Acid lining material of medium-frequency induction furnace and furnace building method thereof

A technology of induction electric furnace and acid furnace lining, which is applied in the direction of lining repair, etc., can solve the problems of the reduction of the thickness of the lining buffer layer, the thickening of the melting temperature of the quartz sand, and the difficulty of forming a compact furnace lining, so as to maintain the thickness, reduce the cost of building the furnace, and shorten the baking time. The effect of furnace time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

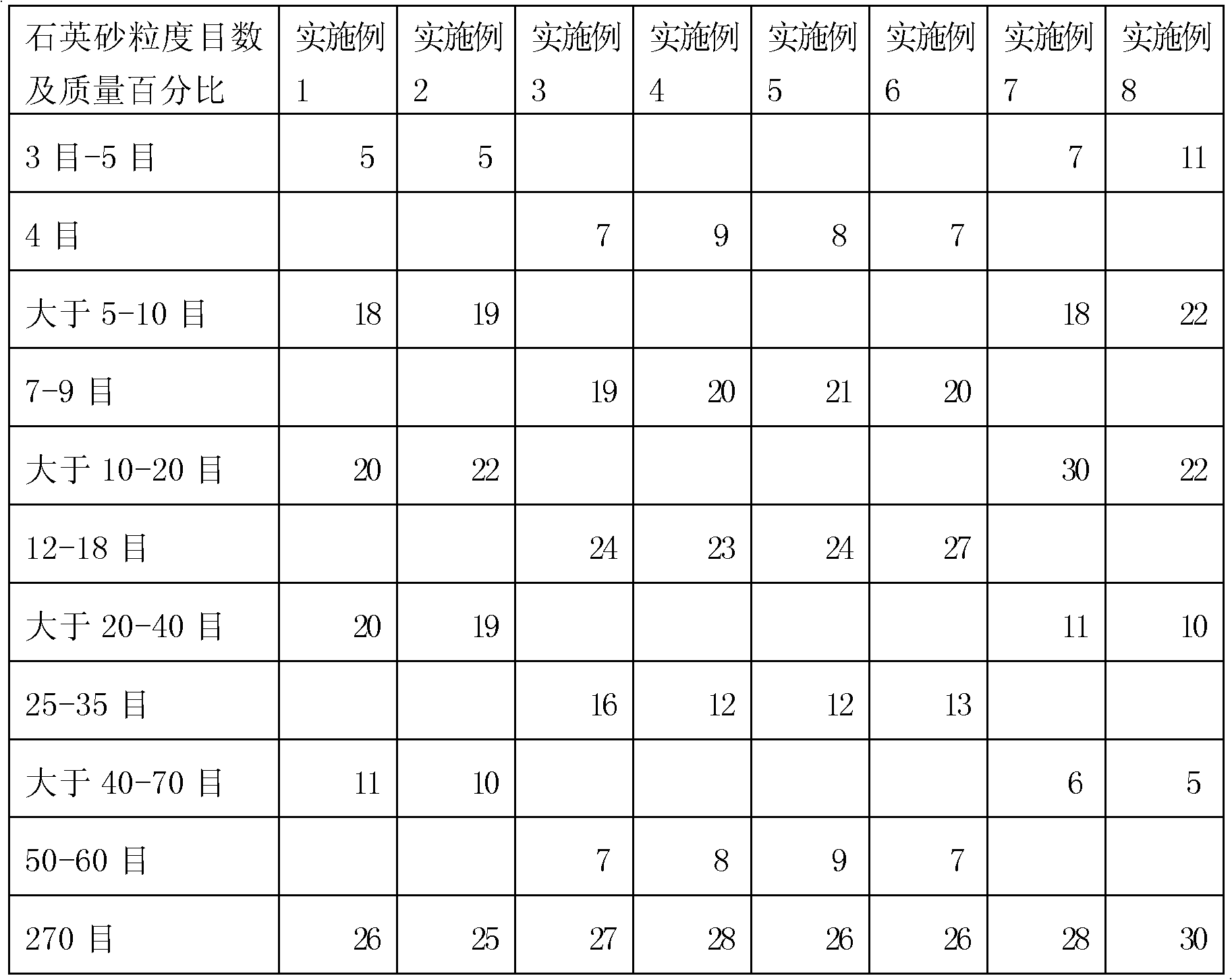

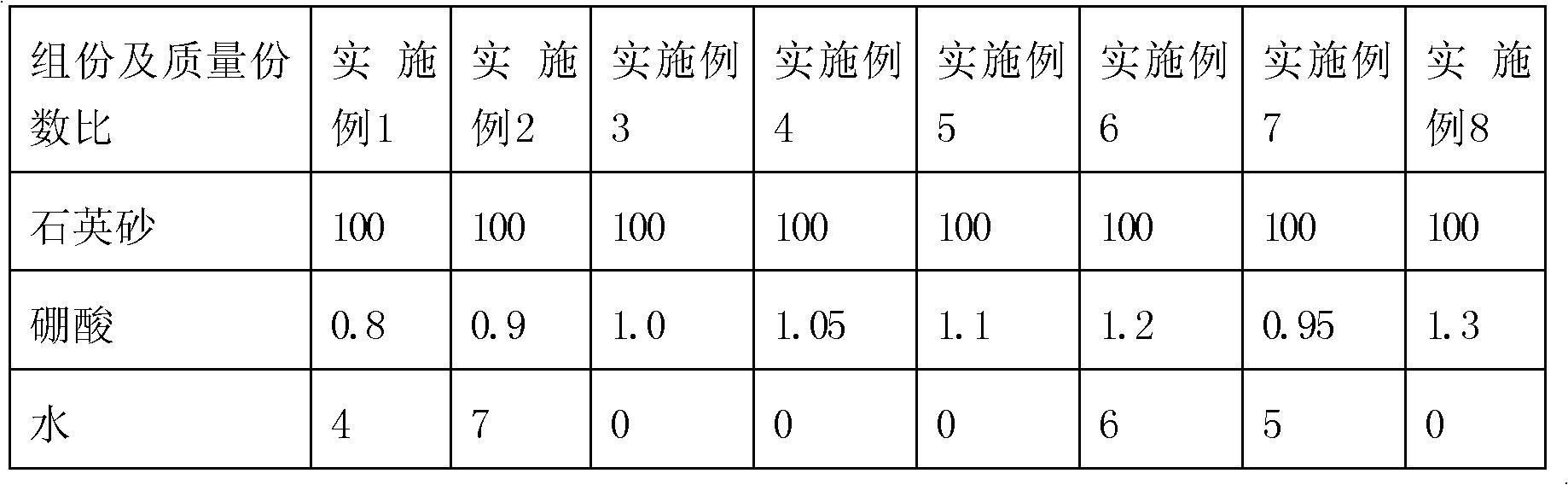

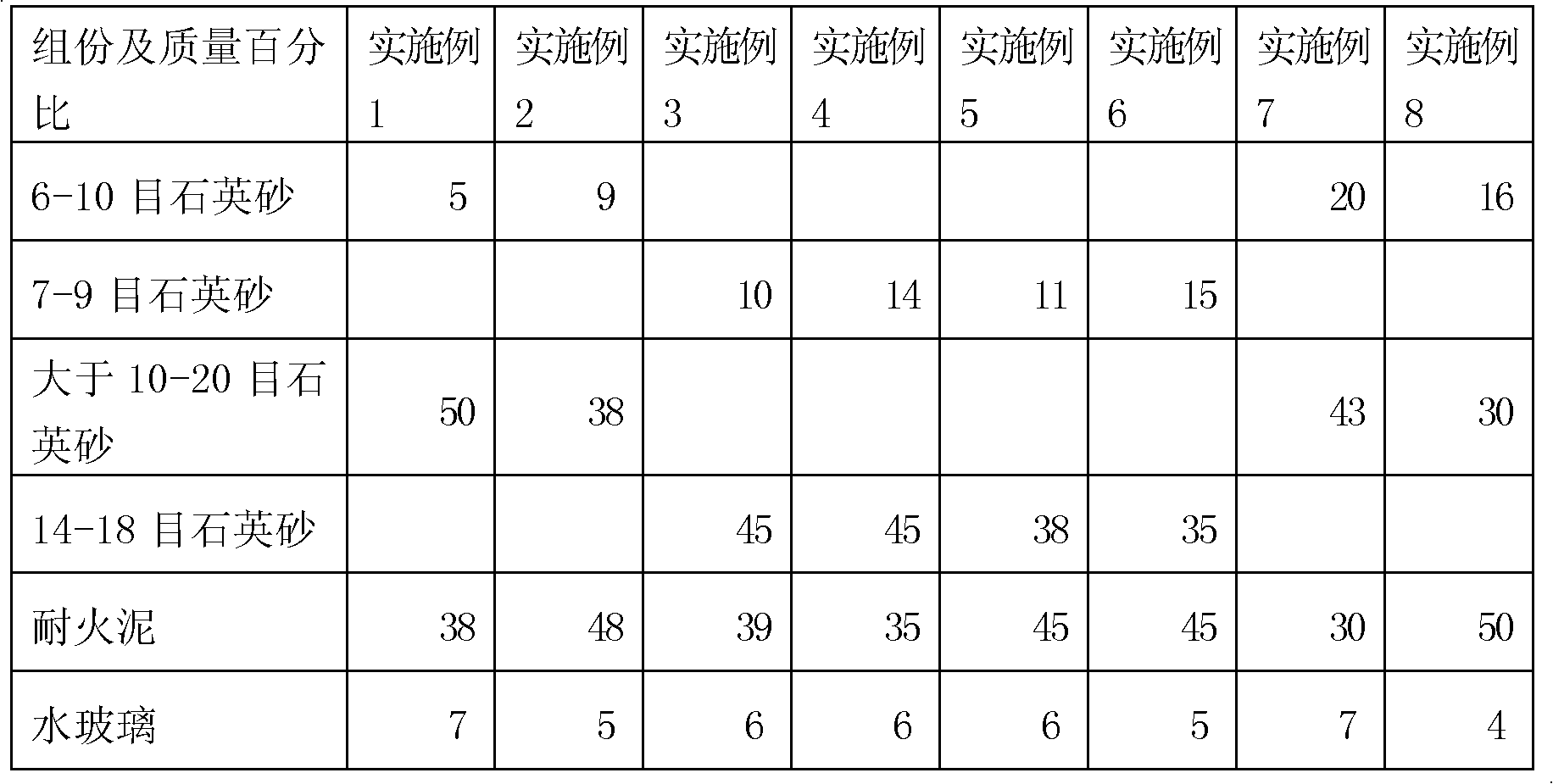

[0013] The acidic furnace lining material of the intermediate frequency induction furnace of the present invention includes furnace body lining material, furnace collar and furnace nozzle material. The furnace body lining material includes quartz sand and boric acid, and the SiO2 of the quartz sand is more than or equal to 98.5%, and the boric acid is industrial boric acid , the proportion of quartz sand and boric acid is 100:0.8-1.3 in parts by mass. According to the mass percentage, the quartz sand of the present invention includes 5-11% quartz sand with a particle size of 3-5 mesh, 18-22% quartz sand with a particle size larger than 5-10 mesh, and 20-30% quartz sand with a particle size larger than 10-20 mesh. 10-20% quartz sand with a particle size greater than 20-40 mesh, 5-11% quartz sand with a particle size larger than 40-70 mesh, and 25-30% quartz sand with a particle size of 270 mesh and boric acid, by changing the particle size and composition of the quartz sand rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com