Detection device and detection method for sealing performances of expansion tanks

A technology of leak detection and expansion tank, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, can solve problems such as equipment damage and poor sealing performance, and reduce thermal cracking Tendency, no hot cracking tendency, the effect of improving the corrosion resistance of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

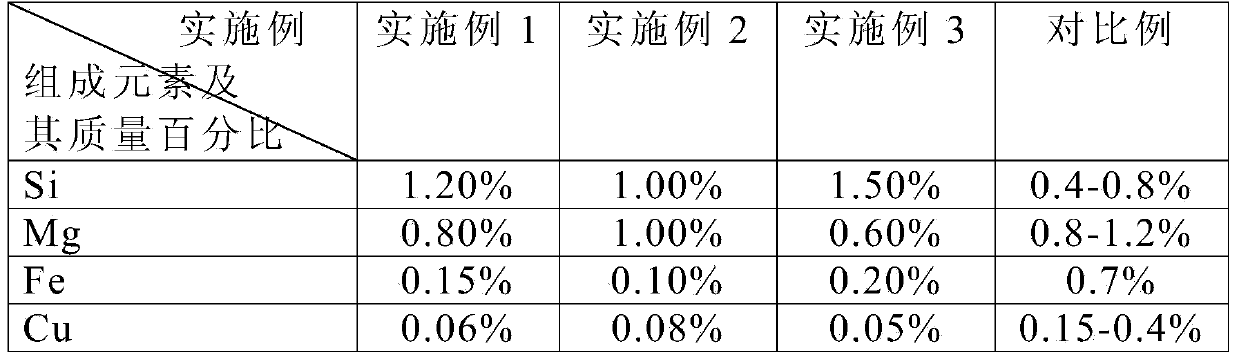

[0045] Batching: according to the mass percentage batching of each constituent element composition described in the frame in the expansion tank sealing test equipment of the embodiment 1 of Table 1;

[0046] Melting: Melt the above ingredients at 730°C to form molten aluminum, stir evenly and perform degassing first, then use C 2 Cl 6 The refining agent is used for refining treatment, the refining treatment temperature is 710°C, the refining time is 9 minutes, and it is left to stand for 10 minutes after refining; then the ternary or quaternary sodium salt modification agent is used for modification treatment, the modification treatment temperature is 710 °C, and the modification time is 18 minutes ;

[0047] Molding: pour the aluminum liquid after the above treatment in the mold to obtain the frame blank, the pouring temperature is 690°C, the mold temperature is 300°C, and the mold opening time is 200s;

[0048] Heat treatment: Carry out heat treatment on the poured frame b...

Embodiment 2

[0050] Batching: batching according to the mass percentage of each component element composition described in the rack in the expansion tank sealing test equipment in Example 2 of Table 1;

[0051] Melting: Melt the above ingredients at 720°C to form molten aluminum, stir evenly and perform degassing first, then use C 2 Cl 6 The refining agent is used for refining treatment, the refining treatment temperature is 720 ° C, the refining time is 8 minutes, and it is left to stand for 12 minutes after refining; then the ternary or quaternary sodium salt modification agent is used for modification treatment, the modification treatment temperature is 720 ° C, and the modification time is 15 minutes ;

[0052] Molding: pour the aluminum liquid after the above treatment in the mold to obtain the frame blank, the pouring temperature is 680°C, the mold temperature is 320°C, and the mold opening time is 220s;

[0053] Heat treatment: Carry out heat treatment on the poured frame blank. H...

Embodiment 3

[0055] Batching: according to the mass percentage batching of each constituent element composition described in the frame in the expansion tank sealing test equipment of the embodiment 3 of Table 1;

[0056] Melting: Melt the above ingredients into aluminum liquid at 740°C, stir evenly and degas first, then use C 2 Cl 6 The refining agent is used for refining treatment, the refining treatment temperature is 700°C, the refining time is 10 minutes, and it is left to stand for 8 minutes after refining; then the ternary or quaternary sodium salt modification agent is used for modification treatment, the modification treatment temperature is 700 °C, and the modification time is 20 minutes ;

[0057] Molding: pour the aluminum liquid after the above treatment in the mold to obtain the frame blank, the pouring temperature is 700°C, the mold temperature is 280°C, and the mold opening time is 180s;

[0058] Heat treatment: Carry out heat treatment on the poured frame blank. Heat trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com