Stainless steel wire rod for standard parts and method for manufacturing same

A technology of stainless steel plate and manufacturing method, applied in the direction of temperature control, etc., can solve the problems of high production cost 304HC, long AOD oxygen decarburization time, high content of precious metal nickel, and achieve good cold working performance, saving nickel resources, and uniform composition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

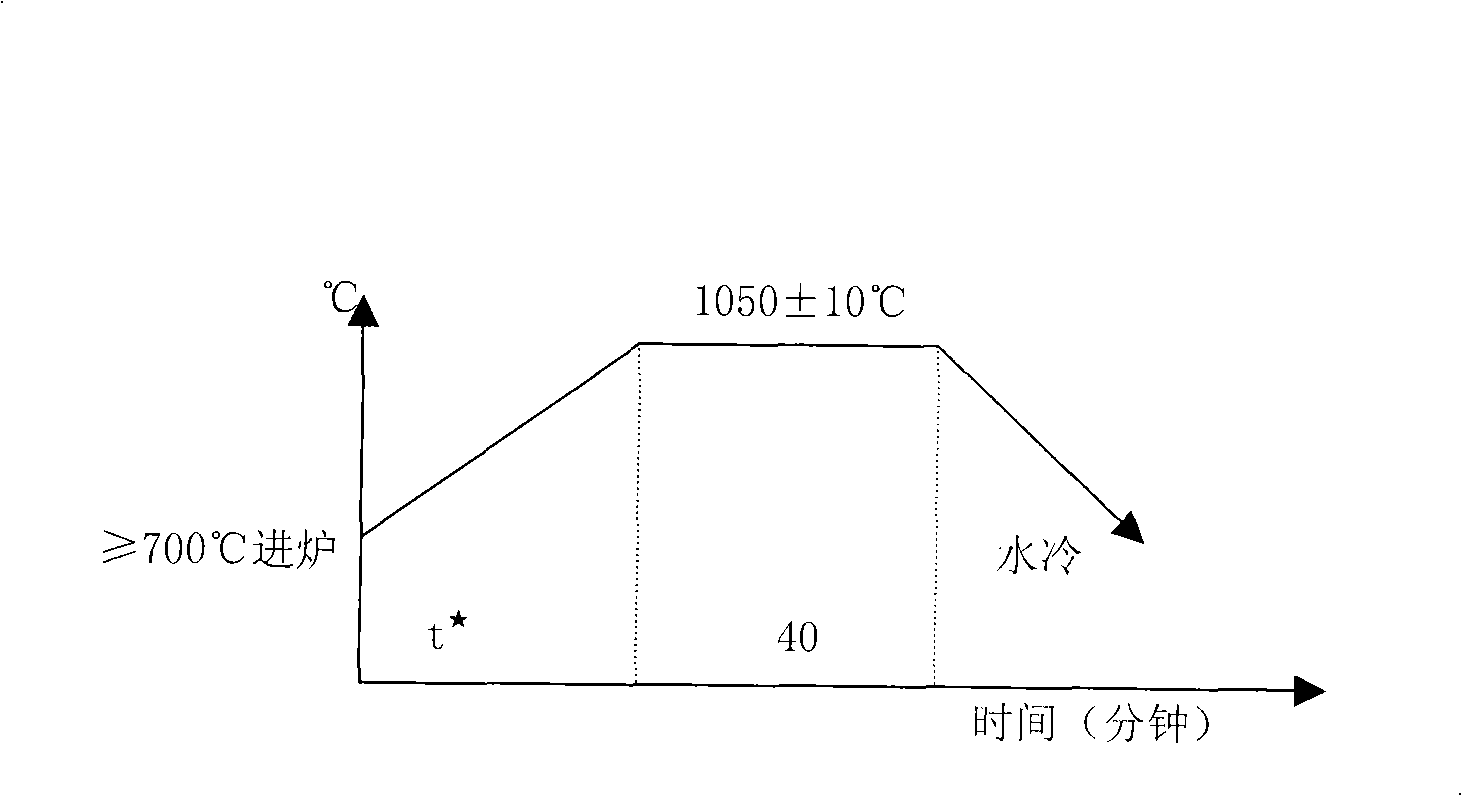

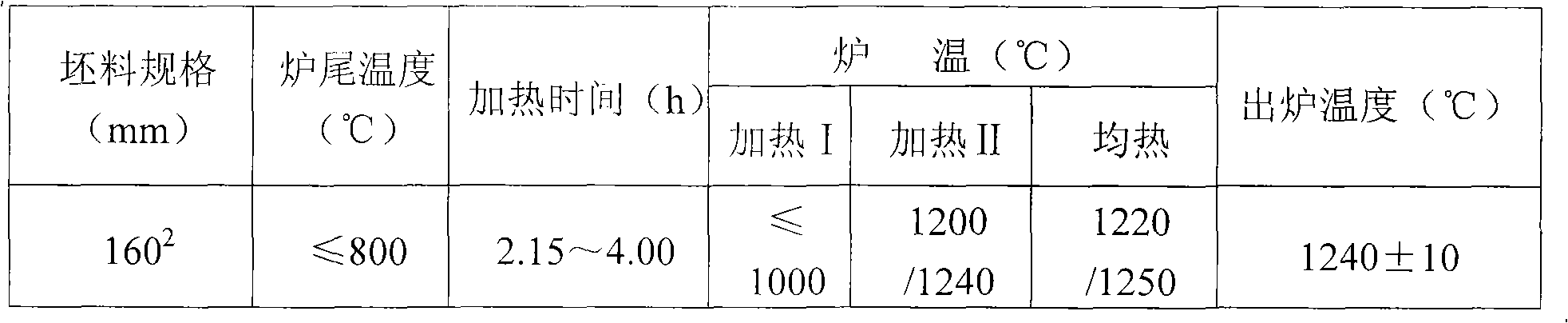

[0071] See Table 1 for chemical composition; see figure 1 , After the steel is melted in an electric arc furnace, it is added to the AOD for oxygen decarburization and refining treatment. After that, it is continuously cast into a 160×160 billet; after the surface grinding and finishing treatment, the billet is put into a walking furnace for heating. ℃~1237℃, the soaking zone temperature is 1230℃~1250℃, the billet exit temperature is 1245℃, the total heating time is 3 hours and 14 minutes, and the heating process is shown in Table 2 below.

[0072] Table 1

[0073] Unit: mass percentage

[0074] Reality

apply

example

C

Si

mn

P

S

Ni

Cr

Cu

Fe

1

0.06

0.20

14.35

0.021

0.004

0.97

13.28

2.52

margin

2

0.04

0.11

13.80

0.024

0.003

1.12

13.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com