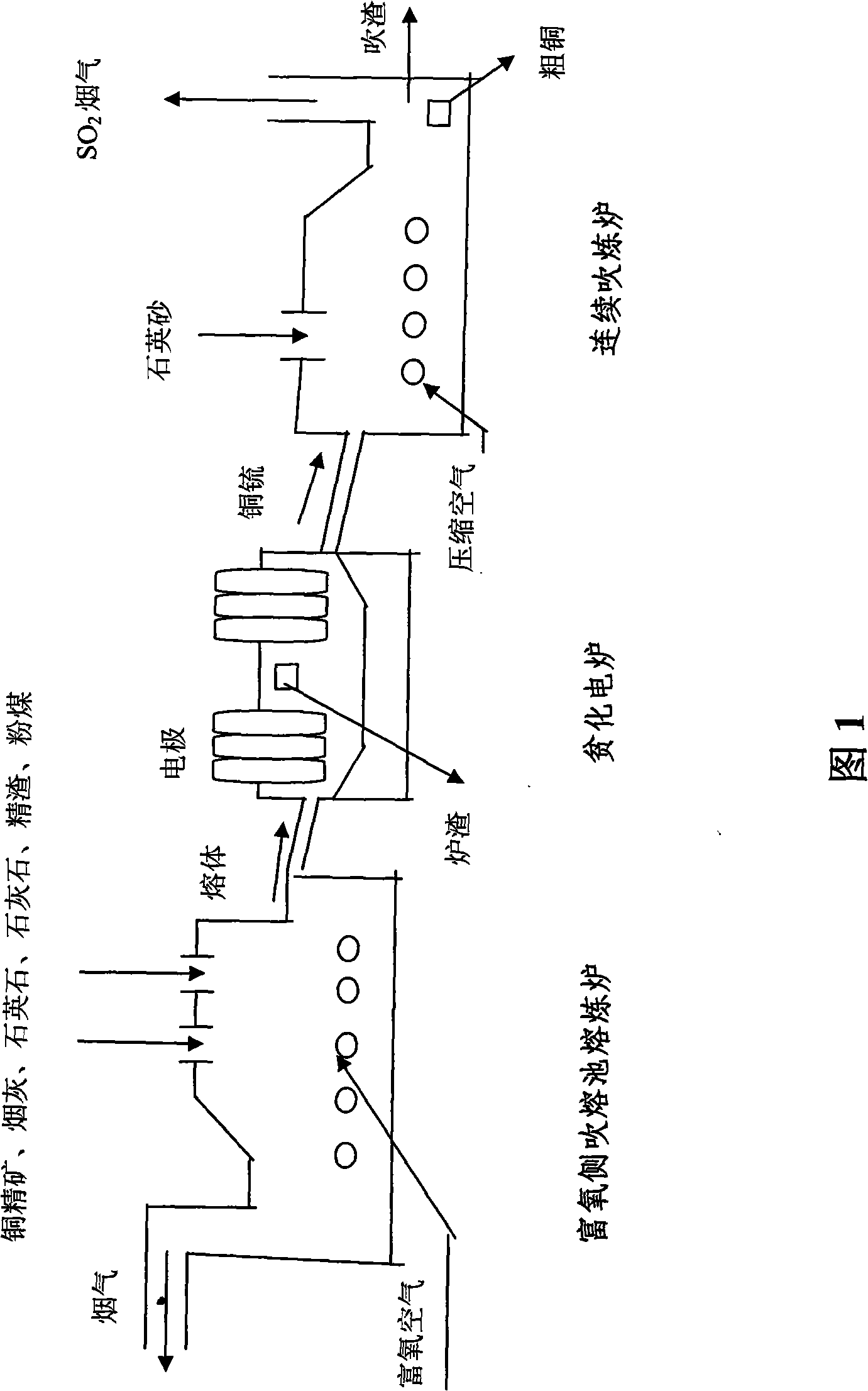

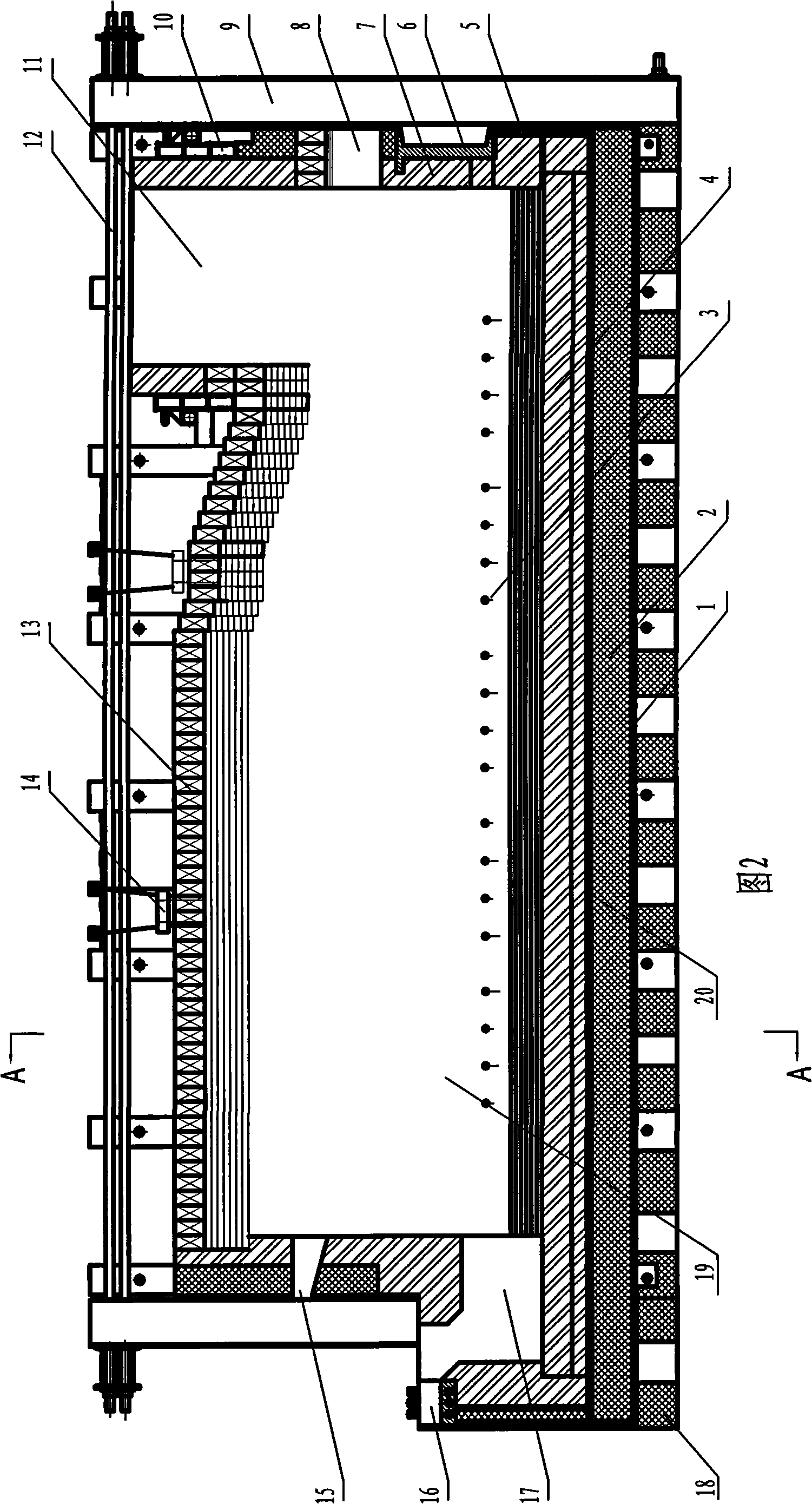

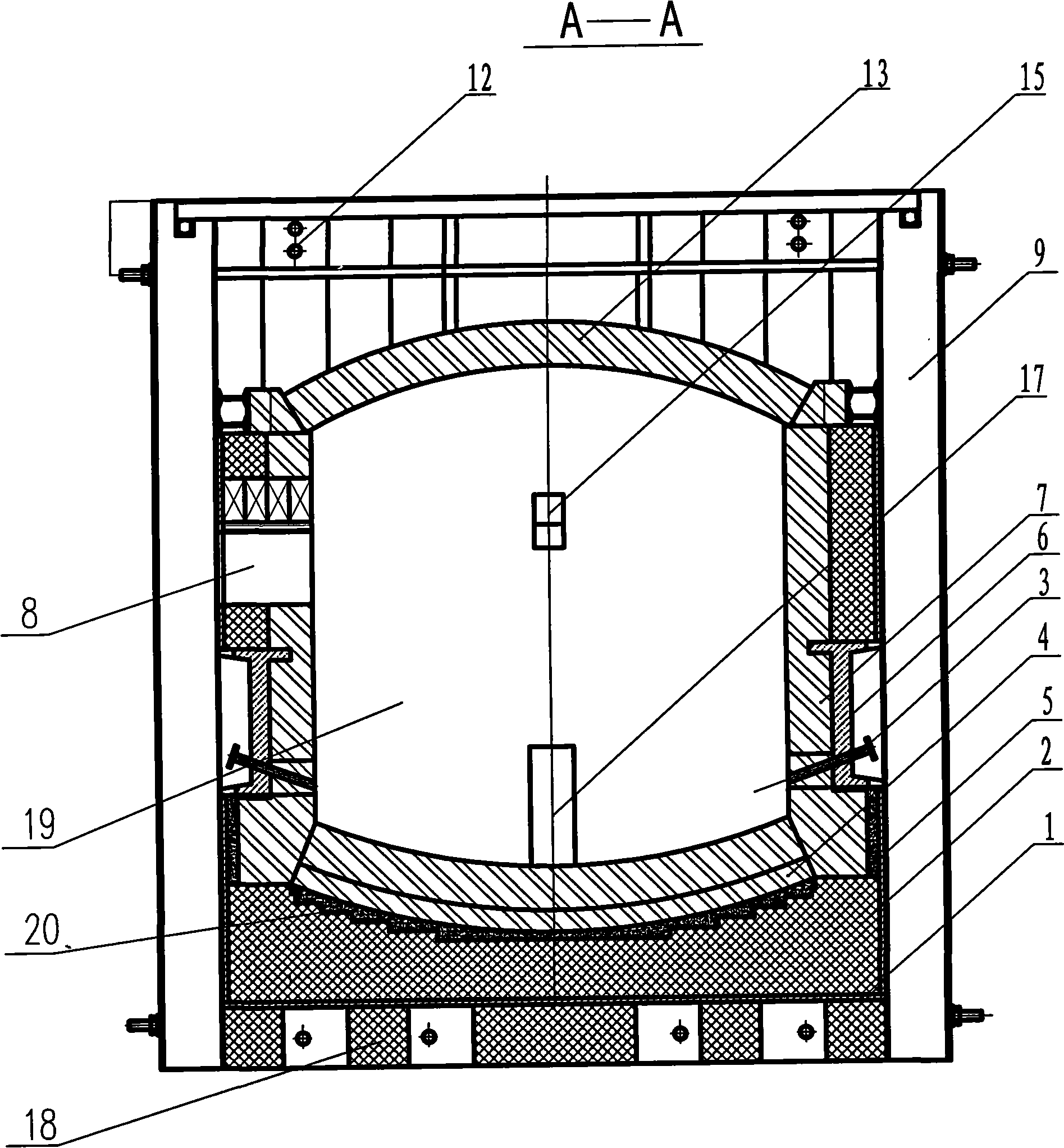

Manufacturing technique for oxygen-enriched side blowing molten pool raw copper smelting and special equipment thereof

InactiveCN101275185ALess investmentReduce energy consumptionRotary drum furnacesCrucible furnacesMelting tankHigh pressure oxygen

The invention disclose a production process for melting blister copper in a bath by side-blowing of oxygen enrichment and special apparatuses thereof, the process comprises the steps of melting concentrate of copper, diluting the slug and air refining copper matte, which is to say, adding the material comprising copper, quartz, limestone and fine coal into the furnace of bath and blowing the high pressure oxygen enrichment air into the furnace, the formed copper matte, slug are ceaselessly flowed into a diluting electric furnace, manufacturing acid after recycling waste heat by smoke gas at high temperature; overheating the slug through an electrode and separating the slug from copper matte to obtain the diluted slug and copper matte which is fed into the continuously-air-refining furnace through a chute slipway; reacting the copper matte with arenaceous quartz under the effect of compressed air to obtain the blister copper, performing mineral dressing to the air-refined slug, manufacturing the acid with SO<2>; the invention has less process investment, high heat utilization rate, low energy consumption, good effect of environmental protection, compact apparatus structure, small occupied area, great processing ability, light sticking in air flue, simple operations, diverse measures in adjusting the condition of furnace which is easy to control, high level of mechanization and low labor intensity.

Owner:YANTAI PENGHUI COPPER IND

Slag adjusting and furnace protecting method for controlling rising of converter bottom and furnace wall slag deposition

InactiveCN102127612AIncrease the content of MgOImprove furnace protection effectManufacturing convertersSteelmakingSludge

The invention belongs to the technical field of steelmaking and provides a slag adjusting and slag splashing furnace protecting method for controlling rising of a converter bottom and furnace wall slag deposition, solving the problems that the effective volume is reduced and the center of gravity of a furnace body shifts as slag stacked at the converter bottom rises and slag deposits at the lining of the furnace wall when the traditional slag splashing furnace protecting process is adopted. The method provided by the invention is characterized by adopting a two-step slag adjusting method, primary slag adjusting is carried out before molten steel is tapped, a boric sludge-magnesia slag adjusting agent is added into a furnace to reduce the viscosity of the slag, slag deposition at the lining of the unilateral furnace wall and slagging at the converter bottom in the tapping process can be prevented, the slag remaining and no steel remaining operation is adopted in the follow-up tapping process; and secondary slag adjusting is carried out after tapping, namely a magnesia carbon slag adjusting agent (coke powder and material containing magnesium oxide) is added into the slag remained in the furnace, and then the slag splashing slag protecting process is carried out. By adopting the method provided by the invention, the rising of the converter bottom and thickening of slag depositedon the furnace wall can be controlled, the thickness uniformity of the furnace wall can be guaranteed, and the slag splashing furnace protecting effect is obviously improved, thus the service life ofthe lining of a converter can be greatly prolonged.

Owner:JIANGSU UNIV

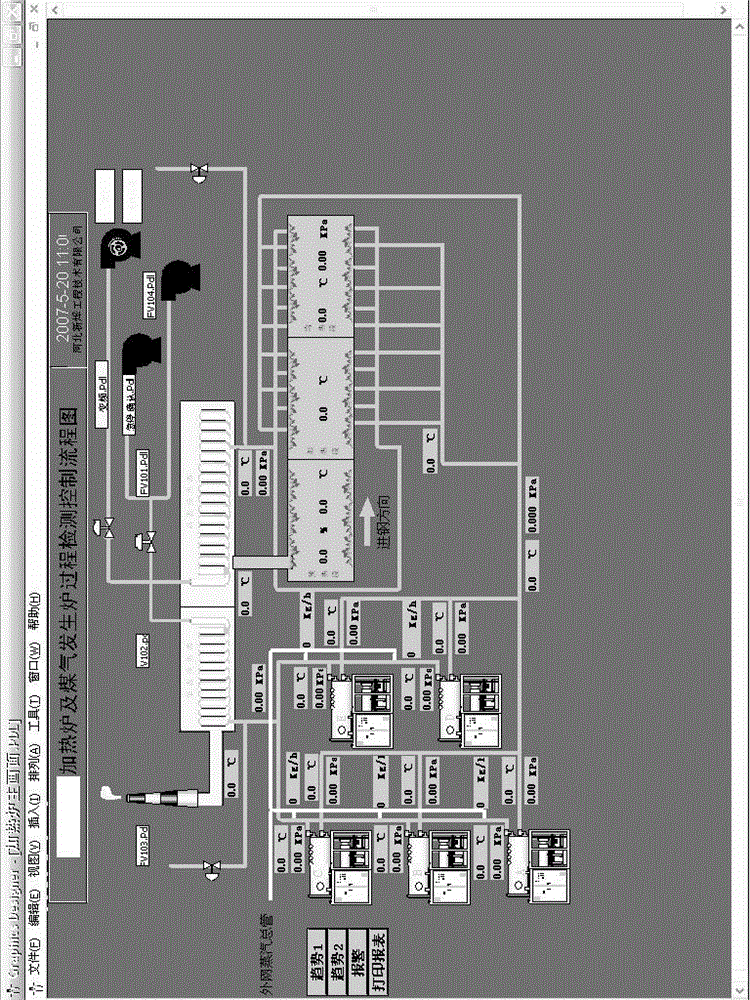

High-efficiency intelligentized heating furnace control method

ActiveCN102721288AGuaranteed reasonablenessRealize cross controlControl devices for furnacesFurnace temperatureThermodynamics

The invention relates to the technical field of heating furnaces of heat treatment equipment applied in the steel rolling industry, in particular to a high-efficiency intelligentized heating furnace control method. The method adopts a PLC (programmable logic controller) system for field control and an upper computer operating system communicating and connected with the PLC system to form an intelligent control system, and moreover, the intelligent control system is utilized to efficiently, scientifically and intelligently control a heat furnace. The method is characterized in that the intelligent control system controls and sets the heating furnace in the following six aspects: (1) furnace temperature control; (2) internal pressure control; (3) air-fuel ratio control; (4) safety protection system control; (5) adoption of an human-machine interface (HMI) on the intelligent control system; (6) history data recording. The method can reasonably control heating temperature, furnace temperature and furnace pressure at each stage in real time, increases the heating utilization rate, has an outstanding effect in saving energy and reducing consumption, increases the production efficiency, reduces the production cost, and prolongs the furnace service life.

Owner:HEBEI XINYE ENG TECH

Low-cost slagging and dephosphorizing technique for high-phosphorus molten iron through converter smelting

ActiveCN105671237ALow costIncreased (MgO) contentManufacturing convertersProcess efficiency improvementAlkalinitySlag

The invention discloses a low-cost slagging and dephosphorizing technique for high-phosphorus molten iron through converter smelting. The slagging and dephosphorizing technique comprises the steps of slag remaining and splashing, primary charging, primary blowing, turning down and deslagging, secondary feeding, secondary blowing, and terminal control and steel tapping, all final slag is reserved for slag splashing after steel tapping, and the steps are repeated circularly. The obtained final slag comprises, 35-48% of CaO, 8-14% of MgO, 8-13% of SiO2, 10.20-18.50% of TFe, and 2.50-5.60% of P2O5, and the alkalinity is 2.5-6. By the adoption of the slagging and dephosphorizing technique, smelting of the high-phosphorus molten iron is integrally optimized; materials, such as high-cost slagging agents, magnesite pellets and light-burned magnesian limestone, are partially or completely replaced by low-cost and environment-friendly sintered and returned mines and raw magnesian limestone, and a corresponding technological system is set; and the extra heat is balanced while smooth dephosphorizing is guaranteed, the slag oxidation, the P2O5 content and the final slag MgO content are improved, the slagging cost is reduced by over 8 yuan / t while a furnace lining is protected and the dephosphorizing effect is achieved, the furnace age is prolonged from 12000 times to 15000 times, and the application value and popularization value are high.

Owner:WUKUN STEEL

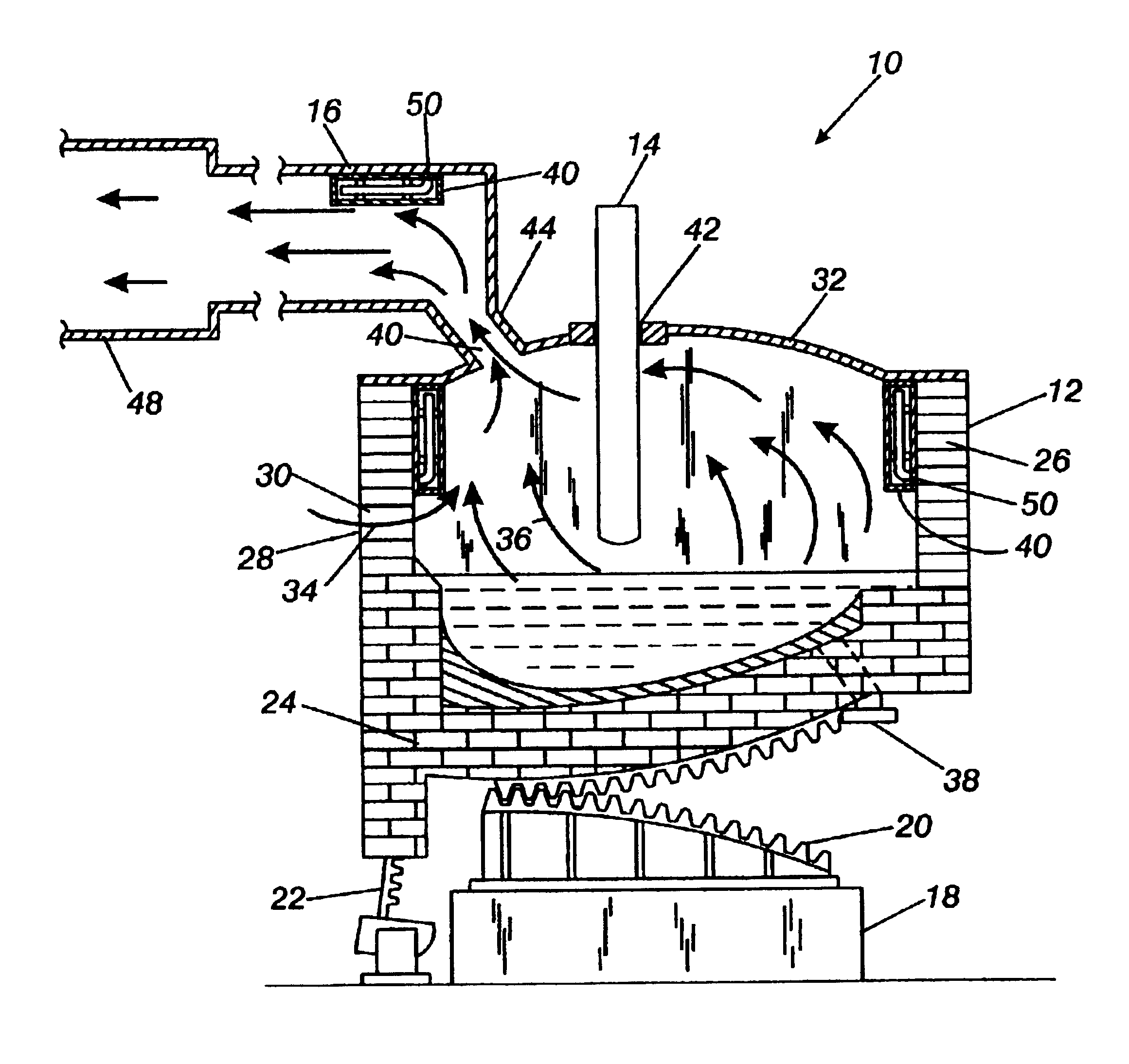

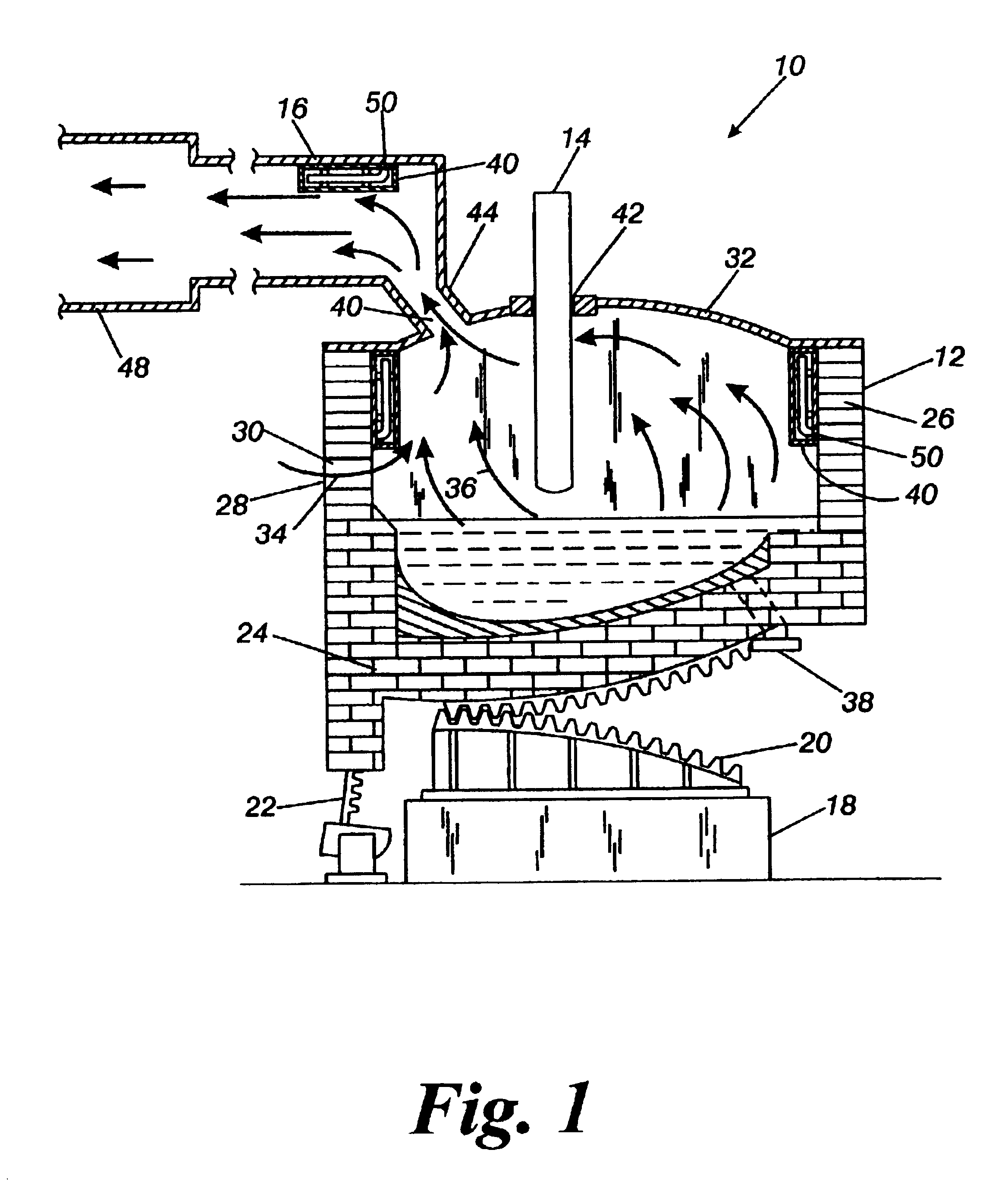

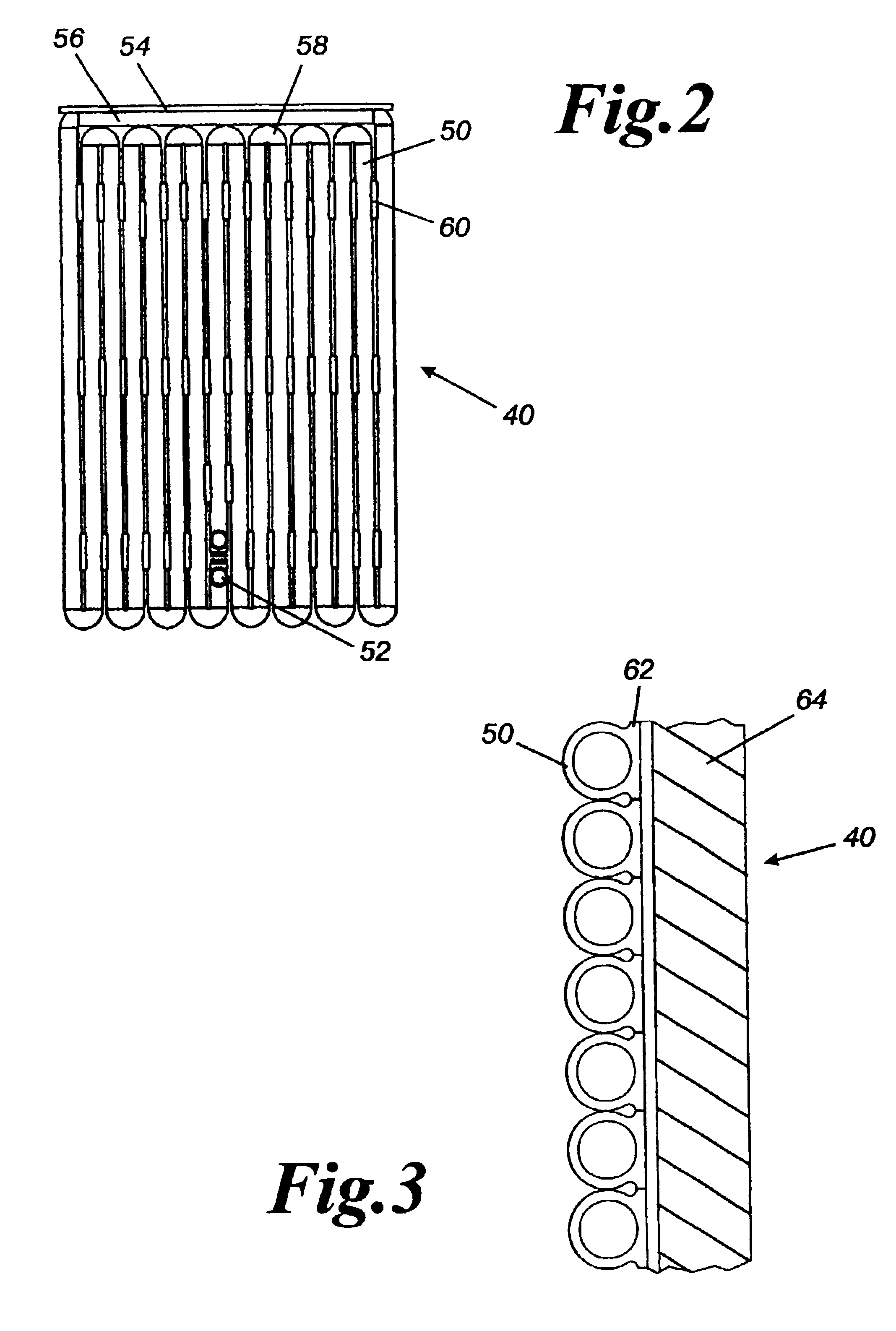

System and method for steel making

InactiveUS6890479B2Improve conductivityHigh hardnessTuyeresBlast furnace detailsProduction rateAlloy

A metallurgical furnace, which includes a furnace shell, an exhaust system, and a gas cleaning system, further includes a plurality of improved pipes and fume ducts throughout to increase operational life and productivity. The pipes and fumes ducts are comprised of an aluminum-bronze alloy which provides enhanced properties over prior art materials including thermal conductivity, modulous of elasticity and hardness. The use of the alloy also minimizes maintenance requirements of the pipes and fume ducts, thereby extending their operational life. In operation, gases formed from smelting or refining are evacuated from the furnace shell through the exhaust system into the gas cleaning system. The gases, as well as the system, are water cooled by way of the plurality of pipes displaced throughout.

Owner:AMERIFAB INC

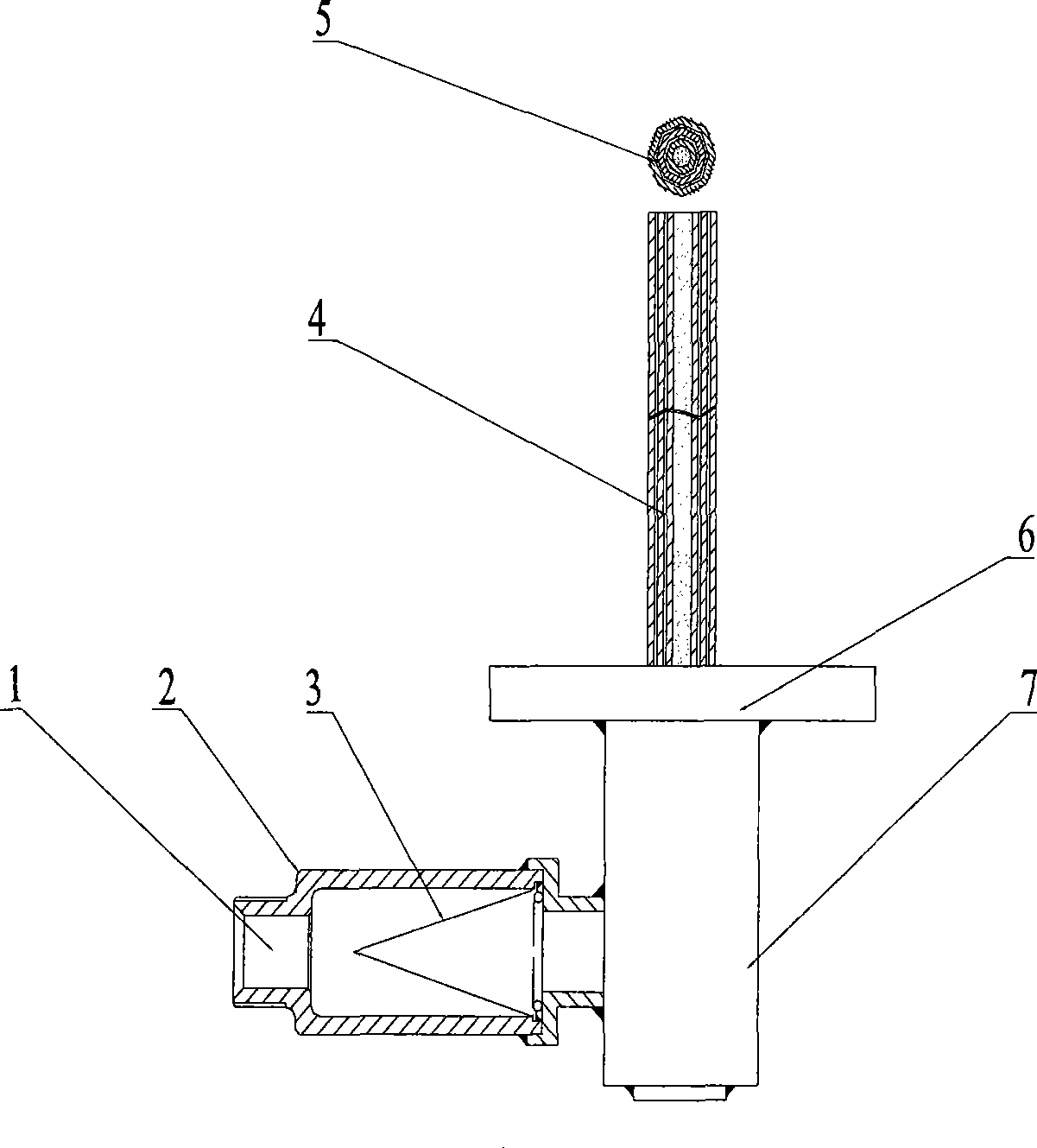

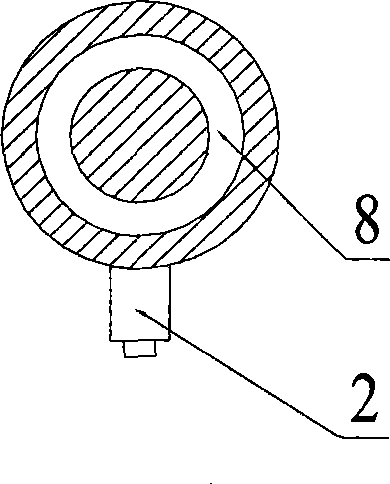

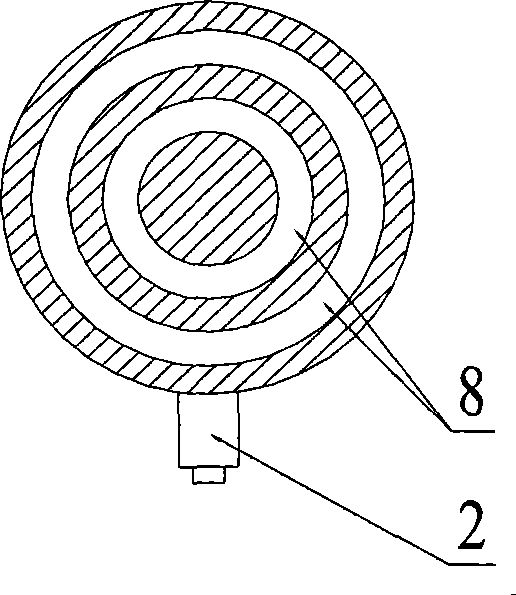

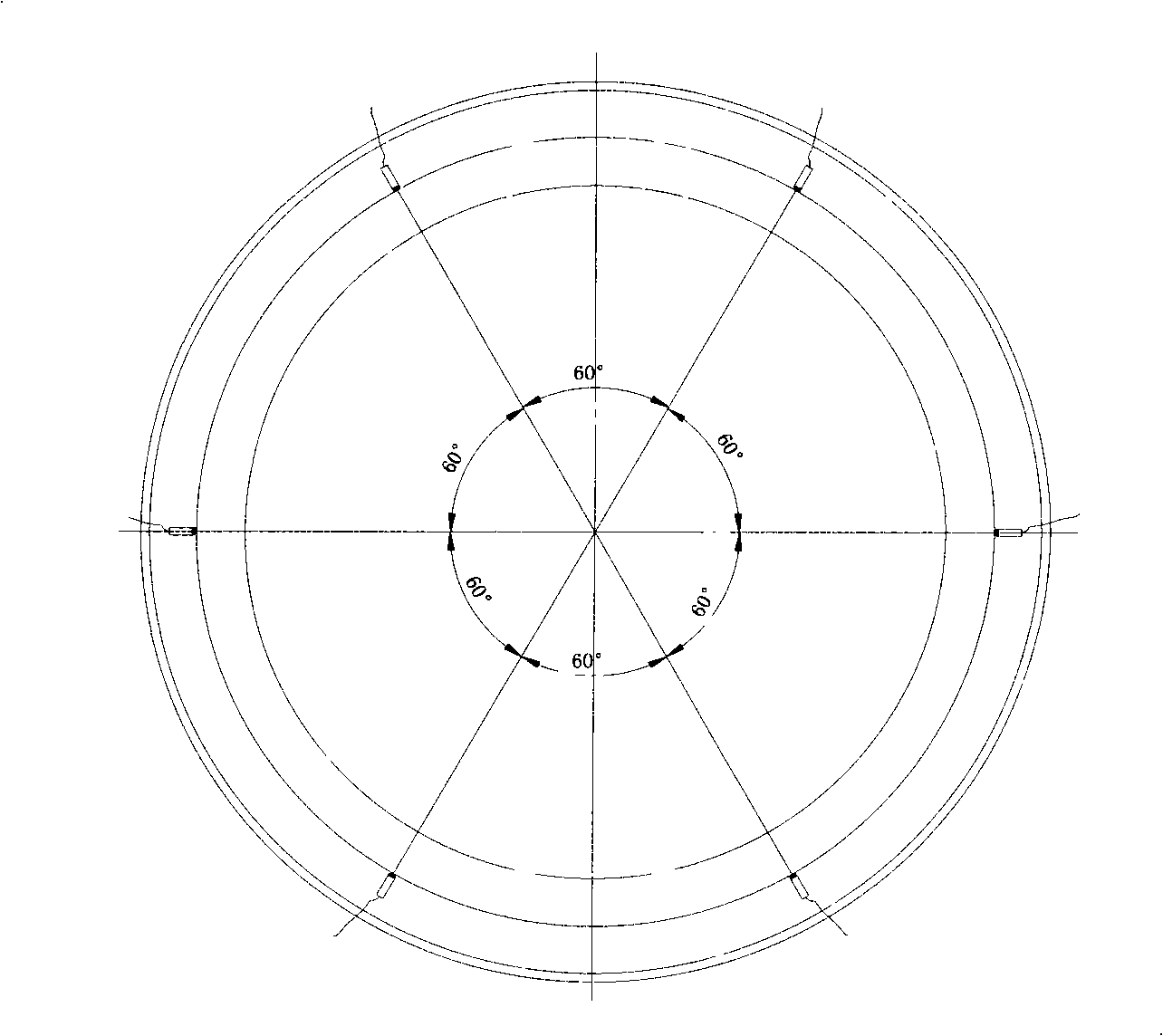

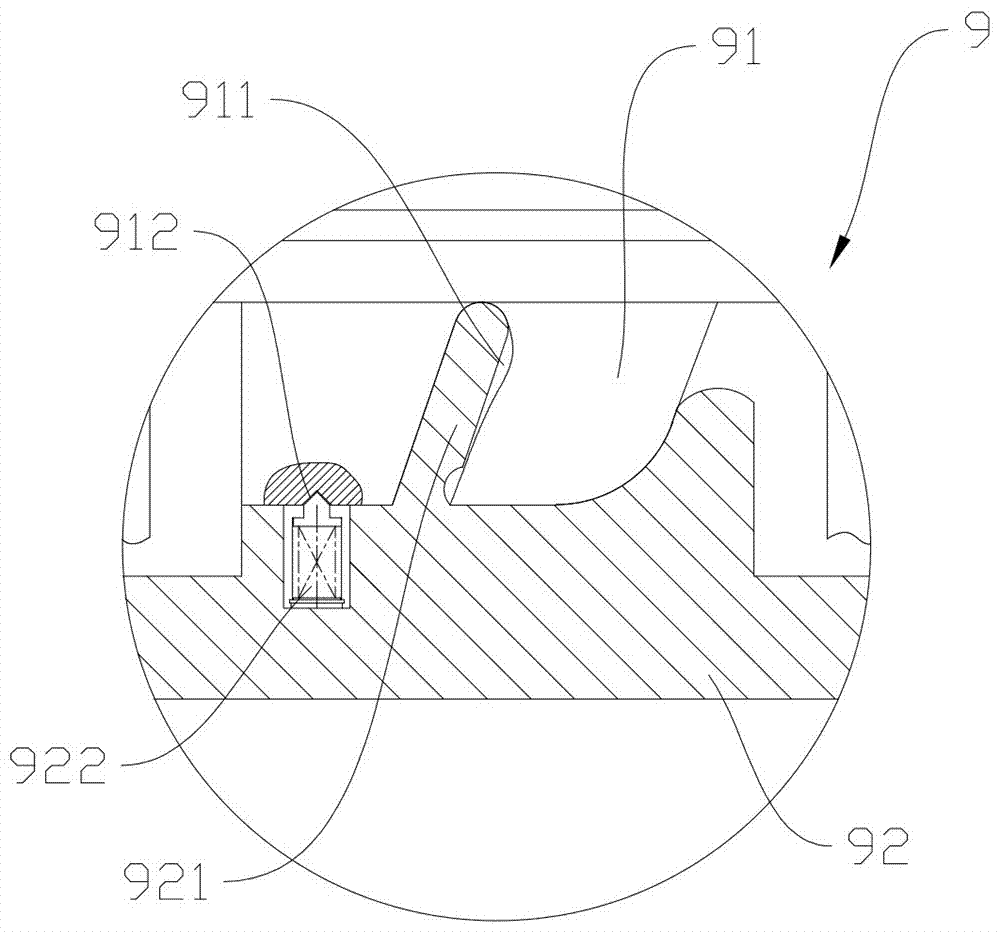

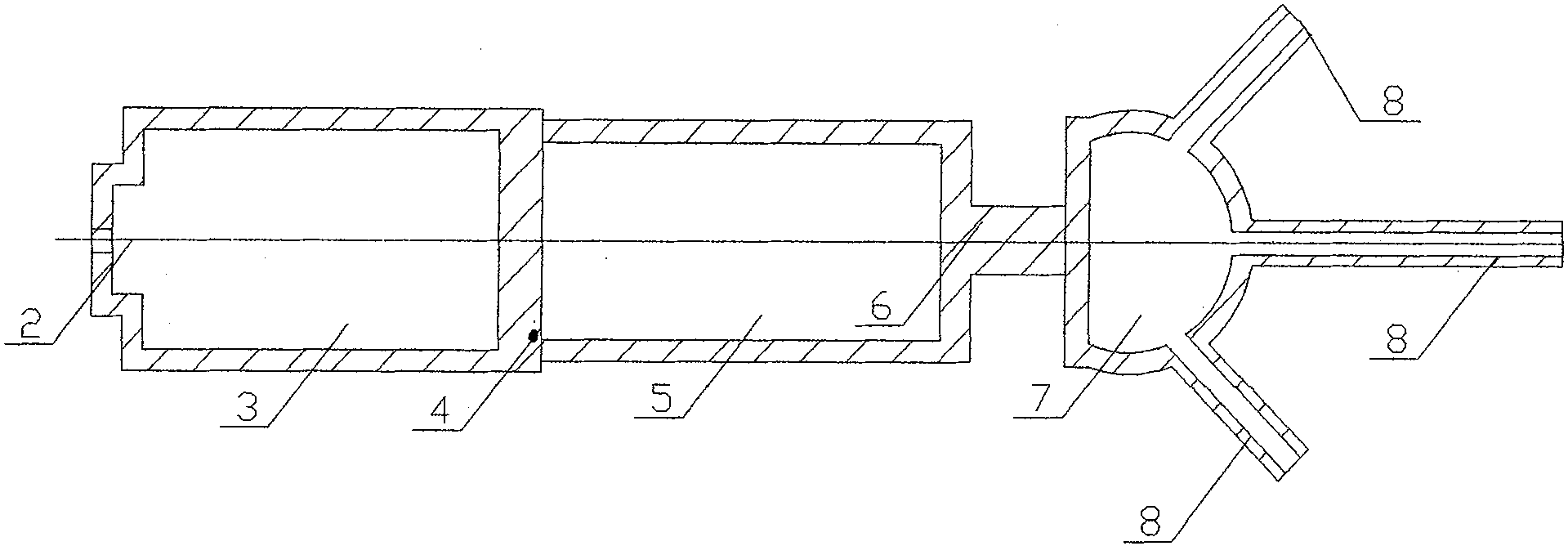

Multifunctional circular seam type gas supply element for steel melting

ActiveCN101487072AImprove furnace lifeSolve the worldwide metallurgical problem of low service lifeManufacturing convertersElectric furnaceWorking lifeAir separation

A steel-making multifunctional circular seam type air supply unit belongs to the steel-making technique field, and comprises a gas ejector pipe, a mounting flange, an air separation chamber and an air inlet chamber, wherein, the gas ejector pipe consists of 2 to 5 layers of pipes which are sheathed concentrically; the pipe in the innermost layer is called a central pipe; the seam width among circular seams among all the layers of the pipes is 0.2 to 3.0mm. A spot or a rib resurface-welded by stainless steel is used for ensuring the precise location of seam width and for preventing molten steel from moistening the interior wall of steel pipes, thus not easy to be jammed by pouring in. The gas ejector pipe is connected with the mounting flange which is connected with the air separation chamber used for distributing the air coming from the air inlet chamber to enter each circular seam of the gas ejector pipes to be sprayed out; and the air separation chamber is connected with the air inlet chamber. The steel-making multifunctional circular seam type air supply unit has the advantages of raising the furnace campaign to over 10000 with maximum over 30000 from 2000; and the complex blowing rate is 100 percent. The bottom blowing air supply unit is not replaced in the whole furnace campaign period, thus solving the problem of short working life of the combined blown converter, which is also a worldwide problem in metallurgy.

Owner:CENT IRON & STEEL RES INST

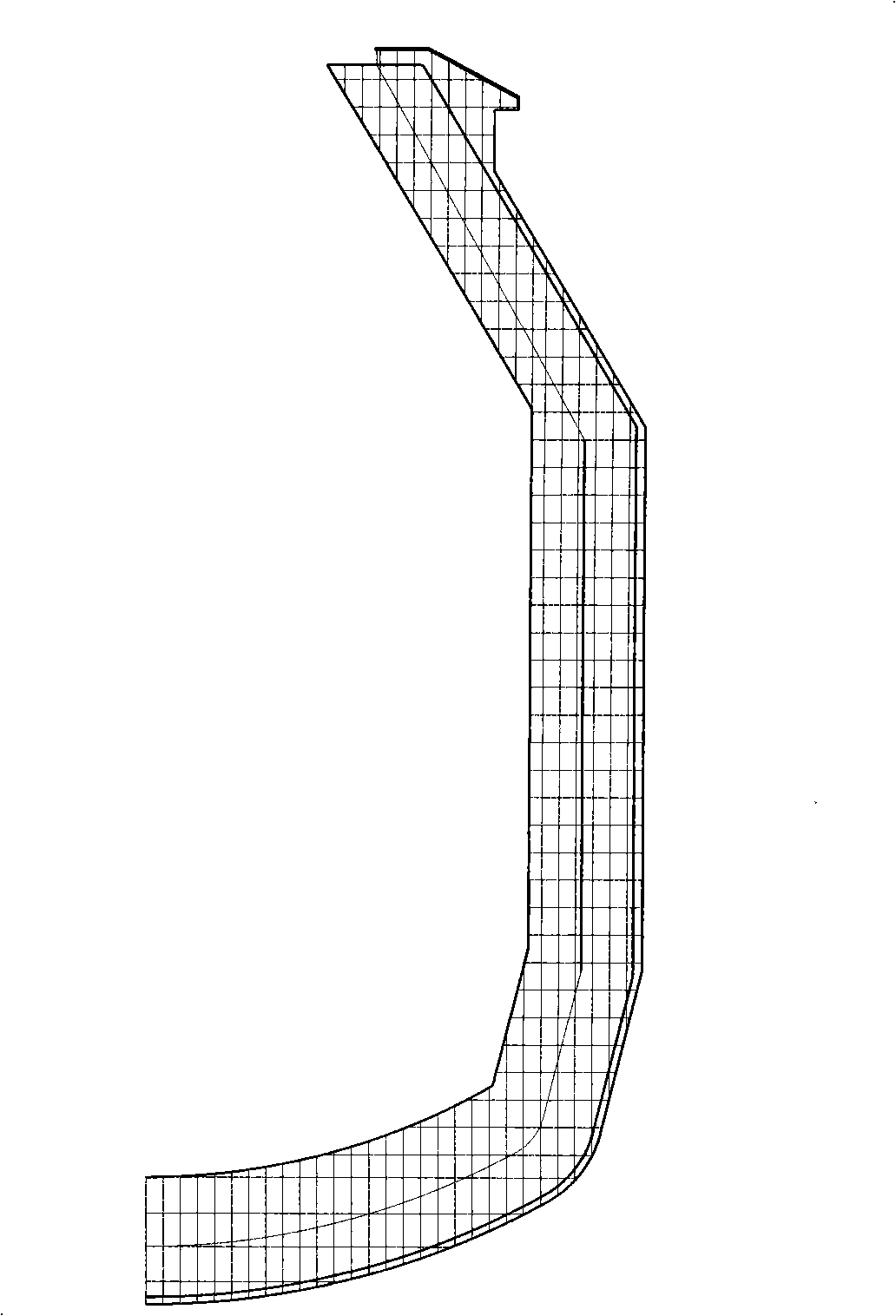

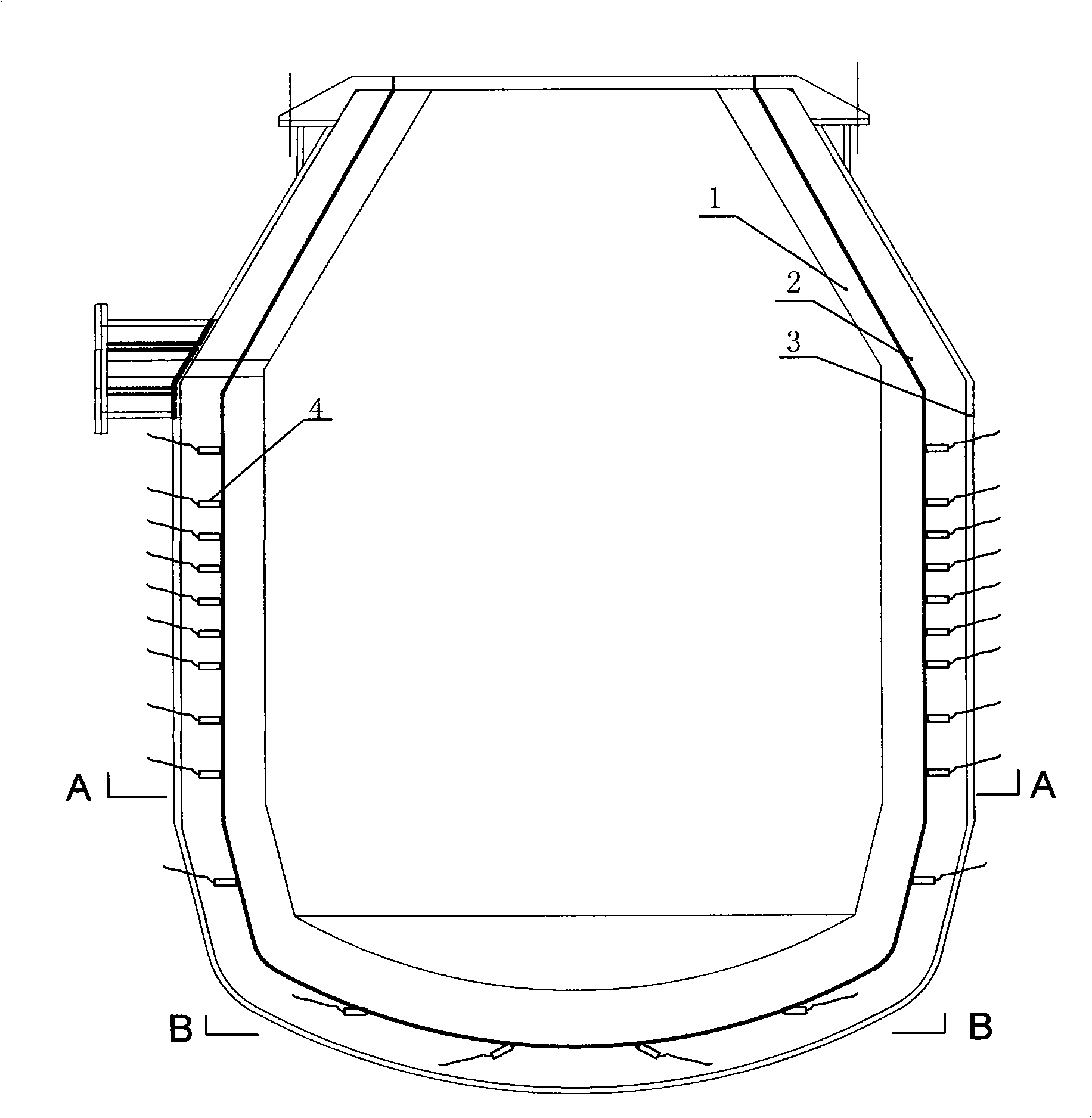

Convertor lining thickness online testing method and device thereof

ActiveCN101514896ASimple processImprove measurement accuracyThermometer detailsThermometers using electric/magnetic elementsMeasurement pointFinite element software

The invention discloses a converter lining thickness online testing method and a device thereof. The testing method comprises the following steps: (1) establishing a converter value module by finite element software to perform a steady-state calculation on converter lining temperature and thickness so as to determine distribution of temperature in a converter lining, setting measuring points in a converter body, and obtaining a converter lining temperature-thickness reference table; (2) according to the determined measuring points in step 1, burying thermocouple temperature measuring devices in a lining permanent layer of the converter and the bottom of the converter body; (3) according to data acquired in step 2, combining the converter lining temperature-thickness reference table obtained in step 1 to backward calculate the converter lining thickness; and (4) determining whether to perform repair treatment on the converter lining or not according to the lining thickness obtained in step 3. The device adopted by the invention comprises the converter body (1), and the thermocouple temperature measuring device is arranged in the lining permanent layer (2) of the converter body (1). The method and the device have simple working procedures and high measuring accuracy, and can effectively improve the campaign length of the converter.

Owner:HUATIAN ENG & TECH CORP MCC

Treatment method for slag adjustment before slag splashing protection of converters

InactiveCN102392097AImprove fire and corrosion resistanceGuaranteed lifeManufacturing convertersSteelmakingConverters

The invention belongs to the technical field of steel making and provides a treatment method for slag adjustment before slag splashing protection of converters, which is used for solving the existing problems of bad slag hanging effect in high iron oxide type slag splashing protection after high-temperature steel tapping and short lining life. The method provided by the invention is characterized in that: coke powder, magnesite and titanium white are used as slag adjustment agents; the coke powder is capable of decreasing the ferric oxide in residual slag and reacting with the titanium white to generated titanium carbide with high melting point; and the titanium carbide acts synergistically with the magnesite to increase the viscosity and the melting temperature of the slag. Therefore, by using the invention, the adherence stability and high temperature and slag steel erosion resistance of the slag on furnace walls can be markedly improved, the slag splashing protection effect can be improved and the lining life of the converters can be greatly prolonged.

Owner:JIANGSU UNIV

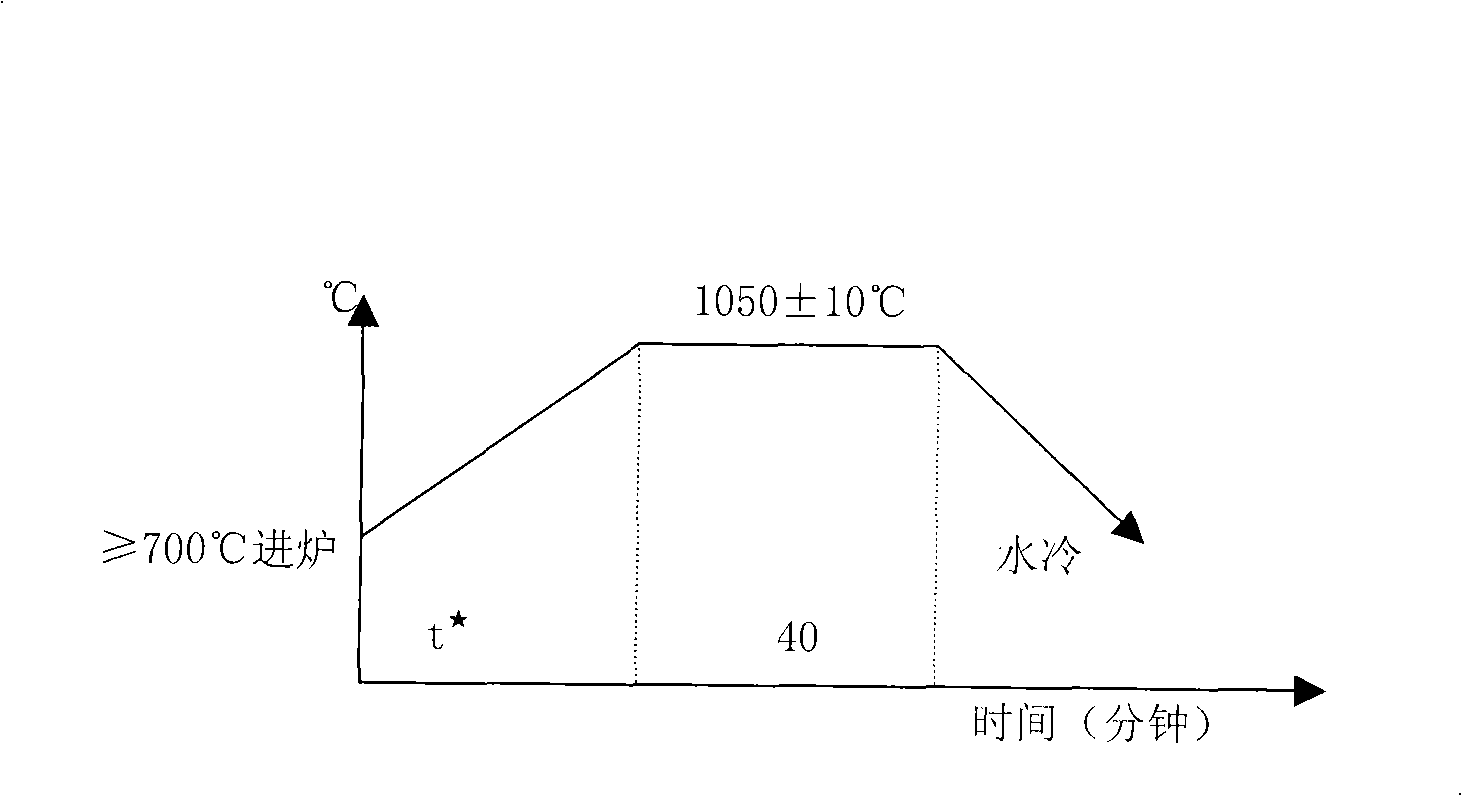

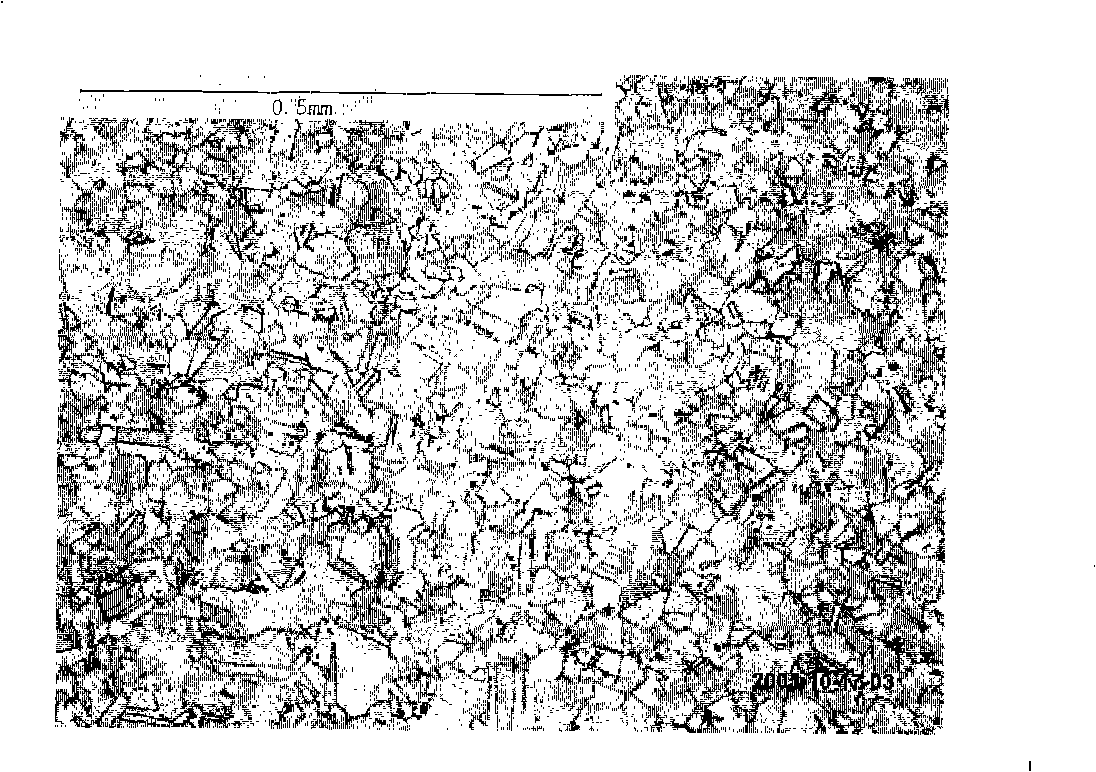

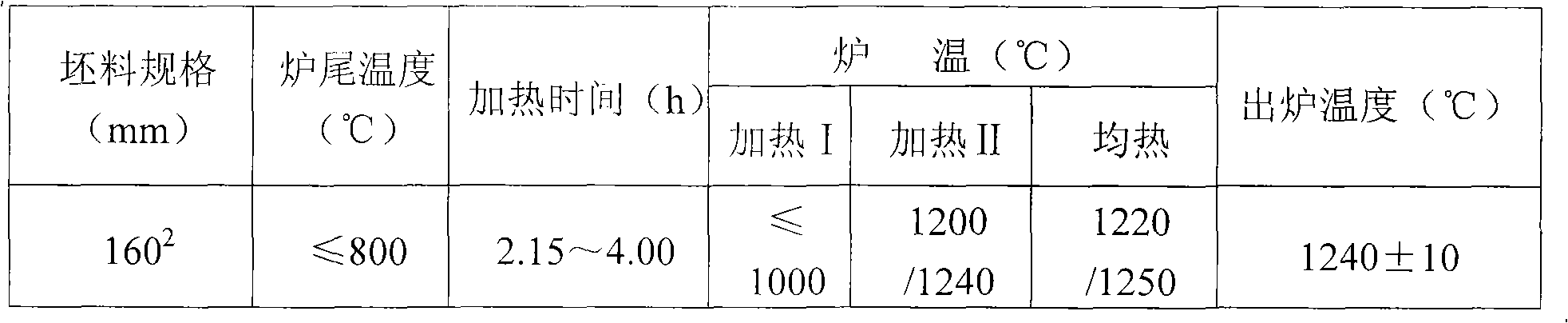

Stainless steel wire rod for standard parts and method for manufacturing same

The invention discloses a stainless steel wire rod used on a standard part as well as a manufacturing method, the stainless steel wire rod comprises the compositions, in weight percent: C: 0.03 to 0.08, Si<=0.55, Mn: 13.50 to 15.50, P<0.045, S <0.020, Cr: 12.50 to 14.00, Ni: 0.80 to 1.45, Cu: 1.75 to 3.50, balance Fe and unavoidable impurities. The manufacturing method includes the following steps of: 1. adopting an electric furnace plus an AOD secondary refining process for smelting, and continuous casting to form billet, 2. rolling, with a soaking temperature of between 1220DEG C and 1250DEG C, an initial rolling temperature >=1180DEG C, and a finishing temperature of between 950DEG C and 1050DEG C; 3. solid solution heat treatment, with a solid solution temperature of 1050DEG C+-10DEG C, the heat preservation time of 40 minutes, and the heating time of 30 to 60 minutes, and water cooling after exiting the furnace; and 4. acid washing. The wire rod and the manufacturing method reduce the nickel and chromium content and effectively save the nickel resource, and have greatly reduced costs of steel per ton compared with 304HC, and have excellent cold working performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Aluminum silicon carbide carbon brick for torpedo tank and preparation method thereof

The invention relates to an aluminum silicon carbide carbon brick for a torpedo tank and a preparation method thereof. The aluminum silicon carbide carbon brick comprises the raw materials by weight percent: 10-30% of special grade alumina, 15-35% of sub-white fused alumina being 1-3mm, 5-15% of silicon carbide, 2-10% of andalusite, 5-15% of crystalline flake graphite, 5-15% of 325-mesh sub-white fused alumina, 1-10% of nitride, 2-3% of metal aluminum powder and 3-5% of phenolic resin. The aluminum silicon carbide carbon brick is prepared by mixing the raw materials in the proportion, molding and drying. According to the invention, a corundum mullite phase is formed in the process of using the finished product and combined with nitride by adjusting the composition of the raw materials and adding nitride, so that the corrosion resistance, the scouring resistance and the high-temperature volume stability of the brick can be improved; compared with the common Al2O3-SiC-C (ASC) brick, the aluminum silicon carbide carbon brick improves the furnace age by about 15%.

Owner:北京首钢耐材炉料有限公司

Method for producing high carbon steel through double-slag high drawing carbon tapping

ActiveCN102559984AGood dephosphorization effectLess slagManufacturing convertersSteelmakingHigh carbon

A method for producing high carbon steel through double-slag high drawing carbon tapping belongs to the technical field of smelting high carbon steel through a converter. The method comprises processing steps as follows: molten iron and steel scraps are loaded in the converter according to a certain molten iron ratio; in a first stage of converter steelmaking, the converting is performed at the oxygen supplying intensity of 2.8 Nm<3> / min / t, active lime and ore fluxing mediums are added in the converter, and a larger bottom blown flow rate is adopted to stir; the converting is performed at a standard lance height in the prior period for the converting of the converter, and then the lance height rises gradually; part of furnace slag is dumped through a rocking furnace; in the second stage for the converting of the converter, the converting is performed at the oxygen supplying intensity of 3.3 Nm<3> / min / t, and active lime and the ore fluxing mediums are added in the converter; the lance height rule that the converting is performed at a higher lance height in the later period and the lance height descends stage by stage is adopted; a small quantity of ores and fluorites are added frequently within 80 to 90 percent of total converting oxygen consumption; after the converting of the converter is finished, deslagging is performed through the rocking furnace of the converter, and temperature measurement and sampling are carried out; and converter tapping is carried out. The method has the advantage of overcoming the shortages of serious rephosphoration caused during the tapping process, low production efficiency, and so on.

Owner:SHOUGANG CORPORATION

Mother liquid foam slag generating method for smelting stainless steel with electric furnace and dephosphorization melted iron

InactiveCN101096717AIncrease production capacityReduce power-on timeElectric furnaceMelting tankElectric arc furnace

The invention discloses a manufacturing method of stainless steel mother liquor foam slag through electric furnace dephosphorized molten iron, which comprises the following steps: 1)adding solid material with waste stainless steel, ferrochromium and silicon into electric furnace through material basket; energising to smelt; setting the quantity of siliconat at 8.5-12kg / t; 2)adding dephosphorized molten iron when the power consumption is 15-22 Mwh; controlling C content of mother liquor at 1.50-4.00%; 3)forming basic smelting pond in the furnace when the power consumption is 160-200Kwh / t; starting to blow carbon powder with content at 2-4kg / t; jetting oxygen with quantity at 2500Nm3 / h-3500Nm3 / h.

Owner:BAOSHAN IRON & STEEL CO LTD

Process for smelting vanadium-containing molten iron converter

InactiveCN101691623AImprove furnace lifeThe smelting process goes smoothlyManufacturing convertersSlagPhosphor

The invention belongs to the technical field of ferrous metallurgy, in particular relates to a process for smelting a vanadium-containing molten iron converter, and solves the technical problem of improving the service life of the vanadium-containing molten iron converter. The process comprises two times of slag making, namely in the first time of slag making, reducing the vanadium content of blown molten iron to below 0.03 percent and discharging formed primary slag, and adding slag making materials in the converter for the second time for smelting. Slag with high vanadium content and phosphor content formed in the first time of slag making is removed possibly, and converter slag which has high melting point and low oxidability and is suitable for slag splashing is formed in the second times of slag making, so that the service life of the vanadium-containing molten iron converter is obviously improved. The method not only can effectively ensure smooth operation of the converter steel making process, but also can produce converter slags more suitable for slag splashing to greatly improve the service life of the converter.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Silicon nitride-silicon carbide composite brick and preparation method thereof

The invention discloses a silicon nitride-silicon carbide composite brick, comprising, by weight, 43 to 80% of silicon carbide sand, 5 to 19% of industrial silicon, 3 to 15% of micro silica powder, 10 to 20% of silicon nitride, 0.5 to 3.5% of a transforming agent, 0.5 to 4% of a toughening agent, 0.5 to 3% of a binder and 0.1 to 1% of an additive. Meanwhile, the invention further discloses a preparation method for a ceramic refractory material, i.e., the silicon nitride-silicon carbide composite brick. The ceramic refractory material provided by the invention has the advantages of novelty, creativity, advancement, practicality, wear resistance, anti-stripping performance, strong acid and alkaline resistance and substantial effects on matching of a monolithic lining and prolongation of an integral furnace age. The preparation method provided by the invention is simple, uses nitrogen and other nitrides in the air as sintering protection gas in the process of preparation, discharges oxygen in the air, thereby increasing a local oxygen-containing rate, and is beneficial and harmless to the natural environment and suitable for energetic popularization.

Owner:宜兴市钰玺窑业有限公司

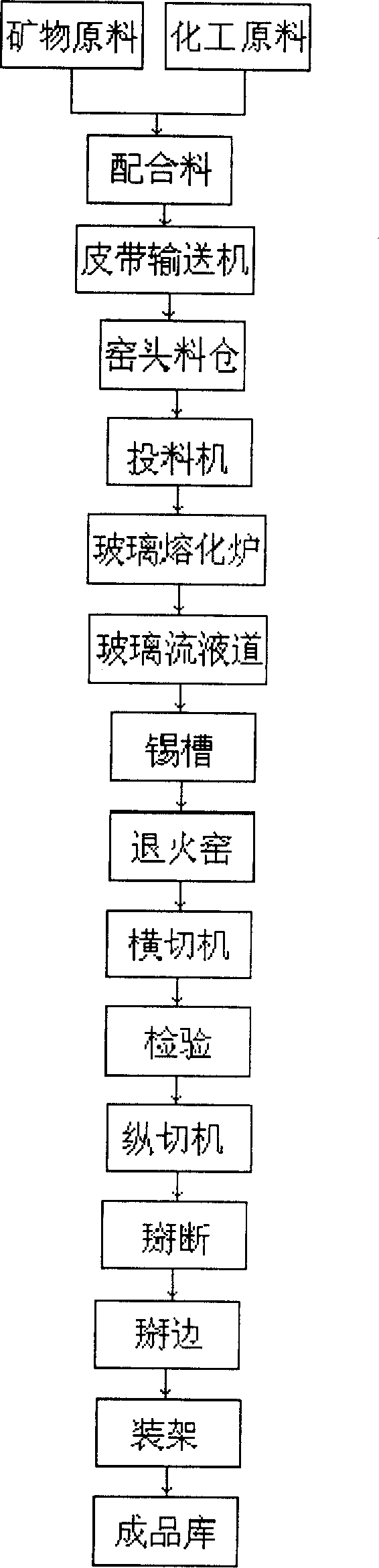

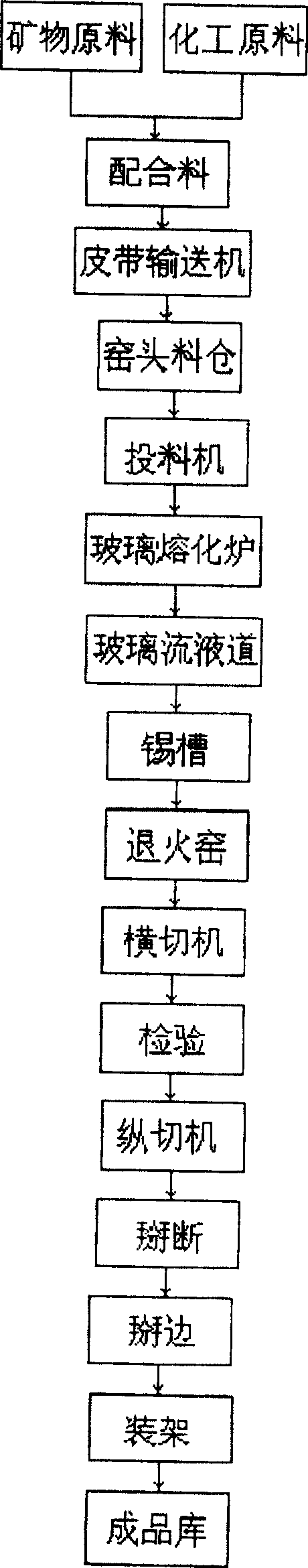

Single-slice fireproof glass

The invention relates to a single-sheet flame-resistant glass with low low-expansion coefficient and high expansion softening temperature, which comprises (by weight percent) the following constituents: SiO2 63-70%, Al2O3 12.5-19%, MgO 1-4%, CaO 6-10%, SrO 0.5-3%, BaO 0.5-2%, K2O 0-1%, Li2O -1% and Na2O 6-10%.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

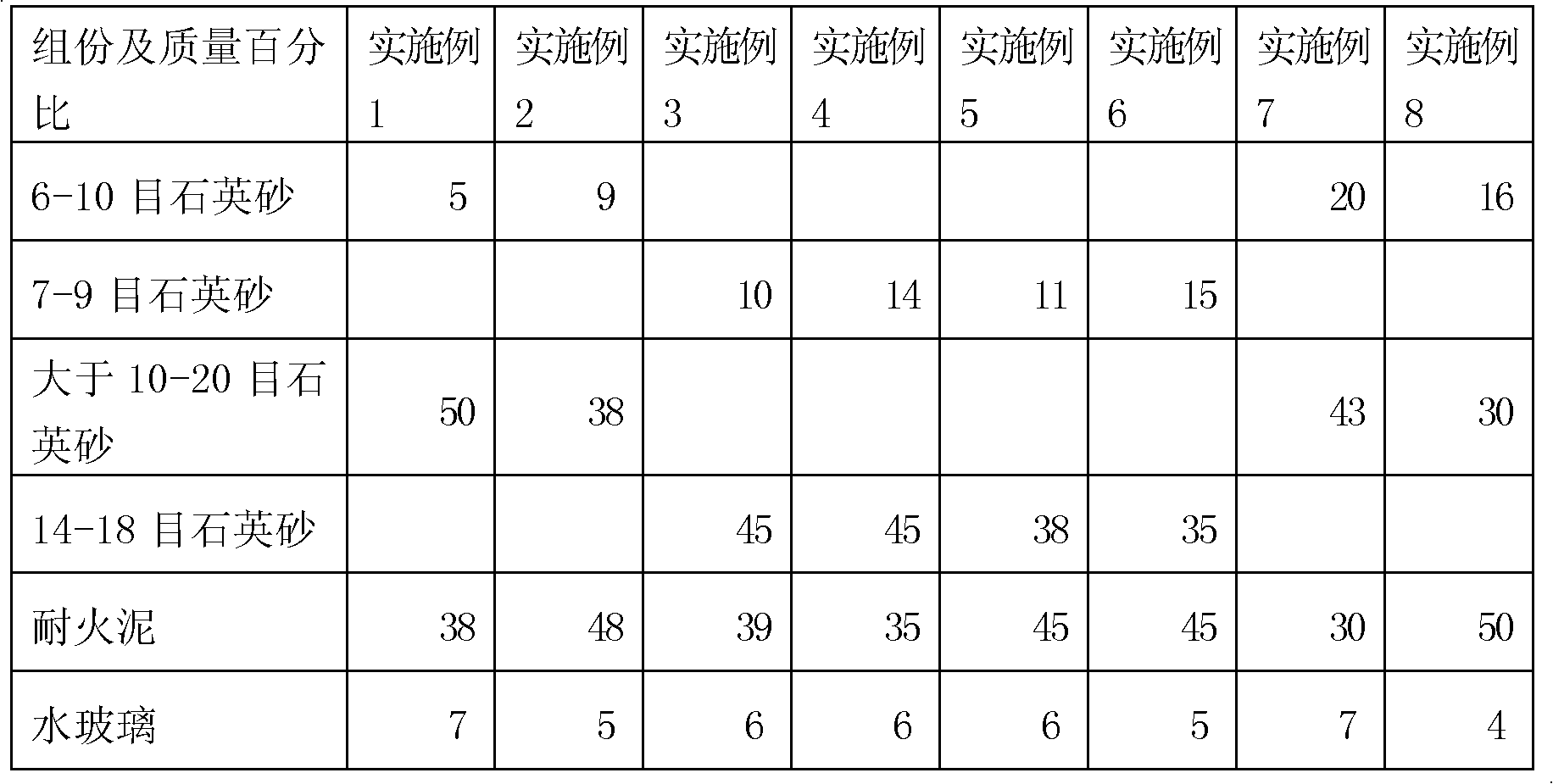

Method for building high-age medium-frequency induction furnace through quartz sand and use method

The invention discloses a method for building a high-age medium-frequency induction furnace through quartz sand and a use method. The method for building the high-age medium-frequency induction furnace comprises the steps that firstly, sand used for ramming a furnace bottom and furnace walls and furnace mouth mixed materials used for ramming a furnace mouth are prepared; secondly, the furnace bottom, the furnace walls and the furnace mouth are rammed in sequence; finally, the furnace bottom, the furnace walls and the furnace mouth are baked and sintered into a whole so that the furnace can be built. The medium-frequency induction furnace manufactured through the method has the advantages of being resistant to high temperature, good in chemical stability, good in rapid-cooling resistance and rapid-heating resistance, small in thermal expansion coefficient, resistant to corrosion by slag and molten liquid and the like. The medium-frequency induction furnace manufactured through the method can be used over 200 times through a trial. Meanwhile, the method comprises the steps that when the medium-frequency induction furnace is used for melting iron each time, the rated power of the medium-frequency induction furnace is controlled within the range between 35% and 40% half hour before the iron is melted; in addition, each time the medium-frequency induction furnace is cooled, nuts in the positions of an induction coil are fastened, and therefore the induction coil is prevented from falling off when the iron is melted. According to the use method, the service life of the medium-frequency induction furnace is further prolonged.

Owner:齐齐哈尔重型铸造有限责任公司

Alumina-silicon carbide-carbon brick for torpedo tank and torpedo tank lining structure therewith

ActiveCN101066880AGood resistance to slag and iron corrosionEasy to match bricks and masonryMelt-holding vesselsAluminiumGraphite

The present invention discloses one kind of alumina-silicon carbide-carbon brick for torpedo tank and the torpedo tank lining structure therewith. The alumina-silicon carbide-carbon brick is produced with the materials including bauxite 10-60 wt%, electromelting corundum 10-50 wt%, silicon carbide 3-20 wt%, graphite 2- 20 wt%, chrome 0.5-5 wt%, metal aluminum 0.2-3 wt%, metal silicon 0.2-3 wt%, binding agent 3-5 wt% and andalusite 3-10 wt%. The brick is suitable for use in torpedo tank, and has high iron slag erosion resistance, high antioxidant capacity and high heat shock stability.

Owner:巩义市第五耐火材料有限公司

Single-slice fireproof glass

The invention relates to a single-sheet flame-resistant glass with low low-expansion coefficient and high expansion softening temperature, which comprises (by weight percent) the following constituents: SiO2 63-70%, Al2O3 12.5-19%, MgO 1-4%, CaO 6-10%, SrO 0.5-3%, BaO 0.5-2%, K2O 0-1%, Li2O -1% and Na2O 6-10%.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

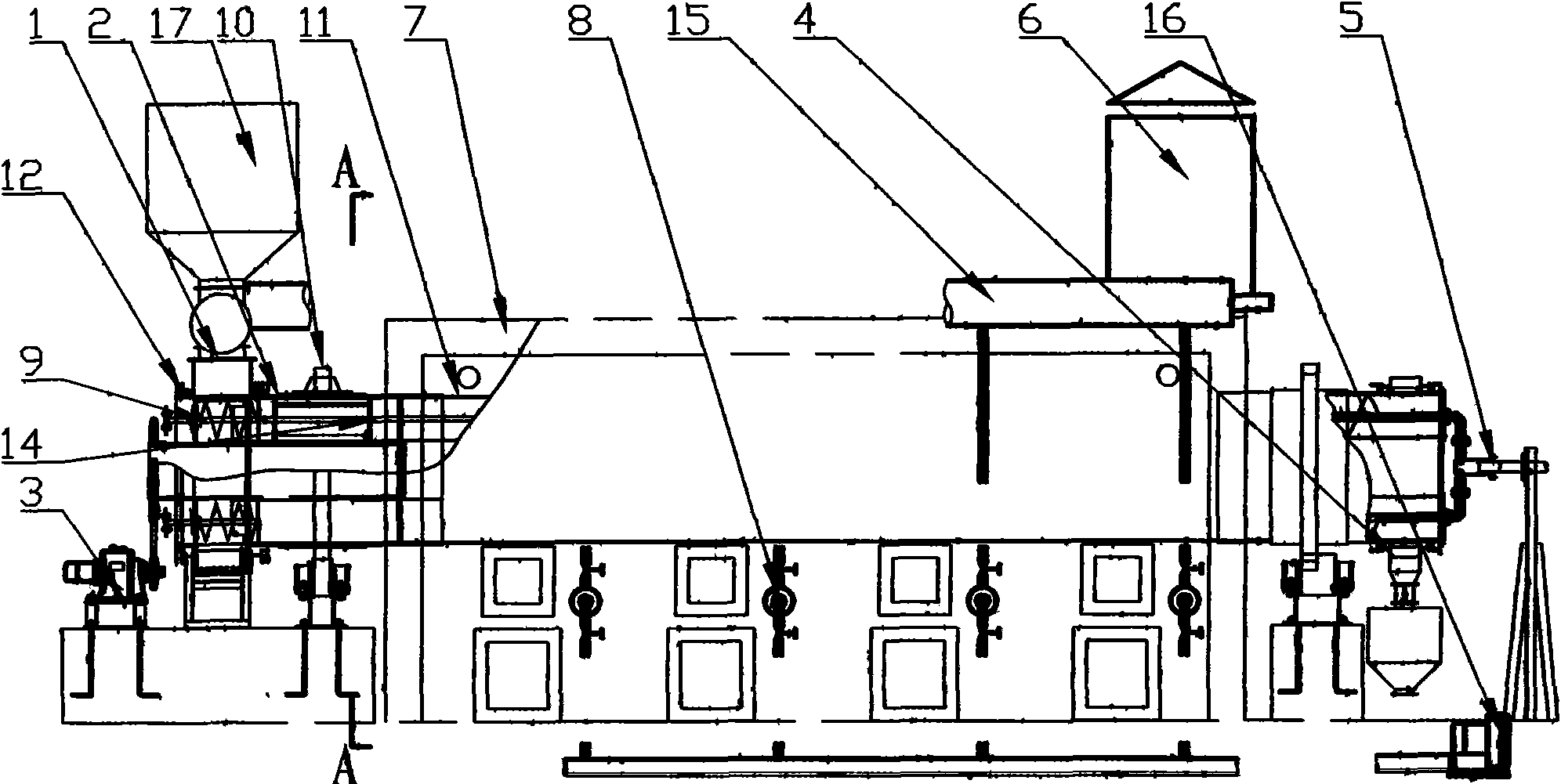

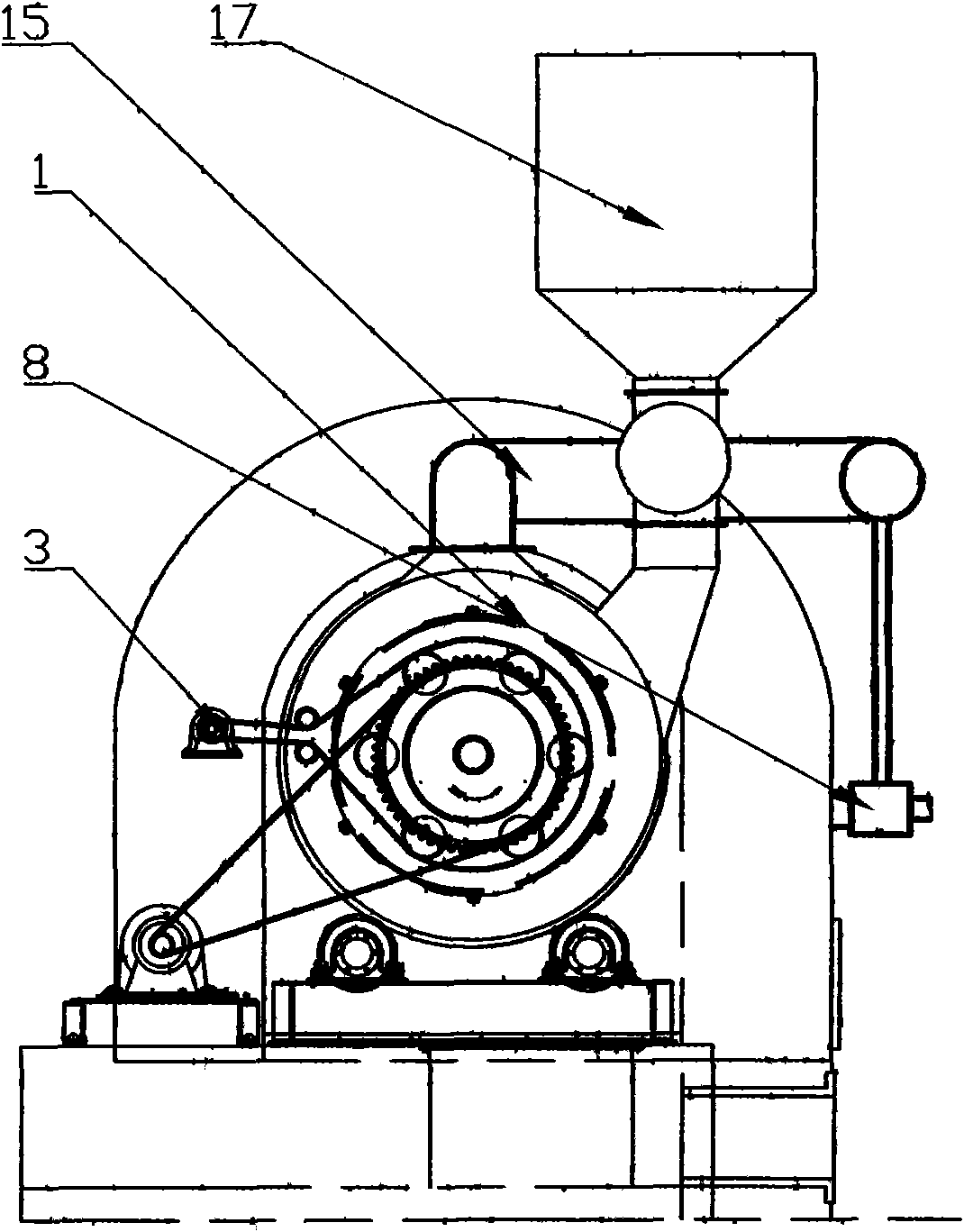

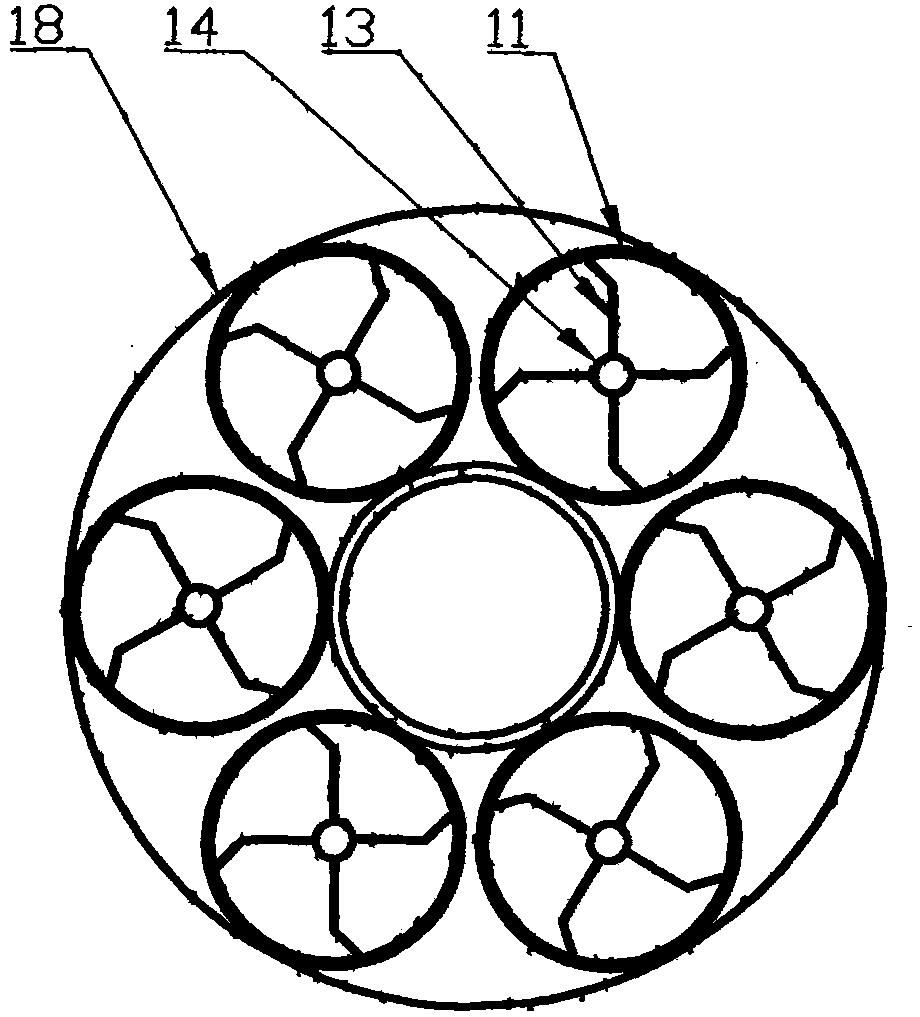

Novel multi-pipe external-heating revolving activation furnace

InactiveCN101891190AAvoid excessive accumulationChange the phenomenon of excessive accumulationCarbon compoundsChemical industryCombustible gasHeating furnace

The invention discloses a novel multi-pipe external-heating revolving activation furnace, and solves the problems of poor activating effect, low yield, easy fracture and the like in the conventional revolving activation furnace. The activation furnace comprises a furnace body, a drive device, a discharge device, a heating furnace, a funnel and the like, wherein the furnace body consists of a plurality of heat-resisting seamless stainless steel pipes and cylinders positioned at the two ends; shovelling plates and steam pipes are arranged in the heat-resisting seamless stainless steel pipes; one end of the furnace body is connected with a feeding / exhaust device through a sealing device; and the other end is connected with the discharge device. The novel multi-pipe external-heating revolving activation furnace stops dangerous elements such as welding stress, changes the phenomenon of overmuch coal material accumulation so that coal materials can be uniformly distributed in a plurality of activation pipes, enlarges the heating area of the coal materials, completely collects and recycles combustible gases produced during the activation, protects the environment, saves energy, has a simple structure, and can greatly prolong a manufacturing cycle and reduce processing cost.

Owner:HUAIBEI DAHUA ACTIVE CARBON

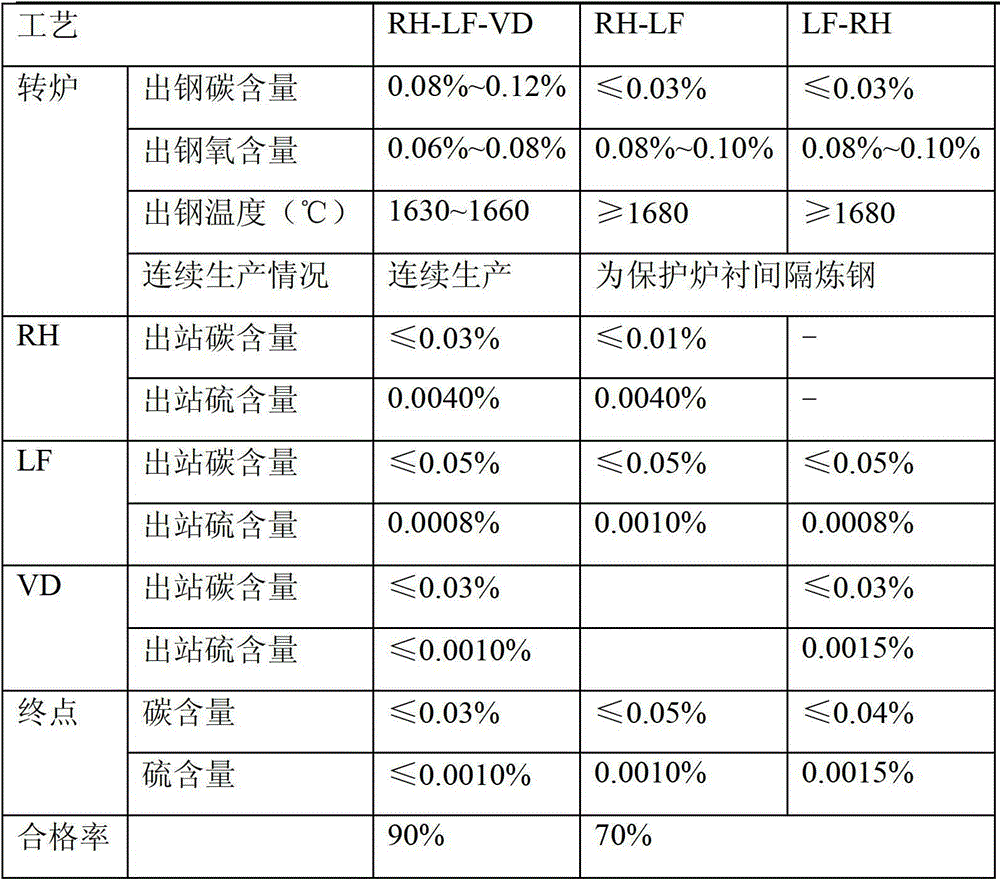

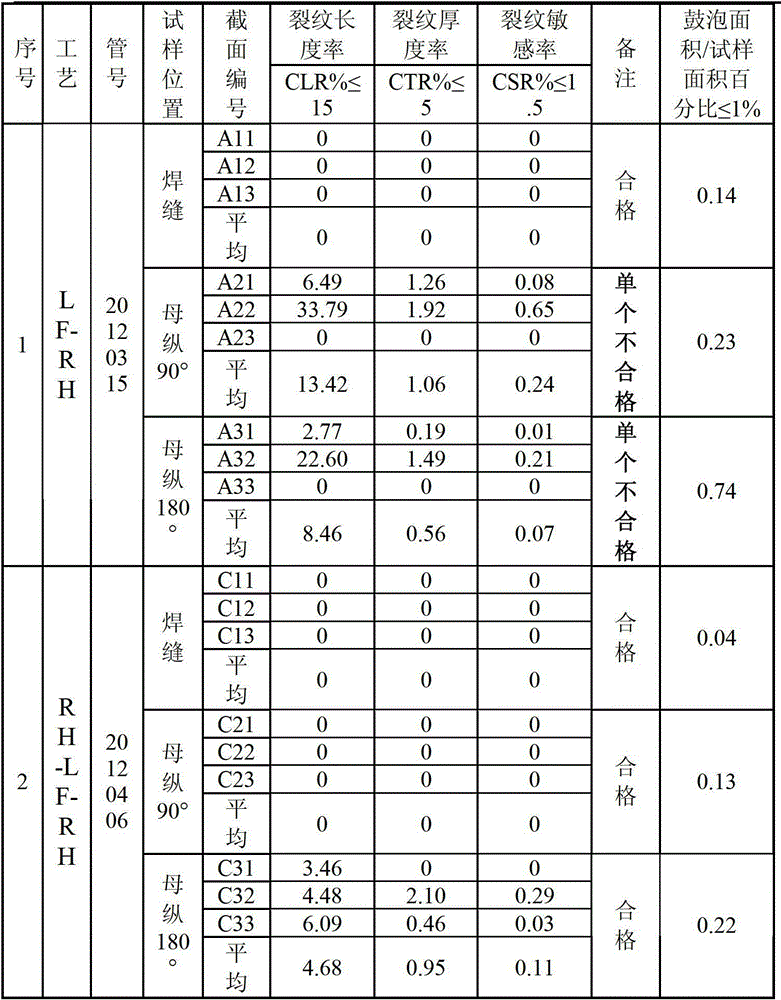

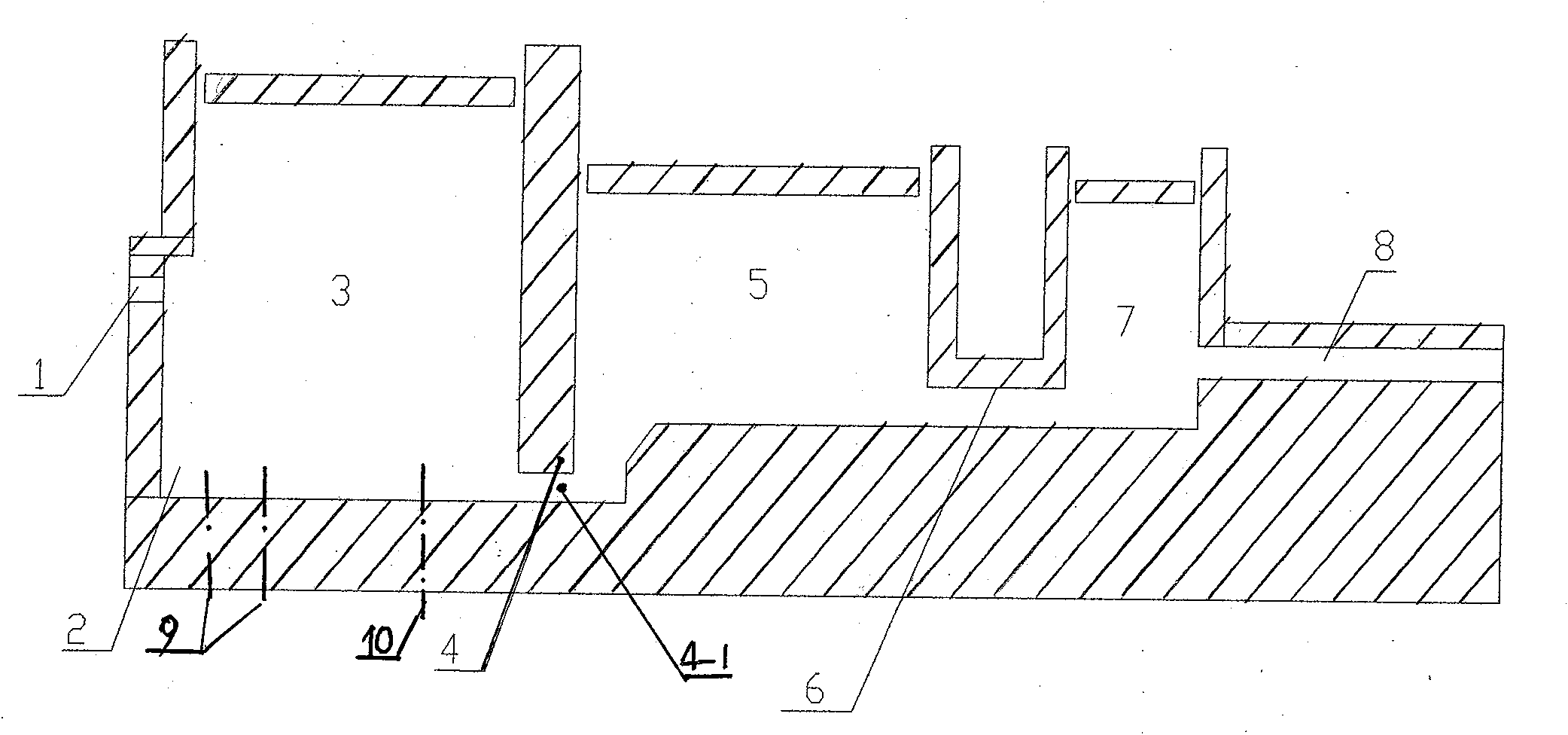

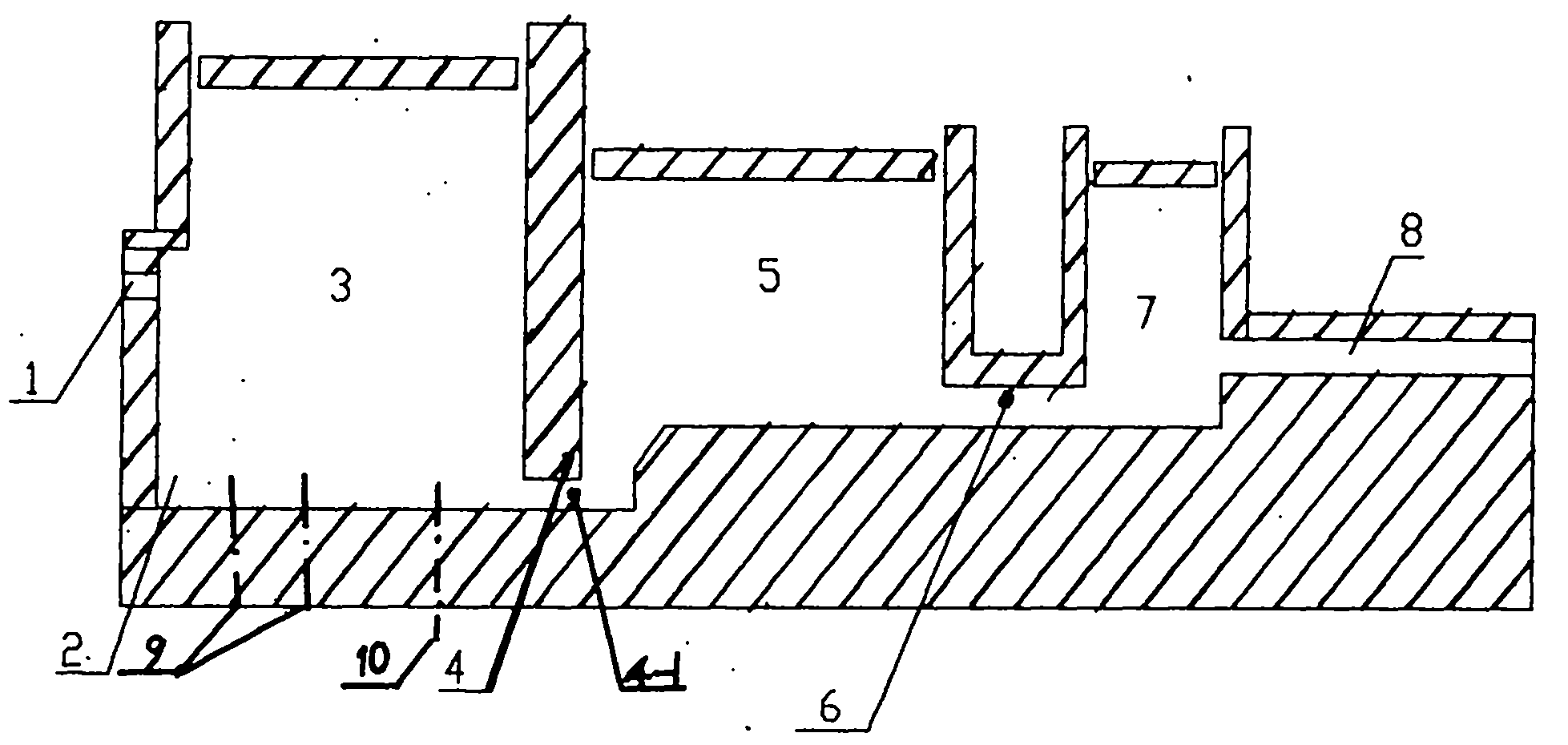

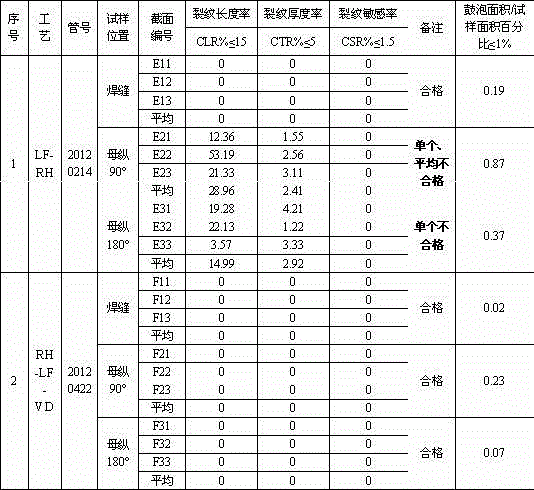

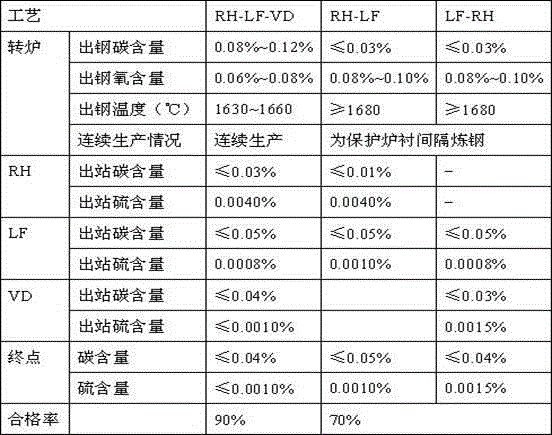

Process for producing anti-acid pipeline steel by Ruhrstahl Heraecus (RH)-ladle furnace (LF)-RH refining

InactiveCN102719614AReduce production burdenReduce non-metallic inclusion contentManufacturing convertersHydrogenStress corrosion cracking

The invention discloses a process for producing an anti-acid pipeline steel by Ruhrstahl Heraecus (RH)-ladle furnace (LF)-RH refining. In the process, the composition of molten steel is controlled by converter smelting and RH-LF-RH refining process, so as to produce a low-carbon low-sulfur anti-acid (hydrogen-induced cracking HIC and stress corrosion cracking SCC resistant) pipeline steel. The specific flow is as follows: pre-desulphuzation of molten steel - converter smelting-primary RH vacuum refining - LF refining desulphuzation - secondary RH vacuum refining - continuous casting. By the secondary RH vacuum refining process, the decarburization burden of the converter and the oxidability of the molten steel can be reduced, and the adverse effect caused by recarburization in the LF refining process can be eliminated; furthermore, the use of a strong deoxidizer is reduced, the production is stabilized, and the composition of the molten steel is ensured to be controlled within a production target stably to meet the control requirements of the anti-acid pipeline steel on the low-carbon low-sulfur and high-purity composition. The carbon content of the finished steel produced by the process of the invention can be stably controlled to be 0.03% to 0.04%, and the sulfur content is stably controlled to be less than or equal to 0.0010%.

Owner:UNIV OF SCI & TECH BEIJING

Method for smelting high-manganese stainless steel through AOD and AOD furnace

ActiveCN107245637APreferential oxidationReduce oxidationProcess efficiency improvementFurnace temperatureSlag

The invention discloses a method for smelting high-manganese stainless steel through AOD. The method comprises a preparatory process, a decarburization process, a prereduction process and a reduction process, wherein in the prereduction process, a ferrosilicon alloy serves as a deoxidizing agent and an alloying agent for deoxidization, manganese is added in a concentrated manner for manganese alloying, manganese is added in a batched manner in the manganese alloying process, heating is conducted while manganese is added, and meanwhile various technological parameters are reasonably controlled. According to the method for smelting the high-manganese stainless steel through AOD, for AOD smelting on the high-manganese stainless steel with the manganese content larger than 15%, the manganese alloying technology is improved, furnace temperature, an oxygen blowing parameter and the using dosage and time of the deoxidizing agent and the alloying agent are reasonably controlled, oxidization or burning loss of manganese are greatly reduced, and not only is the recycling rate of manganese increased, but also the loss, caused by high temperature, of an AOD furnace lining is reduced. The invention further discloses an AOD furnace. Installing of a bottom air blowing tube can be convenient to achieve, pouring of the AOD furnace is uniform and adjustable, slag flowing is uniform and capable of saving labor, the workload is reduced, the slag flowing speed is increased, the slag flowing quality is improved, and the manganese alloying process is accelerated.

Owner:YONGXING SPECIAL STAINLESS STEEL

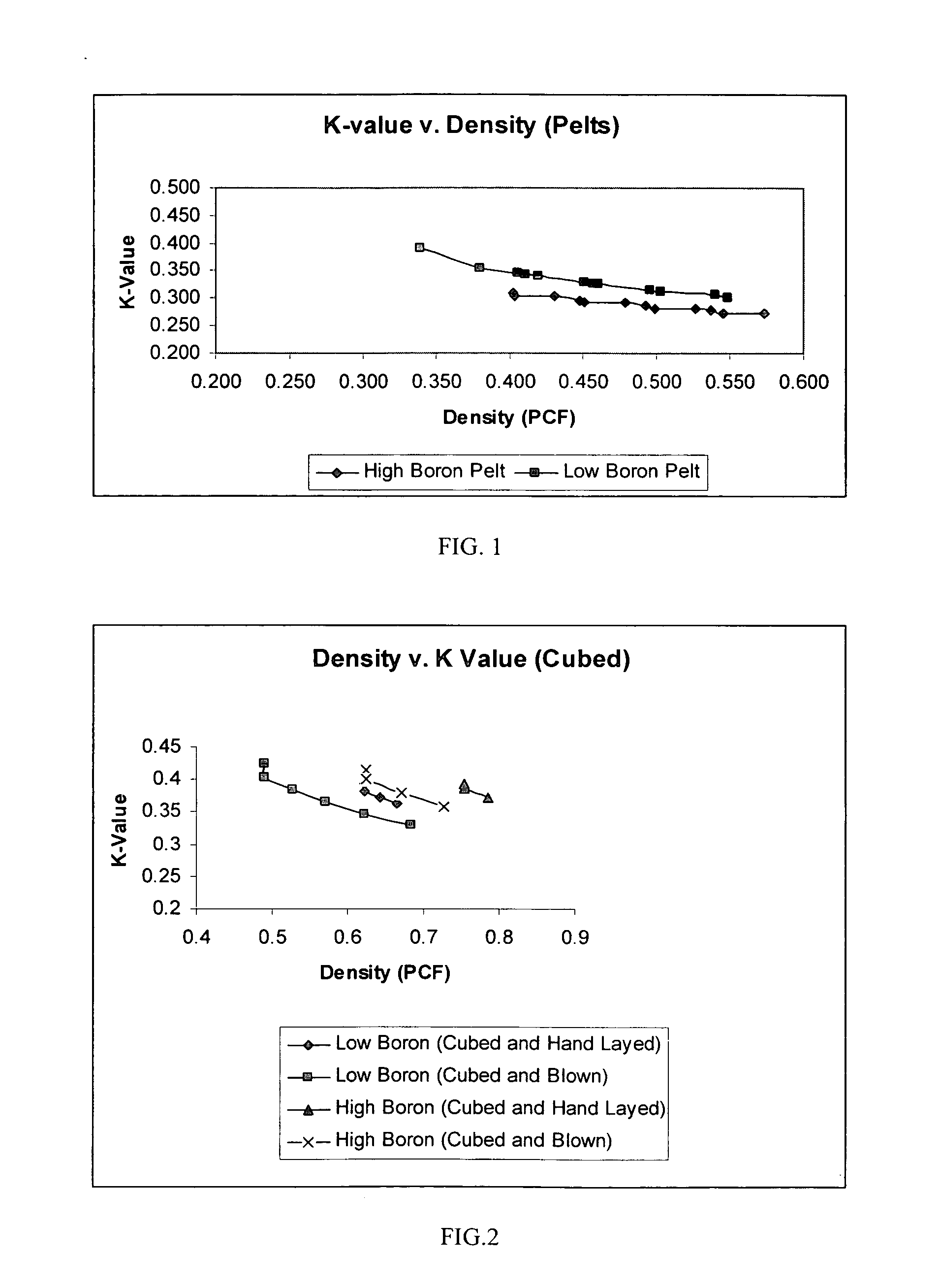

Low boron glass composition for loose-fill fiberglass insulation

ActiveUS20060148634A1Improve furnace lifeReduce the amount of solutionLayered productsThin material handlingGlass fiberVolumetric Mass Density

The present invention relates to fiberglass loose-fill insulation that is insensitive to the content of boron in the composition of the glass. It has been discovered that the level of boron in the glass used for the manufacture of loose-fill glass wool can be substantially reduced without degrading thermal performance. The lowered amount of boron provides for a lower cost batch composition and increased furnace life. The glass composition of the present invention includes a substantially reduced content of boron and preferably an increased amount of sodium dioxide. The primary phase of these glass compositions is typically devitrite (Na2Ca3Si6O16). The glass of the present invention provides a glass fiber blowing wool that does not require an increase in pack density to compensate for the reduced boron content while achieving the similar thermal conductivity. The glass of the present invention is also suitable for use in acoustic insulation.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

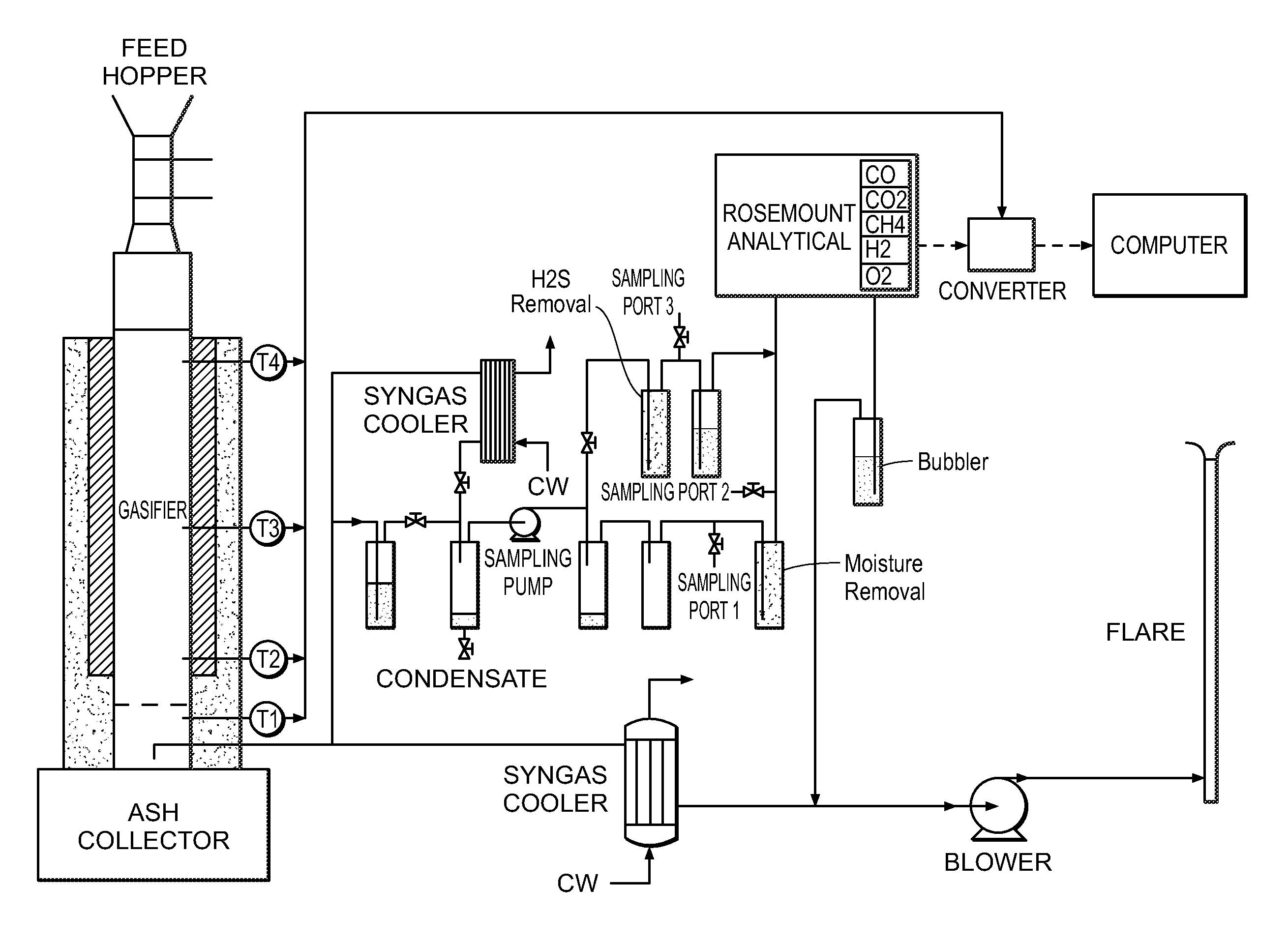

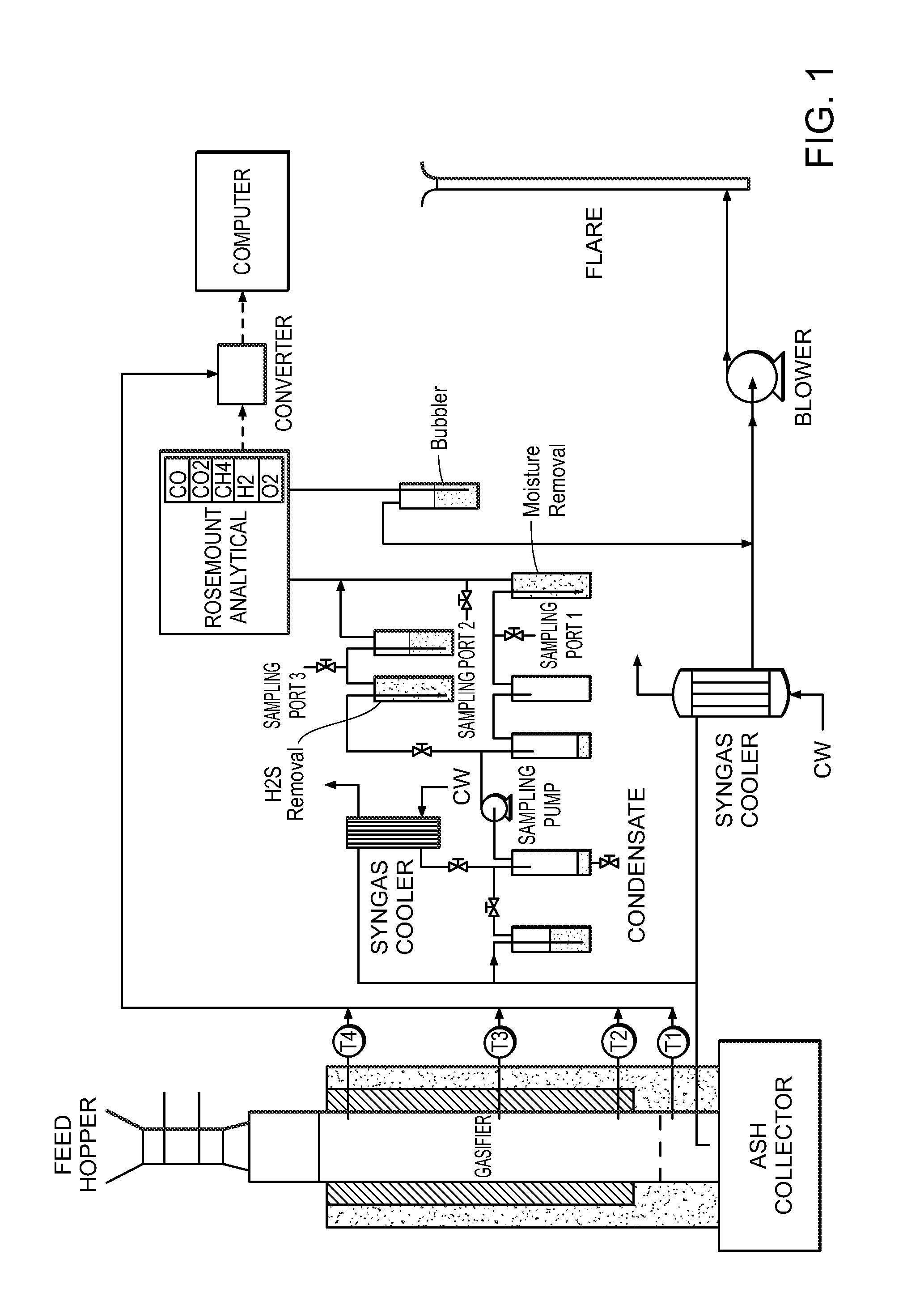

Sorbent containing engineered fuel feed stock

ActiveUS20120210633A1Less-harmful emissionEmission reductionSolid fuel pretreatmentBiofuelsCombustionPower station

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, methods of making the fuel feed stocks, methods of producing energy from the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles and contain a sorbent. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels. In addition, one or more sorbents can be added to the feed stocks in order to reduce the amount of a variety of pollutants present in traditional fuel and feed stocks, including, but not limited, sulfur and chlorine. Further, these feed stocks with added sorbent can mitigate corrosion, improve fuel conversion, extend power generating plant lifetime, reduce ash slagging, and reduced operating temperature.

Owner:REPOWER IP LLC

Induction furnace for high temperature operation

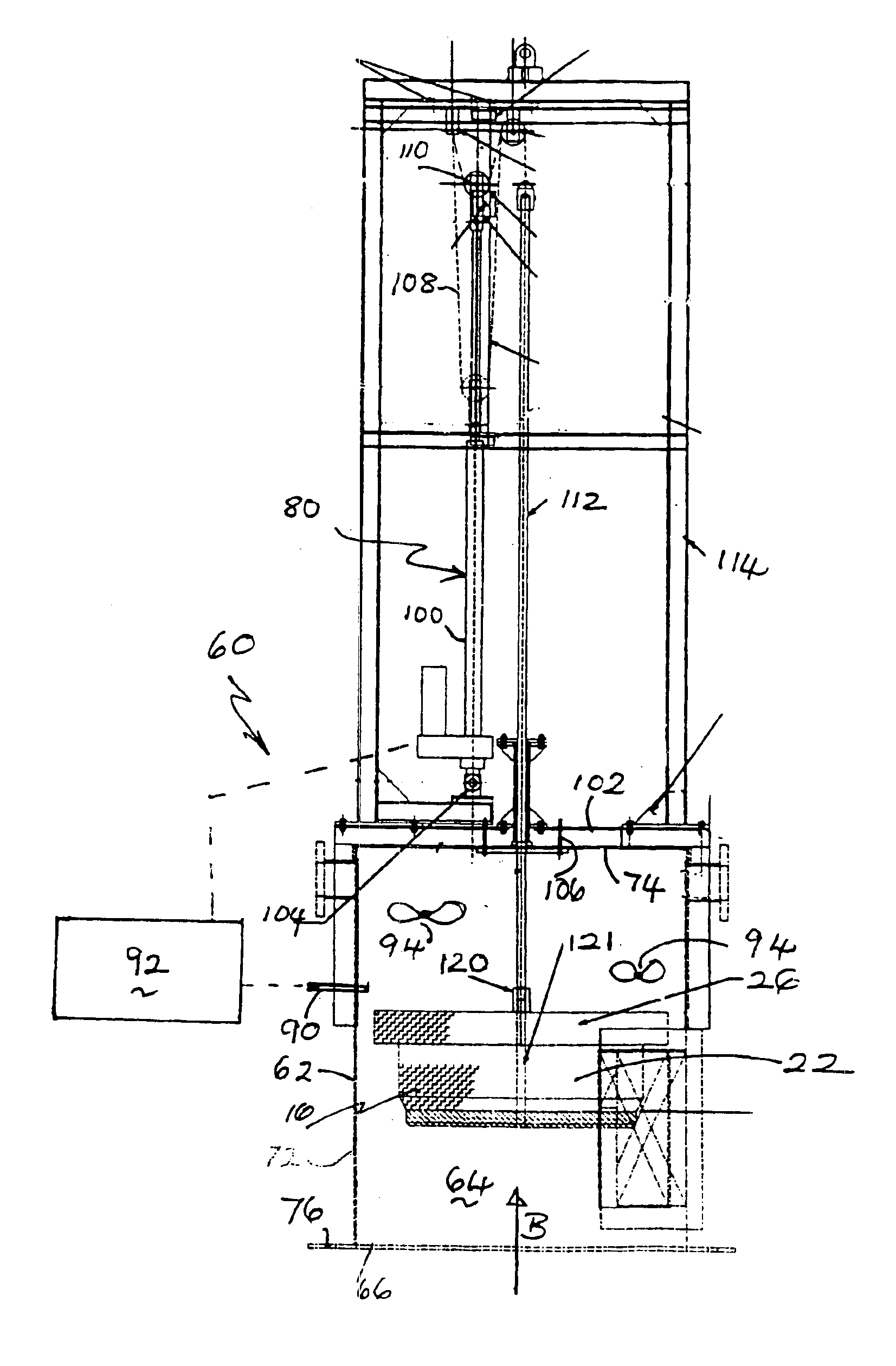

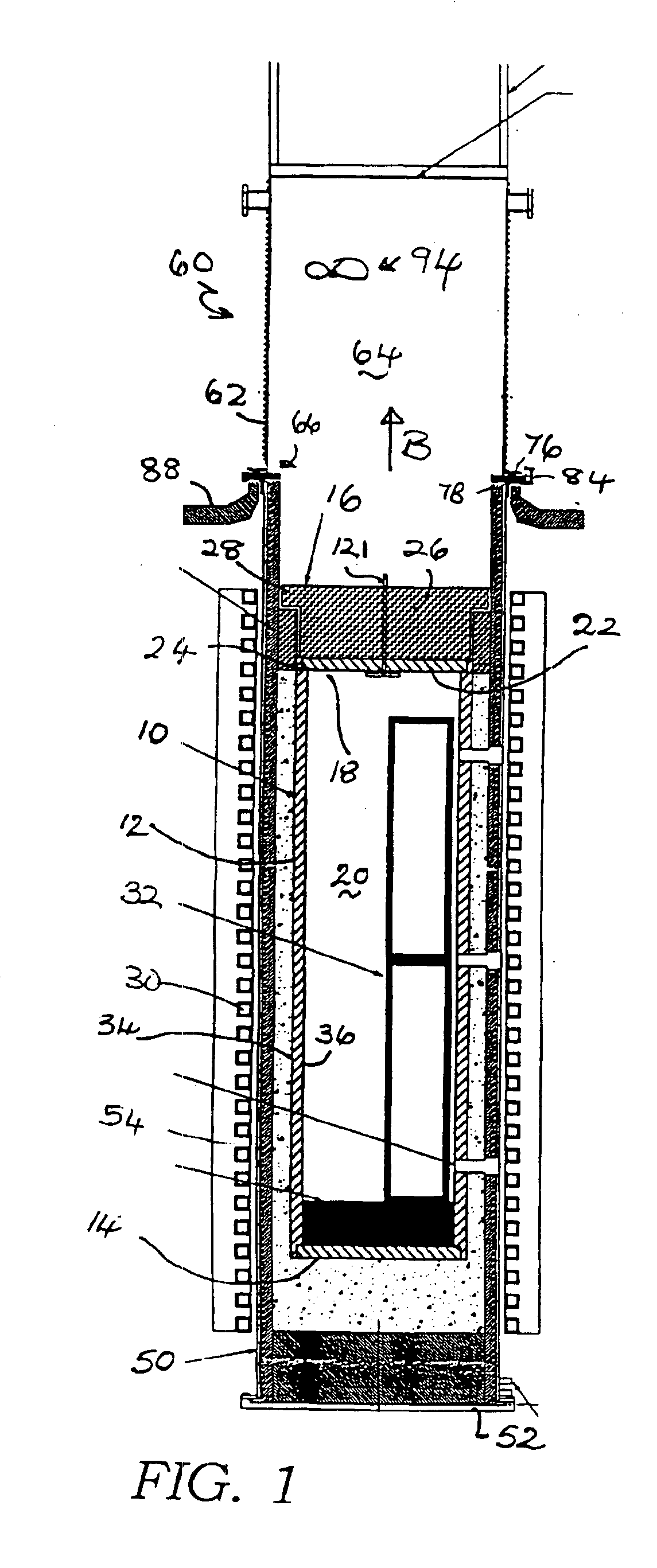

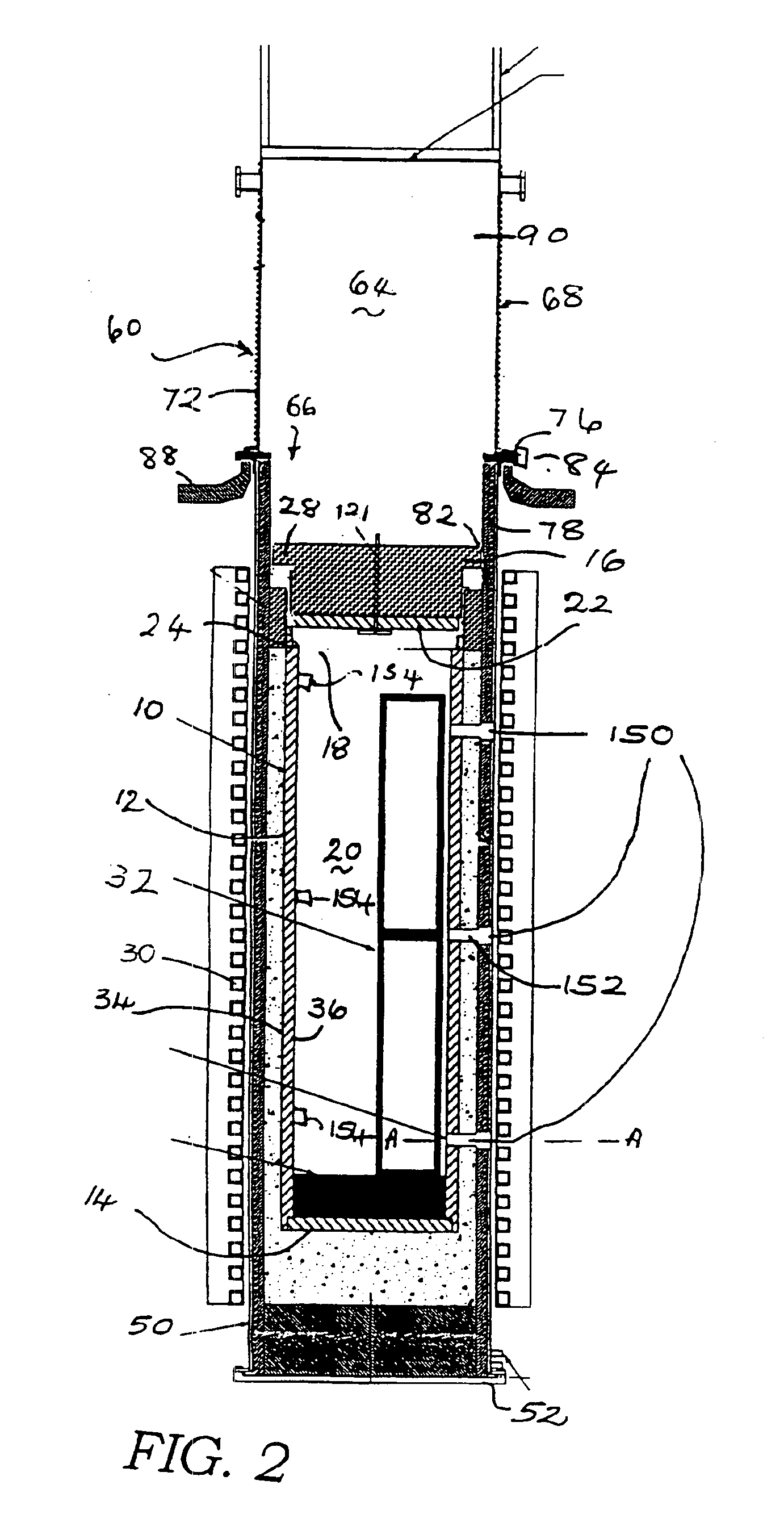

InactiveUS6898232B2Prevent escapeImprove furnace lifeFurnaces without endless coreMechanical apparatusInsulation layerHot zone

An induction furnace capable of operation at temperatures of over 3100° C. has a cooling assembly (60), which is selectively mounted to an upper end of the furnace wall (76). The cooling assembly includes a dome (62), which is actively cooled by cooling water coils (68). During the cool-down portion of a furnace run, cooling initially proceeds naturally, by conduction of heat away from the hot zone through a furnace insulation layer (58). Once the temperature within the furnace hot zone (20) reaches about 1500° C., a lifting mechanism (80), mounted to the dome, raises a cap (16) of the furnace slightly, allowing hot gases from the hot zone to mix with cooler gas in the dome. This speeds up cooling of the hot zone, reducing cool-down times significantly, without the need for encumbering the furnace itself with valves or other complex cooling mechanisms which have to be replaced periodically. The life of a graphite furnace susceptor (10) at the high operating temperature is increased by surrounding the susceptor with a barrier layer (40) of flexible graphite, which inhibits evaporation of the graphite. Additionally, witness disks (154), placed within the susceptor, provide an accurate temperature profile of the hot zone.

Owner:GRAFTECH INT HLDG INC

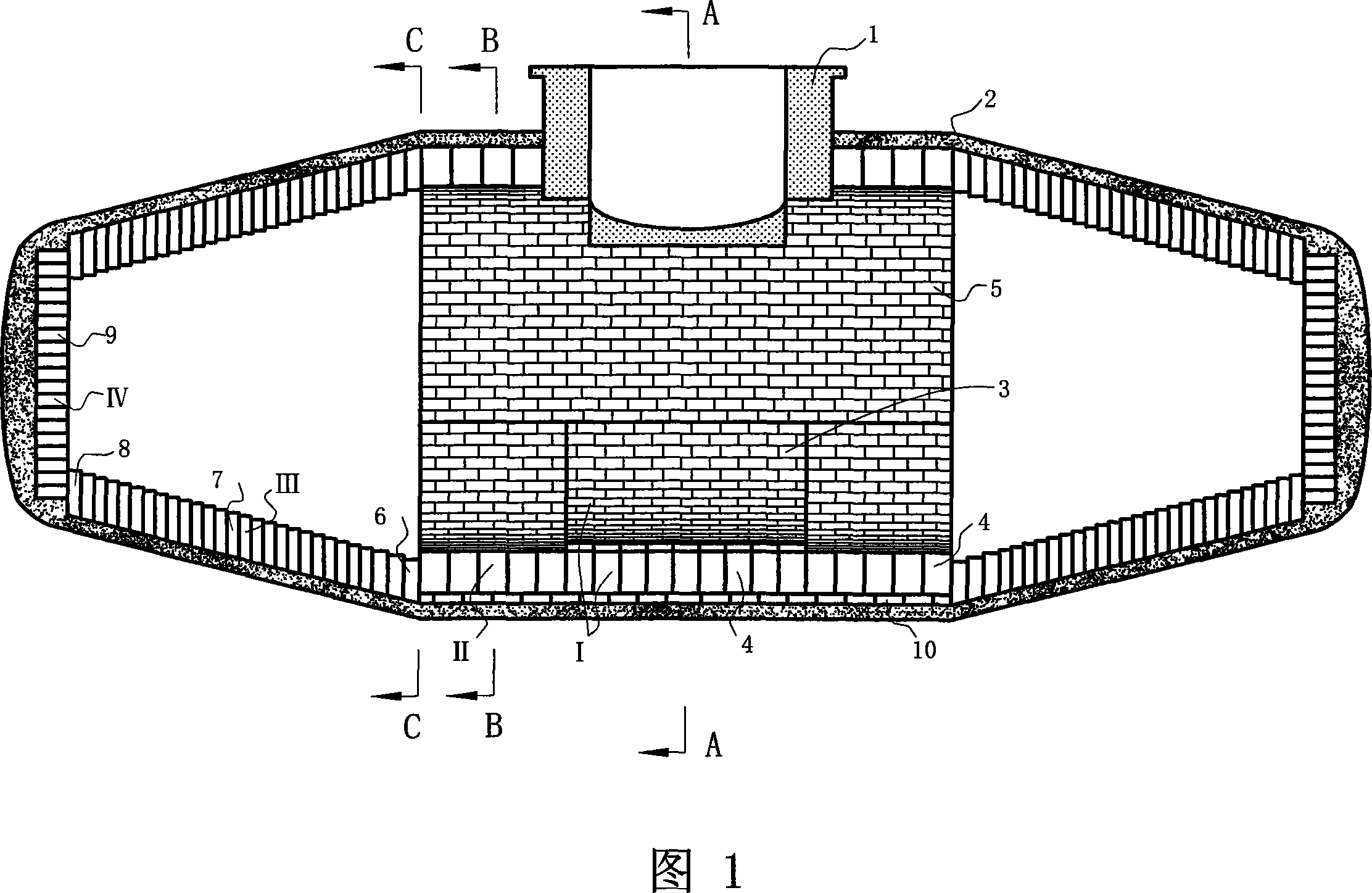

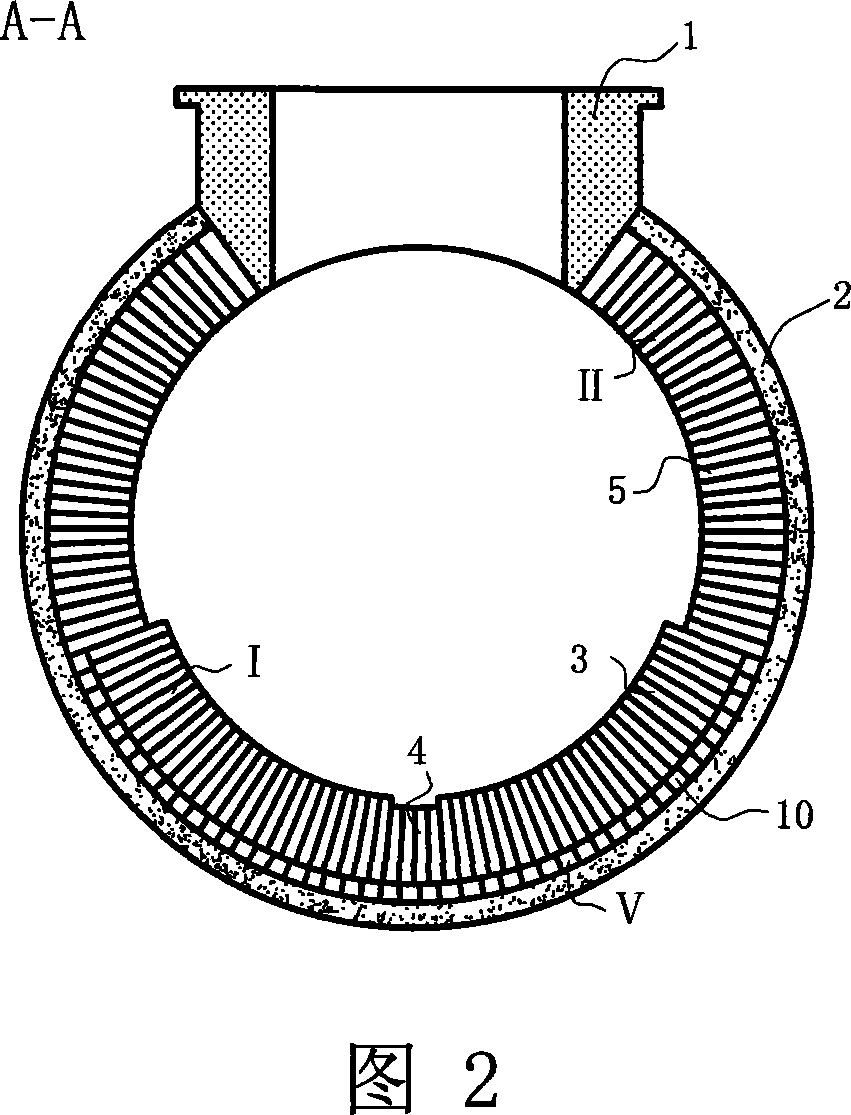

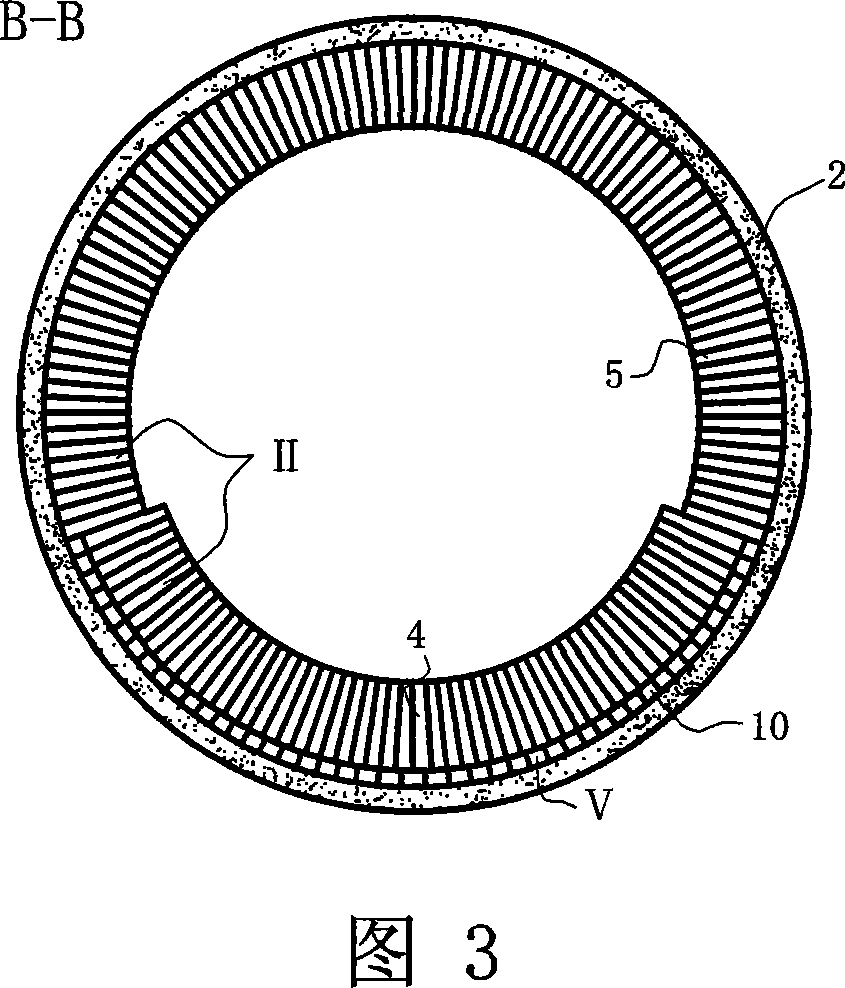

Glass tank for melting high-boron low-alkali or alkali-free glass

InactiveCN101880120AEasy to manageTimely managementTank furnacesGlass productionMelting tankAlkali free

The invention relates to a glass tank for melting high-boron low-alkali or alkali-free glass and manufacturing a TFT-LED glass substrate. The glass tank comprises a heating system matched with the glass tank and is characterized in that: the internal structure of the glass tank comprises a pre-melting tank with a feed inlet, a cross flame melting tank connected with the pre-melting tank, a cross flame clarification tank communicated with the cross flame melting tank through a lower passage of a flow-limiting diaphragm wall, and a cross flame work pool communicated with the cross flame clarification tank through a pipeline; and a forming passage for delivering molten glass is formed on the cross flame work pool. The glass tank reasonably utilizes energy; and the generated molten glass has the advantages of quick temperature rise, uniformity and high defoaming efficiency.

Owner:TUNGHSU GRP

Technique for producing anti-acid pipeline steel by RH-LF-VD refining

InactiveCN102719728AReduce production burdenReduce oxidationManufacturing convertersProcess efficiency improvementMolten steelDecarburization

The invention relates to a technique for producing anti-acid pipeline steel by RH-LF-VD refining. According to the technique, convertor steel making and RH-LF-VD refining techniques are utilized to control the components of molten steel, thereby producing the low-carbon low-sulfur anti-acid (anti-HIC and anti-SCC) pipeline steel. The technique comprises the following steps: predesulfurizing molten iron, smelting in a convertor, carrying out RH vacuum decarburization, carrying out LF heating for desulfurization, carrying out VD vacuum decarburization, carrying out calcium treatment, carrying out soft blowing, continuously casting, and carrying out hot rolling. By using the secondary vacuum refining processes (RH vacuum refining and VD vacuum refining), the invention can reduce the decarburization load of the convertor, lower the oxidizability of the molten steel, eliminate the adverse effect of carburization in the LF furnace refining process, reduce the consumption of a strong deoxidizer, stabilize the production, ensure that the molten steel components are stably controlled within the production target, and satisfy the component control requirements of low carbon, low sulfur and high purity for anti-acid pipeline steel. The carbon content of the finished steel produced by the technical process provided by the invention can be controlled to 0.03%, and the sulfur content can be stably controlled to at most 0.0010%.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com